Page 1

TELPAR

SP-327 Receipt Thermal Printer

For Sales, Technical Support, Warranty Returns and Repairs, please contact us at

Please visit our website at any time at

© Copyright 2008, Telpar, Inc. All Rights Reserved

(Document Name and Revision: SP327Manual050808.doc)

187 Crosby Road

Dover, NH 03820

800-872-4886

www.telpar.com

Page 2

Telpar SP-327 Receipt Thermal Printer Summary

The TELPAR SP-327 Receipt Thermal Printer is a direct thermal printer designed as an

economical solution to the demands of unattended hardcopy devices and applications.

Applications include toll booth receipts, supermarket discount coupons, cash vouchers for

exchanged goods, automated collection machines, parking validation slips, gas station pump

receipts, and gaming machine receipts.

Printer Features:

• Durable All Metal Construction

• Automatic Paper Loading

• Low paper Roll Detection

• Error Status LED and Beeper

• Single Multifunction Power & Paper Feed Switch

• Serial Communication with Status Feedback Modes

• 8 Dots/mm (203 Dots/Inch) Thermal Print Head

• 56mm (2.2 inches) Total Printing Width

• Speeds of up to 10 Character-lines per Second (Ten full lines consisting of 24 characters / line)

• Durable Guillotine Cutter (400,000 Cut Operations Typically)

• 7K Character Buffer

• Four Standard Character Sets

• Raster Graphics

• Bar Coding Capabilities (Barcode 3 of 9 and Interleaved 2 of 5).

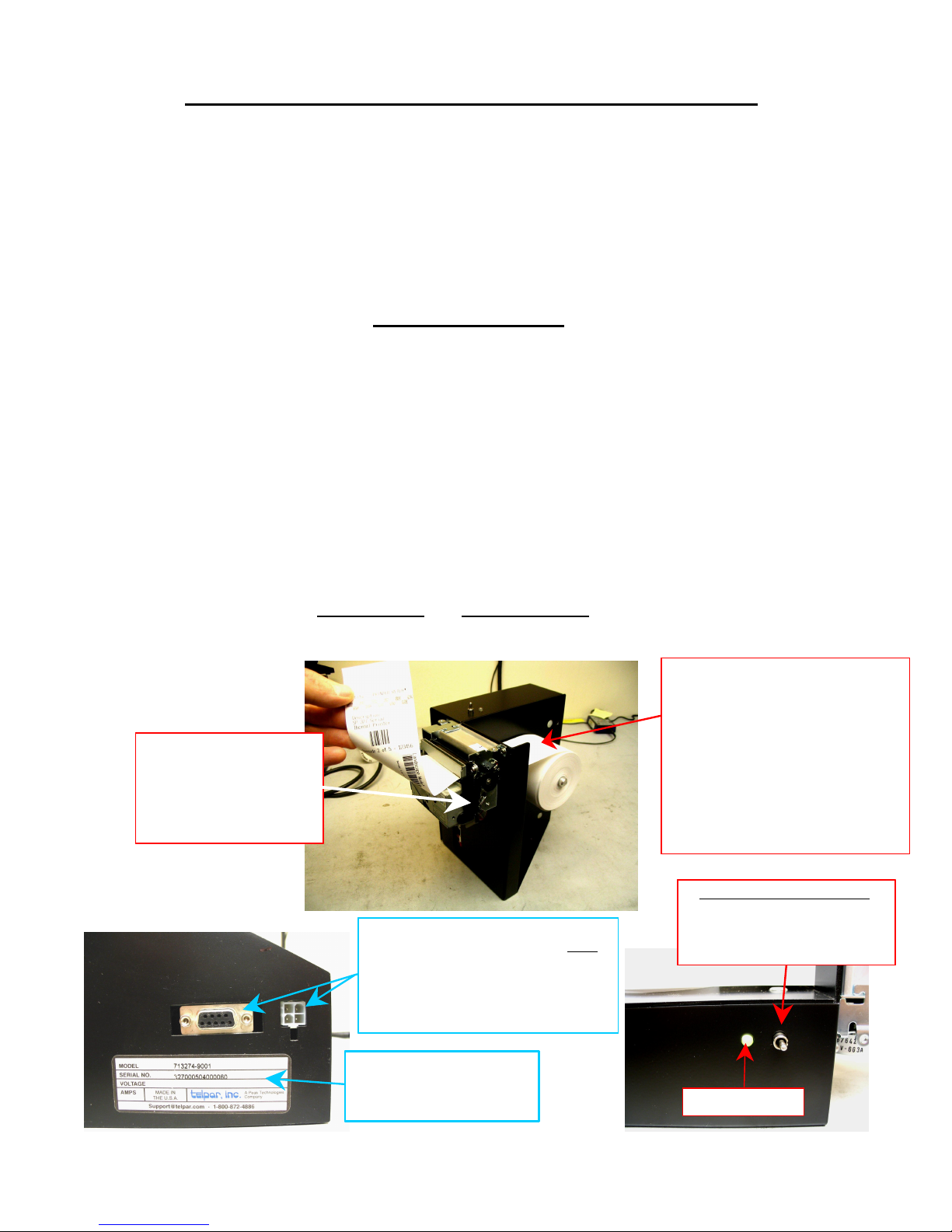

Head-up Lever rotates up

to raise the thermal print

head off the paper to

assist in clearing paper

jams or quick paper

removal.

Four PositionPower Connector (right)

SeeSection 1 onPage1 for Power Cable

Pinout.

Nine position RS-232 DB Sub-Connector

SeeSection 16 onPage8 for Interface

CablePinout.

Serial Label information willbe

used whenrequesting

Technicalor Return / Repair

Assistance from Telpar.

