Tem trol, In c.

Phone - 405-263-7286 Fax - 405-263-4924

INFORMATION COVERING :

SERIES ITF

AIR HANDLERS

OUTDOOR - MOUNTED

AIR HANDLING UNITS

O-ITF-07

INSTRUCTION

MANUAL

INSTALLATION

"START-UP"

OPERATION -

MAINTENANCE

& INSPECTION

TEMTROL, INC. • Okarche, OK • Phone (405) 263-7286 • Fax (405) 263-4924

Manufacturers of Air Conditioning, Heating, Ventilation and Heat Transfer Products

WARRANTIES AND LIMITATIONS OF LIABILITY FOR BREACH OF WARRANTY

Temtrol, Inc., warrants all products to be free from defects in material and workmanship for

twelve (12) months from date of shipment unless a start-up form is on file and accepted by

Temtrol, in which case the warranty is twelve (12) months from the date of start-up, or eighteen

(18) months from date of shipment, whichever is shorter. Said start-up form shall signify that the

equipment has been properly started and adjusted, and is operating under normal conditions,

prescribed ratings and specifications, and was installed by qualified personnel in accordance with

Temtrol instructions and local codes and ordinances. For warranty purposes, start-up occurs

when the equipment and/or blowers are started for operation of the equipment regardless of when

the building may be ready for operation.

Temtrol’s obligation hereunder shall be limited to the exchange of new parts for those returned to

Temtrol’s factory at buyer’s expense and found to be defective, by Temtrol. Replacement parts

shall be shipped F.O.B. Temtrol’s factory. Replacement of parts hereunder shall not operate to

extend the original warranty period as to any part, including replacement parts supplied hereunder.

This warranty does not cover corrosion; normal deterioration; misapplication; labor charges paid

for parts replacement; adjustments; repairs or other work; loss of refrigerant; components supplied

by others; defects in parts resulting from neglect, negligence, accident, fire, explosion, high or low

voltage, jumpering or jamming controls; improper or contaminated fuel; excessive or inadequate

fuel pressure; frozen heating coils; war, or any acts of God.

This warranty is void if equipment is misapplied or if any alterations are made to the basic design or

operating requirements as listed on the original order and shipped from the factory unless approval

is received in writing from Temtrol.

It is expressly understood that this warranty is made IN LIEU OF ALL OTHER WARRANTIES

with the exception of those warranties attached hereto, EXPRESS OR IMPLIED, INCLUDING

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR ANY PARTICULAR PURPOSE

and in consideration of the express warranty herein contained, BUYER EXPRESSLY WAIVES

ANY RIGHT TO CLAIM OTHE R WARRANTIES, EXPRESS AND IMPLIED.

It is further understood that Temtrol’s liability for breach of warranty shall be limited to the terms

of this warranty. Buyer agrees that Temtrol SHALL NOT, IN ANY EVENT, BE LIABLE FOR

CONSEQUENTIAL DAMAGES and that buyer’s sole and exclusive remedy shall be limited to that

provided herein.

Temtrol neither assumes nor authorizes any person to assume for it any obligation or warranty

other than those stated herein.

Any suggestion to the contrary notwithstanding, Temtrol shall not, in any event have any liability

under this warranty unless and until Temtrol has been paid in full for the products supplied. The

warranty period shall begin to run as described above, however, whether or not payment has been

made.

BOX 409 - 15 EAST OKLAHOMA AVENUE - OKARCHE, OKLAHOMA - (405) 263-7286

3-28-07

ITFDetails.idw

File Name:

Date:

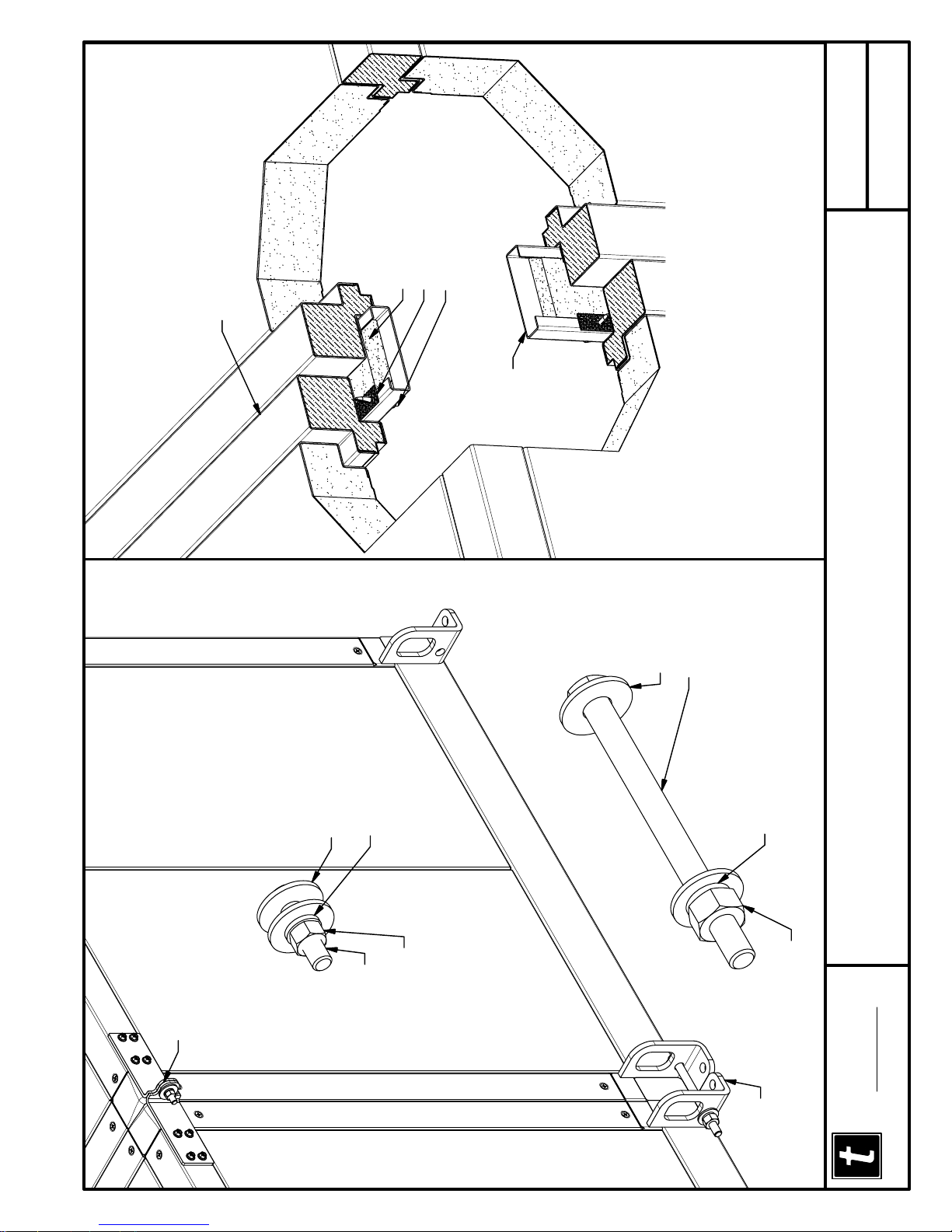

IDC - Insulation

(IDC) 1" x 4" Internal Demount Cover

Factory Pre-insulated & Gasketed.

Caulk Demount Seam

IDC - 1/4"x3/4" Gasket

IDC - Fastener

(IDC)

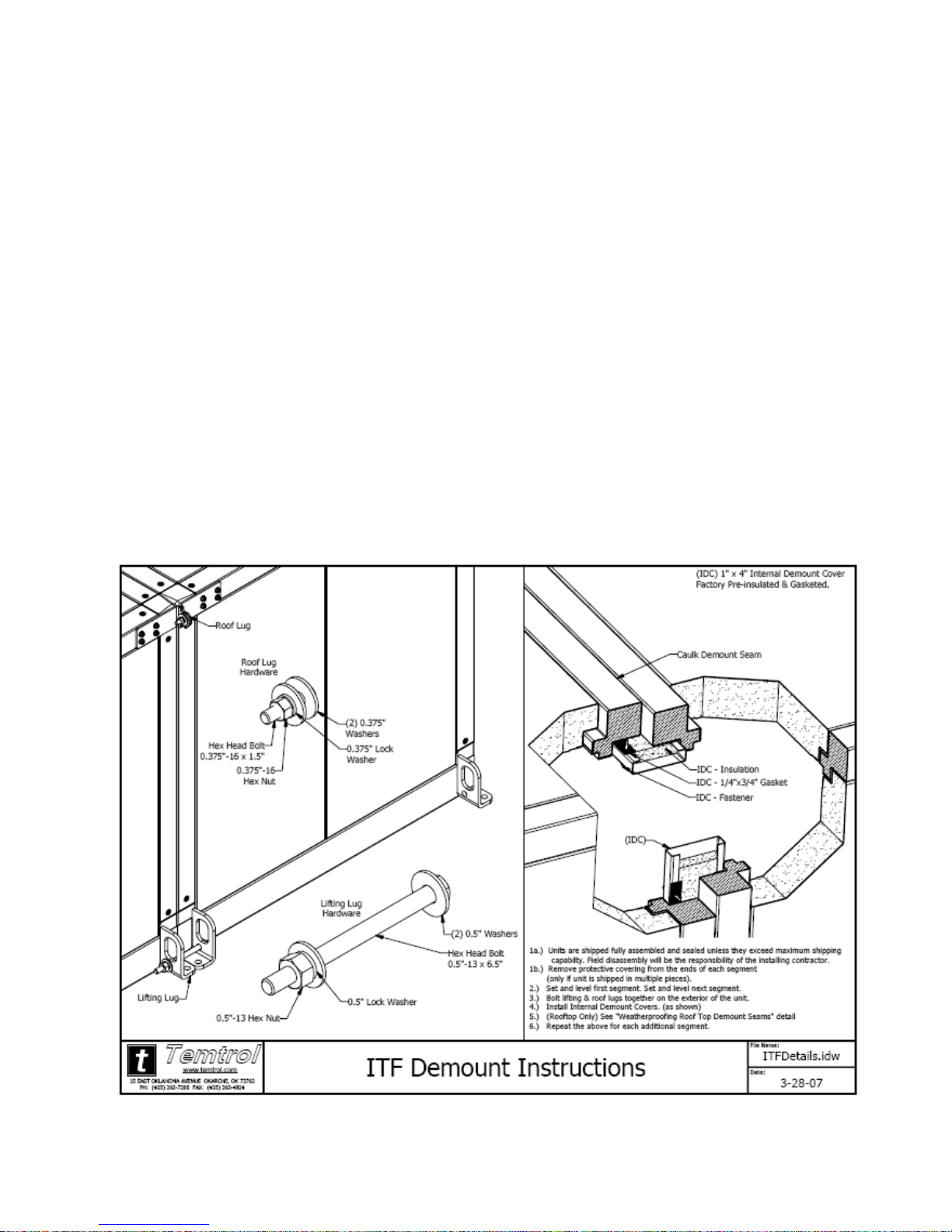

1a.) Units are shipped fully assembled and sealed unless they exceed maximum shipping

capabilty. Field disassembly will be the responsibility of the installing contractor.

1b.) Remove protective covering from the ends of each segment

(only if unit is shipped in multiple pieces).

2.) Set and level first segment. Set and level next segment.

3.) Bolt lifting & roof lugs together on the exterior of the unit.

4.) Install Internal Demount Covers. (as shown)

5.) (Rooftop Only) See "Weatherproofing Roof Top Demount Seams" detail

6.) Repeat the above for each additional segment.

Roof Lug

Roof Lug

Hardware

(2) 0.375"

(2) 0.5" Washers

Hex Head Bolt

0.5"-13 x 6.5"

ITF Demount Instructions

0.375" Lock

Washer

Washers

Hex Nut

0.375"-16

Hex Head Bolt

0.375"-16 x 1.5"

Hardware

Lifting Lug

0.5" Lock Washer

0.5"-13 Hex Nut

www.temtrol.com

Temtrol

Lifting Lug

PH: (405) 263-7286 FAX: (405) 263-4924

15 EAST OKLAHOMA AVENUE OKARCHE, OK 73762

O-ITF-07

Page 1

P.O. Box 409 • 15 East Oklahoma Avenue • Okarche, OK 73762 • (405) 263-7286

Tem trol, In c.

Manufacturers of ….. Customized Air Handling Units

SERIES ITF OUTDOOR - MOUNTED AIR HANDLING UNITS

Delivery, Storage, Installation,

"Start-up", Maintenance and Inspection Instructions

(A) DELIVERY

(1) Equipment is purchased F.O.B. Factory and is the responsibility of receiving party to inspect unit

upon arrival at the destination before unloading or moving unit to its permanent location; inspect

closely for damage which may have been caused in transit. Report damage to delivering carrier

promptly (list damage or shortage on freight bill if possible). If damage is noted or discrepancies

found, the local Temtrol, Inc. sales representative should be notified immediately so that

corrective action may be instigated. Where local repairs or alterations are required, the

representative should be fully informed by the contractor as to the extent and expected cost of

work required. Unauthorized back-charges will not be recognized by Temtrol, Inc.

(B) STORAGE

(1) Should storage of unit be required caution should be taken to set unit relatively level and in clean

location to protect motor, bearings, coils, filters and etc. from excessive dust. Also avoid storage in

location where children play and/or public access. Air handling units should not be used as on site

storage for other mechanical trades. If units are to be stored for an extended period of time the

following maintenance procedures must be performed:

a. Fan wheels should be rotated by hand every 30 days.

b. Each month bearings should be purged with new grease to remove

condensation.

c. Before start-up new grease must be added to the bearings

d. Belts should be removed, then prior to start-up, inspect and replace if necessary,

reinstall belt.

e. All openings and access doors must remain sealed during storage.

f. Dampers must be cleaned and lubricated prior to start-up.

g. Extended storage could result in condensation on the inside of the unit.

Affected areas should be cleaned and dried prior to start-up.

