Page 1

I.O.M. #075 11/05

INSTRUCTION MANUAL • INSTALLATION • OPERATION • MAINTENANCE

TEMPTEK, INC.

525 East Stop 18 Road Greenwood, IN 46142

317-887-0729 fax: 317-881-1277

Service Department fax: 317-885-8683

www.Temptek.com

e-mail: sales@Temptek.com

with CF-1 Instrument

Page 2

Page: 2

Page 3

INSTRUCTION MANUAL

CF Series Portable Chiller

5 - 40 Tons

Air-Cooled & Water-Cooled

COVERING

INSTALLATION

OPERATION

MAINTENANCE

TEMPTEK, INC.

525 East Stop 18 Road Greenwood, IN 46142

317-887-0729 fax: 317-881-1277

Service Department fax: 317-885-8683

www.TempTek.com

e-mail: sales@TempTek.com

Page 4

CF Series Portable Chillers with CF-1 Instrument

Page: 4

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-6352 Fax: 317-881-1277

Service Department Fax: 317-885-8683

Website: www.Temptek.com

Email: service@Temptek.com

TABLE OF CONTENTS

1.0 GENERAL 7

1.1 Introduction 8

1.2 Unit location 8

1.3 Efficiency 8

1.4 Safety 9

1.5 Clean air act 9

1.6 Miscellaneous 9

2.0 INSTALLATION 13

2.1 General 14

2.2 To and From process connections 14

2.3 Water supply connection 15

2.4 Air-cooled condenser 15

2.5 Water-cooled condenser 17

2.6 Electrical connection 18

3.0 OPERATIONS 21

3.1 General 22

3.2 Start up/operations procedure 23

3.3 Instrument/operation 26

3.4 Shut down procedure 30

4.0 TROUBLESHOOTING 31

4.1 Unit Will Not Start 32

4.2 Compressor Hums But Will Not Start 32

4.3 Shuts Off On High Pressure 32

4.4 Shuts Off On Low Pressure 33

4.5 Compressor Shuts Off On Internal Overload 34

4.6 Low Or No Process Pressure Or Water Flow 34

4.7 Cooling Capacity Inadequate 34

4.8 Sensor 35

4.9 Coolant Pump 35

4.10 Crankcase Heater 35

4.11 Chiller Controller 35

5.0 MAINTENANCE 37

5.1 Warranty service procedure 38

5.2 Periodic preventative maintenance 38

5.3 Special maintenance 39

5.4 Solenoid valve service 40

5.5 Pump seal service 42

5.6 Checking the refrigerant charge 45

5.7 Proper cleaning procedure for brazed plate evaporators 45

6.0 COMPONENTS 47

6.1 Water system 48

6.2 Refrigeration system 48

Page 5

CF Series Portable Chillers with CF-1 Instrument

Page: 5

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-6352 Fax: 317-881-1277

Service Department Fax: 317-885-8683

Website: www.Temptek.com

Email: service@Temptek.com

7.0 RELATED DRAWINGS 51

7.1 Mechanical Schematic : Water-Cooled : 5 - 10 Tons 52

7.2 Mechanical Schematic : Water-Cooled : 15 - 40 Tons 53

7.3 Mechanical Schematic : Air-Cooled : 5 - 10 Tons 54

7.4 Mechanical Schematic : Air-Cooled : 15 - 30 Tons 55

7.5 Typical Electrical : Air-Cooled 56

7.6 Typical Electrical : Water-Cooled 57

7.7 Physical Schematic : Air-Cooled : 7.5 - 10 Tons 58

7.8 Physical Schematic : Air-Cooled : 5 Tons 59

7.9 Physical Schematic : Water-Cooled 60

7.10 Duct Schematic for Air-Cooled Chillers 61

8.0 APPENDIX 63

8.1 Operations below 48°F 64

8.2 Water quality control 65

8.3 Inhibited propylene glycol 65

8.4 Sensor current vs temperature 65

8.5 Refrigerant pressure-temperature chart 66

8.6 Chiller capacity and derate chart 67

Page 6

Page: 6

THIS PAGE INTENTIONALLY BLANK

Page 7

CF Series Portable Chillers with CF-1 Instrument

1.0 GENERAL

1.1 INTRODUCTION

1.2 UNIT LOCATION

1.3 EFFICIENCY

1.4 SAFETY

1.5 CLEAN AIR ACT

1.6 MISCELLANEOUS

Page: 7

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-6352 Fax: 317-881-1277

Service Department Fax: 317-885-8683

Website: www.Temptek.com

Email: service@Temptek.com

Page 8

CF Series Portable Chillers with CF-1 Instrument

Page: 8

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-6352 Fax: 317-881-1277

Service Department Fax: 317-885-8683

Website: www.Temptek.com

Email: service@Temptek.com

1.1 INTRODUCTION

A. This manual covers portable chillers from 5 to 40 tons.

B. When calling for assistance from the Manufacturer’s Service

Department, it is important to know the model and serial number of

the particular unit. The model number encodes critical unit

information which is helpful in any attempt to troubleshoot operating

difficulties. The serial number allows the service team to locate

manufacturing and testing records which can have additional

information relating to a particular unit.

1.2 UNIT LOCATION

A. For air-cooled and water-cooled models:

1. These units are designed for indoor use only.

2. For most efficient operation, locate the chiller in a clean, dry

and well ventilated environment.

B. For air-cooled models:

1. The unit has an air-cooled refrigerant condenser. For air-

cooled condensers, a motor driven fan (on models from 5 to

15 tons) or a centrifugal blower (on models from 15 to 30

tons) generates air flow through the condenser to remove

heat from the refrigerant system. The air cooled condenser

on the unit will discharge a maximum of 15,000 BTU’s per

hour per ton of cooling.

2. The unit must have a minimum entering air temperature of

60°F and a maximum entering air temperature of 95°F for

efficient operation.

3. The unit must have a minimum of two feet clearance at the

air intake and six feet at the vertical exhaust air discharge.

4. The unit must

have all enclosure panels in place before

operating compressor. Air will not be drawn through the

condenser coil if they are not in place. This will cause the

compressor to lockout on the high pressure safety fault.

1.3 EFFICIENCY

A. Long term efficiency of operation is largely determined by proper

maintenance of the mechanical parts of the unit and the water

quality. The Manufacturer recommends filtering where required to

prevent solids from plugging critical parts (pumps, heaters, seals for

example). The Manufacturer highly recommends the services of a

competent water treatment specialist be obtained and his

Page 9

CF Series Portable Chillers with CF-1 Instrument

Page: 9

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-6352 Fax: 317-881-1277

Service Department Fax: 317-885-8683

Website: www.Temptek.com

Email: service@Temptek.com

recommendations followed. The Manufacturer accepts no

responsibility for inefficient operation, or damage caused by foreign

materials or failure to use adequate water treatment.

1.4 SAFETY

A. It is important to become thoroughly familiar with this manual and

the operating characteristics of the unit.

B. It is the owner’s responsibility to assure proper operator training,

installation, operation, and maintenance of the unit.

C. Observe all warning and safety placards applied to the chiller.

Failure to observe all warnings can result in serious injury or death

to the operator and severe mechanical damage to the unit.

1.5 CLEAN AIR ACT

A. The unit contains HCFC-22 (chlorodifloromethane). This is a class

2 substance.

B. Effective July 1, 1992, it is unlawful for any person in the course of

maintaining, servicing, repairing, or disposing of refrigeration

equipment to knowingly vent or otherwise dispose of any class 2

substance used as a refrigerant in the manner which permits such

substance to enter the atmosphere.

C. De minimis releases associated with good faith attempts to

recapture, reclaim or recycle such substance shall not be subject to

the prohibition set forth in the preceding paragraph.

1.6 MISCELLANEOUS

A. The unit is designed to circulate temperature stabilized fluid through

the process resulting in process temperature control.

B. The ability of the unit to maintain process temperature control is

significantly affected by the method of installation as outline in

section 2 of this manual.

C. If the operator has any questions concerning the location and

operation of the unit, contact the The Manufacturer’s Service

Department.

Page 10

CF Series Portable Chillers with CF-1 Instrument

Page: 10

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-6352 Fax: 317-881-1277

Service Department Fax: 317-885-8683

Website: www.Temptek.com

Email: service@Temptek.com

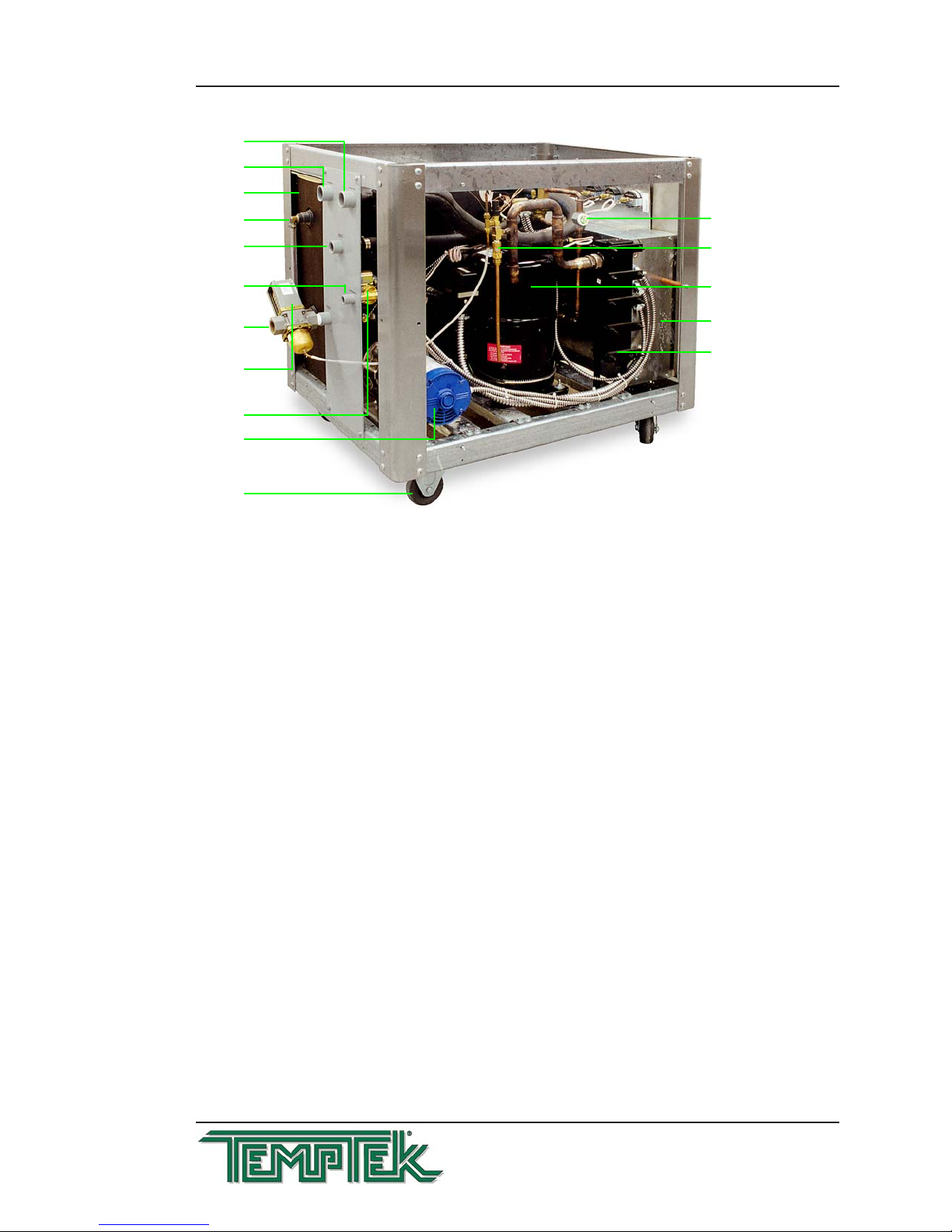

Air-Cooled.

