Tempco tec-220, tec-920 Instruction Manual

Instruction Manual

TEC-220 and TEC-920

Auto-Tune Fuzzy / PID Process

Temperature Controller

Serving Industry Since 1972

Agency Approvals

TEMPCO Electric Heater Corporation

607 N. Central Avenue • Wood Dale, IL 60191-1452 USA

Tel: 630-350-2252 • Toll Free: 800-323-6859

Fax: 630-350-0232 • E-mail: info@tempco.com

Web: www.tempco.com

Manual TEC-220/920 Revision 9/2016

NOTES

Warning Symbol

This symbol calls attention to an operating procedure, practice, or

the like which, if not correctly performed or adhered to, could

result in personal injury or damage to or destruction of part or all

of the product and system. Do not proceed beyond a warning symbol until the indicated conditions are fully understood and met.

Using the Manual

Installers . . . . . . . . . . . . . . . . . . . . . . . . . . . Read Chapter 1, 2

System Designer . . . . . . . . . . . . . . . . . . . . . Read All Chapters

Expert User . . . . . . . . . . . . . . . . . . . . . . . . . Read Page 11

Contents

Page No.

Chapter 1 Overview

1-1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

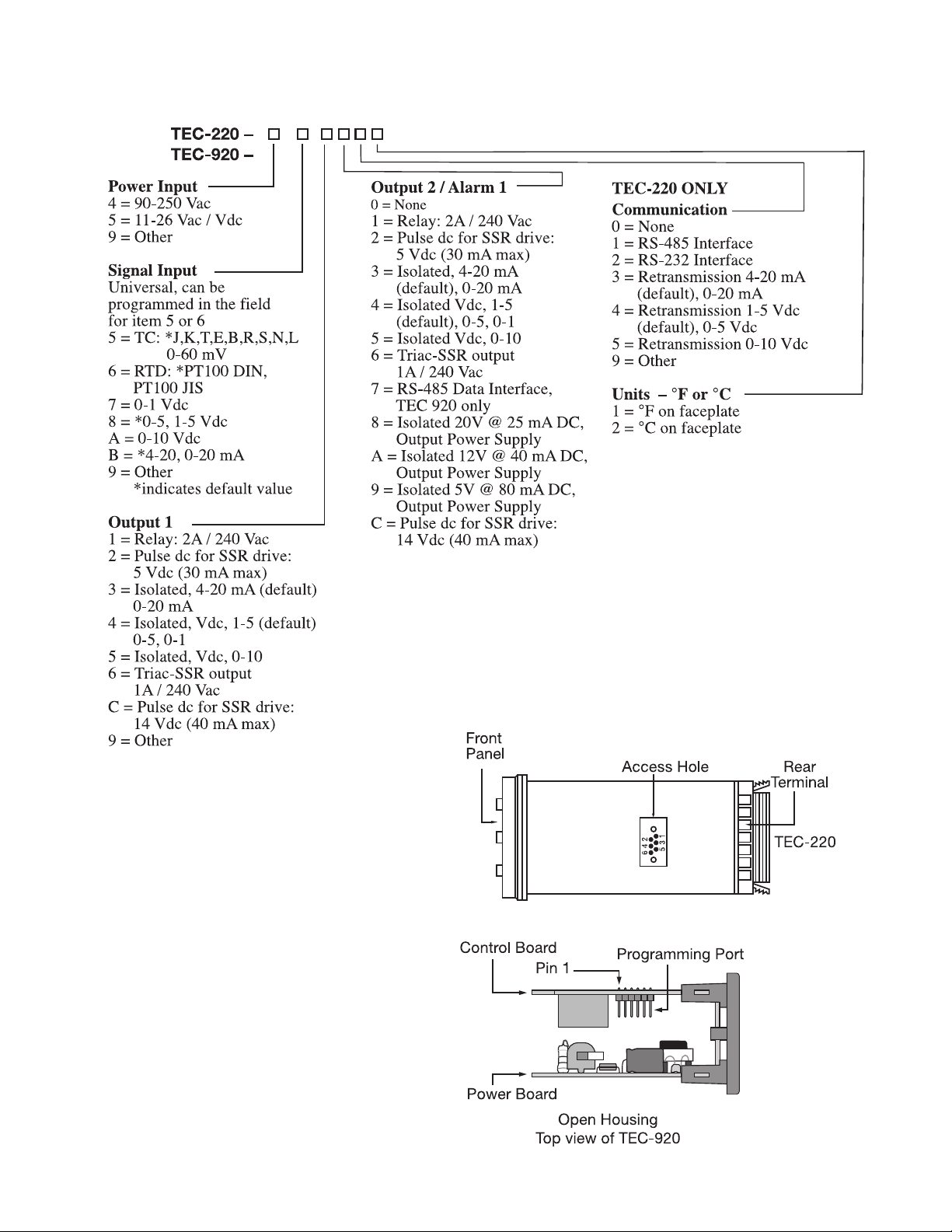

1-2 Ordering Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-3 Programming Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-4 Keys and Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1-5 Menu Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1-6 Parameter Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . 5

Chapter 2 Installation

2-1 Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2-2 Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2-3 Wiring Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2-4 Power Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2-5 Sensor Installation Guidelines . . . . . . . . . . . . . . . . . . . 8

