Page 1

MTP-2232/2242 Modular Thermal Printer

MTP-2222 Printer without presenter

MTP-2200 Series Modular Thermal Printer

User Manual

TELPAR

A Platinum Equity COMPANY

187 Crosby Road

Dover, New Hampshire 03820

Toll Free: 800-872-4886 (from the U.S.A. and Canada only)

603-750-7237

Fax: 603-742-9938

Website: www.telpar.com

E-mail: info@telpar.com

Page 1 of 52

Page 2

Warranty

TELPAR — Printer Limited Warranty

For one (1) year after shipment of the printer product to Buyer, Telpar warrants the product against defects in materials

and workmanship provided the product has been operated and maintained in accordance with manufacturer’s

operating and maintenance specifications. This warranty specifically excludes ribbons, paper and other consumable

items.

THIS WARRANTY IS IN LIEU OF ANY AND ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED. TELPAR

MAKES NO OTHER WARRANTY AND BUYER SPECIFICALLY WAIVES ANY OTHER WARRANTIES, INCLUDING

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. THERE ARE NO

WARRANTIES THAT EXTEND BEYOND THOSE DESCRIBED HEREIN.

Telpar’s liability hereunder is limited to the repair or replacement of defective parts. This liability does not extend to

normal wear and tear. Telpar will, solely at its option, remedy all valid warranty claims either by:

(a) Repairing or replacing the defective unit at Telpar’s factory; or

(b) Repairing or replacing the defective subassembly at Telpar’s factory.

If so directed by Telpar, Buyer shall return the defective unit or subassembly, transportation prepaid by Buyer, to

Telpar’s factory. After repair or replacement has been accomplished, Telpar will return the unit or subassembly,

transportation prepaid by Telpar, to Buyer.

As a precondition to any warranty service, prior to return of any units or subassemblies to Telpar by Buyer, Buyer

must contact Telpar’s Order Administration Services and receive authorization in the form of a Return Material

Authorization (RMA) number. Telpar reserves the right to refuse any goods it has not previously authorized for return,

or any goods shipped without transportation prepaid.

No warranty shall apply to any damage resulting from or caused by Buyer, if Buyer shall make any changes,

modifications, additions or deletions of hardware, software or firmware in the Printer products sold hereunder without

Telpar’s advance written consent.

Warranty service may be obtained by contacting our Customer Service department for instructions:

TELPAR

187 Crosby Road

Dover NH 03820

ATTN.: Warranty Service Department.

Telephone: 800-872-7237

Fax: 603-742-9938

Email: info@telpar.com

Upon inspection, Telpar will make necessary repairs or replacement and return the merchandise, shipping prepaid.

Page 2 of 52

Page 3

Table of Contents

1 General................................................................................................................................... 6

1.1 Applications...................................................................................................................... 7

1.2 Standard Features........................................................................................................... 7

1.3 Options for the MTP-2200 Series.................................................................................. 8

1.4 General Specifications................................................................................................... 8

1.5 Safety / Agency Information............................................................................................ 8

1.6 Power Supply Requirements......................................................................................... 9

1.6.1 External Power Supply (supplied separately)..................................................................... 9

1.6.2 Voltage: 24 VDC ±5%.................................................................................................... 9

1.6.3 3-Pin Hosiden Connector on Printer for Power Supply Connection............................... 9

1.7 Telpar Roll Paper for MTP-2200 Series...................................................................... 10

2 Operator Instructions....................................................................................................... 11

2.1 Unpacking and Inspection............................................................................................ 11

2.2 Paper Loading................................................................................................................ 11

2.2.1 Side-Loading Roll.......................................................................................................... 11

2.2.2 Top Loading Roll........................................................................................................... 11

2.3 Paper Jam....................................................................................................................... 11

2.3.1 Head Up Lever.............................................................................................................. 12

3 Installation........................................................................................................................... 13

3.1 Self Test Mode (also Burn-in and Hex Dump modes)..................................................... 13

3.1.1 Self Test....................................................................................................................... 13

3.1.2 Factory Burn-in Mode.................................................................................................... 13

3.1.3 Hex Dump printing mode................................................................................................ 13

3.1.4 Continuous Factory Burn-in Mode................................................................................... 13

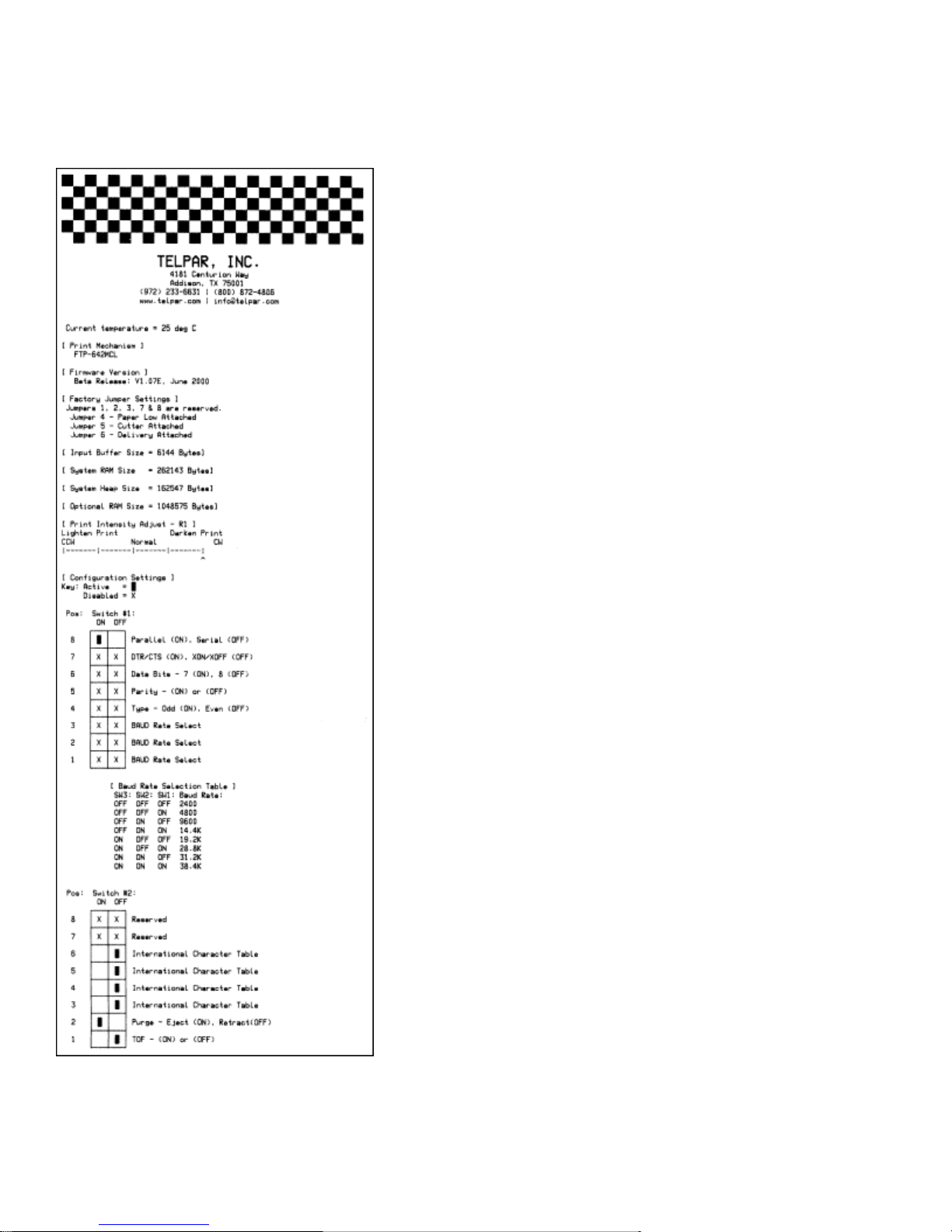

3.1.5 MTP-2242 Self Test Printout........................................................................................... 14

4 Interface Specifications................................................................................................... 15

Page 3 of 52

Page 4

4.1 General........................................................................................................................... 15

