Page 1

Mod.0818 2017-01 Rev.0

NE866B1

HW Design Guide

1VV0301354 Rev. 6 – 2018-02-28

Page 2

NE866B1_Hardware_Design_Guide

1VV0301354 Rev. 6 Page 2 of 70 2018-02-28

SPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE

NOTICE

While reasonable efforts have been made to assure the accuracy of this document, Telit

assumes no liability resulting from any inaccuracies or omissions in this document, or from

use of the information obtained herein. The information in this document has been carefully

checked and is believed to be reliable. However, no responsibility is assumed for

inaccuracies or omissions. Telit reserves the right to make changes to any products

described herein and reserves the right to revise this document and to make changes from

time to time in content hereof with no obligation to notify any person of revisions or changes.

Telit does not assume any liability arising out of the application or use of any product,

software, or circuit described herein; neither does it convey license under its patent rights

or the rights of others.

It is possible that this publication may contain references to, or information about Telit

products (machines and programs), programming, or services that are not announced in

your country. Such references or information must not be construed to mean that Telit

intends to announce such Telit products, programming, or services in your country.

COPYRIGHTS

This instruction manual and the Telit products described in this instruction manual may be,

include or describe copyrighted Telit material, such as computer programs stored in

semiconductor memories or other media. Laws in the Italy and other countries preserve for

Telit and its licensors certain exclusive rights for copyrighted material, including the

exclusive right to copy, reproduce in any form, distribute and make derivative works of the

copyrighted material. Accordingly, any copyrighted material of Telit and its licensors

contained herein or in the Telit products described in this instruction manual may not be

copied, reproduced, distributed, merged or modified in any manner without the express

written permission of Telit. Furthermore, the purchase of Telit products shall not be deemed

to grant either directly or by implication, estoppel, or otherwise, any license under the

copyrights, patents or patent applications of Telit, as arises by operation of law in the sale

of a product.

COMPUTER SOFTWARE COPYRIGHTS

The Telit and 3rd Party supplied Software (SW) products described in this instruction

manual may include copyrighted Telit and other 3rd Party supplied computer programs

stored in semiconductor memories or other media. Laws in the Italy and other countries

preserve for Telit and other 3rd Party supplied SW certain exclusive rights for copyrighted

computer programs, including the exclusive right to copy or reproduce in any form the

copyrighted computer program. Accordingly, any copyrighted Telit or other 3rd Party

supplied SW computer programs contained in the Telit products described in this instruction

manual may not be copied (reverse engineered) or reproduced in any manner without the

express written permission of Telit or the 3rd Party SW supplier. Furthermore, the purchase

of Telit products shall not be deemed to grant either directly or by implication, estoppel, or

otherwise, any license under the copyrights, patents or patent applications of Telit or other

3rd Party supplied SW, except for the normal non-exclusive, royalty free license to use that

arises by operation of law in the sale of a product.

Page 3

NE866B1_Hardware_Design_Guide

1VV0301354 Rev. 6 Page 3 of 70 2018-02-28

USAGE AND DISCLOSURE RESTRICTIONS

I. License Agreements

The software described in this document is the property of Telit and its licensors. It is

furnished by express license agreement only and may be used only in accordance with the

terms of such an agreement.

II. Copyrighted Materials

Software and documentation are copyrighted materials. Making unauthorized copies is

prohibited by law. No part of the software or documentation may be reproduced,

transmitted, transcribed, stored in a retrieval system, or translated into any language or

computer language, in any form or by any means, without prior written permission of Telit

III. High Risk Materials

Components, units, or third-party products used in the product described herein are NOT

fault-tolerant and are NOT designed, manufactured, or intended for use as on-line control

equipment in the following hazardous environments requiring fail-safe controls: the

operation of Nuclear Facilities, Aircraft Navigation or Aircraft Communication Systems, Air

Traffic Control, Life Support, or Weapons Systems (High Risk Activities"). Telit and its

supplier(s) specifically disclaim any expressed or implied warranty of fitness for such High

Risk Activities.

IV. Trademarks

TELIT and the Stylized T Logo are registered in Trademark Office. All other product or

service names are the property of their respective owners.

V. Third Party Rights

The software may include Third Party Right software. In this case you agree to comply with

all terms and conditions imposed on you in respect of such separate software. In addition

to Third Party Terms, the disclaimer of warranty and limitation of liability provisions in this

License shall apply to the Third Party Right software.

TELIT HEREBY DISCLAIMS ANY AND ALL WARRANTIES EXPRESS OR IMPLIED

FROM ANY THIRD PARTIES REGARDING ANY SEPARATE FILES, ANY THIRD PARTY

MATERIALS INCLUDED IN THE SOFTWARE, ANY THIRD PARTY MATERIALS FROM

WHICH THE SOFTWARE IS DERIVED (COLLECTIVELY “OTHER CODE”), AND THE

USE OF ANY OR ALL THE OTHER CODE IN CONNECTION WITH THE SOFTWARE,

INCLUDING (WITHOUT LIMITATION) ANY WARRANTIES OF SATISFACTORY

QUALITY OR FITNESS FOR A PARTICULAR PURPOSE.

NO THIRD PARTY LICENSORS OF OTHER CODE SHALL HAVE ANY LIABILITY FOR

ANY DIRECT, INDIRECT, INCIDENTAL, SPECIAL, EXEMPLARY, OR CONSEQUENTIAL

DAMAGES (INCLUDING WITHOUT LIMITATION LOST PROFITS), HOWEVER CAUSED

AND WHETHER MADE UNDER CONTRACT, TORT OR OTHER LEGAL THEORY,

ARISING IN ANY WAY OUT OF THE USE OR DISTRIBUTION OF THE OTHER CODE

OR THE EXERCISE OF ANY RIGHTS GRANTED UNDER EITHER OR BOTH THIS

LICENSE AND THE LEGAL TERMS APPLICABLE TO ANY SEPARATE FILES, EVEN IF

ADVISED OF THE POSSIBILITY OF SUCH DAMAGES.

Page 4

NE866B1_Hardware_Design_Guide

1VV0301354 Rev. 6 Page 4 of 70 2018-02-28

APPLICABILITY TABLE

PRODUCTS

NE866B1-E1

Page 5

NE866B1_Hardware_Design_Guide

1VV0301354 Rev. 6 Page 5 of 70 2018-02-28

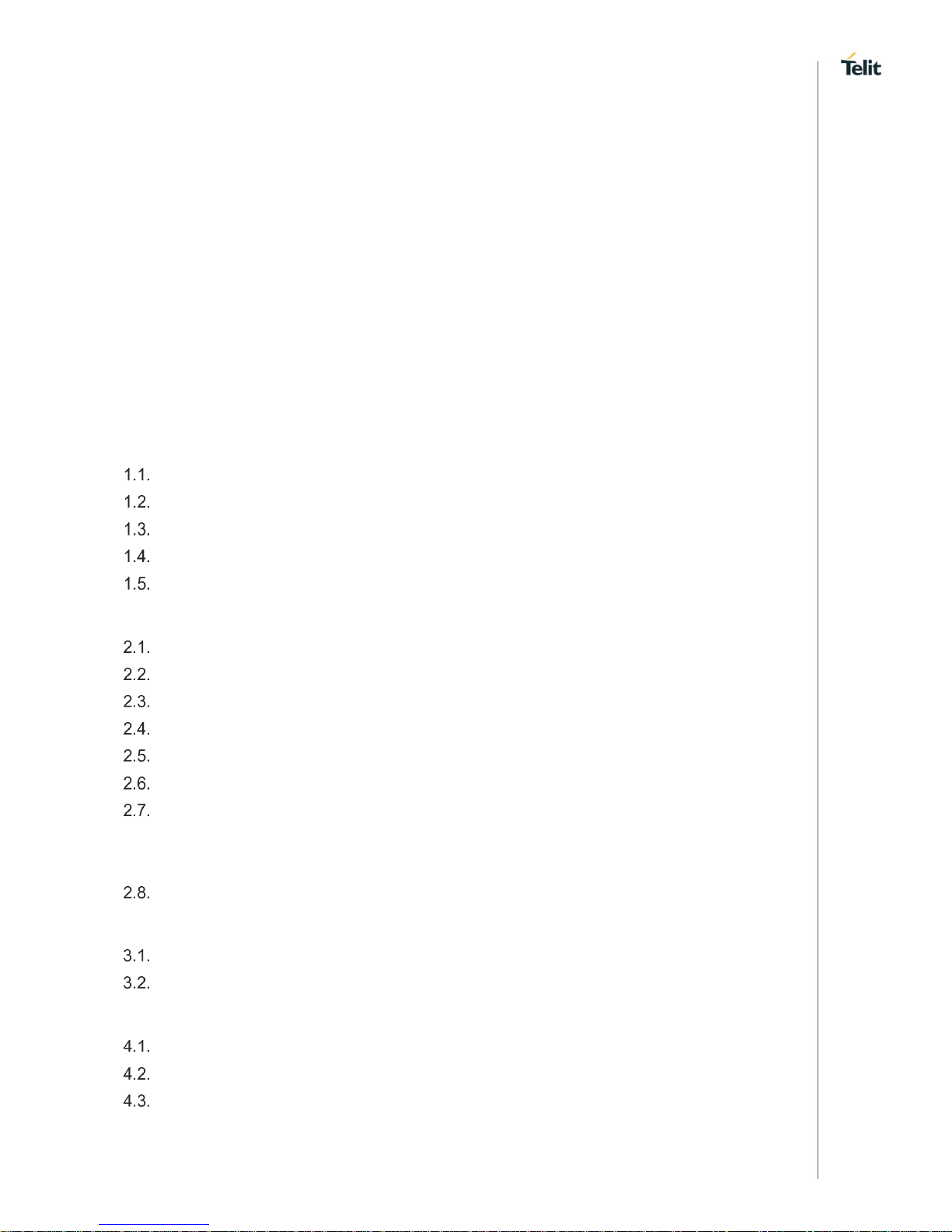

Contents

NOTICE 2

COPYRIGHTS ................................................................................................ 2

COMPUTER SOFTWARE COPYRIGHTS ...................................................... 2

USAGE AND DISCLOSURE RESTRICTIONS ............................................... 3

APPLICABILITY TABLE ................................................................................ 4

CONTENTS .................................................................................................... 5

1. INTRODUCTION .......................................................................... 8

Scope ........................................................................................... 8

Audience....................................................................................... 8

Contact Information, Support ........................................................ 8

Text Conventions .......................................................................... 9

Related Documents .................................................................... 10

2. GENERAL PRODUCT DESCRIPTION ...................................... 11

Overview..................................................................................... 11

Product Variants and Frequency Bands ...................................... 11

Target market ................................................................ ............. 12

Main features .............................................................................. 12

TX Output Power ........................................................................ 13

RX Sensitivity ............................................................................. 13

Mechanical specifications ........................................................... 13

2.7.1. Dimensions ................................ ................................................. 13

2.7.2. Weight ................................ ........................................................ 13

Temperature range ..................................................................... 14

3. PINS ALLOCATION ................................................................... 15

Pin-out ........................................................................................ 15

LGA Pads Layout ........................................................................ 20

4. POWER SUPPLY ....................................................................... 21

Power Supply Requirements ....................................................... 21

Power Consumption ................................................................... 22

General Design Rules ................................................................. 23

4.3.1. Electrical Design Guidelines ....................................................... 23

Page 6

NE866B1_Hardware_Design_Guide

1VV0301354 Rev. 6 Page 6 of 70 2018-02-28

4.3.1.1. +5V Source Power Supply Design Guidelines ............................ 23

4.3.1.2. +12V Source Power Supply Design Guidelines .......................... 24

4.3.1.3. Battery Source Power Supply Design Guidelines ........................ 25

4.3.2. Thermal Design Guidelines ......................................................... 26

4.3.3. Power Supply PCB layout Guidelines ......................................... 27

VAUX/PWRMON Power Output .................................................. 28

3GPP Power Saving Mode (PSM) .............................................. 29

4.5.1. LP_WAKE design guide .............................................................. 30

5. DIGITAL SECTION .................................................................... 31

Logic Levels ................................................................................ 31

Power On.................................................................................... 32

Unconditional Restart.................................................................. 34

Power OFF procedure ................................................................ 37

Communication ports .................................................................. 38

5.5.1. Serial Ports ................................................................................. 38

5.5.1.1. MODEM SERIAL PORT 1 .......................................................... 38

5.5.1.2. MODEM SERIAL PORT 2 .......................................................... 40

5.5.1.3. RS232 LEVEL TRANSLATION ................................................... 40

General purpose I/O ................................................................... 42

5.6.1. Using a GPIO as an INPUT ........................................................ 43

5.6.2. Using a GPIO as an OUTPUT .................................................... 43

I2C Port ...................................................................................... 44

SIM Interface .............................................................................. 44

5.8.1. SIMIN Detection .......................................................................... 44

ADC Converter ........................................................................... 44

6. RF SECTION .............................................................................. 45

Bands Variants ........................................................................... 45

TX Output power ......................................................................... 45

