Temp-Cool TC-18B, TC-12B, TC-60B4, TC-24B, TC-36B Owner's Manual

...

Owner’s Manual

Models: TC-12B - TC-60B4, Digital Thermostat

Unit Specifications .......................................................................................... 2

1-800-836-7432

Warning!

Improper installation, adjustment, alteration, service, or

maintenance can cause injury

or property damage. Please

read instructions before installing, operating or servicing the

TEMP-COOL unit.

Avertissement !

Le fait de modier ou de mal

installer, régler, réparer ou

entretenir cet appareil peut

entraîner des blessures ou des

dommages matériels. On doit

lire attentivement les directives

d’installation, d’utilisation et

d’entretien avant de manipuler

l’unité TEMP-COOL

Rating Information ........................................................................................... 2

Inspection ......................................................................................................... 3

General Description ......................................................................................... 3

Standard Features ..........................................................................................3-4

Optional Features ............................................................................................. 4

Installation Instructions .................................................................................4-5

Unit Operation ..............................................................................................5-6

Preventative Maintenance .............................................................................6-7

Troubleshooting Guide .................................................................................8-9

Installing Replacement Parts ....................................................................10-11

Accessories .................................................................................................... 12

Replacement-Parts List .............................................................................13-14

Wiring Schematic, TC-12B ........................................................................... 15

Wiring Schematic, TC-18B ........................................................................... 16

Wiring Schematic, TC-24B ........................................................................... 17

Wiring Schematic, TC-36B ........................................................................... 18

Wiring Schematic, TC-60B ........................................................................... 19

Wiring Schematic, TC-60B3 ......................................................................... 20

Wiring Schematic, TC-60B4 ......................................................................... 21

This manual is the property

of the owner. Leave with the

unit when set-up and start-up

are complete. TEMP-AIR

Inc. reserves the right to

change design and specications without prior notice.

