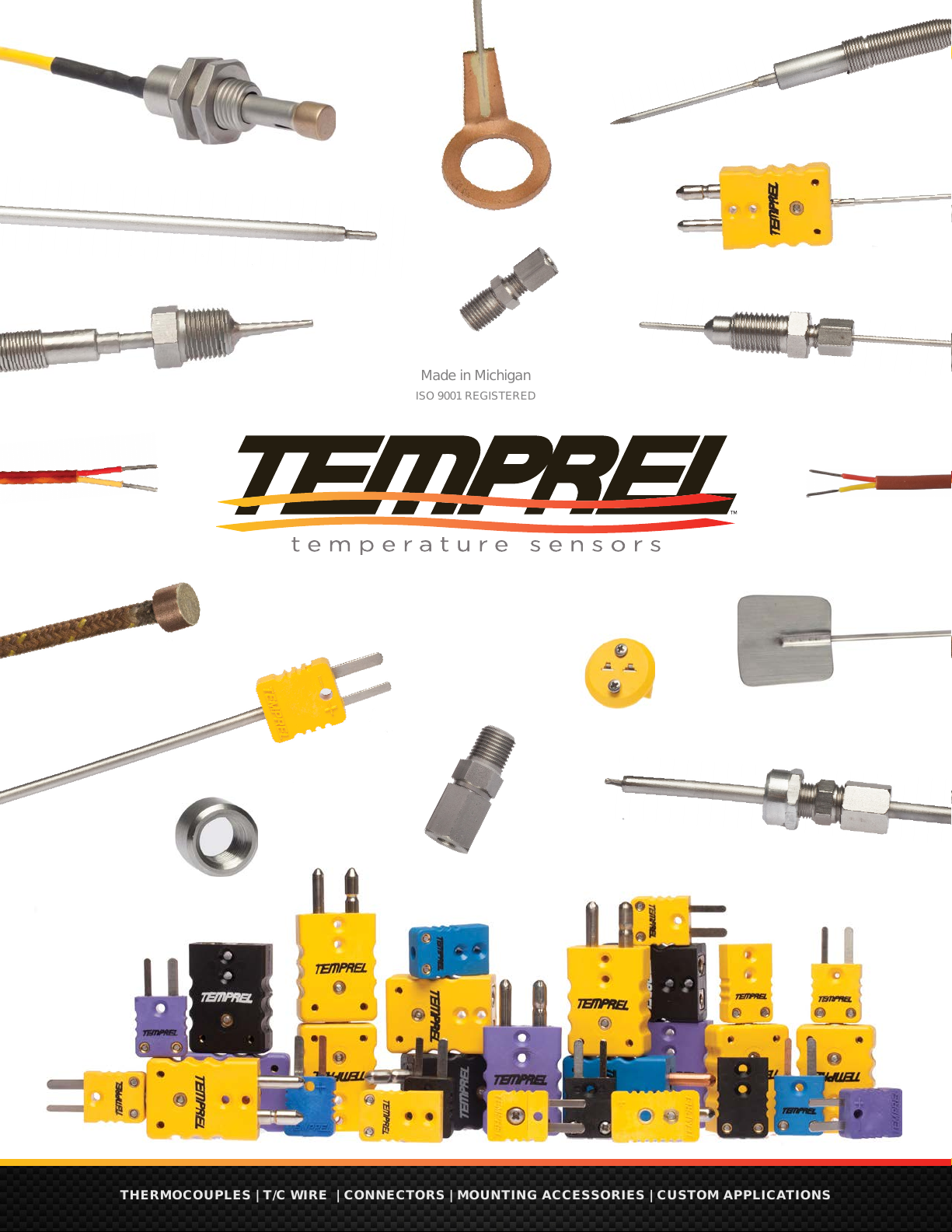

Temprel Inc all products Brochure

THERMOCOUPLES | T/C WIRE | CONNECTORS | MOUNTING ACCESSORIES | CUSTOM APPLICATIONS

ISO 9001 REGISTERED

Made in Michigan

“It’s not about making

something that meets

expectations. It’s about

creating something that

changes them.”

