Tempco TEC-2400, TEC-9400, TEC-8400, TEC-8450, TEC-4400 User Manual And Meeting Notes

...

PID + Fuzzy Logic Process Controller

TEC-2400/9400/8400/8450/7400/4400/6400

User Manual and Meeting Notes

JT rev. 11/29/2018

Warning Symbol

This document contains notices that you should observe to ensure your own personal safety, as well as to

protect the product and connected equipment. These notices are highlighted in the manual by a warning triangle and

are marked as follows.

The danger symbol indicates that death or severe personal injury may result if proper precautions are not taken.

Do not proceed beyond a warning symbol until the indicated conditions are fully understood and met.

Preface

Original equipment manufacturer reserves the right to change information available in this document without

notice. Manufacturer is not liable for any damages incurred to equipment/personal during installation or use of

equipment as explained in this document. User must acquire sufficient knowledge & skills prior to using equipment in

the application and follow all the local standards & regulations to meet safety requirements.

Copyright

The documentation and the software included with this product are copyrighted 2018 by Tempco Electric

Heater Corp. All rights are reserved. Tempco Electric Heater Corp. reserves the right to make improvements in the

products described in this manual at any time without notice.

No part of this manual may be reproduced/copied/translated or transmitted in any form or by any means

without the prior written permission of Tempco Electric Heater Corp. The information we supply is believed to be

accurate and reliable as of this printing. However, we assume no responsibility for its use.

Warning!

Failure of devices such as the thermocouple/RTD sensor, heater output relay or temperature control may result in

severe damage to a product while in process, melting of the heater or a damaging fire. A latching over-temperature

protection device such as a Tempco model TEC-910 or TEC-410 high-limit controller with manual reset must be

installed in your process. This device should remove power to the heating circuit if the above failure occurs. We

recommend this device be classified as a safety control and carry FM, U.L/CSA Listing or certification. Failure to

install high-limit protection where a potential hazard exists could result in damage to equipment, property and possible

severe injury to personnel.

Page 2 of 44

TABLE OF CONTENTS

1! Introduction ------------------------------------------------------------------------------------------------------------------------------------------- 5!

1.1 Introduction ------------------------------------------------------------------------------------------------------------------------------------------- 5

1.2 Features ------------------------------------------------------------------------------------------------------------------------------------------------ 6

1.3 Specifications ----------------------------------------------------------------------------------------------------------------------------------------- 6

1.4 Keys and Displays ------------------------------------------------------------------------------------------------------------------------------------ 9

1.5 Menu Flowchart ------------------------------------------------------------------------------------------------------------------------------------ 10

1.5.1 User Menu ----------------------------------------------------------------------------------------------------------------------------------- 10

1.5.2 Setup Menu ---------------------------------------------------------------------------------------------------------------------------------- 11

1.5.2.1 Basic Menu (bASE) ----------------------------------------------------------------------------------------------------------------- 11

1.5.2.2 Output Menu (oUT) ---------------------------------------------------------------------------------------------------------------- 12

1.5.2.3 Event Input Menu (EI) ------------------------------------------------------------------------------------------------------------- 12

1.5.2.4 Alarm Menu (ALRM) --------------------------------------------------------------------------------------------------------------- 13

1.5.2.5 User Select Menu (SEL) ----------------------------------------------------------------------------------------------------------- 14

1.5.2.6 Communication Menu (CoMM) ------------------------------------------------------------------------------------------------ 14

1.5.2.7 Current Transformer Input Menu (Ct) ---------------------------------------------------------------------------------------- 15

1.5.2.8 Profile Menu (PRoF) --------------------------------------------------------------------------------------------------------------- 16

1.5.3 Manual Mode Menu ---------------------------------------------------------------------------------------------------------------------- 17

1.5.4 Auto-Tuning Mode ------------------------------------------------------------------------------------------------------------------------- 17

1.5.5 Calibration Mode --------------------------------------------------------------------------------------------------------------------------- 17

2! Installation and Wiring --------------------------------------------------------------------------------------------------------------------------- 18!

2.1 Unpacking -------------------------------------------------------------------------------------------------------------------------------------------- 18

2.2 Mounting --------------------------------------------------------------------------------------------------------------------------------------------- 19

2.3 Wiring ------------------------------------------------------------------------------------------------------------------------------------------------- 19

2.3.1 TEC-2400 Terminal Connection --------------------------------------------------------------------------------------------------------- 19

2.3.2 TEC-9400 Terminal Connection --------------------------------------------------------------------------------------------------------- 20

2.3.3 TEC-8400 & TEC-4400 Terminal Connection ---------------------------------------------------------------------------------------- 20

2.3.4 TEC-8450 Terminal Connection --------------------------------------------------------------------------------------------------------- 21

2.3.5 TEC-7400 Terminal Connection --------------------------------------------------------------------------------------------------------- 21

2.3.6 TEC-6400 Terminal Connection --------------------------------------------------------------------------------------------------------- 22

2.4 Wiring Example: Contactor --------------------------------------------------------------------------------------------------------------------- 22

2.5 Wiring Example: Solid State Relay ------------------------------------------------------------------------------------------------------------ 23

3! Programming ---------------------------------------------------------------------------------------------------------------------------------------- 23!

3.1 User Security ---------------------------------------------------------------------------------------------------------------------------------------- 23

3.2 Signal Input ------------------------------------------------------------------------------------------------------------------------------------------ 23

3.3 Control Output -------------------------------------------------------------------------------------------------------------------------------------- 24

3.3.1 Heat Only ON-OFF Control --------------------------------------------------------------------------------------------------------------- 24

3.3.2 Heat only P or PD Control ---------------------------------------------------------------------------------------------------------------- 25

3.3.3 Heat only PID Control --------------------------------------------------------------------------------------------------------------------- 25

3.3.4 Cool only Control --------------------------------------------------------------------------------------------------------------------------- 25

3.3.5 Other Setup Required --------------------------------------------------------------------------------------------------------------------- 26

3.3.6 CPB Programming -------------------------------------------------------------------------------------------------------------------------- 26

3.3.7 DB Programming --------------------------------------------------------------------------------------------------------------------------- 26

3.3.8 Output 2 ON-OFF Control (Alarm function) ----------------------------------------------------------------------------------------- 26

Page 3 of 44

3.4 Soft-Start --------------------------------------------------------------------------------------------------------------------------------------------- 27

3.5 Alarm -------------------------------------------------------------------------------------------------------------------------------------------------- 28

3.5.1 Alarm Types --------------------------------------------------------------------------------------------------------------------------------- 28

3.5.2 Alarm Modes -------------------------------------------------------------------------------------------------------------------------------- 29

3.5.2.1 Normal Alarm: ALMD = NORM ------------------------------------------------------------------------------------------------- 29

3.5.2.2 Latching Alarm: ALMD = LTCH -------------------------------------------------------------------------------------------------- 29

3.5.2.3 Holding Alarm: ALMD = HOLD -------------------------------------------------------------------------------------------------- 29

3.5.2.4 Latching / Holding Alarm: ALMD = LT.HO ------------------------------------------------------------------------------------ 30

3.5.2.5 Set Point Holding Alarm: ALMD = SP.HO ------------------------------------------------------------------------------------- 30

3.5.3 Alarm Delay ---------------------------------------------------------------------------------------------------------------------------------- 30

3.5.4 Alarm Failure Transfer -------------------------------------------------------------------------------------------------------------------- 30

3.6 User Select Menu Configuration --------------------------------------------------------------------------------------------------------------- 30

3.7 Ramp -------------------------------------------------------------------------------------------------------------------------------------------------- 31

3.7.1 Example without Dwell Timer ---------------------------------------------------------------------------------------------------------- 31

3.8 Dwell Timer ------------------------------------------------------------------------------------------------------------------------------------------ 31

3.9 User Calibration ------------------------------------------------------------------------------------------------------------------------------------ 32

3.10 Digital Filter -------------------------------------------------------------------------------------------------------------------------------------- 32

3.11 Failure Transfer --------------------------------------------------------------------------------------------------------------------------------- 33

3.11.1 Output 1 Failure Transfer ------------------------------------------------------------------------------------------------------------ 33

