Page 1

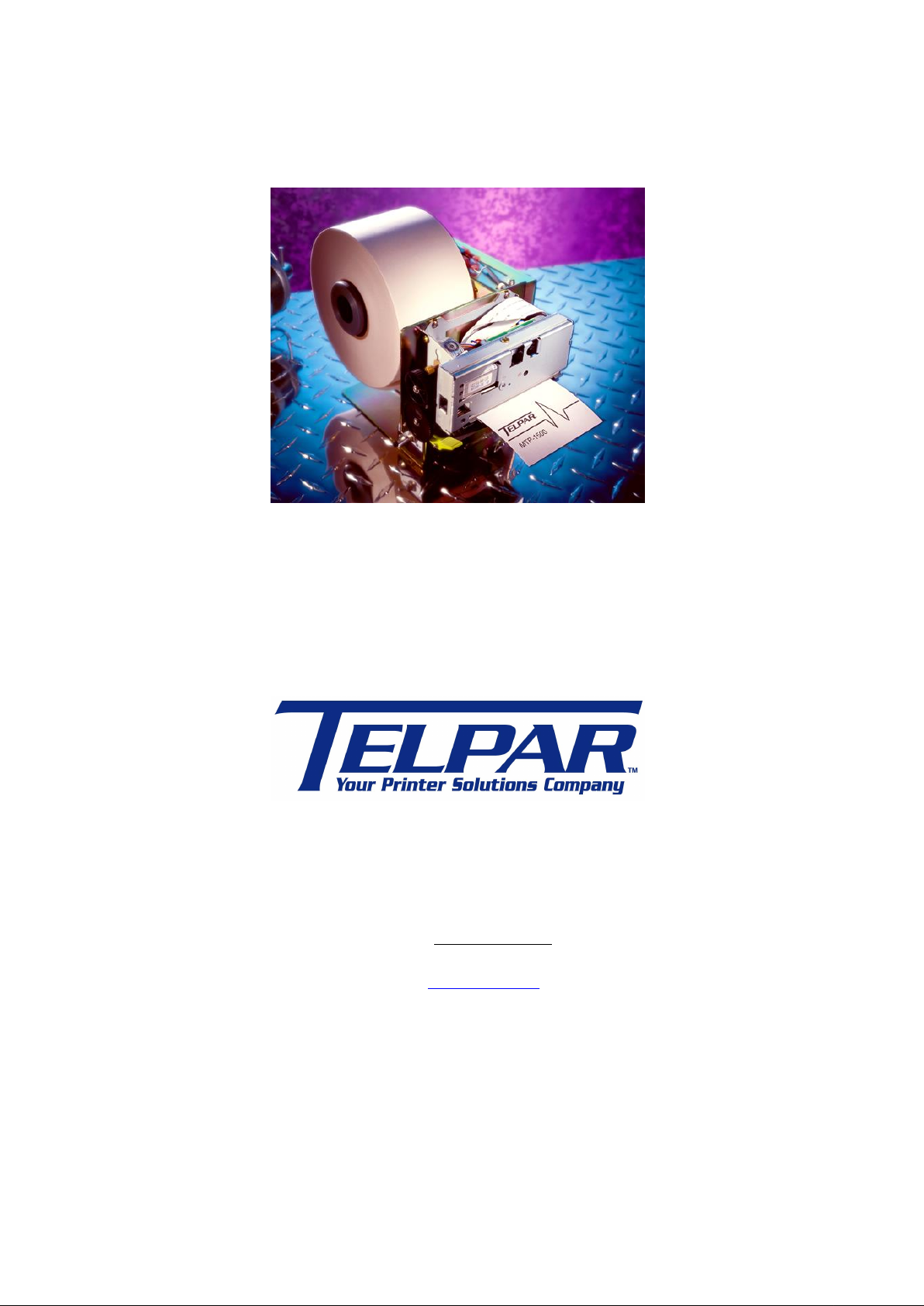

MTP-1530II Modular Thermal Printer

User Manual

Telpar

800-872-4886

Fax: 603-742-9938

Website: www.telpar.com

E-mail: info@telpar.com

© 2012 Telpar (Rev.20120510)

Page 2

Telpar MTP-1530II Receipt Thermal Printer User Manual

Warranty

Telpar — Printer Limited Warranty

.WARRANTIES AND DISCLAIMERS. Products manufactured by Telpar are warranted against defects in

workmanship and materials for a period of twelve (12) months from the date of shipment to the original

user, provided the Product (a) remains unmodified, (b) is used only in the United States or Canada, (c) is

operated under normal and proper conditions, as Telpar determines in its sole discretion, and (d)

Customer provides prompt written notice Telpar of any defects as to parts and/or workmanship to.

Telpar may provide an extended warranty on certain Products or components thereof for an additional

price determined solely by Telpar and such extended warranty shall only be effective to the extent

memorialized in writing by Telpar. Telpar’s sole obligation and Customer’s exclusive remedy for

defective Telpar-manufactured Products is limited to repair or replacement, as Telpar determines in its

sole discretion. The warranty described above does not include any labor or service costs for removing

or replacing parts, or any shipping charges. Any repair performed by Telpar under this warranty does

not extend the original warranty period of any Product. This warranty shall not apply to any Product

which has: (i) been repaired or altered, except by Telpar; (ii) not been maintained in accordance with all

of the operating or handling instructions supplied by Telpar, or (iii) been subjected to misuse, willful

acts, abuse, tampering, negligence or accident, unusual physical or electrical stress, as Telpar

determines in its sole discretion. Customer acknowledges that Telpar provides no warranty for any third

party materials and Telpar is not responsible and will have no liability for any items or services provided

to Customer by any person or entity other than Telpar. Telpar’s duty to perform under any warranty

may be delayed, at Telpar’s sole option, until Telpar has been paid in full for all Products purchased by

Customer. No such delay shall extend the warranty period. To obtain assistance under this limited

warranty, Customer should contact the selling agency or write to: Telpar, Warranty Claims Department,

187 Crosby Road, Dover, NH, 03820, U.S.A. Telephone: 800-872-4886 or fax: 603-742-9938. No person

(including, without limitation, any agent, salesman, dealer or distributor) has the authority to act on

behalf of Telpar to expand Telpar’s obligation beyond the terms of this express warranty, or to state that

the performance of the Product is other than published by Telpar. For Products not manufactured by

Telpar, to the extent permitted Telpar assigns to Customer the benefits of any warranties provided to

Telpar by the manufacturer(s) of the Product. THE FOREGOING IS A LIMITED WARRANTY AND IT IS

THE ONLY WARRANTY PROVIDED BY TELPAR. TELPAR DISCLAIMS ALL WARRANTIES, EXPRESS OR

IMPLIED, INCLUDING ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE AND ALL WARRANTIES OR INDEMNITIES FOR PATENT OR COPYRIGHT

INFRINGEMENT. IN NO EVENT SHALL TELPAR BE LIABLE FOR ANY INDIRECT, INCIDENTAL, SPECIAL

OR CONSEQUENTIAL DAMAGES, INCLUDING LOSS OF PROFITS, REVENUE, DATA, OR USE, INCURRED

BY CUSTOMER OR ANY THIRD PARTY, WHETHER IN AN ACTION IN CONTRACT OR TORT, ARISING

OUT OF OR RELATED TO THIS AGREEMENT, EVEN IF TELPAR OR ANY OTHER PERSONS HAS BEEN

ADVISED OF THE POSSIBILITY OF SUCH DAMAGES. TELPAR’S LIABILITY FOR DAMAGES HEREUNDER

FOR ANY CAUSE WHATSOEVER SHALL IN NO EVENT EXCEED THE AMOUNTS RECEIVED BY TELPAR

FROM THE CUSTOMER FOR THE PRODUCTS. TELPAR SHALL NOT BE RESPONSIBLE FOR ANY LOSS,

DAMAGE OR EXPENSE OF ANY KIND CAUSED DIRECTLY OR INDIRECTLY BY THE USE OR

PERFORMANCE OF THE PRODUCT PROVIDED HEREUNDER.

Upon inspection, Telpar will make necessary repairs or replacement and return the merchandise,

shipping prepaid.

MTP-1530II User Manual (Rev.20120510)Page ii

Page 3

Telpar MTP-1530II Receipt Thermal Printer User Manual

Table of Contents

1 General..................................................................................................................... 6

1.1 Definitions ....................................................................................................................7

1.1.1 Standard Mode versus Page Mode.........................................................................7

1.1.2 Hex Dump Mode .....................................................................................................7

1.1.3 Explanation of Terms used throughout this manual ................................................9

1.2 Applications..................................................................................................................9

1.3 Standard Features .....................................................................................................10

1.4 Specifications.............................................................................................................11

1.5 Power Supply Requirements.....................................................................................11

1.5.1 Voltage: 24 VDC ±10% ........................................................................................11

1.5.2 Power Supply Option from Telpar .........................................................................11

1.5.3 3-Pin Hosiden Connector on Printer for Power Supply Connection ......................12

1.6 Telpar Roll Paper for MTP-1530II Series ...................................................................12

1.7 Sensor Locations and Functions..............................................................................13

2 Operator Instructions ........................................................................................... 15

2.1 Unpacking and Inspection.........................................................................................15

2.2 Paper Loading............................................................................................................15

2.2.1 Side-Loading Roll..................................................................................................15

2.2.2 Black Mark Sensors Load......................................................................................15

2.3 Paper Jam ..................................................................................................................17

2.3.1 Head Open Lever..................................................................................................17

3 Installation............................................................................................................. 18

3.1 Self Test Mode............................................................................................................18

4 Setup and Control of the Printer.......................................................................... 20

4.1 DIP Switch Settings and Memory Switch Settings...................................................20

4.2 LEDs and Error Indication.........................................................................................26

4.3 Control Codes and Control Sequences List.............................................................28

4.4 Control Codes and Control Sequences Definition...................................................31

4.4.1 General Usage Print Commands...........................................................................31

4.4.2 Status Commands.................................................................................................35

4.4.3 Bar Code Commands............................................................................................35

4.4.4 Counter Commands ..............................................................................................36

MTP-1530II User Manual (Rev.20120510)Page iii

Page 4

Telpar MTP-1530II Receipt Thermal Printer User Manual

4.4.5 Top of Form Commands .......................................................................................38

4.4.6 Page Mode Commands.........................................................................................38

4.4.7 NV Memory and Down Load Bit Images Commands ............................................41

4.4.8 Seldom Used Commands......................................................................................43

4.5 Descriptions of Commands.......................................................................................46

4.5.1 Set Print Mode.......................................................................................................46

4.5.2 Set Bit Image Mode...............................................................................................46

4.5.3 Set Raster Bit Image Mode ......................................Error! Bookmark not defined.

4.5.4 Set and Process Graphics Data............................................................................49

4.5.5 Status Commands.................................................................................................54

4.5.6 Enable/Disable Auto Status Back (ASB) mode.....................................................55

4.5.7 Status Bytes Transmitted......................................................................................55

4.5.8 Bar Code Command..............................................................................................56

4.5.9 GS k +m +n +d1∼dn [1D 6B +m +n (DATA)] .........................................................57

4.6 Serial (RS232C) Interface ..........................................................................................59

4.6.1 Serial (RS232C) Interface Specification................................................................59

4.6.2 Serial I/O Connector..............................................................................................59

4.6.3 Flow Control..........................................................................................................60

4.7 Centronics Parallel (IEEE-1284) Interface ................................................................62

4.7.1 Parallel I/O Connector...........................................................................................62

4.8 USB 2.0 Interface .......................................................................................................63

4.9 Ethernet Interface ......................................................................................................64

5 Drivers for the Printer........................................................................................... 69

6 Specifications........................................................................................................ 70

6.1 General Specifications ..............................................................................................70

6.2 Character Sets ...........................................................................................................71

6.2.1 Overview ...............................................................................................................71

PC437 U.S.A., Standard Europe Character Set.................................................................72

Katakana Character Set.....................................................................................................73

PC850 (Multilingual) Character Set....................................................................................74

PC860 (Portuguese) Character Set ...................................................................................75

PC863 Canadian French Character Set.............................................................................76

PC865 Nordic Character Set..............................................................................................77

WPC 1252 Character Set ..................................................................................................78

PC866 Cyrillic #2 Character Set.........................................................................................79

PC852 Latin 2 Character Set .............................................................................................80

MTP-1530II User Manual (Rev.20120510)Page iv

Page 5

Telpar MTP-1530II Receipt Thermal Printer User Manual

PC858 Euro Character Set ................................................................................................81

6.3 Dimensional Drawings of the MTP-1530II (80 mm)..................................................82

MTP-1530II User Manual (Rev.20120510)Page v

Page 6

Telpar MTP-1530II Receipt Thermal Printer User Manual

1 General

The MTP-1530II series of modular thermal printers is designed specifically for the high

performance, size and durability requirements of cut and drop applications. The

compact size and high performance characteristics, coupled with its rugged design also

make it ideal for the kiosk environment.

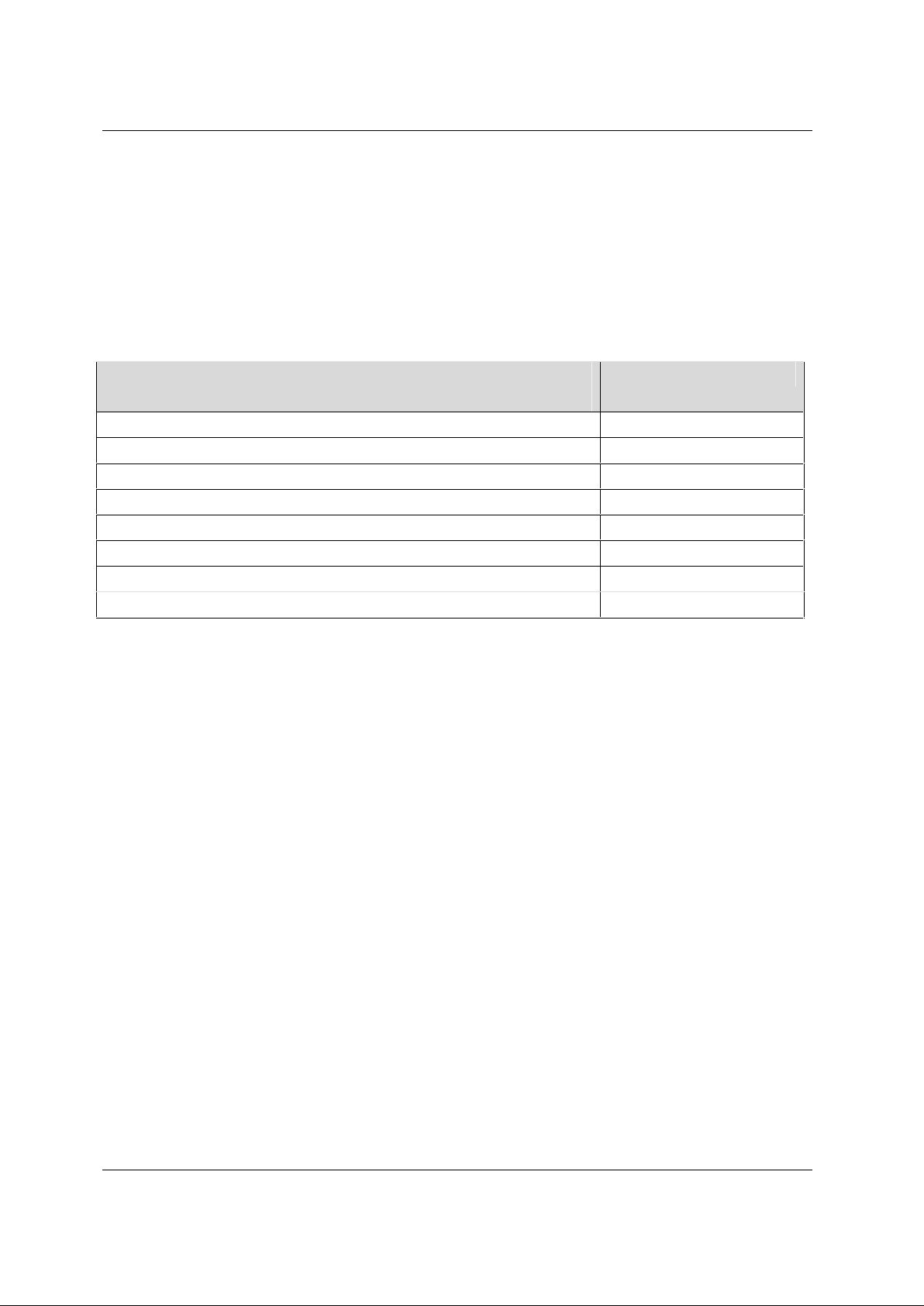

Here are some common options for the MTP-1530II Printer. Please note that all

the options listed below are for use with 80mm (3.15 inch) wide paper:

MTP-1530II Option Description Telpar Part Number

RS-232 Serial Communication, Full Cut Document 901033-0202

RS-232 Serial Communication, Partial Cut Document 901033-0212

Parallel Communication, Full Cut Document 901033-0203

Parallel Communication, Partial Document 901033-0213

USB Communication, Full Cut Document 901033-0201

USB Communication, Partial Cut Document 901033-0211

Ethernet (network) Communication, Full Cut Document 901033-0204

Ethernet (network) Communication, Partial Cut Document 901033-0214

MTP-1530II User Manual (Rev.20120510) Page 6

Page 7

Telpar MTP-1530II Receipt Thermal Printer User Manual

1.1 Definitions

1.1.1 Standard Mode versus Page Mode

The printer operates in two print modes: standard mode and page mode.

In standard mode, the printer prints and feeds paper each time it

receives print data or paper feed commands. In page mode, all the

received print data and paper feed commands are processed in the

specified memory, and the printer executes no operations. All the data in

the memory is then printed collectively when an ESC FF or FF command

is received.

For example, when the printer receives the data "ABCDEF" <LF> in

standard mode, it prints "ABCDEF" and feeds the paper by one line. In

page mode, "ABCDEF" is written to the specified printing area in

memory, and the position in memory for the next print data is shifted by

one line.

The ESC L command puts the printer into page mode, and all

commands received thereafter are processed in page mode. Executing

an ESC FF command prints the received data collectively, and executing

an FF command restores the printer to standard mode after the received

data is printed collectively. Executing an ESC S command restores the

printer to standard mode without printing the received data in page

mode; the received data is cleared from memory instead.

1.1.2 Hex Dump Mode

This function is sometimes useful for diagnosis of application programs

when the printer does not perform as expected. In hex dump mode, the

printer prints the hexadecimal code for each character received rather

than processing the data as printable text and as control commands.

The exception is that DLE EOT (real time STATUS request) and DLE

ENQ (Real time request to printer) are executed as received even in hex

dump mode. The hexadecimal notation is printed at 10 characters per

line on the left side of the page and the printable characters (when

possible) are printed on the right side of the page. Control codes print as

periods on the right side section of the printout to help locate specific

areas of the message to see what codes were actually received by the

printer. After all data has been sent to the printer, pressing the paper

feed button will flush the buffer and print the last line of data received.

Hex dump mode is initiated in any of three ways:

1) Open the platen, hold the paper feed button down, turn on power,

then close the platen and release the paper feed button.

2) Set DIP switch DPSW2 position 5 ON and then turn on power.

MTP-1530II User Manual (Rev.20120510) Page 7

Page 8

Telpar MTP-1530II Receipt Thermal Printer User Manual

3) Send the appropriate GS ( A command. On entering hex dump

mode, the printer prints a 4 line header “Hexadecimal Dump”, a blank

line, “To terminate hexadecimal dump”, “press FEED three times.”

Hex dump mode is terminated by

1) pressing the paper feed button three times in quick succession or

2) by turning DIP switch DPSW2 position 5 OFF and turning power

back on.

Print Sample

Hexadecimal Dump

To terminate hexadecimal dump,

Press Feed button three times.

1B 21 00 1B 26 02 40 40 1B 69 . ! . . & . @ @ . I

1B 25 01 1B 63 34 00 1B 30 31 . % . . c 4 . . 0 1

41 42 43 44 45 46 47 48 49 4A A B C D E F G H I J

Hex Dump of Print Sample

*** COMPLETED ***

MTP-1530II User Manual (Rev.20120510) Page 8

Page 9

Telpar MTP-1530II Receipt Thermal Printer User Manual

1.1.3 Explanation of Terms used throughout this

manual

Receive buffer – Receives data from the host and stores the data

temporarily until it can be processed to the print buffer or

processed as otherwise required.

Print buffer – Stores the image data to be printed.

Start of line – There is no print data in the print buffer and the print

position is not specified by ESC $ or ESC \. Many

commands are effective only at the start of line.

Printable area – For both Standard Mode and Page Mode the length in

the horizontal direction is 72 mm (576 dots per line/8 dots

per mm) for an overall 80 mm paper width.

In page mode the length in the vertical direction is 92 mm

(738 dots per line/8 dots per mm) for an overall 80 mm

paper width version.

Printing area – Printing range set by command. The printing area must

be less than or equal to the printable area.

MBS – Most Significant Bit of a byte of data.

LBS – Least Significant Bit of a byte of data.

OFF LINE – There is no switch for setting the printer On Line or Off Line.

The printer automatically goes Off Line in the following

cases:

a. During power on (or reset through the I/O connector) until the

printer is ready to receive data.

b. During self test.

c. While feeding paper with the paper feed button.

d. When out of paper.

e. When the print platen is open.

f. During a macro execution and in standby status.

g. When an error occurs.

1.2 Applications for the MTP-1530II Printer

• Parking ticket dispensing

• Automated Teller Machines (ATMs)

• Gaming receipts

• Interactive media kiosks

MTP-1530II User Manual (Rev.20120510) Page 9

Page 10

Telpar MTP-1530II Receipt Thermal Printer User Manual

1.3 Standard Features

• Direct thermal printing

• Interfaces:

⇒ Serial (RS232),

⇒ Parallel (IEEE1284),

⇒ USB 2.0,

⇒ Ethernet (10BASE-T and 100BASE-TX )

• Paper widths -- 80 mm (3.15 in)

• Full or Partial Document Cutter – specified at time of order.

• All metal construction

• Paper low sensor

• Paper auto load function

1

• ESC/POS

distribution industry.

• Print Speed – 250 mm/s

• DIP switches accessible without removing cover.

• Paper capacity: 152 mm (6 in) diameter roll with 50 mm diameter core

• Overall size including 152 mm (6 inch) diameter roll of paper:

169.8 mm x 150.3 mm x 243.4 mm (6.68 in H x 5.92 in W x 9.58 in D)

• Inverted print mode

• Character code tables: PC437 (USA, default), Katakana, PC850 (Multilingual),

PC860 (Portuguese), PC863 (Canadian-French), PC865 (Nordic), WPC1252,

PC866 (Cyrillic2), PC852 (Latin2), PC858 (Euro), Space page.

The commands conform to ESC/POS, which is a standard in the

• International character set: Control Boards, have the following: U.S.A.,

France, Germany, England, Denmark (2 choices), Sweden, Italy, Spain (2

choices), Japan , Norway, Latin America, Korea.

• Barcode embedded symbologies: UPC-A, UPC-E, JAN(EAN) 13, JAN(EAN)8,

3 of 9, ITF, CODABAR, Code93, and Code128. Ladder Bar codes can be

printed when using Page Mode.

• Bit image mode

• Reverse video mode

• Underline printing

• Continuous roll paper

• Page Mode

• Two character font sizes. Each can be printed from 1 to 8 times normal width

and/or 1 to 8 times normal height.

• “Smoothing” command (see GS b) – applies only in Page mode.

• Black Mark sensing.

1

ESC/POS is a registered trademark of SEIKO EPSON Corp.

MTP-1530II User Manual (Rev.20120510) Page 10

Page 11

Telpar MTP-1530II Receipt Thermal Printer User Manual

1.4 Specifications

• Resolution: 8 dots/mm (203 dots/in).

• Paper thickness: 0.056 µm to 0.15 µm maximum (0.0022 in to 0.0059 in).

• Operating temperature: -20oC to 70oC (-4oF to 158oF).

• Operating humidity: 10-80% RH (non-condensing, 34°C {93.2°F} is assumed at

80%).

• Peak current for head drive is 6.7A at the moment that all dots are energized.

• Weight: Approx. 3.6lbs (1.6Kg)

• Expected life of mechanism: 15 million lines.

• Expected life of cutter: 1 million cuts.

1.5 Power Supply Requirements

1.5.1 Voltage: 24 VDC ±10%

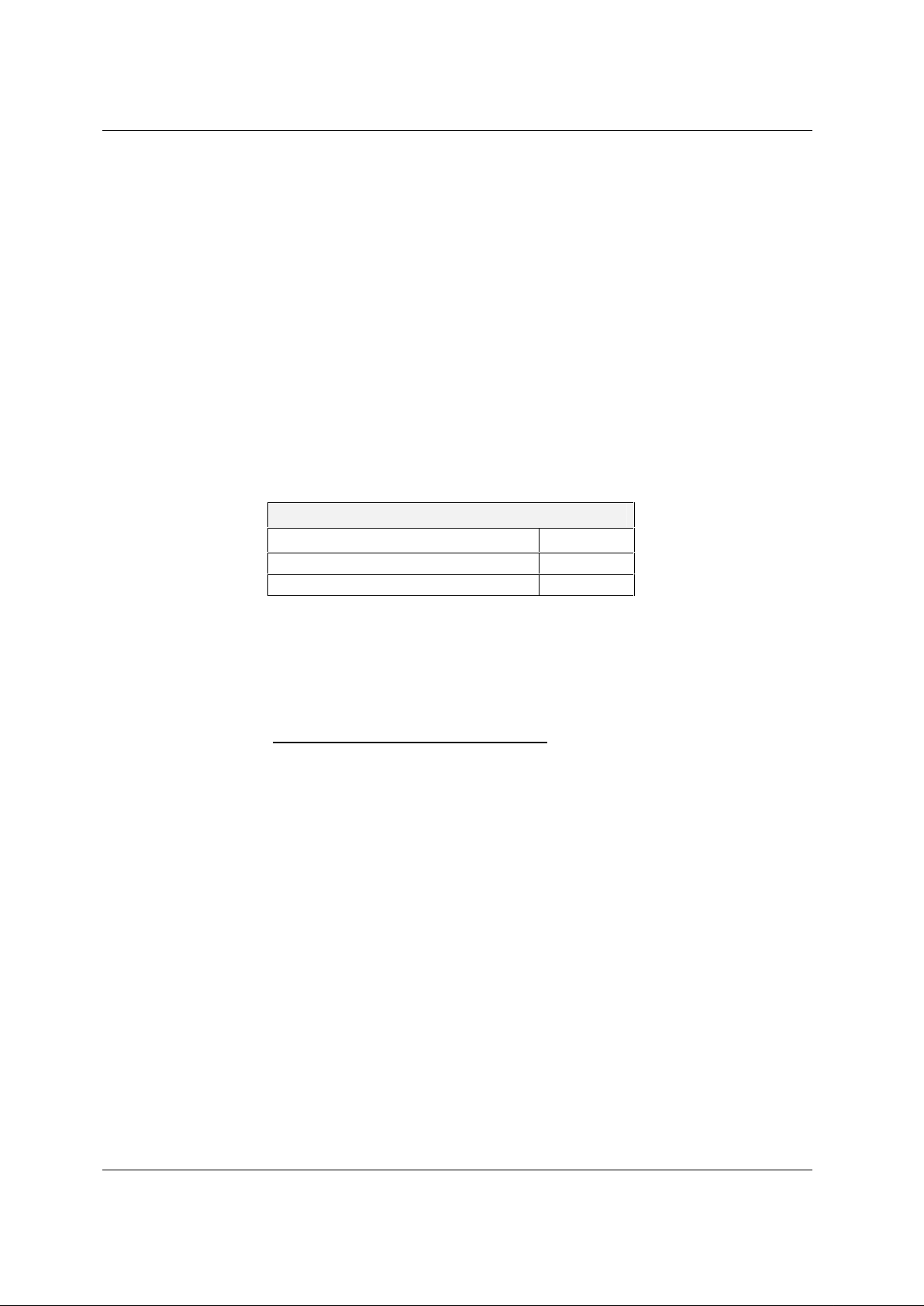

Current Requirements

Peak Current (approximately)

Mean Current (approximately) 3.0 Amps

Stand-by 0.1 Amps

Table 1 Current Requirements

If the number of dots that are energized at the same time is increased, a

higher current will flow; therefore, the user should use power supplies

with a current capacity adequate for the corresponding print duty.

6.7 Amps

1.5.2 Power Supply Option from Telpar

(Telpar Part Number 103929-0200) Telpar offers a safety agency

approved 100 to 240 VAC (50/60Hz) input to 24VDC output power

supply suitable for most printing applications which use the MTP-1530II

Printer. Please ask the Telpar Sales Team for more information.