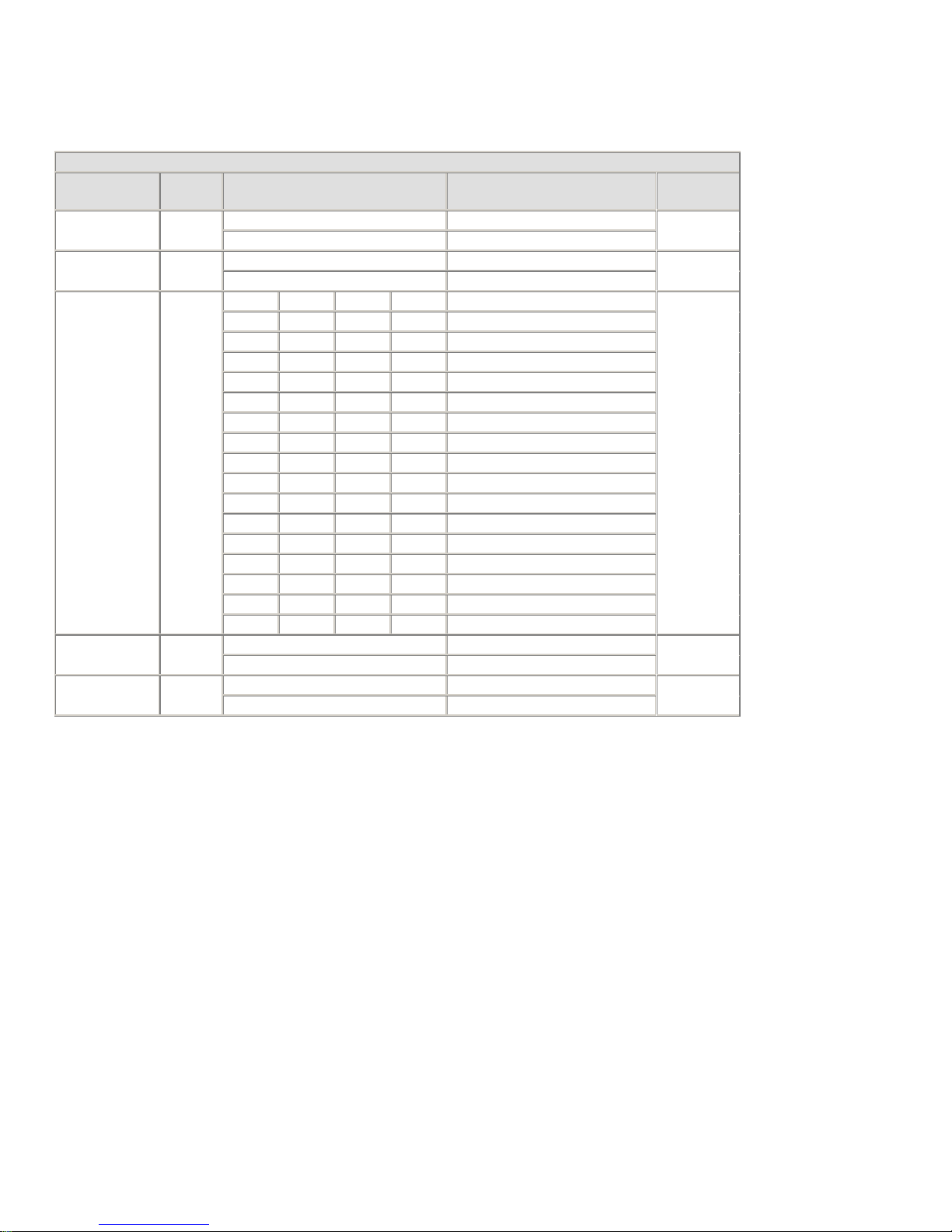

4.1.1 Setting of DIP Switches................................................................................................. 15

4.1.1.1 DSW1 – DIP Switch.................................................................................................. 15

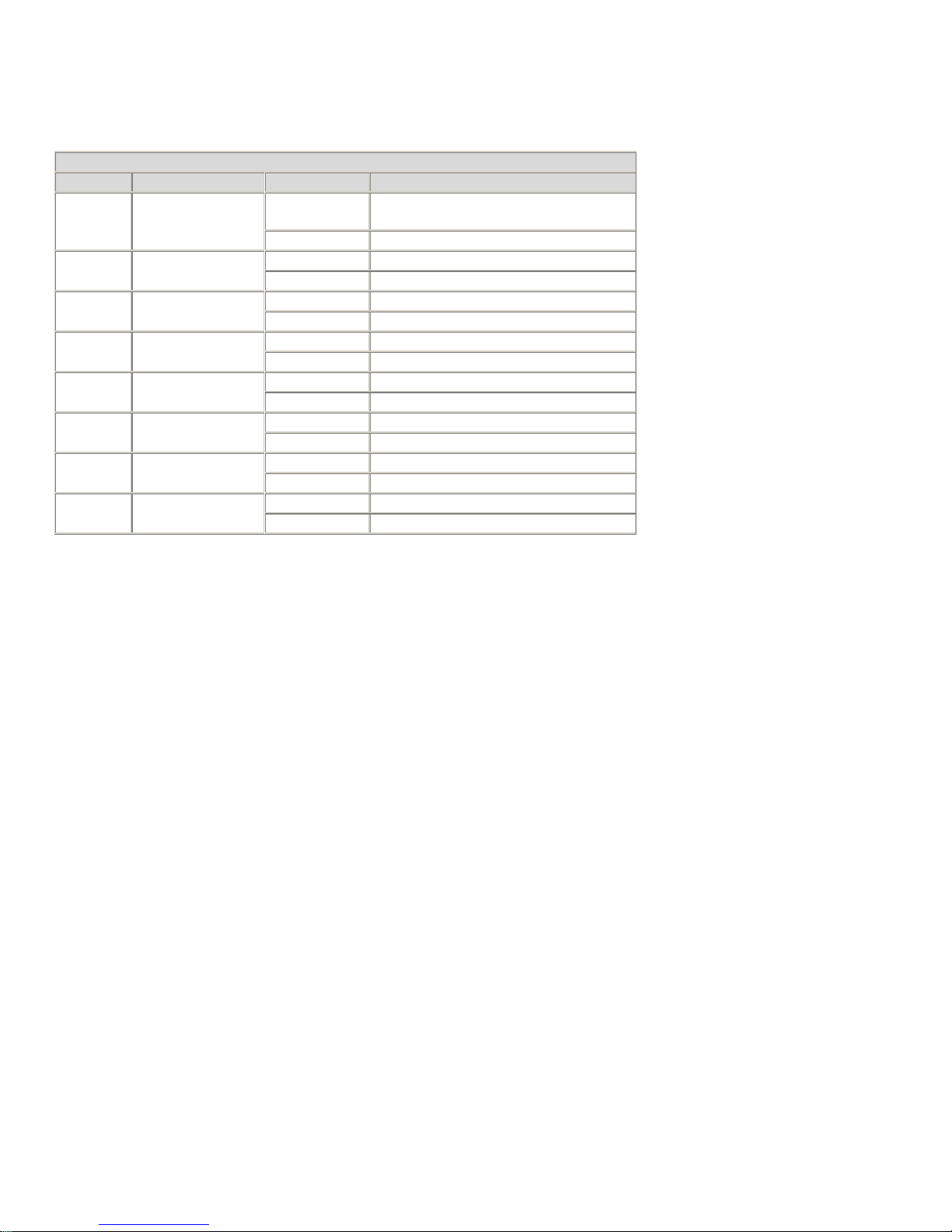

4.1.1.2 DSW2 – DIP Switch 2................................................................ 16

4.1.1.3 JP9 - Configuration straps.................................................................. 17

4.1.1.4 Other Strap Options...................................................................... 18

4.2 Control Codes and Control Sequences..................................................................... 19

4.2.1 General Usage Print Commands..................................................................................... 19

4.2.2 Descriptions of Commands............................................................................................ 24

4.2.2.1 Status commands........................................................... 24

4.2.2.2 Set Print Mode.......................................................... 25

4.2.2.3 Printer Reset............................................... 25

4.2.2.4 Telpar's Window Commands............................... 25

4.2.2.5 Language Monitor Information................................................ 25

4.2.2.6 Bit Image (BI) Graphics Mode Commands............................................... 26

4.2.2.7 Print Bar Code Command................................................................ 26

4.2.2.8 Bar Code 128 definitions................................................................... 27

4.3 Serial (RS-232C) Interface............................................................... 29

4.3.1 Serial (RS-232C) Interface Specification.......................................................................... 29

4.3.2 Serial I/O Connector...................................................................................................... 29

4.3.3 Flow Control................................................................................................................. 30

4.4 Parallel Interface (IEEE-1284)...................................................................................... 30

4.4.1 Parallel I/O Connector, IEEE-1284 Type C....................................................................... 30

4.4.2 Alternate Parallel I/O Connector, IEEE-1284 Type A or B............... 32

5 Detailed Specifications.............................................................. 33

5.1 Detailed Specifications................................................................................................. 33

5.2 Error Detection Function.............................................................................................. 33

Page 4 of 52

Page 5

5.3 Character Sets - Print Samples................................................................................... 35

5.4 MTP-2222 Dimensional Drawings................................................................................ 40

5.5 MTP-2232/MTP-2242 Dimensional Drawings............................................................. 41

5.6 Dimensional Drawings With Presenter....................................................................... 43

6 CE Declaration of Conformity........................................................................................ 46

