Page 1

SP-401 User Manual

SP-401 Series

Panel Mount Thermal Printers

User‘s Manual

Telpar, Inc.

1550 Lakeway Drive, Suite 500

Lewisville, Texas 75057

Phone: 800-872-4886

www.telpar.com

Manual SP-401 – Part No. 790128-0010 (Rev.D – 11/29/04)

Telpar, Inc. Page 1 of 25

Page 2

SP-401 User Manual

1 Introduction........................................................................................................................3

2 Operator Information .........................................................................................................4

2.1 Turn on and Self Test ....................................................................................................4

2.2 Paper Loading ...............................................................................................................5

2.3 Journal Take Up............................................................................................................6

3 Installation .........................................................................................................................7

3.1 Unpacking and Inspection..............................................................................................7

3.2 Installation......................................................................................................................7

3.2.1 Serial RS-232 Interface Cable Suggestion .............................................................7

3.2.2 Parallel Interface Cable...........................................................................................8

4 Interface Specifications.....................................................................................................9

4.1 Serial Interface...............................................................................................................9

4.1.1 Serial Interface Switch Settings ............................................................................10

4.2 Parallel Interface..........................................................................................................11

4.3 Flow Control.................................................................................................................11

5 Programming Information................................................................................................12

5.1 General........................................................................................................................12

5.2 Printable Characters....................................................................................................12

5.3 Graphics Mode.............................................................................................................12

5.4 Text Mode/Data Mode..................................................................................................13

5.5 Real Time Clock Option...............................................................................................13

5.6 Auto Time and Date.....................................................................................................13

5.7 International Character Sets ........................................................................................13

5.8 Control Codes and Escape Sequences.......................................................................14

5.9 Test Program ...............................................................................................................15

6 Maintenance....................................................................................................................16

6.1 Introduction..................................................................................................................16

6.2 Required Tools and Supplies.......................................................................................16

6.3 Cleaning.......................................................................................................................16

6.4 Maintenance Chart.......................................................................................................16

6.5 Warranty......................................................................................................................17

Appendix A. Printable Characters...........................................................................................18

Appendix B. Jumper Designations..........................................................................................19

Appendix C. Specifications.....................................................................................................20

Appendix D. Dimensions ........................................................................................................21

Appendix E. Cleaning Procedure ........................................................................................... 22

Telpar, Inc. Page 2 of 25

Page 3

1 Introduction

This manual contains installation, operating and maintenance procedures for the

Telpar SP-401 series of low cost miniature thermal printers. The SP-401 printers are

available in 20 and 40 column Graphics and Non-Graphics configurations. These

printers are microprocessor controlled to provide a wide range of printing capabilities.

The SP-401 series of printers are small size and of a rugged design, which makes them

ideal for mobile use. In their standard configuration, they may be powered from any AC

or DC power source between 8 and 30 volts. A 115 VAC power supply is available as

an extra cost option, and also a 230 VAC power supply can be ordered as an option.

The SP-401 printers utilize a thermal print head to print dot matrix characters.

International character sets are supported by the SP-401 printers. The serial interfaces

support data rates of 50 to 19200 baud. The parallel interface is a Centronics type

which is compatible with the parallel printer ports on most personal computers.

The SP-401 series of printers may be ordered with a variety of options. Options are

a real time clock, bit image graphics mechanism, paper low sensor, and a paper take

up journal. Please contact Telpar for details regarding these options.

The SP-401 printer is available with either an RS232/20ma loop interface, an RS485/20 ma loop interface, or a parallel interface.

SP-401 User Manual

SP-401, Usage in a Windows Environment

Printing in a Windows environment consists of sending data to the printer in

a BIT-MAPPED GRAPHICS format. Since the printer mechanisms used in the

SP-401 series of printers do not have enough resolution to print graphics well,

no Windows drivers have been written for the SP-401 series of printers and

none are currently planned.

However, testing has shown that the SP-401 series of printers CAN be used

for printing TEXT in a Windows environment by selecting the Generic/Text Only

printer driver which is furnished with Windows. Select the Generic/Text Only

driver and then use ONLY the Roman 10 cpi font. Any graphics images

imbedded in a document (including True Type fonts) will be ignored when the

document is sent to the printer. PAGE SET-UP for using the SP-401/40 column

wide printer is to set all margins to 0 and select a paper width of 4 inches. PAGE

SET-UP for using the SP-401/20 column wide printer is to set all margins to 0

and select a paper width of 2 inches.

