Temco DV1000N/P, DV1200N/P, DV1400N/P, DV1000N, DV1000P Installation And Operating Manual

...

INSTALLER / CONSUMER

C US

SAFETY INFORMATION

PLEASE READ THIS MANUAL

BEFORE INSTALLING AND

USING APPLIANCE

WARNING!

IF THE INFORMATION IN THIS

MANUAL IS NOT FOLLOWED

EXACTLY, A FIRE OR EXPLO

SION MAY RESULT CAUSING

PROPERTY DAMAGE, PERSONAL INJURY OR LOSS OF LIFE.

FOR YOUR SAFETY

Installation and service must

be performed by a qualified

installer, service agency or the

gas supplier.

WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electric switch; do not

use any phone in your building.

• Immediately call your gas supplier from

your neighbor’s phone. Follow the gas

suppliers instructions.

• If you cannot reach your gas supplier

call the fire department.

-

Direct Vent Zero Clearance

Gas Fireplace Heater

Models:

DV1000N/P, DV1200N/P, DV1400N/P

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE

VAPORS AND LIQUIDS IN THE

VICINITY OF THIS OR ANY OTHER APPLIANCE.

WARNING: Improper installation, adjustment, alteration, service or maintenance can cause injury or property

damage. Refer to this manual. For

assistance or additional information,

consult a qualified installer, service

agency or the gas supplier.

U.S. Patents: 5,669,374; 5,562,088; 6,138,667;

Can. Patent: 2,139,684

Homeowner’s Installation and

Operating Manual

INSTALLER: Leave this manual with the appliance.

CONSUMER: Retain this manual for future reference.

76657 5/08 Rev. 31

Temco DV1000/1200/1400 Series

Table of Contents

PLEASE READ THE INSTALLATION & OPERATING INSTRUCTIONS BEFORE USING APPLIANCE.

Thank you and congratulations on your purchase of a Temco Fireplace Products fireplace.

While we have written these instructions as accurately and thoroughly as possible, they may not cover every system,

variation or contingency. Also, questions of interpretation may arise. For more information, solutions to particular problems or clarifications, contact your local distributor or the manufacturer. See the unit rating plate for whom to contact.

IMPORTANT: Read all instructions and warnings carefully before starting installation. Failure to follow these

instructions may result in a possible fire hazard and will void the warranty.

Installation & Operating Instructions

General Information, Warnings, Cautions ............................................................. 3

Requirements for the Commonwealth of Massachusetts ...................................... 4

Fireplace Dimensions ............................................................................................

Locating Your Fireplace ......................................................................................... 6

Framing & Finishing ..............................................................................................

Clearance to Combustibles ................................................................................... 7

Combustible Sidewall Clearance .......................................................................... 7

Mantels ..................................................................................................................

Surround Material .................................................................................................. 7

Gas Specifications

Gas Inlet and Manifold Pressures ......................................................................... 8

Gas Line Installation .............................................................................................. 8

General Venting Information

General Venting .................................................................................................... 9

General Venting Information - Termination Location ...........................................

Termination Clearances .......................................................................................11

Sidewall (General)Venting Information ................................................................ 12

Flex Venting

Sidewall (Horizontal) Venting .............................................................................. 13

Flex Vent Offsets .................................................................................................

Flex Vent Through the Roof (Vertical) Applications ............................................. 15

VSK7 Vertical Flex Vent Kit Installation ............................................................... 15

TDV Series Direct Vent System Installation ........................................................

Sidewall (Horizontal) Venting, General ............................................................... 16

Through the Roof (Vertical) Venting ....................................................................

Elbows & Offsets - General ................................................................................ 17

Sidewall (Horizontal) Venting Information ........................................................... 17

Venting Components ...........................................................................................

Operating Instructions

Glass Door Removal Procedure .........................................................................

Glass Cleaning .................................................................................................... 24

Louvre Installation ............................................................................................... 24

Log Installation ....................................................................................................

Thermostatic Fan Kit - Optional........................................................................... 26

Electrical Services ...............................................................................................

Speed Control Switch .......................................................................................... 26

Millivolt System .................................................................................................... 26

Burner ON/OFF ...................................................................................................

Managing Heat Output ........................................................................................ 27

Fan Operation .....................................................................................................

Flame Characteristics .......................................................................................... 27

Lighting & Operating Instructions ........................................................................ 28

Troubleshooting ...................................................................................................

Maintenance

Unit Adjustment ...................................................................................................

Maintenance ........................................................................................................ 32

Replacement Parts ........................................................................................................ 35

Servicing ..............................................................................................................

Warranty .......................................................................................................................... 36

Installation and Startup Checklist ................................................................................. 37

Warranty Registration ................................................................................................... 39

................................................................................................. 8

......................................................................................................... 12

2

4

6

7

10

13

16

17

20

24

25

26

26

27

29

32

35

76657

Temco DV1000/1200/1400 Series

�

Installation & Operating Instructions

This gas appliance should be installed by a qualified

installer in accordance with local building codes and with

current CSA-B149.1 Installation codes for Gas Burning

Appliances and Equipment. For U.S.A Installations follow

local codes and/or the current National Fuel Gas Code.

ANSI Z223.1/NFPA 54.

FOR SAFE INSTALLATION AND OPERATION PLEASE

NOTE THE FOLLOWING:

1 . This fireplace gives off high temperatures and should be

located out of high traffic areas and away from furniture and

draperies.

2. Children and adults should be alerted to the hazards of the

high surface temperatures of this fireplace and should stay

away to avoid burns or ignition of clothing.

3. CAUTION: Due to high glass surface temperature chil-

dren should be carefully supervised when in the same

room as fireplace.

4. Under no circumstances should this fireplace be modified.

Parts removed for servicing should be replaced prior to

operating this fireplace again.

5. Installation and any repairs to this fireplace must be per

formed by a qualified installer, service agency or gas sup

plier. A professional service person should be contacted to

inspect this fireplace annually. Make it a practice to have

all of your gas fireplaces checked annually. More frequent

cleaning may be required due to excess lint and dust from

carpeting, bedding material, etc.

6. Control compartments, burners and air passages in this fireplace should be kept clean and free of dust and lint. Make

sure the gas valve and pilot light are turned off before you

attempt to clean this fireplace.

7. The venting system (chimney) of this fireplace should be

checked at least once a year and if needed your venting

system should be cleaned.

8. Keep the area around your fireplace clear of combustible

materials, gasoline and other flammable vapor and liquids.

This fireplace should not be used as a drying rack for clothing, nor should Christmas stocking or decorations be hung

in the area of it.

9. Under no circumstances should any solid fuels (wood, coal,

paper or cardboard etc.) be used in this fireplace.

10. For safe operation, the glass door must be closed.

11. Do not use this heater if any part has been under water.

Immediately call a qualified service technician to inspect the

heater and to replace any part of the control system and any

gas control which has been under water.

76657

12. Do not operate appliance unless completely installed as per

installation instructions.

13. This appliance may be used in a bedroom installation. Install

in accordance with local building codes and regulations.

14. Never use your fireplace as a cooking device.

DV1000 / DV1200 / DV1400

Certified To

ANSI Z21.88-2005 / CSA 2.33-2005 / UL 307B

Vented Gas Fireplace Heater

WARNING: Check with your electronics manufac

turer before installing a television or other electronic device above this fireplace.

This appliance may be installed in an aftermarket

permanently located, manufactured home or mobile home, where not prohibited by local codes.

This appliance is only for use with the type of gas

indi-cated on the rating plate. This appliance is

not convertible for use with other gases, unless a

certified kit is used.

IMPORTANT:

PLEASE READ THE FOLLOWING CAREFULLY

Remove any plastic from trim parts before turning the

fireplace ON.

It is normal for fireplaces fabricated of steel to give off

-

-

some expansion and/or contraction noises during the

start up or cool down cycle. Similar noises are found

with your furnace heat exchanger or car engine. It

is not unusual for your gas fireplace to give off some

odor the first time it is burned. This is due to the

manufacturing process.

Please ensure that your room is well ventilated

-open all windows.

It is recommended that you burn your fireplace for at

least four (4) hours the first time you use it. If the optional fan kit has been installed, place the fan switch

in the “OFF” position during this time.

The embers supplied with your fireplace are

made from a high grade rock wool and should be

handled carefully. Wash your hands immediately

after touching to avoid irritation. The embers

must be placed correctly in order to function

properly.

WARNING: When purging the gas line, the glass

front must be removed.

-

3

Temco DV1000/1200/1400 Series

Installation & Operating Instructions

Requirements for the Commonwealth of

Massachusetts

All gas fitting and installation of this heater shall only be

done by a licensed gas fitter or licensed plumber.

For all side wall horizontally vented gas fueled

equipment installed in every dwelling, building or

structure used in whole or in part for residential

purposes, including those owned or operated by the

Commonwealth and where the side wall exhaust vent

termination is less than seven (7) feet above finished

grade in the area of the venting, including but not limited

to decks and porches, the following requirements shall

be satisfied:

Installation of Carbon Monoxide Detectors

At the time of installation of the side wall horizontal

vented gas fueled equipment, the installing plumber

or gas fitter shall observe that a hard wired carbon

monoxide detector with an alarm is installed on each

additional level of the dwelling, building or structure

served by the side wall horizontally vented gas fueled

equipment. It shall be the responsibility of the property

owner to secure the services of qualified licensed

professionals for the installation of hard wired carbon

monoxide detectors.

In the event that the side wall horizontally vented gas

fueled equipment is installed in a crawl space or an

attic, the hard wired carbon monoxide detector with

alarm and battery back-up may be installed on the next

adjacent floor level.

In the event that the requirements of this subdivision

can not be met at the time of completion of installation,

the owner shall have a period of thirty (30) days

to comply with the above requirements; provided,

however, that during said thirty (30) day period, a

battery operated carbon monoxide detector with an

alarm shall be installed.

Approved Carbon Monoxide Detectors

Each carbon monoxide detector as required in

accordance with the above provisions shall comply with

NFPA 720 and ANSI/UL 2034 listed and IAS certified.

Signage

A metal or plastic identification plate shall be

permanently mounted to the exterior of the building at

a minimum height of eight (8) feet above grade directly

in line with the exhaust vent terminal for the horizontally

vented gas fueled heating appliance or equipment. The

sign shall read, in print size no less than one-half (1/2)

inch in size, “GAS VENT DIRECTLY BELOW, KEEP

CLEAR OF ALL OBSTRUCTIONS”.

4

Inspection

The state or local gas inspector of the side wall

horizontally vented gas fueled equipment shall not

approve the installation unless, upon inspection, the

inspector observes carbon monoxide detectors and

signage installed in accordance with the provisions of

248 CMR 5.08(2)(a)1 through 4.

Exemptions

The following equipment is exempt from 248 CMR

5.08(2)(a)1 through 4:

• The equipment listed in Chapter 10 entitled

“Equipment Not Required To Be Vented” in the most

current edition of NFPA 54 as adopted by the Board;

and

• Product Approved side wall horizontally vented gas

fueled equipment installed in a room or structure

separate from the dwelling, building or structure

used in whole or in part for residential purposes.

MANUFACTURER REQUIREMENTS

Gas Equipment Venting System Provided

When the manufacturer of Product Approved side

wall horizontally vented gas equipment provides a

venting system design or venting system components

with the equipment, the instructions provided by the

manufacturer for installation of the equipment and the

venting system shall include:

• Detailed instructions for the installation of the venting

system design or the venting system components;

and

• A complete parts list for the venting system design or

venting system.

Gas Equipment Venting System NOT Provided

When the manufacturer of a Product Approved side

wall horizontally vented gas fueled equipment does

not provide the parts for venting the flue gases, but

identifies “special venting systems”, the following

requirements shall be satisfied by the manufacturer:

• The referenced “special venting system” instructions

shall be included with the appliance or equipment

installation instructions; and

• The “special venting systems” shall be Product

Approved by the Board, and the instructions for

that system shall include a parts list and detailed

installation instructions.

A copy of all installation instructions for all Product

Approved side wall horizontally vented gas fueled

equipment, all venting instructions, all parts lists

for venting instructions, and/or all venting design

instructions shall remain with the appliance or

equipment at the completion of the installation.

76657

S - Rough Opening Width

Rough

Opening

Height

Rough

Opening

Depth

A

C

L

4" (102 mm) Dia.

7" (178 mm) Dia.

