Page 1

Page 1 of 16

Visionary Solutions for Industry®Since 1972 — ISO 9001 Certified

®

®

Temperature Contro llers & Sen sors ◆ Heating E lements ◆ Proc ess Heating Systems

Instructions for Tempco PCM10005 through PCM10008 Enclosure

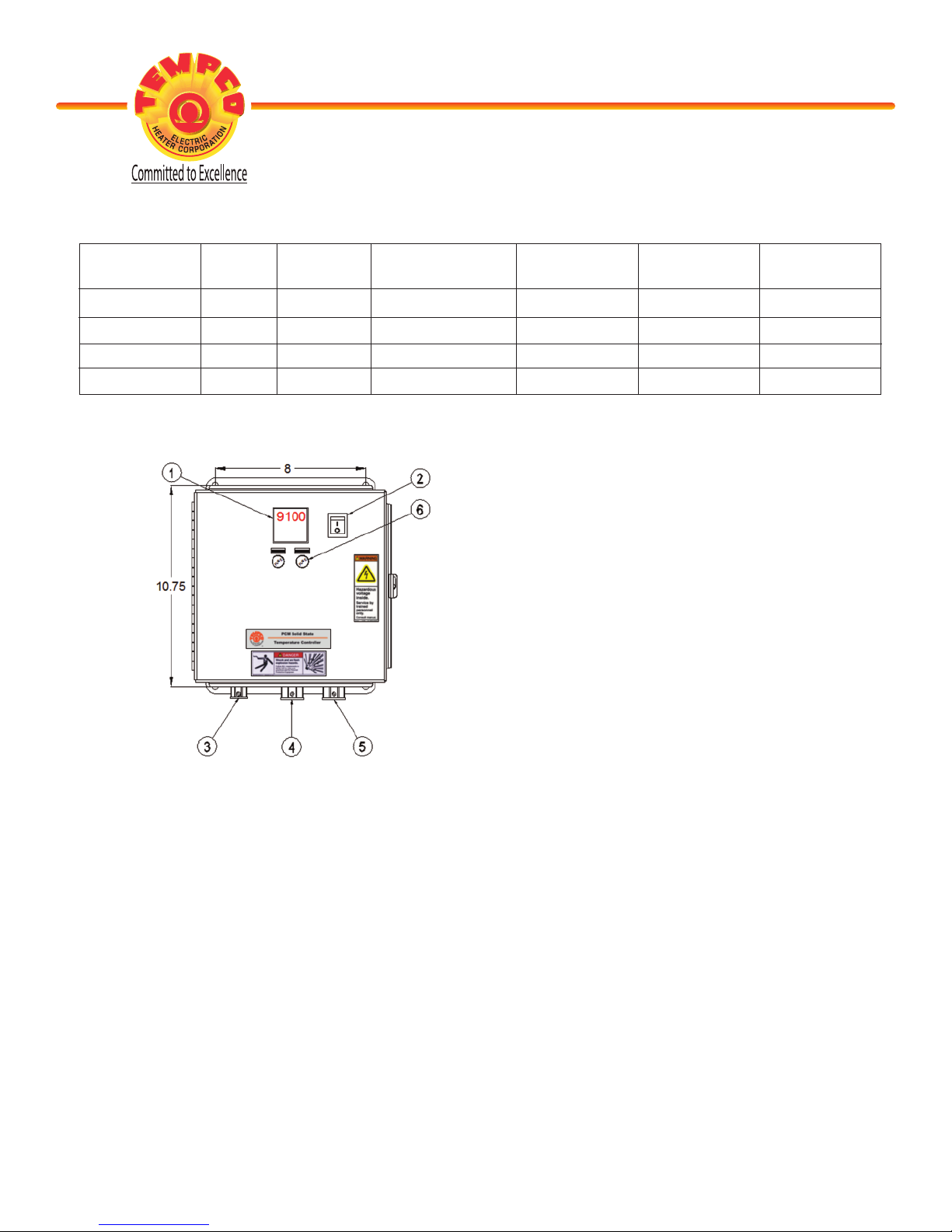

Part Number Input Max. Required Heater Max. Wattage Max. Wattage Mounting

voltage Amperage Fusing 1ph 3ph Dimensions

PCM10005 240VAC 24 30amps 5760 9970W 10.75H x 8W

PCM10006 480VAC 24 30amps 11,520 19,930W 14.75H x 8W

PCM10007 240VAC 48 60amps 11,520 19,930W 14.75H x 8W

PCM10008 480VAC 48 60amps 23,000 39,900W 14.75H x 8W

Component Identification

(Dimensions shown (inches) are for PCM10005 only)

1: TEC-9100 Controller

2: On-Off Rocker Switch

3: 1/2" EMT Conn. For Sensor

4: 3/4" EMT Conn. For Heater Power

5: 3/4" EMT Conn. For Incoming Power

6: 2 Fuse Holders, see spare parts for

fuse replacement

There is no disconnect or heater fusing in this enclosure.

