Page 1

Mod. 0805 2017-01 Rev.6

ML865C1

HW User Guide

1VV0301493 Rev. 2 Preliminary – 2018-09-29

Page 2

HW User Guide Template

1VV0301493 Rev. 2 Page 2 of 86 2018-05-11

SPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE

NOTICE

While reasonable efforts have been made to assure the accuracy of this document, Telit

assumes no liability resulting from any inaccuracies or omissions in this document, or from

use of the information obtained herein. The information in this document has been carefully

checked and is believed to be reliable. However, no responsibility is assumed for

inaccuracies or omissions. Telit reserves the right to make changes to any products

described herein and reserves the right to revise this document and to make changes from

time to time in content hereof with no obligation to notify any person of revisions or changes.

Telit does not assume any liability arising out of the application or use of any product,

software, or circuit described herein; neither does it convey license under its patent rights

or the rights of others.

It is possible that this publication may contain references to, or information about Telit

products (machines and programs), programming, or services that are not announced in

your country. Such references or information must not be construed to mean that Telit

intends to announce such Telit products, programming, or services in your country.

COPYRIGHTS

This instruction manual and the Telit products described in this instruction manual may be,

include or describe copyrighted Telit material, such as computer programs stored in

semiconductor memories or other media. Laws in the Italy and other countries preserve for

Telit and its licensors certain exclusive rights for copyrighted material, including the

exclusive right to copy, reproduce in any form, distribute and make derivative works of the

copyrighted material. Accordingly, any copyrighted material of Telit and its licensors

contained herein or in the Telit products described in this instruction manual may not be

copied, reproduced, distributed, merged or modified in any manner without the express

written permission of Telit. Furthermore, the purchase of Telit products shall not be deemed

to grant either directly or by implication, estoppel, or otherwise, any license under the

copyrights, patents or patent applications of Telit, as arises by operation of law in the sale

of a product.

COMPUTER SOFTWARE COPYRIGHTS

The Telit and 3rd Party supplied Software (SW) products described in this instruction

manual may include copyrighted Telit and other 3rd Party supplied computer programs

stored in semiconductor memories or other media. Laws in the Italy and other countries

preserve for Telit and other 3rd Party supplied SW certain exclusive rights for copyrighted

computer programs, including the exclusive right to copy or reproduce in any form the

copyrighted computer program. Accordingly, any copyrighted Telit or other 3rd Party

supplied SW computer programs contained in the Telit products described in this instruction

manual may not be copied (reverse engineered) or reproduced in any manner without the

express written permission of Telit or the 3rd Party SW supplier. Furthermore, the purchase

of Telit products shall not be deemed to grant either directly or by implication, estoppel, or

otherwise, any license under the copyrights, patents or patent applications of Telit or other

3rd Party supplied SW, except for the normal non-exclusive, royalty free license to use that

arises by operation of law in the sale of a product.

Page 3

HW User Guide Template

1VV0301493 Rev. 2 Page 3 of 86 2018-05-11

USAGE AND DISCLOSURE RESTRICTIONS

I. License Agreements

The software described in this document is the property of Telit and its licensors. It is

furnished by express license agreement only and may be used only in accordance with the

terms of such an agreement.

II. Copyrighted Materials

Software and documentation are copyrighted materials. Making unauthorized copies is

prohibited by law. No part of the software or documentation may be reproduced,

transmitted, transcribed, stored in a retrieval system, or translated into any language or

computer language, in any form or by any means, without prior written permission of Telit

III. High Risk Materials

Components, units, or third-party products used in the product described herein are NOT

fault-tolerant and are NOT designed, manufactured, or intended for use as on-line control

equipment in the following hazardous environments requiring fail-safe controls: the

operation of Nuclear Facilities, Aircraft Navigation or Aircraft Communication Systems, Air

Traffic Control, Life Support, or Weapons Systems (High Risk Activities"). Telit and its

supplier(s) specifically disclaim any expressed or implied warranty of fitness for such High

Risk Activities.

IV. Trademarks

TELIT and the Stylized T Logo are registered in Trademark Office. All other product or

service names are the property of their respective owners.

V. Third Party Rights

The software may include Third Party Right software. In this case you agree to comply with

all terms and conditions imposed on you in respect of such separate software. In addition

to Third Party Terms, the disclaimer of warranty and limitation of liability provisions in this

License shall apply to the Third Party Right software.

TELIT HEREBY DISCLAIMS ANY AND ALL WARRANTIES EXPRESS OR IMPLIED

FROM ANY THIRD PARTIES REGARDING ANY SEPARATE FILES, ANY THIRD PARTY

MATERIALS INCLUDED IN THE SOFTWARE, ANY THIRD PARTY MATERIALS FROM

WHICH THE SOFTWARE IS DERIVED (COLLECTIVELY “OTHER CODE”), AND THE

USE OF ANY OR ALL THE OTHER CODE IN CONNECTION WITH THE SOFTWARE,

INCLUDING (WITHOUT LIMITATION) ANY WARRANTIES OF SATISFACTORY

QUALITY OR FITNESS FOR A PARTICULAR PURPOSE.

NO THIRD PARTY LICENSORS OF OTHER CODE SHALL HAVE ANY LIABILITY FOR

ANY DIRECT, INDIRECT, INCIDENTAL, SPECIAL, EXEMPLARY, OR CONSEQUENTIAL

DAMAGES (INCLUDING WITHOUT LIMITATION LOST PROFITS), HOWEVER CAUSED

AND WHETHER MADE UNDER CONTRACT, TORT OR OTHER LEGAL THEORY,

ARISING IN ANY WAY OUT OF THE USE OR DISTRIBUTION OF THE OTHER CODE

OR THE EXERCISE OF ANY RIGHTS GRANTED UNDER EITHER OR BOTH THIS

LICENSE AND THE LEGAL TERMS APPLICABLE TO ANY SEPARATE FILES, EVEN IF

ADVISED OF THE POSSIBILITY OF SUCH DAMAGES.

Page 4

HW User Guide Template

1VV0301493 Rev. 2 Page 4 of 86 2018-05-11

APPLICABILITY TABLE

PRODUCTS

ML865C1-NA

ML865C1-EA

Page 5

HW User Guide Template

1VV0301493 Rev. 2 Page 5 of 86 2018-05-11

Contents

NOTICE 2

COPYRIGHTS ................................................................................................ 2

COMPUTER SOFTWARE COPYRIGHTS ...................................................... 2

USAGE AND DISCLOSURE RESTRICTIONS ............................................... 3

I. License Agreements ..................................................................... 3

II. Copyrighted Materials ................................................................... 3

III. High Risk Materials ....................................................................... 3

IV. Trademarks .................................................................................. 3

V. Third Party Rights ......................................................................... 3

APPLICABILITY TABLE ................................................................................ 4

CONTENTS .................................................................................................... 5

1. INTRODUCTION .......................................................................... 9

Scope ................................ ........................................................... 9

Audience....................................................................................... 9

Contact Information, Support ........................................................ 9

Text Conventions ........................................................................ 10

Related Documents .................................................................... 11

2. OVERVIEW ................................................................................ 12

3. PINS ALLOCATION ................................................................... 14

Pin-out ........................................................................................ 14

Pin Layout ................................................................................... 19

4. POWER SUPPLY ....................................................................... 20

Power Supply Requirements ....................................................... 20

Power Consumption ................................................................... 21

4.2.1. Current consumption plots .......................................................... 22

General Design Rules ................................................................. 24

4.3.1. Electrical Design Guidelines ....................................................... 24

4.3.1.1. +5V Source Power Supply Design Guidelines ............................ 24

4.3.1.2. +12V Source Power Supply Design Guidelines .......................... 25

4.3.1.3. Battery Source Power Supply Design Guidelines ........................ 26

4.3.2. Thermal Design Guidelines ......................................................... 28

Page 6

HW User Guide Template

1VV0301493 Rev. 2 Page 6 of 86 2018-05-11

4.3.3. Power Supply PCB layout Guidelines ......................................... 29

RTC supply ................................................................................. 30

VAUX Power Output ................................................................... 31

5. DIGITAL SECTION .................................................................... 32

Logic Levels ................................................................................ 32

Power On (Auto-Turning ON ML865) .......................................... 32

Power Off.................................................................................... 35

Wake from deep sleep mode ...................................................... 35

Unconditional Shutdown ( Hardware Unconditional restart) ........ 36

Fast power down ........................................................................ 39

5.6.1. Fast Shut Down by Hardware ..................................................... 39

5.6.2. Fast Shut Down by Software....................................................... 40

Communication ports .................................................................. 40

5.7.1. USB 2.0 HS ................................................................................ 40

5.7.2. SPI.............................................................................................. 42

5.7.3. Serial Ports ................................................................................. 43

5.7.3.1. Modem serial port 1 ................................ .................................... 43

5.7.3.2. Modem serial port 2 ................................ .................................... 45

5.7.3.3. RS232 level translation ............................................................... 46

General purpose I/O ................................................................... 47

5.8.1. Using a GPIO as INPUT ............................................................. 48

5.8.2. Using a GPIO as OUTPUT ......................................................... 49

5.8.3. Indication of network service availability ..................................... 49

External SIM Holder .................................................................... 50

ADC Converter ........................................................................... 50

6. RF SECTION .............................................................................. 52

Bands Variants ........................................................................... 52

TX Output power ......................................................................... 52

RX Sensitivity ............................................................................. 52

Antenna requirements................................................................. 54

6.4.1. PCB Design guidelines ............................................................... 55

6.4.2. PCB Guidelines in case of FCC Certification .............................. 57

6.4.2.1. Transmission line design ............................................................ 57

6.4.2.2. Transmission Line Measurements .............................................. 59

6.4.2.3. Antenna Installation Guidelines ................................................... 61

7. AUDIO SECTION ....................................................................... 62

Page 7

HW User Guide Template

1VV0301493 Rev. 2 Page 7 of 86 2018-05-11

Electrical Characteristics ............................................................. 62

Codec examples ......................................................................... 62

8. GNSS SECTION ......................................................................... 63

GNSS Signals Pin-out................................................................. 63

RF Front End Design .................................................................. 63

8.2.1. Guidelines of PCB line for GNSS Antenna .................................. 63

GNSS Antenna Requirements .................................................... 63

8.3.1. GNSS Antenna specification ....................................................... 64

8.3.2. GNSS Antenna – Installation Guidelines ................................ ..... 64

8.3.3. Powering the External LNA (active antenna) ............................... 64

GNSS Characteristics * ............................................................... 65

9. MECHANICAL DESIGN ............................................................. 66

Drawing ...................................................................................... 66

10. APPLICATION PCB DESIGN .................................................... 68

General ....................................................................................... 68

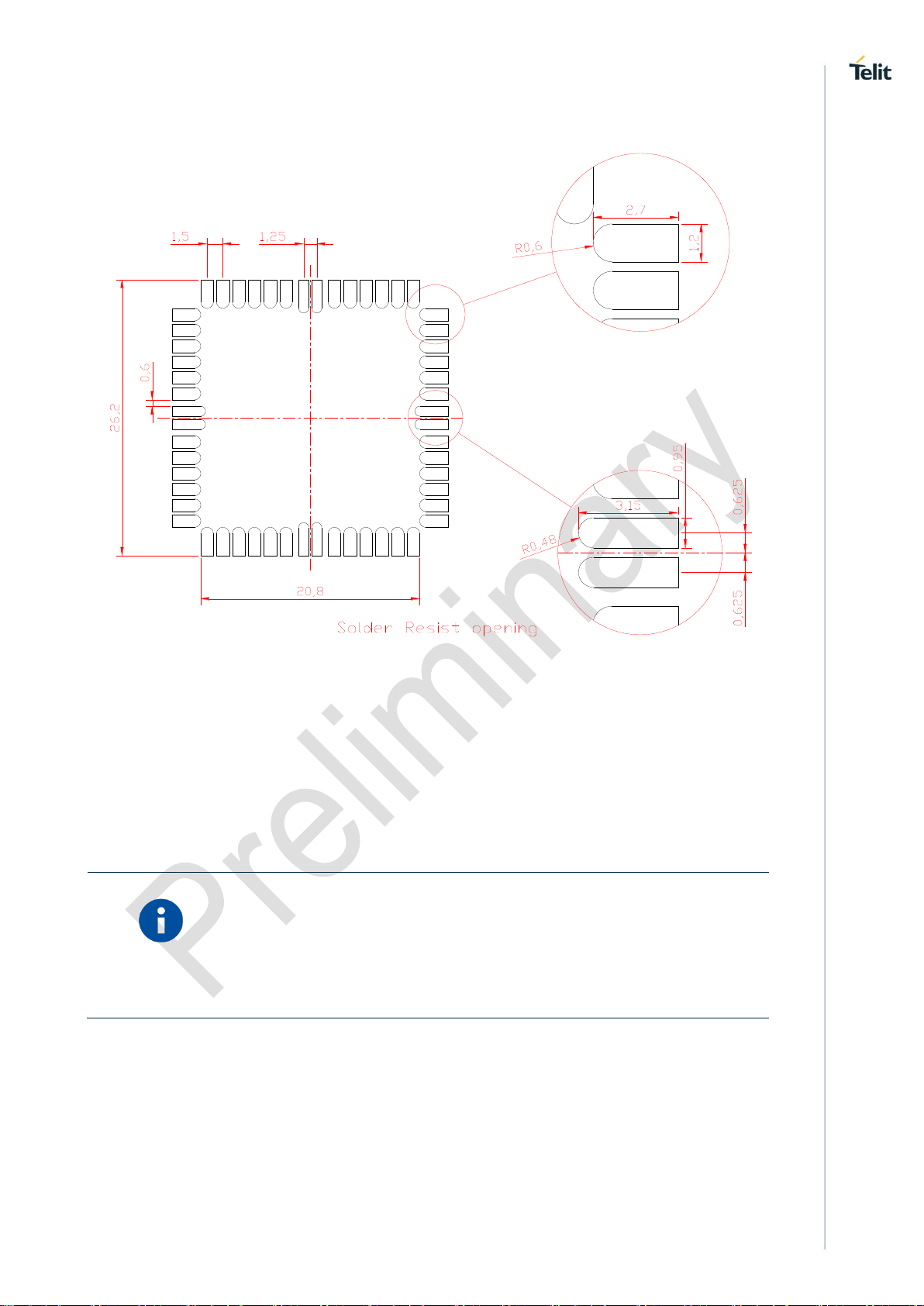

Footprint ..................................................................................... 68

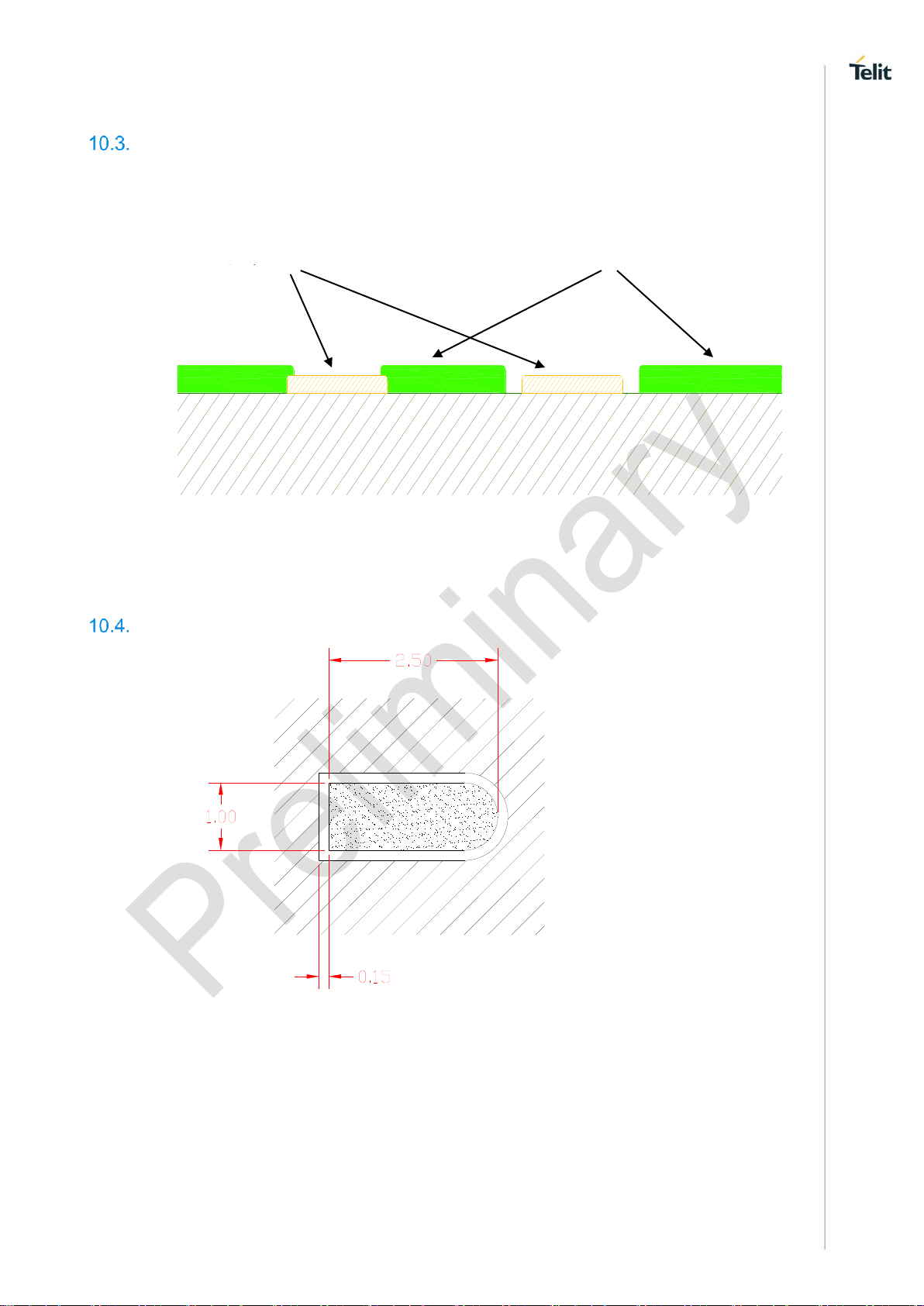

PCB pad design .......................................................................... 70