O-ITF-07

Page 2

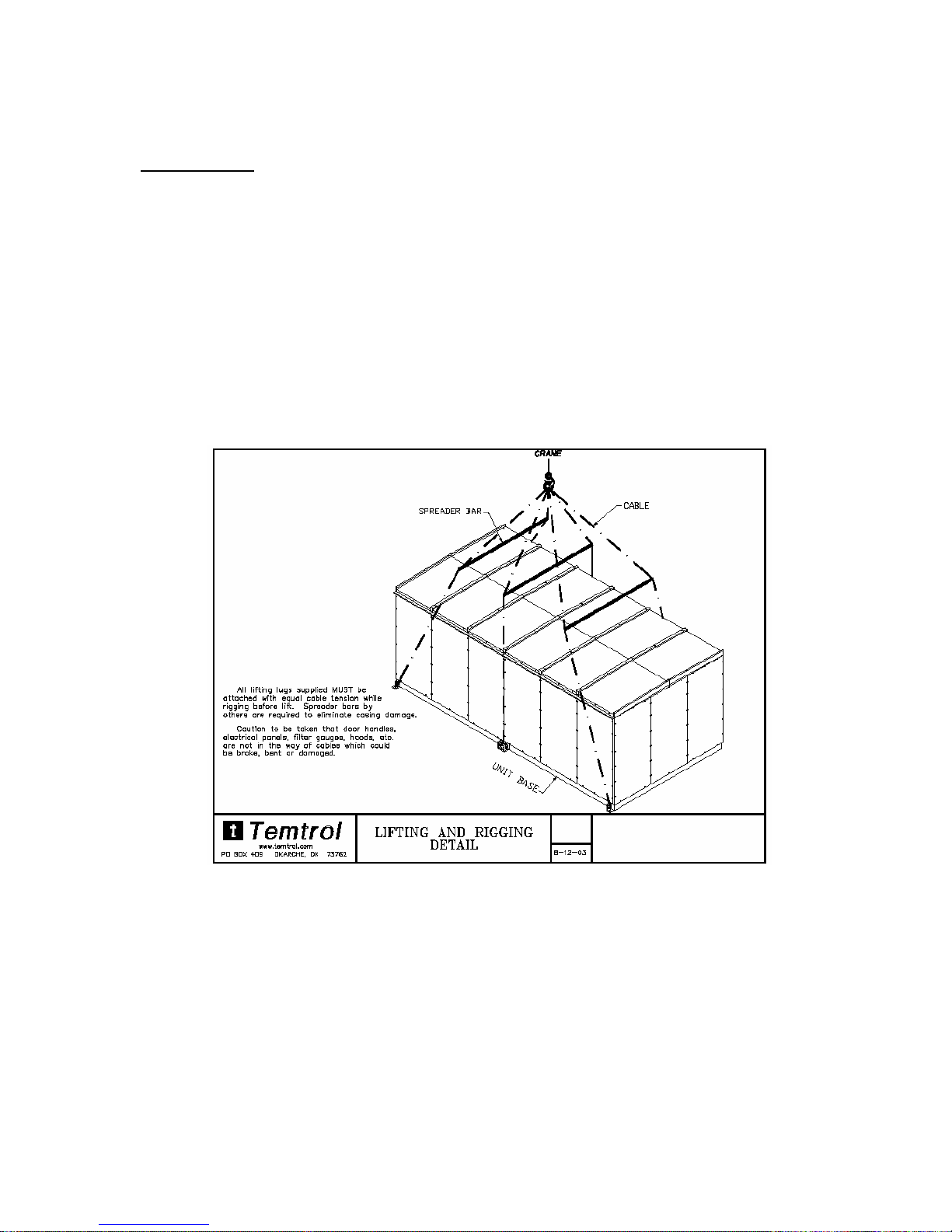

(C) INSTALLATION

(1) An experienced, reliable rigger should be selected to handle the unloading and final placement of

the equipment. Handle equipment with care during installation to avoid damage due to twisting,

bouncing or tilting. Rigger should be advised that the unit contains delicate components and is

to be handled in upright position only. Avoid excessive stress to fans, shafts, bearings,

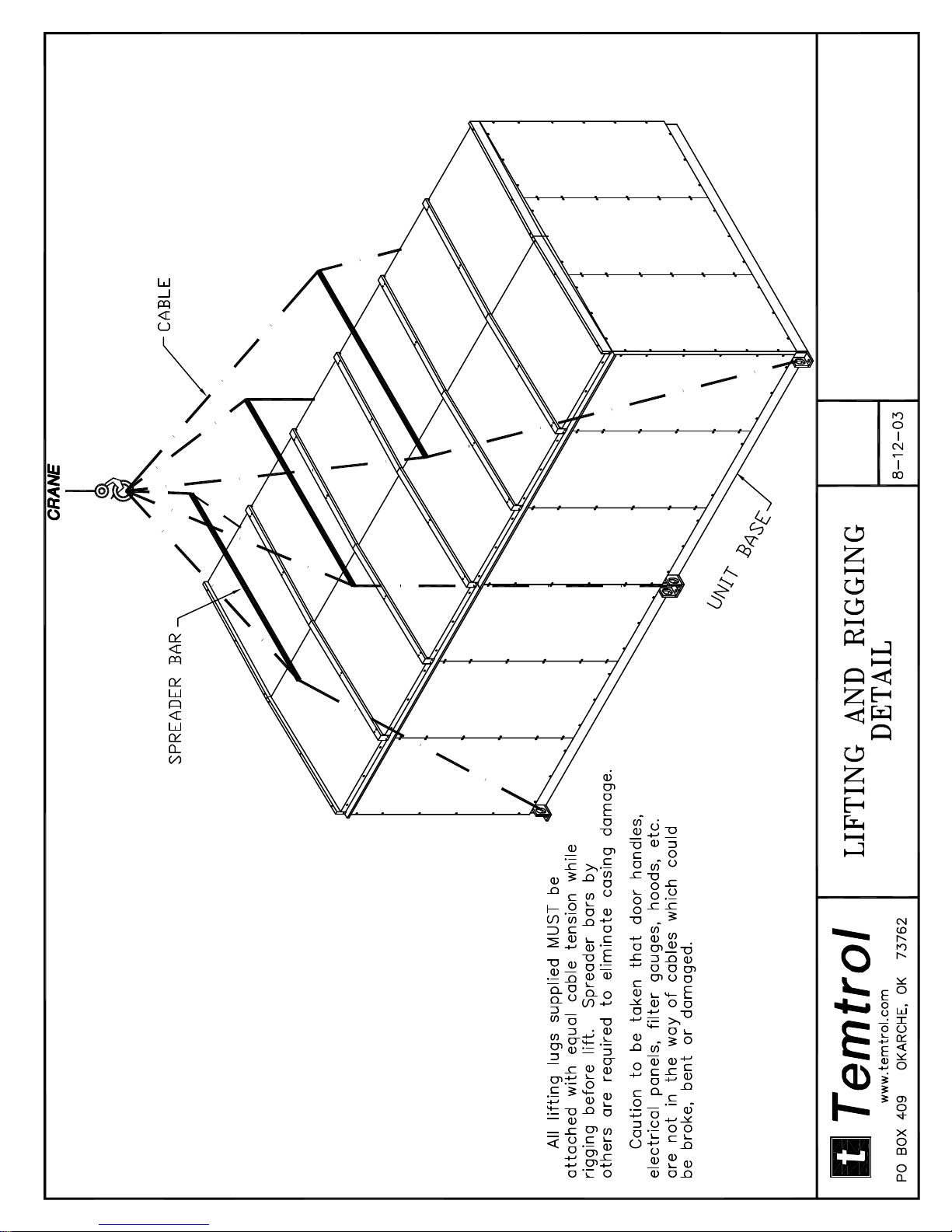

(2) Lifting brackets are provided on the sides of the unit and equal tension of cables at each bracket

is essential for weight distribution and safety. Rigging cables should be as long as the

longest unit piece dimension at corners to prevent stress on assembly.

coil fin and tubes, dampers, isolators, filter accessories, humidifiers, piping, electrical, motors, drives,

access doors and insulation. This will save time and expense during start-up and initial service

warranty period.

Larger Drawing

Located In The

Manual

(3) Roof-curbs (where required) must be installed square and level. Curb should be field welded or

bolted to roof joists or deck field flashing and unit mounting to secure in place. Apply curb

gasket material (furnished with unit) to top of curb before unit mounting. Foundation for curb

must be adequate to support weight of unit without deflection to maintain spirit level of unit after

installation.

O-ITF-07

Page 3

Larger Drawings Located In The Manual

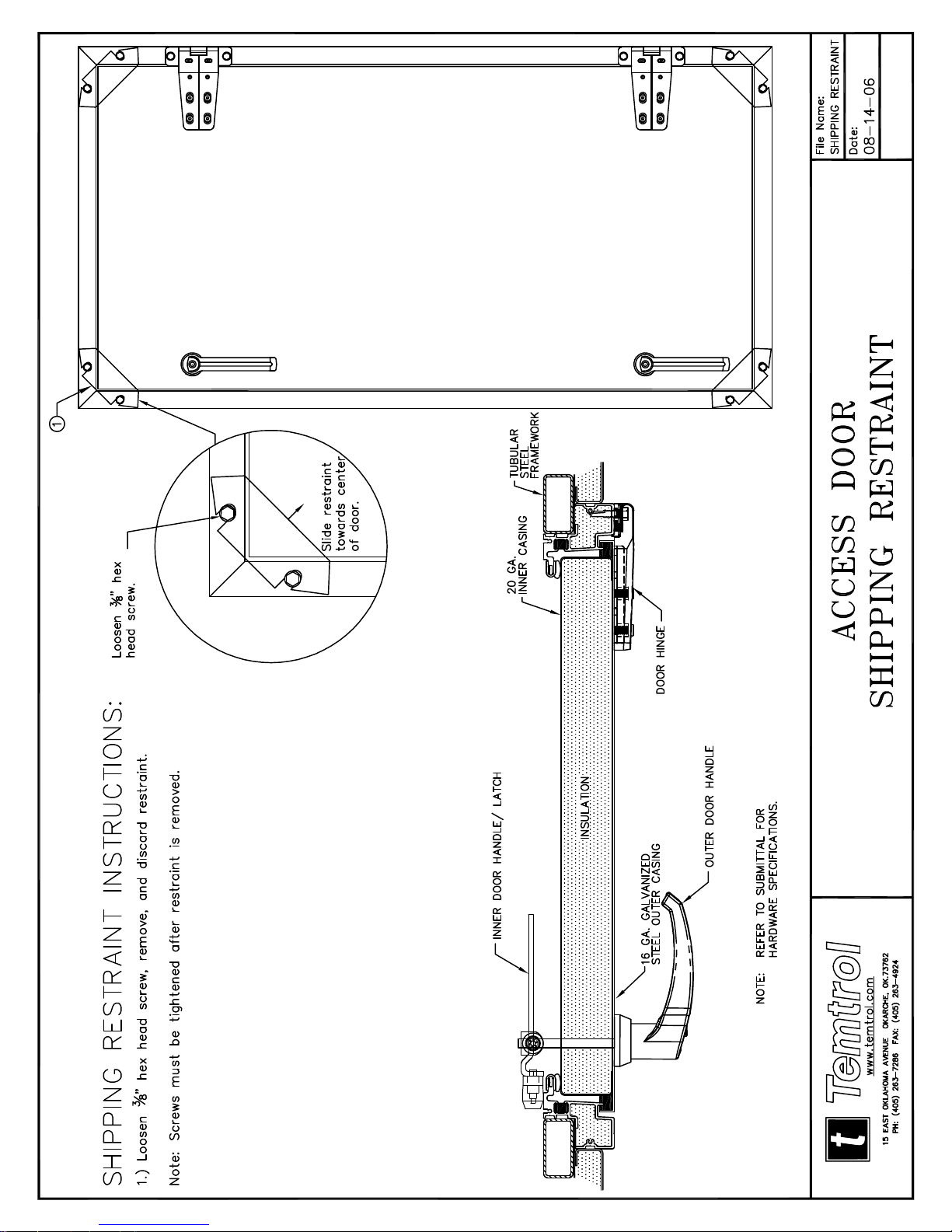

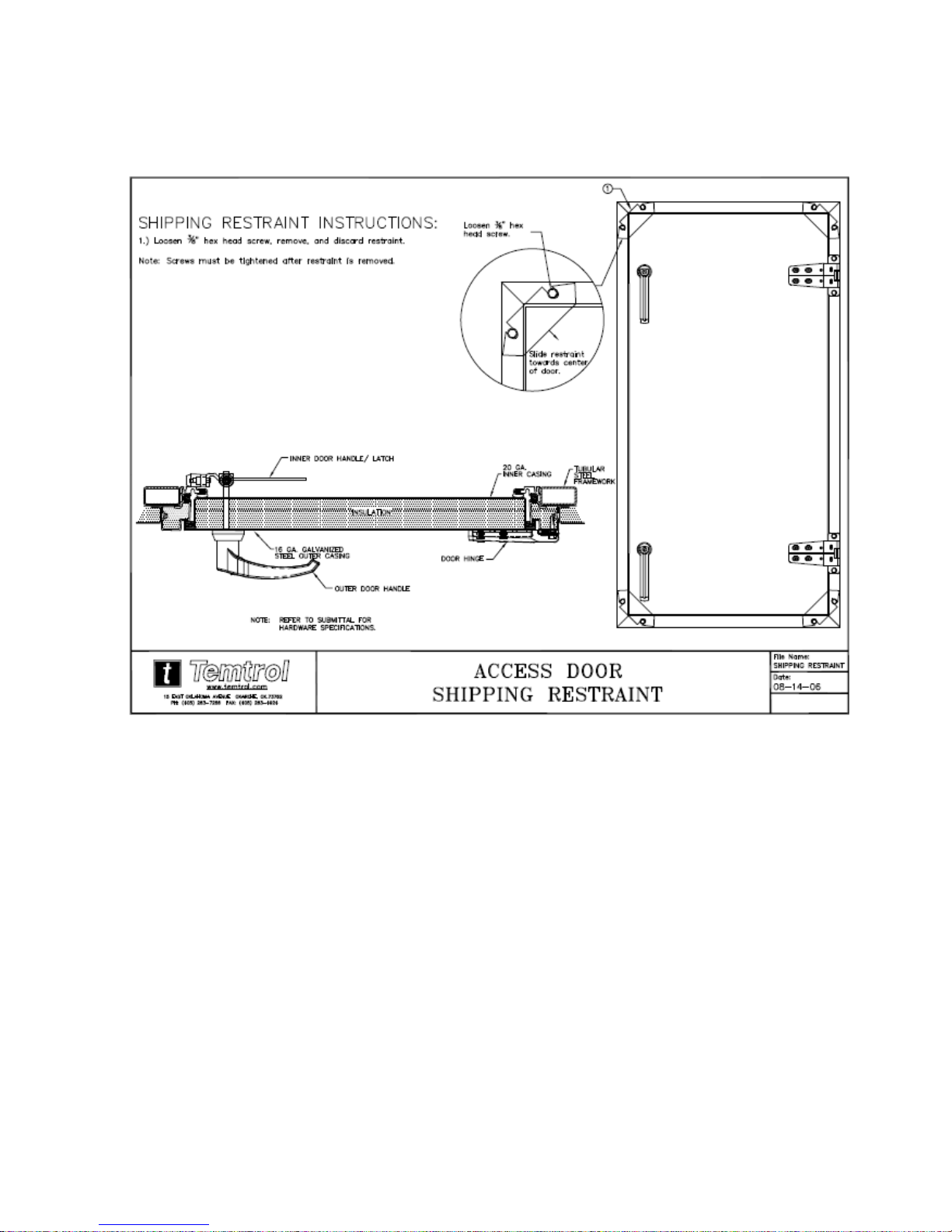

(4) Access Door Shipping Restraint:

a. Loosen 3/8” hex head screws.

b. Slide restraint towards center of door – remove & discard.

c. Retighten hex head screws.

