Page 1

FORM TPM3-EG1 (518)

TempMaster® OmniElite

™

SINGLE PACKAGE ROOFTOP UNITS

ENGINEERING GUIDE

120–150 Tons

Cooling and Heating (Gas, Electric, Water, and Steam)

R-410A

Mod G

LD19506

Page 2

FORM TPM3-EG1 (518)

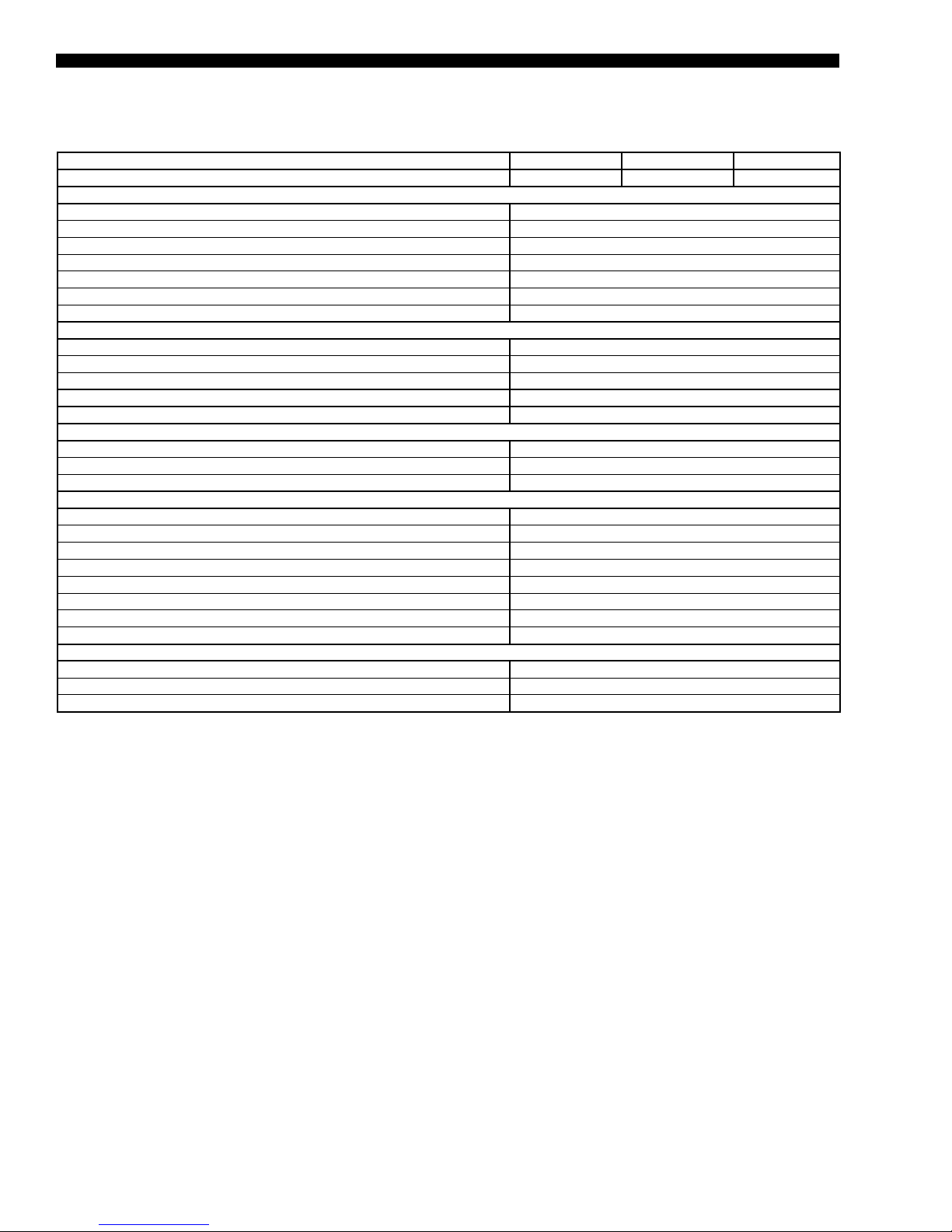

Nomenclature

BASE MODEL NUMBER TMAL120–150

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17

BASE PRODUCT TYPE NOMINAL CAPACITY APPLICATION REFRIGERANT VOLTAGE DUCT LOCATIONS DESIGN SPECIAL GAS HEAT CAPACITY

L : Scroll

A : Air-Cooled

M : Packaged Rooftop

T : TempMaster

0

2

1

1

1

: 120-ton

0

3

: 130-ton

0

5

: 150-ton

V : VAV or SZVAV

C : Cooling Only

N : Natural Gas Heat

G : Natural Gas Heat Stainless Steel Heat Exchanger

M : Modulating Gas Heat

E : Electric Heat

S : Steam Heat

H : Hot Water Heat

E : R-410A

6 : 460 / 3 / 60

4

8 : 575 / 3 / 60

5

B : Bottom Return

R : Rear Return

S : Side Return

B : Bottom Supply

L : Left Supply

R : Right Supply

N : No Gas Heat

L : Low (375 mbh)

M : Medium (750 mbh)

H : High (1125 mbh)

X : Standard Product, IPU

S : Special Product, IPU

G

Approvals

2

ASHRAE

90.1

COMPLIANT

TEMPMASTER

Page 3

FORM TPM3-EG1 (518)

Table of Contents

NOMENCLATURE ................................................................................................................................................... 2

INTRODUCTION ...................................................................................................................................................... 5

FEATURES AND BENEFITS ................................................................................................................................... 7

APPLICATION DATA ............................................................................................................................................. 14

PHYSICAL DATA ................................................................................................................................................... 19

WEIGHT DATA ....................................................................................................................................................... 21

COOLING PERFORMANCE DATA .......................................................................................................................23

HEATING PERFORMANCE DATA – GAS/ELECTRIC HEAT ............................................................................... 38

SUPPLY FAN DATA ............................................................................................................................................... 39

COMPONENT STATIC PRESSURE DROPS ........................................................................................................ 40

ELECTRIC HEAT PRESSURE DROPS ................................................................................................................ 42

GAS HEAT PRESSURE DROPS ........................................................................................................................... 42

EXHAUST FAN DATA ............................................................................................................................................ 43

RETURN FAN DATA .............................................................................................................................................. 44

ELECTRICAL DATA .............................................................................................................................................. 45

CONTROLS ........................................................................................................................................................... 47

POWER WIRING: TMAL120–150 ......................................................................................................................... 55

FIELD CONTROL WIRING ................................................................................................................................... 57

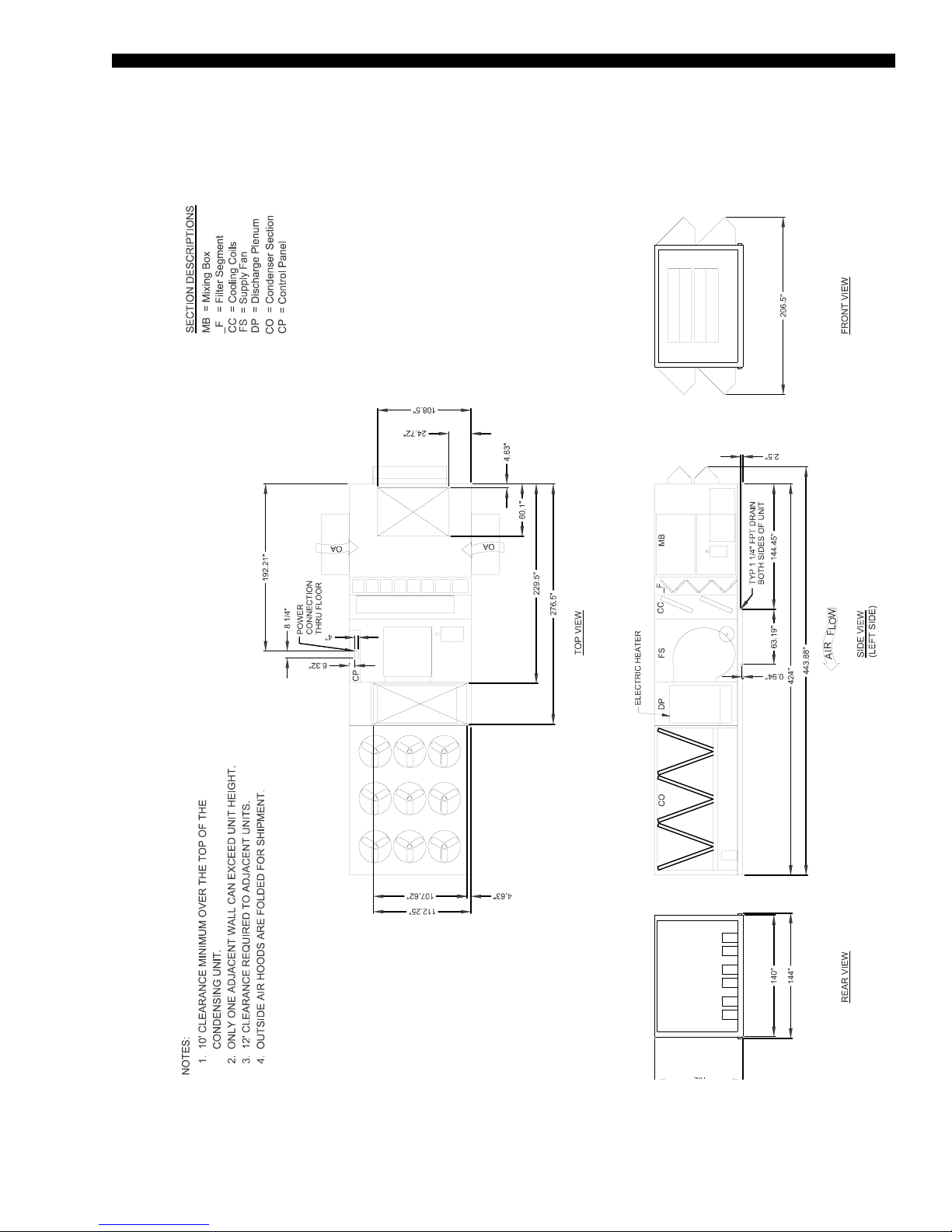

GENERAL ARRANGEMENT DRAWING – 120–150 TON MODELS .................................................................. 59

HOT WATER/STEAM COIL CONNECTION LOCATIONS .................................................................................... 65

POWER/CONTROL ENTRY DRAWING – 120–150 TON MODELS ..................................................................... 66

GUIDE SPECIFICATIONS ..................................................................................................................................... 67

TEMPMASTER

3

Page 4

FORM TPM3-EG1 (518)

THIS PAGE INTENTIONALLY LEFT BLANK.

4

TEMPMASTER

Page 5

Introduction

FORM TPM3-EG1 (518)

The TempMaster® OmniElite™ Single Package Units –

designed to meet the demands of the market for today and

tomorrow.

Better Economy...

Lower total cost of ownership

• TempMaster provides a standard product offering that meets the latest ASHRAE

90.1 energy efciency requirements.

• Unique compressor staging provides quick response to cooling needs and provides

multiple steps of capacity for high part load efciency.

• Fully modulating gas heat and greater steps of capacity control offer superior offdesign performance while maintaining optimum occupant comfort.

• Accurate ventilation control ensures that no more than the proper amount of ventilation air is utilized. This avoids the energy cost of conditioning excess outside air and

simultaneously monitors all other unit functions for maximized energy efciency.

• Flexible design congurations simplify the design process and allows the TempMas-

ter OmniElite to be applied to virtually any building application.

• Accessibility through double-wall access doors, spacious compartments and sup-

portive oors improves serviceability.

LD07431

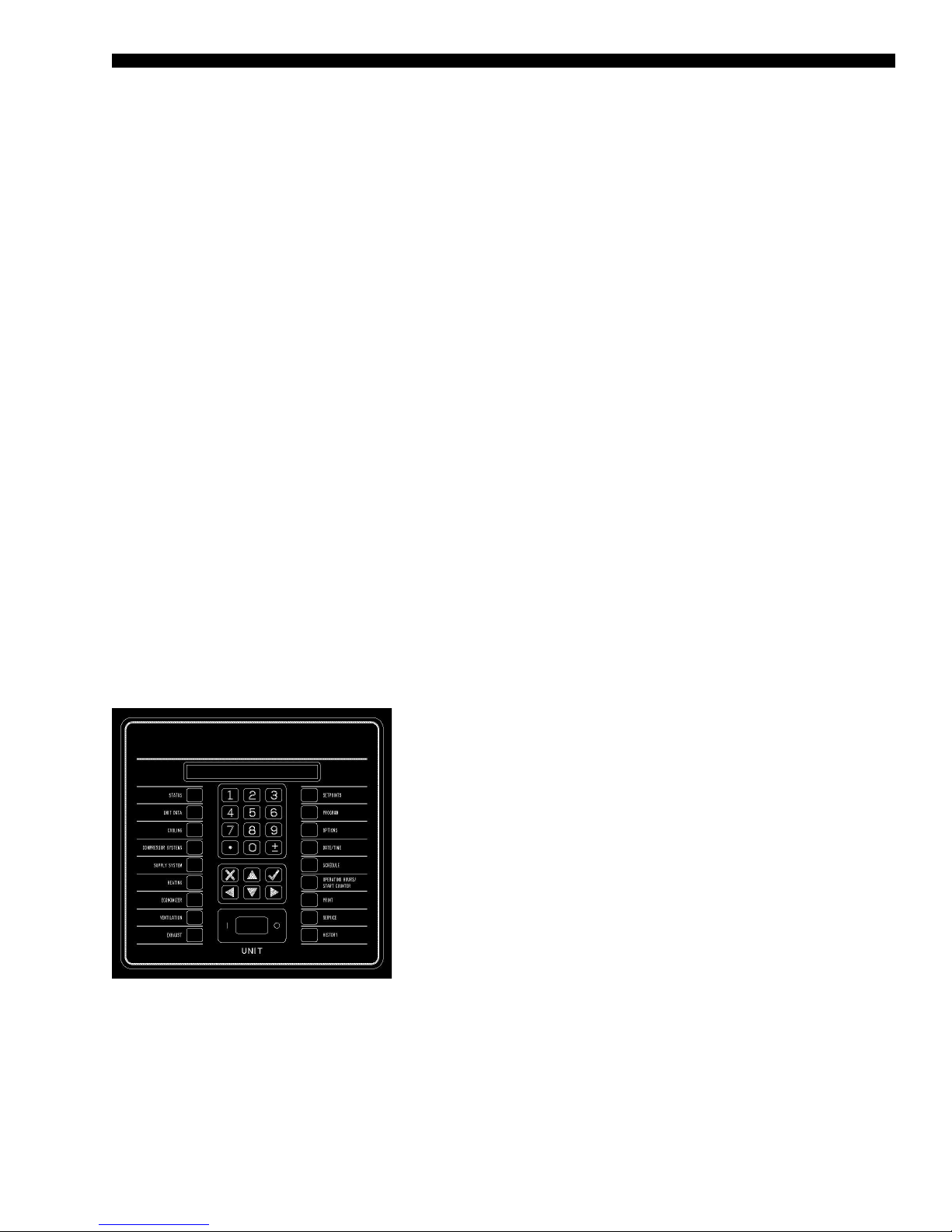

The single package unit user interface uses microprocessor logic to optimize operation of the TempMaster OmniElite single package unit.

Better Ecology...

Indoor air quality (IAQ) features for the indoor environment

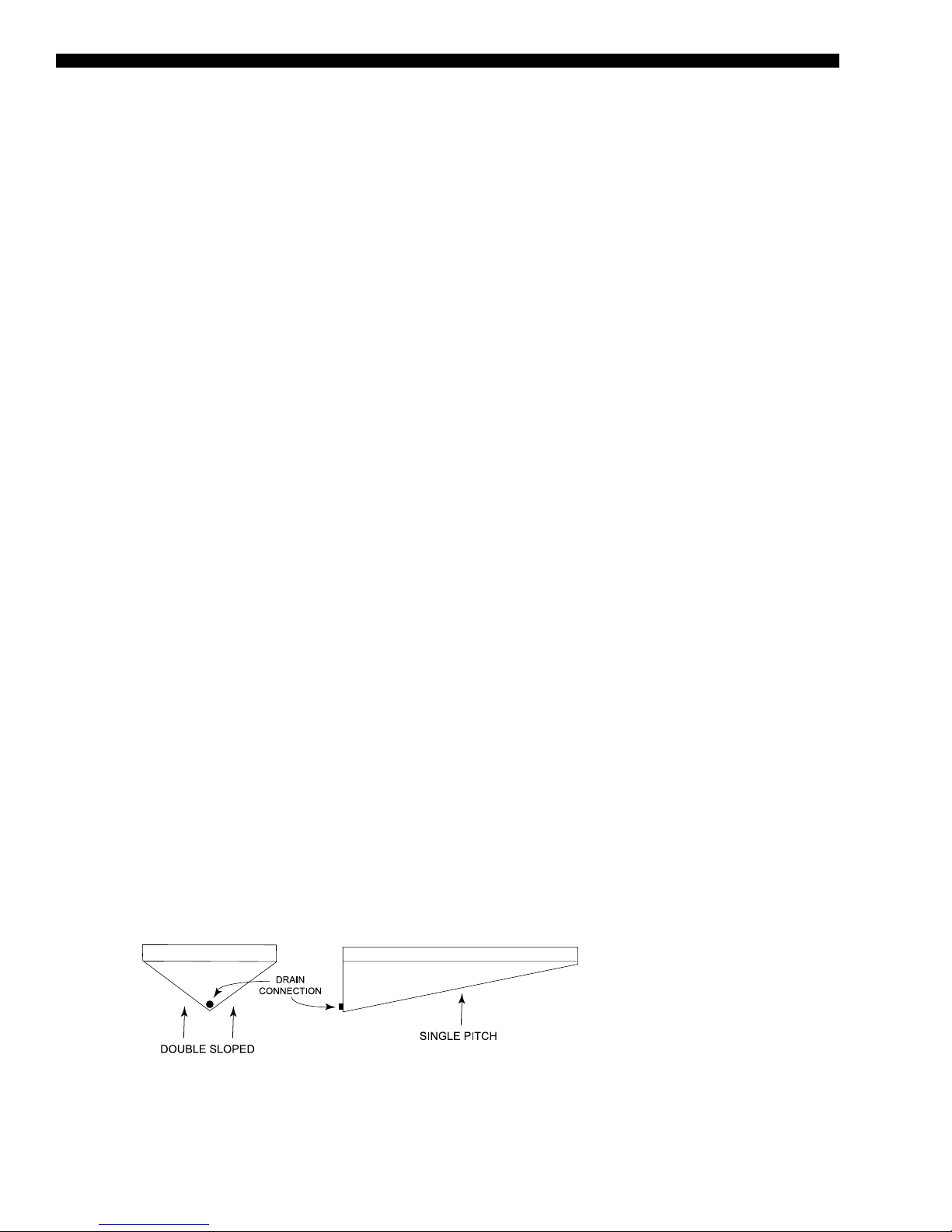

• A double-sloped stainless steel drain pan with a single drain connection ensures that all condensate is voided from the drain pan. It

is also visible and accessible for periodic inspection and cleaning re-

quired by the ASHRAE 62 IAQ standard.