Heater fusing and disconnect must be supplied by the installer.

It is strongly recommended that the process should incorporate a LIMIT CONTROL such

as the TEC-910 which will shut down the equipment at a preset process condition in order

to preclude possible damage to products or system.

1. Dangerous voltage capable of causing injury or death is present within this enclosure. Power

to all equipment must be disconnected before installation or beginning any troubleshooting

procedures. All wiring and component replacement must be made by qualified personnel only.

2. To minimize the possibility of fire or shock, do not expose this console to rain or excessive

moisture.

3. Do not use this enclosure in areas where hazardous conditions exist such as excessive shock,

vibration, dirt, corrosive gases, oil or where explosive gases or vapors are present.

© 2015 Tempco Electric Heater Corporation (Revision 7/8/2015)

607 N. Central Avenue

TEMPCO Electric Heater Corporation

◆ Wood Dale, IL 60191-1452 USA ◆ 630.350.2252 ◆ Fax: 630.350.0232

E-mail: info@tempco.com

◆ Web: www.tempco.com

Page 1 of 16

Page 2

Page 2 of 16

WIRING (for safety, disconnect all power sources prior to wiring)

. Attach the leads from your sensor to the sensor terminal block, terminals 7, 8 & 9. For a ther-

1

mocouple, most commonly the red lead is negative (-) negative, attach that to terminal 9. The

positive lead of the thermocouple should be connected to terminal 8.

The TEC-9100 controller is preprogrammed to accept a type J thermocouple. If another sensor

is used, the “INPT” setting has to be revised.

2. Make sure your service power has been disconnected and locked out.

Please note the enclosed wiring diagram.

Wire your single phase supply to terminals 1 & 2. If you are using three phase power, wire to

terminals 1, 2 & 3.

Connect your heater load to terminals 4 & 5 if using single phase, 4, 5 & 6 if using three phase.

Follow all local and national codes.

Add disconnect and fusing as required.

Before applying power, check tightness of all terminals.

3. An optional NO-NC alarm can be connected to terminals 1, 2 & 3 of the TEC-9100 controller.

This relay is rated at 2 amps, 240 volts. See Alarm Wiring Diagrams on page 6.

OPERATION

1. Refer to the instruction manual provided for complete operation and auto-tuning instructions

for the TEC-9100 temperature controller.

2. Close and secure the door. Switch on the enclosure. Using the up & down pushbuttons on the

TEC-9100 controller, start out with the temperature set low to test your system performance.

If the set point temperature is being maintained, set your desired temperature setpoint.

If your setpoint temperature is not being maintained, please refer to the auto-tuning procedure

in the attached manual.

If auto-tuning does not produce the required results, manual tuning may be necessary.

Note: The signal of the output circuit is wired through output 2 of the TEC-9100 which can

be used as a cut-out in the event of an over-setpoint temperature condition. This is

a deviation contact set to 30º F above the setpoint.

In the event of an over-setpoint temperature condition, output 2 will open, cutting

the control signal to the output relay.

This deviation setpoint can be changed by accessing “SP2” in the TEC-9100 (note

following). This is not meant to be a redundant safety controller.

Refer to our TEC-910 for a safety controller.

SPARE/REPLACEMENT PARTS

Part Number Description

EHD-124-137 (2) TEC Control fuses rated 1 amp, 250VAC, 1/4" x 1-1/4",

Bussmann AGC-1 or equal (PCM10005/PCM10007)

EHD-124-253 (2) TEC Control fuses rated 3/10 amp, 600VAC class CC.

Littelfuse KLDR-3/10 or equal (PCM10006/PCM10008)