1/2" (13 mm)

Q

Q

P

T

I

J

R

B

K

L

M

N

C

H

E

F

G

K

L

M

N

O

D

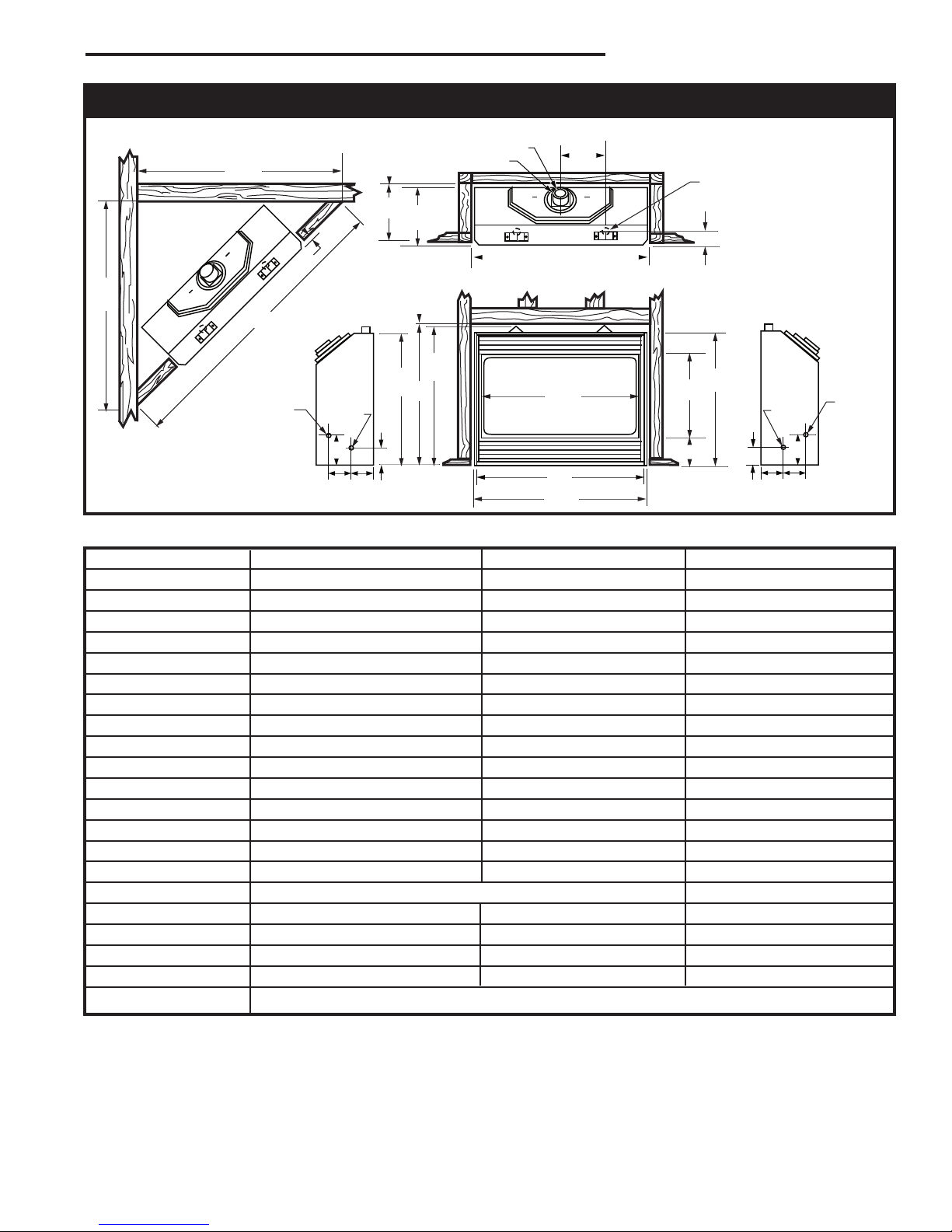

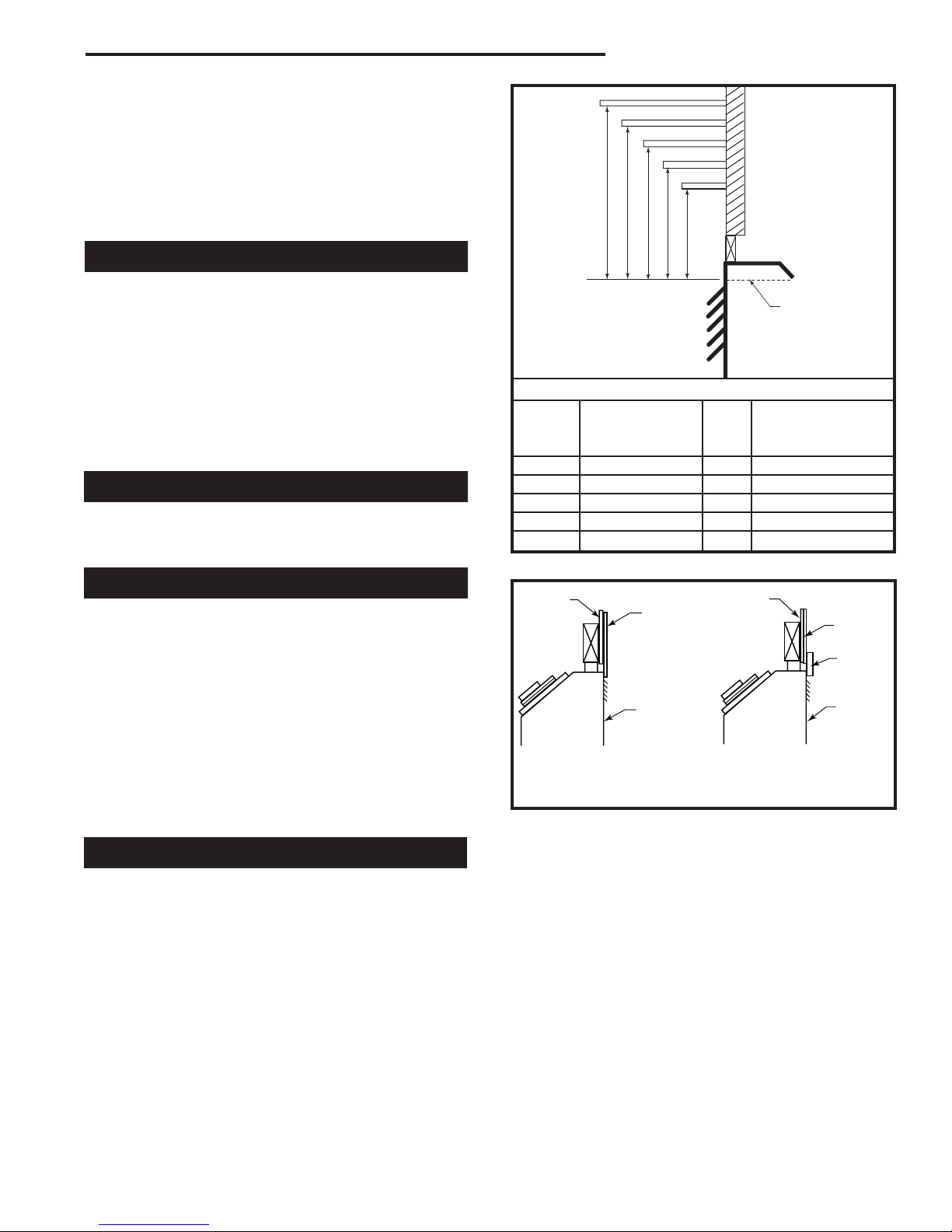

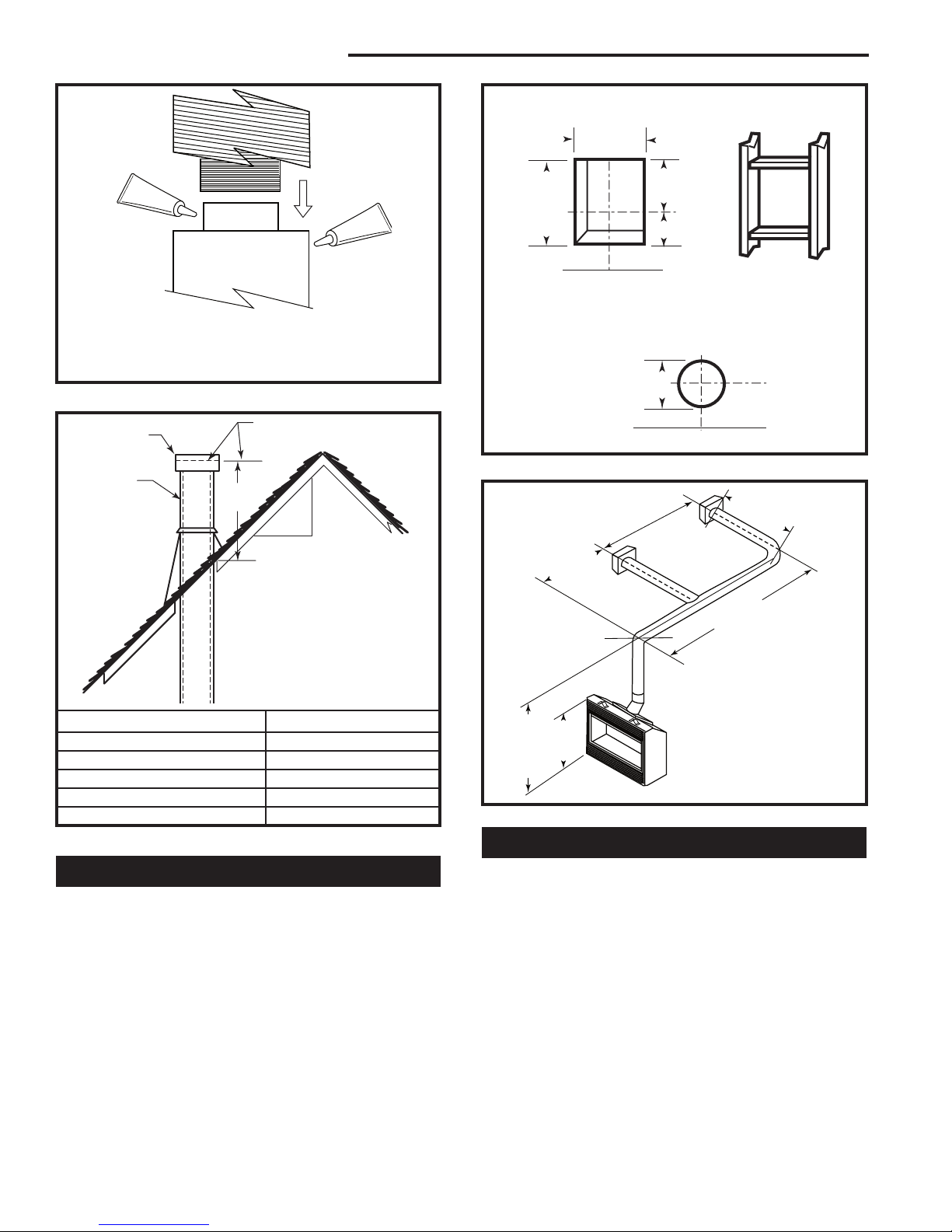

Fireplace Dimensions

Temco DV1000/1200/1400 Series

Bottom Gas Line Access

Gas Line

Access

NOTE: Flex pipe dimaeters are

4” for inner pipe and 7” for outer

pipe.

Fig. 1 Fireplace specifications and framing dimensions.

J Box

Access

J Box

Access

Gas

Line

Access

Ref. DV1000 DV1200 DV1400

A 34

B 28

C 31

D 29

E 16

F 5

G 27

H 32

I 13

J 13

K 1

L 5

M 3

N 3

O 3” (76mm) 3” (76mm) 3” (76mm)

P 63

Q 44

R 30

S 34

T Refer to Figure 3 or 4 for Rough Opening Depth

¹⁄₄” (870mm) 35¹³⁄₁₆” (190mm) 41³⁄₄” (1061mm)

³⁄₈” (721mm) 33” (838mm) 33” (838mm0

¹⁄₈” (791mm) 32⁹⁄₁₆” (827mm) 38³⁄₄” (984mm)

⁷⁄₈” (759mm) 34¹⁄₂” (876mm) 34¹⁄₂” (876mm)

³⁄₄” (426mm) 21³⁄₈” (543mm) 21³⁄₈” (543mm0

³⁄₄” (146mm) 6¹⁄₄” (159mm) 6¹⁄₄” (159mm)

¹⁄₂” (699mm) 32” (813mm) 32” (813mm)

³⁄₄” (832mm) 34¹⁄₄” (870mm) 40¹⁄₄” (1022mm)

¹⁄₈” (333mm) 14¹⁄₄” (362mm) 14¹⁄₄” (362mm)

³⁄₈” (340mm) 13³⁄₈” (340mm) 13³⁄₈” (340mm)

⁵⁄₈” (41mm) 1⁵⁄₈” (41mm) 1⁵⁄₈” (41mm)

¹⁄₈” (130mm) 5⁵⁄₈” (143mm) 5⁵⁄₈” (143mm)

³⁄₄” (95mm) 4¹⁄₂” (114mm) 4¹⁄₂” (114mm)

³⁄₄” (95mm) 4¹⁄₂” (114mm) 4¹⁄₂” (114mm)

Framing Dimensions

⁵⁄₃₂” (1604mm) 64²⁹⁄₃₂” (1633mm) 71³⁄₁₆” (1808mm)

¹¹⁄₁₆” (1135mm) 45⁷⁄₈” (1165mm) 50⁵⁄₁₆” (1295mm)

¹⁄₈” (765mm) 34³⁄₄” (883mm) 34³⁄₄” (883mm)

¹⁄₂” (876mm) 36” (914mm) 42” (1067mm)

76657

5

Temco DV1000/1200/1400 Series

X

A

B

C

10³⁄₄"

(273mm)

Min.

