Page 1

HWP 35, 47, 58

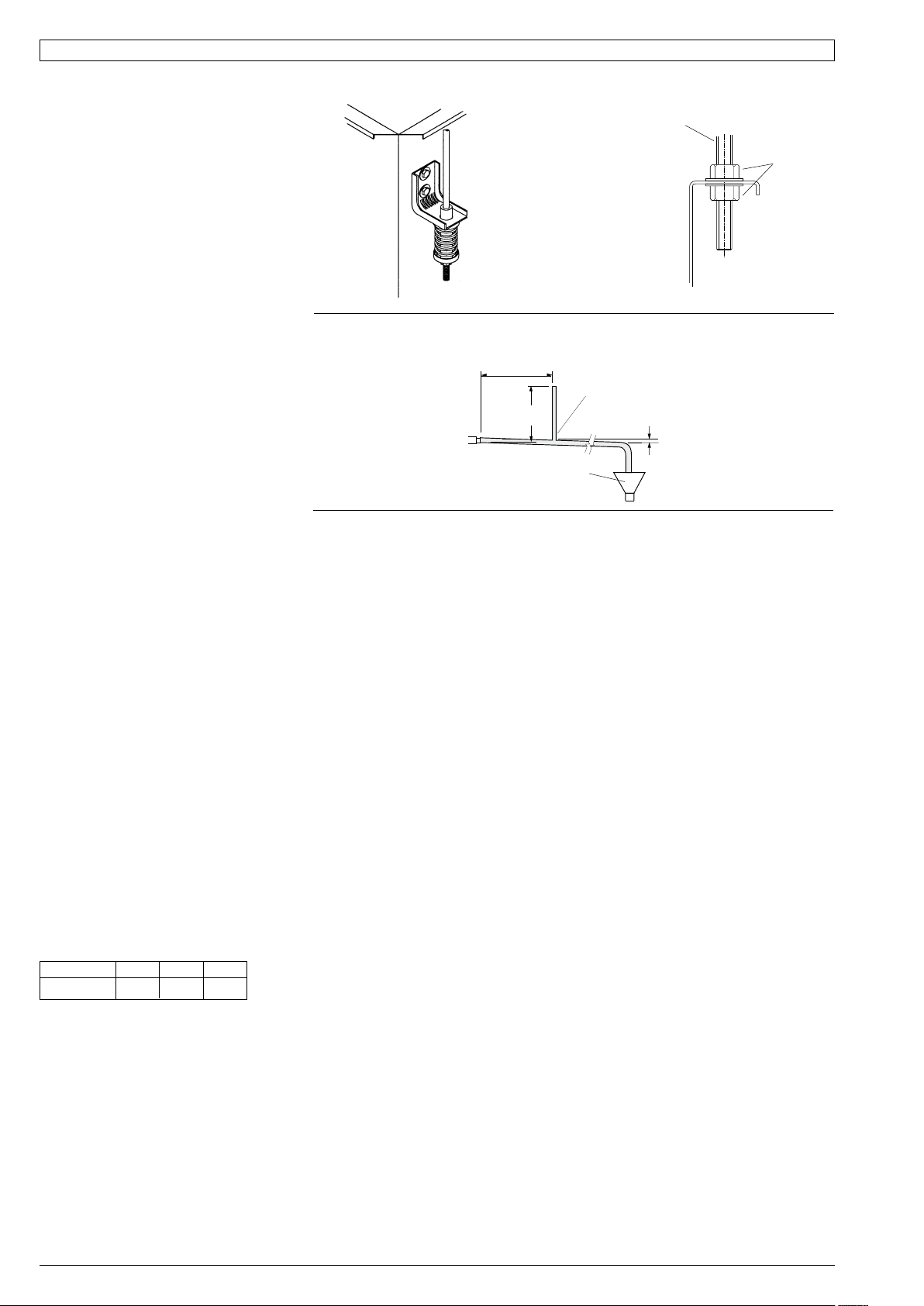

440

HANGING

CENTRES

SLOPING

DRAIN TRAY

355

OVERALL

472

OPTIONAL

SPRING MTG

CENTRES

F

OPTIONAL

SPRING MOUNTING CENTRES

C

55

75

D

COIL

150

OPTIONAL

R/A FILTER BOX WITH

FILTER ACCESS

EACH SIDE

OPTIONAL

FILTER BOX

G

(HEIGHT = 257)

IN

OUT

(WATER)

55

685

OVERALL

40

PROJECTION

Nomenclature

Ducted Water Cooled R410A

Packaged Air Conditioner

Fig. 1 Nomenclature

e.g.