“

“

1

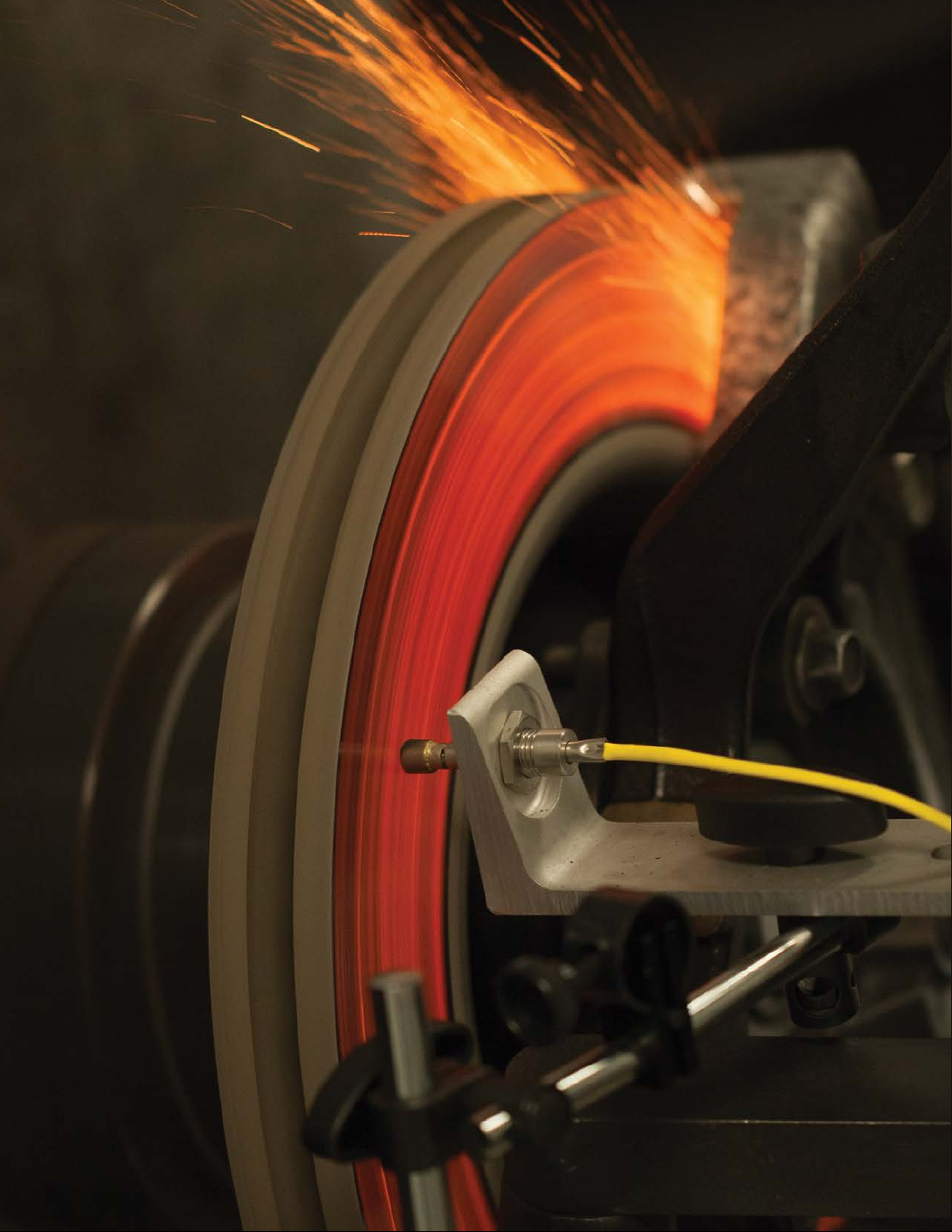

Temprel (an ISO 9001 registered company)

specializes in custom applications.

Working with customers, we can manu-

facture temperature sensing equipment to

meet your custom applications. Temprel

oers high quality, fast turnaround and a

tremendous value.

Founded in 1968 and located in Boyne

City , Michigan, the company has an

experienced sta of well-trained

craftspeople that take pride in being

a “Made-in-Michigan” producer of

high quality temperature sensors.

Temprel has continuously innovated

and improved its manufacturing, assembly

and customer service capabilities. The results

of this forward-thinking approach are improvements in product quality , better delivery times,

expanded product development capabilities and

better-trained, more accessible sales personnel.

WHY TEMPREL?

Temprel’s website (Temprel.com) oers

customers the ability to view stock levels and

purchase products on-line as well as oering

thermocouple information and technical support.

2

3

About Us ..................................................................................................

Index ........................................................................................................

T21 Thermocouples .................................................................................

T23 Thermocouples .................................................................................

T24 Thermocouples .................................................................................

T25 Thermocouples .................................................................................

T26 Thermocouples .................................................................................

T52 Thermocouples .................................................................................

T54 Thermocouples .................................................................................

T100 Thermocouples ...............................................................................

B52 Thermocouples .................................................................................

Egt Exhaust Gas T emperature Thermocouples .......................................

T26 Spark Plug Thermocouples ..............................................................

Rubbing Thermocouples .........................................................................

Connectors ..............................................................................................

Connector Panels ....................................................................................

Brass Hose Couplings .............................................................................

Compression Fittings ...............................................................................

Direct Weld Compression Fittings ...........................................................

Weld on Bungs ........................................................................................

Operating Range .....................................................................................

Color Codes ............................................................................................

Nominal Resistance ................................................................................

Available Calibrations ..............................................................................

Compacted MgO’s ..................................................................................

Measuring Junctions ...............................................................................

Response Time .......................................................................................

Thermocouple Wire ..................................................................................

Thermocouple Wire Construction Characteristics ........................................

Custom Applications ..................................................................................