Water-Cooled.

Air-Cooled Model.

Pressure Gauges

Cover Panel

Enclosure Panel

Electrical Panel

Enclosure

Casters

Instrument

Caster

Liquid Receiver

Compressor

Liquid Line Solenoid

Refrigerant Site Glass

Fan Motor

Protective Fan Shroud

Air Discharge

Hot Gas Bypass Valve

Pump

Expansion Valve

Insulated Reservoir Tank

Page 11

CF Series Portable Chillers with CF-1 Instrument

Page: 11

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-6352 Fax: 317-881-1277

Service Department Fax: 317-885-8683

Website: www.Temptek.com

Email: service@Temptek.com

Condenser Water-Out

Connection

Reservoir Make-Up

Connection

Condenser Water-In Connection

(optional)

Condenser Water

Regulator Valve

From Process Connection

Reservoir

Optional Reservoir Sight Glass

To Process Connection

Pump

Caster

Condenser

Electrical Panel

Compressor

Refrigerant Sight Glass

Expansion Valve

Make-Up Valve

Water-Cooled Model.

Page 12

Page: 12

THIS PAGE INTENTIONALLY BLANK

Page 13

CF Series Portable Chillers with CF-1 Instrument

Page: 13

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-6352 Fax: 317-881-1277

Service Department Fax: 317-885-8683

Website: www.Temptek.com

Email: service@Temptek.com

2.0 INSTALLATION

2.1 GENERAL

2.2 TO AND FROM PROCESS CONNECTIONS

2.3 WATER SUPPLY CONNECTION

2.4 AIR COOLED CONDENSER INSTALLATION

2.5 WATER-COOL CONDENSER INSTALLATION

2.6 ELECTRICAL CONNECTION

Page 14

CF Series Portable Chillers with CF-1 Instrument

Page: 14

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-6352 Fax: 317-881-1277

Service Department Fax: 317-885-8683

Website: www.Temptek.com

Email: service@Temptek.com

2.1 GENERAL

A. All process piping materials (such as hose, rigid piping, valves or

filters) used in process water piping circuitry must be rated for

100°F minimum temperature and 100 PSI minimum pressure.

B. All such materials must have the equivalent or larger diameter of

the particular process connection that length of process water

piping is connected to.

2.2 TO AND FROM PROCESS CONNECTIONS

A. Connect the ‘TO PROCESS’ to the ‘water in’ manifold on the mold

or process.

B. Connect the ‘FROM PROCESS’ port to the ‘water out’ port on the

process manifold.

C. Process water piping circuitry should be designed to avoid an

excessive use of elbows and/or lengths of pipe or hose. If hose is

the material of choice, avoid tight twists or curls and excessive

lengths.

D. Valves and filters may be installed in the process water piping

circuitry to facilitate service and maintenance provided that such

devices maintain the full inside diameter of the process connection.

If installed, all such devices must be open and clean during unit

operation.

Air-cooled model shown.

From Process :

Connect to ‘Water Out’

port on process manifold

Water Make-Up :

Connect to plant’s city

water source.

To Process :

Connect to ‘Water In’ port

on process manifold

Page 15

CF Series Portable Chillers with CF-1 Instrument

Page: 15

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-6352 Fax: 317-881-1277

Service Department Fax: 317-885-8683

Website: www.Temptek.com

Email: service@Temptek.com

2.3 WATER SUPPLY CONNECTION

A. The automatic water supply make-up system continually monitors

the reservoir tank and fills it when needed. Connect as follows:

1. Connect the chiller’s ‘WATER SUPPLY’ port to the plant’s

city water source.

2. Minimum water supply pressure requirement is identified on

the equipment data plate. This is normally 20 psi.

3. Be certain to use a water supply line equipped with a back

flow prevention device to prevent contamination of potable

water.

2.4 AIR COOLED CONDENSER

A. Air-cooled condensers require ambient air temperatures between

60°F and 95°F for efficient operation. Operating above 95°F may

result in elevated condensing pressures and eventual shut-down on

the high pressure safety switch. In such cases, a water assist unit

may be necessary for operations. Air temperatures below 60°F may

result in below normal condensing pressures and poor condensing.

In such cases, a low-ambient damper assembly is required. Check

with the Manufacturer’s service department for more information on

operating with ambients air temperatures above 95°F or below 60°F.

Water-Cooled model shown.

To Process Connection

From Process Connection

Water Supply Connection

Condenser Water-Out Connection

Condenser Water-In Connection

(with optional water regulator valve)

Page 16

CF Series Portable Chillers with CF-1 Instrument

Page: 16

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-6352 Fax: 317-881-1277

Service Department Fax: 317-885-8683

Website: www.Temptek.com

Email: service@Temptek.com

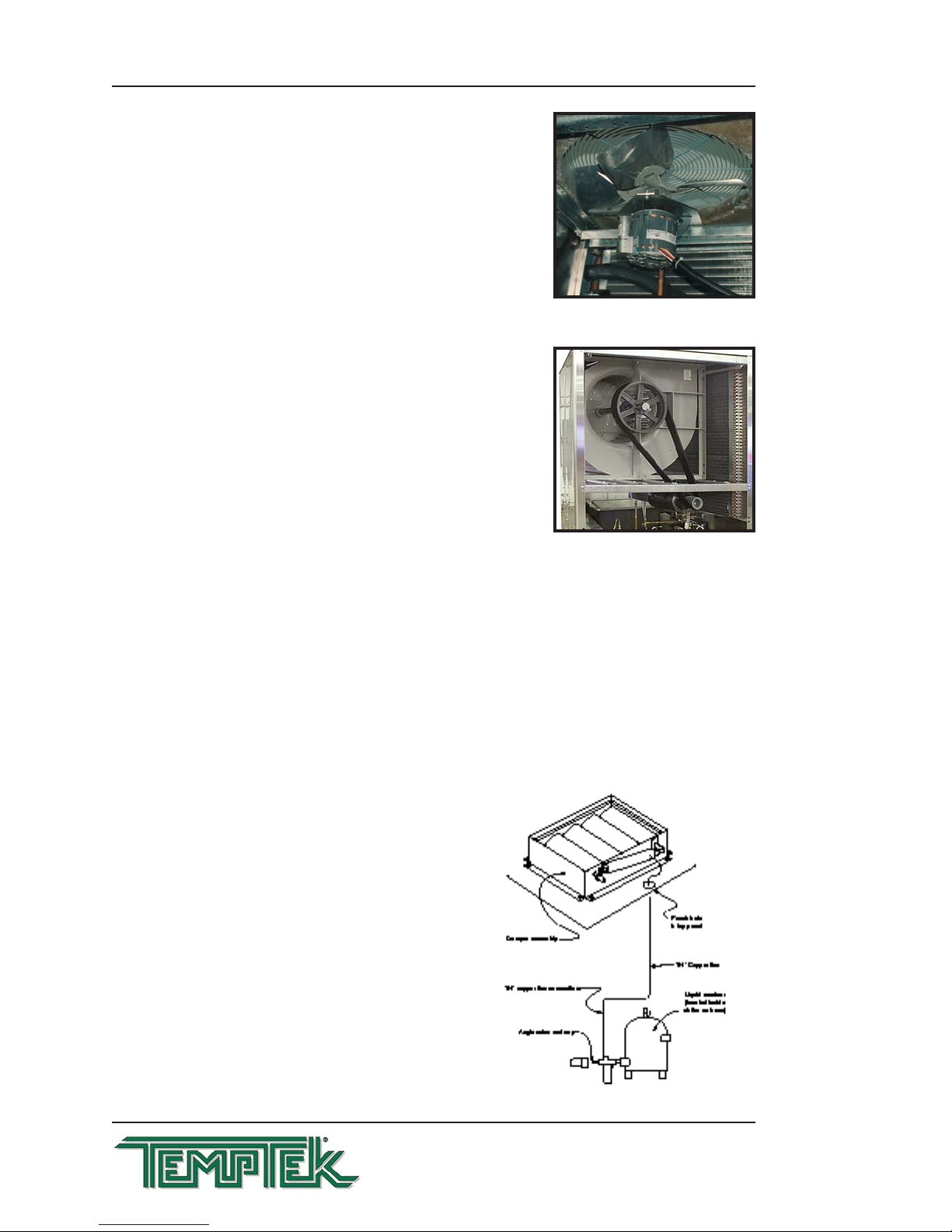

B. Air flow is generated by the motor

mounted fans (figure 2.4A) or

centrifugal blowers (figure 2.4B). Air

flow is from the outside of the chiller,

through the condenser and

exhausted through the top of the

unit. On centrifugal blowers models,

exhaust air can be ducted outside of

the plant’s interior environment.

Special duct work is required and a

HVAC contractor should be

consulted for sizing and material

specifications. Exhaust air can not

be ducted on motor mounted fan

models.

C. A free air space of at least two (2)

feet is required at the condenser

intake and six (6) feet at the

condenser discharge to allow for

proper air flow.

D. At full load, the chiller will discharge

approximately 15,000 BTU’s per

hour per ton of cooling.

E. On blower units, air discharge

duct work should be sized by a

qualified HVAC engineer.

Sizing shall be according to

rated CFM at the static

pressure of .90 inches of

water. See figure 2.4C at right.

F. On blower units, a damper

control assembly is

required in low

ambient temperature

areas or when

outdoor air make-up

is used. The

assembly works in

conjunction with

refrigerant head

pressure to regulate

air flow to maintain

proper refrigerant

head pressure when

condenser intake air

temperature will be

less than 60°F. See

figure 2.4D to the

right.

