Page 1

Model SP-5000 Thermal Printer

User Manual

TELPAR

A Platinum Equity COMPANY

187 Cosby Road

Dover, New Hampshire 03820

Toll Free: 800-872-4886 (from the U.S.A. and Canada only)

603-750-7237

Fax: 603-742-9938

Manual SP-5000 CE/UL Version – Part No. 790136-0020 (Rev. D - 06/03)

Website: www.telpar.com

E-mail: info@telpar.com

Page 1 of 34

Page 2

Table of Contents

1 Introduction............................................................................................................................... 4

1.1 Printer Overview................................................................................................................... 4

1.2 Telpar - Limited Printer Limited Warranty............................................................................ 5

2 Operator Information................................................................................................................ 6

2.1 Printer Top View................................................................................................................... 6

2.2 Printer Status LED............................................................................................................... 6

2.3 Primary AC Power Input....................................................................................................... 6

2.4 Unpacking and Inspection.................................................................................................... 8

2.5 Paper Loading...................................................................................................................... 8

2.6 Intelligent Kiosk Operation.................................................................................................... 8

2.6.1 Enable and Disable of the Delivery System Ticket Removal..................................... 10

2.6.2 Clearing a Paper Jam Condition................................................................................. 11

3 3 Installation............................................................................................................................ 12

3.1 Power Up and Self Test..................................................................................................... 12

4 Interface Specifications.......................................................................................................... 13

4.1 Serial Interface Specifications............................................................................................ 13

4.1.1 SW1 Switch Settings.................................................................................................. 13

4.1.2 SW2 Settings.............................................................................................................. 14

4.1.3 DB-9 RS-232 Serial Interface..................................................................................... 14

4.2 Parallel Interface................................................................................................................. 14

4.3 Flow Control....................................................................................................................... 15

4.4 Parallel Port Handshaking Implementation........................................................................ 15

4.4.1 Scope.......................................................................................................................... 15

4.4.2 Description of Status Signals...................................................................................... 15

Page 2 of 34

Page 3

4.4.3 Description of Changes Required............................................................................... 15

4.5 Parallel Interface Cable...................................................................................................... 16

4.6 Optional Microsoft Windows® Driver Diskettes................................................................. 16

4.6.1 Telpar SP-5000/2 Windows Driver Disk..................................................................... 16

4.6.2 SP-5000/3 Windows Driver Disk................................................................................ 16

4.6.3 SP-5000/4 Windows Driver Disk................................................................................ 17

4.7 Installing a Telpar Printer Driver with Microsoft Windows® 3.1x....................................... 17

4.8 Installing a Telpar Printer Driver with Microsoft Windows® 95.......................................... 17

4.9 Installing a Telpar Printer Driver with Microsoft Windows® NT 3.51 Intel.......................... 18

5 Programming Information...................................................................................................... 19

5.1 Control Codes and Escape Sequences for SP-5000/2..................................................... 19

5.2 Control Codes and Escape Sequences for SP-5000/3..................................................... 20

5.3 Control Codes and Escape Sequences for SP-5000/4..................................................... 21

5.4 Programming Example to Show All Four Character.......................................................... 22

5.5 Non-Volatile Data (with Optional 512KByte Ram).............................................................. 22

5.5.1 An Example of Programming Non-Volatile Data in BASIC......................................... 22

5.5.2 Printing Non-Volatile Data........................................................................................... 22

5.6 Horizontal Graphics Mode.................................................................................................. 23

5.7 Bar Code Operation........................................................................................................... 25

5.7.1 Programming Bar Code Operation in Basic............................................................... 25

5.7.2 3 of 9 Bar Code Description........................................................................................ 25

5.7.3 UPC Bar Code Description......................................................................................... 26

5.8 Echo Back Printer Error Status Byte................................................................................. 27

5.9 Echo Back Printer Mode Status Byte................................................................................. 27

6 SERVICE................................................................................................................................ 28

6.1 Introduction......................................................................................................................... 28

Page 3 of 34

Page 4

6.2 Required Information for Service........................................................................................ 28

6.2.1 Cleaning...................................................................................................................... 28

6.2.2 Printing Malfunctions................................................................................................... 28

7 Trouble Shooting.................................................................................................................... 29

7.1 SP-5000 Trouble Shooting Table....................................................................................... 29

7.2 Clearing a Paper Jam......................................................................................................... 30

8 ASCII Codes........................................................................................................................... 31

9 UPC Code Chart.................................................................................................................... 32

10 Controller Layout.................................................................................................................... 33

11 Printer Specifications............................................................................................................. 34

11.1 Specifications................................................................................................................. 34

11.2 Telpar Roll Paper for SP-5000:...................................................................................... 34

11.3 Options........................................................................................................................... 34

12 FCC Compliance Statement.................................................................................................. 35

13 CE Declaration of Conformity................................................................................................ 36

Page 4 of 34

Page 5

1 Introduction

Manual Revision D.

1.1 Printer Overview

The Telpar SP-5000 is a fast, low cost industrial printer. The SP-5000 will print at a maximum paper feed rate of

2.0 inches per second.

The SP-5000 can provide a variety of output formats. The printer is available with mechanisms which will accept

2.35, 3.125 or 4.40 inch wide thermal paper. The SP-5000 is also capable of high density graphics. MTBF = 400

million (min.) pulses (25% print ratio). The SP-5000 is equipped with a dual configuration 9 pin RS-232 serial

interface, and a Centronics type (DB-25S) parallel interface.

Low maintenance is assured by Telpar’s reliable design and ribbonless thermal print technology. The SP-5000 also

includes a built-in diagnostic self test and a 31K data buffer (128 and 512K optional).

The SP-5000 is housed in a rugged aluminum enclosure. This unit operates through 0° to +122° F with a

constantly regulated print intensity control.

Page 5 of 34

Page 6

1.2 Telpar - Limited Printer Limited Warranty

For one (1) year after shipment of the printer product to Buyer, Telpar warrants the product against defects in

materials and workmanship provided the product has been operated and maintained in accordance with

manufacturer’s operating and maintenance specifications. The warranty specifically excludes ribbons, paper and

other consumable items.

THIS WARRANTY IS IN LIEU OF ANY AND ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED.

TELPAR MAKES NO OTHER WARRANTY AND BUYER SPECIFICALLY WAIVES ANY OTHER WARRANTIES,

INCLUDING WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. THERE ARE NO

WARRANTIES WHICH EXTEND BEYOND THOSE DESCRIBED HEREIN.

Telpar’s liability hereunder is limited to the repair or replacement of defective parts. This liability does not extend

to normal wear and tear. Telpar will, solely at its option, remedy all valid warranty claims either by:

(a) Repairing or replacing the defective unit at Telpar’s factory; or

(b) Repairing or replacing the defective subassembly at Telpar’s factory.

If so directed by Telpar, Buyer shall return the defective unit or subassembly, transportation prepaid by Buyer, to

Telpar’s factory. After repair or replacement has been accomplished, Telpar will return the unit or subassembly,

transportation prepaid by Telpar, to Buyer.

As a precondition to any warranty service, prior to return of any units or subassemblies to Telpar by Buyer, Buyer

must contact Telpar’s Order Administration Services and receive authorization in the form of a Return Material

Authorization (RMA) number. Telpar reserves the right to refuse any goods it has not previously authorized for

return, or any goods shipped without transportation prepaid.

NO WARRANTY SHALL APPLY TO ANY DAMAGE RESULTING FROM OR CAUSED BY BUYER, IF BUYER SHALL MAKE

ANY CHANGES, MODIFICATIONS, ADDITIONS OR DELETIONS OF HARDWARE, SOFTWARE OR FIRMWARE IN THE

PRINTER PRODUCTS SOLD HEREUNDER WITHOUT TELPAR’S ADVANCE WRITTEN CONSENT.