TEC14217 (1) Temperature Control, TEC-9100

Page 2 of 16

Page 3

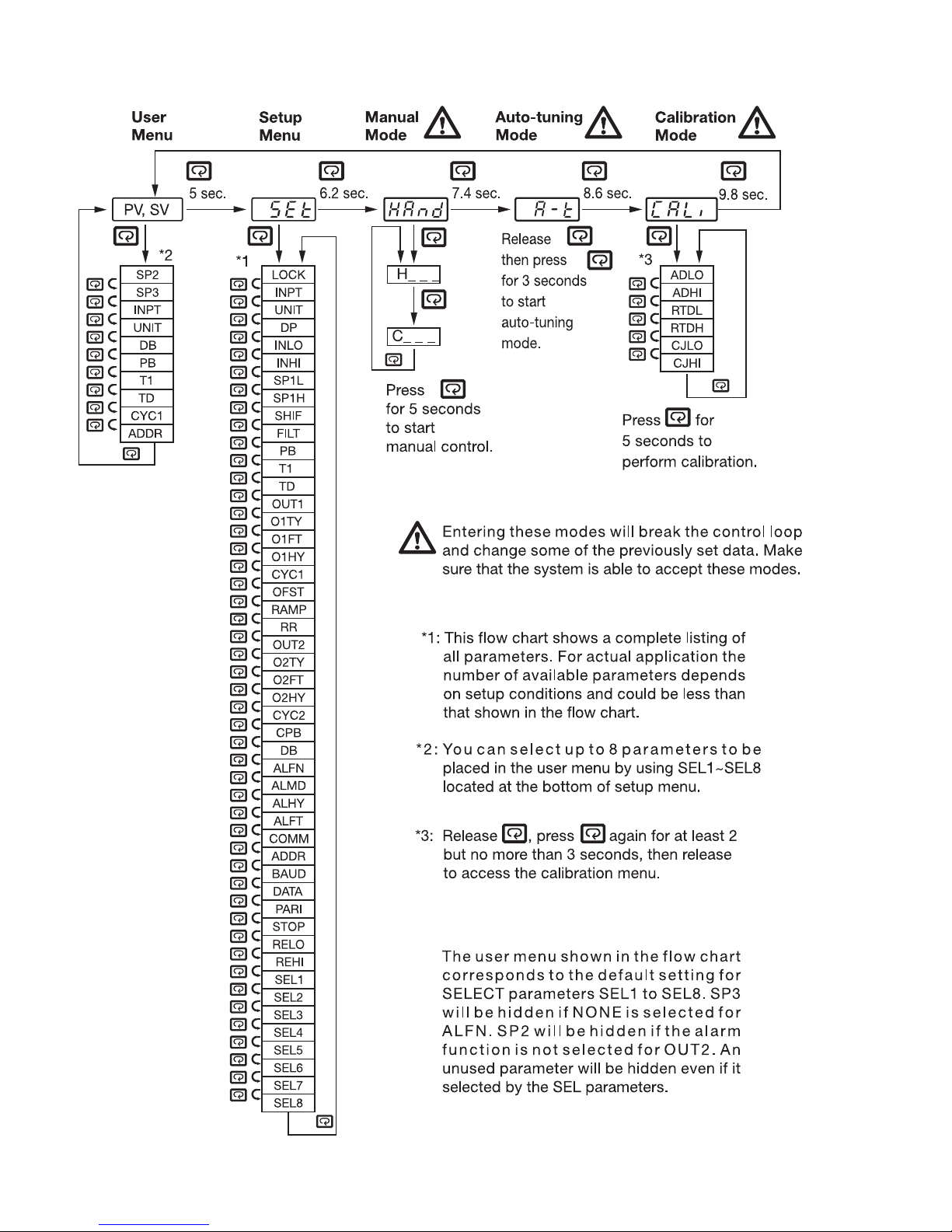

1–5 Menu Overview

Page 3 of 16

Page 4

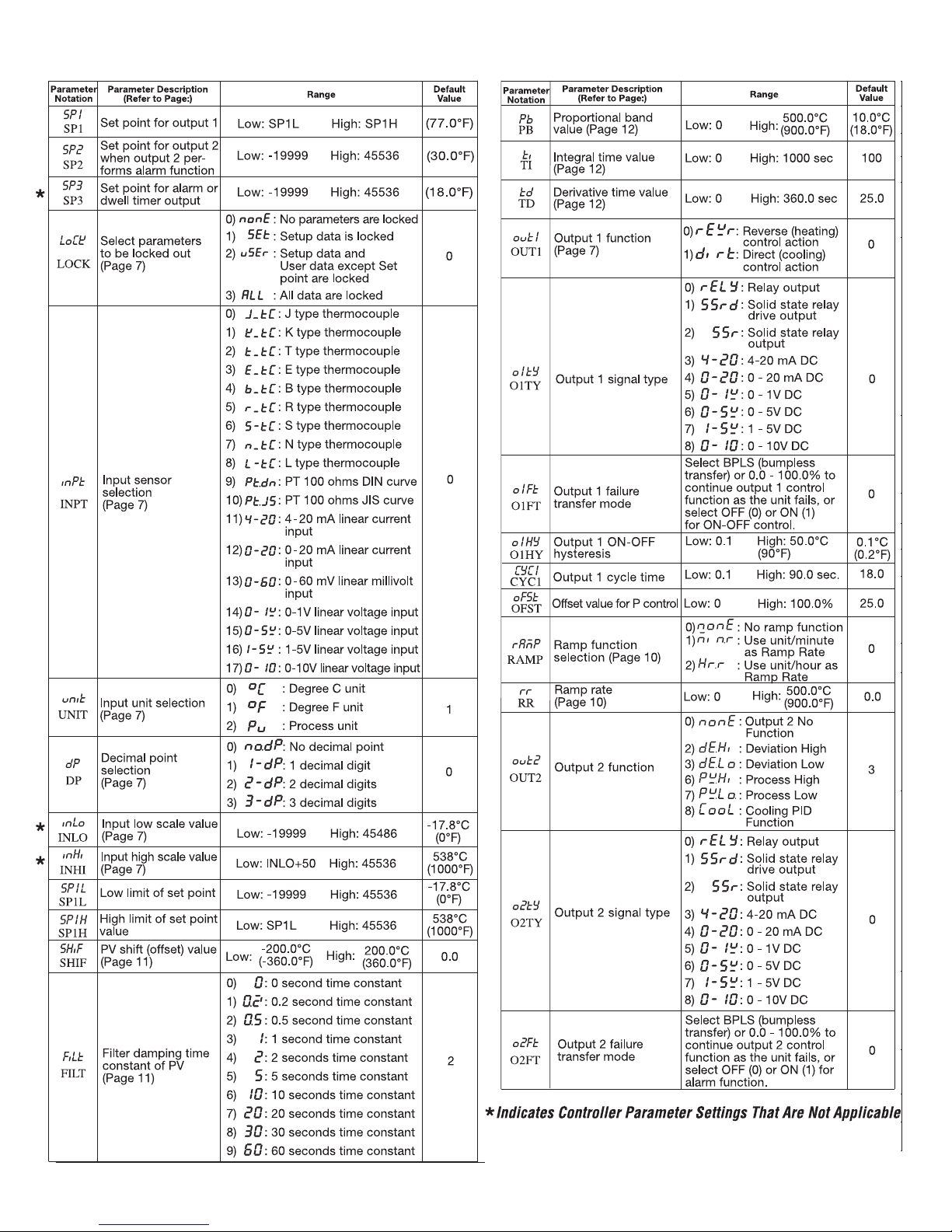