3.11.2 Output 2 Failure Transfer ------------------------------------------------------------------------------------------------------------ 33

3.11.3 Alarm Failure Transfer ---------------------------------------------------------------------------------------------------------------- 33

3.12 Auto-Tuning ------------------------------------------------------------------------------------------------------------------------------------- 33

3.12.1 Auto-Tuning Operation Steps ------------------------------------------------------------------------------------------------------- 34

3.12.2 Auto-Tuning Error ---------------------------------------------------------------------------------------------------------------------- 34

3.12.3 Solutions for an Auto Tuning Error ------------------------------------------------------------------------------------------------ 34

3.13 Manual Tuning ---------------------------------------------------------------------------------------------------------------------------------- 35

3.14 Manual Control --------------------------------------------------------------------------------------------------------------------------------- 36

3.14.1 Exiting Manual Control --------------------------------------------------------------------------------------------------------------- 36

3.15 Data Communication -------------------------------------------------------------------------------------------------------------------------- 36

3.15.1 RS-485 Setup ---------------------------------------------------------------------------------------------------------------------------- 36

3.16 Retransmission --------------------------------------------------------------------------------------------------------------------------------- 37

3.17 Heater Current Monitoring ------------------------------------------------------------------------------------------------------------------ 37

3.18 Event Input --------------------------------------------------------------------------------------------------------------------------------------- 38

3.18.1 Event Input Functions ----------------------------------------------------------------------------------------------------------------- 38

3.19 Remote Set Point ------------------------------------------------------------------------------------------------------------------------------- 39

3.20 Ramp and Soak Program --------------------------------------------------------------------------------------------------------------------- 39

3.20.1 PROF --------------------------------------------------------------------------------------------------------------------------------------- 39

3.20.2 RUN ---------------------------------------------------------------------------------------------------------------------------------------- 40

3.20.2.1 StAR ------------------------------------------------------------------------------------------------------------------------------------ 40

3.20.2.2 CoNt ------------------------------------------------------------------------------------------------------------------------------------ 40

3.20.2.3 PV --------------------------------------------------------------------------------------------------------------------------------------- 40

3.20.2.4 Hold ------------------------------------------------------------------------------------------------------------------------------------ 40

3.20.2.5 StoP ------------------------------------------------------------------------------------------------------------------------------------ 40

3.20.3 RMPU -------------------------------------------------------------------------------------------------------------------------------------- 40

3.20.4 STAR --------------------------------------------------------------------------------------------------------------------------------------- 40

3.20.5 END ----------------------------------------------------------------------------------------------------------------------------------------- 40

Page 4 of 44

3.20.5.1 SP1 -------------------------------------------------------------------------------------------------------------------------------------- 40

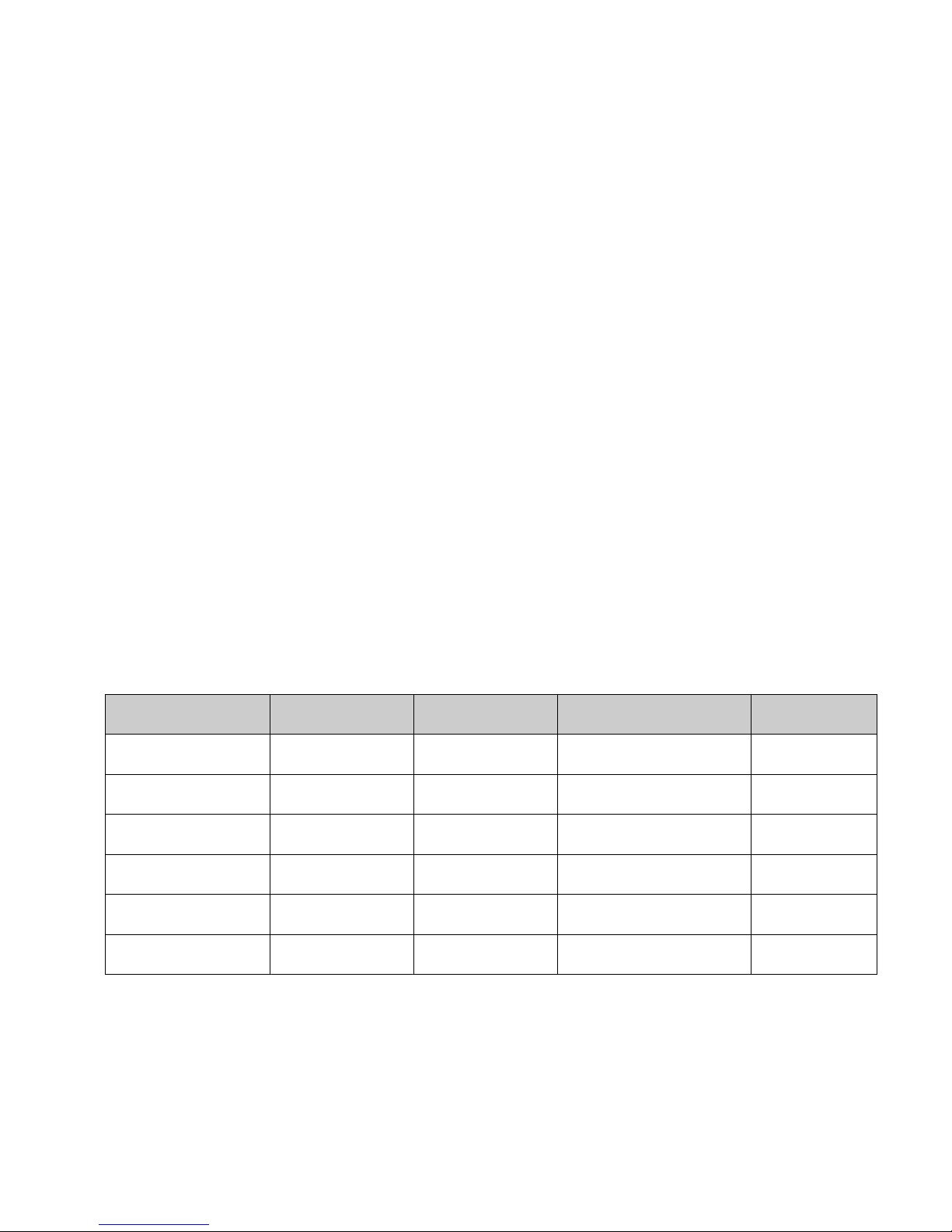

Model No

Mounting Type

DIN Size

Dimensions

LxWxD” (mm)

Depth Behind

Panel in(mm)

TEC-2400

Panel Mount

1/32 DIN

1 x 1 7/8 x 3 3/8”

(24x48x85)

3” (76)

TEC-9400

Panel Mount

1/16DIN

1 7/8 x 1 7/8 x 2 5/16”

(48x48x59)

2” (50)

TEC-8400/TEC-8450

Panel Mount

1/8 DIN

1 7/8 x 3 3/4 x 2 5/16”

(48x96x59)

2” (50)

TEC-7400

Panel Mount

3/16 DIN

2 27/32 x 2 27/32 x 2 5/16”

(72x72x59)

2” (50)

TEC-4400

Panel Mount

1/4 DIN

3 3/4 x 3 3/4 x 2 5/16

(96x96x59)

2” (50)

TEC-6400

DIN RAIL

7/8 x 3 3/4 x 3 5/32”

(22.5x96x80)

3.20.6 PFR ----------------------------------------------------------------------------------------------------------------------------------------- 40

3.20.6.1 CONT ----------------------------------------------------------------------------------------------------------------------------------- 41

3.20.6.2 PV --------------------------------------------------------------------------------------------------------------------------------------- 41

3.20.6.3 SP1 -------------------------------------------------------------------------------------------------------------------------------------- 41

3.20.6.4 OFF ------------------------------------------------------------------------------------------------------------------------------------- 41

3.20.7 Holdback ---------------------------------------------------------------------------------------------------------------------------------- 41

3.20.8 CYC ----------------------------------------------------------------------------------------------------------------------------------------- 42

3.20.9 Running, Holding and Stopping a Profile ---------------------------------------------------------------------------------------- 42

3.20.10 Viewing and Modifying the Profile Progress ------------------------------------------------------------------------------------ 42

3.20.11 Configuring the Profile ---------------------------------------------------------------------------------------------------------------- 42

3.20.11.1 Profile Segment Parameters ------------------------------------------------------------------------------------------------- 42

3.20.11.1.1 Target Set point -------------------------------------------------------------------------------------------------------------- 42

3.20.11.1.2 Ramp Time -------------------------------------------------------------------------------------------------------------------- 42

3.20.11.1.3 Soak Time ---------------------------------------------------------------------------------------------------------------------- 42

4! Factory Default Settings -------------------------------------------------------------------------------------------------------------------------- 43

1 Introduction

1.1 Introduction

The new generation of Tempco PID microprocessor-based Fuzzy logic controller series

incorporates two bright and easy to read LCD Displays which indicate Process Value (PV) and Set point (SP).