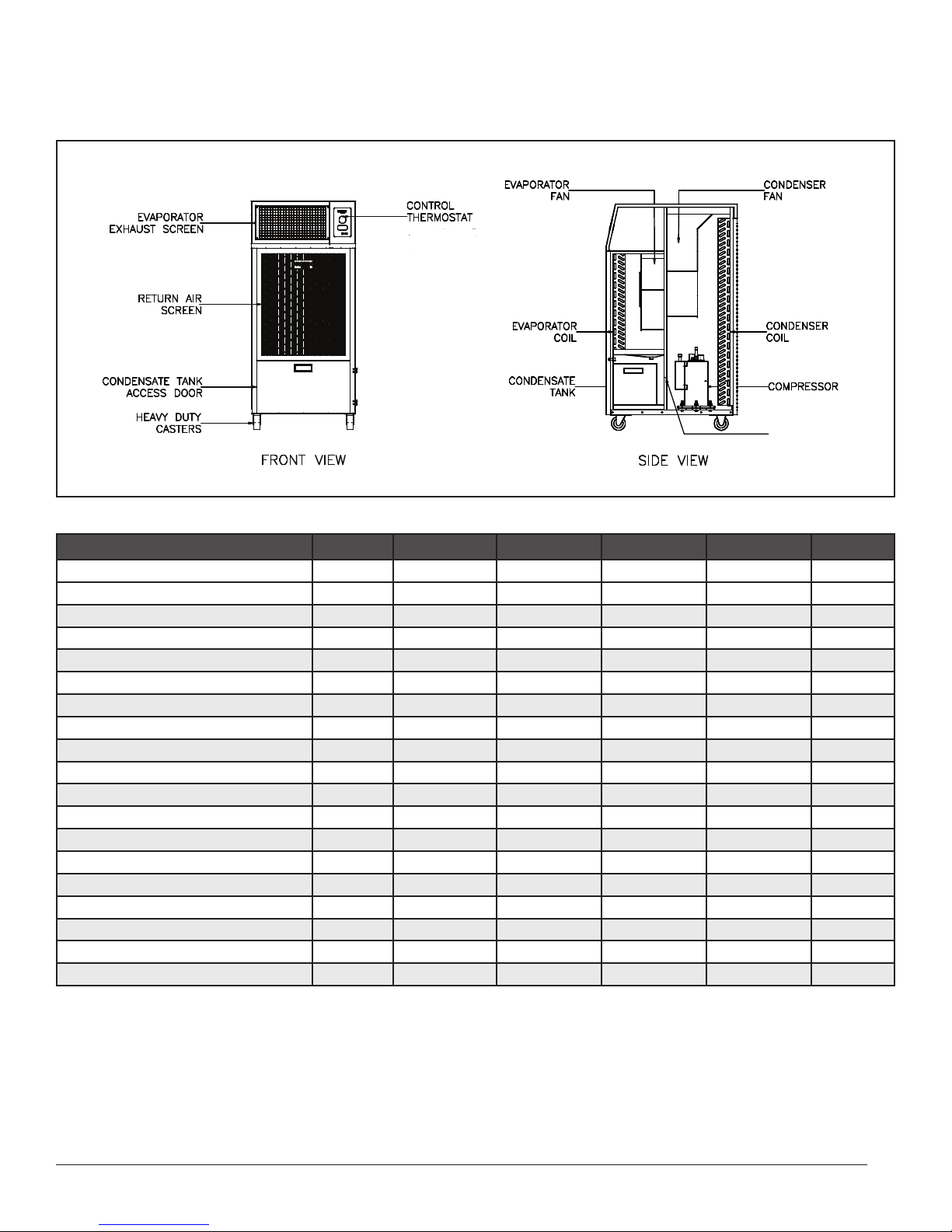

Unit Specications/Rating Information

HIGH PRESSURE

SWITCH

Specifications TC-18B TC-24B TC-36B TC-60B TC-60B3 TC-60B4

Cooling Capacity, BTU/hr

Power Supply2 Volts/Ph/Hz/Amps 115/1/60/15 208-230/1/60/20 208-230/1/60/30 208-230/1/60/60 208-230/3/60/40 460/3/60/20

Thermostat Control Electronic Electronic Electronic Electronic Electronic Electronic

Metering Device TX Valve TX Valve TX Valve TX Valve TX Valve TX Valve

Power Consumption-Cooling, Watts 1,400 3,100 4,500 7,700 8,500 10,000

Current Consumption-Cooling, Amps 12.0 13.5 19.7 33.3 21.4 11.4

Recommended Circuit Amps 15 20 30 60 40 20

Maximum Overcurrent Protective Device, Amps --- --- --- 80 50 25

NEMA Plug Type 5-15P 6-20P 6-30P Wired Wired Wired

Evaporator CFM, Free Discharge 550 750 1,200 2,300 2,300 2,300

Condenser CFM 1,000 1,000 1,500 3,900 3,900 3,900

Maximum ESP, InWC 0.10 0.10 0.10 0.50 0.50 0.50

Maximum Duct Length, ft. 40 40 40 40 40 40

Condensate-Pump Head, ft. 15 15 15 15 15 15

Operating Limits, (min-max) ˚F 65-110 65-105 65-105 65-110 65-110 65-110

Sound Level, dB 61 63 67 71 71 71

R-410-A Charge, oz. 80 80 70 136 136 136

LxWxH, in. 28 x 23 x 47 33 x 26 x 47 30 x 28 x 51 47 x 31 x 64 47 x 31 x 64 47 x 31 x 64

Weight, net wt/shipping wt, lb. 221/279 337/375 336/395 713/775 713/775 713/775

1

17,300 29,600 41,000 75,900 75,900 75,900

1. Rating conditions: 95° F at 60% RH

2. Electrical ratings based on UL 484

TEMP-COOL

™

Owner’s Manual

Portable Cooling Systems

INSPECTION

1. Inspect unit on delivery.

2. Compare unit received with description of product

ordered.

3. Report any damage to the delivery carrier.

4. Request a written inspection report from the Claims

Inspector to substantiate claim.

5. File claims with the delivery carrier.

GENERAL DESCRIPTION

TEMP-COOL Portable Cooling Systems are designed

to spot cool industrial, commercial, institutional and

construction sites. Six models provide from 17,300 to

75,900 BTU/hr. of cooling and from 1740 to 7000 watts

of electric heat. Options include discharge nozzles to

direct conditioned air precisely where needed, and exible duct to transfer condenser hot air either outside or to

an adjacent area.

TEMP-COOL Portable Cooling Systems are completely

self-contained and housed within an insulated cabinet.

The units’ exterior is constructed of galvanized steel and

protected with a tough powder-coated, polyester nish.

All models are equipped with standard heavy-duty casters

for portability.

