Temco PS24RN, PS24RP Installation And Operating

Installation and Operating

Instructions for Gas Log

Heaters

Models: PS24RN, PS24RP

Models with “N” after the model number use natural gas; models with “P” after the model number use propane (LP) gas.

READ AND SAVE THESE INSTRUCTIONS

This appliance operates as an unvented room

heater certified under ANSI Z21.11.2-2000 when

fitted to a solid fuel burning masonry or factory

built fireplace with the flue damper closed. It also

operates as a decorative appliance under ANSI

Z21.60a-2000.CSA 2.26a-2000, when fitted to a solid

fuel burning masonry or factory built fireplace with

the flue damper open. When used as a decorative

appliance, the use of a thermostat is not allowed.

State or local codes may only allow operation of

this appliance in a vented configuration. Check

your state or local codes.

WARNING

If the information in this manual is not followed exactly, a fire or explosion may result causing

property damage, personal injury or loss of life.

FOR YOUR SAFETY

—Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or

any other appliance.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electric switch; do not use any phone in your building.

• Immediately call your gas supplier from a neighbor's phone. Follow the gas supplier’s instruc-

tions.

• If you cannot reach your gas supplier, call the fire department.

—Installation and service must be performed by a qualified installer, service agency or the gas

supplier.

This is an unvented gas-fired heater. It uses air (oxygen) from the room in which it is installed. Provisions

for adequate combustion and ventilation air must be provided. Refer to Section Provisions For Adequate

Combustion and Ventilation Air - Page 4.

Gas Fired

Unvented

Room Heaters

Temco Fireplace Products

410 Admiral Blvd. • Mississauga, Ontario, Canada L5T 2N6 • 905-670-7777

5L24

PATENT NO. US 6,390.808 B1

76683 11/03 Rev. 14

Table of Contents

Minimum Dimensions for Existing Solid Fuel Burning Fireplaces ............................................2

Important Information ...............................................................................................................3

Provisions For Adequate Combustion Air .................................................................................4

Installation

Unpacking.................................................................................................................................6

Fireplace Preparation ...............................................................................................................6

Location ....................................................................................................................................6

Clearances ...............................................................................................................................6

Gas Connection........................................................................................................................7

Gas Line Pipe Sizing ................................................................................................................9

Gas Pressure Check.................................................................................................................9

Log Assembly .........................................................................................................................10

Fireplace Screen ....................................................................................................................10

Decorative Volcanic Ash .........................................................................................................10

Optional Wireless Remote Installation.................................................................................... 11

Millivolt Wall Switch Installation ..............................................................................................11

Lighting Instructions................................................................................................................13

Turning Off Gas to Appliance..................................................................................................13

Match Lighting ........................................................................................................................13

Important Safeguards .............................................................................................................14

Flame Check...........................................................................................................................14

Managing Heat Output ...........................................................................................................15

Maintenance

Cleaning..................................................................................................................................15

Troubleshooting..........................................................................................................................16

Servicing ......................................................................................................................................16

Repair Parts .................................................................................................................................16

Warranty Information..................................................................................................................19

Installation and Startup Checklist .............................................................................................20

Warranty Registration.................................................................................................................22

