Temprite Industries CMA Installation, Operation And Maintenance Manual

IOMCMA-5

INSTALLATION, OPERATION AND

MAINTENANCE MANUAL FOR CMA MODEL

DIRECT GAS-FIRED HEATERS WITH DDC CONTROLS

ATTENTION: READ THIS MANUAL AND ALL LABELS ATTACHED TO THE UNIT CAREFULLY BEFORE

ATTEMPTING TO INSTALL, OPERATE OR SERVICE THESE UNITS! CHECK UNIT DATA PLATE FOR

TYPE OF GAS AND ELECTRICAL SPECIFICATIONS AND MAKE CERTAIN THAT THESE AGREE WITH

THOSE AT POINT OF INSTALLATION. RECORD THE UNIT MODEL AND SERIAL No.(s) IN THE SPACE

PROVIDED. RETAIN FOR FUTURE REFERENCE.

FOR YOUR SAFETY

The use and storage of gasoline or other flammable vapors and liquids in open

containers in the vicinity of this appliance is hazardous.

POUR VOTRE SÉCURITÉ

L'utilisation et l'entreposage d'essence ou d'autres liquides ou produits émettant des vapeurs

infl ammables dans des récipients ouverts à proximité de cet appareil est dangereux.

FOR YOUR SAFETY

If you smell gas:

1. Open Windows

2. Don’t touch electrical switches.

3. Extinguish any open fl ame.

c

4. Immediately call your gas supplier.

Si vous sentez une odeur de gaz :

1. Ouvrez les fenêtres.

2. Ne pas actionner d'interrupteur.

3. Éteindre toute fl amme ouverte.

4. Appelez immédiatement votre

fournisseur de gaz.

POUR VOTRE SÉCURITÉ

WARNING: Improper installation, adjustment, alteration, service or maintenance can

cause property damage, injury or death. Read the installation, operating and maintenance

instructions thoroughly before installing or servicing this equipment.

AVERTISSEMENT : Une installation défi ciente, de même qu'un mauvais réglage,

modifi cation, entretien ou maintenance peuvent occasionner des dommages matériels, corporels voire causer la mort. Lire attentivement les instructions d'installation,

d'utilisation et d'entretien avant d'installer ou d'intervenir sur cet appareil.

WARNING

Install, operate and maintain unit in accordance with manufacturer's instructions to avoid

exposure to fuel substances or substances from incomplete combustion which can cause

death or serious illness. The state of California has determined that these substances

may cause cancer, birth defects, or other reproductive harm.

Installer Please Note: This equipment has been test fi red and inspected. It has been shipped

free from defects from our factory. However, during shipment and installation, problems such as

loose wires, leaks or loose fasteners may occur. It is the installer's responsibility to inspect

and correct any problems that may be found.

4830 Transport Drive, Dallas, TX 75247 Phone: 214-638-6010 Fax: 214-905-0806

7555 Transmere Drive, Mississauga, ON L5S 1L4 Phone: 905-672-6123 Fax: 905-672-6124

www.tempriteheating.com

INSTALLER'S RESPONSIBILITY

SECTION I - FOREWARD

As is the case with any fi ne piece of equipment, care

must be taken to provide the proper attention to the

operation and maintenance details of this machine.

This manual of instructions along with the Digital

Control System user manual has been prepared in

order for you to become well-acquainted with those

details, and in doing so, you will be able to give your

Direct Gas-Fired System the care and attention which

any piece of equipment needs and deserves.

It is the customer and installation personnel

responsibility to determine if the unit is equipped

with all of the safety devices required for the

particular application. Safety considerations

include the accessibility of the unit to non-service

personnel, the provision of electrical lockout

switches, maintenance procedures, and automatic

control sequences. Clearly mark all emergency

shutoff devices.

*IMPORTANCE NOTICE*

Temprite assumes no responsibility for loss or damage

in transit; therefore, you should protect yourself by

following these instructions:

Bill Of Lading

Save your bill of lading. It is a contract, and you will

need it, provided you have to fi le a loss or damage

claim. Remember, claims are outlawed after nine

months.

Loss In Transit

Before you sign for this shipment, check against the bill

of lading, also the transportation company’s delivery

ticket. Make sure that you get the exact total of articles

listed. Should the delivery ticket show more or less

items than are offered, then the carrier’s agent must

mark the difference on your freight bill before you sign.

Visible Damage In Transit

If anything is damaged, accept the shipment only if

the carrier’s agent places a notation on your freight

bill explaining the nature and extent of damage. Upon

inspection of article, make claim to the delivering

carrier.

