TEMCO FIREPLACE PRODUCTS, Inc.

Installation and Operating Instructions for Gas Log Heaters

Models PS24MN, PS24MP

Models ending with “N” use natural gas; models ending with “P” use propane (LP) gas.

This appliance operates as an

unvented room heater certified under

ANSI Z21.11.2-2000 when fitted to a

solid fuel burning masonry or factory

built fireplace with the flue damper

closed. It also operates as a

decorative appliance under ANSI

Z21.60a-2000.CGA 2.26a-2000, when

fitted to a solid fuel burning masonry

or factory built fireplace with the flue

damper open. State or local codes

may only allow operation of this

appliance in a vented configuration.

WARNING

If the information in this manual is not followed exactly, a fire or explosion may result

FOR YOUR SAFETY

• Do not store or use gasoline or other flammable vapors and liquids in the vicinity

of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electric switch; do not use any phone in your building.

• Immediately call your gas supplier from a neighbor's phone. Follow the gas

supplier’s instructions.

• If you cannot reach your gas supplier, call the fire department.

• Installation and service must be performed by a qualified installer, service agency

or the gas supplier.

This is an unvented gas-fired heater. It uses air (oxygen) from the room in which it is

installed. Provisions for adequate combustion and ventilation air must be provided.

GAS FIRED

UNVENTED

ROOM HEATERS

LISTED

5L24

PATENT NO. US 6,390.808 B1

P.O. Box 1349 Manchester, TN 37349

P.O. Box 1148 Perris, CA 92572

1773 Parque Industrial Cachanilla

Mexicali, B.C. 21600

REV. 10/30/02 10:05 AM 76780M

CONTENTS

Important Information ......................................................................................................................................................................Page 3,4

Provision for Adequate Combustion and Ventilation Air ....................................................................................................................4

Installation

Unpacking ..................................................................................................................................................................................................6

Fireplace preparation ................................................................................................................................................................................6

Location ......................................................................................................................................................................................................6

Clearances .................................................................................................................................................................................................6

Gas connection ..........................................................................................................................................................................................7

Piping Chart ...............................................................................................................................................................................................8

Gas pressure check ..................................................................................................................................................................................9

Log positioning ........................................................................................................................................................................................10

Fireplace screen ......................................................................................................................................................................................10

Decorative volcanic ash .........................................................................................................................................................................10

Unit operation

To turn off gas to appliance ...................................................................................................................................................................11

Managing heat output .............................................................................................................................................................................13

Flame check ............................................................................................................................................................................................12

Maintenance ...................................................................................................................................................................................................13

Troubleshooting ............................................................................................................................................................................................14

Repair Parts ....................................................................................................................................................................................................15

Parts List .........................................................................................................................................................................................................15

Warranty Information ...................................................................................................................................................................................16

Installation and Startup Checklist .....................................................................................................................................................17, 18

Warranty Registration ..................................................................................................................................................................................19

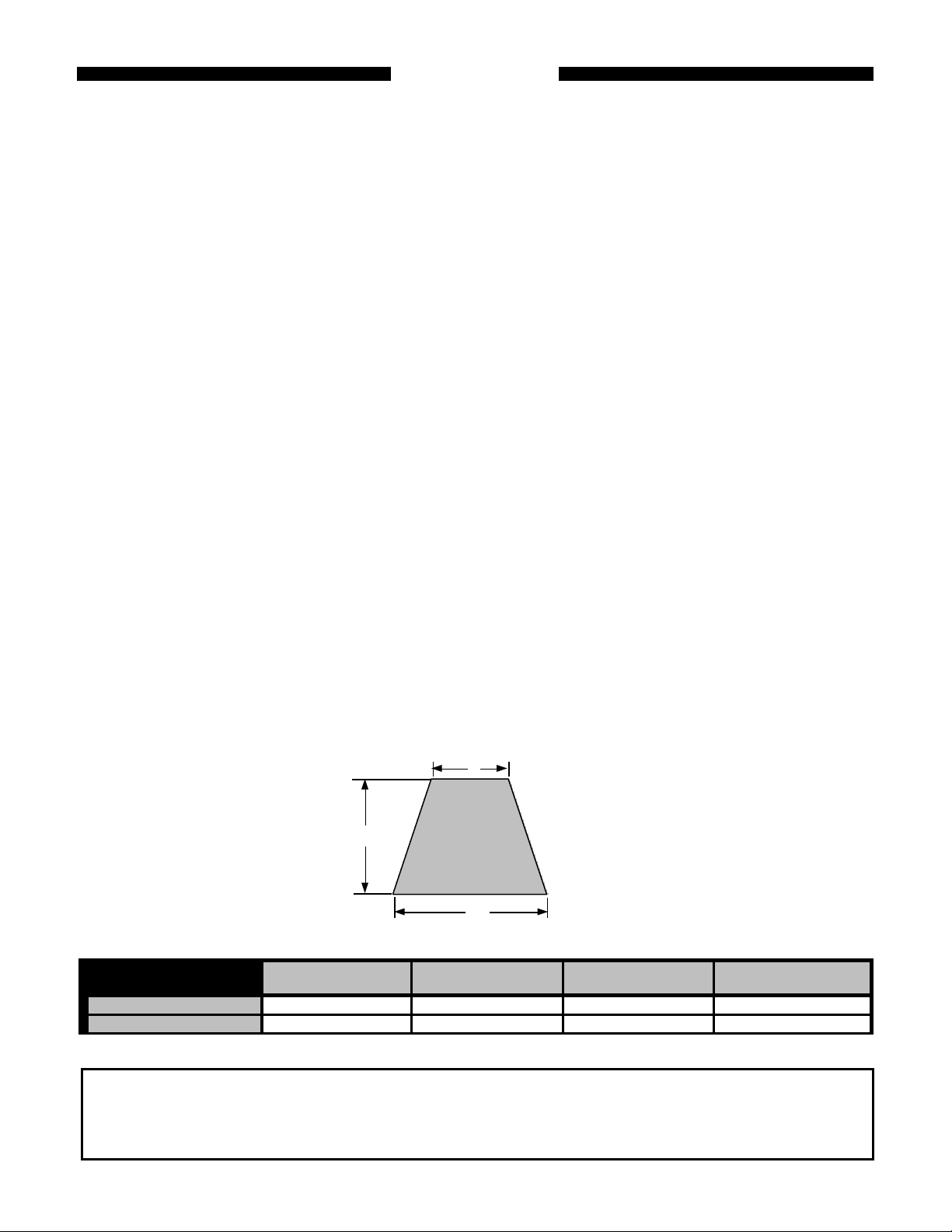

M INIMUM DIMENSIONS FOR EXISTING SOLID FUEL BURNING FIREPLACES.

B

OPENING HEIGHT = H

C

A

HEARTH SIZE TABLE Opening Height

(H)

PS24MN 18" 30" 21" 15"

PS24MP 18" 30" 21" 15"

This appliance may be installed in an aftermarket, permanently located, manufactured (mobile) home, where not

prohibited by local codes.

This appliance is only for use with the type of gas indicated on the rating plate. This appliance is not convertible for

use wi th other gases.

Front Width

(A)

Rear Width

(B)

Depth

(C)

2

IMPORTANT INFORMATION

INSTALLER: P lease leave these instructions with the owner.

OWNER: P lease retain these instructions for future reference.

WARNING: ANY CHANGE TO THIS HEATER OR ITS

CONTROLS CAN BE DANGEROUS.

IMPORTANT: READ THESE INSTRUCTIONS CAREFULLY

BEFORE INSTALLING.

NOTES

• Due to high temperatures, the appliance should be

located out of traffic and away from furniture and

draperies.

• Installation and repair should be done by an

experienced and qualified service person or gas

appliance installer.

• The appliance must be inspected before use and at

least annually by a professional service person. More

frequent cleaning may be required due to excessive lint

from carpeting, bedding material, dust and pet hair, etc.

It is important that the control compartment, burners

and circulating air passageways of the appliance be

kept clean. Refer to instructions on Page 13.

• DO NOT place clothing or other flammable material on

or near the appliance.

• This appliance must only be used with pressures at the inlet

as shown in Table 1, page 10. Failure to check and

document these pressures may void the warranty.

• The installation must conform with local codes or, in the

absence of local codes, with the NATIONAL FUEL GAS

CODE, ANSI Z223, latest edition. If you cannot reference

these codes, DO NOT attempt to install this unit.