Telpar, Inc. Page 3 of 25

Page 4

2 Operator Information

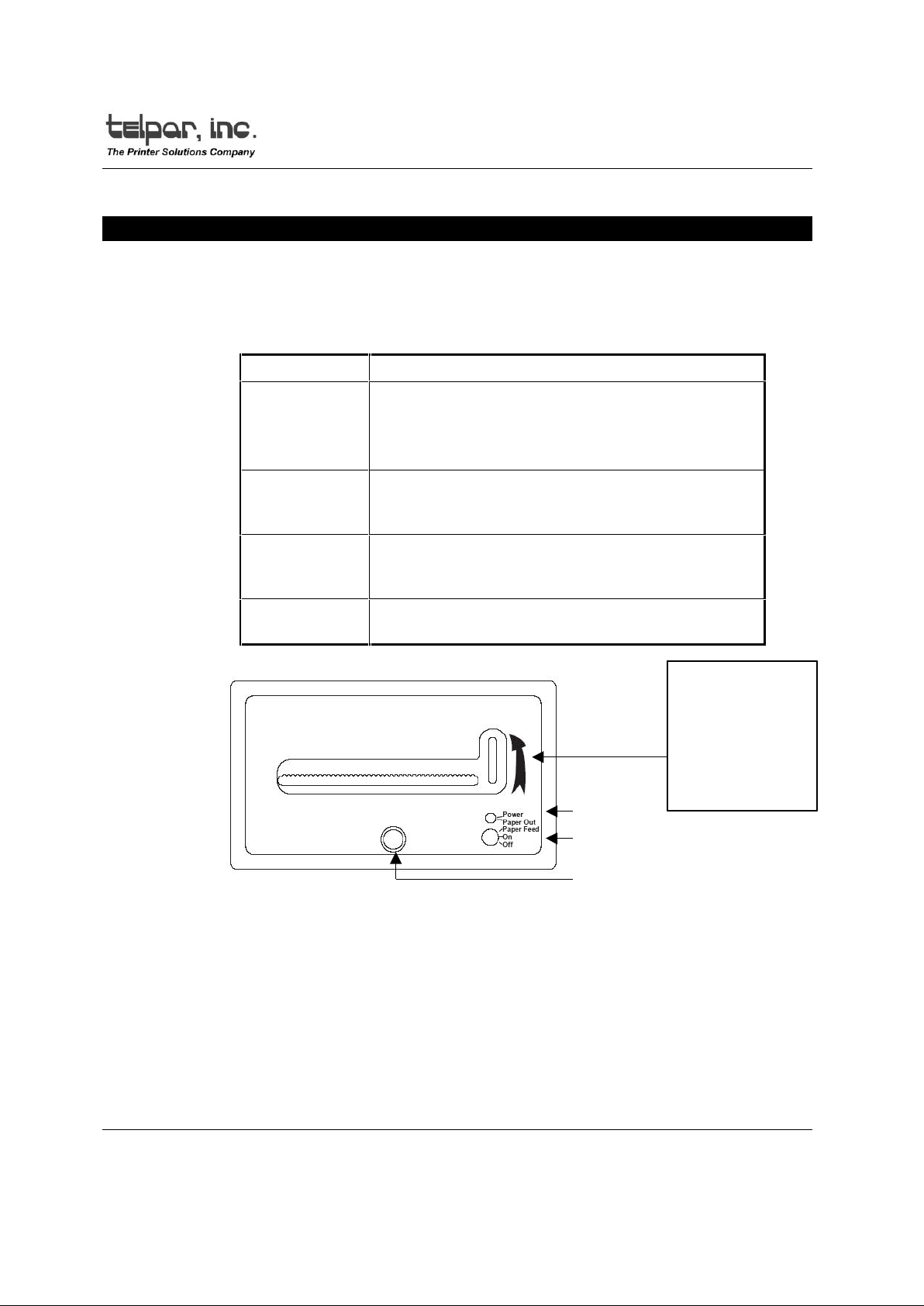

2.1 Turn on and Self Test

The operating controls of the SP-401 have been kept to a minimum. A

convenient self test feature allows the operator to quickly determine that the

printer is operating correctly. The functions of operating controls are as follows:

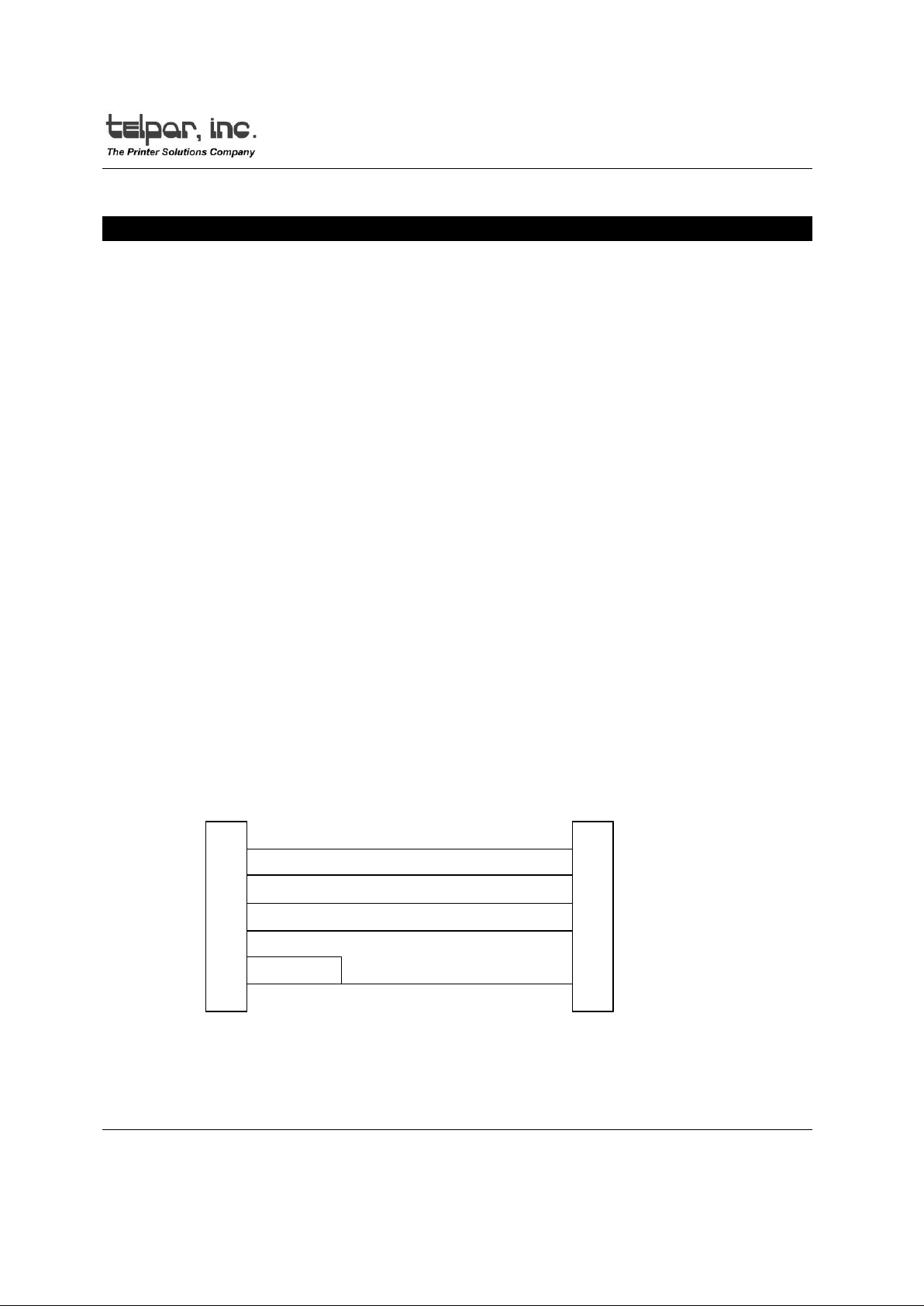

Control Function

Thumb Wheel Used on non-graphic model SP-401 printers to

L.E.D. Indicates power on and paper installed when

Switch Power off in down position, Power on in middle,

Latch To secure the main body of the printer to the

SP-401 User Manual

advance the paper.