MTP-1530II User Manual (Rev.20120510) Page 11

Page 12

Telpar MTP-1530II Receipt Thermal Printer User Manual

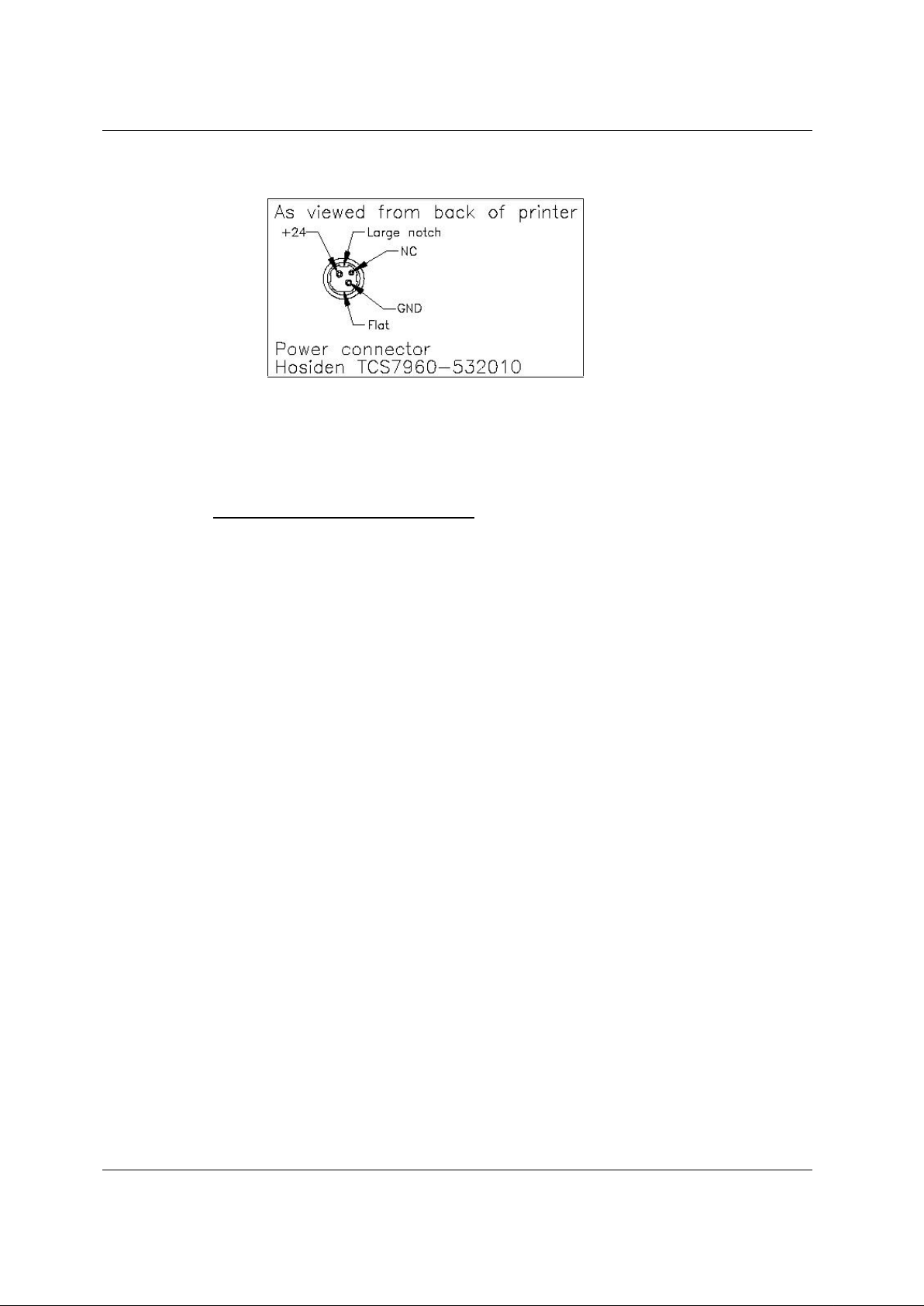

1.5.3 3-Pin Hosiden Connector on Printer for Power

Supply Connection

3-Pin Hosiden Power Supply Connector

1.6 Telpar Roll Paper for the MTP-1530II Printer

Telpar Part Number 251103-8006. Thermal sensitive coating is on the “inside”

of the roll. 52 mm (6 in) outside diameter, 80 mm (3.15 in) wide, length 180 m

(590 ft). For use with the standard 44.5mm diameter (1.75 in diameter) MTP1530II printer spindles.

Specific to Thermal Printers: Telpar, does not warranty damages to the

thermal print head as a result of printing with thermal paper not specified or

approved by Telpar,

MTP-1530II User Manual (Rev.20120510) Page 12

Page 13

Telpar MTP-1530II Receipt Thermal Printer User Manual

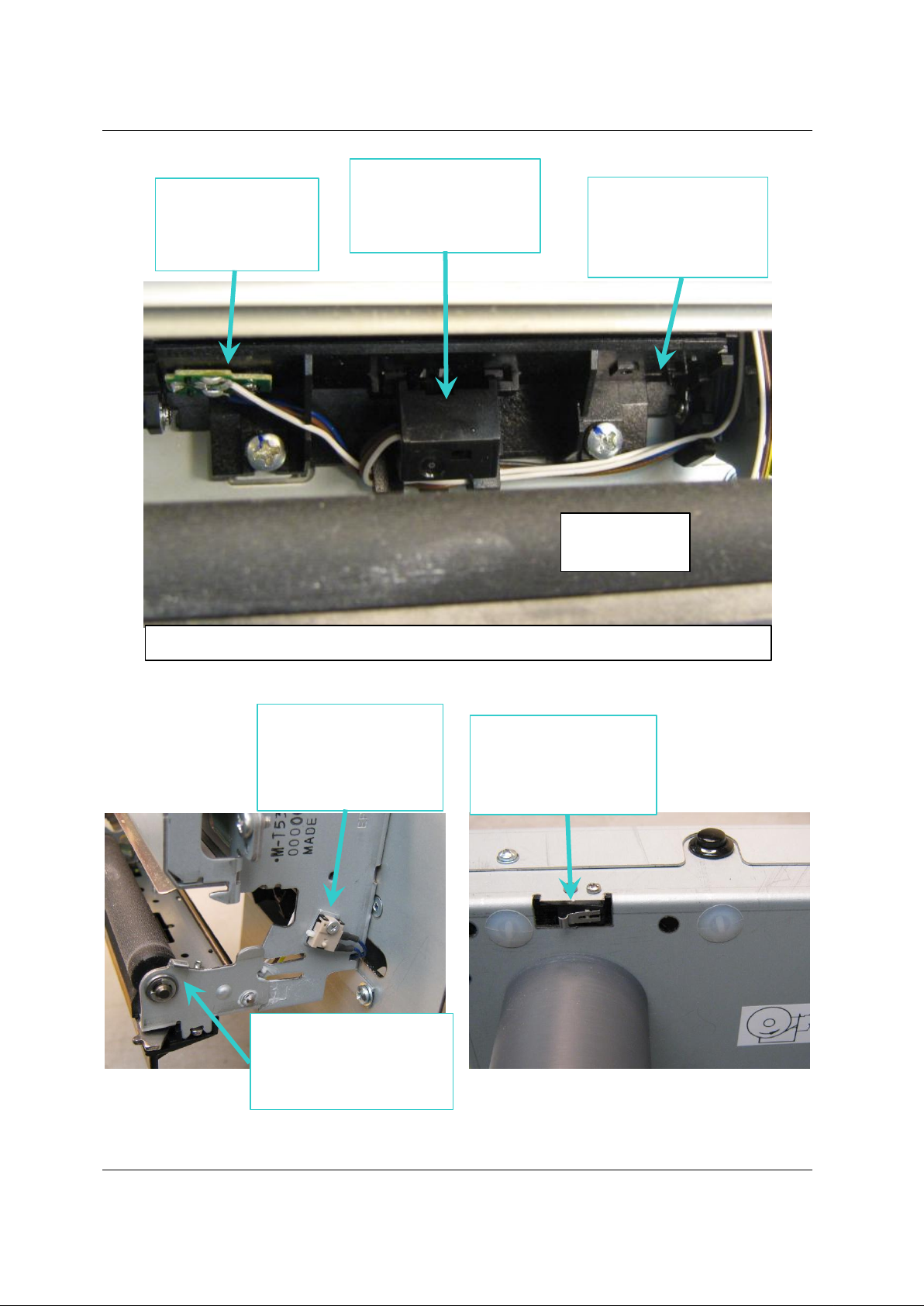

1.7 Sensor Locations and Functions:

The MTP-1530II has six sensors that detect various changes in conditions relating to printer

operation which may alter the course of action the printer will take depending upon the change

detected. The six sensors are listed, described and shown below in this section:

1) Print-head Temperature Sensor: A thermistor sensor detects the temperature of the

printhead. The printer stops printing operation if the print-head Temperature is 75°C

(167°F) or higher. The printer resumes normal operation after the print-head cools off to

70°C (158°F) or lower. (No photo is available for this sensor.)

2) Paper Present Sensor (also know as the Paper End Sensor): This sensor detects

whether or not paper has been loaded into the printer. It triggers the automatic paper

feeding operation when paper is initially fed into the printer mechanism. It also detects

when paper has run out at which time the printer stops all printing operations until additional

paper has been successfully fed into the printer.

3) Platen Open Sensor: A small micro-switch detects whether or not the printer’s platen

(long, rubber roll) has been lowered away from the print-head mechanism (as shown in the

photo below). Printing operation will not be allowed while this sensor detects that the platen

is not locked in place against the print mechanism.

4) Paper Jam Sensor: This sensor, located near the platen (long, rubber roll) detects

whether or not paper has started to wrap around the platen which would result in a paper

jam. If this sensor detects that the paper is wrapping around the platen, all printing

operation will stop until the jam is cleared and the paper path is returned to normal. If a

paper jam does occur, turn the printer off, carefully remove the jammed paper, and then

turn the printer on again.

5) Paper Low Sensor: A small micro-switch mounted on the side of the chassis (see photo

below) detects the presence of a paper roll diameter that is approximately 2.8 to 2.9 inches

(mm) or greater. If the roll falls below this diameter, then the PAPER OUT LED (middle LED

on the printer’s control board – see section 4.1.1) lights to alert that the paper roll is getting

low. If Escape Command ESC c 4 has been sent to the printer prior to the paper low

condition and the paper level falls below the micro-switch sensor, then the printer will stop

printing operation immediately.

6) Black Mark Sensor (please reference section 2.2.2 for more information on Black Mark

detection): This sensor detects a black mark that has been pre-printed on the side of the

paper. Usually the black mark denotes the top or starting point of each individual receipt

contained in a continuous roll of pre-printed paper. If the paper you are using has black

marks pre-printed on it and you wish to have the printer detect the presence of these black

marks, you must have DIP Switch 1, position 1 set to the ON (or up) position (see section

4.1).

NOTE: Typically, the Black Mark sensor is located on the left-hand side of the printer as

looking from the front (see photo below). Therefore, this only detects the black mark on

that side of the paper. If the black mark is located on the other side of the paper, the Black

Mark sensor can be physically moved to its right-hand mounting position on the opposite

side of the mechanism (one small screw must be removed to remove the sensor).

MTP-1530II User Manual (Rev.20120510) Page 13

Page 14

Telpar MTP-1530II Receipt Thermal Printer User Manual

Black Mark Sensor

location

(shown is the bottom

of the sensor)

Paper Present Sensor

location

(shown is the bottom of

the sensor encasement)

Alternate l(right-hand)

mounting location for

the Black Mark Sensor

on the opposite side of

the mechanism

Platen

(long, black

roll)

View of the Front of the printer mechanism with the platen in the down position

Platen Open Sensor

location

Photo shown with the

platen in the open

(down) position.

Paper Low Sensor

Location

Mounted just above the

paper roll spindle.

Paper Jam Sensor

location

(hidden under platen

roll)

MTP-1530II User Manual (Rev.20120510) Page 14

Page 15

Telpar MTP-1530II Receipt Thermal Printer User Manual

2 Operator Instructions

2.1 Unpacking and Inspection

Carefully unpack and inspect your MTP-1530II for any damage that may have

occurred in transit. Should any damage have occurred, notify Telpar, save the

shipping carton and packing materials, and file a damage claim with the carrier.

Specify the nature and the extent of the damage. Before installing or operating

the printer, check the following:

• Printer mechanism and paper path are clear of all packing materials

or other foreign matter.

• Paper is installed. DO NOT OPERATE the printer without paper.

Refer to Section 2.2 - Paper Loading page 15 for paper loading

instructions.

2.2 Paper Loading

2.2.1 Side-Loading Roll

The MTP-1530II series printer is configured as a side-loading printer.

Slide roll of paper over spindle with paper fed under the bottom toward

paper slot (front of unit).

To load paper, turn on the power and feed the straight edge of the paper

into the paper guide. AUTOLOAD will automatic load paper once it is fed

into the paper guide. Once paper has been initially loaded, the paper

feed button may be used. Ensure that the paper is installed correctly and

feeding properly with the thermal side facing up.

2.2.2 Black Mark Sensors Load

The MTP-1530II series printer may be used with the optional Black Mark

Sensor. This requires the use of a pre-printed Top of Form (TOF) Mark

or Black Mark on the form. Dip switch SW1 position 1 must be set to the

ON position to enable black mark operation.

If DIP switch DSW1 position 1 is turned on to enable the Black Mark

sensor when the printer is loaded with plain paper, at Power On the

printer will feed about 17.5 inches of paper looking for a Black Mark

and then go to an error mode since it did not find a Black Mark.

To load paper, turn on the power and feed the straight edge of the paper

into the paper guide. Ensure that the paper is installed correctly and

feeding properly with the thermal side facing up.

If using perforated paper, the perforation should be fed at least 1.27 mm

(0.05 in) past the cut line to avoid a jam at the cutter.

MTP-1530II User Manual (Rev.20120510) Page 15

Page 16

Telpar MTP-1530II Receipt Thermal Printer User Manual

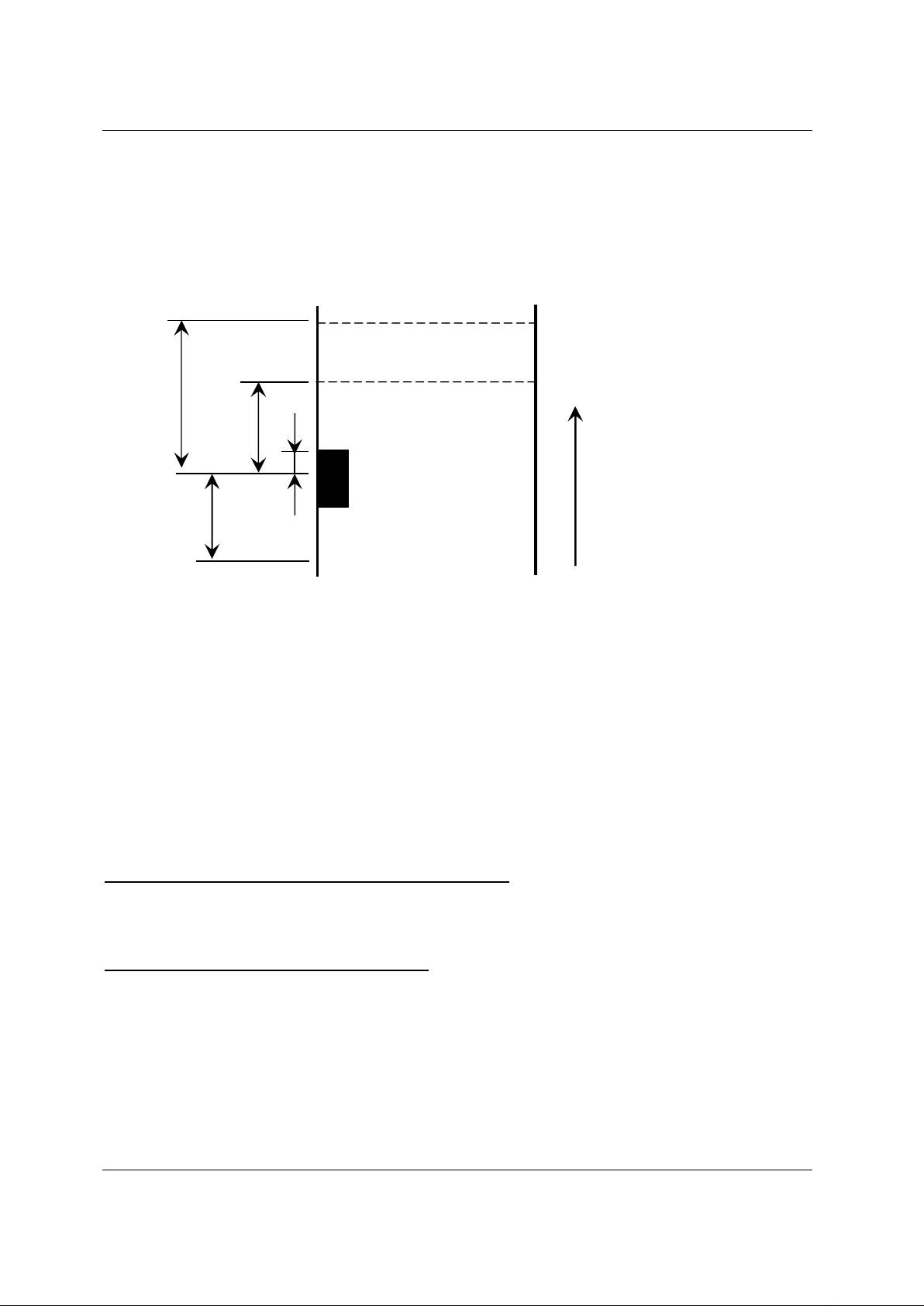

The BM is detected at the position which the top edge of the BM comes into

approximately 0.02 to 0.08in (0.5 to 2 mm) from the center of the BM sensor.