Figure 2.4A

Typical fan assembly

Figure 2.4B

Typical blower assembly

Figure 2.4C

Figure 2.4D

Page 17

CF Series Portable Chillers with CF-1 Instrument

Page: 17

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-6352 Fax: 317-881-1277

Service Department Fax: 317-885-8683

Website: www.Temptek.com

Email: service@Temptek.com

G. All air cooled units must have all enclosure panels in place before

operating compressor. Air will not be drawn through the condenser

coil if they are not in place. This will cause the compressor to

lockout on the high pressure safety fault.

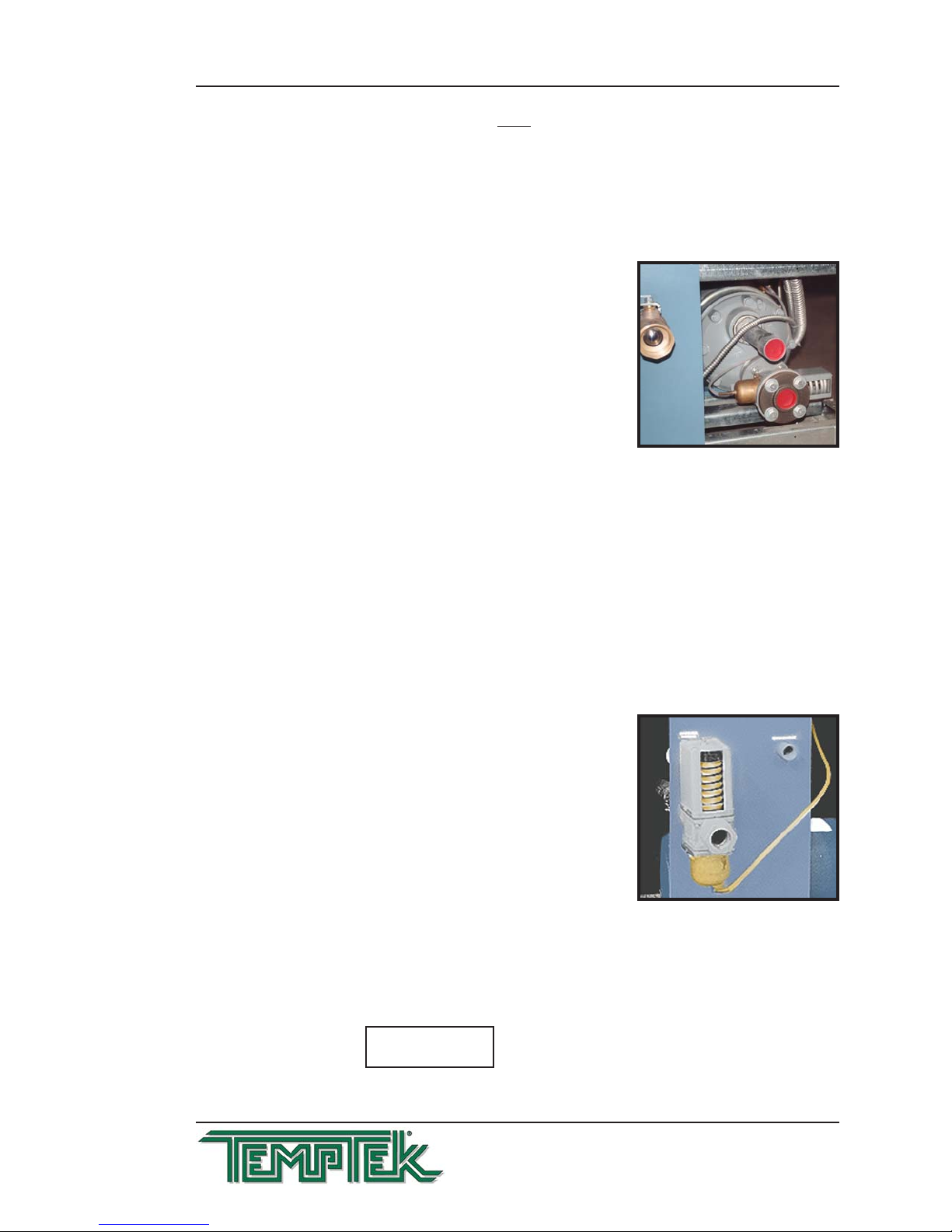

2.5 WATER-COOLED CONDENSER

A. Connect the ‘CONDENSER WATER

IN’ port to the plant’s city water

supply or tower system supply.

1. Required consumption from

a city water source is 1.5

gpm at 65°F per ton of rated

capacity.

2. Required consumption for a

tower water source is 3 gpm

at 85°F per ton of rated

capacity.

B. Connect the chiller’s ‘CONDENSER WATER OUT’ port to the

plant’s drain or tower system return.

1. Note: if dumping to the plant’s open drain, drainage shall

be done according to local codes.

C. The pressure differential requirement between the condenser “water

in” and the condenser “water out” lines must be 30 psi for adequate

efficiency.

D. The installation of a strainer in the

condenser “water in” line is

recommended. This removes solids

from the water supply and serves to

protect the water saver (regulator)

valve.

E. The water saver (regulator) valve

(figure 2.5B) is located in the

condenser “water in” line. During

winter months, or cold seasons, the

valve will throttle the water flow

through the condenser. The amount

of flow is based on the refrigerant head pressure and the regulator

will modulate the valve orifice to maintain 100° - 105°F condensing

temperature for best efficiency*.

Figure 2.5A

Typical condenser connections 30 ton unit

Figure 2.5B

Optional Regulator Valve

* See Temperature-Pressure

chart in Section 8.5 for

refrigerant pressure.

Page 18

CF Series Portable Chillers with CF-1 Instrument

Page: 18

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-6352 Fax: 317-881-1277

Service Department Fax: 317-885-8683

Website: www.Temptek.com

Email: service@Temptek.com

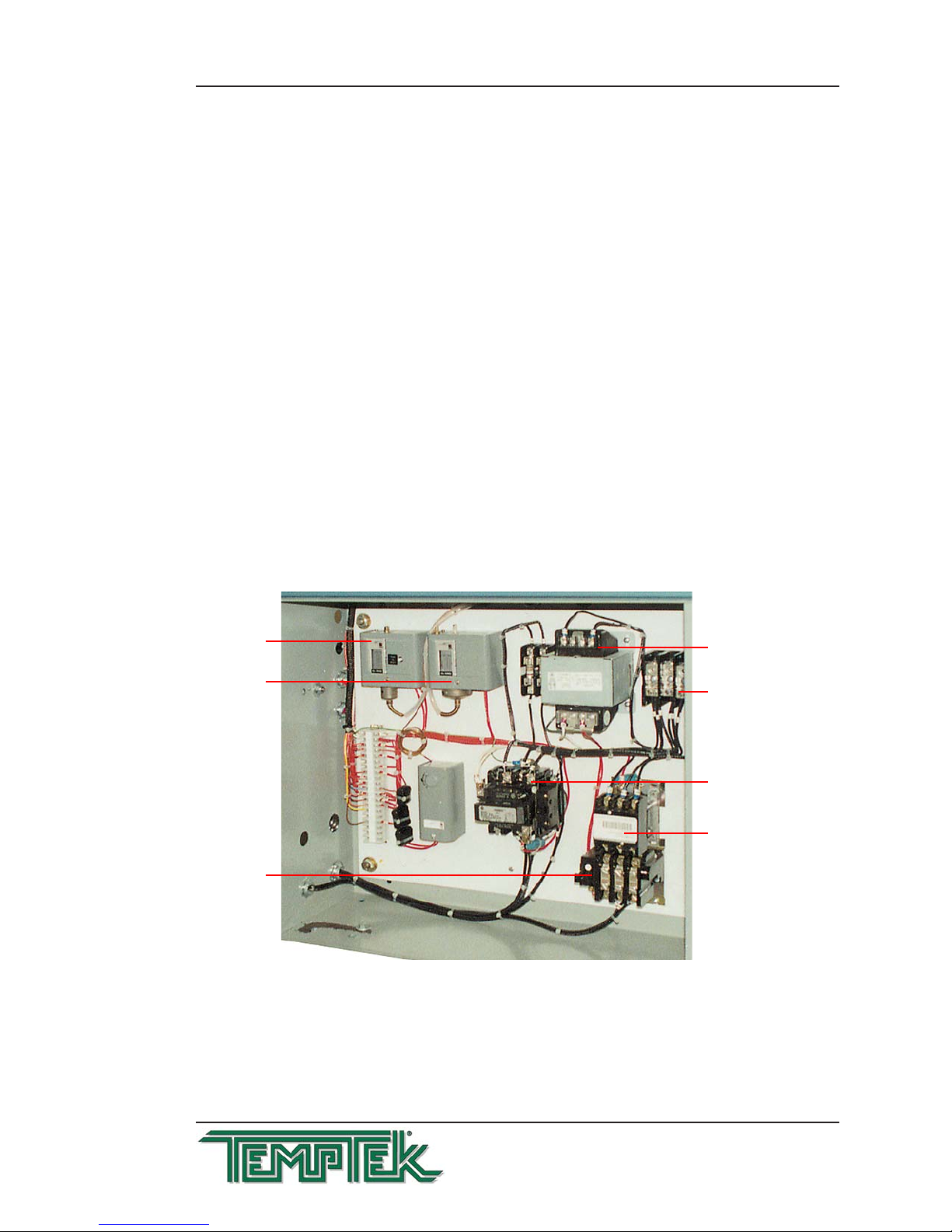

2.5 ELECTRICAL CONNECTION

A. NEMA 1 MODELS

1. Electrical power supply requirements for Nema 1 units are

identified on the equipment data plate. Determine the plant’s

voltage supply is the same as the unit’s voltage

requirements.

WARNING: Do not connect the unit to a voltage supply

not equal to the unit’s voltage requirements as

specified on the unit’s data plate. Use of incorrect

voltage will void the unit’s warranty and cause a

significant hazard that may result in serious personal

injury and unit damage.

2. A customer supplied, four conductor cable is required for

connection to a customer supplied fused disconnecting

means. The fused disconnecting means shall be sized and

installed according to the unit’s power supply requirements

and local electrical codes.

3. Connect the four conductor power cable to power entry

terminal block on the unit’s electrical panel. Then connect

the power cable to the fused disconnect switch.

B. NEMA 12 MODELS

1. NEMA 12 units are constructed with a dust tight electrical

enclosure and branch circuit fusing. Electrical power supply

requirements are identified on the equipment data plate.

