Page 1

I.O.M. #152 updated : 05/10/2017

Temperature Controller

INSTRUCTION MANUAL • INSTALLATION • OPERATION • MAINTENANCE

Oil Unit

For Models with the G500 Series Control Instrument

Model:

Serial Number :

TEMPTEK, INC.

525 East Stop 18 Road Greenwood, IN 46142

317-887-6352 fax: 317-881-1277

Service Department fax: 317-885-8683

www.Temptek.com

E-mail: sales@Temptek.com

Page 2

Page 3

Oil Unit

Temperature Controller

INSTRUCTION MANUAL

VTO Series with

G500 Series Instrument

COVERING

INSTALLATION

OPERATION

MAINTENANCE

TEMPTEK, INC. 525 East Stop 18 Road Greenwood, IN 46143

Phone: 317-887-6352 Fax: 317-881-1277 Service Department fax: 317-885-8683

www.Temptek.com E-mail: sales@Temptek.com

Page 4

Temperature Control Unit : VTO Series with G500 Series Instrument

TABLE OF CONTENTS

1.0 GENERAL 7

1.1 Receiving Instructions 8

1.2 Introduction 8

1.3 Safety 8

1.4 Components 10

2.0 INSTALLATION 13

2.1 General 14

2.2 To and from process connections 14

2.3 Water supply connection 15

2.4 Drain connection 15

2.5 Electrical connection 17

3.0 START UP SEQUENCE 19

3.1 General 20

3.2 System Fill / Operations 20

3.3 Instrument : Quick Start 24

3.4 Instrument : Basic Navigation 25

3.5 Instrument : Operating Screens 26

3.6 Instrument : Fault Screens 27

3.7 Instrument : Main Menu 28

3.8 Instrument : Setpoints Menu 28

3.9 Instrument : Utilities Menu 29

3.10 Instrument : Network Menu 30

3.11 Instrument : Options Menu 32

3.12 Instrument : Machine Menu 32

3.13 Shut Down / Disconnect 33

4.0 TROUBLESHOOTING 35

4.1 Unit will not start (Display is not Illuminated) 36

4.2 Unit will not start (Display is Illuminated) 36

4.3 Unit Stops 36

4.4 Unit Overheats 37

4.5 Unit Underheats 38

4.6 Pressure Relief Valve Leaks 38

5.0 MAINTENANCE 41

5.1 Preventative Maintenance 42

5.1 Pump Seal Replacement 43

5.2 Heater Replacement 45

5.3 Cooling Valve Service 46

5.4 Pressure Switch Service 47

5.5 Electronic Instrument Repair Policy And Procedure 48

525 East Stop 18 Road Greenwood, Indiana 46142

TEMPTEK, INC.

317-887-6352 Fax: 317-881-1277

Email: service@Temptek.com

Page: 4

Page 5

Temperature Control Unit : VTO Series with G500 Series Instrument

6.0 COMPONENTS 49

6.1 Mechanical system 50

6.2 Electrical system 50

7.0 RELATED DRAWINGS 53

7.1 Physical 12 kW Heaters & 1 - 3 HP Pumps 54

7.2 Physical 16-24 kW Heaters & 1 - 3 HP Pumps 55

7.3 Physical 36-48 kW Heaters & 5 - 7.5 HP Pumps 56

7.4 Circuit Schematic with Cooling Circuit 57

8.0 APPENDIX 59

8.1 Model # And Suffix Coding 60

8.2 Water Cooled Process Pumps 61

8.3 Mold Purge Operation 62

525 East Stop 18 Road Greenwood, Indiana 46142

TEMPTEK, INC.

317-887-6352 Fax: 317-881-1277

Email: service@Temptek.com

Page: 5

Page 6

THIS PAGE INTENTIONALLY BLANK

Page: 6

Page 7

Temperature Control Unit : VTO Series with G500 Series Instrument

1.0 GENERAL

1.1 Receiving Instructions

1.2 Introduction

1.3 Safety

1.4 Components

525 East Stop 18 Road Greenwood, Indiana 46142

TEMPTEK, INC.

317-887-6352 Fax: 317-881-1277

Email: service@Temptek.com

Page: 7

Page 8

Temperature Control Unit : VTO Series with G500 Series Instrument

1.1 RECEIVING INSTRUCTIONS

A. Temperature control units are generally shipped skid mounted, boxed and wrapped in

plastic prior to shipment.

B. Unbox the unit before accepting delivery. Check for visible damage and document any

evident damage on the delivery receipt or refuse the shipment. Shipping damage is the

responsibility of the carrier.

C. In order to expedite payment for damages, should they occur, follow proper procedures

and keep detailed records. Take photographs of any suspected damage.

1.2 INTRODUCTION

A. This manual covers temperature control units from 12 to 48 kW of heating capacity

using the G500 Series microprocessor control instrument. The standard uid operating

temperature range for this temperature control unit is 100°F to 500°F. Consult the factory

if you have questions about the operating range of your temperature control unit.

B. The intent of this manual is to serve as a guide in the installation, operation and

maintenance of your temperature control unit. Improper installation can lead to equipment

damage and poor performance. Failure to follow the installation, operation and

maintenance instructions may result in damage to the unit that is not covered under the

limited warranty. This manual is for standard products. The information contained in this

manual is intended to be general in nature. The information is typical only and may not

represent the actual unit purchased.

C. When calling for assistance from the Manufacturer’s Service Department, it is important

to know the model and serial number of the particular unit. The model number includes

critical unit information which is helpful when troubleshooting operating difculties. The

serial number allows the service team to locate manufacturing and testing records which

can have additional information relating to a particular unit.

1.3 SAFETY

A. It is important to become thoroughly familiar with this manual and the operating

characteristics of the unit.

B. It is the owner’s responsibility to assure proper operator training, installation, operation,

and maintenance of the unit.

C. Observe all warning and safety placards applied to the unit. Failure to observe all

warnings can result in serious injury or death to the operator and severe mechanical

damage to the unit.

WARNING: This equipment contains hazardous voltages that can cause severe injury or

death. Disconnect and lock out incoming power before installing or servicing the equipment.

525 East Stop 18 Road Greenwood, Indiana 46142

TEMPTEK, INC.

317-887-6352 Fax: 317-881-1277

Email: service@Temptek.com

Page: 8

Page 9

Temperature Control Unit : VTO Series with G500 Series Instrument

CAUTION

WARNING

J5318-BF

D. Observe all safety precautions during installation, startup and service of this equipment

due to the presence of high voltage. Only qualied personnel should install, startup and

service this equipment.

E. When working on this equipment, observe precautions in literature and on tags, stickers

and labels located on the equipment. Wear work gloves and safety glasses.

F. Before installing and operating the unit, be aware of and follow any local laws and codes

that apply to the installation.

G. Samples of Warning Labels applied to typical temperature control units.

1. Alerts users to the danger of high voltage.

2. Alerts the user to possible explosive danger.

3. Alerts the user to a hot surface danger due to high operating temperatures.

525 East Stop 18 Road Greenwood, Indiana 46142

TEMPTEK, INC.

317-887-6352 Fax: 317-881-1277

Email: service@Temptek.com

Page: 9

Page 10

Temperature Control Unit : VTO Series with G500 Series Instrument

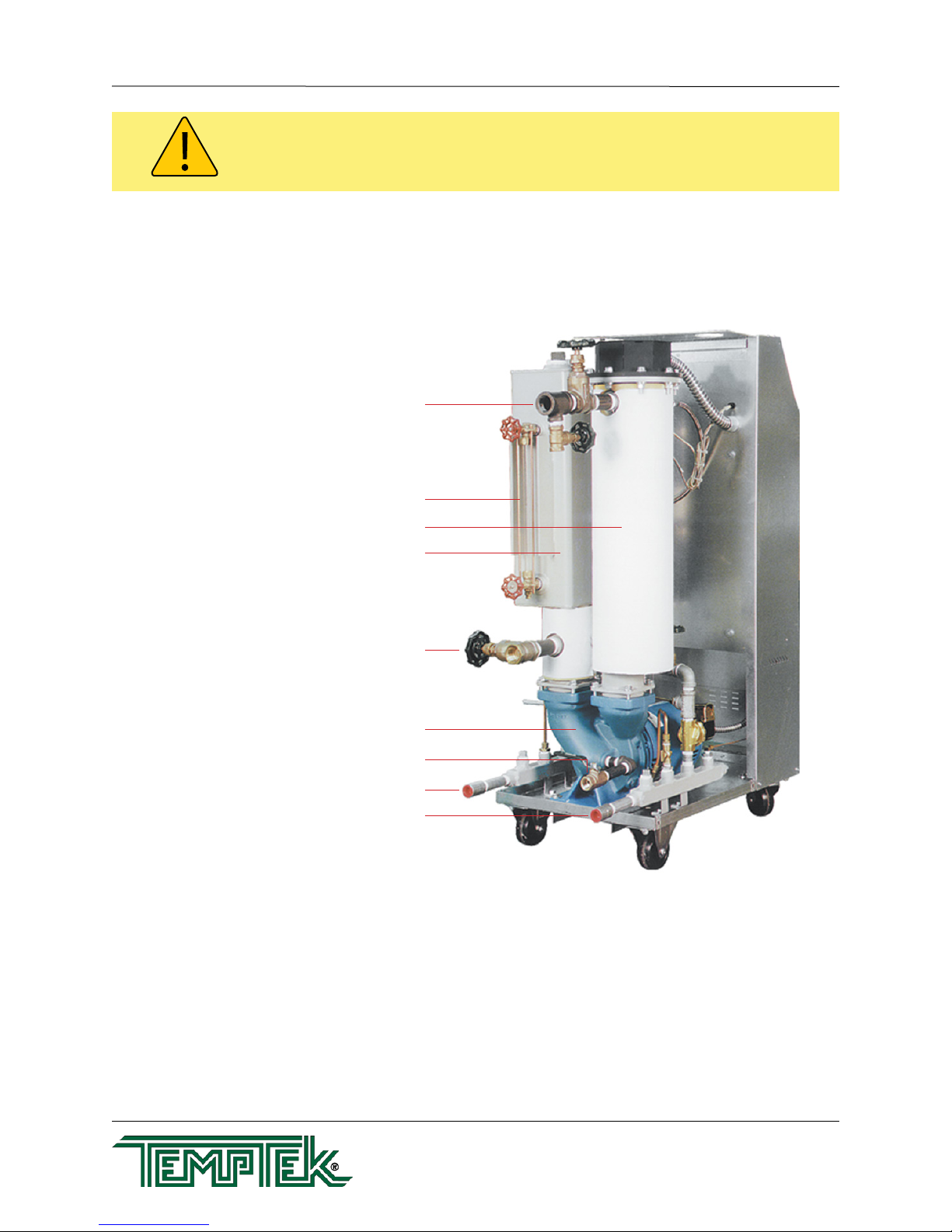

WARNING: Improper fluid quality will void unit warranty.

