Temp-Cast 2000 Installation Manual

INSTALLATION MANUAL

READ THIS ENTIRE MANUAL

INCLUDING THE WARRANTY SECTION

BEFORE STARTING THE INSTALLATION

WARNING!!

TO ENSURE THE SAFE AND

EFFICIENT OPERATION OF THIS

HEATER, SECTION 5 MUST BE

REVIEWED PRIOR TO STARTING

Temp-Cast 2000 Installation Manual February 2010

THE INSTALLATION

2

TABLE OF CONTENTS

SECTION1 – INTRODUCTION

General Information 3

Site Preparation 3

Clearances 3

The Façade 4

Delivery & Handling 4

Tools 4

Additional Materials 4

Combustion Air Supply 5

SECTION 2 – CHIMNEYS & DAMPERS

General Requirements 6

Flue Connections 6

Masonry Chimneys 6

Factory-built Chimneys 7

Base-Exit Dampers 8

Installing the Roof-top Chimney Damper 9

SECTION 3 - STEP-BY STEP ASSEMBLY

Assembly Notes 10

Step-by-Step Installation 11

SECTION 4 - DOOR FRAMES & FACADE

The Door Frame Flange 37

Installing Arched Fire-Box Doors 38

Air Supply Doors 42

Clean-out (Soot) Doors 42

Installing "See-Through" Doors 43

Installing Square Fire-Box Doors 44

Installing Bake Oven Doors 46

The Trim Plate Option 47

Installing the Facade 48

The Masonry Cap 49

SECTION 5 - AVOIDING INSTALLATION ERRORS

SECTION 6 – CERAMIC FIBRE CUTTING PLAN

SECTION 7 –WARRANTY

PAGE #

50

51

53

Temp-Cast 2000 Installation Manual February 2010

Section 1 - Introduction

SECTION 1: INTRODUCTION

GENERAL INFORMATION

The Temp-Cast 2000 is a modular "site-built"

fireplace kit. The assembled modules form the

"core" of the fireplace, including internal flue

passages. The Standard Fireplace package also

contains a cast iron fire grate, two soot cleanout

doors, refractory joint-sealing mortar, corrugated

cardboard spacers, gasket material, and assorted

fasteners.

READ THESE INSTRUCTIONS COMPLETELY

BEFORE BEGINNING THE INSTALLATION.

FAILURE TO FOLLOW THESE INSTRUCTIONS

MAY CREATE A FIRE HAZARD, HAMPER THE

PERFORMANCE OF THE FIREPLACE AND

VOID THE PRODUCT WARRANTY.

IMPORTANT: Review Section 5,

"Avoiding Installation Errors" before

beginning the installation!

3

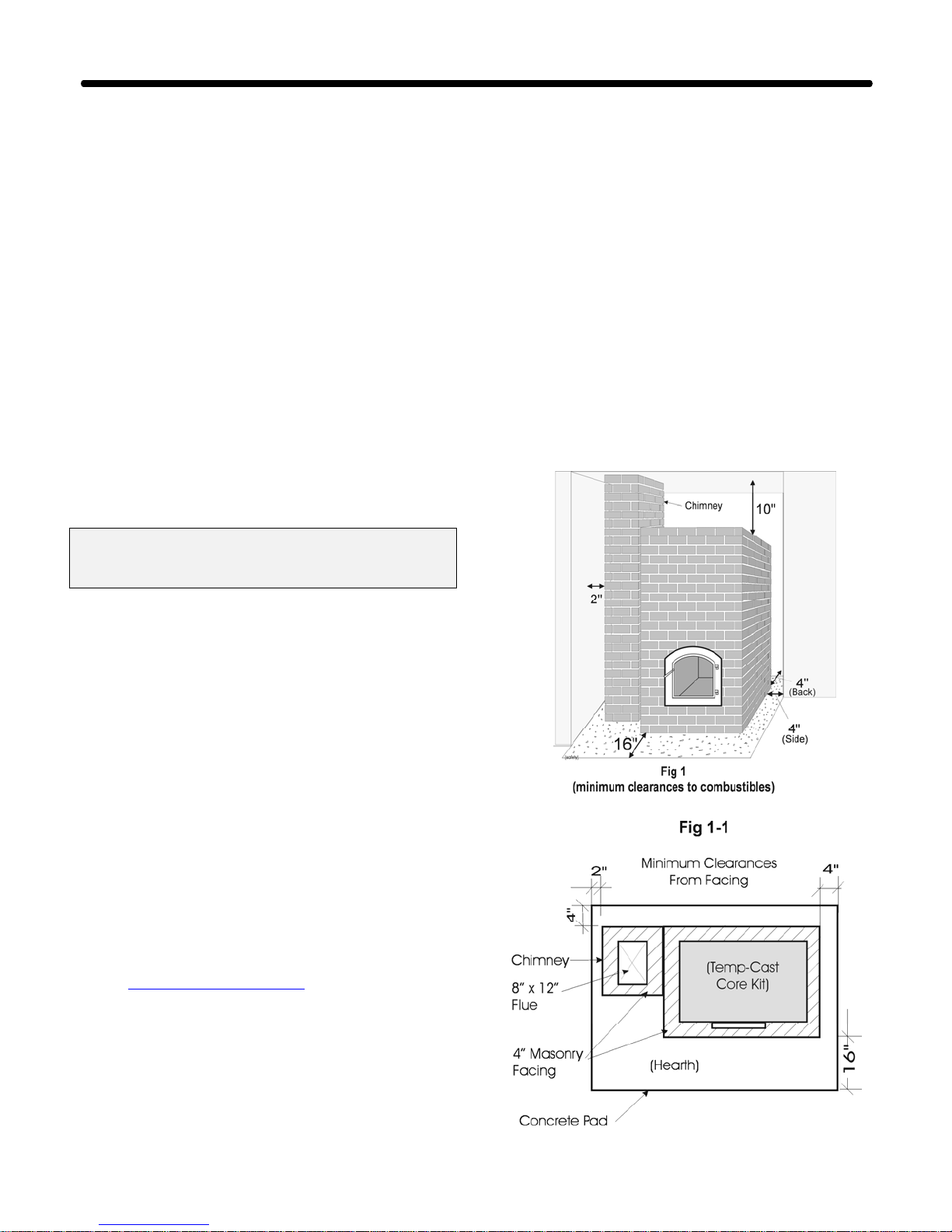

CLEARANCES

A minimum clearance of 4" (100mm) from the back

and sides of the completed fireplace (i.e. from the

masonry facing) to combustible materials is required.

The clearance required from the top of the heater is

10" (250mm).

48” (1200mm) clearance is required in front of the

door & a non-combustible hearth of 16” (400mm)

deep is required, extending 8” either side of the

door.( approx. 38” [1m] wide). Also, a clearance of

2" (50mm) is required between the chimney and any

combustible construction. (See Fig 1 & 1-1 below.)

SITE PREPARATION

The following instructions detail the assembly of the

Temp-Cast 2000 Fireplace, on a properly prepared

and supported concrete pad. Support requirements

are described in the Temp-Cast Planning Guide, and

related Plan Drawings. If you require assistance

with the support details for the fireplace or other

preparatory work, please contact your dealer or the

factory. If you are unsure regarding any aspect of the

installation of this product, please contact:

Temp-Cast Enviroheat Ltd, 3409 Yonge St,

Bedford Park Postal Outlet, Box 94059

Toronto, Ontario, Canada, M4N 3R1.

Tel: 416-322-5197 Fax: 416-486-3624

Toll-free 1-800-561-8594

Email: staywarm@tempcast.com

Temp-Cast 2000 Installation Manual February 2010

Section 1 - Introduction

If necessary, a metal or masonry convection

shield may be placed between your fireplace

facade and the combustible structure, reducing

clearances by up to 67%. Contact your dealer,

local building inspector or the factory for details.

(In new construction, a non-combustible solid

masonry wall or metal stud and "cement-board"

wall will eliminate concern with clearances.)

FAILURE TO MAINTAIN THE MINIMUM

CLEARANCES TO COMBUSTIBLES MAY

CREATE A FIRE HAZARD.

THE FACADE

Once the core is assembled, it must be faced with

additional suitable heat-storing masonry material,

usually installed by a professional mason. (See also

Section 4.) Suitable facade materials include brick,

rock, fieldstone, or soapstone – concrete block

facings are not recommended. (Hollow units must be

filled. If using solid bricks, they should not be

perfectly flat on both sides - a depression is needed

to ensure that bricks do not move during thermal

expansion.) THE FACADE MUST BE BETWEEN

4" (100mm) & 6” (150mm) OF SOLID MASONRY,

STONE OR ROCK. (Substantially thinner facings

may not comply with building codes, due to higher

surface temperatures, requiring greater clearances to

combustibles. Thicker facings will make the heater

slower to respond & more difficult to regulate.)

DELIVERY & HANDLING

The fireplace kit weighs 2800 lbs and is delivered on

a wood pallet, covered with plastic. If unloaded by

forklift, it should be placed on a level and even

surface, so that parts will not fall when the strapping

is cut. Unpacking should be done by at least 2

persons, following the unpacking instructions.