• Any safety screen or guard removed for servicing an

appliance must be replaced prior to operating the

heater.

• The appliance and its appliance main gas valve must be

disconnected from the gas supply piping system during any

pressure testing of that system at test pressures in excess

of 1/2 PSIG (3.5 kpa).

• The appliance must be isolated from the gas supply piping

system by closing its equipment shut-off valve during any

testing of the gas supply piping system at test pressures

equal to or less than 1/2 PSIG.

• DO NOT use this heater in recreational vehicles, bedrooms

or bathrooms.

• If this is the ONLY gas appliance, we recommend a

minimum 200 pound cylinder with a fill gauge. Use of a 100

pound cylinder is not recommended. Other household gas

appliances may require the tank size to be larger. Do not

operate the vent-free heater if the fuel level in the propane

tank is below 1/4 full.

• DO NOT use this heater if any part of it has been

submerged under water. Immediately call a qualified

technician to inspect the appliance and replace any part of

the control system and any gas control which has been

under water.

• Any outside air ducts in the fireplace shall be permanently

closed at the time of appliance installation.

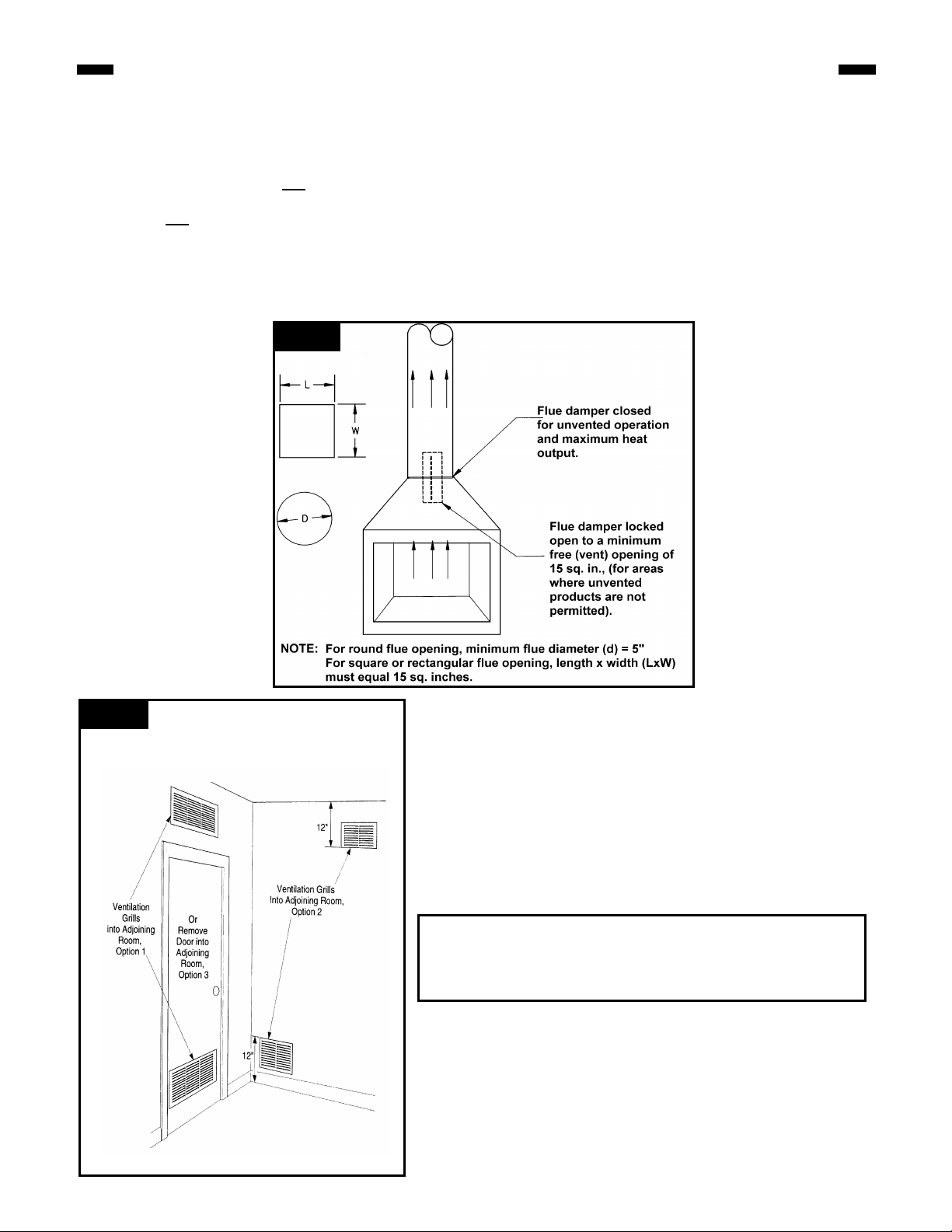

• Check local, state or city codes to determine if unvented

heaters are permitted. If unvented heaters are not

permitted, the fireplace chimney damper must be fixed

at a minimum free (vent) opening area of 15 sq. ins.

This must be accomplished by a clamp or screw on the

chimney damper to stop at the minimum vent area. The

fireplace must also have a minimum free (vent) opening

of 15 sq. ins., (see figure 1).

• This appliance may be installed in an after-market*

manufactured "mobile" home where not prohibited by state

or local codes.

• *After-market: Completion of sale, not for purpose of re-

sale from the manufacturer.

• OUTSIDE AIR DAMPER OR ASH DUMP (IF PRESENT)

MUST BE CLOSED AND SEALED.

• Young children should be carefully supervised when

WARNING: Do not allow fans to blow directly into the

fireplace. Avoid any drafts that alter burner flame

patterns to prevent property damage.

WARNING: Do not use a blower insert, heat

exchanger insert or other accessory not approved for

use with this heater.

WARNING: During manufacturing, fabricating and

shipping, various components of this appliance are

treated with certain oils, films or bonding agents.

These chemicals are not harmful but may produce

annoying smoke and smells as they are burned off

during the initial operation of the appliance, possibly

causing headaches and eye/lung irritation. This is a

normal and temporary occurrence.

WARNING: This appliance is for installation only in a

solid-fuel burning masonry or UL 127 factory-built

fireplace or in a listed ventless firebox enclosure. It

has been designed certified for these installations.

Exception: DO NOT install this appliance in a factorybuilt fireplace that includes instructions stating it has

not been tested or should not be used with unvented

gas logs.

PS24 SERIES BTU / HR INPUT

GAS BURNER OPERATION

REAR BURNER

FRONT & REAR

HIGH LOW HIGH LOW

ONLY

NATURAL 40,000 22,000 25,500 19,000

LP (PROPANE) 40,000 24,000 25,500 19,000

they are in the same room as the appliance.

• An unvented room heater having an input rating of more

than 10,000 btu per hour shall not be installed in a

bedroom or a bathroom.

FOR INSTALLATION OF HIGH ALTITUDE

When installing this fireplace at an elevation above 2,000 feet

(in the United States), it may be necessary to decrease the

input ratin g by changing the existing burner orifice to a smaller

size. Input should be reduced four percent (4%) for each 1,000

feet above sea level, unless the heating value of the gas has

been reduced, in which case this general rule will not apply. to

identify the proper orifice size, check with the local gas utility.

Consult your local gas utility for assistance in determining the

proper orifice for your location.

Ref. No. Description

3

PROVISIONS FOR ADEQUATE COMBUSTION AND VENTILATION AIR

WARNING: This heater shall not be installed in a

confined space or unusually tight construction unless

provisions are provided for adequate combustion

ventilation air.

The National Fuel Gas Code, ANSI Z223.1 defines a

confined space as a space whose volume is less

than 50 cubic feet per 1,000 Btu per hour (4.8m3

per kw) of the aggregate input rating of all

appliances installed in that space and an

unconfined space as a space whose volume is not

less than 50 cubic feet per 1,000 Btu per hour (4.8

m3 per kw) of the aggregate input rating of all

appliances installed in that space. Rooms

communicating directly with the space in which

the appliances are installed, through ope nings not

furnished with doors, are considered a part of the

Today's homes are built more energy efficient than ever.

New materials, increased insulation and new construction

methods help reduce heat loss in homes. Home owners

weather strip and caulk around windows and doors to keep

the cold air out and the warm air in. During heating months,

home owners want their homes as airtight as possible.

