Page 1

Telstra Commander@ E1

05/208+

Installation and Maintenance Manual

DOC - E+ - IM

546/261

(ISSUE 1)

celstra

Page 2

COPYRIGHT 1995 Telstra Technologies Pty Ltd

Telstra Technologies Pty Ltd, is a Standards Australia Quality Endorsed Company. This work is

copyright. All rights reserved. Other than for purposes and subject to conditions prescribed under the

Copyright Act, no part of it may in any form or by any means (electric, mechanical, microcopying,

photocopying, recording or otherwise) be reproduced, stored in a retrieval system or transmitted

without prior permission from Telstra Technologies Pty Ltd.

All enquiries should be addressed to:

Telstra Technologies Pty Ltd

A.C.N.006841 345

Locked Bag 10

HAWTHORN VIC 3 122

AUSTRALIA

0

Registered Trade Mark of Telstra Corporation Limited A.C.N. 05 1775 556

Page 3

Table of Contents

I -

Chapter One - Introduction to the Commander

E105/208+

System

Introduction

.............................................................................................................................. l-l

General Description

.................................................................................................................

I-

1

Keystations

.....................................................................................................................

1 -

1

Power and Termination Unit

............................................................................................

l-2

Power-fail

........................................................................................................................

l-3

Door Station

...................................................................................................................

l-3

System Features

......................................................................................................................

l-5

Keystations

.....................................................................................................................

l-5

Visual Indications

............................................................................................................

l-5

Programmable Facilities

...................................................................................................

1 -

5

SystemFacilities

......................................................................................................................

l-6

Incoming Calls

................................................................................................................

l-6

During a Call

................................................................................................................... l-6

outgoing Calls

................................................................................................................

1-7

Internal Calls

...................................................................................................................

l-8

Equipment

.......................................................................................................................

l-9

Miscellaneous

.................................................................................................................

l-9

Chapter Two - Power and Termination Unit

Introduction

.............................................................................................................................

2-l

General Description

.................................................................................

.

...............................

2-

1

Power and Terminating Board

.........................................................................................

2-2

Optional Facilities Board (Optional)

.................................................................................

2-2

Circuit Blocks - Power and Terminating Board

.........................................................................

2-3

Transformer

...................................................................................................................

.2 - 3

Power Supply

.................................................................................................................

2-3

Electronic Choke

...........................................................................................................

.2-3

Power-fail

.......................................................................................................................

.2-3

Exchange Line Protection

...............................................................................................

.2-3

System Bus

.....................................................................................................................

2-3

Circuit Blocks - Optional Facilities Board..

...............................................................................

2-5

Microcomputer Unit (MCU)

..........................................................................................

.2-5

Data Transmit and Receive

.............................................................................................

.2-5

Door Station Interface

.....................................................................................................

2-5

External Music Source Interface

.....................................................................................

.2-5

Commander E105/208+ Installation and Maintenance Manual

Table of Contents - i

Page 4

Chapter Three - Keystations

Introduction

.............................................................................................................................

3 - 1

General Description

.................................................................................................................

3 - 1

Keystation Main Board

...................................................................................................

3-2

Hold and Ring Detect Board

...........................................................................................

3-2

Keypad Assembly

...........................................................................................................

3 - 2

Circuit Blocks

..........................................................................................................................

3-3

Microcomputer Unit Circuit (MCU Circuit)

....................................................................

.3-3

Power Supply

.................................................................................................................

3-3

Isolation Transformer

.......................................................................................................

3 - 3

Data Transmit and Receive

..............................................................................................

3-4

Speech Circuit

................................................................................................................

3-4

Tone Generator

...............................................................................................................

3 -4

Audio Selector

................................................................................................................

3 -4

Audio Amplifier

...............................................................................................................

3 -4

Line Access Circuit

........................................................................................................

.3-4

HRDB-E Board (In Master Keystation)

..........................................................................

3-4

Chapter Four - Hardware Installation

Introduction

.............................................................................................................................

4-

1

Component Safety Precautions

................................................................................................

4-

1

Installation Checklist

................................................................................................................

4-2

Installation Procedures

.............................................................................................................

4-3

Sales Form Completion/Equipment Ordering

.................................................................

.4-3

Locate and Mount Equipment

.........................................................................................

.4-3

Optional Facilities Board Installation (OFB-E)

...............................................................

4- 11

Connect and Terminate Cables

.....................................................................................

.4-

12

Power-Fail Telephone

..................................................................................................

.4-

17

Protective Earth

...........................................................................................................

.4-

17

General Procedure

.................................................................................................................

4-

18

Power Up.. ..................................................................................................................

.4-18

Check Cabling

.............................................................................................................

.4-

18

Power Down

...............................................................................................................

.4-

18

Plug in Keystations

.......................................................................................................

.4-

18

Keystation Self Test

.....................................................................................................

.4-

18

Test Mode Entry

..........................................................................................................

.4-

18

LEDTests..

..................................................................................................................

.4-19

Programming..

..............................................................................................................

.4-20

Defective Equipment

....................................................................................................

.4-20

Tab/e of Contents

-

ii

Page 5

__

Chapter Five - System Programming

Introduction

.............................................................................................................................

5-l

General Description

................................................................................................................. 5-l

Programming Hardware Locations

...........................................................................................

5-l

DIP Switches

..................................................................................................................

5-l

General Programming Procedure

..............................................................................................

5-3

Keystation Intercom Address

.........................................................................................

.5-3

Master Page-In

...............................................................................................................

5-4

Keystation Access Class

.................................................................................................

5-4

Ring Line 1

.....................................................................................................................

5-6

RingLine

..................................................................................................................... 5-6

DialType

.......................................................................................................................

.5-7

Auto Pause Insert

...........................................................................................................

.5-7

Music-On-Hold

.............................................................................................................

.5-8

Background Music

.........................................................................................................

.5-9

InitialiseandReset

.................................................................................................................

5-10

Access Class Restriction

...............................................................................................

5-10

Exchange Line Auto Answer

.........................................................................................

5-11

Headset Mode

.............................................................................................................

.5-

12

Programming summary

..........................................................................................................

5-13

Software Programming Records

....................................................................................

5-13

Chapter Six - Functional Tests and Maintenance

Introduction

.............................................................................................................................

6-l

General Description

.................................................................................................................

6-l

System Tests and Repair Actions

.............................................................................................

6-2

Key station Installation

.....................................................................................................