STANDARD FEATURES

Serviceability

Normal maintenance for the TEMP-COOL Portable

Cooling Systems requires a minimum amount of effort. The two air lters that cover the coils can easily be

inspected and replaced by removing the grilles holding

them. The TC-18B through the TC-36B have an internal

condensate tank that must be emptied when full. The tank

is in a rollout drawer mounted on ball bearing drawer

slides. The large TC-60B units have an integral condensate pump, with a condensate tube that must be run to a

drain or container.

All of the other components, which are normally

accessed for troubleshooting or replacement, can be

accessed by removing the side panels or top cover. The

electrical control panels can readily be accessed from the

exterior of the unit through access doors. On the TC-18B

through TC-36B the high head pressure reset switch can

be accessed by opening the condensate tank drawer and

pressing the button located on the back wall of the enclosure. On the TC-60B units the reset button is located

in the cord pocket enclosure, which is accessible from

outside the unit.

High-Pressure Safety Switch

All models feature a manual reset, high-pressure switch.

If the refrigeration circuit exceeds the controls pressure

setting, power to the compressor and other critical components is cutoff to prevent damage to the unit.

Note: Determine the reason for the the trip and correct

the problem before resetting the switch (See the

troubleshooting section for suggestions. Wait four

minutes before attempting to reset.)

Digital Temperature Control System

The digital temperature control system allows the user

to select Cooling or Fan Only operating modes. It also

allows the unit to be started or stopped after a predetermined period. The control also has internal functions

that prevent the cooling coil from freezing, prevent the

compressor from cycling excessively and provide a

heating element cool down function when in the heating

mode. See the section covering the operation of the unit for

additional information on the Digital Temperature Control.

Filters

All units are equipped with removable, disposable,

pleated media lters. Located behind the return air and

condenser intake air grilles, they can be removed for

inspection or replacement by removing the grille.

Condensate Tank

The TC-18B through TC-36B are furnished with a ve

gallon, polyethylene condensate tank located in the

drawer on the lower front of the unit. The tank collects

the moisture that condenses on the cooling coil when the

unit is in operation. When full, a magnetic oat in the

tank closes a magnetic proximity switch located above

the tank inside the unit, turning the unit off and causing

“tF” to be displayed on the front panel of the unit. The

condensate tank must be emptied and reinstalled to allow

further operation.

Note: The unit will not operate unless the tank is

drained periodically. Optional condensate pumps

are available that allow continuous operation,

but require a tube to be run from the pump to a

suitable drain.

3

Condensate Pump

G

X

W

Y

G

G

G

G

X

W

Y

G

G

Due to the large amount of condensate produced by the

TC-60B models, condensate tanks are not furnished or

available on these units. Condensate pumps are furnished

as standard on the TC-60B models, and must be piped to

a suitable drain.

Cord Kit (LCDI) (TC-18B, 24B, 36B)

The LCDI cord kit provides both personal shock as well

as cord arcing and re protection. The LCDI cord kit is

preinstalled and must be replaced with an identical cord

kit, available from Temp-Air, Inc., if damaged or if it fails

to operate properly.

INSTALLATION INSTRUCTIONS:

Before Installing:

Check unit for damage. Air conditioners are inspected at

the factory. If any damage has occurred, save the packaging and le a claim with the delivering carrier within fteen working days. TEMP-COOL units require minimal

installation. The smaller units (TC-18B though TC-36B)

can be plugged into the proper receptacle, and are ready

to run immediately. The larger TC-60B units must be

wired to a plug or power source, and the condensate hose

run to a suitable drain or outdoor location before starting

the unit.

OPTIONAL FEATURES:

See “Accessory” section on page 12 for the correct

accessory part numbers.

Condenser Duct:

Condenser discharge air can be removed from the con-

ditioned space with exible duct. Use 40 feet maximum

for all models. Allow six feet for every 90˚ bend. Do not

exceed 0.10 in. w.c. external static pressure at the condenser.

Ceiling Panel Duct Kit:

A ceiling panel duct kit comes complete with exible

duct and a 2 foot by 2 foot ceiling tile adapter, which allows condenser air to be vented to the plenum area above

a suspended ceiling.

Discharge Nozzle Kit:

A dual-nozzle, discharge air assembly optimizes the abil-

ity to direct cool air precisely where needed. The exible

nozzles are attached to a mounting plate that ts over the

evaporator air grille.

