TEMPRATEC C1 Installation Operation & Maintenance

Installation

Operation

Maintenance

Controls

TEMPRATEC C1

Compressed Air Atomizing Burner for

Rapeseed Oil and Heating Oil EL

TEMPRATEC C1

Contents

Page

1. Technical Data ................................................................................................................. 3

2. Dimensions ...................................................................................................................... 4

3. Warnings and Safety Precautions .................................................................................... 5

4. Installation of the Oil Burner ............................................................................................. 6

5. Items to remember when putting equipment into service ................................................. 7

6. Burner settings ................................................................................................................. 8

7. Basic Burner Settings ...................................................................................................... 9

8. Hydraulics Diagram .......................................................................................................... 10

9. Electrical Connections and Switching Diagram ................................................................ 11

10. Oil Connection (Pipeline Dimensions)............................................................................... 12

11. Burner Malfunctions and Possible Causes ....................................................................... 14

12.

Care and Maintenance ..................................................................................................... 15

13.

Nozzle Holder................................................................................................................... 16

14. Putting Equipment Out of Service .................................................................................... 17

15. Guarantee Conditions ..................................................................................................... 17

16. Oil Quality, Rapeseed Oil ................................................................................................. 18

17.

Manufacturer Declaration and Declaration of Conformity ................................................. 19

18.

Installation Instructions .................................................................................................... 20

19.

Putting into service ........................................................................................................... 23

20.

Service Instructions .......................................................................................................... 25