Table of Contents

Section I: Foreword, Table of Contents,

and Important Notice .................................. 2

Section II: General Information .................................... 3

Section III: Installation .................................................4

Section IV: Pre-Start Up .............................................. 8

Section V: Unit Start Up ...............................................9

Section VI: Unit Shut Down ....................................... 11

Section VII: Troubleshooting Guide ........................... 12

Section VIII: Maintenance Schedule

and Lubrication Requirements............... 24

Section IX: Mestek Burner ......................................... 29

Section X: Manifold and Valve Adjustments ..............30

Section XI: Thermistor Curves ...................................31

Section XII: Replacement Parts................................. 32

Section XIII: Recirculating Units ................................ 32

Concealed Damage In Transit

Sometimes transit damage is not noticed until the

goods are unpacked. In such cases, notifi cation to

the carrier must be made within fi fteen (15) days of

receipt of shipment. In such cases, save the packages

and packing material, then notify the transportation

company at once, and request an inspection. When

the inspector calls, have him make out and leave a

“concealed” bad order report. He is obliged to give one

to you. Insist on it.

Disposition Of Damaged Atticles

Never return damaged articles to us. They are the

property of the transportation company when the claim

is fi led. They will give you disposition instructions.

Packing

We comply with the packing requirements of the

transportation companies, and your bill of lading

proved that everything was in good condition when

shipped. That bill of lading contract requires them to

deliver in perfect condition.

– 2 –

SECTION II - GENERAL INFORMATION

A. Purpose

The purpose of this manual is to present a guide for

proper installation, maintenance, and operation of the

Direct Gas-Fired System, and supplement, but not to

replace, the services of qualifi ed fi eld service person-

nel to supervise the initial start-up and adjustment

of the unit. Persons without previous experience with

large commercial and industrial heating equipment

should not attempt the initial adjustment and checkout

procedure which is essential before such installations

may be considered ready for operation. This manual

should be made readily available to all operating personnel as an aid in troubleshooting and proper maintenance.

B. Shipping

Base Direct Gas-Fired units are shipped completely

assembled where shipping limitations allow. Optional

inlet hoods, fi lter and/or damper sections, or other

large accessories are assembled and shipped mounted and wired whenever possible within limitations

of shipping and handling. Any optional accessories

shipped separately are shipped as assembled sections. Any wired accessories which have been disassembled for separate shipment require no additional

conduit or wire for fi eld reassembly. All wire leads will

be tagged for ease of reconnection in the fi eld.

If the unit and/or accessories cannot be installed

immediately, they should be stored in a clean dry

environment. If this is not possible and the unit

must be stored outdoors, it should be protected

from the weather with tarpaulins or plastic

coverings. Do not assume that simply covering a

unit will keep insects, dust and condensation out

of the unit and critical components. Rotate the

fan(s) monthly.

Shipments are made F.O.B. Dallas, Texas by fl at-

bed truck. The unit is securely strapped, tied, and

blocked to prevent shipping damage. All shipments

are checked by an inspector before they are accepted

by the carrier. Parts that are shipped unmounted are

noted on the bill of lading. These parts, where feasible,

are packaged and shipped with the units. Upon receipt

of shipment, all units should be checked against the

bill of lading to insure all items have been received. All

equipment (and any optional accessories) should be

checked carefully for physical damage in the presence

of the carrier’s representative. If parts are missing or

damage has occurred, a claim should be fi led immedi-

ately with the carrier.

All Direct Gas-Fired units are given a complete operations test and control circuit checkout before shipment.

Copies of the wiring diagram, piping diagram and

bill of material are included with each unit shipped. If

correspondence with the factory is necessary, please

provide the unit model and serial number.

C. Optional Factory Service

Periodic service on any piece of mechanical equipment is necessary for effi cient operation. A nationwide

service support network is available to provide quick

and dependable servicing of make-up air, heating,

ventilating, or air handling types of equipment. Factory

start-up service is also available which includes the

presence of a service engineer to supervise the initial

start-up and adjustment of the equipment and provide

instructions for the owner’s maintenance personnel in

proper operations and maintenance. Consult factory

for quotations on start-up or periodic service.

Prior to beginning installation of a unit that has been in

storage for weeks or months, the unit and its components should be closely inspected.

– 3 –

SECTION III - INSTALLATION

FOR CANADIAN INSTALLATIONS ONLY

1. All installations must conform with local building

codes, or, in the absence of local codes, with

current CAN/CGA-B149-Installation Codes For

Gas Burning Appliances and Equipment.

2. All electrical connections must be in accordance with Canadian Electrical Code, Part 1,

CSA Standard C22.1.