Page 1-2

Page 3-4

Page 5-6

Page 7-8

Page 9-10

Page 11-12

Page 13-14

Page 15-16

Page 17-18

Page 19-20

Page 21-22

Page 23-24

Page 25-26

Page 27-28

Page 29-30

Page 31

Page 32

Page 33

Page 34

Page 34

Page 35

Page 35

Page 36

Page 36

Page 37

Page 38

Page 38

Page 39-40

Page 41-42

Back Cover

CATAL OG INDEX

INDEX

4

T

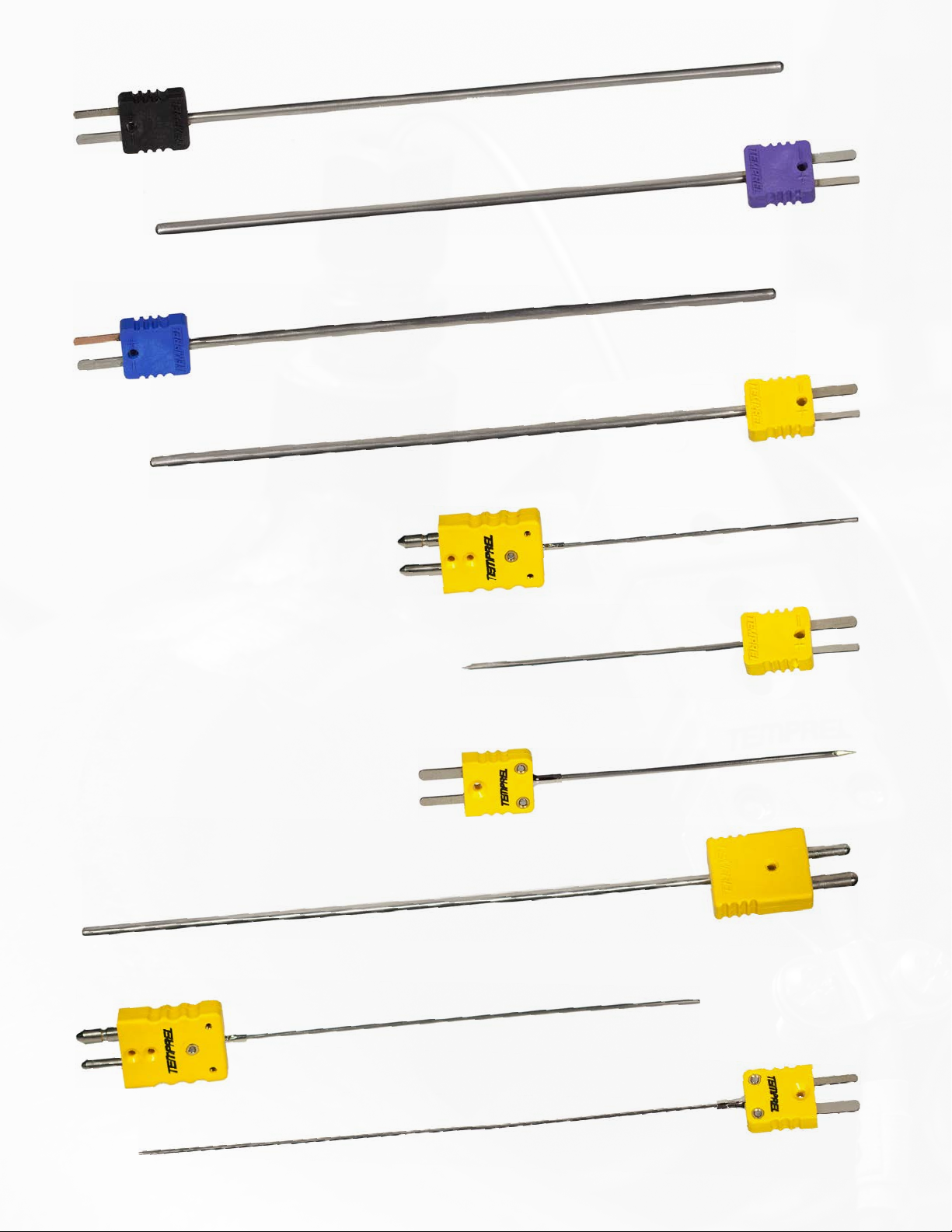

THERMOCOUPLES

21

5

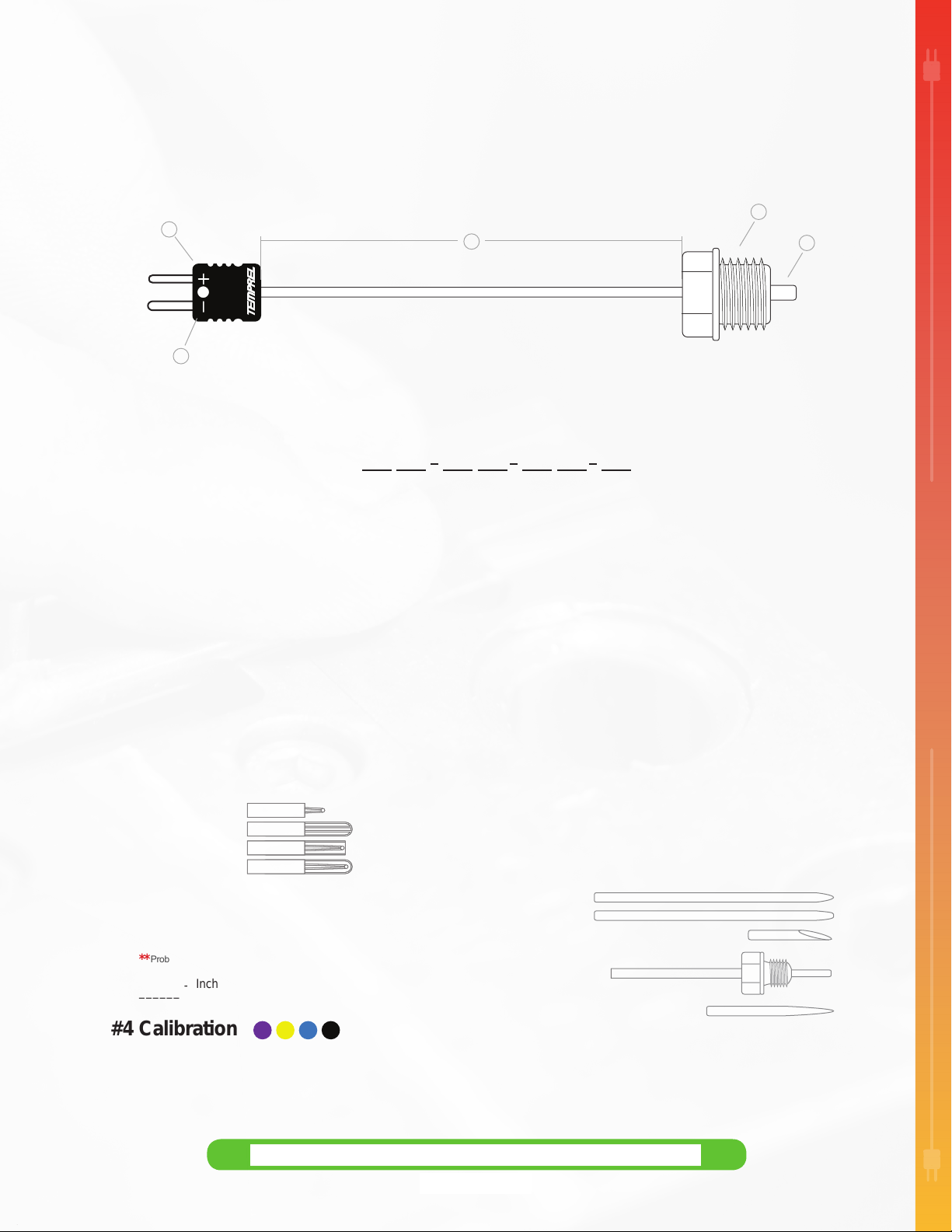

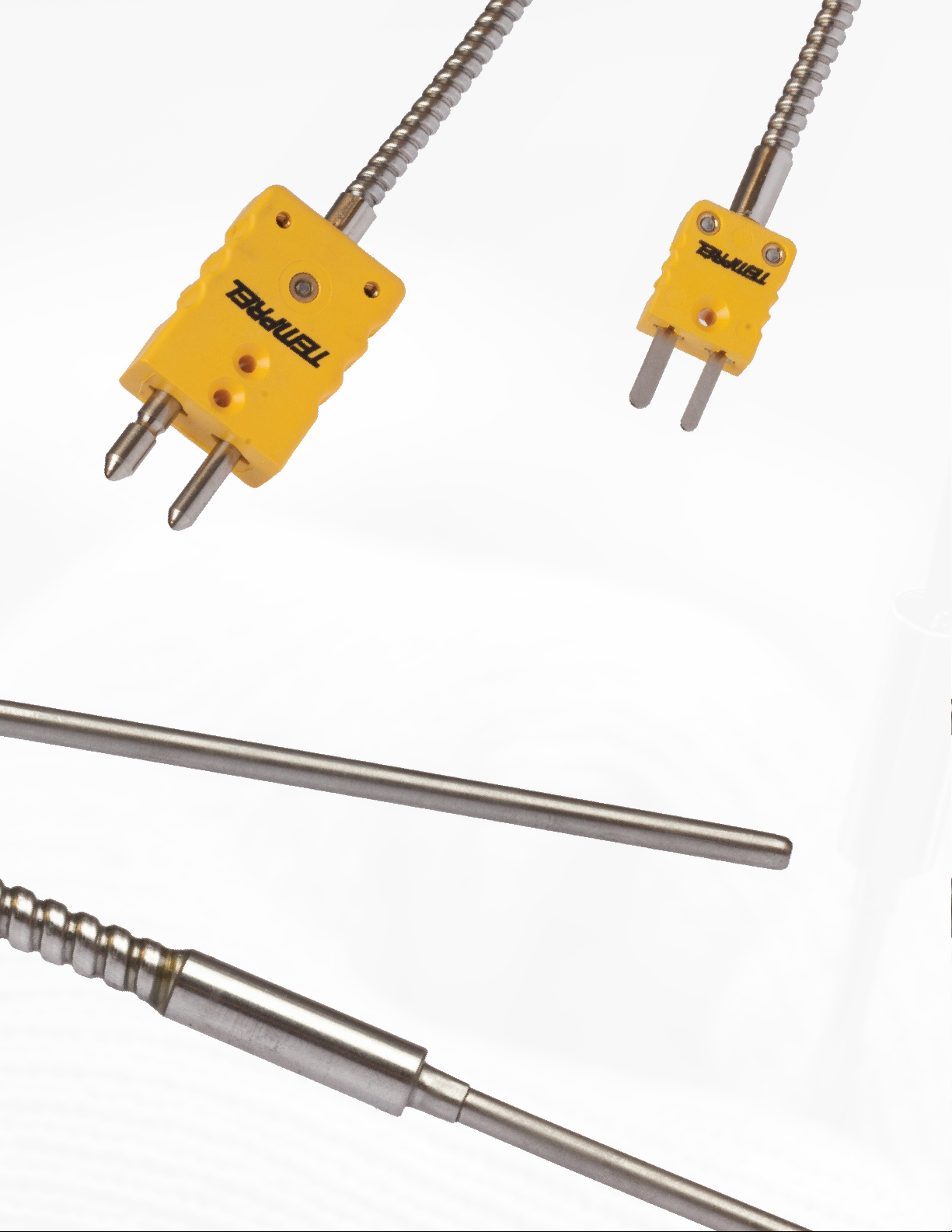

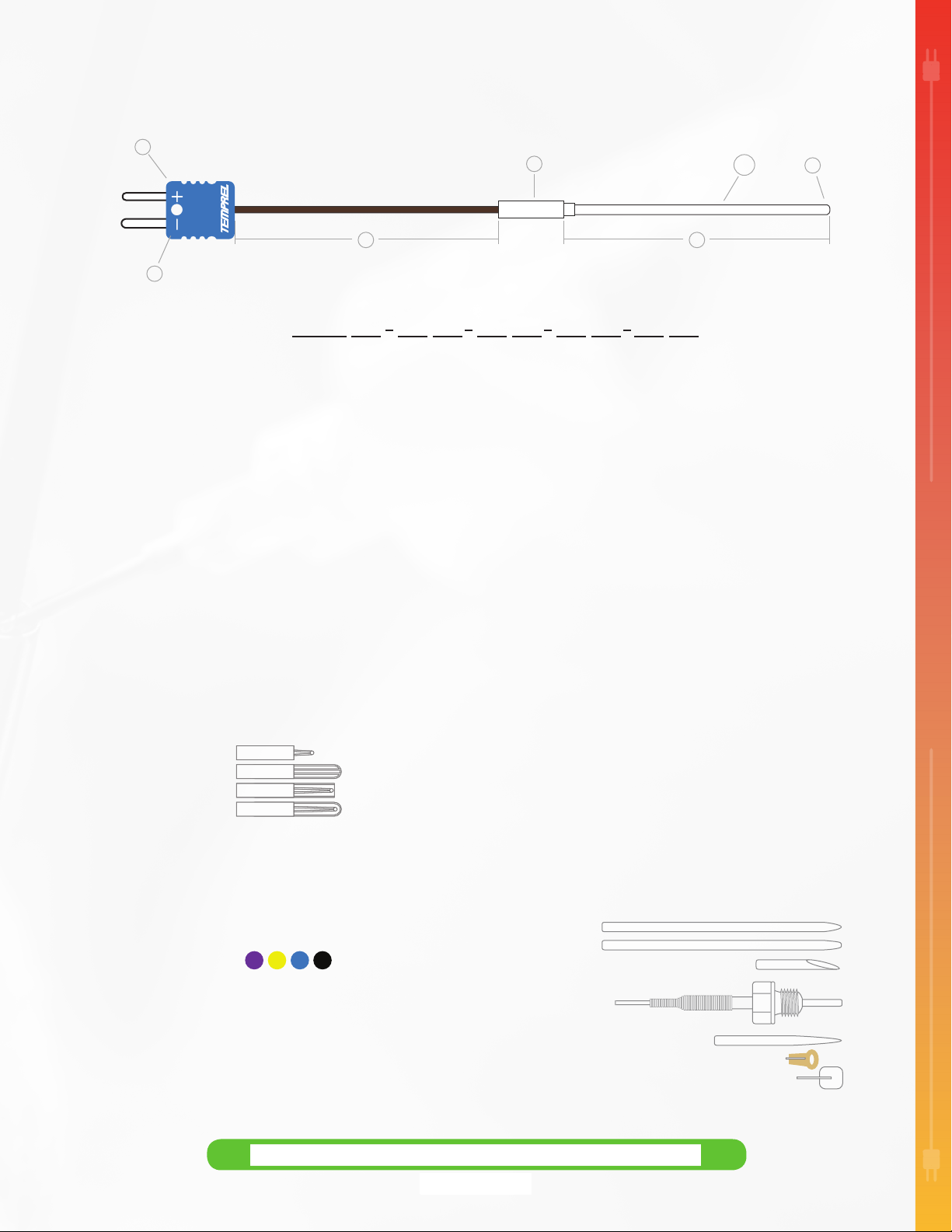

T21 CONFIGURATOR

Quick disconnect thermocouple with compacted MgO insulation