H

Series Size Type

H - Hideaway

W - Water Sourced

P - Packaged

Fig. 2 Dimensions (mm)

HANGING CENTRES

20 X 9 SLOTS

257

DRAIN 19 OD

MODEL A B C D E F G

HWP 35 845 477 40 105 825 900 480

HWP 47 845 477 40 105 825 900 480

HWP 58 1110 742 45 90 1090 1165 745

OVERALL

B

SUPPLY AIR SPIGOT

E

A

Divide by 10

to get approx.

nominal

Capacity in

kilowatts

ELECTRICAL

BOX

CW P 3 5 K

C - Cooling only

CE - Cooling only with electric heat

R - Reverse cycle

K - Refrigerant R410A

S - Single phase power supply

T - Three phase power supply

D - Integrated Thermostat

N - Protection board

S D

ELECTRICAL

CONDUIT HOLES

WATER CONN'S:

TWO BSP MALE

13 mm (1/2")

ACCESS

PANEL

Not to Scale

Net Weight

HWP 35 57 kg

HWP 47 58 kg

HWP 58 75 kg

Installation &

Maintenance

GENERAL

HWP - A general designation which

applies to all versions (refer fig.1)

These HWP units must be installed in

accordance with all national and local safety

codes.

OPTIONS

The following items are available as optional

extras:

1. Condensate Lift-Pump Kit.

2. Filter Box.

High pressure hoses (600 mm long) c/w

fitting and spring mounts are supplied as

standard.

AIR FILTRATION / FILTER BOX (Option)

As air filtration requirements vary, filters are

not supplied with the unit. Filters should

ideally be installed on the return air side of

the unit, no closer than 500 mm from the

back of the unit and easily accessible for

cleaning. To maximise the efficiency of air

flow, the return air filter should be twice the

area of the HWP unit's return air spigot/s. If

efficiency is less of a concern a Filter Box is

available.

The Filter Box is installed by unscrewing

the return air spigot and replacing it with the

Filter Box's filter-integrated spigot. The filter

may be accessed from either side of this

spigot. This box adds 90 mm to the overall

depth of the unit.

INSTALLATION

Positioning & Mounting

HWP units are designed to be used with

simple, short duct layouts. Units should

be located as close to the space to be air

conditioned as acoustic criteria allows; refer

to Fig. 6 for application considerations.

When determining the position of the air

conditioner, allow adequate space around

the unit to facilitate future servicing and

maintenance. Ensure there is enough

working space in front of the electrical

access panel. Allow adequate clearance for

the filter (optional) to be withdrawn to its full

length.

It is recommended that the unit be

mounted using the spring mount system

supplied (Fig.3). This system minimises

transfer of vibration into the building

structure.

If a more rigid installation can be tolerated,

then suspend the unit from four threaded

rods using locknuts (not supplied), as shown

in Fig. 4.

1

Page 2

Mount the unit level as it comes with a

sloping drain tray. This tray is reversible

– but not if using the optional condensate

lift-pump; then the drain exit can only be at

the opposite end to the compressor.

The drain line must have a slope of at least

1 in 50 and must not be piped to a level

above the drain tray. Where required a

condensate lift-pump should be used

(optional extra).

When finally positioned, tighten the lock

nuts on the mounting rods to give a firm

installation (see Fig. 4).

Condensate Drain

The condensate drain is not to be trapped

outside the unit. The drain line must be

maintained at least 19 mm ID along its

full length. Fit a vent pipe within 500 mm

of the unit, 300 mm high and 10 mm

ID (minimum); see Fig. 5. Check drain

by pouring water into the drain tray and

ensuring that it clears. Failure to adhere to

these instructions could cause flooding.

Water Supply & Return

The HWP unit's IN and OUT water

connections are male pipe threaded (refer

Fig. 1). The two temperzone 600 mm

flexible high pressure water hoses supplied

have female pipe threaded connections at

each end. Maximum water pressure for

each hose is 1720 kPa (250 psi). The HWP

unit alone, excluding hoses, will withstand

4480 kPa (650 psi).

Poor quality water supply must be prefiltered and it is essential that adequate

water treatment is maintained, particularly

where open cooling towers are used.

Note: It is required that the water supply

system be fitted with a water flow switch and

water pump safety interlock. These items

prevent the HWP units from going into fail

safe lockout status due to a loss of water

flow. Failure to install the above items would

require the resetting of all HWP units in the

system - either by breaking the power supply

to each unit or breaking the thermostat

control circuit.

HWPSR units require a minimum water

supply temperature of 17°C.

Circuit Balancing Valve

It is recommended that a circuit balancing

valve be fitted to maintain water flow at a

constant rate. The minimum water flow rates

in litres per second (l/s) are as follows:

HWP: 35 47 58

Minimium 0.17 0.27 0.36

Electrical

The air conditioner should be connected

to the appropriate power supply for each

model, as specified in the wiring diagram,

with neutral and adequate earth. The supply

to have an accessible switch to allow

isolation of the unit. Wire the heating and

cooling room thermostat to the electrical

terminals adhering to the wiring diagram

supplied with the unit. All wiring to the air

conditioner must comply with the wiring

regulations of the local electrical authority.

