Tempco TEC-9300 Instruction Manual

Instruction Manual

TEC-9300

Self-Tune Fuzzy / PID Process

Temperature Controller

Serving Industry Since 1972

Agency Approvals: RoHS

TEMPCO Electric Heater Corporation

607 N. Central Avenue • Wood Dale, IL 60191-1452 USA

Tel: 630-350-2252 • Toll Free: 800-323-6859

Fax: 630-350-0232 • E-mail: info@tempco.com

Web: www.tempco.com

Manual TEC-9300 Revision 9/2016

NOTES

Warning Symbol

This symbol calls attention to an operating procedure, practice, or

the like which, if not correctly performed or adhered to, could

result in personal injury or damage to or destruction of part or all

of the product and system. Do not proceed beyond a warning symbol until the indicated conditions are fully understood and met.

Using the Manual

Installers . . . . . . . . . . . . . . . . . . . . . . . . . . . Read Chapters 1, 2

Basic Function User . . . . . . . . . . . . . . . . Read Chapters 1, 3, 5

Enhanced Function User . . . . . . . . . . Read Chapters 1, 3, 4, 5

System Designer . . . . . . . . . . . . . . . . . . . . . Read All Chapters

Expert User . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Read Page 8

CONTENTS

Chapter 1 - Overview

1-1 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1-2 Hardware Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-3 Programming Port and DIP Switch . . . . . . . . . . . . . . . 3

1-4 Keys and Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1-5 Menu Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1-6 System Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1-7 Parameter Description . . . . . . . . . . . . . . . . . . . . . . . . . 8

Page No

Chapter 2 - Installation

2-1 Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2-2 Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2-3 Wiring Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2-4 Power Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2-5 Sensor Installation Guidelines . . . . . . . . . . . . . . . . . . . 16

2-6 Thermocouple Input Wiring . . . . . . . . . . . . . . . . . . . . 16

2-7 RTD Input Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2-8 Linear DC Input Wiring . . . . . . . . . . . . . . . . . . . . . . . 17

2-9 CT/Heater Current Input Wiring . . . . . . . . . . . . . . . . . 18

2-10 Event Input wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

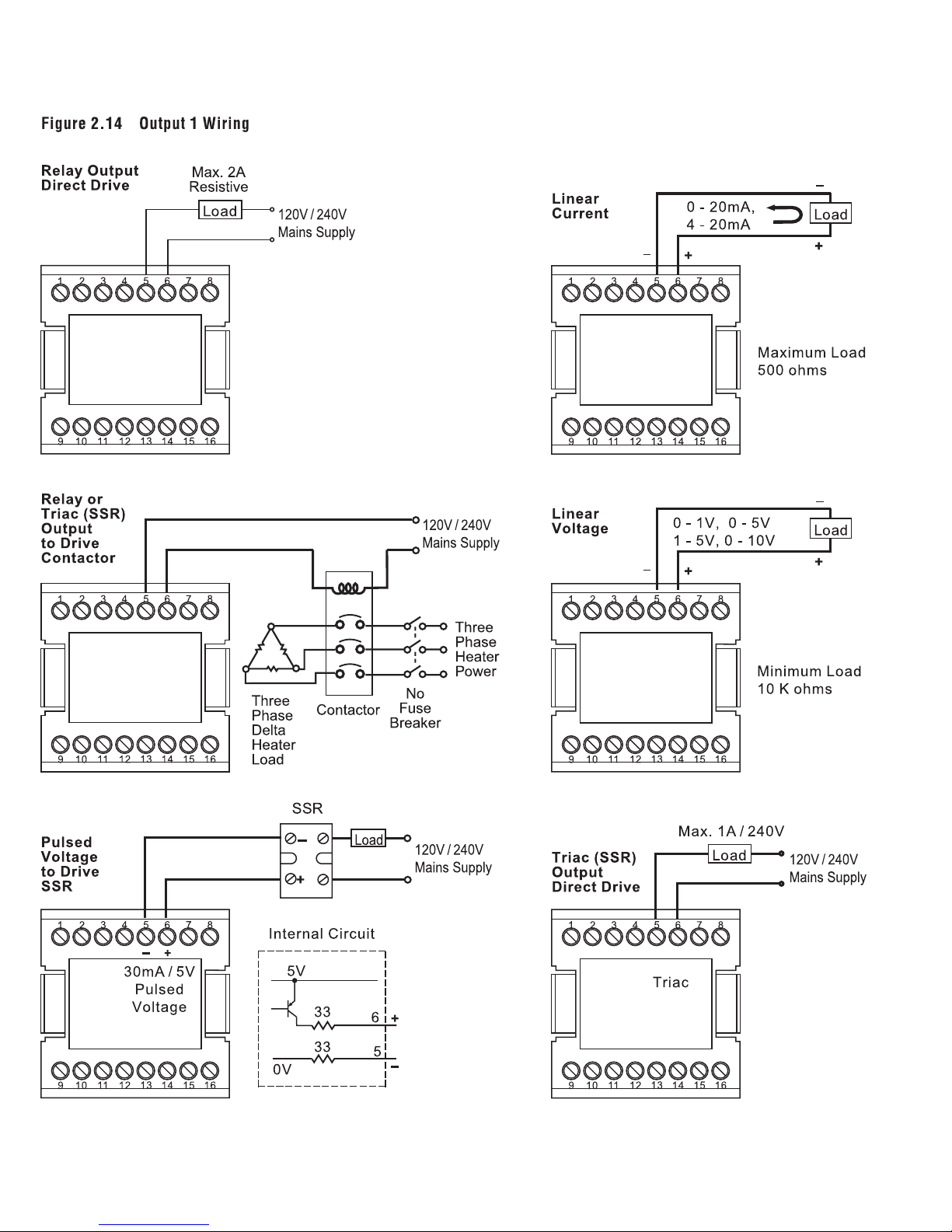

2-11 Output 1 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

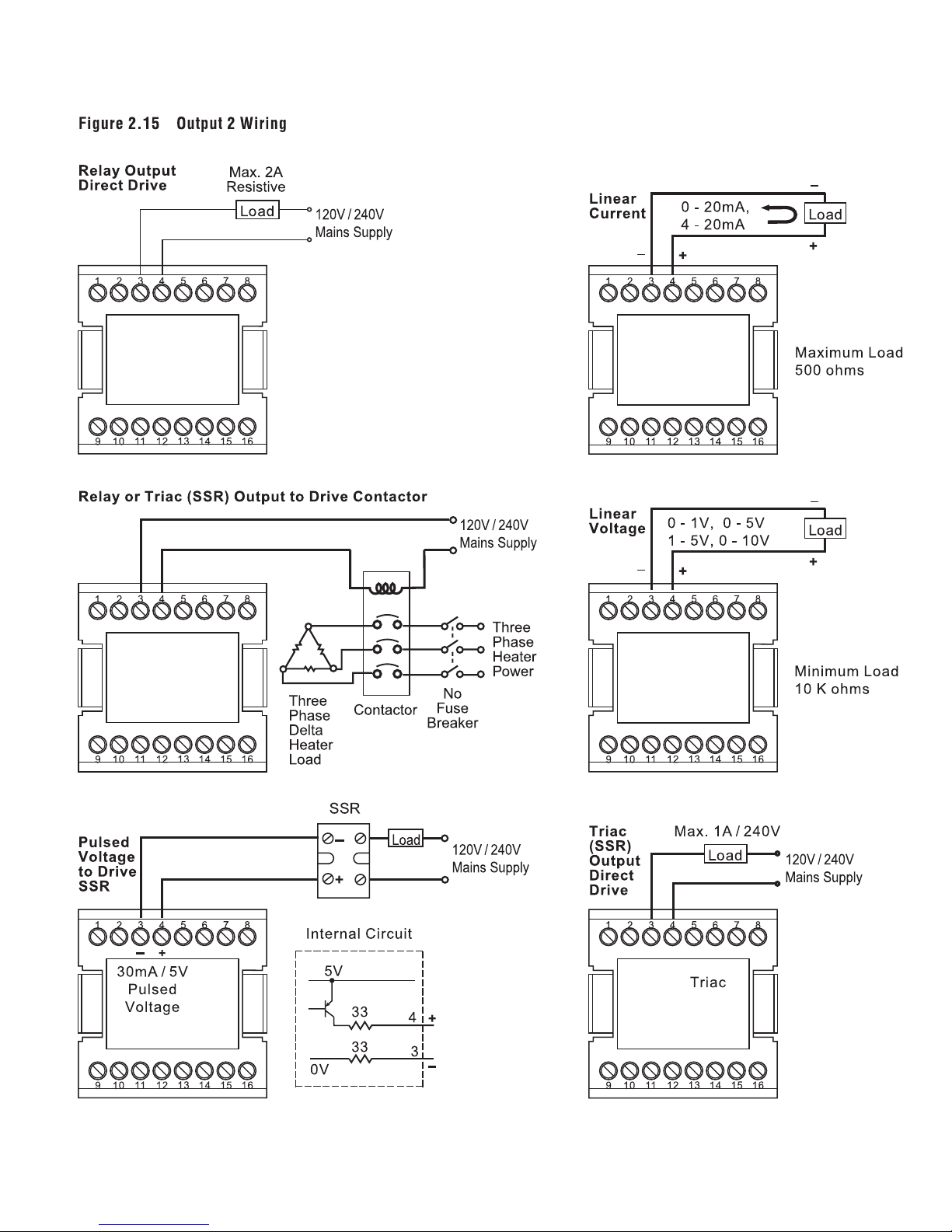

2-12 Output 2 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

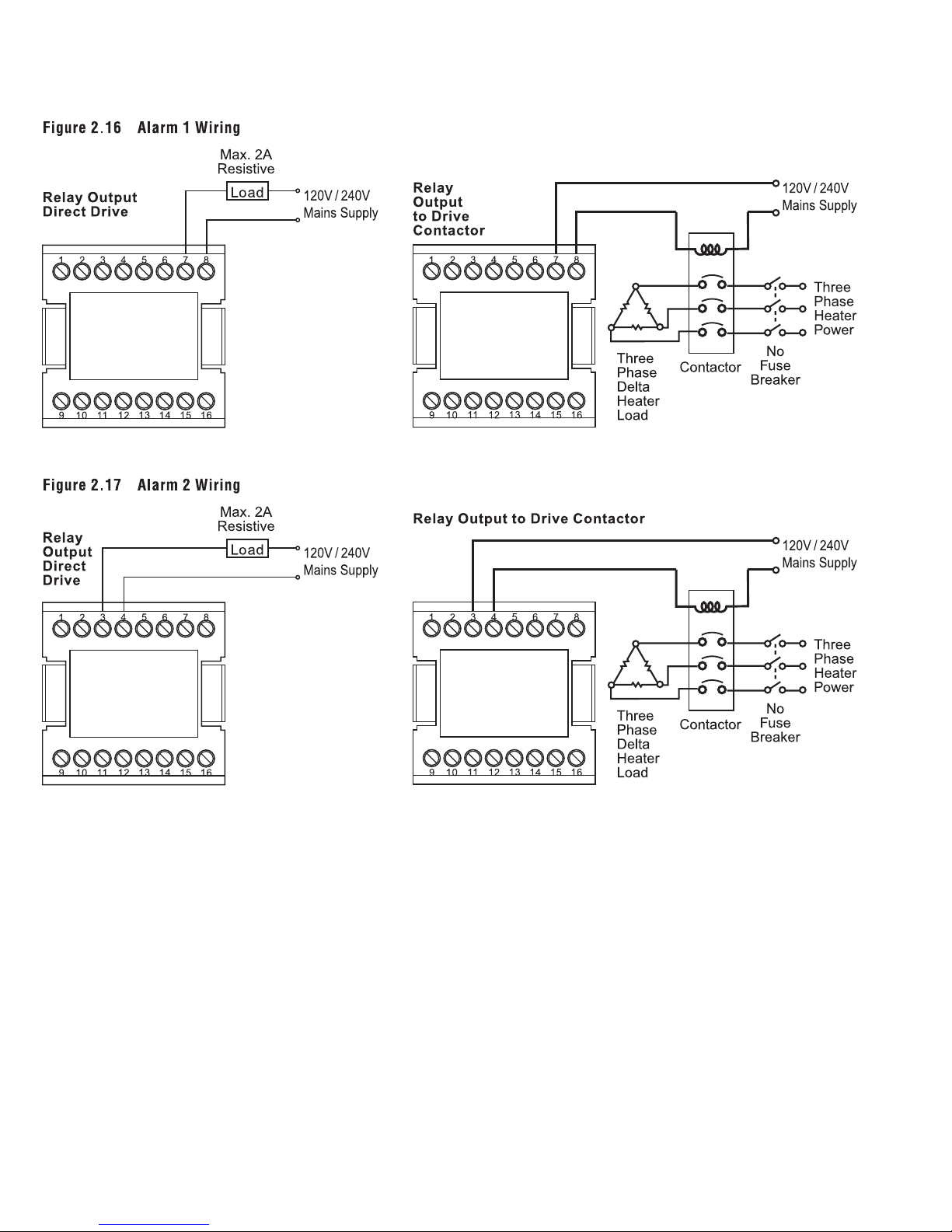

2-13 Alarm 1 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2-14 Alarm 2 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