As soon as possible after delivery, the fireplace

should be unpacked and dry assembled, to become

familiar with

complete and to check for damage. Visible damage

to the pallet or the contents must be reported

immediately to the delivery person and noted on

the shipping bill before accepting delivery.

Hidden damage or missing parts must be reported

to Temp-Cast and to the shipping company within

24 hours.

all the parts, to ensure the delivery is

4

The pieces must be handled with reasonable care to

avoid damage, although minor chips to corners and

edges are acceptable and do not affect installation or

performance. The modules should be stored indoors,

in a dry area. When possible, in cold weather, the

modules should be left in a heated area for a few days

prior to beginning the installation.

TOOLS

The following tools are required to simplify the

assembly process:

48" (1.2m) and 12” levels

powered cutting tool - options include:

1. 4” grinder with diamond blade

2. circular saw with diamond blade

3. masonry “water” saw or gas concrete saw (less

accurate & convenient on smaller cuts)

1/2" (12.5mm) hammer drill & masonry bits

heavy rubber mallet

2" (50mm) margin or pointed trowel

2" packing tape (e.g. “Scotch” tape)

black magic marker

pencil

utility knife

bucket, water & sponge

measuring tape

20 ft (10m) tie-down or web-clamp, for temporary

support of side channels (Step 18).

ADDITIONAL MATERIALS:

all masonry facing & chimney materials

Portland cement (to level the base)

chimney cleanout for rear connections (see

Section 4)

optional air supply door & frame (for slab-on-grade

installations - refer to Fig 1B)

optional chimney damper

6” or 8” combustion air supply duct (e.g.

galvanized duct - see next section)

Temp-Cast 2000 Installation Manual February 2010

Section 1 - Introduction

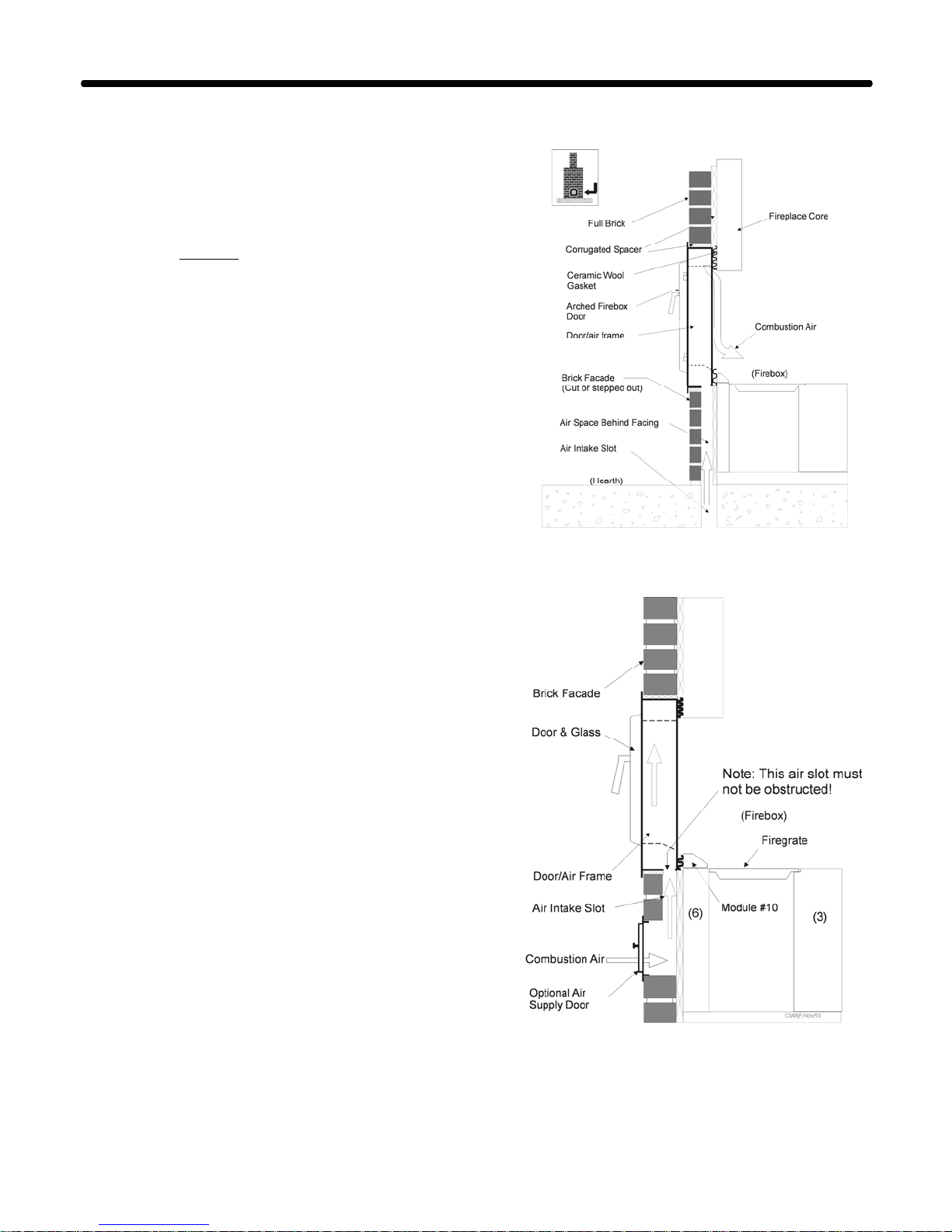

COMBUSTION AIR SUPPLY:

The Temp-Cast heater requires an unrestricted air

supply for proper combustion and maximum

performance. (This section refers to the standard

Temp-Cast “arched” door & air-frame installation.

The Temp-Cast “square” door installation is

described in a separate

Combustion air can be drawn from outside or inside

the house and delivered by way of a 15" x 2"

(380mm x 50mm) air intake formed in front of the

heater during construction of the concrete floor pad.

Air is then directed up behind the facing masonry,

and into the hollow door frame through slots on the

bottom. The air travels up inside the door frame and

feeds the fire from above, creating an "air-wash"

across the doors to keep the glass clean. (See Fig. 1a)

If the installation is designed to use inside air from

the same room as the heater, (such as in a basement

installation ), then an optional "air supply door" must

be purchased and installed under the loading doors.

This will allow combustion air to be drawn from the

room, travel up behind the facade and into the hollow

door frame. (Refer to Fig. 1b).

In a basement installation, outside air can still be

brought into the fireplace, if ceiling height permits.

In this case, a raised hearth can be constructed, and

6" (150mm) of fresh air can be fed into this

(A "false" chimney can be used for this fresh air

supply.) The air is brought to the front of the heater

into a 15" x 2" (380mm x 50mm) masonry slot or

custom-fabricated "boot" and treated as a normal

outside air installation.

In a "See-Through" fireplace, 8” of combustion air

must be supplied and divided equally to both door

frames to provide an "air wash" for each door glass.

(See Fig. 16)

manual.)

structure.

5

Fig 1a

Temp-Cast 2000 Installation Manual February 2010

Fig 1b

SECTION 2: CHIMNEYS & DAMPERS

GENERAL REQUIREMENTS

Temp-Cast fireplaces require an approved

chimney system for safe and satisfactory

performance. Code-approved masonry and

factory-built chimney systems are both

acceptable.

In addition to building code requirements, every

chimney system should:

extend straight up from the base of the

fireplace

be at least 18 ft (5.5m) in height

have an access at the base, with a tight-

fitting metal door, for chimney cleaning

have a cross-sectional area of at least 50 sq.

inches (320 sq cm)

