Page 1

DE910 Series Hardware User

Guide

1vv0300951 Rev.9 – 2015-05-11

Page 2

DE910 Series Hardware User Guide

1vv0300951 Rev.9 – 2015-05-11

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 2 of 77

APPLICABILITY TABLE

PRODUCT

DE910

-

DUAL

DE910

-SC

Page 3

DE910 Series Hardware User Guide

1vv0300951 Rev.9 – 2015-05-11

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 3 of 77

SPECIFICATIONS SUBJECT TO CHANGE WITHOUT NOTICE

Notice

While reasonable efforts have been made to assure the accuracy of this document, Telit

assumes no liability resulting from any inaccuracies or omissions in this document, or from

use of the information obtained herein. The information in this document has been carefully

checked and is believed to be entirely reliable. However, no responsibility is assumed for

inaccuracies or omissions. Telit reserves the right to make changes to any products described

herein and reserves the right to revise this document and to make changes from time to time

in content hereof with no obligation to notify any person of revisions or changes. Telit does

not assume any liability arising out of the application or use of any product, software, or

circuit described herein; neither does it convey license under its patent rights or the rights of

others.

It is possible that this publication may contain references to, or information about Telit

products (machines and programs), programming, or services that are not announced in your

country. Such references or information must not be construed to mean that Telit intends to

announce such Telit products, programming, or services in your country.

Copyrights

This instruction manual and the Telit products described in this instruction manual may be,

include or describe copyrighted Telit material, such as computer programs stored in

semiconductor memories or other media. Laws in the Italy and other countries preserve for

Telit and its licensors certain exclusive rights for copyrighted material, including the

exclusive right to copy, reproduce in any form, distribute and make derivative works of the

copyrighted material. Accordingly, any copyrighted material of Telit and its licensors

contained herein or in the Telit products described in this instruction manual may not be

copied, reproduced, distributed, merged or modified in any manner without the express

written permission of Telit. Furthermore, the purchase of Telit products shall not be deemed

to grant either directly or by implication, estoppel, or otherwise, any license under the

copyrights, patents or patent applications of Telit, as arises by operation of law in the sale of a

product.

Computer Software Copyrights

The Telit and 3rd Party supplied Software (SW) products described in this instruction manual

may include copyrighted Telit and other 3rd Party supplied computer programs stored in

semiconductor memories or other media. Laws in the Italy and other countries preserve for

Telit and other 3rd Party supplied SW certain exclusive rights for copyrighted computer

programs, including the exclusive right to copy or reproduce in any form the copyrighted

computer program. Accordingly, any copyrighted Telit or other 3rd Party supplied SW

computer programs contained in the Telit products described in this instruction manual may

not be copied (reverse engineered) or reproduced in any manner without the express written

permission of Telit or the 3rd Party SW supplier. Furthermore, the purchase of Telit products

shall not be deemed to grant either directly or by implication, estoppel, or otherwise, any

license under the copyrights, patents or patent applications of Telit or other 3rd Party supplied

SW, except for the normal non-exclusive, royalty free license to use that arises by operation

of law in the sale of a product.

Page 4

DE910 Series Hardware User Guide

1vv0300951 Rev.9 – 2015-05-11

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 4 of 77

Usage and Disclosure Restrictions

License Agreements

The software described in this document is the property of Telit and its licensors. It is

furnished by express license agreement only and may be used only in accordance with the

terms of such an agreement.

Copyrighted Materials

Software and documentation are copyrighted materials. Making unauthorized copies is

prohibited by law. No part of the software or documentation may be reproduced, transmitted,

transcribed, stored in a retrieval system, or translated into any language or computer language,

in any form or by any means, without prior written permission of Telit

High Risk Materials

Components, units, or third-party products used in the product described herein are NOT

fault-tolerant and are NOT designed, manufactured, or intended for use as on-line control

equipment in the following hazardous environments requiring fail-safe controls: the operation

of Nuclear Facilities, Aircraft Navigation or Aircraft Communication Systems, Air Traffic

Control, Life Support, or Weapons Systems (High Risk Activities"). Telit and its supplier(s)

specifically disclaim any expressed or implied warranty of fitness for such High Risk

Activities.

Trademarks

TELIT and the Stylized T Logo are registered in Trademark Office. All other product or

service names are the property of their respective owners.

Copyright © Telit Communications S.p.A. 2013.

Page 5

DE910 Series Hardware User Guide

1vv0300951 Rev.9 – 2015-05-11

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 5 of 77

Contents

1. Introduction ................................................. 8

1.1. Scope ..................................................... 8

1.2. Audience .................................................. 8

1.3. Contact Information, Support .............................. 8

1.4. Document Organization ..................................... 9

1.5. Text Conventions ......................................... 10

1.6. Related Documents ........................................ 10

2. General Product Description ................................. 11

2.1. Overview ................................................. 11

2.2. Product Specifications ................................... 12

2.3. RoHS Compliance .......................................... 13

3. DE910 Module Connections .................................... 14

3.1. Pin-Out .................................................. 14

3.1.1. LGA Pads Layout (DE910-DUAL) ............................... 19

3.1.2. LGA Pads Layout (DE910-SC) ................................. 20

4. Hardware Commands ........................................... 21

4.1. Turning on the DE910 module .............................. 21

4.1.1. Initialization and Activation State ........................ 21

4.2. Turning off the DE910 module ............................. 23

4.2.1. Shutdown by Software Command ............................... 24

4.2.2. Hardware Shutdown .......................................... 24

4.3. Hardware Reset ........................................... 25

4.3.1. Hardware Unconditional Shutdown ............................ 25

4.4. Summary of Turning ON and OFF the Module ................. 26

5. Power Supply ................................................ 27

5.1. Power Supply Requirements ................................ 27

5.2. General Design Rules ..................................... 29

5.2.1. Electrical Design Guidelines ............................... 29

5.2.2. + 5V Input Source Power Supply Design Guidelines ........... 29

5.2.3. +12V Input Source Power Supply Design Guidelines ........... 30

5.2.4. Battery Source Power Supply Design Guidelines .............. 31

5.2.5. Thermal Design Guidelines .................................. 31

Page 6

DE910 Series Hardware User Guide

1vv0300951 Rev.9 – 2015-05-11

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 6 of 77

5.2.6. Power Supply PCB layout Guidelines ......................... 32

6. Antenna ..................................................... 35

6.1. CDMA Antenna Requirements ................................ 35

6.1.1. CDMA antenna – PCB line Guidelines ......................... 36

6.1.2. PCB Guidelines in case of FCC certification ................ 37

6.1.3. CDMA Antenna – Installation Guidelines ..................... 39

6.2. Antenna Diversity Requirements ........................... 40

6.3. GNSS Antenna Requirements ................................ 41

6.3.1. Combined GNSS Antenna ...................................... 41

6.3.2. Linear and Patch GNSS Antenna .............................. 41

6.3.3. The Design Considerations to enhanced GNSS performance ..... 41

6.3.4. GNSS Antenna – PCB Line Guidelines ......................... 44

6.3.5. GNSS Antenna – Installation Guidelines ..................... 44

7. USB Port .................................................... 45

8. Serial Port ................................................. 46

8.1. Modem Serial Port 1 ...................................... 47

8.2. Modem Serial Port 2 ...................................... 48

8.3. RS232 Level Translation .................................. 48

9. Audio Section Overview ...................................... 51

9.1. Electrical Characteristics ............................... 51

9.1.1. CODEC Example .............................................. 51

10. General Purpose I/O ......................................... 52

10.1. Logic Level Specification .............................. 53

10.2. Using a GPIO Pad as Input .............................. 53

10.3. Using a GPIO Pad as Output ............................. 54

10.4. Using the Temperature Monitor Function ................. 54

10.4.1. Short Description ........................................ 54

10.5. Indication of Network Service Availability ............. 55

10.6. RTC Bypass Output ...................................... 56

10.7. VAUX/PWRMON Power Output ............................... 57

11. DAC and ADC section ......................................... 58

11.1. DAC Converter .......................................... 58

11.1.1. Description .............................................. 58

Page 7

DE910 Series Hardware User Guide

1vv0300951 Rev.9 – 2015-05-11

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 7 of 77

11.1.2. Enabling DAC ............................................. 58

11.1.3. Low Pass Filter Example .................................. 59

11.2. ADC Converter .......................................... 59

11.2.1. Description .............................................. 59

11.2.2. Using ADC Converter ...................................... 59

12. Test Point .................................................. 60

13. Mounting the Module on your Board ........................... 61

13.1. General ................................................ 61

13.2. Module Finishing & Dimensions .......................... 61

13.3. Recommended foot print for the application ............. 62

13.4. Stencil ................................................ 63

13.5. PCB Pad Design ......................................... 63

13.6. Recommendations for PCB Pad Dimensions (mm) ............ 63

13.7. Solder Paste ........................................... 65

13.7.1. Solder Reflow ............................................ 65

14. Packing System .............................................. 67

14.1. Tray ................................................... 67

14.2. Reel ................................................... 69

14.2.1. Carrier Tape Detail ...................................... 69

14.2.2. Reel Detail .............................................. 70

14.2.3. Packaging Detail ......................................... 70

14.3. Moisture Sensibility ................................... 71

15. Application Design Guide .................................... 72

15.1. Download and Debug Port ................................ 72

16. Conformity Assessment Issues (Problèmes d'évaluation de

conformité)...................................................... 73

17. Safety Recommendations ...................................... 76

18. Document History ............................................ 77

Page 8

DE910 Series Hardware User Guide

1vv0300951 Rev.9 – 2015-05-11

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 8 of 77

1. Introduction

1.1. Scope

The aim of this document is the description of typical hardware solutions useful for

developing a product with the Telit DE910 module.

1.2. Audience

This document is intended for Telit customers who are about to implement their applications

using our DE910 modules.

1.3. Contact Information, Support

For general contact, technical support, to report documentation errors and to order manuals,

contact Telit Technical Support Center (TTSC) at:

TS-EMEA@telit.com

TS-NORTHAMERICA@telit.com

TS-LATINAMERICA@telit.com

TS-APAC@telit.com

Alternatively, use:

http://www.telit.com/en/products/technical-support-center/contact.php

For detailed information about where to buy the Telit modules or for recommendations on

accessories and components visit:

http://www.telit.com

To register for product news and announcements or for product questions contact Telit

Technical Support Center (TTSC).

Our aim is to make this guide as helpful as possible. Please keep us informed of comments

and suggestions for improvements.

Telit appreciates feedback from the users of our information.

Page 9

DE910 Series Hardware User Guide

1vv0300951 Rev.9 – 2015-05-11

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 9 of 77

1.4. Document Organization

This document contains the following chapters:

Chapter 1: “Introduction” provides a scope for this document, target audience, contact and

support information, and text conventions.

Chapter 2: “General Product Description” gives an overview of the features of the product.

Chapter 3: “DE910 Module Connections” deals with the pin out configuration and layout.

Chapter 4: “Hardware Commands” How to operate the module via hardware.

Chapter 5: “Power supply” Power supply requirements and general design rules.

Chapter 6: “Antenna” The antenna connection and board layout design are the most important

parts in the full product design.

Chapter 7: “USB Port” The USB port on the Telit DE910 is the core of the interface between

the module and OEM hardware.

Chapter 8: “Serial ports” Refers to the serial ports of the Telit DE910.

Chapter 9: “Audio Section overview” Refers to the audio blocks of the Base Band Chip of the

DE910 Telit Module.

Chapter 10: “General Purpose I/O” How the general purpose I/O pads can be configured.

Chapter 11: “DAC and ADC section” Deals with these two kinds of converters.

Chapter 12: “Test Pont” Deals with Test Point.

Chapter 13: “Mounting the DE910 on the application board” Mechanical dimensions and

recommendations on how to mount the module on the user’s board.

Chapter 14: “Packing System” Deals with packing system.

Chapter 15: “Application Design Guide” Deals with the design of host system for download

or upgrade.

Chapter 16: “Conformity Assessment Issues” provides some fundamental hints about the

conformity assessment that the final application might need.

Chapter 17: “Safety Recommendation” provides some safety recommendations that must be

followed by the customer in the design of the application that makes use of the Telit DE910.

Page 10

DE910 Series Hardware User Guide

1vv0300951 Rev.9 – 2015-05-11

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 10 of 77

1.5. Text Conventions

Danger – This information MUST be followed or catastrophic equipment failure or bodily

injury may occur.

Caution or Warning – Alerts the user to important points about integrating the module. If

these points are not followed, the module and end user equipment may fail or malfunction.

Tip or Information – Provides advice and suggestions that may be useful when

integrating the module.

All dates are in ISO 8601 format, i.e. YYYY-MM-DD.

1.6. Related Documents

Digital Voice Interface Application Note, 80000NT10061A

Product Description, 80392ST10096A

Telit EVK2 User Guide, 1vv0300704

Page 11

DE910 Series Hardware User Guide

1vv0300951 Rev.9 – 2015-05-11

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 11 of 77

2. General Product Description

2.1. Overview

The aim of this document is the description of typical hardware solutions useful for

developing a product with the Telit DE910 module.

In this document all the basic functions of a mobile device will be taken into account; for each

one of them a proper hardware solution will be suggested and eventually the wrong solutions

and common errors to be avoided will be evidenced. Obviously this document cannot

embrace all hardware solutions and products that may be designed. Avoiding the discussed

wrong solutions must be considered as mandatory. While the suggested hardware

configurations must not be considered mandatory, the information given must be used as a

guide and a starting point for properly developing a product with the Telit DE910 module.

NOTE:

The integration of the CDMA 1xRTT/1xEV-DO Rev. A module within a user application

must be done according to the design rules described in this manual.

