Page 1

UC864

-E-

AUTO

UC864-AWS-AUTO

Hardware User Guide

1vv0300795 Rev. 11 – 2010/11/18

Page 2

UC864-E-AUTO / AWS-AUTO Hardware User Guide

1vv0300795 Rev.11 – 2010/11/18

This document is relating to the following products:

PRODUCT

UC864-E-AUTO

UC864-AWS-AUTO

Reproduction forbidden without Telit Communications S.p.A’s. written authorization - All Rights Reserved. Page 2 of 78

Page 3

UC864-E-AUTO / AWS-AUTO Hardware User Guide

1vv0300795 Rev.11 – 2010/11/18

Disclaimer

The information contained in this document is the proprietary information of Telit

Communications S.p.A. and its affiliates (“TELIT”). The contents are confidential and

any disclosure to persons other than the officers, employees, agents or

subcontractors of the owner or licensee of this document, without the prior written

consent of Telit, is strictly prohibited.

Telit makes every effort to ensure the quality of the information it makes available.

Notwithstanding the foregoing, Telit does not make any warranty as to the

information contained herein, and does not accept any liability for any injury, loss or

damage of any kind incurred by use of or reliance upon the information.

Telit disclaims any and all responsibility for the application of the devices

characterized in this document, and notes that the application of the device must

comply with the safety standards of the applicable country, and where applicable,

with the relevant wiring rules.

Telit reserves the right to make modifications, additions and deletions to this

document due to typographical errors, inaccurate information, or improvements to

programs and/or equipment at any time and without notice. Such changes will,

nevertheless be incorporated into new editions of this application note.

All rights reserved.

© 2008, 2010 Telit Communications S.p.A.

Reproduction forbidden without Telit Communications S.p.A’s. written authorization - All Rights Reserved. Page 3 of 78

Page 4

Contents

UC864-E-AUTO / AWS-AUTO Hardware User Guide

1vv0300795 Rev.11 – 2010/11/18

1. OVERVIEW ............................................................................................................................................................... 6

2. MECHANICAL DIMENSIONS ............................................................................................................................... 7

2.1. UC864-E-AUTO / AWS-AUTO M

3. UC864-E-AUTO / AWS-AUTO MODULE CONNECTIONS............................................................................... 8

3.1.

PIN-OUT ............................................................................................................................................................. 8

4. TEMPERATURE RANGE ..................................................................................................................................... 12

4.1. A

5. HARDWARE COMMANDS .................................................................................................................................. 14

5.1. T

5.2. I

5.3. T

5.4. S

6. POWER SUPPLY .................................................................................................................................................... 22

6.1. P

6.2. G

NTENNA CONNECTOR(S

URNING ON THE

NITIALIZATION AND ACTIVATION STATE

URNING

5.3.1.

5.3.2.

5.3.3.

UMMARY OF TURNING ON AND

OWER SUPPLY REQUIREMENTS

ENERAL DESIGN RULES

6.2.1.

6.2.2.

6.2.3.

OFF

Shutdown by Software Command

Hardware Shutdown

Hardware Unconditional Restart

Electrical Design Guidelines

Thermal Design Guidelines

Power Supply PCB Layout Guidelines

UC864-E-AUTO /

THE

UC864-E-AUTO /

) ................................................................................................................................... 13

.................................................................................................................................... 24

ECHANICAL DIMENSIONS

AWS-AUTO ............................................................................................. 14

................................................................................................................ 15

AWS-AUTO ........................................................................................... 17

........................................................................................................ 18

.............................................................................................................................. 19

......................................................................................................... 20

OFF

THE MODULE

.......................................................................................................................... 22

................................................................................................................ 24

.................................................................................................................. 30

.............................................................................................. 21

................................................................................................. 32

................................................................................. 7

7. ANTENNA(S) ........................................................................................................................................................... 34

7.1. GSM/WCDMA A

7.2. GSM/WCDMA A

8. LOGIC LEVEL SPECIFICATIONS ..................................................................................................................... 36

8.1. R

9. USB PORT................................................................................................................................................................ 38

9.1. USB

10.

10.1. M

10.2. RS232 L

10.3. 5V UART L

11.

11.1. S

11.2. E

ESET SIGNAL

TRANSCEIVER SPECIFICATIONS

SERIAL PORTS .................................................................................................................................................. 40

ODEM SERIAL PORT

EVEL TRANSLATION

AUDIO SECTION OVERVIEW ....................................................................................................................... 48

ELECTION MODE

LECTRICAL CHARACTERISTICS

11.2.1. Input Lines (MIC1 and MIC2) Characteristics

11.3. OUTPUT LINES (

NTENNA REQUIREMENTS

NTENNA - INSTALLATION GUIDELINES

.................................................................................................................................................... 37

.......................................................................................................................................... 40

............................................................................................................................... 43

EVEL TRANSITION

................................................................................................................................................ 48

S

PEAKER

.............................................................................................................................. 46

........................................................................................................................... 50

)

.............................................................................................................................. 51

.......................................................................................................... 34

....................................................................................... 35

.................................................................................................................... 39

..................................................................................... 50

Reproduction forbidden without Telit Communications S.p.A’s. written authorization - All Rights Reserved. Page 4 of 78

Page 5

11.3.1. Output Lines Characteristics

12.

GENERAL PURPOSE I/O ................................................................................................................................. 52

UC864-E-AUTO / AWS-AUTO Hardware User Guide

1vv0300795 Rev.11 – 2010/11/18

................................................................................................................ 51

12.1. L

12.2. U

12.3. U

12.4. U

12.5. U

12.6. U

12.7. U

12.8. M

OGIC LEVEL SPECIFICATIONS

SING A

GPIO P

SING A

GPIO P

SING THE RF TRANSMISSION CONTROL

SING THE

SING THE ALARM OUTPUT

SING THE BUZZER OUTPUT

AGNETIC BUZZER CONCEPTS

AD AS INPUT

AD AS OUTPUT

RFTXMON O

12.8.1. Short Description

12.8.2. Frequency Behavior

12.8.3. Power Supply Influence

12.8.4. Working Current Influence

12.9. U

SING THE TEMPERATURE MONITOR FUNCTION

12.9.1. Short Description

12.9.2. Allowed GPIO

12.10. I

12.11. RTC B

12.12. VAUX1 P

13.

13.1. DAC C

NDICATION OF NETWORK SERVICE AVAILABILITY

DAC AND ADC SECTION ................................................................................................................................ 64

ONVERTER

13.1.1. Description

13.1.2. Enabling DAC

YPASS OUT

OWER OUTPUT

.......................................................................................................................................... 60

........................................................................................................................................... 63

................................................................................................................................................ 64

.............................................................................................................................................. 64

.......................................................................................................................................... 64

13.1.3. Low Pass Filter Example

13.2. ADC C

13.2.1. Description

ONVERTER

................................................................................................................................................ 65

.............................................................................................................................................. 65

13.2.2. Using ADC Converter

............................................................................................................................. 54

.............................................................................................................................. 55

........................................................................................................................... 55

GPIO4 .................................................................................................. 56

UTPUT

GPIO5 .............................................................................................................. 56

GPIO6 ..................................................................................................................... 56

GPIO7 .................................................................................................................... 57

............................................................................................................................ 58

................................................................................................................................... 58

............................................................................................................................... 59

........................................................................................................................ 59

................................................................................................................... 59

................................................................................................... 60

................................................................................................................................... 60

............................................................................................. 62

................................................................................................................................. 63

...................................................................................................................... 65

............................................................................................................................. 65

14.

MOUNTING THE MODULE ON YOUR BOARD ......................................................................................... 66

14.1. A

14.2. C

14.3. T

14.4. M

15.

APPLICATION GUIDE ..................................................................................................................................... 71

15.1. D

15.2. B

15.3. SIM

15.4. EMC

16.

PACKING SYSTEM ........................................................................................................................................... 74

17.

CONFORMITY ASSESSMENT ISSUES ......................................................................................................... 75

18.

SAFETY RECOMMENDATIONS .................................................................................................................... 77

19.

DOCUMENT CHANGE LOG ........................................................................................................................... 78

PPLICATION

LEARANCE AREA

HERMAL DISSIPATION

ODULE SOLDERING

EBUG OF THE

YPASS CAPACITOR ON POWER SUPPLIES

INTERFACE

RECOMMENDATIONS

PCB L

AYOUT

................................................................................................................................. 67

............................................................................................................................................... 69

........................................................................................................................................ 69

........................................................................................................................................... 70

UC864-E-AUTO / AWS-AUTO

.................................................................................................................................................. 72

................................................................................................................................... 73

IN PRODUCTION

............................................................................................................ 72

......................................................................... 71

Reproduction forbidden without Telit Communications S.p.A’s. written authorization - All Rights Reserved. Page 5 of 78

Page 6

upoštevati projektna navodila, opisana v tem

E-

AUTO

/ AWS

UC864-E-AUTO / AWS-AUTO Hardware User Guide

1vv0300795 Rev.11 – 2010/11/18

1. Overview

Overview

OverviewOverview

The aim of this document is the description of some hardware solutions useful for

developing a product with the Telit UC864-E-AUTO and UC864-AWS-AUTO modules.

In this document all the basic functions of a mobile phone will be taken into account;

for each one of them a proper hardware solution will be suggested and eventually the

wrong solutions and common errors to be avoided will be evidenced. Obviously this

document cannot embrace the whole hardware solutions and products that may be

designed. The wrong solutions to be avoided must be considered as mandatory, while

the suggested hardware configurations must not be considered mandatory, instead

the information given must be used as a guide and a starting point for properly

developing your product with the Telit UC864-E-AUTO & UC864-AWS-AUTO modules.

For further hardware details that may not be explained in this document refer to the

Telit UC864-E–AUTO & UC864-AWS-AUTO Product Description document where all

the hardware information is reported.

NOTICE:

(EN) The integration of the GSM/GPRS/EGPRS/WCDMA/HSDPA UC864-E-AUTO & UC864AWS-AUTO cellular module within user application must be done according to the design

rules described in this manual.

(IT) L’integrazione del modulo cellulare GSM/GPRS/EGPRS/WCDMA/HSDPA UC864- EAUTO e UC864-AWS-AUTO all’interno dell’applicazione dell’utente dovrà rispettare le

indicazioni progettuali descritte in questo manuale.

(DE) Die Integration des UC864- E-AUTO & UC864-AWS-AUTO

GSM/GPRS/EGPRS/WCDMA/HSDPA Mobilfunk-Moduls in ein Gerät muß gemäß der in

diesem Dokument beschriebenen Kunstruktionsregeln erfolgen

(SL) Integracija GSM/GPRS/EGPRS/WCDMA/HSDPA UC864- E-AUTO & UC864-AWSAUTO modula v uporabniški aplikaciji bo morala

piročniku.

(SP) La utilización del modulo GSM/GPRS/EGPRS/WCDMA/HSDPA UC864- E-AUTO &

UC864-AWS-AUTO debe ser conforme a los usos para los cuales ha sido deseñado

descritos en este manual del usuario.

(FR) L’intégration du module cellulaire GSM/GPRS/EGPRS/WCDMA/HSDPA UC864- EAUTO & UC864-AWS-AUTO dans l’application de l’utilisateur sera faite selon les règles de

conception décrites dans ce manuel.

(HE)

The information presented in this document is believed to be accurate and reliable. However,

no responsibility is assumed by Telit Communications S.p.A. for its use, nor any infringement

of patents or other rights of third parties which may result from its use. No license is granted

by implication or otherwise under any patent rights of Telit Communications S.p.A. other than

for circuitry embodied in Telit products. This document is subject to change without notice.