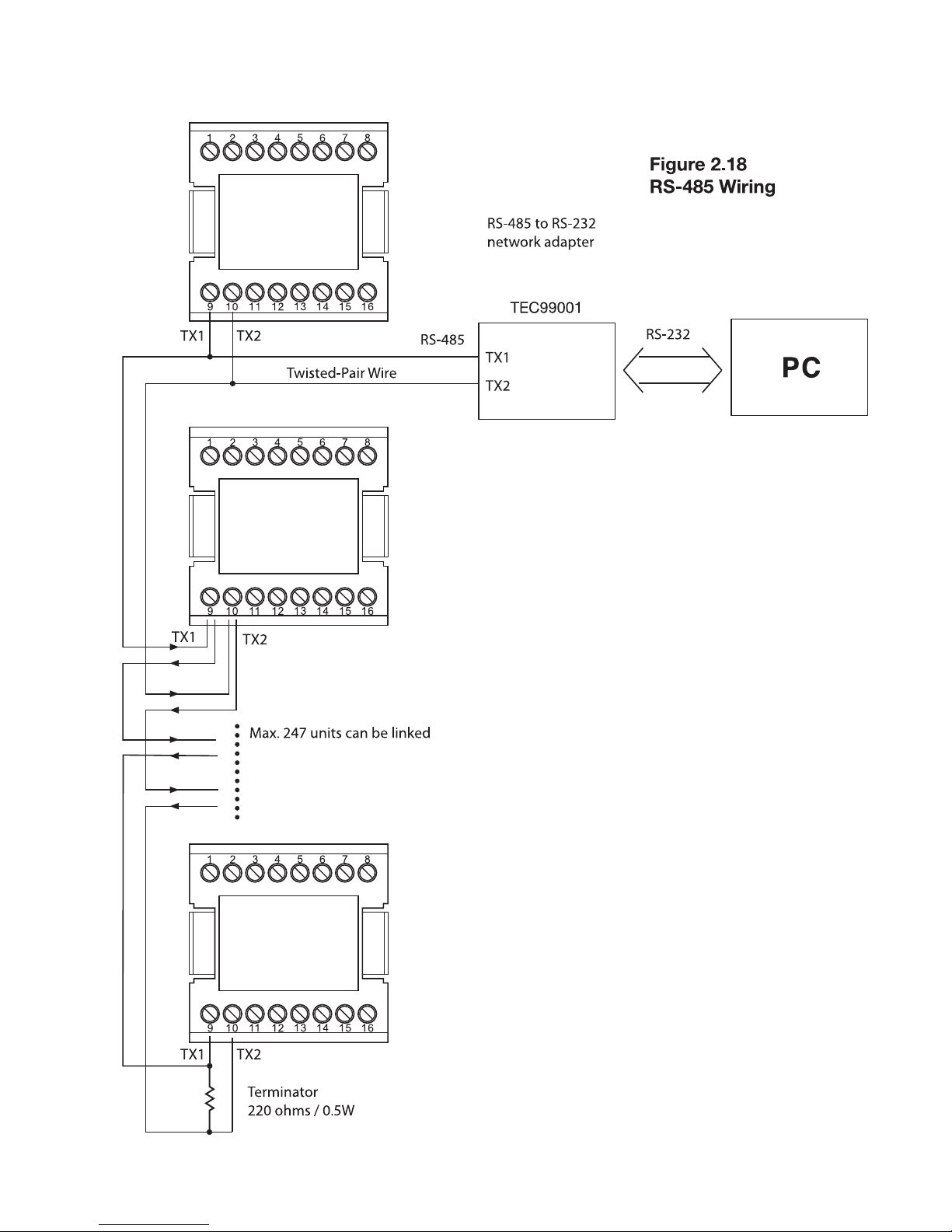

2-15 RS-485 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

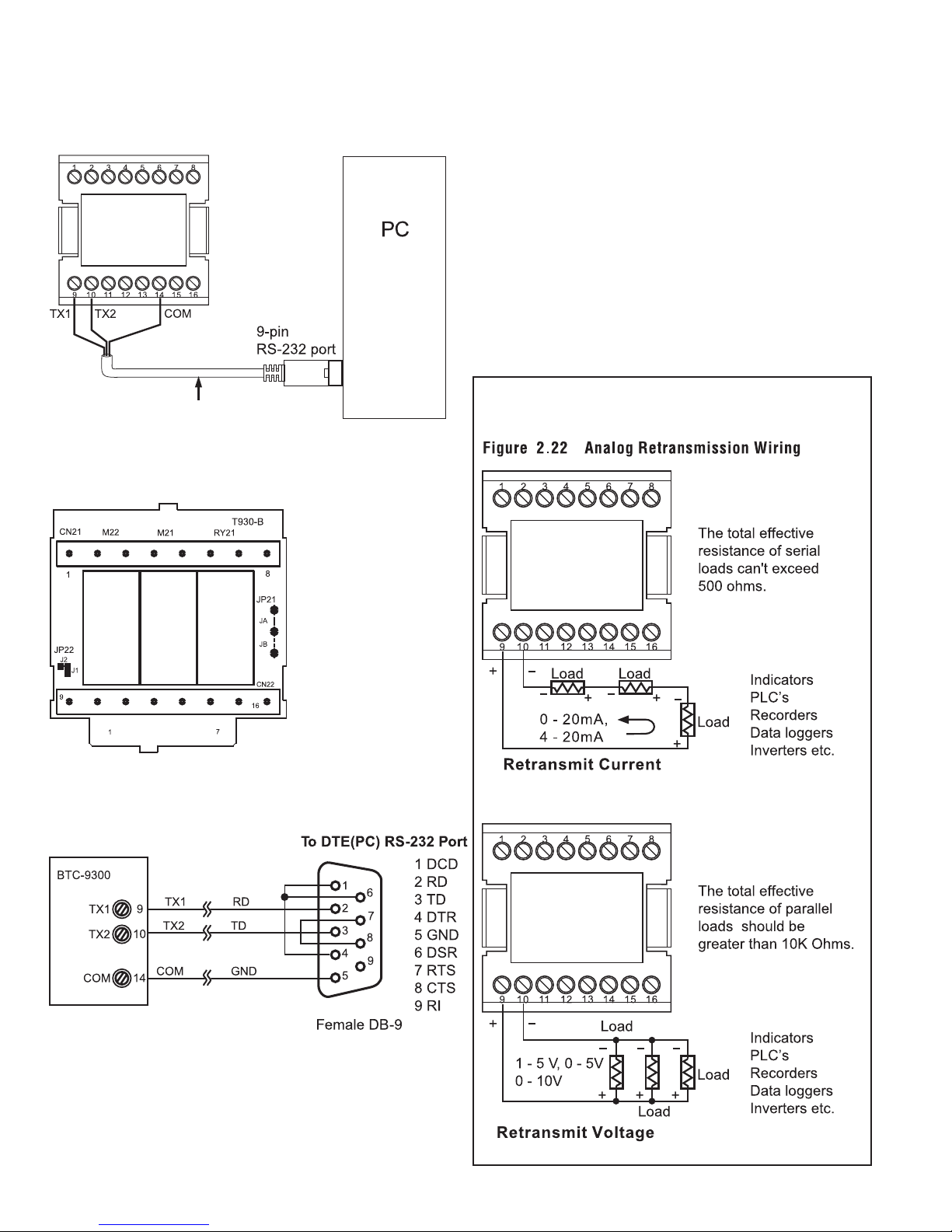

2-16 RS-232 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2-17 Analog Retransmission . . . . . . . . . . . . . . . . . . . . . . . 24

Chapter 3 - Programming Basic Functions

3-1 Input 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3-2 OUT1 and OUT2 Types . . . . . . . . . . . . . . . . . . . . . . . 26

3-3 Configuring User Menu . . . . . . . . . . . . . . . . . . . . . . . . 26

3-4 Heat Only Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3-5 Cool Only Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3-6 Heat-Cool Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3-7 Dwell Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3-8 Process Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3-9 Deviation Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3-10 Deviation Band Alarms . . . . . . . . . . . . . . . . . . . . . . . 32

3-11 Heater Break Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3-12 Loop Break Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3-13 Sensor Break Alarm . . . . . . . . . . . . . . . . . . . . . . . . . 34

3-14 SP1 Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3-15 PV1 Shift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3-16 Failure Transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3-17 Bumpless Transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3-18 Self-tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3-19 Auto-tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3-20 Manual Tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3-21 Signal Conditioner DC Power Supply . . . . . . . . . . . 39

3-22 Manual Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3-23 Display Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

3-24 Heater Current Monitoring . . . . . . . . . . . . . . . . . . . . 40

3-25 Reload Default Values . . . . . . . . . . . . . . . . . . . . . . . . 40

NOTE:

It is strongly recommended that a process should incorporate a LIMIT CONTROL like TEC-910 which will shut

down the equipment at a preset process condition in order to

preclude possible damage to products or system.

Information in this user’s manual is subject to change without

notice.

Copyright © 2016, Tempco Electric Heater Corporation, all

rights reserved. No part of this publication may be reproduced,

transmitted, transcribed or stored in a retrieval system, or translated into any language in any form by any means without the

written permission of Tempco Electric Heater Corporation.

CONTENTS

Page No

Chapter 4 - Full Function Programming

4-1 Event Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4-2 Second Set Point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4-3 Second PID Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

4-4 Ramp and Dwell . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

4-5 Remote Set Point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4-6 Differential Control . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4-7 Output Power Limits . . . . . . . . . . . . . . . . . . . . . . . . . . 44

4-8 Data Communication . . . . . . . . . . . . . . . . . . . . . . . . . . 44

4-9 Analog Retransmission . . . . . . . . . . . . . . . . . . . . . . . . 45

4-10 Digital Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4-11 Sleep Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4-12 Pump Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

4-13 Remote Lockout . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Chapter 5 - Applications

5-1 Pump/Pressure Control . . . . . . . . . . . . . . . . . . . . . . . . 47

5-2 Variable Period Full Wave SSR (VPFW SSR) . . . . . . 47

5-3 Heat Only Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

5-4 Cool Only Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

5-5 Heat-Cool Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

5-6 Ramp and Dwell . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

5-7 Remote Set Point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

5-8 Differential Control . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

5-9 Dual Set Point/PID . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

5-10 RS-485 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

5-11 RS-232 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

5-12 Retransmit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Chapter 6 - Calibration . . . . . . . . . . . . . . . . . . . . 55

Chapter 7 - Error Codes and

Troubleshooting

. . . . . . . . . . . . . . 57

Chapter 8 - Specifications. . . . . . . . . . . . . . . . . 61

Chapter 9 - Modbus Communications . . . 63

Appendix

A-1 Menu Existence Conditions . . . . . . . . . . . . . . . . . . . . 77

A-2 Factory Menu Description . . . . . . . . . . . . . . . . . . . . . 80

A-3 Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

A-4 Memo. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

A-5 Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

NOTES

Chapter 1 Overview

__+_

+

++++

+

Figure 1.1

Fuzzy PID System Block

PID

+ FUZZY CONTROL

1–1 Features

** High accuracy 18-bit input

A–D

** High accuracy 15-bit out-

put D–A

** Fast input sample rate (5

times/second)

** Two function complexity

levels

** User menu configurable

** Pump control

* Fuzzy plus PID micro-

** Unique * Valuable

* Automatic programming

* Differential control

* Auto-tune function

* Self-tune function

* Sleep mode function

* “Soft-start” ramp and dwell

timer

* Programmable inputs (ther-

mocouple, RTD, mA, VDC)

* Analog input for remote set

point and CT

processor-based control

TEC-9300 Fuzzy Logic plus PID microprocessor-based controller incorporates a bright, easy to read, 4-digit LED display

which indicates the process value. Fuzzy Logic technology

enables a process to reach a predetermined set point in the shortest time, with the minimum of overshoot during power-up or

external load disturbance. The units are housed in a 1/16 DIN

case, measuring 48mm x 48mm with 75mm behind-panel depth.

The units feature three touch keys to select the various control

and input parameters. Using a unique function, you can put up to

five parameters at the front of the user menu by using SEL1 to

SEL5 found in the setup menu. This is particularly useful to

OEM’s as it is easy to configure the menu to suit the specific

application.

TEC-9300 is powered by 11–26VAC/VDC or 90–264VAC

supply, incorporating a 2 amp control relay output and dual 2 amp

alarm relay outputs as standard with a second alarm that can be

configured in the second output for cooling purposes or as a dwell

timer. Alternative output options include SSR drive, triac, 4–

20mA and 0–10 volts. TEC-9300 is fully programmable for

PT100, thermocouple types J, K, T, E, B, R, S, N, L, 0–20mA, 4–

20mA, and voltage signal input, with no need to modify the unit.

The input signals are digitized by using an 18-bit A to D converter. Its fast sampling rate allows the TEC-9300 to control fast

processes such as pressure and flow.

Self-tuning can be used to optimize the control parameters as

soon as undesired control results are observed. Unlike auto-tuning, self-tuning will produce less disturbance to the process during tuning, and can be used at any time.

Digital communications formats RS-485, RS-232 or 4–20mA

retransmission are available as an additional option. These

options allow the TEC-9300 to be integrated with supervisory

control systems and software, or alternatively to drive remote displays, chart recorders, or data loggers.

* Event input for changing

function and set point

* Programmable digital filter

* Hardware lockout and

remote lockout protection

* Loop break alarm

* Heater break alarm

* Sensor break alarm and

bumpless transfer

* Analog retransmission

* Signal conditioner DC

power supply

* A wide variety of output

modules available

* Safety UL/CSA/IEC1010–1

* EMC/CE EN61326

* Front panel sealed to NEMA

4X and IP65

* RS-485, RS-232 communi-

cation

Two different methods can be used to program the TEC-9300.