While it is good to make your home energy efficient, you

need fresh air. All fuel-burning appliances need fresh air for

proper combustion.

SUPPLYING ADEQUATE VENTILATION

This appliance must be installed in an unconfined space.

The following information will help you classify yo ur space

and provide adequate ventilation for complete combustion.

An Unconfined Space has a minimum volume of 50 cubic

feet for each 1000 BTU/Hr input rating of all appliances in

the space. (4.8 m3 per kw), (cubic feet equals length x width

x height of space).

A Confined Space has a volume of less than 50 cubic feet

for each 1000 BTU/Hr input rating of all appliances in the

space, (4.8 m3 per kw), (cubic feet equals length x width x

height of space).

DETERMINING IF YOU HAVE A CONFINED OR

UNCONFINED SPACE.

Use this worksheet to determine if you have a confined or

unconfined space.

Space: Includes the room in which you will install heater

plus any adjoining rooms with doorless passageways or

ventilation grills between the rooms.

1. Determine the volume of the space (length x width x

height).

? Length x Width x Height = _____cu. ft. (volume of space)

? Example: Space size 25 ft. (length) x 25 ft. (width) x 8 ft.

(ceiling height) = 5,000 cu. ft. (volume of space)

? If additional ventilation from adjoining room(s) is supplied

with grills or doorless openings, add the volume of these

rooms to compute the total volume of the applicable

space.

2. Divide the space volume by 50 cubic feet to determine

the maximum BTU/Hr the space can support.

? ________(volume of space) ÷ 50 cu. ft. = (Maximum

BTU/Hr the space can support.

? Example: 5,000 cu. ft. (volume of space) ÷ 50 cu. ft. =

100 or 100,000 (maximum BTU/Hr the space can

support)

3. Add the BTU/Hr of all gas burning appliances in the

space.

Gas range ________________BTU/Hr

Vented gas heater __________BTU/Hr

Gas fireplace logs ___________BTU/Hr

Other gas appliances* + ______BTU/Hr

Total = _____BTU/Hr

Example: Gas range 60,000 BTU/Hr

Vent-free logs +29,000 BTU/Hr

Total =89,000 BTU/Hr

? *Do not include direct-vent gas appliances. Direct-vent

draws combustion air from the outdoors and vents to the

outdoors.

4. Compare the maximum BTU/Hr the space can support

with the actual amount of BTU/Hr used.

? __________ BTU/Hr (maximum the space can support)

? __________ BTU/Hr (actual amount of BTU/Hr used)

Example: 100,000 BTU/Hr (maximum the space can

support) 89,000 BTU/Hr (actual amount of BTU/Hr used)

The space in the above example is an unconfined space

because the actual BTU/Hr used is less than the maximum

BTU/Hr the space can support. If the space had been

confined, your options would be as follows:

A. Rework worksheet, adding the space of an adjoining

room. If the extra space provides an unconfined space,

remove door to adjoining room or add ventilation grills

between rooms. See Ventilation Air From Inside

Building.

B. Install a lower BTU/Hr heater, if lower BTU/Hr size

makes room unconfined.

CONVERTING CONFINED SPACE TO UNCONFINED

SPACE.

Additional volume to convert a confined to an unconfined

space could come from an adjoining space. When using an

adjoining spac e, you can provide two permanent openings:

one within 12" of the ceiling and one within 12" of the floor

on the wall connecting the two spaces (see options 1 and 2,

figure 2), or remove the door into the adjoining room.

VENTILATION AIR FROM OUTDOORS FOR

UNUSUALLY TIGHT CONSTRUCTION.

WARNING: If the area in which the heater may be

operated is smaller than that defined as an unconfined

space or if the building is of unusually tight

construction, provide adequate combustion and

ventilation by one of the methods described in the

National Fuel Gas Code, ANSI Z223.1/NFPA 54, Section

5.3 or applicable codes.

4

PROVISIONS FOR ADEQUATE COMBUSTION AND VENTILATION AIR

Unusually tight construction is defined as construction

where:

a. walls and ceilings exposed to the outside atmosphere

have a continuous water vapor retarder with a rating of

one perm (6 x 10.11 kg per pa-sec-m2) or less with

openings gasketed or sealed and

b. weather stripping has been added on openable windows

and doors and

c. caulking or sealants are applied to areas such as joints

around window and door frames, between sole plates

and floors, between wall-ceiling joints, between wall

panels, at penetrations for plumbing, electrical and gas

lines and at ot her openings.

Figure

If your home meets all of the three criteria above, you must

provide additional fresh air.

You may provide two permanent openings: one within 12"

of the ceiling and one within 12" of the floor. Connect these

items directly to the outdoors or spaces open to the

outdoors. These spaces include attics and crawl spaces.

Follow the National Fuel Gas Code NFPA 54/ANSI Z223.1,

Section 5.3, Air for Combustion and Ventilation for required

size of ventilation grills or ducts.

IMPORTANT: Do not provide openings for inlet or outlet air

into attic if attic has a thermostat-controlled power vent.

Heated air entering the attic will activate the power vent.

Figure 2 Ventilation Air from Inside

WARNING: Air openings that provide fresh air from an adjoining

unconfined space shall not be blocked or obstructed in any way.

Installation of unit should allow a minimum of 2" clearance from

any part of the heater to any of the ventilation openings.

5

INSTALLATION

UNPACKING

Open the carton and remove the logs and the chassis.

Remove each of the logs by gripping at either end of the log

while avoidin g any undue pressure.

The carton for each model contains the following: grate/

burner assembly, front,middle and rear logs, top twig, 2

screws, 2 brackets and a bag of volcanic ash.

FIREPLACE PREPARATION

The fireplace needs to be prepared before installing the

unit:

A. Turn off the gas supply if the gas line has been run to the

fireplace.

B. WARNING: Before installing in a solid fuel burning

fireplace, the chimney flue and firebox must be

cleaned of soot, creosote, ashes and loose paint by a

qualified chimney cleaner.

? Note: If your fireplace has been cleaned using chemi-

cals or solvents, these products may have been

absorbed into the fireplace hearth and walls and will be

burned off during the initial break-in period.

C. Any outside air ducts and/or ash dumps in the fireplace

shall be permanently closed and sealed at the time of

appliance installation. This will prevent drafts from

disturbing the flames and interfering with complete

combustion of the gas fuel.

LOCATION

When gas logs are to be installed in a fireplace, inspect the

area surrounding it for possible air drafts that may affect the

flames and possibly cause sooting. Such drafts may be

caused by a ceiling fan near the fireplace, a hot air furnace

register or an open door. When burning the logs, carefully

observe the effect of possible drafts on the flames and take

appropriate measures to eliminate them. For example, the

ceiling fan may be cut off, the hot air register closed, etc.

Centrally locate the gas logs in the fireplace deep enough

into the firepit to accomplish an adequate draft (if use as a

vented appliance is planned). Ensure that the grate’s front

feet sit inside the front edge of the fireplace. Be sure

fireplace meets minimum fireplace dimensions.

