Tengzhou Uni-Tech GH4220 Operation Manual

OPERATION MANUAL

Double Column Band Sawing Machine

Model GH4220

Contents

1. Main Specification ......................................................................................................................1

2. Main Components of Sawing Machine.........................................................................................1

3. Selection of Teeth Number of Saw Blade for Variable Stocks......................................................2

4. Attention for Usage of New Saw Blade Selected..........................................................................3

5. Installation Methods for the Saw Blade ........................................................................................4

6. Fixture Stock.................................................................................................................................5

7. Hydraulic System..........................................................................................................................6

8. Electrical Principle Chart..............................................................................................................8

9. Operation and Maintenance ..........................................................................................................9

10. Usual Major Faults and Solution...............................................................................................10

11. Precautions................................................................................................................................14

12. Packing List ..............................................................................................................................14

1

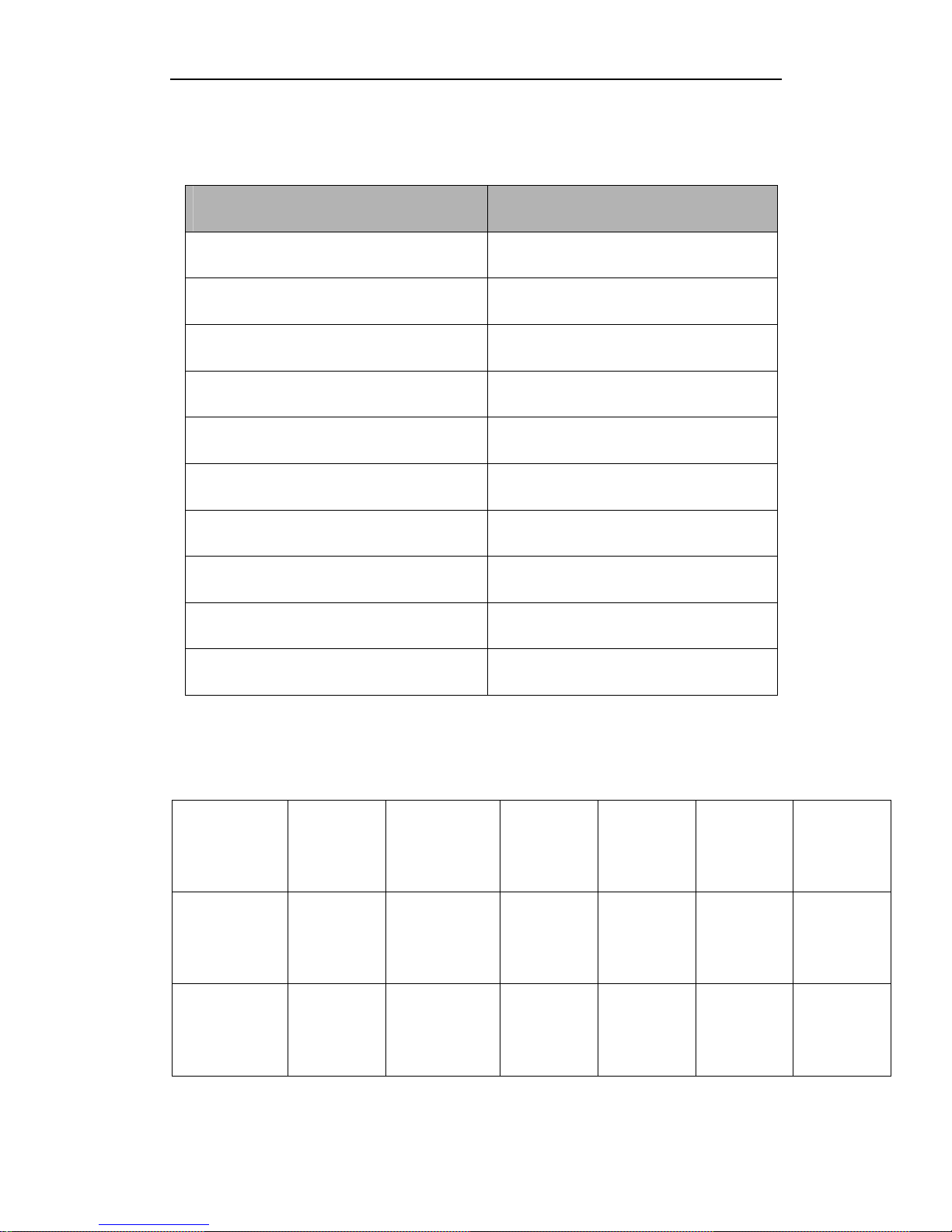

1. Main Specification

Parameter GH4220

Max. cutting range (mm) Φ200□200x200