• Double-wall construction of the roof, oor, doors, and walls prevents insulation bers from entering the conditioned air. The inner liner

also facilitates periodic cleaning of the unit to prevent harmful build-up

of bacteria or contaminants.

• The single package unit control center uses microprocessor

logic to analyze and optimize ventilation decisions and perform de-

mand ventilation, airow compensation, and airow measurement to

maintain the air quality at a healthy level.

TEMPMASTER

5

Page 6

FORM TPM3-EG1 (518)

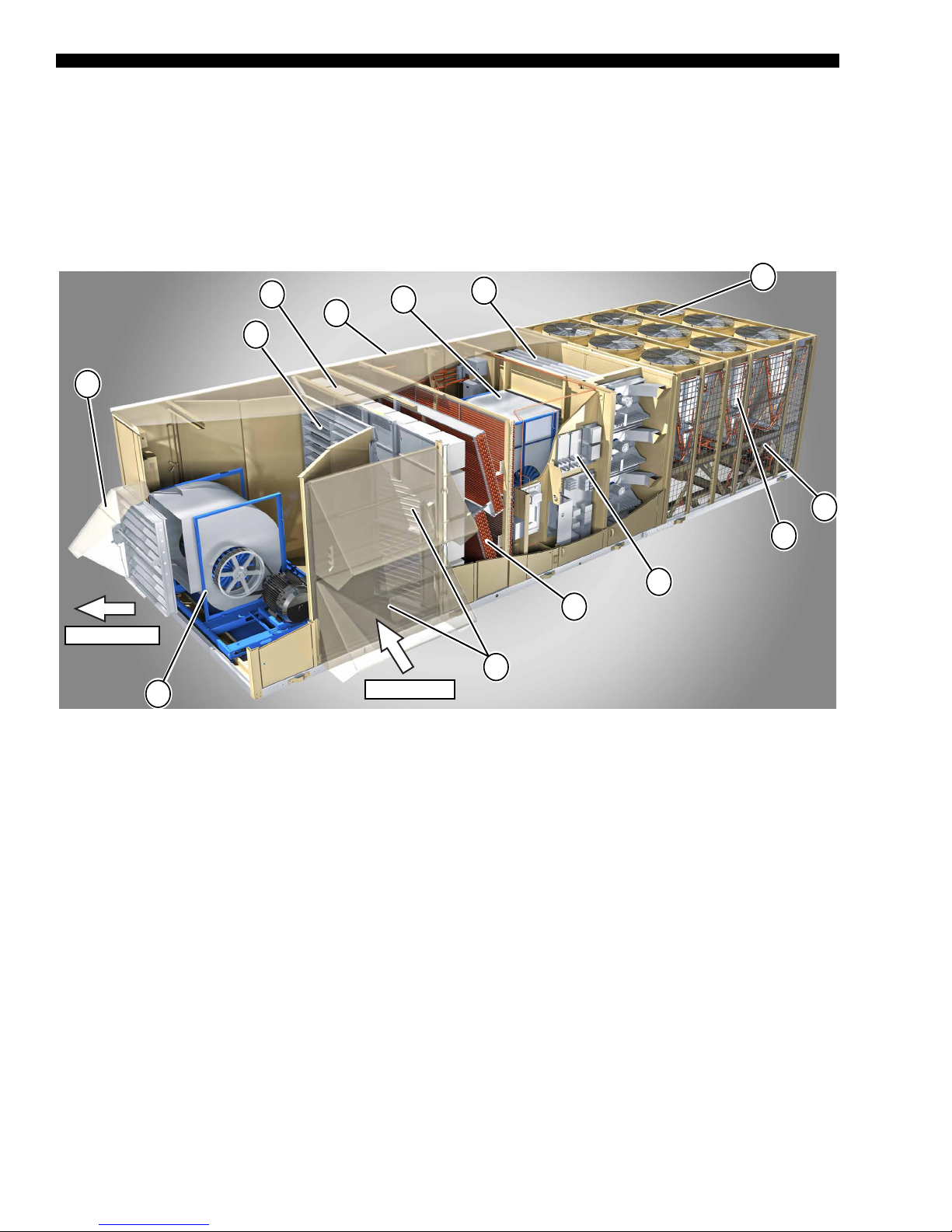

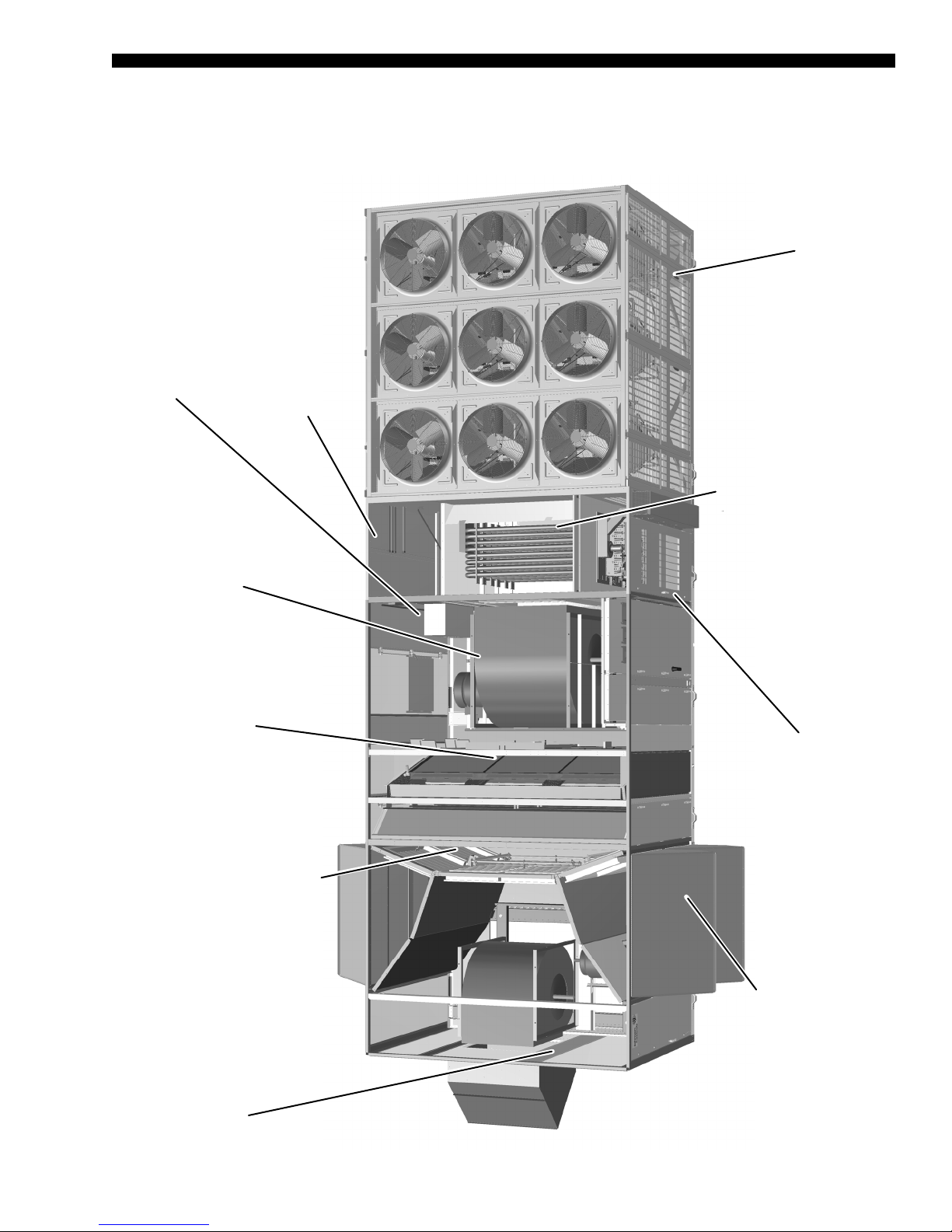

10

9

7

Exhaust Air

8

1. Modulating or staged gas heat

11

12

Outside Air

1

2

3

4

5

6

7

LD21646

7. Rain hoods

2. Condenser fans

3. Scroll compressors

4. Condenser

5. Advanced single package unit controller

6. Evaporator coil

FIGURE 1 - STANDARD CABINET ASSEMBLY

6

8. Exhaust/return fan

9. Economizer

10. Filters section

11. Double-wall construction

12. Double width, double inlet (DWDI) airfoil supply

fan

TEMPMASTER

Page 7

Features and Benefits

AIRFLOW CONFIGURATIONS

Variable Air Volume (VAV) – TempMaster® OmniElite™ units are available for variable air

volume (VAV) applications. Control can be used with a zone sensor or building automation system (BAS). Supply fans are controlled to the supply duct static pressure setpoint,

which can be reset via a BAS, or through a 0–5VDC analog input on the unit controller for

optimized duct static pressure control. The static pressure transducer is provided in the

single package unit, and 5/16-inch or 1/4-inch plastic tubing and static pressure sensor

must be supplied by others and installed approximately 3/4 down the longest duct run.

Single Zone Variable Air Volume (SZVAV) – TempMaster OmniElite units are available

for single zone variable air volume (SZVAV) applications. Control can be used with a zone

sensor or a BAS. Supply fans are controlled based on zone temperature.

COOLING AND HEATING CONFIGURATIONS

FORM TPM3-EG1 (518)

Cooling Only – For applications where no heat is required, or heating is provided else-

where within the building HVAC system, cooling only units include an empty discharge

plenum. Supply duct connections are configurable for bottom, left or right discharge. The

supply air temperature (SAT) sensor is included and factory-installed.

Staged Gas Heat – For applications requiring gas heat for morning warm-up, or other

heating needs, a staged natural gas furnace is available. The furnace is located in the discharge plenum, downstream of the supply fan. The SAT sensor is located across the face

of the supply duct opening in the unit. Furnaces are designed in 375 mbh modules. Three

stages are available for the TMAL120–150. Ignition and safety controls are included and

factory-wired. Units with staged gas heat are ETL listed.

Modulating Gas Heat – For applications requiring gas heat for morning warm-up, supply

air tempering or other heating needs, a modulating natural gas furnace is available for finer

temperature control. The furnace is located in the discharge plenum, downstream of the

supply fan. The SAT sensor is located across the face of the supply duct opening in the unit.

Furnaces are designed in 375 mbh modules in 8:1 turndown increments. Three are available for the TMAL120–150 (8:1, 16:1 or 24:1 turndown). Ignition and safety controls are

included and factory-wired. Units with modulating gas heat are ETL listed.

Electric Resistance Heat – For applications where electric heat is desired, a slip-in electric resistance heat element is available in sizes from 80–250 kW depending on the single

package unit model size. The number of stages varies by size and voltage, but all have a

minimum of two stages of capacity. Units with electric heat are ETL listed.

Hot Water Heat – For applications where hot water is available for heating, a hot water

heating coil is available. A range of coil fin count selections are available to properly size

the heating for the application. Units with hot water heat are ETL listed.

Steam Heat – For applications where steam is available for heating, a steam heating coil

is available. A range of coil fin count selections are available to properly size the heating

for the application. Units with steam heat are ETL listed.

TEMPMASTER

7

Page 8

FORM TPM3-EG1 (518)

Features and Benefits (Cont'd)

POWER OPTIONS

Single-Point Supply with Terminal Block – This configuration is standard, and includes

three terminals for the incoming 3-phase power and is the standard configuration for the

TempMaster OmniElite product. It includes the enclosure, terminal-block, and interconnecting wiring to the compressors, heater and furnace controls, all fans, etc. In this con-

figuration, code requires that a means of disconnect (not provided) must be installed at

the site within line-of-sight of the equipment.

Single-Point Supply with Non-Fused Disconnect Switch – This option is the same as

the single-point with terminal block option except it includes a unit-mounted through-thedoor manual non-fused disconnect switch with an external, lockable handle (in compliance with Article 440-14 of National Electric Code (NEC)). This option provides a means

to isolate the unit power voltage for servicing. Others must supply separate external fusing

which must comply with the NEC and/or local codes.

Dual-Point Supply with Terminal Block – This option includes enclosure, terminal blocks

circuited to the supply and exhaust fans and control transformer, and a second set of

terminal blocks with interconnecting wiring to the compressors, heat (if applicable), and

condenser.

Convenience Outlet – This options includes a powered 115V GFCI convenience outlet that

can be used for powering tools or lights for servicing. A protective cover plate is included

while not in use. The outlet is located on the bottom left hand corner of the power panel.

CONTROL FEATURES AND OPTIONS

Microprocessor-Based Single Package Unit Controller – All TempMaster OmniElite

units are equipped with a factory-installed, programmed and commissioned unit controller

with all I/O capabilities and control sequences. The controls include all on-board diagnostic,

safety and control features to operate the single package unit. A multimedia card interface

is included for software upgrades and can be used for data logging to simplify equipment

troubleshooting. Communication ports are included as standard with three alarm outputs, a

shutdown contact, remote start/stop input, smoke ventilation controls, analog inputs for SAT

and duct static pressure reset, along with a variety of other capabilities.

Standard Ambient – TMAL120–150 models operate down to 50.0°F as standard.

Low Ambient – This option includes low ambient control of all three refrigerant circuits

down to 0.0°F through the use of suction and discharge pressure transducers, as well as

condenser fan speed using a variable frequency drive (VFD) on the first condenser fan of

each circuit.

Pressure Transducers with Readout Capability – This option includes suction and dis-

charge pressure transducers on each circuit and provides pressure readout of all circuits

at the unit control panel.

Wall-Mount Zone Sensor – A 10 kOhm thermister type III NTC zone sensor for wall

mounting. This zone sensor is for sensing temperature only and does not include any

setpoint adjustment features.

Zone Sensor

COMMUNICATIONS

BACnet® MS/TP (RS-485) Communications – This communication option is standard on

every TempMaster OmniElite unit. Communications to the unit are through a twisted pair,

and the wire terminations are on the primary unit control board. See supplemental information for the available control points and protocol implementation conformance statement (PICS)/BACnet® interoperability building blocks (BIBBs) statements of conformity.

8

TEMPMASTER

Page 9

FORM TPM3-EG1 (518)

Modbus™ Remote Terminal Unit (RTU) Communications – This communication option

is standard on every TempMaster OmniElite unit and can be used in lieu of the BACnet

communications (only one can be used at a time). See supplemental information for the

available control points.

FILTER OPTIONS

Filter Options – Cleanable, carbon coated MERV 7 or pleated MERV 8 filters in an an-

gled rack are available. For higher filtration requirements, optional rigid filter racks are

available with 12-inch 65% MERV 11 or 95% MERV 14 efficient rigid filters. Two-inch prefilters are included with rigid filter options. The rigid filter rack option is available without

filter media where field-supplied filters are required.

OUTSIDE AIR DAMPER (OA) OPTIONS

Manual Damper – This option includes a manually adjustable outside air (OA) damper. It

is manually adjustable at the unit by setting a mechanical stop between 0–100%.

Two-Position – This OA damper option is controlled to two positions, opened and closed.

Determination of the damper position is based on the occupancy schedule. In the occupied mode, the OA damper is positioned to the manually configured point (set by mechanical stop). In the unoccupied mode, the damper is fully closed.

Modulating Economizer – This option includes modulating OA and return air (RA) dampers that are software interlocked and positioned by fully modulating, solid state damper

actuators. Control of the damper is via a standard ambient OA dry bulb sensor, or optional

single or comparative enthalpy controls.

Airflow Measurement – Optional outside airflow measurement is available on units

equipped with a modulating economizer.

CO2 Sensors – Optional carbon dioxide (CO2 ) sensors for occupied space that operate

demand ventilation control opening OA dampers to ventilate building. The CO2 sensors

can operate in a single or comparative control scheme.

Rain Hoods on Outside Air (OA) Intakes – For all options with OA intake openings, rain

hoods are provided as standard to keep moisture from entering the equipment. The rain

hoods are an integral part of the unit and are rotated into place at the job site.

RELIEF SYSTEM

Barometric Relief – Optional building air exhaust shall be accomplished through baro-

metric relief dampers installed in the return plenum. The dampers will open relative to the

building pressure. The opening pressure shall be adjustable via a spring tension adjustment.

On/Off Powered Exhaust – This option provides simple building pressure control. It can

be controlled via a building pressure signal, or via OA damper control. This option is not

available for VAV units.

Modulating Powered Exhaust with Damper Control – This option consists of a constant-speed exhaust fan with a discharge damper that is modulated to control the flow

of exhaust air. The damper control logic is based on the building static pressure setpoint

within the single package unit controller. The static pressure transducer is provided in

the return plenum of the single package unit, and 5/16-inch or 1/4-inch plastic tubing and

static pressure sensor must be supplied by others and installed in a representative location in the building.

TEMPMASTER

9

Page 10

FORM TPM3-EG1 (518)

Features and Benefits (Cont'd)

Modulating Powered Exhaust with a VFD – This option consists of a VFD to modulate the

speed of the exhaust fan to control the flow of exhaust air. The VFD control logic is based

on the building static pressure setpoint within the single package unit controller. The static

pressure transducer is provided in the return plenum of the single package unit, and 5/16inch or 1/4-inch plastic tubing and static pressure sensor must be supplied by others and

installed in a representative location in the building.

Powered Return Fan with Exhaust – This option uses single width, single inlet (SWSI)

plenum fan(s) to control building pressure. The fan motors are driven by a VFD to maintain

a constant return plenum pressure. An exhaust hood with a modulating control damper

is used to maintain building pressure via the building static pressure. The static pressure

transducer is provided in the return plenum of the single package unit, and 5/16-inch or

1/4-inch plastic tubing and static pressure sensor must be supplied by others and installed

in a representative location in the building. The powered return fan is also available without the exhaust capabilities. For units with no exhaust capabilities, the HVAC system must

provide alternate means of controlling building pressure.

SUPPLY FAN OPTIONS

Double Width, Double Inlet (DWDI) Airfoil Supply Fan – The standard airfoil blade sup-

ply fan is available on all models for higher static conditions. This offers higher efficiency

and lower sound in certain applications.

Fan Skid Isolation – The entire supply fan assembly is isolated from the unit base with

either 1-inch (standard) or 2-inch deflection springs with seismic restraints.

Supply and Exhaust Fan Motors – Premium efficiency open drip-proof (ODP) and premium efficiency total enclosed fan-cooled (TEFC) motors are available all meeting the

Energy Policy Act of 1992 (EPACT).

Supply Fan VFD and Manual Bypass – For VAV applications, VFDs are provided to

modulate air flow. Optional manual bypass can also be provided to allow full airflow in the

event of a VFD failure.

Direct Drive Plenum (DDP) Fan – A direct drive plenum (DDP) supply fan provides outstanding reliability and efficiency, eliminating the possibility of conditioned air supply interruption due to a broken belt and the pollution of conditioned air with belt dust. The supply

fan can be optionally equipped with a piezo ring to precisely measure the amount of air

delivered to the conditioned space. The speed of the supply fan is controlled by a VFD.

EVAPORATOR SECTION

Double Sloped Stainless Steel Drain Pan – The TempMaster OmniElite’s stainless steel

drain pan is factory-mounted and installed on every unit. A condensate drain trap is needed and must be provided and installed in the field by others.

*NOTE:

This is a visual reference only. Actual drain pan pitch will vary.