PCB pad dimensions .................................................................. 70

Stencil ......................................................................................... 71

Solder paste ............................................................................... 72

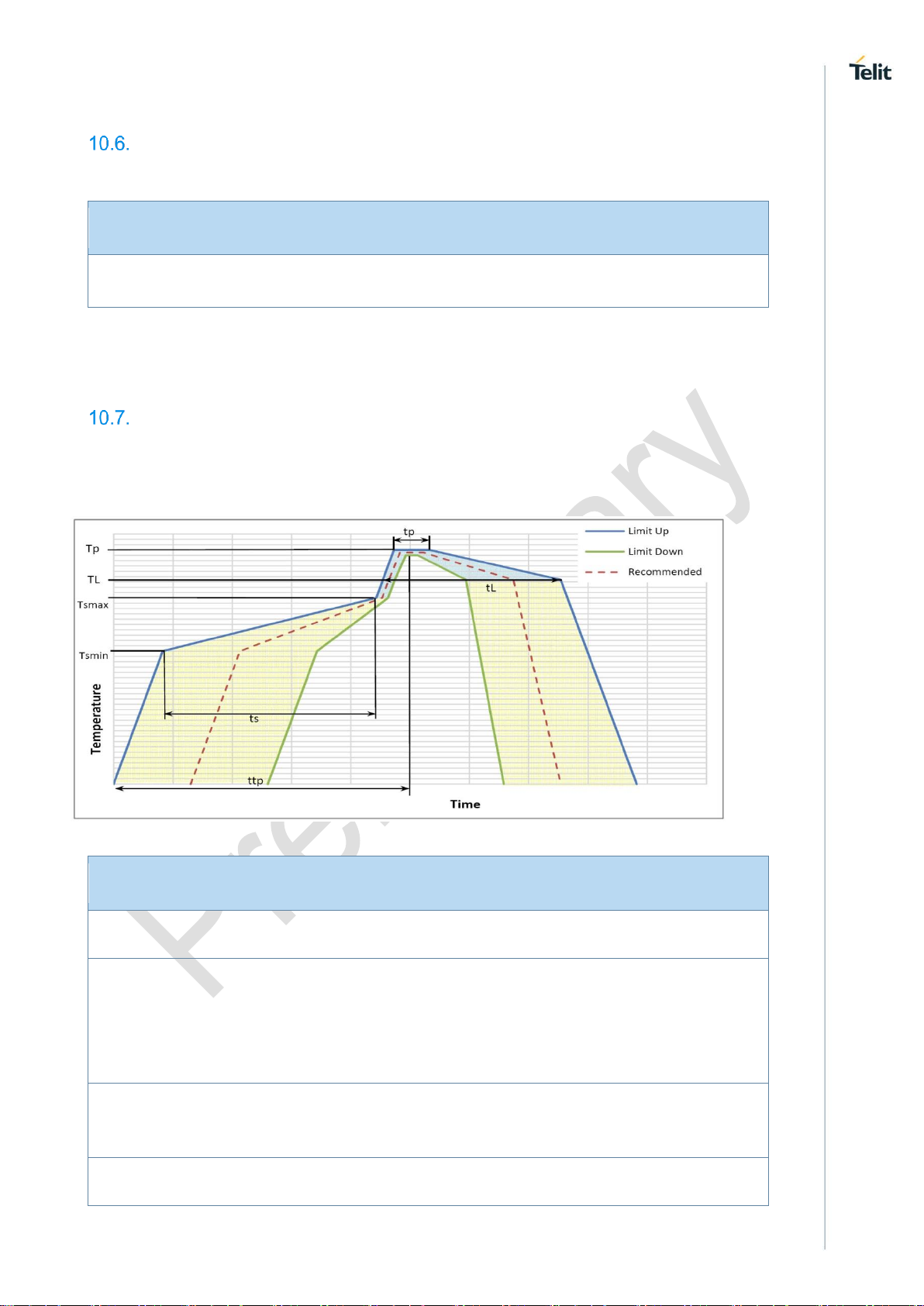

Solder Reflow ............................................................................. 72

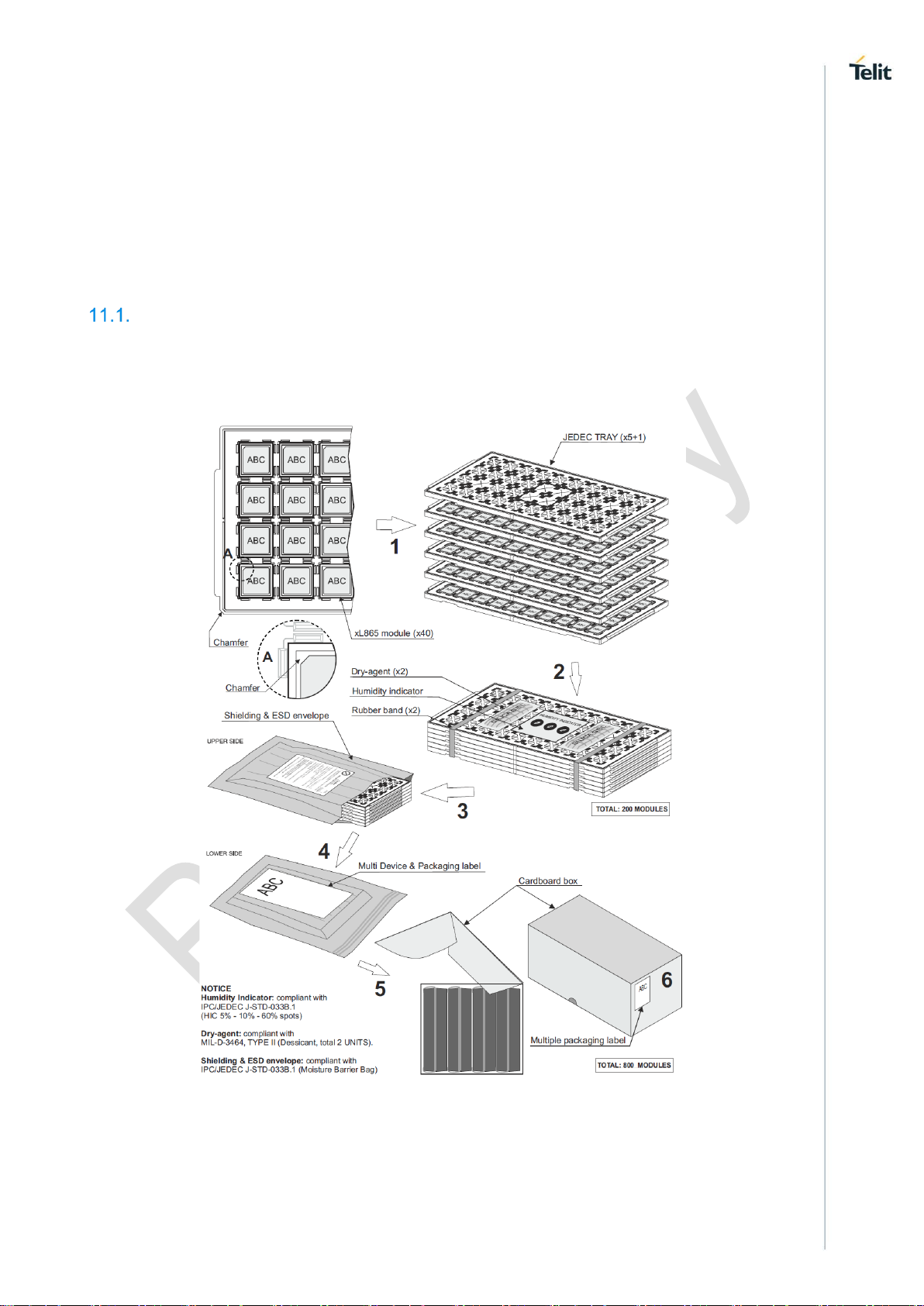

11. PACKAGING .............................................................................. 74

Tray ............................................................................................ 74

Reel ............................................................................................ 76

Moisture sensitivity ..................................................................... 76

12. CONFORMITY ASSESSMENT ISSUES .................................... 79

Approvals.................................................................................... 79

FCC certificates .......................................................................... 79

IC/ISED certificates ..................................................................... 79

FCC/ISED Regulatory notices ..................................................... 79

Declaration of Conformity ........................................................... 81

13. SAFETY RECOMMENDATIONS................................................ 82

READ CAREFULLY .................................................................... 82

14. ACRONYMS ............................................................................... 83

15. DOCUMENT HISTORY .............................................................. 85

Page 8

HW User Guide Template

1VV0301493 Rev. 2 Page 8 of 86 2018-05-11

Page 9

HW User Guide Template

1VV0301493 Rev. 2 Page 9 of 86 2018-05-11

1. INTRODUCTION

Scope

Scope of this document is is the description of some hardware solutions useful for

developing a product with the Telit ML865C1 module.

Audience

This document is intended for Telit customers, who are integrators, about to implement their

application using our ML865C1 module.

Contact Information, Support

For general contact, technical support services, technical questions and report

documentation errors contact Telit Technical Support at:

• TS-EMEA@telit.com

• TS-AMERICAS@telit.com

• TS-APAC@telit.com

• TS-SRD@telit.com

Alternatively, use:

http://www.telit.com/support

For detailed information about where you can buy the Telit modules or for recommendations

on accessories and components visit:

http://www.telit.com

Our aim is to make this guide as helpful as possible. Keep us informed of your comments

and suggestions for improvements.

Telit appreciates feedback from the users of our information.

Page 10

HW User Guide Template

1VV0301493 Rev. 2 Page 10 of 86 2018-05-11

Text Conventions

Danger – This information MUST be followed or catastrophic

equipment failure or bodily injury may occur.

Caution or Warning – Alerts the user to important points about

integrating the module, if these points are not followed, the module and

end user equipment may fail or malfunction.

Tip or Information – Provides advice and suggestions that may be

useful when integrating the module.

All dates are in ISO 8601 format, i.e. YYYY-MM-DD.

Page 11

HW User Guide Template

1VV0301493 Rev. 2 Page 11 of 86 2018-05-11

Related Documents

80000NT10001A - SIM INTEGRATION DESIGN GUIDES Application Note

Page 12

HW User Guide Template

1VV0301493 Rev. 2 Page 12 of 86 2018-05-11

LE910 V2

2. OVERVIEW

The aim of this document is the description of some hardware solutions useful for

developing a product with the Telit ML865C1 module. In this document all the basic

functions of a mobile phone will be taken into account; for each one of them a proper

hardware solution will be suggested and eventually the wrong solutions and common errors

to be avoided will be evidenced. Obviously this document cannot embrace the whole

hardware solutions and products that may be designed. The wrong solutions to be avoided

shall be considered as mandatory, while the suggested hardware configurations shall not

be considered mandatory, instead the information given shall be used as a guide and a

starting point for properly developing your product with the Telit ML865C1 module. For

further hardware details that may not be explained in this document refer to the Telit

ML865C1 Product Description document where all the hardware information is reported.

NOTE:

(EN) The integration of the ML865C1 cellular module within user

application shall be done according to the design rules described in

this manual.

(IT) L’integrazione del modulo cellulare ML865C1 all’interno

dell’applicazione dell’utente dovrà rispettare le indicazioni progettuali

descritte in questo manuale.

(DE) Die Integration des ML865C1 Mobilfunk-Moduls in ein Gerät

muß gemäß der in diesem Dokument beschriebenen

Kunstruktionsregeln erfolgen.

(SL) Integracija ML865C1 modula v uporabniški aplikaciji bo morala

upoštevati projektna navodila, opisana v tem priročniku.

(SP) La utilización del modulo ML865C1 debe ser conforme a los

usos para los cuales ha sido deseñado descritos en este manual del

usuario.

(FR) L’intégration du module cellulaire ML865C1 dans l’application de

l’utilisateur sera faite selon les règles de conception décrites dans ce

manuel.

(HE)

The information presented in this document is believed to be accurate and reliable.

However, no responsibility is assumed by Telit Communications S.p.A. for its use, nor any

Page 13

HW User Guide Template

1VV0301493 Rev. 2 Page 13 of 86 2018-05-11

infringement of patents or other rights of third parties which may result from its use. No

license is granted by implication or otherwise under any patent rights of Telit

Communications S.p.A. other than for circuitry embodied in Telit products. This document

is subject to change without notice.

Page 14

HW User Guide Template

1VV0301493 Rev. 2 Page 14 of 86 2018-05-11

3. PINS ALLOCATION

Warning: ML865C1 is adopting a modified 56-pin xL865 Form Factor,

pin to pin compatible with the previous 48-pin xL865 FF and with 8

additional pads.

The numbering of the pins has been changed accordingly and

attention has to be paid when comparing with previous 48-pin xL865

FF design.

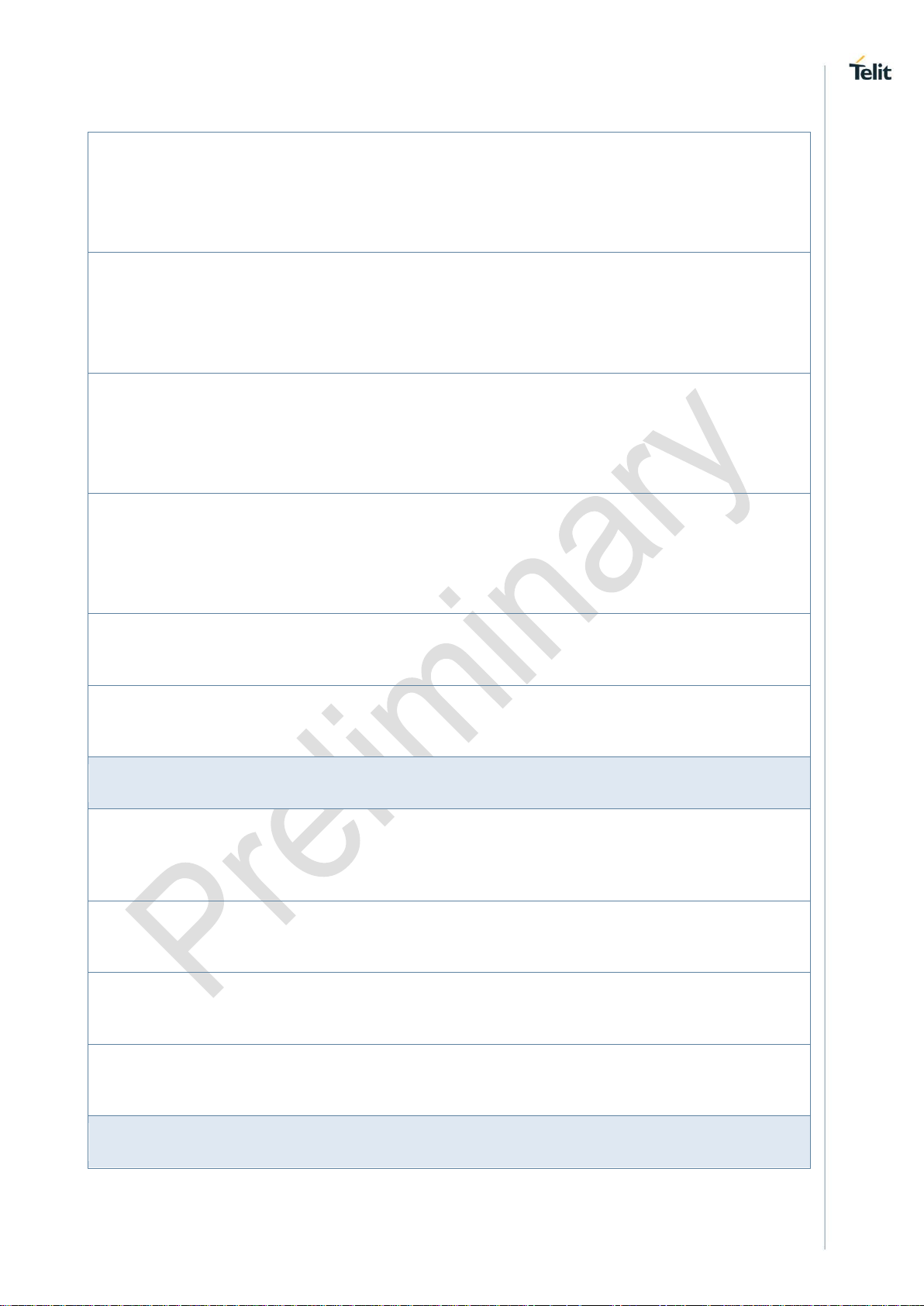

Pin-out

Pin

Signal

I/O Function

Type

Comment

USB HS 2.0 COMMUNICATION PORT

20

USB_D+

I/O

USB differential Data

(+)

3V

19

USB_D-

I/O

USB differential Data

(-)

3V

18

VUSB

I

Power sense for the

internal USB

transceiver.