Page 6 of 34

Page 7

2 Operator Information

2.1 Printer Top View

Printer Status LED

LED PRINTER STATUS

Solid Green Printer Ready

Flashing Green and Red Printer Platen in Open

Position, or Paper Out of

Mechanism

Solid Red Paper Roll Low

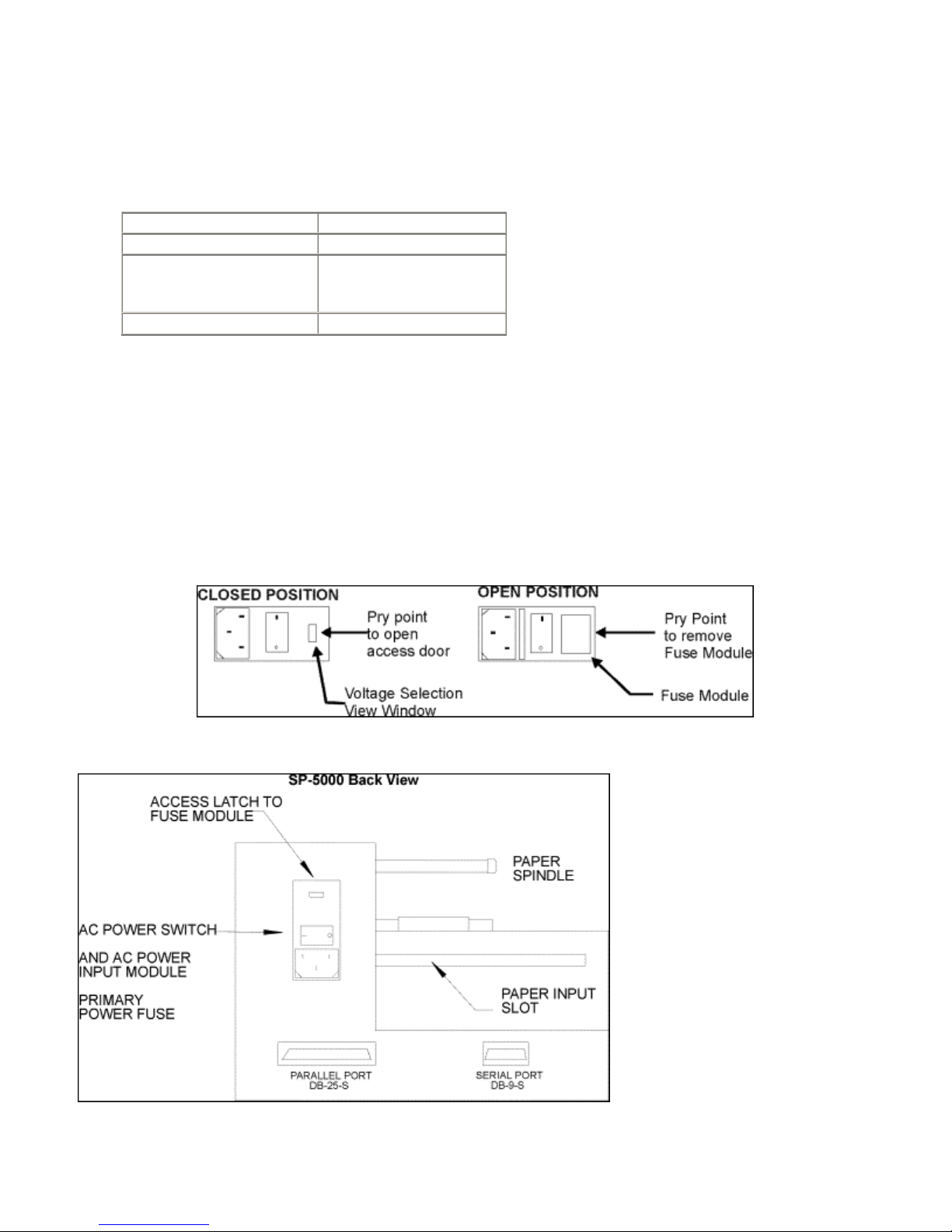

2.3 Primary AC Power Input

The power module is where the main power fuses are located. In this module, the primary power may be set to

115 VAC or 230 VAC. To change the primary AC input voltage, or replace a fuse, perform the following:

1. To gain access to the primary power fuse location, use a small flat blade screw driver to pry open the

access door at the pry point as shown below.

2. Remove the fuse module by using a small flat blade screw driver to pry up on the edge of the fuse

module. The fuse module will pull straight out of the AC input module.

3. Once the fuse module is out of the unit, replace the fuse with a proper rating fuse if necessary, or change

the voltage by rotating the fuse module 180°. Reinstall the fuse module into the AC receptacle with the desired

voltage positioned for display in the view window. The voltage selected can be seen by looking at the voltage

displayed in the view window located on the right side of the module when the access door is closed.

Figure 2 SP-5000 Fuse Module

F1 = 2A/250V for 115 VAC operation

F2 = 1A/250V for 230 VAC operation

Figure 3 SP-5000 Back View

Page 7 of 34

Page 8

2.4 Unpacking and Inspection

Carefully unpack and inspect your SP-5000 for any damage which may have occurred in transit. Should any

damage have occurred, notify Telpar, save the shipping carton and packing materials, and file a damage claim with

the carrier. Specify the nature and the extent of the damage. Before installing or operating the printer, check the

following:

· Ensure that the primary power setting is correct for your installation.

· Ensure that the printer mechanism and paper paths are clear of all packing materials or other foreign

matter.

· Ensure that paper is installed. DO NOT OPERATE the printer without paper.

2.5 Paper Loading

Install a new roll of Telpar approved paper (thermal side up) on the paper spindle. Apply power to the printer. Set

printer platen to the closed position via the paper release lever (shown below) and then feed a straight and clean

leading edge of the paper directly into the paper input slot. Once the optical switch detects the paper, the printer

will automatically feed paper through the mechanism to the proper point.

2.6 Intelligent Kiosk Operation

The SP-5000 has been developed specifically for kiosk applications. The SP-5000 incorporates special mechanical,

electrical, and programming features that make it ideal for un-attended kiosk systems. To enable the Intelligent

Kiosk delivery feature, the printer must receive the escape code sequence ESC+”c” at the end of it’s printing

routine.

Note: The printer can output system status via the RS-232 Serial Interface. For more information see Section

5.8 and 5.9.

An example in BASIC to enable the drive system is as follows:

FOR X = 1 TO 60

LPRINT “SP-5000 PRINTER”

NEXT X

LPRINT CHR$(27) + “c”;

Page 8 of 34

Page 9

2.6.1 Enable and Disable of the Delivery System Ticket Removal

The SP-5000 has the ability to retract the printed, cut and formerly delivered ticket if it has not been removed from

the Delivery System. This feature can be used in KIOSK applications when a customer has requested printed

information from the KIOSK, but has then decided to leave the printed information in the printer. Prior to the

availability of this option, the next printed information ticket would be cleared out of the front of the printer that

usually fell on the floor. Now, the next printed information will enable the previously printed ticket to be drawn

back into the printer and dropped into the open slot behind the Delivery System. KIOSK manufactures must

provide ample space and a receptacle for the retracted tickets to fall inside their KIOSK.

Since not all of Telpar’s customers are interested in using this feature, an Escape Sequence has been added to

allow the enable or disable of this feature.