Do not rotate thumbwheel in a downward motion,

this will damage the paper feed mechanism.

green, paper out when flashing red and green,

optional paper low when red.

and paper advance in the top (spring loaded)

position.

mounting box.

Figure 1 - SP-401 Front Panel

To activate the self test feature, shut the printer off, then in one quick motion,

move the power switch to the paper advance position and hold it there until the

self test text begins. Once the self test routine begins you may let go of the switch

and let the printer finish the self test. To stop the self test before the end of the

message, power down the printer.

For units with Debug Function Test Software (Firmware versions 9.0 and

above) The self test stops after 7 lines are printed and the printer is set to debug

mode. Data sent to the printer while it is in debug mode will be printed out (by the

printer) in the format as sent to the printer. ASCII printable characters (21 through

THUMBWHEEL IS

AVAILABLE ON NONGRAPHICS

VERSIONS ONLY

ARROW SHOWS

DIRECTION TO TURN

WHEEL - TURNING IT

BACKWARDS WILL

CAUSE DAMAGE

LED

SWITCH

LATCH

Telpar, Inc. Page 4 of 25

Page 5

SP-401 User Manual

7 F hex) will be printed out as the actual character for readability 20 hex, the

space character is printed as a rectangle. Non-printable characters will be printed

in Hexadecimal form with a < before and a > after the hexadecimal code. To end

the debug function, power down the printer.

For the highest quality output and maximum thermal head life, it is

recommended that Telpar paper be used.

2.2 Paper Loading

Rotate the printers Front Panel Latch counter clockwise to release the printer

from the panel mount box. Once released, slide the printer out of the box for

paper loading. Install the paper spindle into a the roll of thermal paper. Position

the roll of paper so that it will feed from the top, then place the roll and spindle

into the paper support brackets, making certain that the paper is level. It is

recommended that the paper be cut back beyond and tape or glue residue and

then cut into an arc before feeding into the printer mechanism. (Note: Scissors cut

is preferred).

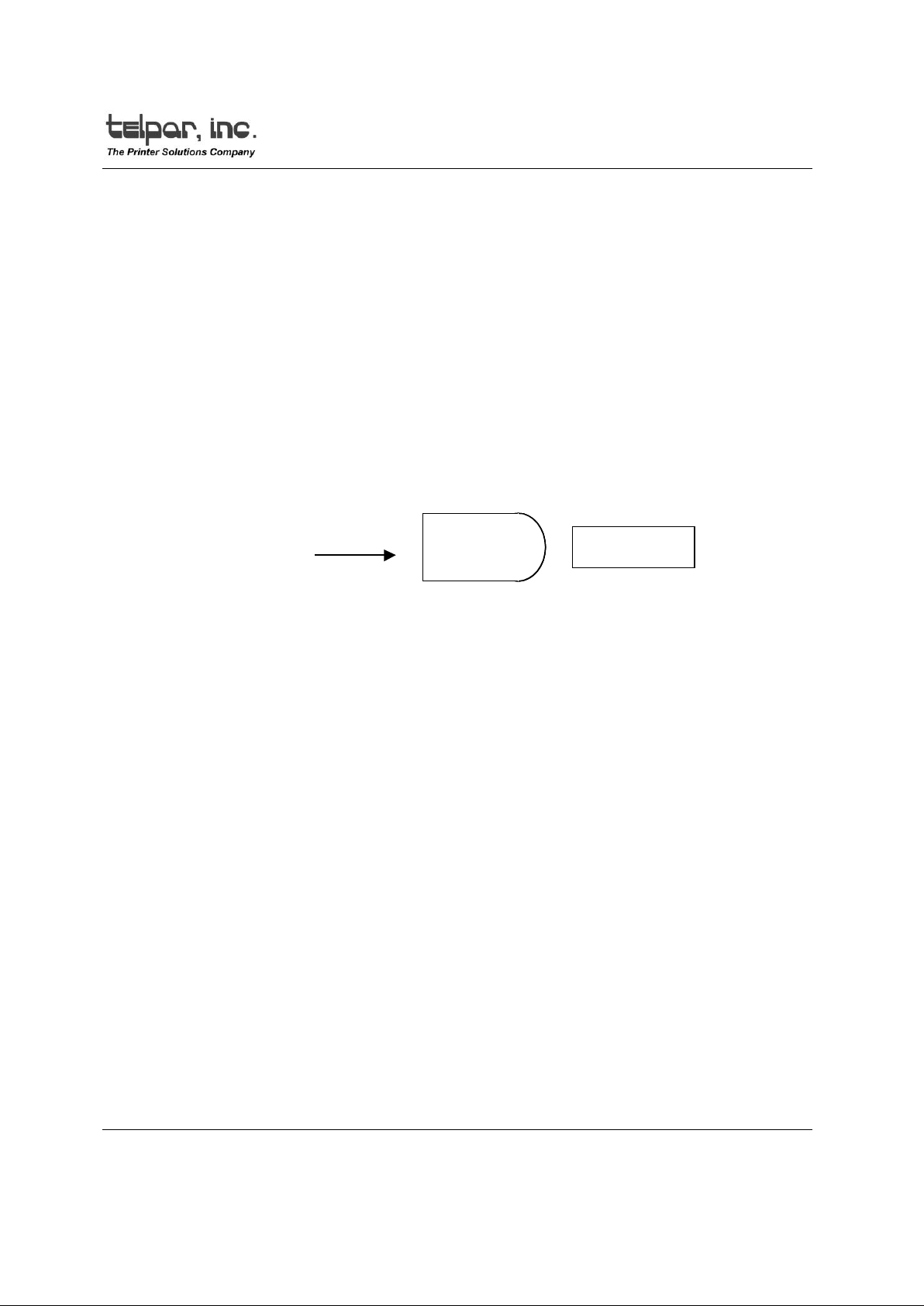

Example of arc cut

leading edgeDirection of feed

To load paper, turn on the power. Now feed the cut edge of the paper into the

guide until the paper stops. This printer will automatically feed the paper 10 line

feeds when the optical sensor detects paper. At this time it is recommended that a

self test be performed to ensure that the paper is installed correctly, (thermal side

up) and that it is feeding properly. The printer may now be installed back into the

panel mount box. Slide printer into the panel box unit fully seated. Rotate the

Front Panel Latch clockwise to fasten the printer in place with the box.