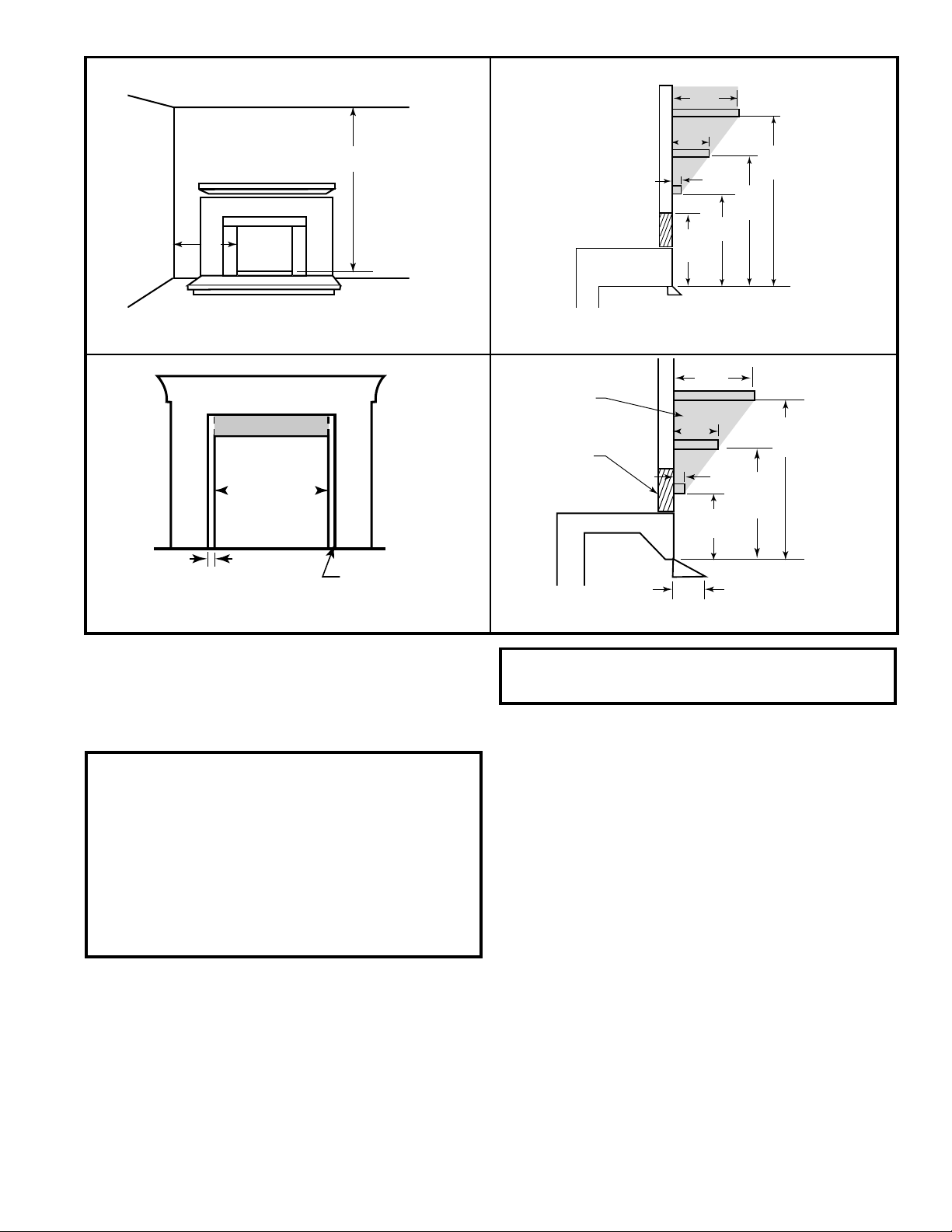

Minimum Dimensions for Existing Solid Fuel Burning Fireplaces

B

Hearth Size Table (H) (A) (B) (C)

PS24RN 18” 30” 21” 15”

C

Opening Height = H

A

PS24RP 18” 30” 21” 15”

This appliance may be installed in an aftermarket, permanently located, manufactured (mobile) home, where not

prohibited by local codes.

This appliance is only for use with the type of gas indicated on the rating plate. This appliance is not convertible for

use with other gases.

2

Opening Height Front Width Rear Width Depth

76683

Important Information

INSTALLER: Please leave these instructions with the

owner.

OWNER: Please retain these instructions for future

reference.

WARNING: Any change to this heater or its controls can be dangerous.

IMPORTANT: READ THESE INSTRUCTIONS CARE-

FULLY BEFORE INSTALLING.

NOTES

• Due to high temperatures, the appliance should be

located out of traffic and away from furniture and draperies.

• Installation and repair should be done by an experienced

and qualified service person or gas appliance installer.

• The appliance must be inspected before use and at least

annually by a professional service person. More frequent

cleaning may be required due to excessive lint from

carpeting, bedding material, dust and pet hair, etc. It is

important that the control compartment, burners and

circulating air passageways of the appliance be kept clean.

Refer to instructions on Page 15.

• DO NOT place clothing or other flammable material on or

near the appliance.

• This appliance must only be used with pressures at the inlet

as shown in Table 1, Page 9. Failure to check and document

these pressures may void the warranty.