(5) Steam coils are drainable if unit is level. Water coils are also drainable except for special

circuiting. When special circuitry has been furnished coil must be protected from freeze damage

by means of anti-freeze liquids or heaters.

(6) Condensate drain lines inside or to roof from pan must be pitched and include a water seal or

trap to prevent the passage of air into or out of the unit via the drain in the field by the contractor.

Intermediate pans for coils more than one high include downspouts to main pan. A minimum of

2 x (S.P.) trap is required in the condensate line to prevent condensate back up.

O-ITF-07

Page 4

(7) Multi-section units if furnished have (IDC) 1” x 4” internal demount cover factory pre-insulated and

gasketed.

1a. Units are shipped fully assembled and sealed unless they exceed maximum

shipping capability. Field disassembly will be the responsibility of the

installing contractor.

1b. Remove protective covering from the ends of each segment – (only if unit

is shipped in multiple pieces).

2. Set and level first segment. Set and level the next segment.

3. Bolt lifting lugs together on the exterior of the unit using factory furnished

hex head bolt (.05” – 13 x 6.5”), (2) 0.5” washers, .05” hex nut plus 0.5”

lock washer.

4. Bolt roof lugs together on the exterior of the unit using factory furnished

Hex head bolt (0.375” – 16 x 1.5”), (2) 0.375” washers, .0375” – 16 hex

nut plus 0.375” lock washer.

5. Caulk demount seam.

6. Install internal demount covers (IDC)

a. IDC- Insulation

b. IDC ¼” x ¾” gasket.

c. IDC Fastener

7. See “Weatherproofing Roof Top Demount Seams” detail – next page (7a)

8. Repeat the above for each additional segment.

Note: Standing seams must fit level and flush to properly seal the demount

Please refer to the bill of lading for the location of the assemble hardware.

Larger Drawings Located In The Manual

O-ITF-07

Page 5

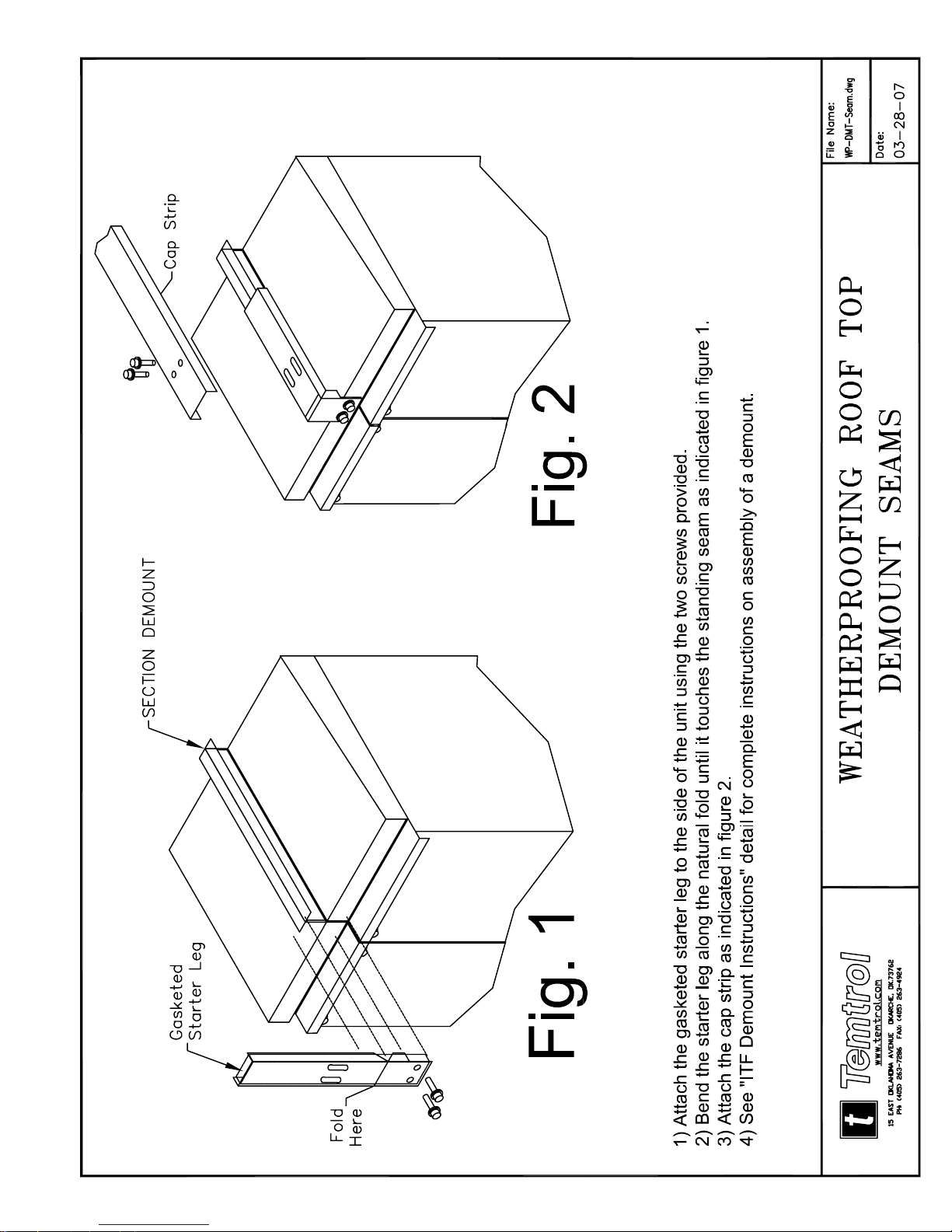

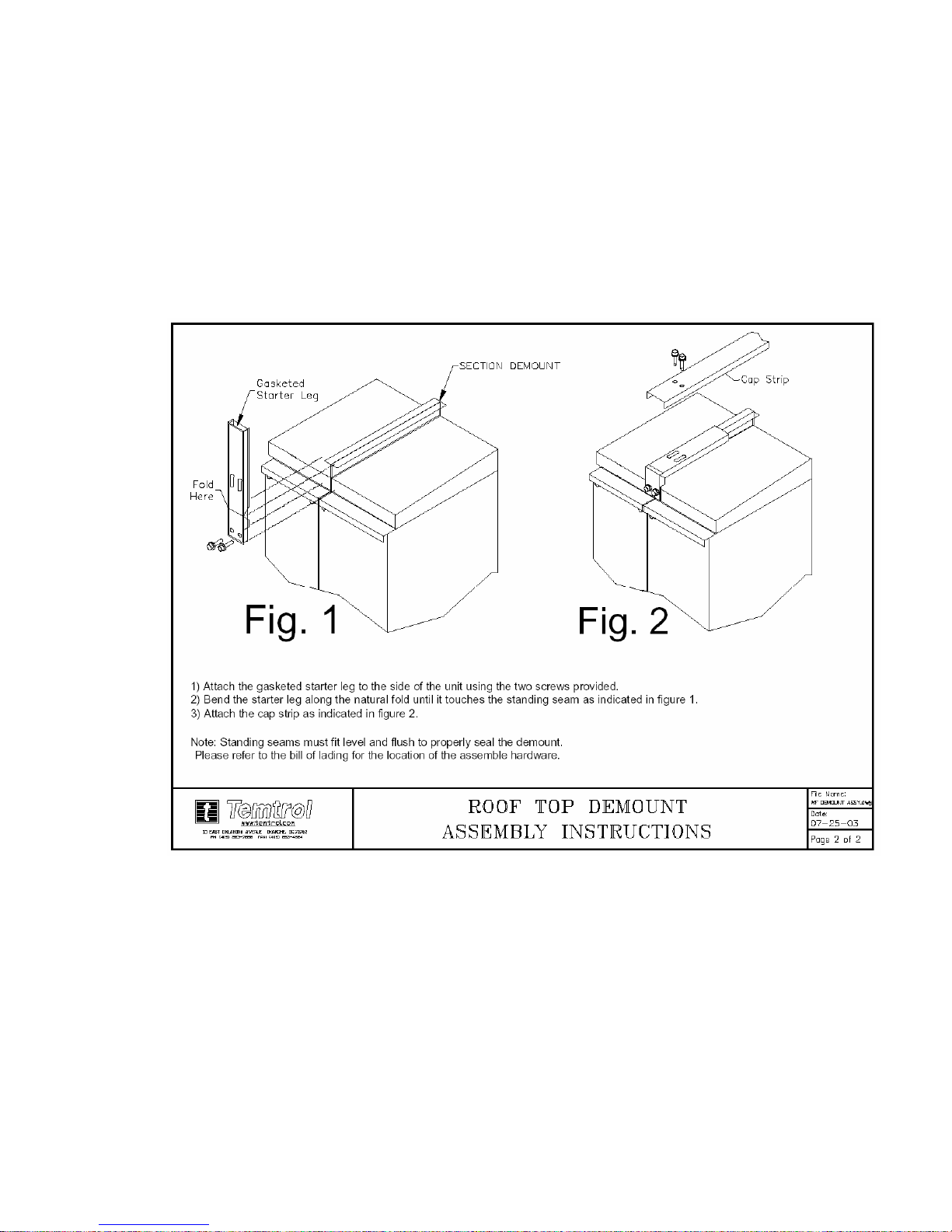

(7a) Weatherproofing roof top demount seams:

1. Attach the gasketed starter leg to the side of the unit using the two screws

provided.

2. Bend the starter leg along the natural fold until it touches the standing seam

as indicated in “Fig. 1.

3. Attach the cap as indicated in “Fig. 2.”

See “ITF Demount Instructions” detail for complete instructions on

assembly of a demount – prior page item (7).

Larger Drawings Located In The Manual

O-ITF-07

Page 6

Larger Drawing

Located In

Manual

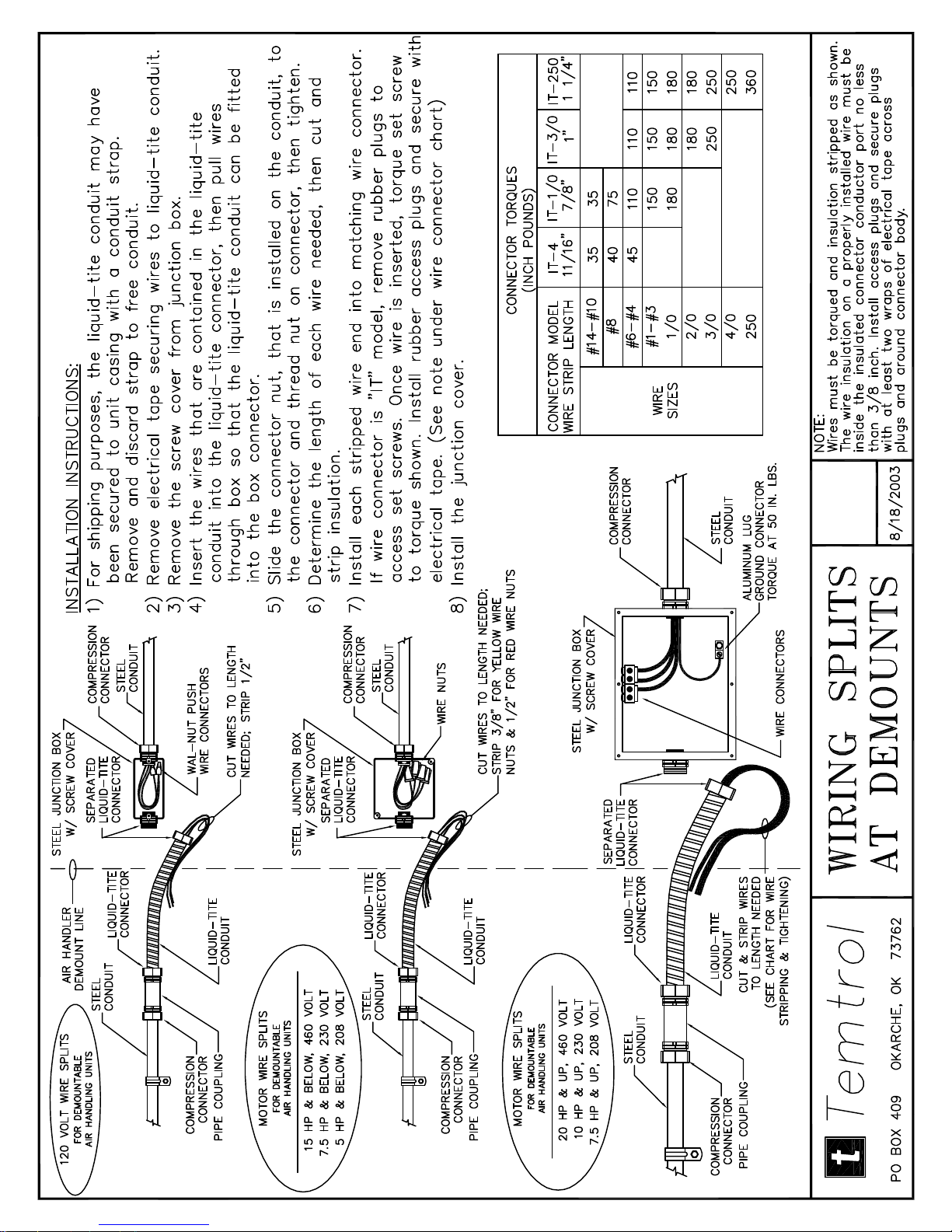

(7b) Wiring Splits at Demounts:

1a. For shipping purposes, the liquid-tite conduit may have been secured to unit

casing with a strap. Remove and discard strap to free conduit.

2a. Remove electrical tape securing wires to liquid-tite conduit.

3a. Remove the screw from junction box.