NOT BE CONNECTED TO ANOTHER

APPLIANCE OR TO ANY AIR DUCTS

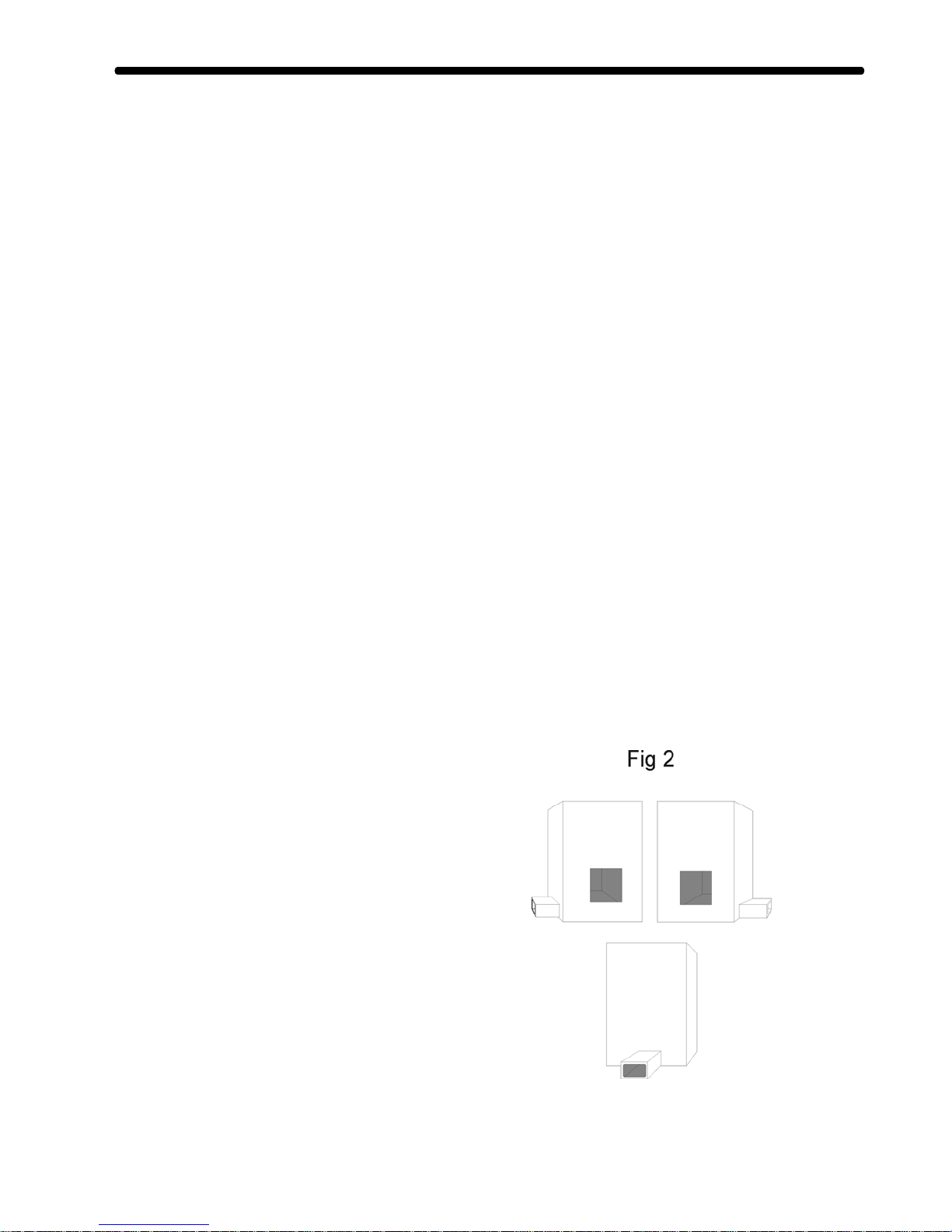

FLUE CONNECTIONS

The chimney connection is made at the bottom

of the fireplace, in the first course. The

connection can be made on either side of the

fireplace or through the back wall, into the cross

manifold. (Refer to Fig. # 2). The flue

connection can be up to 5 ft. long, creating

heated benches & allowing additional flexibility

in chimney locations.

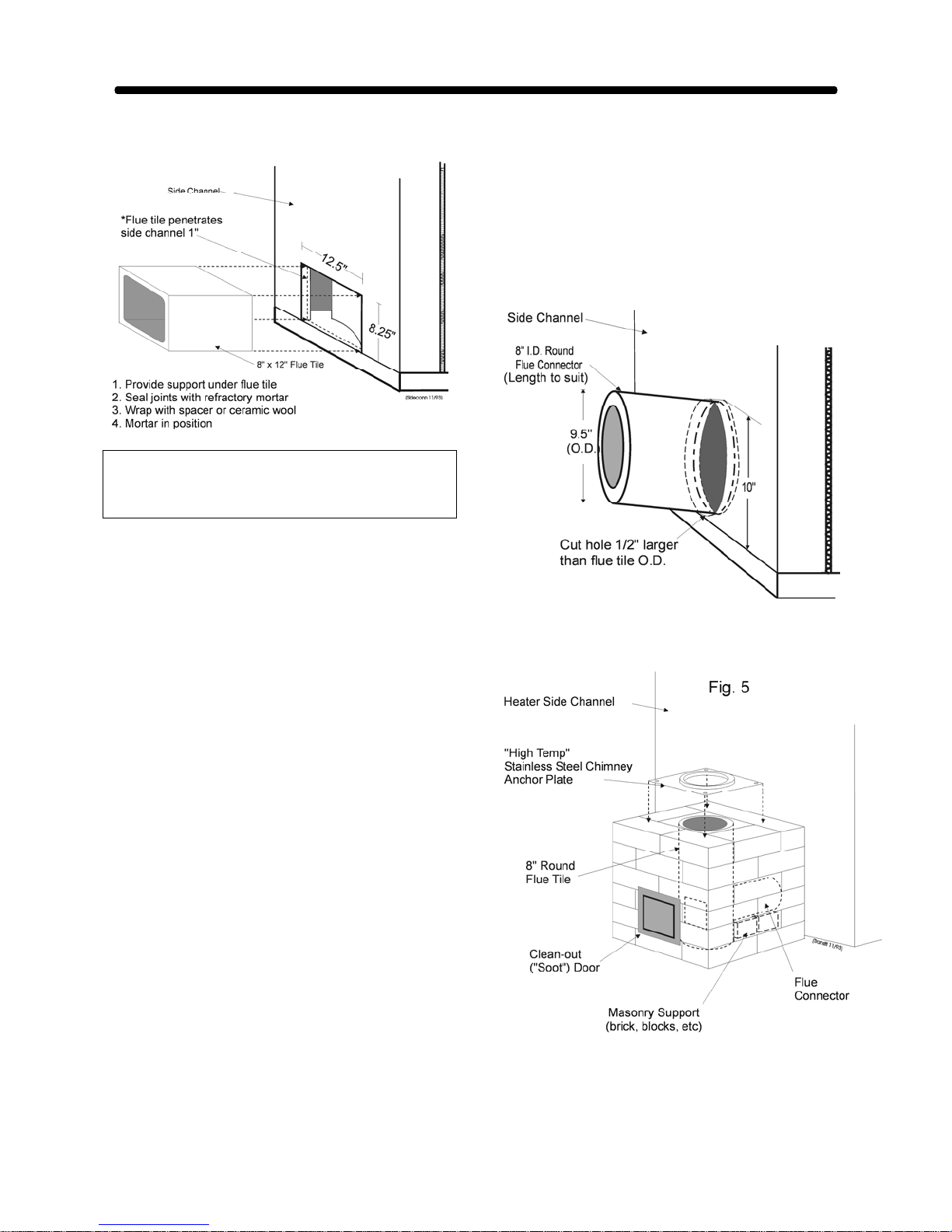

For a side connection, the side channel (Part #

30 or 31) is cut to receive the connector. (see

step 18.) Make this cut carefully so that a

smooth transition from the fireplace to the

chimney results, free of

of the escaping smoke. Use joint sealing mortar

to make it completely smoke tight. The

connector piece penetrates the fireplace side

channel about 1" (25mm), but care must be

taken to ensure that it does not protrude past the

inner edge of the side channel. (See Figs. # 3

and 4.)

If the connection is made at the back of the

fireplace, the cross manifold (Part #3) is cut to

obstructions to the flow

receive the flue connector. This joint must

also be smoke-tight. (See also Section 3,

Step #3.)

MASONRY CHIMNEYS

Due to the thermal mass storage capability

of masonry chimneys, we recommend them

over factory-built chimneys, provided they

are completely inside the home & fitted with

a damper.

Masonry chimneys should have carefully

aligned flue liners, with joints that are

smoke-tight and joined with refractory

mortar. The inside surface of the liner

should be smooth, with all excess mortar

removed. Refractory, clay and UL/ULC

listed stainless steel are all acceptable liners.

An access for a chimney cleanout can be cut

in the first vertical flue tile. (See Fig #10)

6

Temp-Cast 2000 Installation Manual February 2010

Section 2 – Chimneys & Dampers

7

Fig 3

A 4” grinder with a diamond blade is ideal for

cutting accurate & neat holes in the refractory

concrete modules.

FACTORY-BUILT CHIMNEYS

We do not recommend exterior chimneys, (see

Sec. 4 of the Temp-Cast Planning Guide) but if a

chimney on the outside of the house is

unavoidable, then an insulated factory-built (e.g.

"HT" or 2100F.) chimney is the better choice.

When a factory-built chimney is started at the

floor level, there will not be sufficient space to

access the clean-out cap under it. In order to

provide a clean out access, one of the following

2 methods is suggested.

Create a masonry connection to the fireplace,

with 8" (200mm) round flue tile. Add vertical

sections of 8” round flue tile, with a clean-out

access built into the first vertical section. Wrap

the horizontal tile and the first vertical flue tile

with “ceramic wool” blanket & ensure they

cannot be dislodged. Continue with flue tile &

masonry to the point where the transition to

factor-built chimney is wanted – often the

masonry is extended to the first ceiling. If a

roof-top damper is to be installed, the cable

protector for the damper cable must be built into

the masonry chimney where it will be accessible

for daily use – we recommend at least 6 feet

from the floor. Install an anchor plate approved

for the factory-built chimney, on top of the last

masonry section - the factory-built chimney

continues from this point. (See Fig. 5.) If the

factory-built chimney will also be enclosed in

masonry, the layout of the first masonry courses

must take this into account. (Confirm this

connection method with your local building

official.)

