USEFUL OPERATING RANGE

E

J

K

T

Operating Range

0 - 900 °C (32 - 1650 °F)

-200 - 0 °C (-200 - 32 °F)

0 - 750 °C (32 - 1380 °F)

0 - 1250 °C (32 - 2280 °F)

-200 - 0 °C (-325 - 32 °F)

0 - 350 °C (32 - 660 °F)

-200 - 0 °C (-325 - 32 °F)

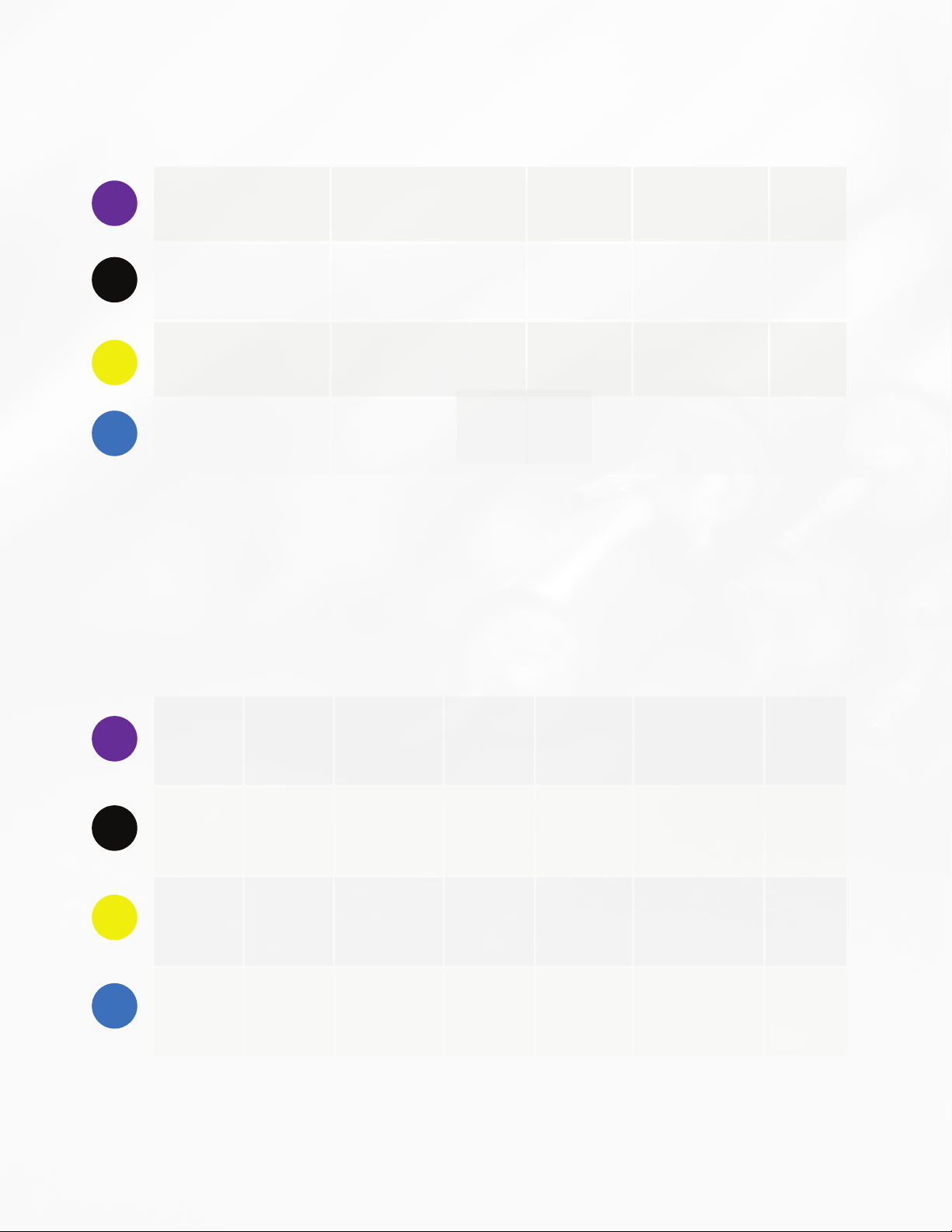

INTERNATIONAL COLOR CODES

Special Limits of Error

± 1.0 °C or ± .4% of Reading

± 1.7 °C or ± .1% of Reading

± 1.1 °C or ± .4% of Reading

± 1.1 °C or ± .4% of Reading

± 2.2 °C or ± .2% of Reading

± .5 °C or ± .4% of Reading

± 1.0 °C or ± 1.5% of Reading

Compared to ANSI Standards

Each

Conductor

Pos. Purple

Neg. Red

Pos. White

Neg. Red

Pos. Y ellow

Neg. Red

Pos. Blue

Neg. Red

ANSI Color Coding

Extension Wire

Purple

Purple

Yellow

Blue

T/C Wire

Brown

Brown

Brown

Brown

E

J

K

T

T/C

TYPE

Overall

EP+

EN+

Overall

JP+

JN+

Overall

KP+

KN+

Overall

TP+

TN+

ANSI

T/C

Brown

Purple

Red

Brown

White

Red

Brown

Yellow

Red

Brown

Blue

Red

ANSI

EXTENSION

Purple

Purple

Red

Black

White

Red

Yellow

Yellow

Red

Blue

Blue

Red

UK

BS1843

Brown

Brown

Blue

Black

Yellow

Blue

Red

Brown

Blue

Blue

White

Blue

Germany

DIN 43714

Black

Red

Black

Blue

Red

Blue

Green

Red

Green

Brown

Red

Brown

Japan

JIS C1610-1981

Purple

Red

White

Yellow

Red

White

Blue

Red

White

Brown

Red

White

IEC

584-3

Violet

Violet

White

Black

Black

White

Green

Green

White

Brown

Brown

White

35

NOMINAL THERMOCOUPLE RESISTANCE

Ohms Per Double Foot @ 20 °C

Wire GA. B & S

14

18

20

22

24

26

28

30

34

36

20 Stranded

Diameter

.064

.040

.032

.025

.020

.016

.013

.010

.006

.005

.038

E

.176

.450

.702

1.129

1.795

2.853

4.537

7.214

18.239

29.000

.648

J

.089

.229

.357

.584

.928

1.476

2.347

3.731

9.434

15.000

.335

K

.147

.377

.588

.937

1.490

2.369

3.767

5.990

15.145

24.080

.538

T

.074

.109

.297

.483

.768

1.221

1.942

3.088

7.808

12.415

.277

22 Stranded

24 Stranded

.030

.024

1.031

1.639

.533

.848

.856

1.361

AVAILABLE THERMOCOUPLE CALIBRATIONS

High temperature connectors available upon request.

J

K

E

.441

.701

TECHNICAL SPECIFICATIONS

T

36

Compacted MgO Thermocouples

All Temprel MgO insulated thermocouples are made using the highest purity MgO for temperatures up to

2300 °F (1260 °C). The thermo-elements are all ANSI special limits of error to give your measurements

the best possible results. The various sheath materials are dependent on the application and the

following will help you make the best selection.

304 SS

310 SS

316 SS

Inconel

Hastelloy X

Maximum temperature of 1650 °F (900 °C) and is the most widely used low

temperature sheath material. It oers good corrosion resistance but is subject to

carbide precipitation in the 900 °F to 1600 °F (480 to 870 °C) range.