The information presented in this document is believed to be accurate and reliable. However,

no responsibility is assumed by Telit Communication S.p.A. for its use, such as any

infringement of patents or other rights of third parties. No license is granted by implication or

otherwise under any patent rights of Telit Communication S.p.A. other than for circuitry

embodied in Telit products. This document is subject to change without notice.

Page 12

DE910 Series Hardware User Guide

1vv0300951 Rev.9 – 2015-05-11

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 12 of 77

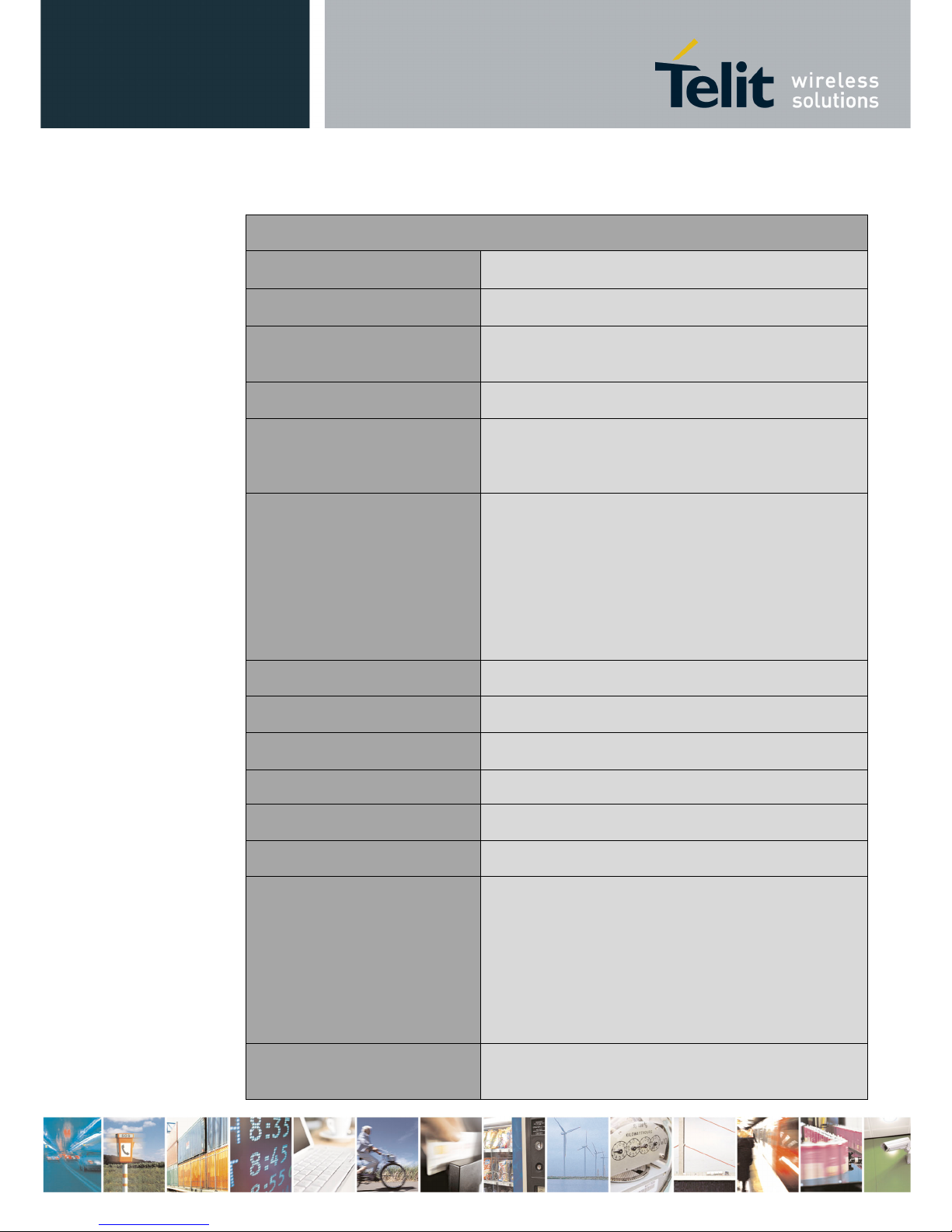

2.2. Product Specifications

DE910 Specifications

Air Interface

CDMA

1xRTT

CDMA 1xEV-DO Rev. A

Frequency Bands

DE910

-

DUAL:

800/1900MHz

DE910-SC: 800MHz

Data Service

CDMA 1x

RTT

: 153.6 Kbps (full

-

duplex)

CDMA 1xEV-DO Rev. A: 3.1Mbps (F/L),

1.8Mbps (R/L)

Location solution

gpsOne

Max. RF out power

CDMA BC0:

Power class 3

(24.4dBm

) for 1xRTT

,

Power class 3 (24dBm) for 1xEV-DO

CDMA BC1: Power class 2 (24.4dBm) for 1xRTT,

Power class 2 (24dBm) for 1xEV-DO

Typical conducted sensitivity

a. CDMA

1xRTT: Better than –108dBm

1xEV-DO: Better than –109dBm

b. GNSS

Acquisition sensitivity: –145dBm

Navigation sensitivity: –160dBm

Tracking sensitivity: –161dBm

Cold-start sensitivity: –145dBm

TTFF: 32 sec @–130dBm

Device dimensions

28.2mm(L) x 28.2mm(W) x 2.05mm(T)

Weight

3.8g

Storage and Operating

Temperature Range

–40 ~ +85°C

Normal operating voltage range

3.4 ~ 4.2V

IO voltage

1.8V

Hardware design

RX diversity on all band

Interface

144

Land

-

Grid-Array

interface

10 general I/O ports maximum including multi-

functional I/Os

State LED output

1 A/D converter

1 D/A converter (PDM output)

Full RS232 CMOS UART: baud rate up to 4Mbps

Reserved two wires CMOS UART for debugging

USB 2.0: baud rate up to 480Mbps

Antenna

Primary a

ntenna

RX Diversity antenna

GPS&GLONASS antenna

Page 13

DE910 Series Hardware User Guide

1vv0300951 Rev.9 – 2015-05-11

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 13 of 77

Audio

PCM interface for Digital audio

Message

SMS (MO/MT)

Approvals

Regulatory:

- DE910-DUAL: FCC, IC

- DE910-SC: CCC, SRRC

Carrier: Verizon, Sprint, Aeris

2.3. RoHS Compliance

As a part of Telit’s corporate policy of environmental protection, the DE910 complies with

the RoHS (Restriction of Hazardous Substances) directive of the European Union (EU

Directive 2011/65/EU).

Page 14

DE910 Series Hardware User Guide

1vv0300951 Rev.9 – 2015-05-11

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 14 of 77

3. DE910 Module Connections

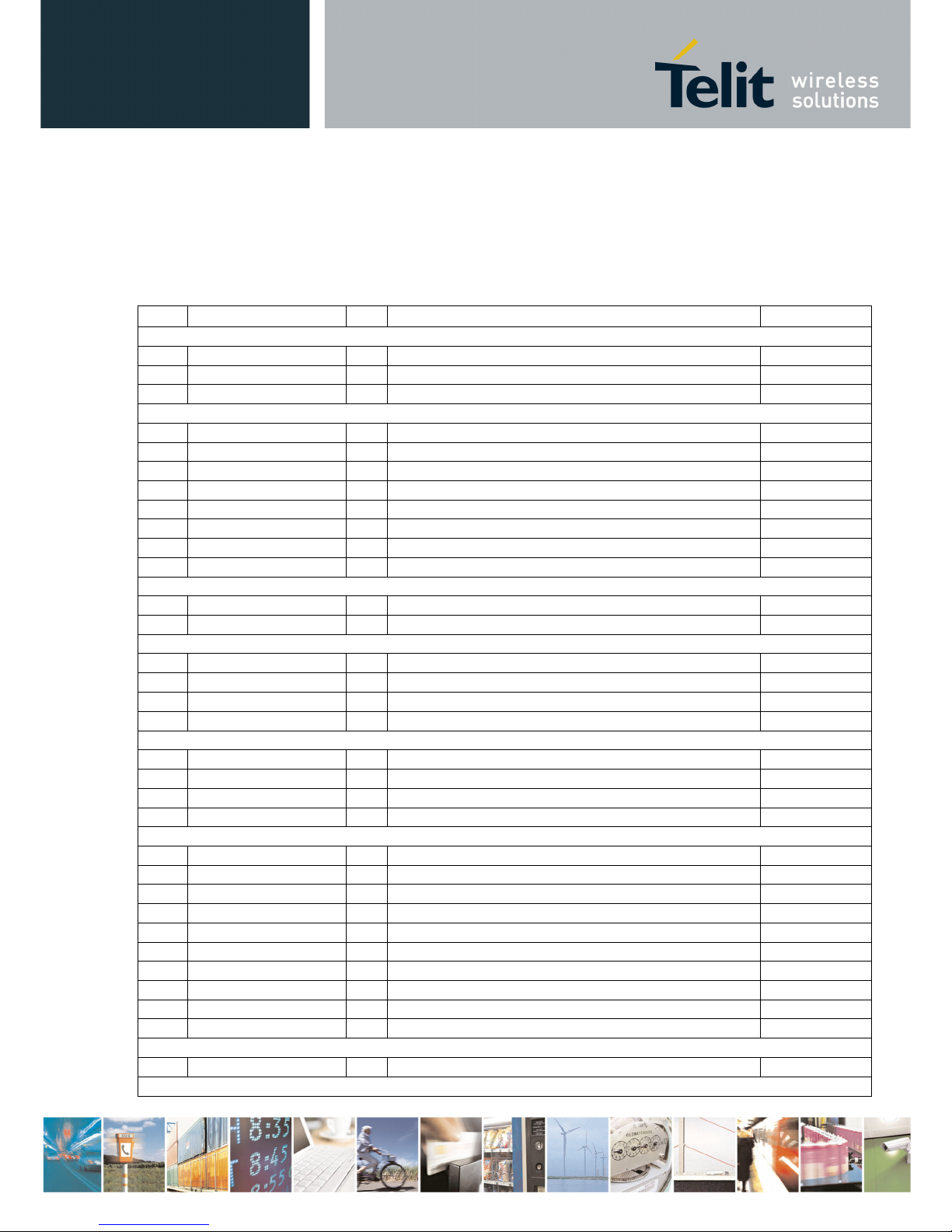

3.1. Pin-Out

Pin

Signal I/O

Function Type

USB HS 2.0 Communication Port

B15

USB_D+

I/O USB differential Data(+)

C15

USB_D

- I/O USB differential Data(

-)

A13

VBUS

I

Power sense for the internal USB transceiver

5V

Asynchronous UART

– Prog. / data +HW Flow Control

N15

C103/TXD

I

Seria

l data input from DTE

CMOS

1.8V

M15

C104/RXD

O

Serial data output to DTE

CMOS 1.8V

M14

C108/DTR

I

Input for Data terminal ready signal (DTR) from DTE

CMOS

1.8V

L14

C105/RTS

I

Input for Request to send signal (RTS) from DTE

CMOS

1.8V

P15

C106/CTS

O

Outp

ut for Clear to send signal (CTS) to DTE

CMOS

1.8V

N14

C109/DCD

O

Output for Data carrier detect signal (DCD) to DTE

CMOS

1.8V

P14

C107/DSR

O

Output for Data set ready signal (DSR) to DTE

CMOS

1.8V

R14

C125/RING

O

Output for Ring indicator signal (RI) t

o DTE

CMOS

1.8V

Asynchronous Auxiliary UART

D15

TX_

AUX

O

Auxillary UART (TX Data to DTE)

CMOS

1.8V

E15

RX_

AUX

I

Auxillary UART (RX Data from DTE)

CMOS

1.8V

RUIM Card Interface

A3

RUIM

VCC

-

External

RUIM

signal

-

Power supply for the SIM

1.8/3V

A5

RUIMIO I/O External

RUIM

signal

- Data I/O

1.8/3V

A6

RUIM

CLK

O

External

RUIM

signal

- Clock

1.8/3V

A7

RUIM

RST O External

RUIM

signal

- Reset

1.8/3V

Digital Voice interface (DVI)

B9

D

VI_WA0

I/O Digital Voice interface (WA0)

CMOS 1.8V

B6

DVI_RX

I

Digital

Voice interface (RX)

CMOS 1.8V

B7

DVI_TX

O

Digital Voice interface (TX)

CMOS 1.8V

B8

DVI_CLK

I/O Digital Voice interface (CLK)

CMOS 1.8V

Digital IO

C8

GPIO_01

I/O GPIO_01 / STAT LED

CMOS 1.8V

C9

GPIO_02

I/O GPIO_02

CMOS 1.8V

C10

GPIO_03

I/O GPIO_03

CMOS 1.8V

C11

GPIO_04

I/O GPIO_04

CMOS 1.8V

B14

GPIO_05

I/O GPIO_05

CMOS 1.8V

C12

GPIO_06

I/O GPIO_06

CMOS 1.8V

C13

GPIO_07

I/O GPIO_07 / DAC_OUT

CMOS 1.8V

K15

GPIO_08

I/O GPIO_08

CMOS 1.8V

L15

GPIO_09

I/O GPIO_09

CMOS 1.8V

G15

GPIO_10

I/O GPIO_10

CMOS 1.8V

ADC Section

B1

ADC

_IN1

AI

Analog/Digital converter input

A/D

RF Section

Page 15

DE910 Series Hardware User Guide

1vv0300951 Rev.9 – 2015-05-11

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 15 of 77

Pin

Signal I/O

Function Type

K1

ANTENNA

I/O CDMA Antenna (50Ohm)

RF

F1

ANT_DIV

I

CDMA Antenna Diversity Input (50Ohm)

RF

GPS Section

R9

ANT_GPS

I

GPS Antenna (50Ohm)