UC864-

Reproduction forbidden without Telit Communications S.p.A’s. written authorization - All Rights Reserved. Page 6 of 78

Page 7

UC864-E-AUTO / AWS-AUTO Hardware User Guide

1vv0300795 Rev.11 – 2010/11/18

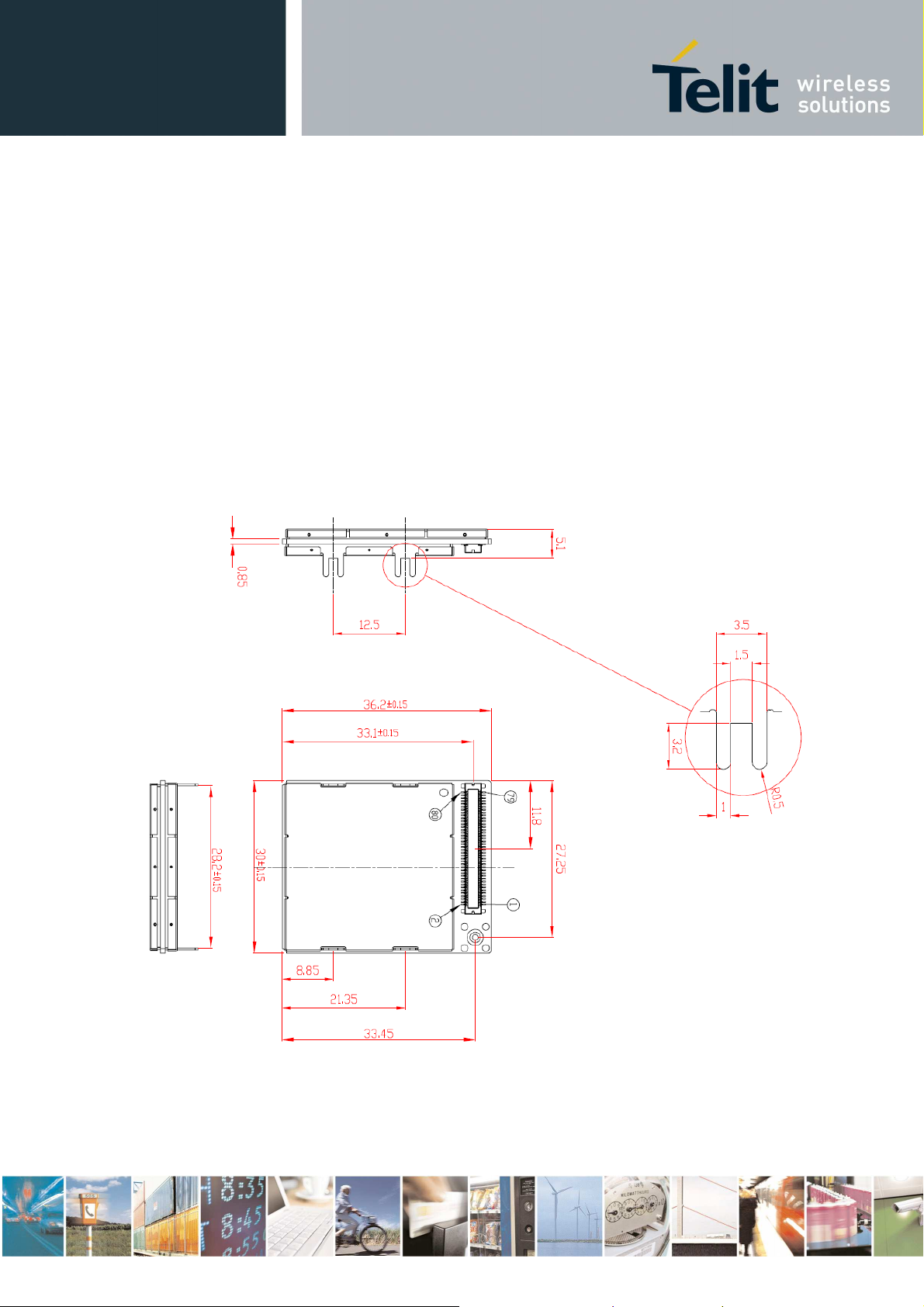

2. Mechanical Dimensions

Mechanical Dimensions

Mechanical DimensionsMechanical Dimensions

2.1. UC864-E-AUTO / AWS-AUTO Mechanical Dimensions

The Telit UC864-E-AUTO / AWS-AUTO module overall dimensions are:

• Length: 36.2 mm

• Width: 30.0 mm

• Thickness: 5.1mm

Reproduction forbidden without Telit Communications S.p.A’s. written authorization - All Rights Reserved. Page 7 of 78

Page 8

Internal

InternalInternal

Internal

Type

TypeType

Type

UC864-E-AUTO / AWS-AUTO Hardware User Guide

1vv0300795 Rev.11 – 2010/11/18

3. UC864

UC864----EEEE----AUTO

UC864UC864

AUTO / AWS

AUTOAUTO

/ AWS----AUTO

/ AWS/ AWS

AUTO MMMModule

AUTO AUTO

odule CCCConnections

odule odule

onnections

onnections onnections

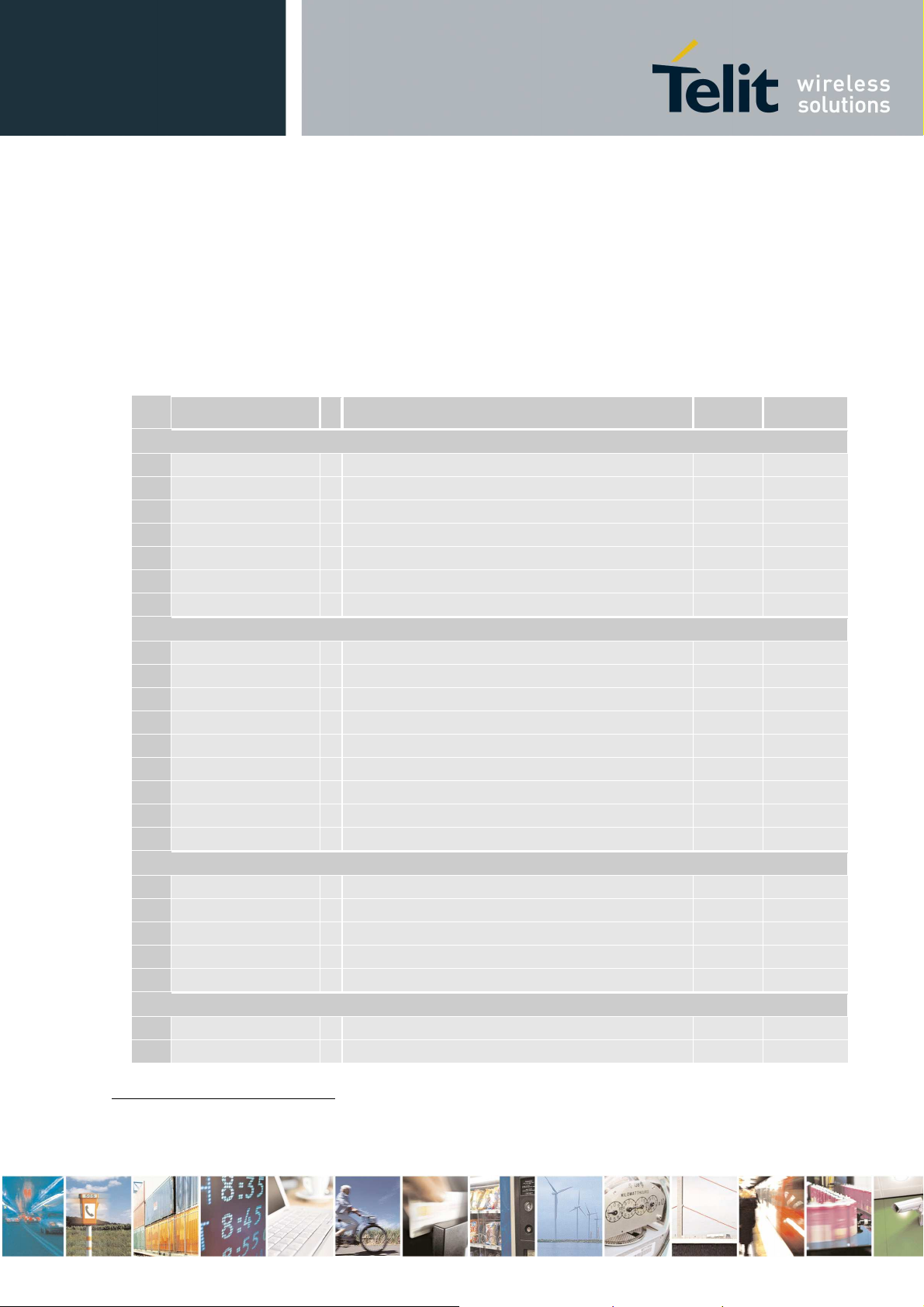

3.1. PIN-OUT

UC864-E-AUTO / AWS-AUTO uses an 80 pin Molex p.n. 53949-0878 male connector

for the connections with the external applications. This connector matches the

54150-0878 models.

Pin

Pin Signal

PinPin

1111 VBATT - Main power supply Power

2222 VBATT - Main power supply Power

3333 VBATT - Main power supply Power

4444 VBATT - Main power supply Power

5555 GND - Ground Power

6666 GND - Ground Power

7777 GND - Ground Power

8888 AXE I Hands-free switching CMOS 2.6V

9999 EAR_HF+ AO Hands-free ear output, phase + Audio

10

10 EAR_HF- AO Hands-free ear output, phase - Audio

1010

11

11 EAR_MT+ AO Handset earphone signal output, phase + Audio

1111

12

12 EAR_MT- AO Handset earphone signal output, phase - Audio

1212

13

13 MIC_HF+ AI Hands-free microphone input; phase + Audio

1313

14

14 MIC_HF- AI Hands-free microphone input; phase - Audio

1414

15

15 MIC_MT+ AI Handset microphone signal input; phase+ Audio

1515

16

16 MIC_MT- AI Handset microphone signal input; phase- Audio

1616

1111

18

18

SIMVCC -

1818

19

19 SIMRST O

1919

20

20 SIMIO I/O External SIM signal - Data I/O 1.8 / 3V

2020

21

21 SIMIN I External SIM signal - Presence (active low) CMOS 2.6V

2121

22

22 SIMCLK O

2222

23

23 RX_TRACE I RX Data for debug monitor CMOS 2.6V

2323

24

24 TX_TRACE O TX Data for debug monitor CMOS 2.6V

2424

Signal I/O

SignalSignal

I/O

I/OI/O

Function

Function

FunctionFunction

Power Supply

Power Supply

Power SupplyPower Supply

Audio

Audio

AudioAudio

SIM Card Interface

SIM Card Interface

SIM Card InterfaceSIM Card Interface

External SIM signal – Power supply for the SIM 1.8 / 3V

External SIM signal – Reset 1.8 / 3V

External SIM signal – Clock 1.8 / 3V

Trace

Trace

TraceTrace

Pull up

Pull up

Pull upPull up

1

On this line a maximum of 10nF bypass capacitor is allowed

Reproduction forbidden without Telit Communications S.p.A’s. written authorization - All Rights Reserved. Page 8 of 78