RX Sensitivity ............................................................................. 45

RED requirements ...................................................................... 45

Antenna requirements................................................................. 46

6.5.1. Main Antenna ............................................................................. 46

6.5.2. PCB design guidelines ................................................................ 47

6.5.3. Antenna installation Guidelines ................................................... 48

7. MECHANICAL DESIGN ............................................................. 49

Mechanical Dimensions .............................................................. 49

Page 7

NE866B1_Hardware_Design_Guide

1VV0301354 Rev. 6 Page 7 of 70 2018-02-28

7.1.1. Mechanical Drawing ................................................................... 49

7.1.2. Top View..................................................................................... 49

7.1.3. Bottom View (as seen from bottom side)..................................... 50

7.1.4. Side View.................................................................................... 51

8. APPLICATION PCB DESIGN ................................ .................... 52

Recommended footprint for the application ................................. 52

PCB pad design .......................................................................... 53

PCB pad dimensions .................................................................. 54

Stencil ......................................................................................... 55

Solder paste ............................................................................... 55

NE866B1 Solder reflow ............................................................... 56

9. PACKING SYSTEM ................................................................... 57

Tray ............................................................................................ 57

Tray Drawing .............................................................................. 59

Tape & Reel ................................................................................ 60

Carrier Tape Drawing.................................................................. 61

Moisture sensitivity ..................................................................... 61

10. CONFORMITY ASSESSMENT ISSUES .................................... 62

Declaration of Conformity ........................................................... 62

11. SAFETY RECOMMENDATIONS................................................ 63

READ CAREFULLY .................................................................... 63

12. REFERENCE TABLE OF RF BANDS CHARACTERISTICS ..... 64

13. ACRONYMS ............................................................................... 67

14. DOCUMENT HISTORY .............................................................. 69

Page 8

NE866B1_Hardware_Design_Guide

1VV0301354 Rev. 6 Page 8 of 70 2018-02-28

1. INTRODUCTION

Scope

This document introduces the Telit NE866B1 module and presents possible and

recommended hardware solutions for developing a product based on this module. All the

features and solutions detailed in this document are applicable to all NE866B1 variants,

where NE866B1 refers to the variants listed in the applicability table.

Obviously, this document cannot embrace every hardware solution or every product that

can be designed. Where the suggested hardware configurations need not be considered

mandatory, the information given should be used as a guide and a starting point for properly

developing your product with the Telit module.

Audience

This document is intended for Telit customers, especially system integrators, about to

implement their applications using the Telit module.

Contact Information, Support

For general contact, technical support services, technical questions and report

documentation errors contact Telit Technical Support at:

• TS-EMEA@telit.com

• TS-AMERICAS@telit.com

• TS-APAC@telit.com

• TS-SRD@telit.com

Alternatively, use:

http://www.telit.com/support

For detailed information about where you can buy the Telit modules or for recommendations

on accessories and components visit:

http://www.telit.com

Our aim is to make this guide as helpful as possible. Keep us informed of your comments

and suggestions for improvements.

Telit appreciates feedback from the users of our information.

Page 9

NE866B1_Hardware_Design_Guide

1VV0301354 Rev. 6 Page 9 of 70 2018-02-28

Text Conventions

Danger – This information MUST be followed or catastrophic

equipment failure or bodily injury may occur.

Caution or Warning – Alerts the user to important points about

integrating the module, if these points are not followed, the module and

end user equipment may fail or malfunction.

Tip or Information – Provides advice and suggestions that may be

useful when integrating the module.

All dates are in ISO 8601 format, i.e. YYYY-MM-DD.

Page 10

NE866B1_Hardware_Design_Guide

1VV0301354 Rev. 6 Page 10 of 70 2018-02-28

Related Documents

• SIM INTEGRATION DESIGN GUIDE 80000NT10001A

• NE866B1_NL865B1_AT_Commands_Reference_Guide 80534ST10817A

• Telit EVB User Guide 1VV0301249

• xE866_IFBD_HW_USER_GUIDE 1VV0301368

Page 11

NE866B1_Hardware_Design_Guide

1VV0301354 Rev. 6 Page 11 of 70 2018-02-28

2. GENERAL PRODUCT DESCRIPTION

Overview

The NE866B1 is the first Category NB1 - aka Narrowband IoT (NB-IoT) - product in the Telit

portfolio. Specified in the Release 13 of the 3GPP standard, Cat NB1 devices are

specifically tailored for IoT applications, offering optimized power consumption and

enhanced coverage. In addition, with its ultra compact 15 x 19 mm LGA footprint, the

NE866B1 is designed for size sensitive applications.

This next generation of products supports the new features specified by 3GPP to boost IoT

applications, such as the Power Saving Mode (PSM) and the extended Discontinuous

Reception (eDRX), which allow the devices to wake up periodically to deliver only very small

amounts of data to the network and then go back to sleep for most of the time, thus allowing

longer battery operation. Enhanced coverage, with up to +20dB in maximum coupling loss

(MCL) compared to the other cellular technologies, is also one of the key benefits of this

new LTE flavor. LTE Cat NB1 devices are therefore optimized in cost, size and power

consumption compared to higher UE categories. These advantages make the NE866B1 the

perfect platform to enable a quick implementation of LTE technology in IoT/M2M where low

cost and low power are more relevant than high speed.

The NE866B1 helps increase the addressable market for LTE technology to include a broad

range of new applications and use cases best served with lower maximum data rate, ultralow power, reduced complexity and cost. Some examples are smart metering, smart

parking, smart agriculture, waste collection, industrial sensors, healthcare monitors, home

automation, and many more low data rate IoT devices. The NE866B1 is offered in a dualband configuration for deployment in the European and Chinese NB-IoT networks, either in

in-band, guard-band or standalone mode; additional regional variants will follow. It is highly

recommended for new designs, but also in particular as a migration path for existing GPRS

devices, both new and updated designs benefit from a significant extension in lifecycle with

LTE Cat NB1.

The NE866B1 supports embedded SIM chip as a mounting option, making it the ideal

solution for durable and rugged designs, and reducing BOM cost and size on the customer’s

application.

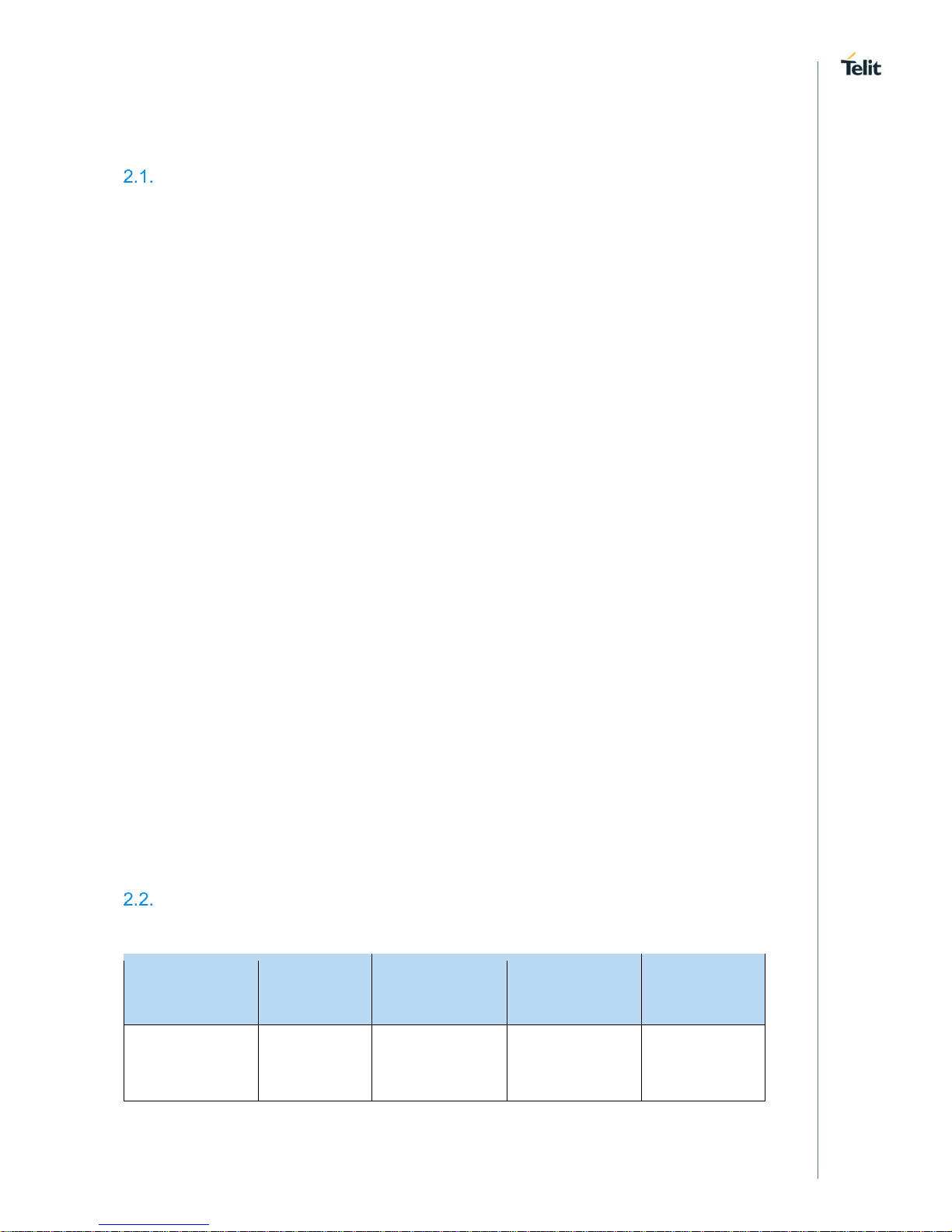

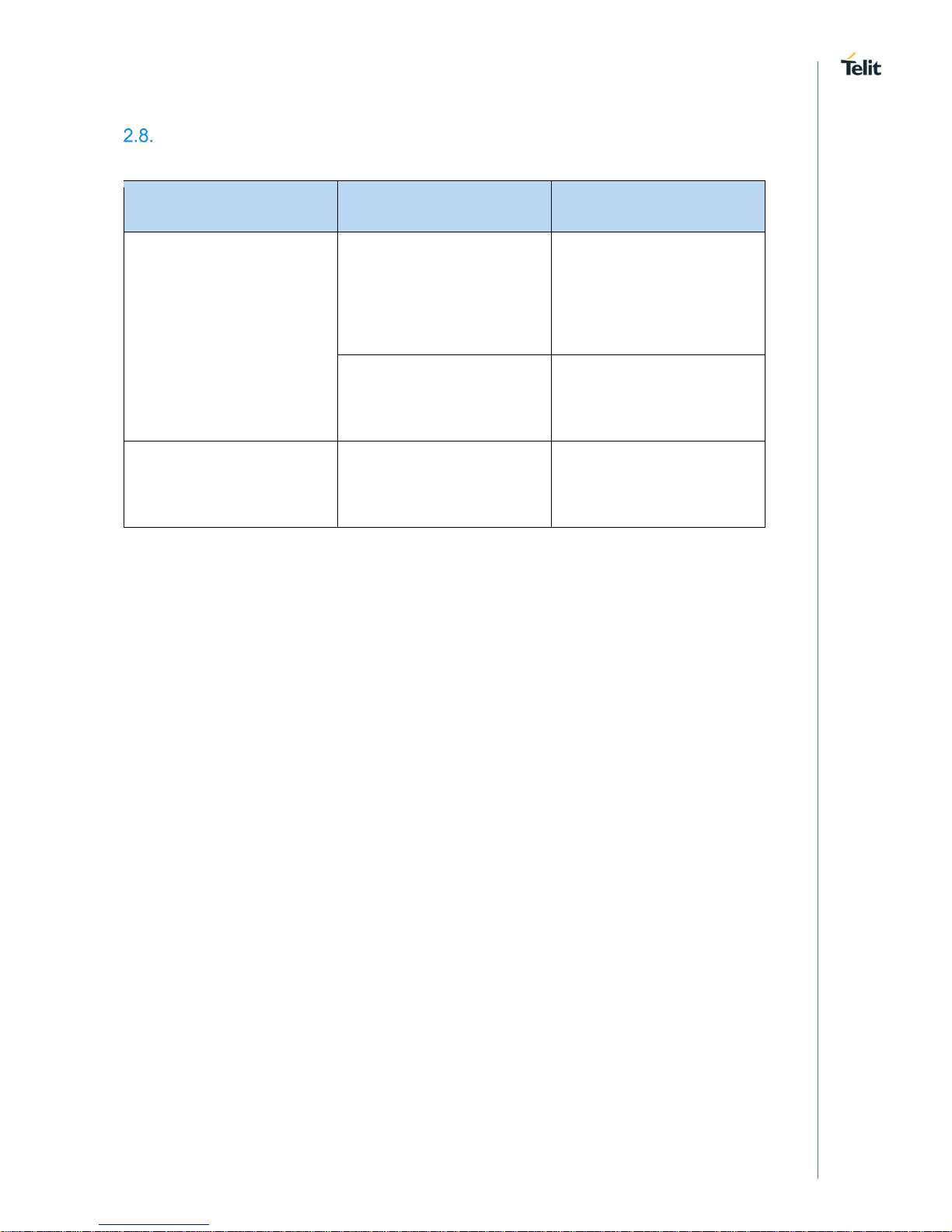

Product Variants and Frequency Bands

NE866B1 bands combinations are listed below:

Product

2G Band

(MHz)

3G Band

(MHz)

4G Band

(MHz)

Region

NE866B1-E1

B20 (800)

B8 (900)

Europe

Refer to Chapter 13 for details information about frequencies and bands.