The Fuzzy Logic technology incorporated on these series controllers enables a process to reach a

predetermined set point in the shortest time with minimum of overshoot during start up (Power ON) or

external load disturbances (example: an oven door being opened).

Different controller models in this series are as follows:

These controllers are powered by an 11-26 or 90-250 VDC/VAC supply, incorporating a 2 Amp control relay output as

a standard. The second output can be used as a cooling control or an alarm. Both outputs can be selected as a 5VDC

or 14VDC logic output, linear current or linear voltage to drive an external device. There are six types of alarms and a

dwell timer that can be configured for the third output. The controllers are fully programmable for Linear current,

Linear Voltage, PT100 and thermocouple types J, K, T, E, B, R, S, N, L, U, P, C, and D. The input signal is

digitized by using an 18-bit A to D converter. Its fast sampling rate allows the controller to control fast processes.

Page 5 of 44

1.2 Features

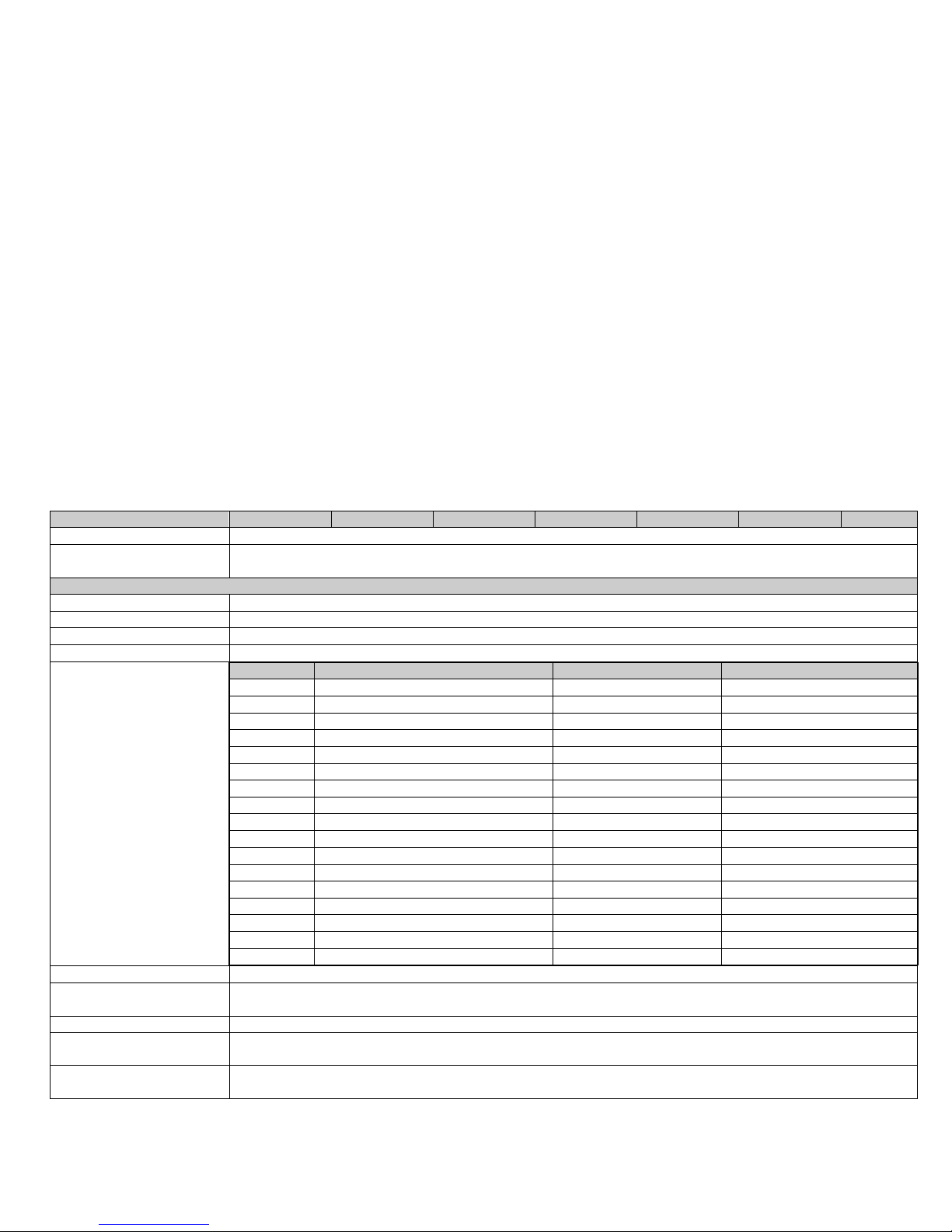

Specification

TEC-2400

TEC-9400

TEC-8400

TEC-8450

TEC-7400

TEC-4400

TEC-6400

Power Supply

90 to 250VAC, 47 to63Hz , 20 to 28 VAC,47-63Hz / 11 to 40 VDC

Power Consumption

TEC-2400/TEC-6400: 8VA, 4W Maximum., TEC-9400: 10VA, 5W Maximum., TEC-7400/TEC-8400/TEC-8450/TEC-4400: 12VA,6W

Maximum

Signal Input

Type

Thermocouple(J,K,T,E,B,R,S,N,L,U,P,C,D), RTD(PT100(DIN), PT100(JIS)), Current(mA),Voltage(Volts)

Resolution

18 Bits

Sampling Rate

5 Times / Second (200msec)

Maximum Rating

-2VDC minimum, 12VDC maximum

Input Characteristics

Type

Range

Accuracy @ 25°C

Input Impedance

J

-120°C to 1000°C( -184°F to 1832°F)

±2°C

2.2 MΩ

K

-200°C to 1370°C (-328°F to 2498°F)

±2°C

2.2 MΩ

T

-250°C to 400°C ( -418°F to 752°F )

±2°C

2.2 MΩ

E

-100°C to 900°C( -148°F to 1652°F )

±2°C

2.2 MΩ

B

0°C to 1820°C( 32°F to 3308°F )

±2°C( 200°C to 1800°C )

2.2 MΩ

R

0°C to 1767.8°C( 32°F to 3214°F )

±2°C

2.2 MΩ

S

0°C to 1767.8°C( 32°F to 3214°F )

±2°C

2.2 MΩ

N

-250°C to 1300°C( -418°F to 2372°F)

±2°C

2.2 MΩ

L

-200°C to 900°C( -328°F to 1652°F )

±2°C

2.2 MΩ

U

-200°C to 600°C (-328°F to 1112°F)

±2°C

2.2 MΩ

P

0°C to 1395°C( 32°F to 2543°F )

±2°C

2.2 MΩ

C

0°C to 2300°C( 32°F to 4172°F )

±2°C

2.2 MΩ

D

0°C to 2300°C( 32°F to 4172°F )

±2°C

2.2 MΩ

PT100(DIN)

-200°C to 850°C( -328°F to 1562°F )

±0.4°C

1.3KΩ

PT100(JIS)

-200°C to 600°C( -328°F to 1112°F )

±0.4°C

1.3KΩ

mA

-3mA to 27mA

±0.05%

2.5Ω

VDC

-1.3VDC to 11.5VDC

±0.05%

1.5MΩ

Temperature Effect

1.5µV /°C for all inputs except mA input, 3.0µV /°C for mA

Sensor Lead Resistance Effect

Thermocouple: 0.2 µV /°Ω; 3-wire RTD: 2.6°C /Ω of Difference of Resistance of two leads