After detecting the BM, the BM is not detected for approximately 0.79in

(20mm).

Cutting Position

Print Starting Position

A

B

C

Paper

Feeding

Approx.0.8 Inch

Direction

(2cm)

Paper

The Figure above shows the BM Detection Position, Print Starting Position, and the Cutting Position

A: 1.32in (for straight paper-path model) 1.46in (for curled paper-path model)

33.6 mm (for straight paper-path model) 37.2 mm (for curled paper-path model)

B: 0.69in (for straight paper-path model) 0.83in (for curled paper-path model)

17.6 mm (for straight paper-path model) 21.2 mm (for curled paper-path model)

C: Approx. 0.02in to 0.08in

Approx. 0.5 to 2mm

Black Mark Print Starting Position and Cutting Position:

At the factory, the print starting position and the cutting position are set to the print head position and the

cutter position respectively when the BM sensor detects the BM.

The print starting position and the cutting position can be changed with the GS ( F command.

Acceptable Width and Interval of Black Mark:

The width and interval of BM for which the printer operation is guaranteed are as follows:

BM width: 3 to 20 mm {0.12in} to {0.79in}

BM interval: 50 to 300 mm {1.97in} to {11.81in}

MTP-1530II User Manual (Rev.20120510) Page 16

Page 17

Telpar MTP-1530II Receipt Thermal Printer User Manual

2.3 Paper Jam

In the event of a paper jam condition do not force paper into the unit, or try to

pry the paper out of the unit, this may damage the thermal print mechanism.

Caution should be exercised when working next to the cutter mechanism, the

blades are sharp and may cause serious injury.

To release paper:

• Turn off power to the printer.

• Push the Head Open lever to the down position.

• Paper can be removed at this time. Once paper is cleared from the

mechanism, return the Head Open lever to the up position.

2.3.1 Head Open Lever

The Head Open lever (green) is located at the left front of the printer

mechanism as shown in the two pictures below. The up position is ready

to print. The down position lowers the platen roller away from the printhead for manually inserting paper or for clearing a paper jam. The down

(open) position signals the microprocessor that the head is open so that

no printing will occur.

Head Open Lever

(shown in its closed position)

position allows for jams near the

platen area to be cleared or for

MTP-1530II User Manual (Revision 20120510) Page 17

Head Open Lever

(shown in its open position)

Placing the lever in the down

loading paper manually.

Page 18

Telpar MTP-1530II Receipt Thermal Printer User Manual

3 Installation

3.1 Self Test Mode

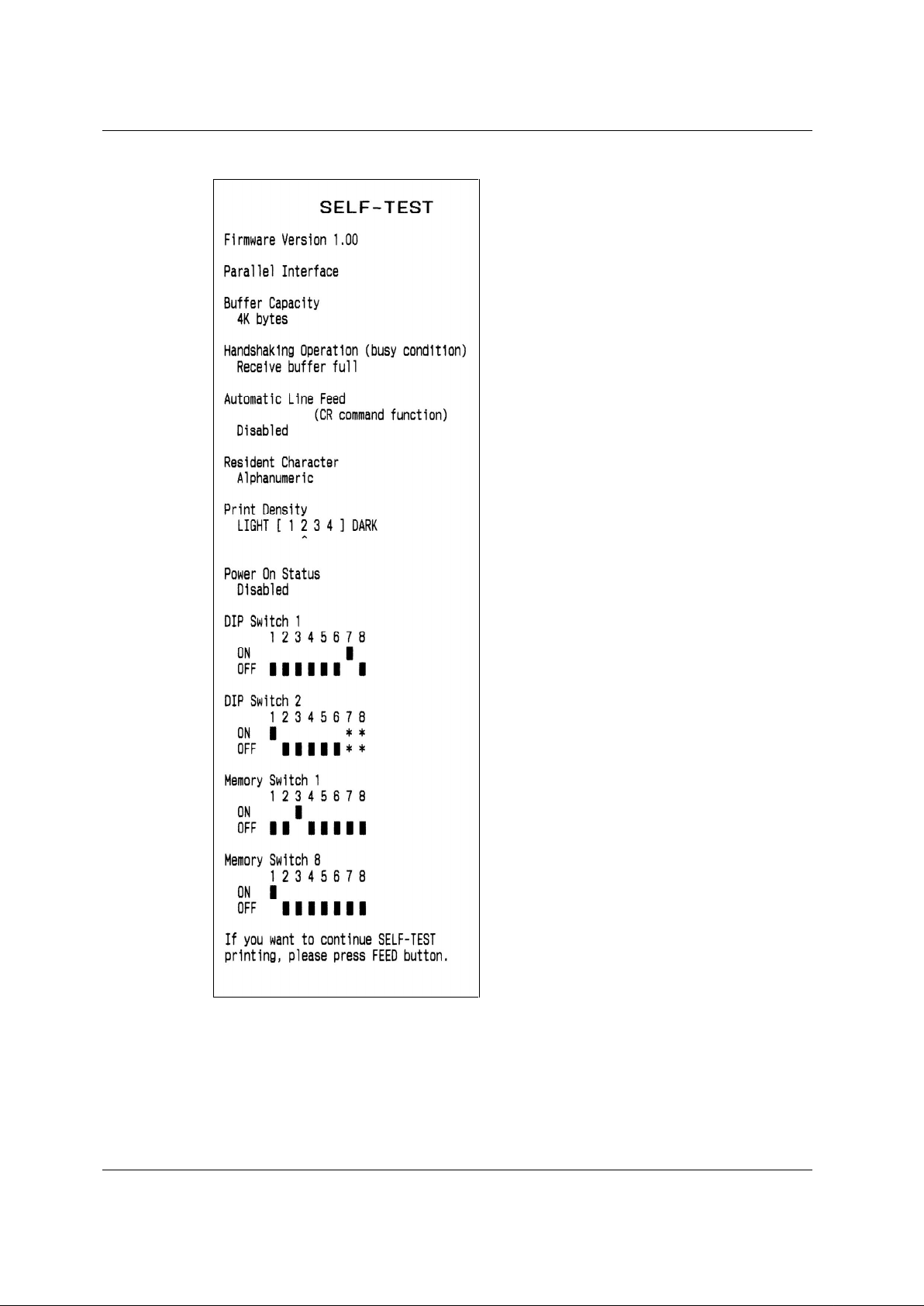

The MTP-1530II has a self-test mode that will print and cut a sample ticket.

To place the unit into self-test mode, first turn power switch off, then press and

hold the FEED push button switch. Next, place the POWER switch in the ON

position to apply power to the printer. Release the FEED Button after printing

starts (within 5 seconds). See a sample of a Self Test Printout on the next

page.

The first part of the self test message prints several fields showing how the

printer is configured. Following the first part of the self test, you have the option

of pressing the paper feed button once more to print a “barber pole” pattern

print test of ASCII Characters, or turning power off and back on to terminate the

self test The printer goes to the off-line (BUSY) state when self test starts and

remains off-line until self test is finished due two either of these actions. All

electrical/mechanical portions of the printer are exercised and checked by this

action, except for the host-to-printer communication interface components.

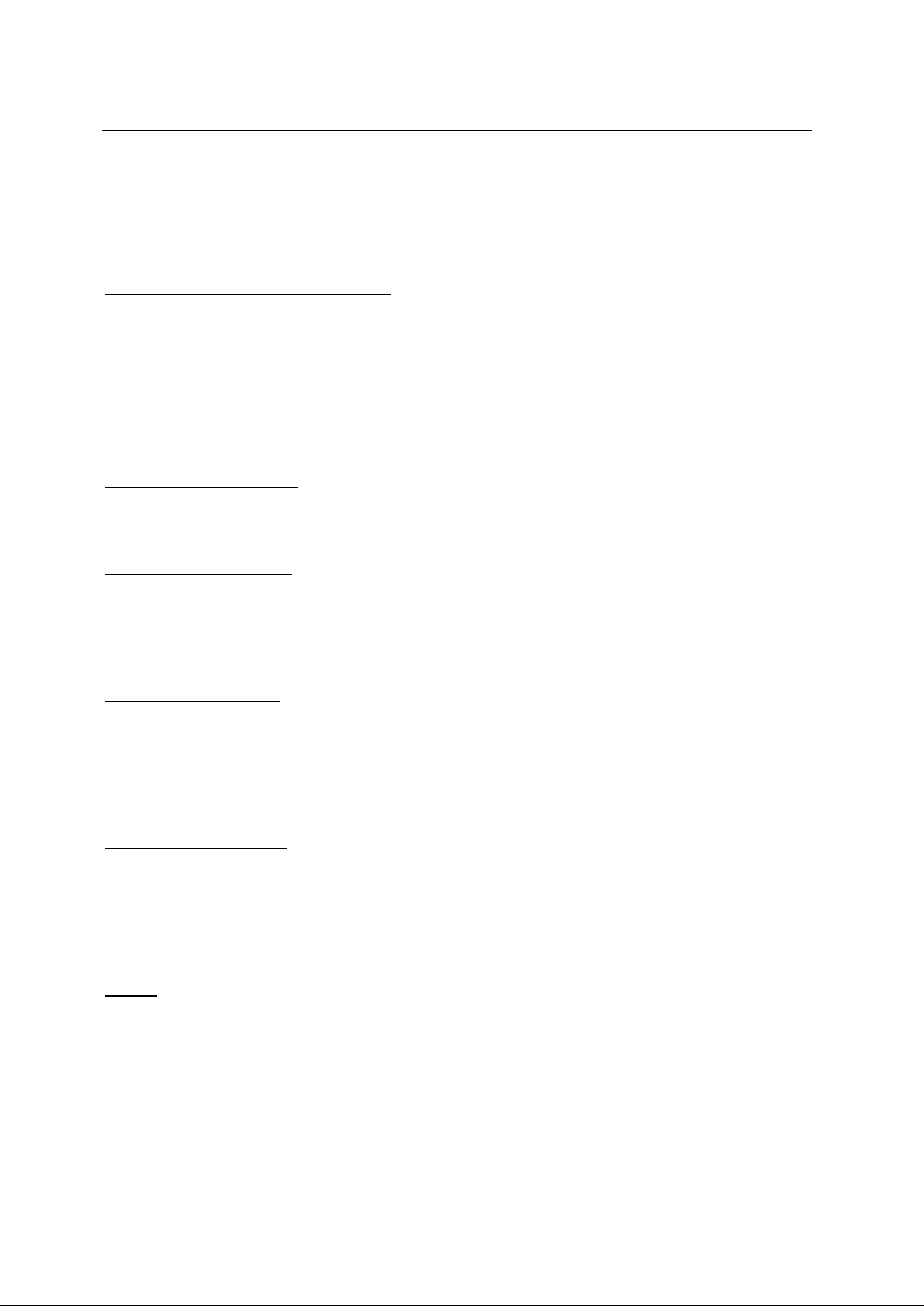

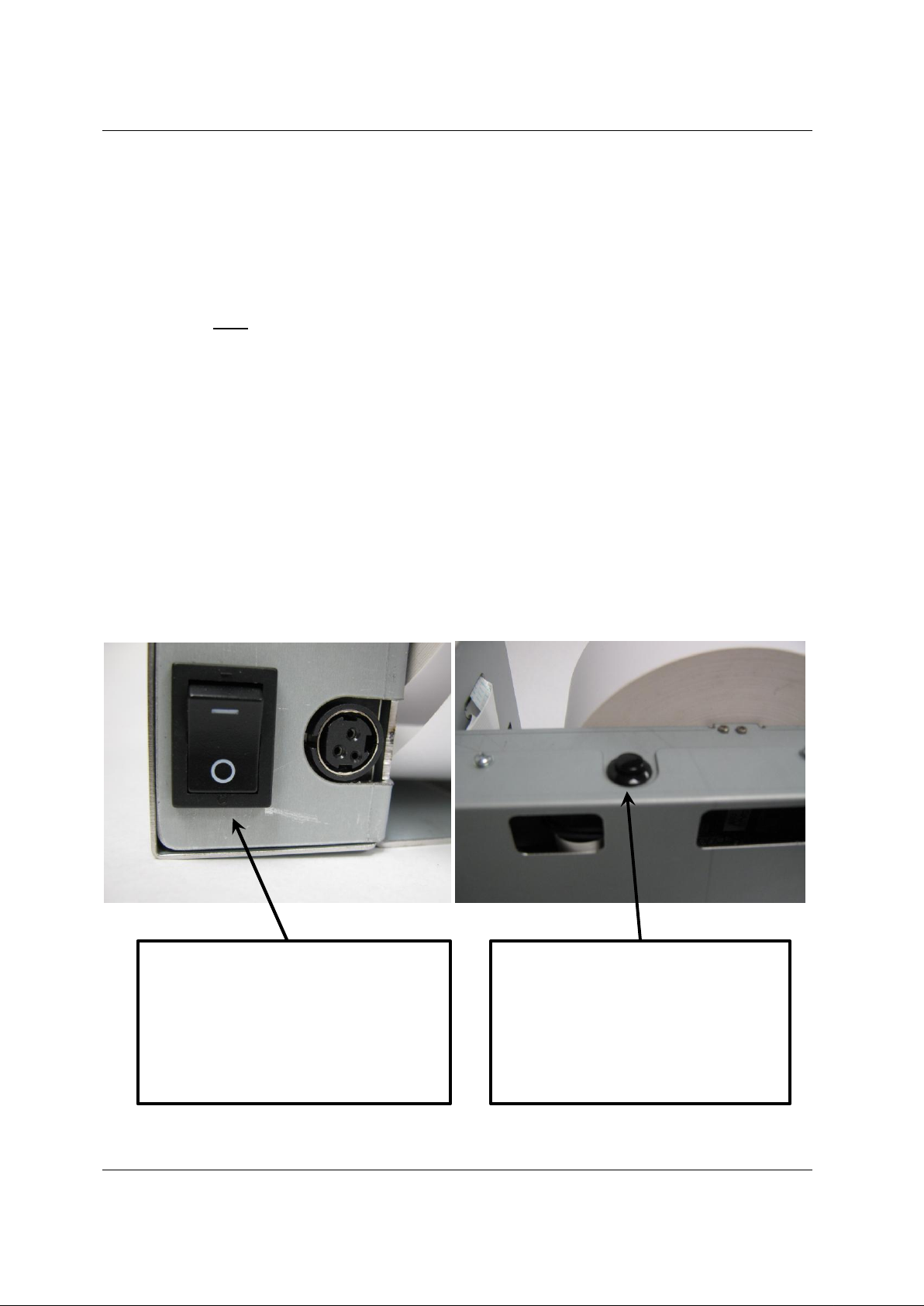

The Power Switch is located at the

rear of the printer next to the power

inlet connector. Pressing the “1”

position on the power switch applies

power to the printer, and pressing the

“0” position on the switch switches off

power from the printer.