D

Y

E

A

B

C

D

F

Y

B

X

X

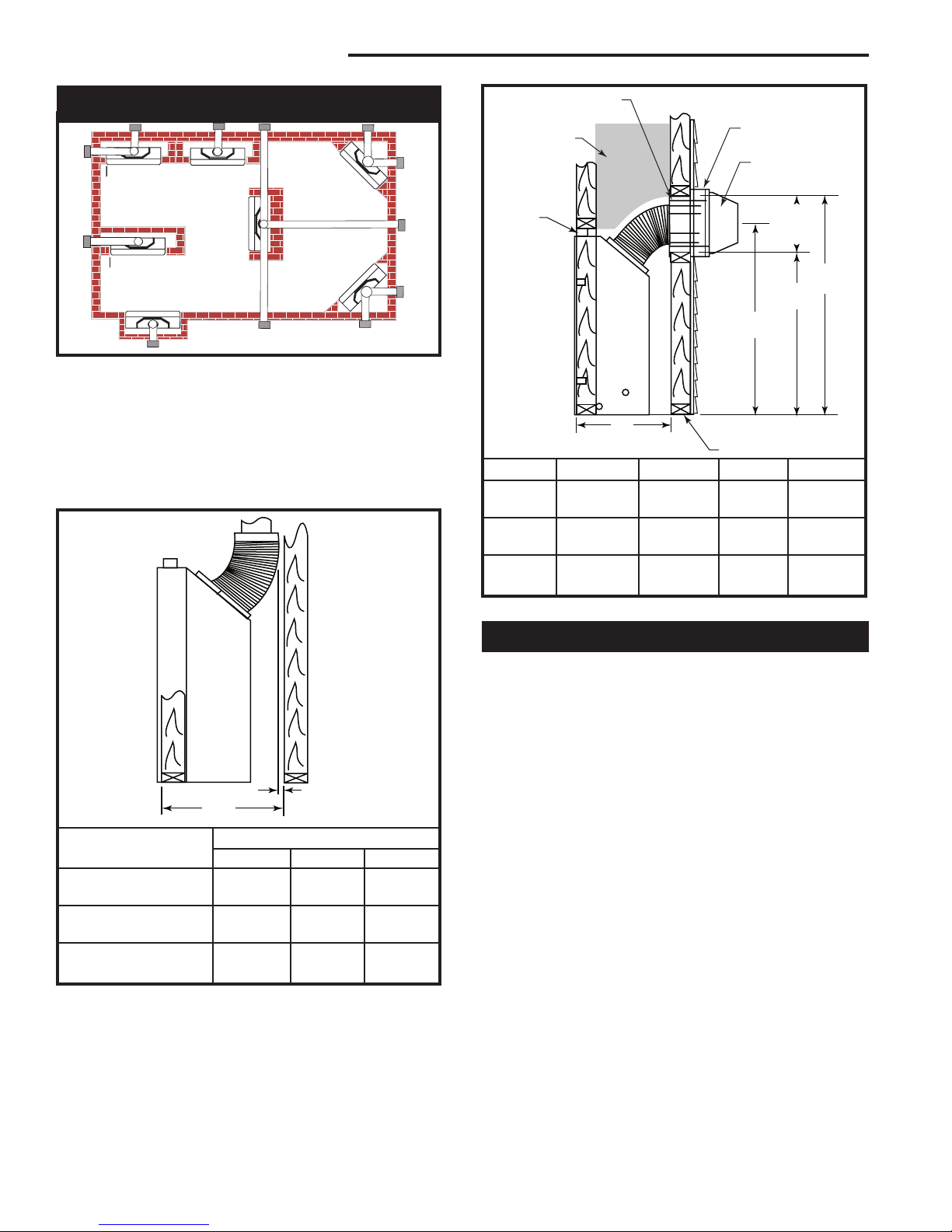

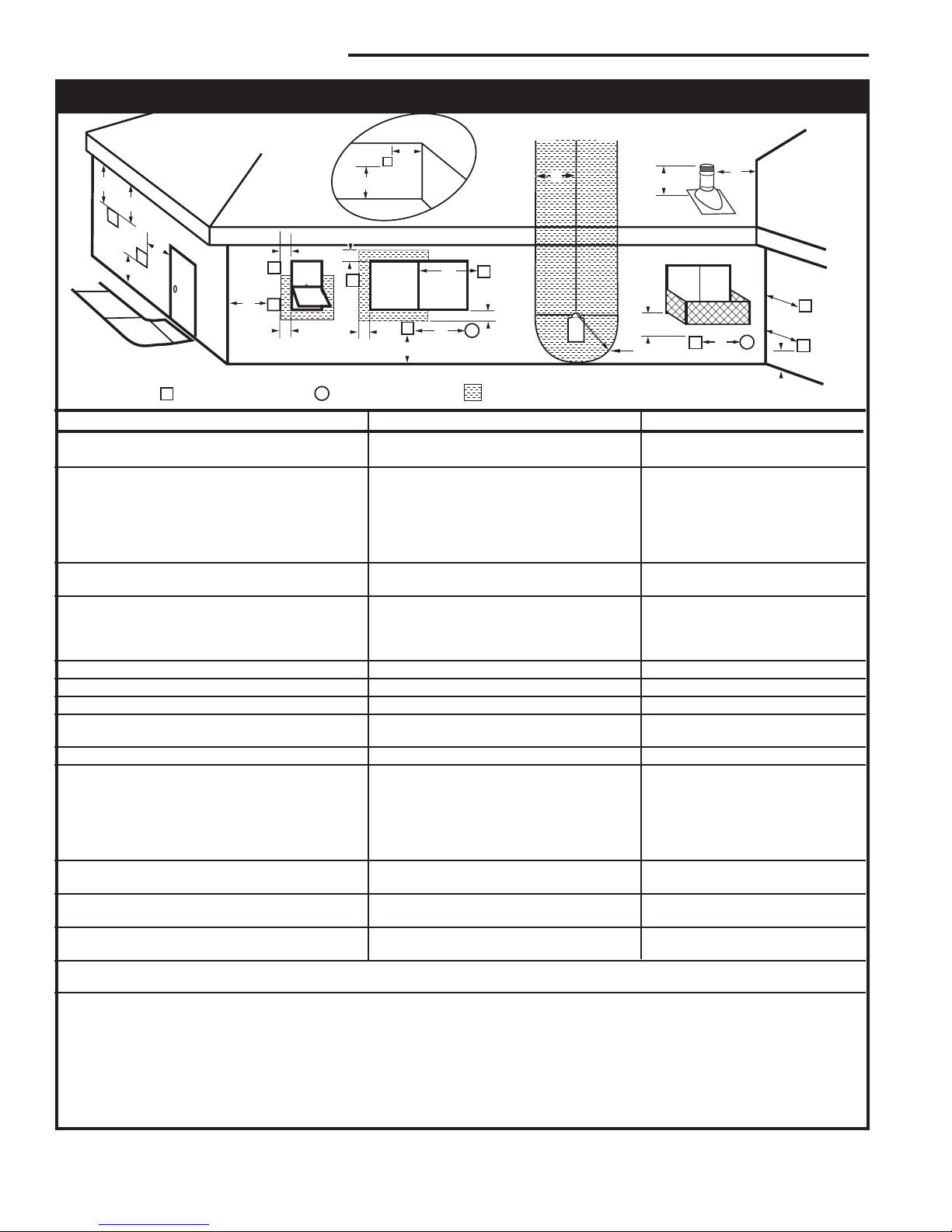

Locating Your Fireplace

LU584-1

Fig. 2 Locate gas fireplace.

A) Flat on wall B) Cross Corner C) As an Island

D) As a room divider E) Flat on wall corner F) Exterior wall

Island installation is possible as long as the horizontal portion of the

vent system does not exceed maximum recommended horizontal run

as outlined in the venting chart on Page 10. When you install your

fireplace as in position ‘B’, ‘D’ or ‘E’, (Fig. 2) a minimum of 1” (25mm)

clearance must be maintained from the perpendicular wall and the

front of the appliance.

Firestop/Wall Sleeve

VEF (Vinyl Siding)

Combustible

Construction

Allowed

Standoff

T176

or BEF (Brick)

Extension flange

Vent Terminal

2 x 4 or 2 x 6 Framing

Model A B C D

DV1000 15³⁄₈” Min. 30¹⁄₈” 25³⁄₈” 36¹⁄₈”

(391mm) (765mm) (645mm) (918mm)

DV1200 16¹⁄₂” Min. 34³⁄₄” 30” 40³⁄₄”

(419mm) (883mm) (762mm) (1035mm)

DV1400 16¹⁄₂” Min. 40³⁄₄” 36” 46³⁄₄”

(419mm) (1035mm) (914mm) (1188mm)

Fig. 4 Minimum framing dimensions with horizontal venting.

1” (25 mm)

Minimum Air Space

T175

Clearance to Combustible Materials

Vent “X”

System Used DV1000 DV1200 DV1400

TEMCO 4/7 Flex 17¹⁄₂” 18¹⁄₂” 19¹⁄₂”

(445 mm) (470 mm) (495 mm)

TEMCO 4/7 Rigid 18¹⁄₂” 19¹⁄₂” 19¹⁄₂”

(470 mm) (495 mm) (495 mm)

Duravent 4/6-5/8 GS 17¹⁄₂” 18¹⁄₂” 18¹⁄₂”

(445 mm) (470 mm) (470 mm)

Fig. 3 Minimum framing depths with vertical takeoff.

6

Framing and Finishing

1. Choose a fireplace location and frame in accordance

with the fireplace dimensions specified on Page 3 of

this manual. When using a surround, the fireplace

must be flush to the wall. Also, allowances must

be made for drywall, tile or any other facing used

around the unit.

2. When the appliance is installed directly on carpeting,

tile or other combustible material other than wood

flooring, the appliance shall be installed on a metal

or wood platform.

3. Pull out the nail tabs which are located on each side

of the fireplace. Move the fireplace into position and

secure to the floor with screws or nails through the

holes provided in the bottom flanges of the side cas

ing. After checking unit for squareness, secure top of

fireplace to the framing with screws or nails using the

nailing tabs provided.

4. Cold climate installation recommendation: when

installing this fireplace against a non-insulated exterior wall or chase, it is recommended that the outer

walls be insulated to conform to applicable insulation

codes. Drywall should be installed around the unit to

prevent insulation from contacting the body.

Note: Never let vapor barrier contact the outer

case of this fireplace or venting.

-

76657

5. Drywall can be extended flush on the bottom, top

A B C D E

V

W

X

Y

Z

Fireplace

and to the outermost part of the sides of the fireplace.

6. Noncombustible materials such as brick and tile

can be extended across the face of the fireplace. If

brass trim kit is going to be installed, brick and tile

will have to be installed flush with the front of this

appliance.

Clearance to Combustibles

Top of unit to ceiling* ................................36” (914 mm)

Front of unit to combustibles ....................36” (914 mm)

Appliance

Top (from standoffs) .................................0” (0mm)

Bottom ......................................................0” (0mm)

Side (from standoffs) .................................0” (0mm)

Back (from standoffs) ................................0” (0mm)

Top of Elbow ...........................................2” (51mm)

* Ceiling height is the minimum height of the room ceiling in front of

the fireplace measured from the top front edge of the fireplace.

Combustible Sidewall Clearance

The perpendicular combustible sidewall or mantel support leg (surround) clearance is 1³⁄₄” (45mm) from the

edge of the recessed door opening.