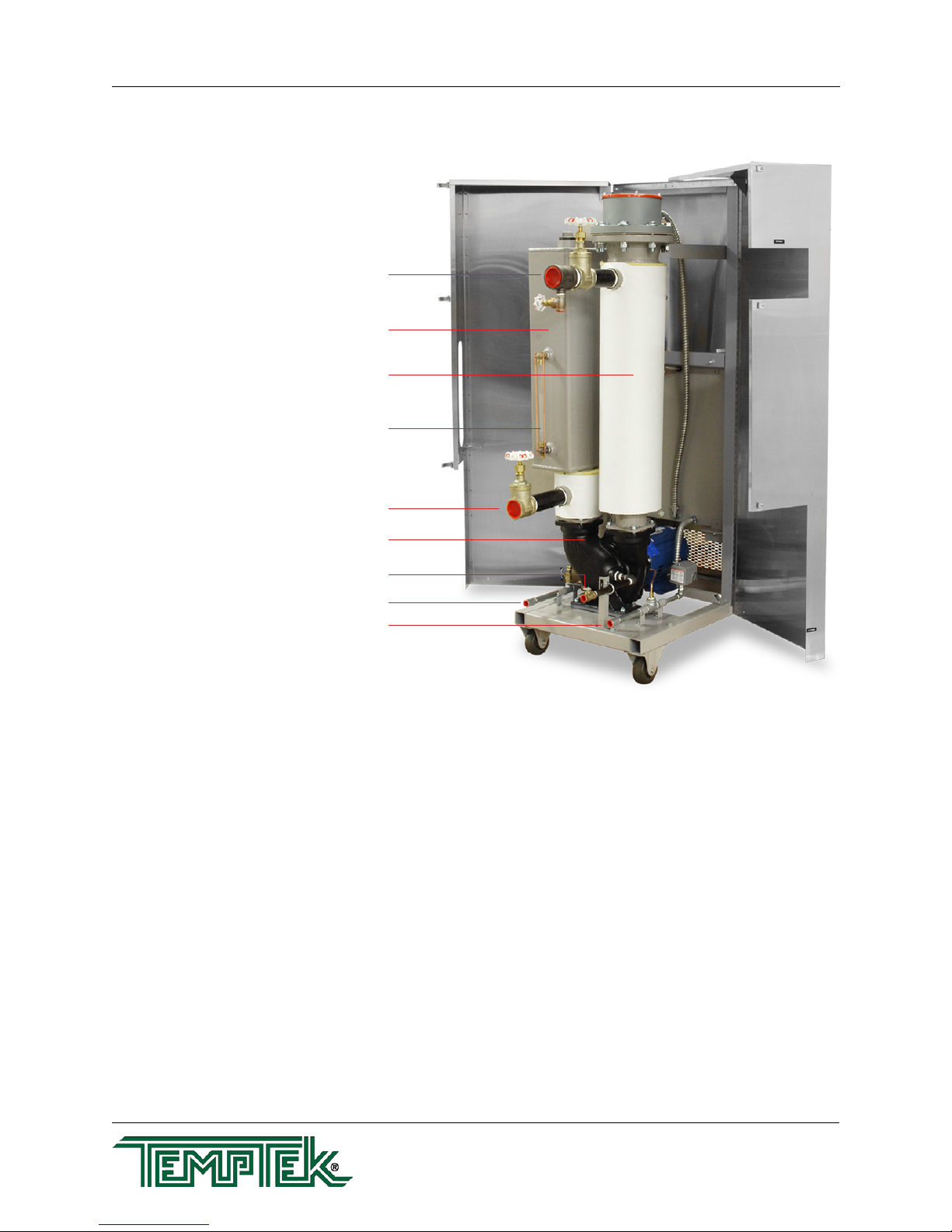

1.4 COMPONENTS

To Process Valve and Connection

Sight Glass

Heat Cylinder

Expansion Tank

From Process Valve and Connection

Process Pump

Fluid Drain Valve

Water Drain Connection

Water Supply Connection

Typical unit with lift-off cabinetry.

525 East Stop 18 Road Greenwood, Indiana 46142

TEMPTEK, INC.

317-887-6352 Fax: 317-881-1277

Email: service@Temptek.com

Page: 10

Page 11

Temperature Control Unit : VTO Series with G500 Series Instrument

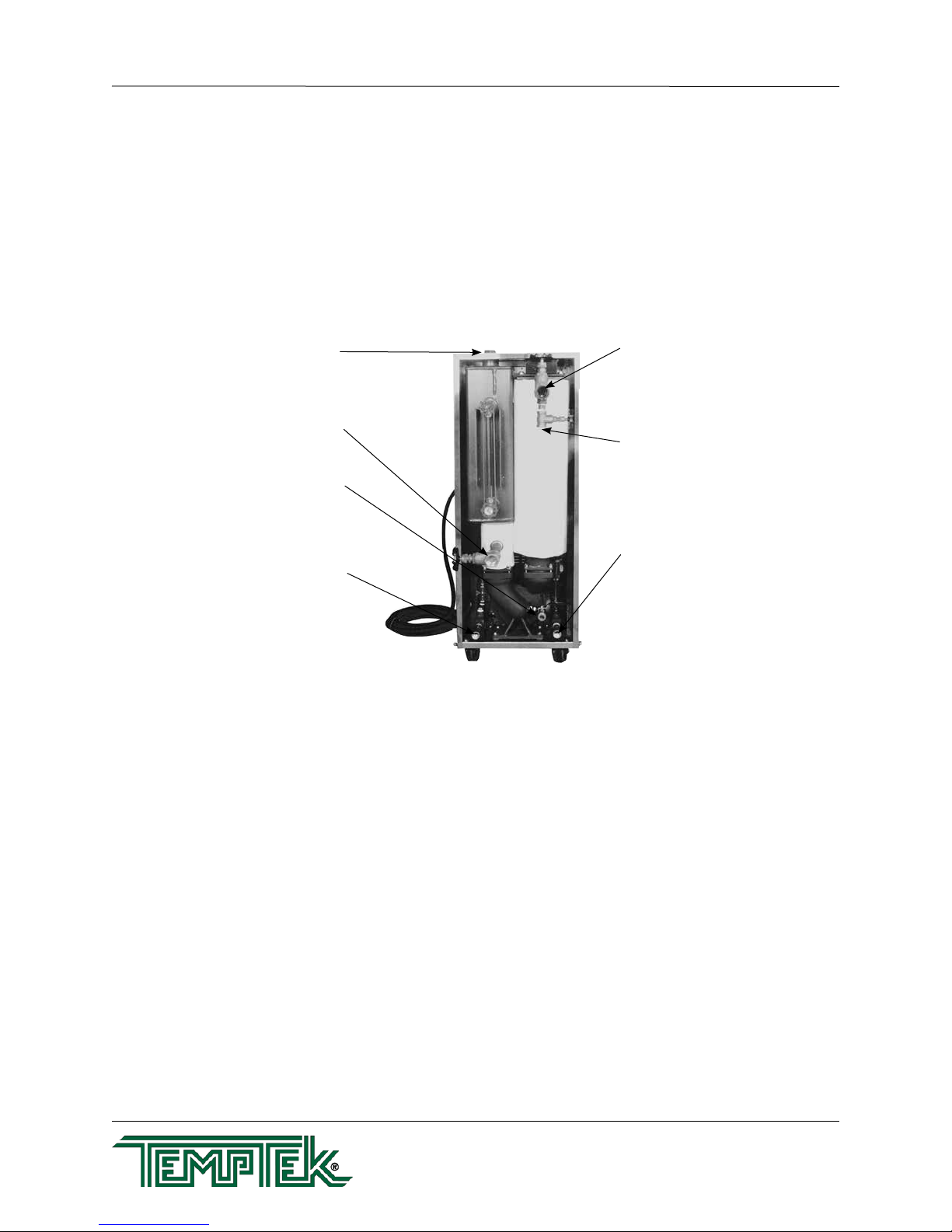

To Process Valve and Connection

Expansion Tank

Heat Cylinder

Sight Glass

From Process Valve and Connection

Process Pump

Fluid Drain Valve

Water Drain Connection

Water Supply Connection

Typical unit with clam shell cabinetry.

525 East Stop 18 Road Greenwood, Indiana 46142

TEMPTEK, INC.

317-887-6352 Fax: 317-881-1277

Email: service@Temptek.com

Page: 11

Page 12

THIS PAGE INTENTIONALLY BLANK

Page: 12

Page 13

Temperature Control Unit : VTO Series with G500 Series Instrument

2.0 INSTALLATION

2.1 General

2.2 To and From Process Connections

2.3 Water Supply Connection

2.4 Drain Connection

2.5 Electrical Connection

525 East Stop 18 Road Greenwood, Indiana 46142

TEMPTEK, INC.

317-887-6352 Fax: 317-881-1277

Email: service@Temptek.com

Page: 13

Page 14

Temperature Control Unit : VTO Series with G500 Series Instrument

2.1 GENERAL

A. Care should be taken to use materials (hose, rigid piping, valves or filters) rated for

the temperature and pressure duty of your unit. Most units have a maximum operating

temperature of 500°F or less and a maximum pressure of 75 PSI. The unit is most

efficient when full size plumbing is run from the unit connections to and from the process.

If necessary, reduce the plumbing size at your process, not at the unit.

