Tempco Photohelic 3005, Photohelic 3003, Photohelic 3008, Photohelic 3006, Photohelic 3002 Installation And Operating Instructions Manual

...

TEMPCO s.a. 4e ave. N°114, Z.I. des Hauts Sarts, B-4040 Herstal, Belgique. T:(32)04-2649458, F:(32)04-2649476, www.tempco.be, tempco@tempco.be

Les photos et caractéristiques présentés dans ce catalogue sont données à titre indicatif et ne sont pas contractuelles.

3.A.01.450-E-100910 page 1/7

The Photohelic®Switch/Gage is a very versatile, precise

pressure switch combined with the time-proven

Magnehelic®pressure gage. Models are available with one

or two phototransistor actuated relays. Gage reading is

unaffected by switch operation. Easy to adjust set points

have knob controls. Applied pressure and switch set points

are fully visible at all times. Deadband is one pointer width less than 1% of full scale. Double-pole double-throw relays

can be easily interlocked to provide variable deadband control. For positive, negative or differential pressure only on

3600S models. Full scale ranges available from 0-.25 in w.c.

to 0-6000 psig.

PHOTOHELIC®SENSING - HOW IT WORKS

In a typical control application, the Photohelic®switch/gage

controls between high and low pressure set points. When

pressure changes, reaching either set point pressure, the

beam from an LED to the limiting phototransistor will be cut

off by the helix-driven light shield. The resulting signal

change is electronically amplified to actuate its DPDT slave

relay and switching occurs. Dead band between make and

break is 1% of full scale or less - just enough to assure positive, chatter-free operation.

Series 3000 Photohelic®Pressure Switch/Gage

Specifications - Installation and Operating Instructions

SPECIFICATIONS

GAGE SPECIFICATIONS

Service: Air and non-combustible, compatible gases.

Wetted Materials: Consult Factory.

Accuracy: Photohelic®, ±2% of full scale at 70°F (21.1°C). ±3%

on -0 and ±4% on -00 models.

Pressure Limits: Photohelic

®

-20" Hg. to 25 psig (-0.677 to

1.72 bar). MP option; 35 psig (2.41 bar), HP option; 80 psig

(5.52 bar). 36003S – 36010S; 150 psig (10.34 bar). 36020S and

higher; 1.2 x full scale pressure.

Temperature Limits: 20 to 120°F.

(-6.67 to 48.9°C) Low temperature option available.

Process Connections: Photohelic

®

, 1/8˝ female NPT.

