查询U209B3供应商

TELEFUNKEN Semiconductors

U209B3/ U209B3–FP

Phase Control Circuit – Tacho Applications

Description:

The integrated circuit U209B3, is designed as a phase

control circuit in bipolar technology. It has also protection

circuit for the supply. Due to integration of many

functions, it leads to significant cost and space saving as

Features

Internal frequency to voltage converter

Externally controlled integrated amplifier

Automatic soft start with minimised ”dead time”

Voltage and current synchronisation

Retriggering

well as increased reliability . At the same time, it gives the

designer free hand to select varieties of regulators to

choose from and switching characteristics according to its

choice.

Triggering pulse typ. 155 mA

Internal supply voltage monitoring

Temperature compensated reference source

Current requirement ≤ 3 mA

Package: DIP14, SO16

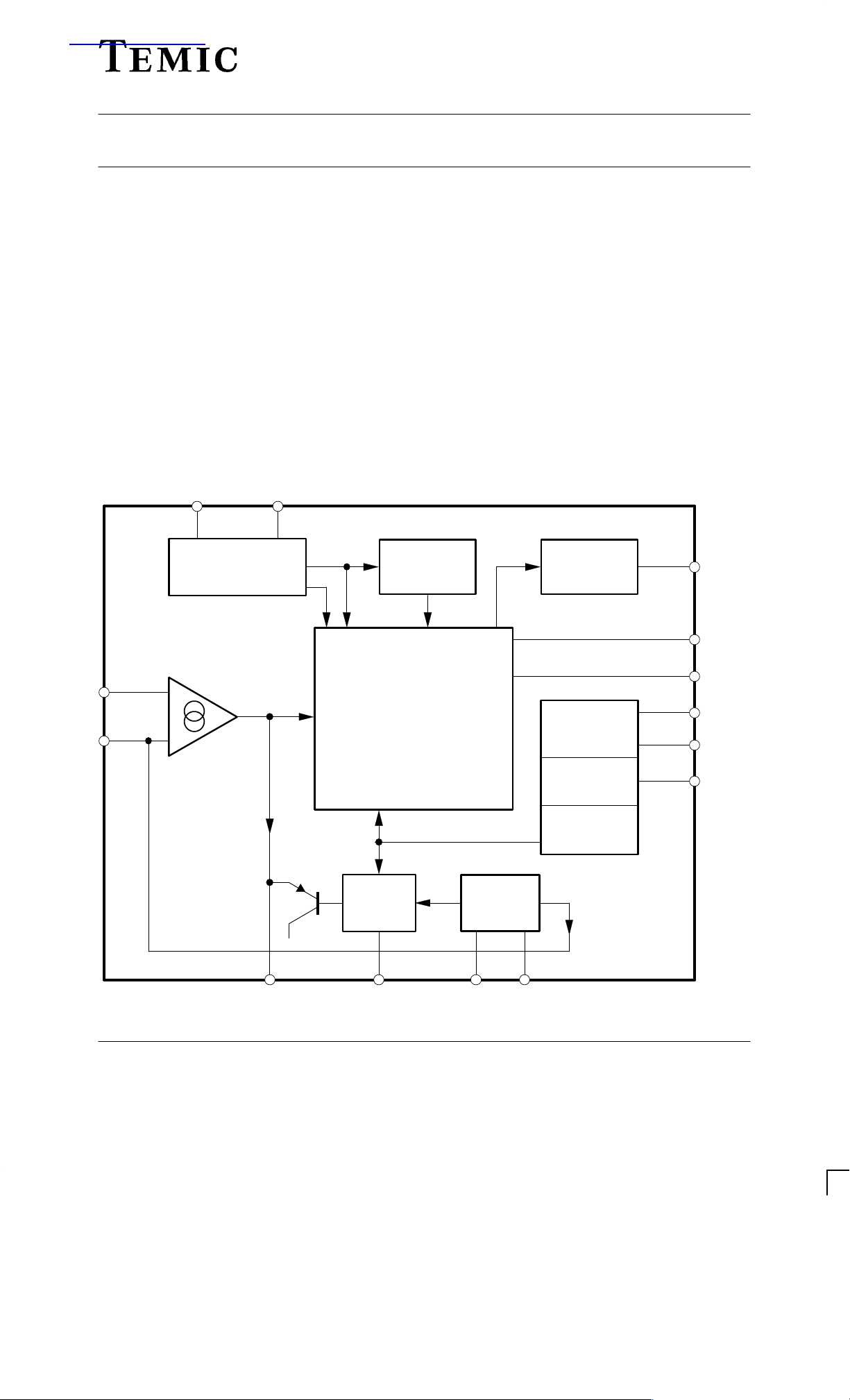

10(10)

9(9)

14(16) 1(1)

Voltage / Current

detector

Control

amplifier

+

–

Automatic

retriggering

Output

pulse

Phase

control unit

= f (V12)

Frequency

Soft start

s

to voltage

converter

Supply

voltage

limitation

Reference

voltage

Voltage

monitoring

4(4)

5(5)

6(6)

3(3)

2(2)

13(15)

–V

GND

S

11(11) 12(12) 8(8) 7(7)

95 10691

Figure 1. Block diagram – SO 16 in bracket

Rev . A1: 01.09.1995 1 (15)