Determine the plant’s voltage supply is the same as the

unit’s voltage requirements.

WARNING: Do not connect the unit to a voltage supply

source not equal to the unit’s voltage requirements as

specified on the unit’s data plate. Use of incorrect

voltage will void the unit’s warranty and cause a

significant hazard that may result in serious personal

injury and unit damage.

2. Appropriate conduit and fittings should be selected which

will maintain the integrity of the cabinet.

3. Supply a power conductor sized according to the unit’s

power supply requirements. Connect the power conductor to

the unit’s power supply entry terminal block or the fused

disconnect switch. Some Nema 12 models may be supplied

with an optional disconnect switch. The owner supplied

fused disconnecting means shall be sized and installed

according to the unit’s power supply requirements and local

electrical codes.

C. CONTROL CIRCUIT WIRING

1. The unit’s supplied control circuit is 110 volt, 1 phase, 60

cycle. The control circuit is supplied by the factory installed

transformer. An inline control circuit fuse is provided.

Page 19

CF Series Portable Chillers with CF-1 Instrument

Page: 19

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-6352 Fax: 317-881-1277

Service Department Fax: 317-885-8683

Website: www.Temptek.com

Email: service@Temptek.com

D. GENERAL

1. Make certain all ground connections to the unit are properly

affixed.

2. Make certain power conductor, disconnecting means, and

fusing are properly sized according to the unit’s power

supply requirements.

E. INFORMATION REGARDING ‘PHASING’ OF SCROLL

COMPRESSORS

1. All portable chillers that have pumps, the compressor(s) will

be set in phase with the pump during the testing process at

the factory.

2. After installation the phase status must be checked by

observing the pump motor shaft on the end of the pump

and comparing its rotation to the directional arrow on the

motor. In either case, if the phase needs to be altered, it

should be done at the main power entry.

Figure 2.5A Typical electrical panel

Refrigerant High Pressure Limit

(protects from excessive condensing pressures)

Refrigerant Low Pressure Limit

(protects from low suction pressures)

Motor Contractor

(supplies voltage to coolant pump motor)

Motor Overload Relay

(protects motor from excessive amperage)

Transformer

(provides different voltages

to instrument and other components)

Power Entry

(connect to power cord grounding lug on panel)

Compressor Contactor

(supplies voltage to compressor)

Page 20

Page: 20

THIS PAGE INTENTIONALLY BLANK

Page 21

CF Series Portable Chillers with CF-1 Instrument

Page: 21

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-6352 Fax: 317-881-1277

Service Department Fax: 317-885-8683

Website: www.Temptek.com

Email: service@Temptek.com

3.0 OPERATIONS

3.1 GENERAL

3.2 START UP/OPERATIONS PROCEDURE

3.3 INSTRUMENT

3.4 SHUT DOWN

Page 22

CF Series Portable Chillers with CF-1 Instrument

Page: 22

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-6352 Fax: 317-881-1277

Service Department Fax: 317-885-8683

Website: www.Temptek.com

Email: service@Temptek.com

3.1 GENERAL

A. Failure to follow the factory required operations procedure may

adversely affect the unit’s ability to adequately control process

temperature and may create a hazardous operating condition which

may result in serious operator injury and/or unit damage.

B. IMPORTANT: if this unit contains a hermetic or semi-hermetic

reciprocating compressor it is equipped with a crankcase heater on

the compressor. While the compressor is idle, the crankcase heater

prevents freon vapor from migrating to and condensing in the

compressor crankcase. If freon is allowed to condense in the

crankcase, it can be drawn into the cylinders upon start up. This can

cause catastrophic damage to the connecting rods, pistons, and

valve plates.

To avoid this, BEFORE THE UNIT IS STARTED, THE POWER

SUPPLY SHOULD BE APPLIED TO THE UNIT FOR AT LEAST 12

HOURS, OR UNTIL THE BOTTOM OF THE COMPRESSOR IS

WARM TO THE TOUCH.

If the power has been disconnected more than two hours, the power

should be applied for six hours before restarting. Power should be

applied to the unit continuously, except for service purposes. The

crankcase heater should be checked for proper operation on a

regular basis.

UNITS WITH SCROLL COMPRESSORS DO NOT HAVE A

CRANKCASE HEATER AND THIS PROCEDURE IS NOT

NECESSARY.

C. The OPERATIONS segment of this manual is divided into the

following sections:

3.2 Start up/operations - follow this segment to start the unit

after the initial install to the process system or to restart the

unit after reinstallation to the same or different process

system. This section includes information on system fill,

electric motor phasing (pump rotation) and process flow

adjustments.

3.3 Chiller Control - follow this segment to start up and

operate the chiller control. This section includes information

on setpoint selection and adjustment, and feature

explanations.

3.4 Shut down procedure - follow this segment to shut down

the unit. This segment includes information on system shut

down, electrical power supply precautions, and

disconnection from system.

Page 23

CF Series Portable Chillers with CF-1 Instrument

Page: 23

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-6352 Fax: 317-881-1277

Service Department Fax: 317-885-8683

Website: www.Temptek.com

Email: service@Temptek.com

3.2 START UP / OPERATION PROCEDURE

A. SYSTEM FILL

1. The unit has an internal reservoir which must be filled and

maintained for proper operation. The unit has a level switch

mounted at the proper water level in the reservoir.

2. WATER QUALITY CONTROL. Lack of, as well as, improper

water treatment can damage the chilling unit. The services

of competent water treatment specialist should be obtained

and their recommendations followed. It is the equipment

owner’s responsibility to prevent damage from foreign

material or inadequate water treatment. See water

treatment section in section 8 of this manual for more

information.

3. FOR OPTIONAL

AUTOMATIC FILL: engage

the water supply to unit. The

level switch will activate the

make-up solenoid (figure

3.2A), which will open and

the water supply will fill the

reservoir tank.

4. MANUAL FILL: disconnect

the electrical power supply

and remove all necessary

cover panels to access the

reservoir. Add fluid directly to

the reservoir. When the

pump is first started, as

process lines are filled and

air is purged, additional fluid

may be required to restore

the reservoir to the correct

level. Verify reservoir level

via the coolant sight glass

(figure 3.2B).

B. ELECTRIC MOTOR PHASING (PUMP ROTATION)

1. The operator must determine the unit is phased correctly by

visually inspecting the rotation of the pump motor shaft. The

procedure is outlined below. Incorrect phasing results in

poor operation and eventual damage to the unit.

a. Supply electrical power to the unit. Once the correct

voltage is supplied to the unit, the POWER switch

on the unit’s control panel will illuminate. Adjust the

Figure 3.2AMake-up solenoid valve

Figure 3.2B

Typical reservoir sight glass

Page 24

CF Series Portable Chillers with CF-1 Instrument

Page: 24

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-6352 Fax: 317-881-1277

Service Department Fax: 317-885-8683

Website: www.Temptek.com

Email: service@Temptek.com

setpoint to 70°F to prevent the compressor from

activating during this procedure.

b. Remove all necessary cover panels to access the

pump motor. Note that the electrical power is

engaged at this point and caution must be

observed while the electrical supply is engaged

and cabinet panels are removed and opened.

c. Locate the electric

motor (figure 3.2C).

The electric motor

can be identified

when the electrical

panel cover is open.

The operator must

identify the motor

shaft inside the

electric motor

housing. The motor

shaft can be seen

through the vent slots in the motor housing or by

removing the shaft cover.

d. Toggle the

illuminated ON/OFF

SWITCH (figure

3.2D). This will

quickly cycle the

pump motor “on”

and then “off”.

e. Observe the motor

shaft. When the

ON/OFF SWITCH is

on, the motor shaft

will rotate. When

switched off, the shaft will slowly “coast” to a stop.

As the shaft slows, the operator can identify the

rotation of the motor shaft. Correct rotation (correct

phase) is “clockwise”, when viewed from the rear of

the motor. Incorrect rotation is “counter-clockwise”

(incorrect phase) when viewed from the rear of the

motor. If the shaft does not rotate when the

ON/OFF SWITCH is on, the operator must identify

the cause as outlined in the troubleshooting and

repair section of this manual.

f. If the motor shaft is phased correctly (shaft turns in

a clockwise direction), continue with step C. If the

motor shaft is NOT phased correctly (shaft turns in

a counter-clockwise direction), correct as outlined in

step 2.

Figure 3.2C

Electric motor

Figure 3.2D

Illuminated On/Off switch

Page 25

CF Series Portable Chillers with CF-1 Instrument

Page: 25

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-6352 Fax: 317-881-1277

Service Department Fax: 317-885-8683

Website: www.Temptek.com

Email: service@Temptek.com

2. If the unit is phased incorrectly, the operator must:

a. Disengage the electrical power supply to the unit at

the unit’s disconnect switch. Follow proper lockout

procedures before proceeding.

b. Once the electrical power supply is disengaged,

reverse any two power leads of the power cord at

the disconnect terminals.

c. Note: reversing any two power leads of the power

cord will correctly phase the power supply to the

unit. The operator must reverse the power leads

at the disconnect switch only and

not

at the

power entry terminals on the unit’s electrical

panel. The unit’s internal electrical system wiring is

phased correctly at the factory and must not be

altered in the field.

C. PROCESS FLOW ADJUSTMENTS

1. The operator must determine and set proper water flow rate

for the most efficient and trouble free operation.

a. Water flow rate through the process is determined

by the pressure losses in the process loop.

Generally, higher flow rates result in turbulent flow

achieving maximum temperature control and lower

maintenance. Since the evaporator in most liquid

chillers is flow sensitive, the efficiency of operation

is directly related to the flow of liquid.

b. Maximum chiller efficiency is obtained at

approximately 2.4 gpm per ton of rated capacity.

Low liquid flow can reduce efficiency and in some

cases allow ice to develop in the evaporator which

can damage the evaporator. Excessive liquid flow

will trip the motor overload protection circuit.

2. Switch on the illuminated ON/OFF SWITCH to activate the

process pump. Wait a few moments to allow air to be purge

from system. Observe the COOLANT pressure gauge for

steady readout. Two items the operator for look for are

low

flow

or

excessive flow

conditions.

3.

LOW FLOW:

If a low flow condition is present, be sure all

process valves are open. If all process valves are open and

a low flow conditions exists, consider the following:

a. To operate under a low flow condition, it is

necessary to install a flow bypass system in the

Page 26

CF Series Portable Chillers with CF-1 Instrument

Page: 26

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-6352 Fax: 317-881-1277

Service Department Fax: 317-885-8683

Website: www.Temptek.com

Email: service@Temptek.com

process circuitry. This will allow a portion of the flow

to bypass the process and return directly to the

chiller. This keeps the total flow above the cutoff

point. Figure 3.2E illustrates a typical bypass loop.

b. Some models may have a factory installed bypass.