2-wire RTD: 2.6°C /Ω of Sum of Resistance of two leads

Burn-out Current

200nA

Common Mode Rejection

Ratio(CMRR)

120 dB

Normal Mode Rejection Ratio

(NMRR)

55dB

The new generation of low cost PID controllers have many features, some of which are listed below.

v High Accuracy 18 Bit A-D Conversion and 15 Bit D-A Conversion

v Fastest Sampling Rate 200msec

v Universal Input

v Fuzzy Logic + PID Technology

v Possibility of both RS-485 and analog retransmission

v 16 Segments of Ramp & Soak

v Current Transformer (CT) Inputs for heater break detection

v Up to 6 Event Inputs

v Remote Set point

v Auto-Tuning

v Bumpless Transfer

v Lockout Protection

v Bidirectional Menu Navigation

v Soft Start function

1.3 Specifications

Page 6 of 44

Page 7 of 44

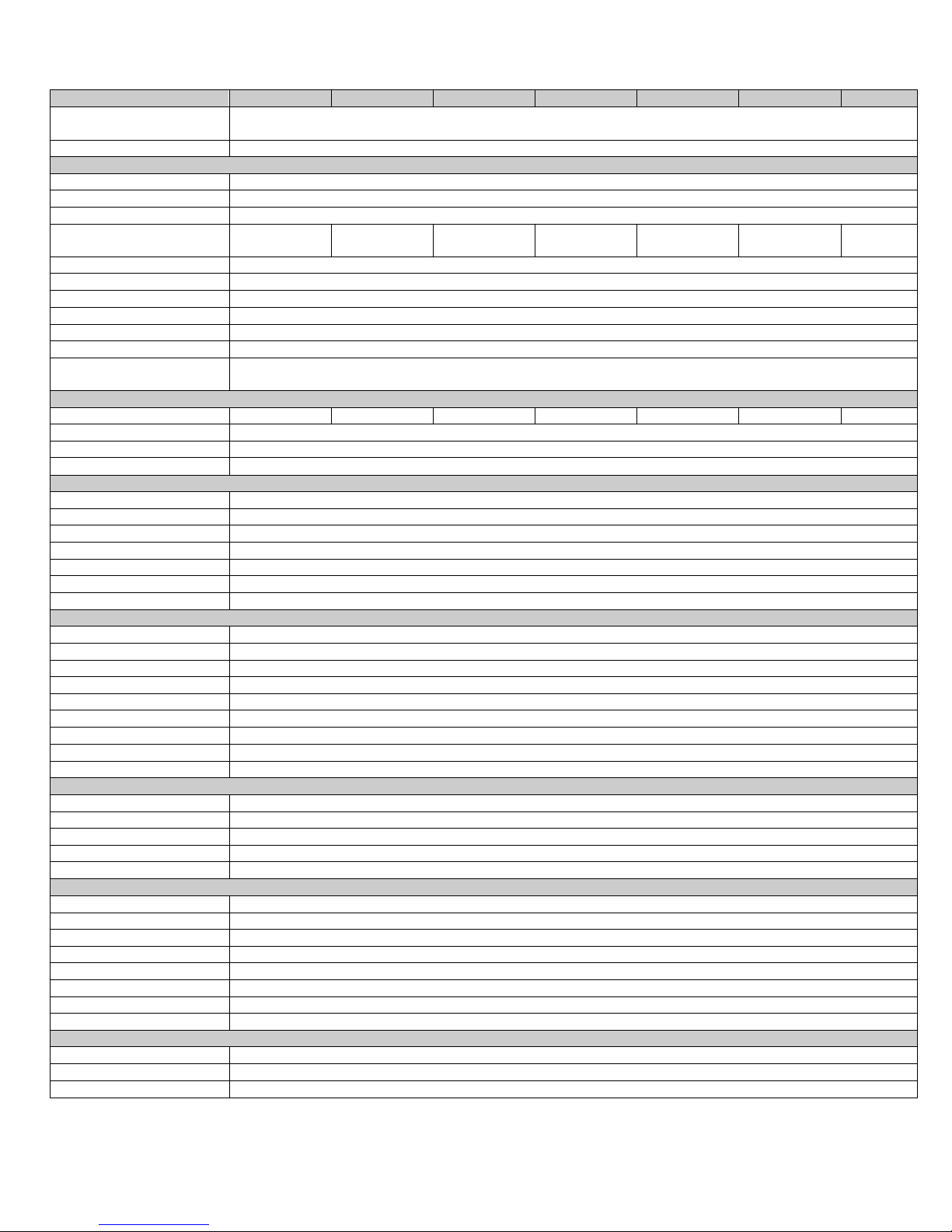

Specification

TEC-2400

TEC-9400

TEC-8400

TEC-8450

TEC-7400

TEC-4400

TEC-6400

Sensor Break Detection

Sensor open for Thermocouple, RTD and mV inputs, Sensor short for RTD input ,

Below 1mA for 4-20mA input, Below 0.25VDC for 1 - 5VDC input, Not available for other inputs.

Sensor Break Response Time

Within 4 seconds for Thermocouple, RTD and mV inputs, 0.1 second for 4-20mA and 1 - 5VDC inputs.

Remote Set Point Input

Type

Linear Current, Linear Voltage

Range

-3mA to 27mA, -1.3VDC to 11.5VDC

Accuracy

±0.05 %

Remote Set Point

Not Available

Not Available

Available

Available

Available

Available

Not

Available

Input Impedance

Current: 2.5Ω, Voltage:1.5MΩ

Resolution

18 Bits

Sampling Rate

1.66 Times/Second

Maximum Rating

280mA maximum for Current Input, 12VDC Maximum for Voltage Input

Temperature Effect

±1.5µV/°C for Voltage Input , ±3.0µV/°C for Current Input

Sensor Break Detection

Below 1mA for 4-20mA input, Below 0.25VDC for 1 - 5VDC input, Not available for other inputs.

Sensor Break Responding

Time

0.1 Second

Event Input

Number of Event Inputs

1 2 6 6 2 6 1

Logic Low

-10VDC minimum, 0.8VDC maximum.

Logic High

2VDC minimum, 10VDC maximum

Functions

See availability table

CT Input

CT Type

CT98-1

Accuracy

±2%of Full scale Reading,±0.2A

Input Impedance

294Ω

Measurement Range

0 to 50AAC

Output of CT

0 to 5VDC

CT Mounting

Wall (Screw) Mount

Sampling Rate

1 Time/Second

Output 1 /Output 2

Type

Relay, Pulsed Voltage, Linear Voltage, or Linear Current

Relay Rating

2A, 240V AC,200000 Life Cycles for Resistive Load

Pulsed Voltage

Source Voltage 5VDC,Current Limiting Resistance 66Ω

Linear Output Resolution

15 Bits

Linear Output Regulation

0.02% for full load change

Linear Output Settling Time

0.1 Sec (Stable to 99.9%)

Isolation Breakdown Voltage

1000 VAC

Temperature Effect

±0.01% of Span/ °C

Load Capacity of Linear Output

Linear Current: 500Ω max., Linear Voltage: 10KΩ min

Alarm

Relay Type

Form A

Maximum Rating

2A,240VAC,200000 Life Cycles for Resistive Load

Alarm Functions

Dwell Timer, Deviation Low, Deviation High, Deviation Band Low, Deviation Band High, Process High, Process Low

Alarm Mode

Latching, Hold, Normal, Latching/Hold

Dwell Timer

0.1 to 4553.6 Minutes

Data Communication

Interface

RS-485

Protocol

Modbus RTU (Slave Mode)