Page 9

Internal

InternalInternal

Internal

Type

TypeType

Type

Analog input used to sense whether a

Input command for switching power ON or OFF (toggle

Pulled up on

UC864-E-AUTO / AWS-AUTO Hardware User Guide

1vv0300795 Rev.11 – 2010/11/18

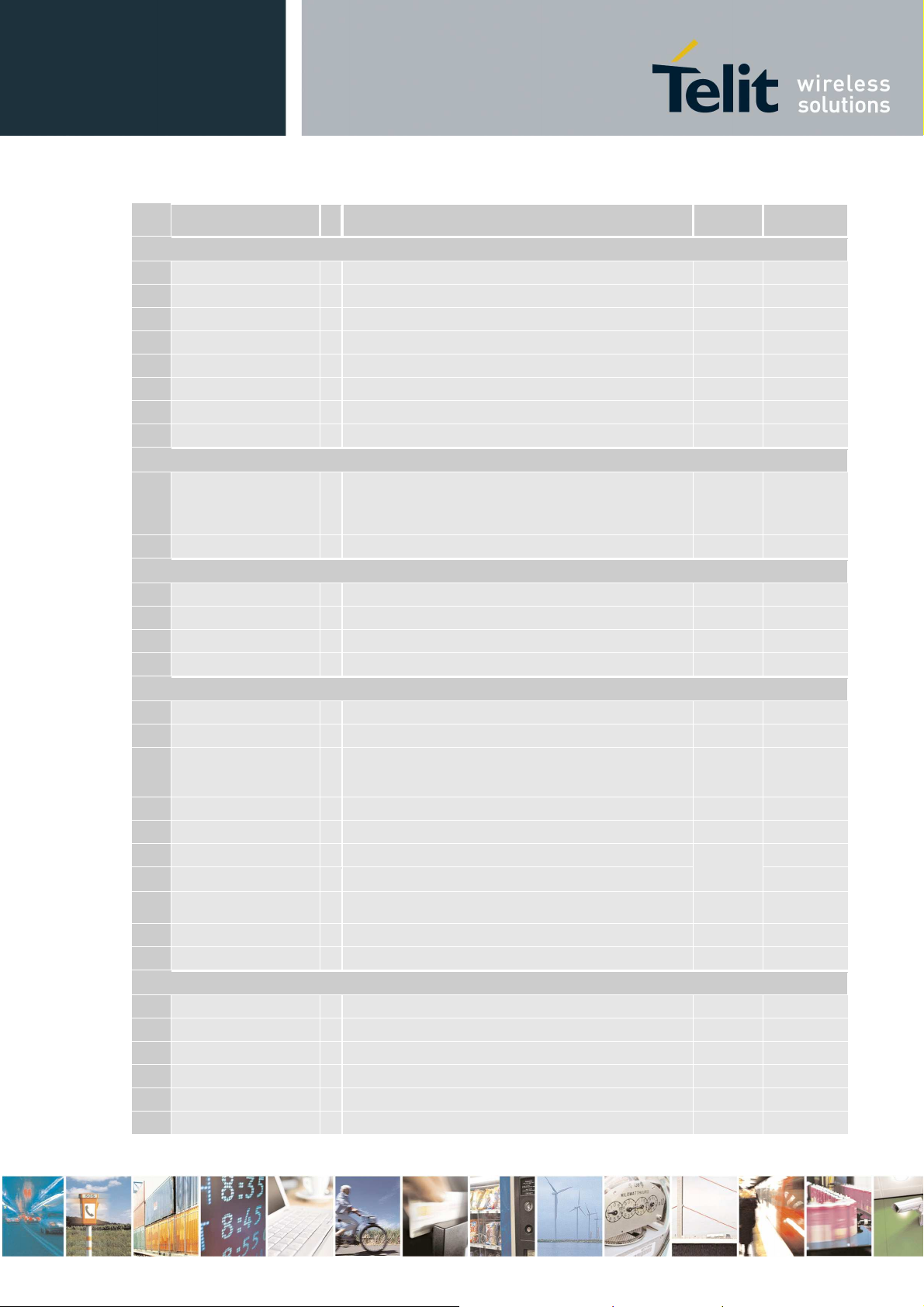

Pin

Pin Signal

PinPin

25

25 C103/TXD I Serial data input (TXD) from DTE Pull-Down CMOS 2.6V

2525

26

26 C104/RXD O Serial data output to DTE Pull-Up CMOS 2.6V

2626

27

27 C107/DSR O Output for Data set ready signal (DSR) to DTE Pull-Down CMOS 2.6V

2727

28

28 C106/CTS O Output for Clear to send signal (CTS) to DTE Pull-Up CMOS 2.6V

2828

29

29 C108/DTR I Input for Data terminal ready signal (DTR) from DTE Pull-Up CMOS 2.6V

2929

30

30 C125/RING O Output for Ring indicator signal (RI) to DTE Pull-Up CMOS 2.6V

3030

31

31 C105/RTS I Input for Request to send signal (RTS) from DTE Pull-Down CMOS 2.6V

3131

32

32 C109/DCD O Output for Data carrier detect signal (DCD) to DTE Pull-Up CMOS 2.6V

3232

Signal I/O

SignalSignal

I/O

I/OI/O

Function

Function

FunctionFunction

Prog. / Data + Hw Flow Control

Prog. / Data + Hw Flow Control

Prog. / Data + Hw Flow ControlProg. / Data + Hw Flow Control

Miscellaneous Functions

Miscellaneous Functions

Miscellaneous FunctionsMiscellaneous Functions

Pull up

Pull up

Pull upPull up

35

35 USB_ID AI

3535

36

36 PCM_CLOCK I/O PCM clock out Pull-Down CMOS 2.6V

3636

DAC and ADC

DAC and ADC

DAC and ADCDAC and ADC

37

37 ADC_IN1 AI Analog/Digital converter input A/D

3737

38

38 ADC_IN2 AI Analog/Digital converter input A/D

3838

39

39 ADC_IN3 AI Analog/Digital converter input A/D

3939

40

40 DAC_OUT AO Digital/Analog converter output D/A

4040

45

45 STAT_LED O Status indicator led CMOS 1.8V

4545

46

46 GND - Ground Ground

4646

48

48 USB_VBUS

4848

49

49 PWRMON O Power ON Monitor 1KΩ CMOS 2.6V

4949

50

50 VAUX1 - Power output for external accessories

5050

51

51 CHARGE AI Charger input

5151

52

52 CHARGE AI Charger input Power

5252

53

53 ON/OFF I

5353

54

54 RESET I Reset input 10KΩ

5454

55

55 VRTC AO Power supply for RTC block Power

5555

56

56 GPIO_19 I/O GPIO19 Configurable GPIO CMOS 2.6V

5656

57

57 GPIO_11 I/O GPIO11 Configurable GPIO CMOS 2.6V

5757

58

58 GPIO_20 I/O GPIO20 Configurable GPIO CMOS 2.6V

5858

59

59 GPIO_04 I/O GPIO4 Configurable GPIO CMOS 2.6V

5959

60

60 GPIO_14 I/O GPIO14 Configurable GPIO CMOS 2.6V

6060

61

61 GPIO_15 I/O GPIO15 Configurable GPIO CMOS 2.6V

6161

peripheral device is connected, and

determine the peripheral type, a host

or a peripheral

Miscellaneous Functions

Miscellaneous Functions

Miscellaneous FunctionsMiscellaneous Functions

AI

Power supply for the internal USB transceiver. This pin is

/A

configured as an analog input or an analog output depending

O

upon the type of peripheral device connected.

command).

Telit GPIOs

Telit GPIOs

Telit GPIOsTelit GPIOs

Analog

47K

Ω

pull-down

10K

Ω

pull-down

4.4V ~5.25V

Power

chip

Reproduction forbidden without Telit Communications S.p.A’s. written authorization - All Rights Reserved. Page 9 of 78

Page 10

Internal

InternalInternal

Internal

Type

TypeType

Type

GPIO_17/

3.0V

3.0V

UC864-E-AUTO / AWS-AUTO Hardware User Guide

1vv0300795 Rev.11 – 2010/11/18

Pin

Pin Signal

PinPin

62

62 GPIO_12 I/O GPIO12 Configurable GPIO CMOS 2.6V

6262

63

63 GPIO_10/ PCM_TX I/O GPIO10 Configurable GPIO / PCM Data Output Pull-Down CMOS 2.6V

6363

64

64 GPIO_22 I/O GPIO22 Configurable GPIO CMOS 1.8V

6464

65

65 GPIO_18/ PCM_RX I/O GPIO18 Configurable GPIO / PCM Data input Pull-Down CMOS 2.6V

6565

66

66 GPIO_03 I/O GPIO3 Configurable GPIO CMOS 2.6V

6666

67

67 GPIO_08 I/O GPIO8 Configurable GPIO CMOS 2.6V

6767

68

68 GPIO_06 / ALARM I/O GPIO6 Configurable GPIO / ALARM CMOS 2.6V

6868

70

70 GPIO_01 I/O GPIO1 Configurable GPIO CMOS 2.6V

7070

71

71

7171

PCM_SYNC

72

72 GPIO_21 I/O GPIO21 Configurable GPIO CMOS 2.6V

7272

73

73 GPIO_07/ BUZZER I/O GPIO7 Configurable GPIO / Buzzer CMOS 2.6V

7373

74

74 GPIO_02 I/O GPIO02 I/O pin CMOS 2.6V

7474

75

75 GPIO_16 I/O GPIO16 Configurable GPIO CMOS 2.6V

7575

76

76 GPIO_09 I/O GPIO9 Configurable GPIO CMOS 2.6V

7676

77

77 GPIO_13 I/O GPIO13 Configurable CMOS 2.6V

7777

78

78 GPIO_05/ RFTXMON I/O GPIO05 Configurable GPIO / Transmitter ON monitor CMOS 2.6V

7878

Signal I/O

SignalSignal

I/O

I/OI/O

I/O GPIO17 Configurable GPIO / PCM Sync Pull-Down CMOS 2.6V

Function

Function

FunctionFunction

USB Interface

USB Interface

USB InterfaceUSB Interface

Pull up

Pull up

Pull upPull up

77779999 USB_D+ I/O USB differential Data (+)

80

80 USB_D- I/O USB differential Data (-)

8080

RESERVED

RESERVED

RESERVEDRESERVED

17

17 -

1717

33

33

3333

34

34

3434

41

41 -

4141

42

42 -

4242

43

43 -

4343

44

44 -

4444

47

47 -

4747

69

69 -

6969

~3.6V

~3.6V

NOTE: RESERVED pins must not be connected

RTS must be connected to the GND (on the module side) if flow control is not used

Reproduction forbidden without Telit Communications S.p.A’s. written authorization - All Rights Reserved. Page 10 of 78

Page 11

UC864-E-AUTO / AWS-AUTO Hardware User Guide

1vv0300795 Rev.11 – 2010/11/18

Note

Note::::

NoteNote

If not used, almost all pins must be left disconnected. The only exceptions are the

following:

Pin

Pin

PinPin

1111 VBATT Main power supply

2222 VBATT Main power supply

3333 VBATT Main power supply

4444 VBATT Main power supply

5555 GND Ground

6666 GND Ground

7777 GND Ground

46

46 GND Ground

4646

25

25 C103/TXD Serial data input (TXD) from DTE

2525

26

26 C104/RXD Serial data output to DTE

2626

31

31 C105/RTS Input for Request to send signal (RTS) from DTE

3131

53

53 ON/OFF

5353

54

54 RESET Reset input

5454

Signal

Signal Function

SignalSignal

Input command for switching power ON or OFF (toggle

command).

Function

FunctionFunction

Reproduction forbidden without Telit Communications S.p.A’s. written authorization - All Rights Reserved. Page 11 of 78

Page 12

UC864-E-AUTO / AWS-AUTO Hardware User Guide

1vv0300795 Rev.11 – 2010/11/18

4. TEMPERATURE RANGE

TEMPERATURE RANGE

TEMPERATURE RANGETEMPERATURE RANGE

The UC864-E-AUTO / AWS-AUTO Temperature ranges are:

Reference Ambient Temperature

Reference Ambient Temperature

Reference Ambient TemperatureReference Ambient Temperature

Normal Operating -10°C to +55°C

Extended Operating -20°C to +70°C

Extreme Range -30°C to +85°C

Storage -40°C to +85°C

Reproduction forbidden without Telit Communications S.p.A’s. written authorization - All Rights Reserved. Page 12 of 78

Page 13

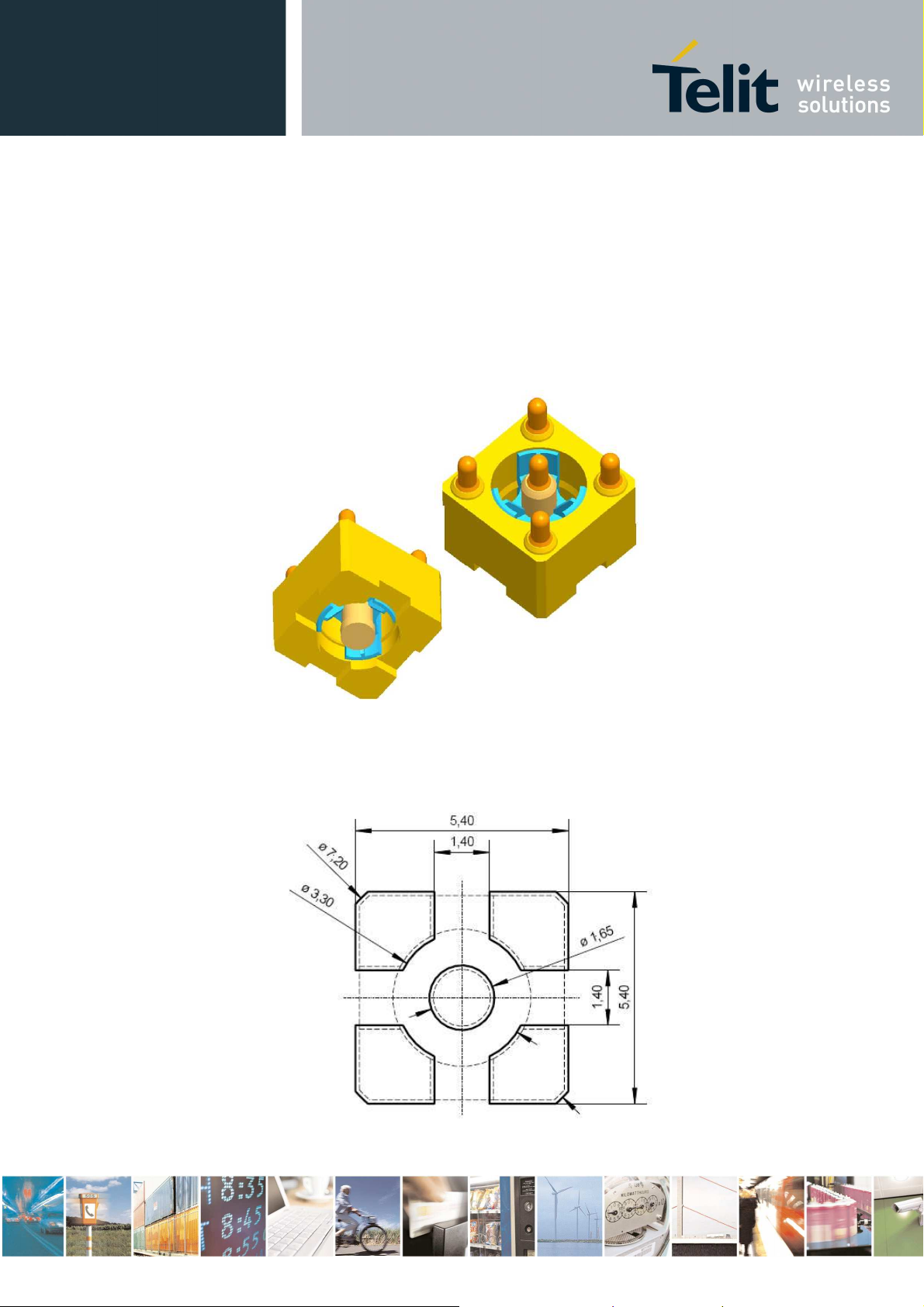

4.1. Antenna Connector(s)

The UC864-E-AUTO / AWS-AUTO module is designed with a 50 Ohm RF PAD that

permits to interface it with an application equipped by a Rosenberger coaxial Board

to board connector.

The counterpart suitable is a Rosenberger 99CI106-030L5.