FIGURE 2 - DRAIN PAN DETAIL

10

LD08022

TEMPMASTER

Page 11

FORM TPM3-EG1 (518)

Double-Wall Construction – Double-wall construction is the standard construction of the

TempMaster OmniElite and incorporates powder coated pre-fabricated outer panels and

corner post for maximum exterior surface protection.

Factory Shrink-Wrap – All TempMaster OmniElite single package units are shipped from

the factory with factory-fresh shrink-wrap packaging. No longer does the contractor need

to worry about dirt and debris clogging up condenser coils or moisture leaking into the air

handler on the units way to the job site or rigging yard.

Copper Fins – For more extreme climates that aggressively can attack aluminum, copper

tube evaporator coils with copper fins are available. (This is not recommended for units in

areas where they may be exposed to acid rain or environments where ammonia is present.)

CONDENSER FEATURES AND OPTIONS

Scroll Compressors – Reliable, efficient, trouble-free operation is the true measure of

a single package unit’s value. That’s why TempMaster OmniElite single package units

use established scroll compressor technology to deliver dependable, economical performance in a wide range of applications. With the TempMaster OmniElite single package

units, you get the latest generation of compressor enhancements added to the scroll’s

inherent strengths. The simplicity of a hermetic scroll compressor allows the use of fewer

moving parts to minimize breakdown.

Compressor Circuiting – The TempMaster OmniElite is designed so that only two scroll

compressors are in tandem within one refrigeration circuit. This means more reliable com-

pressors, and less equipment down time. With multiple circuits, if a compressor should

ever fail on one circuit, the other circuit/s will remain operational to work to maintain occupied loads. The TempMaster OmniElite system has three circuits in a unit.

Compressor Staging - The TempMaster OmniElite refrigeration system is equipped with

a unique staging algorithm. On first call for cooling the system calculates the amount of

cooling capacity needed by the space and automatically brings on enough cooling capacity to meet this calculated need. Comfort cooling is provided quickly without the lag inherent to staging on additional compressors to meet a high demand. Additionally, due to a

three independent circuit design with two compressors on each circuit, the TempMaster

OmniElite can provide superior granularity in terms of staging, which translates to best in

class part load efficiency or IEER.

Condenser Fan Motors – The condenser fan motors used on the TempMaster OmniElite

unit are totally enclosed air over (TEAO) to provide maximum durability through any season.

Replaceable Core Liquid Line Driers – Liquid line driers are standard on the TempMas-

ter OmniElite single package unit.

Post-Coated Condenser Coil Fins – Technicoat coil-coating process used on condenser

coils for seashore and other corrosive applications (with the exception of strong alkalis,

oxidizers, wet bromide, chlorine, and fluorine in concentrations greater than 100 ppm).

Compressor Sound Blankets – Optional compressor acoustic sound blankets are available for sound sensitive applications.

TEMPMASTER

11

Page 12

FORM TPM3-EG1 (518)

Features and Benefits (Cont'd)

ROOF CURBS

Full Perimeter Roof Curbs – This option includes a knock-down 14-inch high roof curb

for use with wood nailer (by others). Roof curb supports the entire perimeter of the unit.

Partial Perimeter Roof Curbs – This option includes a knock-down 14-inch high roof

curb for use with wood nailer (by others). Roof curb supports the air handling section with

a separate support under the condenser end.

CABINET FEATURES AND OPTIONS

Double-Wall Access Doors - Full-sized access doors provide easy access into the unit

for routine maintenance and inspection. Solid wall liners encase insulation and prevent

damage and erosion into the airstream.

Diffuser Section – An optional diffuser section is available downstream of the supply

fan in the extended discharge plenum cabinet option. The diffuser section distributes the

airflow from the fan evenly across the downstream filter bank to optimize filter life and

effectiveness. The diffuser design is optimized to provide uniform flow at minimal airside

pressure loss.

Downstream Final Filter Rack – A 90–95% efficient MERV 14, 12-inch rigid filter rack

and filters shall be provided downstream of the supply fan and diffuser segment for hospital applications. A magnahelic pressure gauge is included and visible from the outside of

the unit for servicing and code compliance.

Blank Section – A blank section shall be provided downstream of the supply fan and diffuser section.

ACCESSORIES

Filter Switch – An optional dirty filter alarm can be provided that will provide an alarm

when the filters require cleaning.

Magnahelic Filter Pressure Gauge – On units equipped with downstream filtration, a

magnahelic filter gauge is included and visible on the exterior of the unit. The filter gauge

measures the air pressure drop for through the rigid filter bank to indicate when replace-

ment is required.

12

TEMPMASTER

Page 13

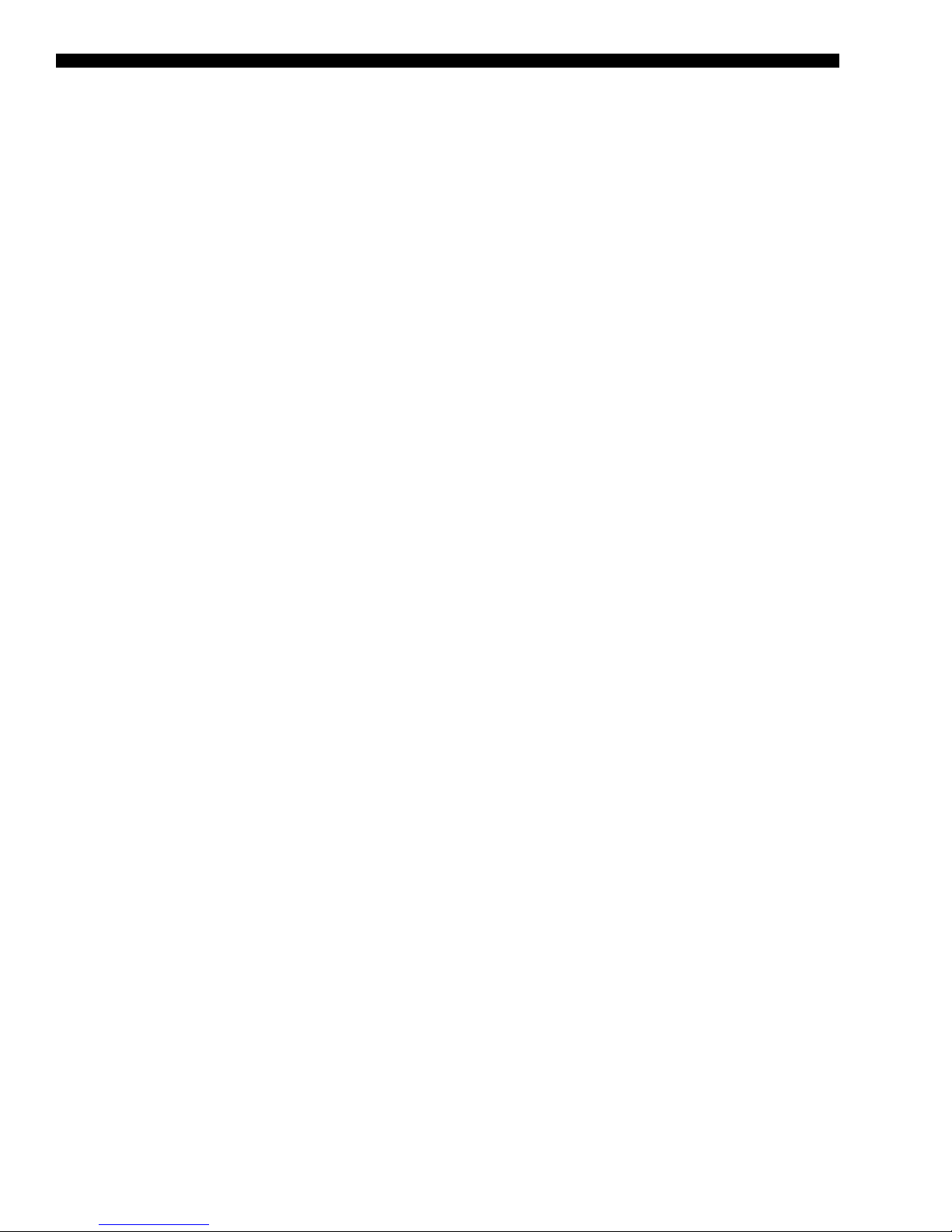

TMAL120–150 MODEL

section

dust and dirt build-up

• Located in conditioned space

Blower variable frequency

drives (VFDs)

• In ltered air stream to prevent

• Remote keypad in control

Side discharge with heat

structure or curb

• Does not require an elevated

application

• Flexible solution for building

FORM TPM3-EG1 (518)

• Standard low ambient to 0.0°F

• Control to discharge pressure

• Quiet part load operation

Shared-fan design

• Eliminates stratication

• Fewer moving parts

• Solid steel shaft

• Isolated assembly

• Laser aligned and

Single supply fan

balanced

risk of carryover

• Angled coil to reduce

steel drain pan

• Standard stainless

Evaporator

• OA from two sides

• Facilitates mixing

Mixing box

• Induced draft furnace

• Accepts gas pressures down to 4.5-inches

• Six-stage base design

24:1 modulating gas heat

control solution

™

communications

™

ISN ConneXsys

®

MS/TP and Modbus

®

• Multimedia card for updates (no EPROM)

• Multimedia card used for data logging

• Integrated TempMaster

• Standard BACnet

Advanced single package unit controller

centrifugal exhaust fans

• Horizontal return for all congurations

• Double width, double inlet (DWDI)

num return fans

• Variable frequency drive (VFD) options

• Single width, single inlet (SWSI) ple-

Exhaust & return fans

TEMPMASTER

ping to reduce freight

• Single piece shipment

• Collapsible for ship-

Collapsible outside air

(OA) hoods

• Fast and easy setup

13

Page 14

FORM TPM3-EG1 (518)

Application Data

GENERAL

The TempMaster® OmniElite™ air conditioning units are designed for outdoor installation.

When selecting a site for installation, be guided by the following conditions:

• Unit must be installed on a level surface.

• For the outdoor location of the unit, select a place having a minimum sun exposure

and an adequate supply of fresh air for the condenser.

• Also avoid locations beneath windows or between structures.

• Optional condenser coil protection should be used for seashore locations or other harsh

environments.

• The unit should be installed on a roof that is structurally strong enough to support the

weight of the unit with a minimum of deection. It is recommended that the unit(s) be

installed not more than 15 feet from a main support beam to provide proper structural

support and to minimize the transmission of sound and vibration. Ideally, the center

of gravity should be located over a structural support or building column.

• Location of unit(s) should also be away from building ue stacks or exhaust ventilators to prevent possible reintroduction of contaminated air through the outside air

intakes.

• Be sure the supporting structures will not obstruct the duct, gas or wiring connections.

• Proper service clearance space of 6 feet around the perimeter of the unit, 8 feet on

one side for coil servicing, and 12 feet to any adjacent units is required to eliminate

cross contamination of exhaust and outside air, and for maintenance tasks such as

coil pull and cleaning. No obstructions should be above the condensing unit section.

LOCATION

Of the many factors that can effect the location of equipment, some of the most important

to consider are structural, acoustical and service clearances. Proper attention should be

made at the design stage to ensure proper structural support. In cases where equipment

is being replaced, be aware of building design to ensure support is adequate for the ap-

plication.

The next most important consideration in applying single package units equipment is that

of sound from the equipment. Special care should be made to keep the single package

unit away from sound sensitive areas such as conference rooms, auditoriums and executive offices and any other room that may have potential for tenant occupancy. Possible

locations could be above hallways, mechanical or utility rooms.

Finally, service clearances should be maintained in single package unit design to ensure

safe access to the unit. Unit clearances are designed so that technicians have enough

space between units, building walls, and edges of building to gain access safely. In cases

where space is limited, please call a local TempMaster representative for additional information.

14

TEMPMASTER

Page 15

FORM TPM3-EG1 (518)

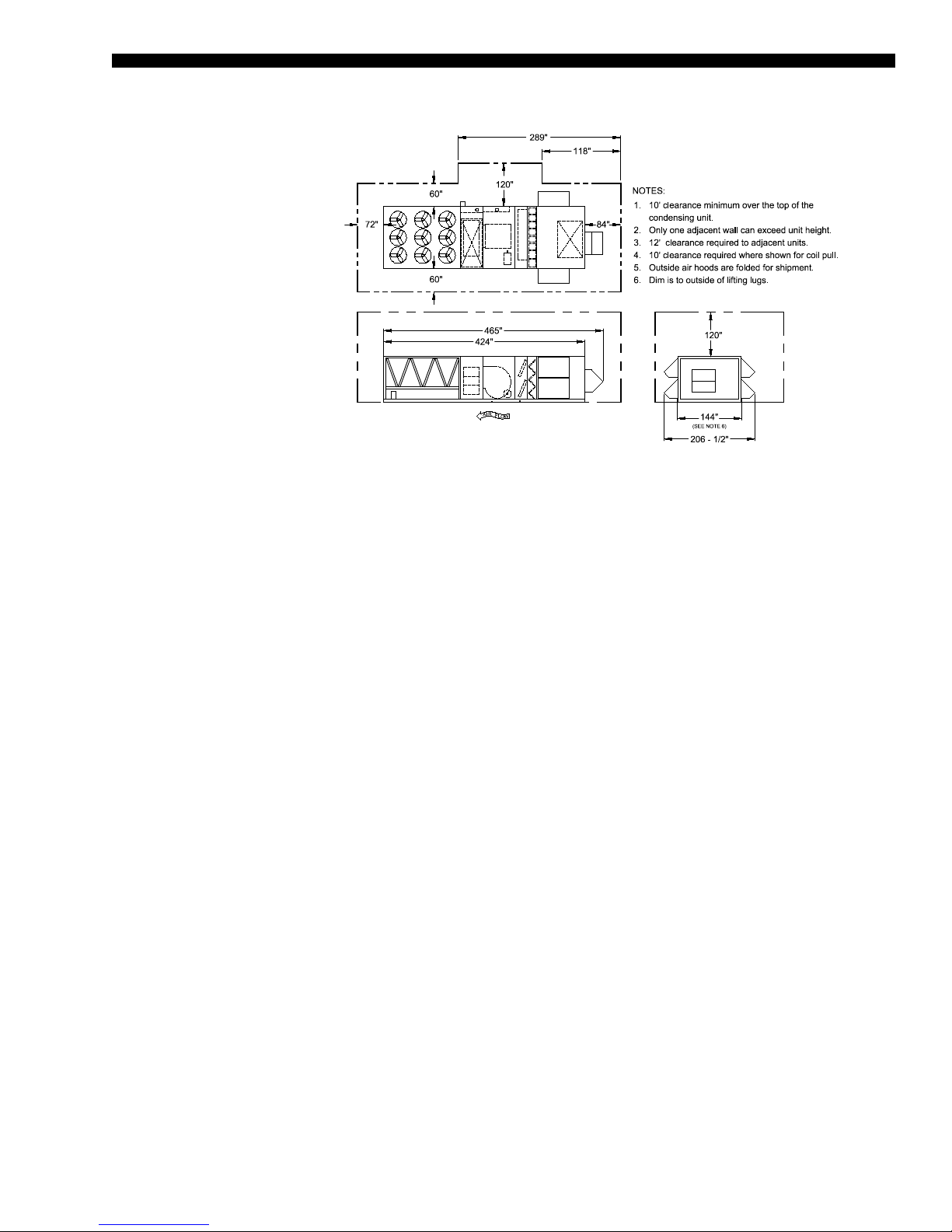

RIGGING

Proper rigging and handling of the equipment is mandatory during unloading and setting

it into position to retain warranty status.

Spreader bars must be used by cranes to prevent damage to the unit casing. All lifting

lugs must be used when lifting the single package unit. Fork lifts will damage the single

package unit and are not recommended.

Care must be taken to keep the unit in the upright position during rigging and to prevent damage to the watertight seams in the unit casing. Avoid unnecessary jarring or rough handling.

UNIT PLACEMENT

• Elevated – Elevated roof curbs or dunnage steel can be used to support the unit in

order to raise it to specic heights. When this type of placement is required, be sure

to keep unit access in mind. Cat walks or other forms of unit access may be required

to one or both sides of the unit, depending on your area of the country and the local

codes that are enforced. Please check with local ofcials to ensure the application

conforms to local codes and regulations.

• Ground Level Locations – It is important that the units be installed on a substantial

base that will not settle, causing strain on the refrigerant lines and sheet metal and

resulting in possible leaks. A one-piece concrete slab with footers extended below

the frost line is highly recommended. Additionally, the slab should be isolated from

the main building foundation to prevent noise and vibration transmission to the building structure.

For ground level installations, precautions should be taken to protect the unit from

tampering by, or injury to, unauthorized persons. Erecting a fence around the unit is

common practice.

• Roof curb – TempMaster offers optional roof curbs designed specically for the

TEMPMASTER

TempMaster OmniElite footprint. These curbs come in full perimeter or open condenser models and are shipped disassembled and require eld assembly and installation. For bottom supply and return openings, the curbs have matching connections

to ease installation. A pipe chase that matches the single package unit pipe chase is

also included in the curb footprint for through-the-curb utility connections.

15

Page 16

FORM TPM3-EG1 (518)

Application Data (Cont'd)

The curb should be located according to the location recommendations above, and

properly sealed to prevent moisture and air leakage into and out of the duct system.

Flexible collars should be used when connecting the ductwork to prevent unit noise

transmission and vibration into the building.

Ductwork should be supported independently of the unit.