Preliminary Information

TELEFUNKEN Semiconductors

U209B3/ U209B3–FP

L

M

1

D

18 k

BYT51J

R

1

2 W

AEG

95 10692

TW11

=

M

V

N600

10

R

230 V ~

4

pulse

Output

220

680 k

2

R

5

3.3 nF

6

2

C

3

Supply

N

F

25 V

22

1

C

S

–V

2

voltage

F

16 V

2.2

10

C

GND

voltage

limitation

Reference

13

Voltage

monitoring

converter

to voltage

Frequency

220 nF

4

C

5

C

Speed sensor

R

1 k

1 nF

5

)

12

Automatic

retriggering

4

R

470 k

Phase

= f (V

control unit

Soft start

s

C

11 12 8 7

8

F

3

2.2

C

220 nF

7

R

16 V

22 k

7

C

F

16 V

8

2 M

speed

Actual

2.2

6

R

68 k

6

C

voltage

100 nF

R

3

220 k

14 1

9

R

47 k

detector

Voltage / Current

11

R

Set speed

voltage

10

31

R

R

100 k

100 k

56 k

Control

amplifier

10

9

C

–

+

R

9

F

2.2 /16 V

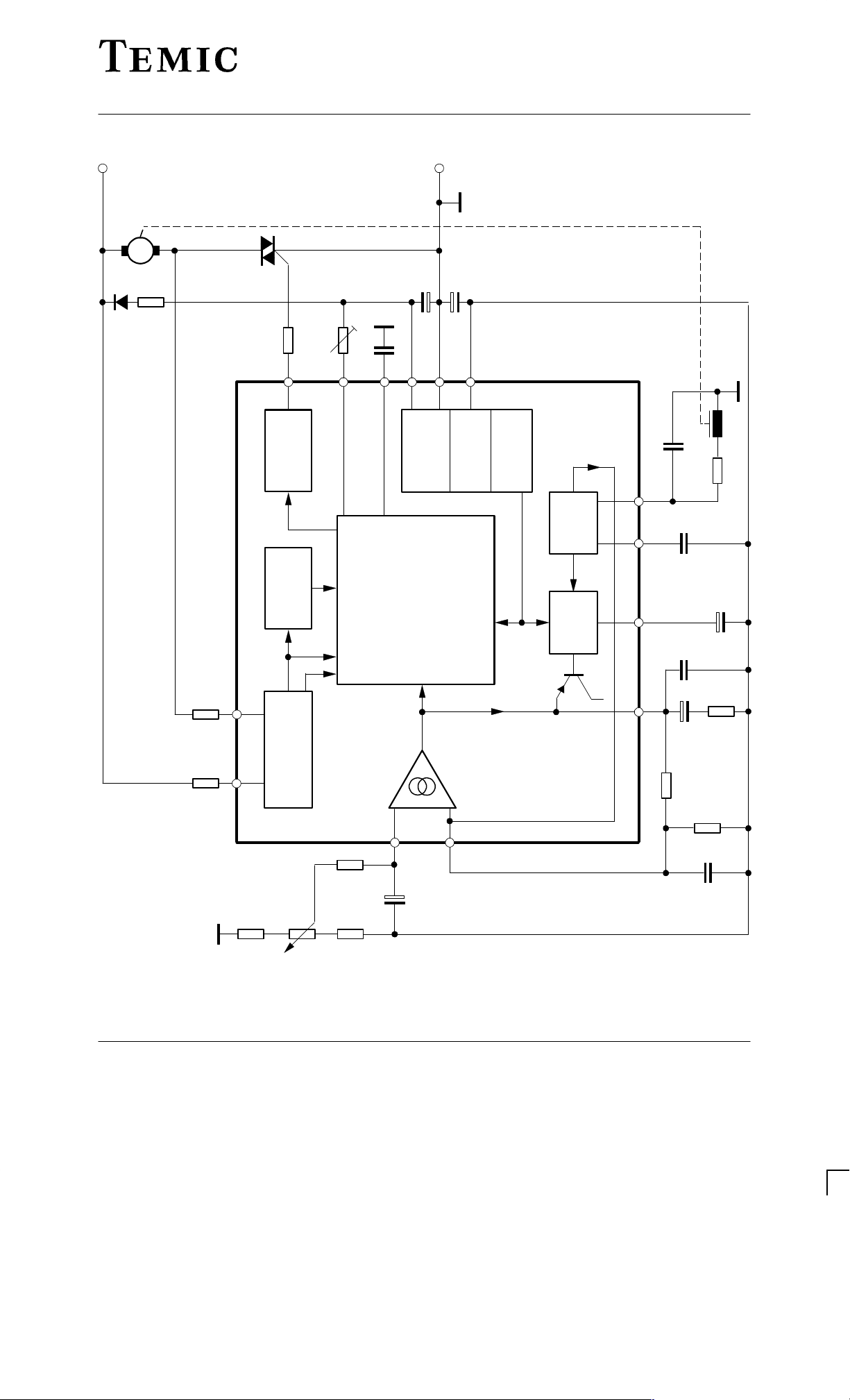

Figure 2. Block diagram with typical circuitry for speed regulation

Rev . A1: 01.09.1995 3 (15)

Preliminary Information

U209B3/U209B3–FP

Description

Mains Supply

The U209B is designed with voltage limiting and can

therefore be supplied directly from the mains. The supply

voltage between Pin 2 (+ pol/) and Pin 3 builds up

and R

across D

1

series resistance can be approximated using (Figure 2):

Further information regarding the design of the mains

supply can be found in the data sheets in the appendix.

The reference voltage source on Pin 13 of typ. –8.9 V

derived from the supply voltage and represents the reference level of the control unit.