RF

R7

GPS_LNA_EN

O

Output enab

le for External LNA supply

CMOS

1.8V

Miscellaneous Function

R13

HW_SHUTDOWN* I Hardware unconditional shutdown

CMOS 1.8V

Open collector

R12

ON_OFF* I Input Command for Power ON/Software shutdown

CMOS 1.8V

Open collector

C14

VRTC

I

VRTC Backup Capacitor

Power

R11

VAUX/PWRMON O

Supply Output for external accessories / Power ON

Monitor

1.8V

Test Point

C3

TP1

Test Point

TP

C4

TP2

Test Point

TP

C5

TP3

Test Point

TP

C6

TP4

Test Point

TP

C7

TP5

Test Point

TP

D3

TP6

Test Point

TP

E3

TP7

Test Po

int TP

Power Supply

M1

VBATT

-

Main Power Supply (Baseband)

Power

M2

VBATT

-

Main Power Supply (Baseband)

Power

N1

VBATT_PA

-

Main Power Supply (PAM)

Power

N2

VBATT_PA

-

Main Power Supply (PAM)

Power

P1

VBATT_PA

-

Main Power Supply (PAM)

Power

P2

VB

ATT_PA

-

Main Power Supply (PAM)

Power

E1

GND

-

Ground

G1

GND

-

Ground

H1

GND

-

Ground

J1

GND

-

Ground

L1

GND

-

Ground

A2

GND

-

Ground

E2

GND

-

Ground

F2

GND

-

Ground

G2

GND

-

Ground

H2

GND

-

Ground

J2

GND

-

Ground

K2

GND

-

Ground

L2

GND

-

Ground

R2

GND

-

Ground

M3

GND

-

Ground

N3

GND

-

Ground

P3

GND

-

Ground

R3

GND

-

Ground

D4

GND

-

Ground

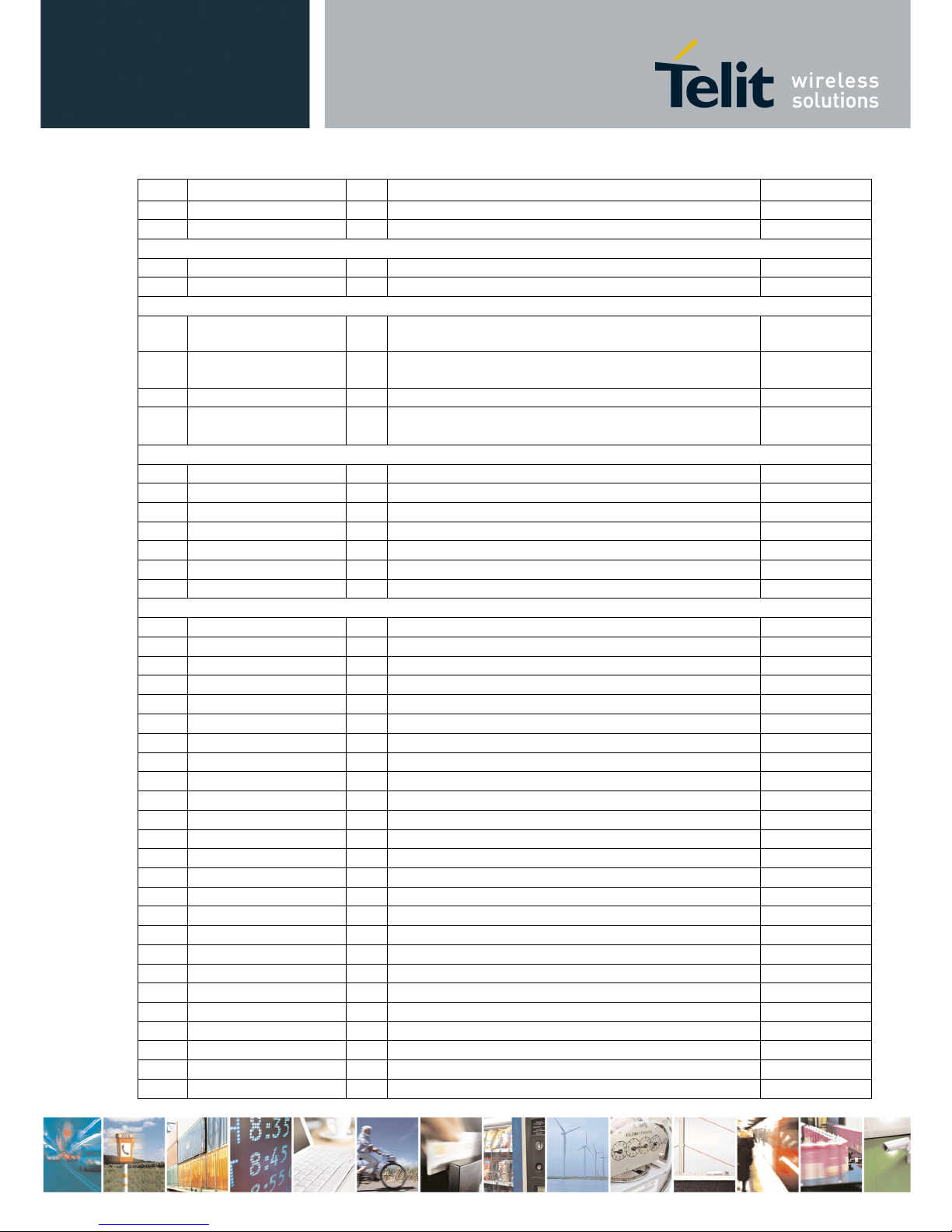

Page 16

DE910 Series Hardware User Guide

1vv0300951 Rev.9 – 2015-05-11

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 16 of 77

Pin

Signal I/O

Function Type

M4

GND

-

Ground

N4

GND

-

Ground

P4

GND

-

Ground

R4

GND

-

Ground

N5

GND

-

Ground

P5

GND

-

Ground

R5

GND

-

Ground

N6

GND -

Ground

P6

GND

-

Ground

R6

GND

-

Ground

P8

GND

-

Ground

R8

GND

Ground

P9

GND

-

Ground

P10

GND

-

Ground

R10

GND

-

Ground

M12

GND

-

Ground

B13

GND

-

Ground

P13

GND

-

Ground

E14

GND

-

Ground

Reserved

C1

Reserved

-

Reserved

D1

R

eserved

-

Reserved

B2

Reserved

-

Reserved

C2

Reserved

-

Reserved

D2

Reserved

-

Reserved

B3

Reserved

-

Reserved

F3

Reserved

-

Reserved

G3

Reserved

-

Reserved

H3

Reserve

d - Reserved

J3

Reserved

-

Reserved

K3

Reserved

-

Reserved

L3

Reserved

-

Reserved

A4

Reserved

-

Reserved

B4

Reserved

-

Reserved

B5

Reserved

-

Reserved

N7

Reserved

-

Reserved

P7

Reserved

-

Reserved

A8

Reserved

-

Reserved

N8

Reserved

-

Reserved

A9

Reserved

-

Reserved

N9

Reserved

-

Reserved

A10

Reserved

-

Reserved

B10

Reserved

-

Reserved

B11

Reserved

-

Reserved

N10

Reserved

-

Rese

rved

A11

Reserved

-

Reserved

N11

Reserved

-

Reserved

Page 17

DE910 Series Hardware User Guide

1vv0300951 Rev.9 – 2015-05-11

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 17 of 77

Pin

Signal I/O

Function Type

P11

Reserved

-

Reserved

A12

Reserved

-

Reserved

B12

Reserved

-

Reserved

D12

Reserved

-

Reserved

N12

Reserved

-

Reserved

P12

Reserved

-

Reserved

D13

Reserved

-

Reserved

E13

Reserved

-

Reserved

F13

Reserved

-

Reserved

G13

Reserved

-

Reserved

H13

Reserved

-

Reserved

J13

Reserved

-

Reserved

K13

Reserved

-

Reserved

L13

Reserved

-

Reserved

M13

Reserved

-

Reserved

N13

Reserved

-

Reserved

A14

Reserved

-

Reserved

D14

Reserve

d - Reserved

F14

Reserved

-

Reserved

G14

Reserved

-

Reserved

H14

Reserved

-

Reserved

J14

Reserved

-

Reserved

K14

Reserved

-

Reserved

F15

Reserved

-

Reserved

H15

Reserved

-

Reserved

J15

Reserved

-

Reserved

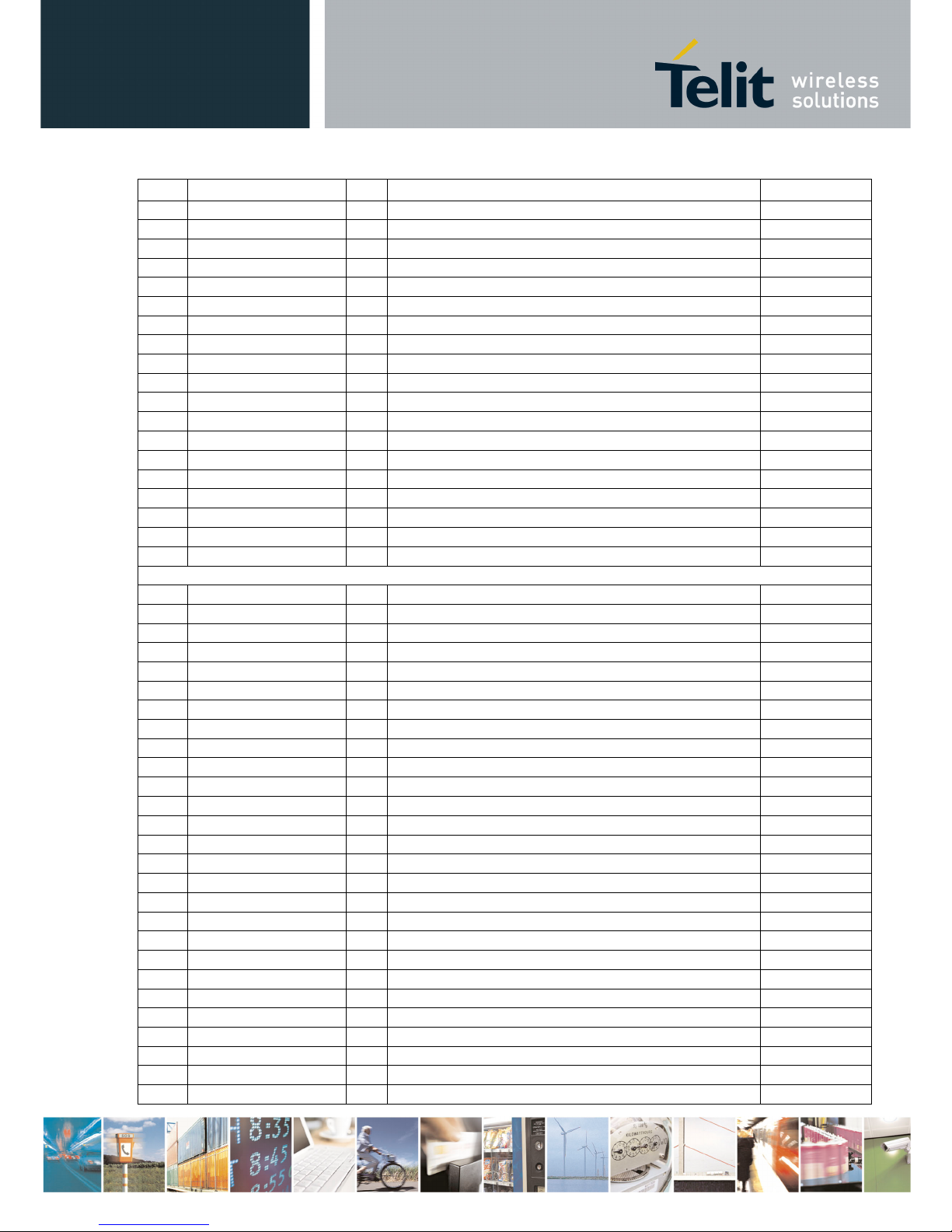

NOTE:

RUIM interface is reserved for Verizon/Sprint/Aeris variants and it is applicable only to

RUIM variants of DE910 (DE910-SC)

WARNING:

Reserved pins must not be connected.

NOTE:

The following table is listing the main Pinout differences between the DE910 variants.