Fig 4

Temp-Cast 2000 Installation Manual February 2010

Section 2 – Chimneys & Dampers

8

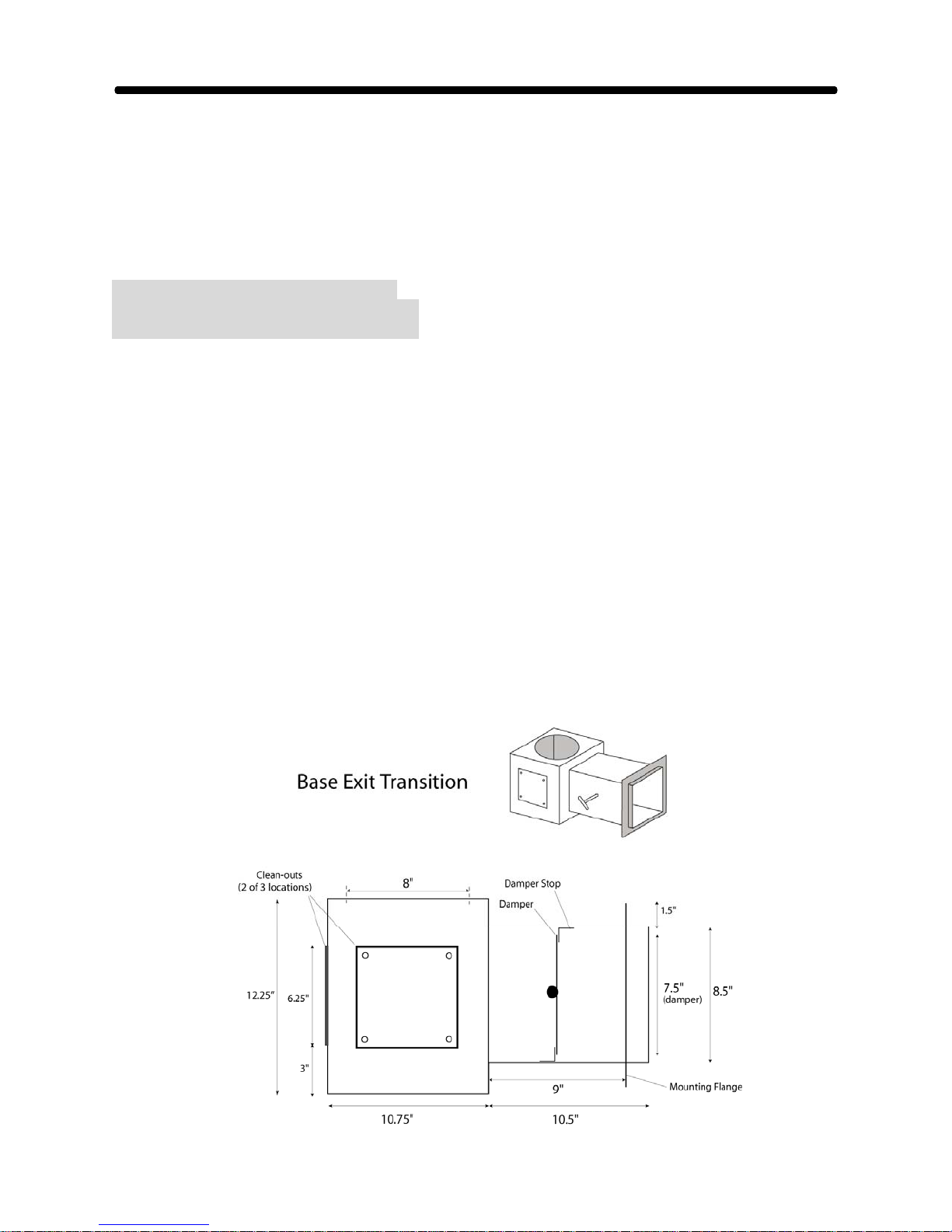

BASE-EXIT DAMPER/TRANSITION

A Temp-Cast base-exit damper/transition is

another method to make a suitable connection

from the heater to a factory-built chimney, and

also incorporates a damper & cleanout access

that is not otherwise possible with factory-built

chimneys. (See Fig 6.)

If you use a damper of any kind, be

certain to read the cautions regarding

carbon monoxide, in the next section.

The following details the installation of the

Temp-Cast base-exit damper/transition.

1. At Step 18, position the base-exit

damper/transition, sitting on the

concrete slab. Mark where the damper

will be installed into the side channel

(Part #30 or 31) or rear manifold (Part

#3), and cut a 9½” x 9½” opening.

2. Cut the damper rod to length, if

required, to extend beyond the masonry

which will enclose the entire assembly.

3. Attach the handle to the rod with the nut

extender and nuts supplied. Check the

operation of the damper to become

familiar with its operation. (The handle

is usually shipped inside the damper.)

4. Attach a strip of ceramic wool to the

outside of the side channel around the

damper opening, with high-temperature

silicone. Lay a strip of ceramic wool on

the bottom edge of the opening and

insert the base-exit damper/transition.

Insert the damper into the opening and

slightly compress the ceramic wool – it

may be helpful to temporarily support

the damper box until masonry work has

been started around it.

5. Cover the damper rod so that it will not

be inadvertently cemented in position

during installation of the masonry facing

– flexible cardboard or ½” copper pipe

(not supplied) may be used for this.

6. With at least 3 metal screws, attach an

approved masonry adapter to the top of

the damper assembly & install the first

vertical section of factory-built chimney.

7. Enclose the entire damper assembly

with at least 4” of solid masonry,

leaving an access for the cleanout. (If

the factory-built chimney will also be

enclosed, the first masonry courses must

take this into account.)

Other methods of connecting factory-built

chimneys may also be acceptable. Consult the

chimney manufacturer, a certified installer or

your local building official.

Fig 6

Temp-Cast 2000 Installation Manual February 2010

Section 2 – Chimneys & Dampers

9

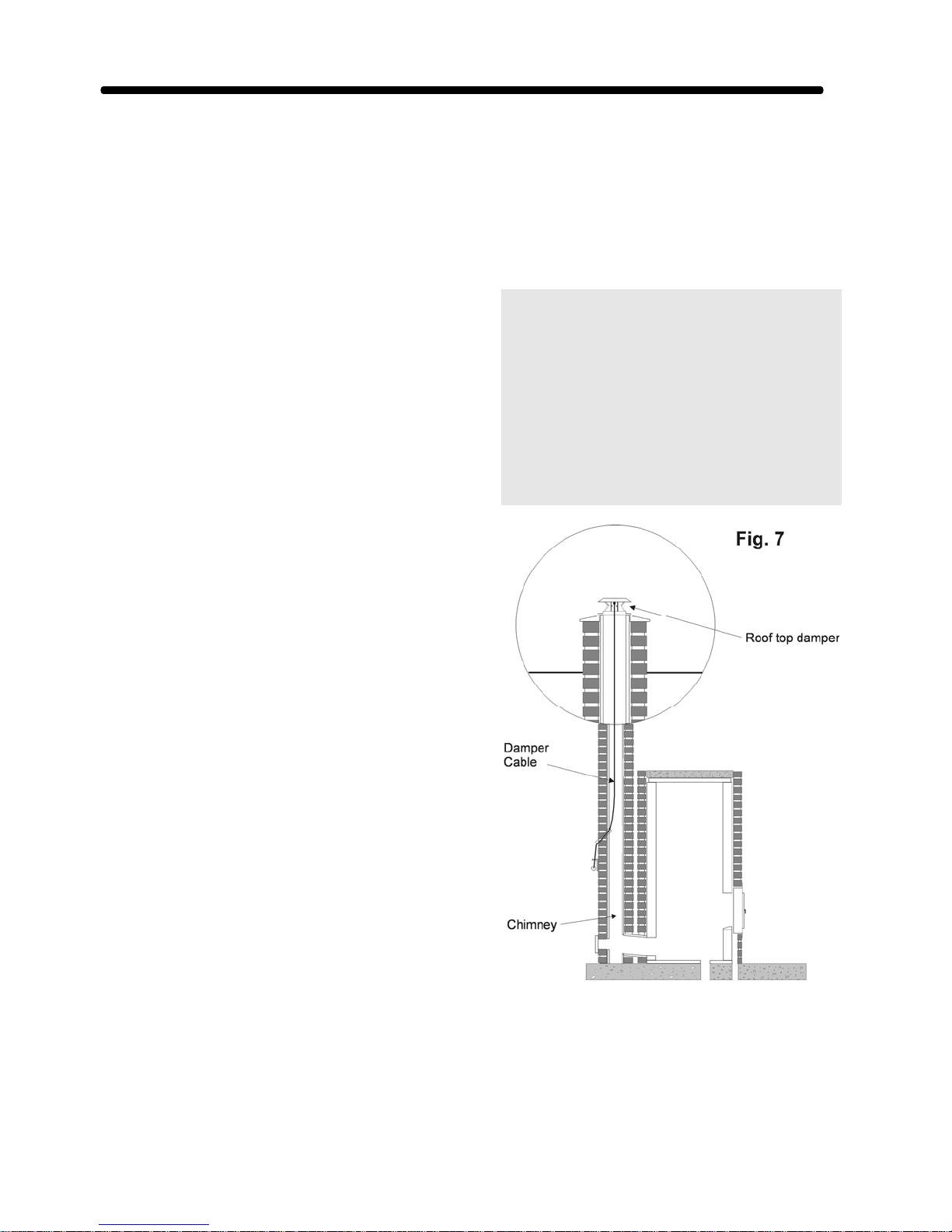

INSTALLING THE ROOF-TOP

CHIMNEY DAMPER

An optional “roof-top” chimney damper is

recommended to allow the chimney to be closed

off when the fire is out. This will let the

chimney mass hold additional heat and greatly

improve the overall heating efficiency of the

system. (Refer to the Temp-Cast Owner's

Manual for proper use of the chimney damper.)