Cutting speed (m/min) Three grade:27/45/69

Feeding speed adjustment Hydraulic stepless

Blade model (mm) 2650x27x0.9

Clamping type Manual

Main motor power (kw) 1.5

Hydraulic pump power(kw) 0.55

Coolant pump power(kw) 0.04

Type of main transmission Worm bar

Machine layout (mm) 1300x800x1100

2. Main Components of Sawing Machine

Saw frame Base Clamping

device

Saw

wheel

Electrical

cabinet

Coolant

tank

Operation

station

Sub-column Leading

device

Oil pump Motor Reducer Coolant

pump

Main oil

cylinder

Clamping

cylinder

Working

light

Driving

wheel

Tension

base

2

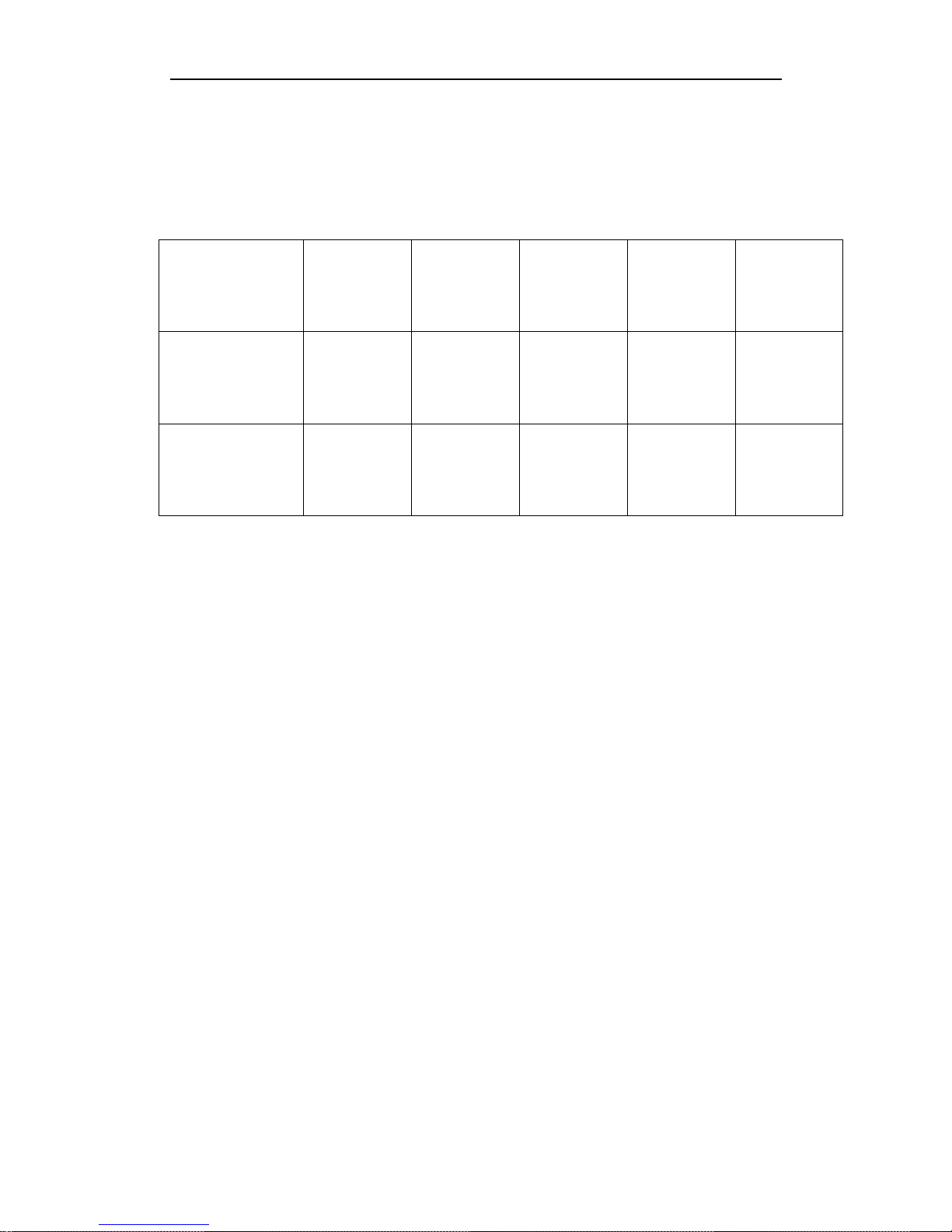

3. Selection of Teeth Number of Saw Blade

for Variable Stocks

Cutting length

(mm)

Less 15 15-25 25-75 75-150 150-250

Teeth number

(difficult)

12-10 10-8 8-6 6-4 4-3

Teeth number

(general)

8-6 4-3 3-2

3

4. Attention for Usage of New Saw Blade

Selected

1. Before loading the new saw blade, keeping the cleaning of the saw

blade wheel and checking if coolant and hydraulic system work

normally

2. Fine and coarse teeth saw blade should be applied according to size

of stocks, please check the above item 3 to choose the suitable saw

blade for your stock so that no any teeth of saw blade broken. For

example, if using small teeth blade (6 teeth blade) to cut big

work-piece (150mm diameter steel rod) will cause too much iron

scurf between teeth, further decrease blade service life.

3. Cutting speed should be lower while cutting material with quite

high hardness

4. The saw blade selecting also should be considered as per the shape

of the stock, teeth-change blade should be used for the profile stock,

keep at least two tooth inside the stock constantly

5. Reasonable to choose coolant liquid for variable stock, oil and

water ratio can be 1:5 for high alloy steel and 1:10 for low alloy

steel and carbon steel

Loading...

Loading...