This equipment must be installed and wired in accordance with regulations of the National Board of

Fire Underwriters, National Electrical Code, and local

governing bodies. The following recommendations are

not intended to supplant any requirements of federal,

state, or local codes having jurisdiction. Authorities

having jurisdiction should be consulted before installations are made. Local codes may require additional

safety controls and/or interlocks.

All installations in airplane hangers must be in accordance with current ANSI/NFPA No. 409. All installations in public garages must be in accordance with

current NFPA No. 88A and NFPA No. 88B.

CAUTION: Do not install heating system in corrosive

or fl ammable atmospheres! Premature failure of, or

severe damage to the unit will result!

During transit, unloading and setting of the unit, bolts

and nuts may have become loosened, particularly

in the pillow block ball bearing assemblies in the fan

section. It is recommended that all nuts and set screws

be tightened. Turn fan shaft by hand to make certain

that blower does not rub against blower housing, and

that bearing set screws are tight. If units are not set

immediately, cover all openings that might be exposed

to the weather.

Open the cover on the electrical control box located on

the unit. Inspect all wire terminals and wiring terminations to ensure that all connections are tight.

If units are not set immediately, cover all openings that

might be exposed to the weather.

Rotate fans monthly.

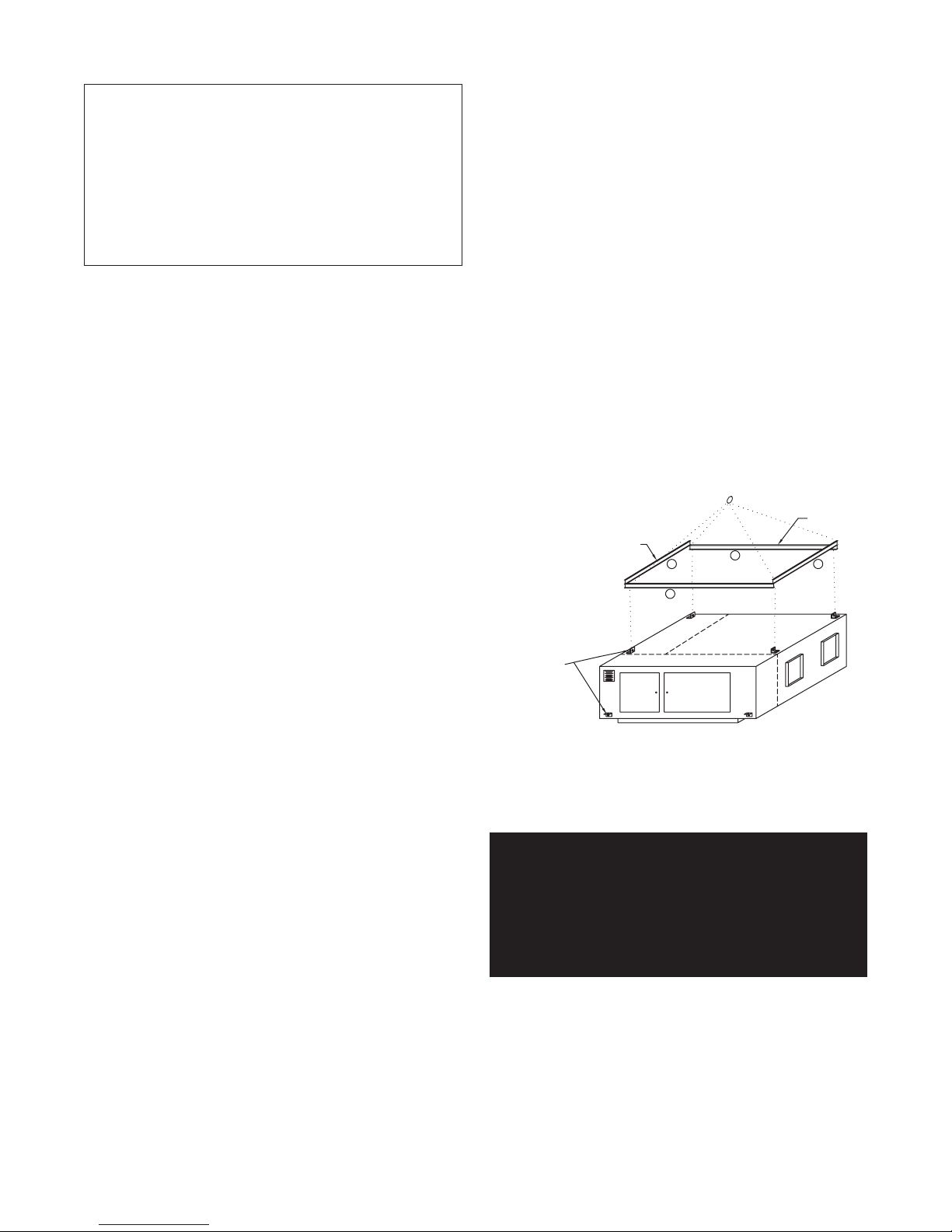

RIGGING AND MOUNTING DATA - DIRECT FIRED UNITS

SPREADER

BAR

SPREADER

BAR

A

B

B

A

CAUTION: Heating system must not be installed in

locations where air for combustion would contain

chlorinated, halogenated or acidic vapors. If located

in such an environment, premature failure of the

unit will occur!