Product BC0 BC1 GPS Notes

DE910-DUAL

Yes Yes Yes Reserved pads: A3, A5, A6, A7

DE910-SC

Yes No Yes

Page 18

DE910 Series Hardware User Guide

1vv0300951 Rev.9 – 2015-05-11

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 18 of 77

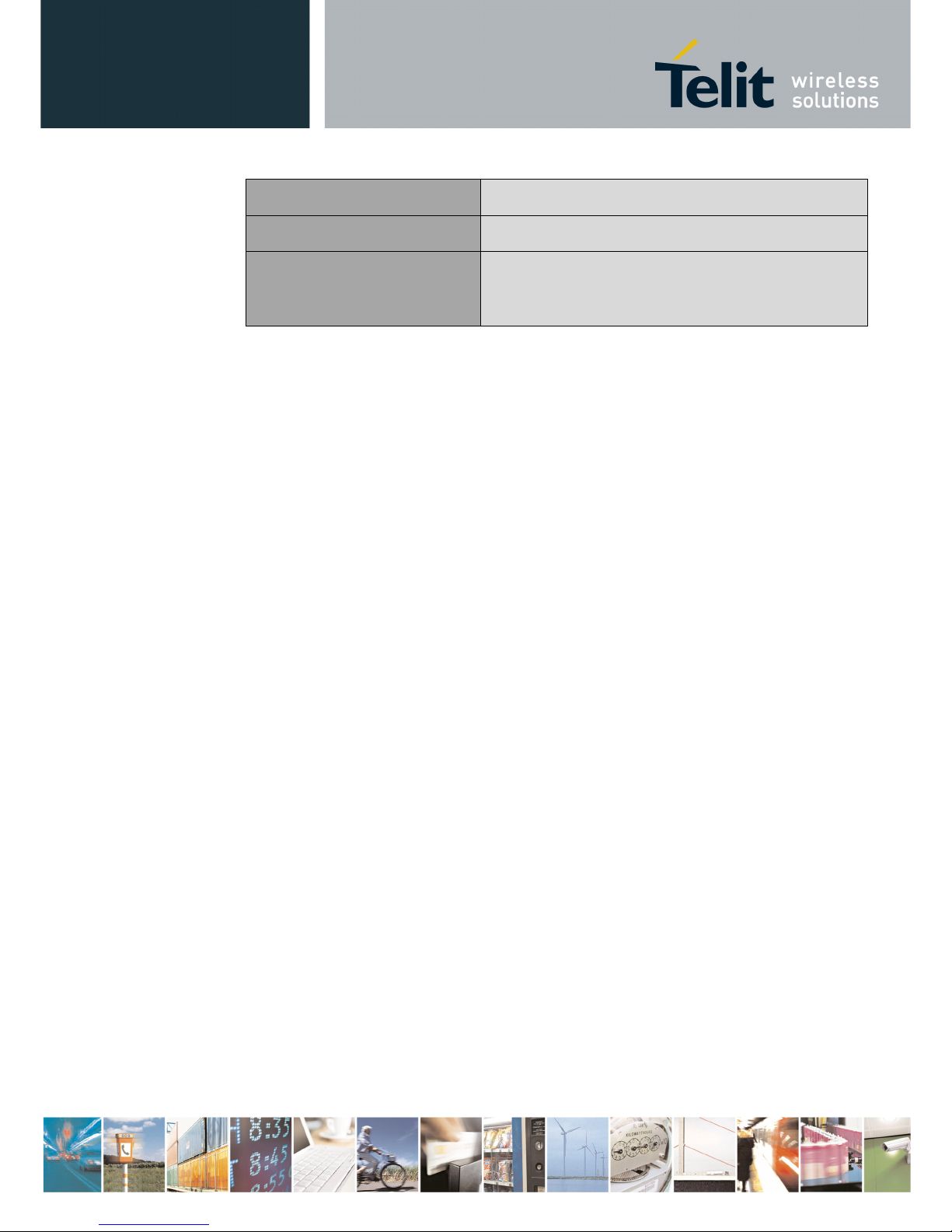

NOTE:

Almost all pins not in use must be left disconnected. The only exceptions are the following

pins:

PAD Signal

M

1,M2,N1,N2,P1,P2

VBATT&VBATT_PA

E1,G1,H1,J1,L1,A2,E2,

F2,G2,H2,J2,K2,L2,R2,

M3,N3,P3,R3,D4,M4,N

4,P4,R4,N5,P5,R5,N6,P

6,R6,P8,R8,P9,P10,R10,

M12,B13,P13,E14

GND

R12 ON_OFF*

R13 HW_SHUTDOWN*

B15 USB_D+

If not used should be connected to

a Test Point

C15 USB_D-

If not used should be connected to

a Test Point

A13 VBUS

If not used should be connected to

a Test Point

N15 C103/TXD

If not used should be connected to

a Test Point

M15 C104/RXD

If not used should be connected to

a Test Point

L14 C105/RTS

If the flow control is not used it

should be connected to GND

P15 C106/CTS

If not used should be connected to

a Test Point

D15 TXD_AUX

If not used should be connected to

a Test Point

E15 RXD_AUX

If not used should be connected to

a Test Point

K1 Main Antenna

F1

ANT_DIV (If supported

by the product)

If not used

it could be left

unconnected, but has to be

disabled by the related AT

Command (AT#RXDIV): please

refer to the AT User Guide for the

related syntax

R9

ANT_GPS (If supported

by the product)

If the GPS is not used it could be

left unconnected

C3,C4,C5,C6,C7,D3,E3 Test Point

RTS must be connected to the GND (on the module side) if flow control is not used.

The above pins are also necessary to debug the application incorporating the module.

Page 19

DE910 Series Hardware User Guide

1vv0300951 Rev.9 – 2015-05-11

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 19 of 77

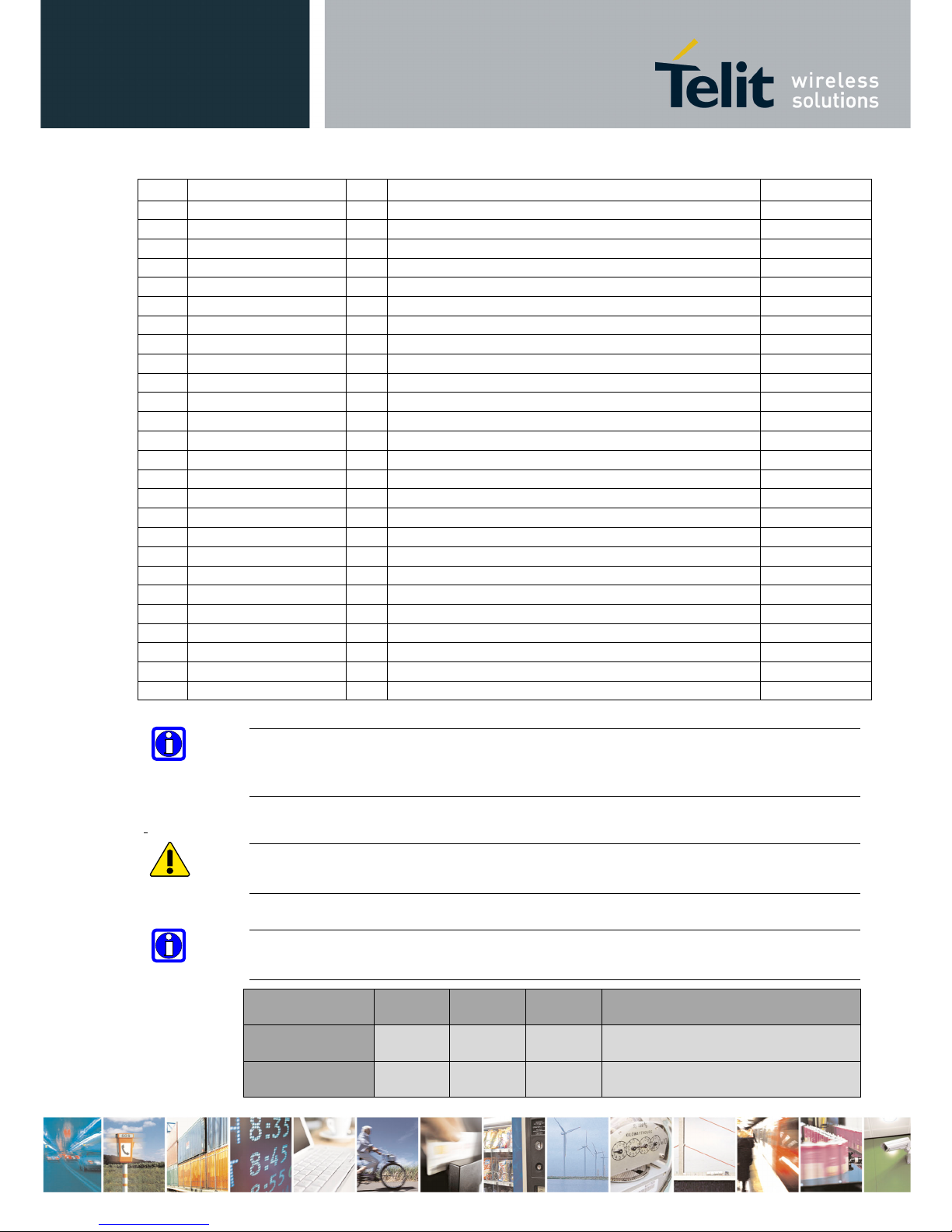

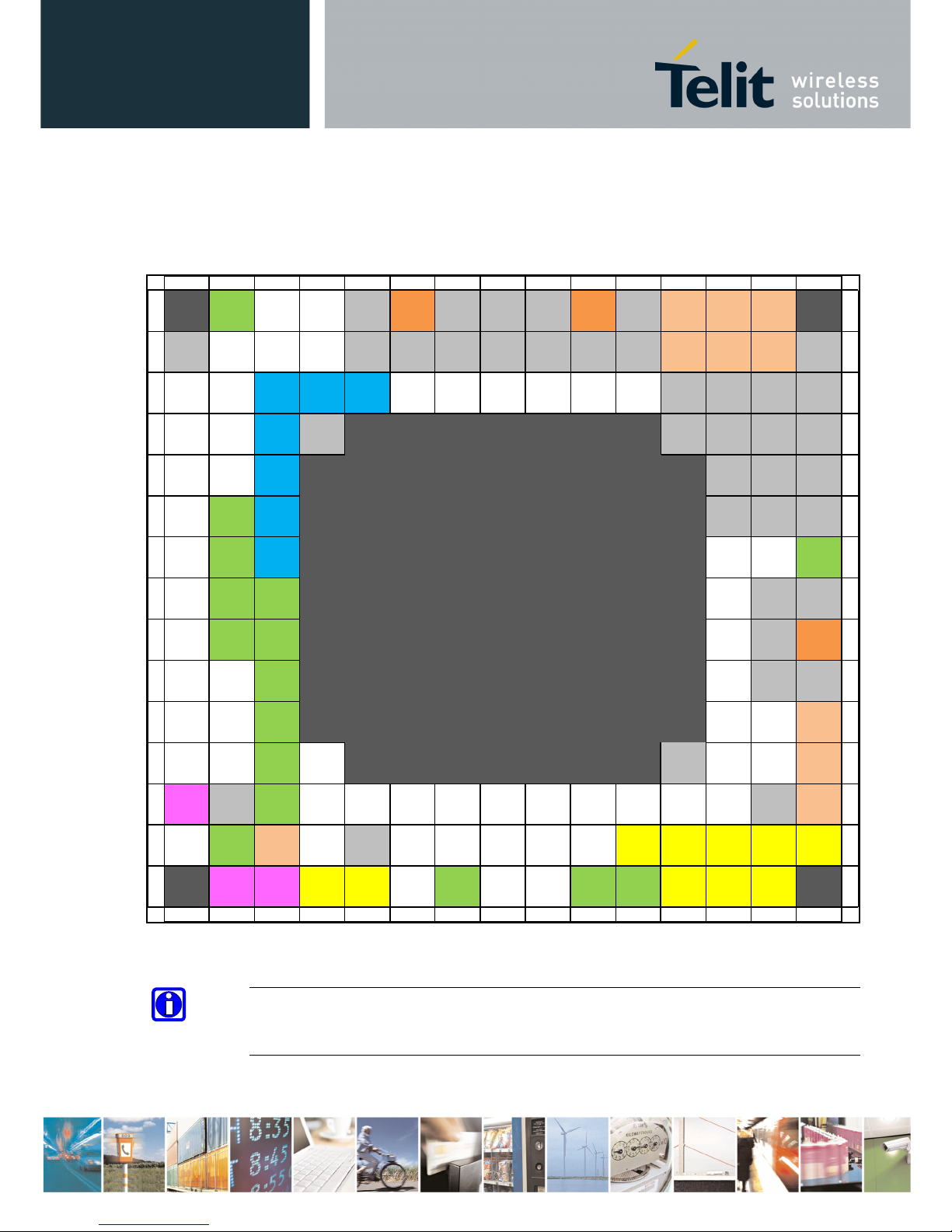

3.1.1. LGA Pads Layout (DE910-DUAL)

A B C D E F G H J K L M N P R

1 ADC_IN1 RES RES GND ANT_DIV GND GND GND ANT ENNA GND VBATT VBAT T_PA VBATT_ PA 1

2 GND RES RES RES GND GND GND GND GND GND GND VBATT VBAT T_PA VBATT_ PA GND 2

3 RES RES TP1 TP6 TP7 RES RES R ES RES RES RES GND GND GND GND 3

4 RES RES TP2 GND GND GND GND GND 4

5 RES RES TP3 GND GND GND 5

6 RES DVI_RX TP4 GND GND GND 6

7 RES DVI_TX T P5 RES RES

GPS_LNA_E

N

7

8 RES DVI_CL K GPIO_01 RES GND GND 8

9 RES DVI_WA0 GPIO_02 RES GND ANT_GPS 9

10 RES R ES GPIO_03 RES GND GND 10

11 RES R ES GPIO_04 RES RES

VAUX/PW R

MON

11

12 RES R ES GPIO_06 RES GND RES RES ON_OFF* 12

13 USB_VBUS GND GPIO_07 R ES R ES RES RES RES RES RES R ES RES RES GND

HW_S HUTD

OWN*

13

14 RES GPIO_ 05 VRT C RES G ND RES RES RES RES RES C105/RT S C108/DTR C109/DCD C107/DSR C125/RING 14

15 USB_D+ USB_D- TX_ AUX RX_AUX RES GPIO_10 RES RES GPIO_08 GPIO_0 9 C104/RXD C103/T XD C106/CTS 15

A B C D E F G H J K L M N P R

Top View

NOTE:

The pin defined as RES must be considered RESERVED and not connected on any pin in the

application. The related area on the application has to be kept empty.