B. Be certain all process piping materials have the equivalent or larger diameter of the

particular process connection.

Fluid fill port:

Use when manually

adding fluid to the unit

From process

connection:

Connect to “fluid out” on

process manifold

Fluid fill/drain connection:

Use when adding fluid from a

pressurized source or when draining

majority of fluid volume from unit

Water drain connection:

Connect to one of the following:

• Plant’s open water drain

• Tower water system return

• Chilled water system return

2.2 TO AND FROM PROCESS CONNECTIONS

A. Connect the unit’s To Process port to the Fluid In port on the process manifold.

B. Connect the unit’s From Process port to the Fluid Out port on the process manifold.

To process connection:

Connect to “fluid in” on process manifold

Compressed air connection:

Connect to plant compressed air source

when purging fluid from mold to unit for

storage

Water supply connection:

Connect to one of the following:

• Plant’s city water source

• Well water source

• Tower water supply

• Chilled water supply

C. Please note: Process piping circuitry should be designed to avoid an excessive use of

elbows and/or lengths of pipe or hose. If hose is the material of choice, avoid tight twists

or curls and excessive lengths.

.

2.3 WATER SUPPLY CONNECTION

A. Connect the unit’s Water Supply port to the plant’s city water, well water, tower water or

chilled water supply.

B. If unit is a Heating Only Unit, the water supply must be a minimum of 1/2 GPM at a

maximum temperature of 100°F for efcient component cooling. If the unit is a Heating

and Cooling Unit including a heat exchanger, the water supply must be a minimum of

3 GPM at a minimum temperature of 100°F. High water ow may be required for your

application depending on the process cooling requirement.

525 East Stop 18 Road Greenwood, Indiana 46142

TEMPTEK, INC.

317-887-6352 Fax: 317-881-1277

Email: service@Temptek.com

Page: 14

Page 15

Temperature Control Unit : VTO Series with G500 Series Instrument

C. The factory recommend minimum operating water supply pressure requirement is a

minimum of 20 PSI. To protect the unit from operating without adequate supply water, a

water pressure switch is plumbed into the supply manifold. If the supply pressure is not

sufcient, the pressure switch will prevent unit operations.

D. On all units, cooling water circulates to the supply manifold, through the pump adapter

cooling jacket, and is then rejected to the drain manifold. This action maintains proper

pump seal cavity temperatures.

E. On units with the installed cooling option, a tube and shell heat exchanger for process

uid cooling is supplied and mounted to the expansion tank.

1. The purpose of the heat exchanger is to cool the process uid. Cooling water

from plant water supply circulates through the “tube” side of the heat exchanger.

The process uid circulates through the “shell” side. Cooling water ow is

controlled by the solenoid valve.

2. A 1/2” ball valve is placed in the heat exchanger water supply line after the

solenoid valve. The ball valve should be open during operations from 100°F to

200°F. During operations with temperatures over 200°F, this valve should be

closed. In such cases, the necessary cooling water is proportioned to the heat

exchanger through the small capillary line, which some water “steams off” to cool

the process uid. The steam and water mixture is then rejected to drain.

2.4 WATER DRAIN CONNECTION:

A. Connect the unit’s Water Drain port to one of the following, determined by the water

supply source:

1. Open water drain for well or city water supply.

2. Tower water system return for tower system water supply.

3. Chilled water system return for chilled water system supply.

B. The factory recommends a minimum of 20 psi pressure differential between the water

supply and water drain line for proper cooling.

1. For units equipped with the cooling feature, the amount of cooling provided by

the unit depends on:

a. Cooling heat exchanger size.

b. The cooling valve size

c. The pressure differential across the valve

d. The temperature difference between the unit set point and the cooling

water temperature

2. Consult factory when selecting the correct cooling valve for your application.

525 East Stop 18 Road Greenwood, Indiana 46142

TEMPTEK, INC.

317-887-6352 Fax: 317-881-1277

Email: service@Temptek.com

Page: 15

Page 16

Temperature Control Unit : VTO Series with G500 Series Instrument

3. In general, the cooling capacity of the standard 3.5 sq ft heat exchanger is 6,000

Bth/hr (2 kW) for every 20°F difference between the cooling water temperature

and the uid temperature.

C. CAUTION: The unit must never be operated with a closed drain line valve. A closed

drain line valve prevents adequate system cooling and will lead to unit overheating.

Overheating of the unit may lead to unit damage and/or serious personal injury.

WARNING: Never operate the Temperature Control Unit with a closed water drain.

2.5 ELECTRICAL CONNECTION

A. Standard Models

1. Electrical power supply requirements for standard units are identied on the

equipment data tag. Verify that available voltage supply is the same as the unit’s

voltage requirements.

WARNING: DO NOT CONNECT THE UNIT TO A VOLTAGE SUPPLY SOURCE

NOT EQUAL TO THE UNIT’S VOLTAGE REQUIREMENTS AS SPECIFIED ON

THE UNIT’S DATA PLATE.

WARNING: Do not connect the unit to a voltage supply not equal to the unit’s voltage

requirements as specified on the unit’s data plate. Use of incorrect voltage will void the unit’s

warranty and cause a significant hazard that may result in serious personal injury and unit

damage.

Use of incorrect voltage will void the unit’s warranty and cause a signicant

hazard that may result in serious personal injury and/or unit damage.

2. For standard units with 12 kW heaters and up to 3 horsepower pumps, a four

conductor cable, 10 foot in length, is provided for connection to an operator

supplied fused disconnect.

3. For units with 16 kW to 48 kW heaters, the owner must provide a four conductor

power cable and the fused disconnect.

4. The owner supplied fused disconnect must be sized and installed according to

the unit’s power supply requirements and local electrical codes.

B. Models With Factory Included Disconnect Switch and Other Custom Features

1. Some units may be customized and include a factory supplied power disconnect

switch and/or higher specication electrical enclosure. Electrical power supply

requirements are identied on the equipment data tag. Verify that available

voltage supply is the same as the unit’s voltage requirements.

525 East Stop 18 Road Greenwood, Indiana 46142

TEMPTEK, INC.

317-887-6352 Fax: 317-881-1277

Email: service@Temptek.com

Page: 16

Page 17

Temperature Control Unit : VTO Series with G500 Series Instrument

WARNING: Electric Shock Hazard. High Voltage is present in the electrical cabinet.

Disconnect power before servicing. Follow all facility lock-out tag-out procedures.

WARNING: DO NOT connect the unit to a voltage supply source not equal

to the unit’s voltage requirements as specied on the unit’s data plate. Use

of incorrect voltage will void the unit’s warranty and cause a signicant

hazard that may result in damage to the unit or serious personal injury.

2. Appropriate conduit and ttings should be selected which will maintain the

integrity of the cabinet.

3. Supply a power conductor sized according to the unit’s power supply

requirements. Connect the power conductor to the unit’s power supply entry

terminal block.

C. Control Circuit Wiring

1. The unit’s supplied control circuit is 110 volt, 1 phase, 60 cycle. The control circuit

is supplied by the factory installed transformer. A control circuit fuse is provided.

D. General

1. Make certain all ground connections to the unit are properly afxed. A proper

connection to earth ground is required. A conduit ground is not a reliable

conductor!

2. Make certain the power conductor, disconnecting means, and fusing are properly

sized according to the unit’s power supply requirements.

3. Make certain all electrical connections are tightly afxed. Any loose wiring

connections must be tighten before engaging the power supply.

4. Make certain no moisture or standing water is present inside the electrical

cabinet.

525 East Stop 18 Road Greenwood, Indiana 46142

TEMPTEK, INC.

317-887-6352 Fax: 317-881-1277

Email: service@Temptek.com

Page: 17

Page 18

Temperature Control Unit : VTO Series with G500 Series Instrument

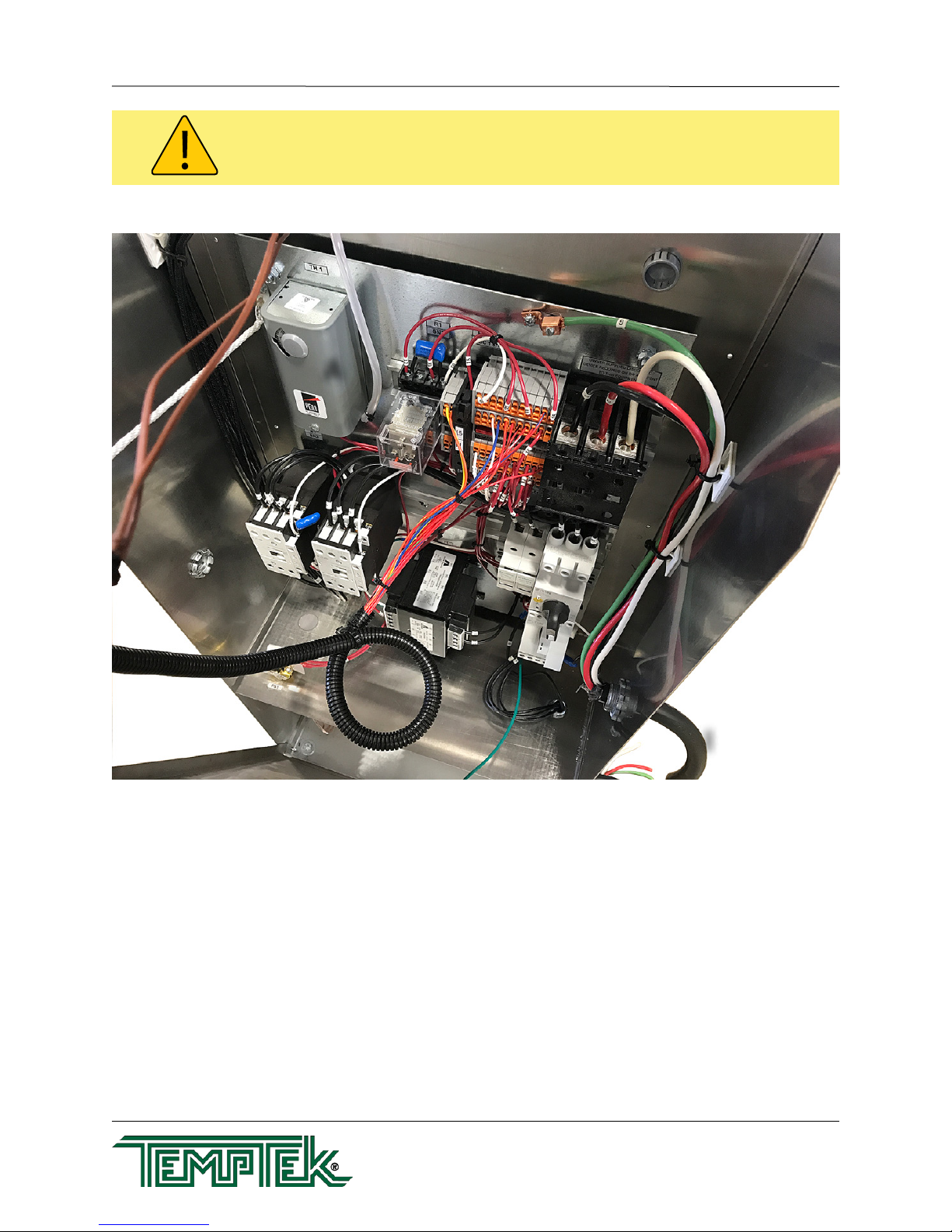

WARNING: Check that all electrical connections are tight before starting.