• The installation must conform with local codes or, in the

absence of local codes, with the NATIONAL FUEL GAS CODE,

ANSI Z223, latest edition. If you cannot reference these codes,

DO NOT attempt to install this unit.

• Any safety screen or guard removed for servicing an

appliance must be replaced prior to operating the heater.

• The appliance and its appliance main gas valve must be

disconnected from the gas supply piping system during any

pressure testing of that system at test pressures in excess of

1/2 psig (3.5 kpa).

• The appliance must be isolated from the gas supply piping

system by closing its equipment shut-off valve during any

testing of the gas supply piping system at test pressures equal

to or less than 1/2 psig (3.5kpa).

• DO NOT use this heater in recreational vehicles, bedrooms or

bathrooms.

• If this is the ONLY gas appliance, we recommend a

minimum 200 pound cylinder with a fill gauge. Use of a 100

pound cylinder is not recommended. Other household gas

appliances may require the tank size to be larger. Do not

operate the vent-free heater if the fuel level in the propane

tank is below 1/4 full.

• DO NOT use this heater if any part of it has been submerged

under water. Immediately call a qualified technician to inspect

the appliance and replace any part of the control system and

any gas control which has been under water.

• Any outside air ducts in the fireplace shall be permanently

closed at the time of appliance installation.

• Check local, state or city codes to determine if unvented

heaters are permitted. If unvented heaters are not permitted, the fireplace chimney damper must be fixed at a

76683

minimum free (vent) opening area of 15 sq. ins. This must

be accomplished by a clamp or screw on the chimney

damper to stop at the minimum vent area. The fireplace

must also have a minimum free (vent) opening of 15 sq.

ins. (Fig. 1)

• This appliance may be installed in an after-market* manufac-

tured "mobile" home where not prohibited by state or local

codes.

*After-market: Completion of sale, not for purpose of re-sale from the

manufacturer.

• OUTSIDE AIR DAMPER OR ASH DUMP (IF PRESENT)

MUST BE CLOSED AND SEALED.

• Young children should be carefully supervised when they

are in the same room as the appliance.

• An unvented room heater having an input rating of more

than 10,000 btu per hour shall not be installed in a bedroom

or a bathroom.

WARNING: Do not allow fans to blow directly into

the fireplace. Avoid any drafts that alter burner

flame patterns.

WARNING: Do not use a blower insert, heat exchanger

insert or other accessory not approved for use with this

heater.

WARNING: During manufacturing, fabricating and

shipping, various components of this appliance are

treated with certain oils, films or bonding agents. These

chemicals are not harmful but may produce annoying

smoke and smells as they are burned off during the

initial operation of the appliance, possibly causing

headaches and eye/lung irritation. This is a normal and

temporary occurrence.

WARNING: This appliance is for installation only

in a solid-fuel burning masonry or UL 127 factorybuilt fireplace or in a listed ventless firebox enclosure. It has been designed certified for these

installations. Exception: DO NOT install this

appliance in a factory-built fireplace that includes

instructions stating it has not been tested or

should not be used with unvented gas logs.

PS24 Series BTU/Hr Input

Gas Burner Operation

Rear Burner

Front & Rear Only

High Low High Low

Natural 40,000 28,000 25,500 19,000

LP (Propane) 40,000 29,000 25,500 20,000

For Installation of High Altitude

When installing this fireplace at an elevation above 2,000 feet

(in the United States), it may be necessary to decrease the

input rating by changing the existing burner orifice to a smaller

size. Input should be reduced four percent (4%) for each 1,000

feet above sea level, unless the heating value of the gas has

been reduced, in which case this general rule will not apply. To

identify the proper orifice size, check with the local gas utility.

Consult your local gas utility for assistance in determining the

proper orifice for your location.

3

Provisions for Adequate Combustion and Ventilation Air

WARNING: This heater shall not be installed in a

confined space or unusually tight construction unless

provisions are provided for adequate combustion

ventilation air.

The National Fuel Gas Code, ANSI Z223.1

defines a

confined space as a space whose volume is less

than 50 cubic feet per 1,000 Btu per hour (4.8m3 per

kw) of the aggregate input rating of all appliances

installed in that space and an unconfined space as a

space whose volume is not less than 50 cubic feet

per 1,000 Btu per hour (4.8 m3 per kw) of the aggregate input rating of all appliances installed in that

space. Rooms communicating directly with the

space in which the appliances are installed, through

openings not furnished with doors, are considered a

part of the unconfined space.