Page 20

DE910 Series Hardware User Guide

1vv0300951 Rev.9 – 2015-05-11

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 20 of 77

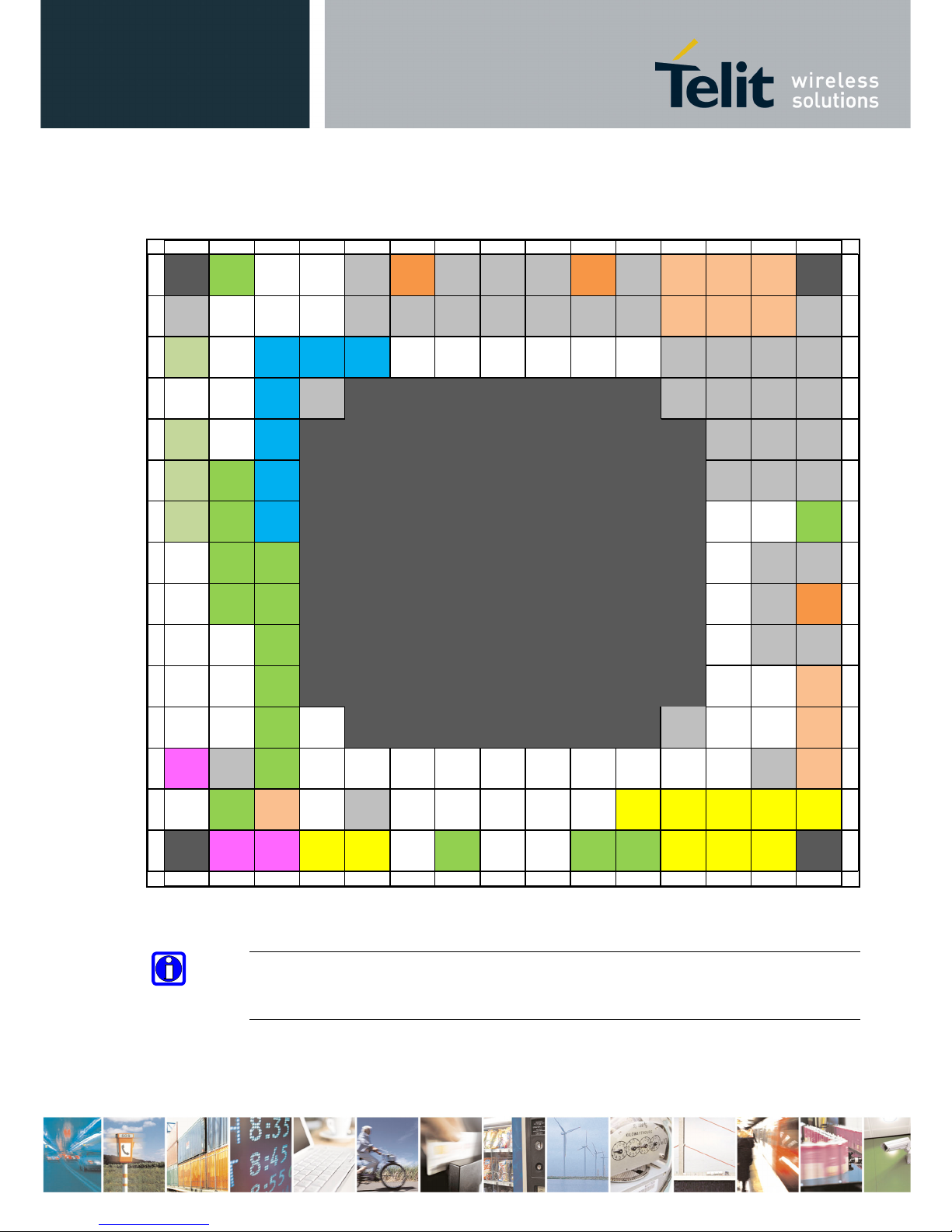

3.1.2. LGA Pads Layout (DE910-SC)

A B C D E F G H J K L M N P R

1 ADC_IN1 RES RES GND ANT_DIV GND GND GND ANT ENNA GND VBATT VBAT T_PA VBATT_ PA 1

2 GND RES RES RES GND GND GND GND GND GND GND VBATT VBAT T_PA VBATT_ PA GND 2

3 RUIMVCC RES TP1 TP6 T P7 RES RES RE S RES RES RES GND GND GND GND 3

4 RES RES TP2 GND GND GND GND GND 4

5 RUIMIO R ES TP3 GND GND GND 5

6 RUIMCLK DVI_RX TP4 GND GND GND 6

7 RUIMRST DVI_T X TP5 RES RES

GPS_LNA_E

N

7

8 RES DVI_CL K GPIO_01 RES GND GND 8

9 RES DVI_WA0 GPIO_02 RES GND ANT_GPS 9

10 RES R ES GPIO_03 RES GND GND 10

11 RES R ES GPIO_04 RES RES

VAUX/PW R

MON

11

12 RES R ES GPIO_06 RES GND RES RES ON_OFF* 12

13 USB_VBUS GND GPIO_07 R ES R ES RES RES RES RES RES R ES RES RES GND

HW_S HUTD

OWN*

13

14 RES GPIO_ 05 VRT C RES G ND RES RES RES RES RES C105/RT S C108/DTR C109/DCD C107/DSR C125/RING 14

15 USB_D+ USB_D- TX_ AUX RX_AUX RES GPIO_10 RES RES GPIO_08 GPIO_0 9 C104/RXD C103/T XD C106/CTS 15

A B C D E F G H J K L M N P R

Top View

NOTE:

The pin defined as RES must be considered RESERVED and not connected on any pin in the

application. The related area on the application has to be kept empty.

Page 21

DE910 Series Hardware User Guide

1vv0300951 Rev.9 – 2015-05-11

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 21 of 77

4. Hardware Commands

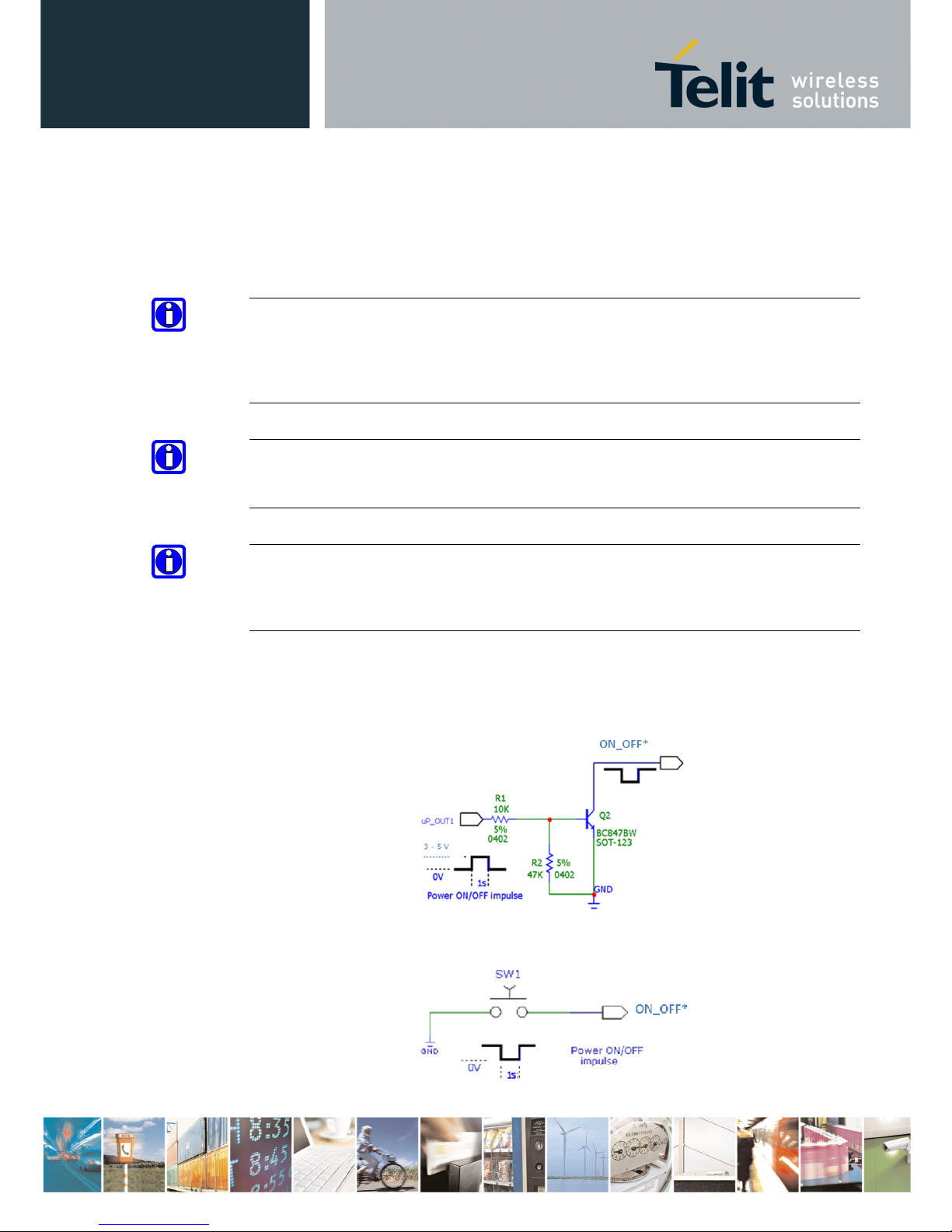

4.1. Turning on the DE910 module

To turn on the DE910, the pad ON_OFF* must be tied low for at least 1 second and then

released.

The maximum current that can be drained from the ON_OFF* pad is 0.1 mA.

A simple circuit to power on the module is illustrated below:

4.1.1. Initialization and Activation State

Upon turning on DE910 module, the DE910 module is not active yet because the boot

sequence of DE910 is still executing internally. It takes about 10 seconds to complete the

initialization of the module internally.

For this reason, it would be useless to try to access DE910 during the Initialization state as

below. The DE910 module needs at least 10 seconds after the PWRMON goes High to

become operational by reaching the activation state.

Page 22

DE910 Series Hardware User Guide

1vv0300951 Rev.9 – 2015-05-11

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 22 of 77

During the Initialization state, any kind of AT-command is not available. DTE must wait for

the Activation state to communicate with DE910.

To check if the DE910 has powered on, the hardware line PWRMON must be monitored.

When PWRMON goes high, the module has powered on.

NOTE:

Do not use any pull up resistor on the ON_OFF* line. It is pulled up internally. Using a pull

up resistor may bring latch up problems on the DE910 power regulator and improper power

on/off of the module. The line ON_OFF* must be connected only in open collector

configuration.

NOTE:

In this document all the lines are inverted. Active low signals are labeled with a name that

ends with "*" or with a bar over the name.

NOTE:

In order to avoid a back powering effect it is recommended to avoid having any HIGH logic

level signal applied to the digital pins of the DE910 module when the module is powered OFF

or during an ON/OFF transition.

For example:

1. To drive the ON_OFF* pad with a totem pole output of a +3/5 V microcontroller

(uP_OUT1):

2. To drive the ON_OFF* pad directly with an ON/OFF button:

Page 23

DE910 Series Hardware User Guide

1vv0300951 Rev.9 – 2015-05-11

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 23 of 77

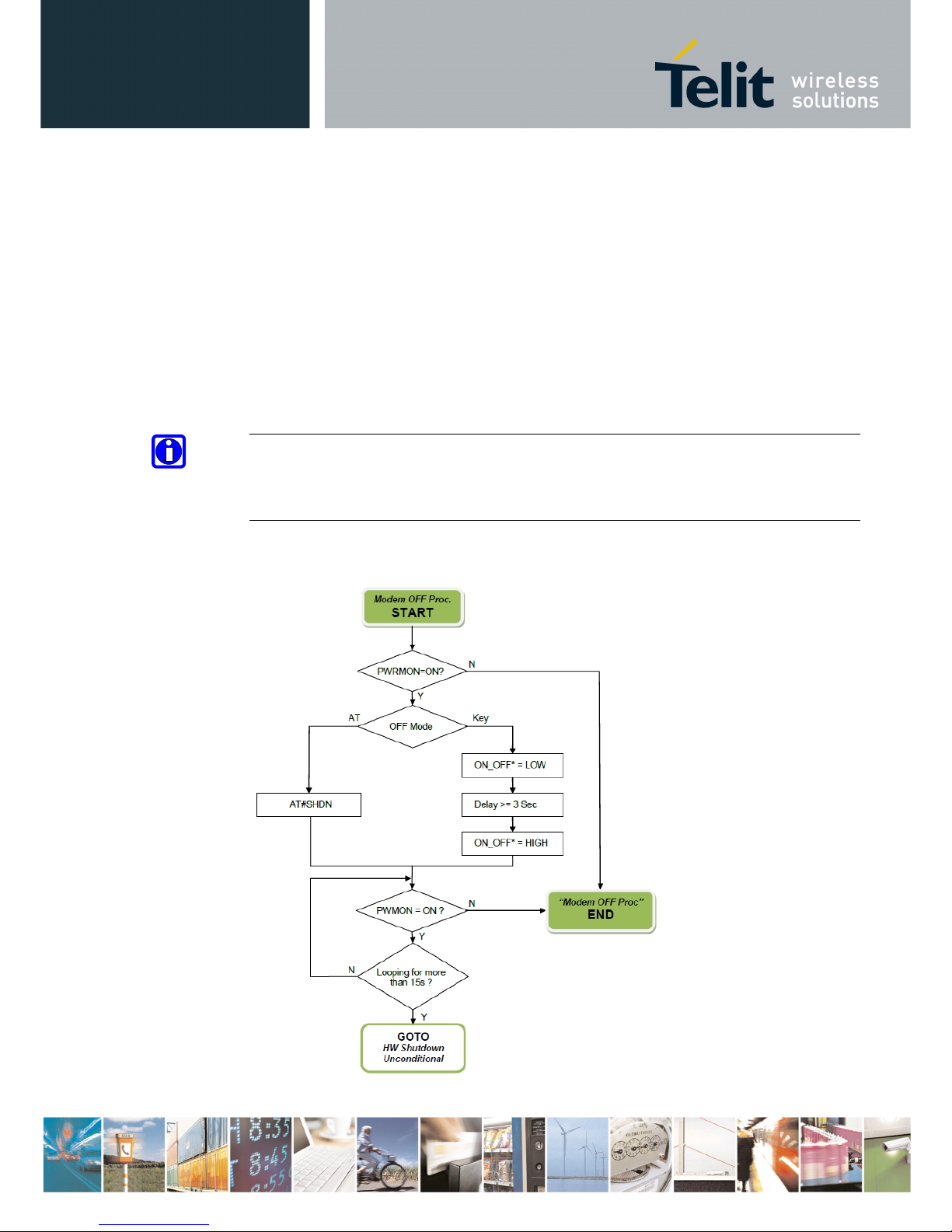

4.2. Turning off the DE910 module

Turning off the device can be done in two ways:

By software command (see DE910 Software User Guide)

By hardware shutdown

When the device is shut down by software command or by hardware shutdown, it issues a

detach request to the network that informs the network that the device will no longer be

reachable.