4a. Insert the wires that are contained in the liquid-tite conduit into the liquid-tite

connector, then pull wire through box so that the liquid-tite conduit can be

fitted into the box connector.

5a. Slide the connector nut, that is installed on the conduit, to the connector and

thread nut on connector, then tighten.

6a. Determine the length of each wire needed, then cut and strip insulation.

7a. Install each stripped wire end into matching wire connector. If wire

connector is “IT” model, remove rubber plugs to access set screws. Once

wire is inserted, torque set screw to torque shown on drawing. Install rubber

access plugs and secure with electrical tape.

Note: Wires must be torqued and insulated stripped as shown.

The wire insulation on a properly installed wire must be

inside the insulated connector conductor port no less than

3/8 inch. Install access plus and secure plus with at least

two wraps of electrical tape across plus and around

connector body.

8a. Install the junction cover.

(8) Observe all pertinent local ordinances and codes covering installation and operation of air

handling equipment. Adequate clearance for the service and removal of components should be

provided (Do Not install unit in a tight space or dangerously close to roof edge especially on

access side).

O-ITF-07

Page 7

(D) "START-UP" SERVICE

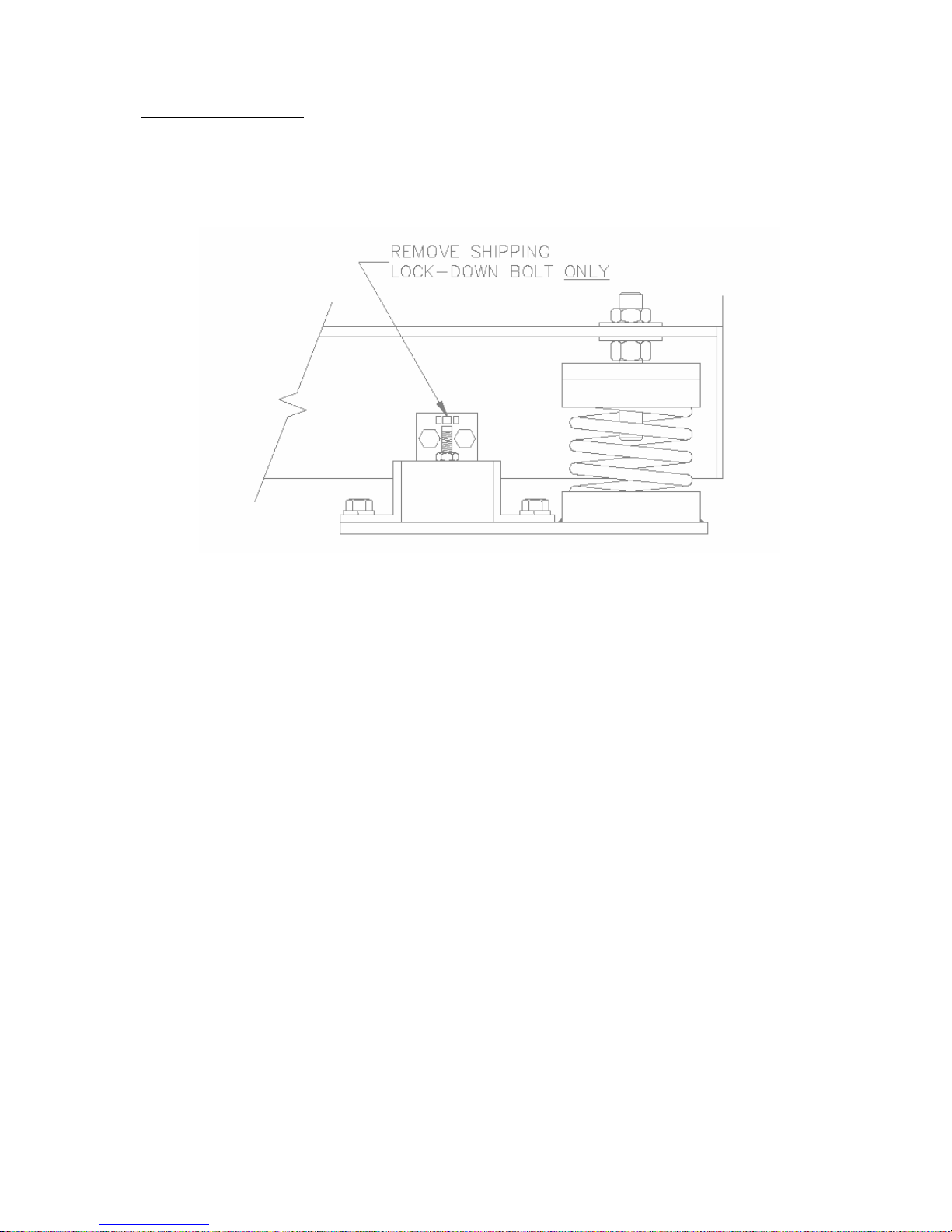

(1) After unit is permanently positioned, fan isolation shipping lock-down bolt, only (see drawing), should

be removed. If load points are not on same plane after supports are removed readjust isolator or shim

until elevation of load points are uniform.

Larger Drawing

Located In The

Manual

(2) Access door to piping compartment is provided if pipe chase is furnished. All plumbing in field

should be done through chase (Do Not puncture casing). Use back-up wrenches on stubouts and

swing joint piping or flex piping to avoid damage to headers and tubes. If, for any reason, it is

necessary to cut a hole in the unit casing, this hole should be cut through a side panel (not

through any access door) and then carefully sealed. If vestibule is furnished all piping should be

run inside the vestibule and plumbed through the chase hole cover plate. Access door to

vestibule or chase compartment should be closed and latched securely to avoid plumbing freeze

up.

(3) Vault type door latches provided on access doors can be adjusted by changing position of bevelled

flange or handle on inside. Access door gasketing must not be removable or leakage of air and

water could result.

(4) Check motor mounting to make sure all nuts are tight. Confirm that the motor voltage, phase,

and HP size are compatible with wiring. Motor nameplate amperage is maximum. All electrical

connections should be tight, complete and properly terminated.

(5) Supply and return air duct flanges are provided and should be attached to ducts with flexible

connector unless fans are internally isolated. Multizone units require field zo ning of individual

zone segments by use of "W" clips which attach to zone separators.

(6) Fan blower wheels should rotate freely. Check motor and fan sheave for proper alignment and

make sure set screws are tight. Check bearing-collar set screws on fan shaft and fan hub set

screws for tightness. Loose collars and/or set screws will ruin the shaft quickly. Ball bearings

have been lubricated at the factory and do not need further attention at start-up. Do Not operate

fans with imbalance. During fan (supply and return) start-up observe the rotation and if fan is

operating backward, reverse two legs of the supply electrical power if three phase.

O-ITF-07

Page 8

(7) Rotate damper (Face & Bypass, Outside Air, Return Air, Exhaust and Zone Dampers) shafts to

test action; rough handling may have caused damper blades to bind. Damper shaft extension

(1/2" shaft) is provided to accept manual or automatic controls. Do Not overdrive damper

motors, this will deform dampers and/or linkage.

(8) Outside air inlet hood and exhaust outlets (if not mounted when shipped) have been predrilled for

attachment in field. After mounting, hoods should be caulked for weatherizing. Both the hood

and the outlets include birdscreen and louvers.

(9) Filters (when furnished by TEMTROL, INC.) are often furnished and mounted in the racks or in

boxes inside the unit. Check to make sure the filter cartridge count is correct. (Filter count is

found on the Data Sheet). If filter count is short, the exact number received should be noted on

the freight bill at the time of delivery. Check to make sure that filter media has been installed

properly in the rails. Check to be sure that the filters called for are used; failure to use the filters

that your TEMTROL, INC. Air Handler has been designed for can cause fan motor overload

and/or cause the coils to become dirty and restrict airflow. Filter access doors should always be

latched firmly to stop air by-pass around filter cartridges.

(10) Check all screws, bolts, nuts, electrical and piping connections for tightness.

(11) If unit heaters are provided check thermostat settings to insure freeze protection.

(12) Supply and return fan drives are provided in the mid-speed adjustment range when variable

speed sheaves are furnished. The motor sheave pitch diameter is field adjustable for the required

air flow. When final adjustments are complete the current draw of the motor should be checked

and compared to full load amperage rating of the motor. After supply fan is set, the return fan

drives should be adjustable for proper pressurization of the building. Sheaves with two or more

grooves should be adjusted by the same number of 1/2 or full turns from closed position to insure

the same pitch diameter so belts bear equal load. DO NOT FORCE BELT OVER THE

GROOVES. Hub type fan sheaves are furnished. Sheaves must be tightened securely before

drive is operated.

(13) Hinged or slide rail motor mounts are furnished with two adjusting bolts. Bolts must be adjusted

equally or so drives maintain proper alignment. Correct belt tension should be acquired by use of

belt tension checker tool. Over tightened belts reduce belt and bearing life substantially, yet belts

must be tight enough to prevent slippage.

(14) Humidifiers if installed include operator, trap, strainer and manifold mounted or furnished and

mounted by contractor. Supply steam connects at top to strainer and return connects at leaving

side of trap. Piping to and from humidifier should not be reduced in size with pitch (of 1/2" in

10') length without sag.

(15) After 24 hours operation re-check "start-up" items.

(16) See Prestart and Operation Check Sheet.

O-ITF-07

Page 9

(E) MAINTENANCE AND INSPECTION SERVICES

(1) FAN - Check blades for dirt and/or grease build-up especially on concave sides. Check set screws

and/or set collars of fan wheel and bearings for tightness. Check bearing mounting bolts and fan

housing cut off blade bolts and nuts for tightness. If fans are furnished with housing drains, see

that "weep holes" in bottom are open. If housing access door is furnished be sure it is properly

sealed and latched. Remove all debris from fan section and unit in general.

(2) BEARINGS AND SHAFT - Ball or Roller bearings are greased at the factory and therefore ready

to run at "start-up"; however routine maintenance and inspection is required there after. Normal

operation of bearings are "cool or warm to touch". High bearing temperature accompanied by

excessive leakage of grease indicates too much grease. High temperature with no grease showing

at the seals, particularly if the bearing seams noisy, indicates too little grease. If running

discloses an excessive amount of grease in the bearings the grease fittings should be removed

until the excess has escaped. Fan shafts should be coated to prevent corrosion yet check

that dirt or debris build-up is not accumulating which could affect balance.

(3) FAN BEARING LUBRICATION - Lubrication intervals vary with the period of operation and

temperature of the air. Do Not Over-Lubricate. The bearing is factory lubricated with Lithium

based grease of NGL1#2 consistency, such as Sinclair Litholene Multipurpose, Avalinia #2,

Texaco Multifax #2, Humble Lidok #2, Mobil Armyac#781 or Phillips Philube L2.

O-ITF-07

Page 10

START – UP REPORT

Temtro l, Inc .

Manufacturers of ….. Customized Air Handling Units

Start – UP Date: ______________________

Job Name: _______________________Unit Serial Number – U ________________

A Start- Up report must be submitted for each unit on the job. For warranty purposes, start – up

occurs when the equipment and/or blowers are started for operation regardless of when the building

may be ready for operation.

GENERAL Initials or 3

1. Inspect the unit for shipping and installation damage.

2. Check Bill of Lading against material received

3. Make sure all packing material has been removed from unit.

4. Inspect unit demounts for proper re-assembly ( if unit shipped in sections )

PRE-START

1. Remove shipping lock down bolts. See drawing on inside Supply Fan access door

2. Check fan wheel set screws for tightness and motor and fan sheave for proper alignment

3. Manually rotate fan wheels and motors to assure freedom of movement

4. Check main supply voltage

5. Check electrical connections for tightness

6. Check main fan amp draw ( Refer to motor nameplate )

7. Check condensate drain traps ( Separate traps are required for each drain connection )

8. Inspect system piping for proper installation

9. Check to see that proper filters are installed

10. Clean inside of unit of all construction dirt and debris

11. Adjust access doors for proper alignment if necessary

P.O. Box 409 • 15 East Oklahoma Avenue • Okarche, OK 73762 • (405) 263-7286 • (405) 263-4924

O-ITF-07

Page 11

OPERATIONAL CHECK

Warning ! Do not operate unit if system is not properly balanced.

1. Check damper operation to assure freedom of movement

2. Momentarily start fan motor and assure correct rotation

3. Check belts for tightness

4. If unit is equipped with variable frequency drive, refer to enclosed manufacturers

recommended start-up procedures.

5. Record motor rpm / amp:

Supply fan # 1 ___________________ rpm Supply Fan # 1 _________________ amps

Supply fan # 2 ___________________ rpm Supply Fan # 2 _________________ amps

Return Fan # 1 __________________ rpm Return Fan # 1 _________________ amps

Return Fan # 2 __________________ rpm Return Fan # 2 _________________ amps

6. Record unit External Static Pressure (esp.) and Total Static Pressure (tsp).

Supply fan # 1 ___________________ esp Supply Fan # 1 _________________ tsp

Supply fan # 2 ___________________ esp Supply Fan # 2 _________________ tsp

Return fan # 1 ___________________ esp Return Fan # 1 _________________ tsp

Return fan # 2 ___________________ esp Return Fan # 2 _________________ tsp

7. Record Unit Supply and Return CFM:

Supply air CFM: ___________________ Return air CFM: ____________________

8. Verify unit is operating at design conditions

9. While unit is in operation verify no excess standing water in drain pan.

P.O. Box 409 • 15 East Oklahoma Avenue • Okarche, OK 73762 • (405) 263-7286 • (405) 263-4924

O-ITF-07

Page 12

Note: After 24 hours of operation re-check set screws on bearing collar and fan hub

for proper tightness.