Mantels

The height that a combustible mantel is fitted above the

fireplace is dependent on the depth of the mantel.

For the correct mounting height and widths, refer to

Figure 5.

Noncombustible mantels and legs may be installed at

any height and width around the appliance. When using

paint or lacquer, it must be heat resistant to prevent

discoloration.

WARNING: Combustible objects must not be placed

on a noncombustible mantel unless the noncombustible

mantel meets the minimum height and width requirements for a combustible mantel.

Temco DV1000/1200/1400 Series

Top of Louvre

Opening

T177

Mantel Chart

Mantel Shelf Mantel from Top

Ref. or Breast Plate Ref. of Louvre Opening

Depth

V 10” (254 mm) A 14” (356 mm)

W 8” (203 mm) B 12” (305 mm)

X 6” (152 mm) C 10” (254 mm)

Y 4” (101 mm) D 8” (203 mm)

Z 2” (51 mm) E 6” (152 mm)

Fig. 5 combustible mantel minimum installation.

Drywall

Tile, Marble, etc.

Fireplace

Front

Noncombustible Facing

Material Overlap of Front Face

Fig. 6 Surround material options.

Drywall

Flush Face Installation

(Recommended when

installing optional trim

surround kits)

Tile,

Marble,

etc.

Optional

Surround

Kits

Fireplace

Front

T178

Surround Material

When using materials around the face of the fireplace,

these materials must be suitable to withstand the temperatures which they will encounter. Also these materials must not extend out in front of the face of the unit, in

effect recessing the unit.

If the material used for surround is not flush with the

face of the unit, then the optional surround kits will not

fit properly.

It is recommended that any material used to surround

the face of the fireplace be noncombustible (i.e. ceramic tile, brick, natural stone, etc.). Combustible materials

such as drywall, are permissible.

76657

Materials such as cultured marble or other synthetic

materials are not recommended as they may discolor,

warp or create odor as a result of exposure to the temperatures of the front of the fireplace.

7

Temco DV1000/1200/1400 Series

Combustible Material

2 x 4 Stud

Minimum Height from

Top Opening to Mantel

Combustible Material

Above Standoff

Optional Hearth

Fig. 7 Gas fireplace installation.

2 x 4 Header

Standoff

T179

Gas Specifications

Max. Min.

Gas Input Input

Model Fuel Control BTU/h BTU/h

DV1000N Natural Hi/Lo 18,500 12,500

DV1000P Propane Hi/Lo 18,500 12,500

DV1200N Natural Hi/Lo 20,000 13,000

DV1200P Propane Hi/Lo 20,000 13,000

DV1400N Natural Hi/Lo 22,000 15,000

DV1400P Propane Hi/Lo 22,000 15,000

Gas Inlet and Manifold Pressures

Natural LP (Propane)

Minimum Inlet Pressure 4.5” w.c. 10.8” w.c.

Maximum Inlet Pressure 14.0” w.c. 14.0” w.c.

Manifold Pressure 3.5” w.c. 10.0” w.c.

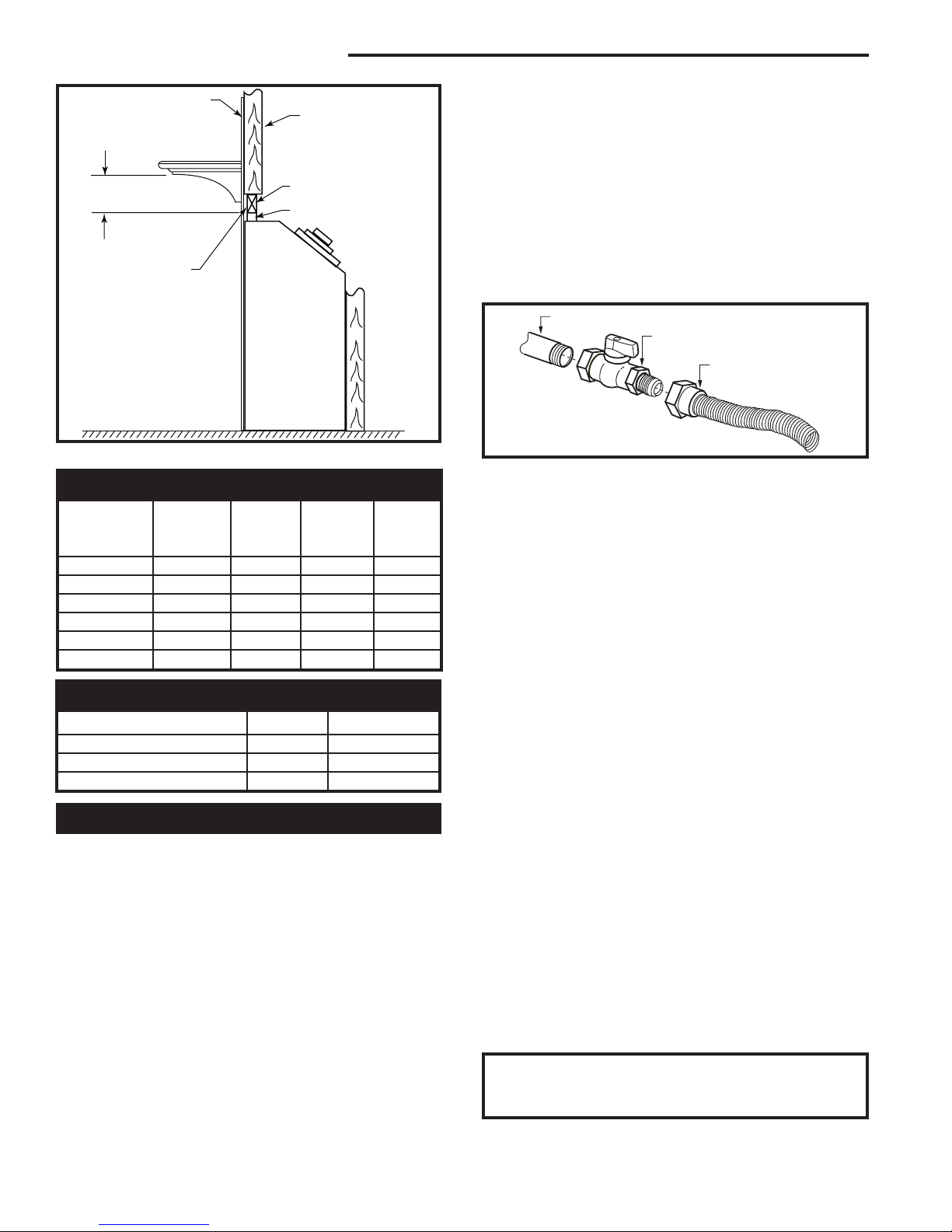

Gas Line Installation

This gas appliance should be installed by a qualified installer in accordance with local building codes and with

current CSA-B149.1 installation codes for Gas Burning

Appliances and Equipment in Canada and the National

Fuel Gas Code ANSI Z223.1/NFPA 54 in the U.S.A.*

1. The gas pipeline can be brought in through the bot

tom or the right or the left side of the appliance. A

hole is provided at all locations to allow for the gas

pipe installation and testing of any gas connection.

2. The gas control inlet is 3/8” NPT. Typical installation

layout for rigid pipe is shown on Page 8.

NOTE: All models are equipped with a flex tube

with a shut off valve having a 1/2” NPT inlet. The

flex line with shut off is shipped in the control valve compartment. Using two wrenches,

-

tighten the flexible tube at the shut off valve and

at the gas control.

3. When using a flex connector,* use only approved

fittings. When a union is installed, provide easy

access in it’s placement for servicing. Refer to gas

specification for pressure details and ratings.

4. When a vertical section of gas pipe is required for

the installation, a condensation trap is needed. In

Canada see CSA - B149.1 for code details. See the

National Fuel Gas Code ANSI Z223.1/NFPA 54 in

the USA.

1/2” Gas Supply

1/2” NPT x 1/2” Flare Shut-off Valve

1/2” Flex Line

(from valve)

FP297a

Fig. 8 Typical gas supply installation.

5. For natural gas, a minimum of 3/8” iron pipe with

a gas supply pressure of 4.5” w.c. (from the gas

meter). Consult with local gas utility and ANSI223.1/

NFPA 54 if any questions arise concerning pipe

sizes.

6. Turn the gas supply to ‘ON’ and check for leaks. DO

NOT USE OPEN FLAME FOR THIS PURPOSE.

Use an approved leak testing solution.

7. The appliance and its appliance main gas valve

must be disconnected from the gas supply piping

system during any pressure testing of that system at

test pressures in excess of 1/2psig (3.5 KPa).

8. The appliance must be isolated from the gas supply piping system by closing its equipment shut off

valve during any pressure testing of the gas supply

piping system at test pressures equal to or less than

1/2psig (3.5KPa).

NOTE: The gas line connection may be made of 3/8”

minimum rigid pipe, 3/8” minimum copper pipe or an approved flex connector. Since some municipalities have

additional local codes, it is always best to consult your

local authorities and the current CSA-B149.1 installation code in Canada or National Fuel Gas Code ANSI

Z223.1/NFPA 54 in the U.S.A.

*Adhere to the following installation requirements in the State of Massachusetts:

• The installer must be a licensed plumber or gas fitter.

• Flex connectors must be Massachusetts approved, cannot

exceed 36” (914 mm) in length, must be a minimum 1/2” dia., and

may not penetrate a wall.

IMPORTANT: Always check for gas leaks with a

soap and water solution. Do not use open flame

for leak testing.

8

76657

General Venting

Temco DV1000/1200/1400 Series

When locating the vent termination, the minimum vent

clearances must be observed. (Page 10, Fig. 9)

NOTE: Local codes may require different clearances.

It is recommended that the termination not be located

within 24” (305mm) of garden sheds, fences, decks,

utility buildings or other obstructions.

Do not locate termination cap where excessive snow or

ice build up may occur. Be sure to check vent termination area after snow falls and clear to prevent accidental

blockage of venting system. When using snow blowers,

make sure snow is not directed towards vent termination area.

This appliance has a “special vent system”. Check

with local codes or in the absence of same, with CSA

B149.1 installation codes in Canada, or the current

National Fuel Gas Code ANSI Z223.1/NFPA 54 in the

USA, regarding special vent termination clearances.

These fireplaces are certified for use with four types of

venting systems

1. Temco 4” x 7” dia. flex vent.

2. Temco TDV series 4” x 7” dia. rigid vent.

3. Simpson Dura-Vent GS series 4” x 6⁵⁄₈” dia. vent.

4. Security Secure Vent series 4” x 6⁵⁄₈” dia. vent.

Review general venting information in this manual, and

information packed with the venting prior to starting the

installation of the fireplace.

• Termination shall not be recessed into a wall or siding.

• Horizontal sections must maintain a minimum 1/4”

rise per linear foot of horizontal run.

• Combustible clearances from any horizontal vent

pipe area must be 2” (51 mm) from top of vent, and

1” (25 mm) from sides and bottom.

• Clearance to combustibles from vertical pipe surface

is 1” (25 mm).

76657

9

Temco DV1000/1200/1400 Series

V

V

V

V

V

V

V

X

X

X

D

E

B

B

B

C

B

M

B

A

J

K

F

L

VENT TERMINATION AIR SUPPLY INLET

AREA WHERE TERMINAL IS NOT PERMITTED

H

I

Fixed

Closed

Fixed

Closed

Operabl

e

Operable

Fixed

Closed

V

B

INSIDE

CORNER DETAIL

V

A

G

V

N

N

V

V

G

G

A

General Venting Information - Termination Location

Canadian Installations1 US Installations

A = Clearance above grade, veranda, porch, 12” (30 cm) 12” (30 cm)

deck, or balcony

B = Clearance to window or door that may be 6” (15 cm) for appliances 6” (15 cm) for appliances

opened < 10,000Btuh (3kW), 12” (30 cm) < 10,000 Btuh (3kW), 9”

for appliances > 10,000 Btuh (3kW) and (23 cm) for appliances > 10,000

< 100,000 Btuh (30kW), 36” (91 cm) Btuh (3kW) and < 50,000 Btuh

for appliances > 100,000 Btuh (30kW) (15kW), 12” (30 cm) for

appliances > 50,000 Btuh (15kW)

C = Clearance to permanently closed window 12” (305 mm) recommended to 12” (305 mm) recommended to

prevent window condensation prevent window condensation

D = Vertical clearance to ventilated soffit located

above the terminal within a horizontal 18” (458 mm) 18” (458 mm)

distance of 2 feet (610mm) from the center

line of the terminal

E = Clearance to unventilated soffit 12” (305 mm) 12” (305 mm)

F = Clearance to outside corner see next page see next page

G = Clearance to inside corner (see next page) see next page see next page

H = Clearance to each inside of center line 3’ (91 cm) within a height of 15’ 3’ (91 cm) within a height of 15’

extended above meter/regulator assembly above the meter/regulator assembly above the meter/regulator assy

I = Clearance to service regulator vent outlet 3’ (91 cm) 3’ (91 cm)

J = Clearance to nonmechanical air supply inlet 6” (15 cm) for appliances < 10,000 6” (15 cm) for appliances

to building or the combustion air inlet to any Btuh (3kW), 12” (30 cm) for < 10,000 Btuh (3kW), 9”

other appliances appliances > 10,000 Btuh (3kW) and < (23 cm) for appliances > 10,000

100,000 Btuh (30kW), 36” (91 cm) Btuh (3kW) and < 50,000 Btuh

for appliances > 100,000 Btuh (30kW) (15kW), 12” (30 cm) for

appliances > 50,000 Btuh (15kW)

K = Clearance to a mechanical air supply inlet 6’ (1.83 m) 3’ (91 cm) above if within 10’

(3 m) horizontally

L = Clearance above paved sidewalk or paved 7’ (2.13 m)† 7’ (2.13 m)†

driveway located on public property

M = Clearance under veranda, porch, deck or 12” (30 cm)‡ 12” (30 cm)‡

balcony

N = Clearance above a roof shall extend a minimum of 24” (610 mm) above the highest point when it passes through the roof

surface, and any other obstruction within a horizontal distance of 18” (450 mm).