- 2 -

1. Technical Data

TEMPRATEC C1

- 3 -

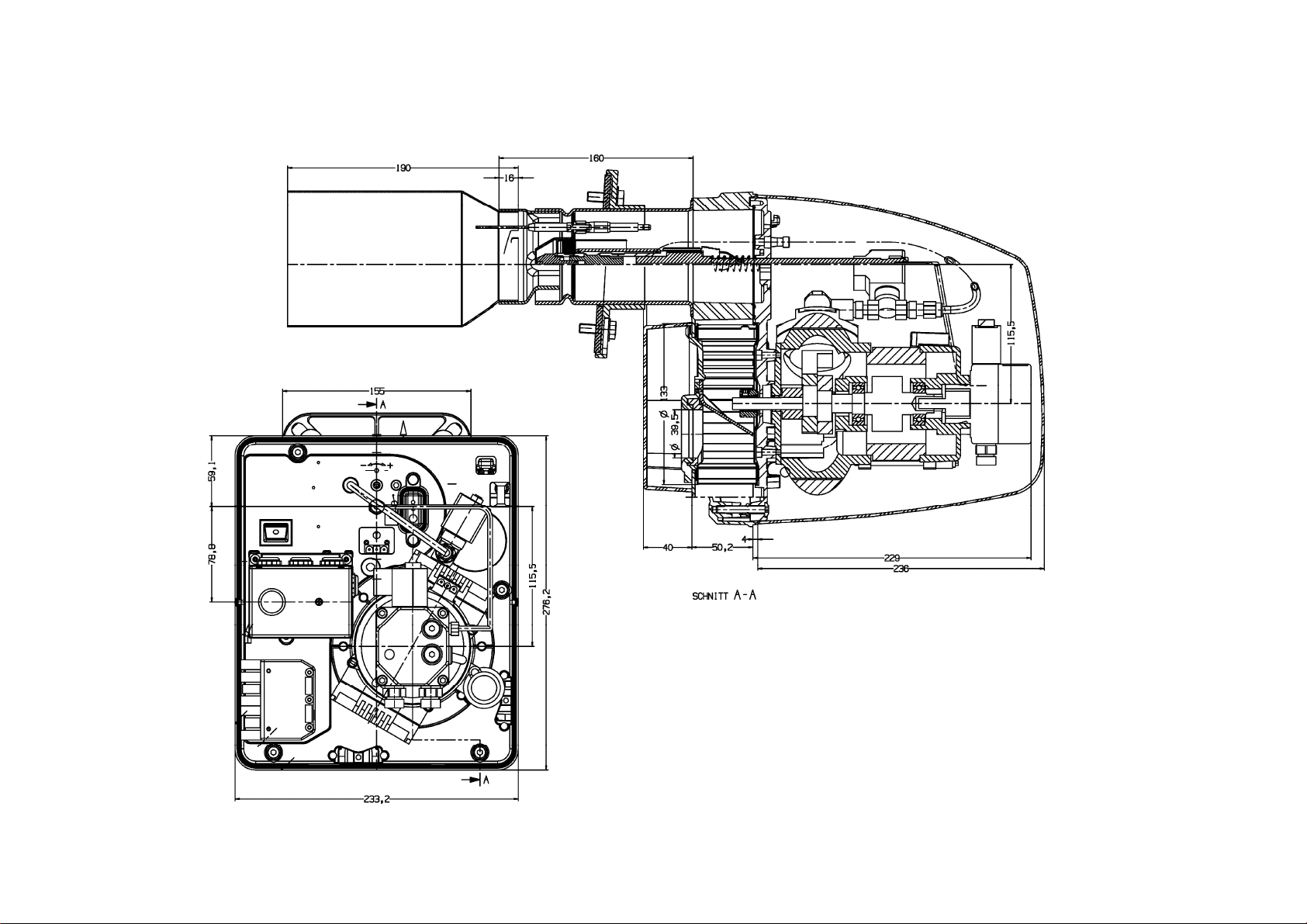

2. Dimensions

Burner type Tempratec C1

Burner output 13 - 31 kW

Oil throughput, heating oil EL 1.1 - 2.6 kg/ h

Oil throughput, rapeseed oil 1.3 - 2.9 kg/ h

NOx Class 3

Electrical power consumption 305 W

TEMPRATEC C1

Basis for testing

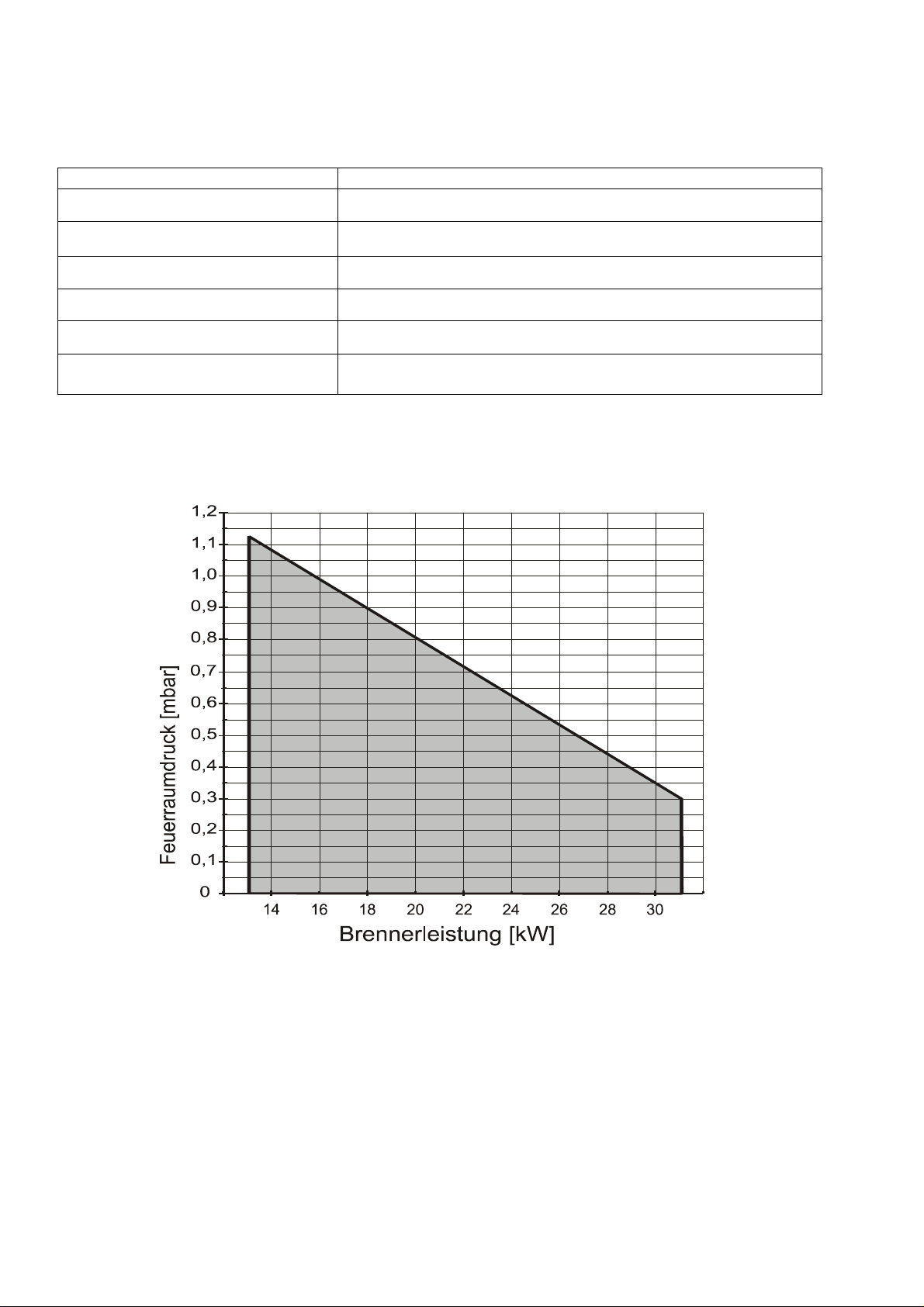

Performance diagram:

Combustion chamber pressure [mbar] Burner output [kW]

DIN EN 267 (99)

1. BImSchV

We reserve the right to make changes conducive to technical advances.

- 4 -

TEMPRATEC C1

Shutting down of burner for a given

3. Warnings and Safety Precautions

IMPORTANT NOTICE

Carefully read the installation

instruction for the burner before

installation and putting into service.

Non-compliance or improper

installation renders the warranty nil

and void.

When installing accessory

components, follow the

corresponding instructions.

DANGER

WARNING!

due to electric current.

Before undertaking any work on the

burner and heating equipment, cut

off all electric power, e.g. by means

of the heater emergency OFF switch

outside the furnace room. Switching

off the regulating device is not

sufficient!

EQUIPMENT DAMAGE

CAUTION!

due to improper installation. Please

comply with engineering standards

as well as building and other legal

regulations regarding construction

and operation of the equipment!

EQUIPMENT DAMAGE

CAUTION!

This burner is equipped for use with

biological fuels with special

components.

Use only original spare parts.

EQUIPMENT DAMAGE

CAUTION!

due to improper cleaning and

maintenance. Perform cleaning and

maintenance steps as instructed,

whereby the entire system must be

tested for faultless functioning!

Eliminate any defects immediately to

avoid damaging the equipment!

IMPORTANT NOTICE

CONCERNING OIL STORAGE

For vegetable oils, storage

temperatures higher than 20°C and

lower than 8°C must be avoided.

Avoid exposure to light. Oil must be

removed from storage via a floating

device to guarantee sediment-free

oil quality. Oil storage, including

laying of the oil lines, must be

realized in such a manner that the