UC864-E-AUTO / AWS-AUTO Hardware User Guide

1vv0300795 Rev.11 – 2010/11/18

Suggested footprint on the application side:

Reproduction forbidden without Telit Communications S.p.A’s. written authorization - All Rights Reserved. Page 13 of 78

Page 14

UC864-E-AUTO / AWS-AUTO Hardware User Guide

1vv0300795 Rev.11 – 2010/11/18

5. Hardware Commands

Hardware Commands

Hardware CommandsHardware Commands

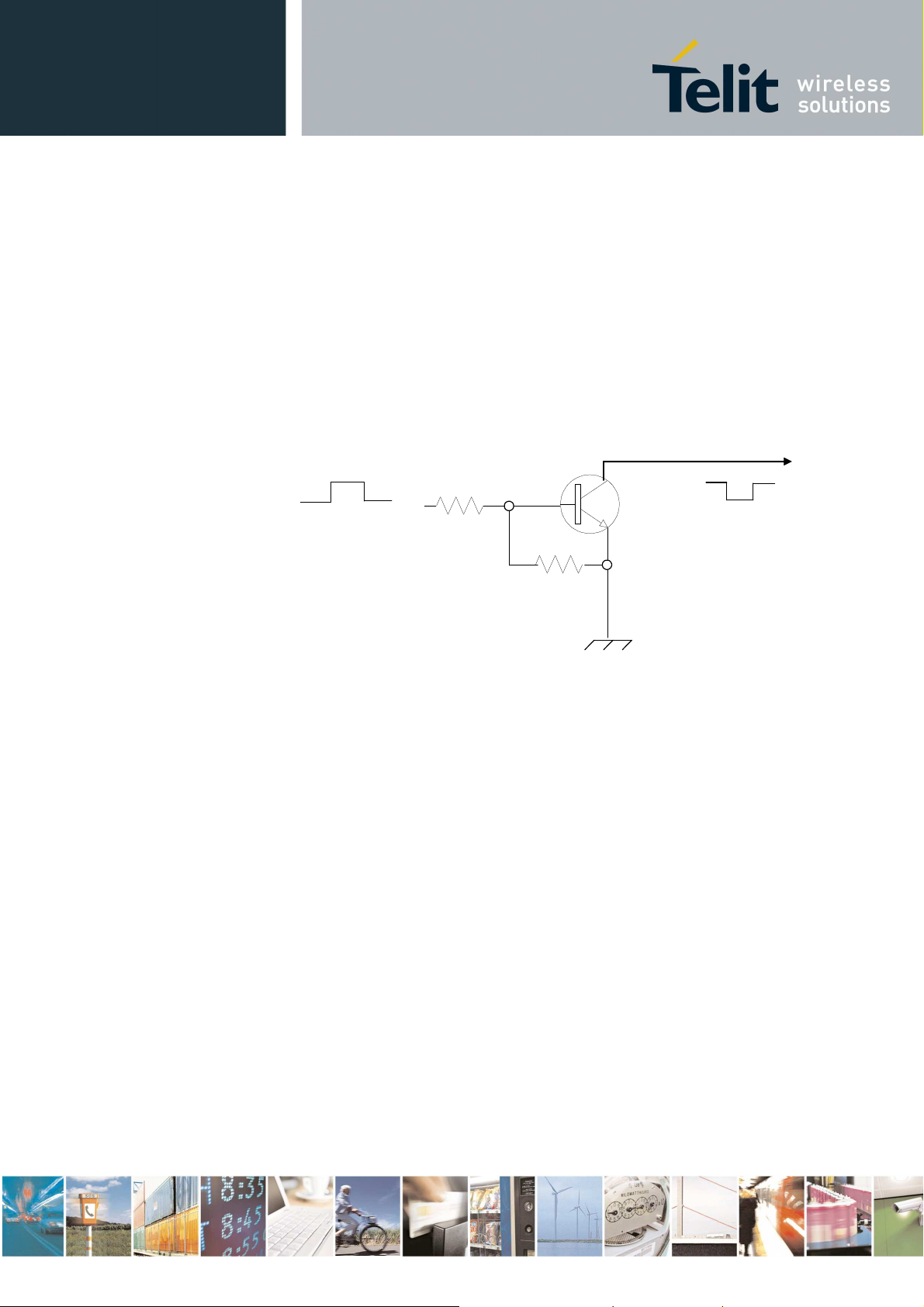

5.1. Turning ON the UC864-E-AUTO / AWS-AUTO

To turn on UC864-E-AUTO / AWS-AUTO, the pad ON# must be tied low for at least 1

second and then released.

The maximum current that can be drained from the ON# pad is 0,1 mA.

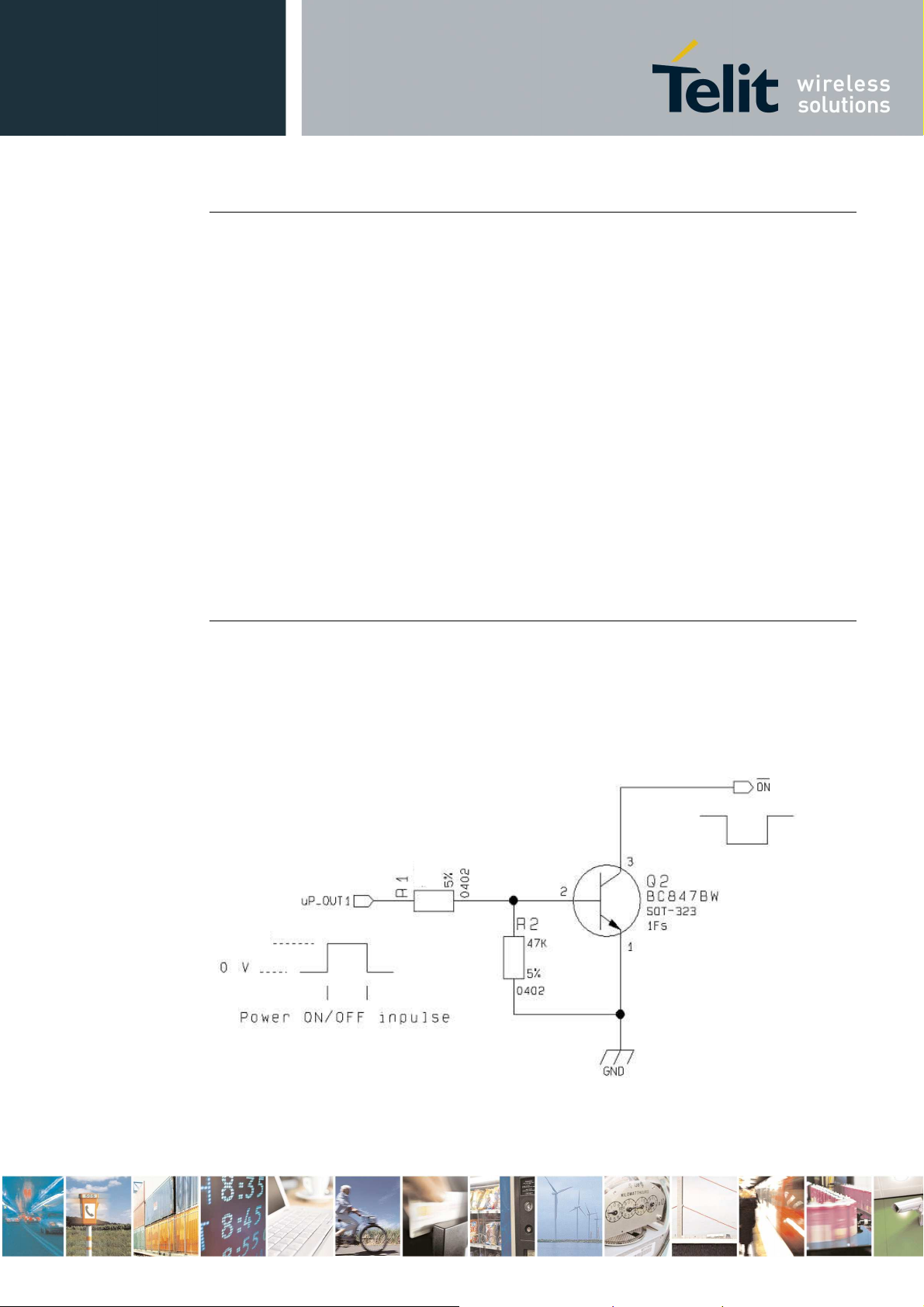

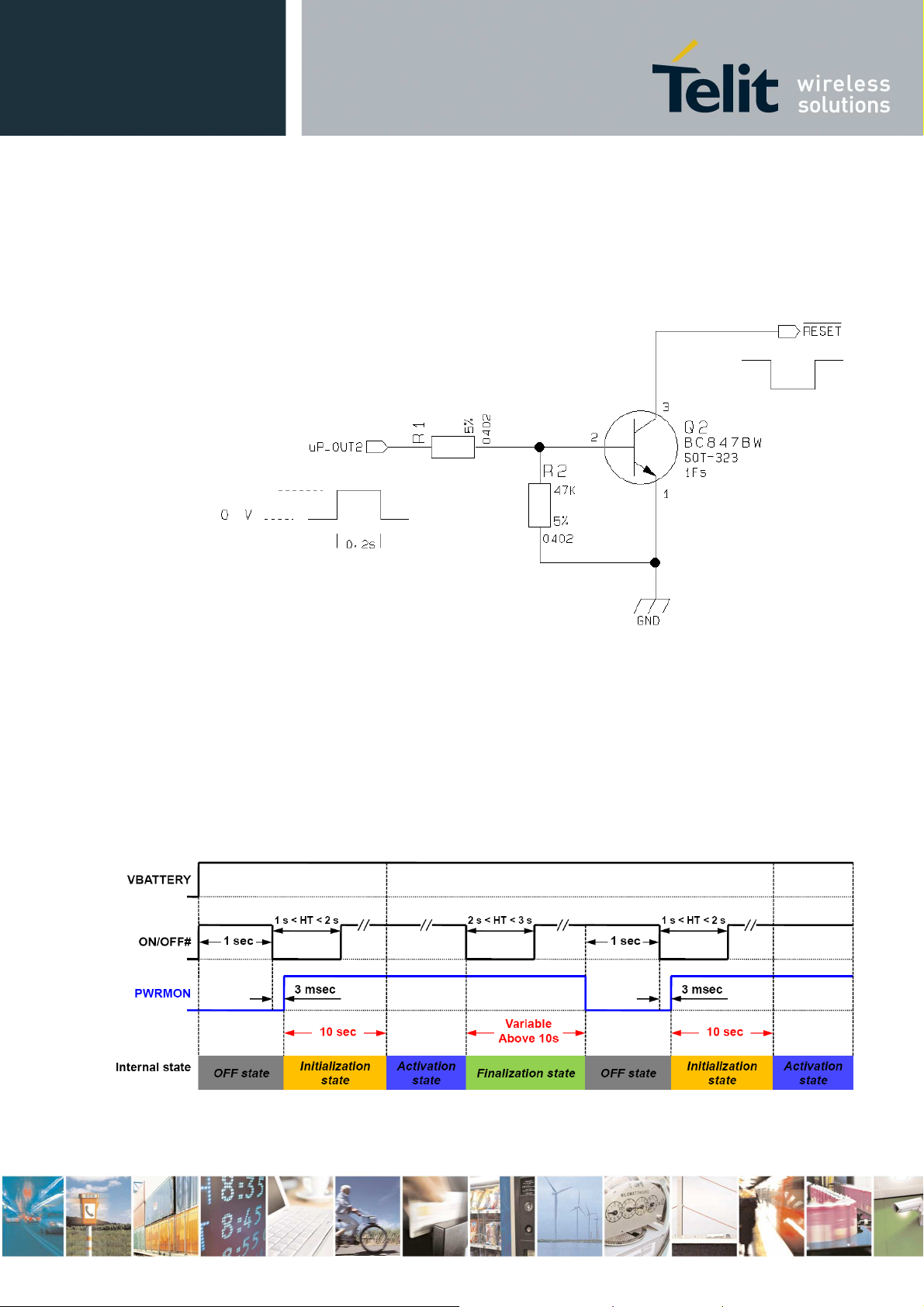

A simple

to do it is:

Power ON impulse

R1

Q1

R2

GND

ON#

circuit

Reproduction forbidden without Telit Communications S.p.A’s. written authorization - All Rights Reserved. Page 14 of 78

Page 15

UC864-E-AUTO / AWS-AUTO Hardware User Guide

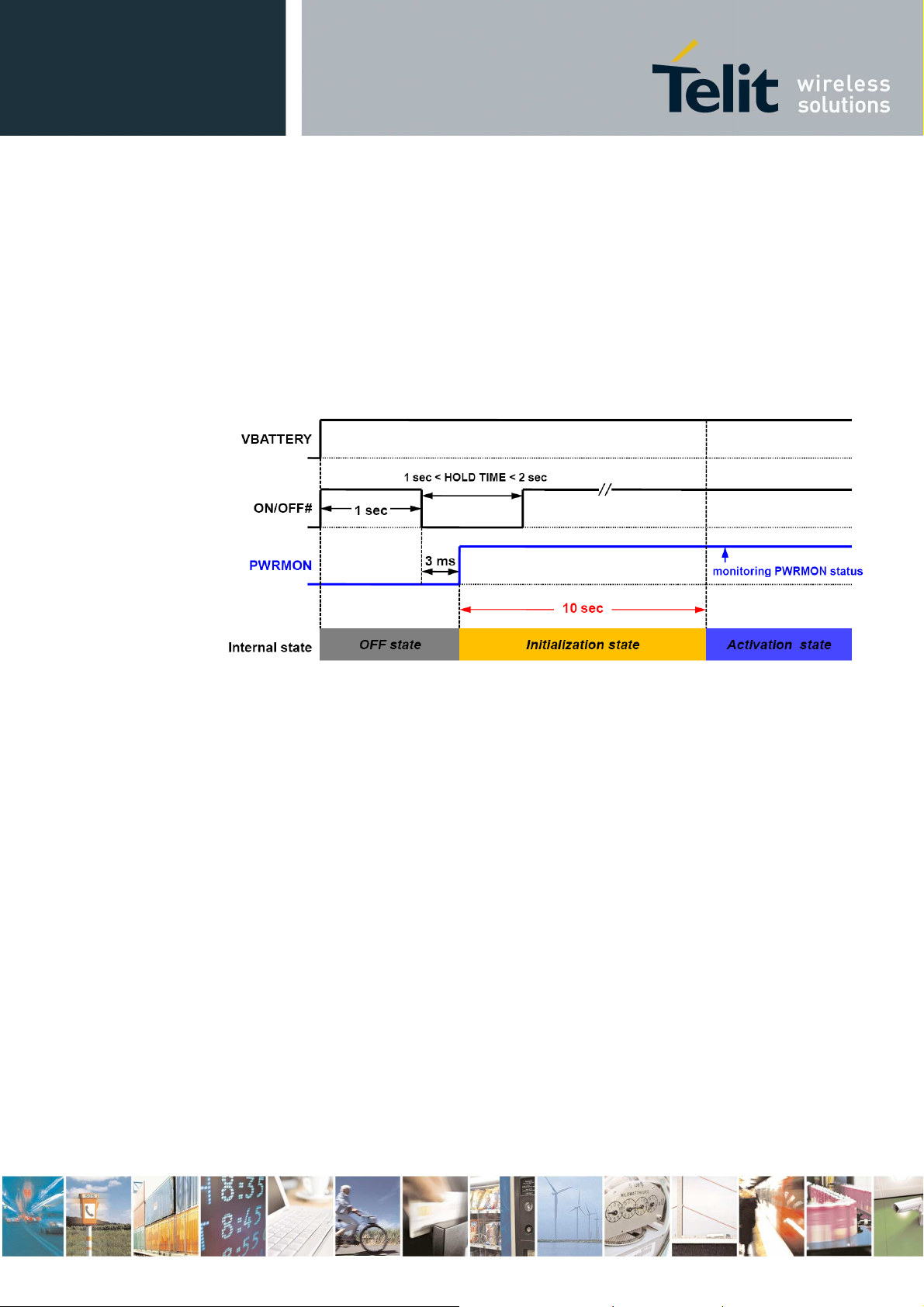

5.2. Initialization and Activation state

Upon turning on UC864-E-AUTO / AWS-AUTO, the module is not activated yet

because the boot sequence of UC864-E-AUTO / AWS-AUTO is still going on internally.