Thermal Paper unwinds from the

top of the roll with the thermal

coated side of the paper facing

down as shown.

To auto feed paperinto the printer,

guidetheleading edge of the paper into

the paper entry slot in thechassis until it

stops. Within asecond, the printer

platen willautomatically grab the paper

andfeed approx. 1.5 inches of paper

throughtheprinterandcutter sections.

Three position Toggle Switch:

Full left position = OFF

MiddlePosition = ON

Full right position = Paper Feed

(Momentary)

Error Status LED

Page 3

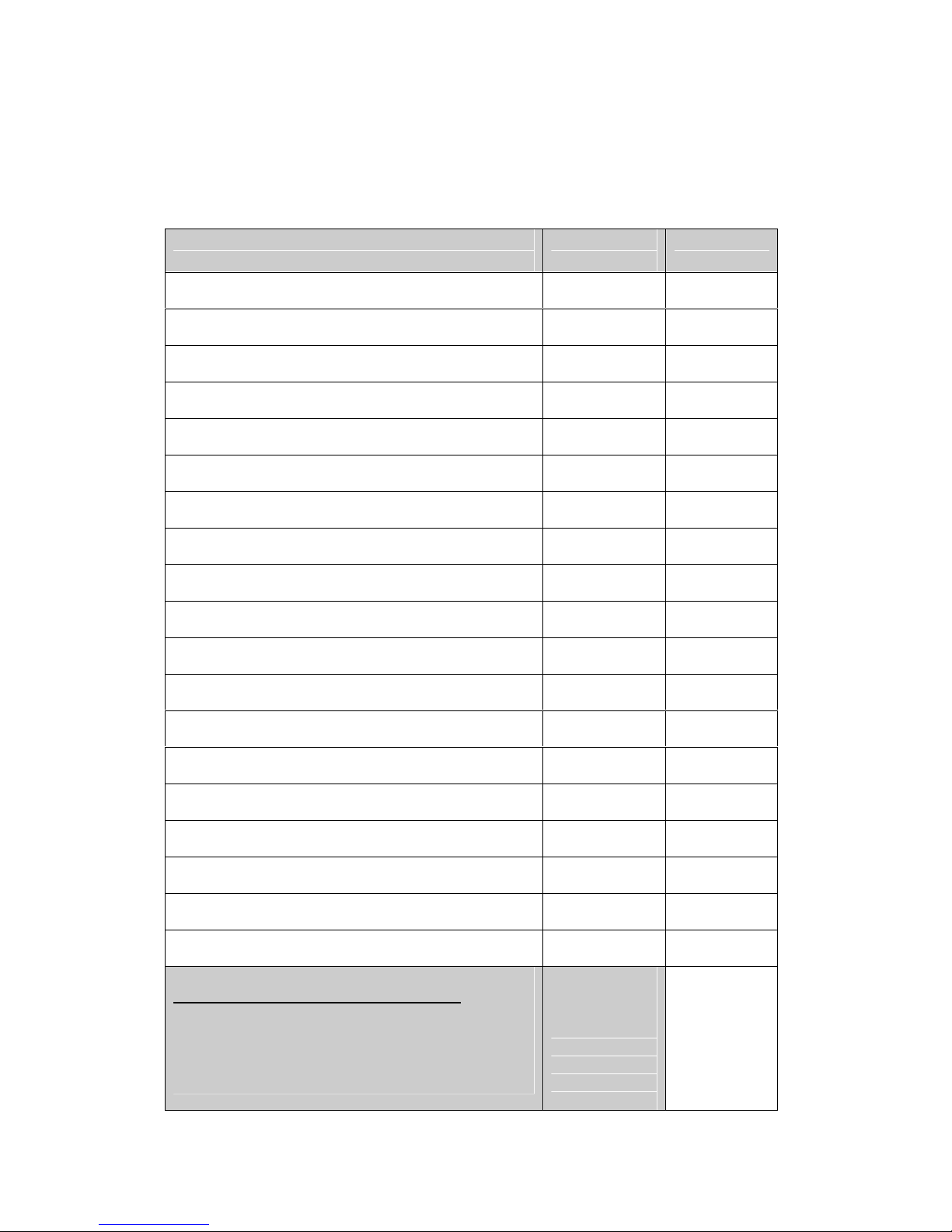

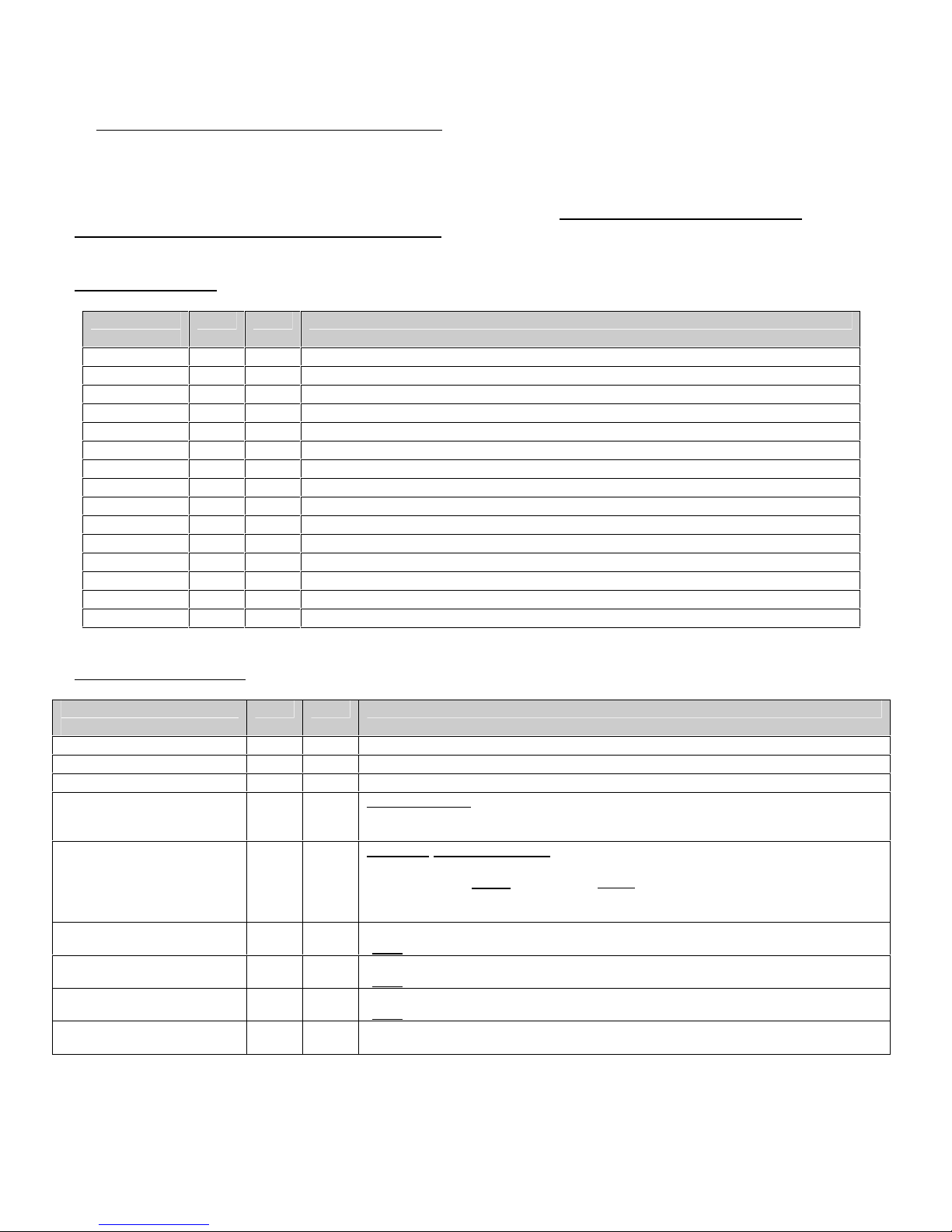

User Manual & Maintenance Manual Table of Contents

User Manual for the SP-327

Topic Description:

Power Requirements

Input Voltage Options

RS-232 Interface

Environmental

Control Codes & Escape Sequences

Echo Back Printer Error Status Byte

Echo Back Printer Mode Status Byte

Paper Cutter Features

Printer Mechanism Features

Controller Features

Self Test Mode

Default RS-232 Settings

Page

Number

1 1

1 2

1 3

1 4

2 5

3 6

3 7

3 8

4 9

5 10

5 11

5 12

Section

Number

Chassis / Mechanism Dimensions

Printed Circuit Board Dimensions

ERROR CODES (LED & Beeper Status)