oil temperature upstream from the

burner is at least + 8°C .

IMPORTANT NOTICE

CONCERNING OIL TANK FILLING

The oil burner must be switched off

before filling the tank. To allow

floating particles to settle, it is

necessary to wait approx. 3 h after

filling before switching on the oil

burner again.

In case of leaky oil lines or an empty

tank, deflagrations may occur due to

air bubble formation.

period

If the heating system is being run on

vegetable oil, the burner must be

flushed with the fuels EL (extra light)

heating oil or automotive diesel for at

least 10 minutes before shutting

down the system for periods longer

than 14 days.

We reserve the right to make technical

changes!

Illustrations, functional steps and technical data

may deviate slightly due to ongoing

developments.

- 5 -

TEMPRATEC C1

4. Installation of the Oil Burner

The sliding flange supplied with the equipment is

used to affix the oil burner to the boiler by means

of four bolts for attachment to the boiler plate.

The jam-fit sliding flange facilitates insertion of

the fire tube into the combustion chamber so as

to meet the requirements of the specific boiler

unit.

The slots in the sliding flange are suitable for

reference diameters from 150 to 180 mm.

When installing the sliding flange, take into

account the tilt of 3° in the direction of the

combustion chamber so that no oil will flow into

the burner when the preheater is warming up.

Comply with the label instruction "TOP"!

Once the flange has been mounted on the boiler,

the fire tube is inserted and the burner is raised

slightly and fitted tight. (4 mm Allen key).

The combustion chamber door is then opened

and the fire tube is fastened down using the

bayonet mount.

4.1 Insertion depths

In some combustion chamber versions,

predefined fire tube insertion depths must be

complied with:

Threepass boiler with recirculation

combustion chamber:

Insert burner until the recirculation slits project

into the combustion chamber insert.

Hot reversed-operation combustion chamber:

Insert burner only until the recirculation slits are

flush with the door insulation.