It takes about 10 seconds to complete the initializing the module internally.

For this reason, it would be useless to try to access UC864-E-AUTO/ AWS-AUTO

during a

AWS-AUTO needs at least 10 seconds after the PWRMON goes High.

Initialization state

as below. To get the desirable stability, UC864-E-AUTO /

1vv0300795 Rev.11 – 2010/11/18

During the

waiting for the

Initialization state

Activation state

, any kind of AT-command is not available. DTE must be

to communicate with UC864-E-AUTO / AWS-AUTO.

Reproduction forbidden without Telit Communications S.p.A’s. written authorization - All Rights Reserved. Page 15 of 78

Page 16

In this document all the lines are inverted. Active low signals are labeled with a name

turns fully on also by supplying power to the Charge pad

UC864-E-AUTO / AWS-AUTO Hardware User Guide

1vv0300795 Rev.11 – 2010/11/18

NOTE:

NOTE:

NOTE: NOTE:

To check if the UC864-E-AUTO / AWS-AUTO has powered on, the hardware line

PWRMON must be monitored. When PWRMON goes high, the module has powered

on.

NOTE:

NOTE:

NOTE: NOTE:

Do not use any pull up resistor on the ON/OFF# line, it is internally pulled up. Using

pull up resistor may bring to latch up problems on the UC864-E-AUTO / AWS-AUTO

power regulator and improper power on/off of the module. The line ON/OFF# must

be connected only in open collector configuration.

NOTE:

NOTE:

NOTE: NOTE:

that ends with a "#" or with a bar over the name.

NOTE:

NOTE:

NOTE: NOTE:

UC864-E-AUTO / AWS-AUTO

(provided there is a battery on the VBATT pads).

For example:

1- Let us assume you need to drive the ON/OFF# pad with a totem pole output of a

+1.8/5 V microcontroller (uP_OUT1):

10k

1.8 / 5V

1s

Reproduction forbidden without Telit Communications S.p.A’s. written authorization - All Rights Reserved. Page 16 of 78

Page 17

UC864-E-AUTO / AWS-AUTO Hardware User Guide

1vv0300795 Rev.11 – 2010/11/18

5.3. Turning OFF the UC864-E-AUTO / AWS-AUTO

Turning off the device can be done in three ways:

• by software command (see UC864-E-AUTO / AWS-AUTO Software User

Guide)

• by hardware shutdown

• by Hardware Unconditional Restart

When the device is shut down by software command or by hardware shutdown, it

issues to the network a detach request that informs the network that the device will

not be reachable any more.

Reproduction forbidden without Telit Communications S.p.A’s. written authorization - All Rights Reserved. Page 17 of 78

Page 18

UC864-E-AUTO / AWS-AUTO Hardware User Guide

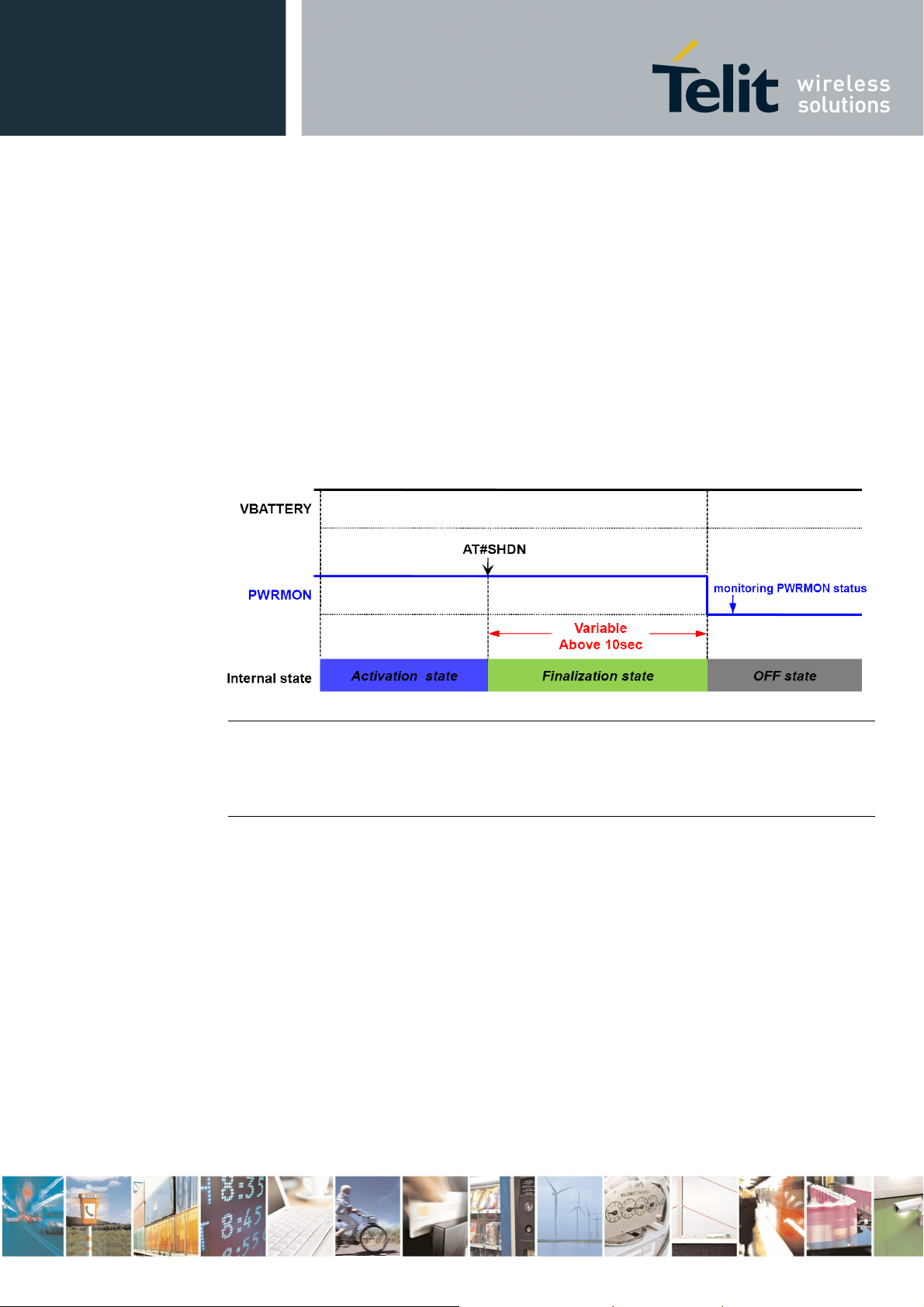

5.3.1. Shutdown by Software Command

UC864-E-AUTO / AWS-AUTO can be shut down by a software command.

When a shut down command is sent, UC864-E-AUTO / AWS-AUTO goes into the

finalization state and finally will shut down PWRMON at the end of this state.

The period of the finalization state can differ according to the situation in which the

UC864-E-AUTO / AWS-AUTO is so it cannot be fixed definitely.

Normally it will be above 10 seconds later from sending a shut down command and

DTE should monitor the status of PWRMON to see the actual power off.

1vv0300795 Rev.11 – 2010/11/18

TIP:

TIP:

TIP: TIP:

To check if the device has powered off, hardware line PWRMON must be monitored.

When PWRMON goes low, the device has powered off.

Reproduction forbidden without Telit Communications S.p.A’s. written authorization - All Rights Reserved. Page 18 of 78

Page 19

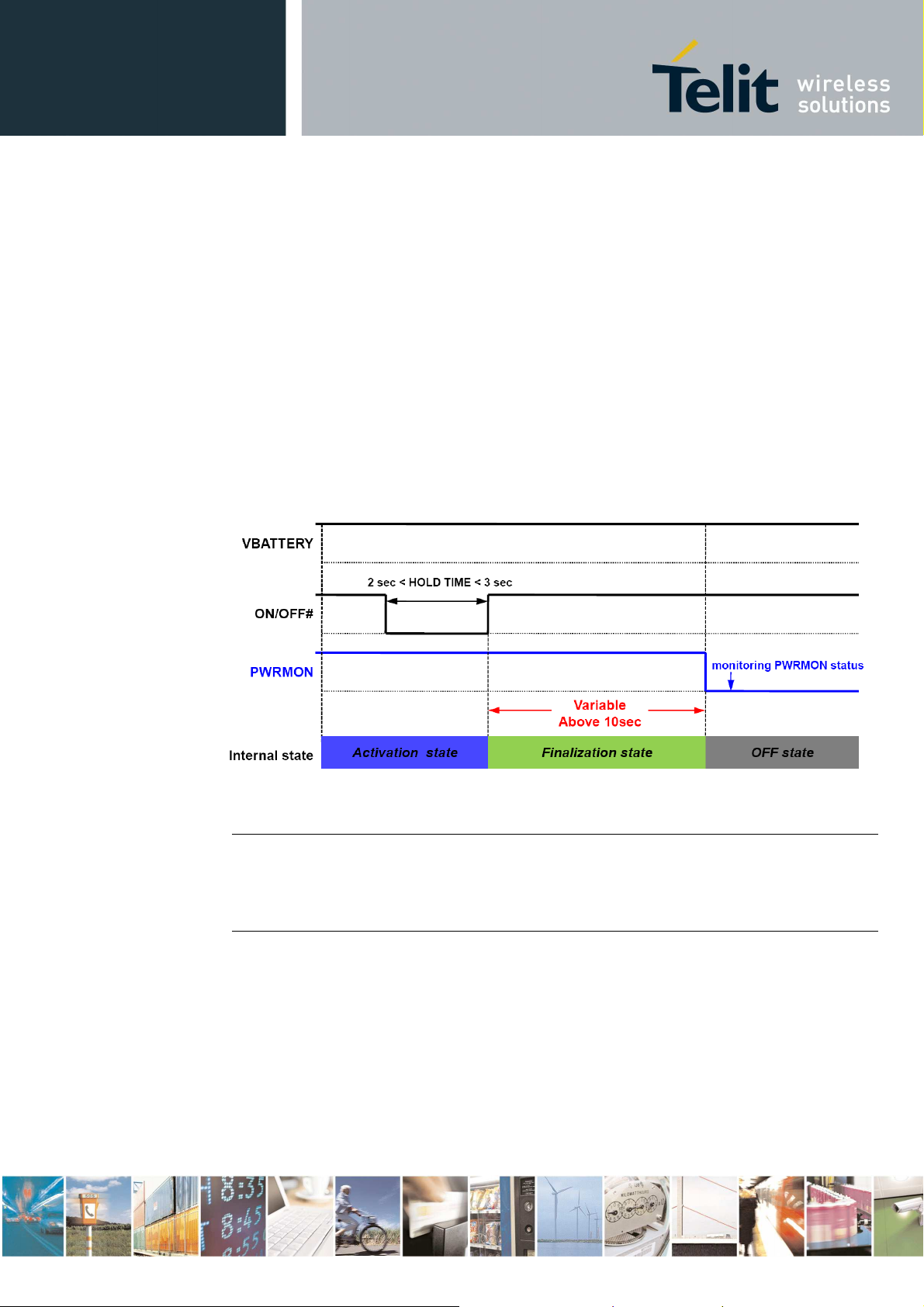

5.3.2. Hardware Shutdown

To turn OFF UC864-E-AUTO / AWS-AUTO the pad ON/OFF# must be tied low for at

least 2 seconds and then released. Same circuitry and timing for the power on must

be used.

When the hold time of ON/OFF# is above 2 seconds, UC864-E-AUTO / AWS-AUTO

goes into the finalization state and finally will shut down PWRMON at the end of this

state.

The period of the finalization state can differ according to the situation in which the

UC864-E-AUTO / AWS-AUTO is so it cannot be fixed definitely.

Normally it will be above 10 seconds later from releasing ON/OFF# and DTE should

monitor the status of PWRMON to see the actual power off.

UC864-E-AUTO / AWS-AUTO Hardware User Guide

1vv0300795 Rev.11 – 2010/11/18

TIP:

TIP:

TIP: TIP:

To check if the device has powered off, hardware line PWRMON must be monitored.

When PWRMON goes low, the device has powered off.