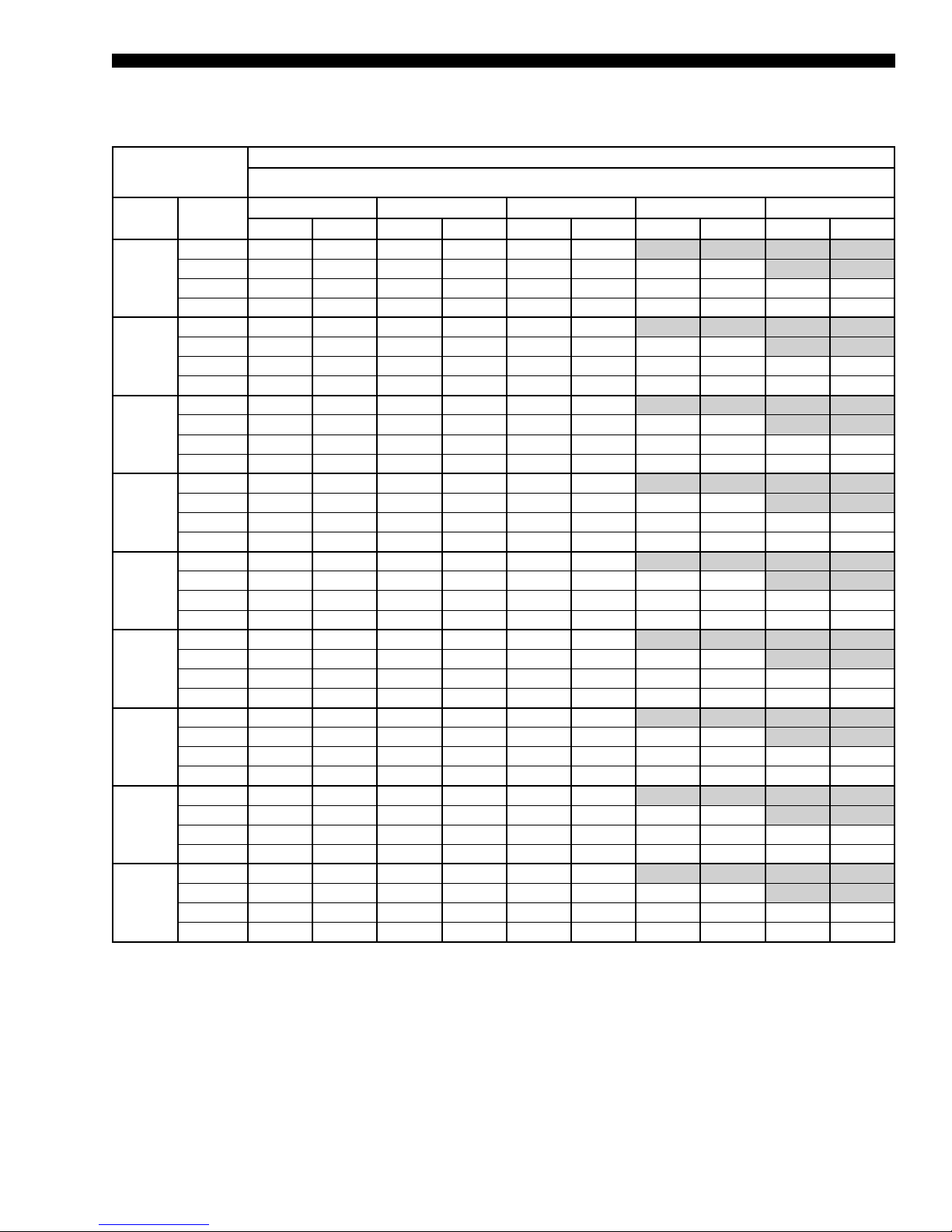

TABLE 1 - SUPPLY AIR DUCT CONN CONFIGURATIONS

SUPPLY AIR

TMAL

120–150

UNIT CONFIGURATION

Cooling only X X X

Cool/electric heat X

Cool/gas heat X X

Cool/hydronic heat X

Cooling only X X X

Cool/hydronic heat X X X

BOTTOM LEFT RIGHT

STANDARD CABINET

EXTENDED CABINET

TABLE 2 - RETURN AIR DUCT CONNECTION CONFIGURATIONS

RETURN AIR

X X

TMAL

120–150

UNIT CONFIGURATION

No exhaust X X

Barometric

relief damper

Powered exhaust fan (all types) X X

Powered return fan X

BOTTOM FRONT

UNIT ORIENTATION

For applications with multiple single package units located in close proximity on the roof,

the orientation of the unit may be important to reduce the potential for re-entrainment of

outside airflow. Regardless of the outside air and exhaust air openings on a unit, all single

package unit applications can permit recirculation of exhaust air to the return, if applied

improperly.

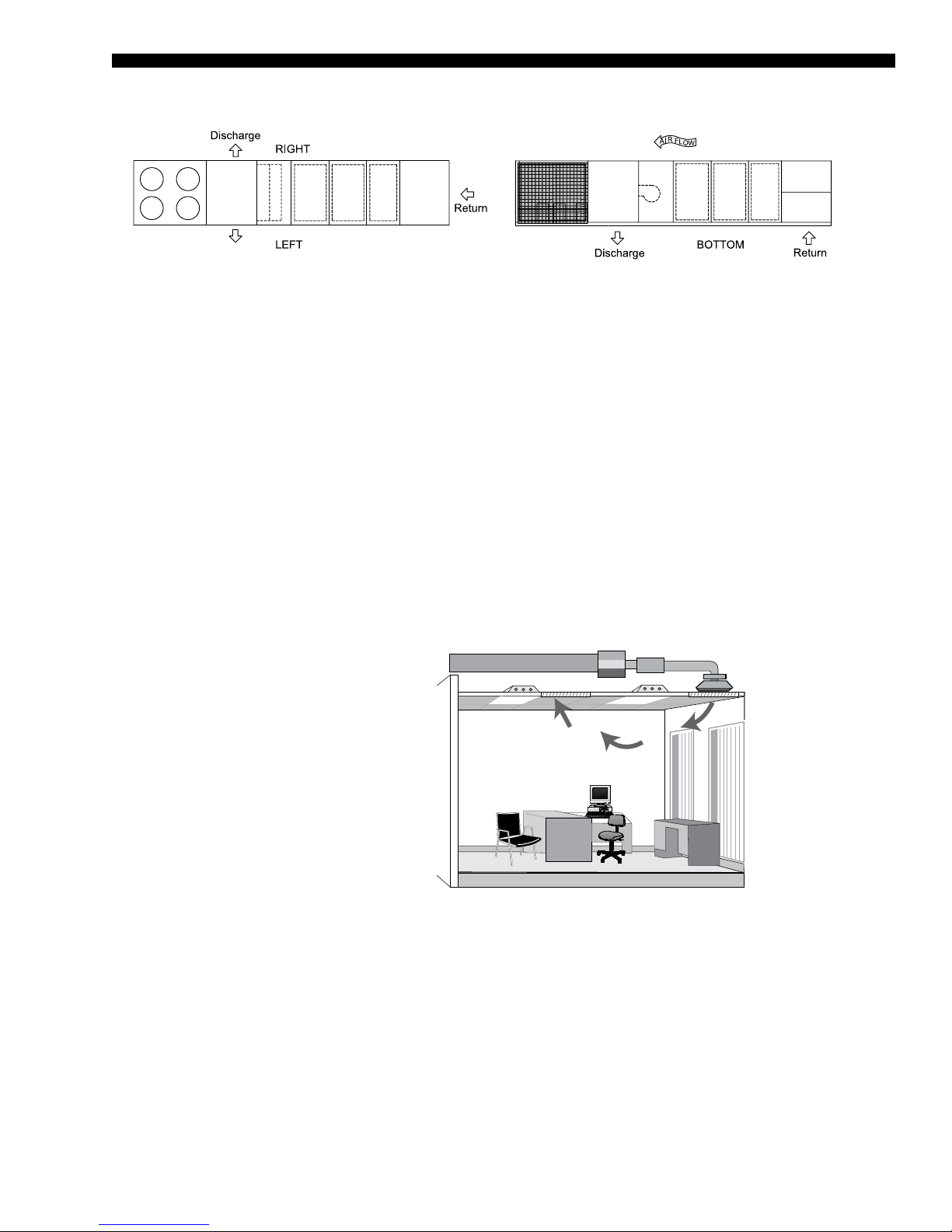

HORIZONTAL APPLICATIONS

The spectrum of applications for single package units in today’s market is continuing to

grow wider by the day. Flexibility in unit design and construction is a must in today’s mar-

ket in order to ensure safe and sound applications of HVAC equipment. The TempMaster

OmniElite has been designed for specific application of horizontal supply and return airflow taking the guess work out of unit application by building a unit specific to these needs.

If the application calls for horizontal supply and return air, TempMaster can ship it from the

factory as a horizontal unit. This option eliminates the need for field modification of equipment saving time and money. The TempMaster OmniElite can support a left discharge on

all units except electric heat and/or right discharge on all cooling only units and hydronic

heat units with an extended cabinet. Return air can be brought through the front or bottom

return air inlet making the unit specific to building needs.

16

TEMPMASTER

Page 17

FORM TPM3-EG1 (518)

TOP VIEW SIDE VIEW

LD08045

FRONT

FRONT

NOTE: This diagram is provided as a visual reference of the TempMaster OmniElite discharge air (DA) & return air (RA) openings & locations

for all sizes. Please refer to the dimensional data for exact size & location of panels and openings.

ECONOMIZER

The economizer section is used for ventilation of the conditioned space to maintain indoor

air quality (IAQ), and also to reduce energy consumption by using outside air cooling in lieu

of mechanical cooling. If outside air is appropriate for cooling, but not sufficient for the cooling demand, mechanical cooling will stage on as necessary until the cooling load is met.

Dual (comparative or differential) enthalpy operation is the most accurate and efficient

means of economizer operation. The IPU controller monitors the return and outside air

energy content, and selects the lower of the two for operation.

VARIABLE AIR VOLUME (VAV) SUPPLY AIR PRESSURE CONTROL

Traditional single package unit systems use inlet guide vanes (IGVs) for duct static pressure control. These control supply duct pressure by modulating dampers (introducing losses

and inefficiencies) on the inlet of the fan, open and closed. TempMaster variable frequency

drives (VFDs) offer superior fan speed control and quieter, energy efficient operation.

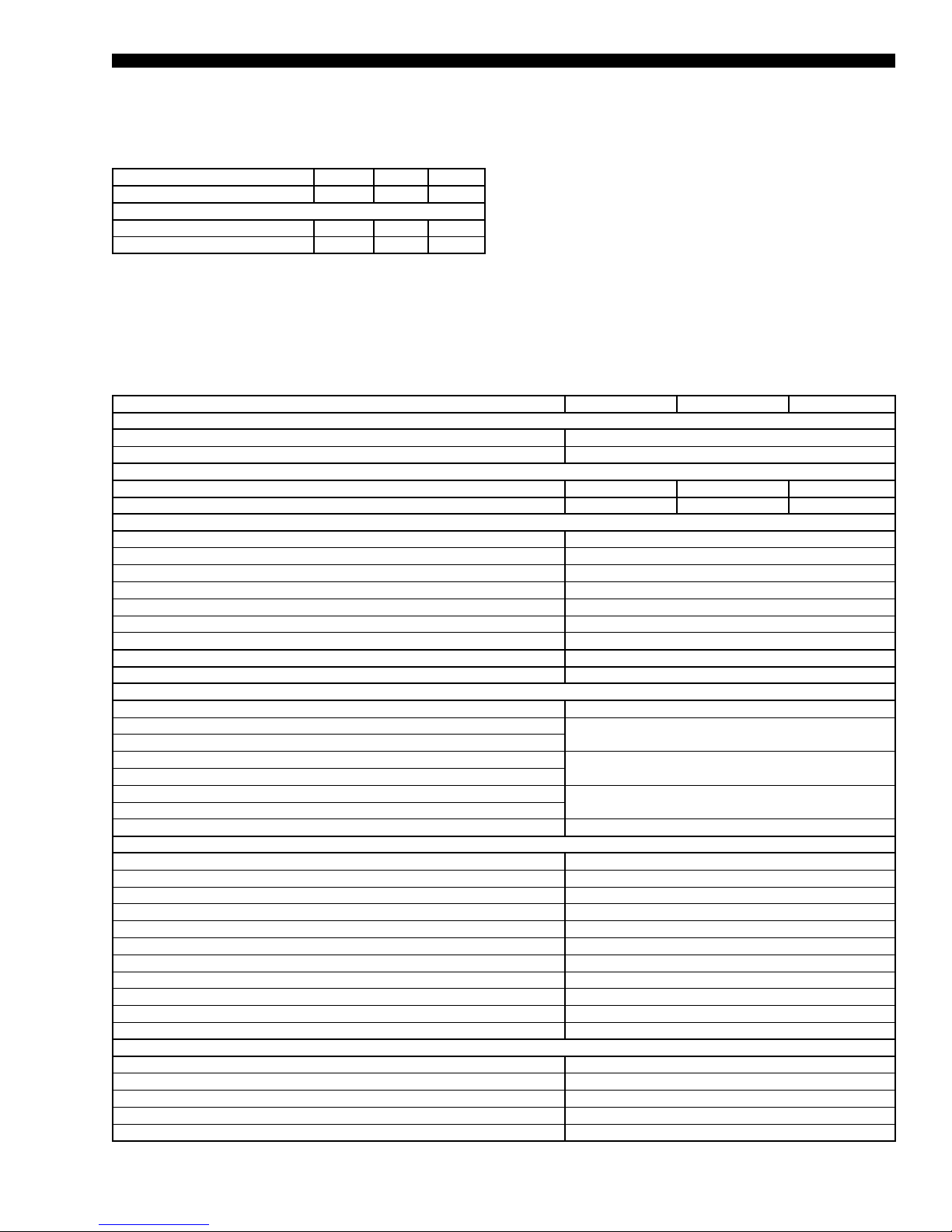

FIGURE 3 - TRADITIONAL OVERHEAD VARIABLE AIR VOLUME (VAV) AIR

DELIVERY SYSTEM

For variable air volume (VAV) applications, the TempMaster OmniElite unit uses a VFD

to modulate fan speed and maintain a constant duct static pressure. VFDs offer superior

control over the operation of the unit at part load, and offer the additional benefits of quieter and more efficient operation when compared to IGV.

BUILDING PRESSURE CONTROL SYSTEMS

Building pressure control systems are often necessary when economizers are used to

bring in outside air. Without proper building exhaust, the building may become over pressurized. The pressure control system maintains the proper building pressure by expelling

the appropriate amount of air from the building.

TEMPMASTER

17

Page 18

FORM TPM3-EG1 (518)

Application Data (Cont'd)

Return fans – For high return static applications, such as buildings with ducted return

systems, a powered return fan may be necessary to maintain building pressure control.

TempMaster offers a powered return fan that is located in the return plenum. This fan

operates coincidentally with the supply fan and draws return air back through the return

ductwork and into a pressurized plenum. A control damper modulates to exhaust air out

of the building and maintain the building pressure. A second control damper modulates

to provide return air from the ductwork to the unit to the single package air mixing section.

The return fan configuration is available in two forms: with and without an exhaust damper.

The option with the exhaust damper provides a means of building exhaust at the unit. In

some applications, the exhaust system is located elsewhere and the single package unit

is not required to provide building exhaust. In these situations, the TempMaster OmniElite

can be offered without the exhaust damper to help reduce installed costs.

Exhaust/relief fans – In this application, a powered exhaust fan may be suitable, however careful consideration of the fan type is necessary. TempMaster offers a centrifugal

powered exhaust fan to perform this function. Some manufacturers use a propeller ex-

haust fan, which cannot handle the static pressure requirements.

For systems with moderate to low return static pressure, an exhaust fan is recommended.

The benefit of the exhaust fan is that it does not run all of the time, and may facilitate com-

pliance with the ASHRAE 90.1 fan motor horsepower requirement.

The exhaust fan operates in parallel with the supply fan. In this arrangement, the supply

fan handles the full static pressure requirements of the system. For normal building pressure control, the exhaust fan operates to draw air from the return plenum and exhaust it

out of the building.

The exhaust fan configuration is available in two forms, modulating and non-modulating.

Modulating is the most common and recommended for the majority of applications, while

non-modulating should be used in only certain circumstances.

In the modulating exhaust system, the volume of airflow exhausted from the building is

proportional to the entering volume of outside air. Control is accomplished via either a discharge damper or a VFD. TempMaster recommends the use of a VFD to reduce energy

consumption, sound levels and improved reliability due to fewer moving parts.

In the non-modulating exhaust system, the exhaust airflow is constant whenever the exhaust fan is operating. This type of control should only be used to either assist a smoke

purge system or when a system requires a constant volume of exhaust airflow.

ACOUSTICAL CONSIDERATIONS

The TempMaster OmniElite unit is designed for lower sound levels than competitive units

by using flexible fan connections, fan spring isolators, double-wall construction, multiple

fan options, and lower speed and horsepower fans. For VAV applications, VFDs are used

instead of inlet guide vanes. Additional sound attenuation can be obtained using compressor sound blankets when necessary.

Even with these equipment design features, the acoustical characteristics of the entire

installation must never be overlooked. Additional steps for the acoustical characteristics

of a single package unit installation should be addressed during the design phase of a

project to avoid costly alterations after the installation of the equipment. During the design

phase of a project, the designing engineer should consider, at a minimum, the impact of

the equipment location, single package unit installation, building structure, and ductwork.

18

TEMPMASTER

Page 19

FORM TPM3-EG1 (518)