In the event of a paper jam condition do not force paper into the unit, or try to

pry the paper out of the unit, this may damage the thermal print mechanism.

Disconnect primary power and interface cable before servicing the unit. Open

printer and remove the face plate by removing the two 4/40 nuts on the back of

the face plate, this will allow access to the printer mechanism. Carefully remove

paper with a set of tweezers, or a small pair of needle-nose pliers. Once paper is

cleared from the mechanism, re-assemble the unit. At this time, re-load the paper.

Telpar, Inc. Page 5 of 25

Page 6

SP-401 User Manual

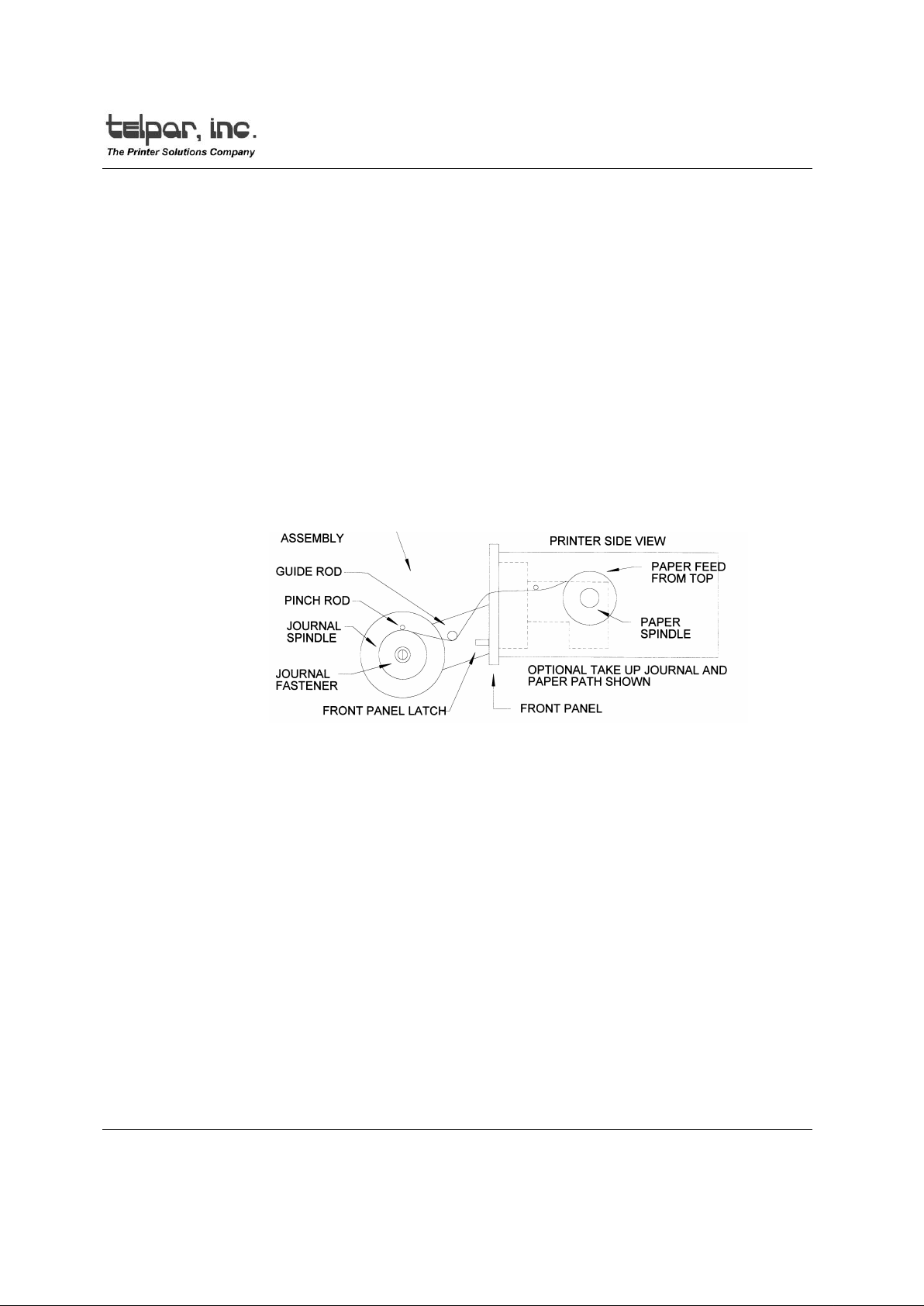

2.3 Journal Take Up

The SP-401 printers are offered with a Journal Take Up as an option. Paper

should be loaded onto the journal only after a self test is performed to ensure that

the printer functions properly. The journal take up is activated automatically when

the printer performs a carriage return or line feed. To install paper onto the take

up journal, feed paper successfully through the printer mechanism to allow

approximately 4 inches of paper to feed out of the face plate. Position the take up

journal to show the pinch rod on top. Unscrew the fastener on the right side of the

take up journal and remove the right side disk and pinch rod assembly. Drape

paper under the guide rod and over the top of the take up journal spinde, then

reinstall right side disk and pinch rod. Paper should be repositioned between the

take up journal and the pinch rod at this time. Power printer and press the paper

advance to remove slack in the paper.