1. Use the keys on the front panel to program the unit manually;

2. Use a PC with setup software to program the unit via the RS485 or RS-232 COMM port.

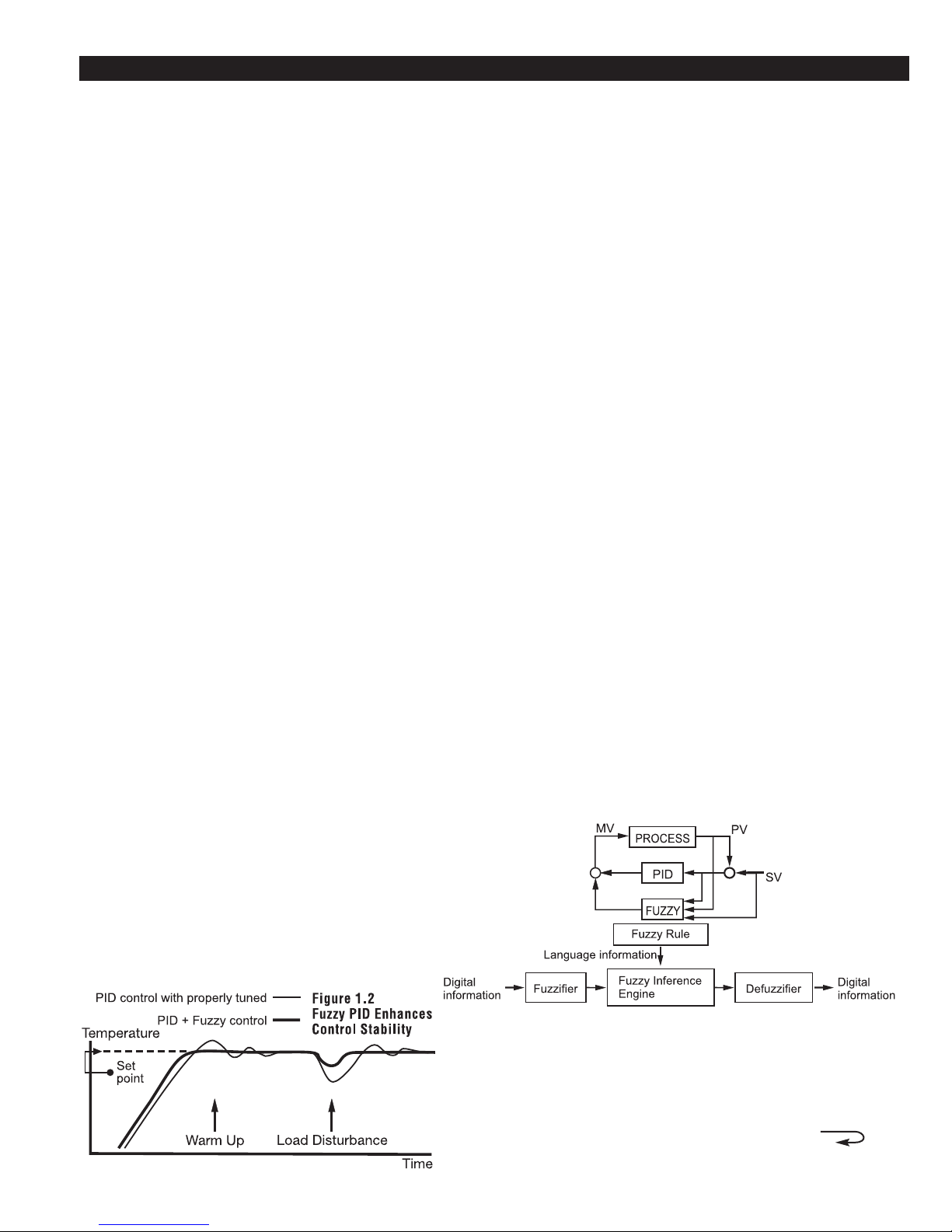

PID control has been used and has proven to be an efficient

controlling method by many industries, yet PID has difficulty

dealing with some sophisticated systems such as second and

higher order systems, long time-lag systems, during set point

change and/or load disturbance circumstances, etc. The PID principle is based on a mathematical model which is obtained by tuning the process. Unfortunately, many systems are too complex to

describe precisely in numerical terms. In addition, these systems

may be variable from time to time. In order to overcome the

imperfections of PID control, Fuzzy Technology was introduced.

What is Fuzzy Control? It works like a good driver. Under different speeds and circumstances, he can control a car well based on

previous experience, and does not require knowledge of the kinetic theory of motion. Fuzzy Logic is a linguistic control which is

different from the numerical PID control. It controls the system

by experience and does not need to simulate the system precisely

as a PID controller would.

The function of Fuzzy

Logic is to adjust PID

parameters internally

in order to make

manipulation of output value MV more

flexible and adaptive

to various processes.

The Fuzzy Rule may

work like this:

• If the temperature difference is large, and the temperature rate is large, then

ΔMV is large.

• If the temperature difference is large, and the temperature rate is small, then

ΔMV is small.

PID+Fuzzy Control

has been proven to be

an efficient method to

improve the control

stability as shown by

the comparison curves

at left:

1

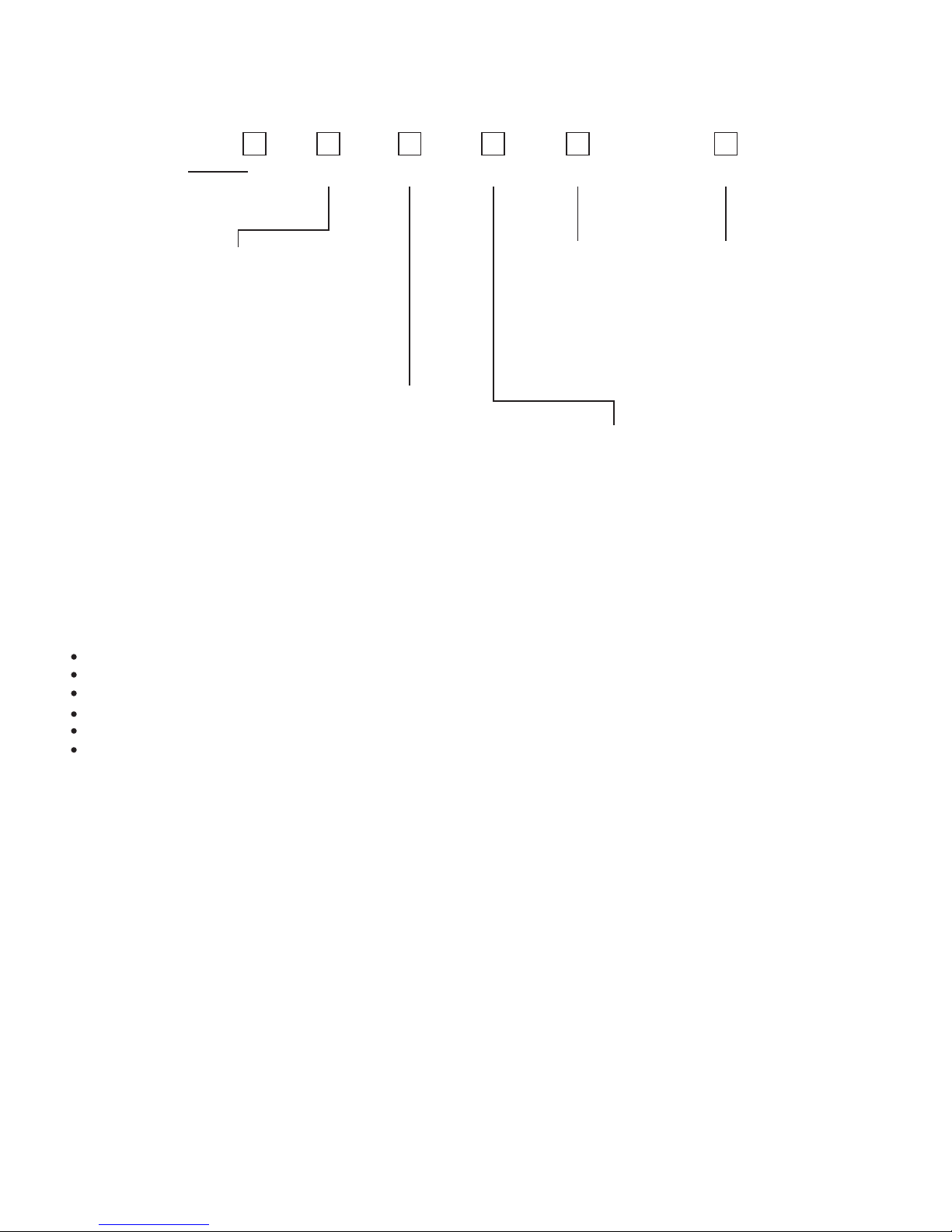

1–2 Hardware Code

Example

Communications

Alarm 1

Output 2 / Alarm 2

Output 1

Signal Input

Power Input

4: 90 - 264 VAC, 50/60 HZ

5: 11 - 26 VAC or VDC

9: Special Order

0: None

1: RS-485

2: RS-232

3: Retransmit 4-20mA/0-20mA

4: Retransmit 1 - 5V / 0 - 5V

5: Retransmit 0 - 10V

9: Special order

1: Standard Input

Input 1 - Universal Input

Thermocouple: J, K, T, E, B,

R, S, N, L

RTD: PT100 DIN, PT100 JIS

Current: 4 - 20mA, 0 - 20 mA.

Voltage: 0 - 1V, 0 - 5V, 1 - 5V,

0 - 10V

Input 2 - CT and Analog Input

***

CT: 0 - 50 Amp. AC Current

Transformer

Analog Input: 4 - 20 mA,

0 - 20mA, 0 - 1V, 0 - 5V,

1 - 5V, 0 - 10V.

Input 3 - Event Input ( EI )

9: Special Order

1: Relay rated 2A/240VAC

2: Pulsed voltage to

drive SSR, 5V/30mA

3: Isolated

4 - 20mA / 0 - 20mA

4: Isolated 1 - 5V / 0 - 5V

5: Isolated 0 - 10V

6: Triac Output

1A / 240VAC, SSR

C: Pulsed voltage to

drive SSR, 14V/40mA

9: Special order

9: Special order

2A / 240VAC

2: Form B Relay

2A / 240VAC

1: Form A Relay

0: None

1 2

3 4

5

6

0: None

1: Form A Relay 2A/240VAC

2: Pulsed voltage to

drive SSR, 5V / 30mA

3: Isolated 4 - 20mA / 0 - 20mA

4: Isolated 1 - 5V / 0 - 5V

5: Isolated 0 - 10V

6: Triac Output, 1A / 240VAC, SSR

7: Isolated 20V / 25mA DC

Output Power Supply

8: Isolated 12V / 40 mA DC

Output Power Supply

9: Isolated 5V / 80mA DC

Output Power Supply

TEC-9300-411111

90 - 264 operating voltage

Input: Standard Input

Output 1: Relay

Output 2: Relay

Alarm 1: Form A Relay

RS-485 Communication Interface

Range set by front keyboard

Alternative between RS-232 and EI

Need to order an accessory TEC99999 if

Heater Break detection is required.

TEC-9300-

***

**

*

*

*

*

**

**

*

*

*

C: Pulsed voltage to

drive SSR, 14V/40mA

A: Special order

NOTE: A part number based on the hardware code and any software pre-programming

will be issued at time of order.

Related Products

TEC99001 Smart network adapter for third party software;

converts 255 channels of RS-485 or RS-422 to

RS-232 network

TEC99003 Smart network adapter for connecting the

TEC99013 Programming cable for the TEC-9300

TEC99923 Data Acquisition Software (DAQ Software)

TEC-9300 programming cable to the PCs RS-232

serial port or to a Serial → USB adapter

2

1–3 Programming Port and DIP Switch

Front

Panel

Rear

Te rm i na l

Figure 1. Access Hole

Overview

. . . . .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Table 1.1 DIP Switch

Configuration

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

TC, RTD, mV

0-1V, 0-5V, 1-5V, 0-1 0V

0-20 mA, 4-2 0 m A

Input 1

Select

.

All para m e te rs a re U nlocked

Only SP1, SEL1 SEL5 a re u n loc ked

Only SP1 is unlocked

All P arameters a re locked

Lockout

1 2

3 4

DIP Switc h

:O N :O F F

Factory Default Setting

*

Access Hole

1

ON DI P

2 3 4

The programming port is used to connect to

the TEC99001 for instant programming

from a computer

is used for off-line automatic setup and testing

procedures only. Do not

attempt to make any connection to these pins

when the unit is being

used for normal control

purposes.

The programming port

the factory, the DIP

switch is set so that TC

and RTD are selected for

input 1 and all parameters

are unlocked, unless

another configuration is

requested.

When the unit leaves

Lockout function is

used to disable the adjustment of parameters as

well as operation of calibration mode. However,

the menu can still be

viewed even under lockout condition.

*SEL1-SEL5 represent

those parameters which

are selected by using

SEL1, SEL2,… SEL5

parameters contained in

the setup menu. The

parameters that have

been selected are then

allocated at the beginning of the user menu.