Air / Water Flow

Refer to HWP 35–58 Data Sheet pamphlets

for detailed information on air handling

performance and water flow rates.

2

Fig. 3 Spring Mounting

PREFERRED

MOUNTING

SYSTEM

(SUPPLIED)

Fig. 5 Condensate Drain

500 mm MAX.

FROM UNIT

300 mm

APPROX.

NO TRAP

REQUIRED

Unit Protection

Unit protection is incorporated in either:

a.) HWP Protection Board, or

b.) SAT-2 Controller,

depending on which HWP model is being

installed.

A pump verification relay ensures that water

is flowing before the compressor will start.

A high pressure lockout protects the unit

from low water flow in cooling mode, or fan

failure in heating mode. Sensors protect

against low air coil temperature and loss of

refrigerant. Units include an anti rapid cycle

device for compressor protection.

HWPSR units also have a low refrigerant

temp. safety thermostat to protect against

icing up of the water within the unit's tube-intube heat exchanger.

A non-specific fault LED/ output signal is

also included for remote fault indication to

building management systems (refer wiring).

Note: Lockout protection can be reset by

switching unit's power supply off and on.

Lockout protection will also reset when the

thermostat switches, or is switched to the

dead zone.

Units Supplied With SAT-2 Thermostat

Any faults detected are displayed on the

SAT-2 Wall plaque (refer Table 1). A nonspecific fault output signal is also included on

SAT-2 Controllers for remote fault indication

to building management systems.

Units Supplied With Electric Heat

HWPSCEKS models supplied with electric

heat include both auto (90°C) and manual

(120°C) high temp. safety thermostats. If the

manual safety t/stat requires resetting, then

the auto safety t/stat has failed and needs to

be replaced.

Fig. 4 Solid Mounting

MOUNTING

ROD

VENT PIPE (10 ID)

FOR LONG

CONDENSATE

DRAIN RUNS

MINIMUM

SLOPE

20 mm PER m

OPEN

DRAIN

(1 IN 50)

Room Thermostat

(Reverse Cycle Models)

The thermostat should be set within the

recommended operating range of between

19°C and 30°C. The thermostat should

not be used as an on-off switch. Refer to

temperzone for a list of other approved

thermostats.

If your unit is supplied with temperzone's

SAT-2 Thermostat, refer to page 3 for

installation instructions.

COMMISSIONING

1. Check that the thermostat is correctly

wired and set at the desired temperature.

2. Check that the air filter (if fitted) is clean.

3. Check that the fan runs freely without

vibration.

4. Check condensate drain and safety drain

tray for free drainage.

Demonstrate the SAT-2 Wall Control (if

supplied) to the owner/user, after having

first thoroughly familiarised yourself with the

User's Operating Instructions. This page is to

remain with the owner/user.

MAINTENANCE

Quarterly

1. Remove lint and dust accumulation from

heat exchange air coil. (Note: failure to

do this may affect efficiency).

2. Check air filters and vacuum or wash

clean as necessary.

3. Check condensate drain for free

drainage.

4. Check compressor compartment for oil

stains indicating refrigerant leaks.

5. Check quality of water supply.

Six Monthly

Check tightness of electrical connections.

Yearly

1. Remove lint and dust accumulation from

heat exchange air coil. (Note: failure to

do this may affect efficiency).

2. Replace air filter if damaged to maintain

adequate air flow and efficiency.

TIGHTEN

LOCKNUTS

FOR

STRENGTH

Page 3

Units Supplied With Integrated Thermostat (SAT-2 Controller)

Components

The following components are supplied in a

box taped inside the supply air spigot:

1. SAT-2 Wall Control plaque, including wall

mounting plate.

2. 10 m interface lead (electrical box-toplaque).

3. User's Operating Instructions booklet.

4. Lithium CR2032 battery (3V).

Optional

1. Remote return air sensor (in box).

2. Remote return air temperature sensor

lead; 1.5, 6, 12 or 25 m.

3. 20 m extended interface lead

(electrical box-to-plaque).

4. SAT-2 Zone Control PCB.

5. Zone Control 24V transformer.

6. Additional SAT-2 Wall Control plaque.

7. Infra red remote control.

Installation

The SAT-2 Controller PCB is supplied preinstalled in the HWP unit's electrical box.

1. Isolate the HWP unit from power supply,

then remove electrical box cover.

2. Remove the SAT-2 box supplied taped

inside the supply air spigot.