Physical Data

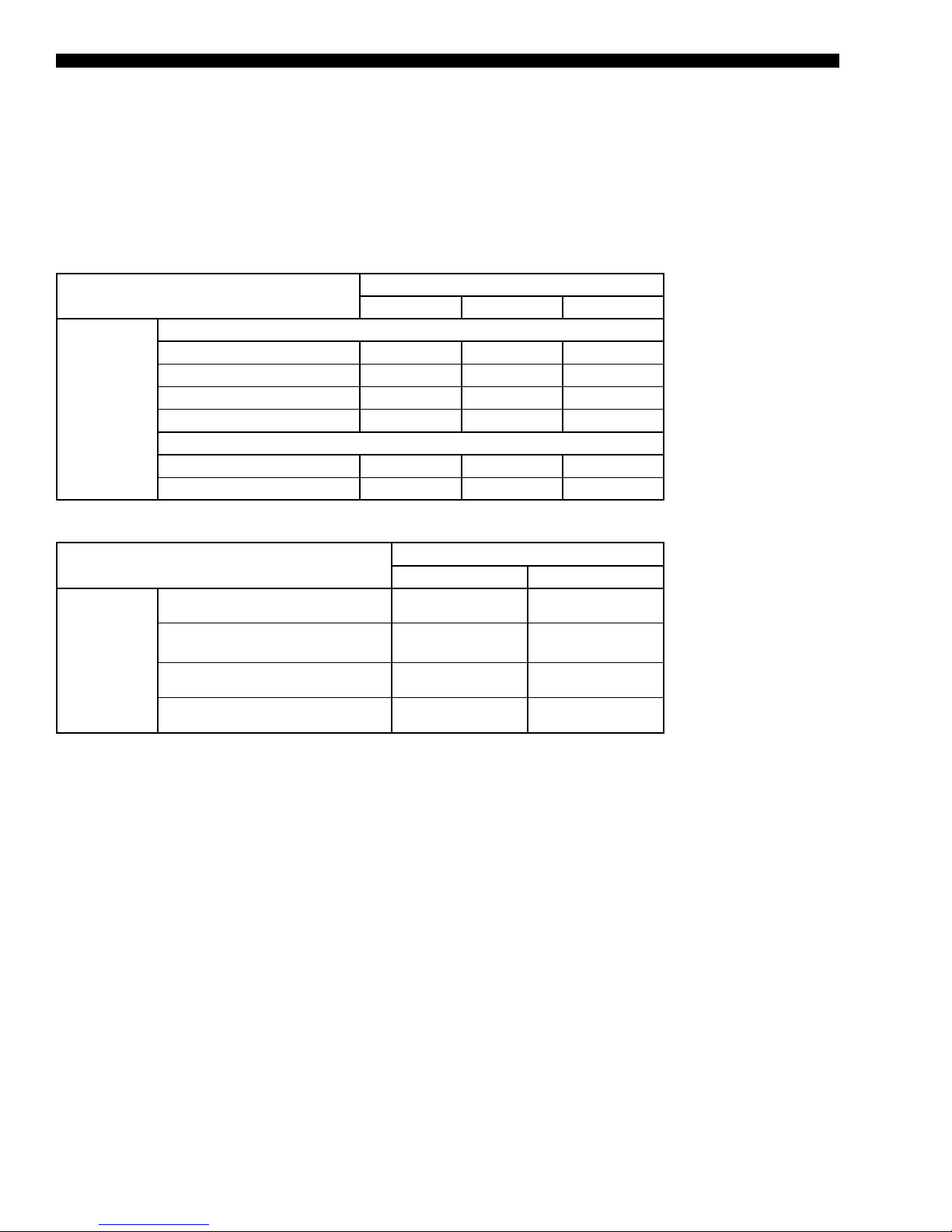

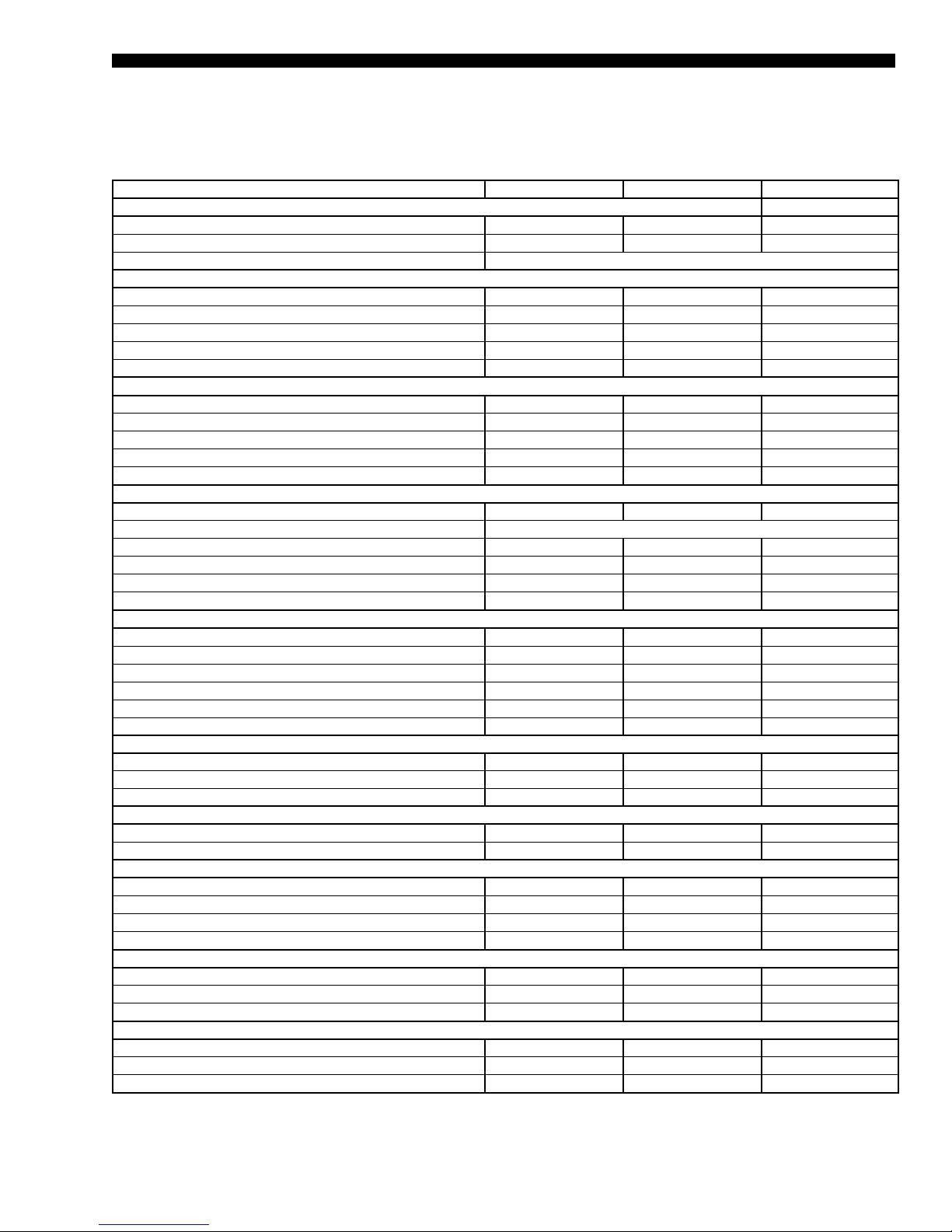

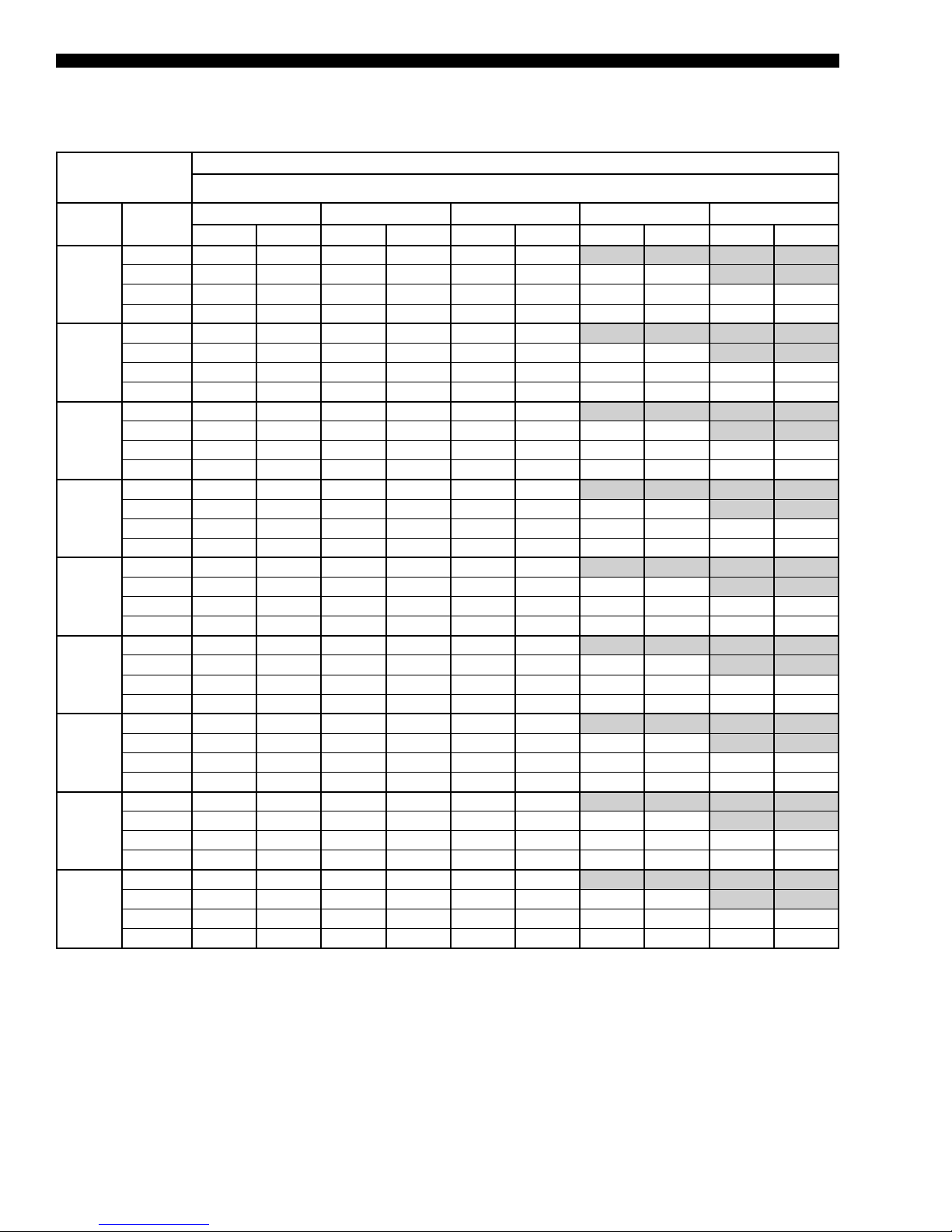

TABLE 3 - PHYSICAL DATA – MODELS 120–150

MODEL SIZE 120 130 150

COMPRESSOR DATA

Quantity/Size (nominal HP) 4x15/2x25 2x15/2x20/2x25 2X15/2X20/2X32

Type Scroll Scroll Scroll

Capacity Steps 14 steps providing capacity control between 12 and 100%

DOUBLE WIDTH, DOUBLE INLET (DWDI) AIRFOIL SUPPLY FAN AND DRIVE

Quantity 1 1 1

Size 40 40 40

Motor Size Range (min. to max. HP) 10–100 10–100 10–100

Airow Range (min. to max. CFM) 30000–52000 32000–52000 36000–52000

Static Pressure Range (min. to max. ESP) 0–6 inches 0–6 inches 0–6 inches

DIRECT DRIVE PLENUM (DDP) SUPPLY FAN AND DRIVE

Quantity 2 2 2

Size 330-100/120 330-100/120 330-100/120

Motor Size Range (min. to max. HP) 10–60 10–60 10–60

Airow Range (min. to max. CFM) 20000–45000/52000 20000–45000/52000 20000–45000/52000

Static Pressure Range (min. to max. ESP) 1–8 inches 1–8 inches 1–8 inches

EXHAUST FAN

Quantity 1 1 1

Type DWDI Forward-Curved

Size 32–32 32–32 32–32

Motor Size Range (min. to max. HP) 7.5–60 7.5–60 7.5–60

Airow Range (min. to max. CFM) 0–50000 0–50000 0–50000

Static Pressure Range (min. to max. ESP) 0–2 inches 0–2 inches 0–2 inches

RETURN FAN

Quantity Fans/Motors 1 1 1

Type SWSI Plenum SWSI Plenum SWSI Plenum

Size 445 445 445

Motor Size Range (min. to max. HP) 10–50 10–50 10–50

Airow Range (min. to max. CFM) 0–50000 0–50000 0–50000

Static Pressure Range (min. to max. iwg) 0–3 0–3 0–3

EVAPORATOR COIL

Size (sq. ft.) 81.7 81.7 81.7

Number Of Rows/Fins Per Inch 5 / 10 5 / 10 5 / 10

Tube Diameter (inches) 1/2 1/2 1/2

CONDENSER COIL

Size (sq. ft.) 262 262 262

Number Of Rows/Fins Per Inch 1/21 1/21 1/21

CONDENSER FANS

Quantity 9 9 9

Type Prop Prop Prop

Diameter (inches) 36 36 36

Power (HP) 2 2 2

FILTERS - 2-INCH CLEANABLE (PRE-FILTER POSITION)

Quantity 36/12 36/12 36/12

Size (length x width in inches) 16x20/20x20 16x20/20x20 16x20/20x20

Total Filter Face Area (sq. ft.) 113.3 113.3 113.3

FILTERS - 2-INCH PLEATED, 30% EFFICIENT (PRE-FILTER POSITION) (MERV 8)

Quantity 36/12 36/12 36/12

Size (length x width in inches) 16x20/20x20 16x20/20x20 16x20/20x20

Total Filter Face Area (sq. ft.) 113.3 113.3 113.3

TEMPMASTER

19

Page 20

FORM TPM3-EG1 (518)

Physical Data (Cont'd)

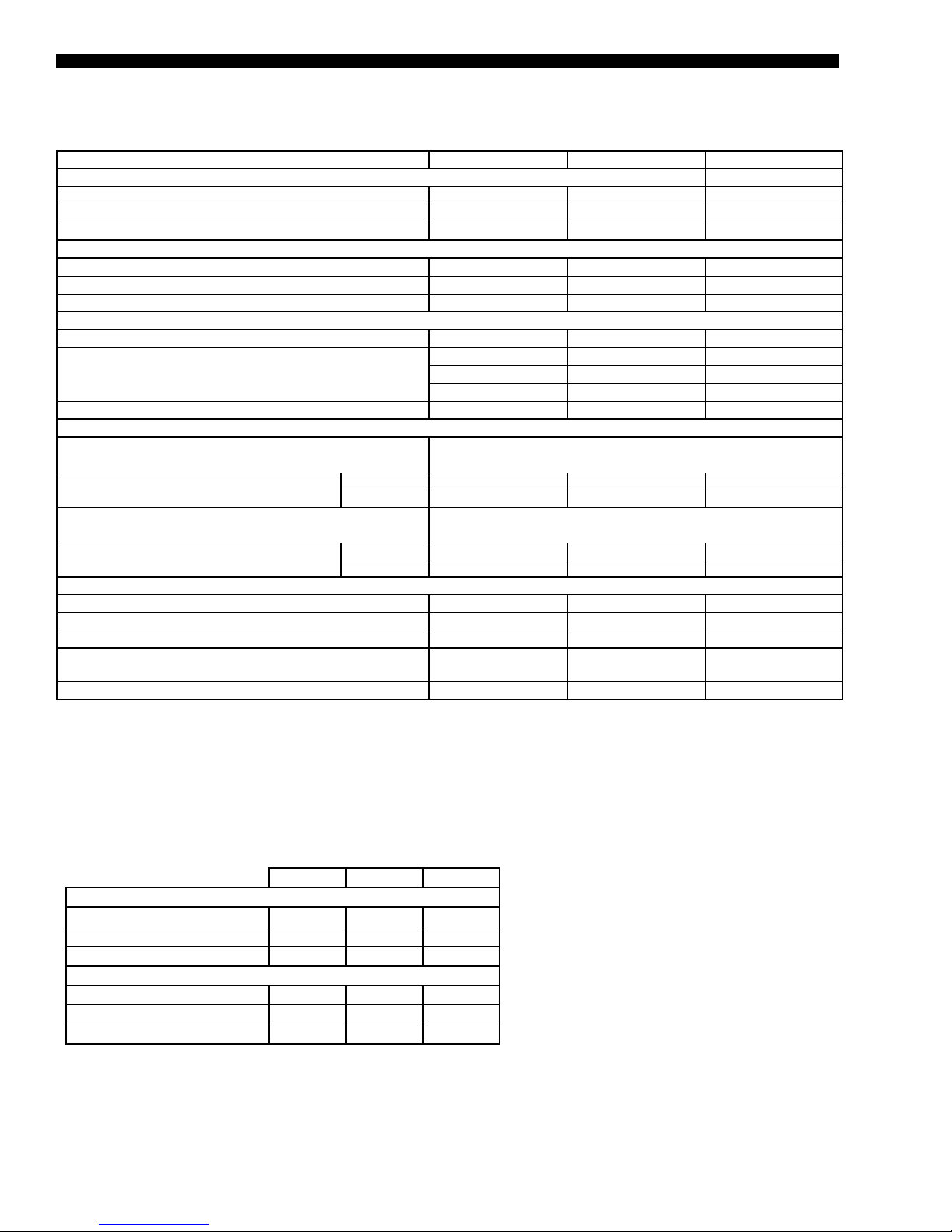

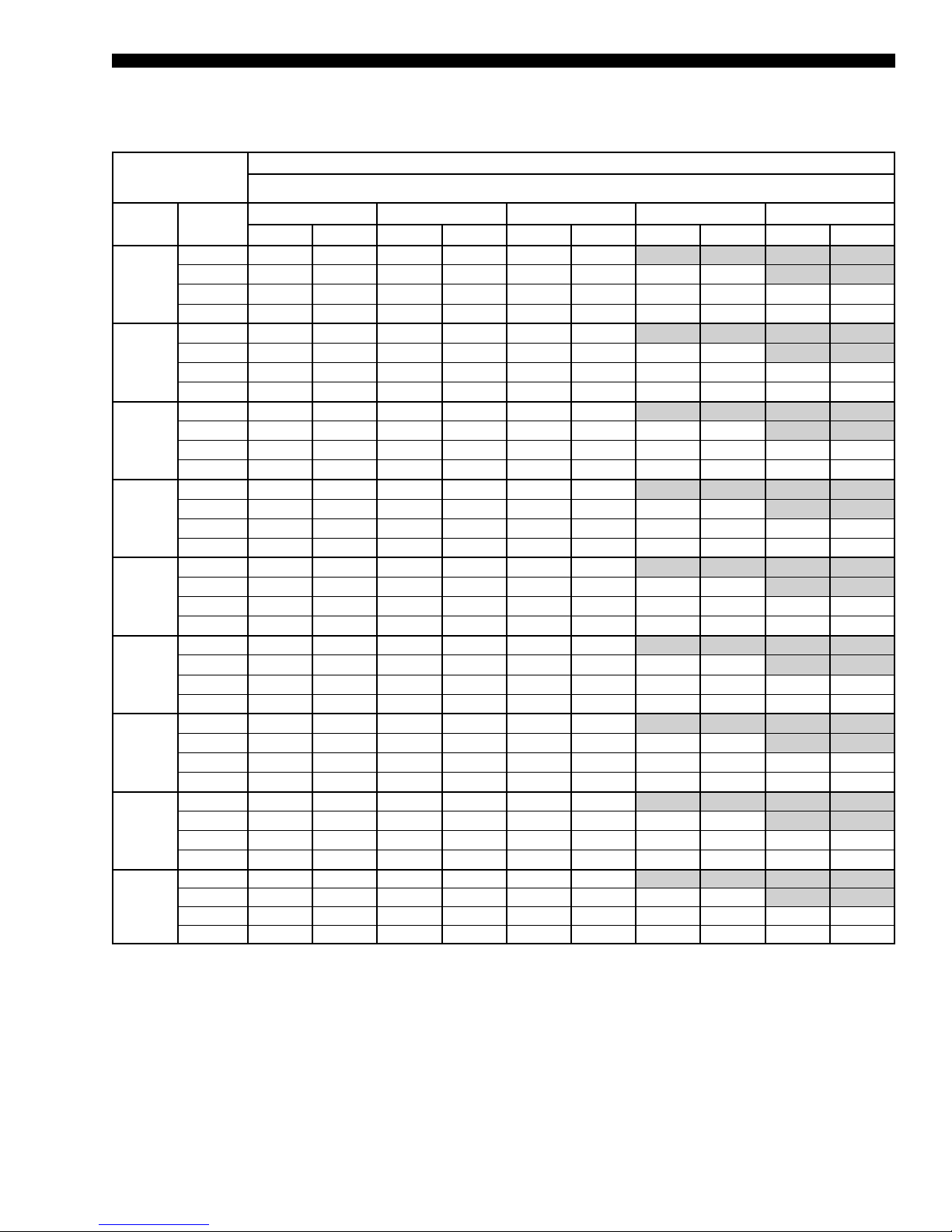

TABLE 3 – PHYSICAL DATA – MODELS 120-150 (CONT'D)

MODEL SIZE 120 130 150

FILTERS - 2-INCH CARBON (PRE-FILTER POSITION) (MERV 7)

Quantity 36/12 36/12 36/12

Size (length x width in inches) 16x20/20x20 16x20/20x20 16x20/20x20

Total Filter Face Area (sq. ft.) 113.3 113.3 113.3

FILTERS - 12-INCH RIGID 65%, 2-INCH 30% PREFILTER (PRE-FILTER POSITION) (MERV 11)

Quantity 7/21 7/21 7/21

Size (length x width in inches) 20x16/20x25 20x16/20x25 20x16/20x25

Total Filter Face Area (sq. ft.) 88.5 88.5 88.5

FILTERS - 12-INCH RIGID 95% (FINAL FILTER POSITION) (MERV 14)

Quantity 5/3/3/4/6/7 5/3/3/4/6/7 5/3/3/4/6/7

12x24,16x20 12x24,16x20 12x24,16x20

Size (length x width in inches)

Total Filter Face Area (sq. ft.) 80.4 80.4 80.4

GAS FURNACE

Staged Furnace Sizes

(input/output/stages)

Gas Pressure Range (min. to max. iwg)

Modulating Furnace Sizes

(input/output/turndown)

Gas Pressure Range (min. to max. iwg)

ELECTRIC HEATERS

Size Range (min. to max. kW) 80-250 80-250 80-250

Heating steps

Minimum steps

MINIMUM OUTSIDE AIR (OA)TEMPERATURE FOR

MECHANICAL COOLING

LOW AMBIENT OPTION MIN. OA TEMP 0 0 0

1

1

Natural 4.5–10.5 inch w.c. 4.5–10.5 inch w.c. 4.5–10.5 inch w.c.