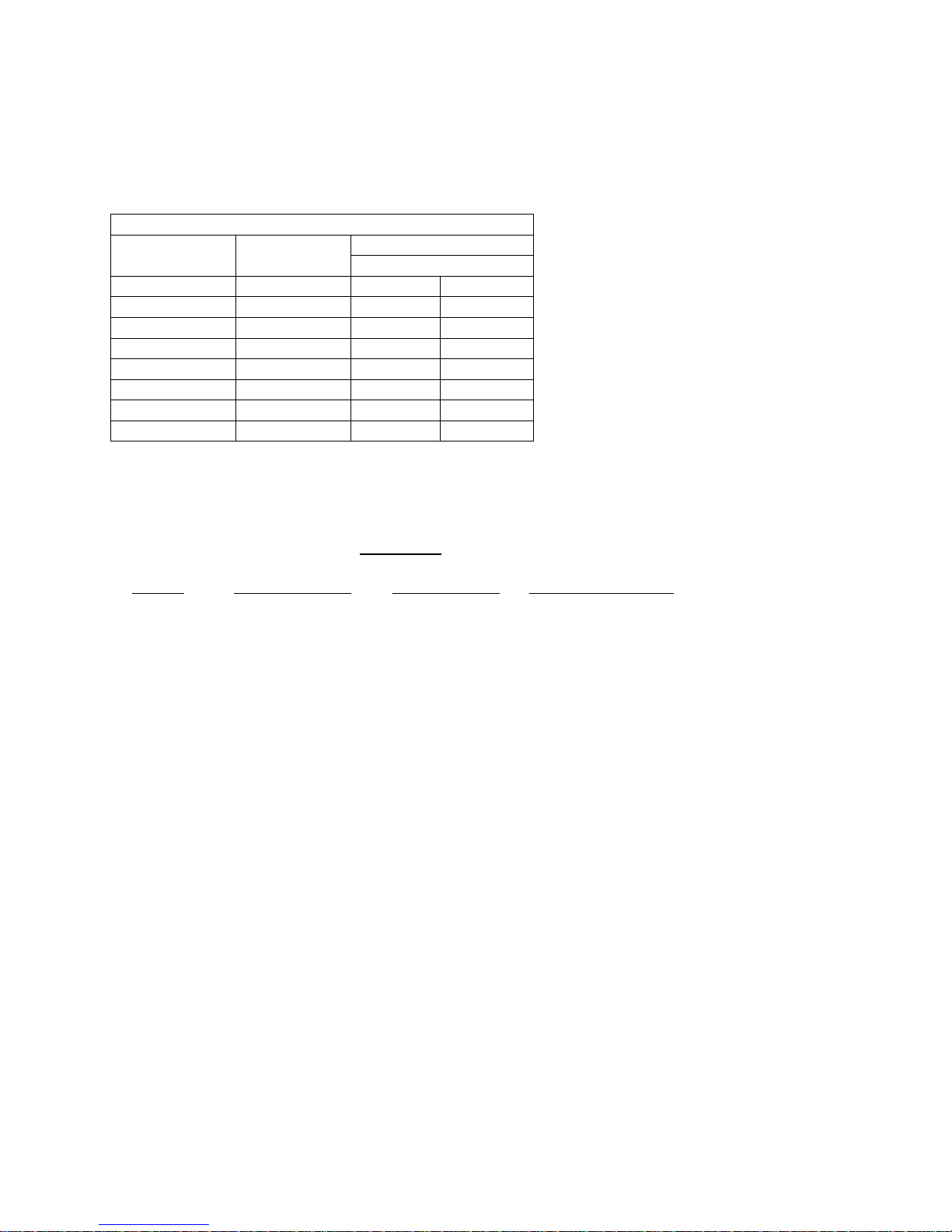

Ball and Roller Bearing Setscrew Tightening Torque

Dia.

Hex Size Across

Flats

#10 (109) 3/32

Min. Recommended Torque

Valuline

in.lbs ft.lbs

1/4 1/8 22 1.8

5/16 5/32 40 3.3

3/8 3/16 65 5.4

7/16 7/32 130 10.8

1/2 1/4 200 16.7

5/8 5/16 290 24.2

3/4 3/8 470 39.2

The following table should be used as a relubrication guide:

Conditions

SPEED

TEMPERATURE CLEANLINESS GREASE INTERVAL

100 RPM Up to 120 degrees F Clean 6 to 12 months

500 RPM Up to 150 degrees F Clean 2 to 6 months

1000 RPM Up to 180 degrees F Clean 2 wks to 2 months

1500 RPM Over 210 degrees F Clean Weekly

Any Speed Up to 150 degrees F Dirty Daily to 2 wks

Any Speed Over 150 degrees F Dirty Daily to 2 wks

Any Speed Any Temperature Very Dirty Daily to 2 wks

Any Speed Any Temperature Extreme Cond. Daily to 2 wks

Add grease slowly with shaft rotating, until a slight bead forms at the seals.

Start – Up performed by: ______________________________ Date: ______________

Notes:

______________________________________________________________________________________________

______________________________________________________________________________________________

______________________________________________________________________________________________

______________________________________________________________________________________________

P.O. Box 409 • 15 East Oklahoma Avenue • Okarche, OK 73762 • (405) 263-7286 • (405) 263-4924

O-ITF-07

Page 13

(4) MOTOR AND MOTOR BEARINGS - Check for dirt and debris accumulation on "air travel"

openings of open type motors to prevent overheating. Relubricate motor bearings every 2000

hours of operation while it is warm and at a stand still. Remove and clean upper and lower

grease plugs. Insert grease fittings into upper hole adding a small amount of clean grease with a

low pressure gun. Run motor 5 minutes before replacing plugs. Excessive grease will overheat

the bearings. Use only high grade mineral grease having a 200 degrees F safe operating

temperature. (If special lubrication instructions are shown on the motor nameplate they will

supersede all other instructions).

(5) SHEAVES - After air balance, require no further adjustment. However, sheave locking devices,

wear, alignment and belt tension should be checked on a regular basis.

(6) DAMPER BLADES AND LINKAGE - should be inspected regularly for dirt and/or debris build

up to insure abnormal wear or damage does not occur. Winterize damper system prior to cold

weather to insure that proper sequence of control is being maintained, paying close

attention to operation of outside air intake. Outside air damper should be checked closely for

minimal leakage when closed.

(7) OUTSIDE AIR INTAKE HOOD - should be checked for debris in birdscreen and/or obstructions

to air flow (such as old boxes, new walls or fences, etc.) around unit. Clean or remove as

required.

(8) WATER COILS - (Heating and Cooling) if not antifreeze protected or heater protected should be

drained as thoroughly as possible and then treated in the following manner:

Fill each coil independently with an antifreeze solution

using a small circulating pump and again drain. Check

freezing point of antifreeze before proceeding to next

coil. Due to a small amount of water always remaining in

each coil, there will be a diluting effect. The small

amount of antifreeze solution remaining in coil must

always be concentrated enough to prevent freeze-up.

Carefully read instruction for mixing antifreeze solution

used. Some products will have a higher freezing point in

its natural state than when mixed with water.

Failure of controls, outside air dampers and air stratification can cause freeze-up and permanent

coil damage if above precautions are not observed. Do Not allow dirt to accumulate between the

fins of coils. Use water, steam or air to remove dirt.

(9) STEAM COIL - fins should be cleaned in the same manner as Water Coils. Steam lines to and

from unit should be checked for pitch, pipe sag and blockage to avoid "Water-hammer".

Strainers and traps require annual cleaning minimum.

(10) CONDENSATE PAN - should be checked for dirt and debris build-up and cleaned. Trap and

drain should also be cleaned especially if blockage is evident.

O-ITF-07

Page 14

(11) FILTER ASSEMBLY - tracks should be checked for rail seal retention where required and all rails

should be cleaned annually to control dirt build-up, filter drag and dust by-pass during change

out of media. Dirty filters reduce the air volume handled by the unit, and thereby its capacity.

Unit should not be run without proper filters or fan motor overload, dirty coil and restricted air

flow will result. Proper media retainers should be used at all times to avoid possible media

"blow-out", which can cause blockage of air flow and/or damage rotating fan and motor parts.

Do not operate media beyond its rated capacities before change out or "blow-out" damage

can result.

(12) CASING AND ACCESS DOORS - should be checked for leakage (air and/or water). Door gasket

must be in proper alignment and if damaged, should be replaced. Inside access panels must be

latched properly to avoid air recirculation.

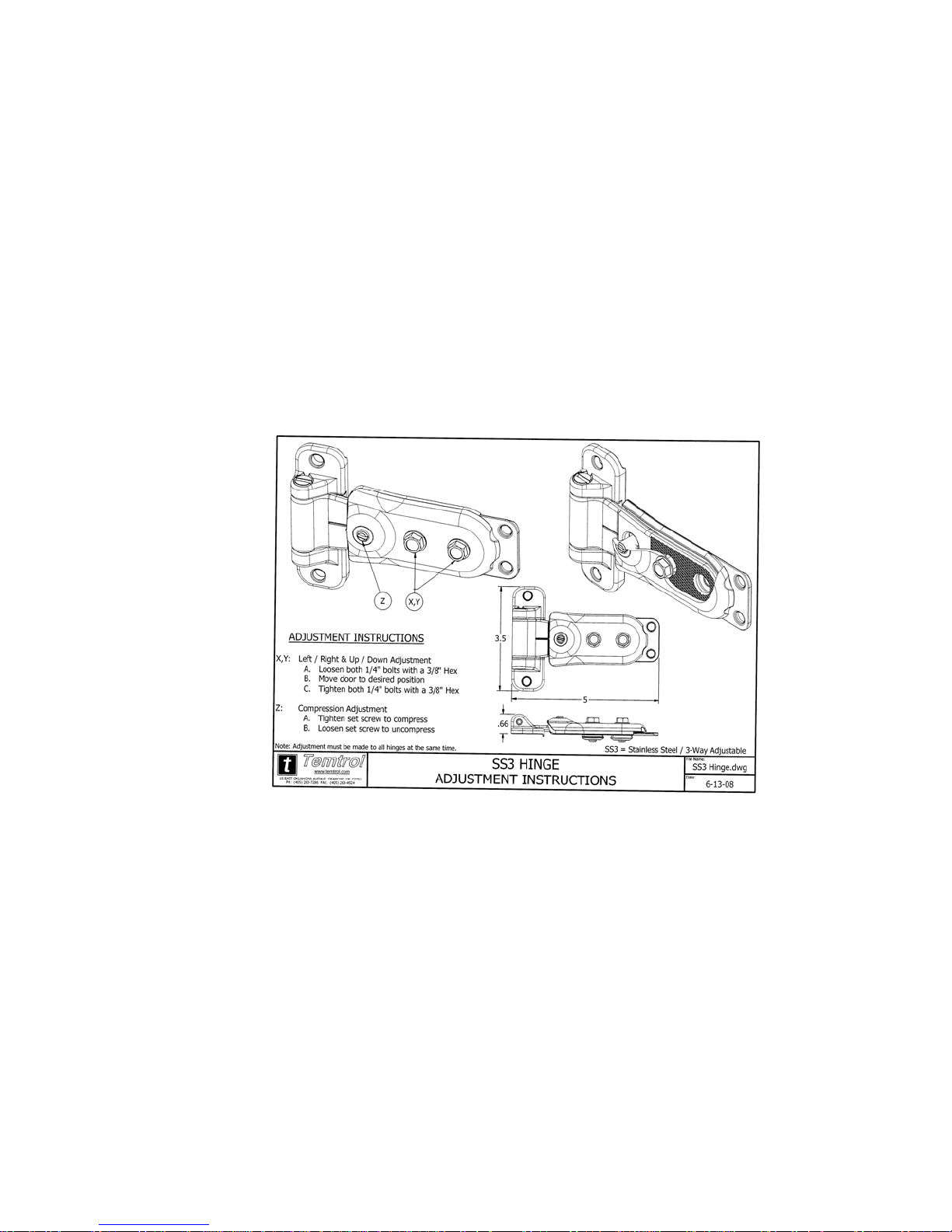

Larger Drawing

Located In The

Manual

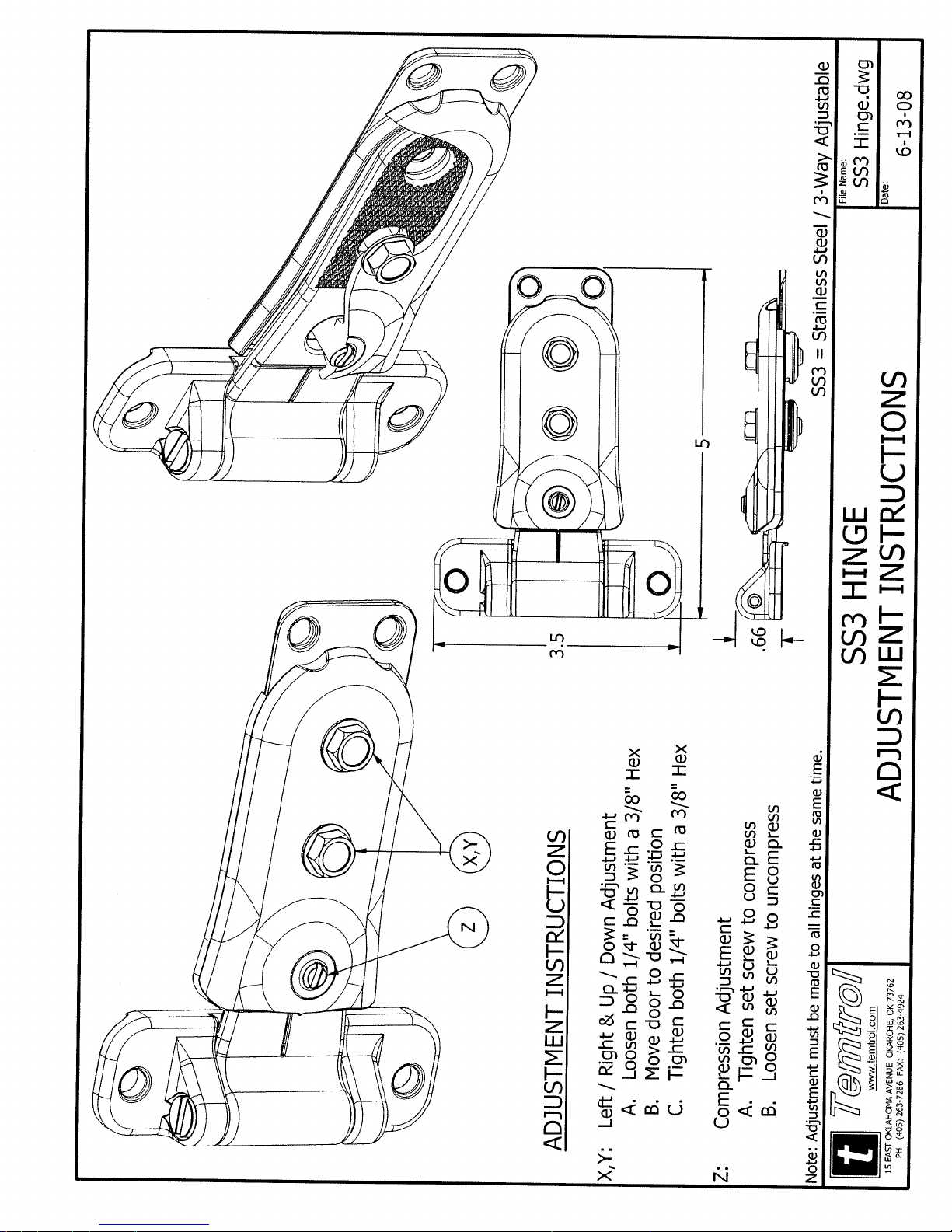

Door Adjustment: (All adjustments must be made to all hinges at the same time)

X,Y: Left/Right and Up/Down adjustment;

A. Loosen both 1/4” bolts with a 3/8” hex.

B. Move door to desired position.

C. Tighten both 1/4” bolts with a 3/8” hex.

Z: Compression Adjustment;

A. Tighten set screw to compress.

B. Loosen set screw to uncompress.

O-ITF-07

Page 15

(13) COILS - can be removed from unit through either end of unit. After removing piping and end

panels, remove bolts holding coil to structural frame at the air entering side of coil. The coil and

casing can then be pulled out.