To

Disable

the removal feature, send the sequence:

ESC + D + 0

Enable

To

the removal feature, send the sequence:

ESC + D + 1

The following BASIC programs enable and disable the feature via programming:

Basic Program Description

10 WIDTH LPRINT 255

20 LPRINT CHR$(27)+”D”+CHR$(1) :REM Enable Purge Ticket

30 End Enables the removal feature

10 WIDTH LPRINT 255

20 LPRINT CHR$(27)+”D”+CHR$(0) :REM Disable Purge Ticket

30 End Disables the removal feature

Additionally, the SP-5000 printer incorporates a DIP switch (SW1-8 located on the main control board) which will

enable or disable this feature. Please note that software can over-ride the hardware (DIP switch) setting.

To enable the optional feature with the DIP switch, the switch must be in the open position. To disable the

feature, move the switch to the closed position. The printer must be turned off (powered down) when making the

switch selections. The default operation (enable or disable) will be activated upon power up of the unit.

only

One key mechanical feature of the SP-5000 is that it will cut and deliver the hard copy

after the printer has

completed printing. This task is accomplished by re-directing the printed hardcopy below the unit. By re-directing

the output of the printer to the queue area while printing, jams due to premature hardcopy removal are

eliminated. The printer will allow a total of 102" (13 seconds) of printing to be re-directed. If this amount is

exceeded, the printer will go into error mode to alert the user of a potential problem.

The SP-5000 incorporates a hardcopy edge sensor located in the intelligent delivery output guide. This sensor

functions as an edge detector and a hardcopy clear sensor. When directed to print, the sensor is used to stop the

intelligent drive rollers to allow the redirection of the printed form. Once the unit has completed printing and has

received the ESC+”c” sequence, the drive rollers will engage and present the hardcopy to the user. The printer is

designed to output then hold approximately 0.5" of the hardcopy to allow manual removal by the user. The

hardcopy clear function is enabled if the drive rollers are jammed during the output sequence. If the drive rollers

are stalled for more than 20 seconds, the unit will reverse the drive rollers to clear the hardcopy from the output

path. If the unit does not clear the form, or the drive rollers jam, the unit will go into error mode to alert the user

of a potential problem.

2.6.2 Clearing a Paper Jam Condition

If a jam does occur in the output section of the intelligent paper delivery system, the output guide and cutter

assembly may be rotated upward to gain access to the mechanism output / cutter input area. To rotate the output

assembly, turn the unit off and remove primary power. Apply light pressure in an upward motion to the front

underside of the output assembly guide. While applying this pressure, push the left then right cutter retention

buttons outward (approximately 1/32") to release the assembly from the print mechanism.

Once free, the assembly may be rotated upward 90° that should provide access to the jam area. Additionally,

open the printer platen with the paper release lever on the left side of the printer. The jammed paper may be

Page 9 of 34

Page 10

removed at this time. Once the paper has been removed, close the printer platen and lower and output assembly

to their home positions. Normal printing may be resumed at this time.

Figure 8 SP-5000 with Output Assembly in Closed Position

Page 10 of 34

Page 11

3 3 Installation

3.1 Power Up and Self Test

The operating controls of the SP-5000 have been kept to a minimum. A convenient self-test feature allows the

operator to quickly determine that the printer is operating correctly.

· Telpar PART# 751502-0060 for the 2.35 inch wide roll.

· Telpar PART# 751503-0060 for the 3.125 inch wide roll.

· Telpar PART# 751504-0060 for the 4.40 inch wide roll.

Note: Each different paper width is used for a specific model only. The correct paper width must be installed

with the appropriate unit and mechanism.

Page 11 of 34

Page 12

4 Interface Specifications

4.1 Serial Interface Specifications

The SP-5000 can be used as either a serial or parallel device. The serial interface parameters are set via SW1 and

SW2. Baud rate, serial parameters and KIOSK options are set with SW1. SW2 is used to set the specific serial

interface configuration.

4.1.1 SW1 Switch Settings

1 2 3 4 5 6 7 8

Baud Rate Stop Parity Data Parity Delivery

Bits Length Odd/ System

Even

Setting

600 Close Open Open

1,200 Open Close Open

2,400 Close Close Open

4,800 Open Open Close

9,600 Close Open Close

19,200 Open Close Close

38,400 Close Close Close

115,200 Open Open Open

1 Close

2 Open

Disable Close

Enable Open

7 Bits Close

8 Bits Open

Even Close

Odd Open

Disable Close

Enable Open

Switches SW1 and SW2 are located on the printer’s main controller board. See next page for switch locations.

Page 12 of 34

Page 13

4.1.2 SW2 Settings

Switch SW2 is used to set the SP-5000 printer’s serial port pinout configuration. The printer can be set to it’s own

configuration or PC/AT pinout.

4.1.3 DB-9 RS-232 Serial Interface

The SP-5000 serial interface incorporates a DB-9 connector whose pinout configuration can be changed via SW2

from the SP-5000 to a PC/AT compatible configuration.

Pin Signal Description

1 GROUND Protective ground

2 TXD Data output from the printer to the host

3 RXD Data input to the printer or display

4 CTS Inhibits TXD line when held at -10v by the host

5 GROUND Signal ground

8 DTR -10v when printer is unable to receive data

There are two conventions used in the RS-232C interface; these are Data Terminal Equipment (DTE) and Data

Communications Equipment (DCE). Examples of DCE are modems, multiplexers, and telephone data line

interfaces. All other equipment which originates or receives data such as terminals (including the SP-5000) or

computers is DTE. The difference between DCE and DTE is that TXD and RXD are reversed, as well as several

control signals.

This allows a piece of DTE to connect directly to a piece of DCE, e.g. a modem to a terminal, with a straight pin for

pin connection in the interconnecting cable. However if two pieces of DTE are to be interconnected it is necessary

to transpose TXD and RXD as well as DTR and CTS in the cable. This type of cable is called a null modem cable

and must be used if the SP-5000 is connected to a host computer’s serial port.

A DB 25S connector is used for the parallel interface. The pin assignments and brief signal descriptions are listed

below.

Pin Signal Description

1 STROBE 1 µsec. pulse to clock data into the printer

2 DATA 0

3 DATA 1

4 DATA 2 Eight data bit input signals to the printer;

5 DATA 3 Signal levels are high for logic 1 and low

6 DATA 4 for a logic 0.

7 DATA 5

8 DATA 6

9 DATA 7

10 ACK 6 µsec pulse from printer when data received

11 BUSY High when printer is unable to receive data

12 PE High when a paper error occurs in printer

13 SELECT High when printer is on line

18-24 GROUND Signal Grounds

4.3 Flow Control

The SP-5000 employs a 31 K byte data buffer (128 and 512 optional) to allow the host computer to rapidly transfer

data. Under some circumstances it may be possible to completely fill the buffer. When the buffer is within 50

bytes of being full, the SP-5000 signals the host computer to pause until a line of data is printed, or until the buffer

is under the 50 byte limit. The flow control information is sent to the host using hardware and software protocols.

The hardware protocol uses the BUSY line of the parallel interface and the DTR line of the serial interface. These

pins are asserted or negated as necessary to turn off and turn on the flow of data.

Page 13 of 34

Page 14

XON and XOFF protocol is offered as an option. The software protocol uses the XON and XOFF ASCII characters

(^Q and ^S) which are sent back to the host to start and stop the data stream. Some host systems may not

support one or both of these protocols. Please contact Telpar for more details regarding the use of this protocol.

4.4 Parallel Port Handshaking Implementation

4.4.1 Scope

This specification describes the hardware and firmware changes required to obtain paper out and jam status

information from the parallel port of the SP-5000 printer.