employing a glass-lled, nylon connector directly on the sheath.

1

7

3

4

Sample shown: T21-MU-6E-CI

2

Connectors#1

J -

Put On Standard-Jack

M -

Molded on Mini-Plug

MJ -

Put On Mini-Jack

MP -

Put on Mini-Plug

P -

Put on Standard-Plug

S -

Molded on Standard-Plug

Junction T ype

#2

E -

Exposed

G -

Grounded

S -

Semi-Shielded

U -

Ungrounded

U2 -

Ungrounded Separate for Dual Element

see page # 29-30

see page # 37-38

Specify Probe Length in Inches#3

Probe lengths may vary +/- .125” unless otherwise specied.

**

Probe length is measured from the tip of the

-

______

probe to the rst xed attachment.

T21 :

1 2 3 4 5 6

(Prex T21 Changes to D21 for Dual Element)

#5

AAA -

AA -

S10 S16 -

BP CP -

HPT -

RT -

7

Calibration#4

T JE K

Probe Diameter

.032”

(34 AWG wire)

.040”

(32 AWG wire)

A -

.062” 1/16”

B -

.090”

(25 AWG wire)

Probe Material#6

S -

304 Stainless Steel

310 Stainless Steel

316 Stainless Steel

(28 AWG wire)

C -

.125” 1/8”

D -

.188” 3/16”

E -

.250” 1/4”

see page # 37-38

I -

Inconel

H -

Hastelloy X

Available Options#7

Leave blank if none of the options listed below are needed.