1 In accordance with the current CSA-B149 Installation Codes

2 In accordance with the current ANSI Z223.1/NFPA 54 National Fuel Gas Codes

† A vent shall not terminate directly above a sidewalk or paved driveway which is located between two single family dwellings and serves both dwell ings

‡ only permitted if veranda, porch, deck or balcony is fully open on a minimum 2 sides beneath the floor:

NOTE: 1. Local codes or regulations may require different clearances.

2. The special venting system used on Direct Vent Fireplaces are certified as part of the appliance, with clearances tested and approved by the

listing agency.

3. CFM Corporation assumes no responsibility for the improper performance of the appliance when the venting system does not

meet these requirements.

Fig. 9 Vent termination clearances.

10

2

76657

2" (51mm)

1" (25mm)

1"

(25mm)

0

5'

46"

(1168mm)

33¹⁄₂"

(851mm)

10'

15'

25'

30'

32'

0 3

'

5' 10'

15'

Outside Corner

Inside Corner

Termination Clearances

Termination clearances for buildings with combustible and noncombustible exteriors.

G =

Combustible

6" (152 mm)

Noncombustible

2" (51 mm)

F =

Combustible

6" (152 mm)

Noncombustible

2" (51 mm)

G

Balcony with no side wall

M =

Combustible &

Noncombustible

12" (305 mm)

M

Balcony with perpendicular side wall

M = 24" (610 mm)

P = 20” (508 mm)

M

F

Alcove Applications*

C

D

C

E

V

V

Combustible &

Noncombustible

V

V

V

E = Min. 6” (152 mm) for

non-vinyl sidewalls

Min. 12” (305 mm) for

vinyl sidewalls

O = 8’ (2.4 m) Min.

O

P

*NOTE: Termination in an alcove space (spaces open only on one side and with an overhang) is permitted with the dimensions

specified for vinyl or non-vinyl siding and soffits. 1. There must be a 3’ (914 mm) minimum between termination caps. 2. All

mechanical air intakes within 10’ (1 m) of a termination cap must be a minimum of 3’ (914 mm) below the termination cap. 3. All

gravity air intakes within 3’ (914 mm) of a termination cap must be a minimum of 1’ (305 mm) below the termination cap.

Fig. 10 Termination clearances.

NOTE: Use only venting systems and components

as certified with the appliance. Use of uncertified vent

systems or components will void the warranty and may

compromise the operation of the fireplace, its systems,

and components as certified with the appliance.

Top of Vent

Combustibles

NOT Allowed in

Shaded Area

4” Dia. Flue

Temco DV1000/1200/1400 Series

No.

of Caps D

1 3’ (914 mm) 2 x D

2 6’ (1.8 m) 1 x D

3 9’ (2.7 m) 2/3 x D

4 12’ (3.7 m) 1/2 x D

D

= # of Termination caps x 3

Min.

C

= (2 / # termination caps) x D

Max.

C

Min.

Max.

Actual

Actual

Actual

Actual

Actual

584-15

Fig. 11 Vent clearances.

76657

7” Dia. Intake

Vent

T181

* Min. Refer to Chart on Page 6

Fig. 12 Venting graph.

A vent guard should be

used whenever the termination is lower than the speci-

*

fied minimum or as per local

codes

T180

11

Temco DV1000/1200/1400 Series

MILL-PAC

MILL-PAC

H

12

x

33"

(838mm)

Minimu

m

53" (1346mm)

Maximum

28' (8.5m)

2' (610mm)

Minimum

B

12" (305mm)

Minimum

A

10' (3m)

Minimum

If length "B" is increased,

length "A" must be decrease

d

by a corresponding amount

10³⁄₄”

(273 mm)

Vent Opening for Combustible Wall

9³⁄₄”

(248 mm)

5⁷⁄₈”

(149 mm)

4⁷⁄₈”

(124 mm)

NOTE: Apply sealant “Mill-Pac” to inner pipe and “Mill-Pac” or high

temperature silicone sealant to outer pipe. Sealant should be applied at every joint in the vent system including at the fireplace and

at the vent terminal.

T182

Fig. 13 Apply sealant at every joint in vent system.

Vent Cap

Gas Vent

Lowest Discharge Opening

Roof Pitch X/12

H (Min.) - Minimum height

from roof to lowest discharge

opening

T183

Roof Pitch H (Min.)

Flat to 6/12 12” (305 mm)

6/12 to 7/12 15” (381 mm)

Over 7/12 to 8/12 18” (457 mm)

Over 8/12 to 16/12 24” (610 mm)

Over 16/12 to 21/12 36” (914 mm)

Fig. 14 Vertical termination location.

Fireplace Hearth

Opening for Noncombustible Wall

8” Dia.

(203 mm)

Min.

Fireplace Hearth

Fig. 15 Locate vent opening on wall.

A vent guard should be used

whenever the termination is

lower than the specified minimum or as per local codes.

Fig. 16 Horizontal vent run.

Flex Venting

Framing Detail

Rnd.

VO584-100

T184

Sidewall (General) Venting Information

Figures 15 and 16 show examples of horizontal termination arrangements using two 90° elbows (Rigid Vent).

NOTE:

1. A maximum of two 90° elbows are permitted.

2. A minimum of 10’ (3 m) vertical from base of unit is

required if two 90° elbows are used.

3. Minimum distance between elbows is 2’ (610 mm).

4. Determine the permitted range of horizontal termination arrangement by using chart above and

deducting 3’ (914 mm) from the maximum horizontal

distance for the second 90° elbow.

12

• Flex vent shall use the spacer springs as included

every foot to ensure proper vent operation.

• The 4” x 7” flex system may be used for all sidewall

applications and vertical venting up to 35’ (10.7 m).

• Flex shall be properly supported so there are no

sags in the system. Supports must be used at least

every 24” (610 mm) on horizontal section and every

36” (914 mm) on vertical. Wire or metal stripping

may be used to support the venting.

• For 4” x 7” flex, the 7” flex has an outside diameter

of 7¹⁄₂” (191 mm) and if installed in a chase the inside diameter of the chase should be 9¹⁄₂” (241 mm)

minimum.

76657

Temco DV1000/1200/1400 Series

A

B

• Lengths of co-axial flex may be joined together using

a flex connector kit (GFPVCK) only, maximum 1 kit

per installation.

An extension collar is included with side wall cap kits to

simplify the connection of the flex pipe to the fireplace.

Refer to Page 14, Figure 22.

ATTENTION: Spacer springs must be installed when

installing flexible venting systems.

Wrap spacer spring around flex flue pipe and overlap

spring ends approximately 2” (610 mm). Tie one end

over the other like a shoelace tie, then reverse direction of spring ends. Lift up hooped spring and slide both

spring ends underneath hooped spring. Spring spacers

should be spaced at approximately 12” (305 mm) intervals for the length of pipe system. Once the springs are

placed around the flue pipe, slide the flue section with

spacer springs into the outer flex pipe.

Spacer

Springs

◆ HFTK (Trapezoid Termination Cap)

The vent starter kit contains the following:

• Horizontal termination

• Wall thimble

• Extension collar

NOTE: HIGH WIND AREAS All termination caps are

tested and certified for wind conditions up to 40 mph

(64 k/h).

A Vinyl Extension Frame Kit No. VEF is required for all

installations where vinyl siding is used with the HFTK

Kit or HSQ47 Horizontal Vent Termination. If a Vinyl

Extension Frame Kit No. VEF is used, measure to outside surface of wall without siding and add 2 additional

inches (51 mm) to the venting length.

A brick extension kit No. BEF is available to extend the

horizontal vent terminal HSQ47 or HFTK kit terminal

beyond the brick surface. If the BEF extension is used,

measure to the outside surface of the framed wall and

add 4 additional inches to the venting length.

Firestop/Wall Sleeve

(included with HFTK)

GFP74FV3

(3’ (914 mm) Flex

Pipe 4” x 7” Dia.)

Exterior Wall

VEF (or BEF) Vinyl

(or Brick) Extension

Flange

HFTK Vent

Termination Kit

Flex Outer Vent

T185

Fig. 17 Wrap spacer spring around flex flue pipe, overlapping

ends.

Flex Flue

CAUTION: Care must be taken when tightening clamps so the flex does not tear at

clamp location.

Sidewall (Horizontal) Venting

For side wall (Horizontal) venting, this appliance is approved for use with a 7” x 4” flexible venting system with

spacers.

Clearance to combustible material from the pipe is 1”

(25 mm). Sides and bottom, 2” clearance from the top.

NOTE: O.D. of pipe is 7¹⁄₂” (191 mm).

Horizontal Vent Kits

◆ CDV-HSK (Round Termination Cap)

The vent starter kit contains the following:

• Horizontal termination

• Wall thimble

• 36” of 7” x 4” flex with spacers and clamps.

• Extension collar

Vent Clamp

(Included

with HFTK)

T176a

NOTE: Typical terminal height “B” is 48” for model DV1000,

60” for models DV1200 and DV1400 with dimension “A” up

to 36”. Please refer to minimum framing dimensions with

horizontal venting chart on Page 5.

Fig. 18 Typical direct vent gas fireplace with horizontal venting.

Flex Vent Offsets

Each installation assumes the use of (1) 45° (bend)

starting off top of unit.

To determine the amount or length of flex vent you need

for a given installation, add the total offset dimension to

the total rise needed. Then add 1 ft. (305 mm) for every

45° bend and/or 2’ (610 mm) for each 90° bend.

76657

13

Temco DV1000/1200/1400 Series

9¹⁄₂

" (241mm)

10¹⁄₂"

(267mm)

2" (51mm)

1" (25mm)

No more than (4) 90° and (2) 45° offsets are to be used

per installation. Vent terminal cap location should be in

accordance with the Venting Graph chart and the Vertical Termination Location information.

1. Measure the total wall thickness. Determine whether

or not the thimble extension is needed. If the combustible wall depth is over 5” (127 mm), the extension should be used. (Fig. 19)

2. Assemble wall thimble with thimble extension flange

to top. Mate thimble to wall plate with the four tabs

provided. Bend tabs over to secure. (Fig. 19)

Telescope Extension

Fig. 20 Install wall thimble with firestop on interior wall.

Inside

Wall

Wall

shield

Exterior Wall

Flange at

Top

Terminal

Cap

Assembly

T187

T186

Fig. 19 The telescope extension must be used if wall thickness is over 5” (127 mm).

3. Install the wall thimble assembly through the framed

opening so the firestop plate is on the interior wall.

(Fig. 20) Telescope section should extend all the way

through wall.

4. Step 1: Apply Mill-Pac to 4” flue inner pipe on cap.

Step 2: Connect 4” flex flue to flue on cap with

band clamp.

Step 3: Apply silicone sealant to 7” outer pipe on

cap.

Step 4: Slide 7” outer flex over inlet and secure with

band clamp.

5. Secure vent cap terminal to exterior wall with screw

type fasteners as needed. (Fig. 21)

6. Connect corrugated side of the extension collar (7”

dia.) into the 7” dia. flex pipe. (Fig. 22) Place a small

bead of silicone around the collar approximately 1/4”

from the leading edge of the corrugation. Insert the

collar firmly into the flex pipe and secure with the

provided (7” dia.) band clamp.