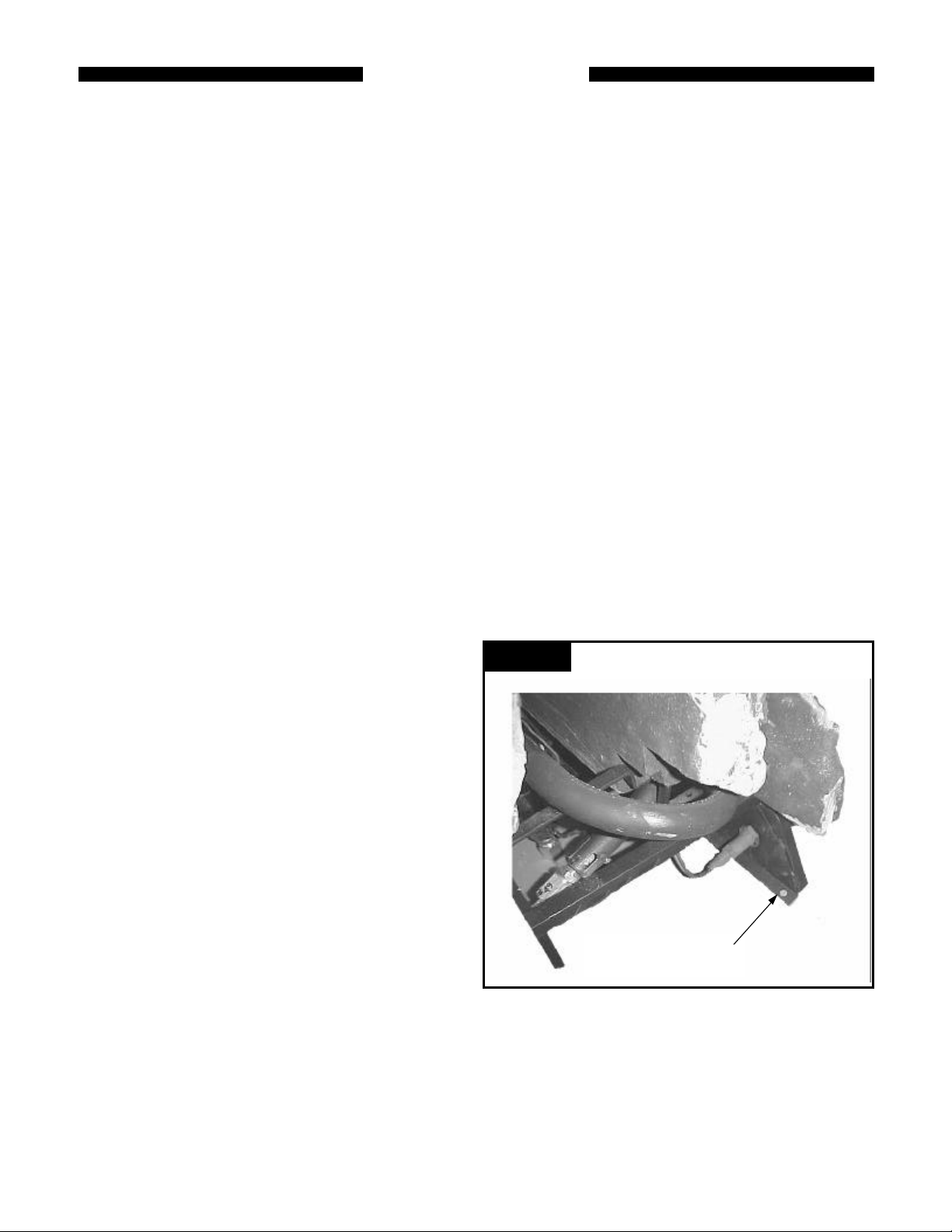

To avoid any movement of the unit during operation,

screw the chassis to the floor of the fireplace using the

screws provided. Failure to do so could cause gas

leaks.

Holes are provided just behind the front grate legs, and

should be used for securement of the log set. After locating

the chassis correctly in the fireplace, mark the hole

positions on the fireplace floor. Drill two 1/8” diameter holes

approximately 1/2" deep.

Use the two screws to secure the chassis to the fireplace

floor, (see figure 3).

is inadvertently closed.

Clearances for Unvented Installation in existing

fireplaces, (jurisdiction permitting)

1. Sidewall Clearances: Clearances from the side of the

fireplace opening to any combustible wall should not be

less than 2". (see figure 4A and 4B).

2. Ceiling Clearances: The ceiling height should not be

less than 62" from the fireplace hearth. (see figure 4A).

3. Mantel Clearances: The use of a canopy* is optional

depending on mantel clearances to the fireplace opening

and projection profile. (see figure 4C and 4D).

? NOTE: Mantel clearances may differ for each vent-free

firebox. Refer to the firebox installation instructions for

clearances.

A. Mantel profile: The minimum distance above the

fireplace opening to combustible material projecting 11/2 ” (tile moldings, breast boards, etc.) is 12-1/2".

? Combustible material projecting 6" (a mantel shelf, for

example) requires a minimum clearance of 19" above

the fireplace opening. Required clearance varies with

the amount of projection, (see figure 4C).

? The mantel profile must fall within the cross -section

shown in figure 4C or 4D.

B. Heat resistant material: Any heat resistant material

suitable for a continuous operating temperature of

120°C (248°F) must cover the wall surface directly

above the fireplace openin g and extend the full width

of the fireplace opening for a distance of 10" above

the opening. (see figure 4C).

Figure 3

CHASSIS SECUREMENT

LOCATION.

CLEARANCES

NOTE: The following instructions regarding installation

clearances and the use and installation of a canopy apply to

use of the appliances as an unvented space heater in

permitting jurisdictions. When installed as a vented

decorative gas appliance, the clearances noted below and

the use of a heat -deflecting canopy are not required.

However, it is recommended that these instructions be

followed even when the appliance will be used as a vented

decorative appli ance in case local codes change to allow

unvented space heaters or in the event that the flue damper

Figure 4A:

Minimum Clearance to Wall & Ceiling

62”

Figure 4C:

MANTEL CLEARANCES (SINGLE OR MULTI- SIDED OPENING FIREPLACES)

Figure 4B:

2”

Side Clearances and Projection

FIREPLACE

HEARTH

LEVEL

GAS CONNECTION

CHECK GAS TYPE. Use only the gas type indicated on the

heater's rating plate. If the gas type indicated on the plate

is not yo ur type of gas supply, DO NOT INSTALL. Contact

your dealer for the proper model.

WARNING

DANGER OF PROPERTY DAMAGE,

BODILY INJURY OR DEATH.

MAKE SURE THE HEATER IS EQUIPPED TO

OPERATE ON THE TYPE OF GAS AVAILABLE.

MODELS DESIGNATED AS NATURAL GAS ARE TO

BE USED WITH NATURAL GAS ONLY. HEATERS

DESIGNATED FOR USE WITH LIQUEFIED

PETROLEUM (L.P.) GAS HAVE ORIFICES SIZED

FOR COMMERCIALLY PURE PROPANE GAS.

THEY CANNOT BE USED WITH BUTANE OR A

MIXTURE OF BUTANE AND PROPANE.

GAS PIPING. The gas supply line must be of an adequate

size to handle the BTU/HR requirements and length of the

run for the unit being installed.

Determine the minimum pipe size from the piping size chart

on page 9. The normal gas connection at this appliance is

1/2" NPT made at the left of the unit.

Always use an an external regulator for all LP installations

to reduce the supply tank pressure to a maximum of 14"

Figure 4D:

WC. This is in addition to the regulator fitted to the heater.

All piping must comply with local codes and ordinances or with

the National Fuel Gas Code (ANSI Z223.1), whichever applies.

GAS CONNECTION. If installation is for L.P. gas, have L.

P. installer use two-stage regulation and make all

connections from storage tank to heater. Refer to the

National Fuel Gas Code for the proper supply tank size with

the Btu's/Hr requirements. If this is the ONLY gas

appliance, we recommend a minimum 200 pound cylinder

with a fill gauge. Use of a 100 pound cylinder is not

recommended. Other household gas appliances may

require the tank size to be larger.

Use pipe wrenches when making the connection to the

valve to prevent turning or damage to gas valve.

Connection between the manual shutoff valve and the gas

valve can be made with an CSA design certified flexible

connector if allowed by local codes. A drip leg (sediment

trap) must be installed, (see figure 5). Tighten all joints

securely.

CAUTION: Failure to install a drip leg (sediment trap)

may result in improper combustion that will produce

soot. Reference Sections 3.7 and 5.5.7 and Figure 5.5.7

of the National Fuel Gas Code for guidance.

WARNING: Connecting directly to an unregulated

LP tank can cause an explosion.

7

Figure 5

PIPED GAS SUPPLY

LESS THAN 6 FEET

IF USING FLEXIBLE CHECK

LOCAL CODES FOR SPECIFIC

REQUIREMENTS

GAS

VALV

All bends in metallic tubing should be smooth, elbows are

recommended.

CAUTION: Shut off the main gas supply before removing end

cap to prevent gas from filling the work area. Test for gas

leakage when installation is complete.

Under no circumstances should internally zinc alloy coated piping be used. According to the LP-Gas Code and

National Fuel Gas Code - If galvanized piping is used, it must be EXTERNALLY coated only! Galvanized water pipe

used for gas installations will result in reduced gas pressure and gas leaks.