**

Bullet Point

Cone Point

Hypodermic Point

Reduced Tip

(Sharpened to needle point)

( .125” to .062” diameter)

®

®

(22 AWG wire)

(19 AWG wire)

(16 AWG wire)

T21 THERMOCOUPLES

6

T

THERMOCOUPLES

23

7

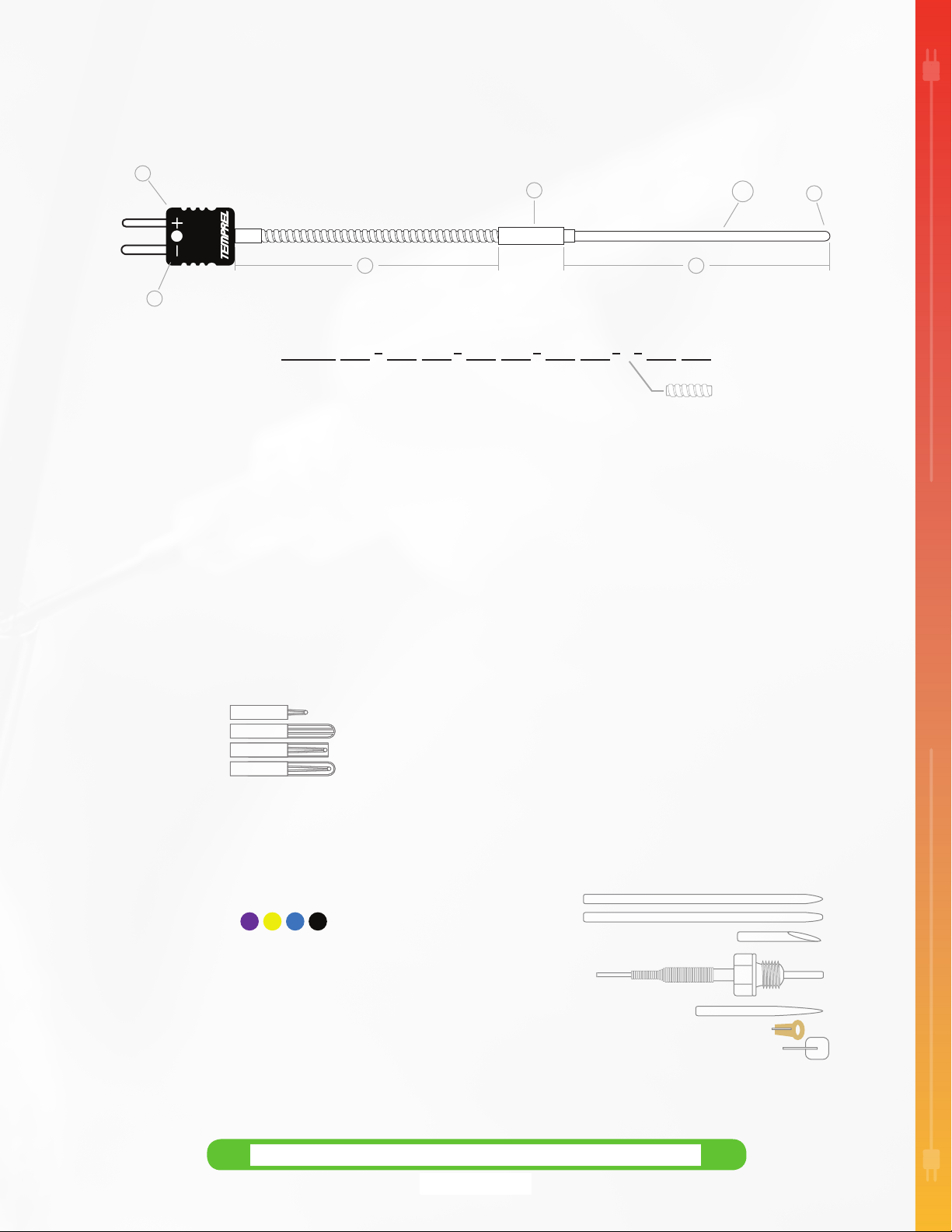

T23 CONFIGURATOR

Quick disconnect thermocouple with compacted MgO insulation

with a xed mount threaded tting mounted directly on the sheath.

7

1

4

Sample shown: T23-MU-6J-CS-14PP

3

2

Connectors#1

J -

Put On Standard-Jack

M -

Molded on Mini-Plug

MJ -

Put On Mini-Jack

MP -

Put on Mini-Plug

P -

Put on Standard-Plug

S -

Molded on Standard-Plug

Junction T ype

#2

E -

Exposed

G -

Grounded

S -

Semi-Shielded

U -

Ungrounded

U2 -

Ungrounded Separate for Dual Element

see page # 29-30

see page # 37-38

Specify Probe Length#3

Probe lengths may vary +/- .125” unless otherwise specied.

**

Inches

-

______

Calibration#4

T JE K

T23 :

1 2 3 4 5 6

(Prex T23 Changes to D23 for Dual Element)

#5

Probe Diameter

AAA -

.032”

(34 AWG wire)

AA -

.040”

(32 AWG wire)

A -

.062” 1/16”

B -

.090”

(28 AWG wire)

(25 AWG wire)

Probe Material#6

S -

304 Stainless Steel

S10 -

310 Stainless Steel

S16 -

316 Stainless Steel

Available Options#7

Custom ttings options available. Call Temprel to learn more.

**

Leave blank for standard probe tip.