(14) WIRING AND COMPONENTS - should be made and remain in accordance with National, State

and local codes that apply to this equipment. Check connections of wiring and retighten so

danger of a poor connection causing overheating and component failure through inadequate

current handling can be avoided. Good practice and safety indicates that before attempting

service to components, de-energize the systems and only after workers are clear of rotating and

electrical devices can unit be energized again.

(15) ULTRAVIOLET (UV) GERMICIDAL IRRADIATION LIGHTS – The United States Environmental

Protection Agency (EPA) believes that molds and bacteria inside buildings have potential to cause

health problems in sensitive individuals

as a factory-engineered and installed option in select commercial air handling products.

When UV lights are factory provided, polymer materials that are susceptible to deterioration by the

UV-C light will be substituted or shielded from direct exposure to the light. In addition, UVCradiation can damage human tissue, namely eyes and skin. To reduce the potential for inadvertent

exposure to the lights by operating and maintenance personnel, electrical interlocks that automatically

disconnect power to the lights are provided at all unit entry points to equipment where lights are

located.

Moisture and your Home; Brochure EPA 402-K-02-003.

1. United States Environmental Protection Agency: A Brief Guide to Mold,

WARNING

!

Equipment Damage, And Personal Safety Risk, From Ultraviolet (UV) Lights!

Temtrol does not recommend field installation of ultraviolet lights in its air handling

equipment for the intended purpose of improving indoor air quality. High intensity

C-band ultraviolet light known to severely damage polymer (plastic) materials and

poses a personal safety risk to anyone exposed to the light without proper personal

protective equipment (can cause damage to eyes and skin). Polymer materials

commonly found in HVAC equipment that may be susceptible include insulation on

electrical wiring, fan belts, thermal insulation, various fasteners and bushings.

Degradation of these materials can result in serious damage to the equipment.

Temtrol accepts no responsibility for the performance or operation of our air

handling equipment in which ultraviolet devices were in stalled outside of the

Temtrol factory.

(16) AIR FILTER GAUGE - "pick-ups" should point against air flow for best results without

restriction. Oil Manometers require split to operate properly (check zero set).

(17) HUMIDIFIER - strainer screen in supply line should be cleaned a few days after put in operation

and thereafter at least once a season - more often if much dirt is found in the screen. The trap

should be inspected at the same time strainer is cleaned.

(18) UNIT HEATER OR ELECTRIC COIL - should be checked for dirt on resisters and removed by

use of air only. DO NOT attempt cleaning without positive shut down.

(1)

. If specified, Temtrol provides ultraviolet lights (UV-C)

O-ITF-07

Page 16

(19) PNEUMATIC OPERATORS - and linkage should be inspected for sequence and travel and

vacuum hose leaks especially prior to cold weather usage where furnished.

(20) OTHER COMPONENTS - not mentioned should be maintained per instructions attached to

component.

(21) REPLACEMENT PART - (if required) orders for service or replacement must include serial

number, model number and unit tag of unit as stamped on serial plate, attached to unit. If

replacement parts are required, state date of installation of unit, date of start-up and date of

failure, along with an explanation of the malfunction and a description of the replacement parts

required. Goods may not be returned except by permission of authorized factory officials of

TEMTROL, INC. at Okarche, Oklahoma and when so returned will be subject to a handling

charge and transportation charges prepaid. Following our personal inspection of the returned

part and if it is determined that the failure is due to faulty material or workmanship, credit will

be issued on customer's purchase order if warranty is still in effect.

O-ITF-07

Page 17

ROOF - MOUNTED

O-ITF-07

CABINET

Panels OITF-0001

Insulation OITF-0002

Neoprene gasketing OITF-0003

Metal flange seal OITF-0004

Lifting lugs OITF-0005

Weatherproof screws OITF-0006

Roof-curb OITF-0007

Curb gasketing OITF-0008

Drain Pan with drain OITF-0009

Pan insulation board OITF-0010

FAN (S/A = Supply Air or R/A = Return Air)

Housing OITF-0101

Cutoff OITF-0102

Inlet funnels OITF-0103

Wheel OITF-0104

Shaft OITF-0105

Bearings OITF-0106

Inlet Vanes OITF-0107

Inlet Vane Linkage OITF-0108

Inlet Screen OITF-0109

Flex Connection OITF-0110

Isolators OITF-0111

Discharge diffuser OITF-0112

Sheave and Bushing OITF-0113

Lubrication fittings OITF-0114

(S/A or R/A) OITF-0201

MOTOR

Horse Power w/ voltage, phase RPM OITF-0202

Mount OITF-0203

Sheave and Bushing OITF-0204

Belts - size and length OITF-0205

Belt guard OITF-0206

DAMPER

Face damper OITF-0301

By-pass damper OITF-0302

Face and ByPass combination OITF-0303

Return air damper OITF-0304

Outside air damper OITF-0305

Relief - exhaust damper OITF-0306

Fan discharge damper OITF-0307

Recirculation damper OITF-0308

Min. outside air damper OITF-0309

Manual quadrant OITF-0310

Interconnecting linkage OITF-0311

Fire damper w/"fuse link" OITF-0312

Operator OITF-0313

COIL

Pre-Cooling OITF-0401

Cooling OITF-0402

Preheat OITF-0403

Heating OITF-0404

Reheat OITF-0405

Balance orifice OITF-0406

Connection grommets OITF-0407

Distributor w/nozzle OITF-0408

Hot gas side-port OITF-0409

Expansion valve OITF-0410

Vent and drain plugs OITF-0411

Top and/or bottom casings OITF-0412

Electric heating OITF-0413

COIL SYSTEMS (Special)

Integral Face & By-pass Heating OITF-0501

Reclaim wheel OITF-0502

Reclaim gas-type OITF-0503

Reclaim fluid run-around type OITF-0504

HUMIDIFIER

Humidifier (Steam) OITF-0601

Water spray OITF-0602

Humidifier pan w/drain OITF-0603

FILTER RACKS

Prefilter OITF-0701

2nd filter OITF-0702

Final filter OITF-0703

Exhaust filter OITF-0704

Roll type OITF-0705

Charcoal type OITF-0706

Retainer frames & clips OITF-0707

Gauges OITF-0708

FILTER MEDIA

Prefilter cartridges OITF-0801

2nd filter cartridges OITF-0802

Final cartridges OITF-0803

Exhaust filter cartridges OITF-0804

Roll media OITF-0805

Charcoal Media or tray OITF-0806

ELECTRICAL

Light fixture OITF-0901

Disconnect(Main or service) OITF-0902

Starter (S/A or R/A) OITF-0903

Panel box OITF-0904

Transformer OITF-0905

Terminal strip OITF-0906

Fuse block OITF-0907

Fuses OITF-0908

Unit heater OITF-0909

ACCESS

Door OITF-1001

Door hinge OITF-1002

Door latch OITF-1003

Drip gutter OITF-1004

Door gasket OITF-1005

Window pane WP-001

FINISH

Internal coating OITF-1101

Pan Mastic OITF-1102

Touch-up paint (external) OITF-1103

Not all listed parts apply to each unit.

Prices on application and as effective on date of shipment.

Many parts are available on open market

.

WHEN ORDERING PARTS the following information

must be given:

Unit Serial Number

Unit Model Number

Part Name + Location

Code Number + Place Number

EXAMPLE:

Job Symbol AH-1 AH-2 AH-3

Model No. ITF-RD20 ITF-RDV11 ITF-RBR15

Serial No. U100168-001 U100167-002 U100168-003

Serial No: = U100168-_______

Model = ITF-RDH11

Fan sheave and bushing - S/A (Supply Air Fan) RZR-OITF-0113

Temtrol, Inc.

RT-0 & M79

Page 18

Temtrol, Inc.

INFORMATION COVERING:

AIR HANDLERS

ROOF - MOUNTED

O-ITF-07

PARTS LIST

JOB SYMBOL :

MODEL NUMBER :

DRAWING NUMBER:

SERIAL NUMBER :

PART NUMBER :

JOB SYMBOL :

MODEL NUMBER :

DRAWING NUMBER:

SERIAL NUMBER :

PART NUMBER :

Temtrol, Inc.

Manufacturers of Air Conditioning, Heating Ventilation and Heat Transfer Products

Okarche, OK

MAINTENANCE

FREQUENCY SCHEDULE

Recommended Maintenance Service for Temtrol Equipment

Type of Service Start-Up Monthly Every 6 Months Shutdown Annually

Inspect General Condition of Unit XX

Clean Debris From Unit XX X

Check and Adjust Fan Belt Tension XX

Check Unit for Unusual Noise or Vibration XX

Check Fan Bearing Locking Collars XX

Check Motor Voltage and Current XX

Lubricate Fan Shaft Bearings X See Below X

Lubricate Motor Base Adjusting Screws XXX

Check Fan for Rotation Without Obstruction X

Check Fan for Proper Rotation X

Inspect Protective Finish X

Replace Filters X

Lubricate Damper Linkage X

Check Fans for Unusual Vibration XX

Clean Outside of Coils XX

IMPORTANT SAFETY NOTES

Before performing any maintenance or inspection, make certain that all power has been

disconnected.

Adequate precautions should be taken to safeguard the equipment and the premises from

damage, also the public from possible injury as appropriate for the installation of these

products.

The following table should be used as a relubrication guide:

Conditions

SPEED TEMPERATURE CLEANLINESS

100 RPM Up to 120 degrees F Clean

500 RPM Up to 150 degrees F Clean

1000 RPM Up to 180 degrees F Clean

1500 RPM Over 210 degrees F Clean

Any Speed Up to 150 degrees F Dirty

Any Speed Over 150 degrees F Dirty

Any Speed Any Temperature Very Dirty

Any Speed Any Temperature Extreme Cond.

GREASE INTERVAL

6 to 12 months

2 to 6 months

2 wks to 2 months

Weekly

Daily to 2 wks

Daily to 2 wks

Daily to 2 wks

Daily to 2 wks

Add grease slowly with shaft rotating, until a slight bead forms at the seals.

Temtrol, Inc.

Phone - 405-263-7286 Fax - 405-263-4924

Trouble

Shooting

TROUBLE SHOOTING GUIDES

FANS

PROBLEM PROBABLE CAUSE

Noise Impeller hitting inlet ring a. Impeller not centered in inlet ring.

b. Inlet ring damaged

c. Crooked or damaged impeller

d. Shaft loose in bearing

e. Impeller loose on shaft

f. Bearing loose in bearing support

Impeller hitting cutoff a. Cutoff not secure in housing

b. Cutoff damaged

c. Cutoff improperly positioned.

Drive a. Sheave not tight on shaft (motor and/or fan)

b. Belts too loose. Adjust for belt stretching after

48 hours of operation.

c. Belts too tight.

d. Variable pitch sheaves not adjusted so each

groove has same pitch dia. (multi-belt drives).

e. Misaligned sheaves

f. Belts worn

g. Isolation base shipping restraints not removed.

h. Belts oily or dirty

SOLUTION

Bearing a. Defective bearing

Shaft Seal Squeal a. Need lubrication

Impeller a. Loose on shaft

Noise (Continued) d. Worn as result of abrasive or corrosive

b. Needs Lubrication

c. Loose on bearing supports

d. Loose on shaft

e. Seals misaligned

f. Foreign material inside bearing

g. Worn bearing

h. Fretting corrosion between inner race and shaft.

b. Misaligned

b. Defective Impeller

Do not run fan - Contact manufacturer.

c. Unbalanced

TROUBLE SHOOTING GUIDES

FANS

PROBLEM PROBABLE CAUSE

Housing a. Foreign material in housing

Electrical a. AC hum in motor or relay

High Air Velocity a. Duct work too small for application.

Pulsation or Surge a. Restricted system causes fan to operate at poor

SOLUTION

material moving through flow passage

b. Cutoff or other part loose (rattling during operation)

b. Starting relay chatter

c. Noisy motor bearings

d. Single phasing a 3 phase motor

b. Fan selection too small for application.

c. Registers or grilles too small for

application.

d. Heating or cooling coil with insufficient

face area for application.

point of rating.

b. Fan too large for application

c. Ducts vibrate at same frequency as fan pulsations.

Rattles and/or Rumbles a. Vibrating duct work

b. Vibrating cabinet parts

c. Vibrating parts not isolated from building.

CFM Low - Insufficient Fan a. Mecanical volume control device is improperly set.

Air Flow b. Fan running backwards

c. Cutoff missing or improperly installed.

d. Dirty fan blades.

e. Loose or slipping belts

f. Fan speed too slow

Duct System a. Actual system is more restrictive (more resistant to flow)

b. Dampers closed

c. Registers closed

d. Leaks in supply ducts

e. Insulating duct liner loose.