6-2

* Exchange Line Seizure

..................................................................................................

6-3

* Incoming Exchange Call

...............................................................................................

6-3

Off-Hook Signalling

........................................................................................................

6-3

Volume Control

...............................................................................................................

6-3

Answering Exchange Call

................................................................................................

6-3

Automatic Answering Exchange Call

................................................................................

6-4

* Outgoing Exchange Call

...............................................................................................

6-4

Decadic to Tone Signalling

...............................................................................................

6-4

Hold

...............................................................................................................................

6-4

Music-On-Hold

..............................................................................................................

6-4

Hold Automatic Ring Back

.............................................................................................. 6-4

* Last Number Redial

....................................................................................................

.6-4

Abbreviated and Speed Dialling

.......................................................................................

6-5

Commander E105/208+ Installation and Maintenance Manual

Table of Contents -

ii/

Page 6

System Memory Back-Up

..............................................................................................

6-S

* PABX Recall

...............................................................................................................

6-5

* Paging

..........................................................................................................................

6-5

Do Not Disturb

...............................................................................................................

6-5

Intercom Signal or Voice Call

..........................................................................................

6-S

Intercom Answering

........................................................................................................

6-5

On-Hook Dialling

............................................................................................................

6-5

* Exchange Line Conference

...........................................................................................

6-6

* Background Music

.......................................................................................................

6-6

*

Door Station

................................................................................................................

6-6

*

Power-fail Telephone

...................................................................................................

6-6

Centel Features

..............................................................................................................

.6-6

Maintenance

............................................................................................................................

6-7

Test Equipment

...............................................................................................................

6-7

Voltage Test Points

..........................................................................................................

6-7

General

...........................................................................................................................

6-8

Fault Finding Tables

.................................................................................................................

6-8

Repair Procedures

.................................................................................................................

6-

15

Printed Board Assemblies

(PBA’s)

...............................................................................

.6-

15

Appendix A - System Characteristics

System Capacities and Limits

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A- 1

System Specifications

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A-2

Electrical

. . , . . . . . . . . . . . . , . . . . . . . . . . , . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A-2

Environmental

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A-2

External Music- On-Hold

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A-2

Dialling

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

...

A-2

Dimensions and Weight

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Appendix B - Parts Serial Item and Code list

Central Equipment

...................................................................................................................

B- 1

Keystations

.............................................................................................................................

B-

1

Miscellaneous Items

.................................................................................................................

B-l

Maintenance Parts

...................................................................................................................

B-2

Documents

..............................................................................................................................

B-2

Appendix C - System User Guide

Table of Contents -

iv

Page 7

Table of Illustrations

IL0

1 -

System Block Diagram

..................................................................................................

l-4

IL02 - PTU

.............................................................................................................................. 2-l

IL03 - PTB-E Circuit Block Diagram

........................................................................................

2-4

IL04 - OFB-E Circuit Block Diagram

.......................................................................................

2-6

IL05 - E

105+

and E208+ Keystation

............

.

..........................................................................

3-2

IL06 - Keystation Circuit Block Diagram

..................................................................................

3-5

IL07 - System Order Form..

.....................................................................................................

4-4

IL08 - Limitations To Wall Mounting

.........................................................................................

4-5

IL09 - Plug-Pack Dimensions

...................................................................................................

4-6

IL 10 - Power And Termination Unit Dimensions

........................................................................

4-7

IL 11 - Power and Termination Unit Mounting

............................................................................

4-7

IL1 2 - Sale/Rental Identifying Window

.....................................................................................

.4-8

IL 13 - Installing The Handset Rest

............................................................................................ 4-9

IL 14 - Keystation Wall Mounting Dimensions

..........................................................................

4-10

IL 15 - Wall Mounting the Keystation

......................................................................................

4-10

IL 16 - Wall Mounting Dimensions For Door Stations

..............................................................

4-

1 1

IL

IL

IL

7 - Commander E

105/208+

Cabling Scheme

...................................................................

.4-

12

8 - Bus Length

..................................................................................................................

4-13

9 - Example Of Allowable Keystation Distances

..............................................................

.:

4- 13

IL20 - Example Of Unacceptable Cabling Scheme

..................................................................

4- 14

IL2

1 -

Power and Termination Unit Terminations

.....................................................................

4-14

IL22 - Modular Socket (KRONE Type)

.................................................................................

4-16

IL23 - Keystation DIP Switches (In Default Settings)

................................................................

5-2

IL24 - No Master Page-In

.......................................................................................................

5-4

IL25 - Program - Local Calls Only

...........................................................................................

5-6

Commander

E105/208t

Installation and Maintenance Manual

Table of

Illustrations -

i

Page 8

IL26 - Program - Ring On Line

1

..............................................................................................

5-6

IL27 - Program - No Ring On Line 2

........................................................................................ 5-6

IL28 - Program - DTMF Dialling

..............................................................................................

5-7

IL29 - Program - Auto Pause Insert..

........................................................................................

5-7

IL30 - Music-On-Hold Links

...................................................................................................

5-8

IL3 1- Program - Internal, External, and No Music-On-Hold

....................................................

5-9

IL32 - External Music-On-Hold Setting on

OFB

.......................................................................

5 -9

IL33 - Internal or No Music-On-Hold Setting on OFB

.............................................................

5-9

Table of

Illustrations -

ii

Page 9

Table of Tables

-

Table1-

Bus Cabling

.............................................................................................................

4-l

Table 2 - Keystation Bus Cabling Terminations

.....................................................................

.4

- 15

Table 3 - Door Station Terminations

.4

-

.....................................................................................

16

Table 4 - Keystation Voltages

...............................................................................................

4-

18

Table 5 - Self Test Key Sequence and LED Responses

........................................................

4-

19

Table 6 - DIP Switch 2 Keystation Options..

...........................................................................

5 - 2

Table 7 - Keystation Address Settings..

-

...................................................................................

5 3

Table 8 - Example of Exception Table

5

-

.....................................................................................

5

Table 9 - Music Source Links

.................................................................................................

5-8

Table 10 - Cable Connections

.................................................................................................

6-2

Table

1 1 -

Power Supply Test Points

.......................................................................................

6-7

Table 12 - Power and Termination Unit Test Points

..................................................................

6-7

-

Table

13 -

KeystationTest

Points

.............................................................................................