Disconnect power before servicing. Follow all facility lock-out tag-out procedures.

A

B

C

G

F

E

H

I

Typical Electrical Panel shown as reference of a RK-1230H model. Refer to the electrical drawing available for specific model.

A High temperature limit. Factory set to 515°F.

B High temperature limit instrument relay.

C Power entry terminal block.

D Motor starter and overload block.

E Transformer fuses.

F Control transformer

G Heater contactors

H Water supply pressure switch

I Power Cord. Note : typically included on most 12 kW models with up to 3 HP pumps. Units with 16 kW to 48 kW

heaters and pumps do not include a power cord.

D

525 East Stop 18 Road Greenwood, Indiana 46142

TEMPTEK, INC.

317-887-6352 Fax: 317-881-1277

Email: service@Temptek.com

Page: 18

Page 19

Temperature Control Unit : VTO Series with G500 Series Instrument

3.0 OPERATIONS

3.1 General

3.2 Machine Start Up and Operation

3.3 Instrument Operation : Quick Start

3.4 Instrument : Basic Navigation

3.5 Instrument : Operating Screens

3.6 Instrument : Fault Screens

3.7 Instrument : Main Menu

3.8 Instrument : Setpoints Menu

3.9 Instrument : Utilities Menu

3.10 Instrument : Network Menu

3.11 Instrument : Features Menu

3.12 Instrument : Options Menu

3.13 Instrument : Machine Menu

3.14 Shut Down / Disconnect

525 East Stop 18 Road Greenwood, Indiana 46142

TEMPTEK, INC.

317-887-6352 Fax: 317-881-1277

Email: service@Temptek.com

Page: 19

Page 20

Temperature Control Unit : VTO Series with G500 Series Instrument

3.1 GENERAL

A. Failure to follow the factory required operation procedures may adversely affect the unit’s

ability to adequately control process temperature and may create a hazardous operating

condition which may result in unit damage or serious operator injury.

B. The Operations segment of this manual is outlined below:

WARNING: Follow all Factory operations procedures. Failure to do so may create a

hazardous operating condition which may result in serious operator injury and/or unit damage.

3.2 Machine start-up/operations procedure - follow this segment to start the unit

after the initial installation or to restart the unit after reinstallation to the same or

different process. This section includes information on system ll, electric motor

phasing (pump rotation) and process ow adjustments.

3.3 Instrument Operation - follow this segment to start up and operate the

instrument. This section includes information on setpoint selection and

adjustment and feature explanations.

3.4 Shut down procedure - follow this segment to shut down the unit. This segment

includes information on system cool down, shut down, electrical power supply

precautions, and disconnection from the system.

3.2 MACHINE START UP AND OPERATION

A. System Fill

1. Use only approve high temperature heat transfer uids in this unit such as

Paratherm NF or an equivalent uid (www.paratherm.com). Never use water in

this unit.

List of Approved Heat Transfer Fluids

• Paratherm OR (https://www.paratherm.com/heat-transfer-uids/paratherm-or-heat-transfer-uid/)

• Paratherm NF (https://www.paratherm.com/heat-transfer-uids/paratherm-nf-heat-transfer-uid/)

• Multitherm PG-1 (http://www.multitherm.com/multitherm-pg-1.html)

• Calo FG (https://lubricants.petro-canada.com/productoverview/brand/calo)

2. The primary method of system ll is through the ll port located on the top of the

unit. Simply remove the cap plug and add uid. Replace the cap plug and tighten

when the ll is complete.

3. The alternate method of system ll is through the ll/drain valve. If a pressurized

source is available, simply connect to the ll/drain valve, open the valve and

engage the supply source. Close the valve when the ll is complete.

4. Proper unit ll is essential for efcient and safe operation. An oil level sight

glass is provided to determine unit ll. For initial ll: units up to 12 KW - ll until

525 East Stop 18 Road Greenwood, Indiana 46142

TEMPTEK, INC.

317-887-6352 Fax: 317-881-1277

Email: service@Temptek.com

Page: 20

Page 21

Temperature Control Unit : VTO Series with G500 Series Instrument

the sight glass is 1/2 full; for units up from 27 to 48 KW ll until the sight glass

is completely full. When the pump is rst started, the oil level will drop as the

heater tank and process are lled. After which, the operator may need to top off

as necessary to maintain oil level near the bottom of the sight glass. Check the

system for any leaks and repair if necessary.

WARNING: Electrical power is engaged and caution should be employed while the cabinet is

open.

B. Electric Motor Phasing (Pump Rotation)

1. The operator must determine the electric motor is phased correctly. This is done

by visually inspecting the rotation of the motor shaft as outlined below. Incorrect

phasing of the unit results in poor operation and eventual damage.

a. Supply electrical power to the unit by engaging the unit’s disconnect

switch. Once the correct voltage is supplied to the unit, the Power light

on the display will illuminate.

b. Open the hinged electrical cabinet panel

cover. Note that the electrical power

is engaged at this point and caution

must be observed while the electrical

supply is engaged and the cabinet

panel is open.

c. Locate the electric motor and identify

the motor shaft inside the electric motor

housing. The motor shaft can be seen

through the vent slots in the motor

housing or by removing the shaft cover.

Remove shaft cover to view the

motor shaft.

d. Toggle the On / Off buttons. This will

cycle the motor “on” and then “off”.

e. Observe the motor shaft as it slows to

a stop to identify the rotation. Correct

rotation is “clockwise”, when viewed

from the rear of the motor. Incorrect

rotation is “counter-clockwise” when

viewed from the rear of the motor. If

the shaft does not rotate when the unit

is started, the operator must identify

the cause as outlined in this manual’s

Correct rotation is clockwise when

viewed from the rear of the motor.

troubleshooting and repair section.

f. If the unit is phased correctly, continue with the start up procedure at step

C. If the unit is phased incorrect, continue with step 2.

525 East Stop 18 Road Greenwood, Indiana 46142

TEMPTEK, INC.

317-887-6352 Fax: 317-881-1277

Email: service@Temptek.com

Page: 21

Page 22

Temperature Control Unit : VTO Series with G500 Series Instrument

2. To correct unit phase:

a. Disengage the electrical power supply to the unit at the unit’s disconnect

switch. Follow proper lockout procedures before proceeding.

b. Once the electrical power supply is disengaged, reverse any two power

leads of the power cord at the fused disconnect terminals.

c. Note: The operator must reverse the power leads at the disconnect

only and not at the power entry terminals on the unit’s electrical

panel. The unit’s internal electrical system wiring is phased correctly at

the factory and must not be altered in the eld.

WARNING: To correct phase ... switch power leads at the disconnect switch only.

C. Process Flow Adjustments

1. The operator must determine and set proper uid ow rate for the most efcient

and trouble free operation.

a. Fluid ow rate through the process is determined by the pressure losses

in the process loop. Generally, higher ow rates result in turbulent ow

achieving maximum temperature control and lower maintenance.

b. If the ow rate exceeds the motor horsepower capacity, the electric motor

will draw excessive amps. This is a result of the process loop’s ability to

ow uid at a greater rate than can be provided by the pump. This will

eventually result in tripping the motor overload relay (overload relays

open) and the unit will shut down and the instrument will indicate an

alarm condition.

2. If an excessive ow situation is encountered and the motor overload circuit

has tripped, the operator must manually reset the overload relay before

operations can continue. Disconnect from power and follow proper lock out tag

out procedures prior to opening the electrical panel cover and identifying the

overload relay.

Overload relays have a switch (pictured below). This switch will be positioned

with the indicator pointing up when in normal operation. The indicator will be

pointing to the left when the overloads are tripped. To reset, simply turn the

Normal Operating Position Tripped Position

525 East Stop 18 Road Greenwood, Indiana 46142

TEMPTEK, INC.

317-887-6352 Fax: 317-881-1277

Email: service@Temptek.com

Page: 22

Page 23

Temperature Control Unit : VTO Series with G500 Series Instrument

WARNING: Electrical power is engaged and caution should be employed while the cabinet is

open.

switch to where the indicator points up.

Some older models have overload relay where a red button that pops out if the

overloads are tripped. Simply push the button in until the overloads are reset.

3. If a motor overload situation persists, the operator must adjust the ow rate to

match the system pressure loss (reduce ow rate) to prevent continual tripping of

the overload relay.

a. Open electrical cabinet panel door. The panel cover is hinged and held

open by a support cable. Note that the electrical power is engaged at

this point and caution must be observed while the cabinet panel is

open.

b. Identify the motor starter block. This block consists of the motor starter

contactor and the overload relay.

c. Place an amp meter on a single power lead coming from the overload

relay.

d. Locate the motor name plate on the pump motor housing. The full load

amp rating for the motor is listed on the name plate.

e. Engage the electrical power supply and start the unit.

f. The amp meter will display the motor amps. Compare the actual motor

amps as displayed on the amp meter to the full load amp rating as listed

on the motor name plate.

g. If the amp draw is excessive (higher than the listed name plate amp

rating), a throttling valve must be installed in the “from process” line. The

throttling valve can be a gate valve or a ball valve.

h. With the throttling valve installed, fully close the valve and then engage

the pump motor. Slowly open the throttling valve and monitor the motor

amps as displayed on the amp meter until the actual motor amps

equal the listed full load amp rating of the motor. The process ow is

now correctly adjusted. The valve should remain in this position during

operation.