4.4.2 Description of Status Signals

Paper Out and Summary Jam Status information is available at the I/O pins of the parallel port as shown in the

following table:

Signal Name PE SLCT /Error Printer Status

Pin No. 12 13 15

Signal Levels: Low High High Ready to Receive Data

Low Low Low Printer Jam

High Low Low Out of Paper

A paper jam may be detected at either one of two different locations in the printer. The locations are in the cutter

and in the delivery system. The printer will indicate the location of a jam by issuing different audible warning

alarms for each location. The summary status sent to the parallel port indicates that a jam condition exists in the

printer but it does not signal the location.

4.4.3 Description of Changes Required

4.4.3.1 Hardware Changes

The following hardware change is required on the SP-5000 Rev. D4 Controller Board:

· Make an etch cut at P2 pin12 (solder side of controller board).

· Add a jumper from P2 pin 12 to U4 pin 5.

· Add a jumper from RP7 pin 8 to RP7 pins 2 and 3.

4.4.3.2 Firmware Changes

Firmware Revision D4-01 or higher is required.

4.5 Parallel Interface Cable

This parallel cable configuration is used to interface the SP-5000 with all IBM and IBM compatible systems. This

cable connects the interface to the printer with a 1:1 cable connection, and is terminated by a DB-25P on each

end. This 25 pin cable configuration is available at most computer supply stores. ex. pin 1 to pin 1, pin 2 to pin

2,...pin 25 to pin 25.

Please Note: Cable length for the standard mode of parallel printing (through MS-DOS) should be limited to 25

feet or less.

When printing through Microsoft Windows® in the fast printing to port mode, cable length must be limited to 6

feet or less. In this mode of print, the standard MS-DOS machine interrupts are not used for printing, which

regulates data flow to the printers parallel port. In this printing mode, Centronics Standards for timing data flows

are not utilized. Telpar suggests that during the printer set up in Microsoft Windows® the fast printing to port

option be de-selected.

4.6 Optional Microsoft Windows® Driver Diskettes

Page 14 of 34

Page 15

Telpar offers optional Microsoft Windows® driver diskettes for use with Microsoft Windows® applications.

4.6.1 Telpar SP-5000/2 Windows Driver Disk

Since the SP-5000/2 has a 2.35 inch wide print area, three Windows print drivers are provided which should allow

for all printing requirements.

The three SP-5000/2 drivers are:

1) SP-5000/2 - Quarter Screen - This driver will print a quarter of the printable screen at the full 200DPI

resolution of the printer. The print area will start at the left of the screen. With this driver there is NO scaling.

2) SP-5000/2 - Half Screen - This driver will print half of the printable screen at the full 200DPI resolution of

the printer. The print area will start at the left of the screen. With this driver the printout is reduced by a factor of

2. For example, a printable document that is approximately 8" wide will be reduced so that the leftmost 4" will fit

on the 2.35" wide SP-5000/2 print area.

3) SP-5000/2 - Full Screen - This driver will print the full printable screen at the full 200DPI resolution of the

printer. With this driver the printout is reduced by a factor of 4. For example, a printable document that is

approximately 8" wide will be reduced to fit on the 2.35" wide SP-5000/2 print area.

It is recommended that the user install all three drivers and experiment until the resolution that meets your

application is determined.

4.6.2 SP-5000/3 Windows Driver Disk

Since the SP-5000/3 has a 3.125 inch wide print area, two Windows print drivers are provided which should allow

for all printing requirements.

The two SP-5000/3 drivers are as follows:

1) SP-5000/3 - Partial Screen - This driver will print 3.125 inches of the printable screen at the full 200DPI

resolution of the printer. The print area will start at the left of the screen. For example, a printable document that

is approximately 8" wide will be truncated so that the leftmost 3.125" will fit on the 3.125" wide SP-5000/3 print

area.

2) SP-5000/3 - Full Screen - This driver will print all of the printable screen at the full 200DPI resolution of the

printer. With this driver the printout is reduced to the 3.125 inch print area of the SP-5000/3. For example, a

printable document that is approximately 8" wide will be reduced to fit on the 3.15" wide SP-5000/3 print area.

It is recommended that the user installs both drivers and experiments until the resolution that meets the

application is determined.

4.6.3 SP-5000/4 Windows Driver Disk

Since the SP-5000/4 has a 4.4 inch wide print area, two Windows print drivers are provided which should allow for

all printing requirements.

The two SP5000/4 drivers are as follows:

1) SP-5000/4 - Half Screen - This driver will print half of the printable screen at the full 200DPI resolution of

the printer. The print area will start at the left of the screen. For example, a printable document that is

approximately 8" wide will be truncated so that the leftmost 4.4" will fit on the 4.4" wide SP5000/4 print area.

2) SP-5000/4 - Full Screen - This driver will print all of the printable screen at the full 200DPI resolution

of the printer. With this driver the printout is reduced by a factor of 2. For example, a printable document that is

approximately 8" wide will be reduced to fit on the 4.4" wide SP5000/4 print area.

Note: It is recommended that the user installs both drivers and experiments until the resolution that

meets the application is determined.

4.7 Installing a Telpar Printer Driver with Microsoft Windows® 3.1x

1) Prepare the Printer to print from the Personal Computer.

1a) Connect the Printer to the power source.

1b) Connect the cable from the PC to the printer.

1c) Apply power to the Printer.

Page 15 of 34

Page 16

Note: Read the README.TXT file on Telpar Driver Disk for additional installation and configuration notes before

continuing.

2) Install the floppy disk with the driver files in your floppy disk drive. From the Windows 3.1x, Main Program

Group, select “Control Panel” and then select “Printers” in the “Control Panel Group”.

3) Click the “Add” Button to view the additional drivers.

4) From the “List of Printers” List Box select “Install Unlisted or Updated Printer”.

5) Click the “Install “ button.

6) Type your floppy disk drive letter in the “Install Driver” Dialog Box and click the “OK” Button.

7) Choose the desired driver by name in the “Add Unlisted or Updated Printer” Dialog Box.

8) Click the “OK” Button to install the driver.

9) Please attempt to solve any potential problems using the Help that is available in Windows 3.1x before

contacting Telpar. If you cannot resolve the problem using the help provided from within Windows 3.1x, contact

Telpar between 9am to 5pm.

4.8 Installing a Telpar Printer Driver with Microsoft Windows® 95

1) Prepare the Printer to print from the Personal Computer.

1a) Connect the Printer to the power source.

1b) Connect the cable from the PC to the printer.

1c) Apply power to the Printer.

Note: If one exists, read the README.TXT file on the Telpar Driver Disk for additional installation and

configuration notes before continuing.

2) From Windows 95, select Start-Settings-Printers.

3) From the “Printers” Window, Click “Add Printer”.

4) From the “Add Printer Wizard” Window, Click the “Next” button.

5) From the next “Add Printer Wizard” Window, Click the “Have Disk...” button.

6) From the “Install From Disk” Window, type in the Floppy Drive Letter you will be installing the driver from

if necessary. Install the Telpar Driver Disk in the Floppy Disk Drive. Click the “OK” button.

7) From the next “Add Printer Wizard” Window, select (highlight) the Printer Driver to be installed and Click

the “Next” button.

8) From the next “Add Printer Wizard” Window, select (highlight) the Port the printer is connected to and

Click the “Next” button.

9) From the next “Add Printer Wizard” Window, change the Printer name if desired in the “Printer name” edit

box. Note: If this is not the only printer installed, answer the question “Do you want your Windows-based

programs to use this printer as the default printer?” by selecting a “Yes” or “No” radio button. Click the “Next”

button.