A. Handling the Equipment

The Direct Gas-Fired unit has been designed for

rigging and handling through the use of special lifting

lugs installed on the sides of each unit. As explained

previously, the basic unit is designed for shipping in

one piece where shipping limitations allow. Some

optional accessories may require fi eld mounting.

The Direct Gas-Fired unit has been designed for

rigging and handling through the use of special lifting

lugs installed at each corner of unit. When unloading

and setting the unit, use the lifting lugs provided or

move the equipment on rollers. Hooks, jacks, or chains

must not be used around the casing, main control

panel or exterior mounted controls.

LIFTING LUGS

PROVIDED IN ONE

OF TWO LOCATIONS

A - USE WHEN LIFTING OVER 3,000 LBS.

B - USE WHEN LIFTING UNDER 3,000 LBS.

08/16/07 C000539A

WARNING: To insure that a proper unit lift is

made, lift unit approximately 24 inches and

verify proper center of gravity lift point. To avoid

dropping of unit, reposition lifting point if unit

is not level. Failure to properly lift unit could

result in death or serious injury or possible

equipment or property-only damage.

– 4 –

B. Locating the Unit

Prior to locating the unit, authorities having jurisdiction should be consulted before installations are made.

Approval permits should be checked against the unit

received.

On Direct Gas-Fired units, which recirculate room air,

outside ventilation air must be provided in accordance

with the information shown on the heater nameplate.

All ventilation air to the heater must be ducted directly

from the outside. See Section XIII.

If in doubt regarding the application of this appliance,

consult the factory.

Use extreme caution in handling the curb. Proper

handling and positioning will assure a water-tight curb

unit installation.

Re-check approval prints prior to installation. Be sure

that there are no obstructions to ducting and that

proper planning has been exercised in connection of

piping and/or electrical services.

The curb assembly may be bolted or welded to either

trusses or roof decking; however, connection to roof

trusses is recommended. The curb is designed to carry

the weight of the unit. Additional support is required for

certain applications.

Locate the unit exactly level. Special attention should

be given to the duct, electrical, and fuel connection

points. Install duct work with adequate fl exible connec-

tions to isolate vibration from the duct work. All duct

work should have taped or caulked seams. Duct work

should be properly sized so as not to inhibit airfl ow.

This information should be cross-checked with the

position of support beams and stand pipes to insure

that clearance dimensions coincide with those of the

unit. The minimum clearance to combustible material

must be maintained as listed in Table 1.

Table 1

Minimum clearance to combustible material,

also consult local codes and regulations.

Clearances to Combustible Material

Vertical Units Horizontal Units

Front* 39 inches 36 inches

Rear 6 inches 6 inches

Right 6 inches 6 inches

Left 6 inches 6 inches

Top 12 inches 12 inches

Floor Zero 6 inches

*Consider control side as front of unit.

**Optimum clearance for shaft removal would be

equivalent to cabinet width.

Make a visual inspection to insure no damage has occured to the unit during installation.

Placement of the curb is critical in squareness and

leveling. Shims for leveling must be applied to the

curb; application of shims to the unit will tend to

destroy the sealing effect after installation. Make sure

sealing tape is in place before unit is set. Be careful

not to allow gaps where two pieces of sealing tape

meet. A bubble level must be used in the leveling

process. Measure across diagonals to check for

squareness. Allowable tolerance is 1/4" difference

between diagonal measurements. Double-check

approval prints before setting the unit.

Upon completion of setting the curb, apply roofi ng

material and fl ashing as required. On outdoor curb

mounted installations, fl ash and seal the roof curb to

prevent leakage. The cross section of factory provided

curb is formed to accept wood nailing strip and insulation provided by others.

D. Location of Accessories

Where applicable, standard or optional accessories will

be placed inside the fan section of the unit for shipment,

and must be removed and installed by the mechanical

or electrical contractor.

Remotely located discharge or inlet dampers must be

equipped with an end switch and interlocked to insure

maximum design opening before starting and running

circuits may be energized.

C. Curb Mounted Units

Outdoor units can be supplied with an optional roof

curb. The curb greatly facilitates installation thereby

reducing installation costs. All connections to the unit:

duct, piping, electrical power and control wiring can

be made through the roof opening. The curb may be

shipped prior to unit shipment. All curbs are shipped

un-assembled from the factory.