NOTE:

In order to avoid a back powering effect it is recommended to avoid having any HIGH logic

level signal applied to the digital pins of the DE910 when the module is powered OFF or

during an ON/OFF transition.

The following flow chart shows the proper turnoff procedure:

Page 24

DE910 Series Hardware User Guide

1vv0300951 Rev.9 – 2015-05-11

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 24 of 77

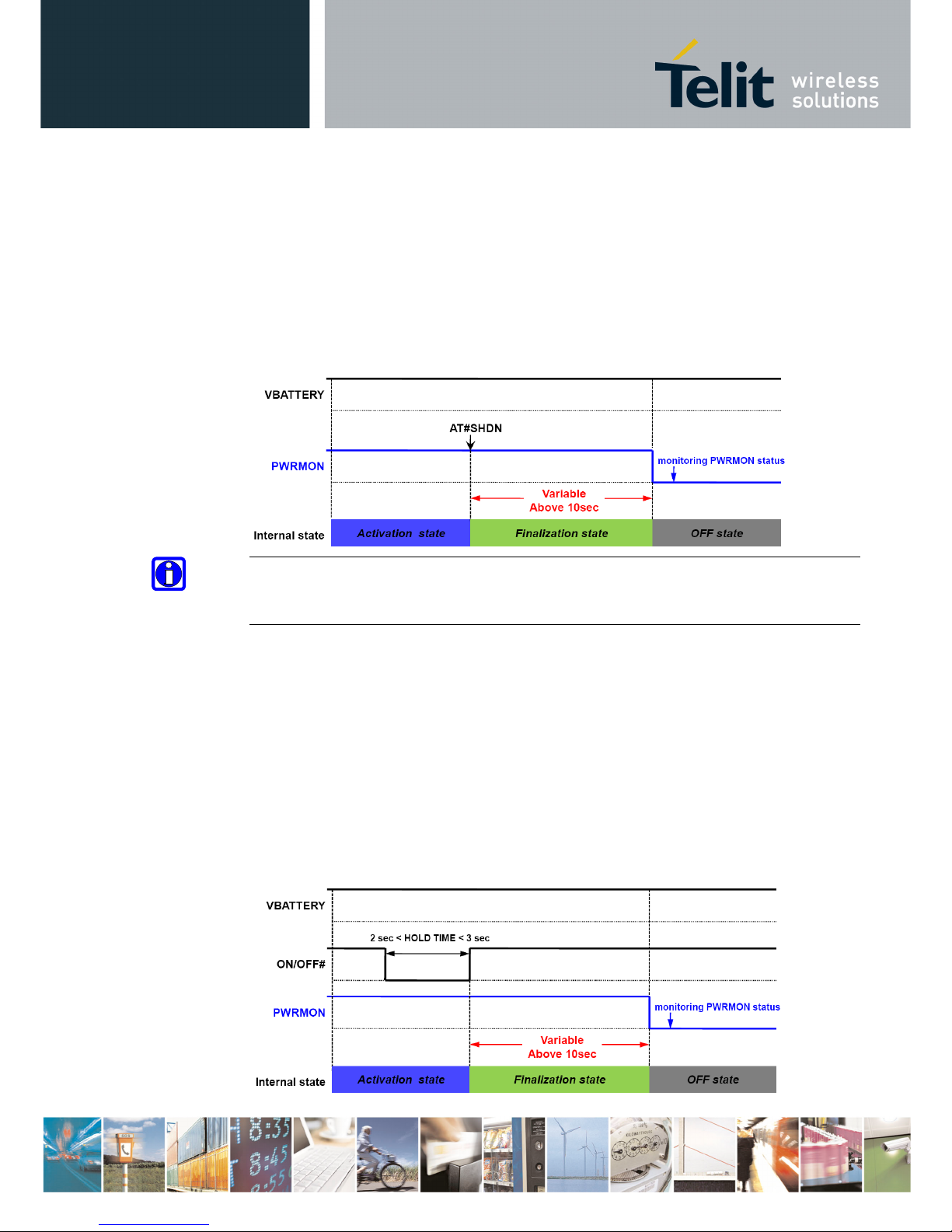

4.2.1. Shutdown by Software Command

The DE910 can be shut down by a software command.

When a shutdown command is sent, the DE910 goes into the finalization state and will shut

down PWRMON at the end of this state.

The period of the finalization state can vary according to the state of the DE910 so it cannot

be fixed definitely.

Normally it will be above 10 seconds after sending a shutdown command and DTE should

monitor the status of PWRMON to see the actual power off.

TIP:

To check if the device has powered off hardware line PWRMON must be monitored. When

PWRMON goes low, the device has powered off.

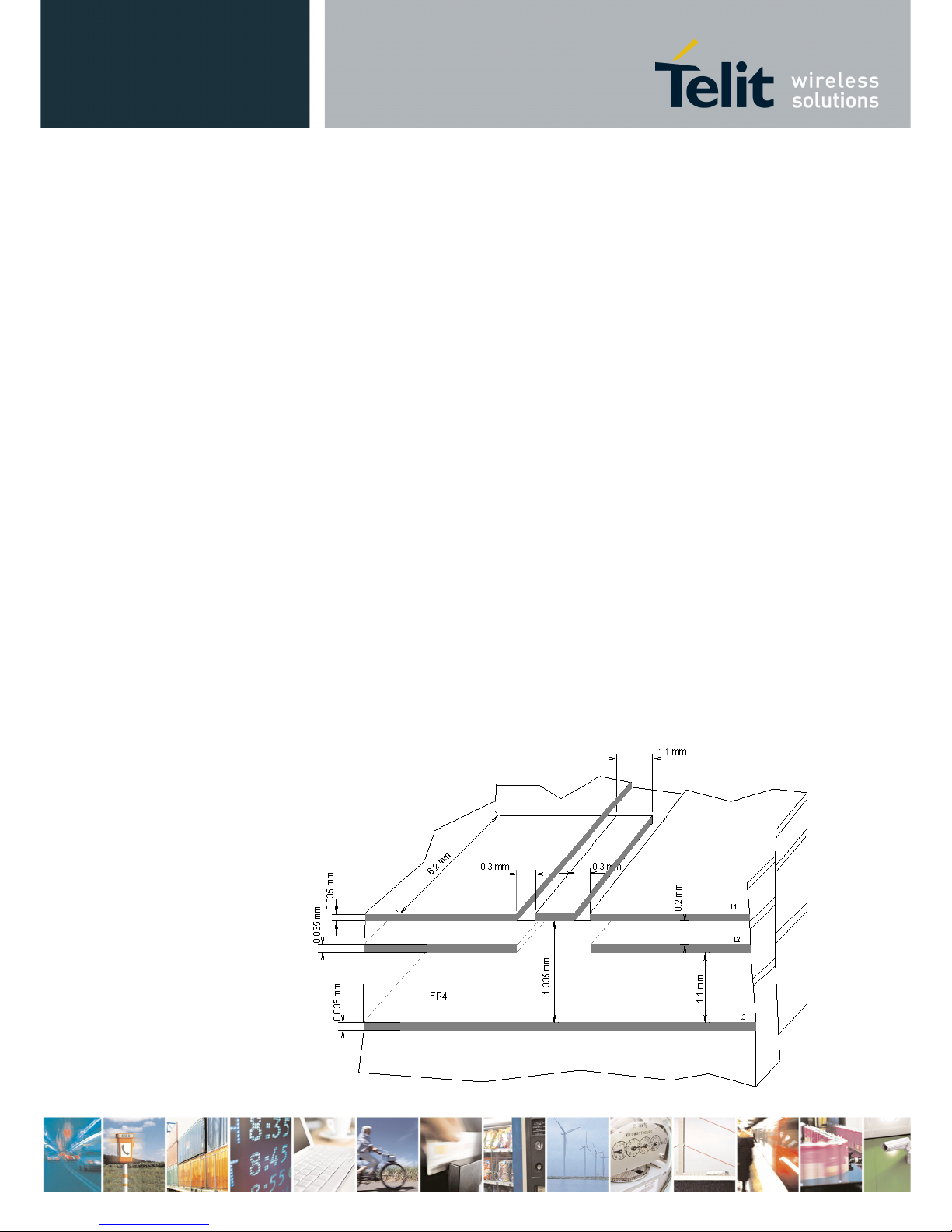

4.2.2. Hardware Shutdown

To turn OFF the DE910 the pad ON_OFF* must be tied low for at least 2 seconds and then

released. The same circuitry and timing for the power on must be used.

When the hold time of ON_OFF* is above 2 seconds, the DE910 goes into the finalization

state and will shut down PWRMON at the end of this state.

The period of the finalization state can vary according to the state of the DE910 so it cannot

be fixed definitely.

Normally it will be above 10 seconds after releasing ON_OFF* and DTE should monitor the

status of PWRMON to see the actual power off.

Page 25

DE910 Series Hardware User Guide

1vv0300951 Rev.9 – 2015-05-11

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 25 of 77

TIP:

To check if the device has powered off, hardware line PWRMON must be monitored. When

PWRMON goes low, the device has powered off.

4.3. Hardware Reset

WARNING:

The Hardware Reset must not be used during normal operation of the device since it does not

detach the device from the network. It shall be kept as an emergency exit procedure to be

done in the rare case that the device gets stuck waiting for some network.

4.3.1. Hardware Unconditional Shutdown

To unconditionally shutdown the DE910, the pad HW_SHUTDOWN* must be tied low for at

least 200 milliseconds and then released.

A simple circuit to unconditionally shutdown the module is illustrated below:

NOTE:

Do not use any pull up resistor on the HW_SHUTDOWN* line or any totem pole digital

output. Using a pull up resistor may bring latch up problems on the DE910 power regulator

and result in improper functioning of the module. The line HW_SHUTDOWN* must be

connected only in open collector configuration.

TIP:

The unconditional hardware Shutdown must always be implemented on the boards and the

software must use it only as an emergency exit procedure.

Page 26

DE910 Series Hardware User Guide

1vv0300951 Rev.9 – 2015-05-11

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 26 of 77

For example:

To drive the HW_SHUTDOWN* pad with a totem pole output of a +3/5 V microcontroller

(uP_OUT2):

4.4. Summary of Turning ON and OFF the Module

The chart below describes the overall sequences for turning the module ON and OFF.

Page 27

DE910 Series Hardware User Guide

1vv0300951 Rev.9 – 2015-05-11

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 27 of 77

5. Power Supply

The power supply circuitry and board layout are a very important part in the full product

design and they strongly reflect on the product’s overall performance. Read carefully the

requirements and the guidelines that follow for a proper design.

5.1. Power Supply Requirements

The external power supply must be connected to VBATT & VBATT_PA signals and must

fulfill the following requirements:

Power Supply

Nominal Supply Voltage

3.8V

Normal Operating Voltage Range

3.4V ~ 4.2V

Extended Operating Voltage Range

3.3V ~ 4.5V

NOTE:

The Operating Voltage Range MUST never be exceeded. Special care must be taken when

designing the application’s power supply section to avoid having an excessive voltage drop.

If the voltage drop is exceeding the limits it could cause a Power Off of the module..

Behavior in the extended operating voltage range might deviate from 3GPP2 specification.

Page 28

DE910 Series Hardware User Guide

1vv0300951 Rev.9 – 2015-05-11

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 28 of 77

Current Consumption

Mode

Average

(mA)

Mode Description

Power off current (Typical)

15uA(*1)

Standby mode

No call in progress (slot cycle index=2, hybrid mode)

AT+CFUN=1

GPS=off

<15

Normal mode; full functionality of the module

GPS=on

<65

AT+CFUN=4

GPS=off

<25

Disabled TX and RX; modules is not registered on the

network

GPS=on

<70

AT+CFUN=5

GPS=off <2.5(*2)

Full functionality with power saving; Module

registered on the network can receive incoming call

sand SMS

GPS=on

<65

Tx and Rx mode

A call in progress

Antenna

Diversity=off

GPS=off

670

CDMA 1x call

GPS=on

735

Antenna

Diversity=on

GPS=off

700

GPS=on

705

Antenna

Diversity=off

GPS=off

650

1xEV-DO call

GPS=on

730

Antenna

Diversity=on

GPS=off

640

GPS=on

685

(*1)The off current is the total supply current from the main battery with the PMIC off and the

32 kHz XTAL oscillator on.

(*2) Standby current consumption depends on network configuration or module configuration.

NOTE:

The Operating Voltage Range MUST never be exceeded. Special care must be taken in order

to fulfill min/max supply voltage requirement.

Page 29

DE910 Series Hardware User Guide

1vv0300951 Rev.9 – 2015-05-11

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 29 of 77

TIP:

The electrical design for the power supply should be made ensuring it will be capable of a

peak current output of at least 1A.