2-6 Sensor Input Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2-7 Control Output Wiring . . . . . . . . . . . . . . . . . . . . . . . . . 8

2-8 Alarm Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2-9 Data Communication . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Chapter 3 Programming

3-1 Lockout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3-2 Signal Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3-3 Control Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3-4 Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3-5 Configuring the Display . . . . . . . . . . . . . . . . . . . . . . . 14

3-6 Ramp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3-7 Dwell Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3-8 PV Shift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3-9 Digital Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3-10 Failure Transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3-11 Auto-tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3-12 Manual tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3-13 Manual Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3-14 Data communication. . . . . . . . . . . . . . . . . . . . . . . . . . 17

3-15 Process Variable (PV) Retransmission. . . . . . . . . . . . 17

Chapter 4 Applications

4-1 Heat Only Control With Dwell Timer . . . . . . . . . . . . . 19

4-2 Cool Only Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4-3 Heat-Cool Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Chapter 5 Calibration . . . . . . . . . . . . . . . . . . 21

Chapter 6 Specifications . . . . . . . . . . . . . 23

Chapter 7 Modbus Communications

7-1 Functions Supported . . . . . . . . . . . . . . . . . . . . . . . . . . 25

7-2 Exception Responses . . . . . . . . . . . . . . . . . . . . . . . . . . 26

7-3 Parameter Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

7-4 Data Conversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

7-5 Communication Examples . . . . . . . . . . . . . . . . . . . . . . 29

Appendix

A-1 Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

A-2 Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

NOTE:

It is strongly recommended that a process should incorporate a LIMIT CONTROL like TEC-910 which will shut

down the equipment at a preset process condition in order to

preclude possible damage to products or system.

Information in this user's manual is subject to change without

notice.

Copyright © 2010, Tempco Electric Heater Corporation, all

rights reserved. No part of this publication may be reproduced,

transmitted, transcribed or stored in a retrieval system, or translated into any language in any form by any means without the

written permission of Tempco Electric Heater Corporation.

Figures & Tables

Page No.