1–6 Parameter Descriptions (page 1 of 2)

❋ Indicates Controller Parameter Settings that are not applicable.

Page 4 of 16

Page 5

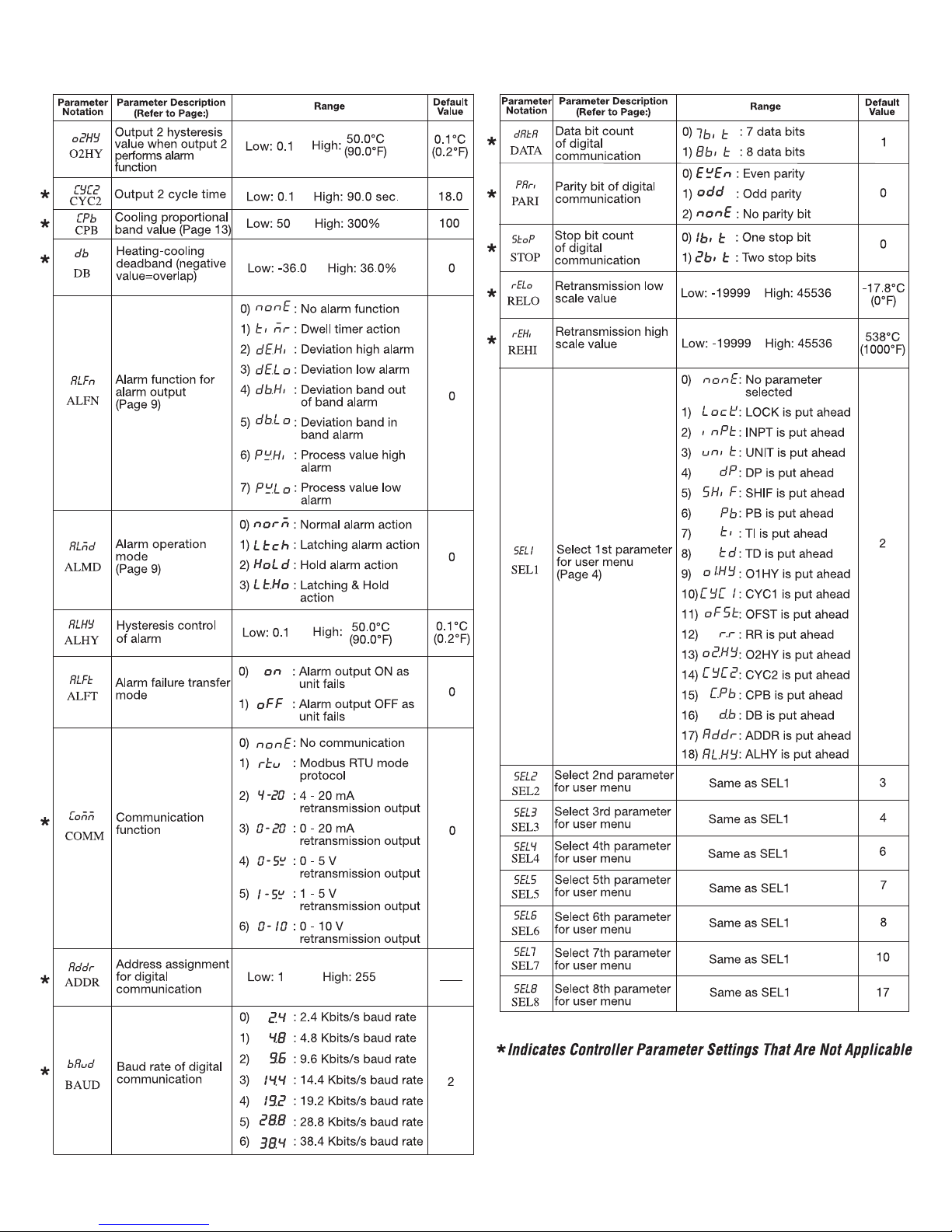

Parameter Descriptions (page 2 of 2)