3-5V

Internal PD

(100K)

Asynchronous Serial Port (USIF0) - Prog. / Data + HW Flow Control

1

C109/DCD/GPO

O

Output for Data carrier

detect signal (DCD) to

DTE

/ GP output

CMOS

1.8V

2

C125/RING/GPO

O

Output for Ring

indicator signal (RI) to

DTE

/ GP output

CMOS

1.8V

Page 15

HW User Guide Template

1VV0301493 Rev. 2 Page 15 of 86 2018-05-11

3

C107/DSR/GPO

O

Output for Data set

ready signal (DSR) to

DTE

/ GP output

CMOS

1.8V

4 C108/DTR/GPI

I

Input for Data terminal

ready signal (DTR)

from DTE

/ GP input

CMOS

1.8V

5

C105/RTS/GPI

I

Input for Request to

send signal (RTS)

from DTE

/ GP input

CMOS

1.8V

6

C106/CTS/GPO

O

Output for Clear to

send signal (CTS) to

DTE

/ GP output

CMOS

1.8V

9

C103/TXD

I

Serial data input

(TXD) from DTE

CMOS

1.8V

10

C104/RXD

O

Serial data output to

DTE

CMOS

1.8V

SIM card interface

11

SIMVCC

-

External SIM signal –

Power supply for the

SIM

1,8 / 3V

12

SIMRST

O

External SIM signal –

Reset

1,8 / 3V

13

SIMCLK

O

External SIM signal –

Clock

1,8 / 3V

14

SIMIO

I/O

External SIM signal –

Data I/O

47k Pull

up

1,8 / 3V

ADC

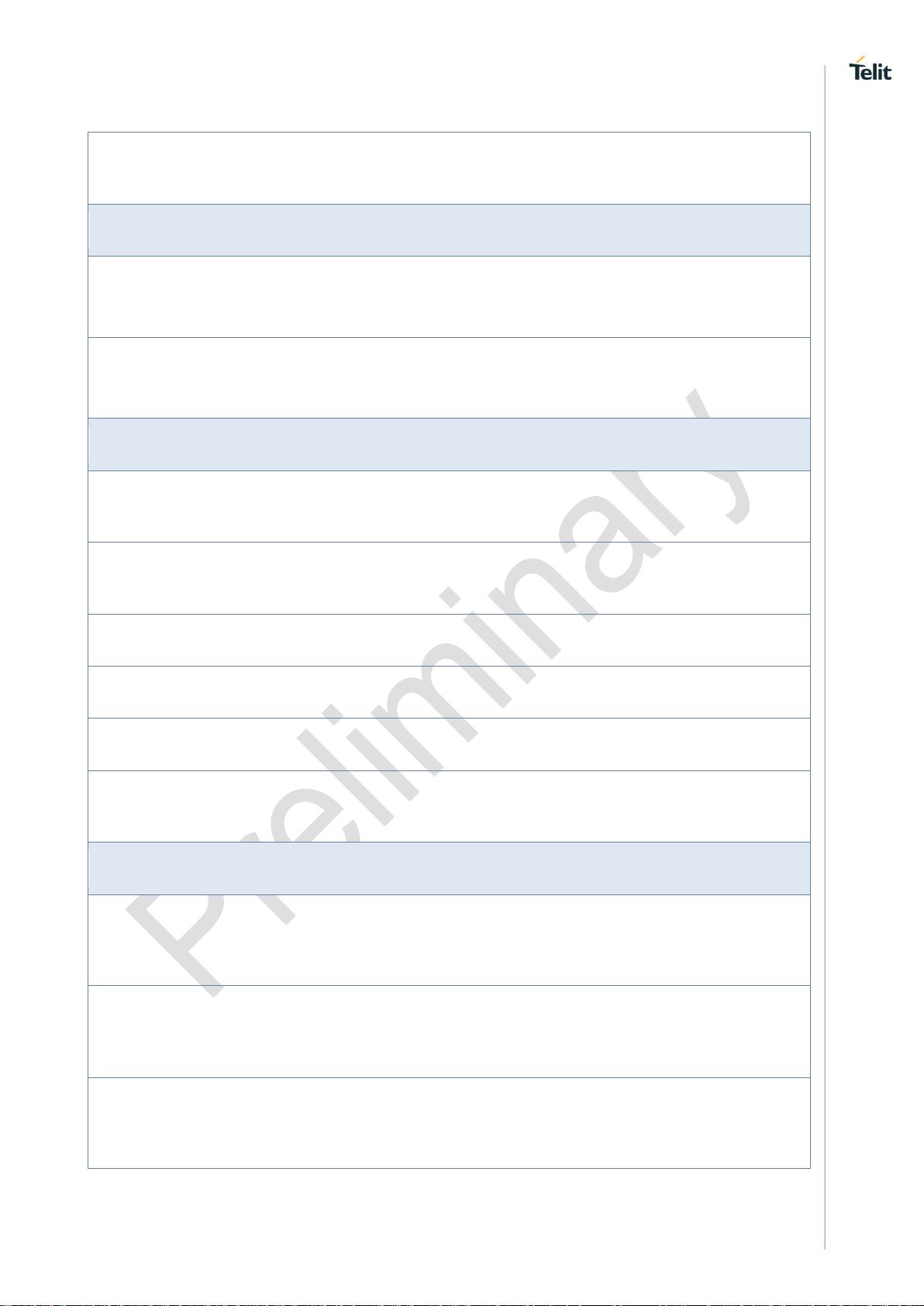

Page 16

HW User Guide Template

1VV0301493 Rev. 2 Page 16 of 86 2018-05-11

15

ADC_IN1

I

Analog/Digital

converter input

Auxiliary

52

RXD_AUX /SPI_MISO

I Auxiliary UART (RX

Data)/SPI_MISO

CMOS 1.8V

53

TXD_AUX / SPI_MOSI

O Auxiliary UART (TX

Data)/SPI_MOSI

CMOS 1.8V

Miscellaneous

7

WAKE

I

ASYNCRONOUS

WAKEUP FROM PSM

1.8V

55

HW_SHUTDOWN*

I

UNCONDITIONAL

SHUTDOWN

1.8V

51

V_AUX/PWRMON

O 1.8V

56

FORCED_USB_BOOT

I 1.8V

40

ANTENNA

I/O

Antenna pad – 50 Ω

RF

37

GNSS_ANT

I/O

GNSS receiver input 50 Ω

RF

GPIO

48

GPIO_01 / DVI_WA0

I/O

GPIO01 Configurable

GPIO / Digital Audio

Interface (WA0)

CMOS 1.8V

47

GPIO_02 /DVI_RX

I/O

GPIO02 I/O pin

Digital Audio Interface

(RX)

CMOS 1.8V

46

GPIO_03 / DVI_TX

I/O

GPIO03 GPIO I/O pin/

Digital Audio Interface

(TX)

CMOS 1.8V

Page 17

HW User Guide Template

1VV0301493 Rev. 2 Page 17 of 86 2018-05-11

45

GPIO_04 / DVI_CLK

I/O

GPIO04 Configurable

GPIO/ Digital Audio

Interface (CLK)

CMOS 1.8V

33

GPIO_05/

GNSS_LNA_EN

I/O

GPIO05 Configurable

GPIO

CMOS 1.8V

32

GPIO_06 / SPI_CS

I/O

GPIO06 Configurable

GPIO /SPI_CS

CMOS 1.8V

31

GPIO_07

I/O

GPIO07 Configurable

GPIO

CMOS 1.8V

30

GPIO_08

I/O

GPIO08 Configurable

GPIO

CMOS 1.8V

29

SPI_CLK

O

SPI_CLK

CMOS 1.8V

X

STAT_LED

O

STAT_LED

CMOS

1.8V

All 8 GPIO

pins can be

configured

Power Supply

44

VBATT

-

Main power supply

(Baseband)

Power

43

VBATT_PA

-

Main power supply

(Radio PA)

Power

42

GND

-

Ground Power

41

GND

-

Ground Power

39

GND

-

Ground Power

38

GND

-

Ground Power

35

GND

-

Ground Power

27

GND

-

Ground Power

23

GND

-

Ground Power

Page 18

HW User Guide Template

1VV0301493 Rev. 2 Page 18 of 86 2018-05-11

21

GND

-

Ground Power

54

GND

-

Ground Power

Reserved

8

RFU

15

RFU

16

RFU

17

RFU

22

RFU

24

RFU

25

RFU

26

RFU

28

RFU

34

RFU

36

RFU

Page 19

HW User Guide Template

1VV0301493 Rev. 2 Page 19 of 86 2018-05-11

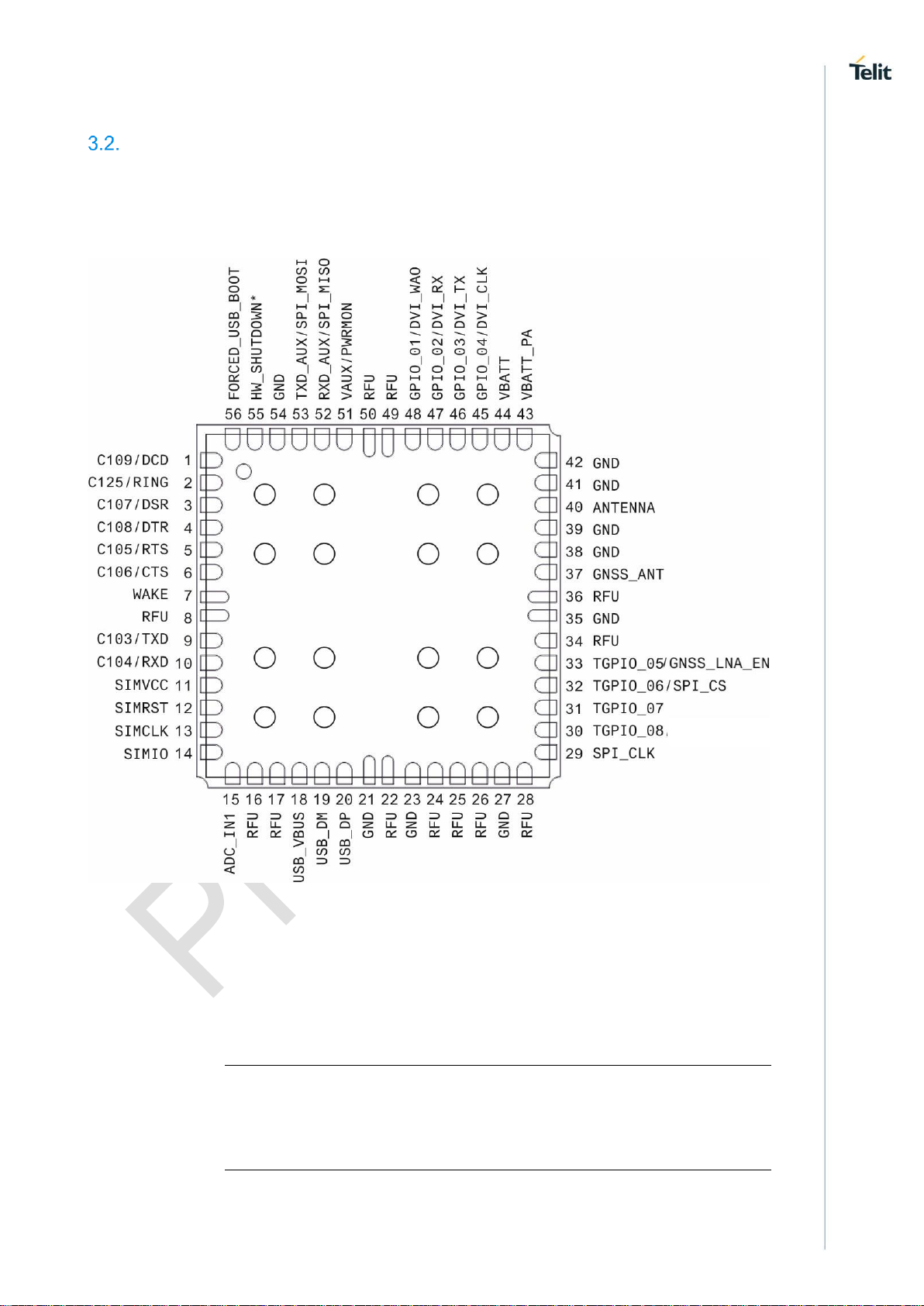

Pin Layout

TOP VIEW

NOTE:

The pins defined as NC/RFU shall be considered RESERVED and must not be

connected to any pin in the application.

Page 20

HW User Guide Template

1VV0301493 Rev. 2 Page 20 of 86 2018-05-11

4. POWER SUPPLY

The power supply circuitry and board layout are a very important part in

the full product design and they strongly reflect on the product overall

performance, hence read the requirements carefully and the guidelines

that will follow for a proper design.

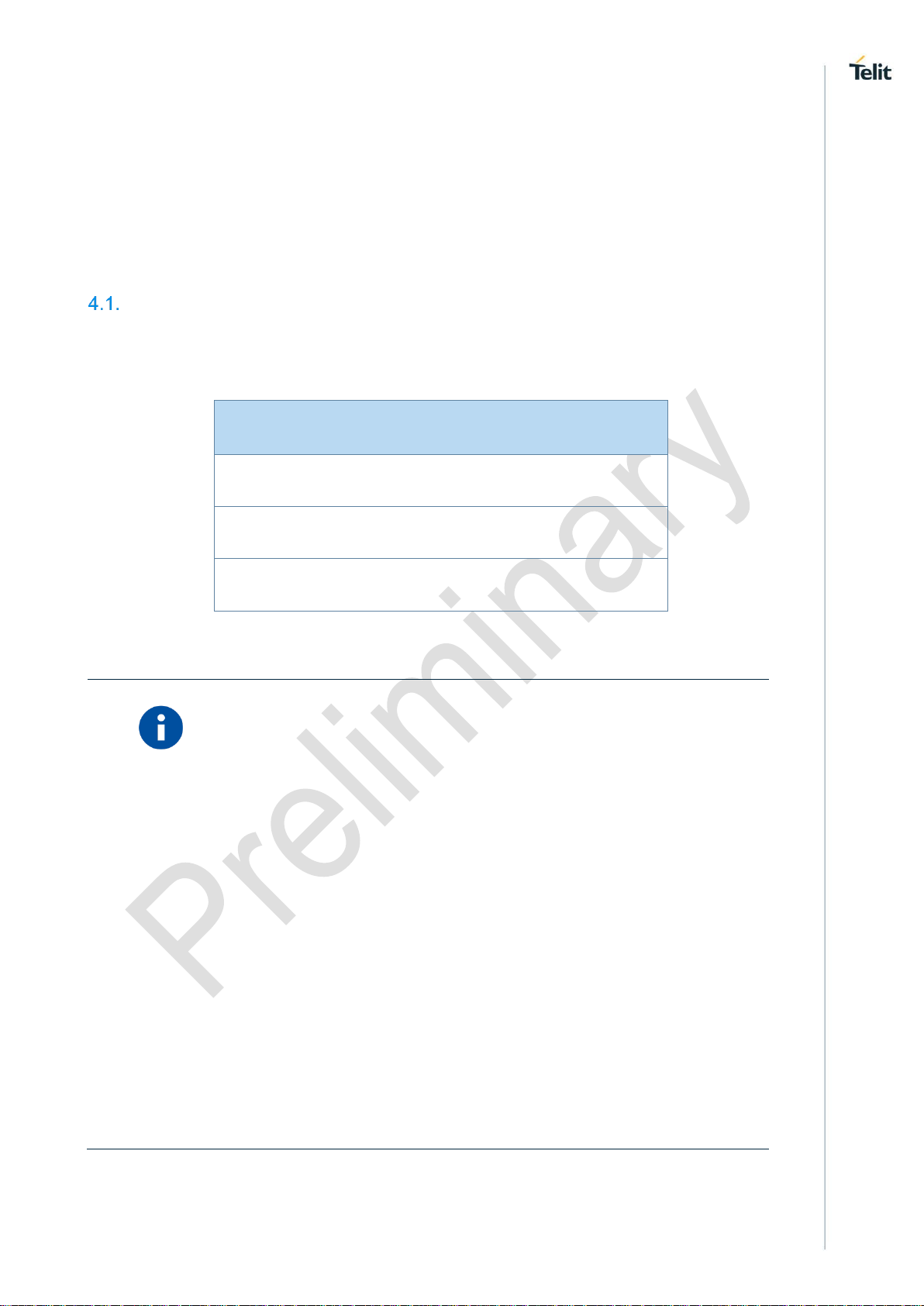

Power Supply Requirements

The external power supply must be connected to VBATT & VBATT_PA

signals and must fulfill the following requirements:

Power Supply

Value

Nominal Supply Voltage

3.8V

Operating Voltage Range

3.40 V÷ 4.20 V

Extended Voltange Range

3.20 V÷ 4.50 V

NOTE:

The Operating Voltage Range MUST never be exceeded; care must

be taken when designing the application’s power supply section to

avoid having an excessive voltage drop. If the voltage drop is

exceeding the limits it could cause a Power Off of the module.

The Power supply must be higher than 3.20 V to power on the

module.

Overshoot voltage (regarding MAX Extended Operating Voltage) and

drop in voltage (regarding MIN Extended Operating Voltage) MUST

never be exceeded;

The “Extended Operating Voltage Range” can be used only with

completely assumption and application of the HW User guide

suggestions.

Page 21

HW User Guide Template

1VV0301493 Rev. 2 Page 21 of 86 2018-05-11

NOTE:

For PTCRB approval on the final products the power supply is

required to be within the “Normal Operating Voltage Range”.