Today's homes are built more energy efficient than ever. New

materials, increased insulation and new construction methods

help reduce heat loss in homes. Home owners weather strip

and caulk around windows and doors to keep the cold air out

and the warm air in. During heating months, home owners

want their homes as airtight as possible.

While it is good to make your home energy efficient, you need

fresh air. All fuel-burning appliances need fresh air for proper

combustion.

Supplying Adequate Ventilation

This appliance must be installed in an unconfined space.

The following information will help you classify your space

and provide adequate ventilation for complete combustion.

An Unconfined Space has a minimum volume of 50 cubic

feet for each 1000 BTU/Hr input rating of all appliances in the

space. (4.8 M

height of space).

A Confined Space has a volume of less than 50 cubic feet

for each 1000 BTU/Hr input rating of all appliances in the

space, (4.8M3 per kw), (cubic feet equals length x width x

height of space).

3

per kw), (cubic feet equals length x width x

Determining if You Have a Confined or

Unconfined Space

Use this worksheet to determine if you have a confined or

unconfined space.

Space: Includes the room in which you will install heater plus

any adjoining rooms with doorless passageways or ventilation

grills between the rooms.

1. Determine the volume of the space (length x width x

height).

Length x Width x Height = _____cu. ft. (volume of space)

Example: Space size 25’ (length) x 25’ (width) x 8’ (ceiling

height) = 5,000 cu. ft. (volume of space)

If additional ventilation from adjoining room(s) is supplied

with grills or doorless openings, add the volume of these

rooms to compute the total volume of the applicable

space.

2. Divide the space volume by 50 cubic feet to determine the

maximum BTU/Hr the space can support.

________(volume of space) ÷ 50 cu. ft. = (Maximum BTU/

Hr the space can support.

Example:

or 100,000 (maximum BTU/Hr the space can support)

3. Add the BTU/Hr of all gas burning appliances in the space.

Example:

*Do not include direct-vent gas appliances. Direct-vent draws

combustion air from the outdoors and vents to the outdoors.

4. Compare the maximum BTU/Hr the space can support

with the actual amount of BTU/Hr used.

__________ BTU/Hr (maximum the space can support)

__________ BTU/Hr (actual amount of BTU/Hr used)

Example:

The space in the above example is an unconfined space

because the actual BTU/Hr used is less than the maximum

BTU/Hr the space can support. If the space had been

confined, your options would be as follows:

A. Rework worksheet, adding the space of an adjoining

B. Install a lower BTU/Hr heater, if lower BTU/Hr size

5,000 cu. ft. (volume of space) ÷ 50 cu. ft. = 100

Gas range BTU/Hr

Vented gas heater BTU/Hr

Gas fireplace logs BTU/Hr

Other gas appliances* +

Total = BTU/Hr

Gas range 60,000 BTU/Hr

Vent-free logs +

Total = 89,000 BTU/Hr

100,000 BTU/Hr (max. the space can support)

89,000 BTU/Hr (actual amount of BTU/Hr used)

room. If the extra space provides an unconfined

space, remove door to adjoining room or add ventilation grills between rooms. See Ventilation Air From

Inside Building.

makes room unconfined.

BTU/Hr

29,000 BTU/Hr

Converting Confined Space to Unconfined

Space

Additional volume to convert a confined to an unconfined

space could come from an adjoining space. When using an

adjoining space, you can provide two permanent openings:

one within 12" of the ceiling and one within 12" of the floor on

the wall connecting the two spaces (see options 1 and 3,

Figure 2), or remove the door into the adjoining room.

Ventilation Air From Outdoors for Unusually Tight Construction

WARNING: If the area in which the heater may be

operated is smaller than that defined as an unconfined

space or if the building is of unusually tight construction,

provide adequate combustion and ventilation air by one

of the methods described in the National Fuel Gas Code,

ANSI Z223.1/NFPA 54, Section 5.3 or applicable local

codes.