List of Figures

Figure 1 - 3-Pin Hosiden Power Supply Connector............................. 9

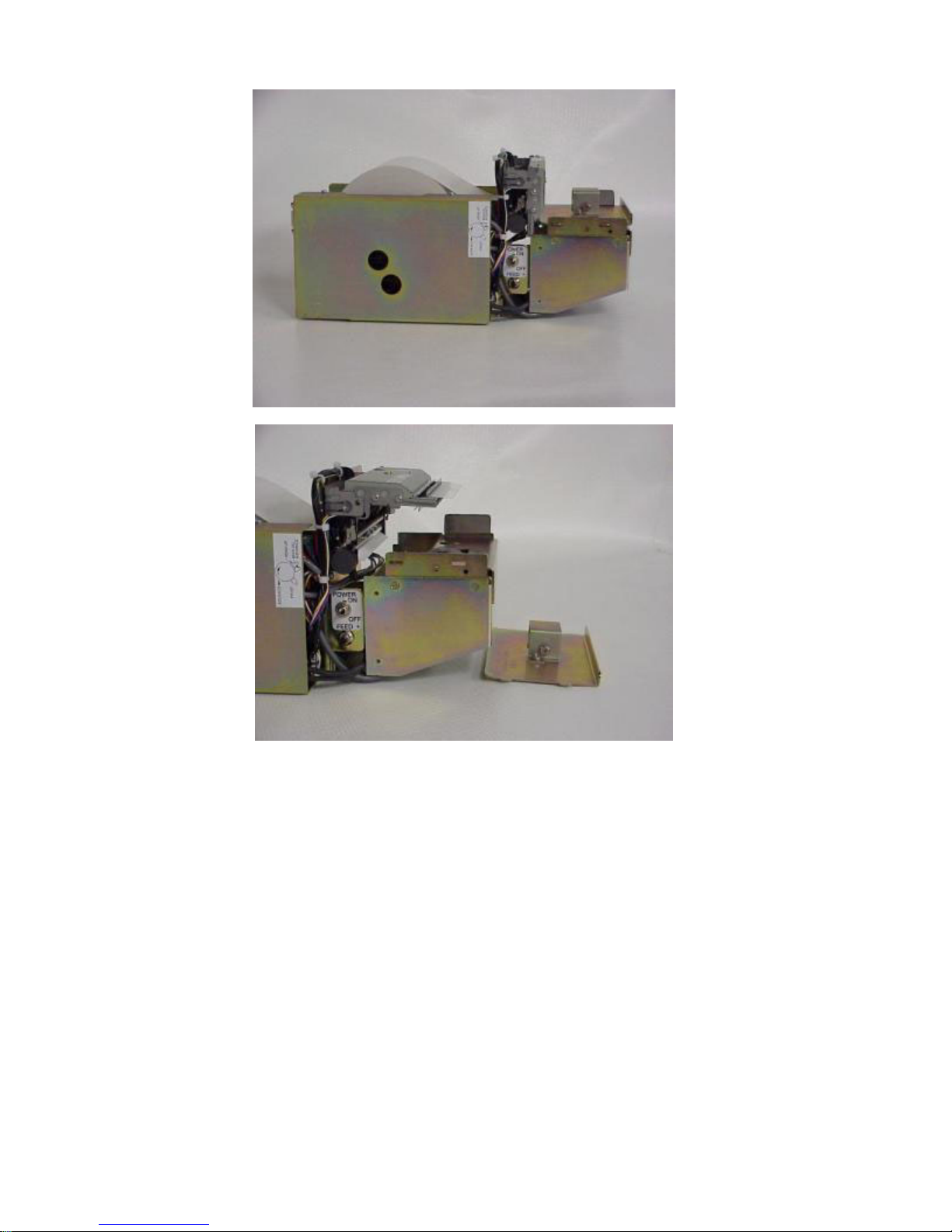

Figure 2 - MTP-2242 with Cutter Mechanism closed............................. 12

Figure 3 - MTP-2242 with Cutter Mechanism open................................ 12

Figure 4 - MTP-2242 Self Test Printout................................ 14

Figure 5 - General Usage Print Commands......................................... 23

Figure 6 - Serial I/O Connector....................................................... 29

Figure 7 - Serial Interface RS-232C......................................... 29

Figure 8 - Parallel I/O Connector......................................... 30

Figure 9 - Code Page 437 Print sample............................... 35

Figure 10 - Code Page 850 Print sample.................................. 35

Figure 11 - Code Page 860 Print sample............................. 36

Figure 12 - Code Page 863 Print Sample....................................... 36

Figure 13 - Code Page 865 Print Sample............................. 37

Figure 14 - Code Page WPC1252 Print sample.............................. 37

Figure 15 - Code Page 858 Print sample.................................... 38

Figure 16 - International Character Sets............................... 39

Figure 17 - MTP-2222 Left Side View.................................. 40

Figure 18 - MTP-2222Top View........................................................ 40

Figure 19 - MTP-2222 Right Side View...................................................... 41

Figure 20 - MTP-2232/MTP-2242 Dimensional Drawing with Mounting Holes (Top View)........... 41

Figure 21 - MTP-2232/MTP-2242 Dimensional Drawing (Side View)................. 42

Page 5 of 52

Page 6

Figure 22 - MTP-2232/2242 Isometric Drawing................. 42

Figure 23 - MTP-2222 with Presenter..................................................... 43

Figure 24 - MTP-2232 with Presenter................................................. 44

Figure 25 - MTP-2242 with Presenter.......................................... 45

Page 6 of 52

Page 7

List of Tables

Table 1 - Current (A) for Printer Head.............................. 9

Table 2 - Peak Current for Motor.............................. 9

Table 3 - DIP Switch 1 (DSW1) Settings.......................................... 15

Table 4 - DIP Switch 2 (DSW2) Settings.............................. 16

Table 5 - Configuration strap Settings............................... 17

Table 6 - Other Strap Options..................................... 18

Table 7 - First Status byte transmitted (and MASK for DLE A command)................ 24

Table 8 - Printer's response to a STATUS REQUEST command......... 24

Table 9 - Set Print Mode Table.............................................. 25

Table 10 - Serial (RS-232C) Interface Specification............. 29

Table 11 - Serial (RS-232C) Interface Pin Assignments.............. 30

Table 12 - Parallel Interface Pin Assignments - IEEE-1284 Nomenclature............... 31

Table 13 - Parallel Interface Pin Assignments - Centronics nomenclature.......... 32

Table 14 - General Specifications........................... 33

Table 15 - Error Detection Functions................................. 34

1 General

The MTP-2200 series of modular thermal printers is designed specifically for the high performance, size and durability

requirements of cut and drop (or cut and present with optional Document Presenter ) applications. The compact size

and high performance characteristic, coupled with its rugged design, makes it ideal for the kiosk environment.

These models make up the MTP-2200 Series covered in this manual:

· MTP-2222 SP - 60 mm (2.36 in) paper width

· MTP-2232 SP - 85 mm (3.35 in) paper width .

· MTP-2242 SP - 114 mm (4.49 in) paper width .

· OPTIONS include: -P = with Document Presenter.

F5 = with 512 Kbytes of FLASH memory.

P1 = with 1 Mbyte of PAGE RAM memory.

1.1 Applications

· Kiosks

· Automated Teller Machines (ATMs)

· Parking ticket dispensing

· Gaming receipts

1.2 Standard Features

Page 7 of 52

Page 8

· Direct thermal printing

· Interfaces : Serial or parallel

· Auto Cutter : full cut/partial cut under software control is standard

· All metal construction

· Adjustable paper low sensor

· Paper auto load function

· ESC/POS

Ò

[1] The commands conform to ESC/POS

· Print speed of up to 80 mm/sec (3.1 in/sec); 640 dot lines/second)

· LEDs visible and DIP switches accessible without removing cover

· Paper capacity : 152 mm (6 in) diameter roll with 50 mm diameter core

· Overall size including 152 mm (6 inch) diameter roll of paper :

• MTP-2222: 163 mm x 115 mm x 231 mm(6.4"H X 4.5"W X 9.1"D)

• MTP-2232/2242: 163 mm x 170 mm x 231 mm(6.4"H X 6.7"W X 9.1"D)

· International character set : U.S.A., France, Germany, England, Denmark (2 choices), Sweden, Italy, Spain (2

choices), Japan, Norway, Latin America and Korea

· Barcode embedded symbologies: UPC-A, UPC-E, EAN 13, EAN 8, 3of 9. ITF, CODABAR, and Code 128

· Two resident font sizes

· Code pages 437, 850, 858, 860, 863, 865, and WPC 1252.

· Bit image mode

· Reverse video mode

· Black mark sensing (TOF mode)

1.3 Options for the MTP-2200 Series

· Paper width :

• 60 mm (2.36 in) – MTP-2222

• 85 mm (3.35 inch) – MTP-2232

• 114 mm (4.49 in) – MTP-2242

· Microsoft

®

Windows® driver [2]

· Document Presenter (-P option)

· FLASH memory , 512Kbytes (F5 option)

· PAGE memory (RAM), 1Mbyte (P1 option)

1.4 General Specifications

· Resolution : 8 dots/mm (203 dots/in)

· Paper thickness : 0.06 mm to 0.10 mm maximum (.0024 in to .0039 in)

· Operating temperature : 5

· Storage temperature : -20

o

C to 40o C (41o F to 104o F)

o

C to 60o C (-4o F to 140o F)

· Operating humidity : 20-85% RH (non-condensing)

· Weight : Standard configuration without paper 2.0 kg (4.5 lbs.)

· Expected life of mechanism: 50 km minimum due to wear

· Expected life of cutter: 3 x 10

5

cuts for the MTP-2242, 5 x 105 cuts for the MTP-2222 and MTP-2232

1.5 Safety / Agency Information

Information Technology Equipment IEC 950

Product Safety: UL 1950 / EN60950

EMC: CFR47 / Part 15 / EN55022

File Number: 188263

Project: 00NK40431

Page 8 of 52

Page 9

1.6 Power Supply Requirements

1.6.1 External Power Supply (supplied separately)

Use a Listed/Certified Power Supply.

Follow local wiring codes for external wiring.

1.6.2 Voltage : 24 VDC ±5%

No requirement for external 5 VDC power supply, the 5 VDC for logic is supplied from the 24 VDC, by a regulator

internal to the printer.

This printer prints using high speed currents at a low duty cycle. Typically, a switching power supply rated at 24 Volts

DC. 2 Amps is all that is needed as long as the power supply does not have too much over current protection.

Current (A) for Printer Head

Printing

rate

Solid

Black-out

Printer

Avg Peak

Model

MTP-2222 1.75 4

MTP-2232 2.25 5

MTP-2242 3 7

Typical

ASCII text

MTP-2222 1 2.5

MTP-2232 1.25 2.5

MTP-2242 1.5 3.5

Table 1 - Current (A) for Printer Head

Current (A) for Motor

Peak = 1.0 A, typical = <0.1 A

Table 2 - Peak Current for Motor

1.6.3 3-Pin Hosiden Connector on Printer for Power Supply Connection

Power Connector::

Hosiden #TCS7960-53-2010

Mating Connector:

Hosiden #TCP8927-53-1100 or

TCP8927-63-1110

Figure 1 - 3-Pin Hosiden Power Supply Connector

1.7 Telpar Roll Paper for MTP-2200 Series

Thermal sensitive coating is on the “inside” of the roll.