The damper is cemented to the top of the

uppermost flue tile of the chimney, and is

controlled by a cable through the centre of the

chimney. (See Fig. 7) The cable is routed

through the side of the flue tile during

construction of the chimney and masonry facing.

(Note: Installation of the damper cable is greatly

simplified if the protective sleeve and steel

cable are installed in the desired area when the

chimney is being built. If this has not been done,

then a string will have to be fished through the

sleeve & secured to the steel cable.) Attach the

cable bracket to the outside of the chimney in a

convenient, unobtrusive location, but always out

of the reach of small children.

For 8” round chimneys, including factory-built

models, a Round-to-Square adapter and a 13” x

13” damper will be required.

NOTE: When a stainless steel (i.e. “factorybuilt”) chimney is used, penetrating the steel

chimney is not permitted. Alternatives

include:

1. Installing a Temp-Cast Base-Exit Damper,

construct a short section of masonry

chimney, install an approved masonry

adapter part and continue with factory-built

chimney through the roof. (See Fig 6.)

2. Starting the installation with a Temp-Cast

Base-Exit Transition, with or without an

integral damper. For exposed chimneys, a

Temp-Cast Base-Exit Transition/Damper

must be used. If the chimney is to be

enclosed to the first ceiling or through to

the roof, you can use the same Temp-Cast

Base Exit Damper/Transition, or obtain an

adapter with a built-in damper, which can

be installed with the first section of

“factory-built” chimney. This permits a

more effective damper, much higher up in

the chimney system. In either case, the

whole chimney assembly and transition can

be enclosed in masonry.

CAUTION: Whenever a full-closure damper is

used, care should be taken to ensure that the fire

is completely out before the damper is shut.

Closing the damper prematurely could cause

combustion gases, especially carbon monoxide,

to be spilled into the home. Carbon monoxide

has the potential to be fatal. We therefore

strongly recommend installation of a carbon

monoxide alarm, available where smoke alarms

are purchased, whenever a damper is used with a

Temp-Cast masonry heater.

Temp-Cast 2000 Installation Manual February 2010

Section 3 - Step-By-Step Assembly

SECTION 3: STEP-BY-STEP ASSEMBLY

ASSEMBLY NOTES

1. Dry-assemble the heater upon

delivery, to check the condition of all

parts and to familiarize yourself with

the modules. (If all of the parts are not

numbered, you may find it helpful to do

so, using this manual, before taking

the unit apart again.)

2. Cutting of flue tiles and fireplace

modules should be done outdoors due

to the excessive dust created. WEAR

SUITABLE EAR, EYE AND LUNG

PROTECTION.

3. A 4” grinder with a diamond blade is

best for cutting holes in flue tiles and

fireplace modules. Or round holes can

be cut as six or eight-sided shapes

with a gas, water or circular saw or

drilled every inch (25mm) and then cut

with a reciprocating saw fitted with a

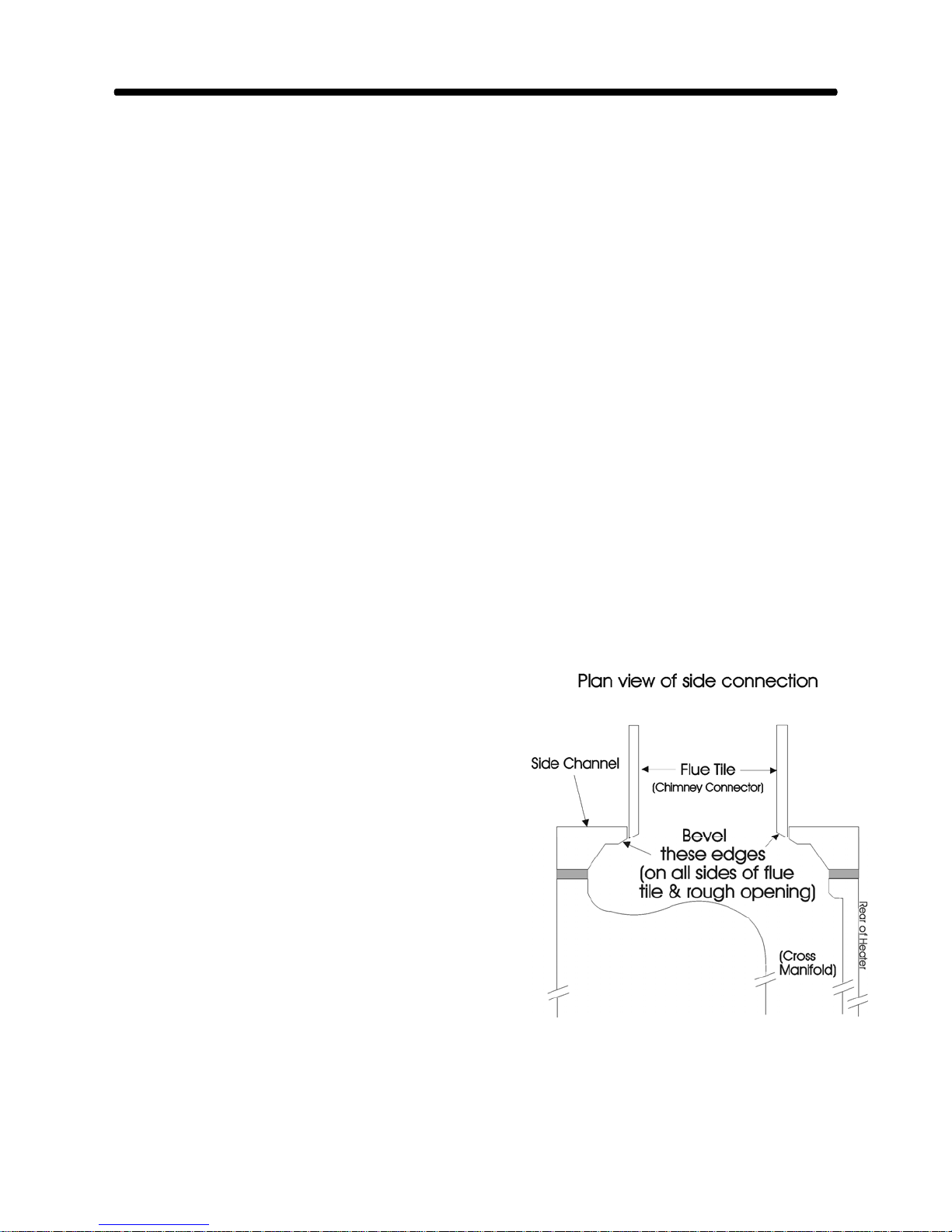

masonry blade. Rounding or beveling

the inside edges of the hole in the

module creates the least resistance to

the flow of smoke and gases,

maximizing draft and performance.

(See Fig. 8)

4. When using the ceramic-fibre gasket

material, it should only be slightly

compressed. Compressing it too

much will defeat its purpose as an

expansion gasket. (A small amount of

refractory mortar can be used to

cement the gasket in position.)

5. Refractory casting occasionally leaves

behind rough spots or small bumps on

the modules. If these rough spots

should occur in a joint between 2

modules, they may prevent a tight joint

and make installation of subsequent

parts more difficult. Remove any such

10

bumps with a rasp or scraping tool

before assembling.

6. Refractory mortar should be used

sparingly, applying a small (1/4” to

3/8”) bead between modules. The

finished joint should have a very thin

skin of refractory mortar, which is the

strongest. (In addition, the parts will

only fit properly if the thinnest possible

joint is created.) Apply a small amount

on the outside edges of the part, where

indicated by the shaded areas. Do not

use a full bed of mortar. Seat the

parts completely, using a rubber

mallet, so that a little mortar squeezes

out. After each course, scrape off and

save excess mortar for possible later

use. Periodically wipe the modules

inside and out with a damp sponge to

ensure that excess mortar has not

been left behind.