6-7

Commander E105/208+ Installation

and

Maintenance

Manual

Table of Tables

-

i

Page 10

Preface

--

The preface explains the structure of the Commander@ E

105/208+

Installation and Maintenance Manual. It describes both the overall

layout and the layout of each chapter. It also defines and illustrates the

conventions used throughout the manual

Purpose of

the Manual

The purpose of the Commander E

105/208+

Manual is to provide you,

as Telstra Technical Staff, with a complete set of clear and concise

installation and maintenance procedures. It should be used when

installing a Commander E

105+

or

E208+

system to ensure the process

is completed correctly, safely and easily. It should also be used for

maintaining the system when problems arise.

Audience

This manual is written solely for Telstra Technical Staff responsible for

the installation and maintenance of the Commander

E105/208+

system.

Organisation of

the Manual

-

The Commander

E105/208+

Installation and Maintenance Manual is

divided into nine sections, six chapters and three appendices.

Chapter One Introduction

This chapter introduces the Commander

E105/208+

system and

to the Commander E105/

explains the difference between the E105+ and E208+ models. It also

208+

System

provides two descriptive lists: System Features and System Facilities.

Chapter Two Power and

Termination Unit

This chapter introduces the Commander E

105/208+

Power and

Termination Unit. It begins with a general description; a more detailled

explanation follows.

Chapter Three

Keystations

This chapter introduces and describes the Commander E

105/208+

keystations. It begins with a general description of the two types of

keystations; a more detailled explanation follows.

Chapter Four Hardware

Installation

This chapter describes the procedures for installing the Commander

E105/208+

system hardware. It begins with an Installation Checklist.

Each point in the checklist is thenexplained in detail.

Chapter Five System

Programming

This chapter contains all the procedures for programming the

Commander E

105/208+

system. It begins with a general programming

procedure and then explains how to program individual features.

Commander

E105/208t

Installation and Maintenance Manual

Preface - i

Page 11

Chapter Six Functional

Tests and Maintenance

This chapter explains the tests required to verify that the Commander

E105/208+ system has been installed and programmed correctly. It

also explains how to maintain the system after a fault has occurred

during testing or normal daily operation.

Appendix A System

This Appendix provides a list of all Commander E

105/208+

system

Characteristics

limits and specifications.

Appendix B Parts Serial

Item and Code list

This Appendix contains a list of every Serial Item number. A code

description and remarks are provided for each item.

Appendix C System User

Guide

This Appendix contains a copy of the Commander E

105/208+

System

User Guide.

Preface -

ii

Page 12

Manual

Conventions

The symbols and typographic conventions used throughout this manual

are as follows.

.

Bullets iternise information and procedures.

Bold

type indicates chapter, section and sub-section

headings-

for example,

‘Manual Conventions’.

Bold

type also indicates illustration

names-

for example,

‘System Block Diagram’.

Illustration numbers appear below the illustration

name-

for example,

System Block Diagram

[IL011

Capital letters within these square brackets [ ] identify

keys-

for example, ‘When the

[REDIAL]

key is pressed.. .’ .

Italics

emphasise important words within the

text-

for example,

‘DO not

over-tighten the screws.’

Commgnder

E105/208t

Installation and Maintenance Manual

Preface -

iii

Page 13

L

Chapter One

Introduction to the

Commander El

05/208+

System

Page 14

Chapter One

Introduction to the

Commander El05/208+ System

Table of Contents

Introduction

......................................

.

........................

.

................

.

.....................

l-l

General Description

...................

.

................

.

.................................

.

.....................

1-l

Keystations

.....................................................................................................................

1 -

1

Program and Data Storage

.....................................................................................

1 -

1

System Communications

........................................................................................

l-2

DIP Switches

.........................................................................................................

l-2

System Master Keystation

.....................................................................................

l-2

Power and Termination Unit

............................................................................................

l-2

Dial Pad Programming

...........................................................................................

l-2

Power and Terminating Board (PTB-E)

..................................................................

l-3

Optional Facilities Board (OFB-E)

.........................................................................

l-3

Power Supply

........................................................................................................

l-3

Power-fail

........................................................................................................................

l-3

Door Station

...................................................................................................................

l-3

System Features

.....................

..~.................................,................,

.....................

1-5

Keystations

.....................................................................................................................

1 -

5

Visual Indications

............................................................................................................

l-5

Programmable Facilities

...................................................................................................

1 -

5

System Facilities

.......................

.

........

.

........................

.

................

.

.....................

1-6

Incoming Calls

................................................................................................................

l-6

Audible

Signalling..

.................................................................................................

l-6

Do Not Disturb..

....................................................................................................

l-6

Exchange Call Automatic Answer

...........................................................................

l-6

Exchange Call Queuing

..........................................................................................

1 -

6

Flexible Ring Assignment

........................................................................................

l-6

DuringaCall

...................................................................................................................

l-6

Call Transfer

..........................................................................................................

l-6

Conference

............................................................................................................

l-6

Hold - Common

....................................................................................................

l-6

Hold - Recall

.........................................................................................................

l-6

Music-On-Hold

.....................................................................................................

l-7

Off-Hook Signalling

...............................................................................................

l-7

PABX Recall

.........................................................................................................

l-7

Chapter One

Page 15

outgoing calls

................................................................................................................

l-7

Access Barring

......................................................................................................

l-7

Automatic Pause Insertion on PABX Lines

.............................................................

l-7

Decadic to Tone Signalling

.....................................................................................

l-7

Direct Exchange Line Access

.................................................................................

l-7

Last Number

Redial

............................................................................................... l-7

Live Key Working

.................................................................................................

l-7

On-Hook

Dialling/Monitor

.....................................................................................

l-7

Station Abbreviated Dialling

...................................................................................

l-8

StationSpeedDialling

............................................................................................

1-8

Internal Calls

...................................................................................................................

1-8

Alternative Point Answering

...................................................................................

1 -

8

Direct Keystation Selection

....................................................................................

l-8

Intercom

................................................................................................................

l-8

Intercom Voice/Ring

Signahing

................................................................................