Page 5 of 16

Page 6

Alarm Wiring

Page 6 of 16

Page 7

Chapter 3 Programming

Press for 5 seconds and release to enter the setup menu. Press

o select the desired parameter. The upper display

t

indicates the parameter symbol, and the lower display indicates

the selected value of the parameter.

3–1 Lockout

There are four security levels that can be selected using the LOCK

parameter.

If NONE is selected for LOCK, then no parameter is locked.

If SET is selected for LOCK, then all setup data are locked.

If USER is selected for LOCK, then all setup data as well as

user data (refer to section 1-5) except the set point are

locked to prevent them from being changed.

If ALL is selected for LOCK, then all parameters are locked to

prevent them from being changed.

3–2 Signal Input

NPT: Selects the sensor type or signal type for signal input.

I

Range: (thermocouple) J-TC, K-TC, T-TC, E-TC, B-TC,

-TC, S-TC, N-TC, L-TC

R

(RTD) PT.DN, PT.JS

UNIT: Selects the process unit

Range: °C, °F

DP: Selects the resolution of process value.

Range: (For T/C and RTD) NO.DP, 1-DP

3–3 Control Outputs

There are four kinds of control modes that can be configured as shown in table 3.1.

Table 3.1 Heat-Cool Control Setup Value

Page 7 of 16

Page 8

Control Outputs, continued…

Heat only ON-OFF control: Select REVR for OUT1. Set PB

proportional band) to 0. O1HY is used to adjust dead band for

(

ON-OFF control. The output 1 hysteresis (O1HY) is enabled

in case PB=0. The heat only on-off control function is shown

in the following diagram:

ool only control: ON-OFF control, P (PD) control, and PID

C

control can be used for cool control. Set OUT1 to DIRT (direct

action). The other functions for cool only ON-OFF control, cool

only P (PD) control, and cool only PID control are the same as

for heat only control except that the output variable (and action)

or cool control is inverse to heat control.

f

NOTE: ON-OFF control may result in excessive overshoot and

ndershoot problems in the process. P (or PD) control will result

u

in a deviation of process value from the set point. It is recommended to use PID control for heat-cool control to produce a stable

and zero offset process value.

Other setup required: O1TY, CYC1, O2TY, CYC2, O1FT and

O2FT are set in accordance with the types of OUT1 and OUT2

installed. CYC1 and CYC2 are selected according to the output

1 type (O1TY) and output 2 type (O2TY). Generally, select

0.5~2 seconds for CYC1 if SSRD or SSR is used for O1TY;

10~20 seconds if relay is used for O1TY. CYC1 is ignored if a

linear output is used. Similar conditions are applied for CYC2

selection.

You can use the auto-tuning program for the new process or directly set the appropriate values for PB, TI, and TD according

to historical records for the repeated systems. If the control behavior is still inadequate, use manual tuning to improve the control. See section 3-12 for manual tuning.

The ON-OFF control may introduce excessive process oscillation

even if hysteresis is minimized. If ON-OFF control is set (i.e.,

PB=0), TI, TD, CYC1, OFST, CYC2, CPB, and DB will be hidden

and have no function in the system. The auto-tuning and bumpless

transfer functions will be disabled as well.

Heat only P (or PD) control: Select REVR for OUT1, set TI to

0. OFST is used to adjust the control offset (manual reset). O1HY

is hidden if PB is not equal to 0. OFST function: OFST is meas-

ured by % with a range of 0–100.0%. In the steady state (i.e.,

process has been stabilized), if the process value is lower than the

set point by a definite value, say 5°C, while 20°C is used for PB,

that is lower by 25%, then increase OFST 25%, and vice-versa.

After adjusting OFST value, the process value will be varied and

eventually coincide with set point.

Refer to section 3-12 “manual tuning” for the adjustment of PB

and TD. Manual reset (adjust OFST) is not practical because the

load may change from time to time and OFST may need to be adjusted repeatedly. PID control can avoid this situation.

Heat only PID control: If REVR is selected for OUT1, PB and

TI should not be zero. Perform auto-tuning for the new process,

or set PB, TI, and TD with historical values. See section 3-11 for

auto-tuning operation. If the control result is still unsatisfactory,

then use manual tuning to improve control. See section 3-12 for

manual tuning. The unit contains a very advanced PID and Fuzzy

Logic algorithm to create a very small overshoot and very quick

response to the process if it is properly tuned.