Reproduction forbidden without Telit Communications S.p.A’s. written authorization - All Rights Reserved. Page 19 of 78

Page 20

UC864-E-AUTO / AWS-AUTO Hardware User Guide

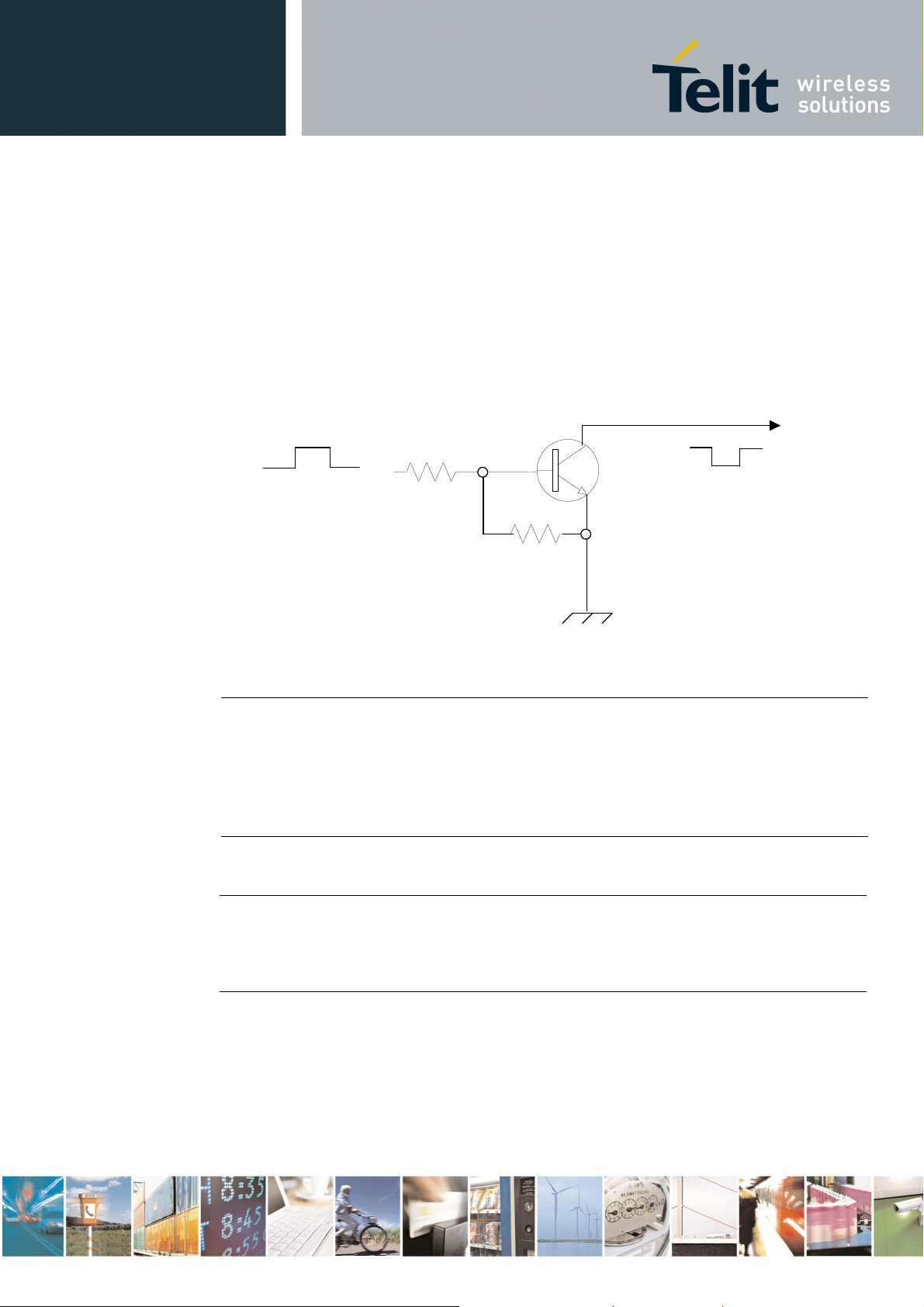

5.3.3. Hardware Unconditional Restart

To unconditionally restart UC864-E-AUTO / AWS-AUTO, the pad RESET# must be tied

low for at least 200 milliseconds and then released.

A simple circuit to do it is:

Unconditional Restart

impulse

1vv0300795 Rev.11 – 2010/11/18

RESET#

GND

NOTE:

NOTE:

NOTE: NOTE:

Do not use any pull up resistor on the RESET# line or any totem pole digital output.

Using pull up resistor may bring to latch up problems on the UC864-E-AUTO / AWSAUTO power regulator and improper functioning of the module. The line RESET#

must be connected only in open collector configuration.

TIP:

TIP:

TIP: TIP:

The unconditional hardware Restart must always be implemented on the boards and

the software must use it as an emergency exit procedure.

Reproduction forbidden without Telit Communications S.p.A’s. written authorization - All Rights Reserved. Page 20 of 78

Page 21

UC864-E-AUTO / AWS-AUTO Hardware User Guide

1vv0300795 Rev.11 – 2010/11/18

For example:

1- Let us assume you need to drive the RESET# pad with a totem pole output of a

+1.8/5 V microcontroller (uP_OUT2):

10k

+1.8 / 5V

5.4. Summary of Turning ON and OFF the module

Below chart describes the overall sequences for Turning ON and OFF.

Reproduction forbidden without Telit Communications S.p.A’s. written authorization - All Rights Reserved. Page 21 of 78

Page 22

UC864-E-AUTO / AWS-AUTO Hardware User Guide

1vv0300795 Rev.11 – 2010/11/18

6. Power Supply

Power Supply

Power SupplyPower Supply

The power supply circuitry and board layout are a very important part in the full

product design and they strongly reflect on the product overall performances. Read

carefully the requirements and the guidelines that will follow for a proper design.

6.1. Power Supply Requirements

The UC864-E-AUTO / AWS-AUTO power requirements are:

Power Supply

Power Supply

Power SupplyPower Supply

Nominal Supply Voltage 3.8V

Max Supply Voltage 4.2V

Supply Voltage Range 3.4V – 4.2V

UC864

UC864----EEEE----AUTO

UC864UC864

Mode

Mode Average(mA)

ModeMode

IDLE mode Stand by mode; no call in progress

AT+CFUN=1

AT+CFUN=4

AT+CFUN=0 or

AT+CFUN=5

WCDMA TX and RX mode

WCDMA Voice 690 WCDMA voice channel

WCDMA data 680 WCDMA data channel

HSDPA 730 HSDPA data channel

GSM TX and RX mode

GSM Voice 320 GSM voice channel

GPRS Class12 650 GPRS data channel

EDGE Class12 430 EDGE data channel

WCDMA 22.0

GSM 15.0

WCDMA 17.8

GSM 17.8

WCDMA 4.1 / 1.3*

GSM 3.3 / 1.3*

Average(mA) Mode D

Average(mA)Average(mA)

* Worst/best case depends on network configuration and is not under module control.

AUTO/ AWS

/ AWS----AUTO

AUTOAUTO

/ AWS/ AWS

Normal mode; full functionality of the module

Disabled TX and RX; modules is not registered on the

network

Power saving; CFUN=0 module registered on the

network and can receive voice call or an SMS; but it is

not possible to send AT commands; module wakes up with

an unsolicited code (call or SMS) or rising RTS line.

CFN=5 full functionality with power saving;

Module registered on the network can receive

incoming call sand SMS

AUTO

AUTOAUTO

Mode Description

Mode DMode D

escription

escriptionescription

Reproduction forbidden without Telit Communications S.p.A’s. written authorization - All Rights Reserved. Page 22 of 78

Page 23

UC864-E-AUTO / AWS-AUTO Hardware User Guide

1vv0300795 Rev.11 – 2010/11/18

In GSM/GPRS mode, RF transmission is not continuous and it is packed into bursts at

a base frequency of about 216 Hz, and the relative current peaks can be as high as

about 2A. Therefore the power supply has to be designed in order to withstand these

current peaks without big voltage drops; this means that both the electrical design

and the board layout must be designed for this current flow. If the layout of the PCB

is not well designed, a strong noise floor is generated on the ground; this will reflect

on all the audio paths producing an audible annoying noise at 216 Hz; if the voltage

drops during the peak, current absorption is too much. The device may even shut

TIP:

TIP:

TIP: TIP:

The electrical design for the Power supply must be made ensuring that it will be

capable of a peak current output of at least 2A.

down as a consequence of the supply voltage drop.

Reproduction forbidden without Telit Communications S.p.A’s. written authorization - All Rights Reserved. Page 23 of 78

Page 24

UC864-E-AUTO / AWS-AUTO Hardware User Guide

6.2. General Design Rules

The principal guidelines for the Power Supply Design embrace three different design

steps:

• the electrical design

• the thermal design

• the PCB layout

6.2.1. Electrical Design Guidelines

The electrical design of the power supply depends strongly on the power source

where this power is drained. We will distinguish them into three categories:

1vv0300795 Rev.11 – 2010/11/18

• +5V input (typically PC internal regulator output)

• +12V input (typically automotive)

• battery

6.2.1.1. + 5V Input Source Power Supply Design Guidelines

• The desired output for the power supply is 3.8V, hence there is not a big

difference between the input source and the desired output and a linear

regulator can be used. A switching power supply will not be suited

because of the low drop-out requirements.

• When using a linear regulator, a proper heat sink must be provided in

order to dissipate the power generated.

• A Bypass low ESR capacitor of adequate capacity must be provided in

order to cut the current absorption peaks close to UC864-E-AUTO / AWSAUTO, a 100µF tantalum capacitor is usually suited.

• Make sure the low ESR capacitor on the power supply output (usually a

tantalum one) is rated at least 10V.

• A protection diode must be inserted close to the power input, in order to

save UC864-E-AUTO / AWS-AUTO from power polarity inversion.

Reproduction forbidden without Telit Communications S.p.A’s. written authorization - All Rights Reserved. Page 24 of 78

Page 25

UC864-E-AUTO / AWS-AUTO Hardware User Guide

1vv0300795 Rev.11 – 2010/11/18

An example of linear regulator with 5V input is:

6.2.1.2. + 12V Input Source Power Supply Design Guidelines

• The desired output for the power supply is 3.8V, hence due to the big

difference between the input source and the desired output, a linear

regulator is not suited and must not be used. A switching power supply

will be preferable because of its better efficiency especially with the 2A

peak current load represented by UC864-E-AUTO / AWS-AUTO.

• When using a switching regulator, a 500kHz or more switching frequency

regulator is preferable because of its smaller inductor size and its faster

transient response. This allows the regulator to respond quickly to the

current peaks absorption.

• In any case, the frequency and Switching design selection is related to the

application to be developed due to the fact the switching frequency could

also generate EMC interferences.

• For car PB battery the input voltage can rise up to 15.8V and this must be

kept in mind when choosing components: all components in the power

supply must withstand this voltage.

• A Bypass low ESR capacitor of adequate capacity must be provided in

order to cut the current absorption peaks. A 100µF tantalum capacitor is

usually suited for this.

Reproduction forbidden without Telit Communications S.p.A’s. written authorization - All Rights Reserved. Page 25 of 78

Page 26

UC864-E-AUTO / AWS-AUTO Hardware User Guide

1vv0300795 Rev.11 – 2010/11/18

• Make sure the low ESR capacitor on the power supply output (usually a

tantalum one) is rated at least 10V.

• For Car applications a spike protection diode must be inserted close to

the power input, in order to clean the supply from spikes.

• A protection diode must be inserted close to the power input, in order to

save UC864-E-AUTO / AWS-AUTO from power polarity inversion. This can

be the same diode as for spike protection.

An example of switching regulator with 12V input is in the below schematic (it is split

in 2 parts):

Reproduction forbidden without Telit Communications S.p.A’s. written authorization - All Rights Reserved. Page 26 of 78

Page 27

UC864-E-AUTO / AWS-AUTO Hardware User Guide

6.2.1.3. Battery Source Power Supply Design Guidelines

• The desired nominal output for the power supply is 3.8V and the

maximum allowed voltage is 4.2V, hence a single 3.7V Li-Ion cell battery

type is suited for supplying the power to the Telit UC864-E-AUTO / AWSAUTO module. The three cells Ni/Cd or Ni/MH 3.6 V Nom. battery types or

4V PB types must not be used directly since their maximum voltage can

rise over the absolute maximum voltage for UC864-E-AUTO / AWS-AUTO

and damage it.

NOTE:

NOTE:

NOTE: NOTE:

Do not use any Ni-Cd, Ni-MH, and Pb battery types directly connected with UC864-EAUTO / AWS-AUTO. Their use can lead to overvoltage on UC864-E-AUTO / AWS-AUTO

and damage it. Use only Li-Ion battery types.

1vv0300795 Rev.11 – 2010/11/18

• A Bypass low ESR capacitor of adequate capacity must be provided in

order to cut the current absorption peaks, a 100µF tantalum capacitor is

usually suited.

• Make sure the low ESR capacitor (usually a tantalum one) is rated at least

10V.

• A protection diode must be inserted close to the power input, in order to

save UC864-E-AUTO / AWS-AUTO from power polarity inversion.

Otherwise the battery connector must be done in a way to avoid polarity

inversions when connecting the battery.

• The battery capacity must be at least 500mAh in order to withstand the

current peaks of 2A; the suggested capacity is from 500mAh to 1000mAh.