Field constructed intake accessories should be properly

designed to minimize the entry of rain and snow.

Adequate building relief must be provided, so as to not

over-pressurize the building, when the heater is

operating at its rated capacity. This can be accomplished by taking into account, through standard

engineering methods, the structure’s designed infi ltra-

tion rate, by providing properly sized relief openings,

by interlocking a powered exhaust system, or by a

combination of these methods.

– 5 –

E. Electrical Connections

F. Field Piping

WARNING: Open all disconnect switches and

secure in that position before wiring unit.

Failure to do so may result in personal injury or

death from electrical shock.

WARNING: Controls must be protected from

water. Do not allow water to drip on the ignition

system.

NOTE: Before installing any wiring, check the unit

rating plate for supply power voltage and minimum

ampacity.

All electrical connections must conform to the current

edition of: ANSI/NFPA No. 70 National Electrical Code

and applicable state and local codes; in Canada, to the

Canadian Electrical Code, Part 1 CSA Standard C22.1

and applicable provincial and local codes.

Since shipment of unit may require disassembly after

factory check and test, reconnection of some electrical

devices will be required in the fi eld. Connect electrical

wires (supplied in factory furnished conduit) to appropriate terminals. All leads are tagged to facilitate fi eld

connections. See wiring diagram provided with equipment. Complete all wiring to any optional accessories

as shown on unit bill of material and electrical wiring

diagram as required before applying voltage to the unit.

Gas Piping

All gas piping must be in accordance with the requirements outlined in the National Fuel Gas Code - ANSI

Z223.1. It is required that a ground union be installed

adjacent to the manifold for easy servicing. A drip leg

and/or fi lter should be provided upstream of the unit’s

inlet gas connection. An additional shut-off must be

located external of the unit’s enclosure. The location of

this valve must comply with all local codes. A 1/8 inch

N.P.T. plugged tapping, accessible for test gauge connection, must be installed immediately upstream of the

gas supply connection to the unit.

WARNING: To avoid equipment damage or

possible personal injury, disconnect gas piping

to this unit until a supply line pressure/leak test

has been completed. Connecting the unit before

completing the pressure/leak test may damage

the unit gas valve and result in a fi re hazard.

DANGER: Never use an open fl ame to detect

gas leaks. Explosive conditions may exist which

would result in personal injury or death.

On vertical units there is a factory installed “Burner

Cleanout” pipe located on the opposite end of the gas

piping compartment. This is a clean out to drain any

condensate that may have collected in the line burner.

Entry location for all fi eld-installed and control wiring is

through the control panel.

If optional disconnect is not furnished with heater, the

fi eld provided disconnect must be of the proper size

and voltage. Refer to unit rating plate for minimum

circuit ampacity and voltage. The disconnect must be

installed in accordance with Article 430 of the current

edition of ANSI/NFPA No. 70 National Electrical Code.

Check the supply voltage before energizing the unit.

The maximum voltage variation should not exceed

± 10%. Phase voltage unbalance must not exceed 2%.

NOTE: Should any original wire supplied with the

heater have to be replaced, it must be replaced

with wiring material having a temperature rating of

at least 105° C.

REMARQUE : Dans le cas où un quelconque des

câbles livrés avec l'unité devait être remplacé, il

doit être remplacé avec des câbles prévus pour

résister à une chaleur d'au moins 105° C.

WARNING: DO NOT connect supply gas to this

pipe.

The gas line should be supported so that no strain

is placed on the unit. Pipe compounds which are not

soluble to liquid petroleum gases should be used on

threaded joints.

Refer to the heater’s rating plate for determining the

minimum gas supply pressure for obtaining the maximum gas capacity for which this heater is specifi ed.

Une tuyauterie adéquatement dimensionnée doit être

posée jusqu'à l'unité. Veuillez noter que la pression de

la tuyauterie d'alimentation en gaz doit correspondre

à celle spécifi ée sur la plaque d'identifi cation, lorsque

l'unité fonctionne à plein rendement.

Refer to the heater’s rating plate for determining the

maximum supply pressure to the heater.

The appliance and its individual shutoff valve must

be disconnected from the gas supply piping system

during any pressure testing of that system at test

pressures in excess of 1/2 PSIG.

– 6 –

The appliance must be isolated from the gas supply

piping system by closing it’s individual manual

shutoff valve during any pressure testing of the gas

supply piping system at test pressure equal to or

less than 1/2 PSIG.

Correctly sized piping must be run to the unit.