3.3 & 3.4 Alarm Figures, next page…

Page 8 of 16

Page 9

3.3 & 3.4 Alarm Figures

Figure 3.3 Output 2 Deviation High Alarm

3–4 Alarm

The controller has one alarm output. There are six types of

alarm functions and one dwell timer that can be selected, and

our kinds of alarm modes (ALMD) are available for each

f

alarm function (ALFN). Output 2 can be configured as another alarm in addition to the alarm output. But output 2 only

provides four kinds of alarm functions and only normal alarm

mode is available for this alarm. When output 2 is used as an

alarm, SP2 sets the trigger point. SP3 sets the trigger point for

Alarm.

A process alarm sets absolute trigger levels. When the

process is higher than SP3, a process high alarm (PV.HI) occurs, and the alarm is off when the process is lower than SP3ALHY. When the process is lower than SP3, a process low

alarm (PV.LO) occurs, and the alarm is off when the process

is higher than SP3+ALHY. A process alarm is independent of

the set point.

A deviation alarm alerts the user when the process deviates

from the set point. When the process is higher than SV+SP3,

a deviation high alarm (DE.HI) occurs, and the alarm is off

when the process is lower than SV+SP3-ALHY. When the

process is lower than SV+SP3, a deviation low alarm

(DE.LO) occurs, and the alarm is off when the process is

higher than SV+SP3+ALHY. The trigger level of the deviation alarm moves with the set point.

A deviation band alarm presets two trigger levels relative to

the set point. The two trigger levels are SV+SP3 and SV-SP3

for alarm. When the process is higher than (SV+SP3) or lower

than (SV-SP3), a deviation band high alarm (DB.HI) occurs.

When the process is within the trigger levels, a deviation band

low alarm (DB.LO) occurs.

There are four types of alarm modes available for each alarm

function. These are: normal alarm, latching alarm, holding

alarm and latching/holding alarm. They are described as follows:

Figure 3.4 Output 2 Process Low Alarm

Normal alarm: ALMD=NORM

When a normal alarm is selected, the alarm output is de-energized in the non-alarm condition and energized in an alarm

condition.

Latching alarm: ALMD=LTCH

If a latching alarm is selected, once the alarm output is energized, it will remain unchanged even if the alarm condition is

cleared. The latching alarm is reset when the RESET key is

pressed after the alarm condition is removed.

Holding alarm: ALMD=HOLD

A holding alarm prevents an alarm when the control is powering up. The alarm is enabled only when the process reaches

the set point value. Afterwards, the alarm performs the same

function as a normal alarm.

Latching/holding alarm: ALMD=LT.HO

A latching/holding alarm performs both holding and latching

functions. The latching alarm is reset when the RESET key is

pressed after the alarm condition is removed.

Alarm failure transfer is activated as the unit enters failure

mode. The alarm will go on if ALFT is set for ON and go off

if ALFT is set for OFF. The unit will enter failure mode when

a sensor break occurs or if the A-D converter of the unit fails.

Page 9 of 16

Page 10

3–5 Configuring User Menu

Most conventional controllers are designed with a fixed order in

which the parameters scroll. The x100 series have the flexibility

o allow you to select those parameters which are most significant

t

to you and put these parameters at the front of the display sequence.

SEL1~SEL8: Selects the parameter for view and change in the

user menu.

Range: LOCK, INPT, UNIT, DP, SHIF, PB, TI, TD, O1HY,

CYC1, OFST, RR, O2HY, CYC2, CPB, DB, ADDR, ALHY

When using the up and down keys to select the parameters, you

may not see all of the above parameters. The number of visible parameters is dependent on the setup condition. The hidden parameters for the specific application are also blocked from the SEL

selection.

Example:

OUT2 set for DE.LO PB= 100.0 SEL1 set for INPT

SEL2 set for UNIT SEL3 set for PB SEL4 set for TI

SEL5~SEL8 set for NONE

Now, the upper display scrolling becomes:

3–6 Ramp

Ramp

The ramping function is performed during power up as well as any

time the set point is changed. If MINR or HRR is chosen for

RAMP, the unit will perform the ramping function. The ramp rate

is programmed by adjusting RR. The ramping function is disabled

as soon as failure mode, manual control mode, auto-tuning mode

or calibration mode is entered.

Example without dwell timer

Select MINR for RAMP, select °C for UNIT, select 1-DP for DP,

set RR=10.0. SV is set to 200°C initially, and changed to 100°C

30 minutes after power-up. The starting temperature is 30°C. After

power-up, the process runs like the curve shown below:

3–7 Dwell Timer

The alarm output can be configured as a dwell timer by selecting

TIMR for ALFN (alarm function). As the dwell timer is config-

red, the parameter SP3 is used for dwell time adjustment. The

u

dwell time is measured in minutes ranging from 0.1 to 4553 minutes. Once the process reaches the set point the dwell timer starts

to count down to zero (time out). The timer relay will remain unchanged until time out. For the dwell timer to control the heater,

the heater circuit (or contactor) must be wired in series with the

alarm relay. Note the following diagram located below and also

Figure 2.20.1 on page 11. When the dwell timer times out, the

heater will be turned off. The dwell timer operation is shown in

the following diagram.