Power Consumption

*Preliminary data

Mode

Average

(mA)

Mode Description

Switched off

0.008mA

Module supplied but switched off

IDLE mode

AT+CFUN=1

12 mA

Normal mode: full functionality of the module

AT+CFUN=4

11 mA

Disabled TX and RX; module is not registered on the

network

AT+CFUN=5

2.3 mA

Paging cycle #64 frames (0.64 sec DRx cycle)

1.4 mA

Paging cycle #128 frames (1.28 sec DRx cycle)

1.1 mA

Paging cycle #256 frames (2.56 sec DRx cycle)

Operative Mode

LTE Data call

190 mA

CAT M1 RB=1, TX=23dBm

115 mA

CAT M1 Channel BW 10MHz, RB=1, TX=0dBm

GPRS

1TX+1RX

GSM 850/900

240 mA

GPRS Sending data mode, TX=33dBm

Page 22

HW User Guide Template

1VV0301493 Rev. 2 Page 22 of 86 2018-05-11

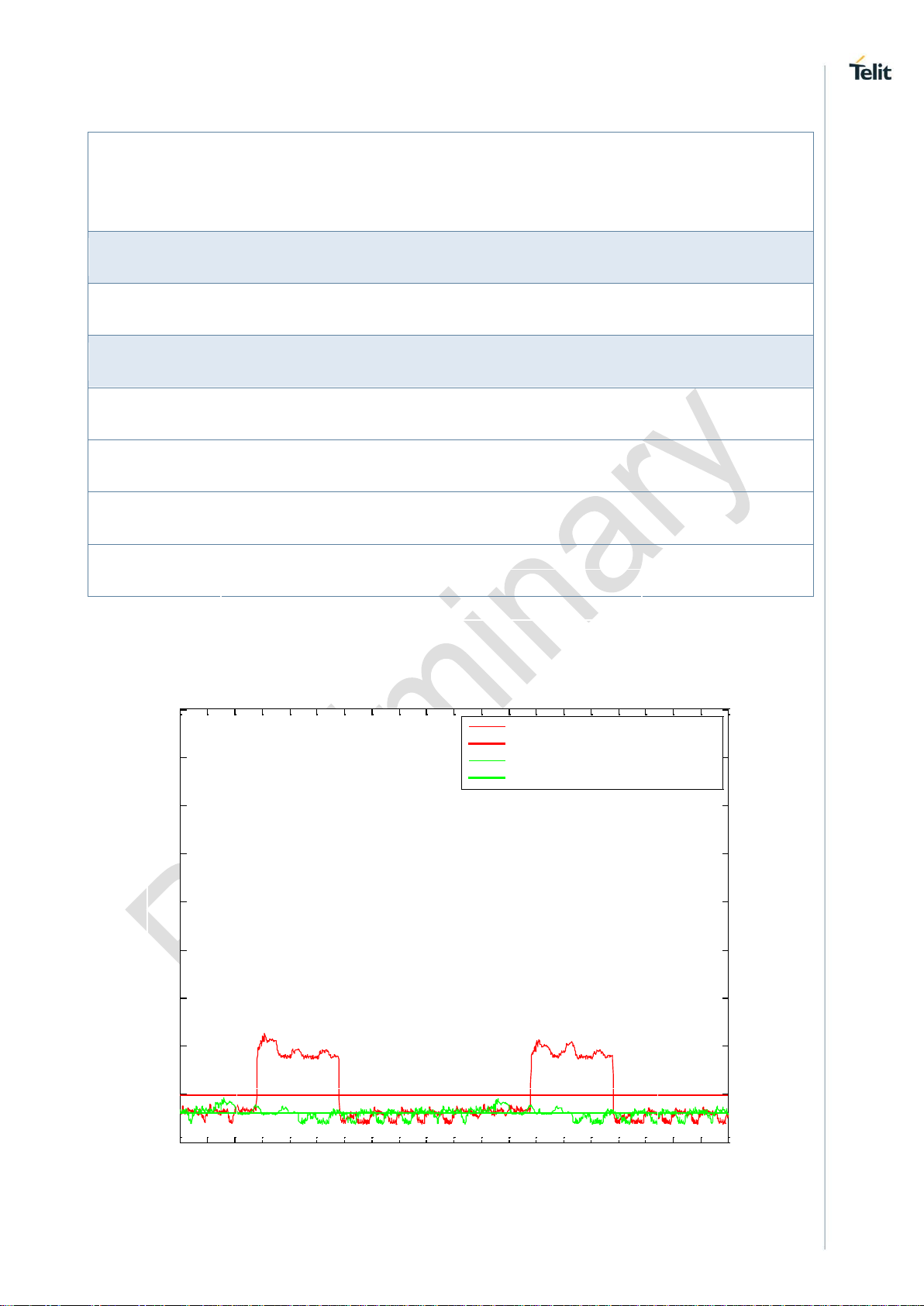

4.2.1. Current consumption plots

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

0

200

400

600

800

1000

1200

1400

1600

1800

Current consumption in LTE data call CAT M1

Current Profile at Max Power (23 dBm)

Average Value at Max Power

Current Profile at Low Power (<0 dBm)

Average Value at Low Power

GPRS

1TX+1RX

GSM 1800/1900

170 mA

GPRS Sending data mode, TX=30dBm

PSM Mode

AT+CPSMS=1

0.008mA

No current source or sink by any connected pin

GNSS ACTIVE

GNSS

29 mA

GNSS Standalone 1Hz Acquisition ( Non-Dpo)

GNSS

30 mA

GNSS Standalone 1Hz Tracking ( Non-DPO)

GPS

28 mA

GPS Standalone 1Hz Acquisition ( Non-Dpo)

GPS

29 mA

GPS Standalone 1Hz Tracking ( Non-DPO)

Current Consumption in LTE data call CAT M1

Time (ms)

Current (mA)

Page 23

HW User Guide Template

1VV0301493 Rev. 2 Page 23 of 86 2018-05-11

NOTE: The electrical design for the Power supply should be made

ensuring it will be capable of a peak current output of at least:

0.6 A for LTE mode (3.80V supply).

2A for GPRS mode (3.80V supply).

NOTE: The reported LTE values are an average among all the

product variants and bands for each network wireless technology.

The support of specific network wireless technology depends on

product variant configuration.

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

0

200

400

600

800

1000

1200

1400

1600

1800

Current consumption in GPRS 1 slot TX

Current Profile at Max Power (33 dBm)

Average Value at Max Power

Current Profile at Low Power (< 0 dBm)

Average Value at Low Power

Time (ms)

Current Consumption in GPRS 1 slot TX

Current (mA)

Page 24

HW User Guide Template

1VV0301493 Rev. 2 Page 24 of 86 2018-05-11

General Design Rules

The principal guidelines for the Power Supply Design embrace three different design

steps:

• the electrical design of the power supply

• the thermal design

• the PCB layout

4.3.1. Electrical Design Guidelines

The electrical design of the power supply depends strongly from the

power source where this power is drained. We will distinguish them into

three categories:

• +5V input (typically PC internal regulator output)

• +12V input (typically automotive)

• Battery

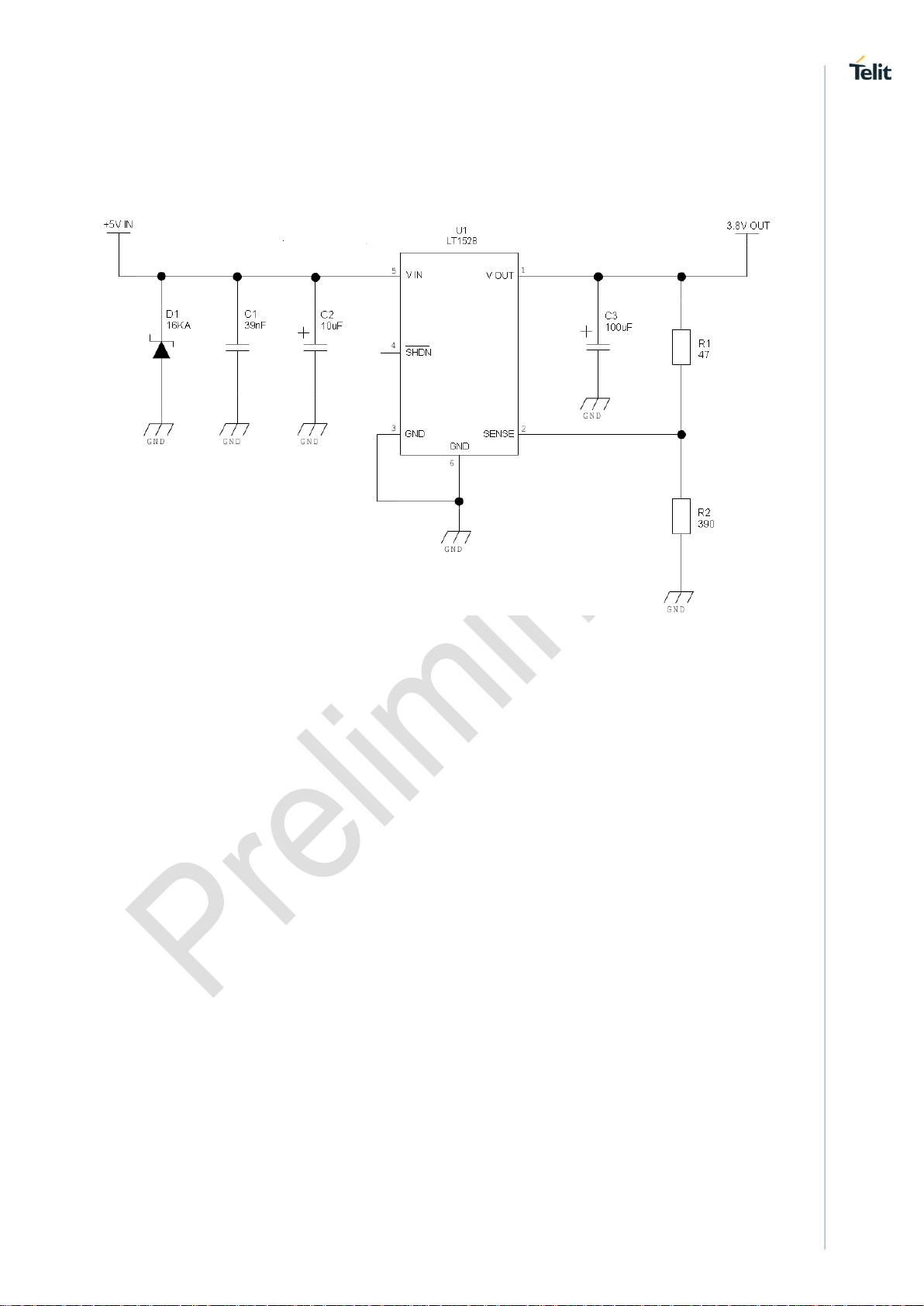

4.3.1.1. +5V Source Power Supply Design Guidelines

• The desired output for the power supply is 3.8V, hence there's not a

big difference between the input source and the desired output and

a linear regulator can be used. A switching power supply will not be

suited because of the low drop out requirements.

• When using a linear regulator, a proper heat sink shall be provided

in order to dissipate the power generated.

• A Bypass low ESR capacitor of adequate capacity must be provided

in order to cut the current absorption peaks close to the ML865C1, a

100μF tantalum capacitor is usually suited.

• Make sure the low ESR capacitor on the power supply output (usually

a tantalum one) is rated at least 10V.

• A protection diode should be inserted close to the power input, in

order to save the ML865C1 from power polarity inversion.

Page 25

HW User Guide Template

1VV0301493 Rev. 2 Page 25 of 86 2018-05-11

An example of linear regulator with 5V input is:

Guidelines

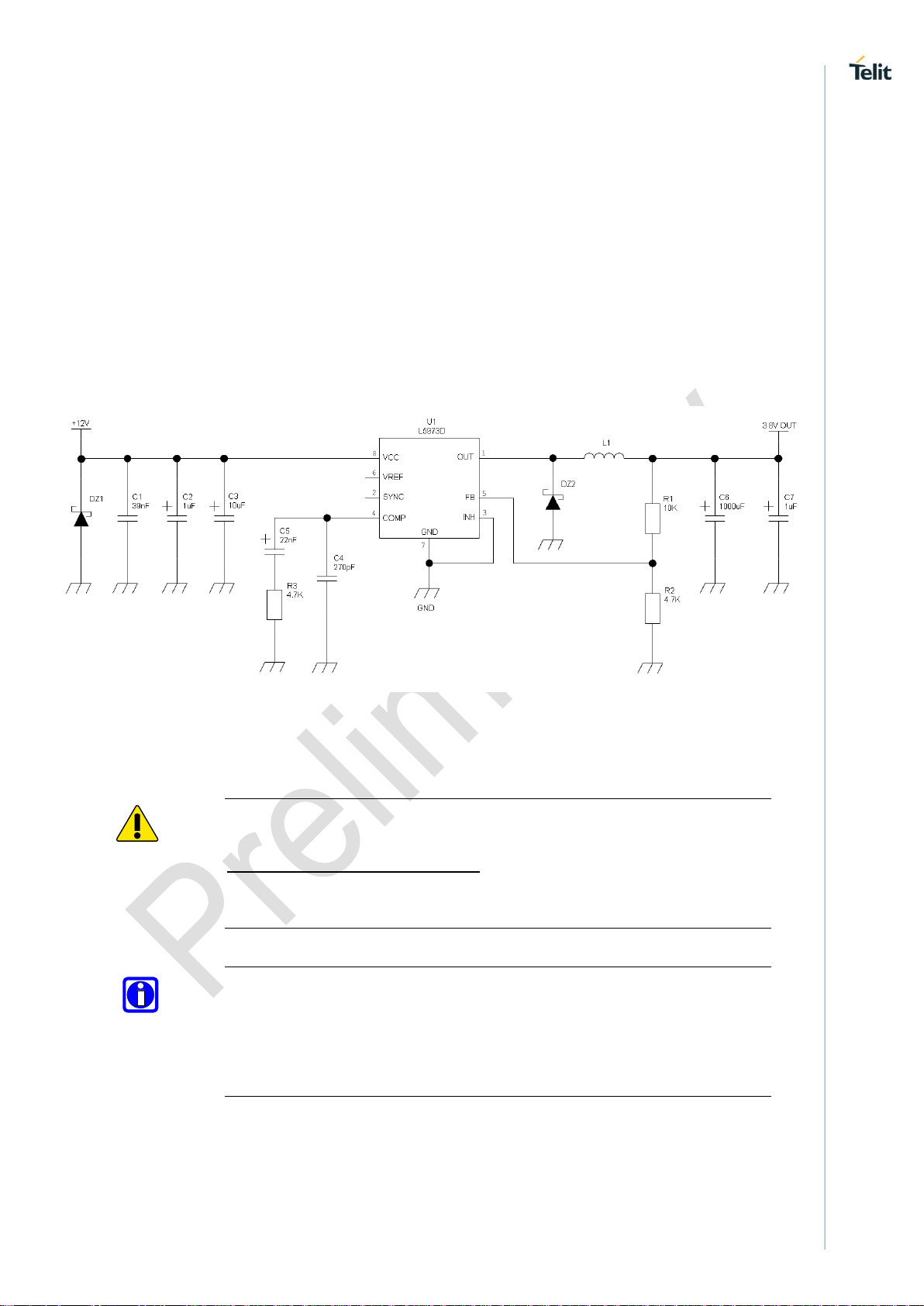

4.3.1.2. +12V Source Power Supply Design Guidelines

• The desired output for the power supply is 3.8V, hence due to the big

difference between the input source and the desired output, a linear

regulator is not suited and shall not be used. A switching power

supply will be preferable because of its better efficiency especially

with the 2A peak current load represented by the ML865C1.

• When using a switching regulator, a 500kHz or more switching

frequency regulator is preferable because of its smaller inductor size

and its faster transient response. This allows the regulator to respond

quickly to the current peaks absorption.

• In any case the frequency and Switching design selection is related

to the application to be developed due to the fact the switching

frequency could also generate EMC interferences.

• For car PB battery the input voltage can rise up to 15,8V and this

should be kept in mind when choosing components: all components

in the power supply must withstand this voltage.

• A Bypass low ESR capacitor of adequate capacity must be provided

in order to cut the current absorption peaks, a 100μF tantalum

capacitor is usually suited.

• Make sure the low ESR capacitor on the power supply output (usually

a tantalum one) is rated at least 10V.

• For Car applications a spike protection diode should be inserted

close to the power input, in order to clean the supply from spikes.

Page 26

HW User Guide Template

1VV0301493 Rev. 2 Page 26 of 86 2018-05-11

• A protection diode should be inserted close to the power input, in

order to save the ML865C1 from power polarity inversion. This can

be the same diode as for spike protection.

An example of switching regulator with 12V input is in the below

schematic:

4.3.1.3. Battery Source Power Supply Design Guidelines

A single 3.7V Li-Ion cell battery type is suited for supply of Telit ML865C1

module.

WARNING:

The three cells Ni/Cd or Ni/MH 3,6 V Nom. battery types or 4V PB types

MUST NOT BE USED DIRECTLY since their maximum voltage can rise

over the absolute maximum voltage for the ML865C1 and damage it.

NOTE:

DON'T USE any Ni-Cd, Ni-MH, and Pb battery types directly connected with

ML865C1. Their use can lead to overvoltage on the ML865C1 and damage it.

USE ONLY Li-Ion battery types.

• A Bypass low ESR capacitor of adequate capacity must be provided in

order to cut the current absorption peaks, a 100μF tantalum capacitor is

usually suited.

Page 27

HW User Guide Template

1VV0301493 Rev. 2 Page 27 of 86 2018-05-11

• Make sure the low ESR capacitor (usually a tantalum one) is rated at

least 10V.

• A protection diode should be inserted close to the power input, in order

to save the ML865C1 from power polarity inversion. Otherwise the

battery connector should be done in a way to avoid polarity inversions

when connecting the battery.

• The battery capacity must be at least 500mAh in order to withstand the

current peaks of 2A; the suggested capacity is from 500mAh to

1000mAh.

Page 28

HW User Guide Template

1VV0301493 Rev. 2 Page 28 of 86 2018-05-11

4.3.2. Thermal Design Guidelines

The thermal design for the power supply heat sink should be done with the

following specifications:

• Average current consumption: 250 mA (LTE modes)

• Average current consumption: 600 mA (GPRS and EDGE modes)

• Supply voltage: 4.50V

NOTE:

Make PCB design in order to have the best connection of GND pads

to large surfaces of copper.

NOTE:

The ML865C1 includes a function to prevent overheating.

Page 29

HW User Guide Template

1VV0301493 Rev. 2 Page 29 of 86 2018-05-11

4.3.3. Power Supply PCB layout Guidelines

As seen on the electrical design guidelines the power supply shall have a

low ESR capacitor on the output to cut the current peaks and a protection

diode on the input to protect the supply from spikes and polarity inversion.