Operation using an externally stabilised DC voltage is not

recommended.

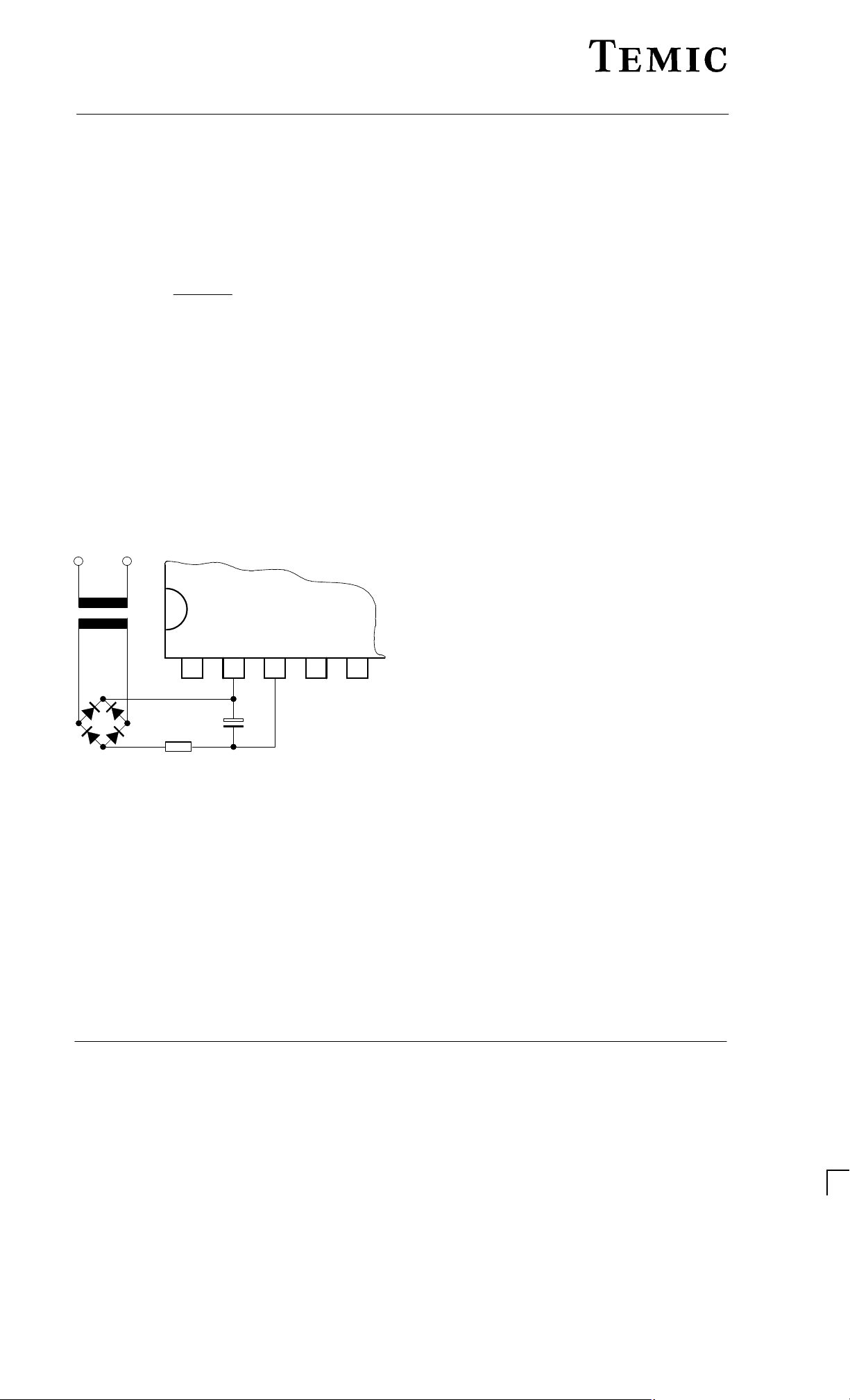

If the supply cannot be taken directly from the mains

because the power dissipation in R

then the circuit shown in the following Figure 3 should be

employed.

~

24 V~

Figure 3. Supply voltage for high current requirements

Phase Control

The function of the phase control is largely identical to

that of the well known integrated circuit U211B. The

phase angle of the trigger pulse is derived by comparing

the ramp voltage, which is mains synchronised by the

voltage detector, with the set value on the control input

Pin 4. The slope of the ramp is determined by C

charging current. The charging current can be varied

using R

also be adjusted using R

on Pin 5. The maximum phase anglea

2

and is smoothed by C1. The value of the

1

VM – Vs

R1 =

2 I

S

would be too large,

1

U21 1B

123

C

R

1

.

2

1

4

5

95 10362

and its

2

max

is

can

TELEFUNKEN Semiconductors

When the potential on Pin 6 reaches the nominal value

predetermined at Pin 11, then a trigger pulse is generated

whose width t

and hence the pulse width can be evaluated by

of C

2

is determined by the value of C

p

(the value

2

assuming 8 ms/nF.

The current sensor on Pin 1 ensures that, for operation

with inductive loads, no pulse will be generated in a new

half cycle as long as current from the previous half cycle

is still flowing in the opposite direction to the supply

voltage at that instant. This makes sure that ”Gaps” in the

load current are prevented.

The control signal on Pin 11 can be in the range 0 V to

–7 V (reference point Pin 2).