· For MTP-2222: 152 mm (6 in) outside diameter, 60 mm (2.36 in) wide, approximate length 180 m (590 ft) P/N

251410-0602

· For MTP-2232 152 mm (6 in) outside diameter, 85 mm (3.35 in) wide, approximate length 180 m (590 ft) P/N

251102-1603

· For MTP-2242 152 mm (6 in) outside diameter, 114 mm (4.49 in) wide, approximate length 180 m (590 ft) -

P/N 251410-0604

Page 9 of 52

Page 10

Specific to Thermal Printers: TELPAR does not warranty damages to the thermal print head as a result of printing

with thermal paper not specified or approved by TELPAR

2 Operator Instructions

2.1 Unpacking and Inspection

Carefully unpack and inspect your MTP-2200 for any damage that may have occurred in transit. Should any damage

have occurred, notify TELPAR, save the shipping carton and packing materials , and file a damage claim with the

carrier. Specify the nature and the extent of the damage. Before installing or operating the printer, check the following:

· Printer mechanism and paper path are clear of all packing materials or other foreign matter.

· Paper is installed. DO NOT OPERATE the printer without paper. Refer to Section 2.2 - Paper Loading for paper

loading instructions.

2.2 Paper Loading

2.2.1 Side-Loading Roll

The MTP-2222 printer is configured as a side-loading printer . Slide roll of paper over spindle with paper fed off the

bottom toward the paper slot (front of unit).

To load paper , turn on the power and feed the straight edge of the paper into the paper guide. Inserting paper will

result in the automatic loading of paper once it is fed into the paper guide

Ensure that the paper is installed correctly and feeding properly with the thermal side facing up.

2.2.2 Top Loading Roll

The MTP-2232 and MTP-2242 printers are configured as a drop in loader . Load the roll of paper by placing the

spindle inside the roll of paper and place spindle in slots with paper fed off the bottom toward the paper slot (front of

unit).

To load paper , turn on the power and feed the straight edge of the paper into the paper guide. Inserting paper will

result in the automatic loading of paper once it is fed into the paper guide.

Ensure that the paper is installed correctly and feeding properly with the thermal side facing up.

2.3 Paper Jam

In the event of a paper jam condition do not force paper into the unit, or try to pry the paper out of the unit, this may

damage the thermal print mechanism . Caution should be exercised when working next to the cutter mechanism , the

blades are sharp and may cause serious injury.

To release paper:

· Move Head Up lever to right of Advance wheel to top position

· Lift cutter mechanism to “Open position (See - MTP-2242 with Cutter Mechanism open ) Paper can be

removed at this time. Once paper is cleared from the mechanism, return the cutter assembly to its home position.

Models MTP-2222 , MTP-2232 and MTP-2242 all operated similarly

· Move Head Up lever to right of Advance wheel to the bottom position to return to printing position

2.3.1 Head Up Lever

The Head Up lever is located by the Paper Feed knob . The down position is ready to print. The middle position

reduces pressure between the printhead and the print platen roller for easier manual feeding. The up position lifts the

printhead off of the platen roller for manually inserting paper or for clearing a paper jam. Both the middle and up

positions signal the microprocessor that the head is up so that no printing will occur.

Page 10 of 52

Page 11

Figure 2 - MTP-2242 with Cutter Mechanism closed

Figure 3 - MTP-2242 with Cutter Mechanism open

3 Installation

3.1 Self Test Mode (also Burn-in and Hex Dump modes)

The MTP-2200 series has a self-test mode that will print and cut a sample document. All electrical and mechanical

portions of the printer are exercised and checked by this action, except for the serial interface or parallel interface

components. The self-test printout also shows pertinent information pertaining to operation of the printer.

3.1.1 Self Test

To place the unit into self-test mode : turn the power switch off, press and hold the FEED push button switch and place

the POWER switch in the ON position, then release the paper feed switch. See Figure 4 - MTP-2242 Self Test

Printout for examples of the self-test printout.

3.1.2 Factory Burn-in Mode

If the paper feed button is held for 4 seconds after power is turned on, the printer will enter the Factory Burn-In Mode.

A hundred shorter sheets will be printed.

Page 11 of 52

Page 12

3.1.3 Hex Dump printing mode

If the paper feed button is held for 8-12 seconds after power is turned on, the printer will enter the Hex Dump Mode.

All codes received will be printed in HEX format rather than causing the normal execution, this may be useful for

troubleshooting applications.

3.1.4 Continuous Factory Burn-in Mode

If the paper feed button is held for 12 seconds after power is turned on, the printer will enter the CONTINUOUS

Factory Burn-In Mode that does not stop after 100 sheets are printed.

Page 12 of 52

Page 13

3.1.5 MTP-2242 Self Test Printout

4 Interface Specifications

4.1 General

Page 13 of 52

Page 14

The MTP-2200 Series may be configured to be a Serial RS-232 interface or an IEEE-1284 Parallel interface by DIP

Switch settings .

4.1.1 Setting of DIP Switches

4.1.1.1 DSW1 – DIP Switch

DIP Switch 1 (DSW1) Settings

Serial-interfacecommunication

baud rate setting

1,2,3

Setup status Setup state Item Bit No

Bit 1 Bit 2 Bit 3 Baud Rate

OFF OFF OFF 2400

ON OFF OFF 4800

OFF ON OFF 9600

Factory

settings

19200

ON ON OFF 14.4K

OFF OFF ON 19.2K

ON OFF ON 28.8K

OFF ON ON 31.2K

ON ON ON 38.4K

OFF Even Parity selection 4

Even

ON Odd

OFF No parity Parity use 5

No parity

ON Parity

6

bits

OFF 8 Number of data

8

ON 7

OFF XON/XOF Serial handshake 7

DTR

ON DTR

Interface

8

OFF Serial

Parallel

ON Parallel

Selection

Table 3 - DIP Switch 1 (DSW1) Settings

Page 14 of 52

Page 15

4.1.1.2 DSW2 – DIP Switch 2

DIP Switch 2 (DSW2) Settings

Item Bit No Setup Status Setup State Factory

settings

1

sensor

OFF Disabled Top of Form

ON Enabled

OFF Retract Purge setting 2

Disabled

Retract

ON Eject

3, 4, 5, 6

3 4 5 6 Intl Char / Code Page

OFF OFF OFF OFF USA / CP437

USA /

CP437

ON OFF OFF OFF France / CP858

OFF ON OFF OFF Germany / CP858

ON ON OFF OFF England / CP858

OFF OFF ON OFF Denmark / CP858

ON OFF ON OFF Sweden / CP858

OFF ON ON OFF Italy / CP858

ON ON ON OFF Spain / CP858

OFF OFF OFF ON Japan / CP850

ON OFF OFF ON Norway / CP865

OFF ON OFF ON Denmark 2 / CP858

ON ON OFF ON Spain 2 / CP858

OFF OFF ON ON Latin America / CP437

ON OFF ON ON Korea / CP850

OFF ON ON ON Reserved

ON ON ON ON Reserved

Reserved 7

Reserved 8

Table 4 - DIP Switch 2 (DSW2) Settings

Page 15 of 52

Page 16

4.1.1.3 JP9 - Configuration straps

JP9 - Configuration straps

Strap# Name

1 Erase FLASH

ON Erase optional FLASH memory when

OFF No affect on FLASH.

ON 2

OFF

ON 3

OFF

ON Paper Low sensor is installed. 4 Paper Low

OFF Paper Low sensor is not installed.

ON Cutter is installed. 5 Cutter

OFF Cutter is not installed.

ON Presenter is installed. 6 Document

Presenter

OFF Presenter is not installed.

ON 7

OFF

ON 8

OFF

Table 5 - Configuration strap Settings

power is turned on.

Page 16 of 52

Page 17

4.1.1.4 Other Strap Options

Other Strap Options

Location Name Position Description

A20 4 Mbit (256K x16) optional FLASH is installed JP1 FLASH size

unmarked 8 Mbit (512K x16) optional FLASH is installed

unmarked < 256K x 8 EPROM installed JP2 EPROM size

256K => 256 x 8K EPROM installed

unmarked <1M x 8 EPROM installed JP3 EPROM size

1M 1M x 8 EPROM installed

unmarked < 512K x 8 EPROM installed JP4 EPROM size

512K => 512K x 8K EPROM installed

32 32K x 8 RAM installed JP5 System RAM

size

512 512K x 8 RAM installed

32 32K x 8 EPROM installed JP6 EPROM size

128 => 128K x 8 EPROM installed

WP Optional FLASH is Write Protected JP7 FLASH option

unmarked Optional FLASH can be overwritten

BBL Boot Block of optional FLASH is locked JP8 FLASH option

Unmarked CAUTION – Boot block can be overwritten

JP9 Configuration See previous section

JP10 Test points Factory use only

JP11 Serial port Factory use only

BF Boot up to FLASH JP12 Boot function

BR Boot up to ROM

Unmarked Install if JP9 is set to BF JP13 Optional

FLASH

OFF Install if JP9 is set to BR

ON Connect drive signal to LED2 and J10 pin 4 JP14 LED2

OFF LED2 and J10 pin 4 have no drive signal

ON Connect drive signal to BUZZER and J10 pin 2 JP15 Buzzer

OFF BUZZER and J10 pin 2 have no drive signal

JP16 Connect LED2

Install ONLY if either JP11 or JP12 (but not both) are installed.

and BUZZER

Table 6 - Other Strap Options

Page 17 of 52

Page 18

4.2 Control Codes and Control Sequences

4.2.1 General Usage Print Commands

General Usage Print Commands

Name

Command

Command

Description

ASCII

hex

Tab HT 09 Move the print position to

the next horizontal tab

position. See ESC D. If a

TAB is received and there

are no more tab positions

set on the current line, the

TAB command is ignored. If

the TAB will exceed the

right margin, an auto-print

is performed and the print

position is set to the start of

the next line.