MTP-1530II User Manual (Revision 20120510) Page 18

The Paper Feed Button is located

on the top, side chassis of the

printer. This button will feed paper

through the printer while it is

pressed, and the button is also used

together with the power button to

print a Self Test printout.

Page 19

Telpar MTP-1530II Receipt Thermal Printer User Manual

MTP-1530II Self Test Printout

MTP-1530II User Manual (Revision 20120510) Page 19

Page 20

Telpar MTP-1530II Receipt Thermal Printer User Manual

4 Setup and Control of the Printer:

4.1 DIP Switch Settings and Memory Switch Settings

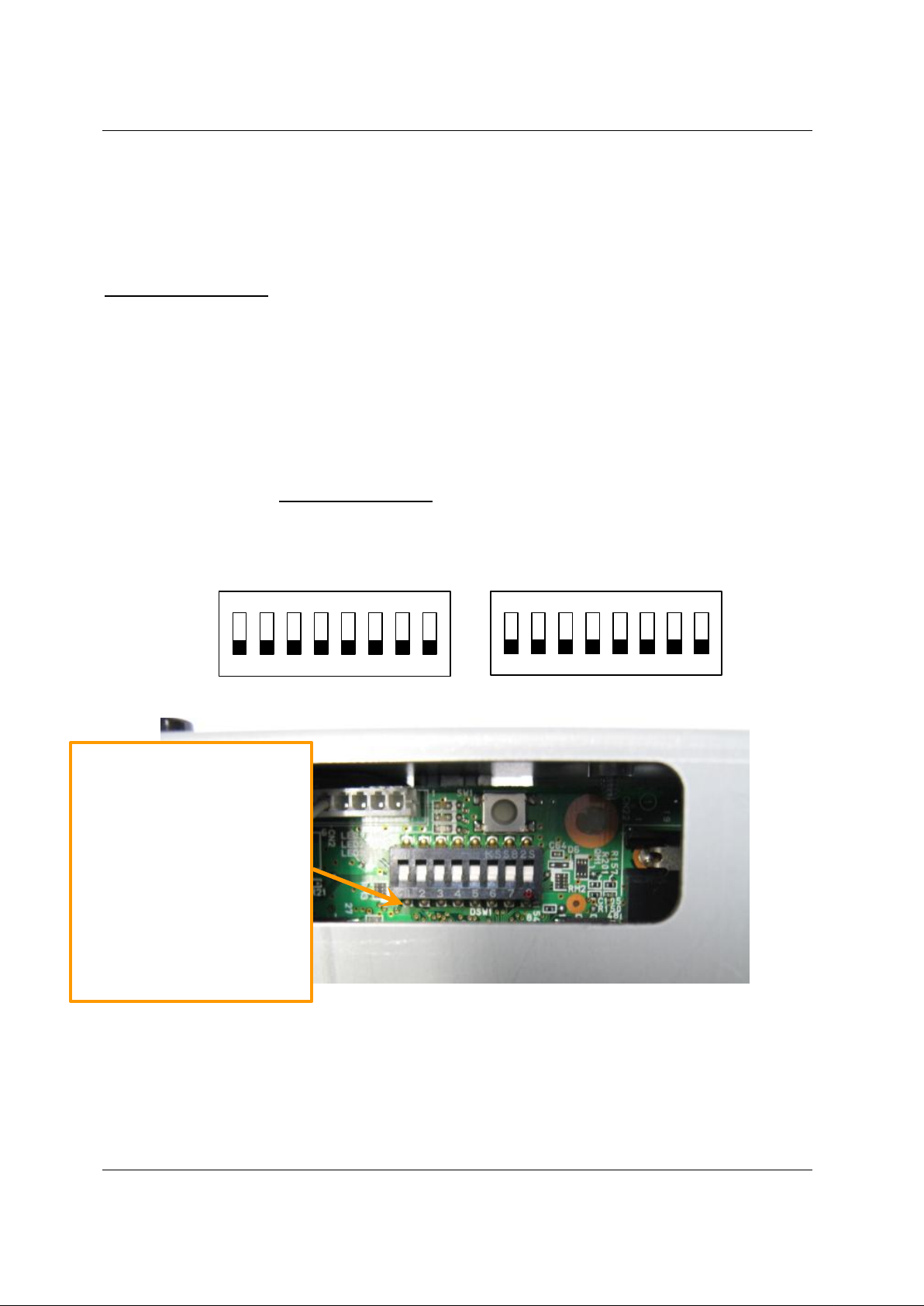

DIP Switch Settings: The MTP-1530II Parallel and Ethernet printers each have a single DIP

Switch located on the main circuit board (Labeled “DSW1”), while the Serial (RS-232) printer

has two DIP Switches located on the main circuit board (labeled “DSW1” and “DSW2”) The

DIP Switch contains a bank of eight individual switches, each of which controls some aspect of

the printer and are described in the tables below. The switches can slide up into the “ON”

position or down into the “OFF” position. A small tip screwdriver or even a pen tip may be

used to change the position of the switches.

The DIP Switch on each type of printer can be accessed through a cutout hole on the metal

circuit board cover (see picture below) Therefore, DIP Switch changes can be made without

removing the cover. IMPORTANT NOTE: If you make any changes to the DIP Switch

settings, you must first cycle power to the printer or reset the printer in order for the changes to

take place.

ON

1 2 3 4 5 6 7

DIP Switch Bank for a

Parallel Printer as looking

through the Chassis.

Note the numbering below

each switch position (1-8,

left to right), and “DSW1”

labeled on the board directly

below the switch. Each

individual switch is turned

“ON” by sliding it all the way

to its up position. Sliding a

switch down turns it “OFF”.

DSW1

ON

1 2 3 4 5 6 7

DSW2 (RS-232 Serial Printer Only)

MTP-1530II User Manual (Revision 20120510) Page 20

Page 21

Telpar MTP-1530II Receipt Thermal Printer User Manual

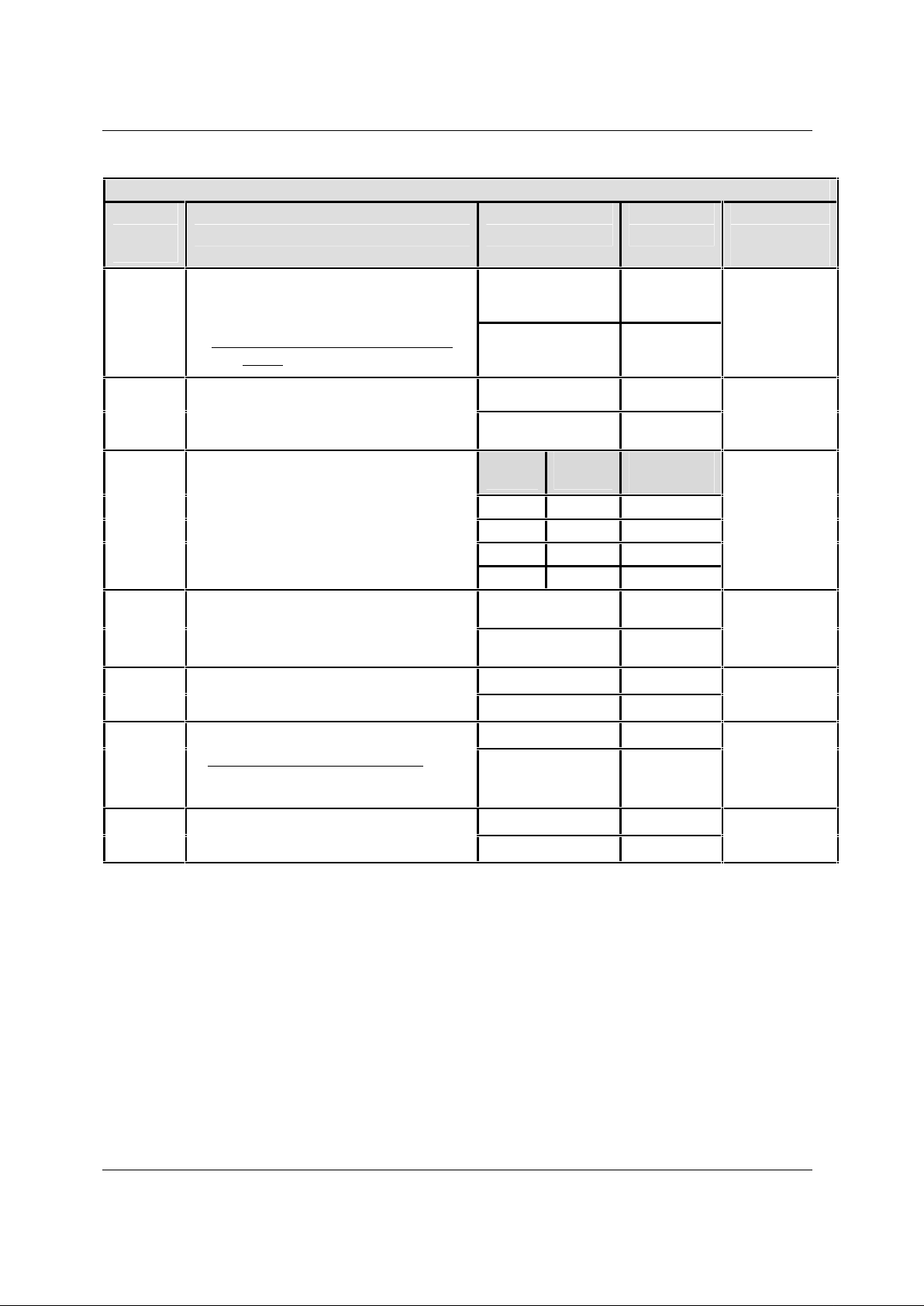

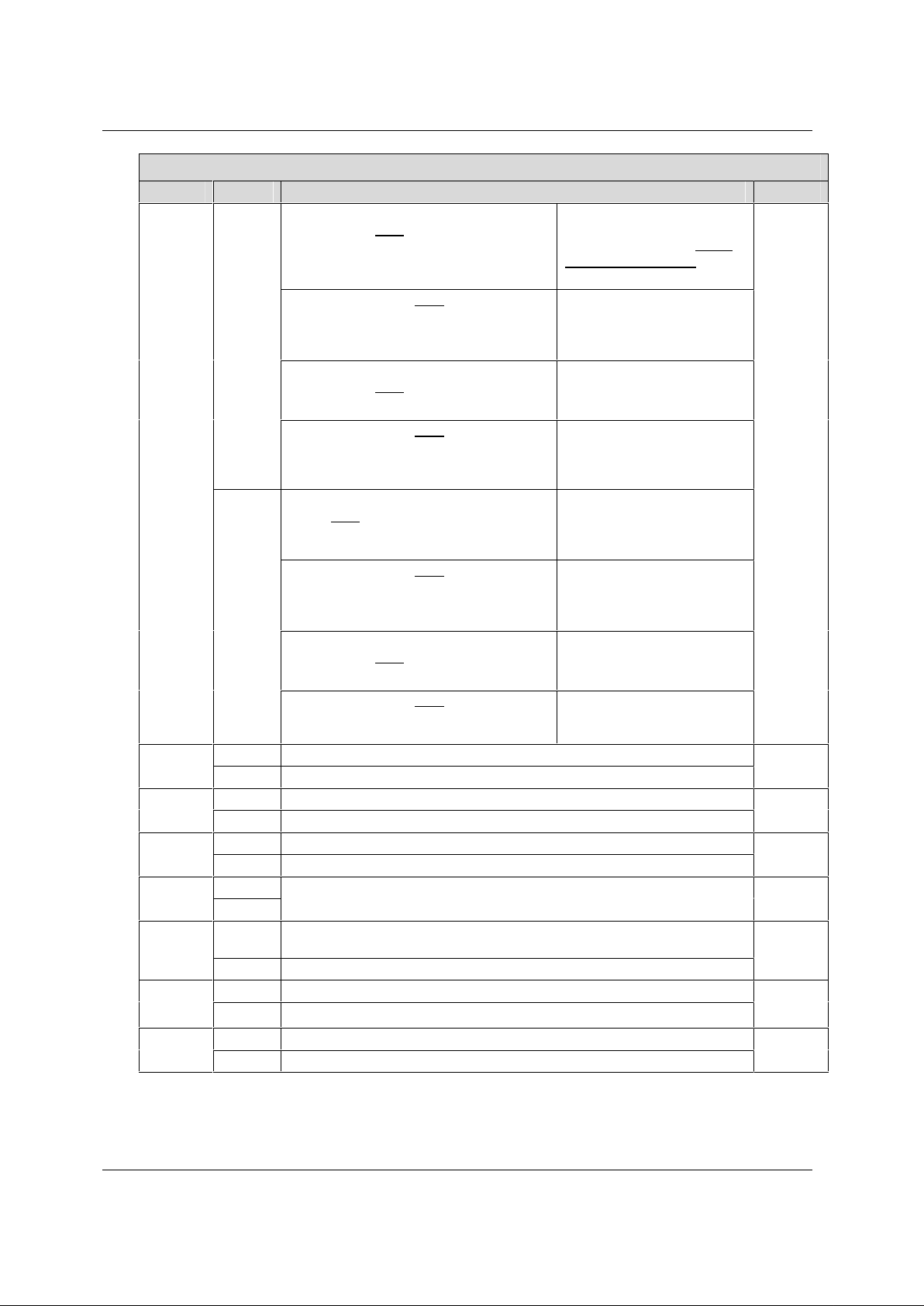

DIP Switch 1 (DSW1) Settings

Switch

Position

No.

Switch Function Description Switch Position Result Shipping

Black Mark Sensor (BM Sensor)

If this switch is set to the “ON” position,

you must use special black mark paper

or the printer will go into an error

mode! (see section 2.2.2)

Setting of Allowable Print Width

2

The MTP-1530II should always have this

switch set to the “ON” position.

Print Darkness Selection

3 and 4

To help achieve the maximum lifespan

of the print-head, it is recommended that

these switches be set to the lowest

intensity level available which still

adequately meets the desired print

darknessfor your printer application.

5 Operation Mode

6 Factory Setting

Fixed to “OFF”

7 Selection of Interface Class

Effective with the USB interface type

only. Reserved (fixed to

Off) with other interface types.

