TEMIC U210B-FP, U210B Datasheet

TELEFUNKEN Semiconductors

U 210 B / U 210 B–FP

Phase Control Circuit – Load Current Feedback Applications

Technology: Bipolar

Features

Externally controlled integrated amplifier

Variable soft start

Automatic retriggering

Voltage and current synchronisation

Case: DIP 14, SO 16

Triggering pulse typ. 125 mA

Internal supply voltage monitoring

Temperature constant reference source

Current requirement ≤ 3 mA

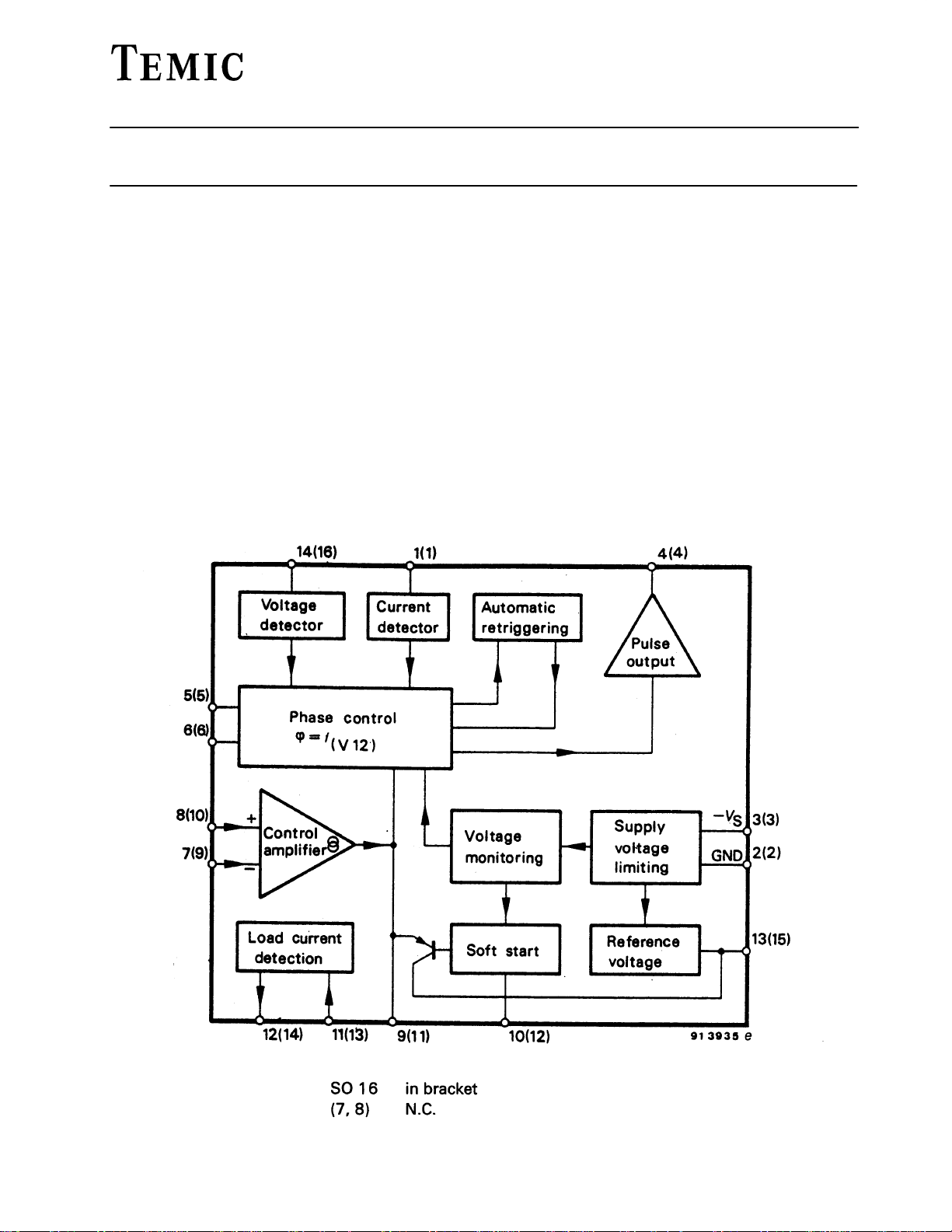

Figure 1 Block diagram

Preliminary Information

1

U 210 B / U 210 B–FP

TELEFUNKEN Semiconductors

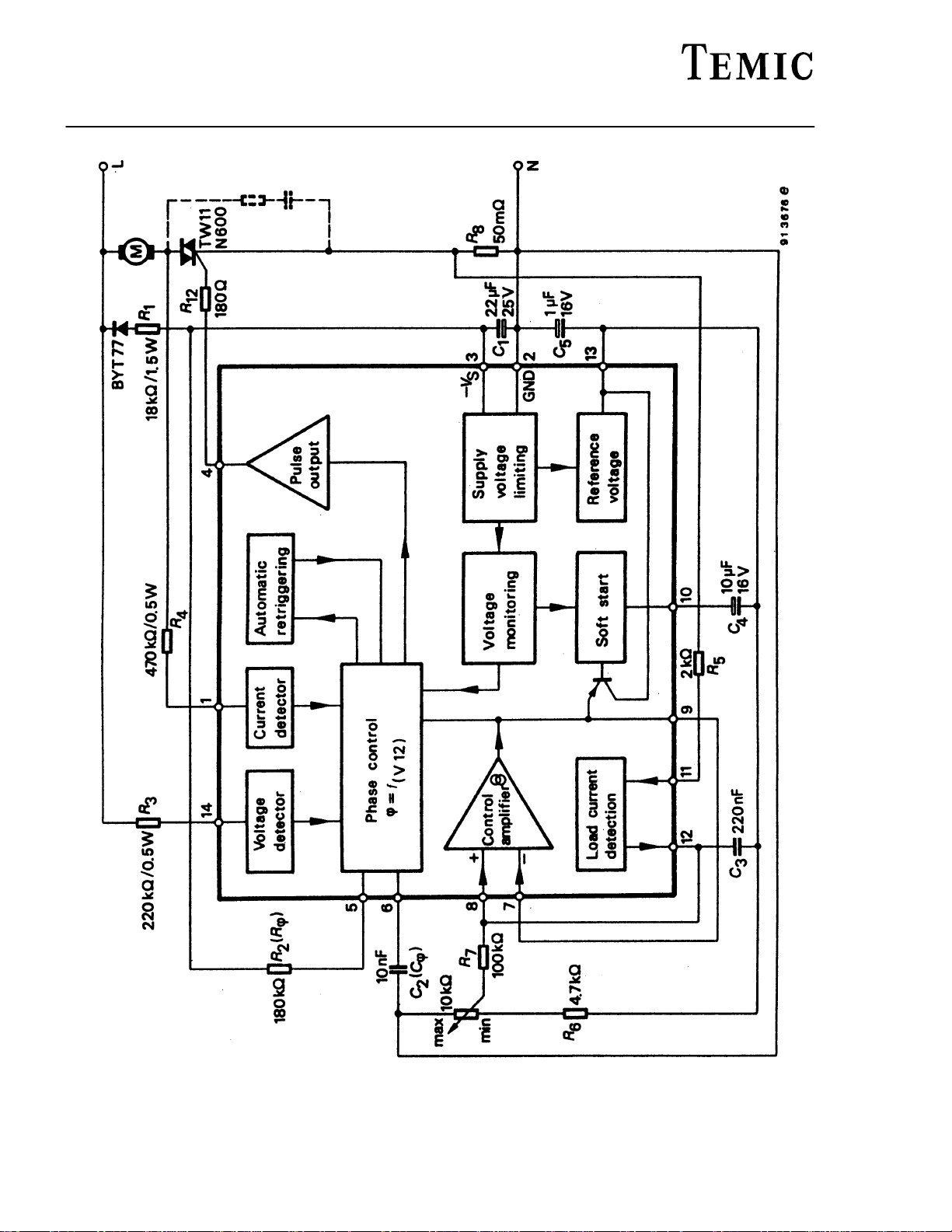

Figure 2 Block diagram with external circuitry

Open loop control with load current compensation

2

Preliminary Information

TELEFUNKEN Semiconductors

U 210 B / U 210 B–FP

Description

Mains supply

The U 210 B is fitted with voltage limiting and can therefore be supplied directly from the mains. The supply voltage

and R

between Pin 2 (+pol/) and Pin 3 builds up across D

1

can be approximated using:

VM–V

2 I

S

S

R1=

Further information regarding the design of the mains supply can be found in the data sheets in the appendix. The reference

voltage source on Pin 13 of typ. –8.9 V is derived from the supply voltage. It represents the reference level of the control

unit. Operating using an externally stabiIised DC voltage is not recommended.