7. Place a small mill-pac bead around the top edge of

the fireplace flue collar. Then, attach the flex tube

over the flue collar with a 4” dia. band clamp.

Flex

Duct

Thimble Extension

Band Clamp

T188

Fig. 21 Secure vent cap terminal to exterior wall.

7” (178 mm)

Band Collar

4” (102 mm)

Band Clamp

and Flex Flue

7”

(178 mm)

Flex Vent

Extension Collar

T189

Fig. 22 Insert collar into flex pipe and secure with band clamp.

ATTENTION:

Spacer springs must be installed when install-

ing flexible venting system.

14

76657

8. To finish connections, place a small bead of silicone

6' (1.8m)

Maximum

35' (10.7m)

Maximum

to the outside of the fireplace inlet flange. Then, slide

the extension collar over the inlet flange and secure

with the three (3) screws provided.

NOTE: We recommend driving in two (2) sheet metal

screws at 180° adjacent to the gear clamp at each joint.

Flex Vent Through the Roof

(Vertical) Applications

All models are approved for:

1. Vertical venting up to 35’ (10.7 m) with 7” x 4” flex.

2. Multiple bends allowed. See section on General

Venting.

3. With each vertical installation, a VSK7MH-2 kit may

be used.

Room Above

Ceiling Joist

Ceiling Level

Temco DV1000/1200/1400 Series

Roof

Attic Insulation

Shield

Joists

7” (178 mm) Dia.

Firestop

Fig. 23 Firestop at ceiling level.

Attic Above Ceiling

(Uninsulated)

Attic Above Ceiling

(Insulated)

Fig. 24 Attic insulation shield.

Firestop

Attic Insulation

Shield

T190

T190

T191

Fig. 25 Typical through-the-roof installation.

The VSK7 Kit contains:

• Vertical Termination Cap and Storm Collar

• 4”/7” dia. x 24” Rigid Pipe (unitized)

• 7” dia. Roof Support Components

• 0/12-5/12 Flashing with Storm Collar

• Tube High Temp Sealant

• 7” dia. Inlet Ext. Collar

• Firestop

• Hardware Pack

• Instruction

VSK7 Vertical Flex Vent Kit Installation

1. Locate the fireplace.

2. Mark ceiling above unit where flex will come through.

*-REFER TO VERTICAL TERMINATION LOCATION

CHART

3. Ceiling opening should be a minimum of 9

(241 x 241 mm) and framed to that size.

4. Mark opening in roof and cut a hole minimum 9¹⁄₂” x

9¹⁄₂” (241 x 241 mm) and frame to that size.

5. Place fireplace in proper location and secure to the

floor.

6. Install the firestop at the ceiling level.

7. If an attic space (insulated or not) is located above

the ceiling, the firestop should be installed to the

underside of the ceiling. The firestop maintains the

proper air-space clearance from the vent to insula-

¹⁄₂” x 9¹⁄₂”

76657

15

Temco DV1000/1200/1400 Series

1" (25mm)

Minimum

tion and building materials. An attic insulation shield

(AS7-8) may be used above the firestop to keep attic

insulation spaced away from the vent system.

8. Rigid pipe section included with vertical termination

must be used in conjunction with the roof support so

that the termination is secure in winds. All vent kit

components can be assembled on the ground first,

then lift complete assembly onto the roof and feed

flex vent down thru the roof opening and firestop

thimble assembly. Then trim off unneeded flex at unit

and make the connection at the fireplace flue and inlet collars. Make sure vent cap will be in accordance

with the vertical termination location chart. Install the

roof flashing below the shingles across the top half,

and above the shingles on the lower half.

9. Install storm collar and caulk around the pipe.

TDV Series Direct Vent System Installation

• The TDV series vent system is specifically approved

only for Temco Direct-Vent fireplace models with a 4”

(102 mm) diameter flue and a 7” (178 mm) diameter

inlet vent system. The use of uncertified venting will

void warranties and may compromise the operation

and safety of the appliance.

• Termination shall not be recessed into a wall or sid

-

ing.

• The vent system shall be properly supported so

there are no sags in the system. Supports must be

used at least every 3’ (914mm) on horizontal section

and every 6’ (1.8m) on vertical.

• Horizontal sections must maintain a minimum 1/4”

rise per linear foot of horizontal run.

• Combustible clearances from any horizontal vent

pipe area must be 2” (51mm) from top of vent, and

1” (25mm) from sides and bottom.

• Clearance to combustibles from vertical pipe surface

is 1” (25mm).

• Prior to securing each vent component, make sure

the sections are pushed together firmly to maintain

vent integrity.

Sidewall (Horizontal) Venting, General

Vent Cap

8: (203 mm)

Dia. Pipe

Must Extend

Through Roof

Flashing

Roof Flashing

Roof

Exterior

VT47 Vertical

Vent Cap

4” (102 mm) Dia.

7” (178 mm) Dia.

Vent Pipe Assembly

(VSK7MH-S)

(VSK7)

Vent System Roof

Support / Clamp

Assembly

Band Clamp

4” (102 mm) Dia. Flex Flue

Band Clamp

7” (178 mm) Dia.

Flex Vent

Storm Collar

Roof Support

Assembly

7” (178 mm) Dia.

Flex Vent

When locating the vent termination, the minimum vent

clearances must be observed.

NOTE: Local codes may require different clearances.

It is recommended that the temination not be located

within 24” (610 mm) of garden sheds, fences, decks,

utility buildings or other obstructions.

Review the “vent termination” section in the appliance

installation instructions.

Do not locate vent terminal where excessive snow or

ice build up may occur. Be sure to check vent termination area after snow falls and clear to prevent accidental

16

Clearance to Combustibles

Fig. 26 Through the roof installation.

T192

NOTE: If offset is required, the upper 45° bend (elbow)

must be supported with an offset support. Support flex

every 3’ (914 mm) when vertical venting.

76657

Temco DV1000/1200/1400 Series

3³⁄₈" (86mm)

7⁷⁄₈"

(200mm)

8"

(203mm)

9¹⁄₈"

(232mm)

B

A

blockage of venting system. When using snow blowers,

make sure snow is not directed towards vent termination area.

The TDV series is considered a “special vent system”.

Check with local codes or in the absence of same, with

CSA B149.1 installation codes regarding special vent

termination clearances.

NOTICE: Flexible and rigid vent system components

are not interchangable unless otherwise specified in the

venting instructions.

NOTICE: Additional venting information regarding

clearances, terminal locations, and safety information is

contained in the installation and operationg instructions

packaged with the appliance.

TDV45S 45°

Elbow

Vent Offset @ 45°

45°

90° Elbow

T193

T194

Installed

Vent Pipe True Length “A” “B”

Component Gain Rise Run

TDV6 4” 2¹¹⁄₁₆” 2¹¹⁄₁₆”

(102mm) (68mm) (68mm)

TDV12 10” 7¹⁄₁₆” 7¹⁄₁₆”

(254mm) (179mm) (179mm)

TDV18 16” 11⁵⁄₁₆” 11⁵⁄₁₆”

(406mm) (287mm) (287mm)

TDV36 34” 24¹⁄₁₆” 24¹⁄₁₆”

(864mm) (611mm) (611mm)

TDV48 46” 32¹⁄₂” 32¹⁄₂”

(1168mm) (826mm) (826mm)

76657

IMPORTANT: Do not mix vent system components with components for other vent systems.

NOTE: Use only venting systems and components

as certified with the appliance. Use of uncertified vent

systems or components will void the warranty and may

compromise the operation of the fireplace, its systems,

and components as certified with the appliance. Use

of uncertified vent systems or components will void the

warranty and may compromise the operation of the

fireplace.

Through the Roof (Vertical) Venting

When the venting penetrates a roof the system must be

insalled in accordance with the current CSA B149.1 installation code (in Canada) or the current National Fuel

Gas Code, ANSI Z223.1/NFPA 54 (in U.S.A.). SEE

CHART FOR VERTICAL TERMINATION LOCATION.

Elbows & Offsets - General

Each installation assures the use of one 45° elbow horizontal or vertical (off top of unit).

Sidewall (Horizontal) Venting Information

1. Make sure fireplace location and termination location

are consistent with requirements for terminations

and vent runs.

2. Secure unit to the floor.

3. Locate vent opening in wall. Maintain 2” (51 mm)

clearance to top of vent from combustibles. Install

wall thimble per instructions supplied with Horizontal

Vent Kit. Refer to Page 14, Figures 19 and 20 for

wall thimble installation.

4. Attach vent components beginning with a TDV45S

elbow. Apply high temperature sealant to the outside leading edge of the fireplace flue pipe, then

install the TDV45S starter elbow and secure it to the

fireplace with the three (3) screws (provided) through

the outer pipe flange and into the fireplace 7” (178 mm)

dia. starter flange.

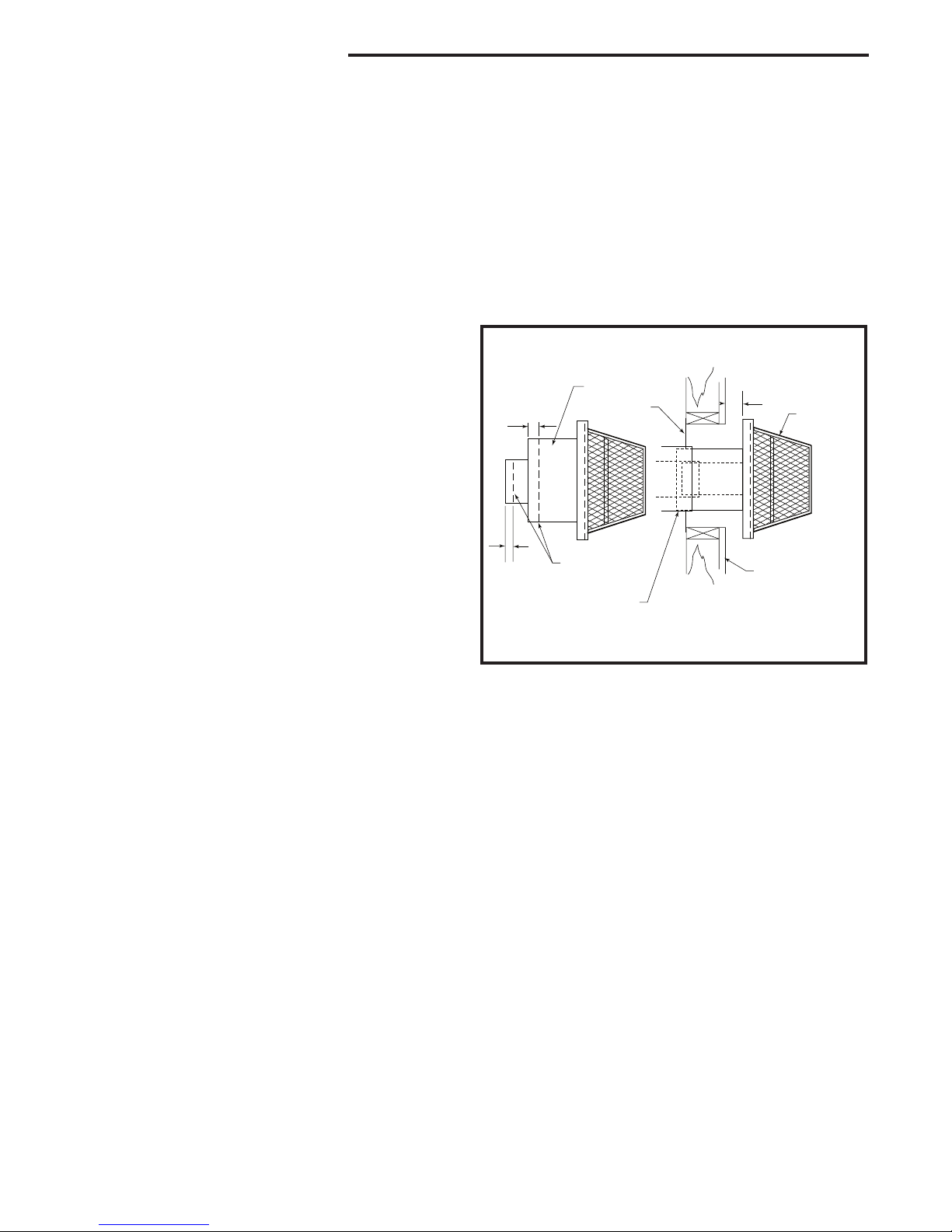

Screw Location

Apply Sealant

to Flue Pipe

Horizontal

Take Off

Illustrated

T196

Fig. 27 Apply high temperature sealant to outside of the flue

pipe.