8 Reserved

Fixed to “OFF”

OFF

ON

OFF

ON

Switch3Switch

4

ON ON

OFF OFF

ON OFF

OFF ON

OFF

ON

NA NA

NA NA

OFF

ON

NA NA

NA NA

No black

mark

detection1

Detects black

marks on

paper

640 dots / line

576 dots /

line

Darkness

Setting

Slightly light

Medium

Slightly dark

Dark

Normal

Printing

Hexadecimal

Dumping

Vendor Class

Printer Class

Default

OFF

ON

Medium

(OFF and OFF)

OFF

OFF

OFF

OFF

DIP Switch 1 (DSW1) Settings

MTP-1530II User Manual (Revision 20120510) Page 21

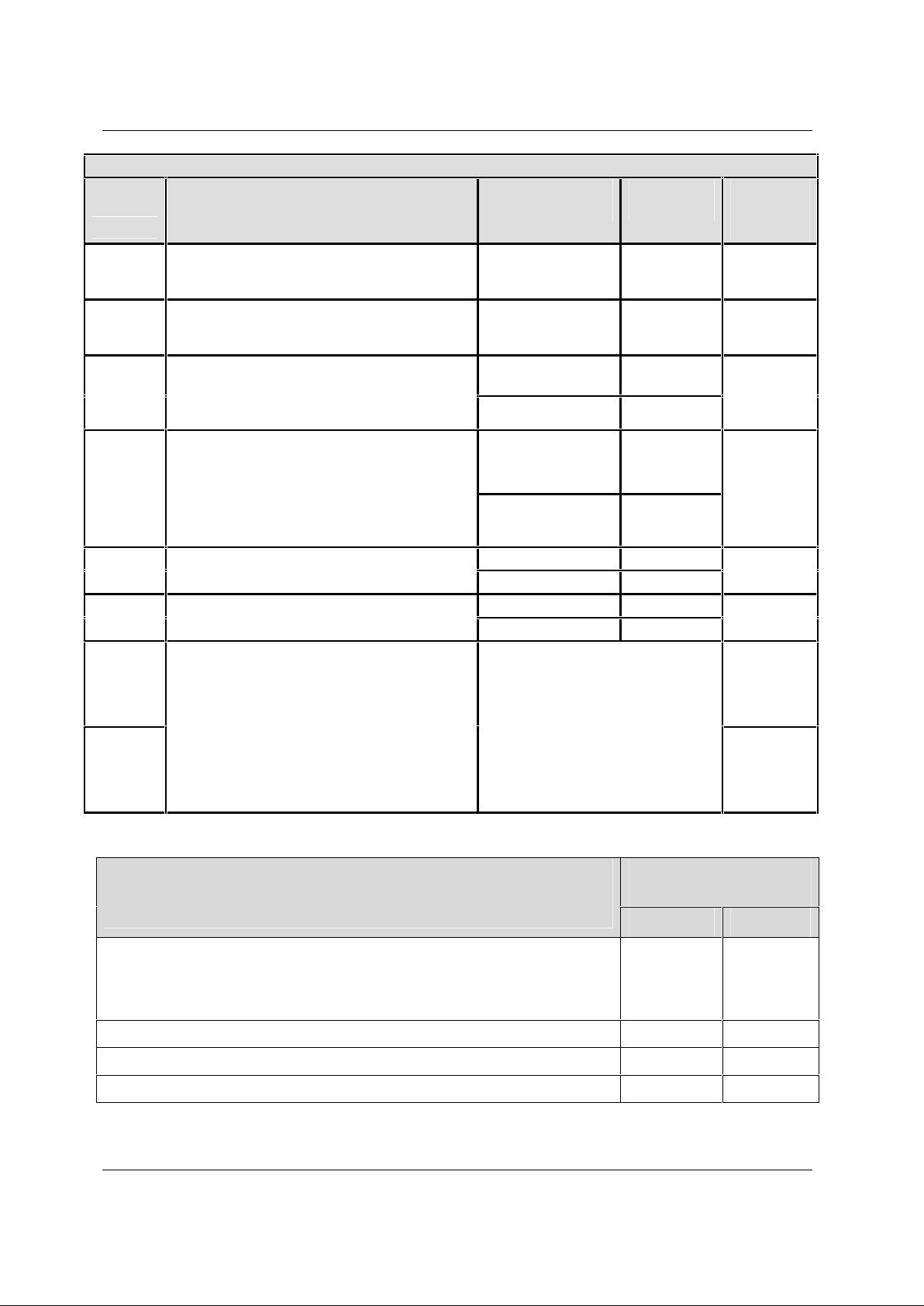

Page 22

Switch

Position

No.

1

Telpar MTP-1530II Receipt Thermal Printer User Manual

DIP Switch 2 (DSW2) Settings – For Serial (RS-232) Communications Only

Switch Function Description Switch Position Result Shipping

Default

RESERVED

Fixed to “OFF”

NA

NA

OFF

RESERVED

2

Fixed to “OFF”

DSR Reset

3

4 Handshaking

5 Parity Check

6 Parity ODD or EVEN

7

See

Table

Below

8

See

Table

Below

Transmission Speed (Baud Rate)

Switches 7 and 8 control the rate at which

the printer receives and transmits

information in bits per second (bps).

The default value for the RS-232 serial

printer is 19200 bits per second, 8 Data

Bits (fixed), 1 Stop Bit (fixed), No Parity

and Hardware Handshaking.

OFF

OFF

ON

OFF

ON

OFF

ON

OFF

ON

SEE THE TABLE BELOW TO

DETERMINE THE SWITCH

SETTINGS FOR POSITIONS 7 and

8 FOR THE VARIOUS BAUD

RATES AVAILABLE.

NA

Disabled

Enabled

HARDWARE:

DTR/DSR or

CTS/RTS

XON/XOFF

Disabled

Enabled

ODD

EVEN

OFF

OFF

OFF

OFF

OFF

ON

OFF

Transmission Speed (Baud Rate) in Bits per second (bps)

Pertains to DIP Switch 2 (DSW2) serial printer ONLY and relate

to the settings of switch positions 7 and 8.

Auto Detect

This setting automatically detects the transmission condition settings of the

serial interface (host). Available settings are 2400, 4800, 9600, 19200,

38400, 57600, and 115200.

9600 only

19200 only

38400 only

DIP Switch 2 (DSW2)

Switch Position

7 8

ON ON

OFF ON

ON OFF

OFF OFF

MTP-1530II User Manual (Revision 20120510) Page 22

Page 23

Telpar MTP-1530II Receipt Thermal Printer User Manual

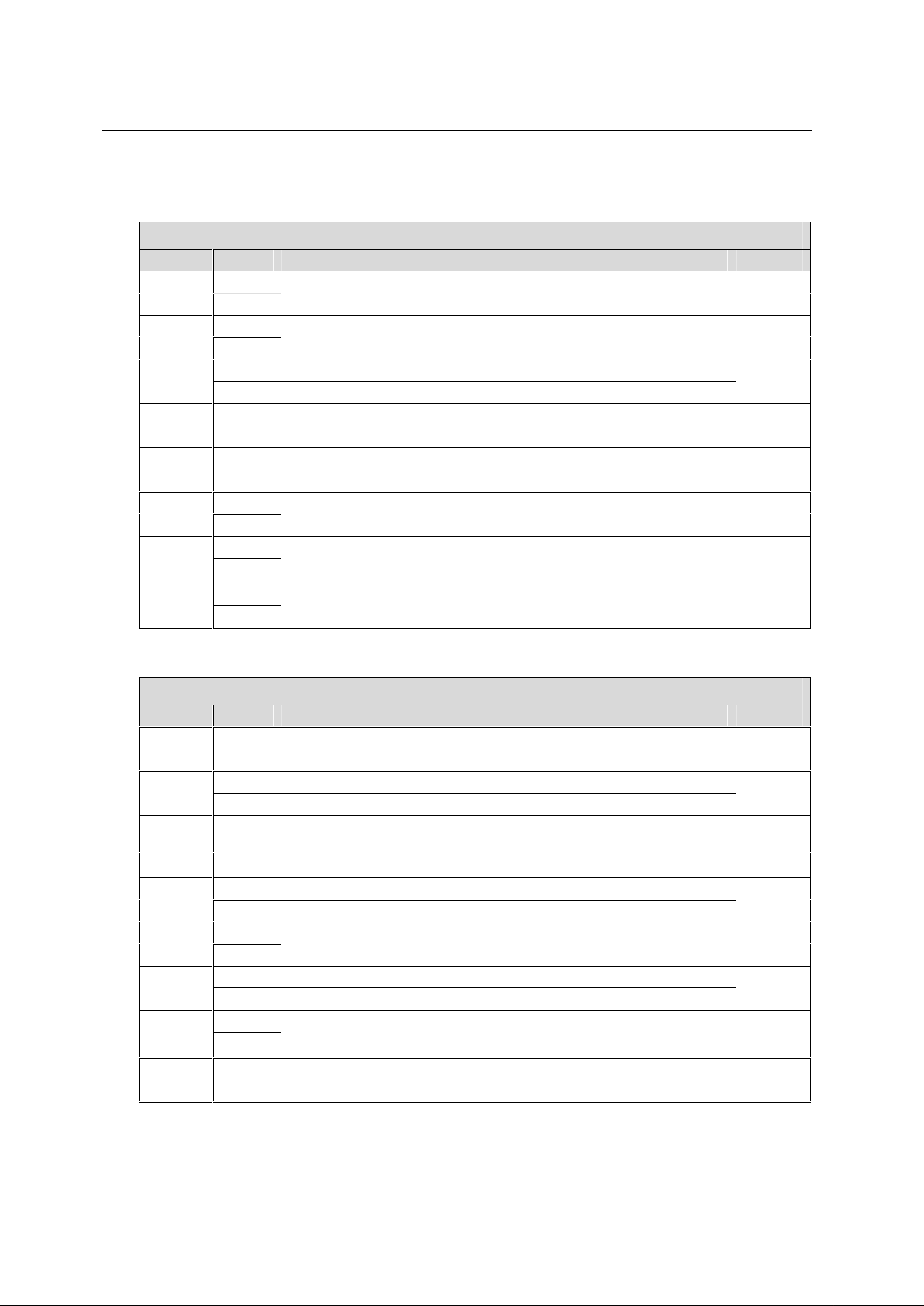

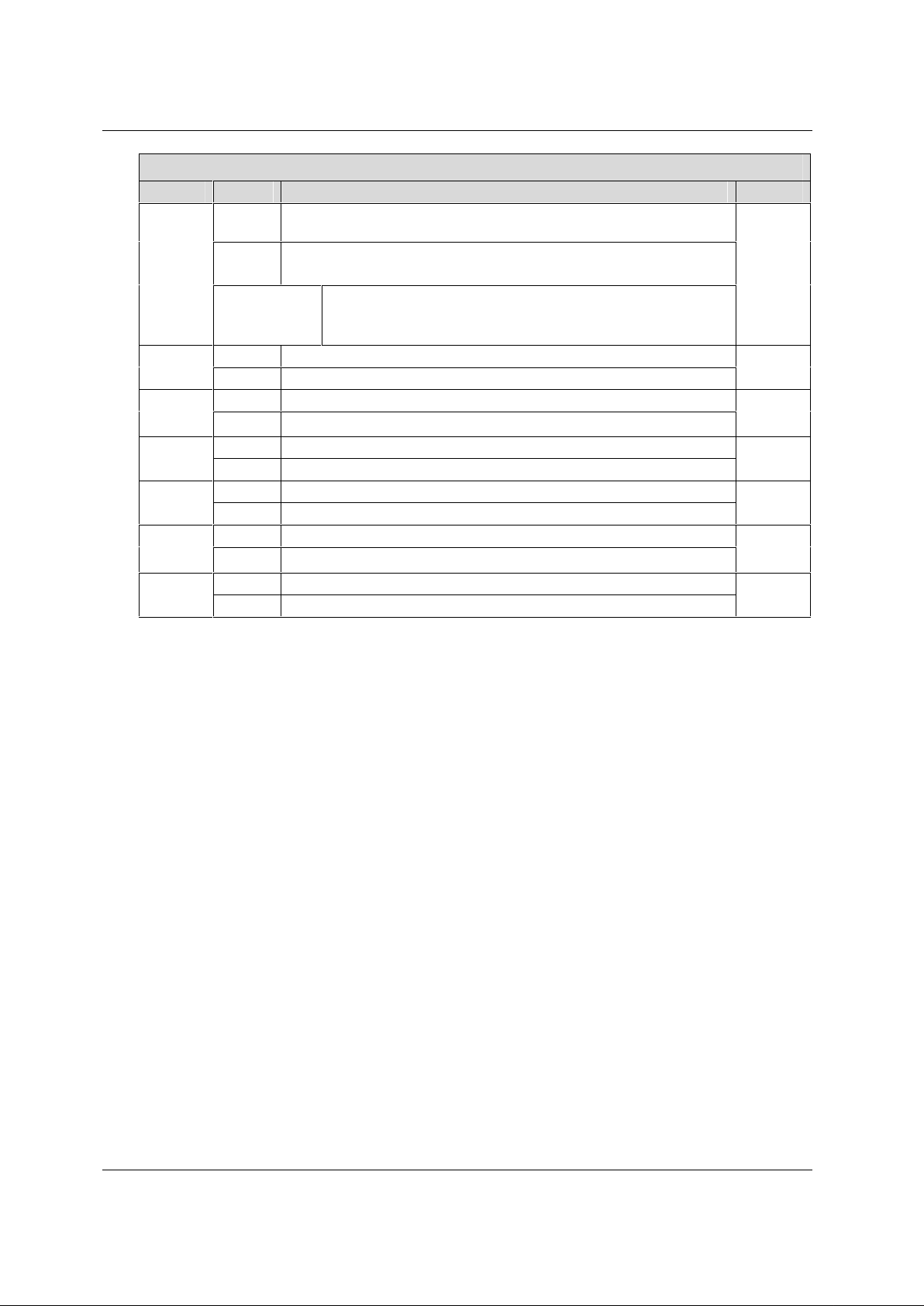

There are 8 MEMORY Switches, only four are currently used

Memory Switch 1

Position State Function Default

ON

1

2

3

4

5

6

7

8

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

BUSY condition when buffer is full

BUSY when buffer is full or when OFF-LINE

Receive error is ignored (serial interface only)

Receive error prints “?” (serial interface only)

Auto line feed enabled (Parallel interface only)

Auto line feed disabled

RESERVED

RESERVED

RESERVED

RESERVED

RESERVED

OFF (0)

OFF (0)

OFF (0)

OFF (0)

OFF (0)

OFF (0)

OFF (0)

OFF (0)

Memory Switch 5

Position State Function Default

ON

1

2

3

4

5

6

7

8

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

Near Paper End Sensor Installed

Near Paper End Sensor NOT Installed

Printer can recover from a recoverable error after a paper jam has

occurred

Printer goes Offline after a paper jam has occurred

Enable Paper Jam Detection

Disable Paper Jam Detection

Disable the USB Power Saving Function

Enable the USB Power Saving Function

RESERVED

RESERVED

RESERVED

RESERVED

OFF (0)

ON (1)

OFF (0)

OFF (0)

OFF (0)

OFF (0)

OFF (0)

OFF (0)

MTP-1530II User Manual (Revision 20120510) Page 23

Page 24

Telpar MTP-1530II Receipt Thermal Printer User Manual

Memory Switch 6

Position State Function Default

ON

1

OFF

ON

2

3

4

5

6

7

8

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON Disable selection of the operation by GS FF

OFF Enable selection of the operation by GS FF

Manual Load of paper (paper fed with

platen open) AND

If Black Mark Sensor enabled

Auto load of paper AND

If Black Mark Sensor enabled

Manual Load of paper (paper fed with

platen open) AND

If Black Mark Sensor disabled

Auto load of paper AND

If Black Mark Sensor disabled

Manual Load of (paper fed with platen

open) AND

If Black Mark Sensor enabled

Auto load of paper AND

If Black Mark Sensor enabled

Manual Load of paper (paper fed with

platen open) AND

If Black Mark Sensor disabled

Auto load of paper AND

If Black Mark Sensor disabled

Disable error signal output

Enable error signal output

Speed has priority over power consumption

Power consumption has priority over speed

Disable auto eject when a paper out is detected

Enable auto eject when a paper out is detected

RESERVED

Enable if using thick type paper (paper which has excellent keeping

quality)

Enable if using normal paper

Detect near end of paper roll by using the Black Mark sensor

Detect near end of paper roll by using the Near End sensor

After the platen is closed, the

printer feeds the paper

approx. 125mm (5 “) to the

Black Mark position, and

then cuts it.