The placement of these components is crucial for the correct working of the

circuitry. A misplaced component can be useless or can even decrease the

power supply performances.

• The Bypass low ESR capacitor must be placed close to the Telit

ML865C1 power input pads or in the case the power supply is a

switching type it can be placed close to the inductor to cut the

ripple provided the PCB trace from the capacitor to the ML865C1

is wide enough to ensure a dropless connection even during the

2A current peaks.

• The protection diode must be placed close to the input connector

where the power source is drained.

• The PCB traces from the input connector to the power regulator

IC must be wide enough to ensure no voltage drops occur when

the 2A current peaks are absorbed. Note that this is not made in

order to save power loss but especially to avoid the voltage drops

on the power line at the current peaks frequency of 216 Hz that

will reflect on all the components connected to that supply,

introducing the noise floor at the burst base frequency. For this

reason while a voltage drop of 300-400 mV may be acceptable

from the power loss point of view, the same voltage drop may not

be acceptable from the noise point of view. If your application

doesn't have audio interface but only uses the data feature of the

Telit ML865C1, then this noise is not so disturbing and power

supply layout design can be more forgiving.

• The PCB traces to the ML865C1 and the Bypass capacitor must

be wide enough to ensure no significant voltage drops occur

when the 2A current peaks are absorbed. This is for the same

reason as previous point. Try to keep this trace as short as

possible.

• The PCB traces connecting the Switching output to the inductor

and the switching diode must be kept as short as possible by

placing the inductor and the diode very close to the power

switching IC (only for switching power supply). This is done in

order to reduce the radiated field (noise) at the switching

frequency (100-500 kHz usually).

• The use of a good common ground plane is suggested.

Page 30

HW User Guide Template

1VV0301493 Rev. 2 Page 30 of 86 2018-05-11

• The placement of the power supply on the board should be done

in such a way to guarantee that the high current return paths in

the ground plane are not overlapped to any noise sensitive

circuitry as the microphone amplifier/buffer or earphone

amplifier.

• The power supply input cables should be kept separate from

noise sensitive lines such as microphone/earphone cables.

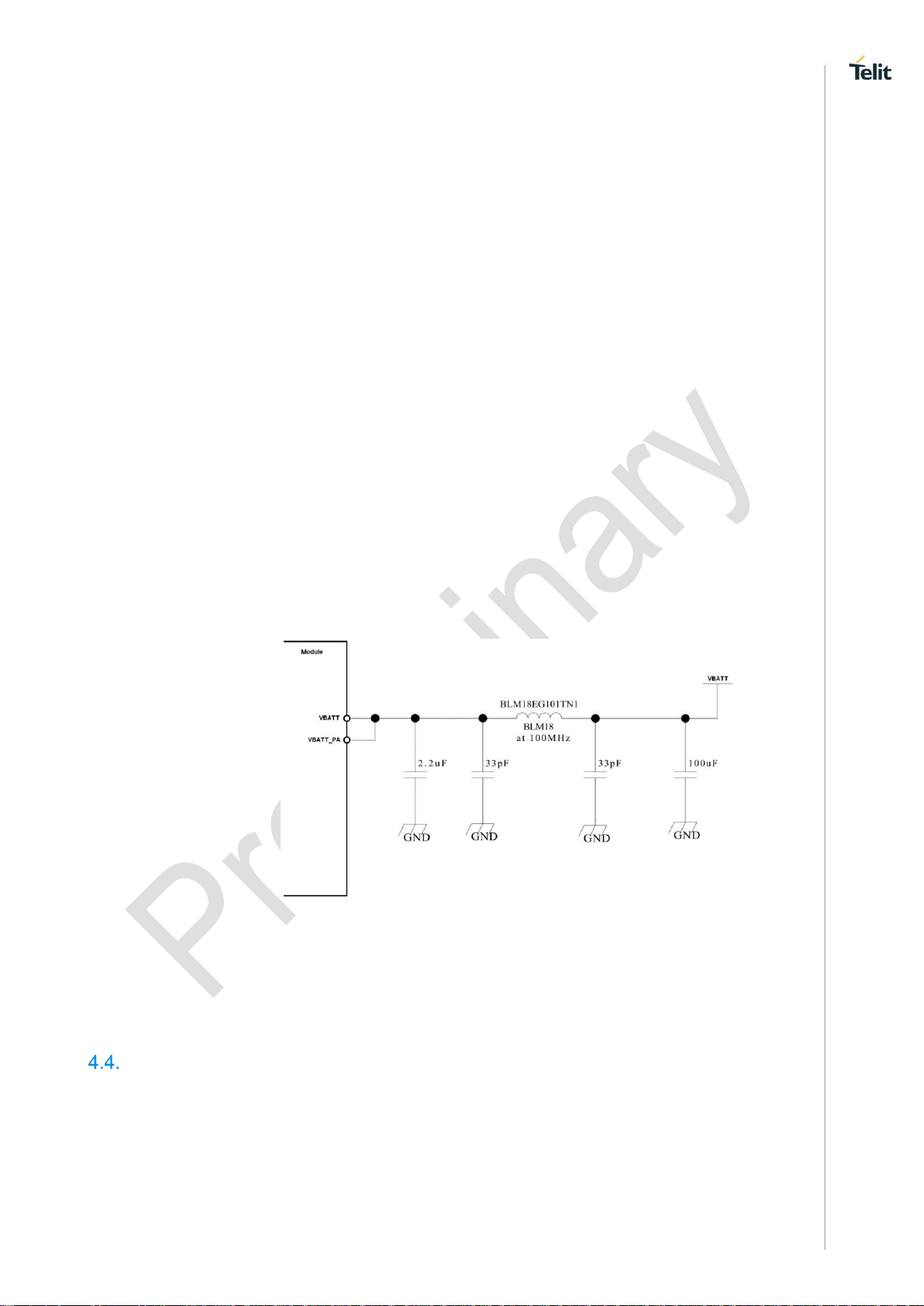

• The insertion of EMI filter on VBATT pins is suggested in those

designs where antenna is placed close to battery or supply

lines.

A ferrite bead like Murata BLM18EG101TN1 or Taiyo Yuden

P/N FBMH1608HM101 can be used for this purpose.

The below figure shows the recommended circuit:

RTC supply

RTC is functional when ML865C1 is in PSM state and VBATT pin is supplied.

RTC settings are erased if VBATT supply is temporary disconnected.

Page 31

HW User Guide Template

1VV0301493 Rev. 2 Page 31 of 86 2018-05-11

VAUX Power Output

A regulated power supply output is provided in order to supply small devices from the

module, like: level translators, audio codec, sensors, and others.

Pin R11 can be used also as PWRMON (module powered ON indication) function,

because is always active when the module is powered ON and cannot be set to LOW

level by any AT command.

Host can only detect deep sleep mode by monitoring of VAUX/PWRMON output pin, since

there is no pin dedicated to PSM status indicator,

The operating range characteristics of the supply are:

Item

Min

Typical

Max

Output voltage

1.78V

1.80V

1.82V

Output current

- - 60mA

Output bypass capacitor

(inside the module)

1uF

If power saving configuration is enabled by AT+CPSMS

Command, VAUX during deep sleep mode period is OFF

Page 32

HW User Guide Template

1VV0301493 Rev. 2 Page 32 of 86 2018-05-11

5. DIGITAL SECTION

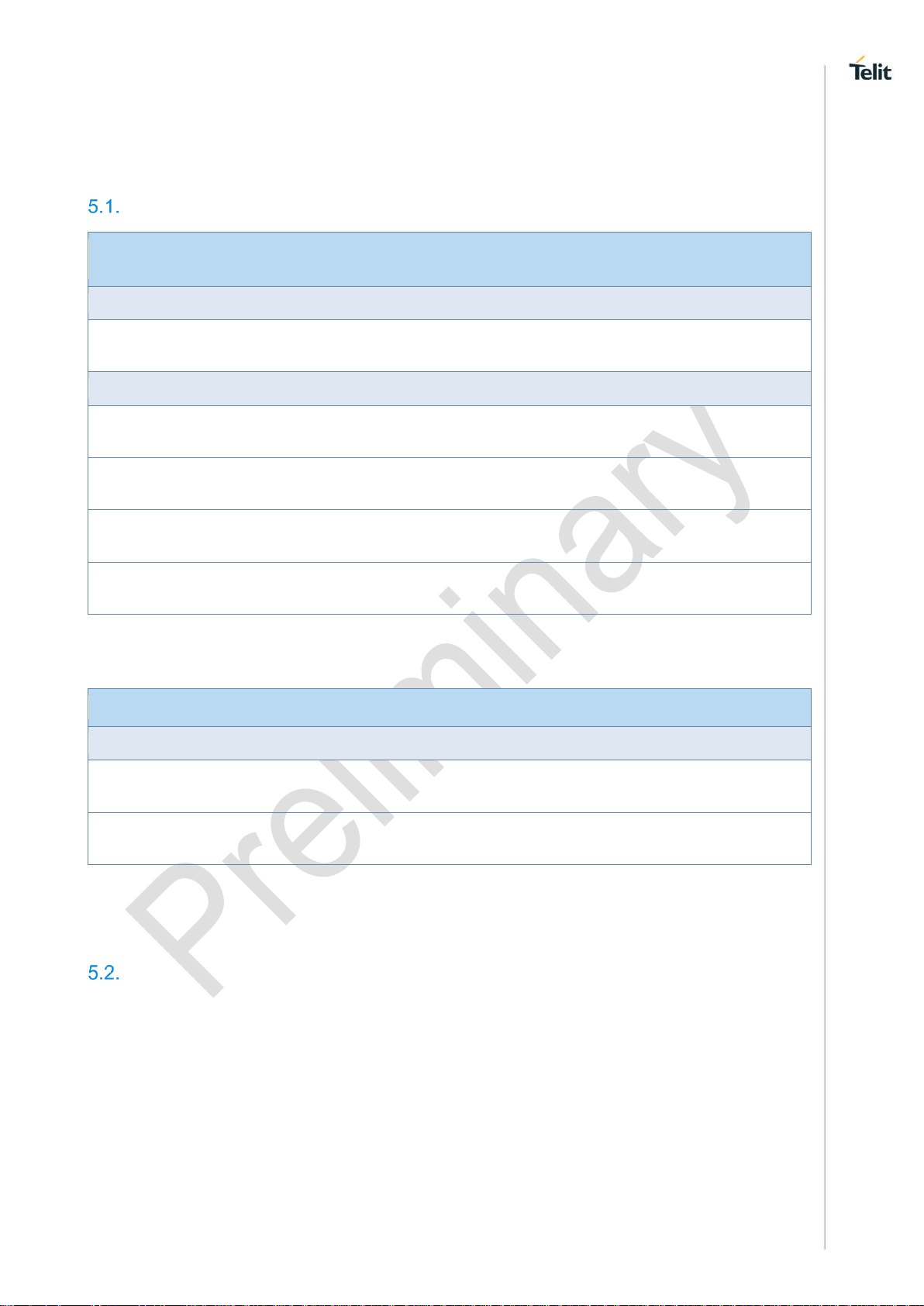

Logic Levels

Power On (Auto-Turning ON ML865)

The ML865C1 will automatically power on itself when VBATT & VBATT_PA are applied to

the module.

V_AUX / PWRMON pin will be at the high logic level and the module can be considered

fully operating after 5 seconds.

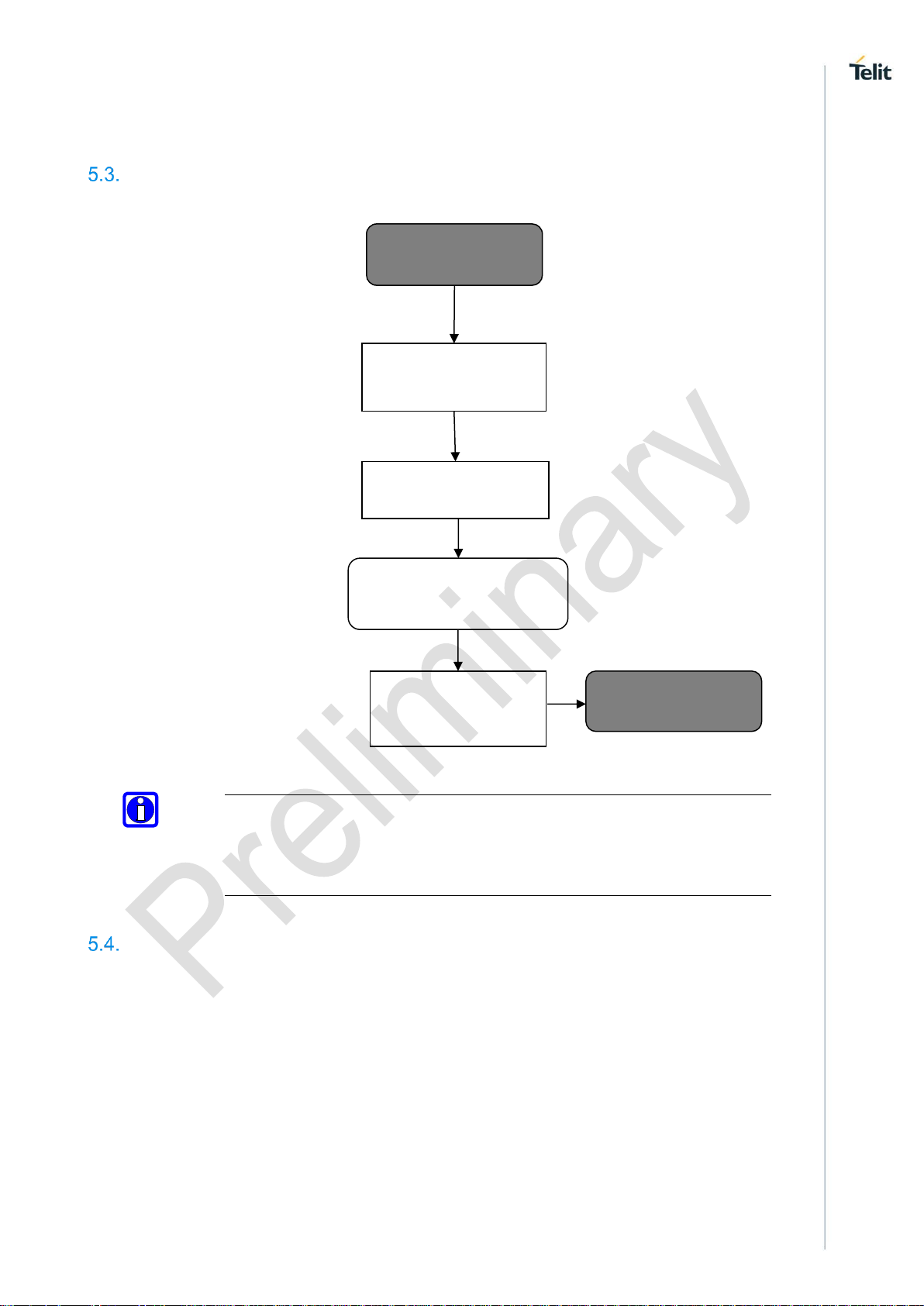

The following flow chart shows the proper turn on procedure:

Parameter

Min

Max

ABSOLUTE MAXIMUM RATINGS – NOT FUNCTIONAL

Input level on any digital pin (CMOS 1.8) with respect to ground

-0.3V

2.1V

Operating Range - Interface levels (1.8V CMOS)

Input high level

1.5V

1.9V

Input low level

0V

0.35V

Output high level

1.6V

1.9V

Output low level

0V

0.2V

Parameter

AVG

CURRENT CHARACTERISTICS:

Output Current

1mA

Input Current

1uA

Page 33

HW User Guide Template

1VV0301493 Rev. 2 Page 33 of 86 2018-05-11

NOTE:

The power supply must be applied either at the same time on pins

VBATT and VBATT_PA.

NOTE:

In order to prevent a back powering effect it is recommended to avoid

having any HIGH logic level signal applied to the digital pins of the

ML865C1 when the module is powered OFF or during an ON/OFF

transition.

Modem ON Proc.

PWR supply ON

and >3.20V?

Y

Delay 1s - 5s for Low

Voltage Operating

Y

Modem Reset Proc.

AT init sequence.

N

Start AT CMD.

N

PWMON = ON?

Y

Delay 300mS

Enter AT<CR>

AT answer in 1second

?

N

Y

N

Page 34

HW User Guide Template

1VV0301493 Rev. 2 Page 34 of 86 2018-05-11

A flow chart showing the AT commands managing procedure is displayed below:

Modem ON Proc.

Disconnect PWR

supply

AT init sequence.

Delay 300mS

Enter AT<CR>

AT answer in

Start AT CMD.

Page 35

HW User Guide Template

1VV0301493 Rev. 2 Page 35 of 86 2018-05-11

Power Off

The following flow chart shows the proper turnoff procedure:

NOTE:

In order to prevent a back powering effect it is recommended to avoid having

any HIGH logic level signal applied to the digital pins of the ML865C1 when

the module is powered off or during an ON/OFF transition.

Wake from deep sleep mode

ML865C1 supports Power Saving Mode (PSM) functionality defined in 3GPP Release 12.

When Periodic Update Timer expires, ML910C1 power off until the next scheduled wakeup time.

Asynchronous event controlled by host can wake up from deep sleep mode by asserting

WAKE pin HIGH for at least 5 seconds.

Host can detect deep sleep mode by polling VAUX/PWRMON pin.

Modem OFF Proc.

AT#SYSHALT

Disconnect PWR

supply

10s timeout

Modem ON Proc

.