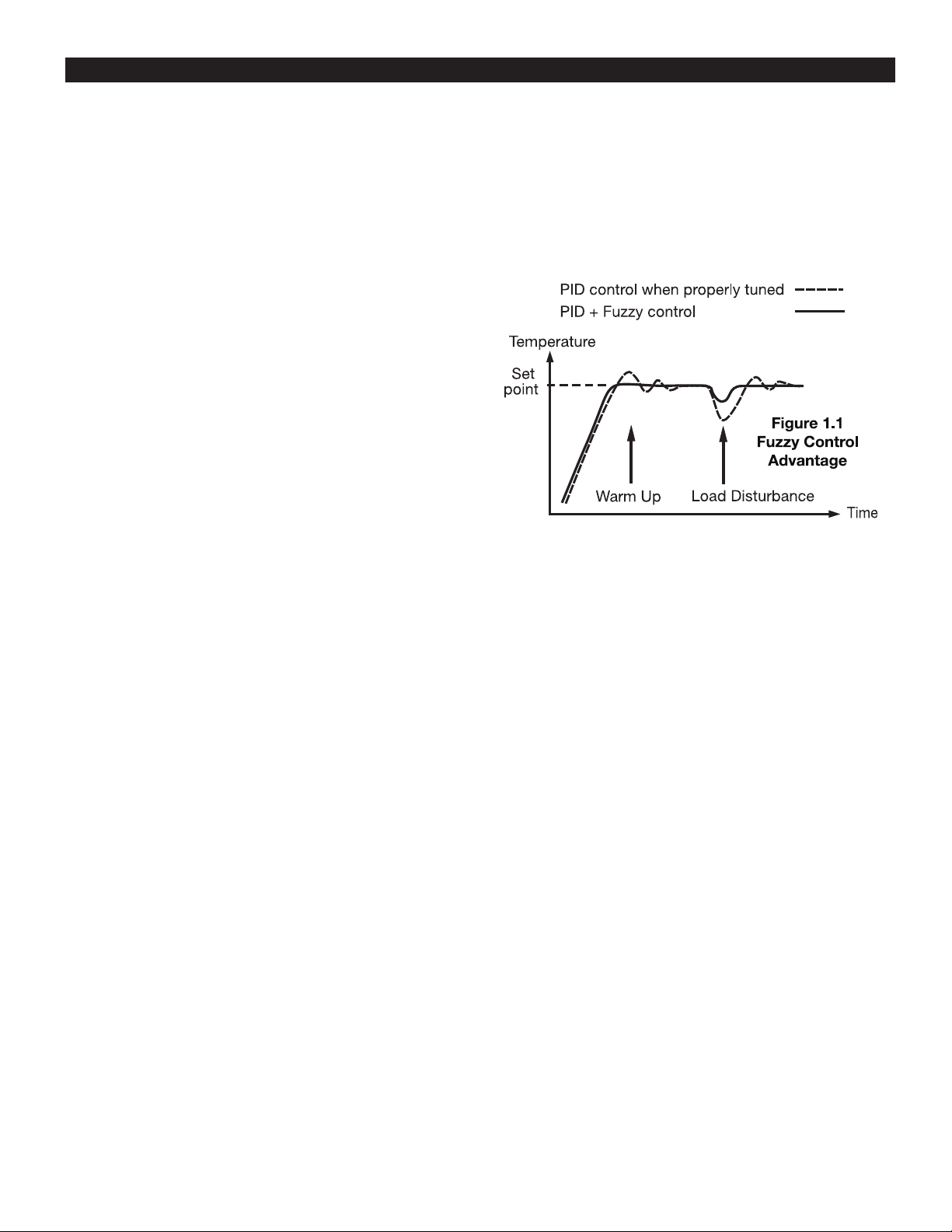

Figure 1.1 Fuzzy Control Advantage. . . . . . . . . . . . . . . . . . 1

Figure 1.2 Programming Port Overview . . . . . . . . . . . . . . . 2

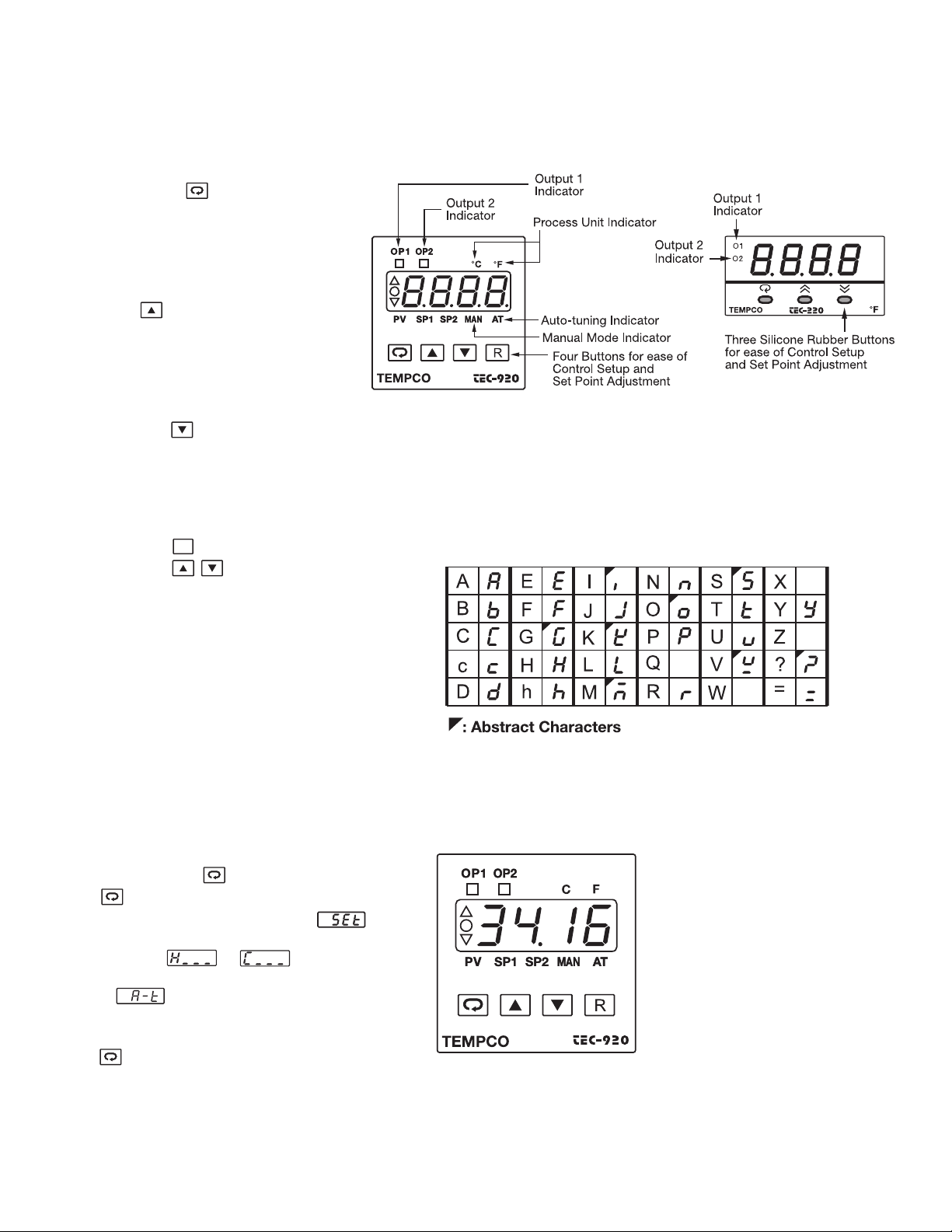

Figure 1.3 Front Panel Description . . . . . . . . . . . . . . . . . . 3

Figure 1.4 Display in Initial Stage. . . . . . . . . . . . . . . . . . . . 3

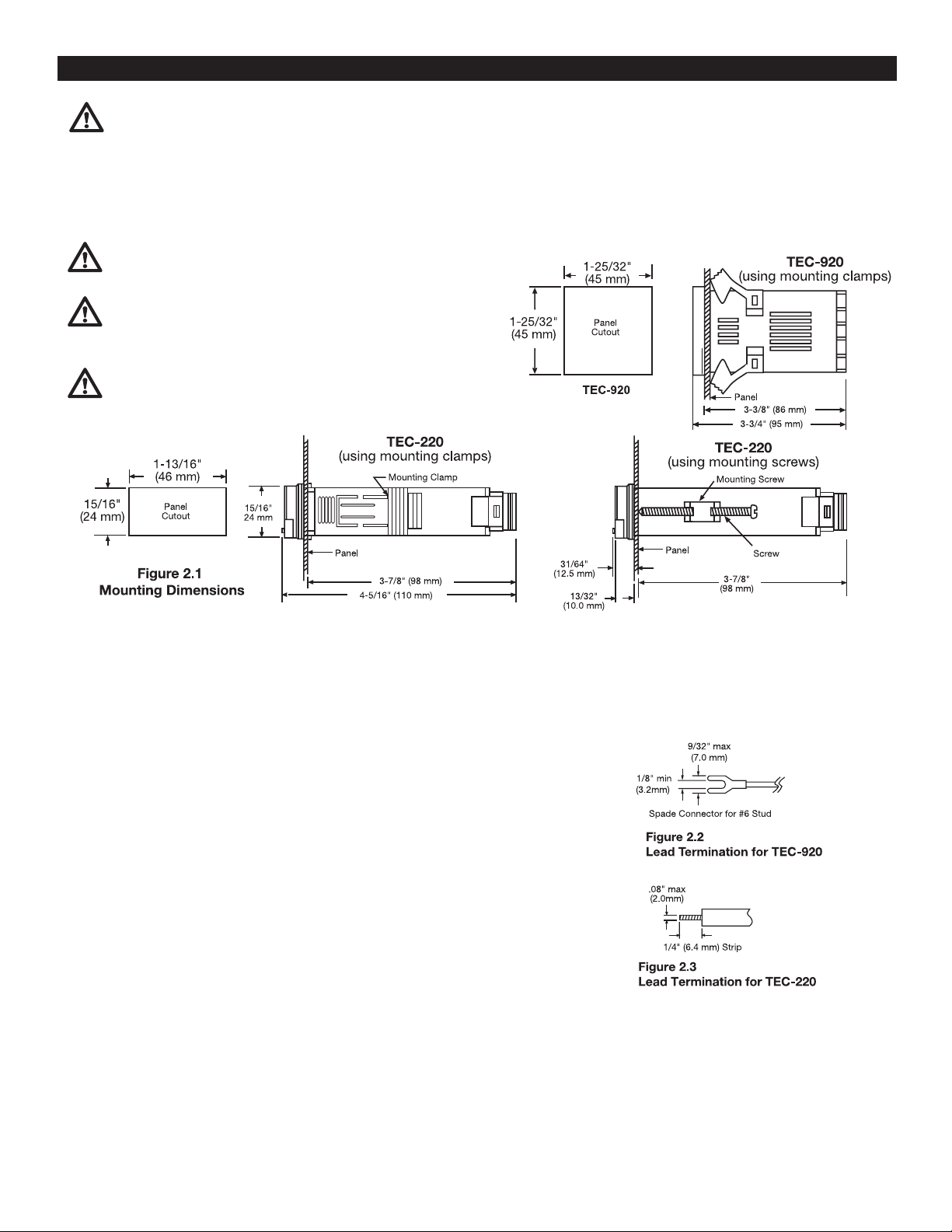

Figure 2.1 Mounting Dimensions and Panel Cutout . . . . . . 7

Figure 2.2 Lead Termination for TEC-920 . . . . . . . . . . . . . 7

Figure 2.3 Lead Termination for TEC-220 . . . . . . . . . . . . . 7

Figure 2.4 Rear Terminal Connection for TEC-220 . . . . . . 8

Figure 2.5 Rear Terminal Connection for TEC-920 . . . . . . 8

Figure 2.6 Power Supply Connections . . . . . . . . . . . . . . . . 8

Figure 2.7 Sensor Input Wiring . . . . . . . . . . . . . . . . . . . . . 8

Figure 2.8 Output 1 Relay or Triac (SSR) to

Drive Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 2.9 Output 1 Relay or Triac (SSR) to

Drive Contactor . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 2.10 Output 1 Pulsed Voltage to Drive SSR . . . . . . 9

Figure 2.11 Output 1 Linear Current . . . . . . . . . . . . . . . . . . 9

Figure 2.12 Output 1 Linear Voltage . . . . . . . . . . . . . . . . . . 9

Figure 2.13 Output 2 Relay or Triac (SSR) to

Drive Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 2.14 Output 2 Relay or Triac (SSR) to

Drive Contactor . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 2.15 Output 2 Pulsed Voltage to Drive SSR . . . . . . 9

Figure 2.16 Output 2 Linear Current . . . . . . . . . . . . . . . . . . 9

Figure 2.17 Output 2 Linear Voltage . . . . . . . . . . . . . . . . . 9

Figure 2.18 Alarm Output to Drive Load . . . . . . . . . . . . . 10

Figure 2.19 Alarm Output to Drive Contactor . . . . . . . . . . 10

Figure 2.20 RS-485 Wiring . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 2.21 RS-232 Wiring . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 2.22 Configuration of RS-232 Cable . . . . . . . . . . . 10

Figure 3.1 Conversion Curve for Linear Type

Process Value . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 3.2 Heat Only ON-OFF Control . . . . . . . . . . . . . . . 12