3

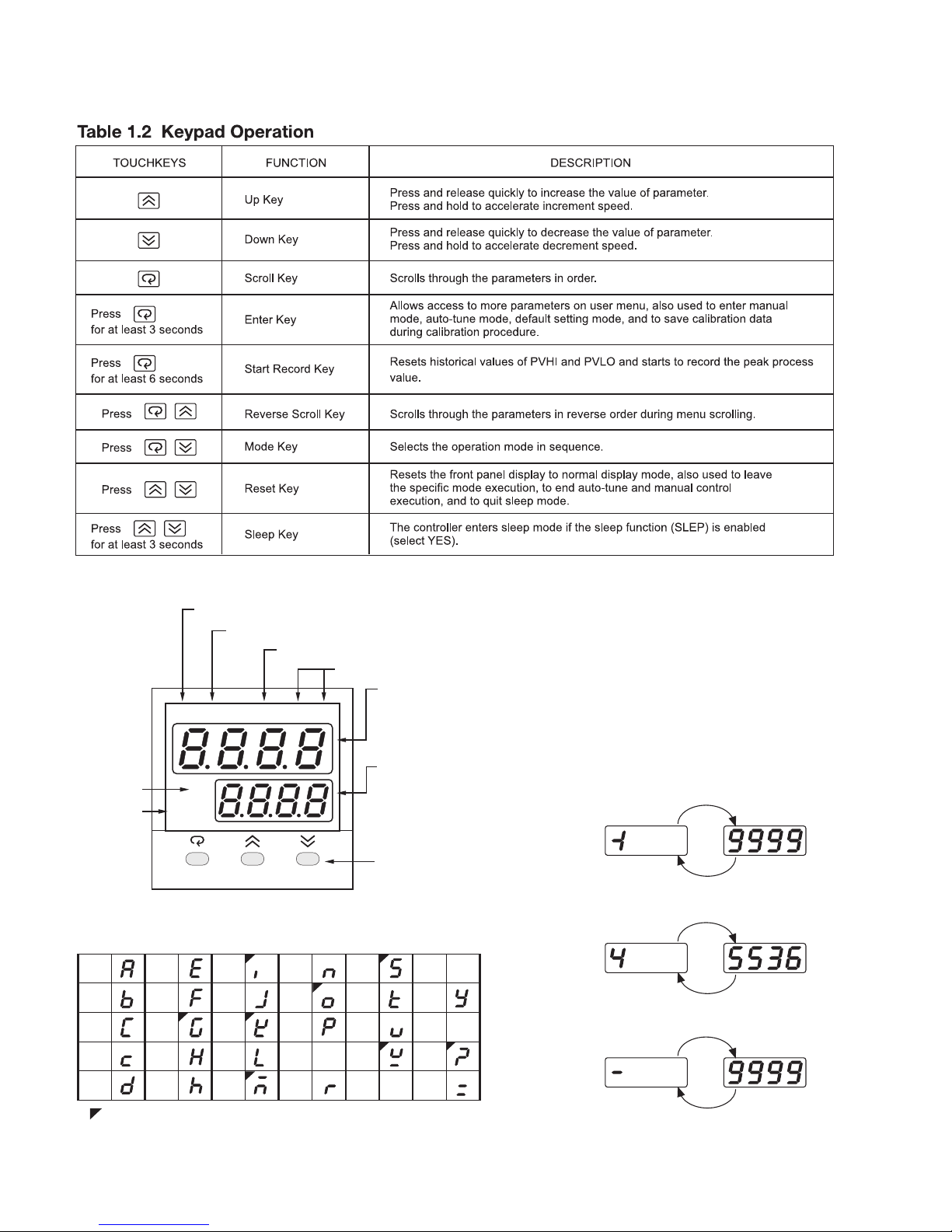

1–4 Keys and Displays

Alarm 1 Indicator

Alarm 2 / Output 2 Indicator

Process Value Indicator

Process Unit Indicator

Upper Display,

to display process value,

menu symbol and error

code etc.

Lower Display,

to display set point value,

parameter value or control

output value etc.

3 Silicone Rubber Buttons

for ease of control setup

and set point adjustment.

Set point

Value

Indicator

Output 1

Indicator

A1 A2 PV

°F

SV

OUT

For a number with decimal point the

display will be shifted one digit right:

-19999 will be displayed by:

45536 will be displayed by:

-9999 will be displayed by:

How to display a 5-digit number

-199.99 will be displayed by -199.9

4553.6 will be displayed by 4553

For a number without decimal point

the display will be divided into two

alternating phases:

TEC

-9300

Indicates Abstract Characters

A E

I

N

S

X

B

F

J

O

T

Y

C

G

K

P

U

Z

c

H

L

Q

V

?

D h

M

R

W

=

°C

Figure 1.4 Front Panel Description

Table 1.3 Display Form of Characters

The unit is programmed by using the three keys on the front panel. The available key functions are listed in the following table.

4

1–4 Keys and Displays continued…

5

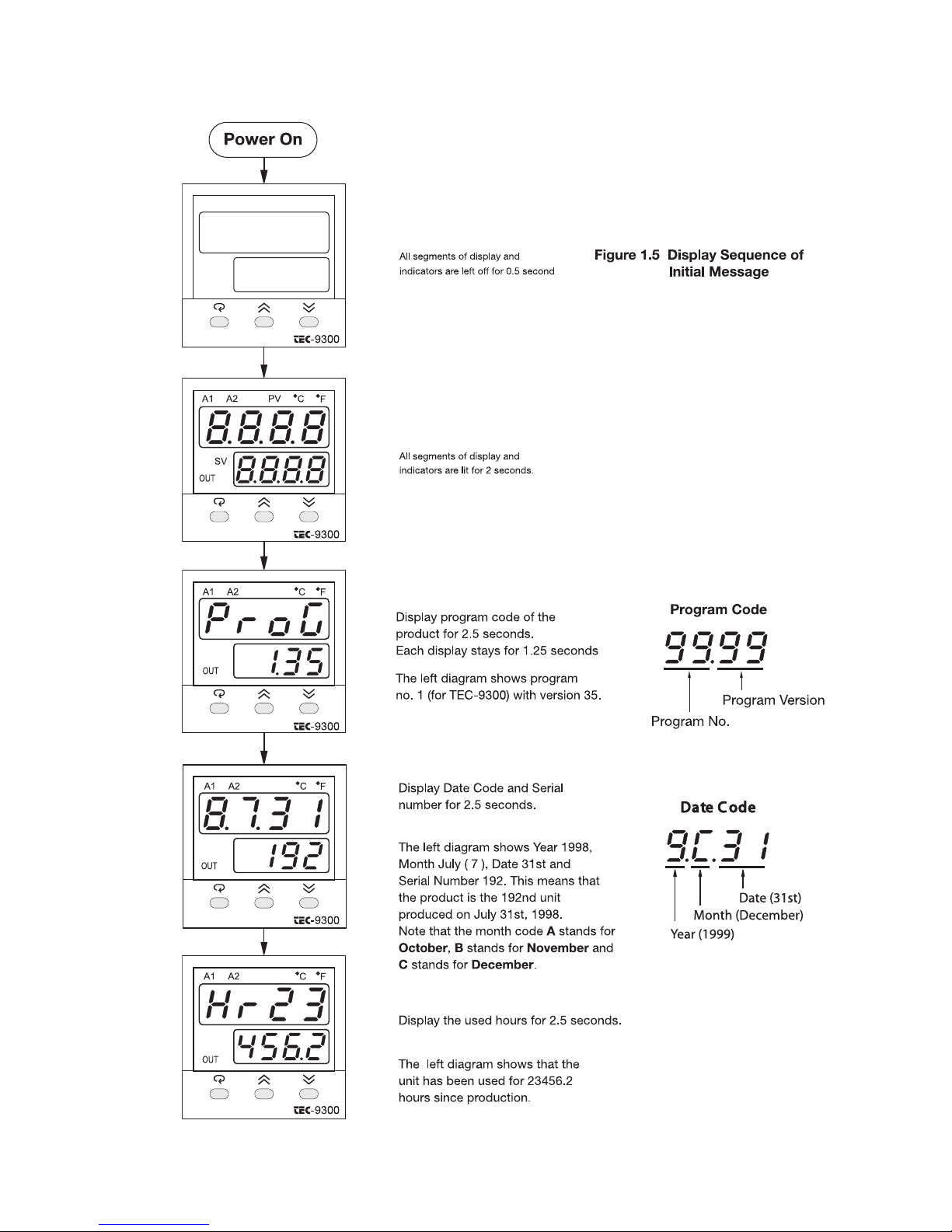

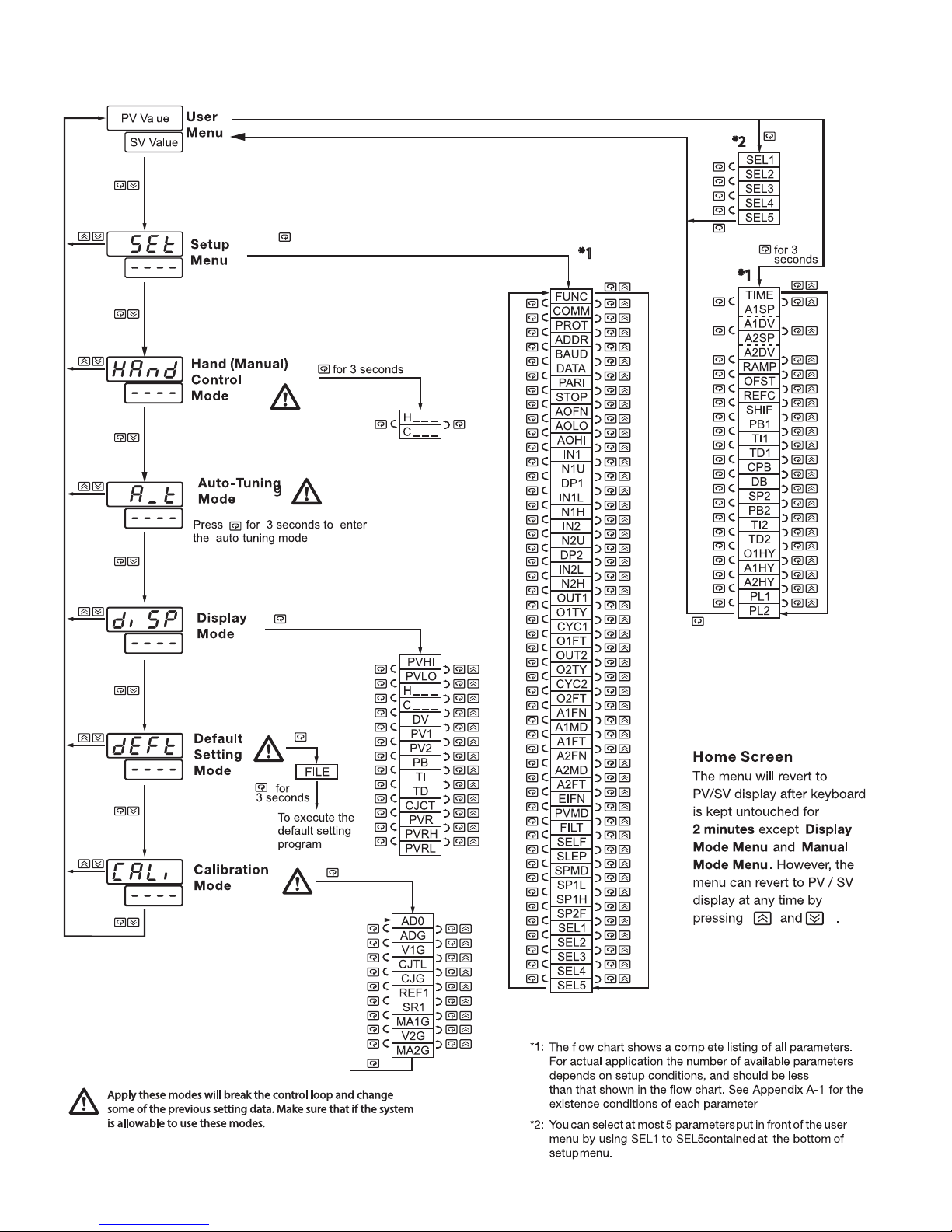

1–5 Menu Overview

e

6

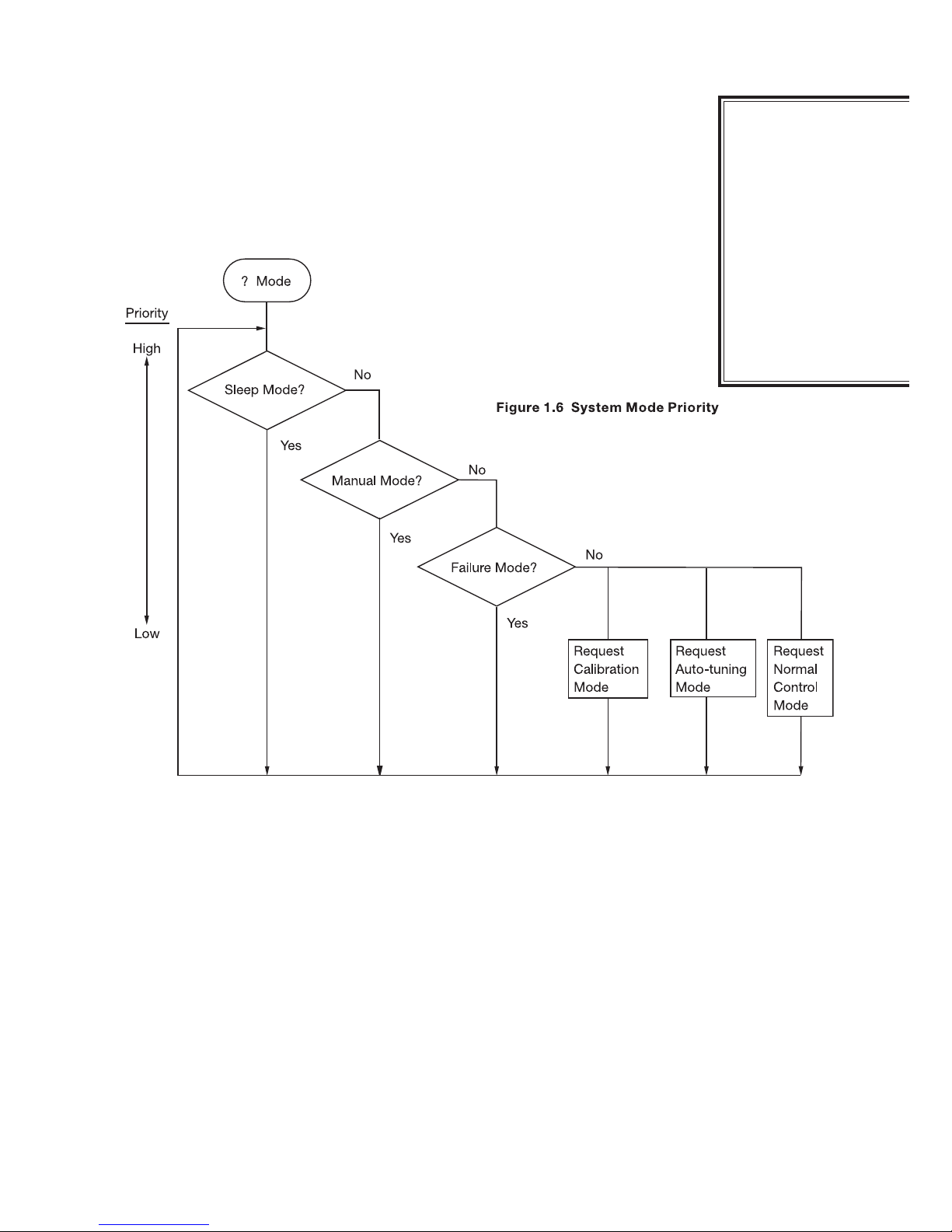

1–6 System Modes

The controller performs closed loop control in its normal control mode condition. The

controller will maintain its normal control mode when you are operating the user menu,

setup menu, display mode, reloading default values, or applying event input signals.