After auto-loading the paper,

printer feeds paper to the

Black Mark position, and

then cuts it.

After the platen is closed,

printer does not feed or cut

paper.

After auto-loading the paper,

the printer feeds the paper

approx. 125mm (5 “), and

then cuts it.

After platen is closed, printer

feeds paper to the Black

Mark position, and then cuts

it.

After auto-loading the paper,

printer feeds paper to the

Black Mark position, and

then cuts it.

After the platen is closed,

printer does not feed or cut

the paper.

After auto-loading the paper,

the printer does not cut the

paper.

OFF (0)

OFF (0)

OFF (0)

OFF (0)

OFF (0)

OFF (0)

OFF (0)

OFF (0)

MTP-1530II User Manual (Revision 20120510) Page 24

Page 25

Telpar MTP-1530II Receipt Thermal Printer User Manual

Memory Switch 8

Position State Function Default

Non-divided energization mode

Two part energization mode

Four-part energization mode

Enable backwards paper feeding

Disable backwards paper feeding

Autocutter is NOT installed

Autocutter is installed

Discards receive data when printer is offline

Keeps receive data when printer is offline

Backwards paper feeding amount = 88 steps

Backwards paper feeding amount = 108 steps

Enable test print when paper is loaded

Disable test print when paper is loaded

Does NOT initialize for Black Mark position when power is turned on

Initializes for Black Mark position when power is turned on

Both

OFF (0)

OFF (0)

OFF (0)

OFF (0)

OFF (0)

OFF (0)

OFF (0)

1 and 2

3

4

5

6

7

8

Both

OFF

1 = ON

2 = OFF

1 = ON or

OFF

2 = ON

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

Note: Not all printer mechanisms allow reverse paper feeding. If reverse

feeding is allowed, after cutting the paper with a GS V command,

paper feeds backwards. The print starting position adjustment

with GS ( F can be set to the backward direction relative to the

cutting position. In this case, the maximum backward feed length

is 14 mm (112 * 0.125mm).

MTP-1530II User Manual (Revision 20120510) Page 25

Page 26

Telpar MTP-1530II Receipt Thermal Printer User Manual

4.2 LEDs and Error Indication

Three LEDs (LED1, LED2, and LED 3) are located below the cutout in

the side chassis (above the DIPSWITCH and next to the on-board paper

feed switch) as shown in the picture and figure below.

Location of

LED 1, LED2,

and LED 3

DIPSWITCH

Board Mounted

Paper Feed Switch

On-Board

Paper Feed

Switch

LED1 (power)

LED2 (paper out)

LED 3 (Error)

LED 1 POWER LED: ON means power is stable and the printer is ready

for operation. OFF means power in not stable.

LED 2 is a PAPER OUT LED, OFF means paper is installed and the

printer is ready for operation. ON means there is no paper

installed in the printer mechanism (or the paper low sensor if

selected). The PAPER OUT LED blinks steadily to specify that

self test has finished the first part of printing and that the user

can press the PAPER FEED button to print the “barber pole”

character print part of the self test. The PAPER OUT LED also

blinks steadily to specify that a MACRO is waiting for the user to

press the PAPER FEED button to continue it’s execution (macro

stand-by mode).

LED 3 is an ERROR LED. OFF means there are no errors and the

printer is ready for operation. ON indicates the printer is OFF

LINE (except during paper feeding using the FEED button, during

self-test printing, and in the error state). The ERROR LED blinks

a defined pattern every 5.12 seconds to notify the user of various

error conditions. When the LED is normally OFF and blinks ON,

an error is indicated which may be recoverable. . When the LED

is normally ON and blinks OFF, an error is indicated which in not

recoverable. For any error that is not recoverable, power should

be turned off as soon as possible.

MTP-1530II User Manual (Revision 20120510) Page 26

Page 27

Telpar MTP-1530II Receipt Thermal Printer User Manual

ERROR LED Blink Rate and Recovery Method Table (below):

Blink Rate Error Description Recovery method

Continuous

(no pauses)

1 blink ON then a paused OFF

condition before the cycle starts

again (each cycle is approx. 5

seconds long).

1 blink OFF then a paused ON

condition before the cycle starts

again (each cycle is approx. 5

seconds long).

2 blinks ON then a paused OFF

condition followed by another blink

ON and a shorter paused OFF

before the cycle starts again (each

cycle is approx. 5 seconds long).

1 blink OFF then a paused ON

condition followed by another blink

OFF before the cycle starts again

(each cycle is approx. 5 seconds

long).

2 blinks OFF then a paused ON

condition followed by another blink

OFF before the cycle starts again

(each cycle is approx. 5 seconds

long).

3 blinks OFF then a paused ON

condition followed by another blink

OFF before the cycle starts again

(each cycle is approx. 5 seconds

long).

4 blinks OFF then a paused ON

condition followed by another blink

OFF before the cycle starts again

(each cycle is approx. 5 seconds

long).

6 blinks ON then a paused OFF

condition beforethe cycle starts

again (each cycle is approx. 5

seconds long).

4 blinks ON then a paused OFF

condition beforethe cycle starts

again (each cycle is approx. 5

seconds long).

Print head

Temperature

too high error

Cutter error

PCB

connection

error

Black Mark

sensor

detection

error

Read/Write

error

High voltage

Low voltage

CPU error

Platen open

Paper Jam

Error

Print head

Temperature is

75°C (167°F) or

higher.

The cutter has

failed to complete

a cut

The printer

mechanism is not

connected or the

internal wiring is

incorrect.

No Black Mark was

detected (even

though the roll of

paper may be

marked correctly)

The CPU has

detected a memory

Read/Write error

The power supply

voltage is too high

The power supply

voltage is too low.

The CPU executes

an incorrect

address or the I/F

board is not

connected.

Print is not

performed due to

the platen being

open

A paper Jam has

occurred.

Automatic when the print head

cools off to 70°C (158°F) or

lower.

Recovers by DLE ENQ1 or DLE

ENQ2 after the cutter Jam has

been corrected.

NOT RECOVERABLE!Turn

power off and check

connections betweenthe printer

mechanism and the controller

board.

Recovers by DLE ENQ1 or DLE

ENQ2 when the paper with the

black mark is inserted correctly

again.

NOT RECOVERABLE!Cycle

power off and on to see if the

error goes away.

NOT RECOVERABLE!Turn

power OFF; correct the problem

before turning back on.

NOT RECOVERABLE!Turn

power OFF; correct the problem

before turning back on.

NOT RECOVERABLE!Cycle

power off and on to see if the

error goes away.

Recovers by DLE ENQ1 or DLE

ENQ2 after the platen is closed.

Open the platen and remove

the jammed paper. Recovers

by DLE ENQ1 or DLE ENQ2.

Printer operation when an error occurs:

The printer executes the following operations when detecting an error.

• Stops all printer operations for the selected paper section.

• Goes BUSY (When memory switch 1-3 is set to off to go BUSY during printer offline.).

• Flashes the ERROR LED.

MTP-1530II User Manual (Revision 20120510) Page 27

Page 28

Telpar MTP-1530II Receipt Thermal Printer User Manual

4.3 Control Codes and Control Sequences List

Location of

Definition

HT Horizontal tab General Execute Yes Yes

LF Print and line feed General Execute Yes Yes

PAGE MODE, print and

return to standard mode

Black Mark mode, print and

feed to print starting

position (Black Mark)

CR Print and carriage return General Execute Yes Yes

CAN Cancel print data PAGE Execute Ignored Yes

DLE

EOT

DLE

ENQ

ESC Escape sequence header --- --- --- --FS FS sequence header --- --- --- --GS GS sequence header --- --- --- --ESC FF Print data PAGE Execute Ignored Yes

ESC SP Set right side character

ESC ! Set print mode(s) General Setting Yes Yes

ESC$ Set absolute print position General, PAGE Execute Yes Yes

ESC % Select/cancel user-defined

ESC & Define user-defined

ESC * Select bit image mode General Execute Yes Yes

ESC - Turn underline on/off General Setting Yes Yes

ESC 2 Select default line spacing General Setting Yes Yes

ESC 3 Set line spacing General Setting Yes Yes

ESC ? Cancel user-defined

ESC @ Initialize printer General Execute,

ESC D Set horizontal tabs General Setting Yes Yes

ESC E Turn emphasized on/off General Setting Yes Yes

ESC G Turn double-strike on/off General Setting Yes Yes

ESC J Print and feed paper General Execute Yes Yes

ESC L Select PAGE MODE PAGE Execute Start line Ignore

ESC M Select character font General Setting Yes Yes

ESC R Select international

ESC S Select standard mode PAGE Execute Ignored Yes

ESC T Select print direction PAGE Setting Value Yes

ESC V Turn rotated print on/off General Setting Yes Value

ESC W Set printing area PAGE Setting Value Yes

ESC \ Set relative print position General, PAGE Execute Yes Yes

ESC a Select justification General Setting Start line Value

ESC c 3 Select paper sensors to

Real time status request STATUS Execute Yes Yes

Real time request to printer General Execute Yes Yes

spacing

character set

characters

characters

character set

output paper out signal

PAGE Execute Ignored YesFF

General, Top of

Form

General Setting Yes Yes

Seldom Setting Yes Yes

Seldom Setting Yes Yes

Seldom Setting Yes Yes

General Setting Yes Yes

General Setting Yes Yes

Class Standard

mode

Execute Yes Disabl

Yes Yes

Setting

Page

mode

ed

d

MTP-1530II User Manual (Revision 20120510) Page 28

Page 29

Telpar MTP-1530II Receipt Thermal Printer User Manual

ESC c 4 Select paper sensors to stop

printing

ESC c 5 Enable/disable panel

buttons

ESC d Print and feed n lines General Execute Yes Yes

ESC t Select character code table General Setting Yes Yes

ESC { Turn inverted print on/off General Setting Start line Value

FS p Print NV bit image

OBSOLETE – Use

GS (L<Function 69>

instead

FS q Define NV bit image

OBSOLETE – Use

GS (L<Function 67>

instead

GS FF Feed paper to Black Mark Top of Form Execute Yes Yes

GS ! Select character size General Setting Yes Yes

GS $ Set absolute vertical print

position

GS * Define download bit image NV & DL Setting Yes Yes

GS ( A Execute test print General Execute Yes Ignore

GS ( E User setup commands Seldom Execute,

GS ( F Set adjustment values Seldom Setting Yes Yes

GS ( M Customize printer control

values

GS / Print download bit image NV & DL Execute Empty Yes

GS : Start/end macro definition Seldom Execute,

GS B Set reverse video on/off General Setting Yes Yes

GS C 0 Select counter print mode Counter Setting Yes Yes

GS C 1 Select count mode (A) Counter Setting Yes Yes

GS C 2 Set counter Counter Setting Yes Yes

GS C ; Select count mode (B) Counter Setting Yes Yes

GS E Select head control method Seldom Setting Yes Yes

GS H Select printing position of

HRI characters

GS I Transmit printer ID Status Execute Yes Yes

GS L Set left margin General Setting Start line Value

GS T Set print position to

beginning of line

GS V Select cut mode and cut

paper

GS W Set printing area width General Setting Start line Value

GS \ Set relative vertical printing

position

GS ^ Execute macro Seldom Execute Yes Yes

GS a Enable/disable Auto Status

Back (ASB)

GS b Turn smoothing mode on/off Setting Yes Yes

GS c Print counter Counter Execute Yes Yes

GS f Select font for HRI

characters

GS h Set bar code height Bar Code Setting Yes Yes

GS k Print bar code Bar Code Execute Empty Yes

General Setting Yes Yes

General Setting Yes Yes

NV & DL Execute Yes Disabl

ed

NV & DL Setting Start line Disabl

ed

PAGE Execute Ignored Yes

d

Start line Disabl

Setting

Seldom Setting Start line Value

Yes Yes

Setting

Bar Code Setting Yes Yes

General Execute Yes Ignore

General Execute Start line Yes

PAGE Execute Ignored Yes

Status Execute,

Setting

Bar Code Setting Yes Yes

Yes Yes

ed

d

MTP-1530II User Manual (Revision 20120510) Page 29

Page 30

Telpar MTP-1530II Receipt Thermal Printer User Manual

GS r Transmit status Status Execute Yes Yes

GS v 0 Print raster bit image

OBSOLETE – Useinstead

GS (L<Function 112 + 50>

GS w Set bar code width Bar Code Setting Yes Yes

GS (L,

GS 8 L

Control Codes and Control Sequences

Specify graphic data Graphics Setting

General Execute Empty Disabl

ed

Yes Yes

and

execute

MTP-1530II User Manual (Revision 20120510) Page 30

Page 31

Telpar MTP-1530II Receipt Thermal Printer User Manual

List of Control Codes and Control Sequece Locations

Control Codes Control Sequences

Bar Code See 4.4.3 Bar Code Commands page 35

Counter See 4.4.4 Counter Commands page 36

General See 4.4.1 General Usage Print Commands page31

NV & DL See 4.4.7 NV Memory and Down Load Bit Images

Commands page 41

Page See 4.4.6 Page Mode Commands page 38

Seldom See 4.4.8 Seldom Used Commands page43

Status See4.4.2 Status Commands page 35

Top of Form See 4.4.5 Top of Form Commands page 38

Disabled Parameters will be processed as normal data.

Empty Enabled only when at the beginning of a line.

Ignored Command code and parameters are ignored.

Start line Enabled only when there is no data in the print buffer

Yes Function is enabled.

List of Control Codes and Control SequencesLocations

4.4 Control Codes and Control Sequences Definition

4.4.1 General Usage Print Commands

General Usage Print Commands

Name Command

ASCII

Tab HT 09 Move the print position to the next

Line feed LF 0A Print data and feed paper. Default line

Form feed FF 0C See Top of Forms Commands.

CR CR 0D If parallel interface is selected and

Real-time

request to

printer

ESC ESC 1B ESC SequenceHeader

FS FS 1C FS SequenceHeader.

GS GS 1D GS Sequence Header.

Set right side

character

spacing

DLE ENQ+n10 05 +n +n=01hex, Recover from error and

ESC (SP)+n1B 20 +n Set spacing to the right of each

Comman

d (hex)

+n = data

byte[hex]

Description

horizontal tab position. Default is a TAB

position every 8 columns. SeeESC D.

spacing = 3.75mm. See ESC 2 and ESC

3

See Page Mode Commands.

automatic line feed is is enabled

(Memory Switch 1-5) then CR is treated

as LF. SeeLF.

restart printing from the line where the

error occurred. +n=02hex, Recover from

an error after clearing the receive and

print buffers.

character to n x 0.125 mm (n x 0.0049”).