Page 12

NE866B1_Hardware_Design_Guide

1VV0301354 Rev. 6 Page 12 of 70 2018-02-28

Target market

NE866B1 can be used for IoT applications, where low power consumption and enhanced

coverage are required rather than high speed data, for example:

• Smart metering

• Smart parking

• Smart agriculture

• Waste collection

• Industrial sensors

• Healthcare monitors

• Home automation

Main features

Function

Features

Modem

• NB-IoT cellular modem for low BW data communication

• Real Time Clock

• Internal IP stack

Interfaces

• Main UART for AT commands

• Auxiliary UART

• I2C

• SPI

• GPIOs

• ADC

• Antenna ports

Page 13

NE866B1_Hardware_Design_Guide

1VV0301354 Rev. 6 Page 13 of 70 2018-02-28

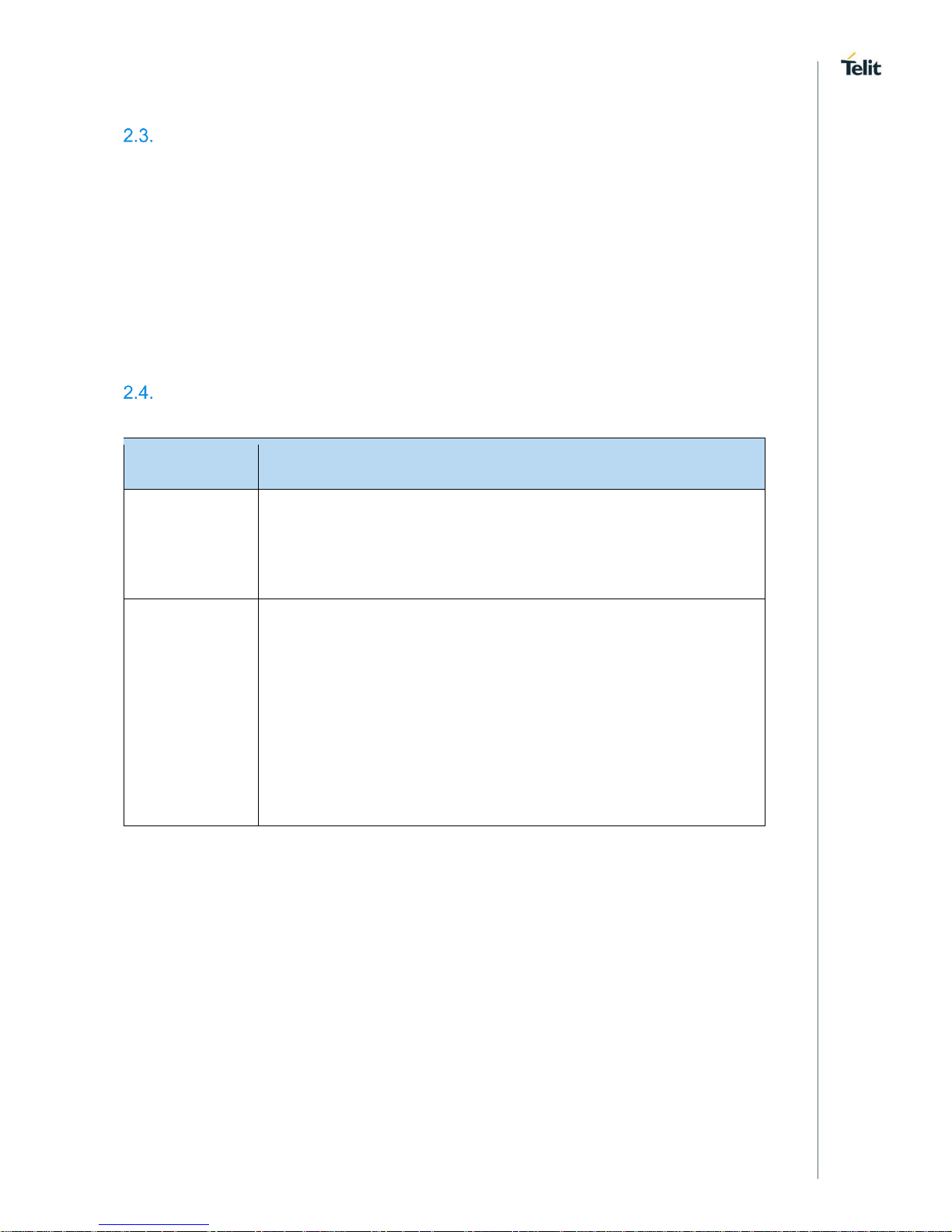

TX Output Power

Band

Power class

LTE All Bands

Class 3 (23dBm)

RX Sensitivity

Product

Band

Sensitivity (dBm)

NE866-B1-E1

B8, B20

-113

Mechanical specifications

2.7.1. Dimensions

The overall dimensions of NE866 family are:

Length: 19 mm

Width: 15 mm

Thickness: 2.2 mm

2.7.2. Weight

The nominal weight of the module is 1.5 grams.

Page 14

NE866B1_Hardware_Design_Guide

1VV0301354 Rev. 6 Page 14 of 70 2018-02-28

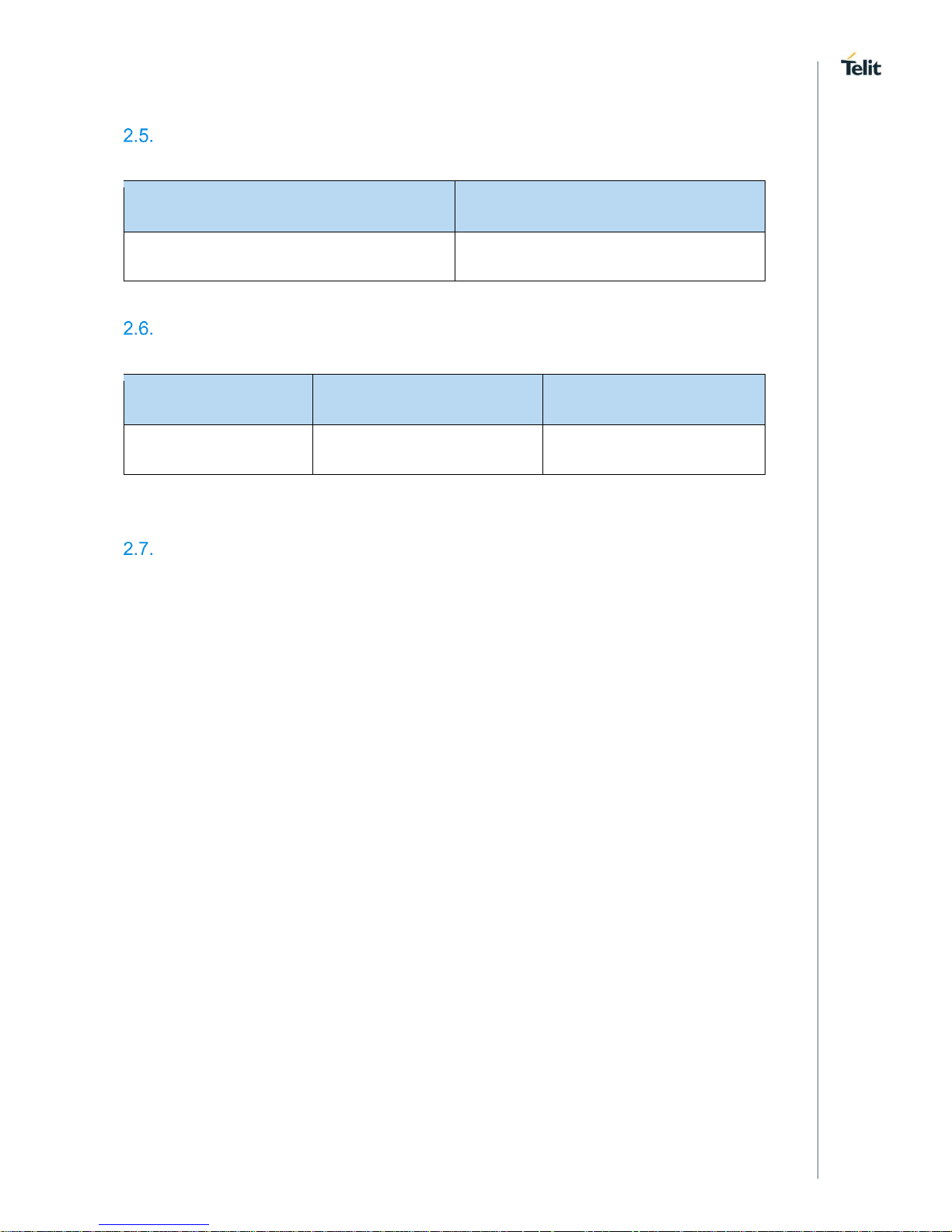

Temperature range

Case

Range

Note

Operating Temperature

Range

–20°C ÷ +55°C

The module is fully

functional(*) in all the

temperature range, and it

fully meets the 3GPP

specifications.

–40°C ÷ +85°C

The module is fully

functional (*) in all the

temperature range.

Storage and non-

operating Temperature

Range

–40°C ÷ +85°C

(*) Functional: the module is able to make and receive data calls and SMS.