Adjust the valve accordingly.

3.3 INSTRUMENT/OPERATION

A. INSTRUMENT START-UP

1. When the correct electrical power and adequate water

supply pressure are supplied to the unit, it is possible to

start the unit.

2. Upon power up, the instrument displays “ChF” indicating

that the unit is in Fahrenheit temperature mode or “ChC”

indicating that it is in Celsius mode. The control then shows

the current setpoint for approximately 2 seconds before

reverting to the To Process temperature. When power is

supplied to the unit, the ON/OFF switch will illuminate.

Figure 3.2E Typical low flow by-pass loop

Figure 3.3A

CF-1 Chiller Control.

Page 27

CF Series Portable Chillers with CF-1 Instrument

Page: 27

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-6352 Fax: 317-881-1277

Service Department Fax: 317-885-8683

Website: www.Temptek.com

Email: service@Temptek.com

3. PRECAUTIONS:

The chiller control is programmed from the factory with a

setpoint range of 48° to 90°F. To operate below 48°F, the

addition of inhibited propylene glycol and modification of the

safety control settings are required. Diligent monitoring of

the water/glycol solution is mandatory to prevent freezing of

the evaporator. Freezing may cause the evaporator to

rupture allowing water and freon to mix which will cause

major damage to the refrigeration system.

On R22, R134A and R407C models operating above 70°F

and R404A models operating above 60°F requires the

addition of a refrigerant crankcase pressure regulating

(CPR) valve. The CPR valve is necessary to prevent

overloading of the compressor which can cause premature

failure. R410A models may be operated up to 80°F without

a CPR valve.

Contact your local refrigeration contractor or the factory for

further information. The operating range of the chiller control

may be changed to 10°F - 90°F by adjusting the Setpoint

Lockout (SPL) jumper. Refer to the technical section of this

manual for more information.

B. INSTRUMENT OPERATION

1. To start the unit, toggle on the illuminated ON/OFF

SWITCH. The chiller control will begin temperature control

operations.

2. To select setpoint temperature, press and hold the UP

ARROW or DOWN ARROW keys until the desired set point

temperature is displayed in the TEMPERATURE WINDOW.

The default range for the setpoint temperature is 48° - 90°F

or 9° - 32°C.

3. The setpoint temperature can be displayed by pressing the

UP ARROW or DOWN ARROW keys. The setpoint

temperature will be displayed for 5 seconds.

4. When the compressor is turned off, the instrument will wait

3 minutes before turning it back on regardless of the To

Process temperature or setpoint. If a fault has occurred, the

control will attempt to turn the compressor on after 3

minutes powered down. If the fault condition remains, the

control will turn the compressor off and retry after 1 minute.

This sequence will repeat until the compressor turns on or

instrument power is cycled.

Page 28

CF Series Portable Chillers with CF-1 Instrument

Page: 28

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-6352 Fax: 317-881-1277

Service Department Fax: 317-885-8683

Website: www.Temptek.com

Email: service@Temptek.com

5. Under normal conditions (no fault conditions, compressor

has been off for three minutes) the instrument will turn on

the compressor when the To Process temperature is above

the setpoint.

The instrument will turn on the hot gas bypass when the To

Process temperature is below the setpoint by no more than

3 degrees.

The instrument will turn off the compressor and hot gas

bypass when the To Process temperature is 4 degrees or

more below the setpoint.

C. INSTRUMENT CONTROLS

1. ILLUMINATED ON/OFF SWITCH: this rocker switch starts

or stops the unit. Electrical power is supplied to the unit

when the switch is illuminated.

2. UP ARROW and DOWN ARROW KEYS: depress and hold

this push button to increase (UP ARROW) or decrease

(DOWN ARROW) the setpoint temperature. If the push

button is pressed momentarily the setpoint value is

incremented or decremented by one degree. If the push

button is held down the setpoint will increase or decrease

continously.

3. SETPOINT LOCK OUT JUMPER: this jumper controls

whether the user is allowed to reduce the setpoint below

48°F or 9°C. If the jumper is in position 1 (farthest from the

SPL label) the user IS NOT ALLOWED to reduce the

setpoint below 48°F or 9°C. If the jumper is in position 2

(closest to the SPL label) the user is allowed to reduce the

setpoint to 10°F or -11°C.

4. TEMPERATURE DISPLAY JUMPER: if this jumper is in the

“F” position, the To Process and Setpoint temperatures are

displayed in Fahrenheit. If the jumper is in the “C” position,

the To Process and Setpoint temperatures are displayed in

Celsius.

5. Probe Calibration: this pot (CALPOT 1) is used to calibrate

the probe circuit.

Setpoint Lock Out Jumper Temperature Display Jumper Probe Calibration

Figure 3.3B

Page 29

CF Series Portable Chillers with CF-1 Instrument

Page: 29

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-6352 Fax: 317-881-1277

Service Department Fax: 317-885-8683

Website: www.Temptek.com

Email: service@Temptek.com

D. STATUS LIGHTS

1. COMPRESSOR: illuminates when compressor is turned on.

2. CAPACITY CONTROL: illuminates when capacity control

system is turned on.

3. REFRIGERANT FAULT: illuminates when there is a high

pressure or low pressure alarm. Check troubleshooting

section of this manual for more details.

High Pressure Alarm. If the chiller control detects a high

pressure condition it will immediately turn off the

compressor and hot gas bypass.

Low Pressure Alarm. After

the compressor is turned on,

the control has a 15 second

buffer for the low pressure

alarm. If a low pressure

condition occurs within the

first 15 seconds, the control

waits the amount of time

specified by the “LP TIME”

potentiometer before

indicating an alarm and

turning off the compressor. If

the condition is corrected

before the time expires, no alarm occurs. If a low pressure

condition occurs 15 seconds after the compressor turns on,

the instrument waits 20 seconds before indicating an alarm

and turning off the compressor.

E. TEMPERATURE DISPLAY

1. A three digit display window indicates the appropriate

temperature. The window also displays the numeric value

for the setpoint temperature.

2. The To Process temperature is always displayed unless a

button has been pressed. If there is a probe error, the

display will show three dashes “---”.

F. PRESSURE GAUGES (OPTIONAL)

1. PROCESS PRESSURE GAUGE: indicates process pump

pressure.

2. REFRIGERANT HEAD PRESSURE GAUGE: indicates

refrigerant pressure on the discharge side of the

compressor. This is the condensing pressure which is

Figure 3.3C

Low Pressure Potentiometer.

Page 30

CF Series Portable Chillers with CF-1 Instrument

Page: 30

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-6352 Fax: 317-881-1277

Service Department Fax: 317-885-8683

Website: www.Temptek.com

Email: service@Temptek.com

critical to equipment efficiency. Head pressure on water

condensed units will vary with ambient temperatures

between 190-290 psig.

3. LOW PRESSURE GAUGE: indicates refrigerant pressure

on the suction side of the compressor. This pressure will

fluctuate with the process temperature.

3.4 SHUT DOWN/DISCONNECT SEQUENCE

A. PRECAUTIONS/WARNINGS

1. The operator must precisely follow all shut down procedures

outlined in this manual. If the operator fails to follow

precisely all procedures outlined in this manual, an unsafe

condition can develop resulting in damage to the unit or

personal injury.

B. UNIT SHUT DOWN

1. To shut down the unit without disconnecting from the

process:

a. Move the ON / OFF switch to the off position.

b. Maintain electrical power to the unit at all times

except for service purposes.

2. To shut down the unit and disconnect from the

process:

a. Move the ON / OFF switch to the off position.

b. Disengage the electrical supply to the chiller at the

disconnecting device.

c. Disconnect all process lines.

Page 31

CF Series Portable Chillers with CF-1 Instrument

Page: 31

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-6352 Fax: 317-881-1277

Service Department Fax: 317-885-8683

Website: www.Temptek.com

Email: service@Temptek.com

4.0 TROUBLESHOOTING

4.1 UNIT WILL NOT START

4.2 COMPRESSOR HUMS BUT WILL NOT START

4.3 SHUTS OFF ON HIGH PRESSURE

4.4 SHUTS OFF ON LOW PRESSURE

4.5 COMPRESSOR SHUTS OFF ON INTERNAL OVERLOAD

4.6 LOW OR NO PROCESS PRESSURE OR WATER FLOW

4.7 COOLING CAPACITY INADEQUATE

4.8 SENSOR

4.9 PUMPS

4.10 CRANKCASE HEATER

4.11 CHILLER CONTROLLER

Page 32

CF Series Portable Chillers with CF-1 Instrument

Page: 32

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-6352 Fax: 317-881-1277

Service Department Fax: 317-885-8683

Website: www.Temptek.com

Email: service@Temptek.com

4.1 UNIT WILL NOT START

A. Power off. Check main disconnect.

B. Main line open. Check fuses.

C. Loose terminals. Tighten terminals with POWER OFF.

D. Control circuit open. check control voltage fuses and transformer.

4.2 COMPRESSOR HUMS BUT WILL NOT START

A. Contactor. Check contacts and contactor operation.

B. Low voltage. Check voltage at main and at the unit. If voltage is OK

at the main but low at the unit, increase wire size. If low at main,

consult your local power company. Voltage must be +/- 10%

nameplate rating.

C. No power on one phase of a three phase unit. Check fuses in

control panel and main disconnect. Also check unit wiring, main

plant fuse and wiring. If the problem is with the main power supply

coming into the plant, call the local power company.

D. Loose terminals. Tighten terminals with POWER OFF.

4.3 SHUTS OFF ON HIGH PRESSURE CONTROL

Note. Refrigerant high pressure will vary with ambient temperature

from minimum of 190 psi to as high as 280 psi. The high pressure

switch manually reset when discharge pressure falls to a safe level.

The switch is located inside the electrical panel.

A. Air-cooled units:

1. Insufficient condenser air flow. Check condenser filter for

dirt, fins may be plugged with dirt or foreign material. Also,

check for proper fan rotation.

Note: all enclosure panels must be attached.

2. Fan motor not operating. Have electrician check fuses

and wiring, motor starter and overloads, and motor. Repair

or replace motor if defective.

B. Water-cooled units:

1. Water regulator valve. Adjust condenser water regulator

valve to maintain 100°F to 105°F refrigerant condensing

Page 33

CF Series Portable Chillers with CF-1 Instrument

Page: 33

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-6352 Fax: 317-881-1277

Service Department Fax: 317-885-8683

Website: www.Temptek.com

Email: service@Temptek.com

temperature*. If valve is defective, have valve repaired or

replaced by a refrigeration serviceman.