6. LOW PROCESS FLOW: The minimum recommended process ow rate is 50%

of unit rated ow. Process restrictions may limit the ow to less than 50%. We

recommend the addition of bypass lines to raise the ow rate to 50%. The best

place to add bypass lines are on the extra ports on the process manifold. If extra

ports are not available, add a tee in the To Process and From Process lines,

install a bypass line between the two tees with a throttling valve. Adjust the valve

for a minimum of 50% of unit rated ow.

525 East Stop 18 Road Greenwood, Indiana 46142

TEMPTEK, INC.

317-887-6352 Fax: 317-881-1277

Email: service@Temptek.com

Page: 23

Page 24

Temperature Control Unit : VTO Series with G500 Series Instrument

Arrow and Select Keys Display Window Power On Button

3.3 INSTRUMENT : QUICK START

Power Off Button

1. Apply power. The Standby screen will illuminate. When Standby is displayed on the

screen, the unit is not running.

2. This unit features an LCD screen. Use the five soft touch buttons to navigate the

available screens and select parameters.

3. A System Safety Fault may prevent startup. Probe, water supply pressure, pump

overload or high temperature limit may display once power is applied and must be

corrected prior to operation.

Sample of Fault display screens. Not all Fault screens are shown here.

4. Adjust the setpoint to the desired value by pressing the Increment or Decrement buttons.

525 East Stop 18 Road Greenwood, Indiana 46142

TEMPTEK, INC.

317-887-6352 Fax: 317-881-1277

Email: service@Temptek.com

Page: 24

Page 25

Temperature Control Unit : VTO Series with G500 Series Instrument

5. The unit is ready to start when no errors are shown on the screen. Press the green start

button.

To Process

Standby

Ready

SetpointStatus

100°F

6. The unit will heat or cool to maintain the setpoint temperature.

3.4 INSTRUMENT : BASIC NAVIGATION

Setpoint : 100°F

Heating : 100%

75°F

A. The instrument has 5 soft keyed buttons.

1. The Home button, when pressed , shows the Home

screen.

2. The Up button, when pressed, will add one unit of

value or will scroll up through a menu.

3. The Down button, when pressed, will subtract one

unit of value or will scroll down through a menu.

4. The Go button, when pressed, will advanced

through a series of screens or save a value.

5. The Back button, when pressed will go backwards

through a series of screens.

B. Prompts on Selection Screens. Selection screens display a

menu of selectable items.

1. The Up button will scroll up through the menu items.

The screen indicators will scroll along with the

pressing of the button.

2. The Down button will scroll down through the menu

items. The screen indicators will scroll along with the

pressing of the button.

Back

Home

Up

Down

Go

3. The Go button will advance to the value screen of the

selected parameter.

4. The Back button will return to the previous screen.

Successive pressing of the Back button will

eventually end at the Home screen.

C. Prompts on Value Screens. Value screens allow the user to

set or change parameter values.

1. The Up button will add to the value of the parameter.

525 East Stop 18 Road Greenwood, Indiana 46142

TEMPTEK, INC.

317-887-6352 Fax: 317-881-1277

Email: service@Temptek.com

Page: 25

Page 26

Temperature Control Unit : VTO Series with G500 Series Instrument

Vertical Indicator

2. The Down button will subtract value from the parameter.

3. The Go button will save the new value to memory.

4. The Back button will cancel the transaction and will

return to the parent screen.

D. Prompts on Success Screens. Success screens appear

once a value is changed and the new value is successfully

saved. The screen shows the name of the parameter and

displays “Success” as indication the value was saved.

1. Use the Go or Back buttons to acknowledge the

prompt.

2. After acknowledging the success, the screen returns to the parent screen.

E. Screen Indicators.

1. Small indication triangles are used as on screen

pointers.

2. The horizontal indicators point to the current

selection. By pressing the Go button, the

screen advances to that selection.

3. The vertical indicator shows that some menu

items are not currently shown on the screen. By

pressing the Down button, the menu will scroll

down to display the menu items not currently

visible. By pressing the Up button, the menu will scroll up.

3.5 INSTRUMENT : OPERATING SCREENS

A. The instrument displays several operating screens to indicate what the unit is doing

as far as heating, cooling and other functions if available. In most operating screens,

the To Process temperature is shown with the operation indicated under the setpoint

temperature, as shown in the example below.

B. Heating. The amount of heating applied to the process is indicated in the Heating

Screen.

Horizontal Indicators

525 East Stop 18 Road Greenwood, Indiana 46142

TEMPTEK, INC.

317-887-6352 Fax: 317-881-1277

Email: service@Temptek.com

Page: 26

Page 27

Temperature Control Unit : VTO Series with G500 Series Instrument

3.6 INSTRUMENT : FAULT SCREENS

A. Faults Preventing Start Up or Operation :

1. System Safety. This fault screen appears if the following occurs:

a. Water Pressure. The unit will not operate without adequate water supply

pressure. Sufcient water supply pressure must be present to close

the water pressure switch. Recommended water supply pressure is 20

PSI. Water supply pressure should not exceed 55 PSI. If water supply

pressure exceeds 55 PSI, a pressure reducing valve must be installed in

the water supply line.

b. Motor Overload. The unit will not start or run if the motor overload

is tripped. During operations, this error is triggered by excessive ow

causing the pump to draw more amps then it is rated for. A throttling

valve should be placed in the from process line to control ow.

2. High Temp. If process temperature exceed 515°F, the high temperature limit

switch opens and the unit shuts down. High temperature conditions are generally

caused by inadequate water supply pressure, a defective cooling valve, an

obstructed drain line or high back pressure in the drain. Determine the cause and

correct. See the troubleshooting section of this manual for more information. The

high temperature limit switch will automatically reset as the unit cools.

B. Faults Not Preventing Start Up or Operation :

1. To Process Sensor. This fault screen will appear if the To Process temperature

sensor is defective and needs to be replaced or if the sensor connection is wet

or loose.

525 East Stop 18 Road Greenwood, Indiana 46142

TEMPTEK, INC.

317-887-6352 Fax: 317-881-1277

Email: service@Temptek.com

Page: 27

Page 28

Temperature Control Unit : VTO Series with G500 Series Instrument

3.7 INSTRUMENT : MAIN MENU

A. The Main Menu offers the ability to set and change values in the following areas:

1. Setpoints.

2. Utilities.

3. Network.

4. Features.

5. Machine.

B. The Main Menu is accessible from the Standby screen by pressing the Go button.

Standby

Ready

C. The Main Menu is also accessible from any Operating screen by pressing the Go button.

In the example below, while on the Cooling screen, pressing the Select button will

advance to the Main Menu.

SetpointStatus

500°F

Main Menu

Setpoints

Utilites

Network

Features

Machine

Back Pick Go

To Process

101°F

Setpoint: 500°F

Heating: 100%

3.8 INSTRUMENT : SETPOINTS MENU

A. Under the Setpoints menu item, the values for the Process Setpoint, Hi Deviation, Low

Deviation can be set or changed.

B. Process Setpoint. Use the Up or Down buttons to change the process setpoint.

Setpoints

Process Setpoint

Hi Deviation

Lo Deviation

Back Pick Go

1. The Setpoint range is from 100°F to 500°F. Please note, the unit can not reduce

process temperature below the provided water supply temperature.

Process Setpoint

Cancel

500°F

Adjust OK

Main Menu

Setpoints

Utilites

Network

Features

Machine

Back Pick Go

Change Setting

Process Setpoint

Success

Acknowledge

2. Once acknowledged, the unit will control to the new setpoint temperature. Press

the Back button repeatedly to return to the Setpoints screen or press the home

button to return to the Home screen.

525 East Stop 18 Road Greenwood, Indiana 46142

TEMPTEK, INC.

317-887-6352 Fax: 317-881-1277

Email: service@Temptek.com

Page: 28

Page 29

Temperature Control Unit : VTO Series with G500 Series Instrument

Setpoints

Hi Deviation

Lo Deviation

Process Setpoint

Back Pick Go

Hi Deviation

5°F

Cancel

Adjust OK

Change Setting

Hi Deviation

Success

Acknowledge

Setpoints

Hi Deviation

Lo Deviation

Process Setpoint

Back Pick Go

Lo Deviation

5°F

Cancel

Adjust OK

Change Setting

Lo Deviation

Success

Acknowledge

Utilities

Software Version

Display Test

Display Sensors

Back Pick Go

Setpoints

Utilites

Network

Features

Machine

Back Pick Go

Main Menu

Utilities

Display Test

Display Sensors

Software Version

Back Pick Go

Software Version

c4139887ele0729

maC8432_2017.a

Back

C. Hi Deviation. The High Deviation value programs the controller to sound the alarm if the

process temperature exceeds the set difference from setpoint. For example, Hi Deviation

= 5°F, Setpoint = 200°F. Hi deviation alarm will sound if the temperature reaches 205°F.

1. The factory default is 10°. The range for the Hi Deviation is from 0°F - 50°F.

2. Once acknowledged, press the Back button repeatedly to return to the Setpoints

screen or press the home button to return to the Home screen.

D. Lo Deviation. The Lo Deviation value programs the controller to sound the alarm if the

process temperature exceeds the set difference from setpoint. For example, Lo Deviation

= 5°F, Setpoint = 200°F. Lo deviation alarm will sound if the temperature cools to 195°F.

1. The factory default is 10°. The range for the Lo Deviation is from 0°F - 50°F.

2. Once acknowledged, press the Back button repeatedly to return to the Setpoints

screen or press the home button to return to the Home screen.

3.9 INSTRUMENT : UTILITIES MENU

A. Items in the Utilities menu include the operations for the Software Version, Display Test

and Display Sensors.