Maximum temperature of 2100 °F (1150 °C) and oers good mechanical and corrosion

resistance similar to 304 SS. Very good heat resistance. Not as ductile as 304 SS.

Maximum temperature of 1650 °F (900 °C) and has the best corrosion resistance

of the austenitic stainless steels. Subject to carbide precipitation in the 900 °F to

1600 °F (480 to 870 °C) range.

®

Maximum temperature 2150 °F (1175 °C) and is the most widely used thermocouple

sheath material. Good high temperature strength, corrosion resistance and is

resistant to chloride-ion stress corrosion, cracking and oxidation. Do not use in

sulfur bearing environments.

®

Maximum temperature 2200 °F (1205 °C) widely used in aerospace applications.

Resistant to oxidizing, reducing and neutral atmospheric conditions. Excellent

high temperature strength.

Standard Probe

Diameters

.032” + .001 - .0005”

.040” + .001 - .0005”

.063” ± .001”

.090” ± .001”

.125” + .002 - .001”

.188” + .002 - .001”

.250” + .003 - .001”

All MgO compacted thermocouples can be bent on a radius of twice the probe diameter.

Inconel ®is the registered trademark of INCO Alloys International.

Hastelloy X

®

is the registered trademark of Haynes International.

Suggested Upper

Temperature Limits

1290 °F (700 °C)

1290 °F (700 °C)

1690 °F (920 °C)

1830 °F (1000 °C)

1960 °F (1070 °C)

2100 °F (1150 °C)

2100 °F (1150 °C)

37

Measuring Junctions

Grounded Junctions

Ungrounded Junctions

Exposed Junctions

Semi Sheield Junctions

The thermo-elements are welded into the end cap using the

same weld rod as the sheath material. Fast time response.

Recommended for high-pressure applications.

The thermo-elements are welded together and are electrically

isolated from the sheath. Recommended for applications where

stray EMF’s would aect the reading.

The thermo-elements are welded together outside of the sheath.

This provides the fastest time response but exposes the elements

to contamination. Electrically isolated from the sheath.

The thermo-elements are welded together outside of the sheath.

This provides the fastest time response but exposes the elements

to contamination. Electrically isolated from the sheath.

Approximate Response Time in Seconds

Values are for 2/3 of total temperature change from 0 to 100% as measured in water.

20-AWG bare wire junction measured in gas.

OUTSIDE

DIAMETER

.020

.032

.040

.062

.090

.125

.188

.250

20 AWG bare wire junction

APPROXIMATE

WIRE GAUGE

38

34

32

28

25

22

19

16

APPROXIMATE

WALL THICKNESS

.003

.004

.006

.009

.012

.017

.025

.033

GROUNDED

JUNCTION

.02

.02

.04

.22

.33

.50

1.00

2.20

UNGROUNDED

JUNCTION

.03

.07

.13

.40

.68

1.10

2.30

4.10

.45

TECHNICAL SPECIFICATIONS

38

Loading...

Loading...