2. Insufficient condenser water flow. Check condenser

water pumping system.

3. Condenser water temperature too high. Check cooling

tower or proper operation city water temperature.

4. Condenser water tubes scaled. Clean with brushes and

chemicals approved by the Advantage Service Department.

C. Improperly set high pressure control. Have refrigeration

serviceman reset or replace the control if defective.

4.4 SHUTS OFF ON LOW PRESSURE CONTROL

Note: The low pressure switch will automatically resets when the pressure

rises above the cut-in pressure. If this does not occur contact the

the Manufacturer’s service department for instructions.

The low pressure switch is set to cut-out at 32°F and cut-in at

36°F - 39°F*. If a low pressure condition exists for more than five

seconds the compressor will stop and a “L-P” fault will appear in

the display window.

After the refrigerant pressure rises above the cut-in pressure, a

three minute time delay will occur before the compressor restarts.

This will protect the evaporator and compressor from damage

should a problem occur in the refrigeration system or if the chiller is

operated under circumstances which could cause damage to the

refrigeration system.

A. Air-cooled units:

Head pressure too low. Check that entering air

temperature is above 60°F. If below 60°F, find out reason

why.

B. Water-cooled units:

Head pressure too low. Adjust condenser water regulating

valve to maintain 100°F - 105°F refrigerant condensing

temperature*. Have refrigeration serviceman repair valve

or replace if defective.

C. Low refrigerant charge. Check for adequate refrigerant charge

(bubbles or misty sight glass indicates low charge). If charge is low,

have system checked for leaks and recharged by a refrigeration

serviceman.

* See Temperature-Pressure

chart in Section 8.5 for

refrigerant pressure.

* See Temperature-Pressure

chart in Section 8.5 for

refrigerant pressure.

* See Temperature-Pressure

chart in Section 8.5 for

refrigerant pressure.

Page 34

CF Series Portable Chillers with CF-1 Instrument

Page: 34

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-6352 Fax: 317-881-1277

Service Department Fax: 317-885-8683

Website: www.Temptek.com

Email: service@Temptek.com

D. Improperly set low pressure switch. Have a refrigeration

serviceman reset control or replace if defective.

E. Restriction in the liquid line.

1. Clogged filter drier. Check for pressure or

temperature drop and have drier core replaced by a

refrigeration serviceman.

2. Liquid line valve or suction valve on

compressor is partially closed. Open fully.

3. Liquid line solenoid not opening fully or leaking

during off cycle. have repaired or replaced if

defective by a refrigeration serviceman.

4. Expansion valve plugged or inoperative. Check

thermal bulb and capillary tube for damage. Have

repaired or replaced if defective by a refrigeration

serviceman.

4.5 COMPRESSOR SHUTS OFF ON INTERNAL OVERLOAD

A. Control does not reset. Have compressor windings and internal

solid state safety control checked by a refrigeration serviceman.

Have it repaired or replace if defective.

4.6 LOW OR NO PROCESS PRESSURE OR WATER FLOW

A. Valves. Check if water valves are open.

B. Pump. Check pump for correct rotation. Check pump suction for

restriction. Replace motor if defective.

C. Filters. Check filter in the chilled water circuit and clean if

necessary.

D. Pressure switch (or flow switch). Readjust or replace if defective.

E. Fuses and wiring. Have electrician check the fuses and wiring.

4.7 COOLING CAPACITY INADEQUATE

A. Low refrigerant charge. Check for adequate refrigerant charge

(bubbles or misty sight glass indicates low charge). If charge is low,

have system checked for leaks and recharged by a refrigeration

serviceman.

B. Hot-gas bypass valve stuck open. Have repaired or replace if

defective by a refrigeration serviceman.

Page 35

CF Series Portable Chillers with CF-1 Instrument

Page: 35

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-6352 Fax: 317-881-1277

Service Department Fax: 317-885-8683

Website: www.Temptek.com

Email: service@Temptek.com

C. Expansion valve plugged or inoperative. Check thermal bulb and

capillary tube for damage. Have repaired or replaced if defective by

a refrigeration serviceman.

D. Plugged filter. Check filter in chilled water circuit and clean.

E. Air in system. Purge air.

4.8 SENSOR

The sensor is a solid state temperature transducer which converts

temperature input to proportional current output. To quickly test for a

defective probe, switch connections between the defective probe

and a probe known to be working properly. A defective sensor will

display a “---” in the display window on the instrument control.

4.9 COOLANT PUMP

A. The centrifugal pump is designed to operate at a specific flow and

pressure at the maximum run load amp draw of the motor. Too

much flow can overload the motor and cause the overload circuit to

open and stop the pump.

B. If the overload trips, check for electrical shorts, loose wires, or

blown fuses. If these check OK, reset the overload circuit and

restart the chiller.

C. Check the amp draw and if overloaded, partially close the from

process line valve until the amp draw drops to the proper level.

4.10 CRANKCASE HEATER

A. If the crankcase heater is not drawing current during the

compressor off cycle, check for a defective crankcase heater,

defective fuses or defective interlock on the compressor starter.

B. Scroll compressors do not have crankcase heaters.

4.11 CHILLER CONTROLLER

A. The display is used for all normal set ups, diagnostics, temperature

readout, and operational information. Note: the display is not field

repairable. It can be easily removed and replaced if required.

B. The CPU contains the software and various electronic components

which make the instrument work. Note: the CPU is not a field

repairable part. It can be easily removed and replaced if a problem

arises.

Page 36

Page: 36

THIS PAGE INTENTIONALLY BLANK

Page 37

CF Series Portable Chillers with CF-1 Instrument

Page: 37

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-6352 Fax: 317-881-1277

Service Department Fax: 317-885-8683

Website: www.Temptek.com

Email: service@Temptek.com

5.0 MAINTENANCE

5.1 WARRANTY SERVICE PROCEDURE

5.2 PERIODIC PREVENTATIVE MAINTENANCE

5.3 SPECIAL MAINTENANCE

5.4 SOLENOID VALVE SERVICE

5.5 PUMP SEAL SERVICE

5.6 CHECKING THE REFRIGERANT CHARGE

5.7 PROPER CLEANING PROCEDURE FOR BRAZED PLATE EVAPORATOR

Page 38

CF Series Portable Chillers with CF-1 Instrument

Page: 38

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-6352 Fax: 317-881-1277

Service Department Fax: 317-885-8683

Website: www.Temptek.com

Email: service@Temptek.com

5.1 WARRANTY SERVICE PROCEDURE

A. In the event of a problem with a chiller that can not be resolved by

normal troubleshooting procedures, the customer is invited to

consult the Service Department for assistance. The correct model

number and serial number of the chiller must be available. The

service department will attempt to isolate the problem and advise

repair procedures. Often times, with the customer’s input and with

the machine diagnostics, problems can be determined with “overthe-phone” consultation.

B. If the problem is beyond the scope of “over-the-phone” consultation,

and if the warranty status of the machine is valid, the Manufacturer

will contact the nearest authorized service contractor and provide

authorization to conduct an “on-site” inspection of the unit in order

to determine the course of repair. If the chiller is not covered by the

warranty, the Manufacturer will advise on the repair and recommend

available service contractors.

C. It is of the utmost importance that you provide the correct model

number and serial number of the machine in question. This will

allow the Service Department to obtain the correct manufacturing

records which will help to properly troubleshoot the problem and

obtain the proper replacement parts when they are required. This

information is stamped on the data tag that is attached to the

electrical enclosure of each machine.

D. The Service Department must be notified prior to any repair or

service of a warranty nature. Warranty claims will not be honored

without prior authorization.

5.2 PERIODIC PREVENTATIVE MAINTENANCE

A. Lubricate all motors. Note that some motors are supplied with

sealed bearings.

B. Tighten all wire terminals.

C. Clean and check motor starter and contactor contacts.

D. Check safety switch settings.

E. Clean condenser fins of dust and dirt (air cooled models only).

F. Back flush evaporator.

G. Check glycol/water solution ratio for operating temperature.

H. Check system for leaks.

Page 39

CF Series Portable Chillers with CF-1 Instrument

Page: 39

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-6352 Fax: 317-881-1277

Service Department Fax: 317-885-8683

Website: www.Temptek.com

Email: service@Temptek.com

I. Refrigerant sight glass: check for bubbles when compressor is

operating at 100%. Check the moisture indicator for a color other

than green.

J. Clean unit.

5.3 SPECIAL MAINTENANCE

A. Any service of the refrigeration system must be accomplished by a

certified refrigeration technician.

1. Addition of compressor oil.

2. Addition of refrigerant.

3. Repair of a refrigerant leak.

4. Adjustment of super heat.

5. Changing of filter-drier or drier core.

6. Repair of a refrigeration solenoid.

Page 40

CF Series Portable Chillers with CF-1 Instrument

Page: 40

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-6352 Fax: 317-881-1277

Service Department Fax: 317-885-8683

Website: www.Temptek.com

Email: service@Temptek.com

5.4 SOLENOID VALVE SERVICE

A. Units with the optional water

make-up system use a solenoid

valve (figure 5.4A) to regulate flow

into the reservoir tank. The solenoid

valve is controlled by the float

switch.

B. Generally, solenoid valves fail due

to poor water quality, low water

flow, or defective valve elements.

C. The operator should follow this

procedure to service the make-up

solenoid valve:

1. Disengage process operations according to the procedure

outlined in section 3.4. The operator must be certain

process fluid temperature is under 100°F and pressure is

relieved (pressure gauge reads “0”) and water system flow

is shut off and all pressure relieved.

2. Disengage main power supply. The operator must verify the

proper lockout procedures are followed.

3. Remove or open any access cover panel and set aside to

gain access to the cooling solenoid valve.

4. The operator must be certain all water system pressure is

relieved.

5. Identify the retaining screw

(figure 5.4B) on the

solenoid valve coil. Remove

the screw. Keeping all

electrical connections

intact, lift the coil off of the

enclosure tube and set

aside.

6. Use a pair of channel lock

pliers or a pipe wrench to

separate the bonnet

assembly from the valve body.

The plunger is “loose” inside the enclosing tube. Be certain

it is retained in the enclosure tube as the bonnet is removed

(figure 5.4C).

7. Identify the diaphragm assembly. Gently remove the

assembly from the valve body (figure 5.4D).

Coil

Figure 5.4B

Retaining screw

Typical water make-up

solenoid valve

Figure 5.4A

Page 41

CF Series Portable Chillers with CF-1 Instrument

Page: 41

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-6352 Fax: 317-881-1277

Service Department Fax: 317-885-8683

Website: www.Temptek.com

Email: service@Temptek.com

8. Identify the mesh screen.

Gently removed the mesh

screen and clean or

replace as necessary.