8

GAS LINE PIPE SIZING

NOTE: To determine the size of the branch gas line from the main gas line to the fireplace, enter the

tables below (for iron pipe or copper tubing) using the distance from the gas meter or second

stage regulator to the furthest appliance on the gas system. Select a pipe or tube diameter which

has enough capacity to meet the maximum input requirement of the fireplace. Regardless, do not

use less than 1/2" diameter for the branch line. For any distances required longer than sho wn in

NOTE: There may be a local gas utility requirement specifying a minimum diameter for gas piping. All units require a 1/2 inch pipe connection at the

gas valve.

Length

Pipe Natural Propane Natural Propane Natural Propane Natural Propane Natural Propane

100' 38 59 79 122 150 235 305 474 460 717

WARNING: Use only internally tinned copper tubing. If correct copper tubing is not used, tubing can deteriorate

and develop gas leaks.

GAS PRESSURE CHECK

Check the inlet pressure to the appliance to ensure that it is

as shown in Table 1. Also check the incoming gas

pressure where the field installed gas line connects to the

gas logs.

Gas Inlet Pressure Natural Propane

Regulator Pressure 4.5 ins. WC 10 ins. WC

*Minimum inlet supply pressure for the purpose of input adjustment

The manifold pressure is controlled by the gas valve and

should be checked at the pressure test point located near

the outlet end of the combination control.

The pressure should be checked with the appliance burning

on high (highest setting) and all other appliances turned on.

One mus t then read the manometer and if pressures are

not 10.0” W.C. for LP or 4.5” W.C. for Natural gas the inlet

pressure must be adjusted or increased until the proper

pressures are attained. If these pressures are greater than

10.2” W.C. for LP or 4.7” W.C. for Natural gas, contact your

these tables, refer to the National Fuel Gas Code.

Cubic Feet per Hour based on 0.3" W.C. Pressure Drop

Specific Gravity for Natural Gas - 0.6 (1000 BTU/Cubic Foot)

Specific Gravity for Propane Gas - 1.6 (2550 BTU/Cubic Foot)

NOMINAL INCHES FOR IRON PIPE SIZES (1,000s BTU/Hr)

of 1/2" D 3/4" D 1" D 1¼" D 1½" D

20' 92 143 190 296 350 546 730 1135 1100 1711

30' 73 115 152 237 285 444 590 918 890 1385

40' 63 97 130 202 245 380 500 778 760 1183

50' 56 87 115 179 215 334 440 683 670 1043

60' 50 79 105 163 196 304 400 622 610 949

70' 46 71 96 151 180 280 370 576 560 872

90' 40 61 84 130 160 250 320 497 490 763

Outside Diameter Copper Tubing, Type L (1,000s BTU/Hr)

Tubing

Length

Feet

1/2"

0.43

10 110 206 348 536

20 76 141 239 368

30 61 114 192 296

40 52 97 164 256

50 46 86 146 224

60 42 78 132 203

80 36 67 113 174

100 32 59 100 154

Table 1

Max. 10.5 ins. WC 13 ins. WC

Normal 7.0 ins. WC 11 ins. WC

Min.* 5.5 ins. WC 10.8 ins. WC

CAPACITY OF PIPING

5/8"

0.545

gas supplier before operating the appliance.

After measuring the pressure, replace the test point plug

and check for leaks.

CAUTION: If the appliance's operating pressures are

not checked and adjusted, improper combustion may

result in soot being produced. Record the results of

the gas pressure check on the appropriate documents.

TESTING THE GAS PIPING. Test all piping for leaks.

When checking gas piping to the heater with gas pressure

less than 1/2 PSI, shut off manual gas valve for the heater.

If gas piping is to be checked with the pressure at or above

1/2 PSI, the heater and manual shut off valve must be

disconnected during testing to prevent damage to the

regulator on the unit. (SEE WARNING).

To ensure that the gas lines and connections do not have

any leaks, a pressure test should be performed. Only a

qualified installer should perform the pressure test to

ensure that the unit is not damaged by high pressures!

WARNING: Be sure that the gas type indicated on

the gas log rating plate concurs with the gas

system in your building.

3/4"

0.666

7/8"

0.785

9

WARNING

DANGER OF PROPERTY DAMAGE,

BODILY INJURY OR DEATH.

NEVER USE A MATCH OR OPEN FLAME TO TEST FOR

LEAKS. NEVER EXCEED SPECIFIED PRESSURES FOR

TESTING. HIGH PRESSURES MAY DAMAGE THE

APPLIANCE REGULATOR WHICH WOULD REQUIRE

REPLACEMENT. LIQUID PETROLEUM (L.P.) IS HEAVIER

THAN AIR AND IT WILL SETTLE IN ANY LOW AREA,

INCLUDING OPEN DEPRESSIONS AND IT WILL REMAIN

THERE UNLESS AREA IS VENTILATED.

NEVER ATTEMPT START-UP OF UNIT BEFORE

THOROUGHLY VENTILATING AREA.

If you connect natural gas to an LP gas unit, you may be

unable to ignite the pilot. If the pilot does ignite, the front

burner flame on the low setting will be bright blue but only

1/4” to 1/2” long and most likely lifting off the burner ports. If

this is the case, turn the unit off immediately and contact the

dealer wher e the unit was purchased.

If you connect LP gas to a natural gas unit, the front

burner flame on the low setting will be about 6” - 8” long. On

the medium and high setting, the front burner flames wi ll be

bright yellow and about 10” in length. Turn the unit off

immediately! If the unit is allowed to run in this condition,

substantial amounts of soot will be generated and emitted

into the house. contact the dealer where the unit was

purchased.

POSITIONING LOGS

1.Unpack and identify the four (4) logs by referring to Figures

6A, 6B and 6C.

2.Position back log into “V” log retainers ensuring that back

grate uprights are positioned in log notches.

3.Position front log with front grate bars fitting into log notches.

Log must fit down onto grate bars. (No gap under log).

4.Position middle log so notches in log fit snugly onto log

retaining bars. NOTE: Pin on left hand side of grate prevents

log from moving forward which would create flame

impingement from the yellow flame burner.

5. Position log retaining clip parallel with back edge of

middle log. Push pointed end of clip into log and fasten

clip to bar with screw provided. NOTE: This clip

maintains upright position of middle log to optimize

glowing ember front surface. (See clip location in Figure

6A).

When you have completed these steps, compare log

positions with Figure 6A. The logs must be positioned as

illustrated.

The top twig may be positioned as shown in either Figure

6B or Figure 6C.

The top twig must be placed in the notches provided on top

of the rear and center logs. The front of the top twig is to

rest of the large knot on the front log.

Caution: Proper location is critical. When positioning the

log set, make sure that the logs do not interfere with the

sides of the fireplace before securing the chassis.

FIREPLACE SCREEN

A fireplace screen must be in place when the appliance

is operating and unless other provisions for combustion air

are made, the screen must have openings for the

introduction of combustion air.

DECORATIVE VOLCANIC ASH

The volcanic ash from the bag provided should be sprinkled

Figure 6A

ash on burner, pilot or logs.

Figure 6B

WARNING: Failure to position the parts in

accordance with this diagram o r failure to use only

parts specifically approved with this heater may

result in property damage or personal injury. See

instruction manual for further information.

Figure 6C

WARNING: Failure to position the parts in

accordance with this diagram or failure to use only

parts specifically approved with this heater may

result in property damage or personal injury. See

instruction manual for further information.

10

around the base of the logset DO NOT place

any material, including volcanic

LOG POSITIONING - TOP VIEW

(ALTERNATE)

TWIG TOP POSITIONING - TOP VIEW

LOG

RETAINING

CLIP

Figure 7

OFF

FOR YOUR SAFETY READ BEFORE LIGHTING

WARNING: If you do not follow these instructions exactly, a fire or explosion may result

causing property damage, personal injury or loss of life.

A. This appliance has a pilot which must be lighted by hand. When

lighting the pilot, follow these instructions exactly.

B. BEFORE OPERATION smell all around the appliance area for

gas. Be sure to smell next to the floor

because some gas is heavier than air

and will settle on the floor.

WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch; do

not use any telephone in your building.

Figure 8

PIEZO

• Immediately call your gas supplier from a neighbor's telephone.

LIGHTING INSTRUCTIONS

1. STOP! Read “FOR YOUR SAFETY READ BEFORE LIGHTING”

before proceeding.

2. Refer to figure 9. To turn off the gas

supply, depress the knob slightly and turn

clockwise to the OFF

position.

3. Wait five (5) minutes to clear out any gas. If

you then smell gas, STOP! follow “B”, in the

safety information above. If you don’t smell

gas, go on to the next step.