Condensate Pump:

A condensate pump automatically drains from the

condensate pan by removing evaporator coil condensate

water allowing continuous operation. The pump must be

connected to the condensate drain and to the air conditioner’s power supply. A hose must be run from the unit

to a convenient drain or outdoor location.

Condensate pumps are standard on the TC-60B models

and optional on all others.

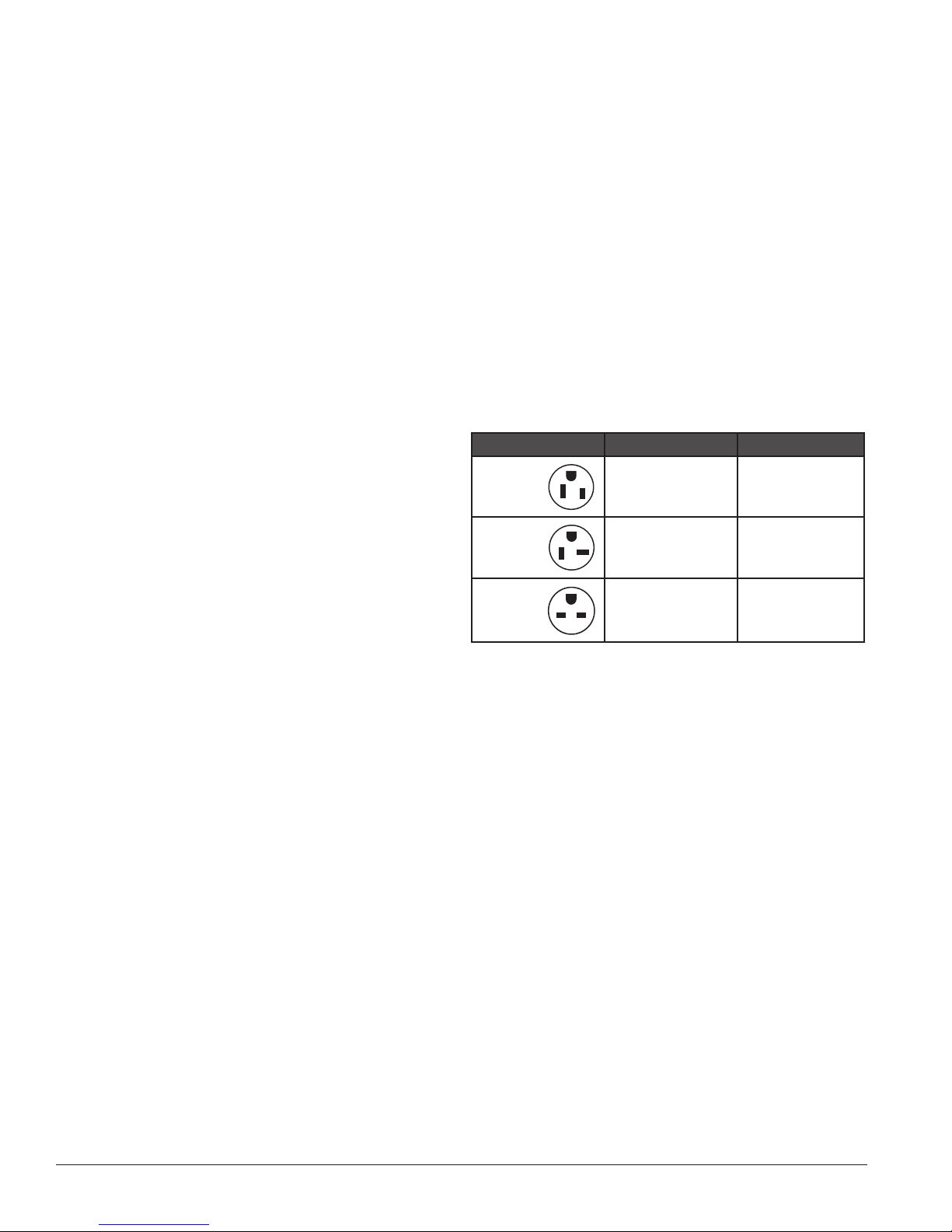

Model Plug Configuration Receptacle

TC-18B

115V

TC-24B

208-230V

TC-36B

208-230V

W

G

X

G

G

15A/115V

NEMA 5-15P

20A/230V

NEMA 6-20P

30A/230V

NEMA 6-30P

NEMA 5-15P

NEMA 6-20P

NEMA 6-30P

Electrical Supply:

Determine the proper power by checking the unit’s rating plate. For the models from the TC-18B through the

TC-36B use the wall outlets and receptacles shown in the

table above. For the TC-60B, B3 and B4, the units must

be wired to a suitable power supply using the appropriate

cord and circuit protection for the electrical ratings on the

nameplate.