1 -

8

Meet-Me Paging

....................................................................................................

l-8

paging

...................................................................................................................

l-8

Voice Call

..............................................................................................................

l-8

Equipment

....................................................................................................................... l-9

Door Station

..........................................................................................................

l-9

Portability

..............................................................................................................

l-9

Powerfail Operation

...............................................................................................

l-9

Power Failure Memory Retention

........................................................................... l-9

Keystation Directory

..............................................................................................

l-9

Wall-Mounting Bracket

..........................................................................................

l-9

Miscellaneous

.................................................................................................................

l-9

Background Music (Optional)

................................................................................

l-9

Call Progress Tones

...............................................................................................

l-9

Confidence Tone

....................................................................................................

l-9

Headset Mode

.....................................................................................................

l-10

Secrecy

...............................................................................................................

l-10

Visual Indication

...................................................................................................

l-10

Commander

E105/208t

Installation and Maintenance Manual

Chapter One

Page 16

Chapter One

Introduction to the Commander El 05/208+ System

-.

Introduction

This chapter provides a general description of the Commander

El051

208+

system, including an explanation of its features and facilities.

General

Description

Kevstations

Program and Data

Storage

The Commander E

105/208+

is an enhancement of the Commander

E105/208

system. It provides the essential features and facilities

expected in a Commander Key System, and at the same time offers

relatively simple installation and maintenance requirements.

The Commander E

105/208+

System features a distributed-intelligence

architecture based on a six-wire bus configuration.

This architecture eliminates the need for bulky main equipment: the

keystations themselves perform the system control functions. The use of

a high-performance CMOS single-chip microcomputer in each

keystation achieves this function.

A fully equipped system comprises eight keystations and one Door

Station, with a maximum bus length of 500 metres (0.5 mm diameter

cable).

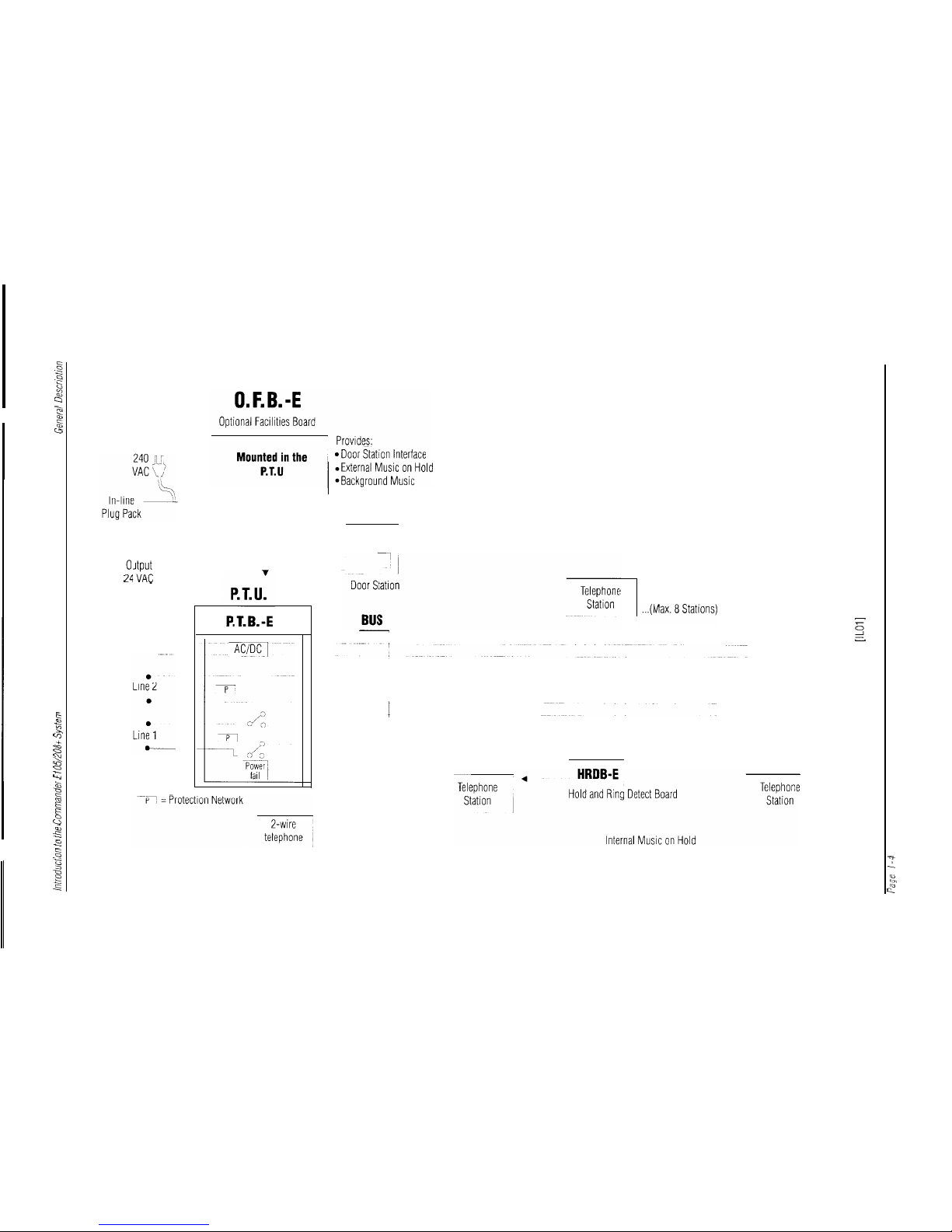

Refer to Illustration 1 - System Block Diagram.

A single-chip microcomputer in each keystation controls all operational

facilities of the Commander

E105/208+

system.

An in-built speaker provides keystation tones.

A RISC microcomputer controls all keypad functions.

The station microcomputer’s program and data are stored in 8K words

of ROM and 2K bits of RAM. They control all keystation and data

communication functions. During a power failure, a supercapacitor

back-up protects abbreviated dialling numbers (stored in RAM). This

back-up also allows keystations to be unplugged and moved at will from

point to point.

Commander E105/20& Installation and Maintenance Manual

Page 1-l

Page 17

Introduction to the Commander E105/20& System

General Description

System Communications

A carrier-sense, multiple-access communications protocol with

frequency-shift keying transmission achieves signalling between

keystations on the system bus.

DIP Switches

Several keystation facilities are individually programmable via“DIP”

switches located in the base of the keystation’s housing.

These include:

.

keystation address

.

master page inclusion

.

STD/IDD access

.

exchange line ring assignment

.

pulse or tone dialling

.

auto pause insertion.

System Master Keystation

Every system installation must include a System Master Keystation. It

contains the Hold and Ring Detect Board (HRDB-E), which provides

all the electronics necessary for:

.

exchange line ring detection

.

line holding

.

internal music on hold.

From a user’s viewpoint, the operation of a system master keystation is

identical to that of a standard keystation.