Address

1 to 247

Baud Rate

2.8KBPS to 115.2KBPS

Parity Bit

None, Even or Odd

Stop Bit

1 or 2 Bits

Data Length

7 or 8 Bits

Communication Buffer

160 Bytes

Analog Retransmission

Output Signal

4-20mA, 0-20 mA,0 - 10VDC

Resolution

15 Bits

Accuracy

±0.05% of Span ± 0.0025% / °C

Page 8 of 44

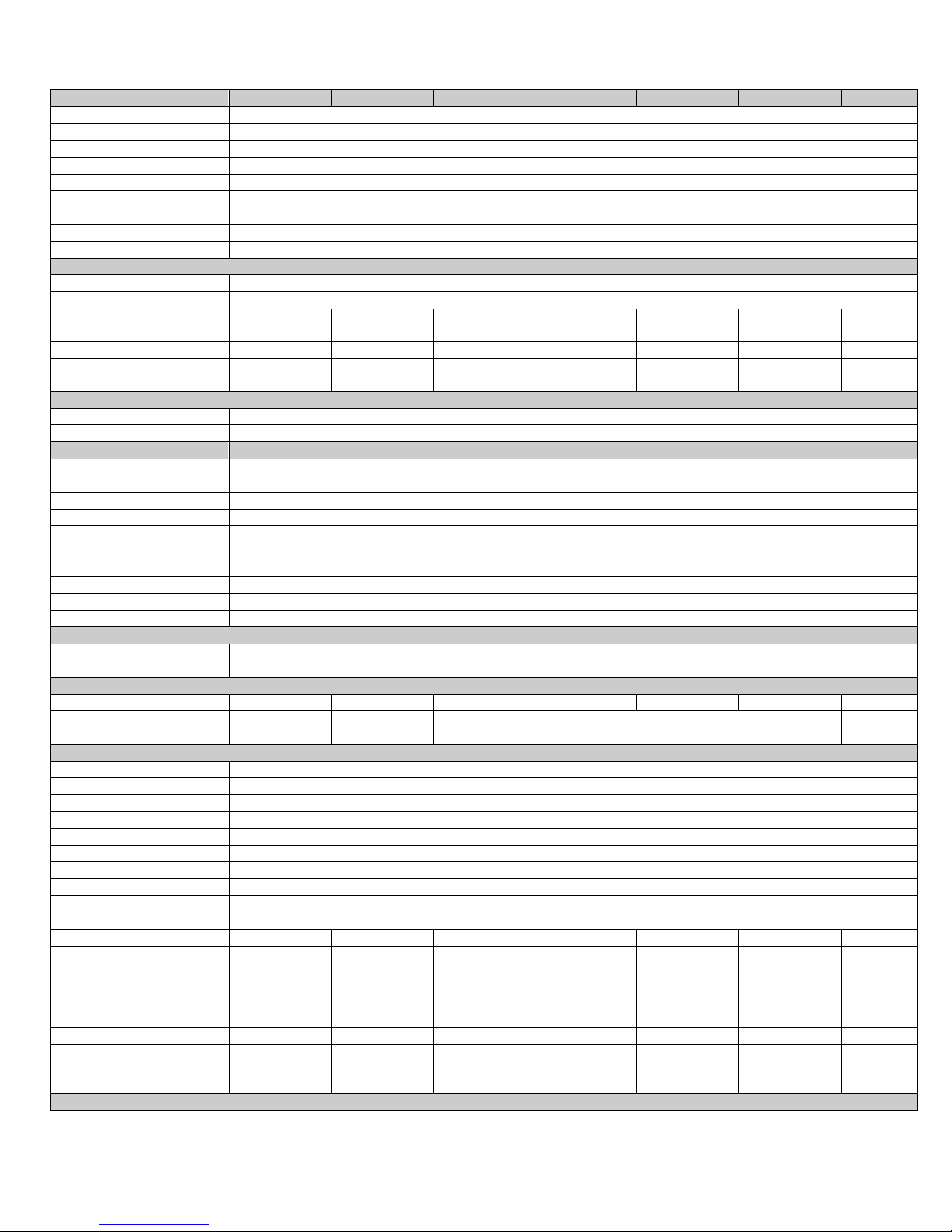

Specification

TEC-2400

TEC-9400

TEC-8400

TEC-8450

TEC-7400

TEC-4400

TEC-6400

Load Resistance

0 to 500Ω for current output , 10KΩ minimum for Voltage Output

Output Regulation

0.01% for full load change

Output Setting Time

0.1Second (stable to 99.9%)

Isolation Breakdown

1000VAC min

Integral Linearity Error

±0.005% of span

Temperature Effect

±0.0025% of span /°C

Saturation Low

0mA or 0VDC

Saturation High

22.2mA or 5.55V,11.1V min

Linear Output Ranges

0 - 22.2mA (0 - 20mA/4 - 20mA), 0 - 5.55VDC (0 - 5VDC, 1 - 5VDC),0 - 11.1VDC (0 - 10VDC)

User Interface

Keypad

4 Keys

Display Type

4 Digit LCD Display

Number of Displays (setpoint,

temperature, ect.)

2 2 3 3 3 3 2

Upper Display Size

0.4”(10mm)

0.58”(15mm)

0.7”(17.7mm)

0.7”(17.7mm)

0.58”(15mm)

0.98”(25mm)

0.31”(8mm)

Lower Display Size

0.19”(4.8mm)

0.3”(7.8mm)

0.4”(11.2mm)

0.4”(11.2mm)

0.32”(8.3mm)

0.55”(14mm)

0.25”(6.5m

m)

Programming Port

Interface

Micro USB

PC Communication Function

Automatic Setup, Calibration and Firmware upgrade

Control Mode

Output 1

Reverse (Heating) or Direct (Cooling) Action

Output 2

PID cooling control, Cooling P band 50~300% of PB, Dead band -36.0 ~ 36.0 % of PB

ON-OFF

0.1~50.0°C (0.1~90.0°F ) hysteresis control ( P band = 0)

P or PD

0 - 100.0 % offset adjustment

PID

Fuzzy logic modified Proportional band 0.1 ~ 500.0°C(0.1~900.0°F), Integral time 0 – 3600 Secs, Derivative Time 0 - 360.0 Secs

Cycle Time

0.1 to 90.0 Seconds

Manual Control

Heat(MV1) and Cool(MV2)

Auto-Tuning

Cold Start and Warm Start

Failure Mode

Auto transfer to manual mode while sensor break or A-D Converter damage

Ramping Control

0 to 500.0°C (0 to 900.0°F)/Minute or 0 to 500.0°C (0 to 900.0°F)/Hour Ramp Rate

Digital Filter

Function

First Order

Time Constant

0,0.2, 0.5, 1, 2, 5, 10, 20, 30, 60 Seconds, Programmable

Profiler

Availability

No

No

Option

Option

Option

Option

No

Number of Programs

NA

NA

1 Program with 16 Segments, 2 Programs with 8 Segments each, or 4

Programs with 4 Segments each

NA

Environmental and Physical Specifications

Operating Temperature

-10°C to 50°C

Storage Temperature

-40°C to 60°C

Humidity

0 to 90 % RH (Non-Condensing)

Altitude

2000 Meters Maximum

Pollution

Degree II

Insulation Resistance

20MΩ Minimum(@500V DC)

Dielectric Strength

2000VAC,50/60 Hz for 1 Minute

Vibration Resistance

10 to 55 Hz , 10m/s2 for 2 Hours

Shock Resistance

200 m/s2(20g)

Housing

Flame Retardant Polycarbonate

Mounting

Panel

Panel

Panel

Panel

Panel

Panel

DIN Rail

Dimensions H*W*D:” (mm)

15/16 x 1 7/8 x 3

13/16”

(24*48*92)

1 7/8 x 1 7/8 x

2 3/8”

(48*48*59)

3 3/4 x 1 7/8 x

2 3/8”

(96*48*59)

1 7/8 x 3 3/4 x

2 3/8”

(48*96*59)

2 27/32 x 2

27/32 x 2 3/8”

(72*72*59)

3 3/4 x 3 3/4 x

2 3/8”

(96*96*59)

3 3/4 x 7/8

x

3 11/16”

(96*22.5*8

3)

Depth Behind Panel” (mm)

3” (84)

2” (50)

2” (50)

2” (50)

2” (50)

2” (50)

Cut Out Dimensions” (mm)

7/8 x 1 25/32”

(22*45)

1 25/32 x 1

25/32” (45*45)

1 25/32 x 3 5/8”

(45*92)

3 5/8 x 1 25/32”

(92*45)

2 11/16 x 2

11/16” (68*68)

3 5/8 x 3 5/8”

(92*92)

Weight Lbs. (grams)

.26 (120)

.35 (160)

.48 (220)

.48 (220)

.41 (190)

.64 (290)

.35 (160)

Approval Standards

Specification

TEC-2400

TEC-9400

TEC-8400

TEC-8450

TEC-7400

TEC-4400

TEC-6400

Safety

UL61010-1, CSA 22.2 No.61010-1-12, EN61010-1 ( IEC1010-1 )

Protective Class

IP66 for Panel (In process), IP20 for terminals and housing. All indoor use.