Reproduction forbidden without Telit Communications S.p.A’s. written authorization - All Rights Reserved. Page 27 of 78

Page 28

UC864-E-AUTO / AWS-AUTO Hardware User Guide

1vv0300795 Rev.11 – 2010/11/18

6.2.1.4. Battery Charge Control Circuitry Design Guidelines

The charging process for Li-Ion Batteries can be divided into 4 phases:

• qualification and trickle charging

• fast charge 1 - constant current

• final charge - constant voltage or pulsed charging

• maintenance charge

The qualification process consists of a battery voltage measure, indicating roughly its

charge status. If the battery is deeply discharged, meaning its voltage is lower than

the trickle charging threshold, then charging must start slowly, possibly with a

current limited to the pre-charging process. The current must be kept very low with

respect to the fast charge value.

During trickle charging the voltage across the battery terminals rises; when it

reaches the fast charge threshold level the charging process goes into a fast charge

phase.

During the fast charge phase the process proceeds with a current limited for

charging; this current limit depends on the required time for completing the charge

and on battery pack capacity. During this phase the voltage across the battery

terminals still raises but at a lower rate. Once the battery voltage reaches its

maximum voltage the process goes into its third state: Final charging. The voltage

measure to change the process status into final charge is very important. It must be

ensured that the maximum battery voltage is never exceeded, otherwise the battery

may be damaged and even explode.

Moreover, for constant final chargers, the voltage phase (final charge) must not start

before the battery voltage has reached its maximum value, otherwise the battery

capacity will be slightly reduced. The final charge can be of two different types:

constant voltage or pulsed. UC864-E-AUTO / AWS-AUTO uses constant voltage.

The constant voltage charge proceeds with a fixed voltage regulator (very accurately

set to the maximum battery voltage) and the current will decrease while the battery

is becoming charged. When the charging current falls below a certain fraction of the

fast charge current value, the battery is considered fully charged, the final charge

stops and eventually starts the maintenance.

The pulsed charge process has no voltage regulation, instead charge continues with

pulses. Usually the pulse charge works in the following manner: the charge is

stopped for some time, let us say few hundreds of ms, then the battery voltage will

be measured and when it drops below its maximum value, a fixed time length

charging pulse is issued. As the battery approaches its full charge, the off time will

become longer and the duty-cycle of the pulses will decrease. The battery is

considered fully charged when the pulse duty-cycle is less than a threshold value,

Reproduction forbidden without Telit Communications S.p.A’s. written authorization - All Rights Reserved. Page 28 of 78

Page 29

UC864-E-AUTO / AWS-AUTO Hardware User Guide

1vv0300795 Rev.11 – 2010/11/18

typically 10%. When this happens, the pulse charge stops and eventually the

maintenance starts.

The last phase is not properly a charging phase, since the battery at this point is fully

charged and the process may stop after the final charge. The maintenance charge

provides an additional charging process to compensate the charge leak typical of a

Li-Ion battery. It is done by issuing pulses with a fixed time length, again few

hundreds of ms, and a duty-cycle around 5% or less.

This last phase is not implemented in the UC864-E-AUTO / AWS-AUTO internal

charging algorithm so once-charged battery is left discharging down to a certain

threshold. It is cycled from full charge to slight discharge even if the battery charger

is inserted. This guarantees that the remaining charge in the battery is a good

percentage and that the battery is not damaged by keeping it always fully charged

(Li-Ion rechargeable batteries usually deteriorate when kept fully charged).

Last but not least, in some applications, it is highly desired that the charging process

restarts when the battery is discharged and its voltage drops below a certain

threshold. This is typical for the UC864-E-AUTO / AWS-AUTO internal charger.

As you can see, the charging process is not a trivial task to do; moreover all these

operations must start only if battery temperature is inside charging range, usually

5°C - 45°C.

The UC864-E-AUTO / AWS-AUTO measures the temperature of its internal

component in order to satisfy this last requirement. This not exactly the same as the

battery temperature but in common use, the two temperatures must not differ too

much and the charging temperature range must be guaranteed.

Reproduction forbidden without Telit Communications S.p.A’s. written authorization - All Rights Reserved. Page 29 of 78

Page 30

UC864-E-AUTO / AWS-AUTO Hardware User Guide

1vv0300795 Rev.11 – 2010/11/18

NOTE:

NOTE:

NOTE: NOTE:

For all the threshold voltages, inside UC864-E-AUTO / AWS-AUTO, all thresholds are

fixed in order to maximize Li-Ion battery performances and do not need to be

changed.

NOTE:

NOTE:

NOTE: NOTE:

In this application the battery charger input current must be limited to less than

400mA. This can be done by using a current limited wall adapter as the power

source.

NOTE:

NOTE:

NOTE: NOTE:

When starting the charger from Module powered off, the startup will be in CFUN4; to

activate the normal mode a command AT+CFUN=1 has to be provided.

There is also the possibility to activate the normal mode using the ON_OFF* signal.

In this case, when HW powering off the module with the same line (ON_OFF*) and

having the charger still connected, the module will go back to CFUN4.

NOTE:

NOTE:

NOTE:NOTE:

It is important to have a 100ųF Capacitor to VBAT in order to avoid instability of the

charger circuit if the battery is accidentally disconnected during the charging activity.

6.2.2. Thermal Design Guidelines

The thermal design for the power supply heat sink must be done with the following

specifications:

• Average current consumption during HSDPA transmission @PWR level

max in UC864-E-AUTO / AWS-AUTO : 730mA

• Average current consumption during class12 GPRS transmission @PWR

level max: 650mA

Reproduction forbidden without Telit Communications S.p.A’s. written authorization - All Rights Reserved. Page 30 of 78

Page 31

UC864-E-AUTO / AWS-AUTO Hardware User Guide

1vv0300795 Rev.11 – 2010/11/18

NOTE:

NOTE:

NOTE: NOTE:

The average consumption during transmissions depends on the power level at which

the device is requested to transmit via the network. The average current

consumption hence varies significantly.

NOTE:

NOTE:

NOTE: NOTE:

The thermal design for the Power supply must be made keeping an average

consumption at the max transmitting level during calls of 730mA rms.

Considering the very low current during idle, especially if Power Saving function is

enabled, it is possible to consider from the thermal point of view that the device

absorbs current significantly only during calls.

If we assume that the device stays in transmission for short periods of time (let us

say few minutes) and then remains for quite a long time in idle (let us say one hour),

then the power supply has always the time to cool down between the calls and the

heat sink could be smaller than the calculated for 730mA maximum RMS current.

There could even be a simple chip package (no heat sink).

Moreover in average network conditions the device is requested to transmit at a

lower power level than the maximum and hence the current consumption will be less

than 730mA (being usually around 250mA).

For these reasons the thermal design is rarely a concern and the simple ground

plane where the power supply chip is placed can be enough to ensure a good thermal

condition and avoid overheating.

For the heat generated by the UC864-E-AUTO / AWS-AUTO, you can consider it to be

during transmission 2W max. This generated heat will be mostly conducted to the

ground plane under the UC864-E-AUTO / AWS-AUTO; you must ensure that your

application can dissipate heat

In the WCDMA/HSDPA mode, since UC864-E-AUTO / AWS-AUTO emits RF signals

continuously during transmission, you must pay special attention how to dissipate

the heat generated.

The current consumption will be up to about 730mA in HSDPA (680mA in WCDMA)

continuously at the maximum TX output power (24dBm). Thus, you must arrange the

PCB area as large as possible under UC864-E-AUTO / AWS-AUTO which you will

mount. You must mount UC864-E-AUTO / AWS-AUTO on the large ground area of

your application board and make many ground vias to dissipate the heat.

The peak current consumption in the GSM mode is higher than that in WCDMA.

However, considering the heat sink is more important in case of WCDMA.

Reproduction forbidden without Telit Communications S.p.A’s. written authorization - All Rights Reserved. Page 31 of 78

Page 32

UC864-E-AUTO / AWS-AUTO Hardware User Guide

As mentioned before, a GSM signal is bursty, thus, the temperature drift is more

insensible than WCDMA. Consequently, if you prescribe the heat dissipation in the

WCDMA mode, you don’t need to think more about the GSM mode.

6.2.3. Power Supply PCB Layout Guidelines

As seen in the electrical design guidelines, the power supply must have a low ESR

capacitor on the output to cut the current peaks and a protection diode on the input

to protect the supply from spikes and polarity inversion. The placement of these

components is crucial for the correct working of the circuitry. A misplaced

component can be useless or can even decrease the power supply performances.

• The Bypass low ESR capacitor must be placed close to the Telit UC864-E-

AUTO / AWS-AUTO power input pads, or in the case the power supply is a

switching type, it can be placed close to the inductor to cut the ripple if the

PCB trace from the capacitor to UC864-E-AUTO / AWS-AUTO is wide

enough to ensure a drop-less connection even during the 2A current

peaks.

1vv0300795 Rev.11 – 2010/11/18

• The protection diode must be placed close to the input connector where

the power source is drained.

• The PCB traces from the input connector to the power regulator. IC must

be wide enough to ensure no voltage drops to occur when the 2A current

peaks are absorbed. Note that this is not made in order to save power

loss but especially to avoid the voltage drops on the power line at the

current peaks frequency of 216 Hz that will reflect on all the components

connected to that supply (also introducing the noise floor at the burst

base frequency.) For this reason while a voltage drop of 300-400 mV may

be acceptable from the power loss point of view, the same voltage drop

may not be acceptable from the noise point of view. If your application

does not have audio interface but only uses the data feature of the Telit

UC864-E-AUTO, then this noise is not so disturbing and power supply

layout design can be more forgiving.

• The PCB traces to UC864-E-AUTO / AWS-AUTO and the Bypass capacitor

must be wide enough to ensure no significant voltage drops to occur when

the 2A current peaks are absorbed. This is a must for the same abovementioned reasons. Try to keep this trace as short as possible.

• The PCB traces connecting the Switching output to the inductor and the

switching diode must be kept as short as possible by placing the inductor

and the diode very close to the power switching IC (only for switching

power supply). This is done in order to reduce the radiated field (noise) at

the switching frequency (usually 100-500 kHz).

• The use of a good common ground plane is suggested.

Reproduction forbidden without Telit Communications S.p.A’s. written authorization - All Rights Reserved. Page 32 of 78

Page 33

UC864-E-AUTO / AWS-AUTO Hardware User Guide

1vv0300795 Rev.11 – 2010/11/18

• The placement of the power supply on the board must be done in a way to

guarantee that the high current return paths in the ground plane are not

overlapped to any noise sensitive circuitry as the microphone

amplifier/buffer or earphone amplifier.

• The power supply input cables must be kept separately from noise

sensitive lines such as microphone/earphone cables.

Reproduction forbidden without Telit Communications S.p.A’s. written authorization - All Rights Reserved. Page 33 of 78

Page 34

UC864-E-AUTO / AWS-AUTO Hardware User Guide

1vv0300795 Rev.11 – 2010/11/18

7. Antenna

Antenna(s)

AntennaAntenna

The antenna connection and board layout design are the most important parts in the

full product design and they strongly reflect on the product’s overall performances.

Read carefully and follow the requirements and the guidelines for a proper design.

(s)

(s)(s)

7.1. GSM/WCDMA Antenna Requirements

As suggested on the Product Description, the antenna for a Telit UC864-E-AUTO /

AWS-AUTO device must fulfill the following requirements:

GSM /WCDMA ANTENNA REQUIREMENTS

GSM /WCDMA ANTENNA REQUIREMENTS

Frequency range

Frequency range Depending by frequency band(s) provided by the network

Frequency rangeFrequency range

Bandwidth

Bandwidth

BandwidthBandwidth

Gain

Gain Gain <

GainGain

Impedance

Impedance 50 Ohm

ImpedanceImpedance

Input power

Input power > 33dBm(2 W) peak power in GSM

Input powerInput power

VSWR absolute max

VSWR absolute max <= 10:1

VSWR absolute maxVSWR absolute max

VSWR recommended

VSWR recommended <= 2:1

VSWR recommendedVSWR recommended

GSM /WCDMA ANTENNA REQUIREMENTSGSM /WCDMA ANTENNA REQUIREMENTS

operator, the customer shall use the most suitable antenna for

that/those band(s)

UC864

UC864----EEEE----AUTO

UC864UC864

80 MHz in GSM900, 170 MHz in DCS

250 MHz in WCDMA2100 band

UC864

UC864----AWS

UC864UC864

70 MHz in GSM850, 140 MHz in PCS

455 MHz in WCDMA1700(AWS) band

WCDMA AWS band : TX = 45MHz, RX = 45MHz

TX-RX freq. separation = 400MHz

7.18 dBi (GSM 850), 2.78 dBi (PCS 1900) and 1.43 dBi (FDD

IV)

> 24dBm Average power in WCDMA

AUTO

AUTOAUTO

AWS----AUTO

AUTO

AWSAWS

AUTOAUTO

Furthermore if the device is developed for the US market, it must comply to the FCC

approval requirements:

This device is to be used only for mobile and fixed application. The antenna(s) used

for this transmitter must be installed to provide a separation distance of at least 20

cm from all persons and must not be co-located or operating in conjunction with any

other antenna or transmitter. End-Users must be provided with transmitter

operation conditions for satisfying RF exposure compliance. OEM integrators must

ensure that the end user has no manual instructions to remove or install the UC864AWS-AUTO module

(GSM 850), 2.78 dBi (PCS 1900) and 1.43 dBi (FDD IV)

.

Antennas used for this OEM module must not exceed 7.18 dBi

gain for mobile and fixed

operating configurations.

Reproduction forbidden without Telit Communications S.p.A’s. written authorization - All Rights Reserved. Page 34 of 78

Page 35

UC864-E-AUTO / AWS-AUTO Hardware User Guide

1vv0300795 Rev.11 – 2010/11/18

7.2. GSM/WCDMA Antenna - Installation Guidelines

• Install the antenna in a place covered by the GSM/WCDMA signal.