10) From the next “Add Printer Wizard” Window, select “Yes” to “Print a Test Page” if the printer is

properly connected, paper is installed, and the Printer power is on, otherwise select “No”. Click the “Finish” button.

Note: Telpar recommends you print the test page. It is useful in determining if the installation was successful.

The printer MUST be turned on and ready to receive data. If it is not, select “No” and you can run the test later.

11) After Clicking the “Finish” button as described above, the driver files will be copied from the Floppy Disk to

the Hard Drive, the newly added printer Icon will appear in the “Printers” Window, a Test Page will print on the

Printer and another Window will appear on the Screen asking if the Test Page was printed properly.

12a) If the Test Page printed properly choose “Yes” on the Window as described above and the Installation is

Complete.

12b) If the Test Page did not print properly, choose “No” on the Window shown above and you will be taken to

the Windows Help and asked a series of questions to help diagnose the problem. Please attempt to solve the

problem using the Help that is available in Windows 95 before contacting Telpar. If you cannot resolve the

problem using the help provided from within Windows 95, contact Telpar between 9am to 5pm.

4.9 Installing a Telpar Printer Driver with Microsoft Windows® NT 3.51 Intel

1) Prepare the Printer to print from the Personal Computer.

1a) Connect the Printer to the power source.

1b) Connect the cable from the PC to the printer.

1c) Apply power to the Printer.

Page 16 of 34

Page 17

2) Install the Telpar Driver Disk in the Floppy Disk Drive.

Note: If one exists, read the README.TXT file on the Telpar Driver Disk for additional installation and configuration

notes before continuing.

3) From Windows NT Program Manager, select the “Main” Program Group and run Control Panel.

4) From the “Control Panel”, select “Printers” to run the “Print Manager”.

5) From the “Printer Manager”, select P

rinter - Create Printer....

6) From the “Create Printer” Window, enter a printer name in the “Printer Name” Edit Box. From the “Print

to” List Box, select the communication port the printer is connected to. From the “Driver” List Box, select “Other...”

(At the bottom of the list).

6a) Once you have selected “Other...”, the Install Driver Window will pop up. Type your Floppy Drive letter in

the “Install Drive” Window and click the “OK”.

7) Select a Driver to install from the “Select Driver” Window and click the “OK” Button. The Driver files

will be copied from the Floppy Disk to the Hard Drive

8) Click the “OK” Button from the “Create Printer” Window.

9) From the “Printer Setup” Window, select a paper size from the “Form Name” List Box. Then click

the “OK” Button.

10) The Printer Driver is now installed, you may now close and exit the “Print Manager”. The printer can be

set as the Default printer for Windows NT, or the printer can be accessed from within Windows NT applications.

11) If you have questions concerning the installation and use of the Windows NT Printer Driver, please read

the README.TXT file on the Telpar Driver Disk for additional installation and configuration notes. If there is no

README.TXT file on the Telpar Driver Disk or the question is not answered in the README.TXT file, contact Telpar

between 9am to 5pm.

Page 17 of 34

Page 18

5 Programming Information

5.1 Control Codes and Escape Sequences for SP-5000/2

CATEGORY SYMBOL DEC (HEX) FUNCTION

Control Code

SLF 10 (0A) Single Line Feed

Print 13 (0D) Carriage Return

S_REQ 19 (13) Echo Back Error Status Byte

M_REQ 21 (15) Echo Back Printer Mode Status Byte

CAN 24 (18) Clear All Buffers

ESC 27 (1B) Escape ESC Sequence

ESC,3,n 51 (33) Set Line Spacing to n dots 6" n=1-255

ESC,@ 64 (40) Reset Printer

ESC,C, n1,n2 67 (43) Bar Code 3 of 9

n1=# of Characters

n2=Height of Code= n2x32 dots

high

ESC, D, n 68 (44) Delivery Ticket Removal

n=1=Enable

n=0=Disable

ESC, c 99 (63) Activate Cutter and Deliver Document

ESC, i,n1,n2 105 (69) Bar Code Interleaf 2 of 5

n1= Horizontal Offset n1x8 dots

offset

n2 = Height of Code n2x32 dots

high

Used with ESC,h,n 104 (68) Horizontal Graphics Tab n=1-255

Optional ESC,j,n 106 (6A) Line Feed in Horiz. Graphics n=1-255

Microsoft ESC,l,n 108 (6C) Horizontal Graphics n=1-255

Windows ESC,m 109 (6D) Print ROM Data

Driver ESC,p,n1,n2, 112 (70) Program 512K Non-Volatile Data

n3,n4 n1=Data Bank Storage Location (0-

30)

n2=Number of Banks Required

n3=Data Byte Remainder

(high Number Multiple

of 256)

n4=Data Byte Remainder

(low number must be 1-

255)

ESC,q,n 113 (71) Print 512K Non-Volatile Data n=0-30

0 Defaults to Print all Data Banks

ESC,s,n 115 (73) Set Character Set Size n=1-4 1=40 col.,

2=25 col., 3=12 col., 4=6 col.

ESC, u, n1,n2 117 (75) UPC Bar Code

n1= Horizontal Offset n1x8 dots

offset,

n2 =Height of Code n2x32 dots

high

Page 18 of 34

Page 19

5.2 Control Codes and Escape Sequences for SP-5000/3

CATEGORY SYM DEC (HEX) FUNCTION

Control Code

SLF 10 (0A) Single Line Feed

Print 13 (0D) Carriage Return

S_REQ 19 (13) Echo Back Error Status Byte

M_REQ 21 (15) Echo Back Printer Mode Status Byte

CAN 24 (18) Clear All Buffers

ESC 27 (1B) Escape

ESC Sequence

ESC,3,n 51 (33) Set Line Spacing to n dots 6" n=1-255

ESC,@ 64 (40) Reset Printer

ESC,C, n1,n2 67 (43) Bar Code 3 of 9

n1=# of Characters

n2=Height of Code= n2x32 dots high

ESC, D, n 68 (44) Delivery Ticket Removal

n=1=Enable

n=0=Disable Delivery

ESC, c 99 (63) Activate Cutter and Deliver Document

ESC, i,n1,n2 105 (69) Bar Code Interleaf 2 of 5

n1= Horizontal Offset n1x8 dots offset

n2 = Height of Code n2x32 dots high

Used with ESC,h,n 104 (68) Horizontal Graphics Tab n=1-255

Optional ESC,j,n 106 (6A) Line Feed in Horiz. Graphics n=1-255

Windows ESC,l,n 108 (6C) Horizontal Graphics n=1-255

Driver

ESC,m 109 (6D) Print ROM Data

ESC,p,n1,n2,

n3,n4 112 (70) Program 512K Non-Volatile Data

n1=Data Bank Storage Location (0-30)

n2=Number of Banks Required

n3=Data Byte Remainder

(high Number Multiple of 256)

n4=Data Byte Remainder

(low number must be 1-255)

ESC,q,n 113 (71) Print 512K Non-Volatile Data n=0-30

0 Defaults to Print all Data Banks

ESC,s,n 115 (73) Set Character Set Size n=1-4 1=57 col.,

2=36 col., 3=18 col., 4=9 col.