Figure 3.3 Output 2 Deviation High Alarm . . . . . . . . . . . . 13

Figure 3.4 Output 2 Process Low Alarm . . . . . . . . . . . . . . 13

Figure 3.5 RAMP Function . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 3.6 Dwell Timer Function . . . . . . . . . . . . . . . . . . . . 14

Figure 3.7 PV Shift Application . . . . . . . . . . . . . . . . . . . . . 15

Figure 3.8 Filter Characteristics . . . . . . . . . . . . . . . . . . . . . 15

Figure 3.9 Effects of PID Adjustment . . . . . . . . . . . . . . . . 16

Figure 4.1 Heat Control Example. . . . . . . . . . . . . . . . . . . . 19

Figure 4.2 Cooling Control Example . . . . . . . . . . . . . . . . . 19

Figure 4.3 Heat-Cool Control Example . . . . . . . . . . . . . . . 20

Figure 5.1 RTD Calibration . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 5.2 Cold Junction Calibration Setup . . . . . . . . . . . . 22

Table 1.1 Display Form of Characters . . . . . . . . . . . . . . . . 3

Table 3.1 Heat-Cool Control Setup Value . . . . . . . . . . . . . 11

Table 3.2 PID Adjustment Guide . . . . . . . . . . . . . . . . . . . . 16

Table A.1 Error Codes and Corrective Actions . . . . . . . . . 30

Appendix

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Returns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

NOTES

Chapter 1 Overview

1–1 General

Tempco’s TEC-220 and TEC-920 Fuzzy Logic plus PID microprocessor-based controllers incorporate a bright easy to read 4digit LED display indicating process value or set point. Fuzzy

Logic technology enables a process to reach a predetermined set

point in the shortest time with a minimum of overshoot during

power-up or external load disturbances.

The TEC-220 is a 1/32 DIN size panel mount controller. The

TEC-920 is a 1/16 DIN size panel mount controller. These units

are powered by 11–26 or 90–250 VDC/VAC 50/60 Hz supply,

incorporating a 2 Amp control relay output as a standard. The

second output can be used as a cooling control, an alarm or a

dwell timer. Either output can use a triac, 5V logic output, linear

current or linear voltage to drive an external device. There are six

types of alarms or a dwell timer that can be configured for the

second output. The units are fully programmable for PT100 RTD

and thermocouple types J, K, T, E, B, R, S, N, and L with no need

to modify the unit. The input signal is digitized by using an 18bit A to D converter. Its fast sampling rate allows the unit to control fast processes.

Digital communications RS-485 is available for the TEC-220 or

TEC-920. RS-232 is available for the TEC-220 only. These

options allow the units to be integrated with supervisory control

systems and software.

A programming port is available for automatic configuration,

without the need to access the keys on the front panel.

By using proprietary Fuzzy modified PID technology, the control loop will minimize overshoot and undershoot in a short time.

The following diagram is a comparison of results with and without Fuzzy technology.

High accuracy

This series is manufactured with custom

designed ASIC (Application Specific

Integrated Circuit) technology which

contains an 18-bit A to D converter for

high resolution measurement (true 0.1°F

resolution for thermocouple and RTD)

and a 15-bit D to A converter for linear

current or voltage control output. The

ASIC technology provides improved

operating performance, low cost,

enhanced reliability, and higher density.

Fast sampling rate

The sampling rate of the input A to D

converter is 5 times/second. The fast

sampling rate allows this series to control

fast processes.

Fuzzy control

The function of Fuzzy control is to adjust

PID parameters from time to time in

order to make manipulation of the output

value more flexible and adaptive to various processes. The result is to enable a

process to reach a predetermined set

point in the shortest time with the minimum of overshoot and undershoot during

power-up or external load disturbance.

Digital communication

The units are equipped with an optional

RS-485 or RS-232 interface cards to provide digital communication. By using the

twisted pair wires up to 247 units can be

connected together via RS-485 interface

to a host computer.

Programming port

A programming port can be used to connect the unit to a PC for quick configuration.

Auto-tune

The auto-tune function allows the user to

simplify initial setup for a new system.

An advanced algorithm is used to obtain

an optimal set of control parameters for

the process, and it can be applied either as

the process is warming up (cold start) or

when the process is in a steady state

(warm start).

Lockout protection

Depending on security requirements, one

of four lockout levels can be selected to

prevent the unit from being changed

without permission.

Bumpless transfer

Bumpless transfer allows the controller to

continue to control if the sensor breaks by

using its previous value. Hence, the

process can be controlled temporarily as

if the sensor reading is normal and constant.

Soft-start ramp

The ramping function is performed during power up as well as any time the set

point is changed. It can be ramping up or

ramping down. The process value will

reach the set point at a predetermined

constant rate.

Digital filter

A first order low pass filter with a programmable time constant is used to

improve the stability of the process value.

This is particularly useful in certain

applications where the process value is

too unstable to be read.

1

1–2 Ordering Code

1–3 Programming Port

A special connector can be used to

connect the programming port to a PC

for automatic configuration.

The programming port is used for offline automatic setup and testing procedures only. Don't attempt to make any

connection to these pins when the unit

is under power.

Figure 1.2

Programming Port Overview

2

1–4 Keys and Displays

R

KEYPAD OPERATION

SCROLL KEY:

This key is used to select a parameter to be

viewed or adjusted.