4. Refer to figure 10. Locate the pilot. It is in the center of the back

burner.

5. Refer to figure 11. Push in the control knob and turn

counterclockwise to the PILOT position.

Hold the control knob in for a few

seconds

6. While still holding in the control knob,

press the ignitor push -button several

times. This will cause a spark at the pilot

which will ignite the pilot gas.

Refer to figure 11. Hold the contro l knob for 20 seconds to prevent the

flame failure detector from shutting off the gas while its probe is

Figure 9

Figure 10

• Follow the gas supplier's instructions.

• If you cannot reach your gas supplier, call the fire department.

C. Use only your hand to push in or turn the gas control knob. Never

use tools. If the knob will not push in or turn by hand, don't try to

repair it. Call a qualified service technician. Force or attempted

repair may cause a fire or an explosion.

E. Do not use this appliance if any part of it has been under water.

Immediately call a qualified service technician to inspect the

appliance and to replace any part of the control system or gas

control which has been under water.

Release the control knob. If the knob does not pop up when

released, stop and immediately call your service technician.

If the pilot will not stay lit after several tries, turn the gas

control knob to OFF and call your service technician or gas

supplier.

When the pilot remains lit, turn gas knob

counterclockwise to the HIGH position.

Depress the knob slightly and turn

counterclockwise to the setting you

prefer.

The front burner may be turned on

or off. Turn knob located on right

hand side of the control panel to

“ON” or “OFF” position. Do not

leave in an intermediate position.

This appliance is fitted with a

transient pilot burner for the sole

purpose of safe, momentary ignition of the main burner in

conjunction with the piezo ignitor. When in operation with the

main burner it contributes to the base heat release and is

turned off by turning the control knob to the OFF position.

The control knob should not be left at the ignition setting

after the pilot has been ignited.

Figure 11

TO TURN OFF GAS TO THE APPLIANCE

Depress the control knob slightly and turn it Clockwise to the OFF position. Refer to Figure 9.

IMPORTANT SAFEGUARDS

Although your gas logs are very realistic in

appearance it is not a real wood-burning fireplace and

must be used for burning rej ected material.

To avoid irreparable damage to the appliance or personal

injury; matches, paper, garbage or any other material

must not be placed or thrown on top of the logs or into the

flames.

To avoid personal injury, do not touch hot surfaces

when the appliance is operating.

Touch only the piezo button and control knob. Avoid

contact with the front screen, canopy or any other part

which will be very hot.

Always ensure that the fireplace screen is in place

when the appliance is operating.

Close supervision is necessary when the appliance is

being operated near children.

Do not use to cook food.

If this is the ONLY gas appliance, we recommend a

minimum 200 pound cylinder with a fill gauge. Use of a

100 pound cylinder is not recommended. Other household

gas appliances may require the tank size to be larger. Do

MATCH LIGHTING

If the pilot cannot be ignited with the piezo, it can be

manually lit with the use of a match and lighter rod.

1. Place the match in the holder and light. With the right

hand, depress and turn the control knob

counterclockwise to the PILOT position. Hold in

not operate the vent free fireplace if the fuel level in the

propane tank is below 1/4 full.

WARNING: The glowing ember base and all the logs

are manufactured from bonded ceramic fiber. This

is a commonly used material in industry worldwide.

In the event of the logs and base being removed,

care should be taken not to damage the bonded

material.

Intentional misuse of, or deliberately fragmenting,

the material could lead to inhaling fibers and be

injurious to health. Insure the logs are properly

This appliance is intended to be used only for

supplemental heat. Do not use it routinely as a primary

heat source. Continuous operation could produce

excessive humidity depending on construction

characteristics and outdoor temperatures (below 200F)

Over time, this could cause condensation to form and

damage wall structures and exterior paint. Do not use this

product duri ng building construction. Dust, debris, paint

2. Take the lighter rod and lighted match and ignite the

pilot.

3. Continue to hold the control knob for an additional 20

seconds to ensure pilot is maintained.

4. Proceed with step 8 in lighting instructions on page 11.

FLAME CHECK

A periodic visual check of the flames should be made. The

pilot flame should always be present when the appliance is

in operation. See figure 22.

In normal operation (at full rate for approximately 15 minutes) the following flame appearance should be observed:

Front Blue Flame Burner: The flame should burn blue

with absolute minimal to no yellow flames visible. Height of

flame should be approximately 3” on high.

Figure 21

Figure 23

Rear Yellow Flame Burner: The flame should be yellow in

color and should extend 6 to 8 inches above the large front

logs.

Typical flame shape as seen in Figure 22.

NOTE: For your safety, the appliance is equipped with an

oxygen depletion system. The system senses the oxygen in

the atmosphere and switches off the gas supply in case the

level of oxygen falls below a safe level. It must not be

altered in any way.

Figure 22

AIR SHUTTER SETTINGS - DIM “A”

“A

MODEL BLUE FLAME

FRONT BURNER

PS24MN

PS24MP .437 .250

12

.250 CLOSED

YELLOW FLAME

REAR BURNER

MANAGING HEAT OUTPUT

The heat output from the appliance can be controlled by the

position of the flue damper on vented fireplaces.

The damper setting should be fully closed for maximum

heat output, partially closed for less heat output and fully

open for minimum heat output.

The appliance may be used in a working solid fuel burning

fireplace with the fuel damper closed only if unvented

appliances are permitted by local state and city codes. It

may also be operated as a decorative appliance whose

The heat output from the appliance when operated as a vent -free heater may be controlled by adjusting the main

gas valve and by turning the front (blue flame) burner on or off. Reference lighting instructions on page, and chart

on page 3. showing inputs at all the settings.

The main gas valve may be adjusted anywhere between high and low to give the desired combination of flame

aesthetics and heat output. The blue flame front burner control must be turned fully to either the “ON” or “OFF”

position.

prime function lies in the aesthetic effect of the flames when

installed in a solid fuel burning fireplace with the flue

damper open. If unvented heaters are not permitted, the

fireplace vent damper must be locked at a minimum free

(vent) area of 15 sq. ins.

Whenever the appliance is operated with the fireplace's

flue damper closed, glass doors - if present - must be

open and the outside air damper and the ash dump (if

the fireplace is equipped with either one) must be

closed.

MAINTENANCE

CLEANING

CAUTION: Before cleaning or moving logs or other parts of

the unit, be sure to read the section on important

safeguards.

Cleaning should be done before the logs are used each

year and after long periods of non-use. Professional

servicing is recommended.

All cleaning should be carried out when the appliance is

cold.

Only limited cleaning will be required under normal use.

Dusting the front grate or the control knob panel may be

required occasionally. Do not use any cleaning fluids to

clean the logs or any other part of the appliance.

If the flames show any unusual shapes or behavior, or if the

burner(s) fail to ignite properly, then the burner holes may

require cleaning. If this occurs contact your nearest dealer

to get the appliance serviced.

Alternatively, the appliance can be cleaned by removing the

logs. Handle the logs gently so as not to damage them.

Always lift each log by holding it carefully at each end.

After the logs are removed allowing access to the burner

area, use a vacuum cleaner to carefully remove dust and

loose particles from the base, logs and from around the

burner. Gloves are recommended when handling the logs.

Use extreme caution in clearing around the pilot (ODS).

The pilot should not be moved or altered from the original

factory setting (Pilot to burner preset location). The burner

should not be removed or taken out of it’s locked and

secure position (proper location of burners are critical).

Lack of proper maintenance may void warranty.

13

14

TROUBLESHOOTING

With proper installation and maintenance, your new gas fireplace should provide years of trouble-free service. If you do

experience a problem, refer to the trouble shooting guide below. This guide will assist you or a qualified servi ce person in the

diagnosis of problems and the corrective action to be taken. Any safety screen or guard removed for servicing an appliance

must be replaced prior to operating the appliance. Use only a qualified service person when making repairs.