Please note that gas line pressure must be

as shown on specifi cation plate when unit is

operating at full input. The high-pressure regulator

and relief valve should be, if possible, mounted

at least 5 to 10 feet upstream from the appliance

regulator on the unit (if possible).

Building Pressure Transducer Piping (PT-13)

Pipe the high side to location inside the building that

will not be affected by air movement. Pipe the low side

to the atmosphere, positioned so it will not be affected

by the wind and not exposed to the elements. Be sure

that all tubing is clean and clear of any debris before

installing tubes on the transducer.

disconnect switch.

2. Field wiring is typically indicated on the wiring

diagram as dashed lines. When running any fi eld

wiring for control circuit be sure wire is sized for

a maximum 10% voltage drop. Check the VA

rating of control circuit transformer to determine

maximum load.

3.

Mount and wire remote control panel, thermostats,

temperature sensors, and any other fi eld installed

controls as indicated on the unit control wiring diagram.

4.

Connect all wires to the appropriate fi eld wiring

terminals and any shielded or twisted wires as indicated

on the unit control diagram.

5. Field wiring shall have a temperature rating of at

least 105°C. The minimum size of the supply cable

circuit shall be suffi cient for the maximum ampacity

of the heater.

L'installation éléctrique d'utilisateur aura une

température qui évalue d'au moins 105°C. La

minimum de source du circuit de câblage sera

suffi sante pour le ampacity maximum de l'appareil

de chauffage.

Flow Station Transducer Piping (PT-15)

Pipe the high side to the upstream connection and

low side to the downstream connection of the Airfl ow

Station as shown in Drawing # C000643 below. Be

sure that all tubing is clean and clear of any debris

before installing tubes on the transducer.

G. Field Wiring and Remote Control Installation

1. Connect the power lines to the line side of

the power distribution block or optional main

AIRFLOW STATION LAYOUT

HEATER

CASING

RA DAMPER

TUBE CONNECTION

STATIC PRESSURE

NOTE: RUN TUBE CONNECTIONS

TO TRANSDUCER (PT-15) IN

UNIT CONTROL ENCLOSURE

LOW PRESSURE

SENSING TUBE

H. Locating Temperature Controls

The room or outdoor sensors should be mounted

where they will not be subjected to direct impact of

the heated air or radiant heat from the sun. It is also

recommended that thermostats, especially those with

mercury bulb contacts, be mounted on a vibration free

surface. The side of building columns away from the

heater or interior walls are usually the location best

suited for mounting thermostats.

Controls with outdoor sensors require that the outdoor

sensor be shielded from direct radiation from the sun. Unit

mounted sensors are factory located and mounted.

HIGH PRESSURE

TUBE CONNECTION

TOTAL PRESSURE

SENSING TUBE

AIRFLOW STATIO N

EXTERIOR INSULATION

FIELD PROVIDED WHEN

MOUNTED OUTDOORS

– 7 –

BULLET

AMPLIFIER WING

(SHEET METAL STRIP)

C000643

SECTION IV - PRE START-UP

Do not attempt start-up without completely reading

and understanding this manual, along with the

Digital Control Sysem user manual.

A. Pre Start-Up

The owners representative or equipment operator

should be present during start-up to receive instructions on care and adjustments of the equipment.

All equipment has been factory tested, adjusted,

metered and inspected to meet conditions set at

the time the order was placed. Only minimal

adjustments should be required. All information

in this service manual is typical. All products are

semi-custom and changes may occur.

Suggested Tools and Instruments

Volt/Ohm Meter Thermometer

Tachometer Ammeter

Manometer (0-10" W.C.) Microammeter

Standard Hand Tools D.C. Volt Meter

Gas Pressure Gauge (0-35 lbs.) BACview 6

CAUTION: Line side of disconnect may be energized.

Follow proper “lockout/tagout” procedures.

NOTE: All servicing and adjustments of the Direct

Gas-Fired unit should be performed by a qualifi ed

service engineer.

Perform a visual inspection, internally and externally,

to make sure no damage has occured and that

everything is secure. This inspection is very important

and should be completed with greatest care given to

detail. A good pre-start inspection will insure against

possible unit damage on start-up and will save

valuable analysis time.

1. Check that the physical condition of the unit

exterior is acceptable.

2. Check that the insulation inside of unit is properly

secured.

3. Remove all shipping blocks, brackets and bolts

from supply fan base with optional isolation base.

4. Check all wiring for loose connections and tighten

if necessary.

5. Inspect all fan and motor bearings and lubricate if

necessary.

CAUTION: DO NOT RUPTURE GREASE SEALS.

6. Inspect pulleys and belts for tightness, tension and

alignment. Do not overtighten belts.