If the supply cannot be taken directly from the mains because the power dissipation in R

circuit shown in the following Figure 3 should be employed.

and is smoothed by C1. The vaIue of the series resistance

1

would be too large, then the

1

Figure 3 Supply voltage for high current requirements

Phase control

The function of the phase control is largely identical to that of the well known components U 111 B and TEA 1007. The

phase angle of the trigger pulse is derived by comparing the ramp voltage, which is mains synchronised by the voltage

detector, with the set value on the control input Pin 9. The slope of the ramp is determined by C

The charging current can be varied using R

on Pin 5. The maximum phase angle

2

can also be adjusted using R2.

max

and its charging current.

2

When the potential on Pin 6 reaches the nominal value predetermined at Pin 9, then a trigger pulse is generated whose

width t

is determined by the value of C

p

(the value of C

2

and hence the pulse width can be evaluated by assuming 8 s/nF).

2

At the same time, a latch is set, so that as long as the automatic retriggering has not been activated, then no more pulses

can be generated in that half cycle.

The current sensor on Pin 1 ensures that, for operation with inductive loads, no pulse will be generated in a new half cycle

as long as current from the previous half cycle is still flowing in the opposite direction to the supply voltage at that instant.

This makes sure that ”Gaps” in the load current are prevented.

The control signal on Pin 9 can be in the range 0 V to –7 V (reference point Pin 2).

If V

pin9

angle

= –7 V then the phase angle is at maximum =

is when V

min

pin9

= V

pin2

.

i .e. the current flow angle is a minimum. The minimum phase

max

Voltage monitoring

As the voltage is built up, uncontrolled output pulses are avoided by internal voltage surveillance. At the same time, all

of the latches in the circuit (phase control, soft start) are reset and the soft–start capacitor is short circuited. Used with

a switching hysteresis of 300 mV, this system guarantees defined start–up behaviour each time the supply voltage is

switched on or after short interruptions of the mains supply.