Very important:

It is important to make sure the recirculation slits

project far enough into the combustion chamber

to ensure exhaust gas recirculation. They must

not be covered by insulation material. The

distance between the rear wall of the boiler and

the must be at least 100 mm.

4.2 Electrical connection

The electrical connection is realized by means of

a plug-in connector acc. to DIN EN 226, the

socket component of which is attached to the

burner. Comply with local EVU and VDE

regulations. Comply with switching diagram!

Pull out burner plug before working on the burner

electrical system.

4.3 Oil connection

The oil hoses provided are connected to the oil

pump and affixed with the clamping device. The

cutoff and filter fixtures must be arranged to

provide for technically appropriate hose

arrangement, i.e. the hoses must not be buckled.

Please use only the oil hoses included with the

equipment and original replacement parts. Only

these hoses will ensure optimized resistance to

aggressive acids contained in the biological

fuels. Use parts made of plastic or special steel

for all parts in contact with oil.

- 6 -

TEMPRATEC C1

5. Items to remember when putting equipment

into service

5.1 Exhaust gas temperature

The exhaust gas temperature should be within

the range of 160°C to 200°C. At temperatures

below 160°C there is a risk of condensate

sooting. It is therefore important to make sure the

stack meets the relevant specifications. The

instructions issued by the boiler manufacturer on

minimum exhaust gas temperature must also be

complied with.

5.2 Harmonization of burner, boiler and stack.

A prerequisite of faultless combustion is a

constant combustion chamber pressure, since

the burner fan output depends on a certain

counterpressure level. Pressure variations result

in air excess or deficiency. Installation of a

draught restriction valve or secondary air

system is necessary to achieve a constant

combustion chamber pressure. The stack crosssection dimension must also be appropriate.

Stack and burner monitoring and heating

engineers can provide technical expertise

concerning the dimensioning of stacks and

secondary air systems.

5.3 Exhaust gas thermometer

Installation of an exhaust gas thermometer or

continuous monitoring of the exhaust gas

temperature using thermometers available from

technical suppliers is recommended. An

appropriate measuring point is the control

opening for stack and burner engineers in the

exhaust gas tube. A rise in exhaust gas

temperature exceeding 30°C indicates initial

formation of deposits in the boiler, which result in

sub-optimum operation of the heating system.

The burner setting should be controlled and

cleaning of the boiler considered. Reference

measurements must ensure that the boiler

temperatures are identical and that the burner

operating times prior to measurement are

approximately the same.

5.4 Operation timer

To control oil consumption, it is recommended

that the C1 burner be supplied with an operation

timer. When comparing oil consumption levels, it

must be taken into account that the external

temperature curve over given months or years

influences the measurement results.

5.5 Fuels

The Tempratec C1 burner is tested and

approved for the fuels heating oil EL and

rapeseed oil acc. to E-DIN 51605:2005-06 (RK

Quality Standard).

5.6 Information concerning the operations

room

The burners may only be installed in rooms in

which air contamination with halogenated

hydrocarbons can be expected, such as

hairdresser businesses, printing businesses,

chemical dry-cleaners, laboratories, etc. if a

sufficient volume of uncontaminated combustion

air is available. The burners may not be operated

in rooms with high levels of dust or humidity, e.g.

washrooms. The heating room must be protected

from frost and well ventilated. If these principles

are not complied with, warranties for any

damages will be nil and void.

- 7 -

TEMPRATEC C1

6. Burner settings:

The C1 burner features the following settings:

6.1. The pump pressure adjustment

Pump pressure adjustment (DV) is used to set

the performance level over the entire

performance range.

The nozzle need not be replaced to change

the output performance level.

S = Suction line

P = Manometer, pump pressure

DV = Pressure adjustment

MV = Solenoid valve

R = Recirculation line

V = Vacuum meter

DL = Nozzle line

The pump pressure covers a range of:

3.0 – 13.5 bar for heating oil EL

5.5 – 18.0 bar for rapeseed oil

6.2. Air valve adjustment

The air valve is adjusted to adapt the combustion

air to the oil volume (output).

Excessive combustion air is

controlled by means of the air

valve using a suitable

emissions metering device.

Non-binding basic settings

are listed in the table “Basic

Settings”.