ESC, u, n1,n2 117 (75) UPC Bar Code n1= Horizontal Offset n1x8 dots offset,

n2 =Height of Code n2x32 dots high

Page 19 of 34

Page 20

5.3 Control Codes and Escape Sequences for SP-5000/4

CATEGORY SYM DEC (HEX) FUNCTION

Control Code

SLF 10 (0A) Single Line Feed

Print 13 (0D) Carriage Return

S_REQ 9 (13) Echo Back Error Status Byte

M_REQ 21 (15) Echo Back Printer Mode Status Byte

CAN 24 (18) Clear All Buffers

ESC 27 (1B) Escape

ESC Sequence

ESC,3,n 51 (33) Set Line Spacing to n dots 6" n=1-255

ESC,@ 64 (40) Reset Printer

ESC,C, n1,n2 67 (43) Bar Code 3 of 9

n1=# of Characters

n2=Height of Code= n2x32 dots high

ESC, D, n 68 (44) Delivery Ticket Removal

n=1=Enable

n=0=Disable Delivery

ESC, c 99 (63) Activate Cutter and Deliver Document

ESC, i,n1,n2 105 (69) Bar Code Interleaf 2 of 5

n1= Horizontal Offset n1x8 dots offset

n2 = Height of Code n2x32 dots high

Used with ESC,h,n 104 (68) Horizontal Graphics Tab n=1-255

Optional ESC,j,n 106 (6A) Line Feed in Horiz. Graphics n=1-255

Windows ESC,l,n 108 (6C) Horizontal Graphics n=1-255

Driver

ESC,m 109 (6D) Print ROM Data

ESC,p,n1,n2,n3,n4 112 (70) Program 512K Non-Volatile Data

n1=Data Bank Storage Location (0-

30)

n2=Number of Banks Required

n3=Data Byte Remainder

(high Number Multiple

of 256)

n4=Data Byte Remainder

(low number must be 1-

255)

ESC,q,n 113 (71) Print 512K Non-Volatile Data

n=0-30

0 Defaults to Print all Data Banks

ESC,s,n 115 (73) Set Character Set Size n=1-4 1=80 col.,

2=50 col., 3=25 col., 4=12 col.

ESC, u, n1,n2 117 (75) UPC Bar Code

n1= Horizontal Offset n1x8 dots

offset,

n2 =Height of Code n2x32 dots

high

Page 20 of 34

Page 21

5.4 Programming Example to Show All Four Character

Basic Program

10 WIDTH LPRINT 255

20 FOR X=1 TO 4

30 LPRINT CHR$(27)+”s”;CHR$(X) :REM SELECT THE CHARACTER SET

40 LPRINT “Text”;X :REM SEND SOME TEXT

50 NEXT X

60 LPRINT “———————————————” :REM CODE BELOW IS FOR FEED + CUT

70 FOR X=1 TO 10

80 LPRINT :REM FEED TO CLEAR DELIVERY

90 NEXT X

100 LPRINT CHR$(27) + “c” :REM CUT THE PAPER

110 END

5.5 Non-Volatile Data (with Optional 512KByte Ram)

Non-volatile data may be down loaded to the SP-5000. A total of 31 (0-30) banks (16Kbytes per bank) may be

used for data downloading purposes. One bank remains for internal printer functions. Graphic images may be

down loaded to the printer via *.PRN files that are created by the SP-5000 Driver for Microsoft Windows® when

printed to a file. A downloading example of a *.PRN graphics image with 24,576 Bytes of data is as follows:

Image Size Example = 24,576 Bytes

· Each bank can accept 16KB - 7Bytes of data for a total of 16377 Bytes per bank

Calculate the Number of Banks Required

· Divide the image size (24,576) by the Bytes per bank (16377) = 24576/16377=1.5006 Banks

· Round up to the next whole number of banks (30 maximum)

· 2 banks will be required)

Calculate the Data Remainder (High and Low)

· 24576-16377=8199 Bytes

8199/256= 32.02734375 (round down to the next whole number) = 32 = H remainder

· 32*256=8192 Bytes

8199-8192=7 Bytes (must be less than 256) = L remainder = 7

To down load the image to the printer, send the following ESC Code:

ESC+p+n1+n2,h,l ESC+p+0,2,32,7

n1 = 0-30 = Banks where data is stored

n2 = Number of banks required

h = High remainder

l = Low remainder

5.5.1 An Example of Programming Non-Volatile Data in BASIC

Basic Program

10 WIDTH LPRINT 255

20 LPRINT CHR$(27)+”p”;CHR$(0);CHR$(2);CHR$(32);CHR$(7);

30 SYSTEM

Prepares printer to accept file (24,576 Bytes) into two banks starting with the first bank (0)

10 LPRINT CHR$(27)+”q”+CHR$(0);

20 SYSTEM

Prints file (24,576 Bytes) starting with the first bank (0 defaults to print all banks)

5.5.2 Printing Non-Volatile Data

A printing utility supplied with the SP-5000 Driver Disk (PT2.EXE) is used to send the data (24,576 Bytes) to the

printer. The format is shown below:

Page 21 of 34

Page 22

Basic and Utility Program Description

10 WIDTH LPRINT 255

20 LPRINT CHR$(27)+”p”;CHR$(0);CHR$(2);CHR$(32);CHR$(7);

30 SYSTEM

Prepares printer to accept file (24,576 Bytes) into two banks starting with the first bank (0)

PT2 *.PRN 1 (1 is the number of times the data is sent) Printing utility supplied with the SP-5000 driver

diskette to down load data to the printer

10 LPRINT CHR$(27)+”q”+CHR$(0);

20 SYSTEM

Prints file (24,576 Bytes) starting with the first bank

(0 defaults to print all banks)

5.6 Horizontal Graphics Mode

Horizontal Graphics Mode is used primarily when printing from Microsoft Windows® with the 0ptional Microsoft

Windows® Driver Diskette from Telpar Corporation. The following 67 byte hexadecimal programming example

emulates

three graphic lines, one dot high (vertically), one inch long each, printed across an 8 1/2 X 11 inch page.

The first line starts 1 inch from the left margin and each line is separated by one inch of space in-between.

Page 22 of 34

Page 23

BYTES - Sequential Data shown in BYTES of Hexadecimal Information

1ST

0D 1B 6A C8 1B 68 0C 1B 6C

0D 0F FF FF FF FF FF

FF FF FF FF FF FF FF 1B 68

0C 1B 6C 0D F0 FF FF

FF FF FF FF FF FF FF FF FF

FF 1B

68 0C 1B 6C 0D

F0 FF FF FF FF FF FF FF FF

FF FF

FF FF 0D 0C 0D

TH

1B 63

67

0D

Code Legend:

0D Carriage return (and 13 byte print command in horz. graphics 0D HEX = 13

DECIMAL)

1B Escape

6A Horizontal Line Feed Command

C8 Decimal equivalent of 200 dot spacing from top of form

68 Horizontal Tab Command

0C Decimal equivalent of 12 byte space from left margin

6C Horizontal Graphics Command

FF Full byte 8 dot print command (255 decimal)

F0 Partial byte dot command (240) with the least significant bit (LSB) toward left

margin of the page

63 Printer cut command

Page 23 of 34

Page 24

5.7 Bar Code Operation

The SP-5000 can print three types of bar codes with its standard programming. The bar code types are 3 of 9,

Interleaved 2 of 5 and UPC codes.