17

Temco DV1000/1200/1400 Series

A

A

A

5. Align the flue and inlet pipes of each vent section

to the mating component, then slide the sections

together. Before a joint in the system is secured,

push the vent components together using moderate

force to ensure joint overlap of approximately 1¹⁄₂”

(38 mm).

6. Secure vent components with a minimum of three (3)

screws at each joint (pipe joint to pipe, joint sealants

are not required). Never use screws in vent systems

longer than 1” (25 mm).

7. Vent sections and elbows may be rotated 360° prior

to securement to obtain the desired direction of vent

run, and provide flexibility.

8. Make sure all horizontal sections have no sags and

maintain a minimum 1/4” (6 mm) rise per linear foot.

9. Using the high temperature sealant provided, apply

a small bead of sealant to both the flue and inlet pipe

extensions on the vent terminal (cap) and install the

horizontal vent terminal to side of building with four

(4) screws provided.

10. If the last section of vent pipe does not allow the

vent terminal to seat against the outside wall, it will

be necessary to replace the last vent section with a

shorter vent section. In addition, you may also measure

the distance between the wall and back flanges of the

terminal base plate. Next, trim off the terminal flue and

inlet pipes to the dimension measured and reinstall the

vent terminal.

ATTENTION: Vent terminal flue and inlet pipes must

overlap last vent section a minimum of 1” (25 mm).

If the horizontal termination is located in an accessible

area below 7” (178 mm), an HTG guard is to be installed over terminal.

A Vinyl Extension Frame Kit No. VEF is required for all

installations where vinyl siding is used with the HFTK

Kit or HSQ47 Horizontal Vent Termination. If a Vinyl Extension Frame Kit No. VEF is used, measure to outside

surface of wall without siding and add an additional 2”

(51 mm) to the venting length.

The flue pipe and inlet pipe of the vent terminal may be

cut back equal amounts as illustrated by Dimension “A”.

Inlet Pipe

Wall Thimble

Cut Lines

Push vent terminal in as

far as vent system will

allow. Use Dimension “A”

as the dimensin needed

to trim off the terminal flue

and inlet pipe.

Fig. 28 Cut the terminal flue and inlet pipes to shorten the

vent section.

HSQ47

Vent

Terminal

Exterior Wall

T197

18

76657

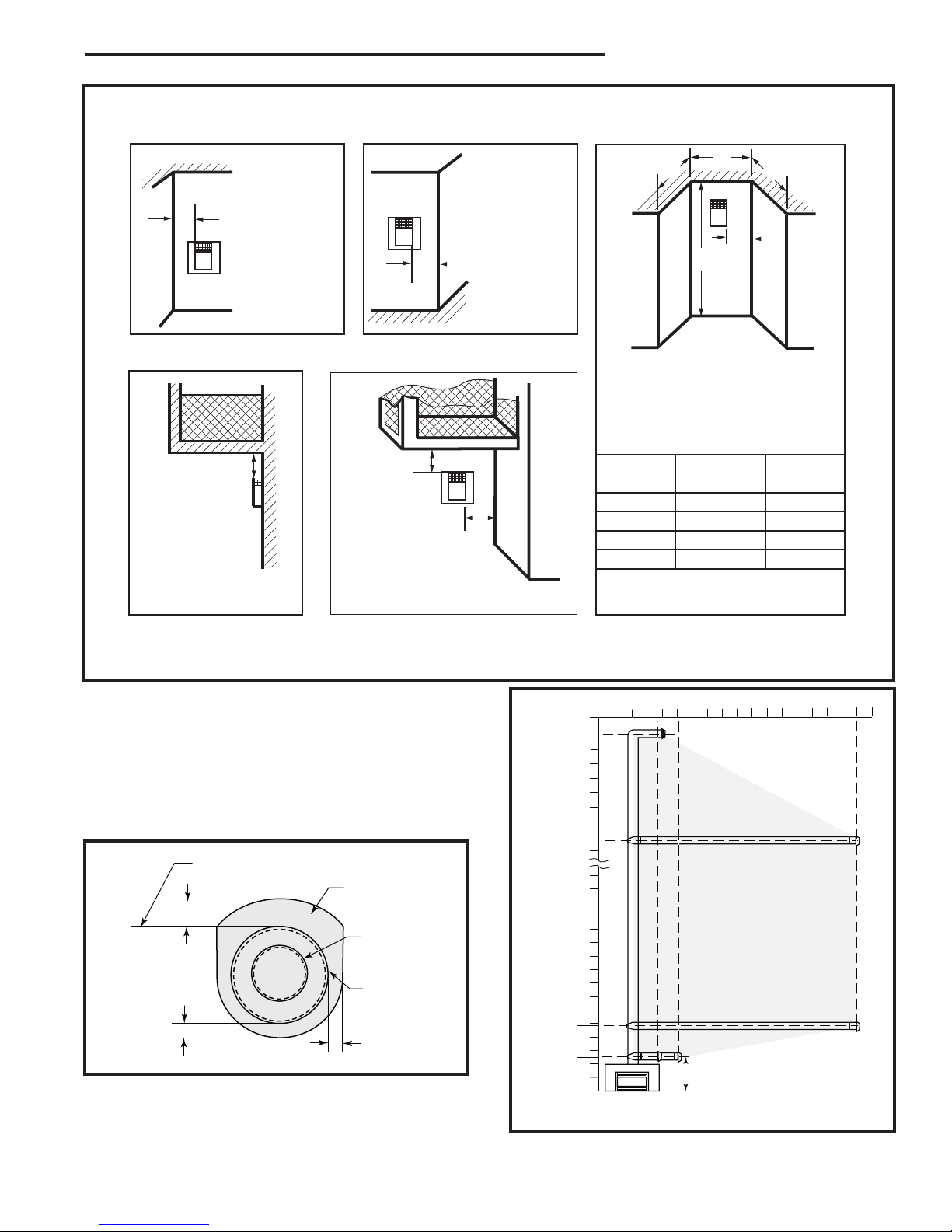

Temco DV1000/1200/1400 Series

C

A

Min.

B

Min.

D

M* Min.

N Max.

L

(Ref.)

E

F

10" (254mm)

Min.

1/2"

(13mm)

L

K*

16¹⁄₃₂"

(407mm)

P Min.

G* Min.

O Max.

H

J

10" (254mm)

Min.

Corner Installation

Horizontal Vent

Vertical Vent

TDV90

TDV45

HSQ47

TDV90

TDV45

Cap telescopes may be

cut off to achieve minimum framing depth

Up & Out Vent

Horizontal

HSQ47

Horzontal Vent

HSQ47

TDV45

*NOTE: Refer to Offset Chart

on Page 17 for Maximum

Horizontal Runs

Fig. 29 Typical TDV Series vent applications.

Ref. DV1000 DV1200 DV1400

A 63

B 44

C 9¹¹⁄₃₂” (237 mm) 12” (305 mm) 14¹⁄₈” (359 mm)

D 9

E 37

F 48¹⁄₄” (1226 mm) 53¹⁄₄” (1353 mm) 53¹⁄₄” (1353 mm)

G 18

H 25

J 36¹⁄₄” (921 mm) 41³⁄₈” (1051 mm) 41³⁄₈” (1051 mm)

K 34

L 17

M 24” (610 mm) 25¹⁄₄” (641 mm) 25¹⁄₄” (641 mm)

N 28³⁄₈” (721 mm) 30” (762 mm) 30” (762 mm)

O 23

P 15

76657

⁵⁄₃₂” (1604 mm) 64²⁹⁄₃₂” (1633 mm) 71³⁄₁₆” (1808 mm)

¹¹⁄₁₆” (1135 mm) 45⁷⁄₈” (1165 mm) 50⁵⁄₁₆” (1295 mm)

⁷⁄₁₆” (240 mm) 9⁷⁄₁₆” (240 mm) 9⁷⁄₁₆” (240 mm)

¹⁄₂” (953 mm) 42¹⁄₂” (1080 mm) 42¹⁄₂” (1080 mm)

³⁄₄” (476 mm) 20” (508 mm) 20” (508 mm)

¹⁄₂” (648 mm) 30⁵⁄₈” (778 mm) 30⁵⁄₈” (778 mm)

¹⁄₄” (870 mm) 39³⁄₈” (1000 mm) 39³⁄₈” (1000 mm)

⁷⁄₈” (454 mm) 19¹⁄₂” (495 mm) 19¹⁄₂” (495 mm)

¹⁄₄” (591 mm) 24¹⁄₂” (622 mm) 24¹⁄₂” (622 mm)

¹⁄₄” (387 mm) 16¹⁄₂” (419 mm) 16¹⁄₂” (419 mm)

T198

19

Temco DV1000/1200/1400 Series

Simpson Dura-Vent Venting

Horizontal or Vertical Terminations

The Simpson Dura-Vent Direct Vent System (GS 4”

x 6⁵⁄₈”) offers a complete line of component parts for

installation of both horizontal and vertical installations.

Many items are offered in decorative black, as well as

galvanized finish. The galvanized finish may be used

for installation with your Temco gas fireplace.

The minimum components required for a basic horizontal termination are:

1 Horizontal Termination Cap

1 Flue Adapter (45° Elbow)

1 Wall Penetration Heat Shield

1 Length of pipe to suit wall thickness (see chart)

Wall thickness is measured from the back of the fireplace to the inside mounting surface of termination cap.

For siding (other than vinyl) furring strips may be used,

instead of the vinyl siding standoff, to create a level

surface to mount the vent terminal. The Terminal must

not be recessed into siding. Measure the wall thickness

including furring strips.

If a Vinyl Siding Standoff is required (it must be used

with vinyl siding), measure to outside surface of wall

without siding and add 2” (51 mm).

Flat Wall Installation (All Units)

Wall Thickness Vent Length

inches (mm) Required (inches(mm))

5

(140 - 178 mm) 9¹⁄₂” - 11” 6”

(241 - 279 mm) (152 mm)

12¹⁄₂” - 14” 9”

(318 - 356 mm) (229 mm)

15¹⁄₂” - 17” 12”

(394 - 432 mm) (305 mm)

14¹⁄₂” - 19⁵⁄₈” 11” - 14⁵⁄₈” Adj. Pipe

(368 - 499 mm) (279 - 372 mm)

20¹⁄₂” - 29” 17” - 24” Adj. Pipe

(520 - 737 mm) (432 - 610 mm)

Corner Installation (DV1000)

2³⁄₄” - 4¹⁄₄” 6”

(70 - 108 mm) (152 mm)

5³⁄₄” - 7¹⁄₄” 9”

(146 - 184 mm) (229 mm)

9³⁄₄” - 11¹⁄₄” 6” + 9”

(248 - 286 mm) (152 mm + 229 mm)

12³⁄₄” - 14¹⁄₄” 6” + 12” / 9” + 9”

(324 - 362 mm) (152 + 305 mm) (229 + 229 mm)

13³⁄₄” - 22¹⁄₄” 17” - 24” Adj. Pipe

(349 - 565 mm) (432 - 610 mm)

7³⁄₄” - 12⁷⁄₈” 11” - 14⁵⁄₈” Adj. Pipe

(197 - 327 mm) (279 - 372 mm)

Corner Installation (DV1200)

2³⁄₁₆” - 3¹¹⁄₁₆” 6”

(56 - 94 mm) (152 mm)

5³⁄₁₆” - 6¹¹⁄₁₆” 9”

(132 - 170 mm) (229 mm)

8³⁄₁₆” - 9¹¹⁄₁₆” 12”

(208 - 246 mm) (305 mm)

9³⁄₁₆” - 10¹¹⁄₁₆” 6” + 9”

(233 - 272 mm) (152 + 229 mm)

12³⁄₁₆” - 13¹¹⁄₁₆” 6” + 12” / 9” + 9”

(310 - 347 mm)

13³⁄₁₆” - 21¹¹⁄₁₆” 17” - 24” Adj. Pipe

(335 - 551 mm) (432 - 610 mm)

7³⁄₁₆” - 12⁵⁄₁₆” 11” - 14⁵⁄₈” Adj. Pipe

(183 - 313 mm) (279 - 372 mm)

Corner Installation (DV1400)

7¹⁄₈” - 8⁵⁄₈” 6” + 9”

(181 - 219 mm) (152 + 229 mm)

10¹⁄₈” - 11⁵⁄₈” 6” + 12” / 9” + 9”

(257 - 295 mm) (152 + 229 mm)/(229 + 229 mm)