CFM Low - Insufficient Filters a. Dirty or clogged

Air Flow (continued)

TROUBLE SHOOTING GUIDES

FANS

PROBLEM PROBABLE CAUSE

Coils a. Dirty or clogged

Obstructed Fan Inlets a. Elbows, cabinet walls or other obstructions restrict

No Straight Duct at Fan Outlet a. Fans which are normally used in duct system are

Obstructions in High Velocity a. Obstruction near fan outlet

Air Stream b. Sharp elbows near fan outlet

SOLUTION

air flow. Inlet obstructions cause more restrictive

systems but do not cause increased negative

pressure readings near the fan inlet(s). Fan speed

may be increased to counteract the effect of

restricted fan inlet(s)

tested with a length of straight duct at fan outlet. If

there is no straight duct at the fan outlet, decreased

performance will result. If it is not practical to

install a straight section of duct at the fan outlet,

the fan speed may be increased to overcome

this pressure loss.

c. Improperly designed turning vanes

d. Projections, dampers or other obstructions in part

of system where air velocity is high

CFM High - Too Much System a. Oversized duct work

Air Flow b. Access door open

Fan a. Fan speed too fast

Incorrect Static Pressure System, Fan or Interpretation General Discussion:

of Measurements The velocity pressure at any point of measurement

Incorrect Static Pressure In most systems, pressure measurements are indicators

- Continue - of how the installation is operating. These

c. Registers or grilles not installed

d. Damper set to by-pass coils

e. Filter(s) none in place

f. System resistance much lower than anticipated

is function of the velocity of the air or gas and its density

The static pressure measured in a "loose" or oversized

system will be less than the static pressure in a

"tight" or undersized system for the same air flow rate

measurements are the result of air flow and as such are

TROUBLE SHOOTING GUIDES

FANS

PROBLEM PROBABLE CAUSE

useful indicators in defining system characteristics

Field static pressure measurements rarely correspond

with laboratory static pressure measurements unless

the fan inlet and fan outlet conditions of the installation

are exactly the same as the inlet and outlet conditions

in the laboratory

Static Pressure Low, System System has less resistance to flow than expected

CFM High This is a common occurrence. Fan speed may be

reduced to obtain desired flow rate. This will reduce

HP (operating cost).

Fan a. Backward inclined impeller installed backwards. HP

will be high

b. Fan speed too high

Static Pressure Low, System a. Fan inlet and/or outlet conditions not same as tested.

CFM Low

SOLUTION

Static Pressure High System a. Obstruction in system

CFM Low b. Dirty filters

c. Dirty coils

d. System too restricted

HP High Fan a. Backward inclined impeller installed backwards

b. Fan speed too high

c. Too low system resistance for forward curved fan

System a. Oversized duct work

b. Face and by-pass dampers oriented so coil dampers

are open at same time by-pass dampers are open

c. Filter(s) - left out

d. Access door open

Fan Selection a. Fan not operating at efficient point of rating. Fan size

or type may not be best for application

Fan Does Not Operate Electrical or Mechanical a. Blown fuses

b. Broken belts

c. Loose pulleys

d. Electricity turned off

TROUBLE SHOOTING GUIDES

FANS

PROBLEM PROBABLE CAUSE

SOLUTION

e. Impeller touching scroll

f. Wrong voltage

g. Motor too small and overload protector has broken

circuit

h. Optional thermostats, firestats, freezestats may

lockout fan operation if set incorrectly

TROUBLE SHOOTING GUIDES

ELECTRIC HEATING COILS

PROBLEM PROBABLE CAUSE

Electric Heater Electrical or Mechanical Disconnect switch or main circuit breaker may be

Not Operating in the "OFF" position. If heater has built-in disconnect

switch, door must be closed and switch turned "ON"

before heater will operate

If the fan and heater are interlocked with a fan relay, the

fan must be on before the heater will operate. If an air

flow switch is used, air pressure in the duct must be

sufficient (at least 0.7" W.C.) to close the switch

before the heater will operate

Automatic (or manual) reset thermal cutout may have

opened when overheating resulted from insufficient air

flow or poor air distribution. Allow heater temperature

to return to normal so that automatic thermal cutout

may reset or manual reset thermal cutout may be reset.

Correct cause of overheating before proceeding.

Heat limiter(s) may have opened if local "hot spot"

developed or if automatic reset thermal cutout failed to

open first, when overheating occurred. Correct cause

of overheating and replace heat limiter.

Check main fuses, if open, correct cause of failure

before replacing fuses.

SOLUTION

Electric Heater Cycles Electrical or Mechanical Check air inlet and discharge openings for obstructions.

(Will Not Stay On) See that filters are not clogged, fire dampers are open

and air system is balanced

Check to see that the heater terminal box is tight

against duct and heater safety devices are receiving

sufficient air flow. Air flow must be distributed evenly

over entire face area.

Look at heater coils in operation (through observation

port in duct); any red area is not receiving enough air.

(A small amount of redness is permissible inside the coil

insulation bushings). Make sure that air flow through

every part of the heater is sufficient.

Coils must not glow.

If air flow switch is used, contactors may "chatter" if air

flow is not sufficient to keep switch fully on.

If duct has internal insulation, the insulation may be

blocking the safety devices.

Improper Temperature Electrical or Mechanical Make sure associated control equipment, such as

TROUBLE SHOOTING GUIDES

ELECTRIC HEATING COILS

PROBLEM PROBABLE CAUSE

Regulation thermostats, are in the correct location and that

all controls are adjusted according to manufacturer's

specifications for existing field conditions.

Check air system balance to see that correct amount

of air flow is supplied for proper zone control.

Automatic thermal cutout may be opening (cycling)

before room thermostat is satisfied. (see "Electric

Heater Cycles". Insufficient heat may be caused by:

1. Open heat limiter(s) or thermal cutout

2. Incorrect supply voltage

3. Heater too small (in wattage) for application

SOLUTION

4. Faulty or dirty thermocouple

4. Defective motor or capacitor

TROUBLE SHOOTING GUIDES

Gas Furnace by Reznor

PROBLEM PROBABLE CAUSE

Pilot Will Not Light 1. Manual valve turned off 1 Open valve

(Match Lit System) 2. Air in gas line 2 Disconnect pilot line at shut off bleed air from gas

supply line

3. Incorrect lighting procedure 3 Follow instructions on cover of junction box.

4. Dirt in pilot orifice 4 Remove orifice. Clean with compressed air or solvent

(do not ream)

5. Extremely high or low gas 5 Check line pressure, this should be 3 oz or 5 in. water

pressure pressure minimum. 8 oz or 14 in. maximum

6. Bent or kinked pilot tubing 6 Replace tubing

Pilot Lighted But Magnetic 1. Power not turned on or 1 Turn on power, check fuses, turn on thermostat

Gas Valve Will Not Open thermostat not calling for

(All Manual Valves Are heat.

Open) (Match Lit System) 2. Circuit to magnetic valve 2 Check wiring and connections at transformer and

open thermostat

3. Faulty transformer 3 Replace transformer

4 Clean and test with millivolt meter or test kit. Replace

or safety pilot switch defective part.

5. Faulty thermostat 5 Replace thermostat

6. Faulty magnetic valve 6 Replace valve or magnetic head

7. High gas pressure 7 Max. gas pressure 8 oz or 14" W.C.

SOLUTION

Venter Motor Will Not 1. No power to unit 1 Turn on power, check supply fuses or circuit breaker

Start (RPV Models) 2. No 24 volt power to venter 2 Turn up thermostat, check control transformer output

relay Check for loose or improper wire connections

3. Venter relay defective 3 Replace

4 Replace motor or capacitor

Pilot Will Not Light 1. Manual valve not open 1 Open manual valve

(Spark Ignition System) 2. Air in gas line 2 Bleed gas line

(Venter Operation on RPV 3. Dirt in Pilot Orifice 3 Remove and clean with air pressure

Models) 4. Gas pressure too high or 4 Set supply pressure at 5" to 8" for natural gas - 11"

too low for propane

5. Kinked pilot tubing 5 Replace tubing

6. Pilot valve does not open 6 If 24V available at valve, replace valve

7. No Spark: 7

a. Loose wire connection a. Be certain all wire connections are solid

b. Transformer failure b. Be certain 24 volts is available

c. Incorrect spark gap. c. Maintain spark gap 7/64"

Pilot Will Not Light Con't d. Spark cable shorted to d. Replace worn or grounded spark cable

TROUBLE SHOOTING GUIDES

Gas Furnace by Reznor

PROBLEM PROBABLE CAUSE

(Spark Ignition System) ground

(Venter Operation on RPV e. Spark electrode shorted e. Replace pilot if ceramic spark electrode is cracked

Models) to ground or grounded

f. Drafts affecting pilot f. Make sure panels are in place and tightly secured

to prevent improper or unusual drafts at pilot

g. G60 control box not g. Make certain G60 is grounded to furnace chassis

grounded

h. Faulty G60 h. If 24V is available to G60 controller and all other

causes have been eliminated, replace G60

8. Optional lockout device 8 Reset lockout by interrupting control circuit at

interrupting control circuit thermostat

by above causes

9. Faulty combustion air 9 Replace combustion air proving switch

proving switch

Pilot Lights, Main Valve 1. Manual valve not open. 1 Open manual valve

Will Not Open 2. Main valve not operating 2

(Spark Ignition System) a. Defective valve a. Replace if 24V is measured at valve connection

and valve remains closed

b. Loose wire connection b. Check and tighten all wiring connection

3. G60 does not power main 3

valve

a. Loose wire connection a. Check and tighten all wiring connection

b. Flame sensor grounded b. Be certain flame sensor lead is not grounded or

(Pilot lights - spark insulation or ceramic is not cracked. Replace as

continues) required.

c. Gas pressure incorrect c. Set supply pressure at 5" to 8" for natural gas - 11"

for propane

d. Cracked ceramic at d. Replace sensor

sensor

e. Faulty G60 e. If all checks indicate no other cause replace G60

DO NOT ATTEMPT TO REPAIR G60 THERE ARE

NO FIELD REPLACEMENT COMPONENTS

CONTAINED IN THIS DEVICE.

SOLUTION

No Heat 1. Dirty Filters 1 Clean or replace filters

TROUBLE SHOOTING GUIDES

Gas Furnace by Reznor

PROBLEM PROBABLE CAUSE

(Heater Operating) 2. Incorrect manifold pressure 2 Check manifold pressure

or orifices

3. Cycling on limit control 3 Check air throughput

4. Improper thermostat or 4 See thermostat instructions

adjustment

5. Belt slipping on blower 5 Adjust belt tension

Cold Air is Delivered on 1. Fan control heater element 1 Connect as per wiring diagram inside junction box

Start-Up, During improperly wired cover

Operation 2. Defective fan control 2 Replace fan control

3. Incorrect manifold pressure 3 Check manifold and line pressure

Motor Will Not Run 1. Circuit open 1 Check wiring and connections

2. Fan control inoperative 2 Replace fan control

3. Contactor inoperative 3 Replace contactor

4. Defective motor 4 Replace motor

SOLUTION

TROUBLE SHOOTING GUIDES

HEATING COILS

PROBLEM PROBABLE CAUSE

Coil Does Not Operate Steam valve failure a. Check steam valve. If air operated, check proper air

(Steam Coil) pressure. If electrically operated check for no power or

loose connection. If manual valve, check to see if

valve is open. If necessary repair or replace valve.

b. Defective thermostat or wrong setting

Steam trap failure Condensate backs up into coil. Check steam trap,

(Steam Coil) repair or replace

Diverter valve a. Check power to valve as above

(Hot Water Coil)

b. Diverter valve piped wrong

Coil Does Not Deliver No steam or hot water Check boiler for proper steam pressure or hot water

Adequate Heat temperature setting.

Thermostat a. Thermostat improperly located, relocate.

b. Thermostat defective, replace

c. Improper set point, reset

d. Defective controls, see above

SOLUTION

Coil undersized Replace with larger coil

Insufficient steam pressure Check boiler controls

Lack of hot water Hot water pump undersized or malfunctioning

Dirty finned tubes Vacuum or use air hose to gently clean dirt from

finned tubes

Coil Leaks Crack in brazed connection Repair brazed joint

Internal corrosion Replace coil

TROUBLE SHOOTING GUIDES

COOLING COILS

PROBLEM PROBABLE CAUSE

Coil Does Not Deliver Lack of chilled water Chilled water pump undersized or malfunctioning

Adequate Cooling

Dirty finned tubes Vacuum or use air hose to gently clean dirt from

finned tubes

Coil undersized Replace with larger coil

Coil Leaks Crack in brazed connection Repair brazed joint

Internal corrosion Replace coil

Moisture on Walls Excess capicity through Check air flow through coil

Downstream of Cooling cooling coil

Coil

Standing water in drain pan See "Condensate Drain Pan" Section

V.A.V. unit (Low Volume Air Verify that the air flow and water flow are synchronized

Flow - High Volume Water

Flow)

SOLUTION

TROUBLE SHOOTING GUIDES

CONDENSATE DRAIN PAN

PROBLEM PROBABLE CAUSE

Standing Water Unit is not level Check level of unit, shim if required.

in Drain Pan

Drain connection is clogged Remove dirt or debris from drain pan

Condensate drain line to drain Check pitch in line towards floor drain

is not correctly pitched.

Trap is sized incorrectly All condensate drain connections and floor drains

must be trapped. Failure to properly trap a drain will

result in flooding of the drain pan and potential water

damage to the air-handling unit and other building

facilities.

SOLUTION

TROUBLE SHOOTING GUIDES

ELECTRIC MOTORS

PROBLEM PROBABLE CAUSE

Motor Fails to Start Blown fuse or open circuit Replace fuse or reset circuit breaker

breaker

Overload trips Check and reset overload

Improper line connections Check connections with diagram supplied

with motor

Open circuit in winding or Check inside motor to determine if switch is closed.

starting switch. Evidence by Check for loose connections.

humming sound from motor

when switch is closed

Improper current supplied Check to determine that power supply agrees with

motor nameplate specifications.

Mechanical failure Determine that motor and drive turn freely. Check

bearings and lubrication

SOLUTION

Short circuited stator Indicated by blown fuses. Motors must be rewound

Poor stator coil connection Remove end bells and locate with a test lamp.

Defective rotor Look for broken bars or end rings. Replace rotor

Motor overloaded Reduce load or replace unit with larger motor

With a 3 phase power source Check line for open phase

one phase may be open

Defective capacitor Replace capacitor

Motor Stalls Wrong application Change type or replace unit with a larger motor,

consult factory

Overloaded motor Reduce load or replace unit with a larger motor.

Low line voltage Check across AC line and correct if possible

Motor Runs and Then Partial loss of line voltage Check for loose connections. Determine adequacy

TROUBLE SHOOTING GUIDES

ELECTRIC MOTORS

PROBLEM PROBABLE CAUSE

Dies Down of main power supply

Stator shorts when motor Replace stator

warms up.

Motor Does Not Come Up Motor under designed for Replace with a larger motor

to Speed application

Voltage too low at motor Check across AC line and correct if possible

terminals

Line wiring to motor too small Install larger line wiring

Broken rotor bars Look for broken bars or end rings, replace motor.

60 cycle motor connected to Replace unit with a 50 cycle motor.

50 cycle line supply

SOLUTION

Motor Takes Too Long Excessive load Replace with larger motor

to Accelerate

Loose connection(s) Check connections and tighten where necessary

Wrong Rotation Improperly wired to AC line Check wiring diagram on motor nameplate and correct.