4

76683

Unusually tight construction is defined as construction

where:

a. walls and ceilings exposed to the outside atmosphere have

a continuous water vapor retarder with a rating of one perm

(6 X 10.11 kg per pa-sec-m2) or less with openings gasketed

or sealed and

b. weather stripping has been added on openable windows

and doors and

c. caulking or sealants are applied to areas such as joints

around window and door frames, between sole plates and

floors, between wall-ceiling joints, between wall panels, at

penetrations for plumbing, electrical and gas lines and at

other openings.

If your home meets all of the three criteria above, you must

provide additional fresh air.

You may provide two permanent openings: one within 12" of

the ceiling and one within 12" of the floor. Connect these items

directly to the outdoors or spaces open to the outdoors. These

spaces include attics and crawl spaces. Follow the

National

Fuel Gas Code NFPA 54/ANSI Z223.1, Section 5.3, Air for

Combustion and Ventilation

for required size of ventilation grills

or ducts.

IMPORTANT: Do not provide openings for inlet or outlet air into

attic if attic has a thermostat-controlled power vent. Heated air

entering the attic will activate the power vent.

L

W

D

NOTE: For round flue opening,

minimum flue diameter (d) = 5”. For

square or rectangular opening,

length x width (L x W) must equal 15

sq. in.

Fig. 1 Minimum flue diameter and flue damper positions.

Option 1 Vents to

Adjoining

Room

Option 3 Vents to

Adjoining

Room

Option 2 Remove

Door to

Adjoining

Room

Flue Damper Closed for Unvented

Operation and Maximum Heat

Output

Flue Damper Locked Open

to a Minimum Free (Vent)

Opening of 15 sq. in., (for

areas where unvented

products are not permitted)

12”

WARNING: Air openings that

provide fresh air from an adjoining unconfined space shall not be

blocked or obstructed in any way.

Installation of unit should allow a

minimum of 2" clearance from any

part of the heater to any of the

ventilation openings.

12”

T104

Fig. 2 Ventilation options for confined space.

76683

VO370-2

5

Installation

Unpacking

Open both cartons and remove the logs and the chassis.

Remove each of the logs by gripping at either end of the log

while avoiding any undue pressure. Please note that the logs

have been marked for positive identification.

The cartons for all models contain the following: grate/burner

assembly, front, middle and rear logs, top twig, 2 screws, 2

brackets and a bag of volcanic ash.

Fireplace Preparation

The fireplace needs to be prepared before installing the unit:

A. Turn off the gas supply if the gas line has been run to the

fireplace.

B. WARNING: Before installing logs in fireplace, the

chimney flue and firebox must be cleaned of soot,

creosote, ashes and loose paint by a qualified chimney

cleaner or sooting will occur.

Note: If your fireplace has been cleaned using chemicals or

solvents, these products may have been absorbed into the

fireplace hearth and walls and will be burned off during the

initial break-in period.

C. Any outside air ducts and/or ash dumps in the fireplace shall

be permanently closed and sealed at the time of appliance

installation. This will prevent drafts from disturbing the

flames and interfering with complete combustion of the gas

fuel.

Location

When gas logs are to be installed in a fireplace, inspect the

area surrounding it for possible air drafts that may affect the

flames and possibly cause sooting. Such drafts may be caused

by a ceiling fan near the fireplace, a hot air furnace register or

an open door. When burning the logs, carefully observe the

effect of possible drafts on the flames and take appropriate

measures to eliminate them. For example, the ceiling fan may

be cut off, the hot air register closed, etc.

Centrally locate the gas logs in the fireplace deep enough into

the firepit to accomplish an adequate draft (if use as a vented

appliance is planned). Ensure that the front feet of the grate sit

inside the front edge of the fireplace. Be sure fireplace meets

minimum fireplace dimensions.