Delay 1.5s

Page 36

HW User Guide Template

1VV0301493 Rev. 2 Page 36 of 86 2018-05-11

Unconditional Shutdown ( Hardware Unconditional restart)

HW_SHUTDOWN* is used to unconditionally shutdown the ML865C1. Whenever this

signal is pulled low, the ML865C1 is reset. When the device is reset it stops any

operation. After the release of the line, the ML865C1 is unconditionally shut down, without

doing any detach operation from the network where it is registered. This behaviour is not a

proper shut down because any cellular device is requested to issue a detach request on

turn off. The HW_SHUTDOWN* is internally controlled on start-up to achieve always a

proper power-on reset sequence, so there's no need to control this pin on start-up.

To unconditionally shutdown the ML865C1, the pad HW_SHUTDOWN* must be tied low

for at least 200 milliseconds and then released. The maximum current that can be drained

from the ON* pad is 0,15 mA.

The signal is internally pulled up so the pin can be left floating if not used.

During PSM mode, HW_SHUTDOWN toggle has no effect. The use of HW_SHUTDOWN*

pin is valid only when ML865C1 has VAUX/PWRMON output HI.

WARNING:

The hardware unconditional Restart must not be used during normal

operation of the device since it does not detach the device from the

network. It shall be kept as an emergency exit procedure to be done in

the rare case that the device gets stuck waiting for some network or

SIM responses.

NOTE:

Do not use any pull up resistor on the HW_SHUTDOWN* line nor any

totem pole digital output.

The line HW_SHUTDOWN* must be connected only in open collector

configuration; the transistor must be connected as close as possible to

the HW_SHUTDOWN* pin.

TIP:

The unconditional hardware restart must always be implemented on the

boards and the software must use it as an emergency exit procedure.

Page 37

HW User Guide Template

1VV0301493 Rev. 2 Page 37 of 86 2018-05-11

A simple circuit to do it is:

Page 38

HW User Guide Template

1VV0301493 Rev. 2 Page 38 of 86 2018-05-11

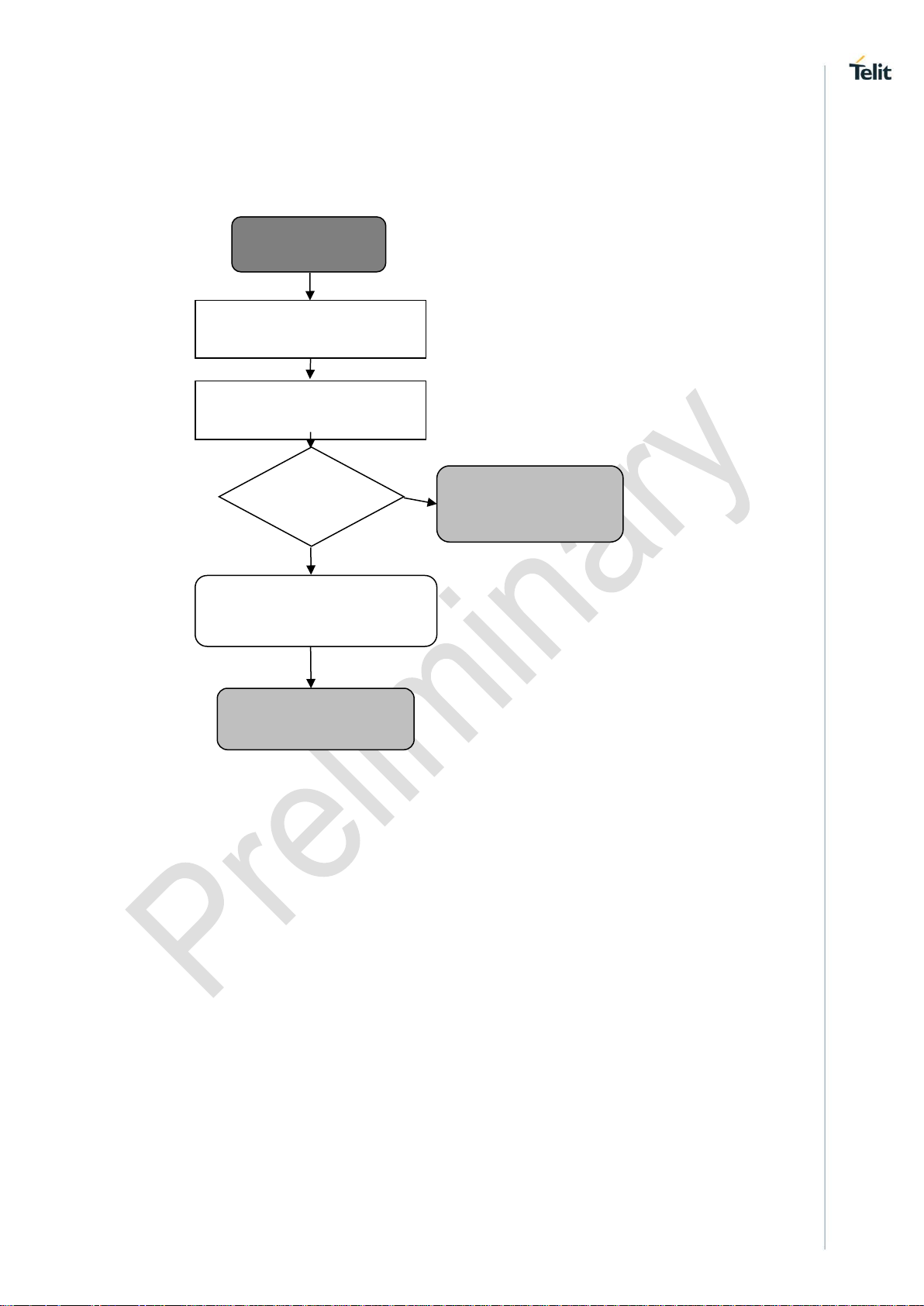

In the following flow chart is detailed the proper restart procedure:

NOTE:

In order to prevent a back powering effect it is recommended to avoid having

any HIGH logic level signal applied to the digital pins of the ML865C1 when

the module is powered OFF or during an ON/OFF transition.

“HW SHUTDOWN

Unconditional”

START.

Reset = LOW

Delay 200ms

Reset = HIGH

Delay 1s

“HW SHUTDOWN

Unconditional”

END

Page 39

HW User Guide Template

1VV0301493 Rev. 2 Page 39 of 86 2018-05-11

Fast power down

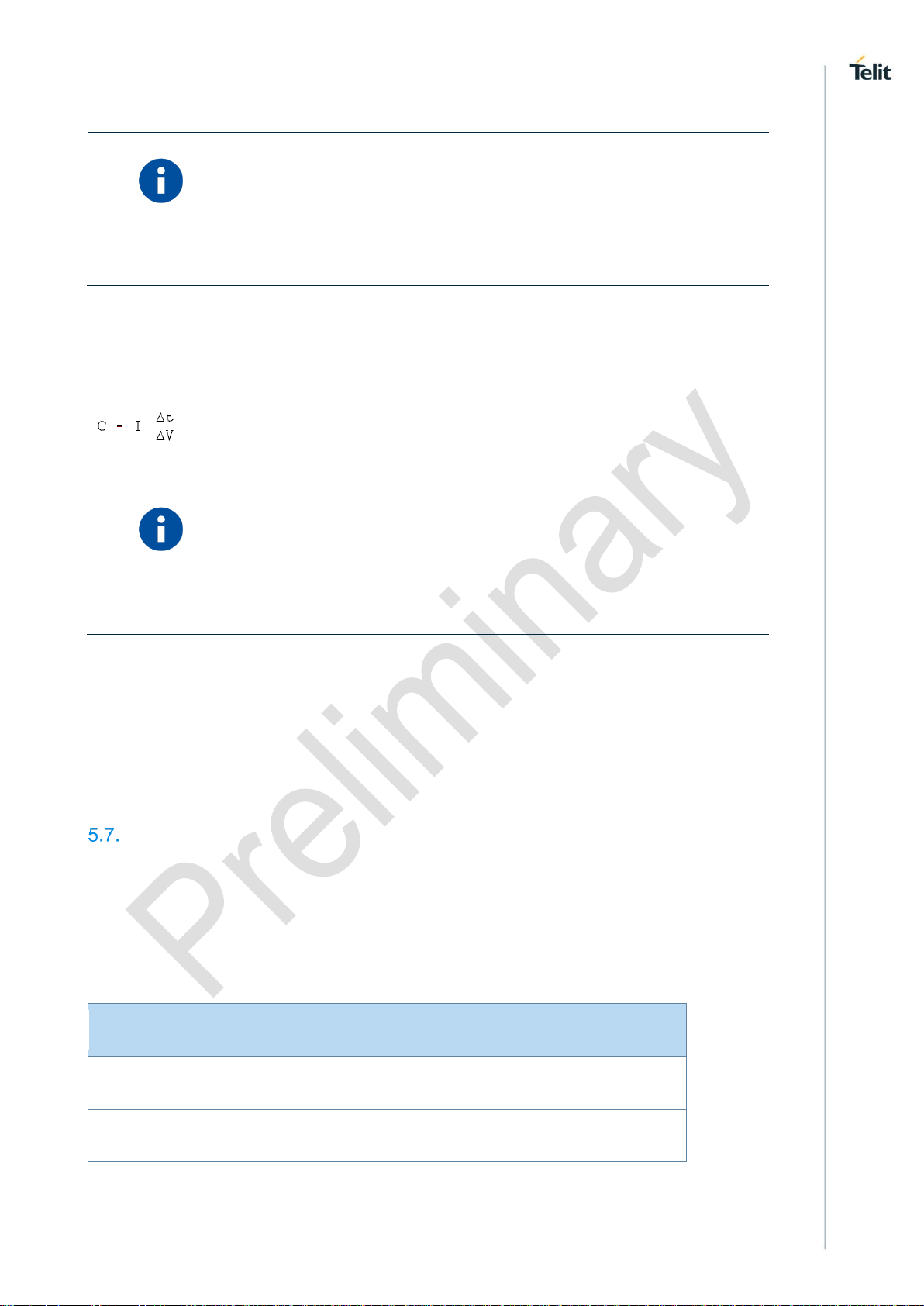

The procedure to power off ML865C1 described in Chapter 5.3 normally takes more than

1 second to detach from network and make ML865C1internal filesystem properly closed.

In case of unwanted supply voltage loss the system can be switched off without any risk of

filesystem data corruption by implementing Fast Shut Down feature.

Fast Shut Down feature permits to reduce the current consumption and the time-topoweroff to minimum values.

NOTE:

Refer to ML865C1 series AT command reference guide (Fast power

down - #FASTSHDN) in order to set up detailed AT command.

5.6.1. Fast Shut Down by Hardware

The Fast Power Down can be triggered by configuration of any GPIO. HI level to LOW

level transition of GPIO commands fast power down.

Example circuit:

Page 40

HW User Guide Template

1VV0301493 Rev. 2 Page 40 of 86 2018-05-11

NOTE:

Consider voltage drop under max current conditions when defining

the voltage detector thereshold in order to avoid unwanted shutdown.

The capacitor is rated with the following formula:

TIP:

Make the same plot during system verification to check timings and

voltage levels.

5.6.2. Fast Shut Down by Software

The Fast Power Down can be triggered by AT command.

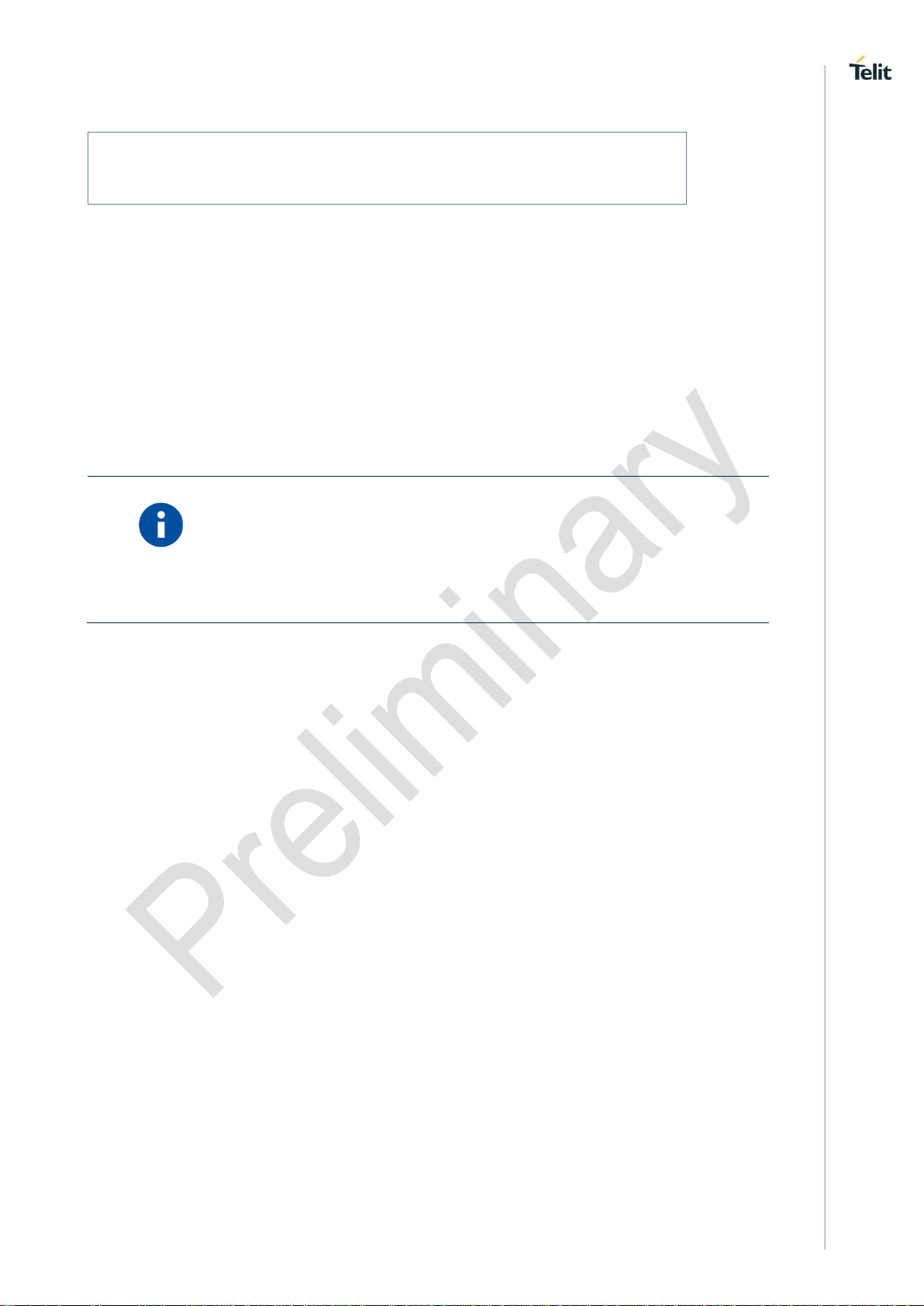

Communication ports

5.7.1. USB 2.0 HS

The ML865C1 includes one integrated universal serial bus (USB 2.0 HS) transceiver.

The following table is listing the available signals:

PAD

Signal

I/O

Function

NOTE

19

USB_D+

I/O

USB differential Data (+)

20

USB_D-

I/O

USB differential Data (-)

Page 41

HW User Guide Template

1VV0301493 Rev. 2 Page 41 of 86 2018-05-11

18

VUSB

AI

Power sense for the internal

USB transceiver.

Accepted range:

3.0V to 5.5V

100K pull down

The USB_DPLUS and USB_DMINUS signals have a clock rate of 480 MHz, therefore

signal traces should be routed carefully. Trace lengths, number of vias and capacitive

loading should be minimized. The characteristic impedance value should be as close as

possible to 90 Ohms differential.

ESD protection can be added to USB D+/D- lines in case of external connector for cable

connection.

Proper components for USB 2.0 must be used.

NOTE:

Disconnect or assert to GND the VUSB pin before activating the

Power Saving Mode.

Page 42

HW User Guide Template

1VV0301493 Rev. 2 Page 42 of 86 2018-05-11

5.7.2. SPI

The ML865C1 Module is provided by a standard 3-wire master SPI interface + chip select

control.

The following table is listing the available signals:

PAD

Signal

I/O

Function

Type

NOTE

29

SPI_CLK

O

SPI Clock

CMOS

1.8V

52

SPI_MISO

I

SPI MISO

CMOS

1.8V

Shared

with

RX_AUX

53

SPI_MOSI

O

SPI MOSI

CMOS

1.8V

Shared

with

TX_AUX

32

SPI_CS

O

SPI Chip Select

CMOS

1.8V

NOTE:

Due to the shared functions, SPI port and TX_AUX/RX_AUX port

cannot be used simultanously.

Refer to ML865C1 series AT command reference guide for port

configuration.

Page 43

HW User Guide Template

1VV0301493 Rev. 2 Page 43 of 86 2018-05-11

SPI Connections

5.7.3. Serial Ports

The ML865C1 module is provided with by 2 Asynchronous serial ports:

• MODEM SERIAL PORT 1 (Main)

• MODEM SERIAL PORT 2 (Auxiliary)

Several configurations can be designed for the serial port on the OEM hardware, but the

most common are:

• RS232 PC com port

• microcontroller UART @ 1.8V (Universal Asynchronous Receive Transmit)

• microcontroller UART @ 5V or other voltages different from 1.8V

Depending from the type of serial port on the OEM hardware a level translator circuit may

be needed to make the system work. On the ML865C1 the ports are CMOS 1.8.

5.7.3.1. Modem serial port 1

The serial port 1 on the ML865C1 is a +1.8V UART with all the 7 RS232 signals. It differs

from the PC-RS232 in the signal polarity (RS232 is reversed) and levels.