EMC

EN61326

1.4 Keys and Displays

KEYPAD OPERATION

SCROLL KEY:

This key is used to scroll through a menu to select a parameter to be viewed or adjusted.

UP KEY:

This key is used to increase the value of the selected parameter.

DOWN KEY:

This key is used to decrease the value of the selected parameter.

RESET KEY:

This key is used to:

1. Revert the display to the home screen.

2. Reset a latching alarm once the alarm condition is removed.

3. Stop manual control mode, Auto-Tuning mode or calibration mode.

4. Clear an Auto-Tuning or communication error message.

5. Restart the dwell timer when the dwell timer has timed out.

6. Enter the manual control menu if failure mode occurs.

ENTER KEY: Press and hold for 5 seconds or longer to:

1. Enter the setup menu. The display will show .

2. Enter manual control mode. Press and hold for 6.2 seconds, then let go, to select manual control

mode. The display will show .

3. Enter Auto-Tuning mode. Press and hold for 7.4 seconds, then let go to select Auto-Tuning

mode. The display will show .

4. Perform calibration of a selected parameter during the calibration procedure. Press and hold for

8.6 seconds, then let go to select calibration mode.

During power-up, the upper display will show PROG and the lower display will show the

Firmware version for 6 seconds.

Page 9 of 44

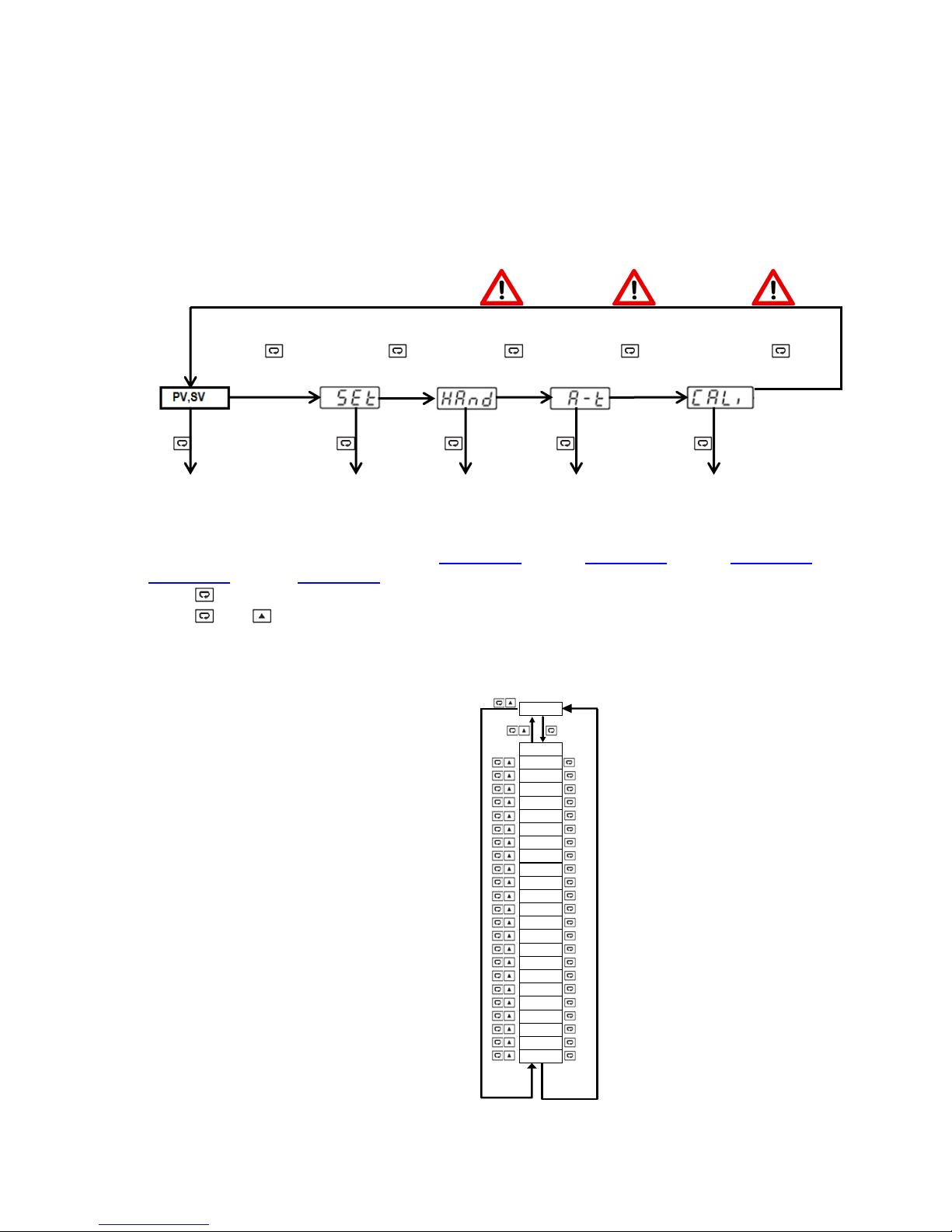

1.5 Menu Flowchart

User Menu

Setup

Menu

Manual Mode

Auto-Tuning Mode

Calibration Mode

To access

parameter

In the User Menu,

Refer to

Section 1.5.1

To access

parameter in

the Setup Menu,

Refer to

Section 1.5.2

To start

Manual Control

Mode, Refer to

Section 1.5.3

To start

Auto-Tuning

Mode, Refer to

Section 1.5.4

To access

Calibration Mode,

Refer to

Section 1.5.5

PV,SV

SP1

SP2

SP3

SP4

SP5

SP6

SP7

SFtR

CT1R

CT2R

DTM R

PASS

RUN

CYCR

STEP

TIMR

SEL1

SEL2

SEL3

SEL4

SEL5

SEL6

SEL7

SEL8

The Menu has been divided in to 5 groups. They are as follows:

1. User Menu

2. Setup Menu

3. Manual Mode Menu

4. Auto-Tuning Mode Menu

5. Calibration Mode Menu (not recommended, calibration section has been removed)

5 Sec 6.2 Sec 7.4 Sec 8.6 Sec 9.8 Sec

5 Sec 5 Sec 2 Sec Min

3 Sec Max

Press for the next parameter

Press and key to return to the previous parameter.

1.5.1 User Menu

The below user menu parameters are available depending on user selection.