Doubled for Double Wide. Does not

affect the Kanji character set. Set values

independently in Page and Normal

modes.

MTP-1530II User Manual (Revision 20120510) Page 31

Page 32

Telpar MTP-1530II Receipt Thermal Printer User Manual

Set Print mode

Set absolute

print position

Select Bit

Image mode

Turn underline

mode on/off

Set default line

spacing

Set Line feed

pitch

Printer reset ESC @ 1B 40 Resets the printer to the mode it was in

Set Horizontal

Tab positions

Turn

emphasized

mode on/off

Turn doublestrike mode

on/off

ESC ! +n 1B 21 +n

ESC $ +n+m1B 24 n m Current print position is set to (n + m x

ESC +m

+n1 +n2

+d1∼dn

ESC - +n 1B 2D +n n=0 (00 or 30 hex) Turn underline off.

ESC 2 1B 32 Set 3.75 mm line spacing (30 dot lines).

ESC 3 +n 1B 33 +n

ESC D

+d1∼dn

NUL

ESC E +n 1b 45 +n LSB = 0 Turn emphasized mode off.

ESC G +n 1B 47 +n LSB = 0 Turn double strike mode off.

1B 2A +m

+n1 +n2

(data)

1B 44

(DATA) 00

Set Print mode. See Section 4.5.1 - Set

Print Mode. See ESC M, ESC E, ESC -,

GS!.

256) x 0.125 mm from the beginning of

the line. SeeESC \, GS $, GS\. See

Page mode.

Set Bit Image mode. See 4.5.2. - Set Bit

Image Mode

n=1 (01 or 31 hex) Turn on 1 dot line

high underline. n=2 (02 or 32 hex) Turn

on 2 dot line high underline. See ESC !.

See ESC 3.

Set single line spacing to n dot lines (n x

0.125mm). Set independently in Page

and Normal mode. Default = 30. See

ESC 2.

when power was turned on. Clears the

data in the print buffer but does not the

data in the receive buffer. The DIP

switches and MEMORY switches are not

rechecked. The MACRO definition is not

cleared.

Set from 1 to 32 tab positions. Data

values range from 1 to 255 in ascending

order. If a data value is less than the

previous data value, this command is

terminated. NUL terminates this

command when less than 32 TAB

positions are being set. ESC D NUL

clears all tab positions. Default is every

8 columns.

LSB = 1 Turn emphasized mode on. See

ESC !.

LSB = 1 Turn double strike mode on.

Printout is the same as emphasized.

See ESC E.

MTP-1530II User Manual (Revision 20120510) Page 32

Page 33

Telpar MTP-1530II Receipt Thermal Printer User Manual

Name Command

ASCII

Forward

paper feed

for n dot

lines

Select

character

font

Select

International

character

set

Rotate print

Set relative

print position

Select

justification

Select paper

sensors to

output paper

end status

Select paper

sensor to

stop printing

Panel

buttons

enable/disab

le

Forward line

feed for n

character

lines

Select

Character

code table

Set/Reset

Inverted

print

Select GS ! +n 1D 21 +n Characters can be printed in sizes from

ESC J +n 1B 4A +n

ESC M +n 1B 4D +n n=0 (00 or 30 hex) selects FontA

ESC R +n 1B 52 +n

ESC V +n 1B 56 +n n = 1 (01 or 31 hex) Rotate the print 90

ESC \ +n +m 1B 5C n

ESC a +n 1B 61 n n=0 (0 or 30 hex) Left justify. n=1 (01

ESC c 3 +n 1B 63 33+nBit 1 enables or disables the paper low

ESC c 4 +n 1B 63 34+nSetting bit 0 or bit 1 high causes the

ESC c 5 +n 1B 63 35+nLSB = 0 Paper feed button is enabled.

ESC d +n 1B 64 +n

ESC t +n 1B 74 +n

ESC {+n

Command

+n = data

byte[hex]

Print if needed then feed paper n dot

lines. Range = 0 to 255dec. If BM is

enabled, this command can feed paper

past the mark.

(12x24). n=1 (01 or 31 hex) selects

FontB (9x17). See ESC !

Select international character set. See

Section Error! Reference source not

found. – Error! Reference source not

found. +++ reprint section

degrees clockwise. n = 0 (00 or 30 hex)

Cancel the rotation. Rotated characters

do not get underlined. Double wide

becomes double high and double high

becomes double wide. Not Page mode.

See ESC ! and ESC -.

Set printing to current print position +

m

1B 7B +n LSB = 1, upside-down printing. LSB =

(n+(m*256)). Ignored if specified

setting exceeds the printable area. See

Page mode.

or 31 hex) Center justify. n=2 (02 or 32

hex) Right justify. Normal mode only,

must be received at the start of a line.

See HT, ESC $, and ESC \.

sensor. Bit 3 enables or disables the

paper out sensor. A value of 1 enables

and a value of 0 disables. Applies to

the parallel interface ONLY.

Paper Low sensor to be used as a

Paper Out sensor.

LSB = 1 Paper feed button is disabled.

During a macro instruction standby the

feed button is always enabled but will

not feed paper.

Print if needed then feed paper n

character lines. Range= 0 to 255dec.

Maximum amount of paper fed = 1016

mm (40”). Can feed past marks in BM

mode.

See section 6.2 - Character Sets

0, normal printing. This command must

be received at the start of a line to be in

effect for that line. Does not apply in

page mode.

Description

MTP-1530II User Manual (Revision 20120510) Page 33

Page 34

Telpar MTP-1530II Receipt Thermal Printer User Manual

character

size

Test print GS ( A 02hex

00hex +n +m

Reverse

video

Set left

margin

Set print

position to

the

beginning of

print line

Cut

command

Set Right

Margin

Print raster

bit image

General Usage Print Commands

GS B +n 1D 42 +n Bit 0 = 0 (default) turns off and bit 0 = 1

GS L +n +m 1D 4C +n+mSet the left margin to dot position m x

GS T +n 1G 54 +n n=0 (either 00 or 30hex) sets the print

GS V m 1D 56 +m+nIf m = 1 (either 01hex or 31hex) a cut is

GS W +n +m

GS v 0 +m

+x1 +x2 +y1

+y2 +data

1 to 8 times normal in either width or

height. Bits 0, 1, and 2 set the

character width multiplier. Bits 4, 5,

and 6 set the character height

multiplier. A value of 0 = Normal size.

Does not apply to HRI characters when

printing bar codes. See ESC !.

1D 28 41

02 00 +n

+m

10 57 +n+mSets the print width to m x 256 + n

1D 76 30

m x1 x2

y1 y2 data

n = 0 or 1 or 2 (00, 01, 02, 30, 31, or

32 hex). m=1 (01 or 31 hex) causes a

Hexadecimal dump print pattern. ).

m=2 (02 or 32 hex) causes a Printer

Status print pattern. m=3 (03 or 33 hex)

causes a “barber pole” print pattern.

Must be received at the start of a line.

A cut is performed following the print

test. The printer is reset following the

print test, even download characters or

bit image are erased.

turns on reversevideo printing. Does

not apply to bit image, user-defined bit

image, bar codes and the HRI part of

bar codes, or spaces skipped by HT,

ESC $, or ESC \ commands. Does not

affect the space between character

lines. Underline does not apply while

reversevideo is enabled.

256+n. Must bereceived at the start of

a line. Does not apply in Pase mode.

See GS W.

position to the start of the print line

after deleting data in the print buffer.

n=1 (either 01 or 31hex) sets the print

position to the start of the print line

after printing data in the print buffer.

performed and the +n byte must not be

sent. If m is a capital B (42hex) then

paper is fed for n dot lines and then a

cut is performed.

relative to the left margin. Must be

received at the start of a line. See GS

L.

Error! Reference source not found.

OBSOLETE – Use

GS (L,<Function 112 + 50> instead

MTP-1530II User Manual (Revision 20120510) Page 34

Page 35

Telpar MTP-1530II Receipt Thermal Printer User Manual

4.4.2 Status Commands

Because some of the bits in the status responses are fixed, the user can

confirm the command to which the status belongs and differentiate the

status responses from XON/XOF as shown:

Response to Status Commands

Response to Bit Pattern

GS r 0 x x 0 x x x x

XON 0 0 0 1 0 0 0 1

XOF 0 0 0 1 0 0 1 1

DLE EOT 0 x x 1 x x 1 0

ASB (1stbyte) 0 x x 1 x x 0 0

ASB 2nd-4

Response to Status Commands

th

The transmit buffer is 99 bytes long. If more than 99 bytes are stored up

without being transmitted, the status bytes that have no place to be

stored will be thrown away.

Status Commands

Name Command

ASCII

Real-time STATUS

request

Transmit printer ID GS I +n 1D 49 +n See section 4.4.5

Enable/disable

Automatic Status

Back (ASB)

Status Commands

DLE EOT+n10 04 +n See section 4.4.5

GS a +n 1D 61 +n See section 4.4.5

Command+n =

data byte[hex]

0 x x 0 x x x x

Description

4.4.3 Bar Code Commands

Bar Code Commands

Name Command

ASCII

Select print

position for HRI

characters

Select font for HRI GS f +n 1D 66 +n n = 0 (either 00hexor 30hex),

Set Bar code

GS H n 1D 48 +n n = 0 (either 00hex or 30hex),

GS h +n 1D 68 +n

Command

+n = data

byte[hex]

Description

no HRI printed. n = 1 (either

01hex or 31hex), HRI printed

above the bar code. . n = 2

(either 02hex or 32hex), HRI

printed below the bar code. n

= 3 (either 03hex or 33hex),

HRI printed both above and

below the bar code. The font

used is specified by GS f.

Default = 0.

print the HRI using FontA

(12x24). n = 1 (either 01hexor

31hex), print the HRI using

FontB (9x17). Default = 0.

Set the bar code height in

MTP-1530II User Manual (Revision 20120510) Page 35

Page 36

Telpar MTP-1530II Receipt Thermal Printer User Manual

height dots. Default = 162. Range= 1

Print bar code GS k +n

(data+ NUL

Set bar code width GS w +n 1D 77 +n n defines the width of lines

Bar Code Commands

1D 6B +n (data)00Selects the bar codetype and

4.4.4 Counter Commands

Counter Commands

Name Command

ASCII

Select

counter print

mode

Select count

mode (A)

Set counter GS C 2 +n1

GS C 0 +n

+m

GS C 1 +n1

+n2 +m1

+m2 +n +r

+n2

Command

+n = data

byte[hex]

1D 43 30 +n+mn = 00 hex, prints the actual digits

indicated by the number value. n =

01 hex through 05 hex sets the

number of digits to be printed. m=0

(either 00 hex or 30 hex), align right

with leading spaces. m=1 (either 01

hex or 31 hex), align right with

leading zero. m=2 (either 02 hex or

32 hex), align left with trailing

spaces. If n = 0 then m has no

meaning. Default is n=m=0.

1D 43 32 +n1

+n2 +m1

+m2 +n +r

1D 43 32 +n1

+n2

n1+n2*256 = start count.

m1+m2*256 = end count. n = step

amount. r = the repetition number

when the counter value is fixed.

Count up mode is set when

n1+n2*256 < m1+m2*256 and n and

r are not =0. Count down mode is set

when n1+n2*256 > m1+m2*256 and

n and r are not =0. Counting stops

when n1+n2*256 = m1+m2*256 and

n and r are not =0. n = the amount to

increment the count by. R = the

repetition number when counter

value is fixed.

n1+n2*256 sets the value of the

serial number counter. In count-up

mode; if the counter value goes

outside the counter operation range

set by GS C 1 or GS C ;, it is forced

to convert to the minimum value set

by GS c. In count-down mode; if the

counter value goes outside the

counter operation range set by GS C

to 255dec.

prints. See Section 4.5.8 - Bar

Code Command.

used for printing bar codes in

mm. For codes Code39, ITF,

and CODABAR: n=2, 0.250 &

0.625. n=3, 0.375 & 1.000.

n=4, 0.500 & 1.250. n=5,

0.625 & 1.625. n=6, 0.750 &

2.000. For codes UPC-A,

UPC-E, JAN13, JAN8,

Code93, and CODE128; the

smaller number listed above =

the Modulo Width. Default = 3.

Description

MTP-1530II User Manual (Revision 20120510) Page 36

Page 37

Telpar MTP-1530II Receipt Thermal Printer User Manual

1 or GS C ;, it is forced to convert to

the maximum value set by GS c.

Select count

mode (B)

Print counter GS c 1D 63 Sets the serial counter value in the

Counter Commands

GS C ; s1 ;

s2 ; s3 ; s4 ;

s5 ;

1D 43 3B s1

3B s2 3B s3

3B s4 3B s5

s1 through s5 are all character

strings made up of the ASCII

characters 0 through 9. s1 and s2

range from 0 to 65535 and s3

through s5 range from 0 to 255. s1

and s2 specify the counter range. s3

= the amount to increment the count

by. S4 = the repetition number when

the counter value is fixed. s5 = the

counter value. Count-up mode is

selected by s1 < s2 and s3 and s4

are not =0. . Count-down mode is

selected by s1 > s2 and s3 and s4

are not =0. Counting stops when s1

= s2 or s3 = 0 or s4 = 0.

print buffer and increments or

decrements the counter value based

on the count mode selected by GS C

0 and either GS C 1 or GS C ;. In

count up mode the counter value is

set to the minimum value if it goes

out of the range set by GS C 1 or GS

C ;. In count down mode the counter

value is set to the maximum value if

it goes out of the range set by GS C

1 or GS C ;.

MTP-1530II User Manual (Revision 20120510) Page 37

Page 38

Telpar MTP-1530II Receipt Thermal Printer User Manual

4.4.5 Top of Form Commands

Top of Form Commands

Name Command

ASCII

Form feed FF 0C Print if needed then feed paper to the

Feedto

Black Mark

Top of Form Commands

GS FF 1D 0C Feed paper to the next Black Mark

Command

+n = data

byte[hex]

Description

next Black Mark if the BM sensor is

enabled. See GS ( F, GS FF, and

DSW1 position 1).

position. Ignored unless enabled by

Dip SW 1 position 1. See GS ( F, FF)

and Dip Switch settings.

For additional information black mark sensing, see Section 2.2.2 Black

Mark Sensors Load.

4.4.6 Page Mode Commands

Bar Code Commands

Name Command

ASCII

Form feed FF 0C Print and return to standard mode.

CAN CAN 18 Cancel print data in page mode. See

Print data in

Page mode

Set absolute

print position

Select Page

mode

ESC FF 1B 0C Prints all buffered data in the printing

ESC $ +n +m 1B 24 n m In Page mode with the starting

ESC L 1B 4C Must be received at the start of a

Command

+n = data

byte[hex]

Description

Printed data is cleared from the data

buffer. The printing area set by ESC

W is reset to the default setting. See

ESC FF, ESC L, and ESC S

ESC L and ESC W.

area. Printed data is not cleared from

the data buffer. ESC T and ESC W

values are not cleared. See FF, ESC

L, and ESC S.

position (See ESC T) set to the top

left corner or the bottom right corner

this is a horizontal position but with

the starting position set to the top

right corner or the bottom left corner

this is a vertical position. See ESC \,

GS $, GS\.

line. Settings of ESC SP, ESC 2,

ESC 3 have independent values in

page mode and standard mode. ESC