UP KEY:

This key is used to increase the value of the

selected parameter.

DOWN KEY:

This key is used to decrease the value of the

selected parameter.

Figure 1.3

Front Panel Description

RESET KEY: for TEC-920,

for TEC-220

This key is used to:

1. Revert the display to show the process value.

2. Reset the latching alarm, once the alarm condition is removed.

3. Stop the manual control mode, auto-tuning

mode, and calibration mode.

4. Clear the message of communication error and

auto-tuning error.

5. Restart the dwell timer when the dwell timer has

timed out.

6. Enter the manual control menu when in failure

mode.

ENTER KEY: Press for 5 seconds or longer.

Press for 5 seconds to:

1. Enter setup menu. The display shows .

2. Enter manual control mode — when manual

control mode or is selected.

3. Enter auto-tuning mode — when auto-tuning

mode (for 220) or AT (for 920) is selected.

4. Perform calibration to a selected parameter during the calibration procedure.

Press for 6.2 seconds to select calibration mode.

Table 1.1 Display Form of Characters

Displays program code of the

instrument for 2.5 seconds.

The diagram at left shows

program no. 34, version 16

for the TEC-920.

The program no. is 33 for the

TEC-220.

Figure 1.4

Display in Initial Stage

3

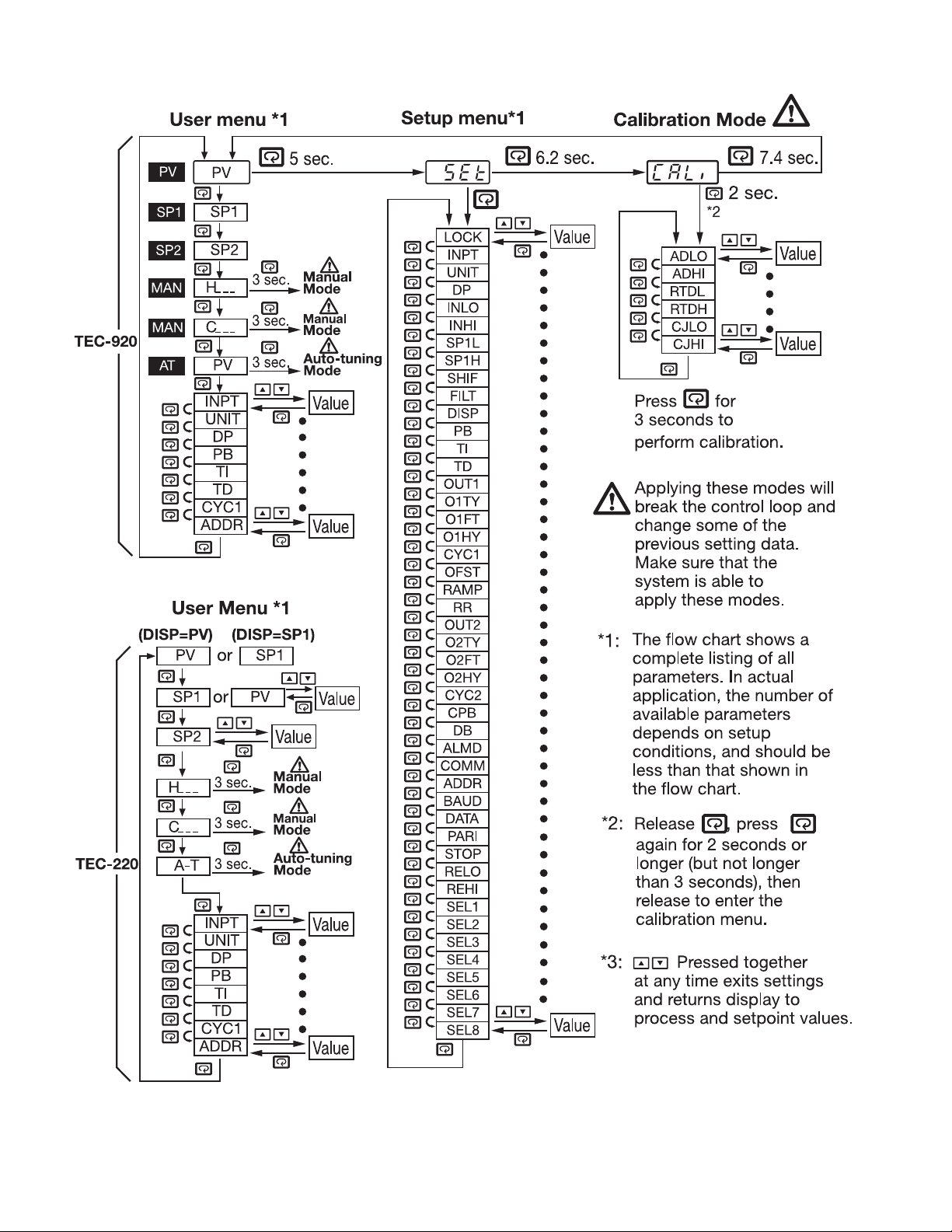

1–5 Menu Overview

4

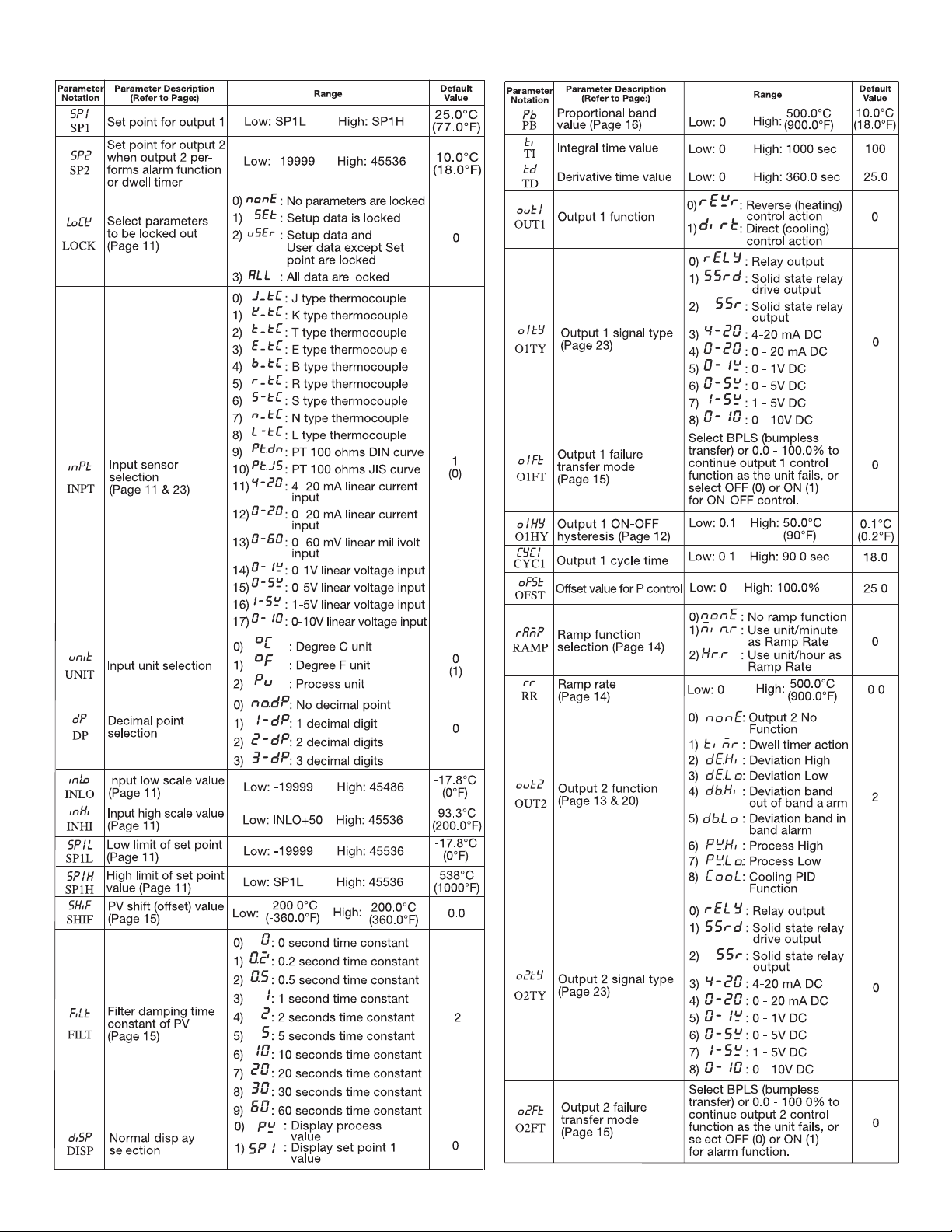

1–6 Parameter Descriptions

5

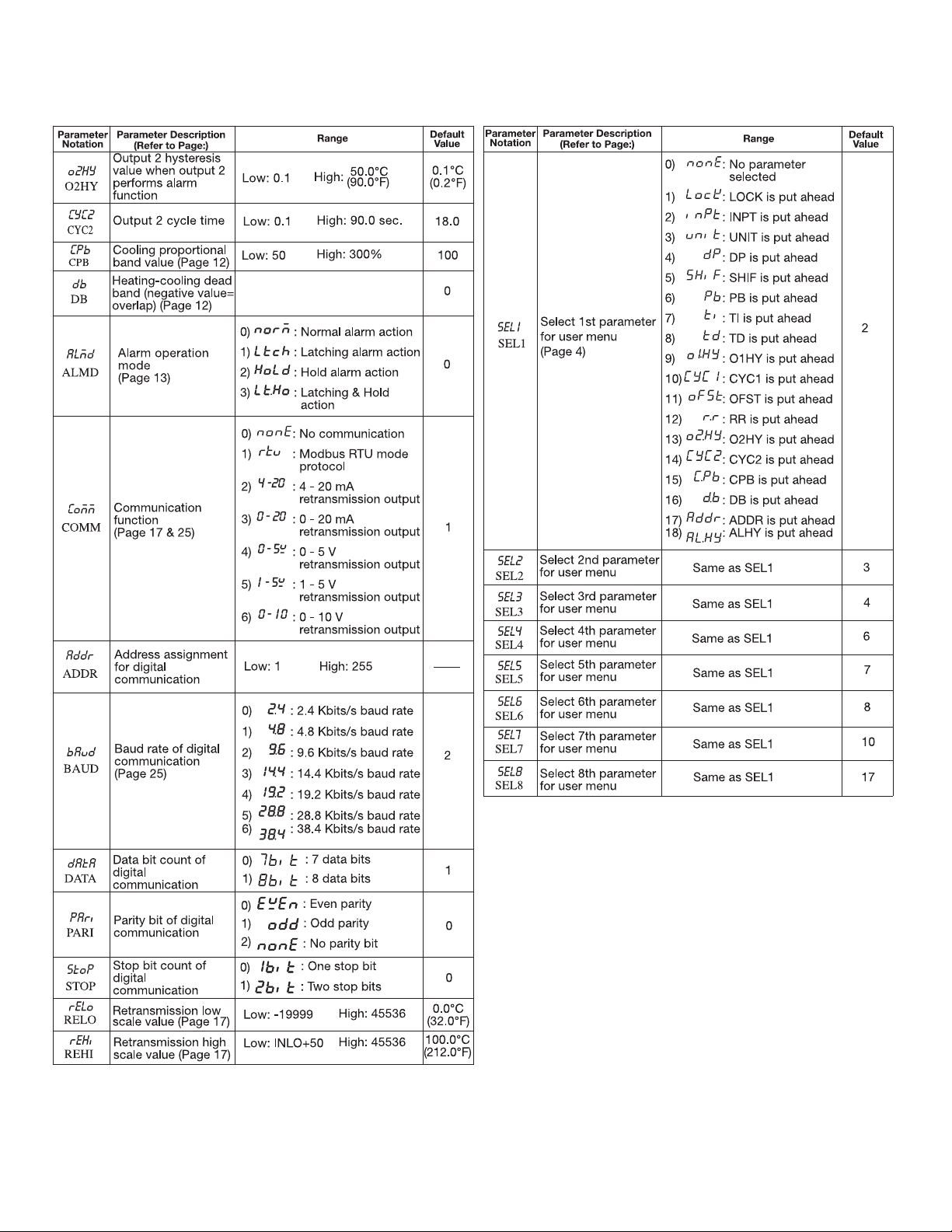

1–6 Parameter Descriptions, continued…

6

Chapter 2 Installation

Dangerous voltages capable of causing death are some-

times present in this instrument. Before installation or

beginning any troubleshooting procedures, the power to all

equipment must be switched off and isolated. Units suspected of