Operating the units at an improper voltage, frequency, or

improper phase orientation (see TC-60B3 and 4 – 3 Phase

Wiring Instructions below) voids the warranty.

Note: Extension cords may be used if rated at a

minimum of 120VAC at 20 amps for the model

TC-18B, 230VAC at 20 amps for the model

TC-24B, and 230VAC at 30 amps for the model

TC-36B. All extension cords must have a

functional grounding connector and t the LCDI

cord supplied with the unit.

Extension cords cannot be used on the TC-60B

models.

TEMP-COOL

™

Owner’s Manual

Portable Cooling Systems

TIMER SLEEP

HOUR TEMP

HOUR TEMP

MODE

COOL

FAN

TC-60B3 and B4 – 3 Phase Wiring Instructions:

Only qualied personnel should install TC-60B units.

Extra care is required on the three phase units, the TC60B3 and TC-60B4, to insure they are connected in phase

with the incoming power. If the unit is not in phase the

condenser fan and compressor operate in reverse and

damage the compressor. If the unit is not in phase with

the power supply, the compressor will make more noise

than normal and the condenser fan will deliver very

little air. The evaporator fan can not be used to check the

phase. It has a single phase motor that operates in the correct direction regardless of the phase sequence.

or outside location. Do not crimp or bend the tubing,

or place it where something might be set on the

tubing restricting its ow. No portion of the

discharge tube should be more than 10 feet above the

level of the pump.

5. Attach any required accessories and ductwork.

6. Plug in or wire the unit to an acceptable power source.

7. When power is applied 06 should appear briey on

the control display and disappear. The unit is now

ready for use.

Cooling Operation:

1. Press the POWER BUTTON to start the unit. The

evaporator (cooling) fan will start and the current

space temperature will be shown on the digital

display. The unit will start in the last mode used.

2. Select the Cooling mode by using the MODE button

to step through the three available modes (Cool, Heat

and Fan) until the cooling mode indicator light comes

on. The unit is now in the cooling mode.

If the wiring phase sequence is incorrect, reversing any

two of the three incoming power leads will solve the

problem.

UNIT OPERATION:

Placing the Unit:

1. Locate the unit on a at, level service.

2. Keep entering and leaving air openings free of

obstructions. Maintain at least 18” of clearance

between air inlet or outlet and any wall or other

obstruction.

3. For a unit with a condensate tank, check the tank

to make sure it is in place and empty.

4. For a unit with condensate pump, make sure the

condensate discharge tubing is connected to the outlet

connection of the unit and runs to a suitable drain

3. Press the Up or Down temperature button to see the

current cooling setpoint temperature. Adjust the

setpoint temperature to the desired value by pressing

the Up or Down temperature button repeatedly, until

the desired temperature is reached. The display will

ash six times at the new setpoint then the actual

room temperature will be displayed. In the cooling

mode up to ve minutes may lapse between turning

the unit on or resetting the temperature and the

compressor starting. This delay is a result of the anti

short cycling program in the thermostat. A green dot

will appear in the lower right hand corner of the

temperature display when the compressor is being

energized.

4. The compressor and condenser fan will continue

to operate until the space temperature drops to the

setpoint temperature. At that point the compressor

and condenser fan will shut off, but the evaporator

fan will continue to run until the unit is turned off.

Fan Operation:

1. Press the POWER BUTTON to start the unit. The

evaporator (cooling) fan will start and the current

space temperature will be shown on the digital

display. The unit will start in last mode used.

2. Select the Fan mode using the MODE button to step

5

through the two available modes (Cool and

Fan) until the fan mode indicator light comes on. The

unit is now in the Fan mode.

3. Pressing the Up or Down temperature buttons has no

effect on the temperature display, since neither the

cooling nor heating functions are active. The tempera-

ture display displays the current room temperature.

4. To stop the fan, turn the unit off using the power

button.