Fig. 8

Temp-Cast 2000 Installation Manual

Section 3 - Step-By-Step Assembly

11

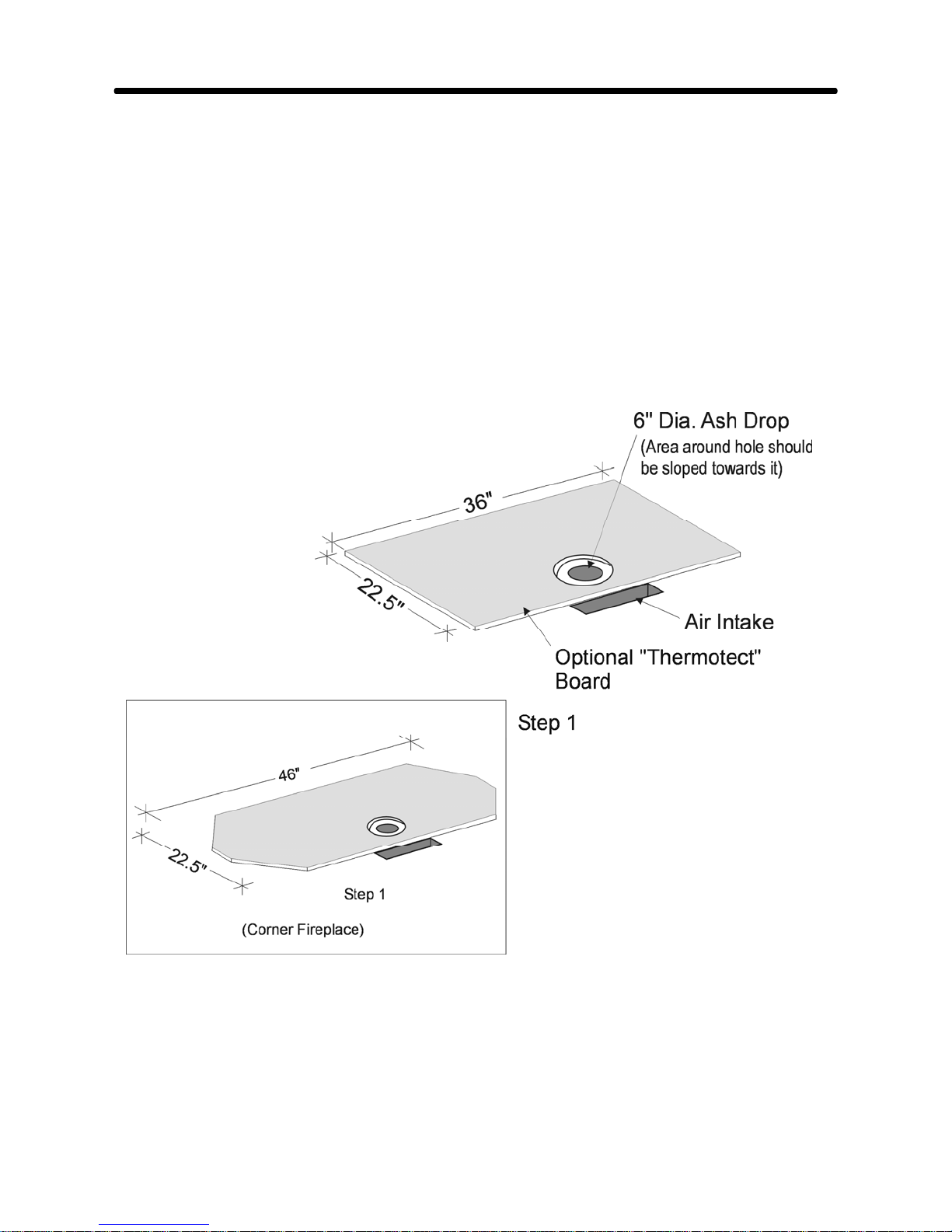

STEP 1: "THERMOTECT" INSULATING BOARD

If an optional insulating board is to be installed, it is installed before starting the Levelling Pad.

Cut the board to size as indicated and place it in position. Check that it is square to the concrete

floor pad. Ensure that the air intake hole is located immediately in front of the board and centered.

(It is also advisable at this point to double check that there will be sufficient clearances to

combustible construction around the fireplace.)

If you have followed the Temp-Cast Planning Guide, the area around the 6" diameter Ash Drop

hole in the concrete pad will be sloped towards the hole for a few inches all around. Cut an

appropriately sized hole in the insulating board so that the sloped area around the hole is not

obstructed. Lay the board in position as illustrated.

Temp-Cast 2000 Installation Manual

Section 3 - Step-By-Step Assembly

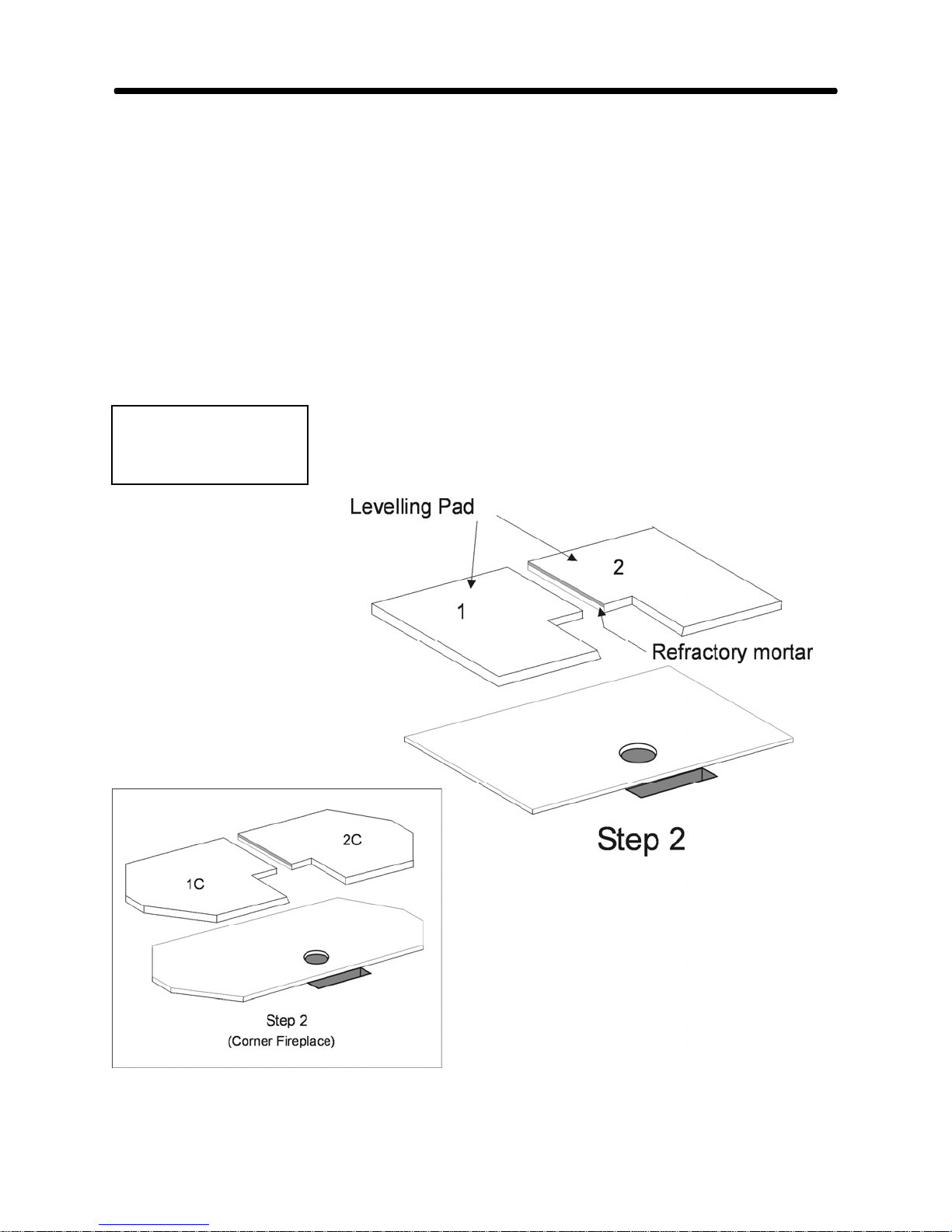

STEP 2:

"Dry" assemble (i.e. without mortar) the two halves of the Leveling Pad (Part #1 & #2) on the

"Thermotect" board (optional), or on the concrete floor pad, so that the air intake slot is not

obstructed and is centered in front of the Leveling Pad. Ensure that the 6" (150mm) diameter ash

drop is located within the cut-out section of the base. CHECK THAT THE FLOOR IS

REASONABLY LEVEL BEFORE STARTING TO INSTALL THE LEVELLING PAD ADDITIONAL MORTAR MAY BE NEEDED TO LEVEL IT AS REQUIRED.

Lay the two halves of the Leveling Pad in a 1/2" (12mm) bed of common mortar, using refractory

mortar between them. Using the 48" level, tap the base into the mortar, ensuring that it is level.

Before the mortar has set, tap down along the centre-line of the leveling pad, so that the centre of

the pad is about 3/16” lower than the sides. (See illustration below.) This centre-line gap will

ensure that parts in the upper courses lean in slightly, simplifying installation.