(3 Phase) (Wrong sequence of phases) Reverse any two motor leads at line connection

Motor Overheats Motor overloaded Replace with larger motor.

(Temperature Rise Above

Ambient Greater Than Motor fan may be clogged with Remove fan cover and clean, replace fan cover

Nameplate Specifications) dirt preventing proper

ventilation

Motor (3 phase) may have Check to insure that all connections are tight

one phase open

Partially shorted stator coil Must be rewound

Line voltage too high Check across AC line and correct. Step-down

transformer may be required

Motor Overheats Line voltage too low Check across AC line. Consult power company.

-Continue- Step-up transformer may be required

TROUBLE SHOOTING GUIDES

ELECTRIC MOTORS

PROBLEM PROBABLE CAUSE

(Temperature Rise Above

Ambient Greater Than Rotor rubs stator bore Check motor bearings and replace

Nameplate Specifications)

Worn bearings Replace bearings and seals

Motor Vibrates When Motor mounting bolts loose Tighten mounting bolts

Connected to Driven

Equipment Rigid type coupling used to Replace coupling with a proper coupling

connect motor to driven

equipment

Driven equipment unbalanced Balance driven equipment

Worn motor bearings Replace bearings and seals

Motor (3 phase) running on Check for open circuit and correct

single phase

SOLUTION

Bent motor shaft Replace shaft or rotor

Rapid Motor Bearing Excessive overhung load Check overhung load, retension drive.

Wear due to over tensioned drive

Excessive overhung load Check "NEMA Sheave Selection Guide" in the

due to a smaller diameter Browning Catalog. Replace sheave with one of size

sheave than recommended equal to or greater than listing

minimum used on motor

shaft

TROUBLE SHOOTING GUIDES

VARIABLE SPEED DRIVES

PROBLEM PROBABLE CAUSE

Short Belt Life Spin burns from belt slipping Tension belts

on drive under stalled load

conditions or when starting

Gouges or extreme cover Eliminate obstruction or realign drive to provide

wear caused by belts on clearance

drive guard or other objects

High ambient temperature a. Use Gripnotch Belts

b. Provide ventilation

c. Shield belts

Grease or oil on belts a. Check for leaky bearings

b. Clean belts and sheaves

Worn sheaves Replace sheaves

Center distance shorter than Increase center distance by using longer belts.

recommended minimum Replace standard driven sheave with a companion

when using standard sheave sheave

as a companion sheave

SOLUTION

Belt misalignment Realign drive with sheave set at mean pitch diameter

Belts Turn Over in Grooves Damaged cord section in Replace belts

belts. Frayed or gouged

belts.

Excessive vibration Tension belts, replace belts if damaged.

Flat idler pulley misaligned Realign idler

Worn sheaves Realign drive

Belt Squeal Excessive overload. High Tension drive or redesign and replace drive.

starting load. Belts not

tensioned properly.

Insufficient arc of contact Increase center distance or use Gripnotch Belts

Belt Breakage Foreign material in drive Provide drive guard

TROUBLE SHOOTING GUIDES

VARIABLE SPEED DRIVES

PROBLEM PROBABLE CAUSE

Belts damaged during Replace belts

installation

Shock or extreme overload Eliminate overload cause or redesign drive.

Belt Stretch Beyond Worn sheaves Replace Sheaves

Take-up

Under designed drive Redesign and replace drive

Take-up slippage Reposition take-up

Drive excessively tensioned Properly tension drive

Damaged cord section Replace belts and properly install

during installation

Excessive Vibration Damaged belt cord section Replace belts

SOLUTION

Loose belts Tension drive

Belts improperly tensioned Tension drive with slack of each belt on the same

side of the drive

Belts too Long at Insufficient take-up Use shorter belts

Installation

Drive improperly set up Recheck driver and driven machine set up

Wrong size belts Use correct size belts

Belts too Short at Insufficient take-up Use longer belts

Installation

Drive improperly set up Recheck driver and driven machine set up

Wrong size belts Use correct size belts

Belts Mismatched at Belts matched by code Replace belts with Machine Matched Belts

Installation number only

Belts Mismatched at Old belts and new belts used Replace with new belts

Installation together on the same drive

TROUBLE SHOOTING GUIDES

VARIABLE SPEED DRIVES

PROBLEM PROBABLE CAUSE

- Continue Different brand name belts Replace with a set of Machine Matched Belts

used on same drive

Driver and driven shaft shifted Realign drive

Worn sheaves Replace sheaves

Belts Mismatched Belts improperly tensioned, Replace belts and tension drive with slack of

After Service causing more stretch of some each belt on the same side of the drive

belts than others

Old belts and new belts used Replace with new belts

together on the same drive

Different brand name belts Replace with a set of Machine Matched Belts.

used on same drive

SOLUTION

Driver and driven shafts Realign drive

shifted from parallel

Belt cord section damaged Replace belts and install properly

during installation

Drive Fails to Adjust Fretting corrosion (drive Sheave must be disassembled, cleaned and

allowed to operate at one lubricated, then reassembled.

speed over a period of time).

FWR/FWT 10

Page 1

P.O. Box 409 • 15 East Oklahoma Avenue • Okarche, OK 73762 • (405) 263-7286

Temtrol, Inc.

Manufacturers of ….. Customized Air Handling Units

®

FWR

FWT

MODEL FWR/FWT – Fanwall Technology

®

FWR – Fanwall Retrofit – Field Installed Fan Cubes

FWT – Fanwall – Factory Installed Fan Cubes/Array

Installation, Operation

And

Maintenance Guide

Temtrol, Inc., has a policy of continuous product improvement, and reserves the right to change design and specifications without

notice.

Temtrol, Inc.

Manufacturers of ….. Customized Air Handling Unit s

Improper installation, adjustment, alteration service or maintenance

can cause property damage, injury or death. Read the installation,

operating and maintenance instructions thoroughly before installing

or servicing this equipment.

®

!

FOR YOUR SAFETY

FWR/FWT 10

Page 2

WARRANTIES AND LIMITATIONS OF LIABILITY FOR BREACH OF WARRANTY

Temtrol, Inc., warrants all products to be free from defects in material and workmanship for twelve (12)

months from date of shipment unless a start-up form is on file and accepted by Temtrol, in which case the

warranty is twelve (12) months from the date of start-up, or eighteen (18) months from date of shipment,

whichever is shorter. Said start-up form shall signify that the equipment has been properly started and

adjusted, and is operating under normal conditions, prescribed ratings and specifications, and was installed

by qualified personnel in accordance with Temtrol instructions and local codes and ordinances. For warranty

purposes, start-up occurs when the equipment and/or blowers are started for operation of the equipment

regardless of when the building may be ready for operation.

Temtrol’s obligation hereunder shall be limited to the exchange of new parts for those returned to Temtrol’s

factory at buyer’s expense and found to be defective, by Temtrol. Replacement parts shall be shipped F.O.B.

Temtrol’s factory. Replacement of parts hereunder shall not operate to extend the original warranty period as

to any part, including replacement parts supplied hereunder.

This warranty does not cover corrosion; normal deterioration; misapplication; labor charges paid for parts

replacement; adjustments; repairs or other work; loss of refrigerant; components supplied by others; defects

in parts resulting from neglect, negligence, accident, fire, explosion, high or low voltage, jumpering or

jamming controls; improper or contaminated fuel; excessive or inadequate fuel pressure; frozen heating coils;

war; or any acts of God.

This warranty is void if equipment is misapplied or if any alterations are made to the basic design or operating

requirements as listed on the original order and shipped from the factory unless approval

is received in writing from Temtrol.

It is expressly understood that this warranty is made IN LIEU OF ALL OTHER WARRANTIES with the

exception of those warranties attached hereto, EXPRESS OR IMPLIED, INCLUDING WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR ANY PARTICULAR PURPOSE and in consideration of the

express warranty herein contained, BUYER EXPRESSLY WAIVES ANY RIGHT TO CLAIM OTHER

WARRANTIES, EXPRESS AND IMPLIED.

It is further understood that Temtrol’s liability for breach of warranty shall be limited to the terms of this

warranty. Buyer agrees that Temtrol SHALL NOT, IN ANY EVENT, BE LIABLE FOR CONSEQUENTIAL

DAMAGES and that buyer’s sole and exclusive remedy shall be limited to that provided herein.

Temtrol neither assumes nor authorizes any person to assume for it any obligation or warranty other

than those stated herein.

Any suggestion to the contrary notwithstanding, Temtrol shall not, in any event have any liability under this

warranty unless and until Temtrol has been paid in full for the products supplied. The warranty period shall

begin to run as described above, however, whether or not payment has been

Note: IMPROPER INSTALLATION AND/OR OPERATION OF FWR/FWT CUBE

WILL VOID WARRANTY

FACTORY PARTS

TEMTROL, INC. Parts Department:

Phone: (405) 263-7286

Fax: (405) 6263-4924

Email: sbausterst@temtrol.com

Address: 15 East Oklahoma Ave.

Okarche, OK 73762

Temtrol, Inc.

Manufacturers of ….. Customized Air Handling Unit s

®

FWR/FWT 10

Page 3

(A) GENERAL DESCRIPTION

FWR

FWT

The Temtrol FANWALLTechnology® is a fan-array approach to air handler design that uses several

smaller fans to replace one larger fan, providing design flexibility, reducing maintenance costs, and increasing

energy savings.

A1. FWR – Fanwall Retrofit – Field Installed Fan Cubes

A2. FWT – Fanwall – Factory Installed Fan Cubes/Array

(B) STORAGE

(1) Should storage of FWR/FWT cubes be required caution should be

taken to set FWR/FWT cubes indoors in a clean location to protect

motor, fans, coplanar and etc., from excessive dust. Also avoid

storage in location where children play and/or public access. If

units are to be stored for an extended period of time the following

maintenance procedures must be performed:

d. Manually rotate motor/wheel monthly.

FWR/FWT Cube

(2) A complete fan wheel/motor spare assembly storage requirements for motors and generators

that will not be placed in service for at least six months from date of shipment. Improper

motor storage will result in seriously reduced reliability and failure. An electric motor that does

not experience regular usage while being exposed to normally humid atmospheric conditions

is likely to develop rust in the bearings or rust particles from surrounding surfaces may

contaminate the bearings. The electrical insulation may absorb an excessive amount of

moisture leading to the motor winding failure.

a. A wooden crate “shell” should be constructed to secure the motor during

storage.

This is similar to an export box but the sides & top must be secured to the

wooden base with lag bolts (not nailed as export boxes are) to allow opening

and

reclosing many times without damage to the “shell”.

Minimum resistance of motor winding insulation is 5 Meg ohms or

the calculated minimum, which ever is greater. Minimum resistance

is calculated as follows: Rm = kV + 1 where: (Rm is minimum

resistance to ground in Meg−Ohms and kV is rated nameplate

voltage defined as Kilo−Volts.) Example: For a 480VAC rated motor

Rm =1.48 meg−ohms (use 5 MÙ). For a 4160VAC rated motor Rm =

5.16 meg−ohms.

Complete fan wheel/motor

spare assembly

b. Storage Preparation:

1. Some motors have a shipping brace attached to the shaft to prevent

damage during transportation. The shipping brace, if provided, must be

removed and stored for future use. The brace must be reinstalled to hold

the shaft firmly in place against the bearing before the motor is moved.

Temtrol, Inc.

Manufacturers of ….. Customized Air Handling Unit s

®

FWR/FWT 10

Page 4

2. Store in a clean, dry, protected warehouse where control is maintained

as follows:

a. Shock or vibration must not exceed 2 mils maximum at 60 hertz,

to prevent the bearings from brinelling. If shock or vibration

exceeds this limit vibration isolation pads must be used.

b. Storage temperatures of 10°C (50°F) to 49°C (120°F) must be

maintained.

c. Relative humidity must not exceed 60%.

d. Motor space heaters (when present) are to be connected and

energized whenever there is a possibility that the storage ambient

conditions will reach the dew point. Space heaters are optional.

Note: Remove motor from containers when heaters are energized,

re-protect if necessary.

3. Measure and record the resistance of the winding insulation (dielectric

withstand) every 30 days of storage.

a. If motor insulation resistance decreases below the minimum

resistance, contact your Baldor District office.

b. Place new desiccant inside the vapor bag and reseal by taping it

closed.

c. If a zipper closing type bag is used instead of the heat sealed

type bag, zip the bag closed instead of taping it. Be sure to place

new desiccant inside bag after each monthly inspection.

d. Place the shell over the motor and secure with lag bolts.

4. Where motors are mounted to machinery, the mounting must be such

that the drains and breathers are fully operable and are at the lowest

point of the motor. Vertical motors must be stored in the vertical

position. Storage environment must be maintained as stated in step 2.

5. Motors with antifriction bearings are to be greased at the time of going

into extended storage with periodic service as follows:

a. Motors marked “Do Not Lubricate” on the nameplate do not need

to be greased before or during storage.

b. Ball and roller bearing (antifriction) motor shafts are to be

rotated manually every 3 months and greased every 6 months in

accordance with the Maintenance section of this manual.

c. Sleeve bearing (oil lube) motors are drained of oil prior to

shipment. The oil reservoirs must be refilled to the indicated

level with the specified lubricant, (see Maintenance). The shaft

should be rotated monthly by hand at least 10 to 15 revolutions

to distribute oil to bearing surfaces.

Temtrol, Inc.

Manufacturers of ….. Customized Air Handling Unit s

®

FWR/FWT 10

Page 5

d. “Provisions for oil mist lubrication” – These motors are packed

with grease. Storage procedures are the same as paragraph 5b.

e. “Oil Mist Lubricated” – These bearings are protected for

temporary storage by a corrosion inhibitor. If stored for greater

than 3 months or outdoor storage is anticipated, connected to

the oil mist system while in storage. If this is not possible, add

the amount of grease indicated under “Standard Condition” in

Section 3, then rotate the shaft 15 times by hand.

6. All breather drains are to be fully operable while in storage (drain plugs

removed). The motors must be stored so that the drain is at the lowest

point. All breathers and automatic “T” drains must be operable to allow

breathing and draining at points other than through the bearings around

the shaft. Vertical motors should be stored in a safe stable vertical

position.

7. Coat all external machined surfaces with a rust preventing material.

An acceptable product for this purpose is Exxon Rust Ban # 392.

8. a. Non−Regreaseable Motors:

Non−regreasable motors with “Do Not Lubricate” on the

nameplate should have the motor shaft rotated 15 times to

redistribute the grease within the bearing every 3 months or

more often.

b. All Other Motor Types