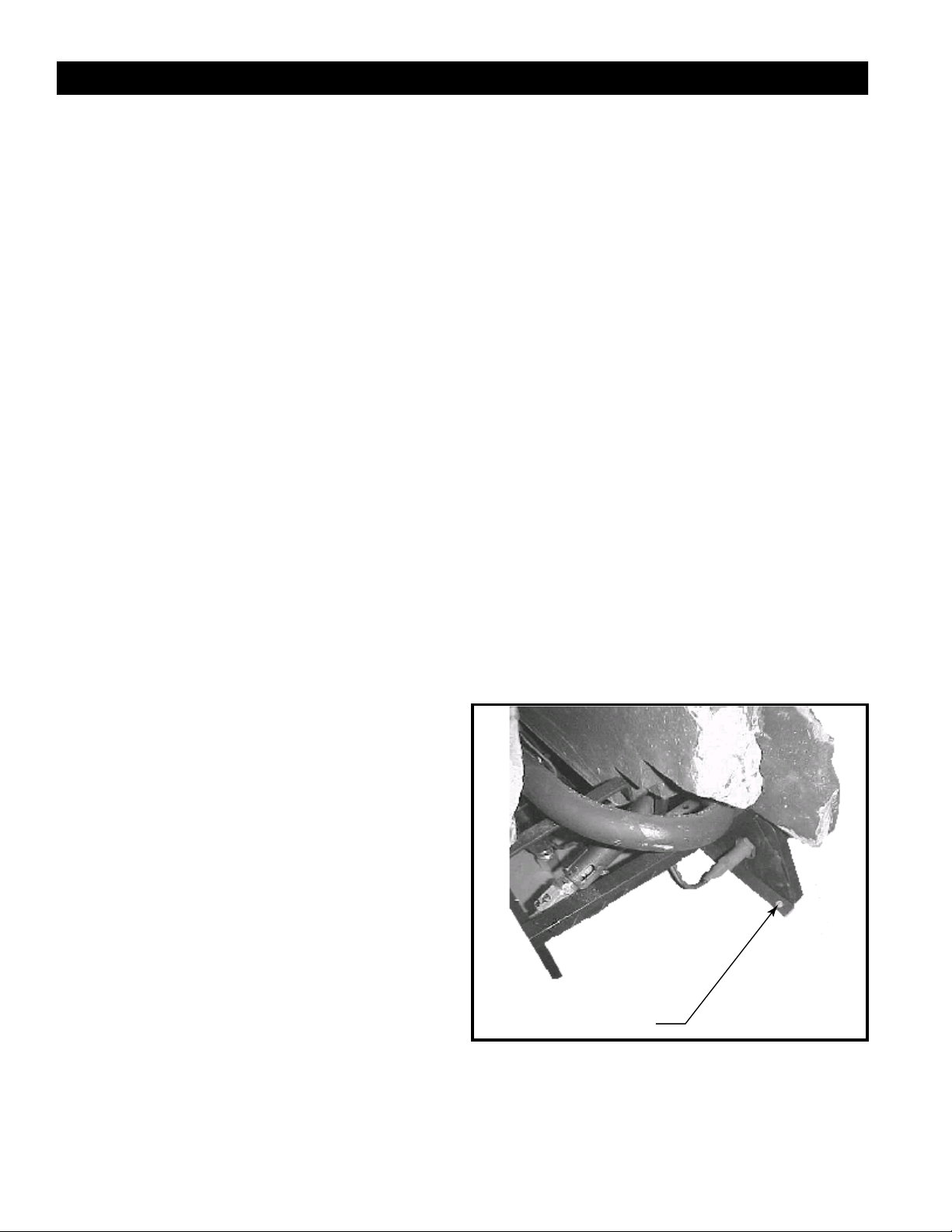

To avoid any movement of the unit during operation, screw

the chassis to the floor of the fireplace using the screws

provided. Failure to do so could cause gas leaks.

Holes are provided just behind the front grate legs and should

be used for securing the log set. After locating the chassis

correctly in the fireplace, mark the hole positions on the

fireplace floor. Drill two 1/8” diameter holes approximately 1/2”

deep.

Use the two screws to secure the chassis to the fireplace floor.

(Fig. 3)

Clearances

NOTE: The following instructions regarding installation clear-

ances and the use and installation of a canopy apply to use of

the appliances as an unvented space heater in permitting

jurisdictions. When installed as a vented decorative gas

appliance, the clearances noted below and the use of a heatdeflecting canopy are not required.

However, it is recommended that these instructions be followed

even when the appliance will be used as a vented decorative

appliance in case local codes change to allow unvented space

heaters or in the event that the flue damper is inadvertently

closed.