Character Sizes for Various Fonts

Paper Roll Part Number for Reordering

Serial RS-232 Cable Pinout Suggestion

Sample Code in MS Visual Basic 6.0

Maintenance Manual for the SP-327

Introduction

Cleaning

Cutter Assembly

Examples of Printing Problems

Maintenance Chart

6 13

6 14

7 15

7 15

7 15

8 16

9, 10 17

MM1

MM2

MM3

MM4

MM5

Page 4

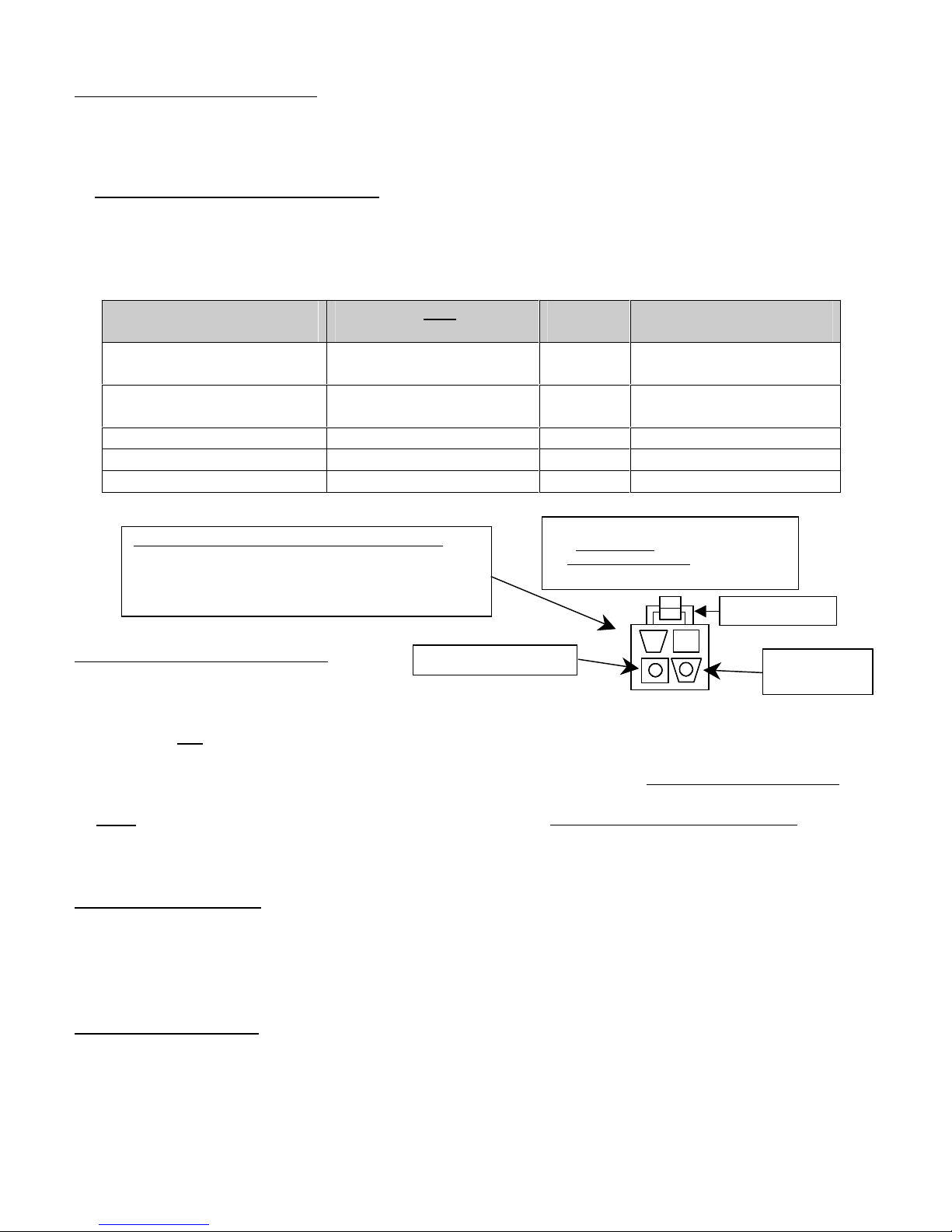

1 ). POWER REQUIREMENTS:

The Table below shows both the peak and average amperages with their associated duty cycles for a typical SP-327 printer

performing various printing operations. The SP-327 operation requires large peak current pulses at low duty cycles.

Therefore, the average power requirement is typically low.

NOTE on GRAPHICS MODE CURRENT: The average current required in graphics modeis verylow since it is limited

by the data transfer rate. The Graphics Command requires the transmission ofat least 5 characters to print 8 dots on a line. A

baud rate set at 9600 (approx. 1 msec / char transmission time) produces a 0.1 amp peak or a 10 mAmp average at a 12% duty

cycle. The Graphics Command requires a minimum of 60 characters to print all 448 dots on a line. In this situation, a 6 amp

peak or 140 mAmp average is produced at a 2.3% dutycycle.

Font Type or

Operational Condition

24 Characters / Line

(Printing Full line ofthe letter ‘H’)

48 Characters / Line

(Printing Full line ofthe letter ‘H’)

MaximumPeak Current Typical

Duty Cycle

6.5 Amps 30% 2 Amps

5.5 Amps 42% 2.3 Amps

Average Current

Graphics (Fire ALL 448 dots) 6.0 Amps LOW Less Than 0.20 Amps

Idle (on but doing nothing) 0.070 Amps Typical NA NA

Paper Feeding (noprint) 0.150 AmpsTypical NA NA

Mating Connector andTerminal Socket Part Numbers:

1 MolexP/N 39-01-2045 or -2040 2x2 socket connector.

2 Terminals for aboveMolexP/N 44485-1211 or 1212 sockets.

2). INPUT VOLTAGE OPTIONS:

Pin 1 = VAC or +24VDC

The diagrambelow shows the

FRONT FACE of thePower Supply

CABLE CONNECTOR which mates to

the SP-327 Power Connector:

Connector Key

Pin 2 = VAC or

DC Common

For most typical printing applications, the SP-327 standard input voltage rating is:

• 18 VAC rms power supply rated at least 20VA

OR

• 24 VDC regulated power supply rated at least 2.1Amps (50Watts)

An optional 115 V.A.C. wall transformer & Cable assembly is available à Telpar Part # 780327-0010.

Note: All raw input voltage options listed aboveare provided with input transient suppression circuitry that will

protect the print/cut mechanism and electronics from momentary over voltage conditions commonly found in

switching power supplies and vehicular power sources.

3). RS-232 INTERFACE:

The SP-327 comes standard with an RS-232C Bi-directional communication interface.

Default RS-232 Settings (in Standard Firmware) are the following:

Baud Rate = 9600 bps, 8 Data Bits, 1 Stop Bit, No Parity, and Hardware Handshaking.

An RS-232 Cable Pinout diagram can be found in section 16 (page 8).

4). ENVIRONMENTAL:

Normal operating temperature of the SP-327 is - 40°C to + 60° C (- 40°F to + 140°F).

The SP-327 has a compensating circuit that maintains print intensity for the temperature range specified above.

Page 1

Page 5

5) CONTROL CODES and ESCAPE SEQUENCES

The TELPAR Model SP-327 uses the following Control Codes and Escape Sequences to control special features of

the printer such as printing in landscape mode, condensed mode, printing barcodes (3 of 9 and I 2of 5 only),

performing a paper cut, and many other features. The tables below describe these codes and sequences and what

they do. For examples of using some of these codes and sequences, please see section 17 for sample

programming code written in MS Visual Basic 6.0.