= –7 V then the phase angle is at maximum = a

If V

11

max

i. e. the current flow angle is a minimum. The minimum

phase anglea

is when V

min

11

= V

pin2

.

Voltage Monitoring

As the voltage is built up, uncontrolled output pulses are

avoided by internal voltage surveillance. At the same

time, all of the latches in the circuit (phase control, soft

start) are reset and the soft–start capacitor is short

circuited. Used with a switching hysteresis of 300 mV,

this system guarantees defined start–up behaviour each

time the supply voltage is switched on or after short

interruptions of the mains supply .

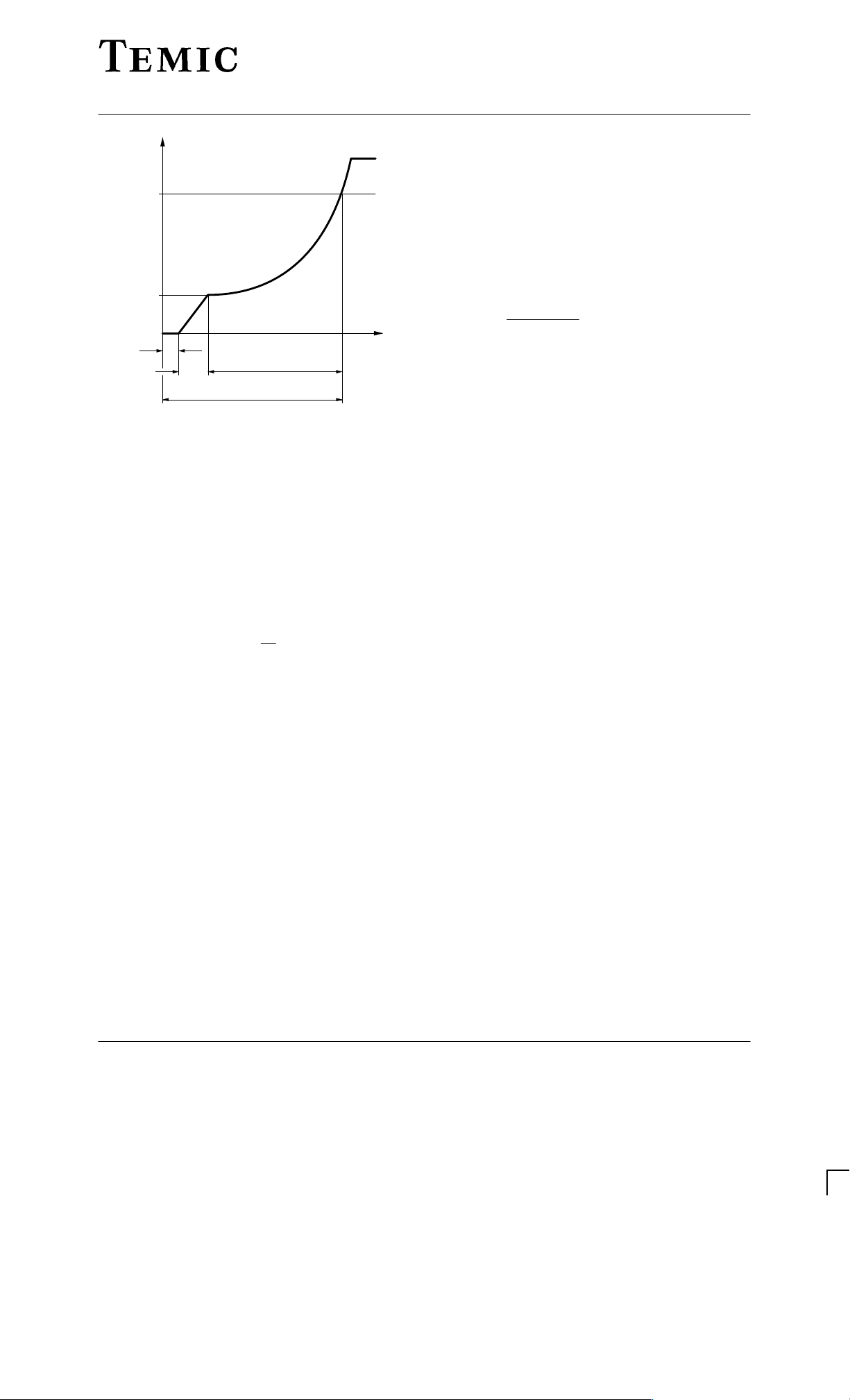

Soft–Start

As soon as the supply voltage builds up (t1), the integrated

soft–start is initiated. The figure below shows the

behaviour of the voltage across the soft–start capacitor

and is identical with the voltage on the phase control input

on Pin 11. This behaviour guarantees a gentle start–up for

the motor and automatically ensures the optimum run–up

time.

is first charged up to the starting voltage Vo with

C

3

typically 30 mA current (t

charging current to approx. 4 mA, the slope of the charging

function is substantially reduced so that the rotational

speed of the motor only slowly increases. The charging

current then increases as the voltage across C

giving a progressively rising charging function which

more and more strongly accelerates the motor with

increasing rotational speed. The charging function

determines the acceleration up to the set–point. The

charging current can have a maximum value of 50 mA.