Line feed LF 0A Data on the current line is

printed, paper is fed one

line based on the current

line spacing, and the print

position is set to the left

margin. If the current line

spacing is set to less than

the current font height then

paper is fed to print the

current font height (see

ESC 2, ESC 3 +n, and ESC

C +n).

Form Feed FF 0C Feed paper to end of page

as defined by the default

page length of 11 inches or

as modified by the US C

command. If TOF mode is

enabled (DIP switch 2

position 1 or ESC c 1 +n))

then paper is fed until the

next BLACK MARK is

detected. To advance to

the BLACK MARK if TOF

mode is not enabled use

the GS FF command.

DLE DLE 10 Data Link Escape

Sequence Header.

Enable Auto Status Back DLE A +n1

+n2

10 41 +n1

+n2

+n1 and +n2 define a mask

to enable the transmission

of the STATUS bytes when

a user defined event

occurs. See Section 4.2.2.1

- Status commands .

Default = 00 00 (ASB

disabled).

Page 18 of 52

Page 19

Buffered STATUS request DLE B 10 42 The STATUS bytes are

transmitted when this

command is processed out

of the receive buffer. See

Section 4.2.2.1 - Status

commands .

Real time STATUS request DLE R 10 52 The STATUS bytes are

transmitted when this

command is received by

the printer. See Section

4.2.2.1 - Status commands

.

User selected data string DLE U +n1

+n2

10 55 +n1

+n1

When DLE U +n1 +n2 is

processed out of the

receive buffer, the printer

will transmit DLE U +n1 +n2

back to the host.

ESC ESC 1B ESCAPE Sequence

Header.

GS GS 1D GROUP SEPARATOR

Sequence Header.

US US 1F UNIT SEPARATOR

Sequence Header.

Reverse Video ON ESC RS 1B 1E Printing is reversed to white

characters on black

background. Reverse video

requires more power to

print and is less readable.

(Same as GS B 01).

Name

Command

Command

Description

Reverse

Video OFF

ASCII

ESC US 1B 1F Printing is set to default

hex

mode of black print on

white background. (Same

as GS B 00).

Set Print

mode

ESC ! +n

1B 21 +n

Set Print mode = font A or

B, Double high, Double

wide. See Section 4.2.2.2 Set Print Mode .

Select Bit

Image mode

ESC \ +m

+n1 +n2

+d1~dn

1B 2A +m

+n1 +n2

(data)

Select Bit Image mode. +m

= ?. n2*256 + n1 =

Number of DOT LINES of

data to follow. (data) = the

amount of data required to

complete the sequence.

Telpar does not fully

support this command.

Please refer to US *

command which follows.

Underline ESC - +n 1B 2D +n Bit 0 of n = 0 turns

underlining OFF. Bit 0 of n

= 1 turns underlining ON.

Default is OFF.

Set 1/6” line

ESC 2 1B 32 Set 1/6 inch line spacing.

spacing

Page 19 of 52

Page 20

Set Line feed

pitch

ESC 3 +n 1B 33 +n

Set line spacing to n dot

lines. If the n specified is

less than the height to print

text using the currently

selected character set then

printing will cause enough

paper feeds to print the

entire line but a print

command with no data in

the buffer will cause paper

to feed by this amount.

Default is 1/8 inch

Printer reset ESC @ 1B 40 Initialize. See Section

4.2.2.3 - Printer Reset .

Set page

length

ESC C +n 1B 43 +n Set page length to n

character lines using the

current font. Overwrites the

page length defined by US

C.

Set Horizontal

Tab positions

ESC D

+d1~dn

NUL

1B 44

(data) 00

Set from 1 to 32 tab

positions in the current

character size. Data values

range from 1 to 255 in

ascending order. The NUL

character (00 hex)

terminates this command if

less than 32 tab settings

are being set. If a data

value is less than the

previous data value, this

command is terminated.

ESC D NUL clears all tab

positions. Default is every 8

columns. Print after a tab

starts in the column

following the tab setting

specified.

Forward

paper feed for

n dot lines

ESC J

+n

1B 4A +n

Feed paper n dot lines. If

there is data in the buffer, it

is printed and paper is fed

the difference of the +n and

the amount needed to print

the data. Range = 0 to 255

dec.

Select

International

character set

ESC R

+n

1B 52 +n

Select international

character set. Range = 0

through 15 dec. See Figure

16 - International Character

Sets for characters affected

for each character set.

Select

justification

for bar code

ESC a +n 1B 61 +n n=00hex, left justify.

n=01hex, center justify.

n=02hex, right justify. GS L,

GS W, and ESC \ will also

affect the bar code

justification.

Page 20 of 52

Page 21

Name

(

Command

Command

Description

Select paper

type

Paper sensor

to output PE

signal

Paper sensor

to stop

printing

Select CODE

PAGE

ASCII

ESC c 1

+n

hex

1B 63 31

+n

Bit 0 = 0, Normal paper.

Bit 0 = 1, TOF (Black Mark

sensor) enabled. Default is

based on Dip switch 2

position 1.

ESC c 3

+n

1B 63 33

+n

Command is not

implemented, all four bytes

will be ignored.

ESC c 4

+n

1B 63 34

+n

Command is not

implemented, all four bytes

will be ignored.

ESC t +n 1B 74 +n n = 0, code page 437

(standard USA).

n = 2, Code page 850

(Multilingual).

n = 3, Code page 860

(Portuguese).

n = 4, Code page 863

(Canadian-French).

Feed to Top

of Form

Select

character size

Reverse

video

n = 5, Code page 865

(Nordic);

n=10 hex, WPC1252;

n=13 hex, Code page 858

(Multilingual with Euro

character)

GS FF 1D 0C If TOF mode is disabled

(DIP switch 2 position 1 or

ESC c 1 +n) then paper is

fed until the trailing edge of

the Black Mark sensor is

detected, the current page

length is reached, or the

printer runs out of paper.

GS ! 1D 21 +n Bits 7,6,5,4 for width, Bits

3,2,1,0 for height. Can

select 1,2,4, or 8 times

normal size. 0hex = 1X

size, 1hex = 2X size, 2hex

= 4X size, and 3hex = 8X

size.

GS B +n 1D 42 +n Bit 0 of n = 1 causes

Reverse Video to be

printed (same as ESC RS).

Bit 0 of n = 0 turns Reverse

Video off

same as ESC

Page 21 of 52

Page 22

US).

HRI position GS H +n 1D 48 +n Select HRI printing position

for bar codes, n = 00hex

no HRI printed. n = any

value other than 00hex,

HRI printed below the bar

code.

Set left

margin

GS L +nH

+nL

1D 4C +nH

+nL

Sets the left margin to

nH*256 + nL dot positions

from the left side of the

print head. Default = 0

(leftmost dot). The value

being set must be equal to

or less than the right

margin minus 80 dots. If the

margin is set to any invalid

value this command is

ignore. Range = 0 to Right

Margin - 80.

Paper cut

GS V +n

+m

1D 56 +n

+m

If n = 0 (either 00hex or

30hex) a full cut is

performed and the +m byte

is not needed. If n = 1

(either 01hex or 31hex) a

partial cut is performed and

the +m byte is not needed.

If n is a capital A (41hex)

then paper is fed for m dot

lines and then a full cut is

performed. If n is a capital

B (42hex) then paper is fed

for m dot lines and then a

partial cut is performed. If a

presenter is installed, only

full cuts are performed.

Name

Command

Command

Description

Set Right

Margin

ASCII

GS W +

nH + nL

hex

10 57 + nH

+ nL

HRI font GS f 1D 66 +n Not implemented, the

Set Bar code

GS h +n [1D 68 +n

Set the right margin to

nH*256 + nL dot positions

from the left side of the

print head. Default =

maximum dot count for the

printer mechanism minus 1.

The value being set must

be equal to or greater than

the left margin plus 80 dots.

If the margin is set to any

invalid value this command

is ignore. Range = Left

Margin +80 to rightmost

dot.

controller selects a font and

size to best fit under the bar

code being printed.

Set the bar code height in

Page 22 of 52

Page 23

height dots. Default = 64. Range -

1 to 255 dec.

Bar code

printing

GS k +m

+n +d1~dn

[1D 6B +m

+n (DATA)]

Selects the bar code type

and prints. See Section

4.2.2.7 – Print Bar Code

Command .

Set Bar code

magnification

GS w +n [1D 77 +n]

Set the width of the bars

used to print bar codes.

The width of a narrow bar is

set to n. Range = 1 to 8.

Default = 2. A setting of

n=1 prints a bar code so

small it is possibly not

readable..

Bit image

command

US * +nH

+nL +data

1F 2A +nH

+nL +data

256*nH +nL defines how

many bytes of bit image

data will follow. See

Section 4.2.2.6 - Bit Image

(BI) Graphics Mode .

Set Page

Length

US C +nH

+nL

1F 43 +nH

+nL

Sets the page length to

256*nH +nL dot lines.

Default is 11 inches.

Overwrites the page length

set by ESC C.

Eject/retract

ticket

US E 1F 45 +n Bit 0 of n = 0 sets the mode

to RETRACT an untaken

ticket back into the printer.

Bit 0 of n = 1 sets the mode

to EJECT an untaken ticket

out the front of the printer.