Page 10 of 44

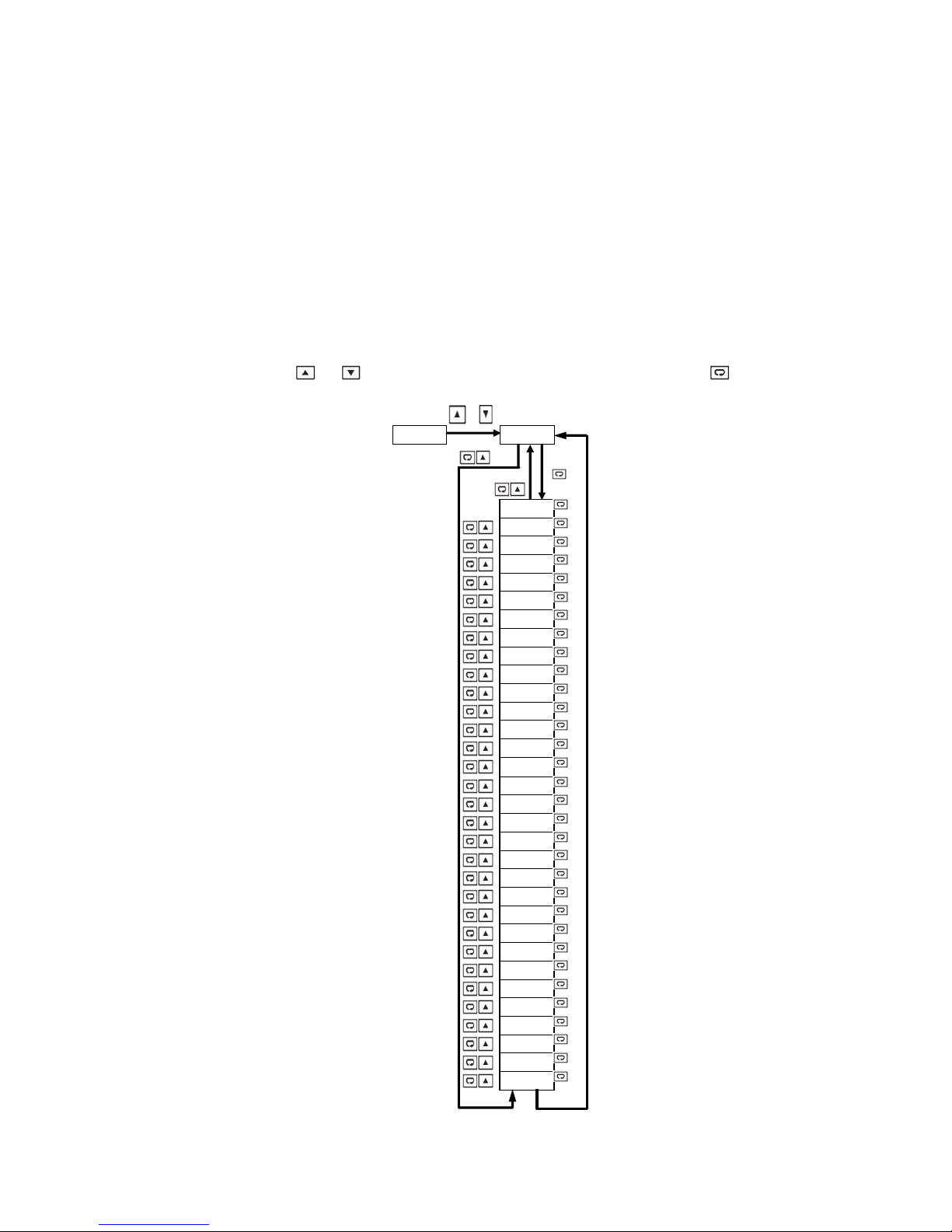

1.5.2 Setup Menu

or

SET bASE

OFS1

OFS2

OFS3

INPT

UNIT

DP

INLO

INHI

SP1L

SP1H

FILT

DISP

PB

TI

TD

RAMP

RR

RETY

RELO

REHI

RMSP

RINL

RINH

CODE

OFSTL

OFSTH

CALO

CAHI

SFT

SFL1

SFL2

SFtH

The setup menu has been categorized in to eight categories. They are listed below.

1.5.2.1 Basic Menu (bASE)

Use or key to get bASE in the lower display, then use the key to enter to basic

menu parameters.

1. Basic Menu

2. Output Menu

3. Alarm Menu

4. Event Input Menu

5. User Select Menu

6. Communication Menu

7. Current Transformer Input Menu

8. Profile Menu

Page 11 of 44

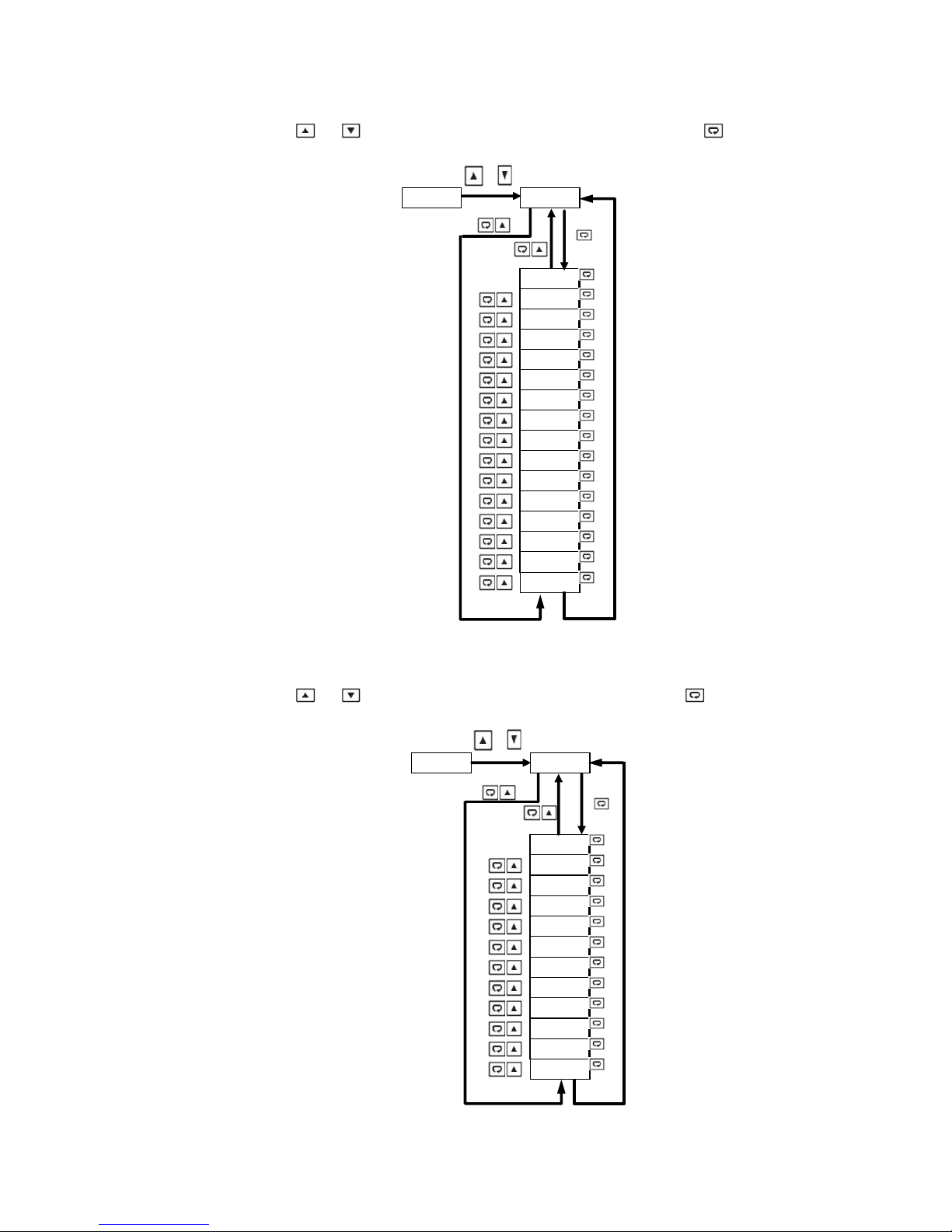

1.5.2.2 Output Menu (oUT)

or

SET OUT

OUT1

O1TY

O1FT

O1HY

CYC1

OFST

OUT2

O2TY

O2FT

CYC2

CPB

DB

PL1L

PL1H

PL2L

PL2H

or

SET EI

E1FN

SP2

E2FN

SP3

E3FN

SP4

E4FN

SP5

E5FN

SP6

E6FN

SP7

Use or key to get oUT in the lower display, then use the key to scroll through

output menu parameters.

1.5.2.3 Event Input Menu (EI)

Use or key to get EI in the lower display, then use the key to scroll through event

input menu parameters.