Power and Termination

Unit

The other major component of the Commander

E105/208+

system is

the Power and Termination Unit (PTU). This compact unit houses the

Power and Terminating Board (PTB-E) and Optional Facilities Board

(OFB-E).

The PTU and OFB-E for the Commander E

105/208+

are the same as

that used on Commander E

105/208.

Dial Pad Programming

Several keystation facilities are individually programmed via the station

dial pad. These programming steps are password protected.

Page l-2

Page 18

General DescriDtion

introduction to

the Commander E105/208+ System

Power and Terminating

Board (PTB-E)

Optional Facilities Board

(OFB-E)

Power Supply

Commander

E105/208t

Installation and Maintenance Manual

Page 1-3

Powerfail

Door Station

The PTB-E provides output terminals for the bus and input terminals for:

.

a maximum of two exchange or PABX lines

.

plug-pack power supply

.

telecommunications reference conductor (if required)

.

power-fail telephone

.

external music source.

This board also supplies system power supply regulation and the system

power-fail relay, as well as exchange line electrical protection.

An OFB-E is installed in the PTU to provide any or all of the following

facilities:

.

Door Station

.

external music on hold

.

background music

Equipped with the same high performance microcomputer as the

keystdtions, the OFB-E contains the required intelligence for bus

communications and control functions for the optional features.

The OFB-E is connected to the PTB-E via a flat cable.

Input power is supplied to the PTB-E via a double-insulated,

mains-

operated, in-line plug-pack.

During a power failure, exchange line calls can still be made and

received at a specially provided two-wire telephone that is automatically

switched across the first incoming exchange pair.

The Door Station is a compact unit incorporating a speaker and

microphone. A Door Station provides two-way communications

between any unsupervised area and a keystation.

Page 19

Introduction

to

the

Commander

E105/208+

System

General

Descriotion

-

System Block Diagram

[IL011

Page

l-4

Page 20

Svstem Features

introduction to

the Commander

E105/208t

System

System

Features

Keystations

Four types of stations are associated with the Commander E

105/208+

system:

.

E105+ Master Keystation

Contains the hold and ring detection circuitry.for the

E105-t

System.

.

E208+

Master Keystation

Contcrins

the hold and ring detection circuitry

for

the

E208+

system.

.

E208+ Standard Keystation

.

Door Station

For use on both

E105+

and

E208+

systems.

NOTE:

Both Commander E

105+

and Commander E208+ Master

Keystations have keys provided for 2 exchange lines. The

E

105+

Master Keystation however differs from the

E208+

in that the

inbuilt

HRDB-E (Hold and Ring Detect Board) is

only equipped to handle 1 exchange line.

Standard Keystations are identical for both size systems.

Visual Indications

Visual indicators on each keystation show the status of:

.

Exchange lines

idle

incoming ring

hU.SY

hold

conference

.

Intercom circuit

free

busy

incoming cull

.

Do Not Disturb

.

Speaker On.

Programmable Facilities

Several options and facilities can be programmed at each keystation via

“DIP” switch settings. The DIP switches are located under the base of

the keystation.A small protective cover must be removed to access the

DIP switches. Further options are programmed via the keystation dial

pad. These options are password protected.

Commander

E105/208t

lnstailation

and

Maintenance

Manuai

Page

1-5

Page 21

Introduction to the Commander E 105/208+

System

System facilities

System Facilities

Incoming Calls

Audible Signalling

Do Not Disturb

Exchange Call Automatic

Answer

Exchange Call Queuing

Flexible Ring Assignment

During a Call

Call Transfer

Conference

Hold - Common

Hold - Recall

Distinctive ring tones from the keystation loudspeaker signal incoming

exchange line, intercom and hold recall calls.

NOTE:

The exchange line ring cadence is internally generated within

the system

anddoes not

track the exchange ring cadence.

When invoked, this facility blocks the audible signals of all incoming

exchange line and intercom calls. Each keystation provides visual

indication of DND.

Each keystation can be programmed to automatically answer incoming

exchange line calls when the handset is lifted.

When Exchange Call Automatic Answer is selected, and more than 1

call is ringing, lifting the handset will answer the oldest call.

Each keystation can be programmed to signal or not

signal

exchange line calls by an audible tone on a per-line basis.

incoming

Allows an exchange line call to be transferred to another keystation after

it has been announced.

Allows the establishment of a conference with one external and two

internal parties or three internal parties.

Places a call on hold for any keystation to retrieve.

When an exchange line call is placed on hold, a reminder ring signal is

activated every 90 seconds at the keystation that initiated the hold

condition.

Page l-6

Page 22

Svstem facilities

Introduction to

the Commander

E105/208t

System

Music-On-Hold

Off-Hook Signalling

PABX Recall

Outgoing Calls

Access Barring

Automatic Pause

Insertion on PABX lines

Decadic to Tone

Signalling

Direct Exchange line

Access

last Number Redial

live Key Working

On-Hook

Dialling/Monitor

Automatically transmits music to a caller on hold. The music may be

generated internally, or provided by an external source. (The Optional

Facilities Board is required for externally provided Music-On-Hold).

Provides a muted audible exchange line signal to a busy keystation when

it receives an incoming exchange line call.

When the system operates behind a PABX, this facility enables access

to the facilities of the host PABX. Only TLB is provided.

Restricts the range of numbers that can be

dialled

on akeystation. Each

keystation can be programmed for one of two classes of Access Barring

via a DIP switch located in the keystation.

Class 1

unrestricted access

Class 2

access restricted to exception table entries plus access to

OOO,OO8,013,016n >

n, 122n > n, 11441 > 11440,

13n >

n,0175,18nn.

Exception Table is 8 entries of 4 digits each.

When using the abbreviated dial and redial facilities on PABX lines, the

system automatically inserts a three-second pause.

After connecting a keystation to a called party on a decadic exchange

line, the dial pad can be used to send further numbers in tone (DTMF)

signalling.

Direct access to exchange lines by any keystation using a single key.

Press [REDIAL] to automatically redial the last number

dialled.

After pressing an exchange line key, the loudspeaker automatically

activates to allow the

dialling

of a number without lifting the handset.

Enables a keystation to originate a call and monitor its progress without

lifting the handset. However, you must use the handset to speak to the

called party.