SYMPTOM POSSIBLE CAUSE CORRECTIVE ACTION

1. Pilot will not light

2. Pilot will not stay lit

3. Main burner will not light

• Air in the gas line

• Low gas pressure

• Gas supply turned off

• Blockage in gas line

• ODS pilot orifice is clogged

• Control knob not in pilot position

• Control knob not pressed in while in

pilot position

Ignitor did not spark:

• Ignitor electrode positioned wrong

• Ignitor electrode broken

• Ignitor cable pinched or broken

• Partially clogged ODS pilot orifice

• Ignitor cable not connected to ignitor

• Corrosion of thermocouple contact

• Bad gas valve

• Control knob not pressed in long

enough

• Thermocouple connection loose at

gas control or damaged

• Pilot flame not touching the

thermocouple

• Low gas supply pressure

• Burner orifice clogged

• Control knob not in ON position

• Purge gas lines and repeat ignition operation

• Check gas pressure

• Turn on gas supply

• Check gas passage way

• Call a qualified person

• Turn control knob to pilot position

• Press in control knob while in pilot position

• Correct electrode position

• Replace assembly

• Free ignitor cable, if damaged replace it

• Contact qualified service person or your gas

• Connect cable to ignitor

company

• Clean thermocouple contact

• Replace gas valve

• After pilot lights, keep control knob pressed in

for 60 seconds

• Tighten connection finger tight + 1/4 turn or

replace thermocouple or replace ODS pilot

assembly

• Contact a qualified service person

• Contact your gas supplier

• Clean burner orifice

• Turn control knob to ON position

4. Heater shuts off on ODS

Repair and replacement work should only be done by a

qualified service technician.

• Not enough fresh air is available

• Low gas pressure

• ODS pilot partially lit

SERVICING

Always shut off the gas supply and make sure the

appliance is cool before beginning any service operation.

Always check for gas leaks after servicing.

• Open window

• Contact your gas company

• Contact a qualified service person

REPAIR PARTS

Always include the correct name, part number, model

number and serial number of the appliance when ordering

service parts. Refer to the parts list below.

Contact your dealer before warranty work is performed.

Use manufacturer's authorized parts only. If you desire to

communicate with the factory, write to Customer Service at:

REPLACEMENT PARTS

Ref.

No. Description

1 GRATE ASSEMBLY 76512 76512 1

2 LOG - SUPPORT 76511 76511 2

3 LOG RETAINER CLIP 76517 76517 1

4 PILOT BRACKET 76513 76513 1

5 YELLOW FLAME BURNER 76719 76719 1

6 BLUE FLAME BURNER 76720 76720 1

7 PILOT 73312 73311 1

8 TUBE - PILOT 76784 76784 1

9 GAS VALVE 76721 76722 1

10 REGULATOR SCP. 74557 73333 1

11 REGULATOR BRACKET 76754 76754 1

12 IGNITOR W/NUT (PIEZO) 65180 65180 1

13 WIRE IGNITOR (AD COM MON) 74017 74017 1

14 MANIFOLD TUBE/SPLIT NUT 76519 76519 1

15 MANIFOLD TUBE/SPLIT NUT 76520 76520 1

16 INJECTOR #43 (NATURA L) 76775 —— 1

17 INJECTOR #49 (NATURA L) 76771 —— 1

18 INJECTOR #56 (PROPANE ) —— 76776 1

19 INJECTOR #1.45 (PROPANE) —— 76774 1

20 ON/OFF VALVE 76718 76718 1

21 CONTROL KNOB 76525 76525 2

22 3/8 PIPE TO 3/8 COMPRESSION

CONNECTOR

23 BRACKET, CAST TEE 76514 76514 1

24 3/8” TEE 71134 71134 1

25 LOCKSET 3/16” PILOT FITTING 71076 71076 1

27 SUPPLY TUBE 76805 76805 1

— LAVA GRAVEL ASSY 76255 76255 1

— EMBER COALS 74511 74511 1

— 24” LOG KIT PL24 PL24 1

28 FRONT LOG 24” 75974 75974 1

29 MIDDLE LOG 24” 75973 75973 1

30 REAR LOG 24” 75972 75972 1

31 TWIG (24” OR 28”) 76398 76398 1

— 28” LOG KIT PL28 PL28 1

— FRONT LOG 28” 76839 76839 1

— MIDDLE LOG 28” 76840 76840 1

— REAR LOG 28” 76894 76894 1

31 TWIG (24” OR 28”) 73698 73698 1

PS24MN PS24MP Qty

PCOA055 PCOA055 3

30

29

TEMCO FIREPLACE PRODUCTS, INC.

P.O. Box 1349 Manchester, TN 37349

TEMCO FIREPLACE PRODUCTS, INC.

P.O. Box 1148 Perris, CA 92572

TEMCO FIREPLACE PRODUCTS, INC.

1773 Parque Industrial Cachanilla

Mexicali, B.C. 21600

28

Figure 24

31

15

Limited Warranty

TEMCO Vent-Free Gas Fireplaces

This warranty is limited to TEMCO Vent-Free Gas Logs & Fireplaces (henceforth, Product) manufactured by TEMCO Fireplace

Products, Inc. (henceforth, TEMCO).

ONE YEAR WARRANTY

TEMCO warrants all components of the Product to be free of defects in materials and workmanship for a period of one year from the

date of installation, with the exception of the warranty on logs and ember base. If, by the sole determination of TEMCO, any

component covered under this warranty is found to be defective, TEMCO will, at its option, repair or replace the defective component

at no charge and will pay labor cost incurred as specified in the current TEMCO Labor Allowance Schedule, 71313. If TEMCO

determines replacement or repair is not economically practical, TEMCO will, at its option, refund the purchase price of the Product.

Date of installation and purchase price must be verified by acceptable proof of purchase prior to warranty action.

This warranty covers only parts and labor as provided above. In no case shall TEMCO be responsible for materials,

components or construction which are not manufactured or supplied by TEMCO, or the labor necessary to install, repair or remove

such materials, components or construction.

FIVE YEAR WARRANTY

TEMCO warrants the ceramic fiber and refractory components and burners originally packed with the product to be free of defects in

material and workmanship for a period of five (5) years from the date of installation, with the exception of breakage. If any ceramic

components or refractory components are broken, such breakage must be reported as a Warranty Claim at the time of installation.

Breakage claims arising after the initial installation will not be covered under any part of this warranty. Periodic maintenance must

have been performed.

QUALIFICATIONS

For the above warranties to apply:

The Product must be installed by a qualified installer; strictly in accordance with TEMCO installation instructions,

and in compliance with local codes and ordinances. The logs must be placed strictly in accordance with the arrangement

described in the installation instructions.

The Product must be operated and maintained according to the instructions furnished. Alteration of the Product in any way

is prohibited and voids any and all warranties. Removal of the data plate alters the Product and voids the warranty.

The installer must have completed the Installation and Startup Checklist, a copy of which must be submitted along

with proof of purchase, to obtain prior approval for warranty repair or replacement and to affect a warranty claim. The

Checklist is found on pages 17 and 18 of this manual.

The limited warranty applies only to the original owner of the Product or the original owner of the dwelling in which the Product

was installed. Use of any parts other than genuine factory provided replacement parts shall void this warranty.

Limitations

TEMCO is not responsible for any incidental or consequential damages caused by possible defects in the Product. The

duration of any implied warranty with respect to the Product is limited to the duration of the foregoing warranties.

Some states and provinces do not allow exclusion of incidental or consequential damages or limits on the duration of implied

warranties, so these li mitations may not apply to you.

Warranty Fulfillment

Claims require specific agreement and consent from TEMCO Technical Services prior to performing any warranty

repair or replacement. TEMCO reserves the right to investigate any and all warranty claims. The appliance must not be

removed prior to such investigation other than on direction from TEMCO.

Please provide the following information when communicating with TEMCO Technical Services, its Dealers or Distributors

regarding service under this warranty.

Model Number:_______________________________ Serial Number:_____________________________________

Date of Installation:______/______/_______ Purchased From:_____________________________________________

TEMCO reserves the right to decide on the method of settlement (if any). This limited warranty is given in lieu of any other expresse d

or implied warranty, and supersedes all other TEMCO Product warranties.

TEMCO GAS LOGS & FIREPLACES

INSTALLATION AND STARTUP CHECKLIST

Customer Copy

NOTE: TEMCO gas logs and fireplaces require installation by a qualified gas appliance installer. A copy of this checklist must be

submitted, along with proof of purchase, when applying to Technical Services for prior written approval of warranty repair or replacement.

All Vent-Free Gas Fireplaces and Logs

Read and understand installation instructions before attempting instal lation.