B. Software Version. The software version number is the current version of the controller’s

software. This number came be useful when troubleshooting at times.

TEMPTEK, INC.

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-6352 Fax: 317-881-1277

Email: service@Temptek.com

Page: 29

Page 30

Temperature Control Unit : VTO Series with G500 Series Instrument

Network

Baud Rate

Address

Protocol

Back Pick Go

Setpoints

Utilites

Network

Features

Machine

Back Pick Go

Main Menu

Setpoints

Utilites

Network

Features

Machine

Back Pick Go

Main Menu

Setpoints

Utilites

Network

Features

Machine

Back Pick Go

Main Menu

Setpoints

Utilites

Network

Features

Machine

Back Pick Go

Main Menu

Utilities

Display Test

Display Sersors

Software Version

Back Pick Go

Utilities

Display Test

Display Sersors

Software Version

Back Pick Go

Sensor Display

To Process:

037.7°C (100°F)

Cold Junction:

033.5°C (92°F)

Network

Baud Rate

Address

Protocol

Back Pick Go

Protocol

SPI CCP

Modbus RTU

CAMAC

Cancel

Adjust OK

Change Setting

Protocol

Success

Acknowledge

1. Select the Software Version item from the Utilities Menu to advance to the

software version screen.

2. Press the Back button to return to the Utilities menu.

C. Display Test. The Display Test will test the entire for bad pixels or sectors.

1. Select the Display Test item from the Utilities Menu to advance to the Display

Test screen.

2. The test will show a blank screen. If any bad pixels or sectors are detected, those

pixels or sectors will be dark. If dark pixels or sectors are indicated, contact the

factory repair or replacement options.

D. Display Sensors. Not active on this unit

3.10 INSTRUMENT : NETWORK MENU

A. Items in the Network menu include Protocol, Address and Baud Rate

B. Protocol: This is the data format for communication between the unit and the host

computer. Available values are

• SPI CCP

• Modbus RTU

• CAMAC.

TEMPTEK, INC.

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-6352 Fax: 317-881-1277

Email: service@Temptek.com

Page: 30

Page 31

Temperature Control Unit : VTO Series with G500 Series Instrument

Network

Baud Rate

Address

Protocol

Back Pick Go

Baud Rate

2400

9600

19200

38400

115200

Cancel

Adjust OK

Change Setting

Baud Rate

Success

Acknowledge

Network

Baud Rate

Address

Protocol

Back Pick Go

Address

1

Cancel

Adjust OK

Change Setting

Address

Success

Acknowledge

Setpoints

Utilites

Network

Features

Options

Back Pick Go

Main Menu

Setpoints

Utilites

Network

Features

Options

Back Pick Go

Main Menu

Setpoints

Utilites

Network

Features

Back Pick Go

Main Menu

Options

Remote Start

Back Pick Go

SPI is the standard Society of Plastics Industry, Inc. protocol. CAC is the CAMAC

protocol used on older Milacron machines. Modbus RTU is used in serial communication

and is a common serial communications protocol for industrial equipment.

1. Press the Select button to select Protocol.

2. Use the Up or Down arrow buttons to select the preferred protocol.

3. Use the Select button to save the selection and conrm success.

C. Baud Rate: This is the data transfer rate of between the unit and the host computer.

1. Press the Select button to select Baud Rate.

2. Use the Up or Down arrow buttons to select the baud rate. The available rate

units are 1200, 2400, 9600, 19200 and 38400.

3. Press the Select button to save the selection and conrm success.

D. Address: This is the number assigned to the unit in a network.

1. Press the Select button to select Address.

2. Use the Up and Down arrow keys to select the address for this unit. The factory

default is 1. The selection range is from 1 - 10.

3. Press the Select button to save the address and conrm success.

3.11 INSTRUMENT : OPTIONS MENU

A. One selections is available under the Options menu : Remote and Auto Start.

B. Please note: this option requires factory or eld installation of optional equipment.

TEMPTEK, INC.

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-6352 Fax: 317-881-1277

Email: service@Temptek.com

Page: 31

Page 32

Temperature Control Unit : VTO Series with G500 Series Instrument

Options

Remote Start

Back Pick Go

Remote Start

Cancel

Adjust OK

Enabled

Disabled

Change Setting

Remote Start

Success

Acknowledge

Setpoints

Utilites

Network

Options

Machine

Back Pick Go

Main Menu

Setpoints

Utilites

Network

Options

Machine

Back Pick Go

Main Menu

Setpoints

Utilites

Network

Back Pick Go

Main Menu

Machine

Max. Setpoint

Heat Only Mode

Units

Back Pick Go

Machine

Max. Setpoint

Heat Only Mode

Units

Back Pick Go

Max. Setpoint

Cancel

Adjust OK

500°F

Change Setting

Max. Setpoint

Success

Acknowledge

Machine

Back Pick Go

Max. Setpoint

Heat Only Mode

Units

Units

Cancel

Adjust OK

English

Metric

Change Setting

Units

Success

Acknowledge

C. Remote Start (optional features not included on all units) :

1. Select Remote Start from the Options menu.

2. Advance to the Remote Start Enable / Disable scree. Select Enabled to enable

the remote start feature. Select Disabled to disable the feature. Refer to Section

8.4 for more information.

3. Once acknowledged, press the Back button repeatedly to return to the Options

screen or press the home button to return to the Home screen.

3.12 INSTRUMENT : MACHINE MENU

A. The Machine Menu allows the units to set values for the Max Setpoint, Units and Heat

Only Mode.

B. Max Setpoint. This feature is useful in some application where the setpoint must never

be changed above a certain temperature. The Maximum Setpoint can never exceed

500°F in the unit.

1. Use the Up or Down arrow keys to select the Max Setpoint and then press the

Select button to save and conrm success.

2. The value range for the Max Setpoint is 100°F to 500°F. The factory default is

500°F.

C. Units. This screen controls how the temperature is displayed. The options are English

TEMPTEK, INC.

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-6352 Fax: 317-881-1277

Email: service@Temptek.com

Page: 32

Page 33

Temperature Control Unit : VTO Series with G500 Series Instrument

Machine

Back Pick Go

Max. Setpoint

Heat Only Mode

Units

Heat Only Mode

Cancel

Adjust OK

Enable

Disable

Change Setting

Heat Only Mode

Success

Acknowledge

(°F) or Metric(°C).

1. Use the Up or Down arrow keys to select the Unit display and then press the

Select button to save and conrm success.

2. The factory default value is English.

D. Heat Only Mode. This limits the unit to only the Heat Mode. This feature is useful when

the unit has an installed heat exchanger for cooling.

1. Use the Up or Down arrow keys to select the Heat Only Mode and then press the

Select button to save and conrm success.

2. The factory default value is Disabled.

3.14 SHUT DOWN - DISCONNECT

A. UNIT SHUT DOWN

1. Decrease the setpoint temperature lower than 100°F and allow the unit to cool to

the temperature.

2. Press the stop button.

3. Relieve residual static pressure before disconnecting or servicing the unit.

4. Follow all lock-out tag-out requirements.

5. Confirm that no voltage is going to the unit heater.

525 East Stop 18 Road Greenwood, Indiana 46142

TEMPTEK, INC.

317-887-6352 Fax: 317-881-1277

Email: service@Temptek.com

Page: 33

Page 34

THIS PAGE INTENTIONALLY BLANK

Page: 34

Page 35

Temperature Control Unit : VTO Series with G500 Series Instrument

4.0 TROUBLESHOOTING

4.1 Unit will not start (Display is not Illuminated)

4.2 Unit will not start (Display Illuminated)

4.3 Unit Stops

4.4 Unit Overheats

4.5 Unit Underheats

4.6 Water Pressure Relief Valve Leaks

525 East Stop 18 Road Greenwood, Indiana 46142

TEMPTEK, INC.

317-887-6352 Fax: 317-881-1277

Email: service@Temptek.com

Page: 35

Page 36

Temperature Control Unit : VTO Series with G500 Series Instrument

4.1 UNIT WILL NOT START (DISPLAY IS NOT ILLUMINATED)

A. One or more fuses at the main disconnect device are open (blown). Determine continuity

at each fuse. If continuity is not determined, replace the fuse. Then determine cause of

blown fuse.

B. Control circuit transformer fuse is open (blown). Determine continuity at the control circuit

transformer fuse. If continuity is not determined, replace the fuse.

4.2 UNIT WILL NOT START (DISPLAY ILLUMINATED)

A. Power supply is ON. The operator can determine that electrical power supply to the unit

is “on” when the instrument display is illuminated. Even with the main power supply on,

the unit is prevented from operating by one of the following conditions:

1. Water supply pressure inadequate. The display shows

a Fault : System Safety screen. The unit is prevented

from operation without adequate water supply pressure

by the pressure switch. Sufcient water supply pressure

must be present to close the switch.

2. Motor overload switch opened. This display shows

a Fault : System Safety screen. The electric motor is

protected from overload conditions by a set of thermal overload relays. These

relays will open (trip). If the overload relay is open, it must be reset before

operation can continue. An excessive ow condition must be isolated and

corrected immediately.

System Fault Screen.

Indiacates a water supply or

a pump overload fault.

3. High temperature limit switch open. The display

4.3 UNIT STOPS

A. The operator should determine the main power supply to the unit is ON by an illuminated

display. With the main power supply “on”, the unit will be prevented from starting by the

following conditions:

1. Water supply pressure inadequate. The display shows

shows a Fault : System Safety screen. The unit is

prevented from operations at temperatures exceeding

515°F by a “high temperature limit switch”. This switch

is installed in the To Process temperature sensor. If this

switch is open (due to a high temperature condition), the

unit cannot be started and must “cool down” before the

“high temperature limit switch” will automatically reset.

a Fault : System Safety screen. The unit is prevented

from operation without adequate water supply pressure

by the electrical panel mounted pressure switch.

Sufcient water supply pressure must be present to

close the switch.

High Temp Limit Fault

Screen.

System Fault Screen.

Indiacates a water supply or

a pump overload fault.

525 East Stop 18 Road Greenwood, Indiana 46142

TEMPTEK, INC.