Under certain conditions, the normal control mode will transfer to an exception mode.

The exception modes include: sleep mode, manual mode, failure mode, calibration

mode, and auto-tuning mode. All of these modes perform in an open loop control except

auto-tuning mode which performs ON-OFF while configuring PID values control. The

mode transfer is governed by the priority conditions. A lower priority mode can not alter

a higher priority mode, as shown in figure 1.6.

System Modes

Sleep mode:

See section 4-11.

Manual mode:

See section 3-23.

Failure mode:

See section 3-17.

Calibration mode:

See chapter 6.

Auto-tuning mode:

See section 3-20.

Normal control mode:

See section 3-24, 3-26, 4-1

Calibration mode, auto-tuning mode, and normal control mode are in the

same priority level. Sleep mode is in the highest priority level.

7

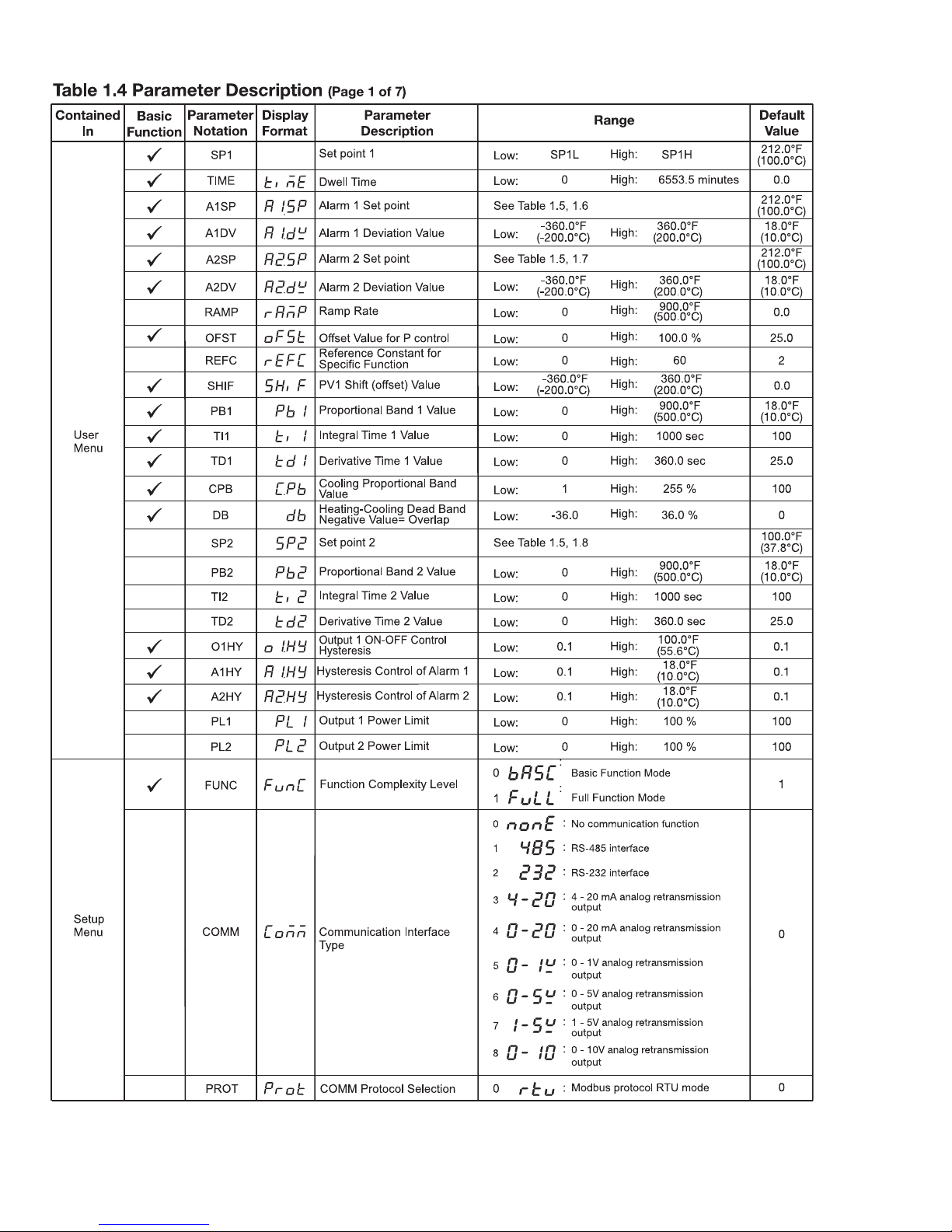

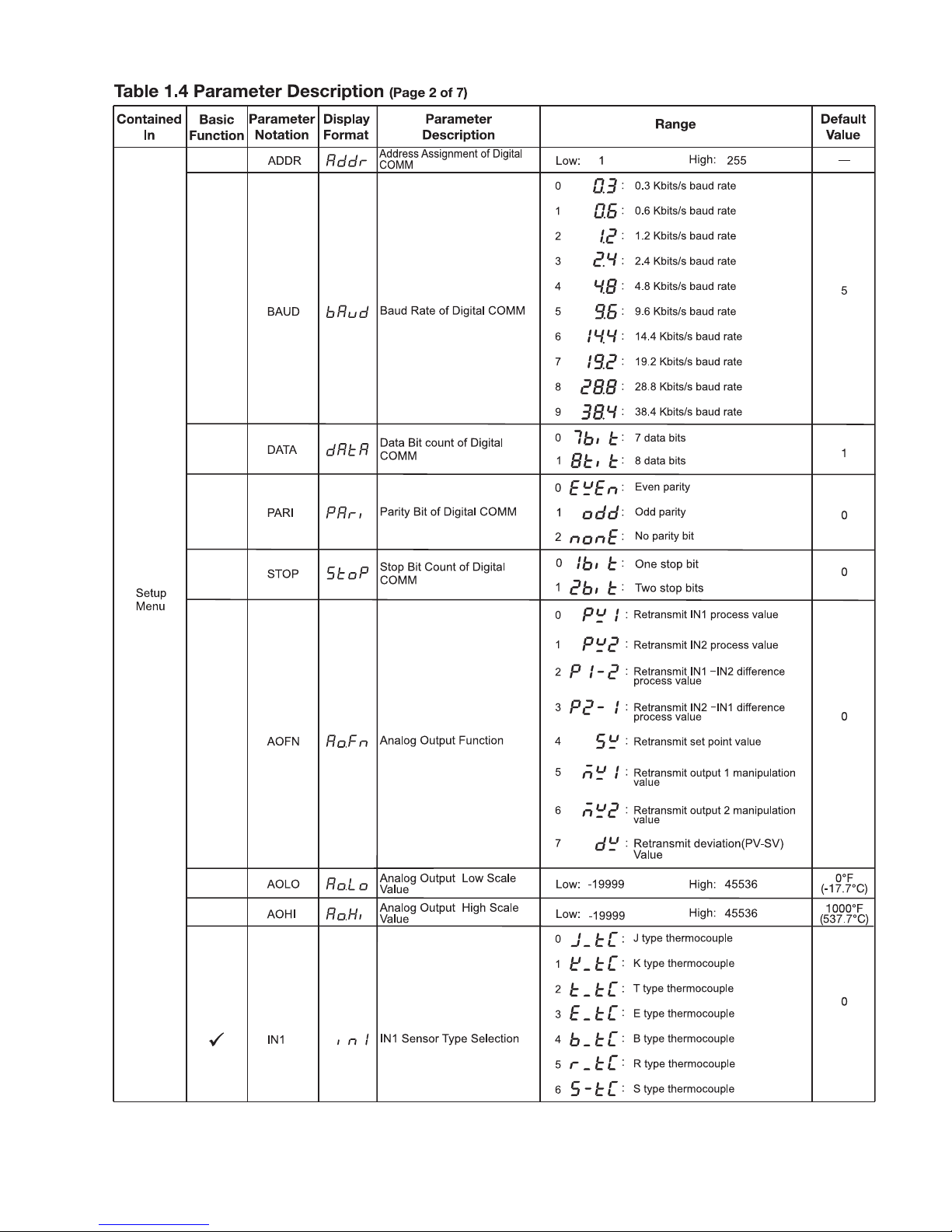

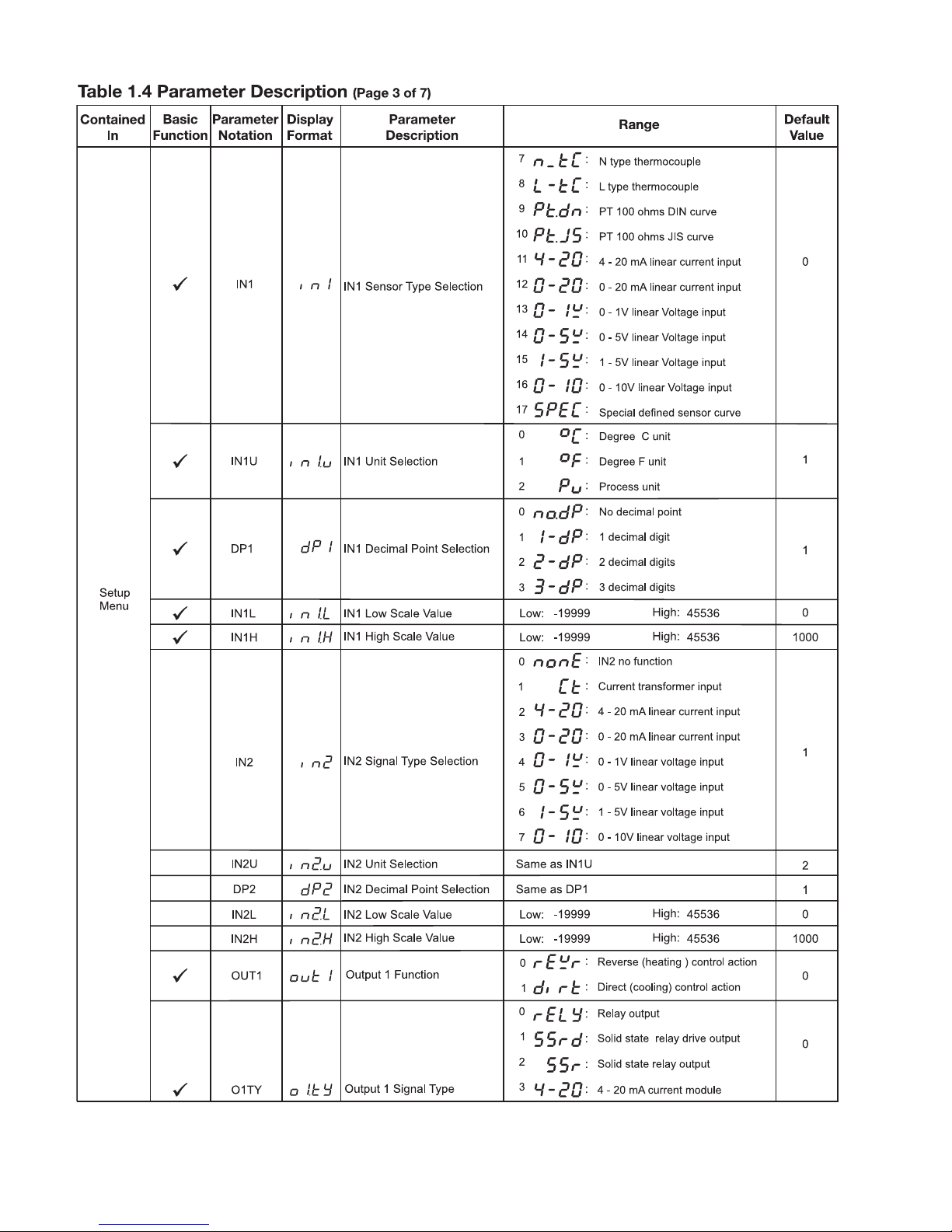

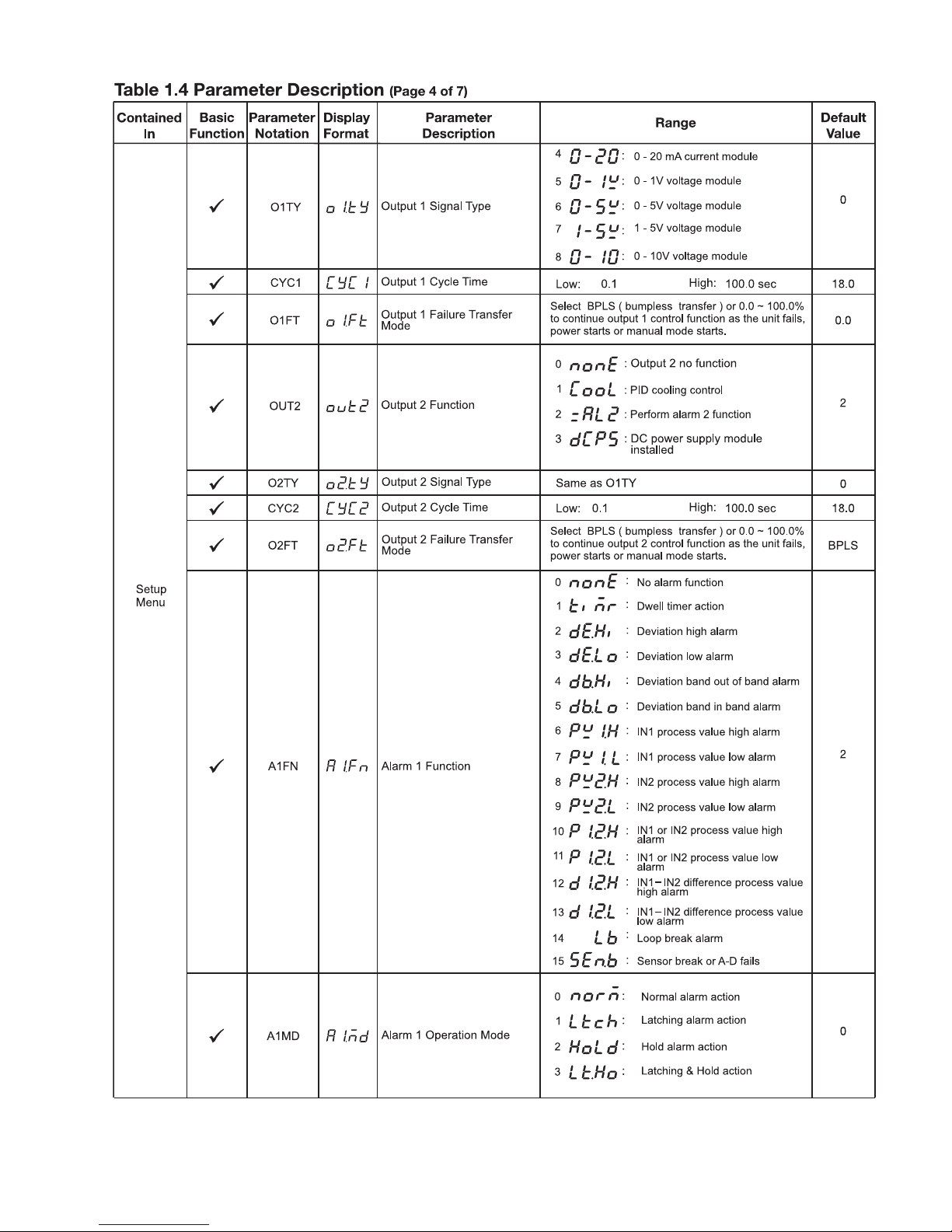

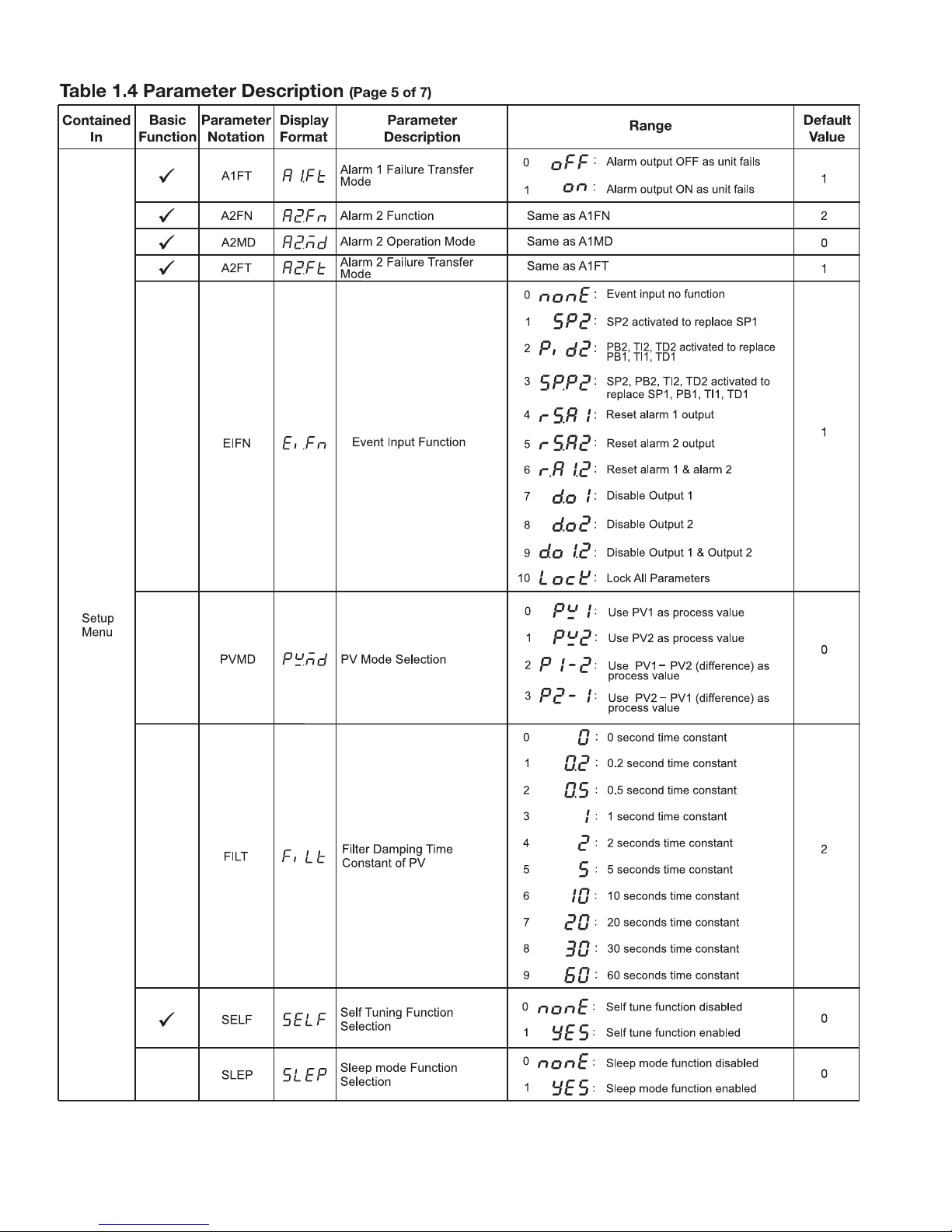

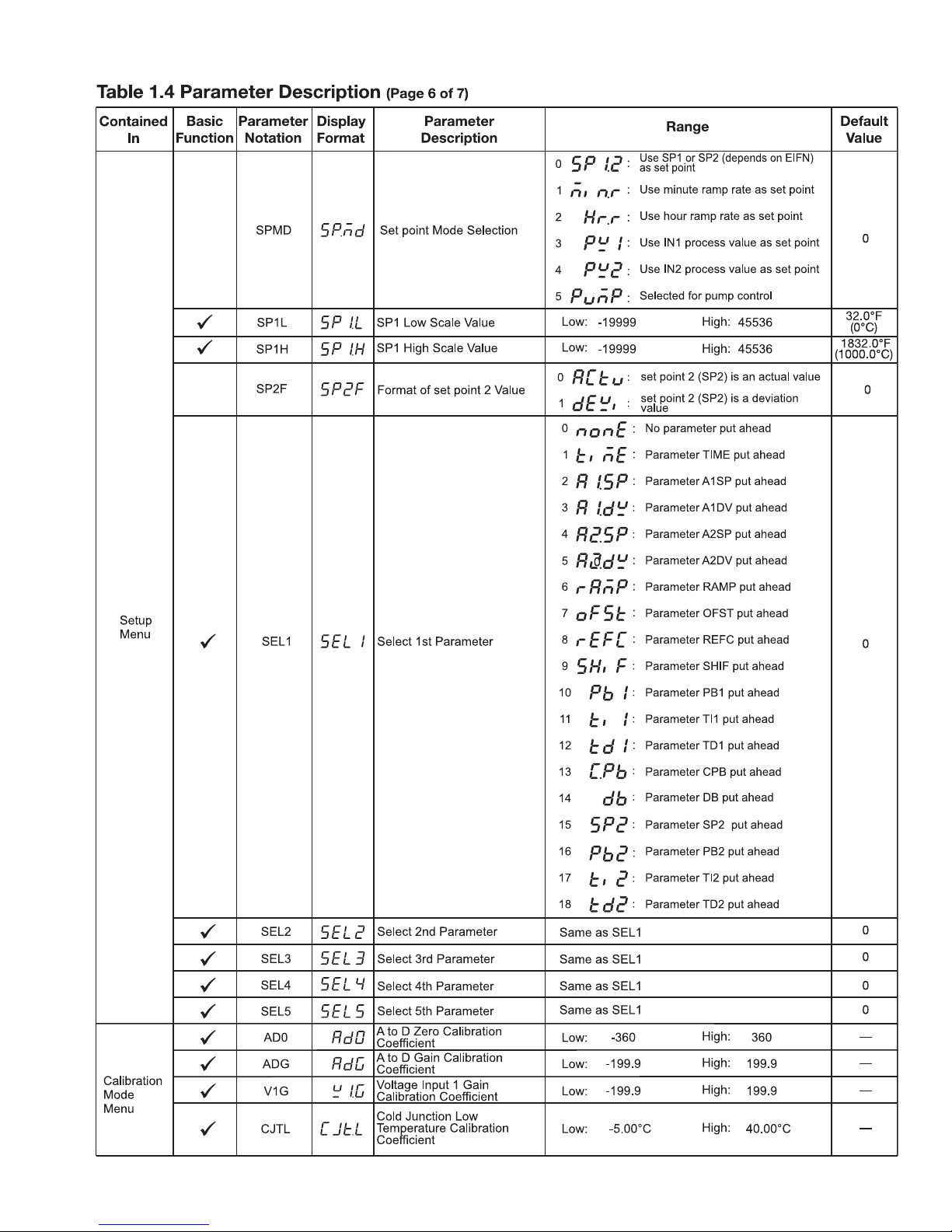

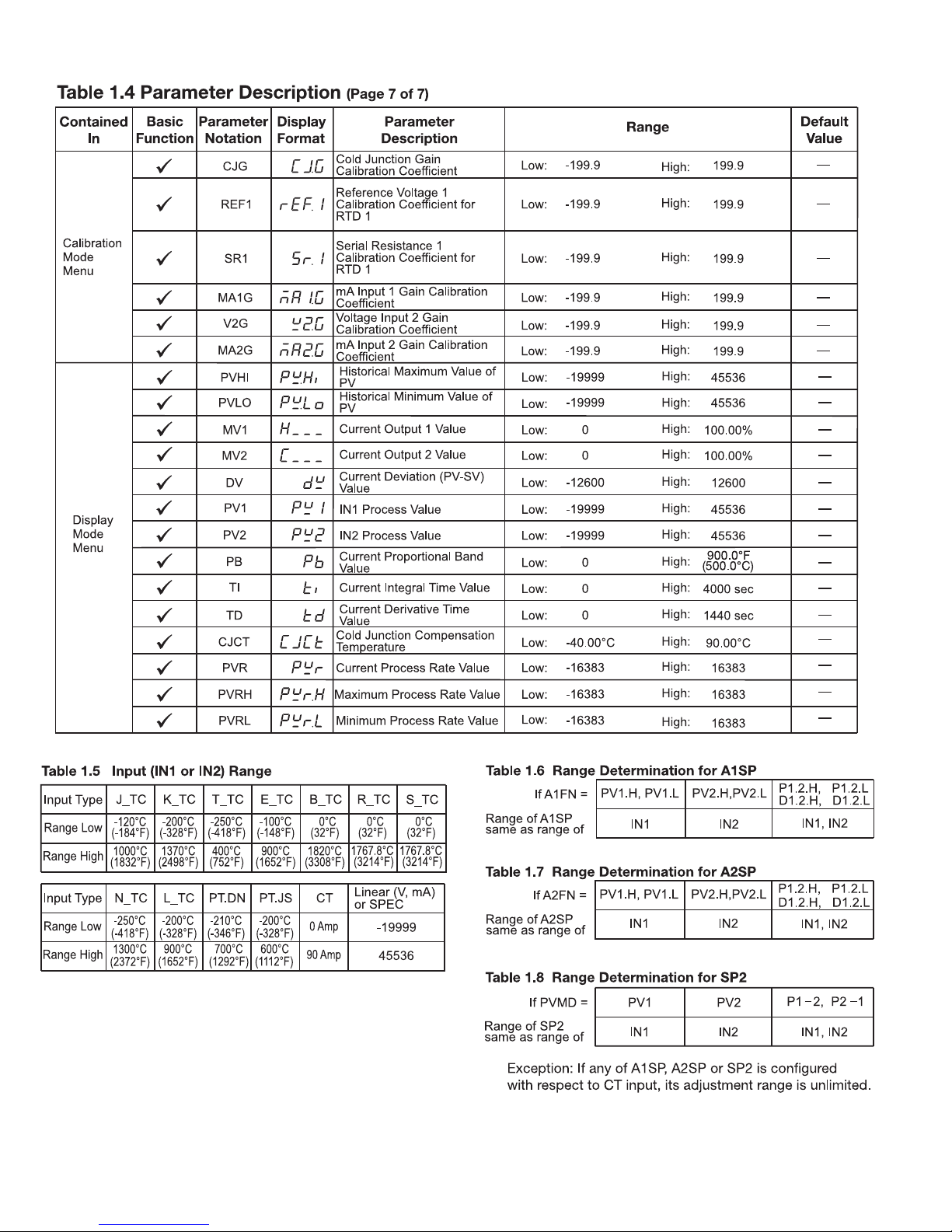

1–7 Parameter Description

8

NOTE: For RS-232:

Short J1, Open/Cut J2

Using RS-232 will disable Event Input Function

NOTE: Parameter 1N1 continued on next page

9

10

NOTE: Parameter O1TY continued on next page

11

12

Note: Calibration menu is for supplier configuration use only.