Weights

#1 & 2 - 49 lbs

#1C & 2C - 59 lbs

12

Temp-Cast 2000 Installation Manual

Section 3 - Step-By-Step Assembly

13

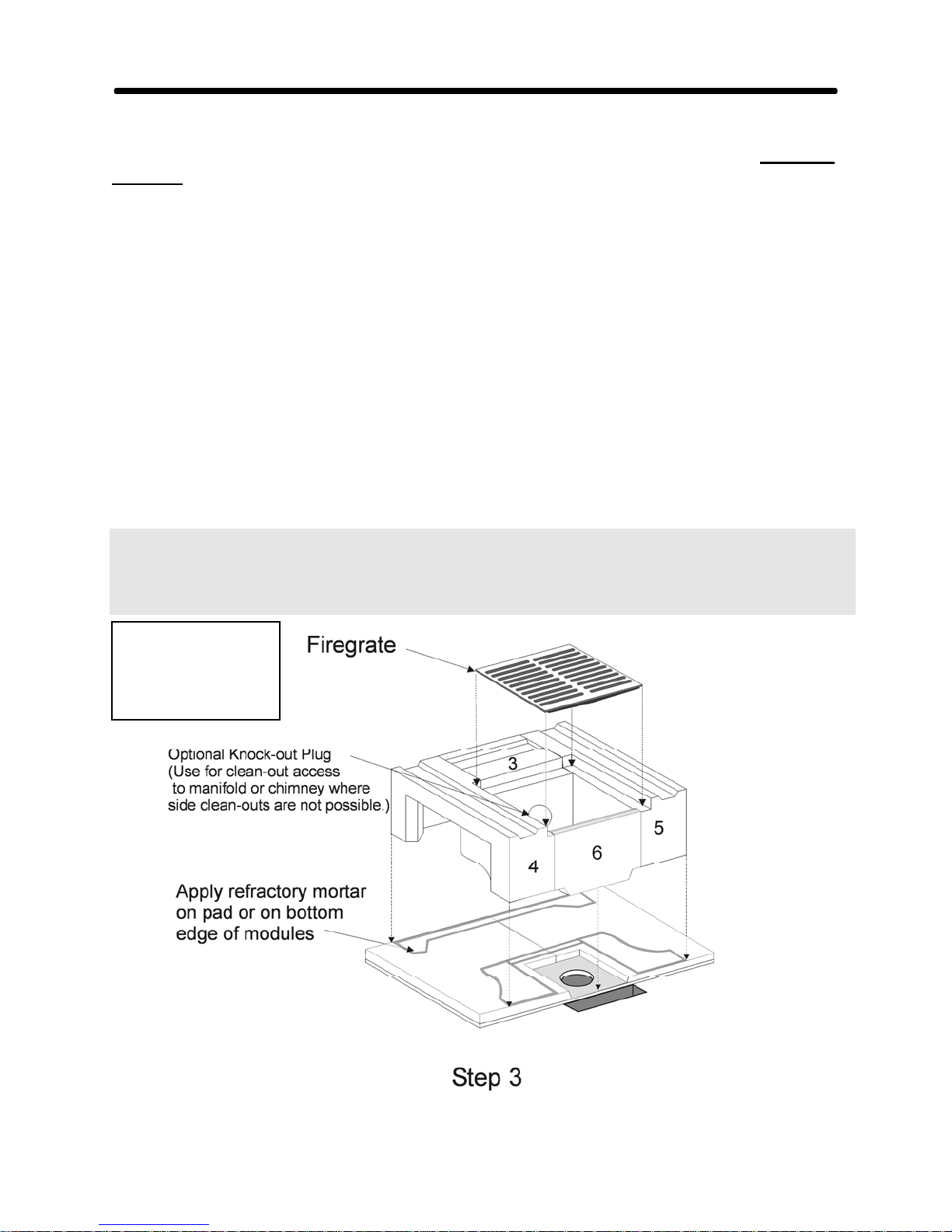

STEP 3:

When the Leveling Pad can support weight, dry assemble the first course of modules, including

the grate, as in the accompanying drawings, to check for proper fit. This course must be centered

on the Leveling Pad, so that equal space is left on both sides for the heat exchange channels - mark

the correct placement with a pencil.

If the chimney is to be connected at the rear of the fireplace, mark the cross manifold (#3) to be

cut for the flue connection. Take this part outdoors and cut a hole for the flue connector being

used. For flue tile or HT chimney, cut the hole the same size as the inside dimensions of the flue

connector. The flue connector or HT adapter will then be mortared or attached to the outside of

the cross manifold - Part #3. (Holes for a side connection are discussed at Step 18.)

Once the layout of fireplace and chimney connection, all dimensions and locations of cleanout

doors have been confirmed, draw a line on the Leveling Pad to mark the outside edges of the base

course. Now remove the modules, (cut the flue hole in #3 if required) and re-assemble, using a

small amount of the refractory mortar provided on the bottom edges and between modules. Seat

the parts with the rubber mallet, then reach inside the cross manifold and wipe off all excess

mortar.

NOTE: once final assembly has been started, the entire core should be assembled in a continuous

operation, so that minor adjustments to previous courses can be made before the refractory mortar

has set. Place the fire-grate in position, which should fit loosely to allow for expansion. Cover it

to keep clean.

Weights

#3 - 61 lbs

#4& #5 - 82 lbs

#6 - 22 lbs

Temp-Cast 2000 Installation Manual

Section 3 - Step-By-Step Assembly

14

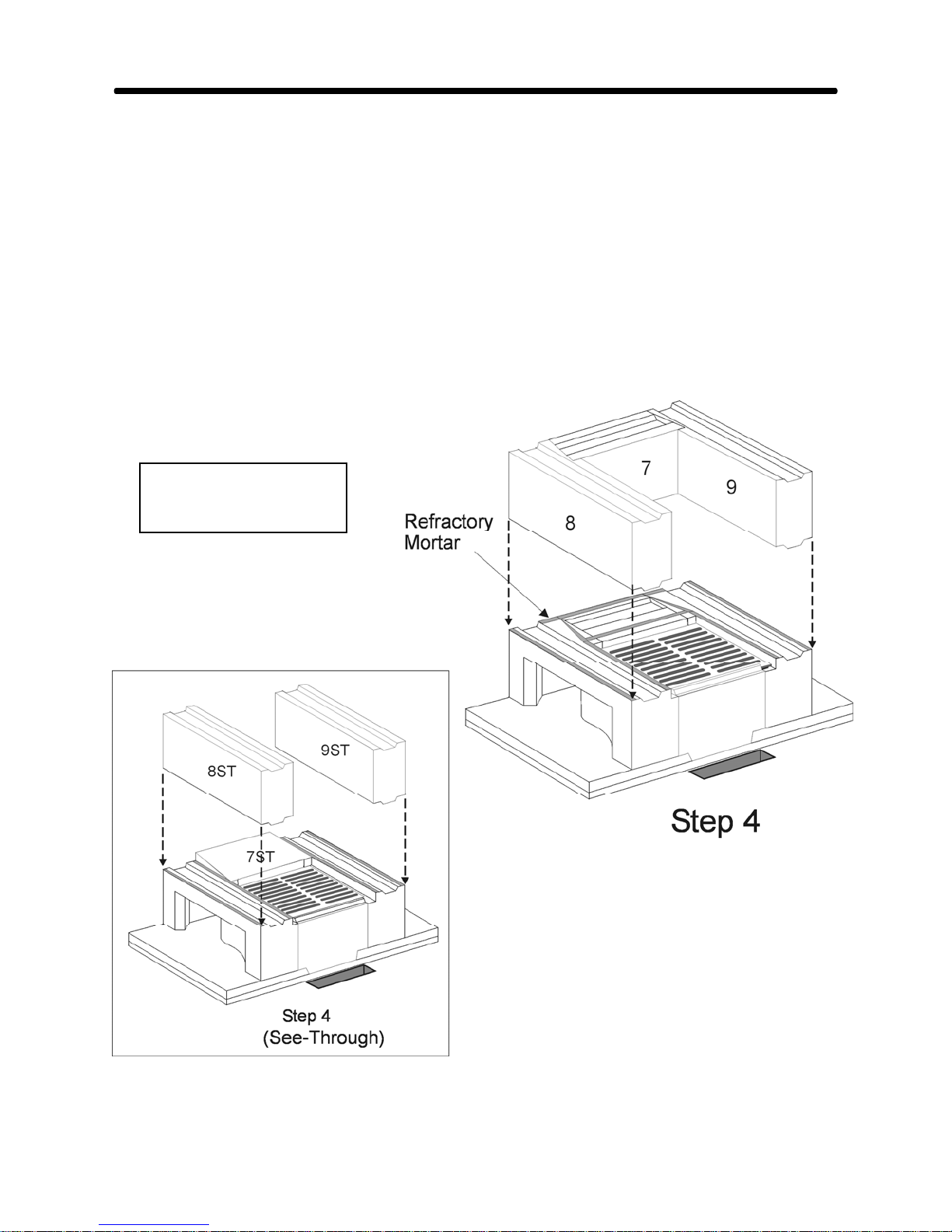

STEP 4:

Assemble the second course, parts #7, #8 & #9. A small bead (½”) of refractory mortar is laid on

the outside edges where the two parts meet. (The bead can be laid either on the part being laid on

or the previous part - whichever is easier.) Note that the parts are numbered in the order that they

should be placed. (For a Temp-Cast "See-Through" fireplace, these 3 parts are slightly different,

as in the accompanying illustration.)