being faulty must be disconnected and removed to a properly

equipped workshop for testing and repair. Component replacement and internal adjustments must be made by a qualified maintenance person only.

This instrument is protected by double insulation. To

minimize the possibility of fire or shock hazards do not

expose this instrument to rain or excessive moisture.

Do not use this instrument in areas under hazardous con-

ditions such as excessive shock, vibration, dirt, moisture,

corrosive gases or oil. The ambient temperature of the area

should not exceed the maximum rating specified in chapter 6.

Remove stains from this instrument using a soft, dry

cloth. To avoid deformation or discoloration do not use

harsh chemicals, volatile solvent such as thinner or strong detergents to clean this instrument.

2–1 Unpacking

Upon receipt of the shipment, remove the unit from the carton

and inspect the unit for shipping damage.

2–2 Mounting

Make the panel cutout according to the dimensions shown in

Figure 2.1.

Take the mounting clamp away and insert the controller into the

panel cutout. Reinstall the mounting clamp.

2–3 Wiring Precautions

• Before wiring, verify the correct model number and options on the label.

Switch off the power while checking.

• Care must be taken to ensure that the maximum voltage rating specified on

the label is not exceeded.

• It is recommended that the power for these units be protected by fuses or circuit breakers rated at the minimum value possible.

• All units should be installed in a suitable enclosure to prevent live parts from

being accessible to human hands and metal tools. Metal enclosures and/or

subpanels should be grounded in accordance with national and local codes.