After time out, the dwell timer can be restarted by pressing the

RESET key.

The timer stops counting during manual control mode, failure

mode, the calibration period and the auto-tuning period.

If the alarm is configured as a dwell timer, ALHY and ALMD are

hidden.

Figure 3.5 RAMP Function

Note: When the ramp function is used, the lower display will show

the current ramping value. The ramping value is an artificially determined setpoint created and updated by the control to match the

ramp rate set by the user. However, it will revert to show the set

point value as soon as the up or down key is touched for adjustment. The ramping value is initiated to process value either on

power-up or when RR and/or the set point are changed. Setting

RR to zero means no ramp function.

Figure 3.6 Dwell Timer Function

Dwell Timer Function Wiring Diagram

Page 10 of 16

Page 11

3–8 PV Shift

n certain applications it is desirable to shift the con-

I

troller display value (PV) from its actual value. This

can easily be accomplished by using the PV shift

function.

The SHIF function will alter PV only.

Example: A process is equipped with a heater, a sensor, and a subject to be warmed up. Due to the design

and position of the components in the system, the

sensor could not be placed any closer to the part.

Thermal gradient (differing temperatures) is common and necessary to an extent in any thermal system for heat to be transferred from one point to

another. If the difference between the sensor and the

subject is 35°C, and the desired temperature at the

subject to be heated is 200°C, the temperature at the

sensor should be 235°C. You should enter -35°C to

subtract 35°C from the actual process display. This

in turn will cause the controller to energize the load

and bring the process display up to the set point

value.

3–9 Digital Filter

In certain applications, the process value is too unstable to be

read due possibly to electrical noise. A programmable low-pass

filter incorporated in the controller is used to improve this. It

is a first-order filter with the time constant specified by the

FILT parameter. The default value of FILT is set at 0.5 seconds

before shipping. Adjust FILT to change the time constant from

0 to 60 seconds. 0 seconds means no filter is applied to the

input signal. The filter is characterized by the following diagram:

Note

The filter is available only for PV, and is performed for the displayed value only. The controller is designed to use unfiltered

signal for control even if the filter is applied. A lagged (filtered)

signal, if used for control, may produce an unstable process.

Figure 3.7 PV Shift Application

Figure 3.8 Filter Characteristics

3–10 Failure Transfer

The controller will enter failure mode if one

of the following conditions occurs:

1. SBER occurs due to input sensor break

or input current below 1mA if 4–20 mA

is selected or input voltage below 0.25V

if 1–5V is selected.

2. ADER occurs due to the A-D converter

of the controller failing.

Output 1 and output 2 will perform the failure transfer function as the controller enters

failure mode.

Output 1 failure transfer, if activated, will

perform:

1. If output 1 is configured as proportional

control (PB≠ 0), and BPLS is selected

for O1FT, then output 1 will perform

bumpless transfer. Thereafter, the previ-

ous averaging value of MV1 will be

used for controlling output 1.

2. If output 1 is configured as proportional

control (PB≠ 0), and a value of 0 to

100.0% is set for O1FT, then output 1

will perform failure transfer. Thereafter,

the value of O1FT will be used for controlling output 1.

3. If output 1 is configured as ON-OFF

control (PB=0), then output 1 will be

driven OFF if OFF is set for O1FT and

will be driven ON if ON is set for O1FT.

Output 2 failure transfer, if activated, will

perform:

1. If OUT2 is configured as COOL, and

BPLS is selected for O1FT, then output

2 will perform bumpless transfer. There-

after, the previous averaging value of

MV2 will be used for controlling output

2.

2. If OUT2 is configured as COOL, and a

value of 0 to 100.0% is set for O2FT,

then output 2 will perform failure transfer. Thereafter, the value of O1FT will

be used for controlling output 2.

3. If OUT2 is configured as alarm function,

and O2FT is set to OFF, then output 2

will go off. Otherwise, output 2 will go

on if O2FT is set to ON.

Alarm failure transfer is activated as the

controller enters failure mode. Thereafter,

the alarm will transfer to the ON or OFF

state preset by ALFT.

Page 11 of 16

Page 12

3–11 Auto-tuning

The auto-tuning process is performed near the set point.

The process will oscillate around the set point during

he tuning process. Set the set point at a lower value if over-

t

shooting beyond the normal process value is likely to cause

damage.

Auto-tuning is applied in cases of:

Initial setup for a new process

•

• The set point is changed substantially from the previous

auto-tuning value

• The control result is unsatisfactory

Operation:

1. The system has been installed normally.

2. Set the correct values for the setup menu of the unit, but

don’t set a zero value for PB and TI, or the auto-tuning program will be disabled. The LOCK parameter should be set

at NONE.