BP -

Bullet Point

CP -

Cone Point

HPT -

Hypodermic Point

18PP -

1/8” Pipe Plug

14PP -

1/4” Pipe Plug

38PP -

3/8” Pipe Plug

RT -

Reduced Tip

7

C D E -

see page # 37-38

I -

Inconel

H -

Hastelloy X

(Sharpened to needle point)

( .125” to .062” diameter)

.125” 1/8”

.188” 3/16”

.250” 1/4”

®

®

(22 AWG wire)

(19 AWG wire)

(16 AWG wire)

T23 THERMOCOUPLES

8

T

THERMOCOUPLES

24

9

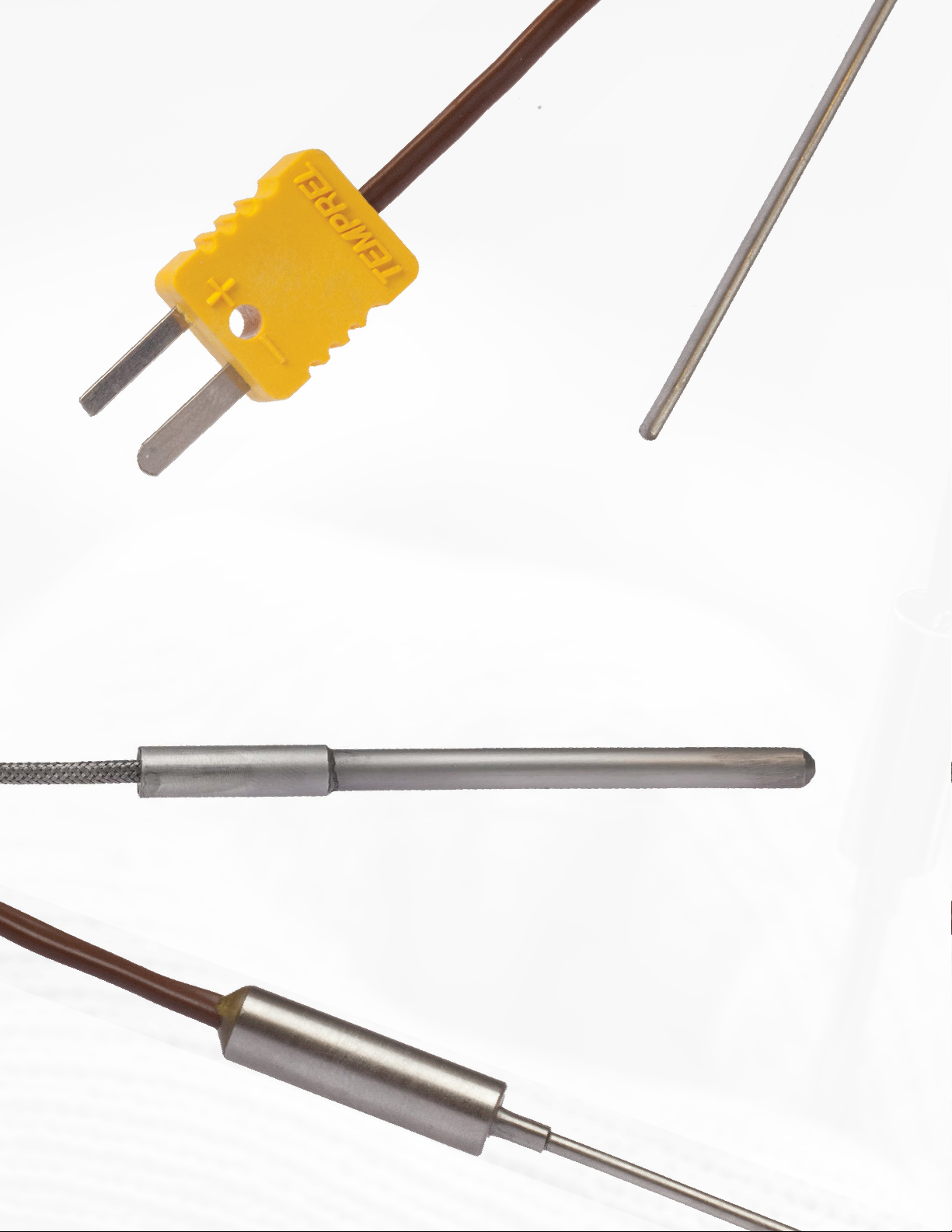

T24 CONFIGURATOR

A sheathed thermocouple with compacted MgO insulation, utilizing a heavy duty

transition tting and lead protected by stainless steel interlocking armor.

(Stainless steel interlocking armor comes standard with T24.)

1

7

4

Sample shown: T24-MU-4J-CS-LC4-A-2F

10

38

2

T24 :

1 2

Connectors#1

J -

Put On Standard-Jack

M -

Molded on Mini-Plug

MJ -

Put On Mini-Jack

MP -

Put on Mini-Plug

O -

Open Wire end, No Connector Option

OC -

Open Wire

P -

Put on Standard-Plug

S -

Molded on Standard-Plug

S3 -

Molded on 3 Prong Standard-Plug

T -

Terminals

Junction T ype

#2

E -

Exposed

G -

Grounded

S -

Semi-Shielded

U -

Ungrounded

U2 -

Ungrounded Separate for Dual Element

#3

Specify Probe Length in Inches

Probe lengths may vary +/- .125” unless otherwise specied.

**

Probe length is measured from the tip of the

-

______

probe to the rst xed attachment.