Commander E105/208+ Installation and Maintenance Manual

Page

1-7

Page 23

Introduction to the Commander E105/208+ System

System

Facilities

Station Abbreviated

Dialling

Station Speed Dialling

Internal Calls

Alternative Point

Answering

Direct Keystation

Selection

Intercom

Intercom Voice/Ring

Signalling

Meet-Me Paging

Paging

Voice Call

By pressing [MEMORY] and then dialling a memory location

(O-9),

each keystation can access up to ten programmed numbers having a

maximum of 19 digits. Each keystation has its own ten-number

memory.

When the handset is lifted or the station is ‘off-hook’, and an exchange

line is selected, up to 8 speed dial keys can be used to select preprogrammed speed dial numbers. These numbers are a subset of those

used for station abbreviated dialling.

Allows any keystation to answer an intercom call directed to another

keystation by pressing [CONF].

Allows single-button access to another keystation by pressing the

required DSS key (1 to 8).

Establishes a private call between any two keystations.

Allows the keystation user to select to make either an intercom signal

call or an intercom voice call. An intercom signal call is when an

intercom ring is sent to the called keystation. An intercom voice call is

when, after a short tone, the caller can speak directly to the called party

through the called station’s

inbuilt

speaker.

In both cases, the called party must lift the handset to speak to the

calling party.

After a paging announcement, the paged person can contact thecalling

party by pressing [PAGE] on any keystation.

Allows paging of all other keystations through theirloudspeakers from

any keystation. Individual keystations can be programmed to bar the

reception of a page announcement. (Note that keystations programmed

not to receive page calls are also excluded from receiving Door Station

chimes).

Allows a keystation user to call any keystation and speakdirectly

through the speaker of the called keystation.

Page

1-6

Page 24

System

Facilities

Introduction to the Commander

E105/208t

System

Door Station

Portability

Powerfail Operation

Power Failure Memory

Retention

Keystation Directory

Wall-Mounting Bracket

Miscellaneous

Background Music

(Optional)

Call Progress Tones

Confidence Tone

Provides two-way communication between an unsupervised areaand

any keystation on the system. (Note that keystations programmed not

to receive paging calls are also excluded from receiving door station

chimes.) (The Optional Facilities Board is required to provide the Door

Station facility.)

Allows movement of keystations to other sockets in the systemwhile

still retaining their identity and abbreviated dialling information.

During a power failure, exchange line calls can be made and received at

a specially provided two-wire telephone.

Retains the keystation’s abbreviated dialling memory during an extended

power failure for a minimum of 24 hours.

A directory label designed to adhere to the face of each keystation is

provided for the recording of extension numbers and abbreviated dial

numbers.

Enables keys stations to be wall-mounted.

Music supplied from an external source can be broadcast through

keystation loudspeakers, and turned on and off at each keystation as

required. The music automatically turns off when a call is in progress.

The Optional Facilities Board and an external music source (including a

Telstra approved Line Isolation Unit) are required to provide this facility.

Tones indicate the call

status to

the user.

A low-level, audible tone indicates that a key press is registered. The

user enables or disables this facility.

Commander

E105/208t

installation and Maintenance Manual

Page I-9

Page 25

Introduction to the Commander

E105/208t

System

System

Facilities

Headset Mode

A keystation handset may be replaced by a suitable Austel permitted

headset. When connected and activated, the [SPKR] key is used to

perform the off-hook function. Headset mode is protected against

activation and deactivation by a two-key activation sequence.

Secrecy

Visual Indication

All external and internal calls provide secrecy.

Visual display is provided at each keystation to indicate:

.

all incoming exchange line calls

.

exchange line held condition

.

exchange line in-use condition

.

exchange line in conference

.

other conditions such as intercom line status, Do Not Disturb,

Speaker On and Headset Mode selected.

~

Page l-10

Page 26

Chapter Two

Power and Termination Unit

L

Page 27

Chapter Two

Power and Termination Unit

Table of Contents

Introduction

......................................................................................................

2-1

General Description

............................................................................................

2-1

Power and Terminating Board

.........................................................................................

2-2

Optional Facilities Board (Optional)

.................................................................................

2-2

Circuit Blocks . Power and Terminating Board

...........................................................

2-3

Transformer

....................................................................................................................

2-3

Power Supply

.................................................................................................................

2-3

Electronic Choke

............................................................................................................

2-3

Powerfail

........................................................................................................................

2-3

Exchange Line Protection

................................................................................................

2-3

System Bus

.....................................................................................................................

2-3

Circuit Blocks.Optional Facilities Board

.................................................................

2-5

Microcomputer Unit (MCU)

...........................................................................................

2-5

Data Transmit and Receive

..............................................................................................

2-5

Door Station Interface

.....................................................................................................

2-5

External Music Source Interface

......................................................................................

2-5

Chapter Two

Page 28

I -

Introduction

Chapter Two

Power and Termination Unit

This chapter provides a general description of the Power and

Termination Unit and its two major components: the Power and

Terminating Board (PTB-E) and Optional Facilities Board (OFB-E). It

also includes PTB-E and OFB-E circuit block diagrams and a

description of all circuit blocks depicted in both diagrams.

General

Description

The Power and Termination Unit (PTU) houses the Power and

Terminating Board (PTB-E) and Optional Facilities Board (OFB-E).

Refer to

Illustration 2 - PTU.

The PTU is a wall-mounted plastic housing that contains:

.

exchange line terminations

.

system bus terminations

.

line protection circuitry

.

power-fail relay

.

system power regulation and reticulation.

An in-line, mains-operated plug-pack, supplied as part of the PTU,

supplies the

PTU’s

AC power.

@lstra

PI1 0 -

COMMANDER-E

PTU

[IL021

Commander E105/208+ Installation and Maintenance Manual Page 2-l

Page 29

Power and Termination

Unit

General

Description

Power and Terminating

Board

Board Code - PTB-E

Location - PTU Base

Description - The PTB-E provides:

.

the system terminal strip

Used to terminate: incoming exchange lines; the system bus;

the power-fail station and external background music inputs.

.

power supply circuitry

.

exchange line protection.

Optional Facilities Board

(Optional)

Board Code - OFB-E

Location - PTU Cover

Board Description - An OFB-E is installed in the PTU when any of

the following optional facilities are required:

.

Door Station

.

external music-on-hold

.

background music

The OFB-E uses the same microcomputer as the keystations. It

contains: the intelligence required for bus communications, the control

features necessary for the optional facilities and the Door Station input

terminals. The OFB-E connects to the PTB-E via a flat cable.