9. Clean the valve body.

10. Reset the mesh screen into

the valve body.

11. If a new diaphragm

assembly was obtained,

continue with step 12. If

not, disassemble the

diaphragm assembly and

note component order

(figure 5.4E). Clean the

valve port, plate, collar and

O-ring. Once cleaned,

reassemble the diaphragm.

12. Set the reassembled

diaphragm assembly or the

new assembly back into the

valve body. The stem

should be facing out of the

valve body.

13. Inset the plunger with

spring first into the

enclosing tube of the top

bonnet (figure 5.4F).

Holding the plunger in the

enclosure tube, set the top

bonnet onto the valve body

and tighten.

14. Place the coil onto the top

bonnet and replace the

retaining screw.

15. Open the water supply and

drain valves (if installed) to

circulate water through the

supply and drain manifolds.

Check the solenoid valve

for leakage. Restart the unit

as outlined in section 3.

Figure 5.4F

Plunger

Spring

Top bonnet

Enclosure tube

Top bonnet

Figure 5.4C

Enclosure tube

Plunger

Diaphragm assembly

Figure 5.4D

O-Ring

Diaphragm assembly

Mesh screen

Figure 5.4E

O-Ring

Diaphragm and stem

Collar

Plate

Page 42

5.5 PUMP SEAL SERVICE

A. The coolant pump seal

is a carbon/niresist

shaft seal assembly

including a stationary

member, rotating

member and tension

spring (figure 5.5A).

B. The operator can

determine the pump

seal is leaking when

fluid is identified leaking from the pump case adapter.

Generally, a pump seal will leak due to inadequate unit

pressure, excessive flow and poor fluid quality.

C. The operator should follow this procedure to replace the pump seal:

1. Disengage process operations according to the procedure

outlined in section 3.4. The operator must be certain

process fluid temperature is under 100°F and pressure is

relieved (COOLANT pressure gauge reads “0”) and water

make-up flow is shut off and all pressure relieved.

2. Disengage main power supply. The operator must verify the

proper lockout procedures

are followed.

3. Access the pump motor by

opening or removing any

cover panels as necessary

(figure 5.5B).

4. Drain machine. The

machine can be drained by

using the drain valve

located on the pump case.

Drain fluid into a suitable

container for reuse or

disposal according to

manufacturer’s instructions

(if a glycol solution is

used).

5. Locate and remove the

three motor wire leads from

the motor wiring terminals.

The operator should “map”

the wire terminal locations

to ensure correct rewiring.

The power cord should be

CF Series Portable Chillers with CF-1 Instrument

Page: 42

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-6352 Fax: 317-881-1277

Service Department Fax: 317-885-8683

Website: www.Temptek.com

Email: service@Temptek.com

Stationary member

Rotating Member

Tension Spring

Figure 5.5A

Pump motor

Figure 5.5B

Pump motor

Figure 5.5C

Page 43

removed from the motor

housing (figure 5.5C).

6. Locate and remove the

pump casing bolts. These

bolts secure the motor and

motor adapter to the pump

casing (figure 5.5D).

7. Separate the motor and

motor adapter from the

pump casing to expose the

pump impeller (figure

5.5E). Remove the motor

and motor adapter from the

unit and place on a

workbench to continue the

procedure.

8. Locate and remove the

dust cap from motor end to

expose slotted motor shaft.

The motor shaft is free to

rotate, but must be secured

to remove the impeller. To

secure the motor shaft,

insert a flat bladed screw

driver in slot to hold the

shaft stationary (Figure

5.5F).

9. Locate and remove impeller

locking screw (Figure

5.5G). Using a socket and

ratchet, the impeller

retaining screw can be

removed. Once the

retaining screw is removed,

the impeller can be

“unthreaded” from the

motor shaft to expose the

pump seal assembly.

10. Remove all seal parts

(Figure 5.5H). Note seal

component arrangement to

facilitate reassembly.

11. Clean motor shaft and

lubricate with a mild soap

solution.

CF Series Portable Chillers with CF-1 Instrument

Page: 43

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-6352 Fax: 317-881-1277

Service Department Fax: 317-885-8683

Website: www.Temptek.com

Email: service@Temptek.com

Typical pump casing bolt

Figure 5.5D

Motor shaft

Figure 5.5F

Typical impeller

Figure 5.5G

Impeller

Figure 5.5E

Page 44

CF Series Portable Chillers with CF-1 Instrument

Page: 44

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-6352 Fax: 317-881-1277

Service Department Fax: 317-885-8683

Website: www.Temptek.com

Email: service@Temptek.com

12. Install new stationary seal

member in pump casing

cavity (figure 5.5I). The

operator must be certain

the stationary seal member

is fully squared and seated

in cavity.

13. Slide the rotating member

onto lubricated pump shaft

(figure 5.5J). The operator

must be certain not to

damage or tear rubber

bellows assembly.

14. Place the spring onto the

rotating member.

15. Align the impeller, spring

and rotating member before

reinstalling the impeller

(figure 5.5K). The operator

must be certain the spring

and rotating member are

aligned before the impeller

is fully tighten and the

impeller retaining screw is

reinstalled.

16. Clean pump casing,

cavities, impeller and Oring before reassembly.

17. Mate the motor and motor

adapter to the pump

casing. Reinstall the pump

casing bolts.

18. Reconnect the motor power

cord and leads.

19. Restore all cover panels as

were removed.

E. When the pump seal replacement

procedure is complete, the operator

may restart the unit according the

section 3.

Stationary member

Figure 5.5I

Stationary member

Figure 5.5J

Seal members

Figure 5.5K

Seal components

Figure 5.5H

Page 45

CF Series Portable Chillers with CF-1 Instrument

Page: 45

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-6352 Fax: 317-881-1277

Service Department Fax: 317-885-8683

Website: www.Temptek.com

Email: service@Temptek.com

5.6 CHECKING THE REFRIGERANT CHARGE

A. All standard chillers are

manufactured with thermostatic

expansion valves as the metering

device to the evaporator.

B. All standard chillers have a

refrigerant sight glass (figure 5.6A)

with a moisture indicator. To check

the refrigerant charge under normal

operating conditions:

1. Remove the plastic cap

covering the sight glass.

2. Start the chiller and allow system pressures and

temperatures to stabilize.

3. With the unit operating at 100% capacity (not in the

“capacity control” mode) the sight glass should appear clear

with no foam or bubbles evident. If foam or bubbles are

evident, the chiller has suffered from a loss of refrigerant

and should be checked by a qualified refrigeration

technician.

4. The “dot” in the middle of the sight glass is the moisture

indicator. It should appear green at all times. A white or

yellow color indicates moisture has invaded the refrigeration

system, which is detrimental to the life of the compressor.

The filter-drier should be replaced by a qualified

refrigeration technician.

5.7 PROPER CLEANING PROCEDURE

FOR BRAZED PLATE EVAPORATORS

A. The brazed plate evaporator is

made of stamped stainless steel

plates, furnace brazed together

with copper based joints. The

complex geometry of the flow

passages promotes turbulent

flow which gives high efficiency

and reduces fouling by mineral

deposits. Large solids such as

plastic pellets or chunks of mineral deposits will collect at the water

inlet port at the evaporator and restrict flow through some of the

passages. If this possibility exists, the Manufacturer recommends

filters or strainers be added to the “from process” line. If the

evaporator becomes fouled there are a couple of methods for

cleaning.

Sight Glass

Figure 5.6A

Evaporator

Figure 5.6A

Page 46

B. To begin, remove the piping to the “water in” port at the evaporator.

Remove any solids that have collected at this point. Then back flush

the evaporator to remove any solids that may be trapped between

the plates (see back flush procedure below). If there are mineral

deposits adhered to the plates, the evaporator must be back flushed

with a mild acid solution (5% phosphoric or 5% oxalic acid is

recommended.) After cleaning rinse with clear water before

returning to service. Continue with step C on the next page.

C. Back flushing procedure:

1. Turn off all power to the machine. For chillers with a

reservoir tank, drain the tank to below the evaporator outlet.

For chillers without a reservoir tank, drain total unit.

2. Connect a water supply hose to the evaporator water outlet.

If acid cleaning, connect the discharge hose from the acid

pump to the evaporator outlet port.

3. Connect a hose to the evaporator water supply port and to

an appropriate containment vessel. If acid cleaning, connect

the evaporator water inlet port to an acid solution reservoir

tank. Dispose of all back flush fluid according to local

codes.

4. The cleaning fluid source should have at least 20 psi

available. If acid cleaning, follow the instructions supplied

with the acid solution carefully.

5. When the procedure is complete, reinstall all water lines to

original factory orientation. Restart the unit and check for

proper operation.

6. Note: this procedure is not normal maintenance.

Maintaining proper water quality and filtration will minimize

the need to back flush the evaporator.

CF Series Portable Chillers with CF-1 Instrument

Page: 46

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-6352 Fax: 317-881-1277

Service Department Fax: 317-885-8683

Website: www.Temptek.com

Email: service@Temptek.com

BRAZED PLATE HEAT EXCHANGER

(EVAPORATOR)

FREON OUT

FREON IN

ORIGINAL WATER OUT PORT

BACKFLUSH WATER IN PORT

(SUPPLY BACKFLUSHING WATER

FLOW TO THIS PORT)

ORIGINAL WATER IN PORT

BACKFLUSH WATER OUT PORT

(ROUTE WATER TO PROPER

SEWER OR DRAIN CONTAINER)

Page 47

CF Series Portable Chillers with CF-1 Instrument

Page: 47

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-6352 Fax: 317-881-1277

Service Department Fax: 317-885-8683

Website: www.Temptek.com

Email: service@Temptek.com

6.0 COMPONENTS

6.1 WATER SYSTEM

6.2 REFRIGERATION SYSTEM

Page 48

6.1 WATER SYSTEM

A. MOTOR/PUMP ASSEMBLY: the

motor/pump assembly circulates

chilled fluid to the process loop. The

pump assembly is built of total

stainless steel to maintain water

quality (figure 6.1A).

6.2 REFRIGERATION SYSTEM

A. COMPRESSOR: hermetic or semi-

hermetic compressors take low

pressure/low temperature

refrigerant gas and compress the

gas into high pressure/high

temperature gas (figure 6.2A).

B. AIR COOLED CONDENSER: the

air cooled condenser removes

BTU’s from the compressed

refrigerant gas. The action causes

the gas to “condense” into a liquid

state still under high pressure. Air

flow across the condenser is

achieved via a motor driven fan

assembly or centrifugal blower

(figure 6.2B).

C. FILTER-DRIER: the filter-drier

removes contaminants and

moisture from the liquid refrigerant

(figure 6.2C).