• The Antenna must be installed to provide a separation distance of at least

20 cm from all persons and must not be co-located or operating in

conjunction with any other antenna or transmitter;

• Antenna must not be installed inside metal cases;

• Antenna must be installed also according Antenna manufacturer

instructions.

Reproduction forbidden without Telit Communications S.p.A’s. written authorization - All Rights Reserved. Page 35 of 78

Page 36

UC864-E-AUTO / AWS-AUTO Hardware User Guide

1vv0300795 Rev.11 – 2010/11/18

8. Logic L

Logic Level

Logic LLogic L

Where not specifically stated, all the interface circuits work at 2.6V CMOS logic

levels. The following table shows the logic level specifications used in the Telit

UC864-E-AUTO / AWS-AUTO interface circuits:

NOTE:

NOTE:

NOTE: NOTE:

Do not connect UC864-E-AUTO / AWS-AUTO’s digital logic signal directly to OEM’s

digital logic signal of with level higher than 3.0V.

For 2.6V CMOS signals:

Input level on any

digital pin when on

Input voltage on

analog pins when on

Input high level 2.0V 2.9 V

Input low level -0.3V 0.6V

Output high level 2.15V 2.6V

Output low level 0V 0.45V

evel SSSSpecifications

evel evel

Absolute Maximum Ratings

Absolute Maximum Ratings ----Not Functional

Absolute Maximum Ratings Absolute Maximum Ratings

Parameter

Parameter

ParameterParameter

Level

Level

LevelLevel

pecifications

pecificationspecifications

Not Functional

Not FunctionalNot Functional

UC864

UC864----EEEE----AUTO

UC864UC864

-0.3V +3.0V

-0.3V +3.0 V

Ope

Operating Range

rating Range ---- Interface levels

OpeOpe

rating Range rating Range

UC864

UC864----EEEE----AUTO

UC864UC864

AUTO / AWS

AUTOAUTO

Min

Min Max

MinMin

Interface levels

Interface levelsInterface levels

AUTO / AWS

AUTOAUTO

Min

Min Max

MinMin

/ AWS----AUTO

/ AWS/ AWS

/ AWS----AUTO

/ AWS/ AWS

AUTO

AUTOAUTO

Max

MaxMax

AUTO

AUTOAUTO

Max

MaxMax

For 1,8V signals:

Operating Range

Operating Range ---- Interface levels (1.8V CMOS)

Operating Range Operating Range

Lev

Level

el

LevLev

elel

Input high level 1.5V 2.1V

Input low level -0.3V 0.5V

Output high level 1.35V 1.8V

Output low level 0V 0.45V

Reproduction forbidden without Telit Communications S.p.A’s. written authorization - All Rights Reserved. Page 36 of 78

Interface levels (1.8V CMOS)

Interface levels (1.8V CMOS)Interface levels (1.8V CMOS)

UC864

UC864----EEEE----AUTO

UC864UC864

AUTO / AWS

AUTOAUTO

Min

Min Max

MinMin

/ AWS----AUTO

/ AWS/ AWS

Max

MaxMax

AUTO

AUTOAUTO

Page 37

8.1. Reset Signal

Signal

Signal Function

SignalSignal

RESET Phone reset

RESET is used to reset the UC864-E-AUTO / AWS-AUTO module. Whenever this

signal is pulled low, UC864-E-AUTO / AWS-AUTO is reset. When the device is reset it

stops all operations. After the release of the reset UC864-E-AUTO / AWS-AUTO is

unconditionally shut down, without doing any detach operations from the network

where it is registered. This behavior is not a proper shutdown because the device is

requested to issue a detach request on turn off. For this reason, the Reset signal

must not be used for normally shutting down the device, but only as an emergency

exit in the rare case the device remains stuck waiting for some network response.

UC864-E-AUTO / AWS-AUTO Hardware User Guide

Function I/O

FunctionFunction

I/O PIN Number

I/OI/O

I 54

1vv0300795 Rev.11 – 2010/11/18

PIN Number

PIN NumberPIN Number

The RESET is internally controlled on start-up to achieve always a proper power-on

reset sequence. There is no need to control this pin on start-up. It may only be used

to reset a device already on, that is, not responding to any command.

NOTE:

NOTE:

NOTE: NOTE:

Do not use this signal to power off UC864-E-AUTO / AWS-AUTO. Use the ON/OFF

signal to perform this function or the AT#SHDN command.

Reset Signal Operating levels:

Signal

Signal Min

SignalSignal

RESET Input high 2.0V* 2.6V

RESET Input low 0V 0.2V

* This signal is internally pulled up so the pin can be left floating if not used.

If unused, this signal may be left unconnected. If used, it must always be connected

with an open collector transistor to permit the internal circuitry the power on reset

and under voltage lockout functions.

Min Max

MinMin

Max

MaxMax

Reproduction forbidden without Telit Communications S.p.A’s. written authorization - All Rights Reserved. Page 37 of 78

Page 38

does NOT support host device operation at the moment,

UC864-E-AUTO / AWS-AUTO Hardware User Guide

1vv0300795 Rev.11 – 2010/11/18

9. USB Port

USB Port

USB PortUSB Port

UC864-E-AUTO / AWS-AUTO includes an integrated universal serial bus (USB)

transceiver, compatible with USB 2.0 specifications and supporting the USB FullSpeed (12 Mb/s) mode. In HSDPA (High Speed downlink Packet Access) mode, the

downlink data speed rates up to 7.2Mbps. Hence OEMs need to interface UC864-EAUTO / AWS-AUTO to applications in full-speed (12Mbits/s) mode.

This is the main communication port suggested for the OEM application.

UC864

UC864----EEEE----AUTO

UC864UC864

Signal

Signal

SignalSignal

USB_VBUS 48

USB_D- 80

USB D+ 79

USB_ID

(for future use)

/ AWS

/ AWS----AUTO

/ AWS/ AWS

AUTO

AUTOAUTO

AUTO

AUTOAUTO

Pad No.

Pad No.

Pad No.Pad No.

35

Usage

Usage

UsageUsage

Power supply for the internal USB transceiver. This pin is configured

as an analog input or an analog output depending upon the type of

peripheral device connected.

Minus (-) line of the differential, bi-directional USB signal to/from the

peripheral device

Plus (+) line of the differential, bi-directional USB signal to/from the

peripheral device

Analog input used to sense whether a peripheral device is

connected and if connected, to determine the peripheral type, host or

slave

NOTE:

NOTE:

NOTE:NOTE:

UC864-E-AUTO / AWS-AUTO

that is, it works as a slave device. Consequently USB_ID must be opened (not

connected).

Reproduction forbidden without Telit Communications S.p.A’s. written authorization - All Rights Reserved. Page 38 of 78

Page 39

TRM

TRM

UC864-E-AUTO / AWS-AUTO Hardware User Guide

1vv0300795 Rev.11 – 2010/11/18

9.1. USB transceiver specifications

This is the on-chip USB transceiver specifications

Parameter

Parameter Comments

ParameterParameter

USB_VBUS

USB_VBUS ::::

USB_VBUSUSB_VBUS

Supply Voltage 4.5 5.0 5.25 V

Supply Current 25 mA

Input Lev

Input Levels for Low

Input LevInput Lev

Receiver Threshold (single-end) 0.8 2.0 V

Differential Input Sensitivity |D+ - D-|, V

Differential Common-mode Range Includes V

Output Levels for Low

Output Levels for Low----/full

Output Levels for LowOutput Levels for Low

Low R

High R

Output Signal Crossover Voltage 1.3 2.0 V

Terminations :

Terminations :

Terminations :Terminations :

Internal pull-up resistor V

Internal pull-down resistor D+ to GND, D- to GND 14.3 15 24.8 kΩ

High-Z state output impedance

Termination Voltage An internal supply voltage, V

Driver

Driver ccccharacteristics

Driver Driver

Transition time :

Rise time

Fall time

Rise/fall time matching 90 111 %

Series output resistance D+, D- 28 33 44

Driver characteristics

Driver characteristics –––– LLLLow speed

Driver characteristics Driver characteristics

Transition time :

Rise time

Fall time

Rise/fall time matching 80 125 %

USB_ID (for future use only)

USB_ID (for future use only)

USB_ID (for future use only)USB_ID (for future use only)

ID pin pull-up resistance 108 140 182 kΩ

A device detection threshold t

B device detection threshold t

els for Low----/full

els for Lowels for Low

haracteristics –––– FFFFull speed

haracteristics haracteristics

/full----speed :

speed :

/full/full

speed :speed :

/full----speed :

speed :

/full/full

speed :speed :

ull speed

ull speedull speed

ow speed

ow speedow speed

= 1.5 kΩ to 3.6 V 0.3 V

= 15 kΩ to GND 2.8 3.6 V

to D+, V

0 V < VD < 3.6V; measured at D+

and D- pins to GND

CL = 50 to 125 pF

C

= 50 to 125 pF

CL = 50 to 600 pF

C

= 50 to 600 pF

< 1 us, V

< 1 us, V

Comments Min

CommentsComments

= 0.8V to 2.5V 0.2 V

0.8 2.5 V

to D- 1.425

= 50mV

= 50mV

Min Typ

MinMin

300

3.0 3.3 3.6 V

4

4

75

75

Typ Max

TypTyp

1.5 1.575 kΩ

0.15*V

0.8*V

Max Unit

MaxMax

20

20

300

300

kΩ

V

V

Unit

UnitUnit

ns

ns

ns

ns

Ω

Reproduction forbidden without Telit Communications S.p.A’s. written authorization - All Rights Reserved. Page 39 of 78

Page 40

UC864-E-AUTO / AWS-AUTO Hardware User Guide

1vv0300795 Rev.11 – 2010/11/18

10. Serial Ports

Serial Ports

Serial PortsSerial Ports

The serial port on the Telit UC864-E-AUTO / AWS-AUTO is another possible interface

between the module and OEM hardware.

2 serial ports are available on the module:

• MODEM SERIAL PORT;

• MODEM SERIAL PORT 2 (DEBUG).

10.1. Modem Serial Port

Several configurations can be designed for the serial port on the OEM hardware. The

most common are:

• RS232 PC com port;

• microcontroller UART @ 2.6V – 2.9V (Universal Asynchronous Receive

Transmit) ;

• microcontroller UART @ 5V or other voltages different from 2.6V .

Depending on the type of serial port on the OEM hardware, a level translator circuit

may be needed to make the system work. The only configuration that does not need a

level translation is the 2.6V UART.

The serial port on UC864-E-AUTO / AWS-AUTO is a +2.6V UART with all the 7 RS232

signals. It differs from the PC-RS232 in signal polarity (RS232 is reversed) and levels.

Reproduction forbidden without Telit Communications S.p.A’s. written authorization - All Rights Reserved. Page 40 of 78

Page 41

Input for Data terminal ready signal (DTR) from

Input for Request to send signal (RTS) from

Output for Data carrier detect signal (DCD) to

UC864-E-AUTO / AWS-AUTO Hardware User Guide

1vv0300795 Rev.11 – 2010/11/18

The levels for UC864-E-AUTO / AWS-AUTO UART are the CMOS levels:

Absolute Maximum Ratings

Absolute Maximum Ratings ---- Not Functional

Absolute Maximum Ratings Absolute Maximum Ratings

Parameter

Parameter Min

ParameterParameter

Input level on any

digital pin when on

Input voltage on

analog pins when on

Min Max

MinMin

-0.3V +3.0V

-0.3V +3.0 V

Operating Range

Operating Range ---- Interface

Operating Range Operating Range

Level

Level Min

LevelLevel

Interface LLLLevels

Interface Interface

Min Max

MinMin

Input high level 2.0V 2.9 V

Input low level -0.3V 0.6V

Output high level 2.15V 2.6V

Output low level 0V 0.45V

Not Functional

Not FunctionalNot Functional

Max

MaxMax

evels

evelsevels

Max

MaxMax

The signals of the UC864-E-AUTO / AWS-AUTO serial port are:

Internal

Internal

Pin

Pin

PinPin

25

25

2525

26

26

2626

27

27

2727

28

28

2828

29

29

2929

30

30

3030

31

31

3131

32

32

3232

Signal

Signal I/O

SignalSignal

C103/TXD I Serial data input (TXD) from DTE Pull-Down CMOS 2.6V

C104/RXD O Serial data output to DTE Pull-Up CMOS 2.6V

C107/DSR O Output for Data set ready signal (DSR) to DTE Pull-Down CMOS 2.6V

C106/CTS O Output for Clear to send signal (CTS) to DTE Pull-Up CMOS 2.6V

C108/DTR I

C125/RING O Output for Ring indicator signal (RI) to DTE Pull-Up CMOS 2.6V

C105/RTS I

C109/DCD O

I/O Function

I/OI/O

DTE

DTE

DTE

Function

FunctionFunction

InternalInternal

Pulls Up/Dn

Pulls Up/Dn

Pulls Up/DnPulls Up/Dn

Pull-Up CMOS 2.6V

Pull-Down CMOS 2.6V

Pull-Up CMOS 2.6V

Type

Type

TypeType

Internal pull-up or pull-down resistance is not a fixed value and it may differ from case by ca

se.

The resistance can be calculated from the DC characteristics considering a level of 2.6V DC.

In this case I_ILPU(input low leakage current with pull-up) is between -60 and -10uA.

Then the resistance can be calculated as V/I=2.6/60u ~ 2.6/10u = 43.3K ~ 260K.

In case of pull-down, it can be calculated in the same way.