). By then reducing the

2

increases

3

Preliminary Information

Rev . A1: 31.09.19954 (15)

TELEFUNKEN Semiconductors

U209B3/ U209B3–FP

V

C3

V

1

2

V

0

t

1

t

2

Figure 4. Soft–start

t

3

t

tot

95 10272

t

Frequency to Voltage Converter

The internal frequency to voltage converter

(f/V-converter) generates a DC signal on Pin 9 which is

proportional to the rotational speed using an AC signal

from a tacho–generator or a light beam whose frequency

is in turn dependent on the rotational speed. The high

impedance input with a switch–on threshold of typ. –

100 mV gives very reliable operation even when

relatively simple tacho–generators are employed. The

tacho-frequency is given by:

n

60

p[Hz]

5

at the converter

6

(Pin 9) and the

6

.

i

is internally

f =

n = revolutions per minute

p

= number of pulses per revolution

The converter is based on the charge pumping principle.

With each negative half wave of the input signal, a

quantity of charge determined by C

amplified and then integrated by C

output on Pin 9.

, its charging voltage of Vch, R

by C

5

The conversion constant is determined

internally adjusted charge amplification G

k = G

.

C

i

.

.

R

V

5

6

ch

The analog output voltage is given by

= k . f.

V

o

whereas: V

= 6.7 V

ch

G

= 8.3

i

and C

The values of C

5

must be such that for the highest

6

possible input frequency, the maximum output voltage

does not exceed 6 V. While C

does V

R

0

on Pin 8 is approx. 6 kΩ. T o obtain good linearity of the

i

f/V converter the time constant resulting from R

is charging up the

5

and C

i

should be considerably less (1/5) than the time span of the

negative half cycle for the highest possible input

frequency. The amount of remaining ripple on the output

, C

voltage on Pin 9 is dependent on C

and the internal

5

6

charge amplification.

G

=

∆V

o

The ripple ∆V

, however, the maximum conversion speed will than

C

6

o

.

. V

C

i

can be reduced by using larger values of

5

ch

C

6

also be reduced.

The value of this capacitor should be chosen to fit the

particular control loop where it is going to be used.

Control Amplifier

The integrated control amplifier with differential input

compares the set value (Pin 10) with the instantaneous

value on Pin 9

and generates a regulating voltage on the

output Pin 11 (together with external circuitry on Pin 12)

which always tries to hold the real voltage at the value of

the set voltages. The amplifier has a transmittance of typically 110 A/V and a bipolar current source output on Pin

11 which operates with typically ±100 A. The

amplification and frequency response are determined by

R

7

, C7, C

and R

8

power divider, C

left out. Pin 9

(can be left out). For operation as a

8

, C5, R6, C6, R7, C7, C

4

should be connected with Pin 11 and Pin 7

and R

8

can be

8

with Pin 2. The phase angle of the triggering pulse can be

adjusted using the voltage on Pin 10. An internal limiting

circuit prevents the voltage on Pin 11 from becoming

more negative than V

+ 1 V.

13

Pulse Output Stage

The pulse output stage is short circuit protected and can

typically deliver currents of 125 mA. For the design of

smaller triggering currents, the function I

= f (RGT) has

GT

been given in the data sheets in the appendix.

Automatic Retriggering

The automatic retriggering prevents half cycles without

current flow, even if the triacs is turned of f earlier e.g. due

to not exactly centred collector (brush lifter) or in the

event of unsuccessful triggering. If it is necessary, another

triggering pulse is generated after a time lapse of

= 4.5 tP and this is repeated until either the triac fires

t

PP

or the half cycle finishes.

5

Rev . A1: 01.09.1995 5 (15)

Preliminary Information

U209B3/U209B3–FP

TELEFUNKEN Semiconductors

General Hints and Explanation of Terms

To ensure safe and trouble–free operation, the following

points should be taken into consideration when circuits

are being constructed or in the design of printed circuit

boards.

The connecting lines from C

to Pin 6 and Pin 2 should

2

be as short as possible, and the connection to Pin 2

should not carry any additional high current such as

the load current. When selecting C

, a low tempera-

2

ture coefficient is desirable.

The common (earth) connections of the set–point gen-

erator, the tacho–generator and the final interference

suppression capacitor C

of the f/V converter should

4

not carry load current.

The tacho generator should be mounted without

influence by strong stray fields from the motor.