13

14

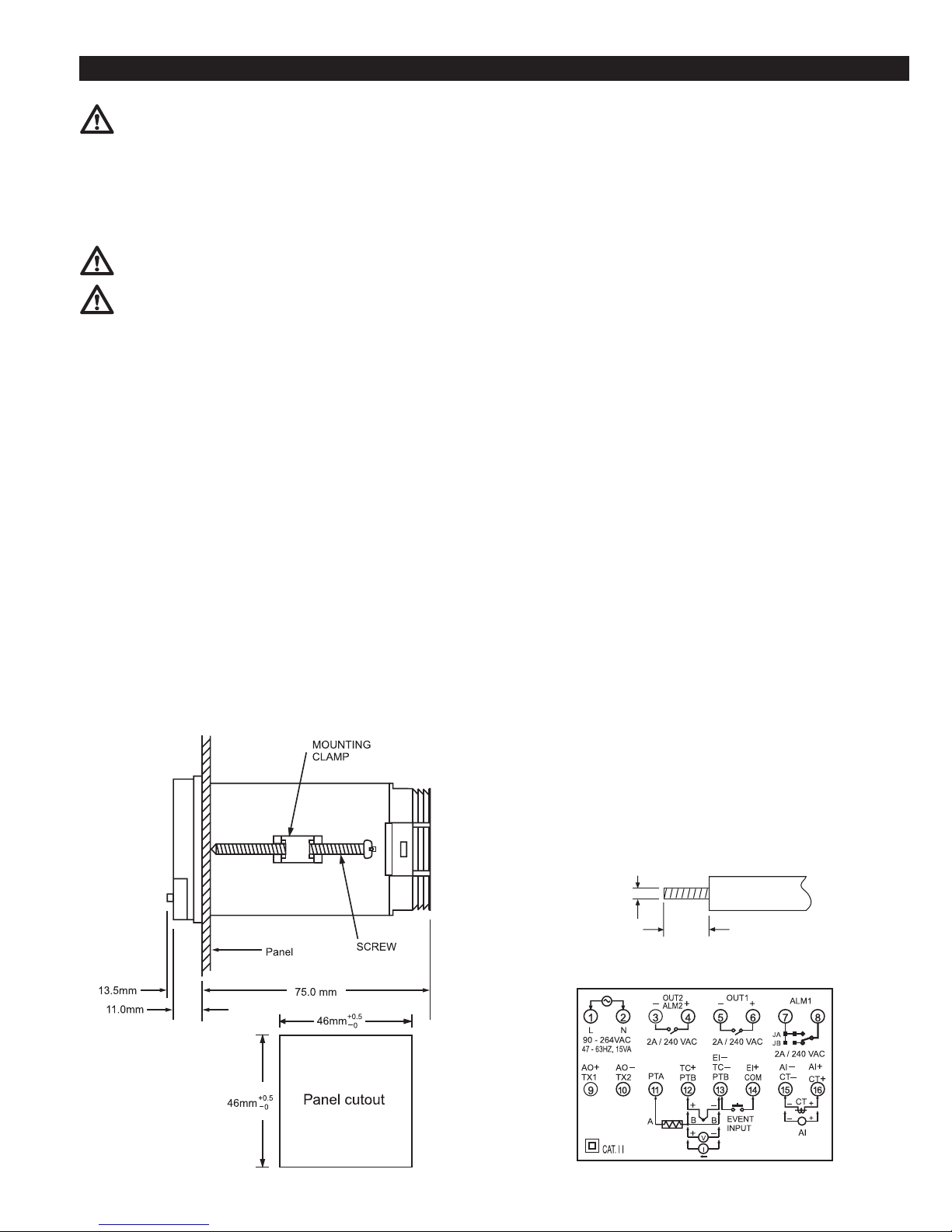

Chapter 2 Installation

Figure 2.1 Mounting Dimensions

Figure 2.2 Lead Termination

Figure 2.3 Rear Terminal Connection Diagram

4.5 ~ 7.0 mm

0.18" ~ 0.27"

2.0 mm

0.08" max.

Dangerous voltage capable of causing death can be pres-

ent in this instrument. Before installation or beginning

any troubleshooting procedures, the power to all equipment must

be switched off and isolated. Units suspected of being faulty

must be disconnected and removed to a properly equipped workshop for testing and repair. Component replacement and internal

adjustments must be made by a qualified maintenance person

only.

To minimize the possibility of fire or shock hazards, do

not expose this instrument to rain or excessive moisture.

Do not use this instrument in areas under hazardous con-

ditions such as excessive shock, vibration, dirt, moisture,

corrosive gases, or oil. The ambient temperature of the areas

should not exceed the maximum rating specified in chapter 8.

2–1 Unpacking

Upon receipt of the shipment, remove the unit from the carton

and inspect the unit for shipping damage.

If there is any damage due to transit, report the damage and file

a claim with the carrier.

Write down the model number, serial number, and date code for

future reference when corresponding with our service center.

The serial number (S/N) is labeled on the box and the housing of

the controller .

2–2 Mounting

Make the panel cutout to fit the dimensions shown in figure 2.1.

Remove both mounting clamps and insert the controller into the

panel cutout. Reinstall the mounting clamps. Gently tighten the

screws in the clamp until the controller front panel fits snugly in

the cutout .

2–3 Wiring Precautions

• Before wiring, verify the correct model number and options on

the label. Switch off the power while checking.

• Care must be taken to ensure that the maximum voltage rating

specified on the label is not exceeded.

• It is recommended that the power for these units be protected

by fuses or circuit breakers rated at the minimum value possible.

• All units should be installed in a suitable enclosure to prevent

live parts from being accessible to human hands and metal

tools. Metal enclosures and/or subpanels should be grounded in

accordance with national and local codes.

• All wiring must conform to appropriate standards of good practice and local codes and regulations. Wiring must be suitable

for the voltage, current, and temperature rating of the system.

• Beware not to over-tighten the terminal screws. The torque

should not exceed 1 N-m (8.9 lb-in or 10 KgF-cm).

• Unused control terminals should not be used as jumper points

as they may be internally connected, causing damage to the

unit.

• Verify that the ratings of the output devices and the inputs as

specified are not exceeded.

• Except for thermocouple wiring, all wiring should use stranded

copper conductor with a maximum gage of 14 AWG.

• Electrical power in industrial environments contains a certain

amount of noise in the form of transient voltage and spikes.

This electrical noise can adversely affect the operation of

microprocessor-based controls. For this reason the use of

shielded thermocouple extension wire which connects the sensor to the controller is strongly recommended. This wire is a

twisted-pair construction with foil wrap and drain wire. The

drain wire is to be attached to ground in the control panel only.

15

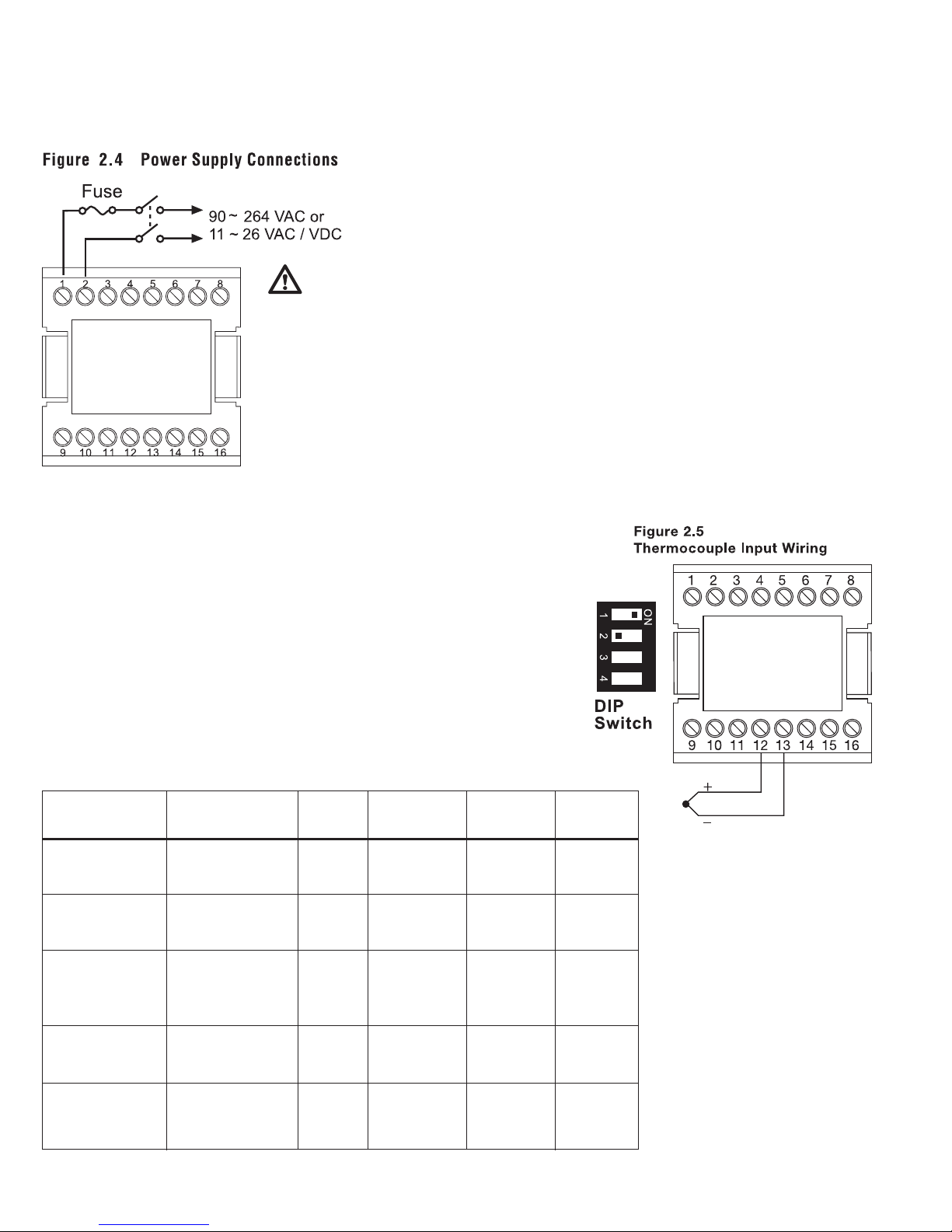

2–4 Power Wiring

The controller is supplied to operate at 11–26VAC/VDC or

90–264VAC. Check that the installation voltage corresponds to

the power rating indicated on the product label before connecting

power to the controller .

This equipment is

designed for installation

in an enclosure which provides

adequate protection against

electrical shock. Metal enclosures must be connected to

earth ground.

Local requirements regarding electrical installation

should be rigidly observed.

Consideration should be given

to prevent unauthorized personnel from gaining access to

the power terminals.

2–5 Sensor Installation Guidelines

Proper sensor installation can eliminate many problems in a

control system. The probe should be placed so that it can detect

any temperature change with minimal thermal lag. In a process

that requires fairly constant heat output, the probe should be

placed close to the heater. In a process where the heat demand is

variable, the probe should be close to the work area. Some experiments with probe location are often required to find the optimum position.

In a liquid process, the addition of a stirrer will help eliminate thermal lag. Since a thermocouple is basically a point

measuring device, placing more than one thermocouple in parallel can provide an average temperature readout and produce

better results in most air-heated processes.

The proper sensor type is also a very important factor in

obtaining precise measurements. The sensor must have the

correct temperature range to meet the process requirements. In

special processes, the sensor might have additional requirements such as leak-proof, anti-vibration, antiseptic, etc.

Standard sensor limits of error are ±4°F (±2°C) or 0.75% of

sensed temperature (half that for special) plus drift caused by

improper protection or an over-temperature occurrence. This

error is far greater than controller error and cannot be corrected on the sensor except by proper selection and replacement .