317-887-6352 Fax: 317-881-1277

Email: service@Temptek.com

Page: 36

Page 37

Temperature Control Unit : VTO Series with G500 Series Instrument

2. Motor overload switch opened. The display shows a Fault : System Safety

screen. The electric motor is protected from overload conditions by a set of

thermal overload relays. These relays will open (trip). If the overload relay is

open, it must be reset before operation can continue. An excessive ow condition

must be isolated and corrected immediately.

3. High temperature limit switch open. The display

shows a Fault : System Safety screen. The unit is

prevented from operations at temperatures exceeding

515°F by a “high temperature limit switch”. If this switch

is open (due to a high temperature condition), the unit

cannot be started and must “cool down” before the

“high temperature limit switch” will automatically reset.

4.4 UNIT OVERHEATS

A. This is evidenced by To Process temperatures consistently above the selected setpoint

temperature.

B. On units equipped with the cooling heat exchanger, check for :

1. Inadequate water supply pressure. The unit must be supplied with adequate

water ow to provide cooling when required. The minimum pressure differential

between the water supply and water drain to achieve full cooling capacity is 20

PSI. The minimum water supply pressure is 20 PSI.

High Temp Limit Fault

Screen.

2. Cooling valve defective. On units with the cooling heat exchanger, the

instrument opens and closes the cooling valve as prescribed by the current

process load. If the valve becomes clogged with process water debris or scaled

with mineral deposits, its operation is hindered or fully prevented and adequate

process water discharge to drain is prevented. The operator must service the

cooling valve and remove any loose debris. Massive debris or scale deposits

may necessitate replacement of the internal valve.

3. Heat exchanger is fouled or undersized for duty. Clean or replace heat

exchanger.

C. On all units, check for :

1. Water drain line obstruction. The operator must determine if the water drain

line is obstructed by the following conditions. Section 2.4 outlines the parameters

of correct drain line installation.

a. Closed drain line valve. An installed but partially or fully closed valve

in the drain line prevents full discharge to drain and contributes to an

overheating condition. The operator should determine the drain line is

open.

b. High drain back pressure. Pressurized plant drain lines will prevent

ow to drain if the differential between the water supply pressure

and the drain line pressure is inadequate. The factory recommended

minimum differential is 20 psi. If the differential is less than the factory

525 East Stop 18 Road Greenwood, Indiana 46142

TEMPTEK, INC.

317-887-6352 Fax: 317-881-1277

Email: service@Temptek.com

Page: 37

Page 38

Temperature Control Unit : VTO Series with G500 Series Instrument

recommendation, plant service personnel should take measures to

reduce drain line pressure.

4. Instrument defective. The instrument is life-tested and found to be eld reliable.

However, in the case where the instrument is determined to be defective, the

operator contact the Service Department for information. The instrument is not a

eld serviceable component.

4.5 UNIT UNDERHEATS

A. This is evidence by operations with To Process temperatures consistently below the

selected setpoint temperature.

1. Process water leakage. On units equipped with the cooling heat exchanger,

a defective cooling valve allows water to circulate through the heat exchanger

providing unwanted cooling. A defective cooling valve should be repaired

immediately.

2. More ow than necessary being supplied to pump seal cooling. Throttle

pump seal cooling to 1/2 GPM at 100°F maximum temperature.

3. Heater element failure. A failed heater element will not input adequate heat

into the process to elevate the process water temperature. The operator must

check the amps at the heater contactor with the contactor energized. Zero amps

at the contactor indicate a failed heater or burnt wire connections. The operator

should remove the failed heater and replace with a new heater according to the

procedure outlined in section 5.2.

4. Unit capacity too low. This occurs when the process requires more heat than

the unit is capable of producing. The only option in such cases is to install a unit

with an adequate heater kW rating for the load.

5. Instrument defective. The instrument is life-tested and found to be eld reliable.

However, in the case where the instrument is determined to be defective, the

operator contact the Service Department for information. The instrument is not a

eld serviceable component.

525 East Stop 18 Road Greenwood, Indiana 46142

TEMPTEK, INC.

317-887-6352 Fax: 317-881-1277

Email: service@Temptek.com

Page: 38

Page 39

Temperature Control Unit : VTO Series with G500 Series Instrument

4.6 WATER PRESSURE RELIEF VALVE LEAKS

A. The unit has a 150 psi pressure relief valve mounted in the water circuit. If the valve is

found to be leaking, the operator should check the following:

1. Back ow prevention device in water supply line. If a back ow prevention

device (check valve, pressure regulator, closed valve) is installed in the water

supply line, increased pressures from thermal expansion are unable to move into

the water supply line. This will increase the unit’s internal pressure causing the

pressure relief valve to leak.

2. Valve contamination. The pressure relief valve may become contaminated with

water debris causing the valve not to close properly. If this is the case, ushing

the valve for a moment will cleanse the seat and allow it to work properly. If

ushing the valve does not remedy the leaking, the valve must be replaced.

525 East Stop 18 Road Greenwood, Indiana 46142

TEMPTEK, INC.

317-887-6352 Fax: 317-881-1277

Email: service@Temptek.com

Page: 39

Page 40

THIS PAGE INTENTIONALLY BLANK

Page: 40

Page 41

Temperature Control Unit : VTO Series with G500 Series Instrument

5.0 SERVICE/MAINTENANCE

5.1 Preventative Maintenance

5.2 Pump Seal Replacement

5.3 Heater Replacement

5.4 Cooling Valve Service

5.5 Voltage Change

5.6 Pressure Switch Service

5.7 Electronic Instrument Repair Policy & Procedure

525 East Stop 18 Road Greenwood, Indiana 46142

TEMPTEK, INC.

317-887-6352 Fax: 317-881-1277

Email: service@Temptek.com

Page: 41

Page 42

Temperature Control Unit : VTO Series with G500 Series Instrument

5.1 PREVENTIVE MAINTENANCE

A. The following is a general guide to preventive maintenance. The frequency of

maintenance will vary with each application, installation conditions, ow rates, hours of

use and operating temperatures.

B. Preventive maintenance:

1. Tighten all wiring connections.

2. Check plumbing. Repair any leaks. The factory recommends using a high

temperature graphite paste and teon tape on all plumbing connections.

3. Descale water cooling channels in the pump seal cooling adapter.

4. Descale water cooling channels in the heat exchanger (if installed).

5. Check process uid for degradation. The operating conditions affects the usable

life of the process uid. Most heat transfer uid manufacturers have an analysis

program where a sample of process uid can be sent to the manufacturer to

determine when the uid should be replaced. Some manufacturers even have

reclamation programs of the spent uid.

6. Check sight glass for proper operation. Due to oil degradation, the sight glass

feeder tubes may become clogged. In such cases, the sight glass may show

an inaccurate level. Follow proper shut down procedures before removing sight

glass to check feeder tubes.

7. Tighten heater contactor terminals.

525 East Stop 18 Road Greenwood, Indiana 46142

TEMPTEK, INC.

317-887-6352 Fax: 317-881-1277

Email: service@Temptek.com

Page: 42

Page 43

Temperature Control Unit : VTO Series with G500 Series Instrument

5.2 PUMP SEAL REPLACEMENT

A. Most units use a pump seal that is a carbon/ceramic shaft seal assembly including a

stationary member, rotating member and tension spring.

B. The life cycle of the pump seal is determined by hours of use, operating temperature and

water quality. Poor water quality is the primary reason for premature pump seal failure.

C. The operator should follow this procedure to replace the pump seal:

1. Disengage process operations and relieve all system pressure.

2. Disengage main power supply following all lock out tag out requirements. Verify

the display is off.

3. Remove the lift-off access panel and set aside (Figure 5.1B).

4. Drain machine by removing the pump casing drain plug.

5. Remove the three motor wire leads from the motor wiring terminals. The operator

should “map” the wire terminal locations to ensure correct rewiring. The power

cord should be removed from the motor housing.

6. Locate and remove the 4 pump casing bolts. These bolts secure the motor and

motor adapter to the pump casing.

7. Separate the motor and adapter from the pump casing to expose the pump

impeller. Remove the motor and adapter from the unit and place on a workbench

to continue the procedure.

8. Locate and remove the dust cap from the motor to expose slotted motor shaft.

The motor shaft is free to rotate, but must be secured to remove the impeller. To

secure the motor shaft, insert a at bladed screw driver in slot to hold the shaft

stationary.

9. Locate and remove impeller locking screw. Using a socket and ratchet, the

impeller retaining screw can be removed. Once removed, the impeller can be

“unthreaded” from the motor shaft to expose the pump seal assembly.

10. Remove all seal parts. Note seal component arrangement to facilitate

reassembly.

11. Clean the motor shaft and lubricate with a mild soap solution.

12. Install new stationary seal member in pump casing cavity. Be certain the

stationary seal member is fully squared and seated in cavity.

525 East Stop 18 Road Greenwood, Indiana 46142

TEMPTEK, INC.

317-887-6352 Fax: 317-881-1277

Email: service@Temptek.com

Page: 43

Page 44

Temperature Control Unit : VTO Series with G500 Series Instrument

13. Slide the rotating member onto the lubricated pump shaft. Be certain not to

damage or tear the rubber bellows assembly.

14. Place the spring onto the rotating member.

15. Align the tension spring and rotating member before reinstalling the impeller. Be

certain the spring and rotating member are aligned before the impeller is fully

tightened and the impeller retaining screw is reinstalled.

16. Clean the pump casing, cavities, impeller and O-ring before reassembly.

17. Mate the motor and adapter to the pump casing. Reinstall the 4 pump casing

bolts.

18. Reconnect the motor power cord and leads.

E. When this procedure is complete, the operator may restart the unit. In many cases, a

new pump seal will experience a small amount of leakage for a short time. This is normal.

After a few moments, the new seal will take seat and the leak will stop.

525 East Stop 18 Road Greenwood, Indiana 46142

TEMPTEK, INC.

317-887-6352 Fax: 317-881-1277

Email: service@Temptek.com

Page: 44

Page 45

Temperature Control Unit : VTO Series with G500 Series Instrument

5.3 HEATER REPLACEMENT

A. The heater is a ange mounted assembly and inserted into the cylinder tank and secured

by bolts.