See DIP SWITCH 2

position 2 for the default.

Set timeout to

use before an

untaken ticket

is purged

US K 1F 4B +n If a document is cut and

presented (but not

removed) and another

document is sent to the

printer, the first document

will not be purged (either

Ejected or Retracted) until

+n seconds after the first

document is presented.

Default is 5 second.

Global IEEE1284

STATUS

Enable /

Disable

US S +n 1F 53 +n Low order nibble of +n = 0

disables all STATUS

transmissions in IEEE-1284

parallel mode. Low order

nibble of +n = 1 thru F

enables STATUS

transmission. Default is

disabled. See Section

4.2.2.1 - Status commands

.

Name

Command

Command

Description

Start of

ASCII

US b 1F 62 Used only by Telpar's

hex

Document for

Windows drivers. See

Page 23 of 52

Page 24

WINDOWS Section 4.2.2.4 - Telpar's

Window Commands.

End of

Document for

WINDOWS

US e 1F 65 Used only by Telpar's

Windows drivers. See

Section 4.2.2.4 - Telpar's

Window Commands.

Set horizontal

Print Position

US x +nH

+nL

1F 78 +nH

+nL

The horizontal print position

is set to (256*nH + nL) * 8

dots from the left margin.

See Section 4.2.2.6 - Bit

Image (BI) Graphics Mode .

Set Relative

Vertical move

US y +nH

+nL

1F 79 +nH

+nL

Causes paper to feed

256*nH + nL dot lines. See

Section 4.2.2.6 - Bit Image

(BI) Graphics Mode

Commands .

Set Horizontal

Print Position

ABSOLUTE

US A 1F 41 Sets the x-move function

(see US x +nH +nL) to be a

move relative to the left

margin. See US R.

Set Horizontal

Print Position

RELATIVE

US R 1F 52 Sets the x-move function

(see US x +nH +nL) to be a

move relative to the current

position. Default setting.

See US A.

Figure 5 - General Usage Print Commands

Page 24 of 52

Page 25

4.2.2 Descriptions of Commands

4.2.2.1 Status commands

All transmission of status in IEEE-1284 mode is disabled at power on. Status transmission must be enabled by the US

S +n command before any STATUS transmission will occur in IEEE-1284 mode.

In case of an ERROR as defined in the table below, the printer transmits DLE E and the 2 status bytes. The response

to a STATUS REQUEST is to transmit DLE (10hex) followed a SOURCE byte that distinguishes what type of status is

being transmitted followed by the two status bytes as defined in the table below.

The SOURCE byte is defined as:

A = Auto Status Back . Is disabled by default but is enabled when the printer receives the DLE A +n1 +n2 command.

+n1 and +n2 define a mask using the same byte/bit structure as in the table below. A "1" in a bit position enables the

automatic transmission of DLE A and the 2 status bytes when an enabled condition occurs. The bit positions marked

as errors in the table will always cause the automatic transmission of DLE E and the 2 status bytes so these positions

will usually be "0" in the user defined mask.

B = Buffered status . DLE B and the 2 status bytes are transmitted when the DLE B command is processed out of the

input buffer.

R = Real Time Status . If enabled by US R +n command, DLE R and the 2 status bytes are transmitted immediately

when the DLE R command is received by the printer.

U = not a true STATUS request. When DLE U +n1 +n2 is processed out of the receive buffer, the printer transmits

DLE U +n1 +n2 back to the host. The user can send DLE U +n1 +n2 anywhere within a document if he needs to know

that the printer has processed the document up to that point.

First Status byte transmitted (and MASK

for DLE A command)

Bit Type Function/condition

7 Status Spare

6 Status Spare

5 Status Receive buffer is full

4 ERROR Cutter Error

3 Status Printer Busy

2 Status Receipt Taken

1 Status Receipt Dropped

0 ERROR Delivery Jam

Table 7 - First Status byte transmitted (and MASK for DLE A command)

Second Status byte transmitted (and MASK

for DLE A command)

Bit Type Function/condition

7 Status Spare

6 Status Print head over temperature

5 Status Spare Sensor

4 Status Paper Low

3 Status Cutter Home

2 Status Paper at Delivery

1 ERROR Paper Out

0 ERROR Head Up

Table 8 - Printer's response to a STATUS REQUEST command

Page 25 of 52

Page 26

4.2.2.2 Set Print Mode

ESC ! +n [1B 21 +n]

+n is defined as:

Bit 7--- Not used.

Bit 6 --- Not used.

Bit 5 --- 0 = Double high print OFF.

1 = Double high print ON.

Bit 4 --- 0 = Double wide print OFF.

1 = Double wide print ON.

Bit 3 --- Not used.

Bit 2 --- Not used.

Bit 1 --- Font size.

Bit 0 --- Font size.

Set Print Mode Table

Bit 1 Bit 0 Font size (WxH)

0 0 FontB (10x30)

0 1 FontA (12x30)

Table 9 - Set Print Mode Table

Both double wide and double high can be selected for either character size. When a printed line contains characters

with different heights, the characters are arranged so that the baseline of all characters lines up. Default = 00hex (Font

B, 10 x 30 matrix) for MTP-2222. Default = 01hex (Font A, 12 x 30 matrix) for MTP-2232 and MTP-2242

4.2.2.3 Printer Reset

ESC @ [1B 40]

Initializes the printer.

Any data received before the ESC @ but not yet printed is cleared. The character size is set to the default font. The

DIP Switch setting sets international character set. Left and Right Margins are set to the defaults. Reverse video is

turned off. Underline printing is turned off. Bar code height is set to 64. Bar code magnification is set to 2.

4.2.2.4 Telpar's Window Commands.

use of device fonts for print speed enhancement, the Begin Document (US b) and End Document (US e) commands

were created for use by the Telpar Windows driver. These two commands should not be sent to the printer by any

other application program since unexpected results will occur.

4.2.2.5 Language Monitor Information

Not available at publication date

Page 26 of 52

Page 27

4.2.2.6 Bit Image (BI) Graphics Mode Commands

BI US * +nH +nL +data 1F 2A +nH +nL +data

256*nH +nL defines how many bytes of bit image data will follow. The data is received sequentially with the first byte

representing the first 8 dot positions at the top left side of the bit image with bit 7 being to the left and bit 0 being to the

right as printed.

XMOVE US x +nH +nL 1F 78 +nH +nL

The horizontal print position is set to (256*nH + nL) * 8 dots from the left margin.

If there is a lot of white space on the current dot line, the XMOVE command can cause the print location pointer to be

moved resulting in less data required to define a dot line of bit image data to be printed. Anytime there is more than 4

bytes of white space (32 dots) the XMOVE command will result in less data being sent to the printer. Another BI

command can follow the XMOVE command until a YMOVE signifies the end of the current dot line.

YMOVE US y +nH +nL 1F 79 +nH +nL

Causes paper to feed 256*nH + nL dot lines. This is also the BI line terminator and print command.

4.2.2.7 Print Bar Code Command

GS k +m +n +d1~dn [1D 6B +m +n (DATA)]

+m selects the bar code type. +n defines the number of data bytes which follow.

If more data is sent than can fit on the printer being used, the bar code is not printed.

+m Bar code +n Valid data comment

41 UPC-A 11 0-9 Checksum generated & printed

42 UPC-E 7 0-9 Checksum generated & printed

43 EAN13 12 0-9 Checksum generated & printed

44 EAN8 7 0-9 Checksum generated & printed

45 Code39 variable 0-9 A-Z sp $%*-./

46 ITF variable. 0-9 If an odd number of data bytes is sent, a leading

zero will be added.

47 CODABAR variable. 0-9 - $ : / . +ABCD

49 CODE128 variable. See Section 4.2.2.8 - Bar Code 128 definitions

74 CODE 39 variable. 0-9 A-Z sp $%*-./ Checksum generated & printed

75 ITF variable. 0-9 Checksum generated & printed. If the data sent

and the checksum causes an odd number of

digits, a leading zero will be printed.

Page 27 of 52

Page 28

4.2.2.8 Bar Code 128 definitions

Code128 Character set: 103 data chars, three different start characters, and a unique stop character.

CodeA consists of the ASCII characters 00hex thru 5Fhex, FNC1 thru FNC4, Shift, CodeB, and CodeC.

CodeB consists of the ASCII characters 00hex thru 7Fhex, FNC1 thru FNC4, Shift, CodeA, and CodeC.

CodeC consists of 2 digit numeral characters 00dec thru 99dec, FNC1, CodeA, and CodeB.

The 103 different bar code patterns have different meanings depending on whether CodeA, CodeB, or CodeC was

specified when the data was received. The data string must start with {A or {B or {C to specify CodeA, CodeB, or

CodeC. A checksum is calculated and printed by the printer.