Figure 2 - SP-401 Paper Feed

Telpar, Inc. Page 6 of 25

Page 7

3 Installation

3.1 Unpacking and Inspection

occurred in transit. Should any damage have occurred, notify Telpar, save the

shipping carton and packing materials, and file a damage claim with the carrier.

Specify the nature and the extent of the damage.

packing materials or other foreign matter.

paper

3.2 Installation

SP-401 User Manual

Carefully unpack and inspect your SP-401 for any damage which may have

Before installing or operating the printer, check the following:

Ensure that the primary power setting is correct for your installation.

1.

Ensure that the printer mechanism and paper path are clear of all

2.

Ensure that paper is installed.

3.

. Refer to Section 2.2 for paper loading instructions.

3.2.1 Serial RS-232 Interface Cable Suggestion

Connect the data interface cable to the SP-401; if the RS-232

interface has been selected use a null modem cable to connect to

the host. If the current loop interface has been selected, a cable will

need to be locally fabricated. A suggested cable diagram is shown

below. For more information on communication signals see section

4.1.

Do not operate the printer without

COMPUTER DB9 PRINTER DB25

2 RXD 2 TXD

3 TXD 3 RXD

4 DTR 6 DSR

5 COM 7 COM

6 DSR

8 CTS 11 BUSY

Telpar, Inc. Page 7 of 25

Page 8

3.2.2 Parallel Interface Cable

This parallel cable configuration is used to interface the SP-401

with all IBM and IBM compatible systems. This cable connects the

interface to the printer with a 1:1 cable connection, and is terminated

by a DB-25P on each end. This 25 pin cable configuration is

available at most computer supply stores. Ex. Pin 1 to pin 1, pin 2 to

pin 2, pin 25 to pin 25.

parallel printing should be limited to 25 feet or less.

Note:

SP-401 User Manual

Cable length for the standard mode of

Note:

Cable length for the standard mode of parallel printing

(through MS-DOS) should be limited to 25 feet or less.

Telpar, Inc. Page 8 of 25

Page 9

4 Interface Specifications

4.1 Serial Interface

The interface connector is located on the rear of the SP-401 printers.

Connector P1 is the serial port. Pin assignments are shown below. See Appendix

B for details.

Note: A valid baud rate must be set at all times for proper printer operation.

See section 4.1.1 for switch settings.

The SP-401 has two types of serial interfaces, RS-232 and 20 mA current

loop RS-485 & 20mA current loop. In general, the RS-232 interface is preferable if

the printer is located close to the host computer and can be connected with a

cable run of 50 feet or less.

RS-232/20 mA Interface

Pin Signal Description

1 GROUND Protective ground

2 TXD Data output from the printer to the host

3 RXD RS-232 data input, or 20mA positive input

5 CTS Inhibits TXD line when held at -10v by the host

7 GROUND Signal ground

11 BUSY -10v when printer is unable to receive data

20 DTR +10v when printer is on line

22 RET -20mA current loop return

SP-401 User Manual

RS-485/20 mA Interface

Pin Signal Description

1 DTR 2 DTR +

3 20 mA

positive input

7 TXD 8 TXD +

10 GND

19 RD 20 RD +

22 20Ma

RETURN

Telpar, Inc. Page 9 of 25

20 Ma current loop RETURN

Page 10

4.1.1 Serial Interface Switch Settings

The data word parameters must be set in the printer to

correspond with the settings of the host computer. These are set

using the DIP switches SW1 located on the back of the SP-401

chassis. See Appendix B for a visual aid.

Set the baud rate using SW1-5 through SW1-8 according to the

table below.

SWITCH SW1-8 SW1-7 SW1-6 SW1-5

BAUD

RATE

50 ON ON ON ON

75 OFF ON ON ON

110 ON OFF ON ON

134.5 OFF OFF ON ON

150 ON ON OFF ON

300 OFF ON OFF ON

600 ON OFF OFF ON

1200 OFF OFF OFF ON

1800 ON ON ON OFF

2000 OFF ON ON OFF

2400 ON OFF ON OFF

3600 OFF OFF ON OFF

4800 ON ON OFF OFF

7200 OFF ON OFF OFF

9600 ON OFF OFF OFF

19200 OFF OFF OFF OFF

SP-401 User Manual

Set the stop bits, data bits and parity using SW1-1 through 4

according to the table below.

Switch Function Off On

SW1-1 Stop bits 2 1

SW1-2 Data Bits 8 7

SW1-3 Parity Enable Disable

SW1-4 Parity Even Odd

Select current loop or RS-232 interface using JP2 and JP3 on the

component side of the back board. See Appendix B for a visual aid

for proper jumper placement.

Jumper RS-232 20 mA

JP3 pins 1,2 pins 2,3

JP2 pins 1,2 pins 2,3

Telpar, Inc. Page 10 of 25

Page 11

4.2 Parallel Interface

A DB 25S connector (P1) is used for the parallel interface. The pin

assignments and brief signal descriptions are listed below.

Pin Signal Description

1 STROBE 1 usec. Pulse to clock data into the

printer

2 DATA 0

3 DATA 1

4 DATA 2 Eight data bit input signals to the printer;

5 DATA 3 Signal levels are high for logic 1 and low

6 DATA 4 for a logic 0.

7 DATA 5

8 DATA 6

9 DATA 7

10 ACK 6 usec pulse from printer when data

received

11 BUSY High when printer is unable to receive

data

12 PE Always low. There is no PAPER ERROR

signal supplied at the parallel interface

13 SELECT High when printer is on line

18-24 GROUND Signal Grounds

SP-401 User Manual

4.3 Flow Control

The SP-401 printers employ a 7K byte data buffer as a standard feature to

allow the host computer to rapidly transfer data. Under some circumstances it

may be possible to completely fill the 7K buffer. When the buffer is within 50

bytes of being full, the SP-401 printers signal the host computer to pause until a

line of data is printed, or until the buffer is under the 50 byte limit. The flow control

information is sent to the host using hardware and software protocols.