B. The operator can determine if the heater requires replacement when the heater draws “0”

amps or when a continuity check of each heater element is negative.

C. Generally, heaters fail due to low uid ow, low uid pressure, air in the system or

defective heating elements.

D. The operator should follow this procedure to replace the heater:

1. Disengage operations and be certain all system pressure is relieved and the

unit’s pressure gauges read “0”.

2. Disengage main power supply. Follow all lock out tag out requirements.

3. Remove the access panel and set aside

4. Drain machine. The machine can be drained by removing the pump casing drain

plug.

5. Remove heater’s junction box cover to locate wiring connections. The operator

should note the wiring connections to ensure correct reinstallation.

6. Disconnect the three power leads from the heater terminals. Remove the power

cord from the junction box.

7. Remove the heater mounting bolts.

8. Remove heater.

9. Before the new heater is installed, the mating surface of the tank should be

cleaned. Once cleaned, place the new heater gasket onto the tank mating

surface. Coat the mating surface with a high temperature gasket sealant.

10. Set new heater into tank. Aligning the bolt pattern of the heater and tank anges.

11. Replace the heater mounting bolts. Alternate to the opposite bolt while tightening.

12. Reconnect the power cable to the heater terminals. Be certain to tighten the

power cord junction box connector. Replace the junction box cover and the lift-off

cover panel.

E. When complete, restart the unit.

525 East Stop 18 Road Greenwood, Indiana 46142

TEMPTEK, INC.

317-887-6352 Fax: 317-881-1277

Email: service@Temptek.com

Page: 45

Page 46

Temperature Control Unit : VTO Series with G500 Series Instrument

5.4 COOLING VALVE SERVICE

A. Units equipped with the cooling heat exchanger uses a solenoid valve as the cooling

valve. The solenoid valve is controlled by the instrument.

B. Generally, the cooling valve may fail due to poor water quality, low water ow, or defective

valve components.

C. The operator should follow this procedure to service the valve.

1. Disengage process operations. The operator must be certain process uid

temperature is under 100°F and pressure is relieved.

2. Disengage main power supply. Follow all lock out tag out requirements.

3. Remove or open any access cover panel and set aside to gain access to the

solenoid valve.

4. Identify the retaining screw on the solenoid valve coil. Remove the screw.

Keeping all electrical connections intact, lift the coil off of the enclosure tube and

set aside.

5. Use a pair of channel lock pliers or a pipe wrench to separate the bonnet

assembly from the valve body. The plunger is “loose” inside the enclosing tube.

Be certain it is retained in the enclosure tube as the bonnet is removed.

6. Identify the diaphragm assembly. Gently remove the assembly from the valve

body.

7. Identify the mesh screen. Gently remove the mesh screen and clean or replace

as necessary.

8. Clean the valve body.

9. Reset the mesh screen into the valve body.

10. If a new diaphragm assembly was obtained, continue with step 12. If not,

disassemble the diaphragm assembly and note component order. Clean the

valve port, plate, collar and O-ring. Once cleaned, reassemble the diaphragm.

11. Set the reassembled diaphragm assembly or the new assembly back into the

valve body. The stem should be facing out of the valve body.

12. Insert the plunger with spring rst into the enclosing tube of the top bonnet.

Holding the plunger in the enclosure tube, set the top bonnet onto the valve body

and tighten.

13. Place the coil onto the top bonnet and replace the retaining screw.

14. Open the water supply to circulate water to the system. Check the solenoid valve

for leakage. Restart the unit as outlined in section 3.

525 East Stop 18 Road Greenwood, Indiana 46142

TEMPTEK, INC.

317-887-6352 Fax: 317-881-1277

Email: service@Temptek.com

Page: 46

Page 47

Temperature Control Unit : VTO Series with G500 Series Instrument

5.5 WATER PRESSURE SWITCH SERVICE

A. Water is used for pump seal cooling and for the optional cooling heat exchanger. It is

important to have an adequate water supply. Water pressure is used as an indication

adequate water supply to the unit. The unit is protected from low pressure operations by

a water pressure switch. This switch is mounted on the water supply manifold.

B. The switch will close and consent the control circuit when sufcient water supply pressure

is presented. The switch is factory set to 20 psi.

C. If insufcient water supply pressure is present, the switch will open and prevent

operations.

1. Shut down unit operations. Be certain proper lock-out procedures are followed.

Also, be certain system pressure is eliminated and the unit’s pressure gauges

read “0” pressure.

2. Drain unit by removing the pump casing drain plug.

3. A capillary runs from the cooling cylinder to the pressure switch. Remove the

capillary connection.

4. The brass elbow mounted on the pressure switch must be removed.

5. Remove the electrical connections to the pressure switch.

6. The pressure switch is mounted onto the electrical cabinet with two 1/2” nuts in

series. Remove the nuts to remove the pressure switch. A new pressure switch

from the factory should be installed by continuing with step 7.

7. Thread one 1/2” nut onto the pressure switch and then place the pressure switch

through the panel in the original mounting hole. Thread the second 1/2” nut from

the bottom of the pressure switch. Tighten to lock the pressure switch in place.

8. Install the brass elbow tting. Teon tape and leak preventative paste should be

used to prevent water leakage. Install the capillary tube and resume operations.

525 East Stop 18 Road Greenwood, Indiana 46142

TEMPTEK, INC.

317-887-6352 Fax: 317-881-1277

Email: service@Temptek.com

Page: 47

Page 48

Temperature Control Unit : VTO Series with G500 Series Instrument

5.6 ELECTRONIC INSTRUMENT REPAIR POLICY AND PROCEDURE

A. All control instruments used in temperature control units are covered by the machine’s

warranty. Proprietary ‘tailor made’ instrument are manufactured specically for the unit.

B . In Warranty Service Incident

1. Call the factory for diagnostic assistance.

2. If a control instrument is determined to be at fault, a new or reconditioned

instrument will be sent as a replacement.

3. Return the defective instrument freight pre-paid for full credit. If the defective

instrument is not returned you will need to pay for it.

C. Out of Warranty Service Incident

1. Call the factory for diagnostic assistance.

2. If a control instrument is determined to be at fault, there are 3 options.

a. Purchase a new instrument as a replacement.

b. Send your instrument back for repair, freight prepaid. For a nominal fee,

your instrument will be repaired and returned.

c. Purchase a new instrument and repair the old one as a back up.

3. If you are sending your instrument back for repair, call the Service Department

for more information. Do not disassemble the instrument.

D. Other Information:

1. Call the factory for current repair charges.

2. Repair warranty: 1 year.

3. Ship to Temptek, 525 East Stop 18 Road, Greenwood, IN 46143. Attention:

Repairs (317-887-0729). Include in the shipping box: Part, purchase order,

contact name, phone number, and symptom (if available).

525 East Stop 18 Road Greenwood, Indiana 46142

TEMPTEK, INC.

317-887-6352 Fax: 317-881-1277

Email: service@Temptek.com

Page: 48

Page 49

Temperature Control Unit : VTO Series with G500 Series Instrument

6.0 COMPONENTS

6.1 Mechanical System

6.2 Electrical System

525 East Stop 18 Road Greenwood, Indiana 46142

TEMPTEK, INC.

317-887-6352 Fax: 317-881-1277

Email: service@Temptek.com

Page: 49

Page 50

Temperature Control Unit : VTO Series with G500 Series Instrument

6.1 MECHANICAL SYSTEM

A. MOTOR/PUMP ASSEMBLY. The unit pump is a multi-component assembly serving to

circulate water through the process system. The pump will increase the system pressure

between 35 - 50 PSI over the plant water supply pressure. The pump is driven by an

electrical motor.

1. Pump casing. The pump casing is an exclusive design. The casing is cast of

iron and anged to accept the heater/discharge and cooling tanks. The casing is

the support element in the pump/motor assembly and is secured to the unit base.

2. Pump adapter. The pump adapter is the mating element between the pump

casing the electric motor. The adapter is machined to accept the pump seal

ush line. The stationary pump seal member is set in the seal cavity of the pump

adapter.

3. Electrical motor. The electric motor is a dual voltage, 3 phase, ODP motor. The

motor serves to turn the pump impeller creating process ow.

4. Impeller. The impeller is custom designed for the unit and creates the higher ow

(gpm) from standard HP ratings.

5. Pump Seal. The pump seal prevents water leakage from the pump adapter.

The seal is made up of three items: The stationary member (seated in the seal

cavity), the rotating member (placed on the motor shaft) and the tension spring.

B. HEATER. The heater is a single voltage, ange mounted immersion heater set in the

pump discharge cylinder. The heater elements have a stainless steel sheath. Electrical

supply to the heater is provided via a mechanical contactor.

C. PRESSURE RELIEF VALVE. The cooling water pressure relief valve is a 150 psi relief

valve serving to discharge excessive cooling water pressure to atmosphere. The valve

can be manually activated by lifting the actuating lever. Use caution. Be sure that the

system is cool or high temperature water or stream may be released.

D. COOLING VALVE. Found on units with the cooling heat exchanger, the cooling valve is

a microprocessor controlled solenoid valve use to provide cooling to the process uid by

allowing cooling water to enter the heat exchanger.

E. PRESSURE GAUGE. The pressure gauge displays the system uid pressure.

6.2 ELECTRICAL SYSTEM

A. INSTRUMENT. The control instrument is designed specically for operating uid

circulating temperature control units. The microprocessor based control instrument

operates all the functions of the unit including cycling the heater and cooling valve for

temperature control.

B. TRANSFORMER. The transformer supplies 110 volts to the controlling instrument.

525 East Stop 18 Road Greenwood, Indiana 46142

TEMPTEK, INC.

317-887-6352 Fax: 317-881-1277

Email: service@Temptek.com

Page: 50

Page 51

Temperature Control Unit : VTO Series with G500 Series Instrument

C. PUMP MOTOR CONTROLLER. The electrical motor is engaged when the motor starter

contacts close, on command by the instrument.

D. HEATER CONTACTOR. The standard heater contactor is a mechanical style contactor.

On command from the instrument, the contactor will close and voltage will be supplied to

the heater. The contactor use should be monitored and the contactor should be replaced