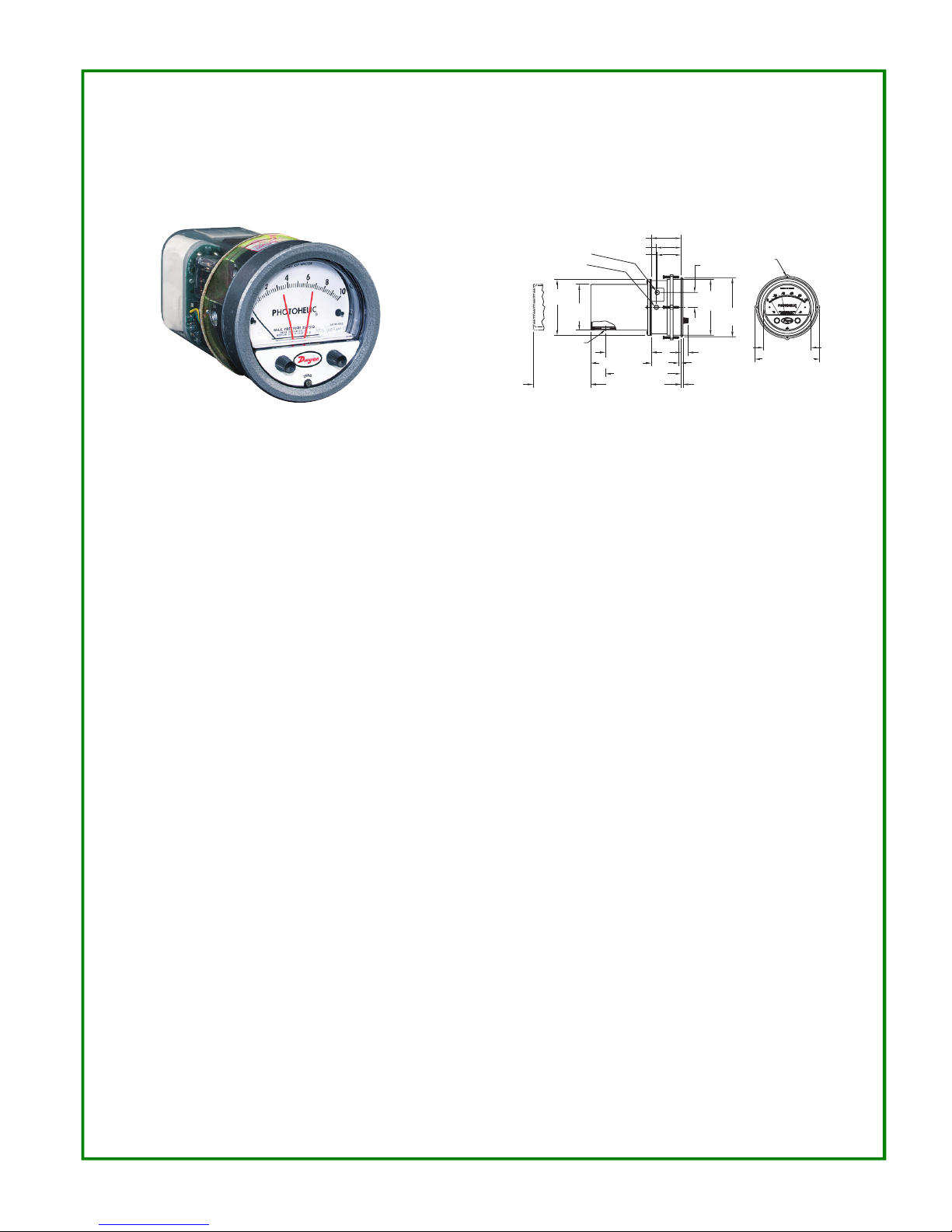

Size: Photohelic®, 4˝ (101.6 mm) dial face, 5˝ (127 mm) O.D. x 8-

1/4˝ (209.55 mm).

Weight: Photohelic

®

, 4 lbs. (1.81 kg).

SWITCH SPECIFICATIONS

Switch Type: Each setpoint has 2 Form C relays (DPDT).

Repeatability: ±1% of full scale.

Electrical Rating: Photohelic

®

, 10A @ 28 VDC, 10A @ 120,

240 VAC.

Electrical Connections: Screw Terminals.

Power Requirements: 120 VAC, 50/60 Hz; 240 VAC & 24 VAC

Power optional.

Mounting Orientation: Diaphragm in vertical position. Consult

factory for other position orientations.

Set Point Adjustment: Adjustable knobs on face.

Agency Approvals: Photohelic

®

UL, CSA, CE.

2-1/2 [63.50]

2-1/16 [52.39]

2 [50.80]

1-1/4

[31.75]

(4) 6-32 HOLES

EQUALLY SPACED ON

A 5-1/8 [130.18] B.C.

Ø4-47/64

[120.25]

Ø5

[127.00]

Ø4 [101.60]

FAC E

5-1/2 [139.70]

O.D.

MOUNTING

RING

5/8 [15.88]

5/8 [15.88] PANEL

MAX

3/16 [4.76]

3-7/8 [98.43]

5-1/8 [130.18]

6-3/8 [161.93]

(7-5/8 [193.68])

4-3/8 [111.13]

HOUSING REMOVAL

3/4 CONDUIT

CONNECTION

Ø4-3/4

[120.65]

3-7/8 SQ

[98.43]

1/8 FEMALE NPT HIGH

PRESSURE CONNECTION

1/8 FEMALE NPT LOW

PRESSURE CONNECTION

*Patent No. 3,862,416

6

TEMPCO s.a. 4e ave. N°114, Z.I. des Hauts Sarts, B-4040 Herstal, Belgique. T:(32)04-2649458, F:(32)04-2649476, www.tempco.be, tempco@tempco.be

Les photos et caractéristiques présentés dans ce catalogue sont données à titre indicatif et ne sont pas contractuelles.