Preliminary Information

3

U 210 B / U 210 B–FP

TELEFUNKEN Semiconductors

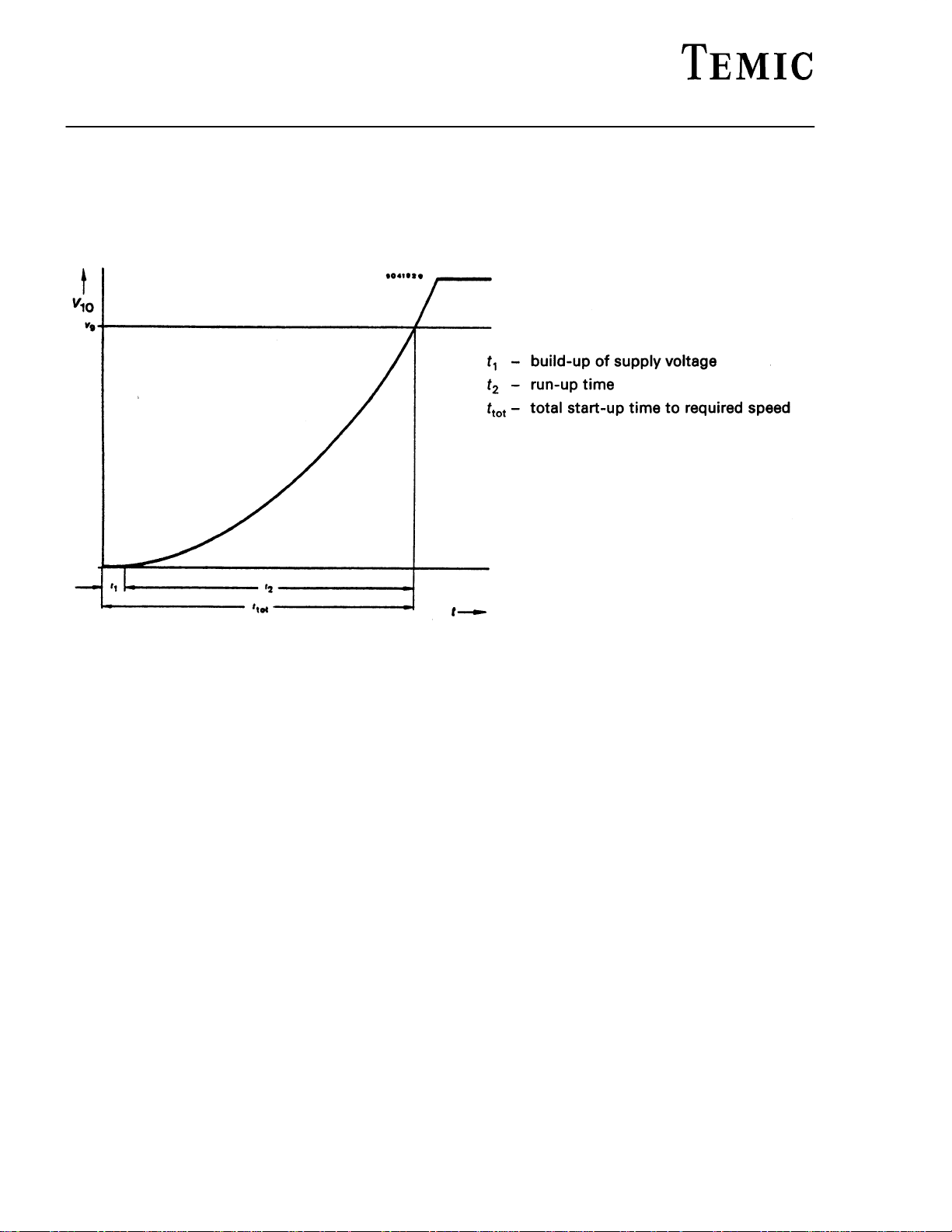

Soft–start

As soon as the supply voltage builds up (t1), the integrated soft–start is initiated. The figure below shows the behaviour

of the voltage across the soft–start capacitor and is identical with the voltage on the phase control input on Pin 9. This

behaviour allows a gentle start–up for the motor.

Figure 4 Soft–start

is first charged with typ. 30 A. The charging current then increases as the voltage across C

C

3

progressively rising charging function with more and more strongly accelerates the motor with increasing rotational

speed. The charging function determines the acceleration up to the set point. The charging current can have a maximum

value of 85 A.

increases giving a

4

Control amplifier

The integrated control amplifier with differential input has a bipolar current output, with typically ±110 A at Pin 9 and

a transmittance of typ. 1000 A/V. The amplification and frequency response are determined by external circuit. For

operation as a power control, it should be connected with Pin 7. Phase angle of the firing pulse can be adjusted by using

the voltage at Pin 8. An internal limiting circuit prevents the voltage on Pin 9 becoming more negative than V

13

+ 1 V.

Load current detection, Figure 2

Voltage drop across R8, dependent of load current, generates an input–current at Pin 11 limited by R5. Proportional output

current of 0.44 x I

Capacitor C

proportionality , can be used according to the application i.e., load current compensation or load current regulation.

3

(CTR) is available at Pin 12. It is proportional with respect to phase and amplitude of load current.

11

integrates the current whereas resistor R

evaluates it. The voltage obtained due to load current

7

Pulse output stage

The pulse output stage is short circuit protected and can typically deliver currents of 125 mA. For the design of smaller

triggering currents, the function I

and the TEA 1007, the pulse output stage of the U 210 B has no gate bypass resistor.

= f (RGT) has been given in the data sheets in the appendix. In contrast to the U 11 1 B

GT

Automatic retriggering

The automatic retriggering prevents half cycles without current flow, even if the triac is turned off earlier e.g. due to not

exactly centred collector (brush lifter) or in the event of unsuccessful triggering. After a time lapse of t

generated another triggering pulse which is repeated until either the triac fires or the half cycle finishes.

4

Preliminary Information

=4.5 tp is

pp

TELEFUNKEN Semiconductors

U 210 B / U 210 B–FP

General hints and explanation of terms

To ensure safe and trouble–free operation, the following points should be taken into consideration when circuits are being

constructed or in the design of printed boards.