D. LIQUID LINE SOLENOID VALVE:

controlled by the instrument, this

valve closes when the compressor

cycles off to prevent refrigerant

liquid from migrating to the

evaporator. The valve opens when

the compressor cycles on.

E. REFRIGERANT SIGHT GLASS:

the refrigerant sight glass indicates

refrigerant charge and moisture

content. Refrigerant charge is

determined by a clear liquid flow.

Bubbles indicate low refrigerant.

Moisture content is indicated by the

color of the element. Element color

is normally green. If the color of the

CF Series Portable Chillers with CF-1 Instrument

Page: 48

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-6352 Fax: 317-881-1277

Service Department Fax: 317-885-8683

Website: www.Temptek.com

Email: service@Temptek.com

Hermetic compressor

Semi-hermetic compressor

Figure 6.2A

Pump Motor Assembly

Figure 6.1A

Typical filter-drier

Figure 6.2C

Fans

Blower

Figure 6.2B

Page 49

element is chartreuse or yellow, the

system has been contaminated

with moisture. In such case, the

filter-drier must be replaced. The

replacement of the filter-drier must

be completed by a qualified

refrigerant service technician

(figure 6.2D).

F. EXPANSION VALVE: the

expansion valve throttles flow of

refrigerant liquid into the evaporator

and creates a pressure drop in the

refrigerant system that allows the

liquid refrigerant to “boil off” inside

the evaporator (figure 6.2E).

G. EVAPORATOR: the evaporator is a

brazed plate heat exchanger where

the refrigerant liquid is allowed to

evaporate (boil off) to absorb heat

(BTU) from the process fluid. As the

heat is absorbed, the process fluid

is chilled (figure 6.2F).

H. HOT GAS BY-PASS SOLENOID:

the hot gas by-pass solenoid

prevents short cycling of the

compressor by reducing the

capacity by 50% when the process

fluid temperature nears the

setpoint.

I. HIGH/LOW PRESSURESTATS:

the high/low pressurestats protect

the refrigeration system from

unsafe operating levels. The high

pressure switch is factory set and

protects the refrigeration components and personnel from potential

damage of injury from excessive high pressure. The high pressure

safety must not be altered in the field for any reason. (See section

8.1 for factory settings.) The low pressure switch is factory set to

open at 32°F and to close at 36° - 39°F.* The low pressure switch

protects the chillers from possible damage due to low operating

pressure. The low pressure switch is field adjustable for setpoints

below 48°F.

NEVER LOWER THE CUT OUT SETTING WITHOUT ADDING

GLYCOL TO THE CIRCULATING SYSTEM. EVAPORATOR

DAMAGE WILL RESULT AND WILL NOT BE COVERED BY THE

WARRANTY.

CF Series Portable Chillers with CF-1 Instrument

Page: 49

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-6352 Fax: 317-881-1277

Service Department Fax: 317-885-8683

Website: www.Temptek.com

Email: service@Temptek.com

Expansion Valve

Figure 6.2E

Refrigerant sight glass

Figure 6.2D

Typical hot gas bypass valve

Figure 6.2H

* See Temperature-Pressure

chart in Section 8.5 for

refrigerant pressure.

Page 50

CF Series Portable Chillers with CF-1 Instrument

Page: 50

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-6352 Fax: 317-881-1277

Service Department Fax: 317-885-8683

Website: www.Temptek.com

Email: service@Temptek.com

J. Liquid receiver: located after the condenser, this component

receives and stores liquid refrigerant leaving the condenser.

K. Service valves: have been provided throughout the system. Only a

qualified refrigeration service technician shall operate these valves.

L. Crankcase heater: insures that freon and compressor crankcase

oil do not mix during the compressor’s “off ” cycles. Power must be

applied to the chiller previous to startup.

M. Oil pressure safety switch: protects the compressor from

lubrication failure.

Page 51

CF Series Portable Chillers with CF-1 Instrument

Page: 51

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-6352 Fax: 317-881-1277

Service Department Fax: 317-885-8683

Website: www.Temptek.com

Email: service@Temptek.com

7.0 RELATED DRAWINGS

7.1 MECHANICAL SCHEMATIC : WATER-COOLED : 2 - 10 TONS

7.2 MECHANICAL SCHEMATIC : WATER-COOLED : 15 - 40 TONS

7.3 MECHANICAL SCHEMATIC : AIR-COOLED : 5 - 10 TONS

7.4 MECHANICAL SCHEMATIC : AIR-COOLED : 15 - 30 TONS

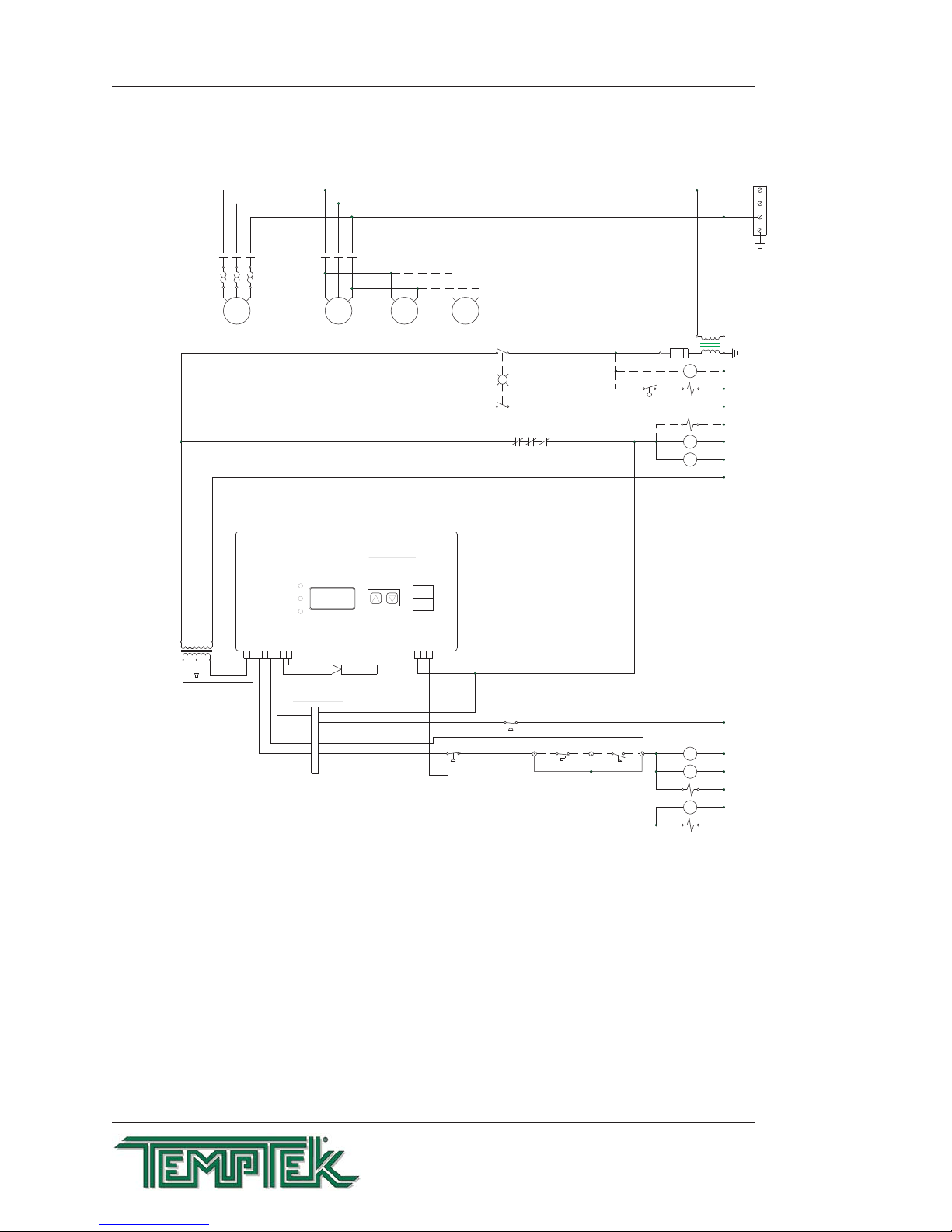

7.5 TYPICAL ELECTRICAL : AIR-COOLED

7.6 TYPICAL ELECTRICAL : WATER-COOLED

7.7 PHYSICAL SCHEMATIC : AIR-COOLED : 7.5 - 10 TONS

7.8 PHYSICAL SCHEMATIC : AIR-COOLED : 5 TONS

7.9 PHYSICAL SCHEMATIC : WATER - COOLED :

7.10 DUCT SCHEMATIC FOR AIR-COOLED CHILLERS

Page 52

CF Series Portable Chillers with CF-1 Instrument

Page: 52

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-6352 Fax: 317-881-1277

Service Department Fax: 317-885-8683

Website: www.Temptek.com

Email: service@Temptek.com

7.1 MECHANICAL SCHEMATIC : WATER-COOLED : 2 - 10 TONS

TO PROCESS

PRESSURE GAUGE

WATER REGULATOR VALVE

COOLANT PUMP

TO PROCESS

SENSOR PROBE

TO PROCESS

PORT CONNECTION

MAKE-UP PORT

CONNECTION

MAKE-UP

SOLENOID VALVE

LEVEL SWITCH

FROM PROCESS

PORT CONNECTION

CONDENSER WATER IN

PORT CONNECTION

CONDENSER WATER OUT

PORT CONNECTION

RESERVOIR TANK

EXPANSION VALVE

EVAPORATOR

SERVICE LID AND FILL PORT

REFRIGERANT

SIGHT GLASS

LIQUID LINE

SOLENOID VALVE

FILTER-DRIER

SERVICE VALVE

HOT GAS

BYPASS VALVE

COMPRESSOR

(may be Scroll Hermetic

or Recip Semi-hermetic)

HEAD PRESSURE GAUGE

HIGH PRESSURE

SAFETY SWITCH

SUCTION LINE PRESSURE GAUGE

LOW PRESSURE SAFETY SWITCH

WATER COOLED CONDENSER

Page 53

CF Series Portable Chillers with CF-1 Instrument

Page: 53

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-6352 Fax: 317-881-1277

Service Department Fax: 317-885-8683

Website: www.Temptek.com

Email: service@Temptek.com

7.2 MECHANICAL SCHEMATIC : WATER-COOLED : 15 - 40 TONS

TO PROCESS

PRESSURE GAUGE

WATER REGULATOR VALVE

COOLANT PUMP

TO PROCESS

SENSOR PROBE

TO PROCESS

PORT CONNECTION

MAKE-UP PORT

CONNECTION

MAKE-UP

SOLENOID VALVE

LEVEL SWITCH