Propane 11.0–13.0 inch w.c. 11.0–13.0 inch w.c. 11.0–13.0 inch w.c.

Natural 4.5–10.5 inch w.c. 4.5–10.5 inch w.c. 4.5–10.5 inch w.c.

Propane 11.0–13.0 inch w.c. 11.0–13.0 inch w.c. 11.0–13.0 inch w.c.

16x25, 20x20 16x25, 20x20 16x25, 20x20

20x24, 20x25 20x24, 20x25 20x24, 20x25

1125 mbh/900 mbh/6 stages

1125 mbh/900 mbh/24:1 turndown

2-6 2-6 2-6

2 2 2

50 50 50

NOTES

1. Electric heat steps and airow range depends on voltage and size. Consult the air pressure drop tables for specic number of steps for a

given voltage.

TABLE 4 - REFRIGERANT CHARGE DATA

120 130 150

REFRIGERANT CHARGE (STD CABINET)

SYS 1 - lb (kg) 41 (18.6) 41 (18.6) 41 (18.6)

SYS 2 - lb (kg) 73 (33.1) 82 (37.2) 77 (34.9)

SYS 3 - lb (kg) 97 (44.0) 98 (44.4) 106 (48.1)

REFRIGERANT CHARGE (EXTD CABINET)

SYS 1 - lb (kg) 43 (19.5) 43 (19.5) 43 (19.5)

SYS 2 - lb (kg) 75 (34.0) 84 (38.1) 79 (35.8)

SYS 3 - lb (kg) 100 (45.4) 101 (45.8) 109 (49.4)

20

TEMPMASTER

Page 21

Weight Data

FORM TPM3-EG1 (518)

TABLE 5 - APPROXIMATE BASE OPERATING

WEIGHTS (LBS)

MODEL SIZE 120 130 150

SINGLE PIECE UNIT 18,238 18,847 18,938

TWO PIECE UNIT

Air Handler Section 12,131 12,325 12,332

Condenser Section 6,096 6,510 6,597

NOTES:

• Weights above are total weight excluding the curb

• Standard cabinet

• Cooling only

• 60 HP supply fan with variable frequency drive (VFD)

• Comparative enthalpy economizer

• Barometric relief exhaust

• Bottom supply and return

• 2-inch pleated lters

• Condenser section wire guards

• Weights represent approximate operating weights and have a

+/- 10% accuracy. To calculate weight for a specic conguration, contact a TempMaster sales representative.

TABLE 6 - COMPONENT WEIGHTS (LBS)

MODEL SIZE 120 130 150

CABINET, AIR HANDLING SECTION

Sheet Metal (Note 1) 6,310

Control Panel (Note 2) 705

REFRIGERANT

Refrigerant Charge (R-410A) 210 230 230

COMPRESSORS 826 1,661 1,738

CONDENSER ASSEMBLY

Sheet Metal 2,477

Coils 864

Condenser Fans 90

Condenser Motors 450

Condenser Grills 90

Wire Guards 266

Louvered Panel Guards 432

DWDI AIRFOIL SUPPLY FAN SKID WITHOUT MOTOR (NOTE 3) 1,696

SUPPLY FAN MOTOR DRIVE 80

DUAL DIRECT DRIVE PLENUM (DDP) FAN SKIDS WITHOUT MOTOR

Frame 215T DDP 330-100/120 565/579

Frame 254T DDP 330-100/120

Frame 256T DDP 330-100/120

Frame 284T DDP 330-100/120

Frame 286T DDP 330-100/120

Frame 324T DDP 330-100/120

Frame 326T DDP 330-100/120

Frame 364T DDP 330-100/120 709/722

MOTOR (SUPPLY/EXHAUST/RETURN)

7.5 HP 151

10 HP 165

15 HP 255

20 HP 286

25 HP 379

30 HP 437

40 HP 578

50 HP 700

60 HP 885

75 HP 930

100 HP 1,225

VARIABLE FREQUENCY DRIVE (VFD) (SUPPLY/EXHAUST/RETURN)

5–10 HP 16

15–25 HP 27

30–40 HP 51

50–75 HP 77

100 HP 110

584/597

608/621

692/705

TEMPMASTER

21

Page 22

FORM TPM3-EG1 (518)

Weight Data (Cont'd)

TABLE 6 – COMPONENT WEIGHTS (LBS) (CONT'D)

MODEL SIZE 120 130 150

EVAPORATOR COILS 921 1,106 1,106

FILTERS

2-inch Cleanable Aluminum 74

2-inch Pleated 40

2-inch Carbon 94

Return Filter - 2-inch Throwaway (Note 4) 30

Return Filter - 12-inch 60–65% (Note 4) 393

Return Filter - 12-inch 90–95% (Note 4) 388

Final Filters 327

ECONOMIZER

Outside Air Dampers 255

Outside Air Hoods 291

Outside Air Filters 103

EXHAUST FAN SKID WITHOUT MOTOR 1,147

RETURN FAN SKID WITHOUT MOTOR 1,574

EXHAUST

No Exhaust - End Panels 332

Exhaust Fan (Damper and Hood) 516

Return Fan (Damper and Hood) 539

HEATING OPTIONS

Electric Heat - 80 kW 660

Electric Heat - 108 kW 680

Electric Heat - 150 kW 700

Electric Heat - 200 kW 720

Electric Heat - 250 kW 740

Gas Heat - 1125 mbh 1,455

Hot Water Coil (2 rows x 14 ns per inch) 417

Steam Coil (1 rows x 10 ns per inch) 534

MISCELLANEOUS

Open Perimeter Curb 684

Enclosed Perimeter Curb 1,110

Airow Measurement Option 45

NOTES:

1. Sheet metal, air handling cabinet cooling only.

2. Includes all options.

3. Motor base is included in fan skid.

4. Filters only. Does not include the lter rack.

Weights represent approximate operating weights and have a +/- 10% accuracy. To calculate weight for a specic conguration, contact a

TempMaster sales representative.

22

TEMPMASTER

Page 23

Cooling Performance Data

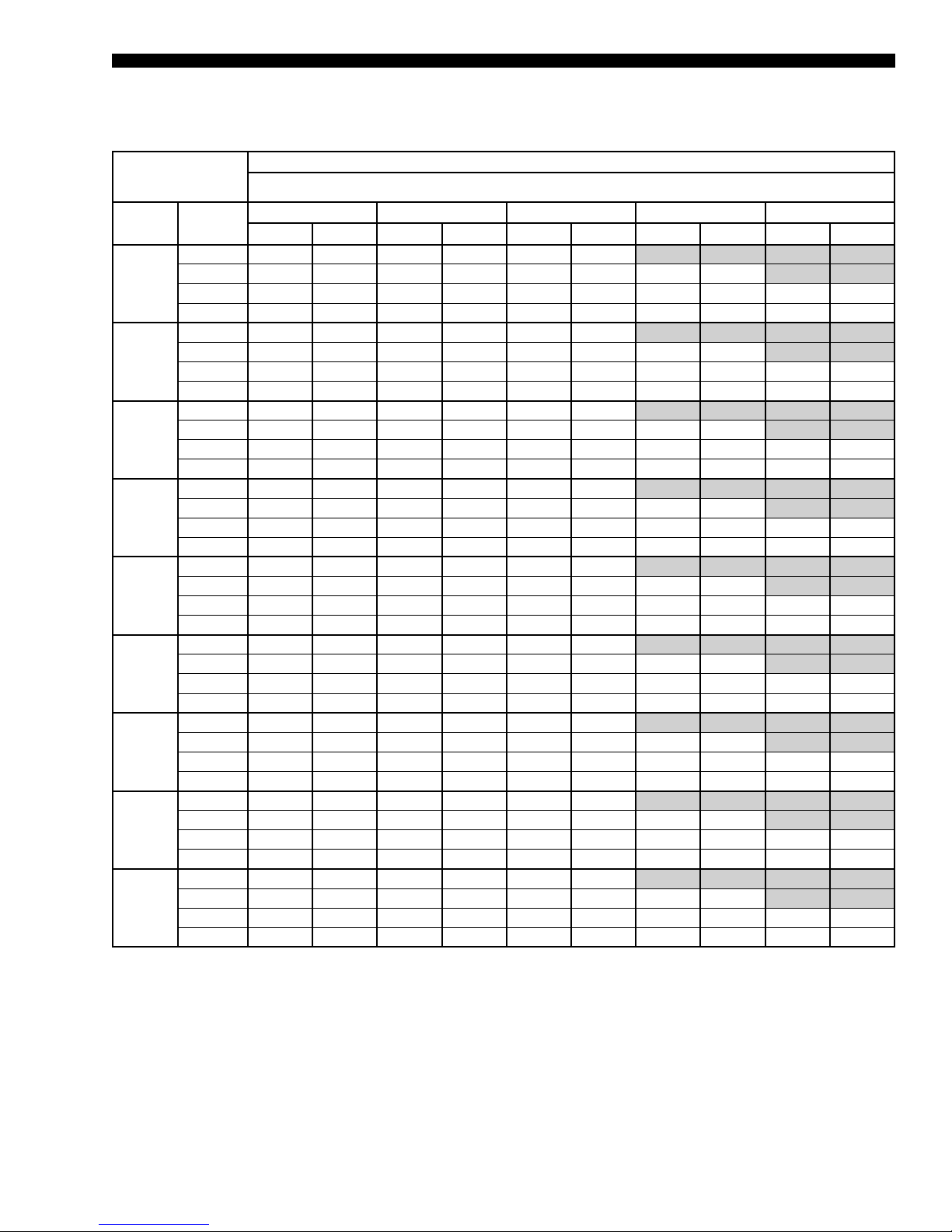

TABLE 7 - COOLING PERFORMANCE DATA* – 120 TON MODEL

AIR ENTERING

EVAPORATOR

COIL

CFM

32000

34500

37000

39500

42000

44500

47000

49500

52000

* Rated performance is at sea level. Cooling capacities are gross cooling capacity.

WET

BULB (°F)

75 1778.4 1080.0 1777.1 907.1 1773.2 732.3

71 1660.9 1202.8 1660.9 1031.4 1659.3 855.9 1659.3 674.7

67 1552.6 1325.4 1552.6 1155.3 1550.9 974.7 1550.9 797.9 1550.9 621.1

62 1491.5 1443.6 1425.1 1309.3 1423.2 1126.8 1421.7 951.0 1420.2 775.1

75 1802.4 1124.4 1800.2 935.7 1797.3 745.6

71 1684.4 1258.4 1684.0 1071.4 1682.8 879.6 1682.8 683.4

67 1587.6 1376.3 1586.2 1210.8 1584.9 1013.5 1584.9 822.0 1584.9 630.6

62 1530.6 1488.1 1462.4 1355.8 1461.0 1183.4 1459.9 992.1 1458.7 800.8

75 1826.5 1168.9 1823.4 964.3 1821.4 758.9

71 1707.9 1314.0 1707.0 1111 .4 1706.2 903.3 1706.2 692.2

67 1622.5 1427.2 1619.8 1266.2 1618.9 1052.2 1618.9 846.1 1618.9 640.0

62 1569.7 1532.6 1499.7 1402.3 1498.8 1240.0 1498.0 1033.3 1497.3 826.5

75 1850.5 1213.4 1846.5 992.8 1845.5 772.2

71 1731.4 1369.5 1730.1 1151.3 1729.7 927.0 1729.7 700.9

67 1657.5 1478.0 1653.4 1321.7 1653.0 1091.0 1653.0 870.2 1653.0 649.5

62 1608.8 1577.1 1537.0 1448.8 1536.5 1296.6 1536.2 1074.4 1535.8 852.2

75 1874.6 1257.9 1869.6 1021.4 1869.6 785.5

71 1754.8 1425.1 1753.1 1191.3 1753.1 950.7 1753.1 709.6

67 1692.4 1528.9 1687.0 1377.1 1687.0 1129.7 1687.0 894.3 1687.0 658.9

62 1648.0 1621.6 1574.3 1495.3 1574.3 1353.2 1574.3 1115.6 1574.3 877.9

75 1889.9 1301.0 1886.2 1049.3 1885.6 797.6

71 1770.3 1479.3 1768.2 1229.8 1767.5 972.4 1767.5 717.1

67 1702.0 1551.9 1698.0 1424.0 1698.0 1159.6 1698.0 910.3 1698.0 660.9

62 1679.4 1656.2 1597.8 1528.5 1572.1 1374.8 1571.1 1130.2 1570.1 885.7

75 1905.3 1344.1 1902.8 1077.1 1901.6 809.6

71 1785.8 1533.5 1783.3 1268.3 1781.9 994.0 1781.9 724.5

67 1711.6 1575.0 1708.9 1470.9 1708.9 1189.5 1708.9 926.2 1708.9 662.9

62 1710.8 1690.8 1621.4 1561.6 1569.9 1396.3 1567.9 1144.9 1565.8 893.5

75 1920.6 1387.2 1919.3 1105.0 1917.5 821.7

71 1801.2 1587.6 1798.4 1306.7 1796.3 1015.7 1796.3 731.9

67 1721.2 1598.0 1719.9 1517.7 1719.9 1219.4 1719.9 942.2 1719.9 664.9

62 1742.1 1725.4 1644.9 1594.8 1567.7 1417.9 1564.6 1159.5 1561.6 901.2

75 1935.9 1430.3 1935.9 1132.8 1933.5 833.7

71 1816.7 1641.8 1813.5 1345.2 1810.7 1037.3 1810.7 739.4

67 1730.8 1621.0 1730.8 1564.6 1730.8 1249.3 1730.8 958.1 1730.8 666.9

62 1773.5 1760.0 1668.4 1627.9 1565.5 1439.4 1561.4 1174.2 1557.3 909.0

92.0°F 86.0°F 80.0°F 74.0°F 68.0°F

TMBH SMBH TMBH SMBH TMBH SMBH TMBH SMBH TMBH SMBH

OUTDOOR AMBIENT TEMPERATURE 75.0°F

ENTERING DRY BULB TEMPERATURE

FORM TPM3-EG1 (518)

TEMPMASTER

23

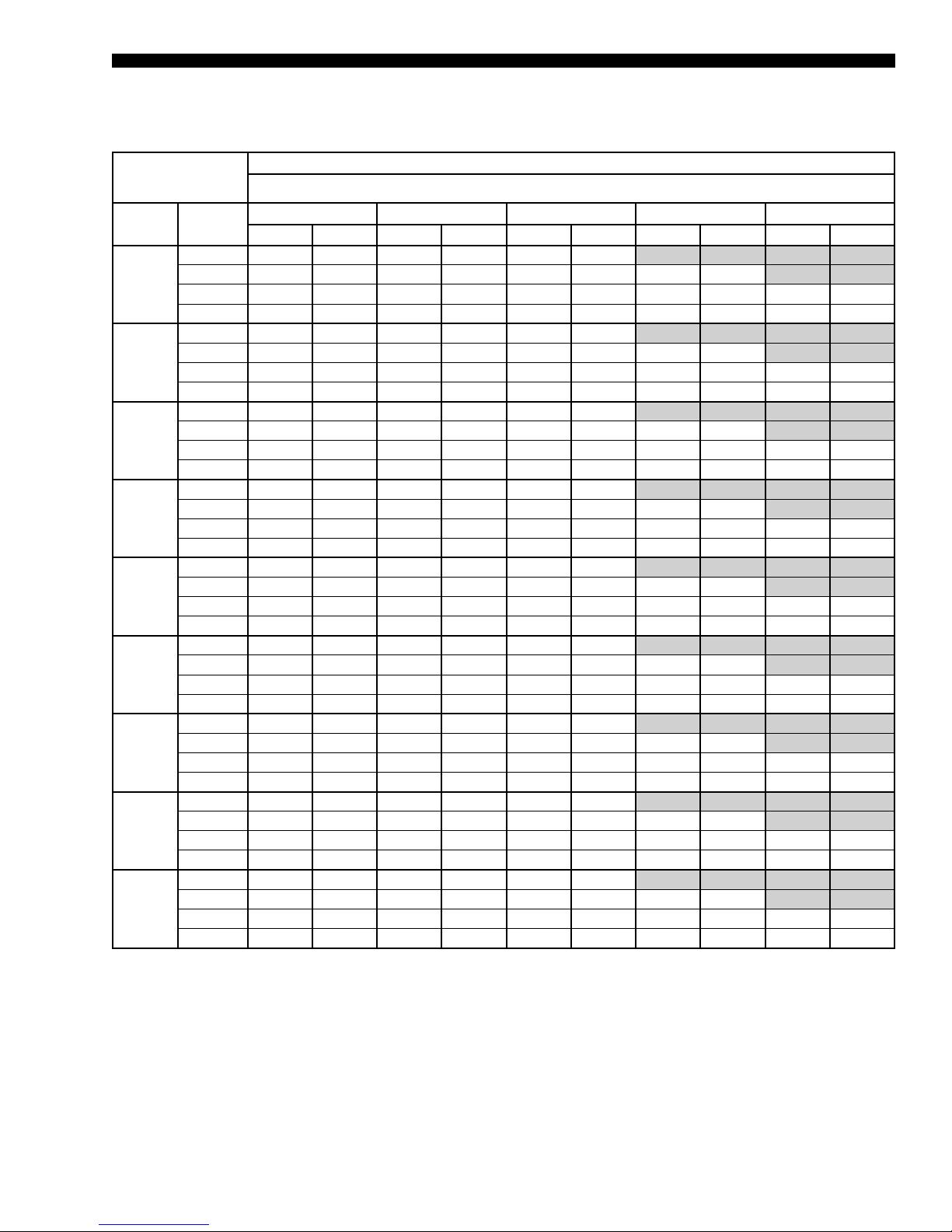

Page 24

FORM TPM3-EG1 (518)

Cooling Performance Data (Cont'd)

TABLE 7 – COOLING PERFORMANCE DATA* – 120 TON MODEL (CONT’D)

AIR ENTERING

EVAPORATOR

COIL

CFM

32000

34500

37000

39500

42000

44500

47000

49500

52000

* Rated performance is at sea level. Cooling capacities are gross cooling capacity.