Absolute Maximum Ratings

Reference point Pin 2, unless otherwise specified

V

Mains

Supply

V

GT

Trigger

Pulse

V

L

Load

Voltage

I

L

Load

Current

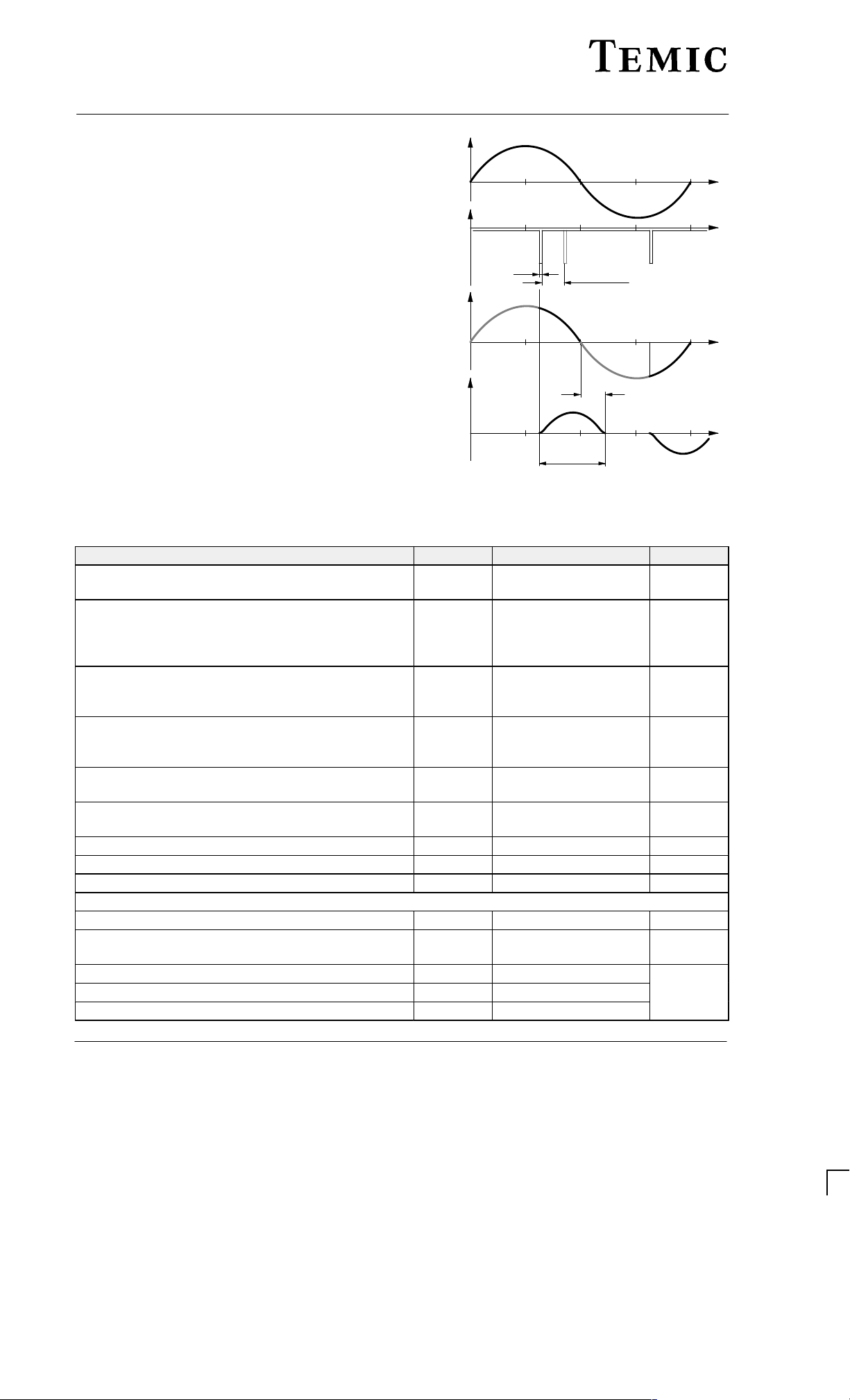

Figure 5. Explanation of terms in phase relationship

p/2 p 3/2p 2p

t

p

t

= 4.5 t

pp

p

f

F

95 10716

Parameters Symbol Value Unit

Current requirement Pin 3

t ≤ 10 ms

Synchronisation current Pin 1

Pin 14

t < 10 ms Pin 1

t < 10 ms Pin 14

–I

–i

I

syncI

I

syncV

±i

±i

f/V converter:

Input current Pin 7

t < 10 ms

I

±i

Phase control: Pin 11

Input voltage

Input current

–V

±I

Soft–start:

Input voltage Pin 12

–V

Pulse output:

Reverse voltage Pin 4

V

Amplifier

Input voltage Pin 10 –V

Pin 8 open Pin 9 –V

Reference voltage source

Output current Pin 13 I

T

amb

amb

= 45 °C

= 80 °C

P

Power dissipation T

Storage temperature range T

Junction temperature T

Ambient temperature range T

amb

eff

o

tot

stg

S

S

30

100

5

mA

mA

5

i

v

i

I

I

I

R

I

I

35

35

3

mA

13

0 to 7

500

mA

|V13| to 0 V

V

to 5 V

S

|VS|

|V13| to 0 V

V

7.5 mA

570

mW

320

–40 to +125 °C

j

125

–10 to +100

Preliminary Information

Rev . A1: 31.09.19956 (15)