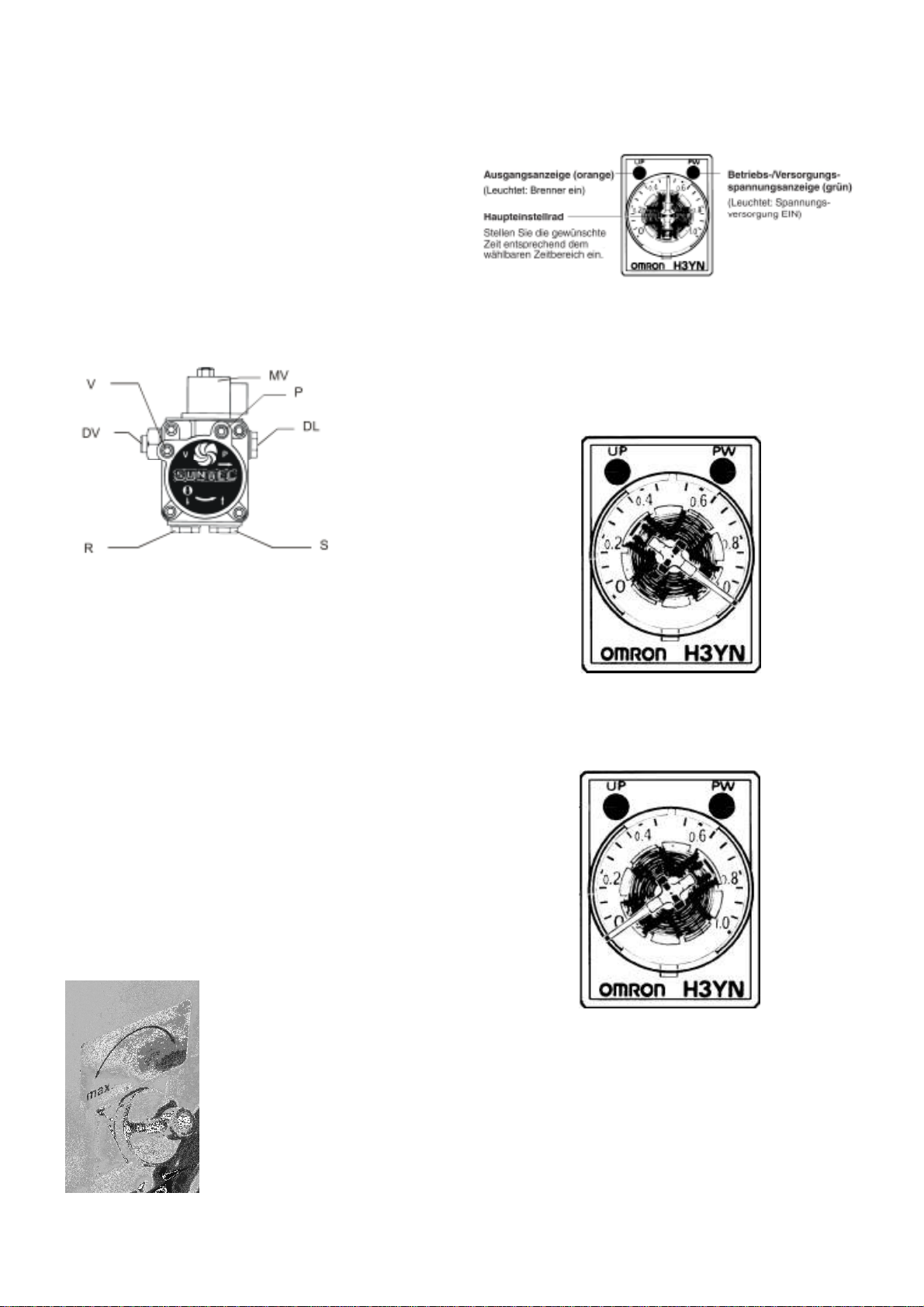

6.5. Startup delay

Output display (orange) Operational / supply voltage

(lights up: burner on) display (green)

Main adjustment wheel (lights up: voltage supply ON)

Set time accordingly.

During the adjustable startup delay time, the

temperature of the entire nozzle holder is

monitored to make sure it is high enough before

the burner starts up.

Basic setting for startup delay:

Time setting (t): approx. 10 min.

Turn knob to the right until it hits the stop.

To undertake service work on the

operationally warm burner, the settings wheel

can be turned to the right until it hits the stop.

This reduces the startup delay to 1 min..

After the service work is completed, the settings

wheel is always once again turned to the right

until it hits the stop to avoid startup problems.

- 8 -

Loading...

Loading...