Page 12 of 44

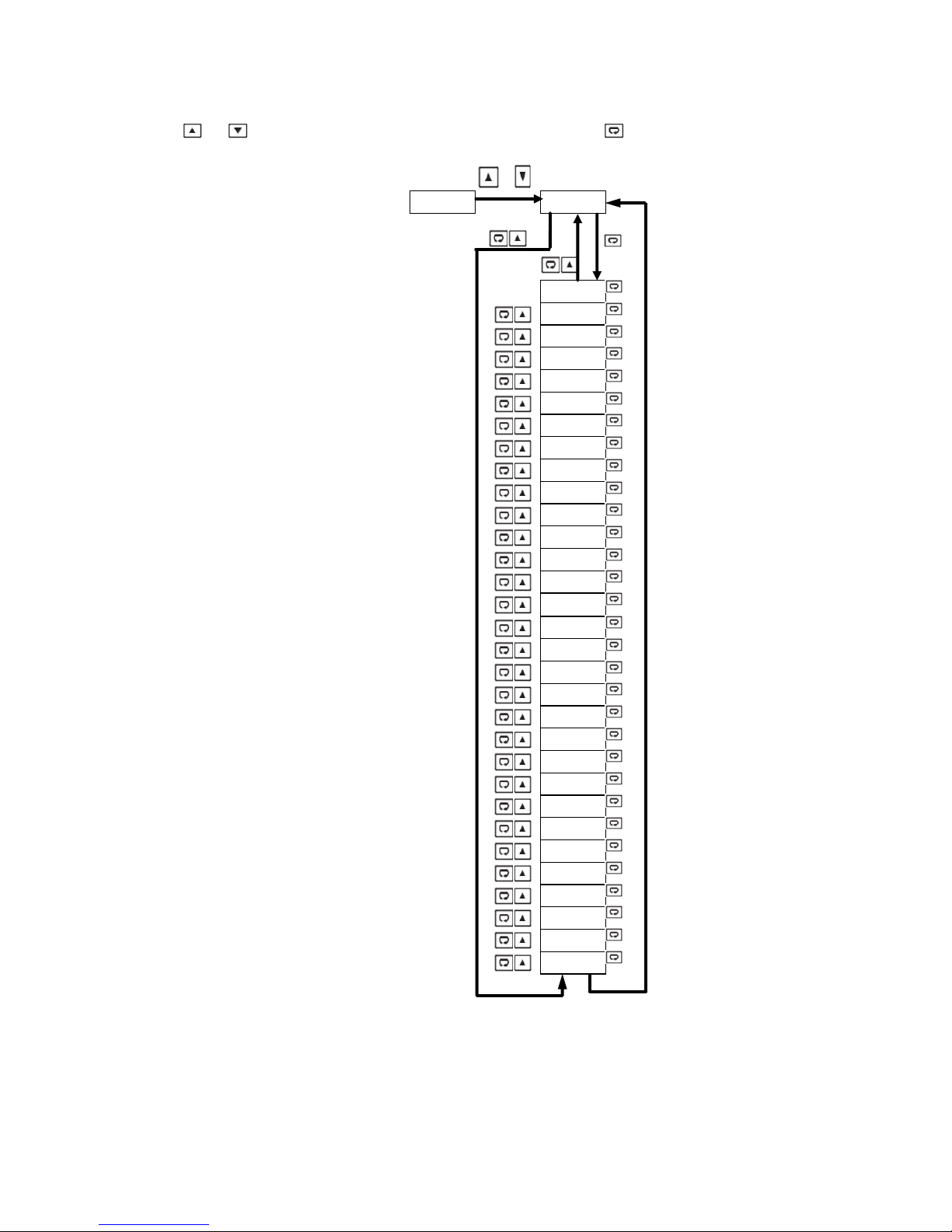

1.5.2.4 Alarm Menu (ALRM)

or

SET ALRM

A1 FN

A1 MD

A1 HY

A1 FT

A1 SP

A1 DV

A1 DL

A2 OT

A2 FN

A2 MD

A2 HY

A2 FT

A2 SP

A2 DV

A2 DL

A3 OT

A3 FN

A3 MD

A3 HY

A3 FT

A3 SP

A3 DV

A3 DL

A4 OT

A4 FN

A4 MD

A4 HY

A4 FT

A4 SP

A4 DV

A4 DL

Use or key to get ALRM in the lower display, then use the key to scroll through alarm menu

parameters.

Page 13 of 44

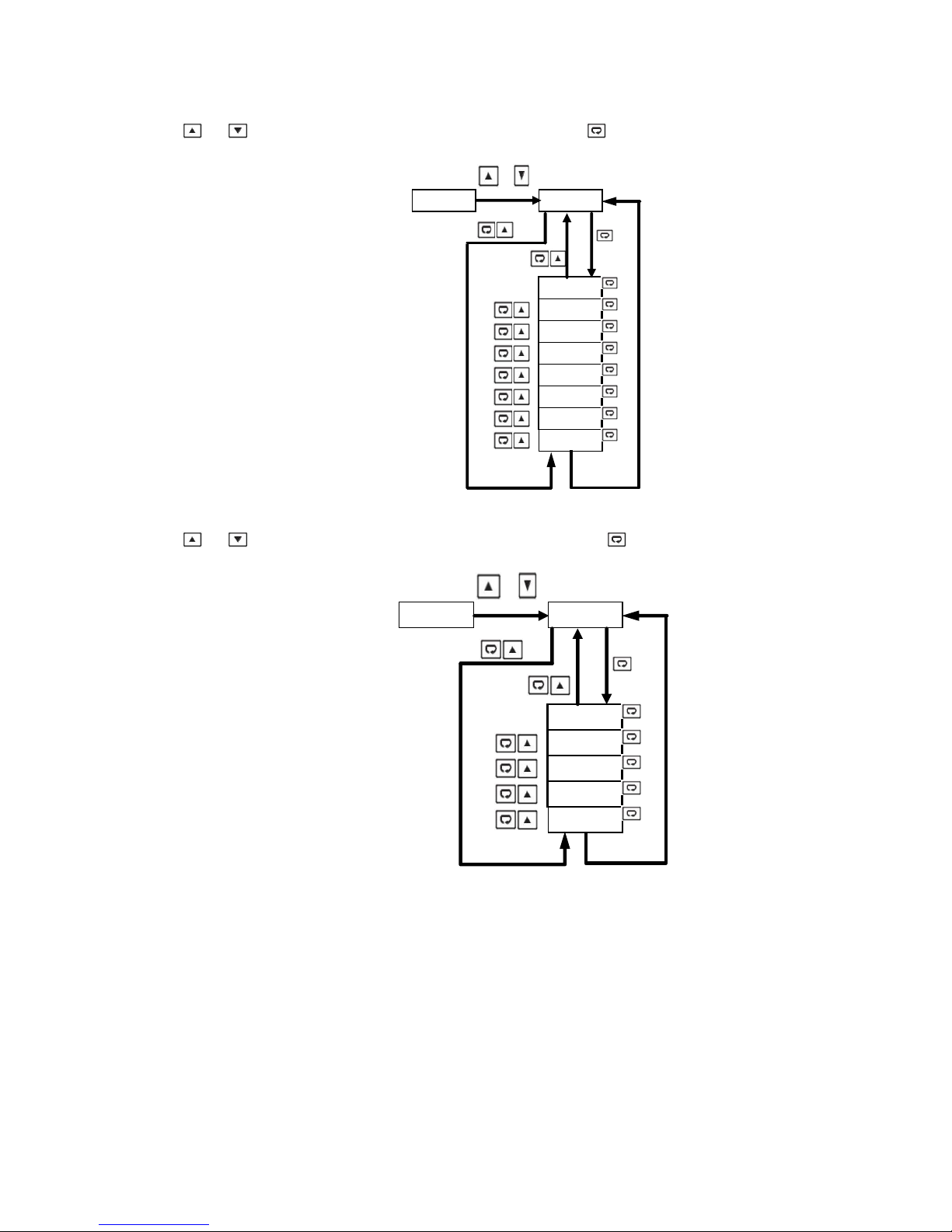

1.5.2.5 User Select Menu (SEL)

or

SET SEL

SEL1

SEL2

SEL3

SEL4

SEL5

SEL6

SEL7

SEL8

or

SET CoMM

ADD R

BAUD

DATA

PARI

ST OP

Use or key to get SEL in the lower display, then use the key to scroll through the “select” user

menu parameters.

1.5.2.6 Communication Menu (CoMM)

Use or key to get CoMM in the lower display, then use the key to scroll through the

communication menu parameters.

Page 14 of 44

Loading...

Loading...