CONTROL CODES:

Control

HEX DEC Description

Code

STX 02H 2

ETX 03H 3

RLF 08H 8

SLF 0AH 10

PT 0DH 13

SO 0EH 14

SI 0FH 15

DBLH 10H 16

NDBH 11H 17

Landscape Print, Start of Text (ie. Print rotated 90 degrees)

Landscape Print, End of Text (ie. Print rotated 90 degrees)

ReverseLine Feed (one line feed space – registration after may not be exact)

Single Line Feed – feeds amount of paper as specified by ESC ”3” n (see table below)

Print Command – allows information from host to be printed to the printer

Enable DoubleWidth Print

Enable Condensed Print

Enable DoubleHeight Print

Disable Double Height Print

DC2 12H 18 Disable Condensed Print

S_REQ 13H 19

DC4 14H 20

M_REQ 15H 21

CAN 18H 24

ESC 1BH 27

Ask for Printer Status (Error Status) SeeSection 6

Disable Double Width Print

Ask for current Print Mode, See Section 7

Clears all data in the buffer

Escape Bit

ESCAPE SEQUENCES:

Escape

HEX DEC Description

Sequence

ESC “@” 40H 64

ESC ”3” n 33H 51

ESC “c” 63H 99

ESC “C” n1 n2 Data CR 43H 67

ESC “i” n1 n2 Data CR 69H 105

ESC “h” n 68H 104

ESC “j” n 6AH 106

ESC “l” n Data 6CH 108

ESC “r” n 72H 114

Reset Printer (clears all data in the buffer)

Set Line feed space to n * 0.0097 Inches (Default n = 4). See SLF in Tableabove.

Initiate a paper cut

Bar Code 3 of 9. n1 = Indent space from margin in mm,

Height of Barcode= n2 * 4mm (n2 must be > 0. Therefore, the smallest barcode

height = 4mm).

Bar Code Interleaved 2 of 5. n1 = Indent space from margin in mm,

Height of Barcode= n2 * 4mm (n2 must be > 0. Therefore, the smallest barcode

height = 4mm). NOTE: Use only an EVEN number of data bytes à the printer will

generatean error message if either an odd number of data bytes or an illegal

character is received.

Fill n bytes of space (blank) in when using raster graphics.

(Note: Print Density = 8 Dots / mm, Printing width = 56mm, or 448 Dots per Line)

Perform n dot steps.

(Note: Print Density = 8 Dots / mm, Printing width = 56mm, or 448 Dots per Line)

N bytes of raster graphics.

(Note: Print Density = 8 Dots / mm, Printing width = 56mm, or 448 Dots per Line)

n = 0 to set light print

n = 1 to set dark print

Page 2

Page 6

6). ECHO BACK PRINTER ERROR STATUS BYTE:

The user has the option of polling the printer for error status. This is accomplished bysending the printer the control code

S_REQ 13H. The printer will then transmit back to the host the following one byte status:

BIT WEIGHT DESCRIPTION

0 Paper Low = 1

1 Paper Out = 1

2 Cutter Jam = 1

3

4

Not used

Not used

5 Buffer Full = 1

6 Buffer Empty = 1

7

Not used

7). ECHO BACK PRINTER MODE STATUS BYTE:

The user has the option of polling the printer for mode status. This is accomplished by sending the printer the control code

M_REQ 15H. The printer will then transmit back to the host the following one byte status indicating the current print

modes:

BIT WEIGHT DESCRIPTION

0 Landscape Print ON = 1

1 Double Wide ON = 1

2 Not used

3 Double High ON = 1

4 2 of 5 Bar-code ON = 1

5 Not used (always = 0)

6 Not used (always = 0)

7 Condensed Print ON = 1

8). PAPER CUTTER FEATURES:

• The SP-327 is equipped with a long life guillotine paper cutter that is user activated via the escape code ESC c.

• The printer controller board monitors the paper cutter's home switch. If the cutter blade is not on the home position

(example: due to tampering), then the controller card will energize the cutter and home the guillotine blade.

• When the cutter is energized, an internal watch timer is set for 1 second. If the cutter blade does not reach the home

position within this allotted time the controller board will set bit 2 of the STATUS byte to a logic one indicating a

cutter jam has occurred. The same condition will occur if the cutter blade overshoots the home position.

• Also provided is a solid state thermal overload circuit for the cutter (this is to protect the cutter motor from a locked

rotor or micro processor malfunction).

• The paper cutter's MTBF( mean time between failure) is 400,000 cuts .The MTBF may be severely shortened if

TELPAR paper is not used. Contact TELPAR for replacement paper (see section 15 on page 7 for the part number for

replacement Telpar paper for the SP-327).

Page 3

Page 7

9) PRINT MECHANISM FEATURES:

• 8 Dots/mm (203 Dots/Inch) Thermal Printhead

• 56mm (2.2 inches) Total Printing Width

• Mechanical dot density is 448 dots per line

• Print speeds of up to 10 character-lines per second (10 full lines consisting of 24 characters per line)

• Integrated Paper Out / Top of Form Sensor

• Embedded Thermistor for monitoring Print Head Temperature

• One piece cutter / mechanism assembly with tapped holes for easymechanical mounting and service.

Page 4

Page 8

10). CONTROLLER FEATURES (Circuit Board Assembly):

• Standard 7K ram buffer

• Socketed External program EPROM

• Print head protected bya power switch watch dog timer

• OPTIONAL dip switch selectable baud rate (100-38.4 k bps)

11). SELF TEST MODE:

The SP-327 has a self test mode that will print and cut a sample ticket utilizing all of its control code features. The printer

does NOT have to be connected to the host via the serial port to print a Self Test ticket.

NOTE: The printer’s Power / Feed Switch has three valid positions of operation: OFF, ON (middle position), and

PAPER FEED (the Paper Feed position is temporary – the switch should spring back into the ON position whenever the

switch is released from the Paper Feed position).

To placethe unit into self test mode, first turn the power switch to the off position. Next, push the power switch all the way

over to the Paper Feed position. Release the switch after one second, and a self test sample will be printed and cut. All

electrical/mechanical portions of the printer are exercised and checked bythis action.

12) SP327 Standard Default RS232 Parameters

(Fixed in Firmware on all standard Models)

NOTE: Custom Firmware may use different parameters based on customer request

Baud Rate 9600

Parity NONE

Data Bits 8 Data Bits

Stop Bits 1 Stop Bit

Flow Control Hardware

Page 5.