Page 15

NE866B1_Hardware_Design_Guide

1VV0301354 Rev. 6 Page 15 of 70 2018-02-28

3. PINS ALLOCATION

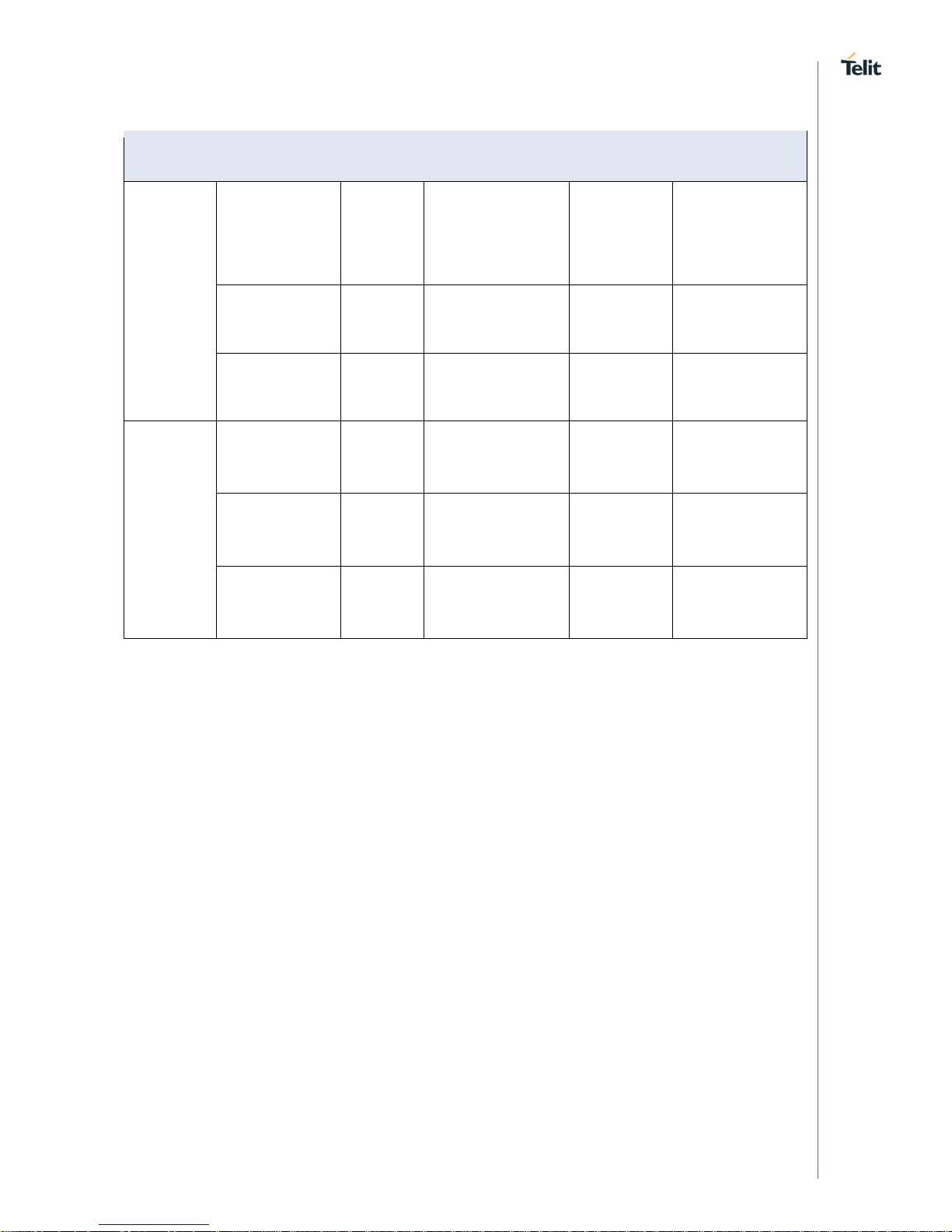

Pin-out

Pin

Signal

I/O

Function

Type

Comment

Asynchronous Serial Port - Prog. / Data / SPI / I2C / GPIO

A4

TXD

I

Serial data input

from DTE

CMOS 1.8V

A5

RXD

O

Serial data output

to DTE

CMOS 1.8V

B1

GPIO1

I/O

GPIO

CMOS 1.8V

Default

function

SPI_CS

O

SPI External CS

CMOS 1.8V

Alternate

Function

I2C_SDA

I/O

I2C Data

CMOS 1.8V

Alternate

Function

A1

SPI_CLK

O

SPI Clock

CMOS 1.8V

Page 16

NE866B1_Hardware_Design_Guide

1VV0301354 Rev. 6 Page 16 of 70 2018-02-28

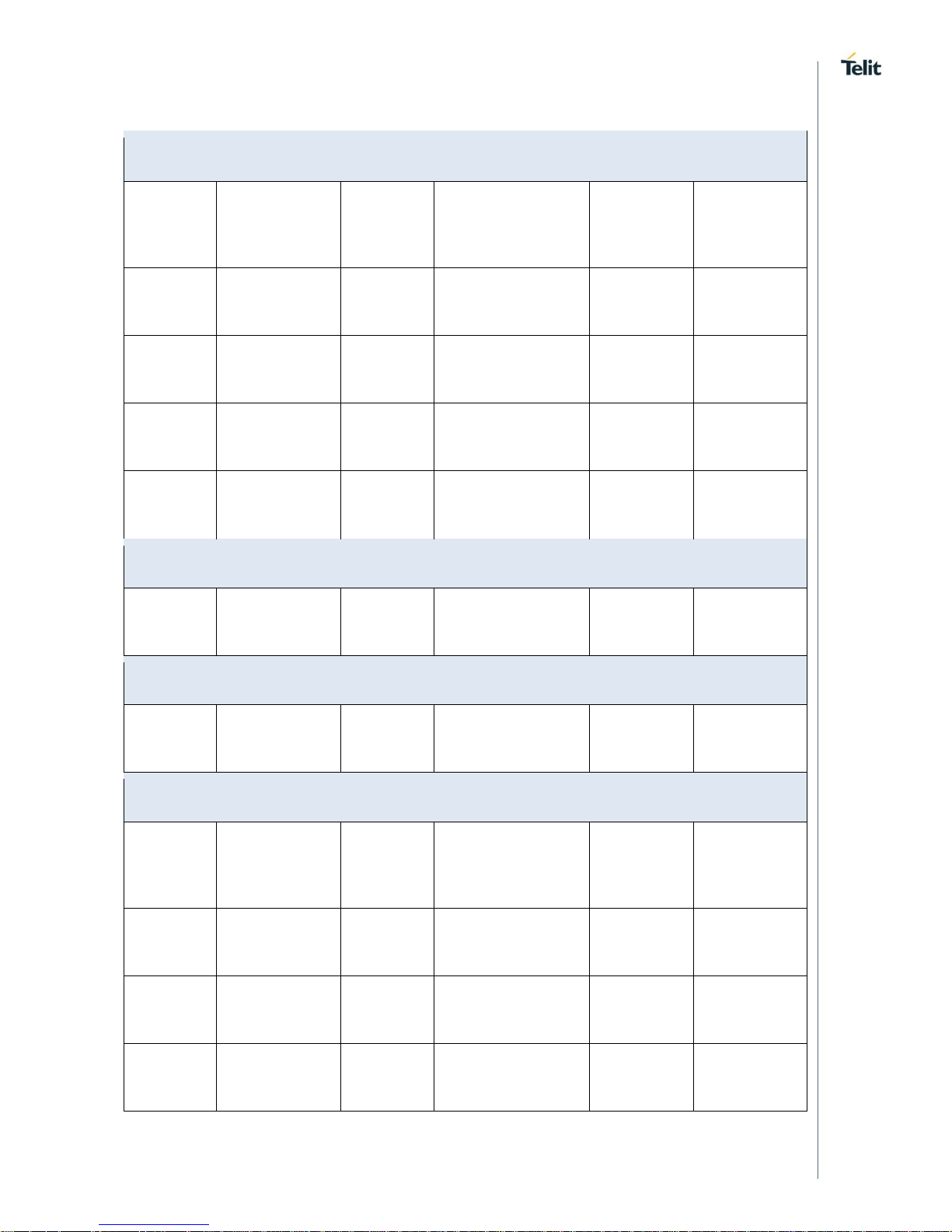

Asynchronous Auxiliary Serial Port 2 / SPI / I2C / GPIO

C1

TX_AUX

O

Auxiliary UART

(TX Data to DTE)

CMOS 1.8V

Primary Logging

Port

Default Function

SPI_MOSI

O

SPI Master Data

Out

CMOS 1.8V

Alternate

Function

GPIO2

I/O

GPIO

CMOS 1.8V

Alternate

Function

C2

GPIO3

I/O

GPIO

CMOS 1.8V

Default Function

SPI_MISO

I

SPI Master Data

In

CMOS 1.8V

Alternate

Function

I2C_SCL

I/O

I2C Clock

CMOS 1.8V

Alternate

Function

Page 17

NE866B1_Hardware_Design_Guide

1VV0301354 Rev. 6 Page 17 of 70 2018-02-28

SIM card interface

C7

SIMVCC

-

External SIM signal

– Power supply for

the SIM

1.8V Only

See next

chapters

B7

SIMRST

O

External SIM signal

– Reset

CMOS 1.8

A7

SIMCLK

O

External SIM signal

– Clock

CMOS 1.8

A6

SIMIO

I/O

External SIM– Data

I/O

CMOS 1.8

B5

SIMIN

I

SIM Presence

input

CMOS 1.8

See next

chapters

ADC

F4

ADC_IN1

AI

Analog/Digital

converter input

A/D

RF Section

G2

ANT

I/O

LTE Main Antenna

(50 ohm)

RF

Miscellaneous Functions

G4

RESET*

I

Reset Input

VBATT

Pull up to

VBATT

(10Kohm)

G5

SLP_IND

O

Modem Sleep or

PSM Indication

CMOS 1.8

Do not Drive

this pad

G6

VAUX/POWE

RMON

O

1.8V stabilized

output

Power

D3

LP_WAKE

I

LPM / PSM Wake

Up

Analog

Page 18

NE866B1_Hardware_Design_Guide

1VV0301354 Rev. 6 Page 18 of 70 2018-02-28

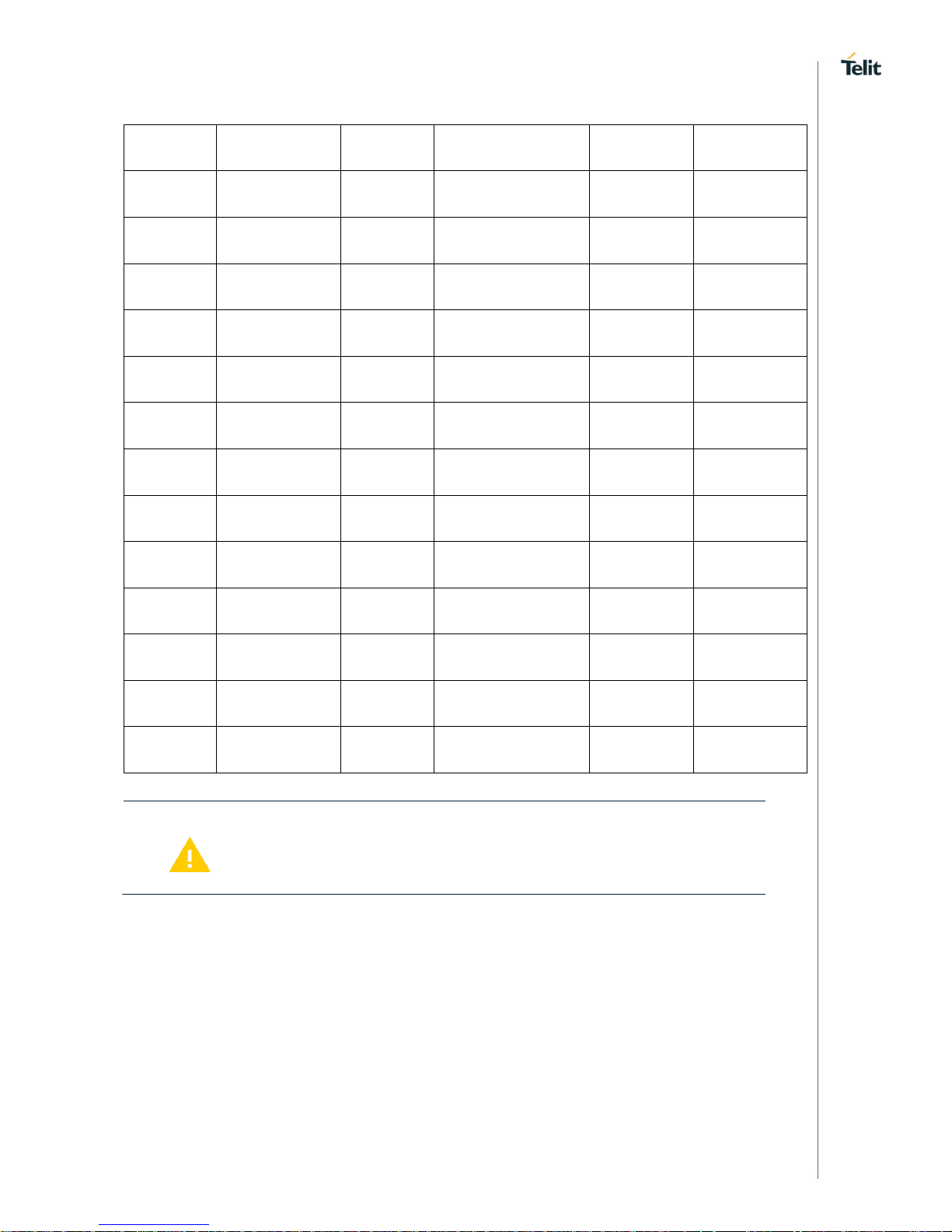

Power Supply

E1

VBATT

-

Main power supply

(Baseband)

Power

E2

VBATT

-

Main power supply

(Baseband)

Power

D1

GND

-

Ground

Power

F1

GND

-

Ground

Power

G1

GND

-

Ground

Power

D2

GND

-

Ground

Power

F2

GND

-

Ground

Power

C3

GND

-

Ground

Power

E3

GND

-

Ground

Power

F3

GND

-

Ground

Power

G3

GND

-

Ground

Power

F6

GND

-

Ground

Power

Reserved pins

A2

RESERVED

-

RESERVED

A3

RESERVED

-

RESERVED

B2

RESERVED

-

RESERVED

B3

RESERVED

-

RESERVED

B4

RESERVED

-

RESERVED

B6

RESERVED

-

RESERVED

Page 19

NE866B1_Hardware_Design_Guide

1VV0301354 Rev. 6 Page 19 of 70 2018-02-28

C4

RESERVED

-

RESERVED

C5

RESERVED

-

RESERVED

C6

RESERVED

-

RESERVED

D4

RESERVED

-

RESERVED

D5

RESERVED

-

RESERVED

D6

RESERVED

-

RESERVED

D7

RESERVED

-

RESERVED

E4

RESERVED

-

RESERVED

E5

RESERVED

-

RESERVED

E6

RESERVED

-

RESERVED

E7

RESERVED

-

RESERVED

F5

RESERVED

-

RESERVED

F7

RESERVED

-

RESERVED

G7

RESERVED

-

RESERVED

WARNING:

Reserved pins must not be connected

Page 20

NE866B1_Hardware_Design_Guide

1VV0301354 Rev. 6 Page 20 of 70 2018-02-28

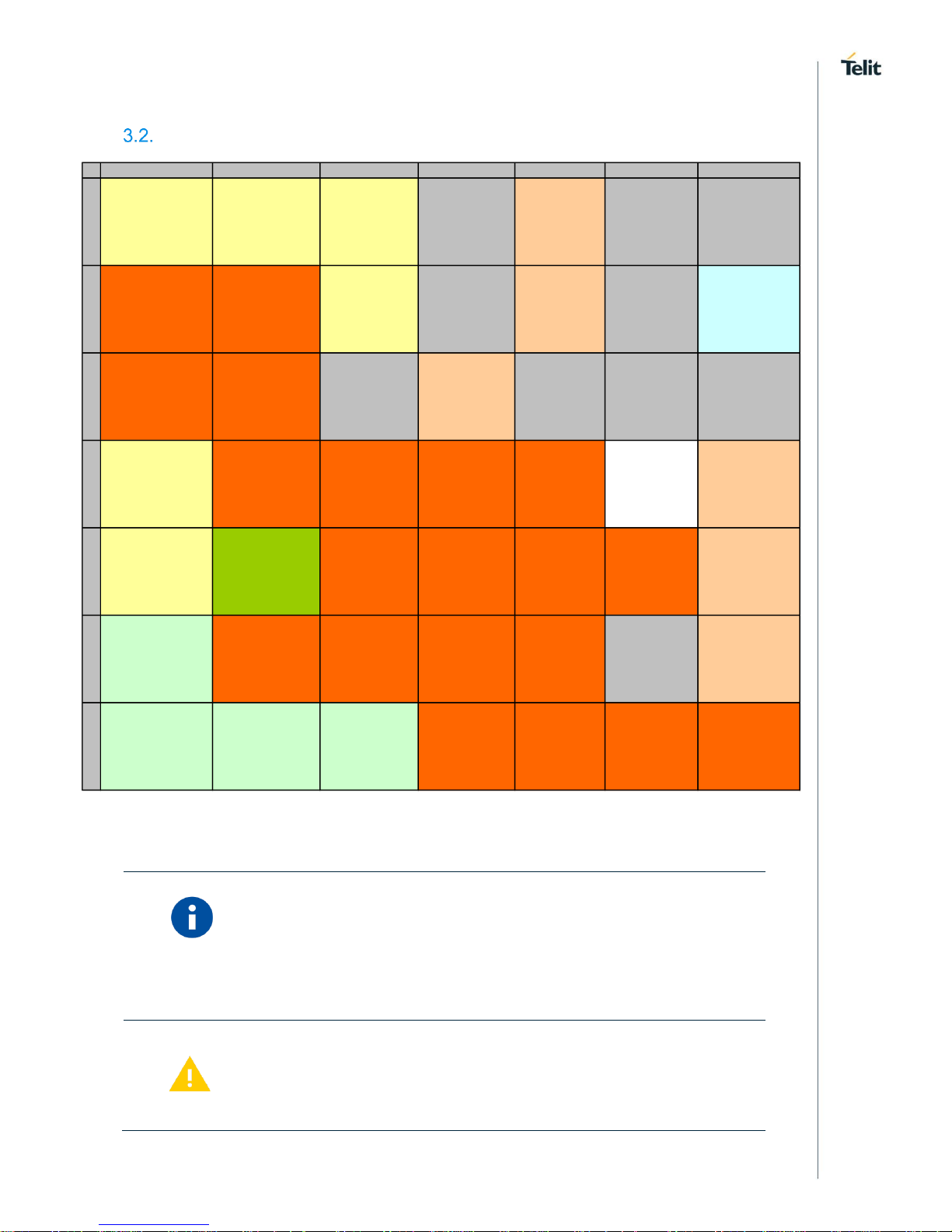

LGA Pads Layout

TOP VIEW

NOTE:

Alternate functions are marked with dark blue text while default

functions are black text

For more information, please refer to the related SW documentation

WARNING

Reserved pins must not be connected.

A B C D E F G

1 SPI_CLK

GPIO1

SPI_CS

I2C_SDA

TX AUX

SPI_MOSI

GPIO2

GND VBATT GND GND

2 RFU RFU

GPIO3

SPI_MISO

I2C_SCL

GND VBATT GND ANT

3 RFU RFU GND LP_WAKE GND GND GND

4 TXD RFU RFU RFU RFU ADC_IN1 RESET*

5 RXD SIM_IN RFU RFU RFU RFU SLP_IND

6 SIMIO RFU RFU RFU RFU GND VAUX/PWRMON

7 SIMCLK SIMRST SIMVCC RFU RFU RFU RFU

Page 21

NE866B1_Hardware_Design_Guide

1VV0301354 Rev. 6 Page 21 of 70 2018-02-28

4. POWER SUPPLY

The power supply circuitry and board layout are a very important part in the full product

design and they strongly reflect on the product overall performances, hence read carefully

the requirements and the guidelines that will follow for a proper design.

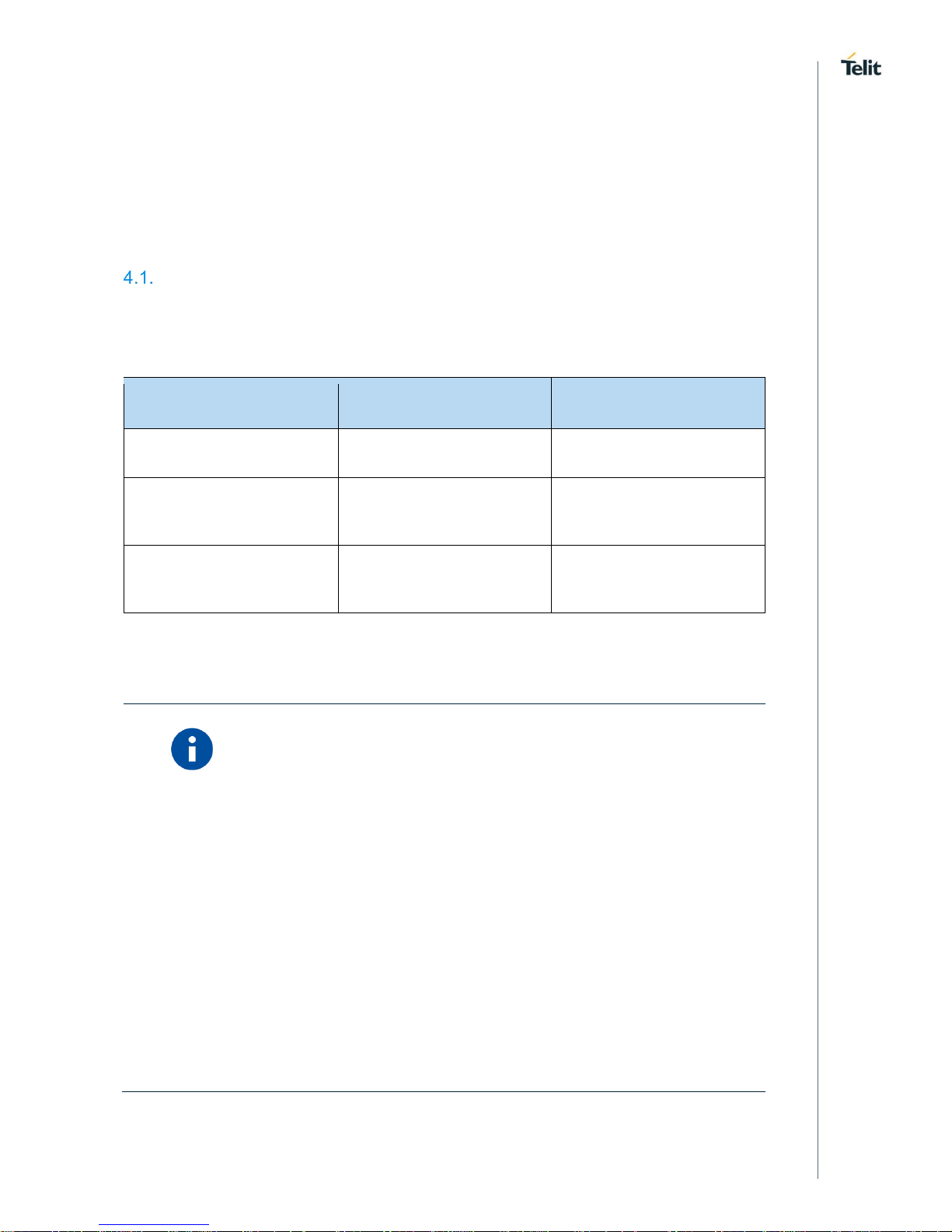

Power Supply Requirements

The external power supply must be connected to VBATT signal and must fulfil the

following requirements:

Power Supply

Value

Power Supply

Nominal Supply Voltage

3.8V

Nominal Supply Voltage

Normal Operating Voltage

Range

3.40 V÷ 4.20 V

Normal Operating Voltage

Range

Extended Operating

Voltage Range

3.10 V÷ 4.20 V

Extended Operating

Voltage Range

NOTE:

The Operating Voltage Range MUST never be exceeded; care must

be taken when designing the application’s power supply section to

avoid having an excessive voltage drop.

If the voltage drop is exceeding the limits it could cause a Power Off

of the module.

Overshoot voltage (regarding MAX Extended Operating Voltage) and

drop in voltage (regarding MIN Extended Operating Voltage) MUST

never be exceeded;

The “Extended Operating Voltage Range” can be used only with

completely assumption and application of the HW User guide

suggestions.

Page 22

NE866B1_Hardware_Design_Guide

1VV0301354 Rev. 6 Page 22 of 70 2018-02-28

Power Consumption

Mode

Typical

Mode Description

AT+CFUN=1

2 mA

Normal mode - Full functionality with PSM

disabled. (module is idle @DRX Mode with

1.28 sec paging cycle)

AT+CFUN=0

< 4 µA

TX/RX disabled, module is not registered to

the network

DRX paging modes (Full

functionality with power saving

enabled)

377.8 µA

TX=22dBm, T3324 = 30sec,

T3412 = 2621.44 s (~44min)

95.2 µA

TX=22dBm, T3324 = 30sec,

T3412 = 10485.76s (~175 min)

246.3 µA

C-eDRX = 10.24 sec

AT#PSM = 1

< 4 µA

Power Saving Enabled

NB-IoT Data Call

90mA

BW=3.75KHz, Single tone data call

(TX=0dBm)

90mA

BW=15KHz, Single tone data call

(TX=0dBm)

155 mA

BW=3.75KHz, Single tone data call

(TX=20dBm)

155 mA

BW=15KHz, Single tone data call

(TX=20dBm)

195 mA

BW=3.75KHz, Single tone data call

(TX=23dBm)

195 mA

BW=3.75KHz, Single tone data call

(TX=23dBm)

Current consumptions specification refers to typical samples and typical material.

Values represent an average measurement done over few seconds.

Values may vary depending on network and environmental conditions. Power

consumptions values obtained with VBATT = 3.8V

Page 23

NE866B1_Hardware_Design_Guide

1VV0301354 Rev. 6 Page 23 of 70 2018-02-28

General Design Rules

The principal guidelines for the Power Supply Design embrace three different design steps:

• The electrical design

• The thermal design

• The PCB layout.

4.3.1. Electrical Design Guidelines

The electrical design of the power supply depends strongly from the power source where

this power is drained. We will distinguish them into three categories:

• +5V input (typically PC internal regulator output)

• +12V input (typically automotive)

• Battery

4.3.1.1. +5V Source Power Supply Design Guidelines

• The desired output for the power supply is 3.8V, hence there's not a big difference

between the input source and the desired output and a linear regulator can be

used. A switching power supply will not be suited because of the low drop out

requirements.

• When using a linear regulator, a proper heat sink shall be provided in order to

dissipate the power generated.

• A Bypass low ESR capacitor of adequate capacity must be provided in order to cut

the current absorption peaks close to the Module, a 100μF capacitor is usually

suited.

• Make sure the low ESR capacitor on the power supply output rated at least 10V.

An example of linear regulator with 5V input is:

Page 24

NE866B1_Hardware_Design_Guide

1VV0301354 Rev. 6 Page 24 of 70 2018-02-28

4.3.1.2. +12V Source Power Supply Design Guidelines

• The desired output for the power supply is 3.8V, hence due to the big difference

between the input source and the desired output, a linear regulator is not suited and

shall not be used. A switching power supply will be preferable because of its better

efficiency.

• When using a switching regulator, a 500kHz or more switching frequency regulator

is preferable because of its smaller inductor size and its faster transient response.

This allows the regulator to respond quickly to the current peaks absorption.

• In any case the frequency and Switching design selection is related to the

application to be developed due to the fact the switching frequency could also

generate EMC interferences.

• For car PB battery the input voltage can rise up to 15,8V and this should be kept in

mind when choosing components: all components in the power supply must

withstand this voltage.

• A Bypass low ESR capacitor of adequate capacity must be provided in order to cut

the current absorption peaks, a 100μF capacitor is usually suited.

• Make sure the low ESR capacitor on the power supply output is rated at least 10V.

For Car applications, a spike protection diode should be inserted close to the

power input, in order to clean the supply from spikes.

An example of switching regulator with 12V input is in the below schematic:

Page 25

NE866B1_Hardware_Design_Guide

1VV0301354 Rev. 6 Page 25 of 70 2018-02-28

4.3.1.3. Battery Source Power Supply Design Guidelines

The desired nominal output for the power supply is 3.8V and the maximum voltage allowed

is 4.2V, hence a single 3.7V Li-Ion cell battery type is suited for supplying the power to the

Telit NB866B1 module.

• A Bypass low ESR capacitor of adequate capacity must be provided in order to cut

the current absorption peaks, a 100μF tantalum capacitor is usually suited.