WET

BULB (°F)

75 1708.2 1052.4 1706.8 879.6 1702.1 704.6

71 1596.2 1175.4 1595.9 1004.0 1594.2 828.6 1594.2 647.4

67 1489.4 1296.6 1488.0 1126.1 1487.1 945.9 1487.1 769.1 1487.1 592.4

62 1442.9 1407.3 1378.7 1286.1 1377.8 1104.2 1377.0 928.8 1376.3 753.5

75 1731.2 1097.0 1729.6 908.4 1726.0 718.3

71 1618.4 1230.9 1617.9 1044.0 1616.7 852.4 1616.7 656.2

67 1525.2 1346.8 1510.0 1177.0 1509.4 980.0 1509.4 788.7 1509.4 597.4

62 1462.6 1430.7 1414.5 1329.2 1394.3 1151.2 1393.7 960.4 1393.1 769.5

75 1754.2 1141.6 1752.3 937.3 1750.0 732.1

71 1640.6 1286.5 1640.0 1084.1 1639.2 876.2 1639.2 665.1

67 1561.1 1397.0 1532.1 1227.9 1531.7 1014.2 1531.7 808.3 1531.7 602.3

62 1482.4 1454.1 1450.3 1372.3 1410.8 1198.2 1410.4 991.9 1410.0 785.6

75 1777.1 1186.1 1775.1 966.1 1773.9 745.8

71 1662.8 1342.1 1662.1 1124.1 1661.7 900.1 1661.7 674.0

67 1597.0 1447.2 1554.2 1278.8 1554.0 1048.4 1554.0 827.8 1554.0 607.3

62 1502.1 1477.4 1486.1 1415.5 1427.3 1245.3 1427.1 1023.5 1426.9 801.7

75 1800.1 1230.7 1797.8 995.0 1797.8 759.5

71 1685.1 1397.6 1684.2 1164.1 1684.2 923.9 1684.2 682.8

67 1632.9 1497.4 1576.3 1329.7 1576.3 1082.6 1576.3 847.4 1576.3 612.2

62 1521.9 1500.8 1521.9 1458.6 1443.8 1292.3 1443.8 1055.1 1443.8 817.8

75 1813.5 1273.6 1811.5 1022.3 1811.0 771.0

71 1702.5 1439.3 1697.2 1202.2 1696.8 945.2 1696.8 690.0

67 1647.6 1528.4 1593.1 1379.7 1592.8 1115.4 1592.8 866.2 1592.8 617.1

62 1566.3 1548.8 1532.5 1480.0 1472.1 1341.6 1466.1 1088.5 1460.1 835.3

75 1826.8 1316.4 1825.1 1049.6 1824.3 782.5

71 1720.0 1480.9 1710.2 1240.3 1709.4 966.6 1709.4 697.1

67 1662.3 1559.5 1609.9 1429.7 1609.3 1148.2 1609.3 885.0 1609.3 621.9

62 1610.7 1596.8 1543.1 1501.4 1500.5 1391.0 1488.4 1121.9 1476.3 852.8

75 1840.2 1359.2 1838.8 1076.9 1837.5 794.0

71 1737.4 1522.5 1723.2 1278.4 1722.0 987.9 1722.0 704.3

67 1677.0 1590.6 1626.7 1479.7 1625.8 1180.9 1625.8 903.9 1625.8 626.8

62 1655.1 1644.7 1553.7 1522.7 1528.8 1440.3 1510.7 1155.3 1492.6 870.3

75 1853.5 1402.1 1852.4 1104.3 1850.7 805.5

71 1754.8 1564.1 1736.2 1316.5 1734.7 1009.2 1734.7 711.4

67 1691.7 1621.6 1643.5 1529.7 1642.4 1213.7 1642.4 922.7 1642.4 631.7

62 1699.5 1692.7 1564.4 1544.1 1557.1 1489.6 1533.0 1188.7 1508.8 887.8

92.0°F 86.0°F 80.0°F 74.0°F 68.0°F

TMBH SMBH TMBH SMBH TMBH SMBH TMBH SMBH TMBH SMBH

OUTDOOR AMBIENT TEMPERATURE 85.0°F

ENTERING DRY BULB TEMPERATURE

24

TEMPMASTER

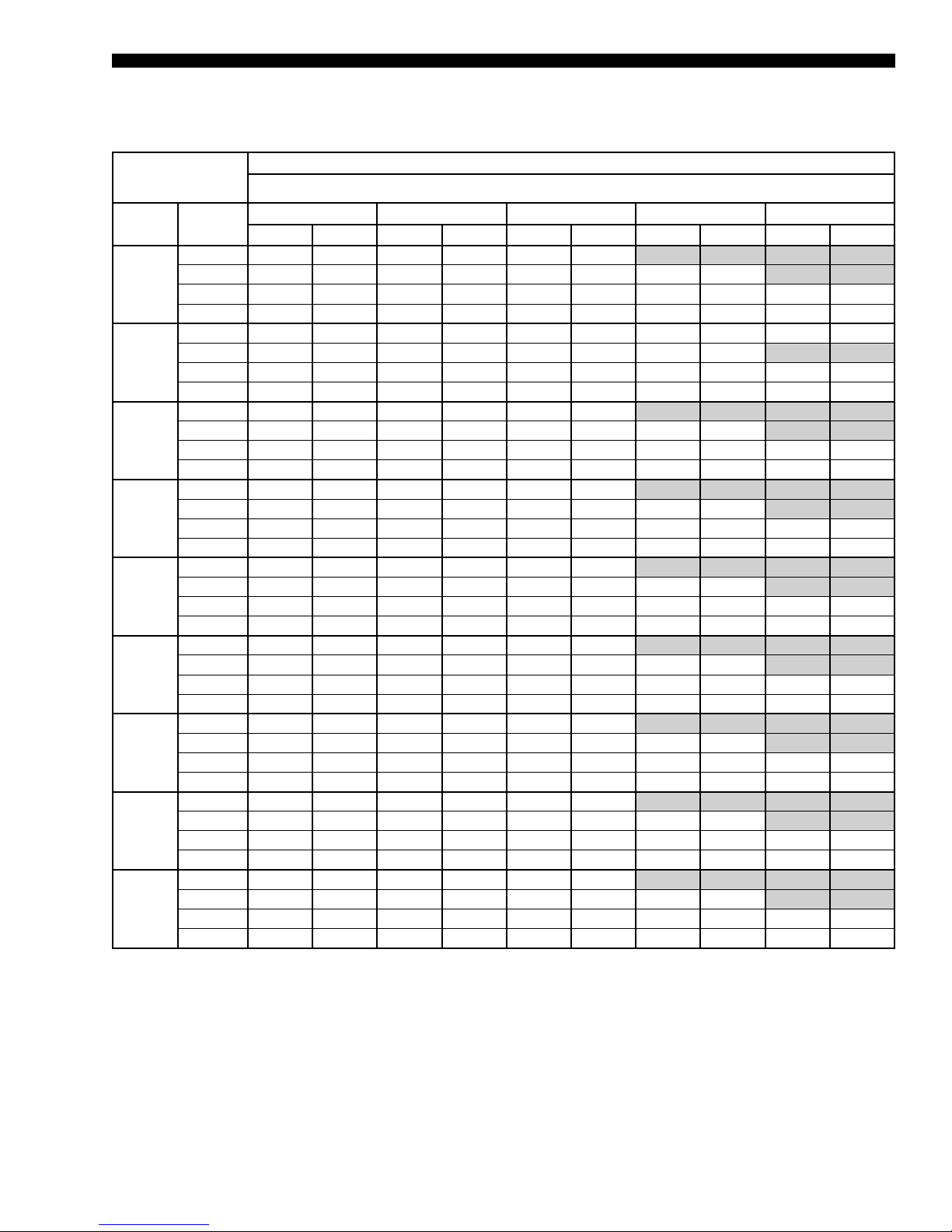

Page 25

TABLE 7 – COOLING PERFORMANCE DATA* – 120 TON MODEL (CONT’D)

AIR ENTERING

EVAPORATOR

COIL

CFM

WET

BULB (°F)

92.0°F 86.0°F 80.0°F 74.0°F 68.0°F

TMBH SMBH TMBH SMBH TMBH SMBH TMBH SMBH TMBH SMBH

75 1638.0 1024.8 1636.5 852.0 1631.0 676.9

32000

71 1531.5 1147.9 1530.8 976.6 1529.1 801.2 1529.1 620.1

67 1426.1 1267.7 1423.3 1096.8 1423.3 917.0 1423.3 740.4 1423.3 563.7

62 1394.2 1371.1 1332.3 1262.8 1332.3 1081.5 1332.3 906.7 1332.3 731.8

75 1659.1 1069.3 1657.3 880.8 1653.1 690.6

34500

71 1552.2 1203.4 1550.6 1016.3 1549.4 824.7 1549.4 628.7

67 1461.8 1315.7 1443.7 1147.6 1443.6 950.9 1443.6 759.7 1443.6 568.4

62 1433.4 1416.0 1364.8 1312.7 1344.1 1127.1 1344.1 936.6 1344.1 746.1

75 1680.3 1113.8 1678.0 909.5 1675.3 704.3

37000

71 1572.9 1259.0 1570.4 1056.0 1569.8 848.3 1569.8 637.3

67 1497.4 1363.7 1464.1 1198.5 1463.9 984.9 1463.9 779.0 1463.9 573.2

62 1472.6 1461.0 1397.3 1362.5 1355.9 1172.7 1355.9 966.5 1355.9 760.3

75 1701.5 1158.3 1698.8 938.3 1697.4 717.9

39500

71 1593.6 1314.5 1590.2 1095.6 1590.1 871.8 1590.1 645.8

67 1533.1 1411.7 1484.5 1249.3 1484.2 1018.8 1484.2 798.3 1484.2 577.9

62 1511.7 1505.9 1429.7 1412.4 1367.7 1218.2 1367.7 996.4 1367.7 774.6

75 1722.6 1202.7 1719.5 967.0 1719.5 731.6

42000

71 1614.3 1370.0 1610.0 1135.3 1610.4 895.3 1610.4 654.4

67 1568.8 1459.7 1504.9 1300.1 1504.5 1052.7 1504.5 817.7 1504.5 582.6

62 1550.9 1550.9 1462.2 1462.2 1379.5 1263.8 1379.5 1026.3 1379.5 788.8

75 1734.8 1245.5 1731.9 994.2 1731.6 743.0

44500

71 1634.0 1399.1 1622.2 1173.4 1622.5 916.8 1622.5 661.7

67 1589.7 1500.3 1517.7 1348.8 1516.9 1084.1 1516.9 835.1 1516.9 586.1

62 1569.5 1569.5 1461.7 1461.7 1421.8 1332.8 1410.8 1070.5 1399.7 808.3

75 1746.9 1288.3 1744.2 1021.4 1743.7 754.4

47000

71 1653.7 1428.2 1634.5 1211.6 1634.5 938.2 1634.5 668.9

67 1610.7 1541.0 1530.6 1397.5 1529.2 1115.4 1529.2 852.5 1529.2 589.5

62 1588.1 1588.1 1461.3 1461.3 1464.1 1401.8 1442.0 1114.8 1419.9 827.7

75 1759.0 1331.1 1756.6 1048.5 1755.8 765.8

49500

71 1673.3 1457.3 1646.7 1249.7 1646.6 959.7 1646.6 676.2

67 1631.6 1581.6 1543.4 1446.1 1541.6 1146.8 1541.6 869.9 1541.6 593.0

62 1606.7 1606.7 1460.8 1460.8 1506.4 1470.8 1473.3 1159.0 1440.1 847.2

75 1771.1 1373.8 1768.9 1075.7 1767.9 777.2

52000

* Rated performance is at sea level. Cooling capacities are gross cooling capacity.

71 1693.0 1486.4 1658.9 1287.8 1658.6 981.1 1658.6 683.4

67 1652.6 1622.3 1556.2 1494.8 1553.9 1178.1 1553.9 887.3 1553.9 596.4

62 1625.4 1625.4 1460.3 1460.3 1548.7 1539.8 1504.5 1203.2 1460.3 866.6

OUTDOOR AMBIENT TEMPERATURE 95.0°F

ENTERING DRY BULB TEMPERATURE

FORM TPM3-EG1 (518)

TEMPMASTER

25

Page 26

FORM TPM3-EG1 (518)

Cooling Performance Data (Cont'd)

TABLE 7 – COOLING PERFORMANCE DATA* – 120 TON MODEL (CONT’D)

AIR ENTERING

EVAPORATOR

COIL

CFM

32000

34500

37000

39500

42000

44500

47000

49500

52000

* Rated performance is at sea level. Cooling capacities are gross cooling capacity.

WET

BULB (°F)

75 1566.4 997.6 1565.7 825.2 1562.9 651.4

71 1458.7 1117.9 1456.5 946.1 1455.6 771.1 1455.6 590.2

67 1378.5 1229.5 1359.3 1068.5 1359.3 888.8 1359.3 712.3 1359.3 535.8

62 1348.2 1325.4 1282.9 1214.4 1257.9 1045.7 1257.9 870.9 1257.9 696.2

75 1583.1 1041.0 1582.6 853.1 1580.5 663.9

71 1478.3 1173.5 1476.2 986.3 1473.8 794.3 1473.8 598.5

67 1409.4 1276.3 1377.2 1118.7 1376.9 922.1 1376.9 731.0 1376.9 539.9

62 1384.4 1364.2 1312.9 1252.3 1273.0 1093.1 1272.7 904.8 1272.3 716.5

75 1599.9 1084.5 1599.5 881.1 1598.2 676.4

71 1497.9 1229.1 1495.9 1026.4 1491.9 817.6 1491.9 606.8

67 1440.4 1323.2 1395.0 1168.9 1394.6 955.4 1394.6 749.7 1394.6 543.9

62 1420.5 1402.9 1342.9 1290.2 1288.2 1140.5 1287.4 938.6 1286.7 736.8

75 1616.6 1127.9 1616.5 909.0 1615.8 688.9

71 1517.5 1284.7 1515.7 1066.6 1510.1 840.8 1510.1 615.0

67 1471.3 1370.1 1412.9 1219.1 1412.2 988.8 1412.2 768.4 1412.2 548.0

62 1456.6 1441.7 1372.9 1328.1 1303.3 1187.9 1302.2 972.5 1301.0 757.1

75 1633.4 1171.3 1633.4 936.9 1633.4 701.4

71 1537.1 1340.3 1535.4 1106.7 1528.2 864.0 1528.2 623.3

67 1502.2 1417.0 1430.7 1269.3 1429.8 1022.1 1429.8 787.1 1429.8 552.0

62 1492.8 1480.5 1402.9 1366.0 1318.4 1235.3 1316.9 1006.4 1315.4 777.4

75 1644.0 1213.9 1643.3 963.6 1643.2 712.4

71 1557.6 1366.3 1544.6 1144.1 1539.2 885.4 1539.2 630.5

67 1522.5 1453.2 1447.0 1313.5 1441.3 1053.5 1441.3 804.5 1441.3 555.5

62 1512.1 1502.9 1411.7 1384.1 1347.8 1276.6 1341.1 1034.5 1334.5 792.3

75 1654.6 1256.5 1653.2 990.2 1653.1 723.5

71 1578.1 1392.4 1553.8 1181.6 1550.1 906.9 1550.1 637.7

67 1542.9 1489.5 1463.4 1357.8 1452.8 1084.9 1452.8 821.9 1452.8 559.0

62 1531.4 1525.2 1420.6 1402.1 1377.1 1318.0 1365.3 1062.6 1353.5 807.2

75 1665.2 1299.1 1663.0 1016.9 1662.9 734.5

71 1598.6 1418.4 1563.0 1219.0 1561.1 928.3 1561.1 645.0

67 1563.2 1525.7 1479.7 1402.0 1464.3 1116.3 1464.3 839.4 1464.3 562.5

62 1550.7 1547.6 1429.4 1420.2 1406.5 1359.3 1389.5 1090.7 1372.6 822.1

75 1675.8 1341.7 1672.9 1043.6 1672.8 745.5

71 1619.1 1444.4 1572.2 1256.4 1572.1 949.8 1572.1 652.2

67 1583.6 1562.0 1496.1 1446.2 1475.8 1147.7 1475.8 856.8 1475.8 566.0

62 1570.0 1570.0 1438.2 1438.2 1435.9 1400.7 1413.8 1118.9 1391.7 837.1

92.0°F 86.0°F 80.0°F 74.0°F 68.0°F

TMBH SMBH TMBH SMBH TMBH SMBH TMBH SMBH TMBH SMBH

OUTDOOR AMBIENT TEMPERATURE 105.0°F

ENTERING DRY BULB TEMPERATURE

26

TEMPMASTER

Page 27

TABLE 7 – COOLING PERFORMANCE DATA* – 120 TON MODEL (CONT’D)

AIR ENTERING

EVAPORATOR

COIL

CFM

32000

34500

37000

39500

42000

44500

47000

49500

52000

* Rated performance is at sea level. Cooling capacities are gross cooling capacity.

WET

BULB (°F)

75 1494.8 970.4 1494.8 798.4 1494.8 625.8

71 1386.0 1087.8 1382.1 915.6 1382.1 741.0 1382.1 560.4

67 1331.0 1191.2 1295.3 1040.1 1295.3 860.5 1295.3 684.2 1295.3 507.9

62 1302.2 1279.7 1233.4 1166.0 1183.5 1009.8 1183.5 835.2 1183.5 660.5

75 1506.6 1012.7 1505.8 824.8 1504.4 636.1

71 1402.2 1138.6 1397.9 954.9 1397.9 763.9 1397.9 568.4

67 1356.6 1237.9 1310.8 1089.9 1310.8 893.5 1310.8 702.5 1310.8 511.6

62 1334.4 1316.0 1260.6 1205.2 1200.2 1058.5 1200.2 868.3 1200.2 678.1

75 1518.3 1054.9 1516.8 851.1 1514.1 646.3

71 1418.3 1189.4 1413.7 994.3 1413.7 786.8 1413.7 576.3

67 1382.2 1284.7 1326.3 1139.6 1326.3 926.4 1326.3 720.8 1326.3 515.3

62 1366.7 1352.3 1287.7 1244.5 1216.9 1107.2 1216.9 901.5 1216.9 695.8

75 1530.1 1097.2 1527.8 877.5 1523.7 656.6

71 1434.5 1240.2 1429.5 1033.6 1429.5 809.7 1429.5 584.3

67 1407.8 1331.4 1341.7 1189.4 1341.7 959.4 1341.7 739.1 1341.7 518.9

62 1398.9 1388.5 1314.9 1283.7 1233.6 1155.9 1233.6 934.6 1233.6 713.4

75 1541.8 1139.4 1538.8 903.8 1533.3 666.8

71 1450.7 1291.0 1445.3 1072.9 1445.3 832.6 1445.3 592.2

67 1433.5 1378.2 1357.2 1239.1 1357.2 992.3 1357.2 757.5 1357.2 522.6

62 1431.1 1424.8 1342.0 1322.9 1250.3 1204.6 1250.3 967.8 1250.3 731.0

75 1551.5 1181.9 1548.3 930.7 1544.4 678.6

71 1474.3 1318.8 1455.4 1110.9 1455.4 854.1 1455.4 599.4

67 1453.7 1409.1 1376.9 1278.7 1367.3 1023.5 1367.3 774.7 1367.3 525.9

62 1452.0 1447.2 1360.5 1346.2 1268.5 1218.8 1268.5 984.5 1268.5 750.1

75 1561.1 1224.5 1557.9 957.6 1555.5 690.3

71 1498.0 1346.7 1465.4 1149.0 1465.4 875.5 1465.4 606.6

67 1474.0 1440.0 1396.6 1318.4 1377.4 1054.8 1377.4 791.9 1377.4 529.1

62 1472.9 1469.7 1379.1 1369.5 1286.7 1233.1 1286.7 1001.2 1286.7 769.3

75 1570.8 1267.0 1567.4 984.5 1566.5 702.1

71 1521.6 1374.5 1475.5 1187.0 1475.5 897.0 1475.5 613.8

67 1494.2 1470.8 1416.2 1358.0 1387.5 1086.0 1387.5 809.2 1387.5 532.4

62 1493.8 1492.2 1397.6 1392.8 1304.8 1247.3 1304.8 1017.8 1304.8 788.4

75 1580.4 1309.5 1576.9 1011.4 1577.6 713.8

71 1545.2 1402.4 1485.5 1225.0 1485.5 918.4 1485.5 620.9

67 1514.5 1501.7 1435.9 1397.6 1397.6 1117.2 1397.6 826.4 1397.6 535.6

62 1514.6 1514.6 1416.1 1416.1 1323.0 1261.5 1323.0 1034.5 1323.0 807.5

92.0°F 86.0°F 80.0°F 74.0°F 68.0°F

TMBH SMBH TMBH SMBH TMBH SMBH TMBH SMBH TMBH SMBH

OUTDOOR AMBIENT TEMPERATURE 115.0°F

ENTERING DRY BULB TEMPERATURE

FORM TPM3-EG1 (518)

TEMPMASTER

27

Page 28

FORM TPM3-EG1 (518)

Cooling Performance Data (Cont'd)

TABLE 8 - COOLING PERFORMANCE DATA* – 130 TON MODEL

AIR ENTERING

EVAPORATOR

COIL

CFM

32000

34500

37000

39500

42000

44500

47000

49500

52000

* Rated performance is at sea level. Cooling capacities are gross cooling capacity.