Page 30

I -

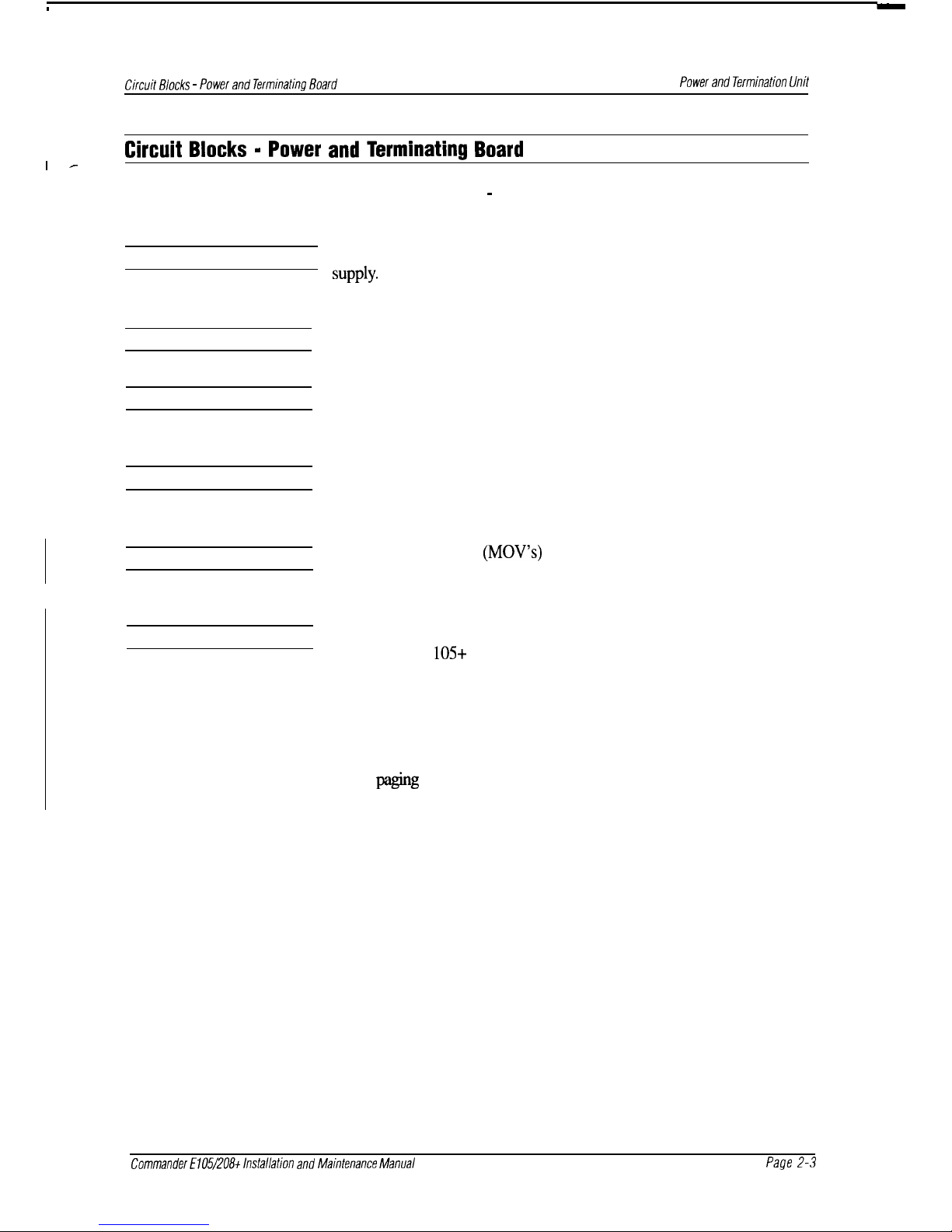

Circuit

Blocks - Power and Terminating Board

Power and Termination Unit

Circuit Blocks - Power and Terminating Board

Refer to

Illustration 3 - PTB-E Circuit Block Diagram.

Transformer

A double-insulated plug-pack that delivers 24V AC Nom. to the power

supply.

Power Supply

Delivers DC voltages for the system bus communications pair.

Electronic Choke

Decouples the Audio and Frequency Shift Keying signals from the DC

feed.

Powerfail

When power fails, a relay releases that switches each exchange line pair

in the system to a standard two-wire telephone.

Exchange line Protection

Metal Oxide Varistors

(MOV’s)

isolate exchange line pairs from high

voltage surges on the exchange lines.

System Bus

The system bus consists of a pair of wires for each exchange line (the

Commander E

105+

system contains one spare pair) and a single pair

for the following:

.

system communication

.

power reticulation

.

intercom

.

paging

.

conference calls.

Commander

E105/208t

Installation and Maintenance Manual

Page 2-3

Page 31

Power and Termination Unit

Circuit

Blocks - Power and Terminating Board

240V

AC

Exchange lines

Powerfail ports

Plug Pack

, Transformer

Powerfail

Power

SUPPiY

Electronic

Choke

~ protection

System Bus

1 ’

Terminal Strip

b

I

To keystations

PTB-E Circuit Block Diagram

[IL031

Page 2-4

Page 32

Ciicuit Hocks -

Ootional Facilities Board

Power and Term/nation Unit

Circuit Blocks - Optional

Facilities

Board

Refer to

Illustration 4 - OFB-E Circuit Block Diagram.

Microcomputer Unit

NW

The OFB-E Microcomputer Unit controls:

.

Door Station interface

.

external music source interface

It works in conjunction with the keystation microcomputer to control the

systems’ optional facilities.

NOTE:

PABX Earth Recall is not available on the Commander

E

105/208+.

Data Transmit and

Receive

Converts data transmitted on the bus pair into logic levels for the

Microcomputer Unit.

Door Station Interface

Provides circuitry to connect a single Door Station to the system.

Intercom transmission between the door and keystation is via the bus

intercommunication channel.

External Music Source

Interface

Provides circuitry for the connection of an external music source to the

system. Background music and music-on-hold are relayed to the

keystations via the bus intercommunicationchannel.

Commander

E105/20&

Installation and Maintenance Manual

Page 2-5

Page 33

Power and Termination Unit

Circuit

Blocks - Optional Facilities Board

Bus

<

I

Door

<

Station

External

Music

/

Data

>I

Transit

I

and Receive

I

\

>I

<

<

Exchange

Lines

Earth

OFB-E Circuit Block Diagram

[IL041

>I

MCU

Page 2-6

Page 34

-

L

Chapter Three

Keystations

Page 35

Chapter

Three

Keystations

Table of Contents

Introduction

......................................................................................................