The hardware protocol uses the BUSY line of the parallel interface or the

BUSY line of the serial interface. These pins are asserted or negated as

necessary to turn off and turn on the flow of data. The software protocol (Serial

interface only) uses the XON and XOFF ASCII characters (^Q and ^S) which are

sent back to the host to start and stop the data stream. Some host systems may

not support one or both of these protocols.

Telpar, Inc. Page 11 of 25

Page 12

5 Programming Information

5.1 General

The SP-401 printers have several different operation modes. Standard

printers can print text and dot addressable graphics.

5.2 Printable Characters

When the SP-401 printers are initially powered up and placed on-line, their

default mode is to process incoming data as ASCII text characters and print them

out in the normal font. The standard printable character set is listed in Appendix A

of this manual.

5.3 Graphics Mode

The SP-401 Series printers can print dot addressable graphics. There is a

mechanism dedicated for graphics use which allows the dot lines to connect

vertically after a line feed. Please contact Telpar for details on this optional

mechanism. The host computer controls each dot printed and each dot directly

corresponds to one bit of a graphics byte.

The following sequence must be sent to the printer at the beginning of each

line of graphics.

ESC+”S”+n1+n2+n3+n4 (256 Dot per Line)

The sequence ESC+”S” enables the graphics mode. The length of the bit

image data is declared by the digits n1, n2, n3, n4. The printer will return to the

character mode once the number of graphics characters has been printed.

Graphics data sent after the maximum number of columns has been reached will

be truncated.

An example of graphics where 192 bytes of bit image data are input as

follows:

1BH, 53H, 30H, 31H, 39H, 32H, = ESC+”S”+0+1+9+2

The relationship between graphics data and the printer dot head is as follows:

SP-401 User Manual

Print Head Graphics Data

1 (Top) DO (LSB)

2 D1

3 D2

4 D3

5 D4

6 D5

7 D6

8 (Bottom) D7 (MSB on graphics models only)

Telpar, Inc. Page 12 of 25

Page 13

SP-401 User Manual

5.4 Text Mode/Data Mode

The SP-401 printers can print in either Text mode or Data mode. To print in

Data mode shut off printer and jumper pins 1&2 of header P1 on the main board.

The printer will remain in this print mode until the jumper P1 is removed. The

difference between Text Mode printing and Data Mode printing is that Text Mode

print is upside down and right to left when exiting the printer, Data Mode is right

side up and left to right when exiting the printer. See Appendix B for a visual aid

on jumper placement.

5.5 Real Time Clock Option

The SP-401 is capable of printing the time and date on command with the

installation of the Real Time Clock Option. To display the time that is currently set,

the printer must receive the control code 05 decimal, (05) hex. To set the time to a

new value the printer must receive the escape sequence ESC,t and the new

parameters in the following format; hh:mmA (hrs:minutes A for am., P for pm., ex.

12:22P. To display the date that is currently set, the printer must receive the

control code 06 decimal, (06) hex. To change the value of the date that is

currently set, the printer must receive the escape sequence ESC,d and the new

parameters in the following format; mm-dd-yy (month-day-year), ex. 01-22-95.

5.6 Auto Time and Date

The auto time date option can only be used in conjunction with the real time

clock option. This feature allows the time and date to be printed automatically

after the printer has received a carriage return. To enable this feature, jumper pins

1 and 2 of header JP6 on the serial interface board, or pins 1 and 2 of header

JP4 on the parallel interface board. (back board) See Appendix B for a visual aid

on jumper placement.

5.7 International Character Sets

International Character Sets are available for the SP-401 series printers.

Standard printers are initialized with the U.S.A. character set. Once a set has

been changed to another the printer will stay in that character set until another set

is chosen, or the printer is powered down. To change the international character

the printer must receive the following ESC sequence: ESC+”R”+n (n=0-6). See

the list below for the n character set designations.

n NATION n NATION

0 JAPAN 4 SWEDEN

1 FRANCE 5 ITALY

2 GERMANY 6 U.S.A.

3 U.K. 7 CUSTOM

Telpar, Inc. Page 13 of 25

Page 14

5.8 Control Codes and Escape Sequences

SP-401 User Manual

Category Symbol Decimal

(hex)

Control Code

PRNT_T 05 (05) * Display Time (optional)

PRNT_D 06 (06) * Display Data (optional)

Bell 07 (07) Causes a “flash” of power/paper

Asterisk LF 10 (OA) Single Line Feed

Denotes CR 13 (OD) Carriage Return (print buffer)

Optional SO 14 (OE) Double Width Print On

Codes SI 15 (OF) Double Width Print Off

RESET

(CAN)

ESC 27 (1B) Escape

ESC

Sequence

ESC,S

ts

ESC,d

ts

ESC, t

ts

24 (18) Clears all Data from Print Buffer

83 (53) Enables Bit Image Graphics (256

100 (64) * Set Date Format mm-dd-yy

116 (74) * Set Time Format hh:mmA A for

Function

out led.

Byte max.) See Section 5.3

am P for pm

Telpar, Inc. Page 14 of 25

Page 15

SP-401 User Manual

5.9 Test Program

This is a test program written in BASIC for the SP-401 Parallel Interface

printer. This program will test the standard control code and escape sequences

executed by the SP-401.