Use the rubber mallet to seat the modules. Remove excess mortar and wipe inside and out with a

damp sponge as work progresses.

NOTE: When installing the modules on this course and subsequent courses around the firebox

opening, take care that the parts are flush at the front of the fireplace. This will produce the most

level surface on which to install the door frame later.

Weights

#7 - 52 lbs

#8, #8ST, #9, #9ST - 68

Temp-Cast 2000 Installation Manual

Section 3 - Step-By-Step Assembly

15

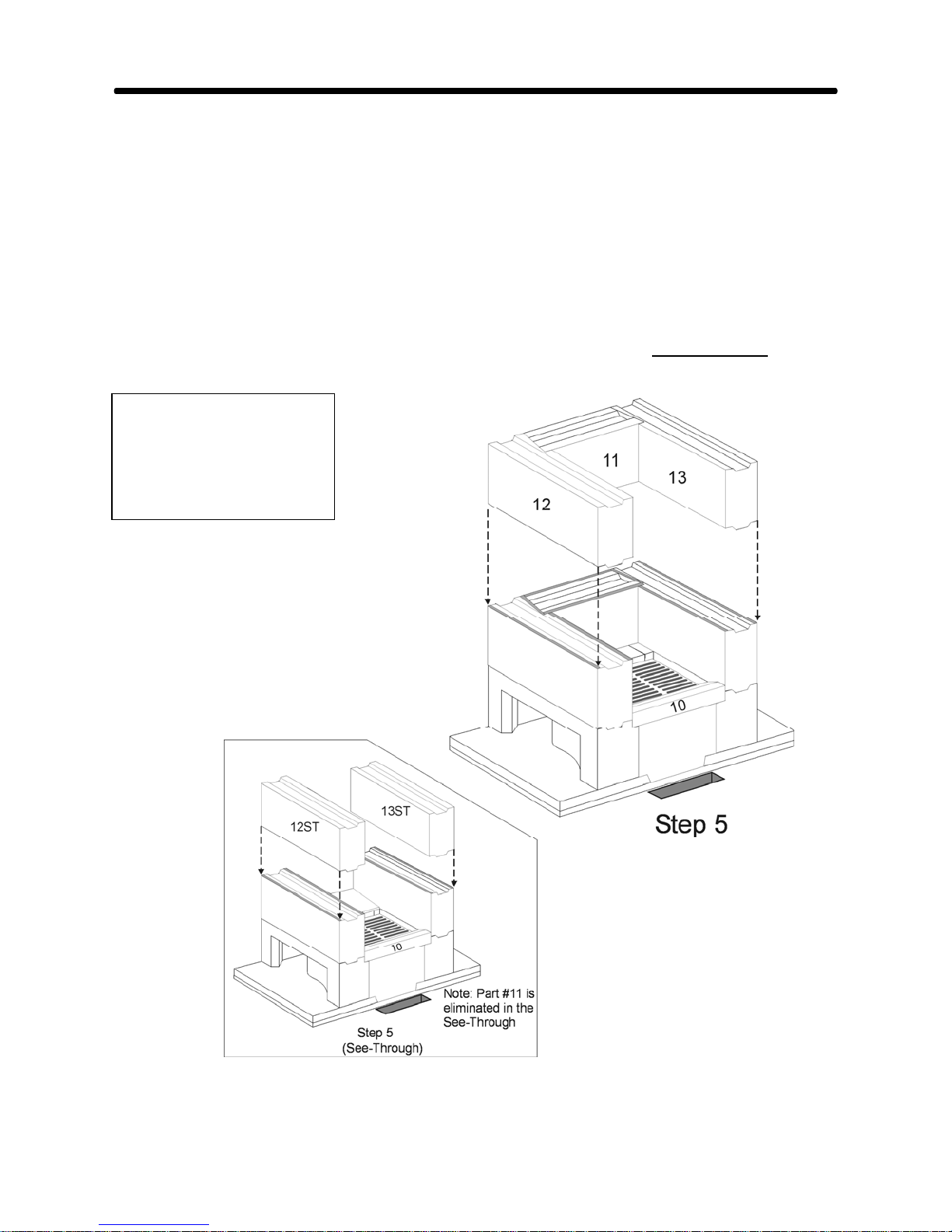

STEP 5:

Install Parts# 10, 11, 12 &13, using refractory mortar. Also “butter” the ends of part #10, so there

are no gaps on the ends. (Note that parts 11 thru 13 are identical to the previous course.) (In the

"See-Through" fireplace, there is no part #11.)

Seat with the rubber mallet and ensure that joints are tight.

Remember to keep the front edges of the modules aligned and use a 48” level to ensure that the

four sides are plumb.

Leveling the courses is not critical – it is sufficient if the courses are approximately level.

Weights

#10 - 12 lbs

#11 - 52 lbs

#12 & #13 - 68 lbs

#12ST & #13ST - 68 lbs

Temp-Cast 2000 Installation Manual

Section 3 - Step-By-Step Assembly

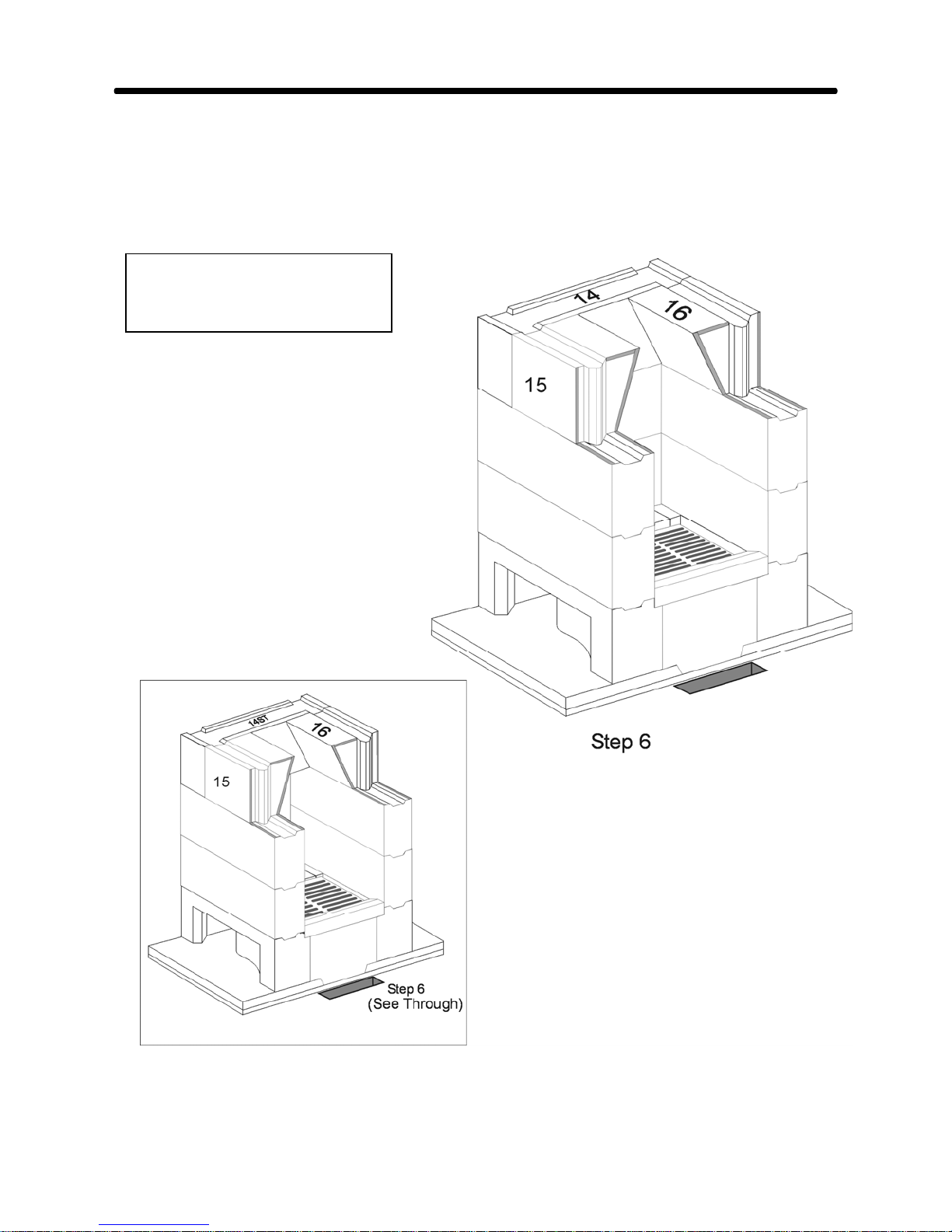

STEP 6:

Install the lintel course, parts 14, 15 & 16, in order, using a small (3/8”) bead of refractory mortar

on the outside edges of the adjoining parts.

Weights

#14 & #14 ST- 86 lbs

#15 & #16 - 64 lbs

16

Temp-Cast 2000 Installation Manual

Loading...

Loading...