5.7.1 Programming Bar Code Operation in Basic

3 of 9 Code

10 WIDTH LPRINT 255

20 LPRINT “Default Text”

30 LPRINT CHR$(27) + “C” + CHR$(5) + CHR$(2); :REM 3 OF 9 Barcode

40 LPRINT “12345”

50 LPRINT “12345 3 OF 9”

60 FOR X = 1 TO 10

70 LPRINT

80 NEXT X

90 LPRINT “Default Text”

100 LPRINT CHR$(27) + “c”; :REM Cut

Interleaved 2 of 5

10 WIDTH LPRINT 255

20 LPRINT “Default Text”

30 LPRINT CHR$(27) + “i” + CHR$(0) + CHR$(2); :REM Interleaved 2 of 5 Barcode

40 LPRINT “012345”

50 LPRINT “012345 Interleaved 2 of 5”

60 FOR X = 1 TO 10

70 LPRINT

80 NEXT X

90 LPRINT “Default Text”

100 LPRINT CHR$(27) + “c”; :REM Cut

UPC Code

10 WIDTH LPRINT 255

20 LPRINT “Default Text”

30 LPRINT CHR$(27) + “u” + CHR$(1) + CHR$(2); :REM UPC Barcode

40 LPRINT “012345678905”

50 LPRINT “012345678905 UPC CODE”

60 FOR X = 1 TO 10

70 LPRINT

80 NEXT X

90 LPRINT “Default Text”

100 LPRINT CHR$(27) + “c”; :REM Cut

5.7.2 3 of 9 Bar Code Description

The bar code printing option allows code 39 character strips to be printed by the SP-5000. Code 39 is so named

because of the original 39 character set. It is also called 3 of 9 because in any given character 3 of the 9 elements

are always wide. Each character is made up of 5 bars and 4 spaces; two of the 5 bars are wide and one of the

four spaces is wide, making 40 possible characters. Four additional characters, $, /, +. and % are formatted with

all the bars narrow and three spaces wide. The complete character set includes a start/stop character (*) and 43

data characters comprising 10 digits, 26 letters and the characters -, .,$, /, +,%, and space. Only upper case alpha

characters are supported; unpredictable or unreadable code may result otherwise. The characters $, /, +, and %

represent their corresponding ASCII characters only if they are followed by a digit, space, symbol, or stop code. If

one of these characters is followed by a letter, the pair is then decoded. For example, a string $C represents the

control code end of text or ^C in ASCII; the string +C represents a lower-case c.

Page 24 of 34

Page 25

5.7.3 UPC Bar Code Description

The Universal Product Code is a numerical only code. This code contains ten digits that may be of odd or even

parity that totals 20 unique patterns. (12 Numeric Digits) The two six digit halves are surrounded by left, center

and right guard patterns. The left half uses the odd parity encodations of digits, and the right half uses the even

parity encodations. The first digit of a UPC Version A code represents the number system. It indicates what type of

product the symbol is indicating. The next five digits comprise a code identifying the product’s manufacturer, and

the next five digits represent the product code. The final digit is a check digit whose value is mathematically based

on all of the other numbers coded in the symbol. A weighting scheme is used in its calculation, so that the check

digit also protects against transportation errors if the data is manually entered. A UPC Version A symbol is

arranged into two halves. Center guard bars separate the first and last six digits. Two left guard bars and two

right guard bars then enclose the two symbol halves. The various guard bars can be thought of as start and stop

patterns. The actual data is encoded as two bars and two spaces in a character that is seven modules wide. This

is called a 7,2 code that has 20 unique patterns.

Page 25 of 34

Page 26

5.8 Echo Back Printer Error Status Byte

The user has the option for polling the printer for error status. This is accomplished by sending the printer the

control code S-REQ (13H). The printer will then transmit back to the host the following one byte status:

Note: This feature will output information from the RS-232 Interface only.

Bit Weight Description

0 Paper Low = 1

1 Paper Out = 1

2 Cutter Jam = 1

3 Ticket Taken =1

4 For Future Use

5 Buffer Full = 1

6 Buffer Empty = 1

7 For Future Use

5.9 Echo Back Printer Mode Status Byte

Note: This feature will output information from the RS-232 Interface only.

Bit Weight Description

0 For Future Use

1 For Future Use

2 For Future Use

3 For Future Use

4 Interleaved 2 of 5 On = 1

5 For Future Use

6 For Future Use

7 For Future Use

Page 26 of 34

Page 27

6 SERVICE

6.1 Introduction

The SP-5000 printer is designed to require a minimum of maintenance and service. This section provides

instructions for cleaning and maintenance. Electrical and mechanical repairs should be performed by qualified

personnel only. Make certain that all electrical connections are disconnected before any service is performed on

the SP-5000.

6.2 Required Information for Service

When contacting Telpar for service, please have the following information available:

· Model Number

· Serial Number

· Date Purchased

This product information will help to speed service response time and reduce the possibility of relay of incorrect

information regarding your specific product.

6.2.1 Cleaning

The SP-5000 exterior cabinet may be cleaned with a non-abrasive cleanser. Care should be taken to prevent liquids

from entering inside the mechanical assembly. If in a dirty environment the mechanism may be cleaned with

alcohol and a cotton swab. The mechanism may also be “blown out” with compressed air. Do not direct air flow

directly to the printer platen, this may damage the printing surface on the platen. When the mechanism is clean

and free of dirt, a light silicon lubricant may be applied (sparingly) to the moving mechanical components.

6.2.2 Printing Malfunctions

Examples of Printing Problems (Cause and Effect)

Poor Print Quality

· Dirty Thermal Print Mechanism/Head

· Worn Print Head

· Poor Quality Thermal Paper

· Damaged Thermal Print Head

Premature Wear of Thermal Print Head

· Printing with paper not approved by Telpar

· Printing in an environment where abrasive particulate is allowed to enter the print mechanism

Page 27 of 34

Page 28

7 Trouble Shooting

7.1 SP-5000 Trouble Shooting Table

Item Problem Possible Cause Solution

1

No powe (LED off)

rPower not connected Fuse blown

Connect unit to power

2

3

Pape will no feed or

r t

load

Will not sel test

f

Power switch not on

Paper jammed in mechanism

Wrong paper

No straight edge on paper.

Paper release lever up

Defective paper sensor.

No power

Did not hold line feed long enough

Paper not installed properly

Paper jam

Check fuses

Turn power switch on

Check for paper jam

Check paper type.

Cut edge straight, or fold

over and crease

Move lever to down

position.

Contact Telpar for service

(972) 233-6631

Check as outlined above

Hold line feed longer

Check roll orientation

Clear jam

4

5

Paper feeds but does

no print

Will not print in

pa allel mode

t

r

Defective line feed switch

Paper release lever Up

Paper upside down

Wrong paper

Paper release lever not locked

Interface cable

No interface connection

Check cable length

Check MODE Command to redirect parallel in DOS

Page 28 of 34

Contact Telpar

Return paper release to

down position

Turn roll over

Use Telpar paper

Return paper release to

down position

Improper pin out

Cable not connected

Cable too long (< 6 feet

required)

Check MODE Command,

try print screen under

DOS

Page 29

6

Will no prin pa allel

t t r

in MS

®

Windows

Wrong printer selected

Wrong port selected

Install/select printer

Select LPT

x

7

8

9

10

Will not print se ial r

Will not print se ial in

MS-Windows

r

®

Light print on one

side

Light print

Wrong paper (poor quality)

Cable too long

Fast print direct to port

enable/disable

Interface cable pin-out

Communication parameters

Interface select switch.

Interface cable configuration

Communication parameters

Interface selection

Printer selection

Wrong Communication port

selected

Paper jammed onto one side

Paper off of print head

Less than 6 feet required

Try changing (typically

disabled)

Check cable pin-out

Check SW1 settings

Check SW2 position

Check configuration

Check setting

Check setting

Check selection

Check selection

Align paper

Check paper release lever

Use Telpar paper

11

12

13

14

15

Delive y jam

Does no cut

r

t

Low paper not

unctional

f

Paper retracts

immedia ely

t

Paper not retracting

Paper release not locked

Paper partially jammed

Wrong paper (paper wound

wrong)

Ticket too short

Queue area blocked

Paper jam

Wrong paper

Cutter jammed

Paper not on roll properly

Paper low sensor dirty

Wrong paper

Printable character sent after ESC

“c” cut command

Dip switch not enabled. Enable switch

Check paper release lever

Check mechanism for jam

Use Telpar paper

Print minimum length

Allow room for paper to

“bubble” in queue area

Clear jam

Use Telpar paper

Contact Telpar

Re-align or replace roll

Clean with soft brush

Use Telpar paper

Change program to

remove printable

character

Page 29 of 34

Page 30

16

Delive y does no

r t

retain ticket

Delivery sensor blocked

Delivery sensor dirty

Clear blockage

Clean with soft brush

17

18

Beeper and red/green

LED flashing

Delivery drops ticket

on deliver

Delivery sensor defective

Indicates no paper

Paper release lever up.