Assure that the model to be installed is of the CORRECT FUEL TYPE. Check markings on the shipping container (Model#s

ending in “N” are natural gas products; model#s ending in “P” are LP gas products.), tags on the burner assembly, and

color of the ODS safety pilot tube.

(Aluminum for natural gas; brass for LP gas)

Notes: REGULATORS ARE NOT FIELD-ADJUSTABLE. ANY ATTEMPT TO ADJUST VOIDS THIS WARRANTY.

In order to ensure adequate combustion air, make sure that the model being installed has the appropriate heating

capacity for the unconfined space available. Allow a minimum of 50 cubic feet of unconfined space per 1000 BTU’s for all

gas appliances.

Assure that gas line size is adequate for the model’s input rating (BTU’s per hour), the length of run form the meter or second

stage regulator to the farthest gas appliance, and other gas appliances on the system. A drip leg or sediment trap is required.

LP models require a minimum tank size of 120 gallons water capacity and two stage regulation.

Assure that installation meets local codes and ordinances.

Assure that there are no fans or blowers in the fireplace area.

Check for leaks before lighting.

Using a manometer, verify proper gas pressure at the manifold with unit at maximum setting and other appliances

operating.

inlet pressure:__________ (ins. wc) manifold pressure:__________ (ins. wc)

Verify proper ignition of ODS and front and rear burners, as well as proper appearance of flames.

Verify that ceramic fibe r and refractory components are properly positioned and secure. (Rear burner must not contact

logs.)

Verify adequate clearance to mantels and other combustibles.

Demonstrate correct operation of the product to the consumer. Note: LP models must not be operated if fuel tank is less than

1/4 full.

Observe the consumer operating the product properly.

Explain and demonstrate proper periodic maintenance.

Explain that operation with logs positioned other than as described in the manual voids the warranty and will cause poor

combustion and sooting.

Verify the consumer’s understanding that warranty service work that is not pre-approved by the manufacturer’s Technical

Service Department (other than routine maintenance) may not qualify for reimbursement.

Answer any questions the consumer may have about TEMCO vent-free products.

Vent-Free Gas Logs Only

Verify that the fireplace in which the logs are to be installed is either a solid-fuel burning fireplace (either factory-built or

masonry) with a working flue system connected to it or an approved vent -free firebox.

Verify that the fireplace has been thoroughly cleaned by a professional chimney sweep. If solvents have been used to clean

the hearth, they must be allowed to evaporate before proceeding with installation.

Check firebox dimensions for adequate height, width, and depth.

Verify that the grate assembly is attached to the firebox floor.

Verify that any ash dump or outside air inlets are permanently sealed to avoid drafts within the firebox.

Verify that no additional logs, ornaments, or non-approved blower devices have been added.

Repair any broken or damaged logs prior to operation.

Check mantel clearances and verify installation of canopy if necessary.

Glass doors must be removed or opened completely during operation of logs.

Please sign below that checklist has been completed and understood. DATE INSTALLED ______/______/______

Installer Phone Consumer Phone

TEMCO GAS LOGS & FIREPLACES

INSTALLATION AND STARTUP CHECKLIST

Installer’s Copy

NOTE: TEMCO gas logs and fireplaces require installation by a qualified gas appliance installer. A copy of this checklist must be

submitted, along with proof of purchase, when applying to Technical Services for prior written approval of warranty repair or replacement.

All Vent-Free Gas Fireplaces and Logs

Read and understand installation instructions before attemptin g installation.

Assure that the model to be installed is of the CORRECT FUEL TYPE. Check markings on the shipping container (Model#s

ending in “N” are natural gas products; model#s ending in “P” are LP gas products.), tags on the burner assembly, and

color of the ODS safety pilot tube.

(Aluminum for natural gas; brass for LP gas)

Notes: REGULATORS ARE NOT FIELD-ADJUSTABLE. ANY ATTEMPT TO ADJUST VOIDS THIS WARRANTY.

In order to ensure adequate combustion air, make sure that the model being ins talled has the appropriate heating

capacity for the unconfined space available. Allow a minimum of 50 cubic feet of unconfined space per 1000 BTU’s for all

gas appliances.

Assure that gas line size is adequate for the model’s input rating (BTU’s per hour), the length of run form the meter or second

stage regulator to the farthest gas appliance, and other gas appliances on the system. A drip leg or sediment trap is required.

LP models require a minimum tank size of 120 gallons water capacity and two stage regulation.

Assure that installation meets local codes and ordinances.

Assure that there are no fans or blowers in the fireplace area.

Check for leaks before lighting.

Using a manometer, verify proper gas pressure at the manifold with unit at maximum setting and other appliances

operating.

inlet pressure:__________ (ins. wc) manifold pressure:__________ (ins. wc)

Verify proper ignition of ODS and front and rear burners, as well as proper appearance of flames.

Verify that ceramic fiber and refractory components are properly positioned and secure. (Rear burner must not contact

logs.)

Verify adequate clearance to mantels and other combustibles.

Demonstrate correct operation of the product to the consumer. Note: LP models must not be operated if fuel tank is less than

1/4 full.

Observe the consumer operating the product properly.

Explain and demonstrate proper periodic maintenance.

Explain that operation with logs positioned other than as described in the manual voids the warranty and will cause poor

combustion and sooting.

Verify the consumer’s understanding that warranty service work that is not pre-approved by the manufacturer’s Technical

Service Department (other than routine maintenance) may not qualify for reimbursement.

Answer any questions the consumer may have about TEMCO vent-free products.

Vent-Free Gas Logs Only

Verify that the fireplace in which the logs are to be installed is either a solid-fuel burning fireplace (either factory-built or

masonry) with a working flue system connected to it or an approved vent -free firebox.

Verify that the fireplace has been thoroughly cleaned by a professional chimney sweep. If solvents have been used to clean

the hearth, they must be allowed to evaporate before proceeding with installation.

Check firebox dimensions for adequate height, width, and depth.

Verify that the grate assembly is attached to the firebox floor.

Verify that any ash dump or outside air inlets are permanently sealed to avoid drafts within the firebox.

Verify that no additional logs, ornaments, or non-approved blower devices have been added.

Repair any broken or damaged logs prior to operation.

Check mantel clearances and verify installation of canopy if necessary.

Glass doors must be removed or opened completely during operation of logs.

Please sign below that checklist has been completed and understood. DATE INSTALLED ______/______/______

Installer Phone Consumer Phone

CUSTOMER COPY

Model # __________________________________________ Serial

#_________________________________________

I certify that I have followed all codes and regulations and adhered to the TEMCO installation instructions. I have

completed the proper installation and startup checklist.

Installers Signature Print Installer’s Name

Purchaser

Address

Phone

Retailer

Address

Phone

Date of Purchase

WARRANTY REGISTRATION

Please Answer the Following Questions (Check Box):

1. Type of Home Single Family Duplex Apt. Mobile Home

Cabin/Vacation

2. Installed in (Room) Living Family Great Rec Bedroom

Other

3. Other Choices Considered Vented Decorative Gas Logs/Fireplace

Woodburning Fireplace Gas Insert Woodburning Insert

Direct-Vent gas Fireplace/Logs

4. Why Did You Choose Vent-Free? (Ra nk in Order of Importance: 1-6)

___Efficiency ___Zone/supplemental heating ___Stand-by-heat

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

PLEASE CUT ALONG DOTTED LINE

To register your warranty, please provide the information indicated on this form and mail it to:

TEMCO Fireplace Products, Inc.

301 Perimeter Park Drive

Suite 227

Nashville, TN 37211

Model # __________________________________________ Serial

#_________________________________________

I certify that I have followed all codes and regulations and adhered to the TEMCO installation instructions. I have

completed the proper installation and startup checklist.

Installers Signature Print Installer’s Name

Purchaser

Address

Phone

Retailer

Address

Phone

Date of Purchase

WARRANTY REGISTRATION

Please Answer the Following Questions (Check Box):

1. Type of Home Single Family Duplex Apt. Mobile Home

Cabin/Vacation

2. Installed in (Room) Living Family Great Rec Bedroom

Other

3. Other Choices Considered Vented Decorat ive Gas Logs/Fireplace

Woodburning Fireplace Gas Insert Woodburning Insert

Direct-Vent gas Fireplace/Logs

4. Why Did You Choose Vent-Free? (Rank in Order of Importance: 1-6)

___Efficiency ___Zone/supplemental heating ___Stand-by-heat

Loading...

Loading...