• Make sure the low ESR capacitor (usually a tantalum one) is rated at least 10V.

• A protection diode should be inserted close to the power input, in order to save the

NB866B1 from power polarity inversion. Otherwise the battery connector should be

done in a way to avoid polarity inversions when connecting the battery.

• The selected battery should be capable of supporting the max peak currents of

~0.5A.

NOTE:

DON'T USE any Ni-Cd, Ni-MH, and Pb battery types directly

connected with NB866B1. Their use can lead to overvoltage on the

NB866B1 and damage it. USE ONLY Li-Ion battery types.

Page 26

NE866B1_Hardware_Design_Guide

1VV0301354 Rev. 6 Page 26 of 70 2018-02-28

4.3.2. Thermal Design Guidelines

The thermal design for the power supply heat sink should be done with the following

specifications:

• Average current consumption during NB-IoT transmission @ Max PWR level at min

battery level : 195 mA

• Average current during idle: 5.3 mA

Considering the very low current during idle, especially if Power Saving function is enabled,

it is possible to consider from the thermal point of view that the device absorbs current

significantly only during calls.

If we assume that the device stays into transmission for short periods of time (let's say few

minutes) and then remains for a quite long time in idle (let's say one hour), then the power

supply has always the time to cool down between the calls and the heat sink could be

smaller than the calculated one for 300mA maximum RMS current, or even could be the

simple chip package (no heat sink).

Moreover, in the average network conditions the device is requested to transmit at a lower

power level than the maximum and hence the current consumption will be less than the

195mA (@23dBm), being usually around 150 mA (@20dBm).

For these reasons the thermal design is rarely a concern and the simple ground plane where

the power supply chip is placed can be enough to ensure a good thermal condition and

avoid overheating.

The generated heat will be mostly conducted to the ground plane under the NE866B1; you

must ensure that your application can dissipate it.

NOTE:

The average consumption during transmissions depends on the

power level at which the device is requested to transmit by the

network. The average current consumption hence varies significantly.

Page 27

NE866B1_Hardware_Design_Guide

1VV0301354 Rev. 6 Page 27 of 70 2018-02-28

4.3.3. Power Supply PCB layout Guidelines

As seen on the electrical design guidelines the power supply shall have a low ESR capacitor

on the output to cut the current peaks on the input to protect the supply from spikes. The

placement of this component is crucial for the correct working of the circuitry. A misplaced

component can be useless or can even decrease the power supply performances.

• The Bypass low ESR capacitor must be placed close to the Telit NE866B1 power

input pads or in the case the power supply is a switching type it can be placed close

to the inductor to cut the ripple provided the PCB trace from the capacitor to the

NB866B1 is wide enough to ensure a dropless connection even during an 1A current

peak.

• The protection diode must be placed close to the input connector where the power

source is drained.

• The PCB traces from the input connector to the power regulator IC must be wide

enough to ensure no voltage drops occur when a 1A current peak is absorbed.

• The PCB traces to the NB866B1 and the Bypass capacitor must be wide enough to

ensure no significant voltage drops occur. This is for the same reason as previous

point. Try to keep this trace as short as possible.

• To reduce the EMI due to switching, it is important to keep very small the mesh

involved; thus, the input capacitor, the output diode (if not embodied in the IC) and

the regulator have to form a very small loop. This is done in order to reduce the

radiated field (noise) at the switching frequency (100-500 kHz usually).

• A dedicated ground for the Switching regulator separated by the common ground

plane is suggested.

• The placement of the power supply on the board should be done in such a way to

guarantee that the high current return paths in the ground plane are not overlapped

to any noise sensitive circuitry as the microphone amplifier/buffer or earphone

amplifier.

• The power supply input cables should be kept separate from noise sensitive lines

such as microphone/earphone cables.

• The insertion of EMI filter on VBATT pins is suggested in those designs where

antenna is placed close to battery or supply lines.

A ferrite bead like Murata BLM18EG101TN1 or Taiyo Yuden P/N

FBMH1608HM101 can be used for this purpose.

The below figure shows the recommended circuit:

Page 28

NE866B1_Hardware_Design_Guide

1VV0301354 Rev. 6 Page 28 of 70 2018-02-28

VAUX/PWRMON Power Output

A 1.8V regulated power supply output is provided in order to supply small devices from

the module. The signal is present on Pad G6

This output is always active as long as the module is powered (VBATT applied). It is also

active during module sleep mode/ PSM mode.

The operating range characteristics of the supply are:

Item

Min

Typical

Max

Output voltage

1.7V

1.80V

1.9V

Output current - -

50mA

Output bypass

capacitor

(inside the module)

100nF

NOTE:

The Output Current MUST never be exceeded; care must be taken

when designing the application section to avoid having an excessive

current consumption.

If the Current is exceeding the limits it could cause a Power Off of the

module.

Warning:

The current consumption from VAUX/PWRMON increases the

modem temperature.

Page 29

NE866B1_Hardware_Design_Guide

1VV0301354 Rev. 6 Page 29 of 70 2018-02-28

3GPP Power Saving Mode (PSM)

The NE866 is supporting a new feature introduced in 3GPP Rel.12 that allows the Module

to skip idle mode tasks for a longer time period while still maintaining the NAS context.

This feature permits to reduce the overall power consumption when there is no required

data activity with the network for a long time.

Additional hardware lines are defined to support this feature and to synchronize the

activities with the external Host processor.

PIN DESCRIPTION

Signal

Function

I/O

PAD

LP_WAKE

Low Power Wake Up.

Used to wakeup the NE866 from any of the low

power modes (either modem or apps).

I

D3

SLP_IND

Modem Sleep or PSM indication.

“0” – NE866B1 modem is in Sleep mode / PSM

“1” - NE866B1 modem is not in sleep mode /

PSM

O

G5

NOTE:

SLP_IND signal indicates the status of the modem subsystem only

SLP_IND cannot be used to determine if the entire module is at low

power mode.

Page 30

NE866B1_Hardware_Design_Guide

1VV0301354 Rev. 6 Page 30 of 70 2018-02-28

4.5.1. LP_WAKE design guide

LP Wake signal could be used by the host to wake up the NE866B1 from any of the sleep

modes (either modem sleep or application sleep or both)

LP Wake signal can be configured to wakeup the system at either rising or falling edge or

both edges.

In most cased the most convenient configuration is falling edge as shown in the application

circuit below.

NOTE:

LP_WAKE is an analog input to a comperator but should be treated

as a digital input from the application side.

• Rising edge is considured when the signal crossed the level

of 1.2V and going up.

• Faling edge is considered when the signal crossed the level of

0.7V and going down.

GND

R1

R2

Q1

From Host

Assert high for Wake

LP_WAKE

1M ohm

1.8V

Page 31

NE866B1_Hardware_Design_Guide

1VV0301354 Rev. 6 Page 31 of 70 2018-02-28

5. DIGITAL SECTION

Logic Levels

ABSOLUTE MAXIMUM RATINGS:

OPERATING RANGE - INTERFACE LEVELS (1.8V CMOS):

Parameter

Min

Max

Input high level

1.25V

1.95V

Input low level

0V

0.35V

Output high level

1.42V

1.85V

Output low level

0V

0.2V

LEAKAGE CURRENT CHARACTERISTICS:

Parameter

AVG

Input leakage current

±10uA

Output leakage current

±10uA

DRIVE STRENGTH

Parameter

AVG

Max drive strength

10mA

Parameter

Min

Max

Input level on any digital pin (CMOS 1.8) with respect

to ground

-0.3V

2.1V

Input level on any digital pin (CMOS 1.8) with respect

to ground

when VBATT is not supplied

-0.3V

0.3V

Page 32

NE866B1_Hardware_Design_Guide

1VV0301354 Rev. 6 Page 32 of 70 2018-02-28

Power On

The NB866B1 will automatically power on itself when VBATT is applied to the module.

VAUX / PWRMON pin will be then set at the high logic level.

The following flow chart shows the proper turn on procedure:

PWRMON=ON

?

“Modem ON Proc”

START

PWR Supply ON

PWRMON=ON

?

Delay = 8 s

AT Init Sequence

Enter AT<CR>

Delay 1s – 5s

Delay = 8 sec

Start AT CMD

AT Answer in

1sec?

Modem Reset Proc

Page 33

NE866B1_Hardware_Design_Guide

1VV0301354 Rev. 6 Page 33 of 70 2018-02-28

A flow chart showing the AT commands managing procedure is displayed below:

“Start AT CMD”

START

Delay = 300 msec

Enter AT <CR>

Disconnect PWR Supply

AT answer in

1 sec ?

GO TO

“Modem ON Proc.”

“Start AT CMD”

END

Page 34

NE866B1_Hardware_Design_Guide

1VV0301354 Rev. 6 Page 34 of 70 2018-02-28

Unconditional Restart

To unconditionally restart the NE866B1, the pad RESET* must be tied low for at least 200

milliseconds and then released.

The maximum current that can be drained from the RESET* pad is 1 mA.

The hardware unconditional Restart must not be used during normal operation of the

device since it does not detach the device from the network. It shall be kept as an

emergency exit procedure to be done in the rare case that the device gets stuck waiting

for some network or SIM responses.

Do not use any pull up resistor on the RESET* line nor any totem pole digital output.

Using pull up resistor may bring to latch up problems on the NE866B1 power regulator

and improper functioning of the module.

The line RESET* must be connected only in open collector configuration; the transistor

must be connected as close as possible to the RESET* pin.

The unconditional hardware restart must always be implemented on the application board

as the software must be able to use it as an emergency exit procedure.

PIN DESCRIPTION

Signal

Function

I/O

PAD

RESET*

Unconditional Reset of the Module

I

G4

OPERATING LEVELS

The RESET* line is connected to 1.8V with a Pull Up so the electrical levels are on this pin

are aligned with the other CMOS 1.8V digital I/O’s.

WARNING:

The hardware unconditional Reset must not be used during normal

operation of the device since it does not detach the device from the

network. It shall be kept as an emergency exit procedure.

Page 35

NE866B1_Hardware_Design_Guide

1VV0301354 Rev. 6 Page 35 of 70 2018-02-28

A typical circuit for implementing an unconditional RESET is shown below:

NOTE:

In order to avoid a back powering effect it is recommended to avoid

having any HIGH logic level signal applied to the digital pins of the

NE866B1 when the module is powered off or during a reboot

transition.

Using bidirectional level translators which do not support High Z

mode during power off is not recommended.

Page 36

NE866B1_Hardware_Design_Guide

1VV0301354 Rev. 6 Page 36 of 70 2018-02-28

In the following flow chart is detailed the proper restart procedure:

In order to prevent a back powering effect it is recommended to avoid

having any HIGH logic level signal applied to the digital pins of the

NE866B1 when the module is powered OFF or during an ON/OFF

transition.

Using bidirectional level translators which do not support High Z

mode during power off is not recommended.

Modem Reset

Proc.

Reset = LOW

Delay 200ms

Delay 1s

Apply Power

On Procedure

Page 37

NE866B1_Hardware_Design_Guide

1VV0301354 Rev. 6 Page 37 of 70 2018-02-28

Power OFF procedure

The NE866B1 does not provide any means of software driven shutdown.

In case that power off is required (for example when modem is not used for a long time),

the below procedure should be followed in order to eliminate any possible damage due to

unexpected power cut.

WARNING:

Please carefully follow the recommended procedure for shut down and

power off.

Not following the recommended shut-down and power off procedures might

damage the device and consequently void the warranty.

Modem Power Off

Proc

AT+CFUN=0

In PSM mode?

AT+COPS=2

Yes

No

Power Off supply

Page 38

NE866B1_Hardware_Design_Guide

1VV0301354 Rev. 6 Page 38 of 70 2018-02-28

Communication ports

5.5.1. Serial Ports

The NB866B1 module is provided with by 2 Asynchronous serial ports:

• MODEM SERIAL PORT 1 (Main)

• MODEM SERIAL PORT 2 (TX Only, used for logging)

Several configurations can be designed for the serial port on the OEM hardware, but the

most common are:

• RS232 PC com port

• microcontroller UART @ 1.8V (Universal Asynchronous Receive Transmit)

• microcontroller UART @ 5V or other voltages different from 1.8V

Depending from the type of serial port on the OEM hardware a level translator circuit may

be needed to make the system work.

On the NB866B1 the ports are CMOS 1.8.

5.5.1.1. MODEM SERIAL PORT 1

The serial port 1 on the NB866B1 is a +1.8V UART with only 2 RS232 signals.

It differs from the PC-RS232 in the signal polarity (RS232 is reversed) and levels.

Serial port 1 is considered a “low power UART” and is avalable during LPM and PSM

such that any activity in the TXD pin (NE866B1 input) will wakeup the system.

The following table lists the signals of Serial port 1:

RS232

Pin

Signal

Pad

Name

Usage

2

RXD

A5

Transmit line *see

Note

Output transmit line of NB866B1

UART

3

TXD

A4

Receive line *see

Note

Input receive of the NB866B1

UART

This pin also serves as a sleep

wakeup source.