Calibration#4

#5

Probe Diameter

AAA -

.032”

(34 AWG wire)

AA -

.040”

(32 AWG wire)

A -

.062” 1/16”

B -

.090”

(25 AWG wire)

see page # 29-30

(wire blunt cut)

(Specify type & size when placing your order)

see page # 37-38

T JE K

C -

.125” 1/8”

D -

.188” 3/16”

(28 AWG wire)

E -

.250” 1/4”

3 4 5 6

(Prex T24 Changes to D24 for Dual Element)

Probe Material#6

S -

304 Stainless Steel

S10 -

310 Stainless Steel

S16 -

316 Stainless Steel

Transition#7

LA -

Stainless Steel with High Temperature Epoxy (600

LC -

Stainless Steel with High Temperature Ceramic Potting (2800

LE -

Stainless Steel with Epoxy Potting (500

Specify Wire Length in Inches#8

-

______

Wire Insulation#9

(solid wire)

2F

(solid wire)

2G

(solid wire)

2K

(solid wire)

2P

(solid wire)

2T

Available Options#10

Leave blank for standard probe tip.

**

BP -

Bullet Point

CP -

Cone Point

HPT -

Hypodermic Point

18PP -

1/8” Pipe Plug

14PP -

(22 AWG wire)

(19 AWG wire)

(16 AWG wire)

38PP -

RT -

W -

WP -

1/4” Pipe Plug

3/8” Pipe Plug

Reduced Tip

Washer

Weld Pad

A

7 8 9 10

Interlocking Armor

see page # 37-38

I -

H -

Length as measured from transition to the connector.

(stranded wire)

4F

(stranded wire)

4G

(stranded wire)

4K

(stranded wire)

4P

(stranded wire)

4T

( .125” to .062” diameter)

(Only available with .062“ or 1/16” probe diameter)

(Only available with .062” or 1/16” probe diameter)

- Fiberglass

- High Temp Fiberglass

- Polyimide

- PVC

- Fluoropolymer FEP

(Sharpened to needle point)

®

Inconel

Hastelloy X

®

o

F)

o

F)

o

F)

T24 THERMOCOUPLES

10

T

THERMOCOUPLES

25

11

T25 CONFIGURATOR

Flexible lead wire transition joint sheathed thermocouple with compacted MgO insulation,

utilizing a heavy duty transition tting and lead protected by stainless steel wire overbraid.

1

7

10

2

4

T25 :

Connectors#1

Multiple connectors may be selected. Not all combinations available.

**

J -

Put on Standard-Jack

JSR -

Put on Standard-Jack with Strain Relief

M -

Molded on Mini-Plug

MJ -

Put on Mini-Jack

MJSR -

MPSR -

Put on Mini-Jack with Strain Relief

MP -

Put on Mini-Plug

Put on Mini-Plug with Strain Relief

O -

Open Wire end, No Connector Option

OC -

Open Wire

P -

Put on Standard-Plug

PSR -

Put on Standard-Plug with Strain Relief

S -

Molded on Standard-Plug

S3 -

Molded on 3 Prong Standard-Plug

T -

Terminals

Junction T ype

#2

E -

Exposed

G -

Grounded

S -

Semi-Shielded

U -

Ungrounded

U2 -

Ungrounded Separate for Dual Element

see page # 29-30 see page # 37-38

(wire blunt cut)

(Specify type & size when placing your order)

see page # 37-38

Specify Probe Length in Inches#3

Probe lengths may vary +/- .125” unless otherwise specied.

**

Probe length is measured from the tip of the

-

______

Calibration#4

#5

Probe Diameter

AAA -

AA -

A -

B -

probe to the rst xed attachment.

.032”

(34 AWG wire)

.040”

(32 AWG wire)

.062” 1/16”

.090”

(28 AWG wire)

(25 AWG wire)

T JE K

C D -

E -

8

Sample shown: T25-MU-4T-CS-LE4-4T

1 2 3 4 5 6

(Prex T25 Changes to D25 for Dual Element)

S10 S16 -

HPT -

18PP 14PP -

.125” 1/8”

.188” 3/16”

.250” 1/4”

(22 AWG wire)

(19 AWG wire)

(16 AWG wire)

38PP -

WP -

3

7 8 9 10

Probe Material#6

S -

304 Stainless Steel

310 Stainless Steel

316 Stainless Steel

I -

H -

®

Inconel

Hastelloy X

®

Transition#7

LA -

Stainless Steel with High Temperature Epoxy (600

LC -

Stainless Steel with High Temperature Ceramic Potting (2800

LE -

Stainless Steel with Epoxy Potting (500

GP -

Overbraid Grounded to Transition

P -

Molded on Plastic Rated (525

o

F)

o

F)

Specify Wire Length in Inches#8

-

______

Length as measured from transition to the connector.

Wire Insulation#9

Append prex “R” to the begining of any options listed below to call for

**

Stainless Steel Overbraid on wire. Example “R4F”

(solid wire)

2F

(solid wire)

2G

(solid wire)

2K

(solid wire)

2P

(solid wire)

2T

4F

4G

4K

4P

4T

(stranded wire)

(stranded wire)

(stranded wire)

(stranded wire)

(stranded wire)

- Fiberglass

- High Temp Fiberglass

- Polyimide

- PVC

- Fluoropolymer FEP

Available Options#10

Leave blank for standard probe tip.

**

BP -

Bullet Point

CP -

Cone Point

Hypodermic Point

1/8” Pipe Plug

1/4” Pipe Plug

3/8” Pipe Plug

RT -

Reduced Tip

W -

Washer

Weld Pad

(Only available with .062“ or 1/16” probe diameter)

(Sharpened to needle point)

( .125” to .062” diameter)

(Only available with .062” or 1/16” probe diameter)

o

F)

o

F)

T25 THERMOCOUPLES

12

T

THERMOCOUPLES

26

13

Loading...

Loading...