3.A.01.450-E-100910 page 2/7

INSTALLATION

1. Location

All parts of the Dwyer Photohelic®pressure switch/gage are

ruggedly constructed and will stand a moderate amount of

vibration, physical shock, and handling. Normal care in handling and installation is all that is required. In cases where

instrument panel vibration is severe, the panel should be a

spring mounted or the amplifier-relay unit mounted remotely on a more stable surface.

Select a location where the ambient temperature will not

exceed 120°F. Pneumatic pressure sensing lines may be run

any necessary distance. For example, 250 foot sensing lines

will not affect accuracy but will damp the reading slightly. Do

not restrict lines. If pulsating pressure or vibration causes

excessive pointer oscillation or relay chatter, consult factory

for additional damping means.

2. Position

The Photohelic®may be mounted as an integral package or

the amplifier-load relay assembly and housing may be

mounted remotely from the indicating gage-phototransistor

unit. Extension cords with 7 pin plugs and receptacles are

available from Dwyer for interconnection of the two units.

The unit may be mounted in any desired position, scale vertical or horizontal, without affecting its accuracy, but must

be rezeroed if position is changed from horizontal to vertical

or vice versa. The -0 and -00 models must be mounted with

the scale vertical.

3. Mounting

The Photohelic

®

is normally mounted before making electrical connections, as the electrical enclosure is independent

of the mounting means and may be removed at any time.