5.2. General Design Rules

The principal guidelines for the Power Supply Design embrace three different design steps:

the electrical design

the thermal design

the PCB layout

5.2.1. Electrical Design Guidelines

The electrical design of the power supply depends strongly on the power source where this

power is drained. We will distinguish them into three categories:

+5V input (typically PC internal regulator output)

+12V input (typically automotive)

Battery

5.2.2. + 5V Input Source Power Supply Design

Guidelines

The desired output for the power supply is 3.8V, hence there is not a big

difference between the input source and the desired output so a linear regulator

can be used. A switching power supply will not be suitable because of the low

drop-out requirements.

When using a linear regulator, a proper heat sink must be provided in order to

dissipate the power generated.

A Bypass low ESR capacitor of adequate capacity must be provided in order to

cut the current absorption peaks close to the DE910. A 100μF tantalum capacitor

is usually suited.

Make sure the low ESR capacitor on the power supply output (usually a tantalum

one) is rated at least 10V.

A protection diode must be inserted close to the power input in order to save the

DE910 from power polarity inversion.

Page 30

DE910 Series Hardware User Guide

1vv0300951 Rev.9 – 2015-05-11

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 30 of 77

An example of a linear regulator with 5V input:

5.2.3. +12V Input Source Power Supply Design

Guidelines

The desired output for the power supply is 3.8V, hence due to the big difference

between the input source and the desired output, a linear regulator is not suitable

and must not be used. A switching power supply would be preferable because of

its better efficiency, especially with the 1A peak current load represented by

DE910.

When using a switching regulator, a 500 kHz or more switching frequency

regulator is preferable because of its smaller inductor size and its faster transient

response. This allows the regulator to respond quickly to the current peaks

absorption.

In any case, the frequency and switching design selection is related to the

application to be developed due to the fact the switching frequency could also

generate EMC interferences.

For car PB battery the input voltage can rise up to 15.8V and this must be kept in

mind when choosing components: all components in the power supply must

withstand this voltage.

A bypass low ESR capacitor of adequate capacity must be provided in order to

cut the current absorption peaks. A 100μF tantalum capacitor is usually suited for

this.

Make sure the low ESR capacitor on the power supply output (usually a tantalum

one) is rated at least 10V.

For car applications a spike protection diode must be inserted close to the power

input in order to clean the supply from spikes.

A protection diode must be inserted close to the power input in order to save the

DE910 from power polarity inversion. This can be the same diode as for spike

protection.

Page 31

DE910 Series Hardware User Guide

1vv0300951 Rev.9 – 2015-05-11

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 31 of 77

An example of switching regulator with 12V input is in the schematic below:

5.2.4. Battery Source Power Supply Design

Guidelines

The desired nominal output for the power supply is 3.8V and the maximum voltage allowed is

4.2V. A single 3.7V lithium-ion cell battery type is ideal to supply power to the Telit DE910

module.

WARNING:

The three battery cells (Ni/Cd or Ni/MH 3.6V nom. battery types or 4V PB types) MUST

NOT be used directly because their maximum voltage can rise over the absolute maximum

voltage for the DE910 and cause damage. USE only Li-Ion battery types.

A bypass low (usually a 100uF tantalum) ESR capacitor with adequate capacity

must be provided in order to cut the current absorption peaks.

Make sure the low ESR capacitor (usually a tantalum) is rated at least 10V.

A protection diode must be inserted close to the power input in order to protect

the DE910 module from power polarity inversions when connecting the battery.

The battery capacity must be at least 500mAh in order to withstand the current

peaks of 1A. The suggested battery capacity is from 500mAh to 1000mAh.

5.2.5. Thermal Design Guidelines

The thermal design for the power supply heat sink must be done with the following

specifications:

Average current consumption during CDMA 1x / 1xEV-DO transmission @PWR

level max : 750 mA

Page 32

DE910 Series Hardware User Guide

1vv0300951 Rev.9 – 2015-05-11

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 32 of 77

Average GPS current during GPS ON (Power Saving disabled) in DE910 : 55

mA

NOTE:

The average consumption during transmissions depends on the power level at which the

device is requested to transmit via the network. The average current consumption hence varies

significantly.

Considering the very low current during idle, especially if the Power Saving function is

enabled, it is possible to consider from the thermal point of view that the device absorbs

current significantly only during calls.

If we assume that the device stays in transmission for short periods of time (a few minutes)

and then remains for quite a long time in idle (one hour), then the power supply always has

time to cool down between the calls and the heat sink could be smaller than the calculated for

750mA maximum RMS current. There could even be a simple chip package (no heat sink).

Moreover in average network conditions the device is requested to transmit at a lower power

level than the maximum and hence the current consumption will be less than 750mA (usually

around 250 mA).

For these reasons the thermal design is rarely a concern and the simple ground plane where

the power supply chip is placed can be enough to ensure a good thermal condition and avoid

overheating.

The heat generated by the DE910 must be taken into consideration during transmission at

24.4dBm max during calls. This generated heat will be mostly conducted to the ground plane

under the DE910. The application must be able to dissipate heat.

In the CDMA 1x/1xEV-DO mode, since DE910 emits RF signals continuously during

transmission, special attention must be paid to how to dissipate the heat generated.

The current consumption will be up to about 750mA in CDMA 1x continuously at the

maximum TX output power (24.4dBm). Thus, you must arrange the area on the application

PCB must be as large as possible under DE910.

The DE910 must be mounted on the large ground area of the application board and make

many ground vias to dissipate the heat.

5.2.6. Power Supply PCB layout Guidelines

As seen in the electrical design guidelines, the power supply must have a low ESR capacitor

on the output to cut the current peaks and a protection diode on the input to protect the supply

from spikes and polarity inversion. The placement of these components is crucial for the

correct operation of the circuitry. A misplaced component can be useless or can even decrease

the power supply performance.

The bypass low ESR capacitor must be placed close to the Telit DE910 power

input pads, or if the power supply is a switching type, the capacitor can be placed

close to the inductor to cut the ripple if the PCB trace from the capacitor to

Page 33

DE910 Series Hardware User Guide

1vv0300951 Rev.9 – 2015-05-11

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 33 of 77

DE910 is wide enough to ensure a drop-less connection even during the 1A

current peaks.

The protection diode must be placed close to the input connector where the power

source is drained.

The PCB traces from the input connector to the power regulator IC must be wide

enough to ensure no voltage drops occur when the 1A current peaks are absorbed.

While a voltage drop of hundreds of mV may be acceptable from the power loss

point of view, the same voltage drop may not be acceptable from the noise point

of view. If the application does not have an audio interface but only uses the data

feature of the Telit DE910, then this noise is not as disruptive and the power

supply layout design can be more forgiving.

The PCB traces to DE910 and the Bypass capacitor must be wide enough to

ensure no significant voltage drops occur when the 1A current peaks are absorbed.

This is a must for the same above-mentioned reasons. Try to keep this trace as

short as possible.

The PCB traces connecting the switching output to the inductor and the switching

diode must be kept as short as possible by placing the inductor and the diode very

close to the power switching IC (only for switching power supply). This is done

in order to reduce the radiated field (noise) at the switching frequency (usually

100-500 kHz).

The use of a good common ground plane is suggested.

The placement of the power supply on the board must be done in a way to

guarantee that the high current return paths in the ground plane are not

overlapped with any noise sensitive circuitry such as the microphone

amplifier/buffer or earphone amplifier.

The power supply input cables must be kept separate from noise sensitive lines

such as microphone/earphone cables.

The insertion of EMI filter on VBATT pins is suggested in those designs where

antenna is placed close to battery or supply lines.

A ferrite bead like Murata BLM18EG101TN1 or Taiyo Yuden P/N

FBMH1608HM101 can be used for this purpose.

The below figure shows the recommended circuit:

Page 34

DE910 Series Hardware User Guide

1vv0300951 Rev.9 – 2015-05-11

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 34 of 77

Page 35

DE910 Series Hardware User Guide

1vv0300951 Rev.9 – 2015-05-11

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 35 of 77

6. Antenna

The antenna connection and board layout design are the most important parts in the full

product design and they strongly reflect on the product’s overall performance. Read carefully

and follow the requirements and the guidelines for a proper design.

6.1. CDMA Antenna Requirements

The antenna for a Telit DE910 device must fulfill the following requirements:

CDMA Antenna Requirements

Frequency range

Depending

on

the

frequency band(s) provided by the

network operator, the customer must use the most suitable

antenna for that/those band(s)

Bandwidth

70 MHz

in CDMA BC0

140 MHz in CDMA BC1

Gain

Gain <

5.12

dBi in CDMA BC0

Gain < 6.12dBi in CDMA BC1

Impedance

50 Ohm

Input power

> 24.4dBm Average Power in CDMA

VSWR absolute max

≤ 5:1 (Limit to avoid permanent damage)

VSWR recommended

≤ 2:1 (Limit to fulfill all regulatory requirement)

When using the Telit DE910, since there’s no antenna connector on the module, the antenna

must be connected to the DE910 antenna pad (K1) by means of a transmission line

implemented in the PCB.

In the case that the antenna is not directly connected at the antenna pad of the DE910, then a

PCB line is required.

Page 36

DE910 Series Hardware User Guide

1vv0300951 Rev.9 – 2015-05-11

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 36 of 77

This transmission line shall fulfill the following requirements:

Antenna Line on PCB Requirements

Characteristic Impedance

50Ohm

Max Attenuation

0.3dB

Coupling with other signals shall be avoided

Cold End (Ground Plane) of antenna shall be equipotential to the DE910 ground pads

Furthermore if the device is developed for the US and/or Canada market, it must comply with

the FCC and/or IC approval requirements:

This device is to be used only for mobile and fixed application. The antenna(s) used for this

transmitter must be installed to provide a separation distance of at least 20 cm from all

persons and must not be co-located or operating in conjunction with any other antenna or

transmitter. End-Users must be provided with transmitter operation conditions for satisfying

RF exposure compliance. OEM integrators must ensure that the end user has no manual

instructions to remove or install the DE910 module. Antennas used for this OEM module

must not exceed 5dBi gain for mobile and fixed operating configurations.

6.1.1. CDMA antenna – PCB line Guidelines

Make sure that the transmission line’s characteristic impedance is 50ohm.

Keep line on the PCB as short as possible since the antenna line loss shall be less than

around 0.3dB.

Line geometry should have uniform characteristics, constant cross section, avoid

meanders and abrupt curves.

Any kind of suitable geometry/structure ( Microstrip, Stripline, Coplanar, Grounded

Coplanar Waveguide … ) can be used for implementing the printed transmission line

afferent the antenna.

If a Ground plane is required in line geometry, that plane has to be continuous and

sufficiently extended so the geometry can be as similar as possible to the related

canonical model.

Keep, if possible, at least one layer of the PCB used only for the Ground plane; If

possible, use this layer as reference Ground plane for the transmission line.

It is wise to surround (on both sides) of the PCB transmission line with Ground. Avoid

having other signal tracks facing directly the antenna line track.

Avoid crossing any un-shielded transmission line footprint with other tracks on

different layers.

The Ground surrounding the antenna line on PCB has to be strictly connected to the

main Ground plane by means of via holes (once per 2mm at least) placed close to the

ground edges facing line track.

Place EM noisy devices as far as possible from DE910 antenna line.

Keep the antenna line far away from the DE910 power supply lines.

Page 37

DE910 Series Hardware User Guide

1vv0300951 Rev.9 – 2015-05-11

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 37 of 77

If EM noisy devices are present on the PCB hosting the DE910, such as fast switching

ICs, take care of shielding them with a metal frame cover.

If EM noisy devices are not present around the line, use of geometries like Micro strip

or Grounded Coplanar Waveguide are preferred since they typically ensure less

attenuation when compared to a Strip line having same length.

6.1.2. PCB Guidelines in case of FCC

certification

In the case FCC certification is required for an application using DE910-DUAL,

according to FCC KDB 996369 for modular approval requirements, the transmission

line has to be similar to that implemented on module’s interface board and described in

the following chapter.