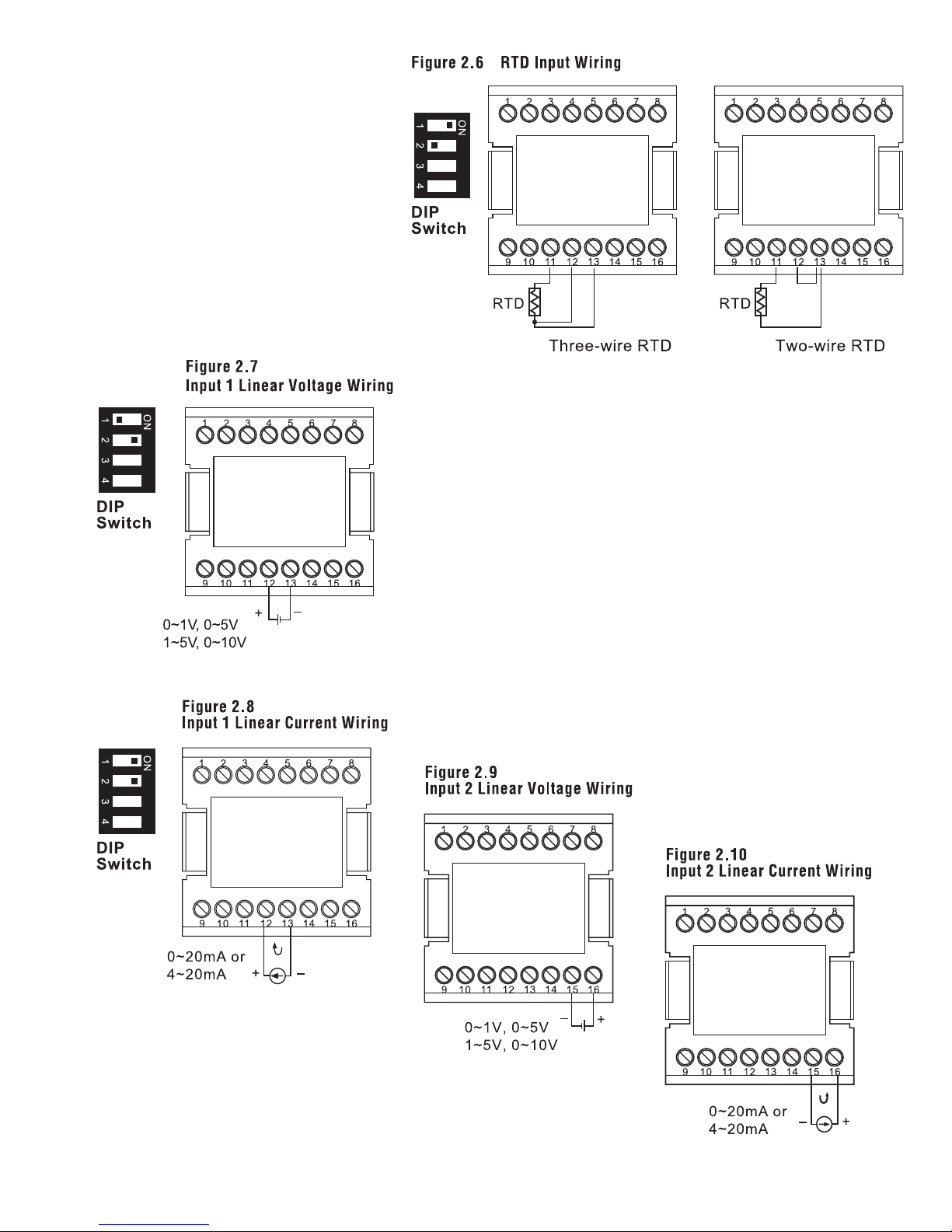

2–6 Thermocouple Input Wiring

The thermocouple input connections are shown in figure 2.5. The correct type of

thermocouple extension lead-wire or compensating cable must be used for the entire

distance between the controller and the thermocouple, ensuring that the correct

polarity is maintained throughout. Joints in the cable should be avoided, if possible.

If the length of the thermocouple plus the extension wire is too long, it may affect

the temperature measurement. A 400 ohms K type or a 500 ohms J type thermocouple lead resistance will produce approximately 1°C temperature error .

The color codes used on the thermocouple extension leads are shown in table 2.1.

Table 2.1 Thermocouple Cable Color Codes

Thermocouple Cable British American German French

Type Material BS ASTM DIN NFE

T

* blue * blue * brown * blue

J

* black * black * blue * black

Nickel-Chromium

K (Ni-Cr)

Nickel-Aluminum

(Ni-Al)

R Pt-13%Rh, Pt

S Pt-10%Rh, Pt

* green * green * white * green

B

Wire * grey * grey Wire

Copper (Cu)

Constantan (Cu-Ni)

Iron (Fe)

Constantan (Cu-Ni)

Pt-30%Rh

Pt-6%Rh

+ white + blue + red + yellow

– blue – red – brown – blue

+ yellow + white + red + yellow

– blue – red – blue – black

+ brown + yellow + red + yellow

– blue – red – green – purple

* red * yellow * green * yellow

+ white + black + red + yellow

– blue – red – white – green

Use + grey + red Use

Copper – red – grey Copper

* Color of overall sheath

16

2–7 RTD Input Wiring

The RTD connections are shown in figure

2.6, with the compensating lead connected to

terminal 12. For two-wire RTD inputs, terminals

12 and 13 should be linked. A three-wire RTD

offers the capability of lead resistance compensation, provided that the three leads are the same

gauge and equal in length.

For the purpose of accuracy, two-wire RTD

should be avoided, if possible. A 0.4 ohm lead

resistance in a two-wire RTD will produce 1°C

temperature error.

2–8 Linear DC Input Wiring

DC linear voltage and linear current connections for input 1 are shown in

figure 2.7 and figure 2.8.

DC linear voltage and linear current connections for input 2 are shown in

figure 2.9 and figure 2.10.

17

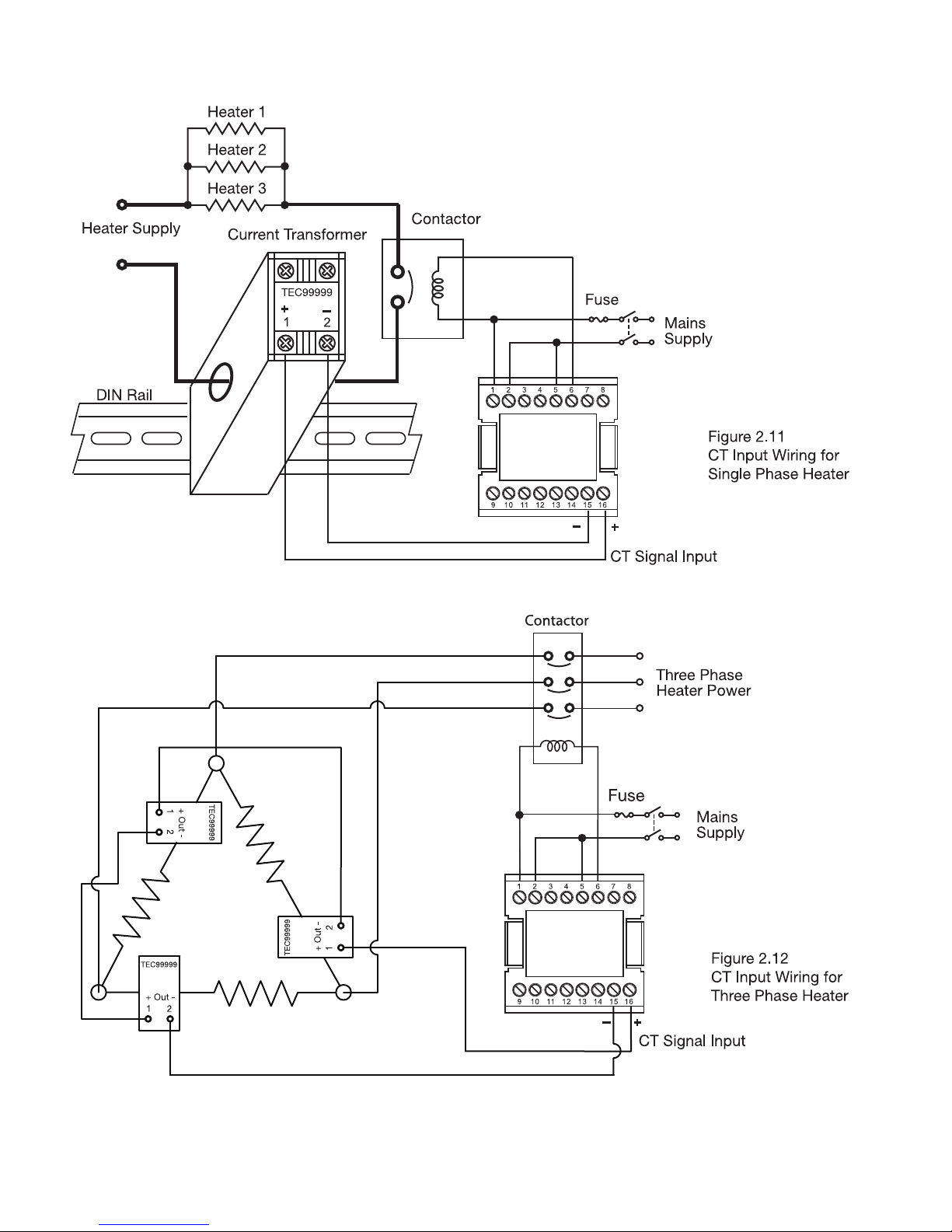

2–9 CT/Heater Current Input Wiring

Make sure that the total current through TEC99999 does not exceed 100A rms in a 3-Phase system.

18

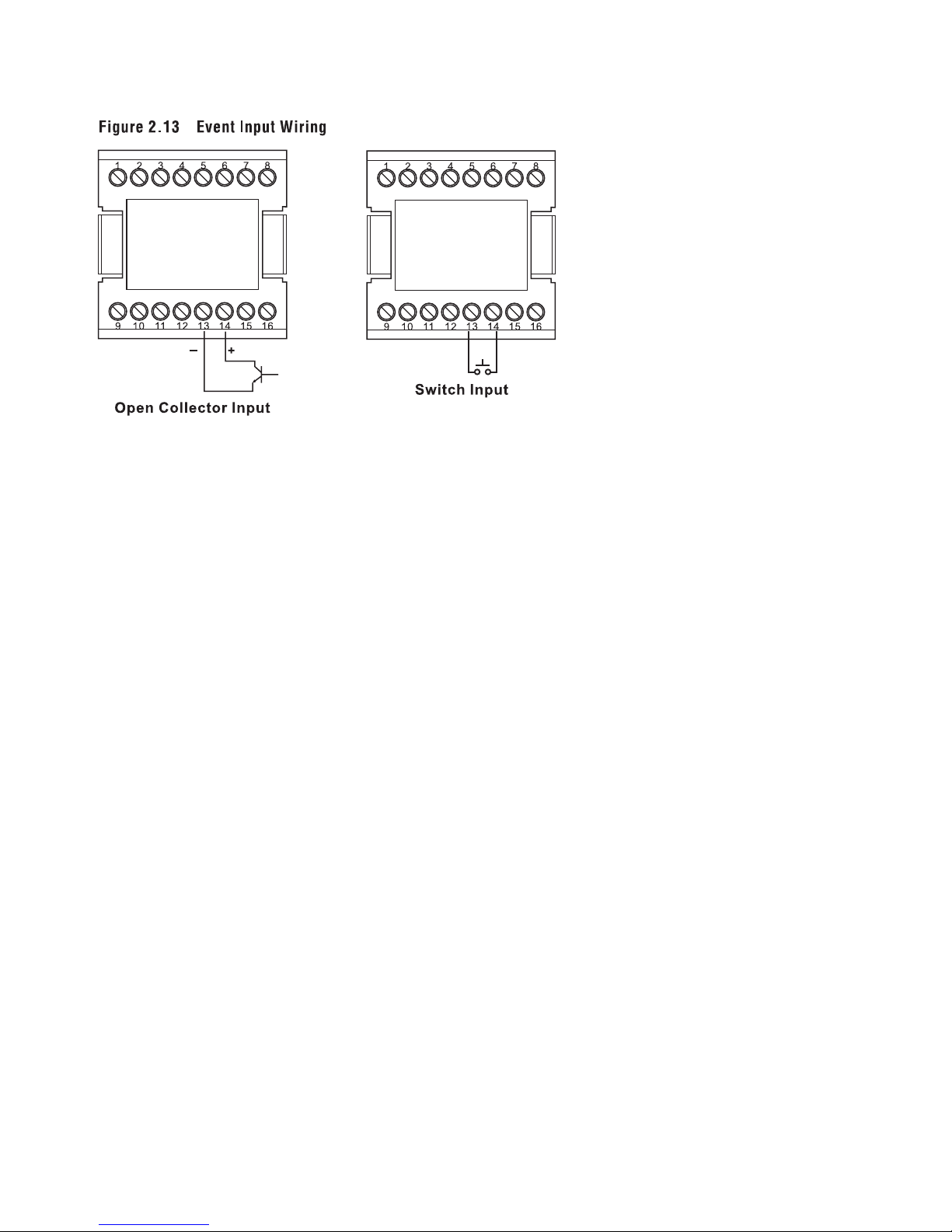

2–10 Event Input wiring

The event input can accept a switch signal as well

as an open collector signal. The event input function (EIFN) is activated when the switch is closed

or an open collector (or a logic signal) is pulled

down.

Also refer to section 4-1 for event input functions.

19

2–11 Output 1 Wiring

20

2–12 Output 2 Wiring

21

2–13, 2–14 Alarm 1 and 2 Wiring

Note: Both Form A and B contacts are available for the alarm 1 relay.

Order the correct form for alarm 1 to suit your needs.

22

2–15 RS-485

23

2–16 RS-232

Figure 2.20 Location of Jumper JP22

Figure 2.21 Configuration of RS-232 Cable

Figure 2.19 RS-232 Wiring

TEC99014

Note: If the TEC-9300 is configured for RS-232 communication, the EI (event input) is disconnected internally. The unit can

no longer perform event input function (EIFN).

When you connect an RS-232 module (CM94-2) to the connectors on the CPU board (C930), jumper JP22 on the terminal

board (T930) must be modified as following: J1 must be shorted

and J2 must be cut and left open. The location of JP22 is shown

in the diagram below, left (Fig. 2.20).

2–17 Analog Retransmission

If you use a conventional 9-pin RS-232 cable instead of

TEC99014, the cable must be modified according to the circuit diagram above.

24

Loading...

Loading...