5

GND

D1, F1, G1,

D2, F2, C3,

E3, F3, G3, F6

Ground

Ground

Page 39

NE866B1_Hardware_Design_Guide

1VV0301354 Rev. 6 Page 39 of 70 2018-02-28

NOTE:

According to V.24, some signal names are referred to the application

side, therefore on the NB866B1 side these signal are on the opposite

direction:

TXD on the application side will be connected to the receive line

(here named TXD)

RXD on the application side will be connected to the transmit line

(here named RXD)

For a minimum implementation, only the TXD, RXD lines can be

connected.

In order to avoid a back powering effect it is recommended to avoid

having any HIGH logic level signal applied to the digital pins of the

NB866B1 when the module is powered off or during a reboot

transition.

Using bidirectional level translators which do not support High Z

mode during power off is not recommended.

NOTE:

By default, since UART port uses the low power mode, HW flow

control is not used

Page 40

NE866B1_Hardware_Design_Guide

1VV0301354 Rev. 6 Page 40 of 70 2018-02-28

5.5.1.2. MODEM SERIAL PORT 2

The secondary serial port on the NB866B1 is a CMOS1.8V with only TX signal which is

used for logging.

The signals of the NB866B1 serial port are:

PAD

Signal

I/O

Function

Type

NOTE

C1

TX_AUX

O

Auxiliary UART (TX Data

to DTE)

CMOS

1.8V

Main Debug & logging

port

NOTE:

In order to avoid a back powering effect it is recommended to avoid

having any HIGH logic level signal applied to the digital pins of the

NB866B1 when the module is not supplied or during a

powerup/reboot transition.

Using bidirectional level translators which do not support High Z

mode during power off is not recommended.

NOTE:

TX_AUX is shared with SPI functionality

SPI and AUX UART cannot work simultaniously

5.5.1.3. RS232 LEVEL TRANSLATION

In order to interface the NB866B1 with a PC com port or a RS232 (EIA/TIA-232) application

a level translator is required. This level translator must:

• invert the electrical signal in both directions;

• Change the level from 0/1.8V to +15/-15V.

The RS232 UART 16450, 16550, 16650 & 16750 chipsets accept signals with lower levels

on the RS232 side (EIA/TIA-562), allowing a lower voltage-multiplying ratio on the level

translator. Note that the negative signal voltage must be less than 0V and hence some sort

of level translation is always required.

The simplest way to translate the levels and invert the signal is by using a single chip level

translator. There are a multitude of them, differing in the number of drivers and receivers

and in the levels (be sure to get a true RS232 level translator not a RS485 or other

standards).

Page 41

NE866B1_Hardware_Design_Guide

1VV0301354 Rev. 6 Page 41 of 70 2018-02-28

By convention the driver is the level translator from the 0-1.8V UART to the RS232 level.

The receiver is the translator from the RS232 level to 0-1.8V UART.

In order to translate the whole set of control lines of the UART you will need:

• 5 drivers

• 3 receivers

An example of RS232 level adaptation circuitry could be done using a MAXIM transceiver

(MAX218).

In this case the chipset is capable to translate directly from 1.8V to the RS232 levels

(Example done on 4 signals only).

NOTE:

The digital input lines operating at 1.8V CMOS have an absolute

maximum input voltage of 2.2V. The level translator IC outputs on the

module side (i.e. module inputs) will cause damage to the module

inputs if the level translator is powered by a +3.8V supply. So the

level translator IC must be powered from a dedicated +1.8V power

supply to match the module I/O level.

The RS232 serial port lines are usually connected to a DB9 connector with the following

layout:

Page 42

NE866B1_Hardware_Design_Guide

1VV0301354 Rev. 6 Page 42 of 70 2018-02-28

General purpose I/O

The NB866B1 module is provided by a set of Configurable Digital Input / Output pins

(CMOS 1.8V)

Input pads can only be read; they report the digital value (high or low) present on the pad

at the read time.

Output pads can only be written or queried and set the value of the pad output.

Alternate functionality is avalable for the GPIO's as shown in the below table.

The alternate functinality is selected as a group and by function rather than by pad.

Please refer to the AT Commands User Guide for more details on selecting the pads

alternate functinality.

The following table shows the available GPIO's on the NB866B1 and their functionality:

PAD

Signal

Default

Function

Alt Func #1

(I2C + GPIO)

Alt Func #2

(I2C + Log)

Alt Func #3

(GPIO)

Alt Func #4

(SPI)

B1

GPIO1

GPIO1

I2C_SDA

I2C_SDA

GPIO1

SPI_CS

C1

GPIO2

TX_AUX

GPIO2

TX_AUX

GPIO2

SPI_MOSI

C2

GPIO3

GPIO3

I2C_CLK

I2C_CLK

GPIO3

SPI_MISO

NOTE:

When using SPI functionality, the SPI_CLK function is assigned to

pad A1.

NOTE:

The internal GPIO’s pull up/pull down could be set to the preferred

status for the application using the AT#GPIO command.

Please refer for the AT Commands User Guide for the detailed

command Syntax.

WARNING:

During power up the GPIOs may be subject to transient glitches.

Page 43

NE866B1_Hardware_Design_Guide

1VV0301354 Rev. 6 Page 43 of 70 2018-02-28

5.6.1. Using a GPIO as an INPUT

The GPIO pads, when used as inputs, can be connected to a digital output of another

device and report its status, provided this device has interface levels compatible with the

1.8V CMOS levels of the GPIO. If the digital output of the device to be connected with the

GPIO input pad has interface levels different from the 1.8V CMOS, then it can be buffered

with an open collector transistor with a 47K pull up to VAUX.

NOTE:

In order to avoid a back powering effect it is recommended to avoid

having any HIGH logic level signal applied to the digital pins of the

NB866B1 when the module is powered off or during a

powerup/reboot transition.

Using bidirectional level translators which do not support High Z

mode during power off is not recommended.

The VAUX /PWRMON pin can be used for input pull up reference.

5.6.2. Using a GPIO as an OUTPUT

The GPIO pads, when used as outputs, can drive 1.8V CMOS digital devices or

compatible hardware. When set as outputs, the pads have a push-pull output and

therefore the pull-up resistor may be omitted.

Page 44

NE866B1_Hardware_Design_Guide

1VV0301354 Rev. 6 Page 44 of 70 2018-02-28

I2C Port

The NE866B1 supports a dedicated port for I2C communication

I2C speed is limited to 10KHz.

The following table lists the available I2C signals on the NE866B1:

PAD

Signal

I/O

Default State

NOTE

B1

I2C_SDA

I/O

Pull Up

C2

I2C_SCL

I/O

Pull Up

Please refer to the AT command user guide for more information.

NOTE:

The I2C port is shared with SPI. When SPI is used, I2C cannot be

used and vice versa.

SIM Interface

The NE866B1 supports a standard SIM card interface with the below exceptions:

• 1.8V I/O only (3V SIM is not supported).

• SIM PIN (SIM lock) feature is not supported.

• SIM power OFF during PSM is an expected behavior

For more info on SIM implementation, please refer to the related User Guide (SIM Holder

Design Guides, 80000NT10001a).

5.8.1. SIMIN Detection

PIN B5 is used as SIM DETECT input.

As long as SIMIN is not pulled low by the application board the module will use the

internal eSIM.

For using an external SIM the user must assert SIMIN low

NE866B1 modules ordered without eSIM support will always use the external SIM

regardless of the SIMIN state

ADC Converter

The NB866B1 is provided by one ADC converter. It is able to read a voltage level in the

range of 0.2÷1.7 volts applied on the ADC pin input, store and convert it into 10 bit word.

The input line is named as ADC_IN1 and it is available on Pad F4

The following table is showing the ADC characteristics:

Item

Min

Typical

Max

Unit

Input Voltage range

0.2

-

1.7

Volt

AD conversion

- - 10

bits

Page 45

NE866B1_Hardware_Design_Guide

1VV0301354 Rev. 6 Page 45 of 70 2018-02-28

6. RF SECTION

Bands Variants

The following table is listing the supported Bands:

TX Output power

Product

Bands

Power Class

NE866B1-E1

FDD B8, B20

Class 3 (23dBm)

RX Sensitivity

Technology

3GPP Compliance

NB-IoT

-108.2dBm

NOTE:

For low data rates sensitivity will be better than 3GPP spec

RED requirements

• NE866B1 meets RED requirement Article 10 item 8.

• NE866B1 has been assessed to be used with separation distance more than 20cm.

• NE866B1 reference antenna: LTE MAGNETIC ANTENNA Type n° T- AT305

o 700 - 960MHz / 1710 – 2700MHz

o Antenna Gain - 2.14dBi

• The maximum antenna gain for each frequency band is:

o FDD8: 7dBi

o FDD20: 6.7dBi

Product

Supported LTE bands

NE866B1E1

FDD B8, B20

Page 46

NE866B1_Hardware_Design_Guide

1VV0301354 Rev. 6 Page 46 of 70 2018-02-28

Antenna requirements

6.5.1. Main Antenna

The antenna connection and board layout design are the most important aspect in the full

product design as they strongly affect the product overall performances, hence read

carefully and follow the requirements and the guidelines for a proper design.

The antenna and antenna transmission line on PCB for a Telit NB866B1 device shall fulfil

the following requirements:

Item

Value

Frequency range

Depending by frequency band(s) provided by the network

operator, the customer shall use the most suitable

antenna for that/those band(s)

Bandwidth

LTE Band VIII (900) : 80 MHz

LTE Band XX (800) : 71 MHz : 47 MHz

Impedance

50 ohm

Input power

> 23dBm Average power

VSWR absolute max

≤ 10:1 (limit to avoid permanent damage)

VSWR recommended

≤ 2:1 (limit to fulfill all regulatory requirements)

Page 47

NE866B1_Hardware_Design_Guide

1VV0301354 Rev. 6 Page 47 of 70 2018-02-28

6.5.2. PCB design guidelines

When using the NB866B1, since there's no antenna connector on the module, the

antenna must be connected to the NB866B1 antenna pad by means of a transmission line

implemented on the PCB.

This transmission line shall fulfil the following requirements:

The transmission line should be designed according to the following guidelines:

• Ensure that the antenna line impedance is 50 ohm;

• Keep the antenna line on the PCB as short as possible, since the antenna line loss

shall be less than 0.3 dB;

• Antenna line must have uniform characteristics, constant cross section; avoid

meanders and abrupt curves;

• Keep, if possible, one layer of the PCB used only for the Ground plane;

• Surround (on the sides, over and under) the antenna line on PCB with Ground, avoid

having other signal tracks facing directly the antenna line track;

• The ground around the antenna line on PCB has to be strictly connected to the

Ground Plane by placing vias every 2mm at least;

• Place EM noisy devices as far as possible from NB866B1 antenna line;

• Keep the antenna line far away from the NB866B1 power supply lines;

• If you have EM noisy devices around the PCB hosting the NB866B1, such as fast

switching ICs, take care of the shielding of the antenna line by burying it inside the

layers of PCB and surround it with Ground planes, or shield it with a metal frame

cover.

Item

Value

Characteristic

Impedance

50 ohm

Max Attenuation

0.3 dB

Coupling

Coupling with other signals shall be avoided

Ground Plane

Cold End (Ground Plane) of antenna shall be

equipotential to the NB866B1 ground pins

Page 48

NE866B1_Hardware_Design_Guide

1VV0301354 Rev. 6 Page 48 of 70 2018-02-28

• If you don't have EM noisy devices around the PCB of NB866B1, by using a micro

strip on the superficial copper layer for the antenna line, the line attenuation will be

lower than a buried one;

The following image is showing the

suggested layout for the

Antenna pad connection

(dimensions in mm):

NOTE:

In early samples of NE866B1 the

antenna pad has a closed ring around it

as shown below

In that case, the RF pin (G2) should be

routed through an internal layer of the

board connecting to the PAD on the top

layer ideally through a BLIND via. VIA

diameter should be chosen to achieve

best coaxiality effect thorugh the board.

It is also recommended to bring directly

to the reference RF ground layer the

GND signal present on PADs F1,

F2,F3, G1 and G3.

6.5.3. Antenna installation Guidelines

Install the antenna in a place covered by the LTE signal.

Antenna shall not be installed inside metal cases.

Antenna shall be installed also according to antenna manufacturer instructions.