7. Check set screws on all bearings, pulleys, fans and

couplings for tightness.

8. Check voltage supplied to disconnect switch; the

maximum voltage variation should not exceed

± 10%. Phase voltage unbalance must not exceed 2%.

9. Check thermostat(s) for normal operation.

10. Check that system duct work is installed and free

from obstructions.

11. Check that fans turn free in housing.

12. Check that the area around the unit is clear of

fl ammable vapors or containers of fl ammable

liquids.

13. Check that all piping connections, particularly

unions, are tight. Check all gas piping for leaks

using a soap bubble solution. The most common

types of problems found relative to the gas train

itself is foreign material within the gas piping. This

will interfere with the proper operation of the gas

train components and burner. Purge all air from

gas lines per gas codes.

14. Check that all accessories requiring fi eld wiring

have been properly installed.

15. Check burner for proper location and alignment.

16. Check that fi lters, fi lter stops, accessories and ship

loose items are installed correctly.

17. Check that vent lines (if applicable) are run to

atmosphere on gas regulators and pressure

switches for indoor units. Vent lines should

terminate outside the building, with a turndown

elbow and bug screen. Note that some units will

use vent limiters and vent lines are not required.

If vent lines are even partially plugged, this will

interfere with proper venting of pressure control

devices.

Check that all manual gas shut-off valves are closed.

18.

19. When failure or malfunction of this heater creates a

hazard to other fuel burning equipment, (e.g. when

the heater provides make-up air to a boiler room),

the heater is to be interlocked to open inlet air

dampers or other such devices.

20. Motor overload relay setting should match the

motor’s nameplate full load amperage.

21. Check that dampers and linkages are free to move,

and that linkages are tight.

22. The unit may require that a Return Airfl ow Station

be fi eld installed. Be sure all tubing connections

are in the correct location as shown in drawing

#C000643.

23. Check to ensure all manual reset safety devices

have been reset and limits are in the normal

operating position.

24. If inlet duct is attached to the heater, a purge

timer must be provided and set to purge 4

times the inlet duct volume.

Purge time in seconds = 4 x L x W x H x 60

SCFM

L = duct length in feet, W = duct width in feet,

H = duct height in feet, SCFM = rating plate air

throughput.

Refer to the electrical schematic for the proper

circuit placement. Purge timer P/N 65.0711.00.

– 8 –

SECTION V - UNIT START-UP GENERAL

Before attempting to start the heater read and

understand the the sequence of operations

electrical schematic, ignition module, control

components, gas train, burner and the Digital

Control System user manual.

WARNING: During installation, testing, servicing

and trouble shooting of this product, it may

be necessary to work with live electrical

components. Have a qualified licensed

electrician or other individual who has been

properly trained in handling live electrical

components to perform these tasks. Failure to

follow all electrical safety precautions when

exposed to live electrical components could

result in death or serious injury.

Make sure all manual gas valves are closed.

Make sure all doors and service panels have been

closed or replaced.

Turn main disconnect switch off. Check the incoming

line voltage to match unit rating plate rating. If voltage

is over ±10% of nameplate rating or phase voltage

unbalance is over 2%, notify contractor or power

company.

Fans Are Enabled And Disabled By The Following:

MDT And MRT Standard:

By rotating the remote “Temperature Setpoint” knob

(MP-15).

Clockwise will enable the fans.

Counterclockwise will disable the fans.

MRT-PRO With Smart Room Sensor:

To enable the fans and place the unit in the Occupied

Mode press the “Manual On” button on the face of

the (TS-02) MRT-PRO room sensor. Pressing the

“Warmer” button will add 30-minute increments of

time for a total of 9-hours of operating time. To disable

the fans and place unit in the Unoccupied Mode press

and hold down the “Manual On” button. Alternately

pressing the “Manual On” button will also decrease

the amount of operating time until it reaches zero and

turns the fan off.

MRT Expert or VDT Expert With A BACview (KP-01):

To enable the fans go to “Unit Modes” and enter

[MANUAL], this mode will enable the fans.

To also enable the fans go to “Unit Modes” and enter

[AUTO], this mode has four different functions that

control the fans and unit operation. They are a Time

Clock, Heating and Cooling Night Setbacks, and signal

from an external source to an auxiliary digital input.

To disable the fans go to “Unit Modes” and enter

[OFF].

NOTE: A BACview or PC is required to change Unit

Modes. For a more detailed control sequence see

the (Digital Control System User Manual).

Turn main disconnect switch on and Enable fans.

Damper opens (if applicable). After end switch has

proven damper is open, the blower fan turns on.

(see operating modes in Digital Control System user

manual)

Disable the fans. Check supply blower for proper

rotation.