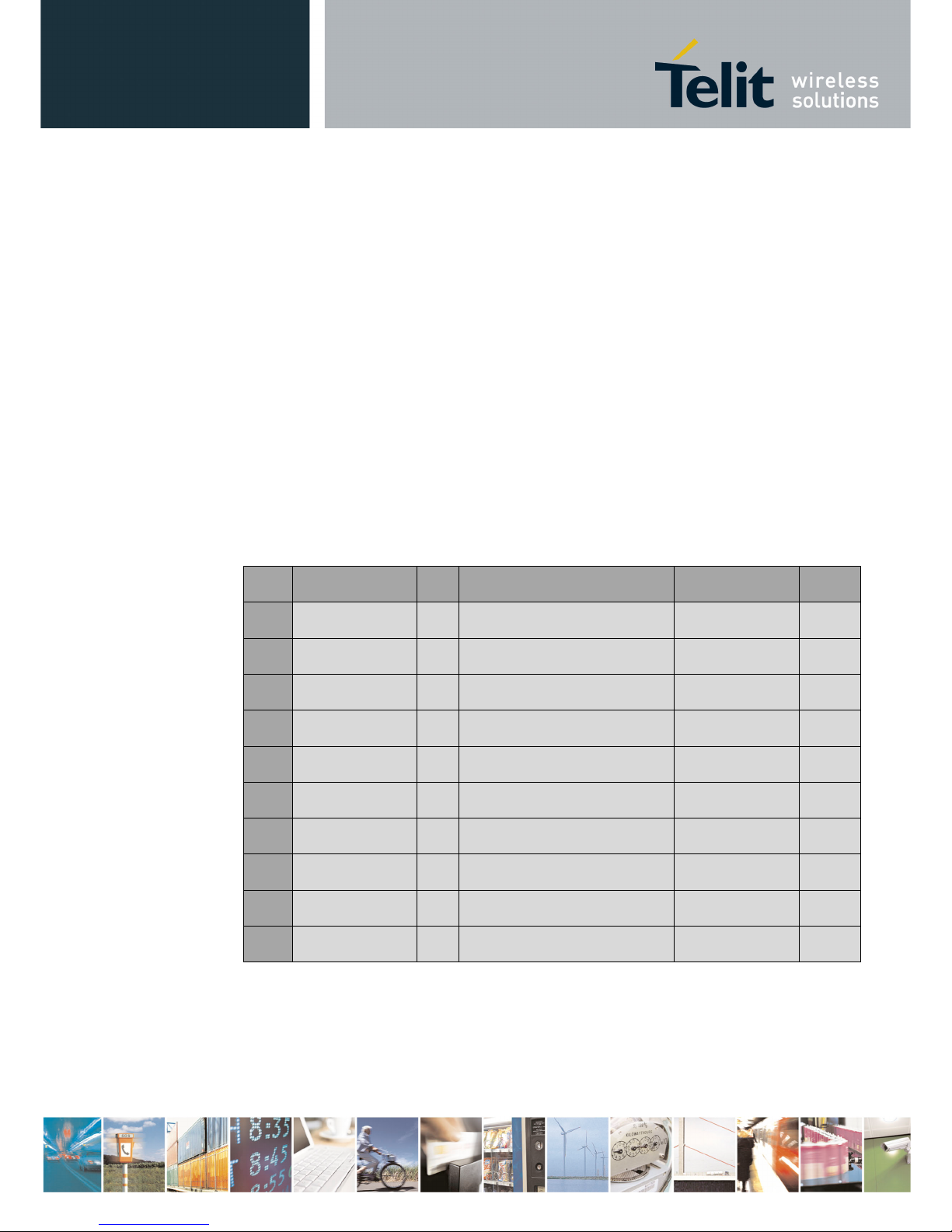

6.1.2.1.1.1. Transmission line design

During the design of the DE910 interface board, the placement of components has been

chosen properly, in order to keep the line length as short as possible, thus leading to

lowest power losses possible. A Grounded Coplanar Waveguide (G-CPW) line has

been chosen, since this kind of transmission line ensures good impedance control and

can be implemented in an outer PCB layer as needed in this case. A SMA female

connector has been used to feed the line.

The interface board is realized on a FR4, 4-layers PCB. Substrate material is

characterized by relative permittivity εr = 4.6 ± 0.4 @ 1 GHz, TanD= 0.019 ÷ 0.026 @

1 GHz.

A characteristic impedance of nearly 50 Ω is achieved using trace width = 1.1 mm,

clearance from coplanar ground plane = 0.3 mm each side. The line uses reference

ground plane on layer 3, while copper is removed from layer 2 underneath the line.

Height of trace above ground plane is 1.335 mm. Calculated characteristic impedance is

51.6 Ω, estimated line loss is less than 0.1 dB. The line geometry is shown below:

Page 38

DE910 Series Hardware User Guide

1vv0300951 Rev.9 – 2015-05-11

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 38 of 77

6.1.2.1.1.2. Transmission line measurements

HP8753E VNA (Full-2-port calibration) has been used in this measurement session. A

calibrated coaxial cable has been soldered at the pad corresponding to RF output; a

SMA connector has been soldered to the board in order to characterize the losses of the

transmission line including the connector itself. During Return Loss / impedance

measurements, the transmission line has been terminated to 50 Ω load.

Return Loss plot of line under test is shown below:

Line input impedance (in Smith Chart format, once the line has been terminated to 50 Ω

load) is shown in the following figure:

Page 39

DE910 Series Hardware User Guide

1vv0300951 Rev.9 – 2015-05-11

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 39 of 77

Insertion Loss of G-CPW line plus SMA connector is shown below:

6.1.3. CDMA Antenna – Installation Guidelines

Install the antenna in a place covered by the CDMA signal.

If the device antenna in the application is located greater then 20cm from the human

body and there are no co-located transmitters then the Telit FCC/IC approvals can be

re-used by the end product.

Antenna shall not be installed inside metal cases.

Antenna shall be installed also according antenna manufacture instructions.

WARNING:

Consider a mechanical design and a low-capacitance ESD protection device to protect DE910

or customer specific requirements from ESD event to Antenna port (K1).

Page 40

DE910 Series Hardware User Guide

1vv0300951 Rev.9 – 2015-05-11

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 40 of 77

6.2. Antenna Diversity Requirements

This product includes an input for a second RX antenna to improve the radio sensitivity. The

function is called Antenna Diversity.

CDMA Antenna Diversity Requirements

Frequency range

Depending frequency band(s) provided by the network operator,

the customer must use the most suitable antenna for that/those

band(s)

Bandwidth

70 MHz in CDMA BC0

140 MHz in CDMA BC1

Impedance

50 Ohm

When using the Telit DE910, since there’s no antenna connector on the module, the antenna

must be connected to the DE910 antenna pad (F1) by means of a transmission line

implemented on the PCB.

In the case that the antenna is not directly connected at the antenna pad of DE910, then a PCB

line is required.

NOTE:

If the RX Diversity is not used/connected, disable the Diversity functionality using the

AT#CRXD command and leave the pad F1 unconnected. Please refer to the AT command

User Guide in detail.

WARNING:

Consider a mechanical design and a low-capacitance ESD protection device to protect DE910

or customer specific requirements from ESD event to Antenna port (F1).

Page 41

DE910 Series Hardware User Guide

1vv0300951 Rev.9 – 2015-05-11

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 41 of 77

6.3. GNSS Antenna Requirements

The use of an active GNSS antenna is required to achieve better performance.

The module is provided with a Digital Output signal to enable the external LNA (pad R7).

Parameter Min Max

Output high level

1.35V 1.8V

Output low level

0.0V 0.45V

6.3.1. Combined GNSS Antenna

The use of combined CDMA/GNSS antenna is not recommended. This solution could

generate extremely poor GNSS reception and also the combined antenna requires an

additional diplexer and adds a loss in the RF route.

6.3.2. Linear and Patch GNSS Antenna

Using this type of antenna introduces at least 3dB of loss if compared to a circularly polarized

(CP) antenna. Having a spherical gain response instead of a hemispherical gain response

could aggravate the multipath behaviour & create poor position accuracy.

6.3.3. The Design Considerations to enhanced

GNSS performance

Depending on the characteristics and requirements unique to the customer’s designs, the use

of an external LNA or an external active antenna may be required to achieve best

performance.

The optional external LNA should be dimensioned to avoid an excessive LNA gain that can

introduce jamming, spurious, degrade IIP3, and saturate the receiver.

The configurations of an external device must fulfill the following requirements:

An external passive antenna (GPS only)

An external active antenna (GPS or GNSS)

An external passive antenna, GNSS pre-Filter , and GNSS LNA (GPS or GNSS)

Page 42

DE910 Series Hardware User Guide

1vv0300951 Rev.9 – 2015-05-11

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 42 of 77

NOTE:

The external GNSS LNA and GNSS pre-Filter shall be required for GLONASS application.

GNSS LNA requirement shall fulfill the following specifications.

Frequency = 1565 ~ 1606MHz

Power Gain|S21|2 = 14 ~ 17dB

NF < 1dB

GNSS pre-Filter requirement shall fulfill the following requirements.

Source and Load Impedance = 50Ohm

Insertion Loss (1575.42 ~ 1576.42MHz) = 1.4dB (Max)

Insertion Loss (1565.42 ~ 1585.42MHz) = 2.0dB (Max)

Insertion Loss (1597.5515 ~ 1605.886MHZ) = 2.0dB (Max)

The external active antenna for the Telit DE910 device must fulfill the following

requirements:

GNSS Antenna Requirements

Frequency range

1575.42MHz (GPS L1)

1597.55 ~ 1605.89MHz (GLONASS)

Bandwidth

±

1.023MHz

(GPS L1)

8.34MHz (GLONASS)

Impedance

50 Ohm

LNA NF

< 1dB

LNA Gain

14 ~ 17dB

LNA Input Voltage

3.0V or 5.0V

NOTE:

The maximum DC voltage applicable to ANT_GPS pin is 5V. In case this is exceeded, a

series capacitor has to be included in the design to avoid exceeding the maximum input DC

level.

Page 43

DE910 Series Hardware User Guide

1vv0300951 Rev.9 – 2015-05-11

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 43 of 77

An example of GNSS antenna supply circuit is shown in the following image:

When using the Telit DE910, since there’s no antenna connector on the module, the antenna

must be connected to the DE910 through the PCB with the antenna pad.

In the case that the antenna is not directly connected at the antenna pad of the DE910, then a

PCB line is required.

This line of transmission shall fulfill the following requirements:

Antenna Line on PCB Requirements

Characteristic Impedance

50Ohm

Max Attenuation

0.3dB

Coupling with other signals shall be avoided

Cold End (Ground Plane) of antenna shall be equipotential to the DE910 ground pads

Furthermore if the device is developed for the US and/or Canada market, it must comply with

the FCC and/or IC requirements.

This device is to be used only for mobile and fixed application.

WARNING:

The DE910 software is implemented differently depending on the configurations of an

external device. Please refer to the AT command User Guide in detail.

Page 44

DE910 Series Hardware User Guide

1vv0300951 Rev.9 – 2015-05-11

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 44 of 77

6.3.4. GNSS Antenna – PCB Line Guidelines

Ensure that the antenna line impedance is 50ohm.

Keep line on the PCB as short as possible to reduce the loss.

Antenna line must have uniform characteristics, constant cross section, avoid meanders

and abrupt curves.

Keep one layer of the PCB used only for the Ground plane; if possible.

Surround (on the sides, over and under) the antenna line on PCB with Ground. Avoid

having other signal tracks directly facing the antenna line track.

The Ground around the antenna line on PCB has to be strictly connected to the main

Ground plane by placing vias once per 2mm at least.

Place EM noisy devices as far as possible from DE910 antenna line.

Keep the antenna line far away from the DE910 power supply lines.

If EM noisy devices are around the PCB hosting the DE910, such as fast switching ICs,

take care of shielding of antenna line by burying it inside the layers of PCB and

surround it with Ground planes; or shield it with a metal frame cover.

If you do not have EM noisy devices around the PCB of DE910, use a strip line on the

superficial copper layer for the antenna line. The line attenuation will be lower than a

buried one.

6.3.5. GNSS Antenna – Installation Guidelines

The DE910, due to its sensitivity characteristics, is capable of performing a fix inside

buildings. However, the sensitivity could be affected by the building characteristics i.e.

shielding.

The Antenna must not be co-located or operating in conjunction with any other antenna

or transmitter.

Antenna shall not be installed inside metal cases.

Antenna shall be installed also according antenna manufacture instructions.

WARNING:

Consider a mechanical design and a low-capacitance ESD protection device to protect DE910

or customer specific requirements from ESD event to GPS port (R9).

Page 45

DE910 Series Hardware User Guide

1vv0300951 Rev.9 – 2015-05-11

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 45 of 77

7. USB Port

The DE910 module includes a Universal Serial Bus (USB) transceiver, which operates at

USB high-speed (480Mbits/sec).

It is compliant with the USB 2.0 specification and can be used for diagnostic monitoring,

control and data transfers.

The table below describes the USB interface signals:

Pin

Signal I/O

Function Type

B15

USB_D+ I/O USB differential Data(+)

C15

USB_D- I/O USB differential Data(-)

A13

VBUS I Power sense for the internal USB transceiver 5V

The USB_DPLUS and USB_DMINUS signals have a clock rate of 480MHz. The signal

traces should be routed carefully. Trace lengths, number of vias and capacitive loading should

be minimized. The impedance value should be as close as possible to 90 Ohms differential.

WARNING:

Consider a mechanical design and a low-capacitance ESD protection device to protect DE910

or customer specific requirements from ESD event to USB lines (B15, C15 and A13).

Page 46

DE910 Series Hardware User Guide

1vv0300951 Rev.9 – 2015-05-11

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 46 of 77

8. Serial Port

The serial ports on the Telit DE910 are the interface between the module and OEM hardware.

2 serial ports are available on the module:

Modem Serial Port 1 (Main)

Modem Serial Port 2 (Auxiliary)

Several configurations can be designed for the serial port on the OEM hardware.

The most common are:

RS232 PC comport

Microcontroller UART@1.8V(Universal Asynchronous Receiver Transmit)

Microcontroller UART@5V or other voltages different from 1.8V

Depending on the type of serial port on the OEM hardware, a level translator circuit may be

needed to make the system work.

Serial port 1 is a +1.8V UART with all the 7 RS232 signals.

Serial port 2 is a +1.8V Auxiliary UART.

The electrical characteristics of the serial port are explained in the following tables:

Absolute Maximum Ratings -Not Functional

Parameter Min Max

Input level on non-power pin with respect to ground

-0.3 +2.3V

Operating Range - Interface levels

Parameter Min Max

Input high level

1.5V 2.1 V

Input low level

-0.3V 0.35V

Output high level

1.35V 1.8V

Output low level

0V 0.45V

Page 47

DE910 Series Hardware User Guide

1vv0300951 Rev.9 – 2015-05-11

Reproduction forbidden without written authorization from Telit Communications S.p.A. - All Rights

Reserved. Page 47 of 77

8.1. Modem Serial Port 1

Serial port 1 on the DE910 is a +1.8V UART with all 7 RS232 signals.

It differs from the PC-RS232 in the signal polarity (RS232 is reversed) and levels.

Pin

Signal I/O

Function Type

N14

DCD O Data Carrier Detect 1.8V

M15

RXD O Transmit line *see Note 1.8V

N15

TXD I Receive line *see Note 1.8V

M14

DTR I Data Terminal Ready 1.8V

P14

DSR O Data Set Ready 1.8V

L14

RTS I Request to Send 1.8V

P15

CTS O Clear to Send 1.8V

R14