The connecting lines from C

be as short as possible, and the connection to Pin 2

should not carry any additional high current such as the

to Pin 6 and Pin 2 should

2

load current. When selecting C

coefficient is desirable.

, a low temperature

2

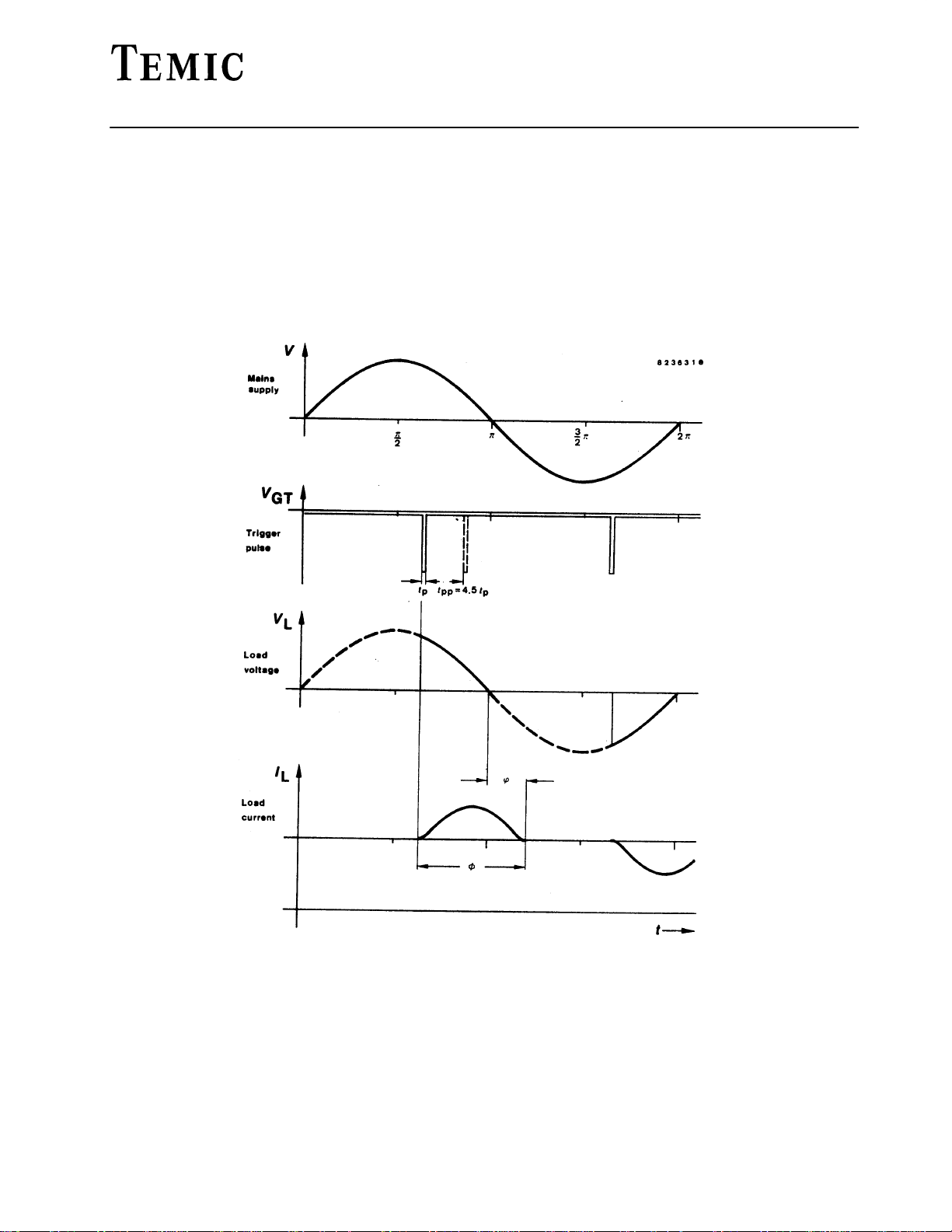

Figure 5 Explanation of terms in phase relationship

Preliminary Information

5

Loading...

Loading...