NOTE: To change rotation of the blower, simply

interchange any two (2) of the line leads of the

motor starter for three (3) phase motors. On single

phase motors refer to motor nameplate.

Enable the fans. Check for proper blower rpm. Check

that all motor amp draws do not exceed rating plate

ratings and overloads are set to motor rating plate

amps.

Check all dampers for proper operation, and linkage

does not bind, see “Sequence of Operation”, and

Digital Control System user manual for damper control

modes.

Disable the fans.

NOTE: Before attempting to light the main burner

you need to review Section X for proper Manifold

and Valve Adjustments. A BACview 6 or PC will be

required to change setpoints.

Check the gas supply pressure by replacing the plug

fi tting on the gas line with a pressure gauge having

appropriate range, and opening the manual gas

valve. Check that the pressure reading is within the

specifi ed range on the rating plate.

NOTE: To adjust gas pressure on supply lines

where a regulator has been installed (to reduce the

inlet pressure to rating plate maximum pressure),

remove dust cap of main gas regulator and turn

adjusting screw clockwise to increase pressure or

counter-clockwise to decrease pressure.

Connect a DC Microammeter between SENSE

terminal and fl ame rod sensing wire.

– 9 –

Open fi rst main gas shut-off valve slowly. Reset high-

low gas pressure switches (if applicable). Check main

gas line for leaks using soap solution.

Heat is Enabled By The Following:

MDT And MRT Standard:

To enable the heat, rotate the “Temperature

Setpoint” knob (MP-15) clockwise to the desired

setpoint above the actual air temperature. The

o

allowable temperature range is 55

to 90oF.

MRT-PRO With Smart Room Sensor:

To enable the heat, press the “Warmer” or “Cooler”

button on the face of the remote MRT-Pro room sensor

(TS-02) to the desired room setpoint. Each push of the

button changes the temperature setpoint by 1o F. The

setpoint can be changed a maximum of + 10oF from

the default of 65oF. Changing the heating setpoint

also changes the cooling setpoint.

MRT Expert or VDT Expert With A BACview (KP-01):

To enable the heat for MRT Expert scroll through

the “Setpoints” menu in the BACview and enter the

desired room Heating Occupied and Unoccupied

Setpoints. For VDT Expert enter the desired Heating

Discharge Air Setpoint.

Energy Savings Modes:

There are 3 Energy Savings Modes that could

disable the burner.

NOTE: A BACview or PC is required to change

Setpoints. For a more detailed control sequence,

see the Digital Control System Users Manual.

Setting Main Flame

CAUTION: You will have approximately three (3)

minutes before the unit shuts down on Freezestat

(Low Discharge Temperature, if you have

disconnected plug wires TS-01 and TS-03). Referred

to in Section X.

NOTE: 3 OR 4 TRIALS MAY BE NEEDED TO

PURGE AIR FROM GAS LINE.

Install manometer at test port on the last tee of the

burner manifold, or MR valve test port.

Slowly open last manual gas shut-off valve.

Enable the fan and burner. Unit will run for 5 seconds

before valve opens and burner lights if all safeties and

limits are in normal operating mode.

NOTE: This is a direct spark ignition burner. Low

fi re may need to be adjusted fi rst in order to light

the burner.

Adjust high fi re pressure reading (from manometer) to

match Normal Manifold Pressure fi ring rate shown on

unit rating plate.

Refer to Valve Adjustment instructions in Section X

for setting high and low fi re gas pressure settings.

The high fi re setting must be made before adjusting

low fi re. Adjust the high fi re setting according to the

Maxitrol Valve Adjustment instructions in Section X.

The high fi re setting must not exceed the pressure

stated on the rating plate.

When adjusting low fi re, there should be a

continuous fl ame along the entire burner length

without any blowout spots. Burner must hold in low

fi re for approximately 10 seconds before modulating up.

Check fl ame signal with burner cycling through full fi ring

range.

Cycle burner several times to insure smooth light off.

Low fi re may need to be readjusted.

There should be a continuous spark for ten (10)

seconds with the last gas cock turned off and the

ignition control (RE-02) should lock out.

Check main gas lines for leaks.

Main fl ame is now set. Make sure burner modulates

and turn thermostat to the desired setting.

United Technologies Electronic Controls Spark

Ignitor (RE-02)

Watch microammeter carefully. Burner must hold in low

fi re for approximately 10 seconds before modulating

up. The reading should be at least 0.5 microamps.

If the read-ing is too low, slowly turn the low-fi re

adjustment on the modulating valve in or out until

satisfactory readings are obtained. When adjusting

low fi re, there should be a continuous fl ame along the

entire burner length without any blowout spots.

– 10 –

Loading...

Loading...