The following table is listing the available signals:

SPI_MISO

SPI_MOSI

SPI_CLK

52

53

29

ML865C1

Application

Processor

SPI_CS

32

Page 44

HW User Guide Template

1VV0301493 Rev. 2 Page 44 of 86 2018-05-11

RS232

Pin

Signal

ML865C1

PAD

Name

Usage

1

C109/DCD

1

Data Carrier

Detect

Output from the ML865C1

that indicates the carrier

presence

2

C104/RXD

10

Transmit line

*see Note

Output transmit line of

ML865C1 UART

3

C103/TXD

9

Receive line

*see Note

Input receive of the ML865C1

UART

4

C108/DTR

4

Data Terminal

Ready

Input to the ML865C1 that

controls the DTE READY

condition

6

C107/DSR

3

Data Set Ready

Output from the ML865C1

that indicates the module is

ready

7

C106/CTS

5

Clear to Send

Output from the ML865C1

that controls the Hardware

flow control

8

C105/RTS

6

Request to

Send

Input to the ML865C1 that

controls the Hardware flow

control

9

C125/RING

2

Ring Indicator

Output from the ML865C1

that indicates the incoming

call condition

Page 45

HW User Guide Template

1VV0301493 Rev. 2 Page 45 of 86 2018-05-11

NOTE:

According to V.24, some signal names are referred to the application

side, therefore on the ML865C1 side these signal are on the opposite

direction:

TXD on the application side will be connected to the receive line

(here named C103/TXD)

RXD on the application side will be connected to the transmit line

(here named C104/RXD)

For a minimum implementation, only the TXD, RXD lines can be

connected, the other lines can be left open provided a software flow

control is implemented.

In order to avoid a back powering effect it is recommended to avoid

having any HIGH logic level signal applied to the digital pins of the

ML865C1 when the module is powered off or during an ON/OFF

transition.

5.7.3.2. Modem serial port 2

The secondary serial port on the ML865C1 is a CMOS1.8V with only the RX and TX

signals.

The signals of the ML865C1 serial port are:

PAD

Signal

I/O

Function

Type

NOTE

53

TX_AUX

O

Auxiliary UART (TX Data to

DTE)

CMOS

1.8V

Shared

with

SPI_MOSI

52

RX_AUX

I

Auxiliary UART (RX Data from

DTE)

CMOS

1.8V

Shared

with

SPI_MISO

Page 46

HW User Guide Template

1VV0301493 Rev. 2 Page 46 of 86 2018-05-11

NOTE:

Due to the shared functions, TX_AUX/RX_AUX port and SPI port

cannot be used simultanously.

In order to avoid a back powering effect it is recommended to avoid

having any HIGH logic level signal applied to the digital pins of the

ML865C1 when the module is powered off or during an ON/OFF

transition.

Refer to ML865C1 series AT command reference guide for port

configuration.

5.7.3.3. RS232 level translation

In order to interface the ML865C1 with a PC com port or a RS232 (EIA/TIA-232)

application a level translator is required. This level translator must:

• invert the electrical signal in both directions;

• Change the level from 0/1.8V to +15/-15V.

Actually, the RS232 UART 16450, 16550, 16650 & 16750 chipsets accept signals with

lower levels on the RS232 side (EIA/TIA-562), allowing a lower voltage-multiplying ratio

on the level translator. Note that the negative signal voltage must be less than 0V and

hence some sort of level translation is always required.

The simplest way to translate the levels and invert the signal is by using a single chip level

translator. There are a multitude of them, differing in the number of drivers and receivers

and in the levels (be sure to get a true RS232 level translator not a RS485 or other

standards).

By convention the driver is the level translator from the 0-1.8V UART to the RS232 level.

The receiver is the translator from the RS232 level to 0-1.8V UART.

In order to translate the whole set of control lines of the UART you will need:

• 5 drivers

Page 47

HW User Guide Template

1VV0301493 Rev. 2 Page 47 of 86 2018-05-11

• 3 receivers

An example of RS232 level

adaptation circuitry could be done

using a MAXIM transceiver

(MAX218)

In this case the chipset is capable

to translate directly from 1.8V to

the RS232 levels (Example done

on 4 signals only).

The RS232 serial port lines are usually connected to a DB9 connector with the following

layout:

General purpose I/O

The ML865C1 module is provided by a set of Configurable Digital Input / Output pins

(CMOS 1.8V). Input pads can only be read; they report the digital value (high or low)

present on the pad at the read time. Output pads can only be written or queried and set

the value of the pad output.

An alternate function pad is internally controlled by the ML865C1 firmware and acts

depending on the function implemented.

Page 48

HW User Guide Template

1VV0301493 Rev. 2 Page 48 of 86 2018-05-11

The following table shows the available GPIO on the ML865C1:

PAD

Signal

I/O

Output

Drive

Strength

Default State

NOTE

48

GPIO_01

I/O

1mA

INPUT – PD (100K)

47

GPIO_02

I/O

1mA

INPUT – PD (100K)

46

GPIO_03

I/O

1mA

INPUT – PD (100K)

45

GPIO_04

I/O

1mA

INPUT – PD (100K)

33

GPIO_05

I/O

1mA

INPUT – PD (100K)

32

GPIO_06

I/O

1mA

INPUT – PD (100K)

31

GPIO_07

I/O

1mA

INPUT – PD (100K)

30

GPIO_08

I/O

1mA

INPUT – PD (100K)

5.8.1. Using a GPIO as INPUT

The GPIO pads, when used as inputs, can be connected to a digital output of another

device and report its status, provided this device has interface levels compatible with the

1.8V CMOS levels of the GPIO.

Input current (@1.8V) is about 18uA (corrisponding to 100K pulldown value) in all GPIO

pin expect GPIO_09 where current is about 100uA. This value is present since ML865

poweron.

If the digital output of the device to be connected with the GPIO input pad has interface

levels different from the 1.8V CMOS, then it can be buffered with an open collector

transistor with a 47K pull up to 1.8V supplied by VAUX/POWERMON R11 pad.

Page 49

HW User Guide Template

1VV0301493 Rev. 2 Page 49 of 86 2018-05-11

NOTE:

In order to avoid a back powering effect it is recommended to avoid

having any HIGH logic level signal applied to the digital pins of the

ML865C1 when the module is powered off or during an ON/OFF

transition.

Refer to ML865C1 series AT command reference guide for GPIO

pins configuration.

5.8.2. Using a GPIO as OUTPUT

The GPIO pads, when used as outputs, can drive 1.8V CMOS digital devices or

compatible hardware. When set as outputs, the pads have a push-pull output and

therefore the pull-up resistor may be omitted.

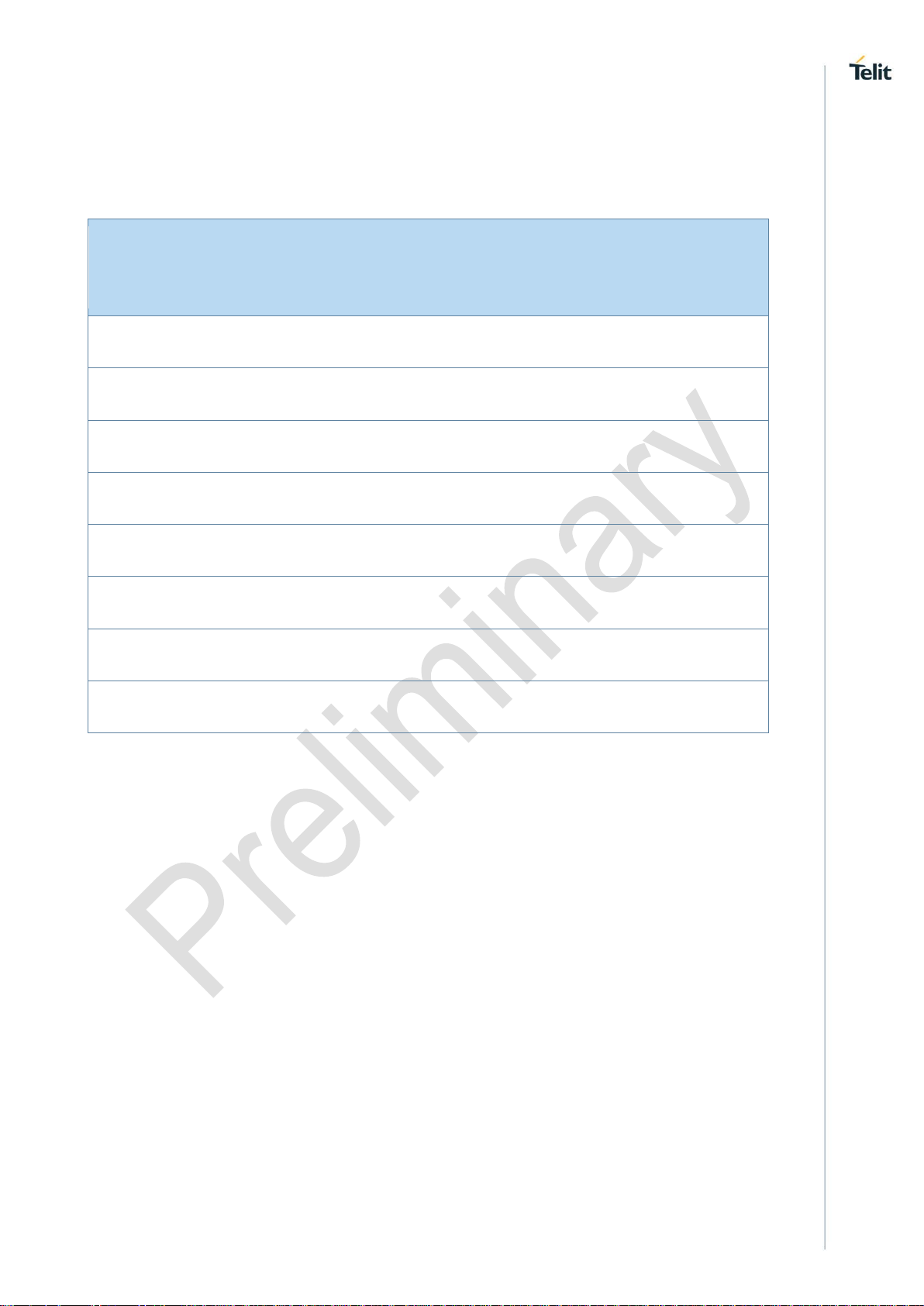

5.8.3. Indication of network service availability The STAT_LED pin status shows information on the network service availability and Call

status.

The function is available as alternate function of GPIO_08 (to be enabled using the

AT#GPIO=1,0,2 command).

In the ML865C1 modules, the STAT_LED needs an external transistor to drive an external

LED and its voltage level is defined accordingly to the table below:.

Device Status

Led Status

Device off

Permanently off

Not Registered

Permanently on

Registered in idle

Blinking 1sec on + 2 sec off

Page 50

HW User Guide Template

1VV0301493 Rev. 2 Page 50 of 86 2018-05-11

Registered in idle + power saving

It depends on the event that triggers the

wakeup (In sync with network paging)

Connecting

Blinking 1 sec on + 2 sec off

The reference schematic for LED indicator,

R3 must be calculated taking in account VBATT value and LED type. :

External SIM Holder

Please refer to the related User Guide (SIM Holder Design Guides, 80000NT10001a).

ADC Converter

The ML865C1 is provided by one AD converters. It is able to read a voltage level in the

range of 0÷1.8 volts applied on the ADC pin input, store and convert it into 10 bit word.

The input lines are named as ADC_IN1 and they are available on Pad 13.

The following table is showing the ADC characteristics:

Page 51

HW User Guide Template

1VV0301493 Rev. 2 Page 51 of 86 2018-05-11

Item

Min

Typical

Max

Unit

Input Voltage range

0 - 1.8

Volt

AD conversion

- - 10

bits

Input Resistance

1 - -

Mohm

Input Capacitance

- 1 -

pF

The ADC could be controlled using an AT command.

The command is AT#ADC=1,2

The read value is expressed in mV

Refer to SW User Guide or AT Commands Reference Guide for the full description of this

function.

Page 52

HW User Guide Template

1VV0301493 Rev. 2 Page 52 of 86 2018-05-11

6. RF SECTION

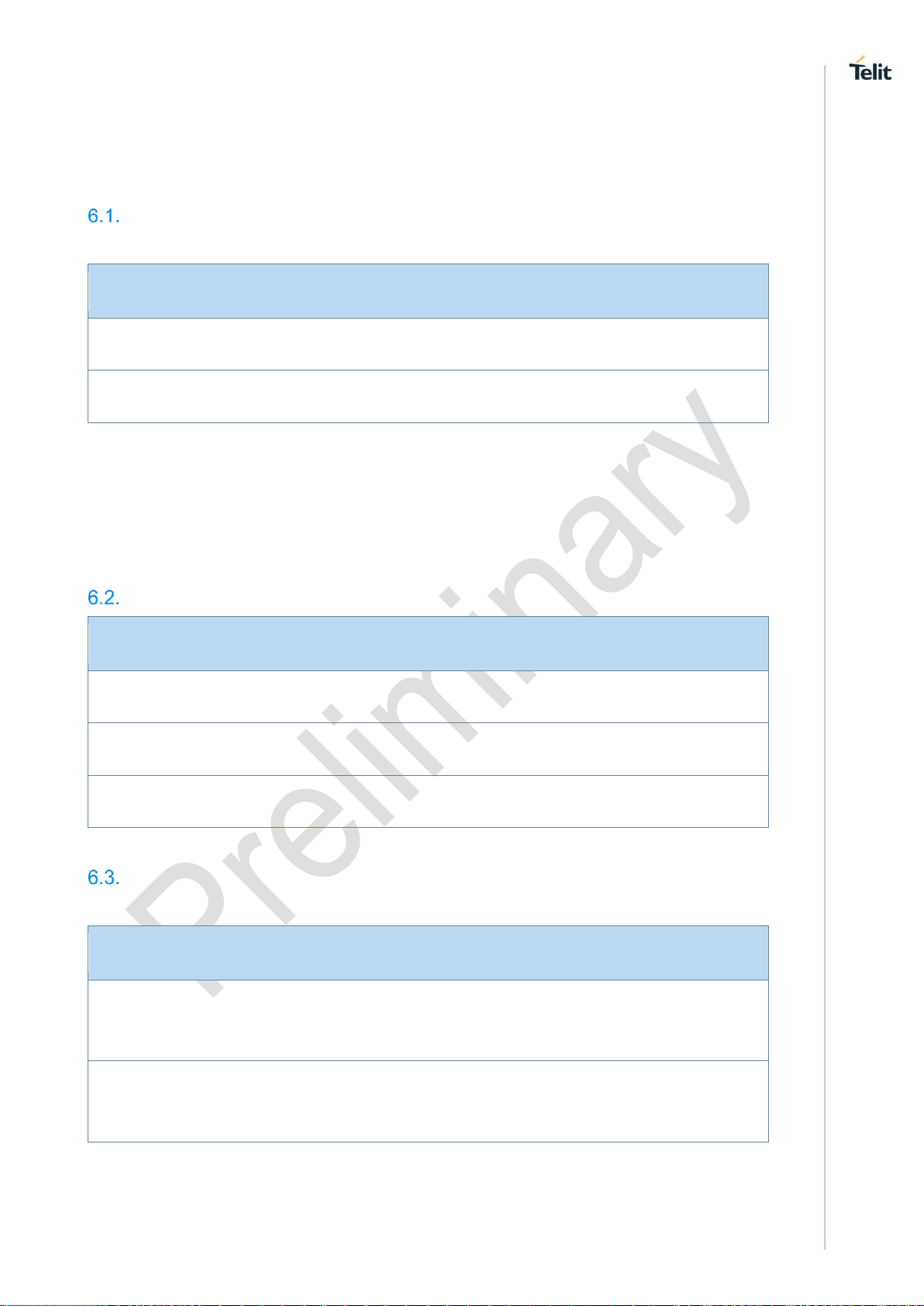

Bands Variants

Product

LTE bands

2G bands

ML865C1-NA

B2,B4,B12, B13

ML865C1-EA

B1,B3,

B5,B8,B18,B19,B20,B26,B28

850/900/1800/1900

TX Output power

Band

Class

RF power (dBm)