TELEFUNKEN Semiconductors

U209B3/ U209B3–FP

Thermal Resistance

Parameters Symbol Maximum Unit

Junction ambient DIP 14

SO 16: on p.c. board

SO 16: on ceramic substrate

Electrical Characteristics

–V

= 13.0 V, T

S

Parameters Test Conditions / Pin Symbol Min Typ Max Unit

Supply voltage for mains

operations

Supply voltage limitation –I

DC supply current –VS = 13.0 V Pin 3 –I

Reference voltage source –IL = 10 mA Pin 13

Temperature coefficient Pin 13 TC

Voltage monitoring Pin 3

Turn–on threshold –V

Turn–off threshold –V

Phase control currents

Current synchronisation Pin 1 ±I

Voltage synchronisation Pin 14 ±I

Voltage limitation ±IL = 5 mA Pin 1, 14 ±V

Reference ramp, Figure 6

Charge current I

Rϕ – reference voltage a ≥ = 180 ° Pin 5,3 Vϕ

Temperature coefficient Pin 5 TCϕ

Output pulse

Output pulse current R

Reverse current Pin 4 I

Output pulse width Pin 5,2 t

Automatic retriggering

Repetition rate Pin 4 tpp/t

Amplifier

Common mode voltage

range

Input bias current Pin 10 I

Input offset voltage Pin 9, 10 V

Output current Pin 11

Short circuit forward transmittance

= 25 °C, reference point Pin 2, unless otherwise specified

amb

Pin 3 –V

= 3 mA Pin 3

S

= 30 mA

–I

S

V

= 5 mA

–I

L

= f (R5),

6

= 1 K ... 820 kW Pin 6

R

5

= 0, VGT = 1.2 V Pin 4 I

V

Pin 9, 10 V

Pin 11

I11 = f (V

) Pin 11 Y

9/10

R

–V

S

Ref

VRef

TON

TOFF

syncl

syncV

I

6

Ref

O

OR

p

ICR

IB

IO

–I

O

+I

O

f

thJA

140

180

100

S

S

13.0 V

14.6

14.7

Limit

16.6

16.8

1.1 2.5 3.0 mA

8.6

8.3

8.9 9.2

9.1

0.5 mV/K

11.2 13 V

9.9 10.9 V

0.35 2.0 mA

0.35 2.0 mA

l

1.4 1.6 1.8 V

1 20 mA

1.06 1.13 1.18 V

Ref

0.5 mV/K

100 155 190 mA

0.01 3.0 mA

8 ms/nF

p

3 4.5 6

(V13–1V) (V2–1V) V

0.01 1 mA

10 mV

75

88

110

120

145

165

1000 mA/V

K/W

V

V

V

mA

Rev . A1: 01.09.1995 7 (15)

Preliminary Information

U209B3/U209B3–FP

TELEFUNKEN Semiconductors

UnitMaxTypMinSymbolTest Conditions / PinParameters

Frequency to voltage converter

Input bias current Pin 7 I

Input voltage limitation ±I

1 mA Pin 7

I =

Pin 7

+V

–V

Turn–on threshold Pin 7 –V

Turn–off threshold Pin 7 –V

Discharge current Figure 2 Pin 8 I

Charge transfer voltage Pin 8 V

Charge transfer gain I9 / I

8

Conversion factor C

= 1 nF, R9 = 100 k k 5.5 mV/Hz

8

Pin 8/9 G

Operating range f/V output Ref. point Pin 13 Pin 9 V

IB

I

I

TON

TOFF

dis

ch

i

O

660

7.25

20 50 mV

6.50 6.70 6.90 V

7.5 8.3 9.0

0.6 2 A

750

8.05

100 150 mV

0.5 mA

0 – 6 V

Linearity ± 1 %

Soft start Figures 7 to 11 Pin 12

f/v–converter non active

Starting current V

Final current V12 = –0.5 V I

= V13, V7 = V

12

2

I

O

O

20 30 50 A

50 85 130 A

f/v–converter active

Starting current V

Final current V12 = –0.5 V I

Discharge current Restart pulse –I

12

= V

13

I

O

O

O

2 4 6 A

30 55 80 A

0.5 3 10 mA

mV

V

Preliminary Information

Rev . A1: 31.09.19958 (15)

TELEFUNKEN Semiconductors

U209B3/ U209B3–FP

240

200

a °

160

120

Phase Angle ( )

80

0

95 10302

100

80

60

m

13

I ( A )

40

Phase Control

Reference Point Pin 2

10nF

4.7nF

0 0.2 0.4 0.6 0.8

Rf ( MW )

2.2nF

C

f

=1.5nF

/t

Figure 6.

Soft Start

1.0

13

V ( V )

95 10305

13

V ( V )

10

8

6

4

2

0

10

Soft Start

8

f/V-Converter Active

Reference Point Pin 16

6

4

Soft Start

f/V-Converter Non Active

Reference Point Pin 16

t=f

(C3)

Figure 9.

95 10303

m

13

I ( A )

95 10304

20

f/V-Converter Non Active

Reference Point Pin 16

0

02468

V13 ( V )

Figure 7.

100

Soft Start

80

f/V-Converter Active

Reference Point Pin 16

60

40

20

0

02468

V13 ( V )

Figure 8.

2

95 10306

0

t=f

(C3)

10

Figure 10.

10

Soft Start

8

Reference Point Pin 16

6

13

V ( V )

4

2

0

t=f

10

Motor Standstill ( Dead Time )

Motor in Action

(C3)

95 10307

Figure 11.

Rev . A1: 01.09.1995 9 (15)

Preliminary Information

U209B3/U209B3–FP

TELEFUNKEN Semiconductors

500

Frequency to Voltage Converter

250

Reference Point Pin 2

0

8

I ( A )

–250

–500

–10 –8 –6 –4 –2

95 10308

V8 ( V )

Figure 12.

100

50

0

12

I ( A )

–50

Reference Point Pin 16

–100

–300 –200 –100 0 200

95 10309

V

10–11

02

Control Amplifier

100

( V )

4

300

(R1)

P ( W )

95 10317

1

R ( k )

95 10315

6

5

4

3

2

1

0

Mains Supply

03 6 912

I

( mA )

tot

Figure 15.

50

40

Mains Supply

30

20

10

0

04812

I

( mA )

tot

15

16

GT

I ( mA )

95 10313

Figure 13.

100

80

60

40

1.4V

20

0

0 200 400 600 800

VGT=0.8V

RGT ( )

Figure 14.

6

Pulse Output

1000

(R1)

P ( W )

95 10316

5

4

3

2

1

0

0102030

Preliminary Information

Figure 16.

( k )

R

1

Figure 17.