Clearances for unvented installation in existing fireplaces,

(jurisdiction permitting)

1. Sidewall Clearances: Clearances from the side of the

fireplace opening to any combustible wall should not be less

than 2”. (Fig. 4A and 4B)

2. Ceiling Clearances: The ceiling height should not be less

than 62" from the top of the fireplace opening. (Fig. 4A)

3. Mantel Clearances: The use of a canopy* is optional

depending on mantel clearances to the fireplace opening

and projection profile.

NOTE: Mantel clearances may differ for each vent-free

firebox. Refer to the firebox installation instructions for

clearances.

A. Mantel profile: The minimum distance above the

fireplace opening to combustible material projecting 1¹⁄₂"

(tile moldings, breast boards, etc.) is 12¹⁄₂".

Combustible material projecting 6" (a mantel shelf, for

example) requires a minimum clearance of 19" above the

fireplace opening. Required clearance varies with the

amount of projection. (Fig. 4C)

The mantel profile must fall within the cross-section

shown in Figures 4C or 4D.

B. Heat resistant material: Any heat resistant material

suitable for a continuous operating temperature of 120°C

(248°F) must cover the wall surface directly above the

fireplace opening and extend the full width of the

fireplace opening for a distance of 10" above the

opening. (Fig. 4C)

Chassis Hole

Location

Fig. 3 Use two (2) screws to secure the chassis to the fireplace

floor.

T152

6

76683

12"

6"

62"

1¹⁄₂"

14

2"

Fireplace Hearth

Level

11¹⁄₂"

27"

20"

Fig. 4A Minimum clearance to wall and ceiling.

Combustible Mantel

Noncombustible

Facing

Fireplace

Mantel Leg

2” Minimum

Clearance

Opening

Mantel Leg

Maximum Projection:

7”

Fig. 4B Side clearances and projection.

Gas Connection

Check Gas Type. Use only the gas type indicated on the

heater's rating plate. If the gas type indicated on the plate is not

your type of gas supply, DO NOT INSTALL. Contact your

dealer for the proper model.

WARNING

DANGER OF PROPERTY DAMAGE,

BODILY INJURY OR DEATH.

Make sure the heater is equipped to operate on

the type of gas available. Models designated as

natural gas are to be used with natural gas only.

Heaters designated for use with liquefied petroleum (LP) gas have orifices sized for commercially pure propane gas. They cannot be used

with butane or a mixture of butane and propane.

Gas Piping. The gas supply line must be of an adequate size

to handle the BTU/HR requirements and length of the run for

the unit being installed.

Determine the minimum pipe size from the piping size chart on

Page 9. The normal gas connection at this appliance is 1/2"

NPT made at the left of the unit.

Always use an external regulator for all LP installations to reduce

the supply tank pressure to a maximum of 14" w.c. This is in

addition to the regulator fitted to the heater.

Fig. 4C Mantel clearances (single or multi-sided opening

fireplaces).

Combustible

Materials Allowed

in Shaded Areas

Heat Resistant

Material

4"

Min.

10"

6"

1¹⁄₂"

7"

Fireplace Opening

21"

12"

Fig. 4D Mantel clearance with canopy.

WARNING: Connecting directly to an unregulated

LP tank can cause an explosion.

All piping must comply with local codes and ordinances or with

the National Fuel Gas Code (ANSI Z223.1), whichever applies.

Gas Line Connection

If installation is for L.P. gas, have L.P. installer use two-stage

regulation and make all connections from storage tank to

heater. Refer to the National Fuel Gas Code for the proper

supply tank size with the Btu's/Hr requirements. If this is the

ONLY gas appliance, we recommend a minimum 200 pound

cylinder with a fill gauge. Use of a 100 pound cylinder is not

recommended. Other household gas appliances may require

the tank size to be larger.

Use two pipe wrenches when making the connection to the

valve to prevent turning or damage to gas valve or regulator.

Connection between the manual shut-off valve and the gas

valve can be made with a CSA design certified flexible connector if allowed by local codes. A drip leg (sediment trap) must

be installed. (Fig. 5) Tighten all joints securely.

CAUTION: Failure to install a drip leg (sediment trap) may

result in improper combustion that will produce soot.

Reference Sections 3.7 and 5.5.7 and Figure 5.5.7 of the

National Fuel Gas Code for guidance.

76683

7

Loading...

Loading...