Page 9

Page 10

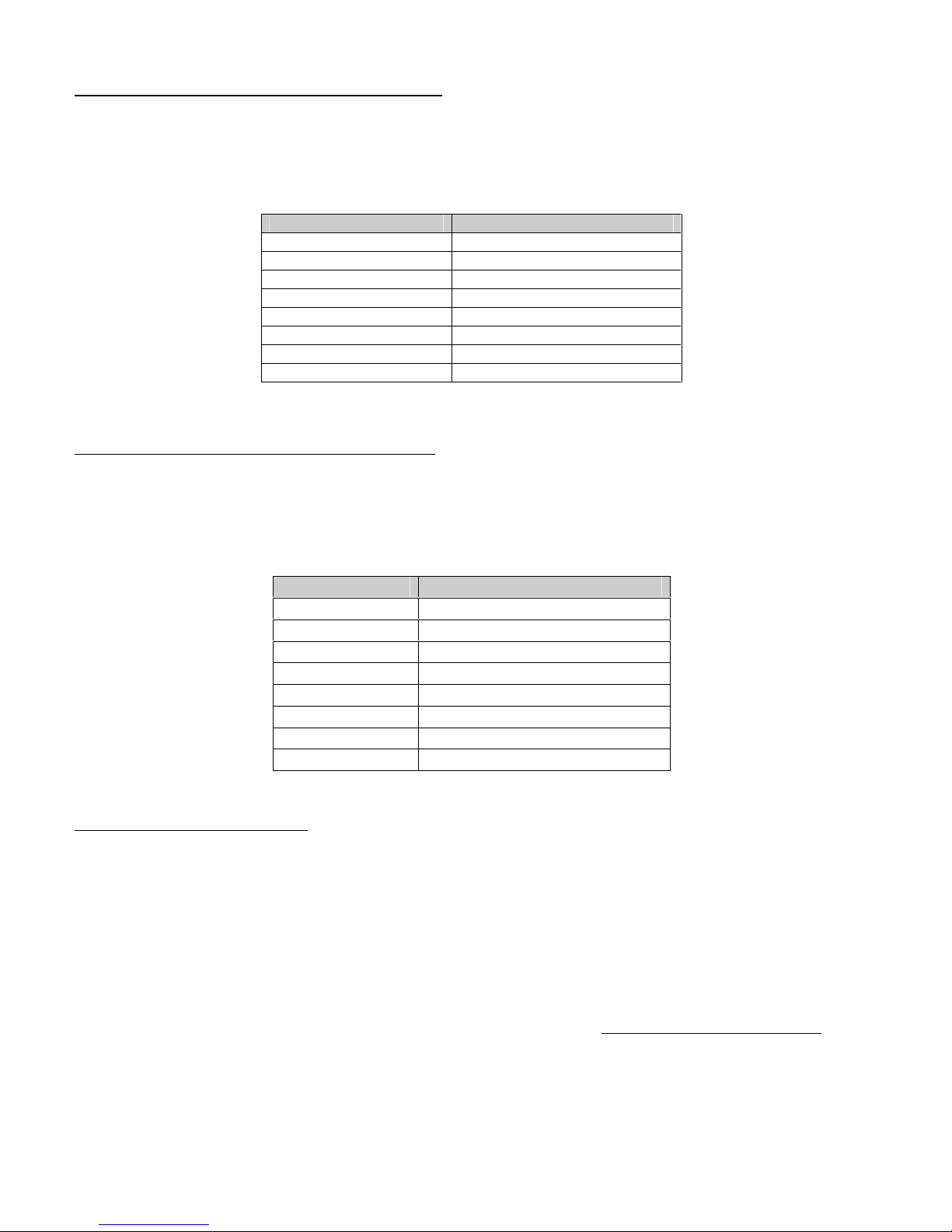

15.) SP327 Error Codes (Lights and Beeper Status)

LED BEEPER

No Paper in Mechanism (Head Closed) Green / Red Flashes ½ Sec Pulses

Head Up Green / Red Flashes ½ Sec Pulses

Cutter Not Home Solid Green Very Fast Pulses

Paper Roll Low *

Normal (Ready) w/ Paper Solid Green OFF

* The Paper Roll Low indication will activate when the diameter of the paper roll

decreases to approximately 43mm (approx. 1.7 inches).

Character Sizes for Various Fonts:

Font Type Characters / Line Lines / Inch

Normal (Default) 24 6.2

Normal Double Wide 12 6.2

Normal Double High 24 4.2

Normal Double Wide & Double High 12 4.2

Condensed 48 11.8

Condensed Double Wide 24 11.8

Condensed Double High 48 6.2

Condensed Double Wide & Double High 24 6.2

Solid RED OFF

PAPER:

The recommended thermal paper for use with the Telpar SP-327 is Telpar Part # 751327-0030.

Please contact Telpar Sales when ordering this paper.

Page 7

Page 11

16)Serial RS-232 Interface Cable Suggestion:

Computer End of Cable (Host) Side TELPAR Printer End of Cable

(9 Position, Female D-Sub Connector) (9 Position, male D-Sub Connector)

Socket Position Pin Position

1 1

Transmit Receive

Receive Transmit

DTR

2 2

3 3

4 4

Jumper

5 5

DSR

6 6

Signal Common Line

7 7

CTS

8 8

Printer Busy Line

9 9

Page 8

Page 12

'Telpar SP-327sampletest code written in MS VisualBasic 6.0

' The MSComm Controlmust be used and setup to runthis program

' Use COM1 Port for RS-232 Communications.

MSComm1.CommPort = 1

' 9600 baud, noparity, 8 data, and 1 stopbit.

MSComm1.Settings= "9600,N,8,1"

' Tell the control to read entirebuffer when Input is used.