3. Set the set point to a normal operating value, or a lower value

if overshooting beyond the normal process value is likely to

cause damage.

4. Press and hold until appears on the display.

5. Then press

will begin to flash and the auto-tuning procedure begins.

NOTE: The ramping function, if used, will be disabled when

auto-tuning is taking place.

Auto-tuning mode is disabled as soon as either failure mode or

manual control mode is entered.

Procedures:

Auto-tuning can be applied either as the process is warming

up (cold start), or when the process has been in a steady state

(warm start). After the auto-tuning procedures are completed,

the AT indicator will cease to flash and the unit will revert to

PID control using its new PID values. The PID values obtained are stored in the nonvolatile memory.

Auto-Tuning Error

If auto-tuning fails an ATER message will appear on the upper

display in the following cases:

• If PB exceeds 9000 (9000 PU, 900.0°F or 500.0°C),

• if TI exceeds 1000 seconds,

• if the set point is changed during the auto-tuning procedure.

Solutions to

1. Try auto-tuning once again.

2. Don’t change the set point value during the auto-tuning pro-

cedure.

3. Don’t set a zero value for PB and TI.

4. Use manual tuning instead of auto-tuning (see section 3-12).

5. Touch RESET key to reset message.

again

for at least 5 seconds. The AT indicator

3–12 Manual Tuning

In certain applications auto-tuning may be inadequate for the

control requirements. You can try manual tuning for these applications.

If the control performance using auto-tuning is still unsatisfactory, the following rules can be applied for further adjustment of PID values:

Figure 3.9 Effects of PID Adjustment

Figure 3.9 shows the effects of PID

adjustment on process response.

Page 12 of 16

Page 13

3–13 Manual Control

R

peration

O

To enable manual control, the LOCK parameter should be set

o NONE, then press for 6.2 seconds;

t

(hand control) will appear on the display. Press for 5 seconds, then the MAN indicator will begin to flash and the lower

display will show . The controller is now in manual

control mode. indicates output control variable for out-

ut 1, and indicates control variable for output 2. Now

p

you can use the up and down keys to adjust the percentage

values for the heating or cooling output.

The controller performs open loop control as long as it stays

in manual control mode.

Exit Manual Control

Pressing the key will cause the controller to revert to its

normal display mode.

Page 13 of 16

Page 14

Table A.1 Error Codes and Corrective Actions

Page 14 of 16

Page 15

WARRANTY

Tempco Electric Heater Corporation is pleased to offer sugges-

ions on the use of its products. However, Tempco makes no war-

t

ranties or representations of any sort regarding the fitness for use,

or the application of its products by the Purchaser. The selection,

application, or use of Tempco products is the Purchaser's responsibility. No claims will be allowed for any damages or losses,

hether direct, indirect, incidental, special, or consequential.

w

Specifications are subject to change without notice. In addition,

Tempco reserves the right to make changes–without notification

to the Purchaser–to materials or processing that do not affect compliance with any applicable specification. TEC Temperature Controllers are warranted to be free from defects in material and

workmanship for two (2) years after delivery to the first purchaser

for use. Tempco's sole responsibility under this warranty, at Tempco's option, is limited to replacement or repair, free of charge, or

refund of purchase price within the warranty period specified.

This warranty does not apply to damage resulting from transportation, alteration, misuse, or abuse.

RETURNS

No product returns can be accepted without a completed Return

aterial Authorization (RMA) form.

M

TECHNICAL SUPPORT

Technical questions and troubleshooting help is available from

Tempco. When calling or writing please give as much background

information on the application or process as possible.

E-mail: techsupport@tempco.com

Phone: 630-350-2252

800-323-6859

Page 15 of 16

Page 16

Complete Your Thermal Loop System

With Over 100,000 Various Items

Available from Stock

• Electric Heating Elements

• Thermocouples and RTD Assemblies

• SCR Power Controls

• Solid State Relays

• Mechanical Relays

• Videographic Data Recorders

• Temperature Measurement

• Current Indicators

• Thermocouple and Power Lead Wire

• Wiring Accessories

The Electric Heating Element, Temperature Controls and

Temperature Sensors Handbook

REQUEST YOUR FREE 960 PAGE COPY TODAY!

Call (800-323-6859) or E-mail (info@tempco.com)

Specify Print Edition, CD-ROM or Both

Serving Industry Since 1972

Experience the Advantages of our Diverse and Innovative Products

TEMPCO Electric Heater Corporation

607 N. Central Avenue • Wood Dale, IL 60191-1452 USA

Tel: 630-350-2252 • Toll Free: 800-323-6859

Fax: 630-350-0232 • E-mail: info@tempco.com

Web: www.tempco.com

© Copyright 2015. All Rights Reserved.

Page 16 of 16

Loading...

Loading...