Mains Supply

40

Rev . A1: 31.09.199510 (15)

TELEFUNKEN Semiconductors

Applications

U209B3/ U209B3–FP

R

5

L

230 VX

N

1N4004

M

22 nF

22 mF

C

14

3

13

220 kW

R

3

D

1

10 V

12 11

33 kW

C

4

10

100 kW

98

R

6

U209B

18 kW

R

1

1.5 W

R

470 kW

C

22 mF

1

25 V

123

4

GND –V

S

4

R

2

470 kW

56

R

ö

3.3 nF

C

2

C

ö

/t

95 10621

7

Figure 18. Phase control (power control) for electric tools

Rev . A1: 01.09.1995 11 (15)

Preliminary Information

U209B3/U209B3–FP

TELEFUNKEN Semiconductors

W

22 k

100 kW

7

R

mF

10

4

C

14

R

13

R

10 V

22 nF

W

15 k

9

R

100 nF

3

C

W

NTC

A34–2/306

12

R

W

10

R

56 k

1.5 nF

5

C

820

R

W

8

R

11

47 k

7

/t

ö

4.7 nF

C

6

C

10 9 8

U209B

56

W

2

R

470 k

4

S

–V

2

ö

C

R

GND

13 12 11

15

14

123

R

68 W

95 10684

W

220 k

2

R

1N4004

1

D

W

1.5 W

18 k

1

R

L

R

W

4

R

470 k

W

180

150 nF

250 V~

230 V~

Figure 19. Temperature controlled fan motor (220 Vac)

Preliminary Information

AEG

TW11N

mF

47

1

C

25 V

Rev . A1: 31.09.199512 (15)

TELEFUNKEN Semiconductors

U209B3/ U209B3–FP

W

22 k

W

100 k

7

R

10

4

C

14

R

13

R

10 V

22 nF

W

15 k

9

R

100 nF

3

C

W

A34–2/306

NTC

12

R

W

10

R

56 k

1.5 nF

5

C

820

11

R

8

R

W

47 k

7

/t

ö

4.7 nF

C

6

C

10 9 8

U209B

56

W

2

R

470 k

4

S

2

ö

C

R

GND –V

13 12 11

W

15

14

123

R

68

W

95 10685

100 k

2

R

1N4004

1

D

L

R

230 V~

8.2 kW

R

1.5 W

1

150 nF

4

R

250 V~

200 k W

W

180

AEG

TW11N

mF

47

1

C

25 V

Figure 20. Temperature controlled fan motor (110 Vac)

Rev . A1: 01.09.1995 13 (15)

Preliminary Information

U209B3/U209B3–FP

Design Calculations for Mains Supply

The following equations can be used for the evaluation of the series resistor R

V

– V

(V

Mmin

Mmax

2 R

R

= 0.85

max

1

P

) =

max

(R1

2 I

– V

1

tot

Smax

Smin

2

)

where:

V

M

V

S

I

tot

I

Smax

I

p

I

x

can be easily evaluated from diagram figure 16 and 17

R

1

= Mains voltage 220 V

= Supply voltage on Pin 4

= T otal DC current requirement of the circuit

+ Ip + I

= I

S

x

= Current requirement of the IC in mA

= Average current requirement of the triggering pulse

= Current requirement of other peripheral components

Dimensions in mm

R

= 0.85

min

1

V

M

– V

TELEFUNKEN Semiconductors

for worst case conditions:

1

Smin

2 I

Smax

94 9445

Preliminary Information

94 8875

Rev . A1: 31.09.199514 (15)

TELEFUNKEN Semiconductors

U209B3/ U209B3–FP

Ozone Depleting Substances Policy Statement

It is the policy of TEMIC TELEFUNKEN microelectronic GmbH to

1. Meet all present and future national and international statutory requirements.

2. Regularly and continuously improve the performance of our products, processes, distribution and operating systems

with respect to their impact on the health and safety of our employees and the public, as well as their impact on

the environment.

It is particular concern to control or eliminate releases of those substances into the atmosphere which are known as

ozone depleting substances (ODSs).

The Montreal Protocol ( 1987) and its London Amendments (1990 ) intend to severely restrict the use of ODSs and

forbid their use within the next ten years. Various national and international initiatives are pressing for an earlier ban

on these substances.

TEMIC TELEFUNKEN microelectronic GmbH semiconductor division has been able to use its policy of

continuous improvements to eliminate the use of ODSs listed in the following documents.

1. Annex A, B and list of transitional substances of the Montreal Protocol and the London Amendments respectively

2. Class I and II ozone depleting substances in the Clean Air Act Amendments of 1990 by the Environmental

Protection Agency (EPA) in the USA

3. Council Decision 88/540/EEC and 91/690/EEC Annex A, B and C (transitional substances) respectively.

TEMIC can certify that our semiconductors are not manufactured with ozone depleting substances and do not contain

such substances.

We reserve the right to make changes to improve technical design and may do so without further notice.

Parameters can vary in different applications. All operating parameters must be validated for each customer

application by the customer. Should the buyer use TEMIC products for any unintended or unauthorized

application, the buyer shall indemnify TEMIC against all claims, costs, damages, and expenses, arising out of,

directly or indirectly, any claim of personal damage, injury or death associated with such unintended or

unauthorized use.

TEMIC TELEFUNKEN microelectronic GmbH, P.O.B. 3535, D-74025 Heilbronn, Germany

Telephone: 49 (0)7131 67 2831, Fax number: 49 (0)7131 67 2423

Rev . A1: 01.09.1995 15 (15)

Preliminary Information

Loading...

Loading...