• All wiring must conform to appropriate standards of good practice and local

codes and regulations. Wiring must be suitable for the voltage, current, and

temperature rating of the system.

• Beware not to over-tighten the terminal screws. The torque should not

exceed 1 N-m (8.9 lb-in or 10 KgF-cm).

• Unused control terminals should not be used as jumper points as they may

be internally connected, causing damage to the unit.

• Verify that the ratings of the output devices and the inputs as specified are

not exceeded.

• Except for thermocouple wiring, all wiring should use stranded copper conductor with a maximum gage of 14 AWG.

• Electrical power in industrial environments contains a certain amount of

noise in the form of transient voltage and spikes. This electrical noise can

adversely affect the operation of microprocessor-based controls. For this

reason the use of shielded thermocouple extension wire which connects the

sensor to the controller is strongly recommended. This wire is a twisted-pair

construction with foil wrap and drain wire. The drain wire is to be attached

to ground in the control panel only.

Note: All model TEC-220 controls are supplied with

both mounting clamps and mounting screws. The

mounting screws have to be used in NEMA 4X applications as they allow the control to be held tighter

into the panel. The mounting clamp teeth are released

by depressing the ends of the clamp together.

Transit Damage

If there is any damage due to transit, report it and

file a claim with the carrier. Write down the model

number, serial number, and date code for future reference when corresponding with our service center.

The serial number (S/N) is labeled on the box and

the housing of the control.

Wiring, continued…

7

Loading...

Loading...