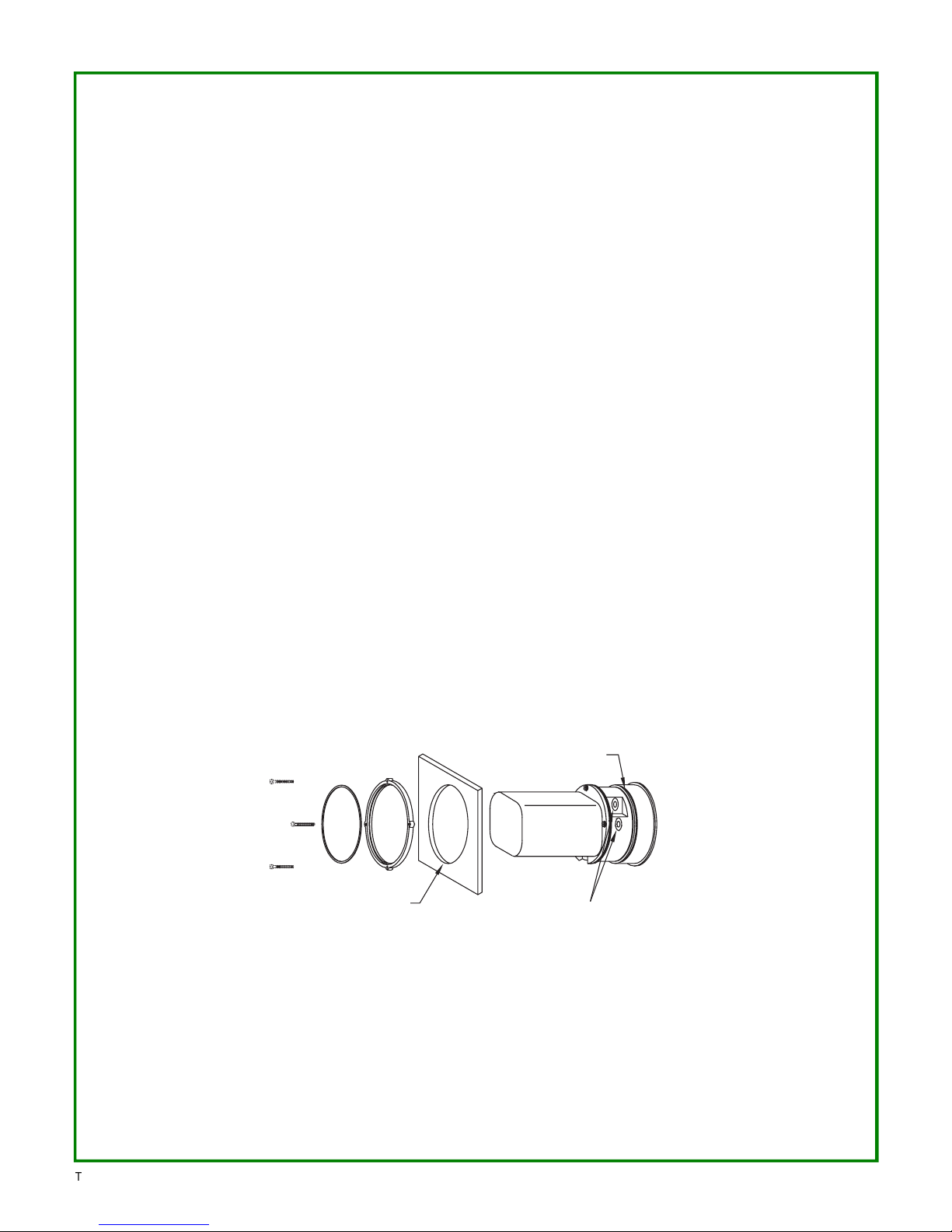

Panel Mounting

Normal mounting is flush or through panel is shown in Fig.

2. Be sure to allow 4-3/8˝ extra space behind the unit for

electrical enclosure removal. Make a single 4-13/16˝ diameter hole in the panel. Insert the entire Photohelic® unit from

the front, then slip on the mounting ring and snap ring from

the rear. Seat the snap ring in its groove, back up the

mounting ring against snap ring and tighten the four (4) 2˝

No. 6-32 clamp screws provided. If behind panel space is

critical, the amplifier-relay unit can be mounted remotely.

See the Remote-Relay Mounting Instructions for details.

Fig. 2

SNAP RING GROOVE

4-13/16˝ (122 mm)

DIA. HOLE REQUIRED

FOR PANEL MOUNTING

1/8˝ MALE NPT PRESSURE CONNECTIONS.

SINGLE HIGH PRESSURE CONNECTION

FOR SERIES 36000A MODELS.

Through Panel Mounting

6

TEMPCO s.a. 4e ave. N°114, Z.I. des Hauts Sarts, B-4040 Herstal, Belgique. T:(32)04-2649458, F:(32)04-2649476, www.tempco.be, tempco@tempco.be

Les photos et caractéristiques présentés dans ce catalogue sont données à titre indicatif et ne sont pas contractuelles.