Delivery system deliver jam .

Delivery system retract jam.

Delivery wheels dirty

Roller assembly not locked down

Contact Telpar

Install new roll of Telpar

paper

Check that paper release

lever is in down position

Paper output queue

blocked

Output roller assembly not

locked down

Ticket prevented from

retracting

Roller assembly not locked

down.

Inspect for damage and

clean

Lock into position

7.2 Clearing a Paper Jam

If a jam does occur in the output section of the intelligent paper delivery system of SP-5000 thermal printer, the

output guide and cutter assembly may be rotated upward to gain access to the mechanism output / cutter input

area. To rotate the output assembly:

1. Turn the unit off and remove primary power by disconnecting the power cord.

2. Using your thumb on each hand, apply light pressure in an outward motion to the latches located on

each side of the plastic cutter frame. While spreading the frame latches, apply a forward and rotating motion with

your forefinger to the cutter assembly.

3. Once free, the assembly may be rotated upward 90º from the pivot, which should provide access to the

jam area.

4. Open the printer platen with the paper release lever on the left side of the printer. The jammed paper

may be removed at this time.

5. Once the paper has been removed, close the printer platen and lower the output assembly to their home

positions. Then, apply power to the unit. Normal printing may be resumed at this time.

Page 30 of 34

Page 31

8 ASCII Codes

Listed below are the printable ASCII characters for the SP-5000. Decimal and Hexadecimal values are given.

Dec Hex Char Dec Hex Char Dec Hex Char Dec

Hex Char

32 20 SP 56 38 8 80 50 P 104

68 h

33 21 ! 57 39 9 81 51 Q 105

69 i

34 22 “ 58 3A : 82 52 R 106

6A j

35 23 # 59 3B ; 83 53 S 107

6B k

36 24 $ 60 3C < 84 54 T 108

6C l

37 25 % 61 3D = 85 55 U 109

6D m

38 26 & 62 3E > 86 56 V 110

6E n

39 27 ‘ 63 3F ? 87 57 W 111

6F o

40 28 ( 64 40 @ 88 58 X 112

70 p

41 29 ) 65 41 A 89 59 Y 113

71 q

42 2A * 66 42 B 90 5A Z 114

72 r

43 2B + 67 43 C 91 5B [ 115

73 s

44 2C , 68 44 D 92 5C \ 116

74 t

45 2D - 69 45 E 93 5D ] 117

75 u

46 2E . 70 46 F 94 5E ^ 118

76 v

47 2F / 71 47 G 95 5F _ 119

77 w

48 30 0 72 48 H 96 60 ‘ 120

78 x

49 31 1 73 49 I 97 61 a 121

79 y

50 32 2 74 4A J 98 62 b 122

7A z

51 33 3 75 4B K 99 63 c 123

7B {

52 34 4 76 4C L 100 64 d 124

7C |

53 35 5 77 4D M 101 65 e 125

7D }

54 36 6 78 4E N 102 66 f 126

7E ~

55 37 7 79 4F O 103 67 g 127

7F DEL

Page 31 of 34

Page 32

9 UPC Code Chart

10 Controller Layout

11 Printer Specifications

11.1 Specifications

· Fixed thermal print head

· Printing speed of up to 1.7 inches/sec

· Operating Temperature: 0°C to 50°C (32°F to 122°F)

· Storage Temperature: -20°C to 60°C (-4°F to 140°F)

· Direct thermal printhead

· Dimensions: (WxHxD) 298 mm x 140 mm x 203 mm

(11.75 in x 5.5 in x 8.0 in)

· Serial RS-232C, 9600 Baud rate, DTR flow control, DB9S connector

· Parallel Centronics type interface, DB25S connector

· Resolution: 8 dots/mm (203 dots/in)

· Paper thickness: 0.05 mm to 0.11 mm maximum (.003 in to .0045 in)

· Abrasion life: 90 km (56 miles) of paper travel

· Humidity: 90% max. RH (non condensing)

· Weight: Standard configuration 3.6 kg 8.0 lbs.)

· Barcode embedded symbologies: 3 of 9, UPC-A, Interleaved 2 of 5

· 4 sizes of character set embedded

· 115 VAC 60 Hz switchable to 230 VAC 50 Hz (factory set)

· Approved for CE listing

11.2 Telpar Roll Paper for SP-5000:

· 152 mm (6 in) outside diameter for SP-5000/2 - P/N 751502-0060

· 152 mm (6 in) outside diameter for SP-5000/3 - P/N 751503-0060

· 152 mm (6 in) outside diameter for SP-5000/4 - P/N 751504-0060

· 76 mm (3 in) outside diameter for SP-5000/4 - P/N 751504-0030

11.3 Options

· 24VDC

· Time and date stamp

· 32K, 128K or 512K nonvolatile memory available

· 203 mm (8 in) diameter, 112 mm (4.4 in) wide paper roll version available.

· Microsoftâ Windowsâ driver

Page 32 of 34

Page 33

12 FCC Compliance Statement

FCC Class B Compliance

Warning: Changes or modifications to this unit not expressly approved by the party responsible for compliance

could void the user’s authority to operate the equipment.

Note: This equipment has been tested and found to comply with the limits designed for a Class B digital

device, pursuant to Part 15 of the FCC Rules. These limits are designated to provide reasonable protection against

harmful interference in an installation. This equipment generates, uses, and can radiate radio frequency energy

and, if not installed and used in accordance with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference will not occur in a particular installation. If this

equipment does cause harmful interference to radio or television reception, which can be determined by turning

the equipment off an on, the user is encouraged to try to correct the interference by one or more of the following

measures:

· Reorient or relocate the receiving antenna.

· Increase the separation between the equipment and receiver.

· Connect the equipment into an outlet on a circuit different from that which the receiver is connected.

· Consult the dealer or an experienced radio TV technician for help.

Note: Shielded cables must be used with this unit to ensure compliance with the Class B FCC limits.

Page 33 of 34

Page 34

13 CE Declaration of Conformity

Category Directive Example Standards

Product Safety 73/23/EEC EN60950 Information Technology

Low Voltage Equipment

Electromagnetic 89/336/EEC EMC EN55022 Information Technology

Compatibility (EMC) Equipment

EN50082-1 Generic Immunity

Manufacturer’s Name: TELPAR

Manufacturer’s Address: 187 Cosby Road

Dover, New Hampshire 03820

Telephone: 603-750-7237

Fax: 603-742-9938

Type of Equipment Printer

Model Number SP-5000

Serial Number: All numbers beginning with 5000C

Year of affixing CE mark: Beginning 1997

Shielded cables must be used with this unit to ensure compliance.

Underwriters Laboratory

Listed Information Technology Equipment

File E188263

Project # 97RT9281 (NWGQ/NWGQ7)

TELPAR

A Platinum Equity COMPANY

603-750-7237

Fax: 603-742-9938

Website: www.telpar.com

E-mail: info@telpar.com

Part No. 790136-0020

Page 34 of 34

Loading...

Loading...