3-l

General Description

.............................................................................

.

..............

3-1

Keystation Main Board

...................................................................................................

3-2

Hold and Ring Detect Board

...........................................................................................

3-2

Keypad Assembly

...........................................................................................................

3 -2

Circuit Blocks

..........................................

.

..............................

.

...........

.

..............

3-3

Microcomputer Unit Circuit (MCU Circuit)

.....

................................................................

3-3

Keypad RISC Processor

.......................................................................................

3-3

Memory

................................................................................................................

3-3

Memory Back-Up Circuit

......................................................................................

3-3

Reset..

...................................................................................................................

3-3

Power Supply

.................................................................................................................

3-3

Isolation Transformer

.......................................................................................................

3-3

Data Transmit and Receive

..............................................................................................

3-4

Speech Circuit

................................................................................................................

3-4

Tone Generator

...............................................................................................................

3 -4

Audio Selector

................................................................................................................

3 -4

Audio Amplifier

...............................................................................................................

3 -4

Line Access Circuit

.........................................................................................................

3-4

HRDB-E Board (In Master Keystation)

..........................................................................

3-4

Line-Hold Circuit

...................................................................................................

3 -4

Ring Detect Circuit

.................................................................................................

3-4

Chapter Three

Page 36

Chapter Three

Keystations

I

Introduction

This chapter provides a general description of the keystation and its two

major printed circuit boards.

It then provides descriptions of each

keystation circuit block and a circuit block diagram.

General

Description

There are 3 types of system keystations.

.

E

105+

Master Keystation

Contains the hold and ring detectiorl circuitry

for

the

Commander El

05+

system.

.

E208+

Master Station

Contains the hold nnd ring detection circuitry for the

Commcmder E208-b

systtm.

.

E208+ Standard Keystation

NOTE:

Both Commander E

105+

and Commander E208+ Master

Keystations have keys provided for 2 exchange lines. The

E

105+

Master Keystation however differs from the

E208+

in that the

inbuilt

HRDB-E (Hold and Ring Detect Board)

and the Control Board are only equipped to handle 1

exchange line.

Standard Keystations are identical for both size systems.

All keystations contain a telephone network that includes:

.

a handset

.

a dial keypad incorporating a RISC processor.

.

non-locking function keys

.

status Light Emitting Diodes (LEDs) (housed in keys)

.

a speaker

.

volume control.

The Master Keystations also carry a line hold and ring detection

HRDB-E circuit board.

Refer to Illustration 5 -

E105+

and

E208+

Keystation.

I

,-

Commander

E105/208t

installation and Maintenance Manual

Page 3-I

Page 37

Keystations

General

Description

Keystation Main Board

Hold and Ring Detect

Board

Keypad Assembly

Board Code - KSB-E-A (Keystation Main Board)

Location - Keystation

Board Description - This board contains a high-performance, single

CMOSchip microcomputer and associated circuitry. It controls all

keystation, system and data communications functions and contains the:

.

keystation power supply

.

speech and audio circuitry

.

data transrnit and receive circuitry

.

line control circuitry.

Board Code - HRDB-E

Location - Master Keystation

Board Description - This board contains circuitry that controls system

ring detection and line holding functions. It also accommodates the

internal music-on-hold feature. This board differs between Commander

E105+ and Commander E208+ systems.

Location - Keystation

Description - This assembly generates

dialling

and system function

signals. It consists of a rubber keypad and printed board assembly

connected to the keystation main board via a ribbon connector. The

assembly is controlled by a RISC processor. This processor also

handles keypad interfacing with the keystation Main Board.

Commander

E105+

and

E208+

Keystation

[IL051

Page 3-2

Page 38

Circuit Blocks

Keystations

Circuit

Blocks

Microcomputer Unit

Circuit

(Mhl

Circuit)

Keypad RISC Processor

_ -

Memory

Memory Back-Up Circuit

Reset

Power Supply

Isolation Transformer

Refer to

Illustration 6 - Keystation Circuit Block Diagram.

Controls keystation operation. The MCU works in conjunction with

other keystations (and the

OFF&E,

if installed) to control the system

operation.

Specifically, the keystation central microcomputer controls the:

.

exchange line interface

.

keystation communications and operation

.

intercom keystation interconnection

.

connection of signal tones to the keystation

.

system option programming.

This process or provides an intelligent interface between the keypad and

the station Microcontroller unit. It provides mapping for all ‘intelligent

keys’, such as DSS/Speed Dial keys and

Centel@

functions keys.

Keystation memory consists of 8K words of ROM (10 bits per word)

and 5 12 words of RAM (4 bits per word).The microcomputer uses the

Random Access Memory (RAM) to store abbreviated dialling codes.

The microcomputer uses Read Only Memory (ROM) to store the

keystation’s operating program.

During brief power down periods, the memory back-up circuitprotects

the abbreviated numbers stored in RAM. This circuit consists of a

supercapacitor (charged ready for use under normal keystation

operating conditions) and associated control circuitry.

When low voltages are detected, the reset circuit transmits an interrupt

signal to the Microcomputer Unit (MCU) and generates a reset pulse

when power is restored.

A DC-DC converter that steps down and isolates bus voltages to

supply the keystation circuit requirements.

Isolates keystation circuitry from the bus.

Commander E105/208+ Installation and Maintenance Manual

Page 3-3

Page 39

Keystations

Circuit Blocks

Data Transmit and

Receive

Converts data transmitted on the bus power pair into logic levels, then

directs the signal to the keystation MCU serial port

signalling

interface.

Speech Circuit

Provides an interface for the telephone network intercom channel,

transmission circuit and handset.

Tone Generator

Provides the DTMF tone and all audible tones emitted by the

keystation.

Audio Selector

This circuit couples either:

.

audio signals from the speech circuit to

the

audio amplifier when

connected to either the telephone line or the bus,

or

.

audible tones from

the

tone generator to the audio amplilier when

required for either audible tones in the earpiece or transmission of

DTMF signals.

Audio Amplifier

Under control of the audio selector, the audio amplifier drives the

keystation speaker. Line access connects lines to the speech circuit by

an MCU-controlled relay.

line Access Circuit

Provides an interface between the speech circuit and either of the

exchange lines. It also provides a solid-state switch fordialling

purposes.