3.A.01.450-E-100910 page 3/7

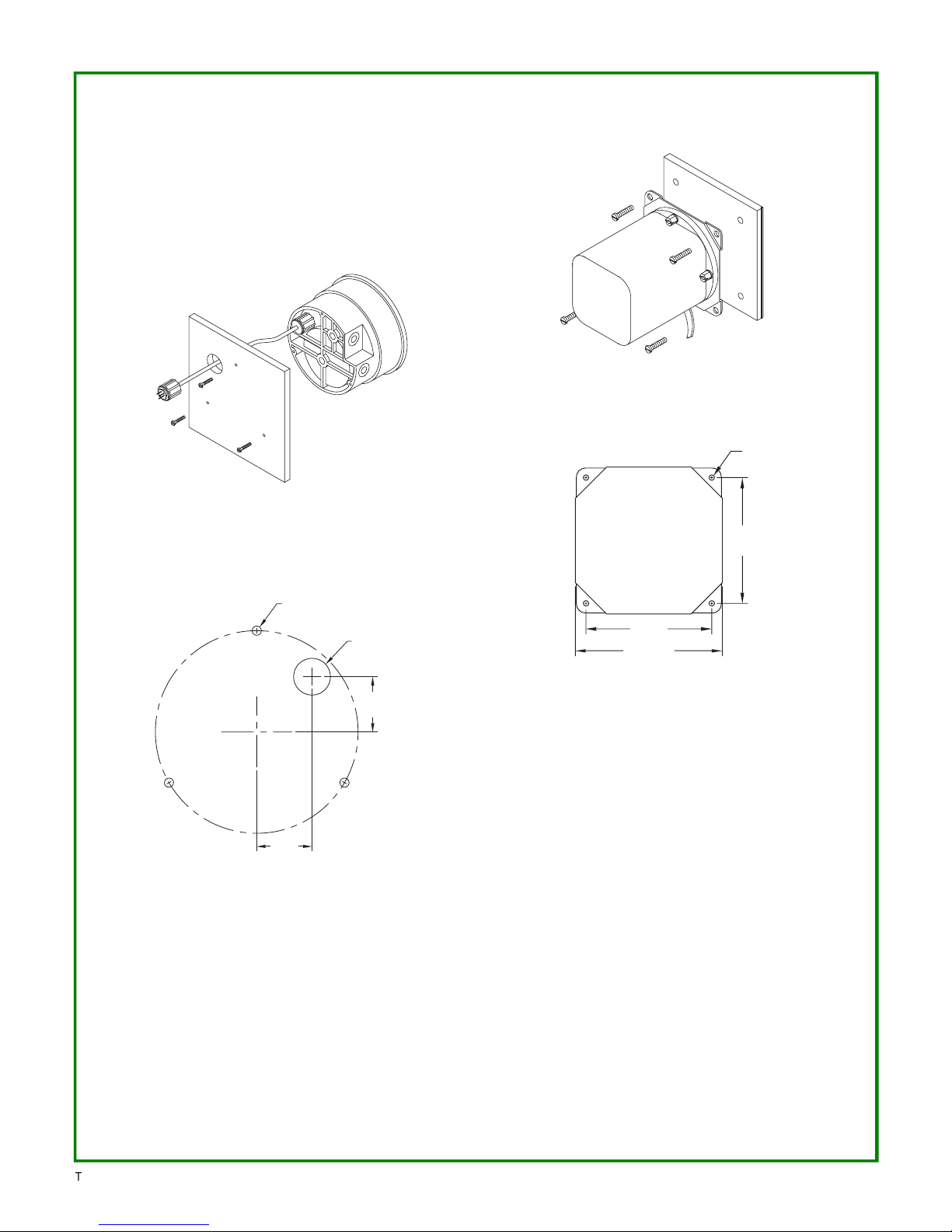

Gage Mounting with Relays Remote

Where it is desirable to mount the amplifier-relay unit separate from the gage-phototransistor unit, the gage may be

mounted either as shown in Fig. 2 (except less amplifierrelay portion) or surface mounted as shown in Fig. 3A. Use

the layout shown in Fig. 3B to locate holes. The complete

package cannot be surface mounted.

Remote Relays Mounting

The amplifier - relay unit may be mounted remotely as

shown in Fig. 4A. Use the hole layout as shown in Fig. 4B

for this option.

Additional mounting information for special requirements is

available from the factory.

4. Pneumatic Connections & Zeroing

After installation but before making pressure connections,

set the indicating pointer exactly on the zero mark, using the

zero adjust screw located at the bottom of the front cover.

Note that this adjustment can only be made with the high

and low pressure taps both open to atmosphere.

Connect the high and low pressure taps to positive, negative, or differential pressure sensing points. Use 1/4˝ diameter metal or other instrument tubing and 1/8˝ NPT adaptors

at the Dwyer Photohelic®pressure switch gage. Adaptors

for rubber or soft plastic tubing are furnished with the instrument for use where this type of connection is preferred.

If the Photohelic®is not used to sense differential pressure,

one of the pressure taps must be left open to atmosphere.

This will allow the reference pressure to enter. In this case,

installation of a Dwyer No. A-331 Filter Plug or similar fitting

in the reference pressure tap is recommended to reduce the

possibility of dust entering the instrument.

NOTE: If the Photohelic®switch/gage is over pressured,

pointer may ‘jump” from full scale back to zero and remain

there until the excess pressure condition is relieved. Users

should be aware of possible false zero pressure indications

under this conditions.

Fig. 3A

Remote Amplifier-Relay Unit

4-9/32

[108.74]

5

[127.00] SQ

4-9/32

[108.74]

Ø3/16

TYP 4 PLACES

Surface Mounting

Fig. 3B

Hole Layout (Front)

1-1/8

[28.58]

1-1/8

[28.58]

THREE 3/16 DIA.

HOLES AT 120°

SURFACE MTG.

3/4 DIA. HOLE

FOR WIRE CONN.

Fig. 4A

Hole Layout

Fig. 4B

Loading...

Loading...