Value used to

calculate

checksum

CodeA CodeB CodeC Value used to

calculate

checksum

CodeA CodeB CodeC

0 (sp) (sp) 00 54 V V 54

1 ! ! 01 55 W W 55

2 " " 02 56 X X 56

3 # # 03 57 Y Y 57

4 $ $ 04 58 Z Z 58

5 % % 05 59 [ [ 59

6 & & 6 60 \ \ 60

7 ' ' 07 61 ] ] 61

8 ( ( 08 62 ^ ^ 62

9 ) ) 09 63 _ _ 63

10 * * 10 64 00hex ` 64

11 + + 11 65 01hex a 65

12 , , 12 66 02hex b 66

13 - - 13 67 03hex c 67

14 . . 14 68 04hex d 68

15 / / 15 69 05hex e 69

16 0 0 16 70 06hex f 70

17 1 1 17 71 07hrx g 71

18 2 2 18 72 08hex h 72

19 3 3 19 73 09hex i 73

20 4 4 20 74 0Ahex j 74

21 5 5 21 75 0Bhex k 75

22 6 6 22 76 0Chex l 76

23 7 7 23 77 0Dhex m 77

24 8 8 24 78 0Ehex n 78

25 9 9 25 79 0Fhex o 79

26 : : 26 80 10hex p 80

27 ; ; 27 81 11hex q 81

28 < < 28 82 12hex r 82

29 = = 29 83 13hex s 83

30 > > 30 84 14hex t 84

31 ? ? 31 85 15hex u 85

32 @ @ 32 86 16hex v 86

33 A A 33 87 17hex w 87

34 B B 34 88 18hex x 88

35 C C 35 89 19hex y 89

36 D D 36 90 1Ahex z 90

37 E E 37 91 1Bhex { 91

38 F F 38 92 1Chex | 92

Page 28 of 52

Page 29

39 G G 39 93 1Dhex } 93

40 H H 40 94 1Ehex ~ 94

41 I I 41 95 1Fhex DEL 95

42 J J 42 96 FNC3 FNC3 96

43 K K 43 97 FNC2 FNC2 97

44 L L 44 98 SHIFT SHIFT 98

45 M M 45 99 CodeC CodeC 99

46 N N 46 100 CodeB FNC4 CodeB

47 O O 47 101 FNC4 CodeA CodeA

48 P P 48 102 FNC1 FNC1 FNC1

49 Q Q 49

50 R R 50

51 S S 51

52 T T 52

53 U U 53

Code128 Start Characters

Value used to calculate checksum Data sent represents

103 {A Start character CodeA

104 {B Start character CodeB

105 {C Start character CodeC

Code128 Stop Character

106 Stop character

Code128, other two character data sequences: Note: Since { is used as a sequence header to specify special

characters, {{ must be sent as data to actually print { in the bar code.

Data sent represents Data sent represents

{1 FNC1 {S Shift

{2 FNC2 {{ {

{3 FNC3

{4 FNC4

4.3 Serial (RS-232C) Interface

4.3.1 Serial (RS-232C) Interface Specification

Serial (RS-232C) Interface Specification

Item Specification

Data receive speed Baud rate selected by DIP switch

Synchronizing method Asynchronous, Full duplex

Handshake DTR/DSR signal or XON/XOFF (selected by DIP

switch)

Input output level RS-232C

Signal level

Space (logic=0) +3 V ~ +12 V

Mark (logic=1) -3 V ~ -12 V

Table 10 - Serial (RS-232C) Interface Specification

4.3.2 Serial I/O Connector

Page 29 of 52

Page 30

Figure 6 - Serial I/O Connector

Page 30 of 52

Page 31

Serial Interface RS-232C

Figure 7 - Serial Interface RS-232C

Serial (RS-232C) Interface Pin Assignments

Pin Name Direction Function

2 RD I RS232 received data.

3 XD O RS232 transmitted data.

4 DTR O Hardware handshake line.

5 GND - Logic ground.

6 DSR I High (“space”) = OK for the printer to transmit

data when requested. The state of DSR is

IGNORED for XON/XOF handshaking if selected.

Table 11 - Serial (RS-232C) Interface Pin Assignments

4.3.3 Flow Control

The MTP-2200 series employs a 6 K byte data buffer to allow the host computer to rapidly transfer data. Under some

circumstances it may be possible to completely fill the buffer . When the buffer is within 50 bytes of being full, the MTP2200 signals the host computer to pause until a line of data is printed, or until the buffer is under the 50-byte limit. The

flow control information is sent to the host using hardware or software protocols as determined by the DIP Switch

setting.

The hardware protocol uses the DTR line of the serial interface. This pin are asserted or negated as necessary to turn

off and turn on the flow of data. The software protocol uses the XON and XOFF ASCII characters (^Q and ^S) which

are sent back to the host to start and stop the data stream. Some host systems may not support one or both of these

protocols.

4.4 Parallel Interface (IEEE-1284)

4.4.1 Parallel I/O Connector, IEEE-1284 Type C

Parallel Interface IEEE-1284

Page 31 of 52

Page 32

Figure 8 - Parallel I/O Connector

Parallel Interface Pin Assignments

J2 Pin# Name Cent. Name Direction Function in Centronics Mode (SPP)

1 PeripheralAck BUSY O High level when printer cannot accept

data.

2 Xflag SLCT O High level when printer is on.

3 PeripheralClk /ACK O Active low pulse when data is accepted

4 -PeripheralReq /ERR O Low level when an error occurs.

5 -AckRev PE O High level when printer is out of paper

6 IO0 DO I/O ASCII data bit 0 (LSB)

7 IO1 D1 I/O ASCII data bit 1

8 IO2 D2 I/O ASCII data bit 2

9 IO3 D3 I/O ASCII data bit 3

10 IO4 D4 I/O ASCII data bit 4

11 IO5 D5 I/O ASCII data bit 5

12 IO6 D6 I/O ASCII data bit 6

13 IO7 D7 I/O ASCII data bit 7

14 -RevReq /INIT I Low level = system reset.

15 HostClk /STB I Active Low Pulse to send data tp printer

16 1284Active /SLCTIN I Low level enables printer.

17 HostAck AFXT I

18 HostLogicHigh I Host Logic High

19 thru 35 GND - Logic ground.

36 PeriphLogicHigh O Peripheral Logic High.

Shell CGND CGND - Chassis ground

Table 12 - Parallel Interface Pin Assignments - IEEE-1284 Nomenclature

Page 32 of 52

Page 33

4.4.2 Alternate Parallel I/O Connector, IEEE-1284 Type A or B

Connector J4 is a 26-position (2x13) straight pin header with pinout like a DB25S for connection directly to a PC

parallel port. J4 is located directly behind J2, which is an IEEE-1284 type C I/O connector. A mass-terminated cable

assembly can connect from J4 to a DB25S (IEEE-1284 type A).

Connector J3 is a 36-position (2x18) straight pin header with pinout like a Centronics connector for connection directly

to a PC printer cable. J4 is located directly behind J2 , which is an IEEE-1284 type C I/O connector. A massterminated cable assembly can connect from J3 to a Centronics type connector to connect to a PC printer cable (IEEE1284 type B).

J2, J3, and J4 are connected in parallel so only one of the three can be used.

Alternate Parallel Interface Pin Assignments

J4 Pin# J3 Pin# Name Direction Function

1 1 /STB I Active Low Pulse to send data tp

printer

2 2 DO I ASCII data bit 0 (LSB)

3 3 D1 I ASCII data bit 1

4 4 D2 I ASCII data bit 2

5 5 D3 I ASCII data bit 3

6 6 D4 I ASCII data bit 4

7 7 D5 I ASCII data bit 5

8 8 D6 I ASCII data bit 6

9 9 D7 I ASCII data bit 7

10 10 /ACK O Active low pulse when data is

accepted

11 11 BUSY O High level when printer cannot accept

data.

12 12 PE O High level when printer is out of paper

13 13 SLCT O High level when printer is on.

14 14 AFXT I Not used.

15 32 /ERR O Low level when an error occurs.

16 31 /INIT I Low level = system reset.

17 36 /SLCTIN I Low level enables printer..

18 PLHi O Peripheral Logic High.

18 thru 25 16, 19 thru

- Logic ground.

30

17 CGND - Chassis ground

Shell Shell CGND Chassis ground

15, 33, 34,

n/c - No connection

35

Table 13 - Parallel Interface Pin Assignments - Centronics nomenclature

5 Detailed Specifications

5.1 Detailed Specifications

Specifications MTP-2222 MTP-2232 MTP-2242

Printing method Thermal-sensitive line dot method

Dot Structure 448 dots/line 576 dots/line 832 dots/line

Dot pitch (horizontal) 0.125 mm (8 dot/mm)-Dot density

Dot pitch (vertical) 0.125 mm (8 dot/mm)-Line feed pitch

Effective printing area 56 mm 72 mm 104 mm

General Specifications

Page 33 of 52

Page 34

Paper width 60 mm 85 mm 114 mm

Paper thickness 0.0024 to 0.0039 inches

Cutting type Full or partial (Software control)

Number of columns (default) 37 columns/line

(12 x 30 dot font)

48 columns/line

(12 x 30 dot font)

69 columns/line

(12 x 30 dot font)

Maximum printing speed 640 dot line/s (80 mm/s)

Character composition,

dimensions (WxH),

12 x 30 dots1.5 x 3.75

mm

12x30 dots 1.5x3.75

mm

12x30 dots

1.5x3.75 mm

Number of characters per line

37 columns

10 x 30 dots 1.25 x 3.75

mm

44 columns

48 columns

10 x 30 dots 1.25 x

3.75 mm

57 columns

69 columns

10 x 30dots 1.25 x

3.75 mm

83 columns

Interface IEEE-1284 Parallel, RS-232C Serial

Power Supply

For head See Section 1.6 - Power Supply Requirements .

For motor DC 24V± 5%, 1.0 A max., <0.1A typical

For cutter DC 24V± 5%, 1.0 A max.

Expected Life

Mechanism

Pulse durability: 1x10

8

pulse/dot (standard driving method)

Wear resistance: 50 km (at 25% printing ratio)

Cutter 5 x 10

5

cuts for MTP-2222 and MTP-2232, 3 x 105 cuts for MTP-

2242

Environ-mental

conditions

Operating temp. 5 to +40°C

Operating

20 to 85% RH (No condensation)

humidity

Storage temp. -20 to +60°C

Storage humidity 5 to 95% RH (No condensation)

Detection

Head temp. By thermistor (applied energy control, abnormal temperature

detection)

Paper Out/Mark

By photointerrupter

detect

Paper Thermal Sensitive paper

Table 14 - General Specifications

5.2 Error Detection Function

Certain ERROR modes are reported when they occur by a sequence of blinks of LEDs DS2 and DS3 located on the

controller board. The ERROR BLINK patterns are listed below and are also printed during a self-test.