10 CLS

20 WIDTH LPRINT 255 :REM sets output line width

30 LPRINT CHR$(14) :REM doublewidth print on

40 LPRINT”SP-401”

50 LPRINT”THERMAL PRINTER”

60 LPRINT CHR$(15) :REM doublewidth print off

70 LPRINT”Telpar”

80 LPRINT”4181CenturionWay”

90 LPRINT”Addison TX 75244’

100 LPRINT”(972) 233-6631”

110 LPRINT CHR$(10) :REM single line feed

120 LPRINT

130 LPRINT

140 LPRINT”THIS IS A GRAPHICS TEST”

150 LPRINT CHR$(27)+”S0255” :REM Length=255

160 FOR X=1 TO 255

170 LPRINT CHR$(255): :REM fires alldots

180 NEXT X

190 LPRINT

200 LPRINT

210 CLS

220 LPRINT”CLOCK TEST” : REM(Note: The Clock Modeis Optional)

230 PRINT”PLEASE HAVE YOUR PRINTER TURNED ON TO SET THE

TIME/DATE”,CHR$(10)

240 FOR X=500 TO 10000 STEP 300:SOUND X,2:NEXT X

250 LPRINT CHR$(14);”CLOCK TEST”

260 LPRINT CHR$(15)

270 INPUT”DO YOU WISH TO CHANGE THE TIME? (Y/N)”;Y$:CLS

280 IF Y$=”N”OR Y$=”n”THEN GOTO 330

290 LPRINT”THE TIME CURRENTLY SET IS”;CHR$(5)

300 PRINT”ENTER TIME AS hh:mmA (hours:minutes A for am P for pm)”

310 INPUT A$

320 LPRINT CHR$(27)+”t”;a$;”THE NEW TIME IS”

330 LPRINT CHR$(14);CHR$(5)

340 LPRINT CHR$(15)

350 INPUT”DO YOU WISH TO CHANGE THE DATE? (Y/N)”;Y$:CLS

360 IF Y$=”N”OR Y$=”n” THEN GOTO 410

370 LPRINT”THE DATE CURRENTLY SET IS”;CHR$(6)

380 PRINT”ENTER THE DATE IN THE FOLLOWING FORMAT mm-dd-yy (month-day-year)”

390 INPUT A$

400 LPRINT CHR$(27)+”d”;A$;”THE NEW DATE IS”

410 LPRINT CHR$(14);CHR$(6)

420 LPRINT CHR$(15)

430 END

Telpar, Inc. Page 15 of 25

Page 16

6 Maintenance

6.1 Introduction

The SP-401 printers are designed to require a minimum of maintenance and

service. This section provides instructions for cleaning and maintenance.

Electrical and mechanical repairs should be performed by qualified personnel

only. Make certain that all electrical connections are disconnected before any

service is performed on the SP-401 printers.

6.2 Required Tools and Supplies

6.3 Cleaning

The SP-401 exterior cabinet may be cleaned with a non-abrasive cleanser.

Care should be taken to prevent liquids from entering inside the mechanical

assembly. If in a dirty environment the mechanism may be removed and the parts

may be cleaned with alcohol and a cotton swab. The mechanism may also be

“blown out” with compressed air. Do not direct air flow to printer platen, this may

remove the soft rubber printing surface from the platen. When the mechanism is

clean and free of dirt, a light silicon lubricant may be applied (sparingly) to the

moving mechanical components.

SP-401 User Manual

Common hand tools

1.

Denatured alcohol

2.

Cleaning rags

3.

Cotton swabs

4.

Lubricant IBM #23, LUBRIPLATE #70, SILCON#35

5.

6.4 Maintenance Chart

Clean Office

or

Light Use

Clean Factory

Environment

Medium Use

Dirty Factory

Environment

Heavy Use

Telpar, Inc. Page 16 of 25

Once Per Year

Monthly

Weekly

Page 17

SP-401 User Manual

6.5 Warranty

Telpar — Printer Limited Warranty

For one (1) year after shipment of the printer product to Buyer, Telpar warrants the product

against defects in materials and workmanship provided the product has been operated and

maintained in accordance with manufacturer’s operating and maintenance specifications. This

warranty specifically excludes ribbons, paper and other consumable items.

THIS WARRANTY IS IN LIEU OF ANY AND ALL OTHER WARRANTIES, EXPRESSED OR

IMPLIED. TELPAR MAKES NO OTHER WARRANTY AND BUYER SPECIFICALLY WAIVES

ANY OTHER WARRANTIES, INCLUDING WARRANTIES OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE. THERE ARE NO WARRANTIES THAT EXTEND

BEYOND THOSE DESCRIBED HEREIN.

Telpar’s liability hereunder is limited to the repair or replacement of defective parts. This liability

does not extend to normal wear and tear. Telpar will, solely at its option, remedy all valid

warranty claims either by:

(a) Repairing or replacing the defective unit at Telpar’s factory; or

(b) Repairing or replacing the defective subassembly at Telpar’s factory.

If so directed by Telpar, Buyer shall return the defective unit or subassembly, transportation

prepaid by Buyer, to Telpar’s factory. After repair or replacement has been accomplished,

Telpar will return the unit or subassembly, transportation prepaid by Telpar, to Buyer.

As a precondition to any warranty service, prior to return of any units or subassemblies to

Telpar by Buyer, Buyer must contact Telpar’s Order Administration Services and receive

authorization in the form of a Return Material Authorization (RMA) number. Telpar reserves the

right to refuse any goods it has not previously authorized for return, or any goods shipped

without transportation prepaid.

No warranty shall apply to any damage resulting from or caused by Buyer, if Buyer shall make

any changes, modifications, additions or deletions of hardware, software or firmware in the

Printer products sold hereunder without Telpar’s advance written consent.

Upon receiving an RMA from Telpar, warranty service may be obtained by returning the

merchandise, freight prepaid, with a copy of your invoice.

Telephone: 800-872-4886 or 972-420-4700

Fax: 972-420-4272

Email: info@telpar.com

Upon inspection, Telpar will make necessary repairs or replacement and return the

merchandise, shipping prepaid.

Telpar, Inc. Page 17 of 25

Page 18

AppendixA. Printable Characters

ASCII codes listed below are the printable ASCII characters for the SP-401 printers.

Decimal and Hexadecimal values are given.