11¹⁄₈” - 19⁵⁄₈” 17” - 24” Adj. Pipe

(283 - 499 mm) (432 - 610 mm)

5¹⁄₈” - 10¹⁄₄” 11” - 14⁵⁄₈” Adj. Pipe

(130 - 260 mm) (279 - 372 mm)

¹⁄₂” - 7” -

(152 + 229 mm)/ (229 + 229 mm)

20

76657

Temco DV1000/1200/1400 Series

A

Flexible Venting Individual System Components

Vent Kit A

GFP74FV3 3’ (914 mm)

GFP74FV10 10’ (3 m)

GFP74FV20 20’ (6 m)

GFP74FV30 30’ (9 m)

HTG

Horizontal Terminal

Guard Kit

(75783)

Attic Insulation

Shield (76093)

AS7-8

HFTK

Horizontal Flex

Terminal Kit

(76478)

RF7612

Roof Flashing

(6/12 to 12/12)

(Used with 7” dia.

pipe system only)

(76049)

SC7

Storm Collar

(Used with 7” dia.

pipe system only)

(760505)

RF705

Roof Flashing

(0/12 to 5/12)

(Used with 7” dia. pipe

system only)

(76048)

VEF

Vinyl Extension

Frame Kit

(For use with HFTK)

GFP7FS

Firestop Spacer

T199

Temco Flex Vent Termination Kits Available

Square Horizontal Cap (uses 7/4 Flex) HFTK

Round Hor. Term. Cap (High Wind)

(Includes 7/4 Flex x 3 ft. long) CDV-HSK

Round Hor. Term. Cap (uses 7/4 Flex) RN47

Vertical Vent Kit

(Includes 7/4 flex x 10 ft. long, Firestop Thimble Assy) VSK7MH-2

Vertical Vent Kit (uses 7/4 Flex) VSK7

TDV Series Direct-Vent System Installation

VEF Vinyl

Extension

Frame for

use with

HSQ47

HTG

Horizontal

Terminal

Guard Kit

(75783)

RF7612

Roof Flash-

ing

(6/12 to

12/12)

(76049)

T204

21

TDV48

TDV45S

Elbow

TDV36 TDV18

TDV90

Elbow

SC7

Storm Collar

(76050)

TDV12 TDV5 TDV1218

Horizontal Vent terminal

(Includes Wall thiumble)

Adjustable

Vent

HSQ47

(75915)

VT47

Vertical Vent

Terminal

(75909)

Firestop Spacer

(7604)

RF705

Roof Flashing

0/12 to 5/12

(76048)

AS7-8

Attic Insula-

tion Shield

(76093)

FS7

NOTE: Flexible and rigid vent system components are NOT interchangeable unless otherwise specified in the venting

instructions.

76657

Temco DV1000/1200/1400 Series

Vertical Termination

Cap

Storm Collar

Adjustable

Flashing

0/12 to 6/12

Pipe Length

(Refer to Parts List)

Pipe Length

(if required)

All Simpson Dura-Vent com

ponents are available from

your Dura-Vent Distributor

-

Vertical

Termination

Kit

Elbow

45 Degree Elbow Adapter

(TGS45) (Horizontal Venting)

50 Degree Elbow Adapter

(TGS50V) (Vertical Venting)

Horizontal Termination Kit 971

Includes: 90° Black Elbow

Wall Thimble Cover

Horizontal Square Termination Cap

24” Black Pipe

11” - 14⁵⁄₈” Adjustable Black Pipe

Basic Horizontal Termination Kit 970

Includes: 90° Black Elbow

Wall Thimble Cover

Horizontal Square Termination Cap

Vertical Termination Kit 978

Includes:

0-12 - 6/12 Pitch Adjustable Flashing

Storm Collar

Low Profile Termination Cap

6” Pipe Length - Black 908B

9” Pipe Length - Black 907B

12” Pipe Length - Galvanized 906

12” Pipe Length - Black 906B

24” Pipe Length - Galvanized 904

24” Pipe Length - Black 904B

36” Pipe Length - Galvanized 903

36” Pipe Length - Black 903B

48” Pipe Length - Galvanized 902

48” Pipe Length - Black 902B

11” - 14⁵⁄₈” Adjustable Pipe - Black 911B

17” - 24” Adjustable Pipe - Black 917B

45° Elbow - Galvanized 945

45° Elbow - Black 945B

Vent Guard

HTG

Horizontal Termination Cap

(Part #984)

Vinyl Siding Standoff

(Part #950)

(Optional)

Wall Penetration Heat Shield

(Wall thimble)

(Part #942)

Alternate Snorkel Termination Cap

Part #982 (14”)

Part #981 (36”)

T200

45° Elbow, Swivel - Galvanized 945G

45° Elbow, Swivel - Black 945BG

90° Elbow - Galvanized 990

90° Elbow, Swivel - Galvanized 990G

90° Elbow, Swivel - Black 990BG

High Wind Termination Cap (Vertical) 991

Vertical Termination Cap 980

Horizontal Square Termination Cap 984

Horizontal Square Termination Cap

w/1” return 984L

Horizontal Square High Wind

Termination Cap 985

Snorkel - 14” Rise Termination Cap 982

Snorkel - 36” Rise Termination Cap 981

Wall Thimble - Support/Box 940

Cathedral Ceiling - Support/Box 941

Brass Trim for Cathedral 3951

Firestop Spacer 963

Flashing 0/12 - 6/12 Roof Pitch 943

Flashing 7/12 - 12/12 Roof Pitch 943S

Storm Collar 953

Vinyl Siding Standoff 950

Wall Strap 988

Wall Penetration Heat Shield (Wall Thimble) 942

Parts Available from TEMCO (Not supplied by DuraVent)

Vent Guard HTG

45° Adapter Elbow (Horizontal Venting) TGS45

50° Adapter Elbow (Vertical Venting) TGS50V

22

76657

Temco DV1000/1200/1400 Series

Secure Vent Venting Components

Standard Horizontal Kit SV0SHK

Includes: 90° Swivel Black Elbow

Decorative Black Plate

Horizontal Termination Cap

Horizontal Kit SV0HK

Includes: 90° Swivel Black Elbow

Decorative black Plate

Horizontal Termination Cap

Adjustable Length 12”

Black Length 24”

Horizontal Kit SV0HK2

Includes: 90° Swivel Black Elbow

Decorative black Plate

Horizontal Termination Cap

Adjustable Length 12”

Black Length 24”

Wall Radiation Shield

Vertical Flat Roof Kit SV0FK

Flat Roof Flashing

Storm Collar

Vertical Termination Cap

Vertical Adjustable Roof Kit SV0FAK

1/12 - 7/12 Includes:

Adjustable Roof Flashing

(1/12 - 7/12)

Storm Collar

Vertical Termination Cap

Vertical Adjustable Roof Kit SV0FBK

8/12 - 12/12 Includes:

Adjustable Roof Flashing

(8/12 - 12/120

Storm Collar

Vertical Termination Cap

6” Pipe Length - Black SV4LB6

6” Pipe Length - Galvanized SV4L6

12” Pipe Length - Black SV4LB12

12” Pipe Length - Galvanized SV4L12

24” Pipe Length - Black SV4LB24

24” Pipe Length - Galvanized SV4L24

36” Pipe Length - Black SV4LB36

36” Pipe Length - Galvanized SV4L36

48” Pipe Length - Black SV4LB48

48” Pipe Length - Galvanized SV4L48

1¹⁄₂” - 6” Adjustable Pipe - Black SV4LBA

1¹⁄₂” - 6” Adjustable Pipe - Galvanized SV4LA

1¹⁄₂” - 12” Adjustable Pipe - Black SV4LBA12

1¹⁄₂” - 12” Adjustable Pipe - Galvanized SV4LA12

1¹⁄₂” - 24” Adjustable Pipe - Black SV4LBA24

1¹⁄₂” - 24” Adjustable Pipe - Galvanized SV4LA24

45° Elbow, Swivel - Black SV4EB45

45° Elbow, Swivel - Galvanized SV4E45

45° Elbow - Black SV4EBR45

90° Elbow, Swivel - Black SV4EB90

90° Elbow - Galvanized SV4E90

90° Elbow - Black SV4EBR90

Vinyl Shield SV4VS

Snorkel Cap 14” SV4STC14

Snorkel Cap 36” SV4STC36

Adjustable Decorative Square

Cathedral Support SV4CSB

Wall Radiation Shield SV4RSM

Collar for Decorative Square

Cathedral Support SV4AC

Attic Radiation Shield SV4RSA

Adjustable Wall Band SV4BM

Roof Support SV4ST

Floor Support SV4SD

Roof Brace SV4BS

Universal Support SV4SU

Flat Roof Flashing SV4F

1/12 - 7/12 Adjustable Roof Flashing SV4FA

8/12 - 12/12 Adjustable Roof Flashing SV4FB

Storm Collar SV4FC

Decorative Black Plate SV4PF

Firestop SV4BF

Horizontal Termination Cap SV4CHC

Vertical Termination Cap SV4CGV

Restrictor Disc SV4RD

45° Adapter Elbow

(Horizontal Venting) SV4E40AT*

*NOTE: This adapter elbow is required on all TEMCO

Direct Vent Fireplaces for installation of Secure Vent

Systems.

76657

23

Temco DV1000/1200/1400 Series

Operating Instructions

WARNING: Do not operate appliance with the glass

front removed, cracked or broken.

• The use of substitute glass will void all product warranties.

• Care must be taken to avoid breakage of the glass.

• Do not operate this fireplace without the glass front

or with a broken glass front.

• Replacement of the glass should be done by a

licensed or qualified service person.

• Do not remove the glass door when unit is hot to

the touch.

• NOTE: Inspect the door gasket. The braided door

seal gasket has a small overlap area near corner of

the top black extrusion. Identify this area and install

the door with this area at the top.

Glass Door Removal Procedure

1. Remove upper and lower louvre assemblies and set

aside. Refer to louvre installation instructions.

2. Using gloves, carefully unlatch the latches (3) along

the bottom edge of the glass door. Then as the top

latches are unlatched, continue to place gentle pressure to the glass door to reduce the chances of the

door being dropped accidentally.

3. Once all latches have been secured, pull the door

(4) outward from the face of the fire chamber.

4. Take care during handling and cleaning of the glass

door so that it is not dropped or accidentally broken.

5. Cleaning of the glass should only be done when the

glass door is cool. Refer to Glass Cleaning section.

6. To reinstall glass door, carefully center the door

onto the face of the fireplace (left to right), second, shift the door assembly upwards slightly, then

secure door with the throw-over latches above and

below the firechamber. By shifting the door upwards

before latching, the upper door latches will be less

visible once the upper louvre is installed.

7. Reinstall the upper and lower louvre assemblies.

Refer to louvre installation.

household cleansers and warm water. After that, the

glass should be cleaned two or three times a season

depending on the amount that the fireplace is used.

To remove, simply unlatch the top and bottom door

latches and carefully pull door forward. Use of gloves

recommended.

Do not clean when the glass is hot.

Do not strike or abuse glass.

Do not place glass door on edge after

removal.

Louvre Installation

The fireplace is shipped without the louvre assemblies

installed. Various styles and finishes are available as

options. Contact your nearest Temco dealer/distributor

for information on the Louvre Kits available.

Model DV1000:

1. To install the upper louvre assembly, the first louvre

blade from the top on each louvre assembly will

hook onto the top tabs of the louvre brackets. (Fig.

30)

2. Once the first louvre blade has engaged the top tab

of the end brackets, swing the bottom of the louvre

assembly inward so the louvre hangs flush with the

fireplace face.

Models DV1200 and DV1400:

1. To install the upper louvre assembly, the second

louvre blade from the top on each louvre assembly

will hook onto the top tabs of the louvre bracket. (Fig.

30)

2. Once the second louvre blade has engaged the top

tab of the end brackets, swing the bottom of the louvre assembly inward so the louvre hangs flush with

the fireplace face.

Glass Cleaning

It will be necessary to clean the glass periodically. During start-up, condensation - which is normal - forms on

the inside of the glass and causes dust, lint, etc. to cling

to the glass surface. Also, initial paint curing can deposit a slight film on the glass. In some geographic areas, a white film may be deposited on the glass due to

combustion of some of the constituents of natural gas.

It is therefore recommended that initially the glass be

cleaned two or three times with non-abrasive common

24

T201

Fig. 30 Hook first or second louvre blade (depending on

fireplace model) onto top tabs of louvre brackets.

76657

Temco DV1000/1200/1400 Series

After completing Steps 1 and 2, the louvre assembly

should look like the illustration shown in Figure 31.

Models DV1000, DV1200 and DV1400: To install the