DS2 blinks ON four times indicated in the table below as T1, T2, T3, and T4. Following each sequence of blinks there

is a pause before starting the next sequence. The ON times of DS2 is the time base used for encoding the error

reporting by DS3.

DS3 blinks ON during some of the four times that DS2 blinks ON. The pattern of ON times of DS3 listed in the table

below indicates the ERROR being reported.

ERROR T1 T2 T3 T4

Paper Out ON OFF OFF OFF

Head Up OFF ON OFF OFF

Cutter Fault OFF OFF ON OFF

Delivery Jam ON OFF ON OFF

Table 15 - Error Detection Functions

Page 34 of 52

Page 35

5.3 Character Sets - Print Samples

Figure 9 - Code Page 437 Print sample

Page 35 of 52

Page 36

Figure 10 - Code Page 850 Print sample

Page 36 of 52

Page 37

Figure 11 - Code Page 860 Print sample

Page 37 of 52

Page 38

Figure 12 - Code Page 863 Print Sample

Page 38 of 52

Page 39

Figure 13 - Code Page 865 Print Sample

Page 39 of 52

Page 40

Figure 14 - Code Page WPC1252 Print sample

Page 40 of 52

Page 41

Figure 15 - Code Page 858 Print sample

Page 41 of 52

Page 42

Figure 16 - International Character Sets

At power on, the International Character Set is determined by the settings of DIP Switch 2. See Section 4.1.1.2 DSW2 – DIP Switch 2 . The International Character Set can then be changed under software control by using the ESC

R command.

Page 42 of 52

Page 43

5.4 MTP-2222 Dimensional Drawings

Figure 17 - MTP-2222 Left Side View

Figure 18 - MTP-2222Top View

Page 43 of 52

Page 44

Figure 19 - MTP-2222 Right Side View

5.5 MTP-2232/MTP-2242 Dimensional Drawings

Figure 20 - MTP-2232/MTP-2242 Dimensional Drawing with Mounting Holes (Top View)

Page 44 of 52

Page 45

Figure 21 - MTP-2232/MTP-2242 Dimensional Drawing (Side View)

Figure 22 - MTP-2232/2242 Isometric Drawing

Page 45 of 52

Page 46

5.6 Dimensional Drawings With Presenter

Figure 23 - MTP-2222 with Presenter

Page 46 of 52

Page 47

Figure 24 - MTP-2232 with Presenter

Page 47 of 52

Page 48

Figure 25 - MTP-2242 with Presenter

6 CE Declaration of Conformity

19111 North Dallas Parkway, Suite 100

TELPAR

Page 48 of 52

Page 49

Dallas, TX 75257 USA

EC Declaration of Conformity

according to

EC EMC Directive (89/336/EEC, 92/31/EEC, 93/68/EEC),

and

EC Low Voltage Directive (73/23/EEC, 93/68/EEC)

We, TELPAR, declare that the following described equipment in our delivered version complies with the appropriate

basic safety and health requirements of the EC EMC Directive (89/336/EEC, 92/31/EEC, 93/68/EEC) and EC Low

Voltage Directive (73/23/EEC, 93/68/EEC) based on its design and type, as brought into circulation by us. In case of

alteration of the machine, not agreed upon by us, this declaration will lose its validity.

Description of the Electrical Equipment: Thermal Printer

Model Number(s): MTP-2222 MTP-2232 MTP-2232SL

MTP-2242 MTP-2242V MTP-2283

Applicable EC Directives EC EMC Directive (89/336/EEC, 92/31/EEC, 93/68/EEC)

& Harmonized Standards: EN 55022 EN61000-4-2

EN 61000-4-3 EN 61000-4-4

EN 61000-4-5 EN 61000-4-6

EN 61000-4-8 EN 61000-4-11

EC Low Voltage Directive (73/23/EEC, 93/68/EEC)

EN 60950

Year in which CE Marking was affixed: 2000

Authorized Signature/Date: Eddie Lee / Dec. 18, 2000

Title of Signatory: Director, Engineering

Page 49 of 52

Page 50

INDEX

5 VDC power supply........................................ 9

Advance wheel........................................ 11, 12

ASCII characters........................................... 30

Auto Cutter..................................................... 7

Auto load....................................................... 7

Auto Status Back.................................... 19, 24

Bar code printing.................................. 7, 22, 26

Bit image command........................ 8, 20, 22, 26

Black mark sensing........................................ 8

Boot function................................................ 18

Buffer........................................................... 30

Buffered status.............................................. 24

Buzzer......................................................... 18

Centronics parallel................................... 15, 30

Character composition, dimensions................ 33

Code pages.................................................... 7

Commands descriptions................................ 24

Communication mode setting......................... 15

Connector J2................................................ 32

Connector J3................................................ 32

Connector J4................................................ 32

Control Codes and Control Sequences............ 19

Cutter............................... 11, 12, 17, 24, 33, 34

Data receive speed........................................ 29

Delivery Jam............................................ 24, 34

Dimensional drawings.................................... 41

DIP switches............................................. 7, 15

Dot structure................................................. 33

Double high print........................................... 25

Double wide print........................................... 25

Drop in loader............................................... 11

DSR............................................................. 30

DTR............................................................. 30

Effective printing area..................................... 33

Eject/retract ticket......................................... 22

End of Document for WINDOWS.................... 23

Environmental condition................................. 33

Error Detection Functions.............................. 35

Expected life............................................. 8, 33

Factory configured......................................... 15

Feed to Top of Form...................................... 21

FLASH option........................................... 8, 18

Form Feed.................................................... 19

Hardware protocol.................................... 29, 30

Head temperature.......................................... 33

Head Up............................................ 12, 24, 34

Hosiden Connector.......................................... 9

HRI font.................................................. 21, 22

IEEE-1284 Parallel interface........................... 15

Interface........................................ 7, 15, 30, 33

International character set.......................... 7, 20

JP9 - Configuration straps.............................. 17

Line feed........................................... 19, 20, 33

Load paper................................................... 11

Maximum printing speed................................ 33

Mechanism specifications.............................. 33

Page 50 of 52

Page 51

Microsoft® Windows® driver.............................. 8

MTP-2222...................................... 7, 10, 12, 33

MTP-2222 Dimensional Drawings.............. 40, 41

MTP-2232...................................... 7, 10, 12, 33

MTP-2232/2242 Isometric Drawing.................. 43

MTP-2232/MTP-2242 Dimensional Drawing 41, 42

MTP-2232/MTP-2242 Dimensional Drawing with Mounting Holes 41

MTP-2242..................... 7, 10, 11, 12, 13, 14, 33

MTP-2242 with Cutter Mechanism closed........ 12

Number of columns....................................... 33

Operating humidity.................................... 8, 33

Operating temperature............................... 8, 33

Options.......................................................... 8

PAGE memory............................................... 8

Paper at Delivery........................................... 24

Paper capacity............................................... 7

Paper Feed knob........................................... 12

Paper jam..................................................... 11

Paper loading................................................ 11

Paper Low........................................... 7, 17, 24

Paper Out.......................................... 11, 24, 34

Paper out/Mark detect................................... 33

Paper path.................................................... 11

Paper thickness........................................ 8, 33

Paper width........................................... 7, 8, 33

Parallel I/O Connector.............................. 30, 32

Peak Current.................................................. 9

Power Supply............................................... 33

Presenter.............................................. 7, 8, 17

Print Commands, General usage.................... 19

Print head over temperature............................ 24

Print mechanism........................................... 11

Print speed..................................................... 7

Printer Busy................................................. 24

Printer Limited Warranty.................................. 2

Printer mechanism........................................ 11

Printer reset............................................ 20, 25

Printing method............................................. 33

Printing rate.................................................... 9

Purge setting................................................ 16

Real Time Status.......................................... 24

Receipt Dropped........................................... 24

Receipt Taken............................................... 24

Resident font sizes......................................... 7

Resolution...................................................... 8

Reverse video mode........................ 8, 19, 20, 21

Roll of paper.............................................. 7, 11

Select character size..................................... 21

Select CODE PAGE...................................... 21

Select International character set.................... 20

Select paper type.......................................... 21

Self-test mode.............................................. 13

Serial (RS-232C) Interface................... 15, 29, 30

Serial port..................................................... 18

Serial-interface-communication baud rate setting 15

Setting of DIP switches.................................. 15

Side-loading printer........................................ 11

STATUS request, Buffered............................. 19

Page 51 of 52

Page 52

STATUS request, Real time........................... 19

Storage humidity........................................... 33

Storage temperature.................................. 8, 33

System RAM size......................................... 18

Thermal paper............................................... 10

Top of Form sensor....................................... 16

Voltage.......................................................... 9

Warranty.................................................. 2, 10

Weight........................................................... 8

XON and XOFF............................................. 30

TELPAR

A Platinum Equity Company

Toll Free: 800-872-4886 (from the U.S.A. and Canada only)

603-750-7237

Fax: 603-742-9938

Website: www.telpar.com

E-mail: info@telpar.com

Part Number. 090410-0010

[1]

ESC/POS is a registered trademark of SEIKO EPSON Corp.

Microsoft and Windows are registered trademarks of Microsoft Corporation.

[2]

Page 52 of 52

Loading...

Loading...