OTHER FUNCTIONS:

PREVENTIVE MAINTENANCE:

TEMP-COOL air-conditioning units provide high performance and reliability with a minimum amount of maintenance. To prolong the life of the unit and insure a high

level of performance, perform regular maintenance as

described below.

The refrigeration and electrical circuits of the

systemshouldbeservicedbyqualiedtechnicians

only. Always disconnect the unit from its

power supply when performing any form of service

requiring the removal of grilles or panels.

Timer ON/OFF:

Use the following instructions to turn the unit ON or OFF

after a period of up to 15 hours.

1. To turn the unit ON after a preset period press the

TIMER button, while the unit is OFF. The display

will ash ve times showing the current delay time in

hours. If a different time delay is required press the

Up or Down Hour buttons until the desired delay time

is displayed. This number can be any whole number

between 1 and 15 hours. When the desired value is

displayed release the key. The selected value will

ash ve times and go blank, but the TIMER light

will remain on. The unit will start in whatever mode

it was in before the timer was set after the specied

delay time. Once set, the timer function can be

cancelled by pressing the TIMER button again.

2. To turn the unit OFF after a delay follow the same

procedure as turning the unit ON after a delay except

start by pressing the TIMER button when the unit is

running. The display will ash the OFF delay time

ve times, then the display will revert back to the

normal temperature display. The timer light will be

on when the OFF delay is active. The delay can be

canceled by pressing the TIMER or turning the

unit OFF.

Sleep:

Press the SLEEP button to raise the setpoint temperature

1˚F when in the cooling mode one hour after the button is

pressed. The unit will run in this mode until it is canceled

by pressing the SLEEP button again or turning the unit

OFF.

Filters:

Dirty lters can restrict airow causing the unit to operate with a reduced efciency. Inspect the lters every six

weeks or more frequently, when operating in a dirty en-

vironment. Replace the lters when dirty with an equivalent lter. Do not attempt to clean the lters or operate

the unit without lters. On the TC-18B through TC-36B,

the lters can be removed by snapping the return air and

condenser air grilles out of the unit by pulling on the

handle at the bottom of the grille. The bottom of the grille

will snap out and the grille can be lowered a few inches

to clear the retaining tabs at the top. The lters are held

in place with plastic clips that can be rotated clear of the

lter. Reverse the procedure for replacing the lters. Pay

attention to the proper direction of air ow indicated on

the new lter.

The TC-60B lters are accessed the same as the smaller

units except the snap-in clamps have been replaced

with screws at the bottom of the grilles that have to be

removed before the grille can be detached. Additional

retainer clips are not used on the larger units. The grille

acts as the lter retainer.

Coil Cleaning:

If the coil becomes dirty it can be cleaned using a vacuum followed by compressed air. Vacuum the face of the

coil where the air enters the coil. Most of the dirt will

be on this side. Use compressed air to blow any remaining dirt out. Work from back to prevent driving the dirt

further into the coil. Keeping clean air lters in place will

greatly reduce the frequency that coils must be cleaned.

Blowers and Blower Motors:

There is nothing that can be serviced on these components other than inspecting the blowers and blower motors to insure they are clean. The blower and motor bear-

TEMP-COOL

™

Owner’s Manual

ings are lubricated and sealed at the factory, and require

no additional lubrication. Dirt on the blower wheels can

be cleaned off with a rag. Dirt should not be a problem if

the air lters are properly maintained and kept in place.

Belt Tension, (TC-60B, 60B3, 60B4 Models only)

The condenser fan on the TC-60B series of air conditioners uses the only blower/motor combination that incorporates V-belts drives. The condition of the belt, along

with its tension and alignment should be checked at least

once a year for proper operation. Replace the belt if it has

cracked or is glazed. Adjust the belt tension for a 3/16”

deection of the belt with 2 pounds of force applied at the

center of the free span.

Sheave Adjustment,

(TC-60B, 60B3, 60B4 Models only)

The condenser fan on the TC-60B series of air conditioners utilizes an adjustable sheave on the motor to drive

the blower. The sheave is preset at the factory and should

not be adjusted. However the blower, motor and drives

should periodically be checked for tightness and alignment. Check the setscrews that connect the sheaves and

blower wheel to the shafts to make sure they are secure.

Make sure the setscrews locking down the adjustable

ange on the motor sheave are secure.

Portable Cooling Systems

The factory setting for the drive on the condenser fan

motor is 4 and turns open from the closed position.

7

Loading...

Loading...