Dec Hex Char Dec Hex Char Dec Hex Char Dec Hex Char

32 20 SP 56 38 8 80 50 P 104 68 h

33 21 ! 57 39 9 81 51 Q 105 69 I

34 22 “ 58 3A : 82 52 R 106 6A j

35 23 # 59 3B ; 83 53 S 107 6B k

36 24 $ 60 3C << 84 54 T 108 6C l

37 25 % 61 3D = 85 55 U 109 6D m

38 26 & 62 3E >> 86 56 V 110 6E n

39 27 ‘ 63 3F ? 87 57 W 111 6F o

40 28 ( 64 40 @ 88 58 X 112 70 p

41 29 ) 65 41 A 89 59 Y 113 71 q

42 2A * 66 42 B 90 5A Z 114 72 r

43 2B + 67 43 C 91 5B [ 115 73 s

44 2C , 68 44 D 92 5C \ 116 74 t

45 2D - 69 45 E 93 5D ] 117 75 u

46 2E . 70 46 F 94 5E ^ 118 76 v

47 2F / 71 47 G 95 5F _ 119 77 w

48 30 0 72 48 H 96 60 ‘ 120 78 x

49 31 1 73 49 I 97 61 a 121 79 y

50 32 2 74 4A J 98 62 b 122 7A z

51 33 3 75 4B K 99 63 c 123 7B {

52 34 4 76 4C L 100 64 d 124 7C |

53 35 5 77 4D M 101 65 e 125 7D }

54 36 6 78 4E N 102 66 f 126 7E ~

55 37 7 79 4F O 103 67 g 127 7F DEL

SP-401 User Manual

APPENDIX

Telpar, Inc. Page 18 of 25

Page 19

Appendix B. Jumper Designations

MainController Board (Top view) Serial RS-232/20mABackBoard

SP-401 User Manual

P1

1

2

Paper Spindle

andGuides

EPROM RAM

SW1

P1 = Data Mode/Text Mode(seesection 5.4)

Open = TextMode

Closed=DataMode

Mechanism Input

Optical Sensor

JP1

Z80 8255

3 1

4 2

JP1 BACK VIEW

PIN LAYOUT

P1

JP3 123

JP2 123

U1

232

JP2,JP3=Jumpers to change RS-232 to 20maloop interface.

Jumper pins 1 and 2 for RS-232.

Jumper pins 2 and 3 for 20maoperation.

JP6 = Auto Time and dateafter carriagereturn

F1 = 2 amp fuse

Jumper RS232 20mA

JP3 pins 1&2 pins 2&3

JP2 pins 1&2 pins 2&3

JP6

2

F1

=

2A

SW11

C1

JP1 = Power input 8 to30 VAC/DC

Pins 1 & 2 AC

Pin 3, NegativeDC

Pin 4, PositiveDC

Figure 3 - Jumper Designations

Parallel Back Board

P1

F1 = 2A

X1

74LS373

Telpar, Inc. Page 19 of 25

1 2

JP4

C1

JP4 = AUTO TIME AND DATE

AFTER CARRIAGE RETURN

OPEN = DISABLE (JUMPER OFF)

CLOSED = ENABLE (JUMPER ON)

Page 20

SP-401 User Manual

Appendix C. Specifications

Specifications SP-401 SERIES Thermal Printers

Performance:

Max. Print Rate 0.6 Lines/second

Line Density 6 Lines/inch

Print Head Life 500,000 character lines

Buffer Size 7000 character

General:

Number of Columns 20,40

Graphics 256 Byte Maximum

Print Modes Data or Text (Jumper Selectable)

Dot Diameter 0.014 inches (0.35mm)

Dot Spacing 0.014 in (0.35 mm) vertical, 0.010 in (0.25 mm) horizontal

Line Spacing 0.060 in (1.5 mm)

Paper Width Roll

Stock 80ft/roll

Temperature Range

Power:

Voltage and Power 10 to 30 vac, 8 to 30 vdc 110 / 230 vac with wall adapters, 2.5

Interface:

Serial RS-232/20 mA serial interface (DB-25S Connector)

RS485/20mA

Parallel Centronics Parallel Type (DB-25S Connector)

3.125 inches (79.4mm) Use Telpar Paper for Best Results

Operating: 0°to +50°C; storage -25°C to +85°C.,90% max.

RH (non condensing)

watts standby, 12 watts printing

Mechanical:

Dimensions 2.7” H x 4.5” W x 5.7” D (68.6 mm x 114.3 mm x 144.8 mm)

Weight 2.25 lb. (1.02 kg.)

Telpar, Inc. Page 20 of 25

Page 21

SP-401 User Manual

Appendix D. Dimensions

The sketches below show printer outline dimensions and panel mounting dimensions.

Top view

Side view

Panel cutout

Telpar, Inc. Page 21 of 25

Page 22

Appendix E. Cleaning procedure

Check unit visually for

damage.

Remove cover by

rotating the latch

counter-clockwise until

the latch disengages

from the cover.

SP-401 User Manual

Once latch disengages

the cover will slide out

easily.

Paper Removal

Caution!,

Remove power prior to

this operation. Do not

insert metal objects of

any kind while printer is

powered, as this will

damage the printer

Telpar, Inc. Page 22 of 25

Page 23

Remove paper by

cutting and pulling it

straight through the

front as shown.

Caution!, Attempting

to pull the paper from

the back of the

mechanism will damage

the printer.

SP-401 User Manual

Cutting

Removal

Plug unit into power

supply and turn on.

Unit should cycle once

then stop and LED

should blink greenamber-red.

Inspect paper path and

stainless steel clip. If

LED isn’t blinking or unit

didn’t cycle properly or

clip is missing,

damaged or dislodged

send unit to Telpar for

repair.

Caution!,

Do not attempt to realign clip as this may

cause further damage

to printer mechanism.

Stainless Steel Clip

LED

Telpar, Inc. Page 23 of 25

Page 24

Turn power off

and remove power

supply. Clean unit

with low-pressure

compressed air.

The following

points are to be

addressed during

cleaning: Front

Plate Exit, Rear

Plate Entrance,

Cam Opening and

Gears. Utilize a

cleaning card with

isopropyl alcohol

to clean platen, if

necessary.

SP-401 User Manual

Front Plate Exit

Rear Plate Entrance

Cam Opening

Gears

Telpar, Inc. Page 24 of 25

Page 25

Plug unit into

power supply reinstall paper and

run a self- test. If

unit fails to

operate properly,

write a brief

description of the

issue on the paper

roll and send the

unit to Telpar for

repair.

SP-401 User Manual

Attach cover onto

the printer

assembly prior to

operation or

shipping.

Telpar, Inc. Page 25 of 25

Loading...

Loading...