Page 49

NE866B1_Hardware_Design_Guide

1VV0301354 Rev. 6 Page 49 of 70 2018-02-28

7. MECHANICAL DESIGN

Mechanical Dimensions

The NE866B1 overall dimensions are:

• Length: 19 mm

• Width: 15 mm

• Thickness: 2.2 mm

• Weight: 1.5 gr

7.1.1. Mechanical Drawing

7.1.2. Top View

The figure below shows mechanical top view of the NE866B1

Page 50

NE866B1_Hardware_Design_Guide

1VV0301354 Rev. 6 Page 50 of 70 2018-02-28

Dimensions are in mm

7.1.3. Bottom View (as seen from bottom side)

Page 51

NE866B1_Hardware_Design_Guide

1VV0301354 Rev. 6 Page 51 of 70 2018-02-28

7.1.4. Side View

Page 52

NE866B1_Hardware_Design_Guide

1VV0301354 Rev. 6 Page 52 of 70 2018-02-28

8. APPLICATION PCB DESIGN

The NB866B1 modules have been designed in order to be compliant with a standard leadfree SMT process

Recommended footprint for the application

Page 53

NE866B1_Hardware_Design_Guide

1VV0301354 Rev. 6 Page 53 of 70 2018-02-28

In order to easily rework the NB866B1 is suggested to consider on the application a 1.5

mm placement inhibit area around the module. It is also suggested, as common rule for

an SMT component, to avoid having a mechanical part of the application in direct contact

with the module.

The area under WIRING INHIBIT (see figure above) must be clear from signal or ground

paths.

PCB pad design

Non solder mask defined (NSMD) type is recommended for the solder pads on the PCB.

PCB

Copper

Pad

Solder Mask

SMD

(Solder Mask Defined)

NSMD

(Non Solder Mask Defined)

Page 54

NE866B1_Hardware_Design_Guide

1VV0301354 Rev. 6 Page 54 of 70 2018-02-28

PCB pad dimensions

The recommendation for the PCB pads dimensions are described in the following image

(dimensions in mm)

It is not recommended to place via or micro-via not covered by solder resist in an area of

0,3 mm around the pads unless it carries the same signal of the pad itself

Holes in pad are allowed only for blind holes and not for through holes.

Page 55

NE866B1_Hardware_Design_Guide

1VV0301354 Rev. 6 Page 55 of 70 2018-02-28

Recommendations for PCB pad surfaces:

Finish

Layer Thickness (um)

Properties

Electro-less Ni / Immersion

Au

3 –7 / 0.05 – 0.15

good solder ability

protection,

high shear force values

The PCB must be able to resist the higher temperatures which are occurring at the leadfree process. This issue should be discussed with the PCB-supplier. Generally, the

wettability of tin-lead solder paste on the described surface plating is better compared to

lead-free solder paste.

It is not necessary to panel the application’s PCB, however in that case it is suggested to

use milled contours and predrilled board breakouts; scoring or v-cut solutions are not

recommended.

Stencil

Minimum stencil thickness recommended is 125um (5 mil)

Solder paste

We recommend using only “no clean” solder paste in order to avoid the cleaning of

the modules after assembly.

Page 56

NE866B1_Hardware_Design_Guide

1VV0301354 Rev. 6 Page 56 of 70 2018-02-28

NE866B1 Solder reflow

Recommended solder reflow profile

Profile Feature

Pb-Free Assembly

Average ramp-up rate (TL to TP)

3°C/second max

Preheat

– Temperature Min (Tsmin)

– Temperature Max (Tsmax)

– Time (min to max) (ts)

150°C

200°C

60-180 seconds

Tsmax to TL

– Ramp-up rate

3°C/second max

Time maintained above:

– Temperature (TL)

– Time (tL)

217°C

60-150 seconds

Peak temperature (Tp)

245 +0/-5°C

Time within 5°C of actual peak temperature (tp)

10-30 seconds

Ramp-down rate

6°C/second max.

Time 25°C to peak temperature

8 minutes max.

Page 57

NE866B1_Hardware_Design_Guide

1VV0301354 Rev. 6 Page 57 of 70 2018-02-28

9. PACKING SYSTEM

Tray

The NB866B1 modules are packaged on trays

The tray is JEDEC compliant, injection molded antistatic Modified Polyphenylene ether

(MPPO). It has good thermal characteristics and can withstand a standard baking

temperature of up to 125°C, thereby avoiding handling the modules if baking is required.

The trays are rigid, thus providing mechanical protection against transport stress. In

addition, they are re-usable and so environmentally sustainable.

There are 2 (two) antistatic rubber bands that enclose each envelope.

The carton box is rigid, offering mechanical protection. The carton box has one flap across

the entire top surface. It is sealed with tape along the edges of the box.

Table 1: Tray Packing

Modules per

Tray

Trays per

Envelope

Modules per

Envelope

Envelopes per Carton

Box

Modules per

Box

98

4+ 1 empty

392

5

1960

Table 2: Packing Quantities

Order Type

Quantity

Minimum Order Quantity (MOQ)

98

Standard Packing Quantity (SPQ)

392

Page 58

NE866B1_Hardware_Design_Guide

1VV0301354 Rev. 6 Page 58 of 70 2018-02-28

Tray organization is shown in the figure below

Page 59

NE866B1_Hardware_Design_Guide

1VV0301354 Rev. 6 Page 59 of 70 2018-02-28

Tray Drawing

WARNING:

These trays can withstand a maximum temperature of 125℃.

Page 60

NE866B1_Hardware_Design_Guide

1VV0301354 Rev. 6 Page 60 of 70 2018-02-28

Tape & Reel

The NE866 modules are available on a T&R packaging as well

NE866B1 is packaged on reels of 200 pieces each as shown in the figure below.

Page 61

NE866B1_Hardware_Design_Guide

1VV0301354 Rev. 6 Page 61 of 70 2018-02-28

Carrier Tape Drawing

Moisture sensitivity

The NB866B1 is a Moisture Sensitive Device level 3, in according with standard

IPC/JEDEC J-STD-020, take care all the relatives requirements for using this kind of

components.

Moreover, the customer has to take care of the following conditions:

a) Calculated shelf life in sealed bag: 12 months at <40°C and <90% relative humidity

(RH).

b) Environmental condition during the production: 30°C / 60% RH according to

IPC/JEDEC J-STD-033A paragraph 5.

c) The maximum time between the opening of the sealed bag and the reflow process must

be 168 hours if condition b) “IPC/JEDEC J-STD-033A paragraph 5.2” is respected

d) Baking is required if conditions b) or c) are not respected

e) Baking is required if the humidity indicator inside the bag indicates 10% RH or more

Page 62

NE866B1_Hardware_Design_Guide

1VV0301354 Rev. 6 Page 62 of 70 2018-02-28

10. CONFORMITY ASSESSMENT ISSUES

Declaration of Conformity

Hereby, Telit Communications S.p.A declares that the NB IOT Module is in compliance

with Directive 2014/53/EU.

The full text of the EU declaration of conformity is available at the following internet

address: http://www.telit.com\red

Page 63

NE866B1_Hardware_Design_Guide

1VV0301354 Rev. 6 Page 63 of 70 2018-02-28

11. SAFETY RECOMMENDATIONS

READ CAREFULLY

Be sure the use of this product is allowed in the country and in the environment required.

The use of this product may be dangerous and has to be avoided in the following areas:

• Where it can interfere with other electronic devices in environments such as

hospitals, airports, aircrafts, etc.

• Where there is risk of explosion such as gasoline stations, oil refineries, etc. It is the

responsibility of the user to enforce the country regulation and the specific

environment regulation.

Do not disassemble the product; any mark of tampering will compromise the warranty

validity. We recommend following the instructions of the hardware user guides for correct

wiring of the product. The product has to be supplied with a stabilized voltage source and

the wiring has to be conformed to the security and fire prevention regulations. The product

has to be handled with care, avoiding any contact with the pins because electrostatic

discharges may damage the product itself. Same cautions have to be taken for the SIM,

checking carefully the instruction for its use. Do not insert or remove the SIM when the

product is in power saving mode.

The system integrator is responsible for the functioning of the final product; therefore, care

has to be taken to the external components of the module, as well as any project or

installation issue, because the risk of disturbing the GSM network or external devices or

having impact on the security. Should there be any doubt, please refer to the technical

documentation and the regulations in force. Every module has to be equipped with a proper

antenna with specific characteristics. The antenna has to be installed with care in order to

avoid any interference with other electronic devices and has to guarantee a minimum

distance from the body (20 cm). In case this requirement cannot be satisfied, the system

integrator has to assess the final product against the SAR regulation.

The European Community provides some Directives for the electronic equipment

introduced on the market. All of the relevant information is available on the European

Community website:

http://ec.europa.eu/enterprise/sectors/rtte/documents/

The text of the Directive 99/05 regarding telecommunication equipment is available,

while the applicable Directives (Low Voltage and EMC) are available at:

http://ec.europa.eu/enterprise/sectors/electrical/

Page 64

NE866B1_Hardware_Design_Guide

1VV0301354 Rev. 6 Page 64 of 70 2018-02-28

12. REFERENCE TABLE OF RF BANDS CHARACTERISTICS

Mode

Freq. Tx

(MHz)

Freq. Rx

(MHz)

Channels

Tx-Rx Offset

PCS 1900

1850.2 ~ 1909.8

1930.2 ~ 1989.8

512 ~ 810

80 MHz

DCS 1800

1710 ~ 1785

1805 ~ 1880

512 ~ 885

95 MHz

GSM 850

824.2 ~ 848.8

869.2 ~ 893.8

128 ~ 251

45 MHz

EGSM 900

890 ~ 915

935 ~ 960

0 ~ 124

45 MHz

880 ~ 890

925 ~ 935

975 ~ 1023

45 MHz

WCDMA 2100 – B1

1920 ~ 1980

2110 ~ 2170

Tx: 9612 ~ 9888

Rx: 10562 ~ 10838

190 MHz

WCDMA 1900 – B2

1850 ~ 1910

1930 ~ 1990

Tx: 9262 ~ 9538

Rx: 9662 ~ 9938

80 MHz

WCDMA 1800 – B3

1710 ~ 1785

1805 ~ 1880

Tx: 937 ~ 1288

Rx: 1162 ~ 1513

95 MHz

WCDMA AWS – B4

1710 ~ 1755

2110 ~ 2155

Tx: 1312 ~ 1513

Rx: 1537 ~ 1738

400 MHz

WCDMA 850 – B5

824 ~ 849

869 ~ 894

Tx: 4132 ~ 4233

Rx: 4357 ~ 4458

45 MHz

WCDMA 900 – B8

880 ~ 915

925 ~ 960

Tx: 2712 ~ 2863

Rx: 2937 ~ 3088

45 MHz

WCDMA 1800 – B9

1750 ~ 1784.8

1845 ~ 1879.8

Tx: 8762 ~ 8912

Rx: 9237 ~ 9387

95 MHz

WCDMA 800 – B19

830 ~ 845

875 ~ 890

Tx: 312 ~ 363

Rx: 712 ~ 763

45 MHz

TDSCDMA 2000 – B34

2010 ~ 2025

2010 ~ 2025

Tx: 10054 ~ 10121

Rx: 10054 ~ 10121

0 MHz

TDSCDMA 1900 – B39

1880 ~ 1920

1880 ~ 1920

Tx: 9404 ~ 9596

Rx: 9404 ~ 9596

0 MHz

LTE 2100 – B1

1920 ~ 1980

2110 ~ 2170

Tx: 18000 ~ 18599

Rx: 0 ~ 599

190 MHz

Page 65

NE866B1_Hardware_Design_Guide

1VV0301354 Rev. 6 Page 65 of 70 2018-02-28

Mode

Freq. Tx

(MHz)

Freq. Rx

(MHz)

Channels

Tx-Rx Offset

LTE 1900 – B2

1850 ~ 1910

1930 ~ 1990

Tx: 18600 ~ 19199

Rx: 600 ~ 1199

80 MHz

LTE 1800 – B3

1710 ~ 1785

1805 ~ 1880

Tx: 19200 ~ 19949

Rx: 1200 ~ 1949

95 MHz

LTE AWS – B4

1710 ~ 1755

2110 ~ 2155

Tx: 19950 ~ 20399

Rx: 1950 ~ 2399

400 MHz

LTE 850 – B5

824 ~ 849

869 ~ 894

Tx: 20400 ~ 20649

Rx: 2400 ~ 2649

45 MHz

LTE 2600 – B7

2500 ~ 2570

2620 ~ 2690

Tx: 20750 ~ 21449

Rx: 2750 ~ 3449

120 MHz

LTE 900 – B8

880 ~ 915

925 ~ 960

Tx: 21450 ~ 21799

Rx: 3450 ~ 3799

45 MHz

LTE 1800 – B9

1749.9 ~ 1784.9

1844.9 ~ 1879.9

Tx: 21800 ~ 2149

Rx: 3800 ~ 4149

95 MHz

LTE AWS+ – B10

1710 ~ 1770

2110 ~ 2170

Tx: 22150 ~ 22749

Rx: 4150 ~ 4749

400 MHz

LTE 700a – B12

699 ~ 716

729 ~ 746

Tx : 23010 ~ 23179

Rx : 5010 ~ 5179

30 MHz

LTE 700c – B13

777 ~ 787

746 ~ 756

Tx : 27210 ~ 27659

Rx : 9210 ~ 9659

-31 MHz

LTE 700b – B17

704 ~ 716

734 ~ 746

Tx: 23730 ~ 23849

Rx: 5730 ~ 5849

30 MHz

LTE 800 – B19

830 ~ 845

875 ~ 890

Tx: 24000 ~ 24149