WET

BULB (°F)

75 1977.8 1208.4 1977.9 1009.4 1967.6 809.2

71 1850.5 1346.7 1851.3 1149.0 1842.1 947.3 1835.9 746.4

67 1731.2 1483.3 1731.7 1286.5 1731.0 1082.6 1726.7 887.3 1722.4 692.0

62 1657.6 1594.5 1592.0 1456.4 1587.7 1247.8 1589.1 1056.8 1590.5 865.7

75 2005.0 1253.3 2004.1 1038.4 1995.8 823.8

71 1875.9 1401.6 1876.5 1188.5 1867.1 970.1 1860.9 755.3

67 1760.5 1526.4 1756.0 1335.2 1754.7 1115.2 1750.3 906.0 1745.9 696.8

62 1694.2 1639.2 1621.6 1496.9 1616.3 1297.4 1616.3 1090.8 1616.2 884.2

75 2032.2 1298.1 2030.4 1067.4 2024.0 838.4

71 1901.3 1456.5 1901.7 1228.0 1892.2 993.0 1885.9 764.3

67 1789.7 1569.5 1780.3 1383.8 1778.3 1147.7 1773.9 924.7 1769.5 701.7

62 1730.7 1683.8 1651.3 1537.4 1644.9 1347.1 1643.4 1124.9 1642.0 902.7

75 2059.4 1343.0 2056.6 1096.4 2052.2 852.9

71 1926.8 1511.5 1926.9 1267.5 1917.2 1015.8 1910.9 773.3

67 1819.0 1612.7 1804.6 1432.4 1802.0 1180.3 1797.5 943.4 1793.0 706.5

62 1767.3 1728.5 1680.9 1577.9 1673.4 1396.7 1670.6 1159.0 1667.8 921.3

75 2086.7 1387.9 2082.8 1125.4 2080.4 867.5

71 1952.2 1566.4 1952.1 1307.0 1942.3 1038.6 1935.8 782.2

67 1848.3 1655.8 1828.9 1481.0 1825.7 1212.8 1821.1 962.1 1816.5 711.4

62 1803.8 1773.1 1710.6 1618.4 1702.0 1446.3 1697.8 1193.0 1693.5 939.8

75 2104.2 1430.8 2099.6 1152.6 2100.6 880.7

71 1969.9 1619.9 1969.5 1345.0 1962.2 1062.0 1957.3 792.1

67 1878.3 1702.7 1845.7 1529.1 1842.2 1243.4 1835.6 978.6 1828.9 713.8

62 1838.0 1809.8 1742.1 1657.4 1713.6 1489.6 1709.1 1221.3 1704.6 953.0

75 2121.8 1473.8 2116.5 1179.8 2120.7 894.0

71 1987.6 1673.3 1986.9 1383.0 1982.0 1085.4 1978.8 802.1

67 1908.4 1749.7 1862.6 1577.1 1858.8 1274.1 1850.1 995.1 1841.3 716.2

62 1872.2 1846.4 1773.6 1696.4 1725.2 1532.9 1720.4 1249.5 1715.7 966.1

75 2139.4 1516.8 2133.4 1207.0 2140.8 907.3

71 2005.4 1726.8 2004.3 1421.0 2001.9 1108.9 2000.3 812.0

67 1938.5 1796.6 1879.4 1625.2 1875.3 1304.7 1864.5 1011.7 1853.7 718.6

62 1906.4 1883.1 1805.1 1735.4 1736.8 1576.2 1731.8 1277.8 1726.7 979.3

75 2156.9 1559.8 2150.2 1234.2 2161.0 920.5

71 2023.1 1780.3 2021.8 1459.1 2021.8 1132.3 2021.8 821.9

67 1968.6 1843.5 1896.2 1673.3 1891.9 1335.4 1879.0 1028.2 1866.1 721.0

62 1940.5 1919.8 1836.6 1774.4 1748.4 1619.5 1743.1 1306.0 1737.8 992.5

92.0°F 86.0°F 80.0°F 74.0°F 68.0°F

TMBH SMBH TMBH SMBH TMBH SMBH TMBH SMBH TMBH SMBH

OUTDOOR AMBIENT TEMPERATURE 75.0°F

ENTERING DRY BULB TEMPERATURE

28

TEMPMASTER

Page 29

TABLE 8 – COOLING PERFORMANCE DATA* – 130 TON MODEL (CONT’D)

AIR ENTERING

EVAPORATOR

COIL

CFM

32000

34500

37000

39500

42000

44500

47000

49500

52000

* Rated performance is at sea level. Cooling capacities are gross cooling capacity.

WET

BULB (°F)

75 1905.1 1180.1 1902.7 980.0 1894.0 780.8

71 1780.5 1317.1 1779.5 1118.9 1775.1 919.1 1770.9 719.0

67 1663.2 1452.1 1665.0 1256.1 1664.6 1052.4 1661.7 857.7 1658.7 663.0

62 1601.2 1550.3 1530.8 1408.8 1527.7 1218.0 1528.0 1026.4 1528.3 834.9

75 1930.8 1224.8 1928.0 1009.2 1920.2 795.0

71 1805.0 1372.1 1803.6 1158.3 1799.9 942.3 1796.1 728.5

67 1694.2 1493.7 1689.6 1305.3 1688.2 1085.3 1685.5 876.9 1682.9 668.5

62 1639.8 1594.6 1566.9 1454.4 1550.7 1265.4 1550.2 1058.5 1549.6 851.6

75 1956.5 1269.5 1953.2 1038.3 1946.3 809.3

71 1829.5 1427.1 1827.8 1197.7 1824.7 965.5 1821.4 738.1

67 1725.2 1535.3 1714.2 1354.5 1711.8 1118.2 1709.4 896.1 1707.1 674.0

62 1678.3 1638.8 1603.0 1500.1 1573.7 1312.9 1572.3 1090.6 1570.9 868.4

75 1982.2 1314.2 1978.4 1067.4 1972.4 823.5

71 1854.0 1482.1 1851.9 1237.2 1849.6 988.7 1846.6 747.6

67 1756.2 1576.9 1738.8 1403.7 1735.3 1151.1 1733.3 915.3 1731.2 679.6

62 1716.8 1683.1 1639.1 1545.8 1596.7 1360.3 1594.4 1122.7 1592.2 885.2

75 2007.8 1358.9 2003.7 1096.5 1998.6 837.7

71 1878.6 1537.1 1876.0 1276.6 1874.4 1012.0 1871.9 757.1

67 1787.3 1618.5 1763.4 1452.9 1758.9 1184.0 1757.2 934.6 1755.4 685.1

62 1755.3 1727.4 1675.2 1591.4 1619.6 1407.7 1616.6 1154.9 1613.5 902.0

75 2022.5 1401.3 2018.0 1123.3 2015.3 850.2

71 1893.8 1588.3 1891.2 1314.2 1889.3 1033.8 1886.7 764.9

67 1814.6 1667.0 1777.0 1500.1 1772.4 1213.9 1769.3 950.6 1766.1 687.2

62 1785.8 1760.8 1699.5 1624.4 1633.1 1452.3 1629.5 1184.3 1625.9 916.3

75 2037.1 1443.6 2032.3 1150.1 2032.0 862.7

71 1908.9 1639.4 1906.4 1351.8 1904.3 1055.7 1901.5 772.6

67 1841.9 1715.5 1790.5 1547.2 1785.9 1243.9 1781.4 966.6 1776.9 689.4

62 1816.4 1794.3 1723.7 1657.5 1646.6 1496.9 1642.4 1213.7 1638.3 930.6

75 2051.8 1486.0 2046.6 1176.8 2048.6 875.1

71 1924.1 1690.6 1921.6 1389.3 1919.3 1077.6 1916.3 780.3

67 1869.3 1764.1 1804.0 1594.4 1799.5 1273.8 1793.5 982.6 1787.6 691.5

62 1846.9 1827.8 1747.9 1690.5 1660.0 1541.4 1655.3 1243.1 1650.6 944.8

75 2066.4 1528.4 2061.0 1203.6 2065.3 887.6

71 1939.3 1741.7 1936.8 1426.9 1934.2 1099.5 1931.1 788.1

67 1896.6 1812.6 1817.5 1641.5 1813.0 1303.7 1805.7 998.6 1798.4 693.6

62 1877.4 1861.2 1772.1 1723.5 1673.5 1586.0 1668.3 1272.6 1663.0 959.1

92.0°F 86.0°F 80.0°F 74.0°F 68.0°F

TMBH SMBH TMBH SMBH TMBH SMBH TMBH SMBH TMBH SMBH

OUTDOOR AMBIENT TEMPERATURE 85.0°F

ENTERING DRY BULB TEMPERATURE

FORM TPM3-EG1 (518)

TEMPMASTER

29

Page 30

FORM TPM3-EG1 (518)

Cooling Performance Data (Cont'd)

TABLE 8 – COOLING PERFORMANCE DATA* – 130 TON MODEL (CONT’D)

AIR ENTERING

EVAPORATOR

COIL

CFM

32000

34500

37000

39500

42000

44500

47000

49500

52000

* Rated performance is at sea level. Cooling capacities are gross cooling capacity.

WET

BULB (°F)

75 1832.5 1151.8 1827.6 950.6 1820.5 752.3

71 1710.4 1287.4 1707.7 1088.7 1708.1 890.9 1705.8 691.6

67 1595.2 1420.9 1598.3 1225.6 1598.2 1022.1 1596.6 828.0 1595.0 634.0

62 1544.9 1506.1 1469.7 1361.2 1467.8 1188.2 1466.9 996.1 1466.1 804.0

75 1854.4 1195.7 1849.7 979.1 1843.1 765.9

71 1731.6 1341.7 1729.4 1127.8 1729.4 913.2 1727.4 700.2

67 1629.8 1443.8 1619.9 1216.4 1619.0 1054.4 1617.4 846.5 1615.8 638.6

62 1583.8 1549.1 1505.0 1406.8 1502.7 1241.7 1501.7 1034.6 1500.7 827.5

75 1876.4 1239.7 1871.8 1007.6 1865.7 779.5

71 1752.9 1395.9 1751.0 1166.8 1750.6 935.5 1748.9 708.8

67 1664.4 1466.8 1641.5 1207.2 1639.8 1086.7 1638.2 865.0 1636.5 643.3

62 1622.8 1592.1 1540.3 1452.3 1537.7 1295.1 1536.5 1073.0 1535.3 851.0

75 1898.3 1283.6 1893.9 1036.1 1888.3 793.0

71 1774.1 1450.1 1772.7 1205.9 1771.9 957.8 1770.4 717.4

67 1699.0 1489.8 1663.1 1198.0 1660.6 1119.0 1658.9 883.5 1657.2 648.0

62 1661.7 1635.2 1575.6 1497.9 1572.7 1348.6 1571.3 1111.5 1569.8 874.4

75 1920.2 1327.5 1916.0 1064.7 1910.9 806.6

71 1795.3 1504.4 1794.3 1244.9 1793.1 980.1 1791.9 725.9

67 1733.6 1512.7 1684.7 1188.8 1681.3 1151.3 1679.7 902.0 1678.0 652.6

62 1700.7 1678.2 1610.9 1543.5 1607.6 1402.1 1606.0 1150.0 1604.4 897.9

75 1934.2 1369.9 1929.9 1091.7 1925.6 818.6

71 1810.4 1554.1 1808.7 1282.4 1806.5 1001.7 1804.1 733.0

67 1756.4 1580.0 1698.2 1294.0 1694.5 1181.5 1692.8 918.8 1691.1 656.0

62 1729.1 1709.3 1635.0 1575.8 1605.4 1439.7 1602.9 1172.3 1600.4 904.9

75 1948.1 1412.3 1943.8 1118.8 1940.3 830.6

71 1825.4 1603.8 1823.0 1319.8 1819.9 1023.4 1816.2 740.1

67 1779.1 1647.2 1711.7 1399.3 1707.7 1211.6 1706.0 935.5 1704.3 659.4

62 1757.5 1740.4 1659.2 1608.0 1603.1 1477.3 1599.7 1194.6 1596.3 911.8

75 1962.0 1454.7 1957.8 1145.9 1955.0 842.7

71 1840.5 1653.5 1837.4 1357.3 1833.3 1045.0 1828.3 747.2

67 1801.9 1714.4 1725.3 1504.5 1720.9 1241.8 1719.2 952.3 1717.5 662.8

62 1785.9 1771.5 1683.3 1640.3 1600.8 1514.9 1596.6 1216.8 1592.3 918.8

75 1976.0 1497.1 1971.7 1173.0 1969.7 854.7

71 1855.5 1703.2 1851.7 1394.8 1846.6 1066.6 1840.5 754.2

67 1824.7 1781.7 1738.8 1609.8 1734.1 1272.0 1732.4 969.1 1730.6 666.2

62 1814.3 1802.7 1707.5 1672.6 1598.6 1552.5 1593.4 1239.1 1588.2 925.7

92.0°F 86.0°F 80.0°F 74.0°F 68.0°F

TMBH SMBH TMBH SMBH TMBH SMBH TMBH SMBH TMBH SMBH

OUTDOOR AMBIENT TEMPERATURE 95.0°F

ENTERING DRY BULB TEMPERATURE

30

TEMPMASTER

Page 31

TABLE 8 – COOLING PERFORMANCE DATA* – 130 TON MODEL (CONT’D)

AIR ENTERING

EVAPORATOR

COIL

CFM

32000

34500

37000

39500

42000

44500

47000

49500

52000

* Rated performance is at sea level. Cooling capacities are gross cooling capacity.

WET

BULB (°F)

75 1744.6 1118.6 1743.0 918.9 1735.1 720.3

71 1631.7 1255.2 1628.8 1056.5 1629.7 858.9 1627.5 659.8

67 1530.6 1392.3 1524.5 1193.1 1523.4 989.0 1521.9 795.1 1520.4 601.2

62 1488.4 1456.1 1417.7 1324.8 1399.8 1155.2 1398.9 963.1 1398.0 771.0

75 1765.1 1162.5 1762.1 946.8 1755.4 733.4

71 1651.8 1309.5 1649.1 1095.4 1649.4 881.1 1646.4 667.8

67 1562.8 1430.2 1543.8 1241.1 1542.1 1020.9 1540.5 813.2 1539.0 605.4

62 1525.3 1496.7 1450.2 1367.3 1436.0 1209.7 1434.9 1002.6 1433.8 795.5

75 1785.5 1206.3 1781.2 974.7 1775.6 746.6

71 1672.0 1363.9 1669.4 1134.4 1669.2 903.3 1665.3 675.8

67 1595.0 1468.1 1563.1 1289.2 1560.7 1052.9 1559.2 831.2 1557.6 609.6

62 1562.3 1537.4 1482.6 1409.8 1472.1 1264.1 1470.9 1042.0 1469.6 819.9

75 1805.9 1250.1 1800.4 1002.6 1795.9 759.8

71 1692.1 1418.2 1689.7 1173.4 1688.9 925.6 1684.1 683.9

67 1627.2 1506.0 1582.3 1337.3 1579.4 1084.8 1577.8 849.3 1576.2 613.8

62 1599.3 1578.1 1515.1 1452.2 1508.3 1318.5 1506.9 1081.4 1505.5 844.3

75 1826.3 1293.9 1819.5 1030.5 1816.2 772.9

71 1712.3 1472.5 1710.0 1212.3 1708.7 947.8 1703.0 691.9

67 1659.4 1544.0 1601.6 1385.3 1598.0 1116.7 1596.4 867.4 1594.8 618.0

62 1636.3 1618.7 1547.5 1494.7 1544.4 1373.0 1542.9 1120.9 1541.3 868.8

75 1841.9 1337.3 1830.8 1057.1 1829.3 784.8

71 1733.2 1520.4 1721.4 1249.1 1719.2 968.7 1713.9 698.9

67 1687.0 1594.4 1612.3 1432.1 1608.3 1146.1 1606.8 883.4 1605.3 620.8

62 1668.9 1654.2 1569.2 1525.2 1540.9 1406.6 1538.9 1141.3 1537.0 876.0

75 1857.6 1380.7 1842.2 1083.7 1842.3 796.6

71 1754.1 1568.2 1732.7 1286.0 1729.7 989.6 1724.8 705.9

67 1714.6 1644.9 1623.1 1478.8 1618.6 1175.5 1617.2 899.5 1615.8 623.6

62 1701.4 1689.7 1590.9 1555.8 1537.5 1440.2 1535.0 1161.7 1532.6 883.3

75 1873.3 1424.1 1853.6 1110.3 1855.3 808.5

71 1775.0 1616.1 1744.1 1322.8 1740.2 1010.6 1735.7 712.9

67 1742.2 1695.3 1633.8 1525.6 1628.9 1204.9 1627.5 915.6 1626.2 626.3

62 1733.9 1725.2 1612.6 1586.3 1534.0 1473.9 1531.1 1182.2 1528.2 890.5

75 1889.0 1467.5 1865.0 1136.9 1868.4 820.4

71 1795.9 1664.0 1755.4 1359.6 1750.7 1031.5 1746.6 719.9

67 1769.8 1745.8 1644.5 1572.3 1639.1 1234.2 1637.9 931.7 1636.7 629.1

62 1766.5 1760.6 1634.2 1616.8 1530.5 1507.5 1527.2 1202.6 1523.9 897.7

92.0°F 86.0°F 80.0°F 74.0°F 68.0°F

TMBH SMBH TMBH SMBH TMBH SMBH TMBH SMBH TMBH SMBH

OUTDOOR AMBIENT TEMPERATURE 105.0°F

ENTERING DRY BULB TEMPERATURE

FORM TPM3-EG1 (518)

TEMPMASTER

31

Page 32

FORM TPM3-EG1 (518)

Cooling Performance Data (Cont'd)