MSComm1.InputLen = 0

' DSR Timeout in mSec

MSComm1.DSRTimeout= 50

' CTS Timeout in mSec

MSComm1.CTSTimeout = 50

' Open theport.

MSComm1.PortOpen= True

' CTS HoldingState

CHolding= MSComm1.CTSHolding

Debug.Print "MSComm1.CTSHolding = " + Str$(MSComm1.CTSHolding)

' DSR HoldingState

DHolding= MSComm1.DSRHolding

Debug.Print "MSComm1.DSRHolding= " + Str$(MSComm1.DSRHolding)

If MSComm1.DSRHolding = False Then

MSComm1.PortOpen= False

GoTo SerialOpps

End If

MSComm1.Output = Chr$(10)

MSComm1.Output = Chr$(13)

'Exampleof Error Status Checking

MSComm1.Output = Chr$(19) 'Get Error Status

While(MSComm1.InBufferCount<= 0)

NahDah= DoEvents() ‘prevents programfrom being lockedin an infinite loop

Wend

'Read Status

A$ = MSComm1.Input

The ticket shown below was

generated using the sample

code found on this page and the

next:

Debug.Print "Status = *" + A$+ "*"

Status$ = Hex$(Asc(A$))

If Right$(Status$, 1) = "0" Then

MSComm1.Output = "Status: PRINTER READY!"

MSComm1.Output = Chr$(10)'LineFeed

MSComm1.Output = Chr$(13)'Carriage Return

MSComm1.Output = Chr$(10)

MSComm1.Output = Chr$(13)

End If

'If there is an error, then Debug.Print info to VB's Immediate Window. Ref User Manual Section 6.0:

If Right$(Status$, 1) = "1" Or Right$(Status$, 1) = "3" Or Right$(Status$,1) = "5" Or Right$(Status$, 1) = "7" Then Debug.Print"PAPER LOW

SENSOR DOES NOT SEE PAPER ROLL."

If Right$(Status$, 1) = "2" Or Right$(Status$, 1) = "3" Or Right$(Status$,1) = "6" Or Right$(Status$, 1) = "7" Then Debug.Print"PAPER OUT

LEVER ON PRINTER MECH MAY BE IN THE PAPER RELEASE POSITION."

If Right$(Status$, 1) = "4" Or Right$(Status$, 1) = "5" Or Right$(Status$,1) = "6" Or Right$(Status$, 1) = "7" Then Debug.Print"POSSIBLE

CUTTER PROBLEM!"

'Exampleof the SP-327 Graphics Mode CheckerBoard

For y = 1 To 3

For x = 1 To 10

' Raster Graphics --> ESC + "l" + #of bytes to follow+ the actualdatabytes

MSComm1.Output = Chr$(27)+ "l" + Chr$(55) + Chr$(255) + Chr$(255) + Chr$(255) + Chr$(255) + Chr$(255)+ Chr$(0) + Chr$(0) +

Chr$(0) + Chr$(0)+ Chr$(0) + Chr$(255) + Chr$(255)+ Chr$(255) +Chr$(255) + Chr$(255) + Chr$(0) + Chr$(0)+ Chr$(0) + Chr$(0) + Chr$(0)

+ Chr$(255) +Chr$(255) + Chr$(255) + Chr$(255) + Chr$(255) + Chr$(0) + Chr$(0)+ Chr$(0) + Chr$(0) + Chr$(0) + Chr$(255) + Chr$(255) +

Chr$(255) + Chr$(255) + Chr$(255)+ Chr$(0) + Chr$(0) + Chr$(0) + Chr$(0)+ Chr$(0) + Chr$(255) + Chr$(255)+ Chr$(255) +Chr$(255) +

Chr$(255) + Chr$(0) +Chr$(0) + Chr$(0)+ Chr$(0) + Chr$(0) +Chr$(255) + Chr$(255) + Chr$(255)+ Chr$(255) + Chr$(255)

MSComm1.Output = Chr$(13)

Nextx

MSComm1.Output = Chr$(13)

Nexty

Page 13

For y = 1 To 3

For x = 1 To 10

' Raster Graphics --> ESC + "l" + #of bytes to follow+ the actualdatabytes

MSComm1.Output = Chr$(27)+ "l" + Chr$(50) + Chr$(0) + Chr$(0) + Chr$(0) +Chr$(0) + Chr$(0)+ Chr$(255) + Chr$(255) + Chr$(255) +

Chr$(255) + Chr$(255) + Chr$(0) + Chr$(0)+ Chr$(0) + Chr$(0) + Chr$(0) + Chr$(255) + Chr$(255)+ Chr$(255) + Chr$(255) + Chr$(255) +

Chr$(0) + Chr$(0)+ Chr$(0) + Chr$(0) + Chr$(0) + Chr$(255) +Chr$(255) + Chr$(255) + Chr$(255)+ Chr$(255) + Chr$(0) + Chr$(0) + Chr$(0)

+ Chr$(0) + Chr$(0) + Chr$(255) + Chr$(255) + Chr$(255) + Chr$(255)+ Chr$(255) +Chr$(0) + Chr$(0) + Chr$(0) + Chr$(0)+ Chr$(0) +

Chr$(255) + Chr$(255) + Chr$(255)+ Chr$(255) + Chr$(255)

MSComm1.Output = Chr$(13)

Nextx

MSComm1.Output = Chr$(13)

Nexty

MSComm1.Output = Chr$(10)

MSComm1.Output = Chr$(13)

MSComm1.Output = Chr$(10)

MSComm1.Output = Chr$(13)

MSComm1.Output = "Description: "

MSComm1.Output = Chr$(13)

MSComm1.Output = "SP-327 Serial"

MSComm1.Output = Chr$(13)

MSComm1.Output = "Thermal Printer"

MSComm1.Output = Chr$(13)

MSComm1.Output = Chr$(10)

MSComm1.Output = Chr$(13)

'Exampleof Interleave2 of 5 Barcode

MSComm1.Output = Chr$(27)+ "i" + Chr$(12) + Chr$(3) + "123456"+ Chr$(13)

MSComm1.Output = Chr$(13)

MSComm1.Output = Chr$(10)

MSComm1.Output = Chr$(13)

MSComm1.Output = "Barcode 2 of 5= 123456"

'MSComm1.Output = Chr$(10)

MSComm1.Output = Chr$(13)

'Exampleof LandscapeMode

MSComm1.Output = Chr$(2)'Enter LandscapeMode

MSComm1.Output = " LandscapeMode!"