3. Remove the Wall Control's interface lead

from this box and connect to the terminal

block (A1/B1/Vcc/GND) on the SAT-2

Controller board. Trace the remaining

length of the lead to the Wall Control's

intended location. Note: Make sure the

coloured wires are connected as per the

wiring diagram.

4. Remove the Wall Control's backing plate

by using a small screw driver to remove

the single screw at the bottom edge of

the plaque.

5. Install the Lithium battery, supplied loose,

positive (+) side up in the Wall Control's

battery holder.

6. Check the wall where the Wall Control

plaque is to be located is flat before

fastening the wall mounting plate.

Alternatively, the mounting plate can

be screwed to a standard wall socket

mounted horizontally.

Note: Use low profile (mush) headed

screws to prevent contact with the PCB

board. Fixing the plate to a distorted

surface may damage the control.

7. Drill hole in wall to allow cable entry.

8. Connect the interface lead to the the

Wall Control board. Note: Make sure

the coloured wires are consistently

connected at each end as per the wiring

diagram.

9. Ensure the interface lead is run

separately and away from main

power supply wires, including the

interconnecting cable. When installing

cabling, trim any excess length to suit

your location.

10. Fill around the interface lead with foam

or cover hole with PVC tape to prevent

draft from wall cavity affecting control

operation. Do not use aluminium duct tape.

11. Secure the Wall Control body to the

mounting plate by replacing the locking

screw removed earlier.

12.Replace the HWP electrical box cover.

Water Valve Control Option

Once the SAT-2 room thermosat reaches

the desired room temperature, it is capable

of switching off both the HWP unit's

compressor and an external water control

valve (if fitted); refer wiring diagram. This

provides economy of operation by reducing

the load on the central water supply system.

Remote Air Temperature Sensor/s

(option)

The air temperature sensor is by default

located in the Wall plaque. Optional remote

air temperature sensors are available

so that the measurement of the room

temperature can be taken away from the

wall plaque, eg. elsewhere in the room or in

the return air duct.

Remote sensor's can be plugged directly

into the Controller board (PCB). This

board accepts up to four sensors which

are designated as 'zones' one to four. The

first return air sensor will automatically

replace the Wall Control sensor and should

be located in the same room as the Wall

Control. The Controller will always use the

average of the zones selected. Refer to the

separate installation instructions supplied

with the PCB for further details.

Ensure all remote sensor wires are run

separately and away from main power

supply wires, including the interconnecting

cable.

Table 1 SAT-2 Controller - Troubleshooting

If an fault is detected, an 'ERR' symbol will light up on the Wall plaque display.

The following error codes may be displayed:

Error Code Fault Remarks

1 Room sensor #1 failure Main board AD3

2 Room sensor #2 failure Main board AD4

3 Room sensor #3 failure Main board AD5

4 Room sensor #4 failure Main board AD6

5 #1 indoor coil sensor failure Main board AD1

6 #1 LST sensor failure Main board AD2

7 #1 insufficient refrigerant

8 #1 compressor overload

9 #1 low pressure failure

10 #1 high pressure failure

11 Room sensor #5 failure At wallpad B

12 Room sensor #6 failure At wallpad A

13 All room sensor failure

14 Float switch failure

15 #1 Low safety thermostat failure

16 Communication failure

17 Hydronic pump switch failure

18 #2 insufficient refrigerant

19 #2 compressor overload

20 #2 Low safety thermostat failure

21 Discharge sensor 1 failure

22 Discharge sensor 2 failure

23 Discharge temp 1 failure

24 Discharge temp 2 failure

Fault Detection

Any faults detected are displayed on the

SAT-2 Wall plaque (refer Table 1). A nonspecific fault output signal is also included

on SAT-2 Controllers for remote fault

indication to building management systems.

NOTE

The manufacturer reserves the right to

make changes in specifications at any time

without notice or obligation. Certified data is

available on request.

This pamphlet replaces the previous

issue no. 3669 dated 12/12.

CKSD & RKSD wiring rev.'s L & J resp.

3

Page 4

Fig. 6 Application Considerations

Recommendations for Noise Isolation:

1. Avoid installing units, with non-ducted return air, directly above

spaces where noise is critical.

2. Use flexible connections between unit and rigid ducting.

3. Use generously sized acoustically lined ducts.

4. If generous duct size is not possible, use turning vanes on bends

to reduce air turbulence (regenerated noise).

5. Use 90° bends in ducting to significantly assist in noise reduction.

4

Page 5

HWP 35–58 CKSD & CEKSD

5

Page 6

HWP 35–58 RKSD

6

Page 7

HWP 35–58 CKSN & CEKSN

7

Page 8

HWP 35–58 RKSN

01/14 Pamphlet No. 3669

© temperzone ltd 2014

Loading...

Loading...