MSComm1.Output = Chr$(10)

MSComm1.Output = Chr$(13)

'Exampleof Barcode 3 of 9 Barcodein landscapemode

MSComm1.Output = Chr$(27)+ "C" + Chr$(1) + Chr$(2) +"*123456*" + Chr$(13)

MSComm1.Output = Chr$(13)

MSComm1.Output = Chr$(15)' Enable Condensed Mode

MSComm1.Output = " Barcode: 3 of 9 = 123456"

MSComm1.Output = Chr$(10)

MSComm1.Output = Chr$(13)

MSComm1.Output = Chr$(3)'End LandscapeMode

MSComm1.Output = Chr$(18)' Disable Condensed Mode

MSComm1.Output = Chr$(10)

MSComm1.Output = Chr$(13)

MSComm1.Output = Chr$(27)+ "c" 'Initiate a paper cut

MSComm1.Output = Chr$(13)

MSComm1.PortOpen= False

End

' End of SP327

'_________________________________________________________

SerialOpps:

MsgBox"Print Operation has been Cancelled. Make sure Power to the printer is ON and/or try a differentCOM Port."

End

Page 14

SP-327 Thermal Printer Maintenance Manual

Introduction

The SP-327 printers are designed to require a minimum of maintenance and service. This section provides basic

instructions for general care, maintenance and cleaning of the thermal print mechanism.

Electrical and mechanical repairs should be performed by qualified personnel only. Make certain that all electrical

connections are disconnected before any service is performed on the SP-327 printers. Personnel involved in repair

and maintenance of the print

mechanism, or other electronic components should take appropriate measuresto guard against electrostatic

discharge. Electrostatic discharge can damage the heating elements and ICs associated with the printer.

..

Required Tools and Supplies 1. Common hand tools 2. Short bristle brush 3. Denatured alcohol 4.

Cleaning rags 5. Cotton swabs

6. Low temperature grease

General Care and Handing

To ensure high print quality and long print head life, always use thermal paper approved by TELPAR Corporation.

Do not operate the printer without paperinstalled in the mechanism. Operation without paper may cause damageto

the thermal print head. When the printer is not in use, it is recommended that the paper release lever be switched

to the release position. This will prevent deformation of the soft print platen from constant spring pressure.

In applications were prolonged dense printing is performed, condensation may occur. This condition occurs when

the thermal print head is heated to the point where is releases water vapor contained within the paper.

Condensation can also appear when printing in extreme low temperatures, or in high humidity environments.

Excessive condensation can cause the paper to stick in the mechanism and cause a jam condition.

Removing Paper from the Mechanism

Excess paper that remains in the print mechanism may be easily removed before cleaning. Paper can be removed

by turning the motor in the reverse direction by hand. Tweezers may be used to remove remaining paper lodged in

the mechanism. Caution should be excised when removing paper with any tool. The surface of the thermal print

head is made of a ceramic material that can be easily damaged. A cotton swab is recommended for removal of

paper dust in this area.

SP-327 Mechanism in a Fully Closed Position

MM1

Page 15

Cleaning

Print quality will deteriorate if paper particles or thermal sensitive residues build on the heating elements

of the thermal print head. To clean the mechanism and print elements, follow the procedure below.

1. Push outward (left and right) on the cutter retaining tabs and flip the cutter assembly forward out of the

way.

2. Once the cutter is out of the way, locate the two upper front cover retaining screws and remove them from the

assembly.

3. Flip the front of the print mechanism forward to gain access to the printer platen and thermal print

elements. .

4. Remove the print platen from the mechanism carriage (note proper orientation of platen and paper

release cam lever position)

5. Once the platen has been removed, the thermal print elements will be visible. The print head may be

cleaned with a cotton swab moistened with alcohol. Do not use an abrasive cleanser, paper or shop cloth

to clean the print head as damage may occur to the heating elements.

6. The print head assembly may be reassembled in the reverse order once the alcohol has been dried

completely.

7. Make certain that cluster gears are free from excessive dust or paper particles. The cluster gears

may be cleaned with compressed air, or with a short bristle brush.

Once the mechanism is reassembled, a test print is recommended. The SP-327 exterior may be cleaned

with a non-abrasive cleanser. Care should be taken to prevent liquids from entering inside the electrical

sub-assemblies.

MM2

Page 16

Cutter Assembly

Prior to any type of service or maintenance to the cutter mechanism, disconnect all power to the printer.

Caution must be observed when service cleaning is being performed on the cutter assembly. Cutter blades are

sharp and may cause serious injury. The cutter assembly can be cleaned with alcohol and cotton swabs. Moisten a

cotton swab to clean the blade and associated mechanical components. Once the cutter assembly has been

cleaned, wipe off excess solvent. Low temperature grease may be applied to the cutter as shown below.

CUTTER IN FLIPPEDPOSITION

MM3

Page 17

MM4

Page 18

MM5

Loading...

Loading...