LTE (UE CAT-M1) all bands

3

23

GSM 850/900

4

33

DCS 1800/PCS 1900

1

30

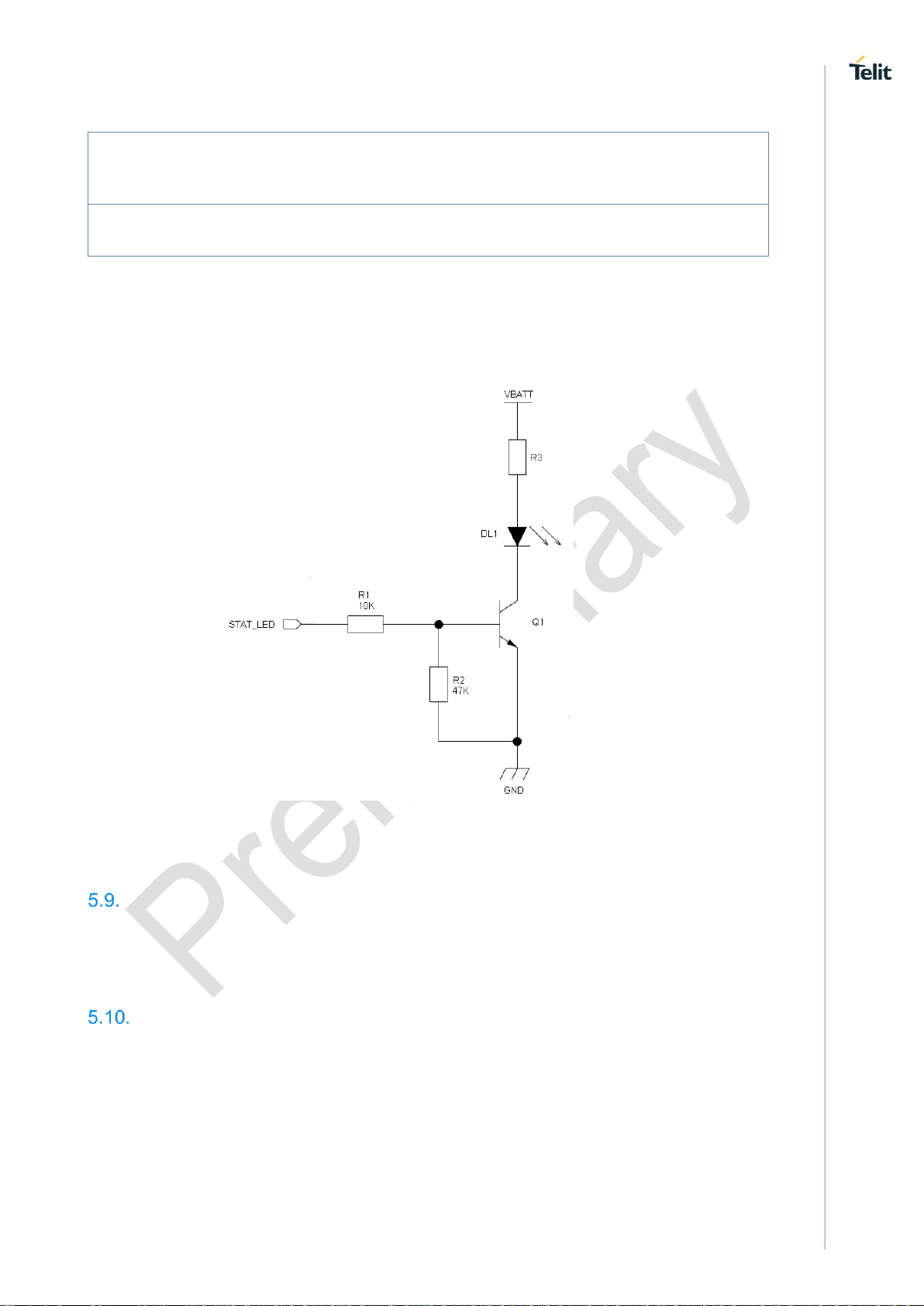

RX Sensitivity

Measurement setup

Band

Measurement conditions

LTE (UE CAT-M1)

Throughput >95%

According to 3GPP 36. 521-1

2G BANDS

BLER <10%, CS2

According to 3GPP 51.010-1

Page 53

HW User Guide Template

1VV0301493 Rev. 2 Page 53 of 86 2018-05-11

ML865C1-NA

Band

REFsens (dBm)

3GPP REFsens (dBm)

Band 2

-105

-100.3

Band 4

-105

-102.3

Band 12

-105

-99.3

Band 13

-105

-99.3

ML865C1-EA

Band

REFsens (dBm)

3GPP REFsens (dBm)

Band 1

-105

-102.3

Band 3

-105

-99.3

Band 5

-105

-100.8

Band 8

-105

-99.8

Band 18

-105

-102.3

Band 19

-105

-102.3

Band 20

-105

-100.8

Band 26

-105

-100.8

Band 28

-105

-100.8

GSM 900

-107

-104

DCS 1800

-106

-104

Page 54

HW User Guide Template

1VV0301493 Rev. 2 Page 54 of 86 2018-05-11

GSM 850

-107

-104

GSM 1900

-106

-104

Antenna requirements

The antenna connection and board layout design are the most important aspect in the full

product design as they strongly affect the product overall performances, hence read

carefully and follow the requirements and the guidelines for a proper design.

The antenna and antenna transmission line on PCB for a Telit ML865C1 device shall fulfil

the following requirements:

ML865C1-NA

Item

Value

Frequency range

Depending by frequency band(s) provided by the network

operator, the customer shall use the most suitable antenna for

that/those band(s)

Bandwidth

140 MHz in LTE Band 2

445 MHz in LTE Band 4

47 MHz in LTE Band 12

41 MHz in LTE Band 13

Impedance

50 ohm

Input power

> 24dBm Average power

VSWR absolute max

≤ 10:1 (limit to avoid permanent damage)

VSWR recommended

≤ 2:1 (limit to fulfill all regulatory requirements)

Page 55

HW User Guide Template

1VV0301493 Rev. 2 Page 55 of 86 2018-05-11

ML865C1-EA

Item

Value

Frequency range

Depending by frequency band(s) provided by the network

operator, the customer shall use the most suitable antenna for

that/those band(s)

Bandwidth

250 MHz in LTE Band 1

170 MHz in LTE Band 3

70 MHz in LTE Band 5

80 MHz in LTE Band 8

60 MHz in LTE Band 18

60 MHz in LTE Band 19

71 MHz in LTE Band 20

80 MHz in LTE Band 26

110 MHz in LTE Band 28

Impedance

50 ohm

Input power

> 24dBm Average power

VSWR absolute max

≤ 10:1 (limit to avoid permanent damage)

VSWR recommended

≤ 2:1 (limit to fulfill all regulatory requirements)

6.4.1. PCB Design guidelines

When using the ML865C1, since there's no antenna connector on the module, the

antenna must be connected to the ML865C1 antenna pad (K1) by means of a

transmission line implemented on the PCB.

This transmission line shall fulfil the following requirements:

Item

Value

Characteristic

Impedance

50 ohm (+-10%)

Max Attenuation

0,3 dB

Page 56

HW User Guide Template

1VV0301493 Rev. 2 Page 56 of 86 2018-05-11

Coupling

Coupling with other signals shall be avoided

Ground Plane

Cold End (Ground Plane) of antenna shall be equipotential to

the ML865C1 ground pins

The transmission line should be designed according to the following guidelines:

• Make sure that the transmission line’s characteristic impedance is 50ohm ;

• Keep line on the PCB as short as possible, since the antenna line loss shall be less

than about 0,3 dB;

• Line geometry should have uniform characteristics, constant cross section, avoid

meanders and abrupt curves;

• Any kind of suitable geometry / structure (Microstrip, Stripline, Coplanar, Grounded

Coplanar Waveguide...) can be used for implementing the printed transmission line

afferent the antenna;

• If a Ground plane is required in line geometry, that plane has to be continuous and

sufficiently extended, so the geometry can be as similar as possible to the related

canonical model;

• Keep, if possible, at least one layer of the PCB used only for the Ground plane; If

possible, use this layer as reference Ground plane for the transmission line;

• It is wise to surround (on both sides) the PCB transmission line with Ground, avoid

having other signal tracks facing directly the antenna line track.

• Avoid crossing any un-shielded transmission line footprint with other signal tracks

on different layers;

• The ground surrounding the antenna line on PCB has to be strictly connected to the

main Ground Plane by means of via holes (once per 2mm at least), placed close to

the ground edges facing line track;

• Place EM noisy devices as far as possible from ML865C1 antenna line;

• Keep the antenna line far away from the ML865C1 power supply lines;

• If EM noisy devices (such as fast switching ICs, LCD and so on) are present on the

PCB hosting the ML865, take care of the shielding of the antenna line by burying it

in an inner layer of PCB and surround it with Ground planes, or shield it with a metal

frame cover.

Page 57

HW User Guide Template

1VV0301493 Rev. 2 Page 57 of 86 2018-05-11

• If EM noisy devices are not present around the line, the use of geometries like

Microstrip or Grounded Coplanar Waveguide has to be preferred, since they

typically ensure less attenuation if compared to a Stripline having same length;

The following image is showing the suggested layout for the Antenna pad

connection:

6.4.2. PCB Guidelines in case of FCC Certification

In the case FCC certification is required for an application using ML865C1, according to

FCC KDB 996369 for modular approval requirements, the transmission line has to be

similar to that implemented on ML865C1 interface board and described in the following

chapter.

6.4.2.1. Transmission line design

During the design of the ML865C1 interface board, the placement of components has

been chosen properly, in order to keep the line length as short as possible, thus leading to

lowest power losses possible. A Grounded Coplanar Waveguide (G-CPW) line has been

chosen, since this kind of transmission line ensures good impedance control and can be

implemented in an outer PCB layer as needed in this case. A SMA female connector has

been used to feed the line.

Page 58

HW User Guide Template

1VV0301493 Rev. 2 Page 58 of 86 2018-05-11

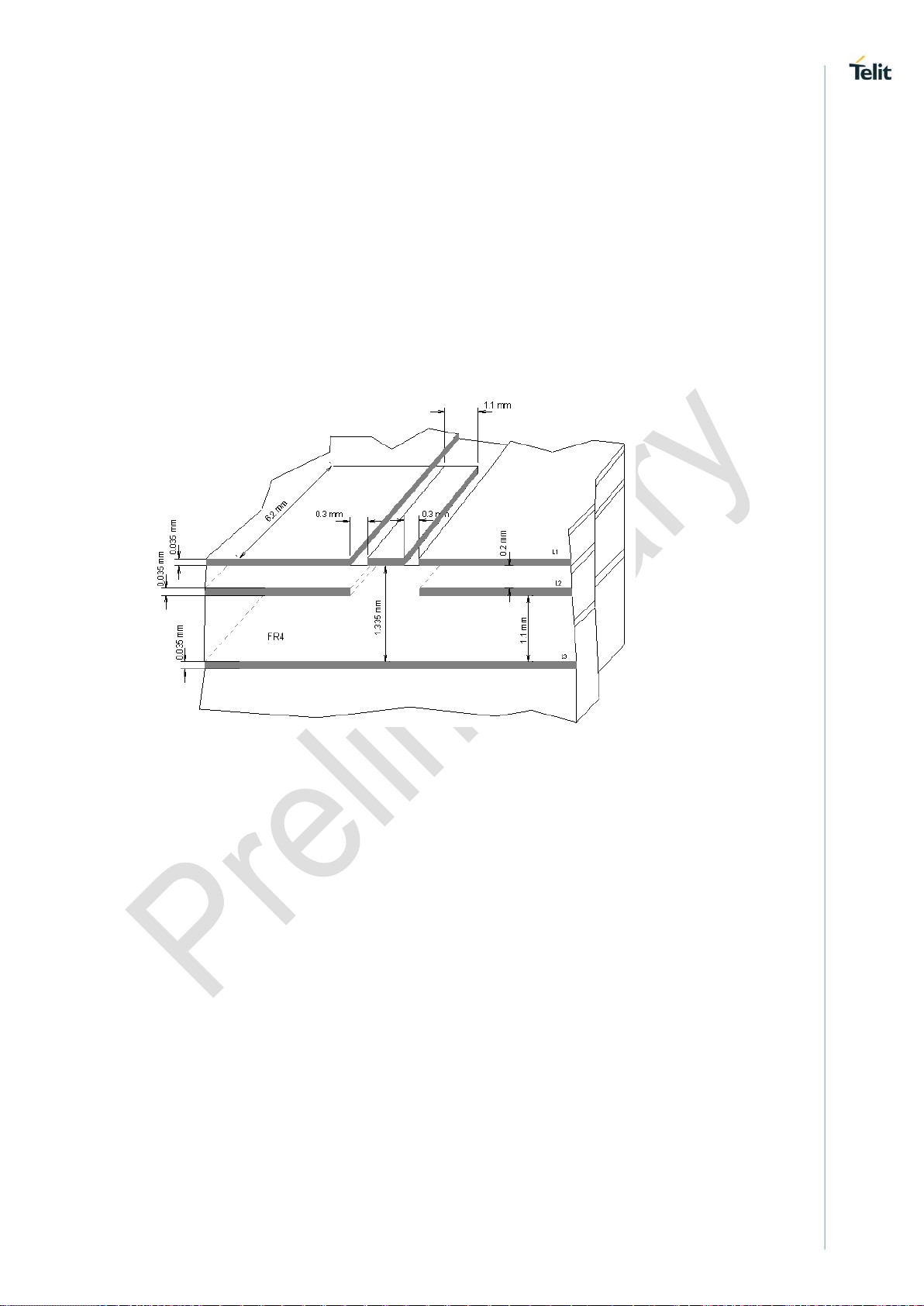

The interface board is realized on a FR4, 4-layers PCB. Substrate material is

characterized by relative permittivity εr = 4.6 ± 0.4 @ 1 GHz, TanD= 0.019 ÷ 0.026 @ 1

GHz.

A characteristic impedance of nearly 50 Ω is achieved using trace width = 1.1 mm,

clearance from coplanar ground plane = 0.3 mm each side. The line uses reference

ground plane on layer 3, while copper is removed from layer 2 underneath the line. Height

of trace above ground plane is 1.335 mm. Calculated characteristic impedance is 51.6 Ω,

estimated line loss is less than 0.1 dB. The line geometry is shown below:

Page 59

HW User Guide Template

1VV0301493 Rev. 2 Page 59 of 86 2018-05-11

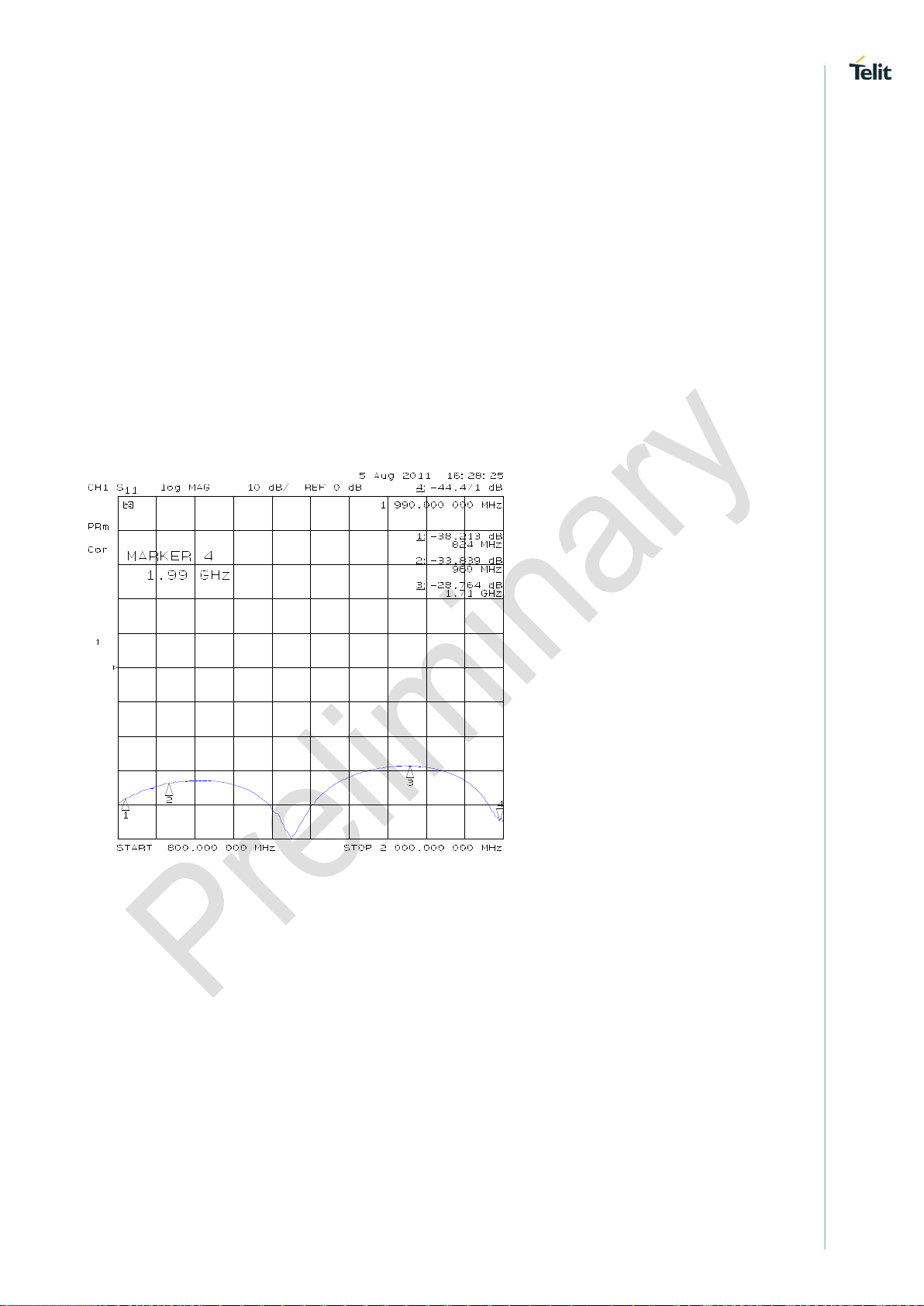

6.4.2.2. Transmission Line Measurements

An HP8753E VNA (Full-2-port calibration) has been used in this measurement session.

A calibrated coaxial cable has been soldered at the pad corresponding to RF output; a

SMA connector has been soldered to the board in order to characterize the losses of the

transmission line including the connector itself. During Return Loss / impedance

measurements, the transmission line has been terminated to 50 Ω load.

Return Loss plot of line under test is shown below:

Page 60

HW User Guide Template

1VV0301493 Rev. 2 Page 60 of 86 2018-05-11

Line input impedance (in Smith Chart format, once the line has been terminated to 50 Ω

load) is shown in the following figure:

Insertion Loss of G-CPW line plus SMA connector is shown below:

Page 61

HW User Guide Template

1VV0301493 Rev. 2 Page 61 of 86 2018-05-11

6.4.2.3. Antenna Installation Guidelines

• Install the antenna in a place covered by the LTE signal with CAT-M1 support.

• Antenna must not be installed inside metal cases

• Antenna must not be installed according Antenna manufacturer instructions

• Antenna integration should optimize the Radiation Efficiency. Efficiency values >

50% are recommended on all frequency bands

• Antenna integration should not perturb the radiation pattern described in Antenna

manufacturer documentation.

• It is preferable to get an omnidirectional radiation pattern to

• Antenna Gain must not exceed values indicated in regulatory requirements, where

applicable, in order to meet related EIRP limitations. Typical antenna Gain in most

M2M applications does not exceed 2dBi

• If the device antenna is located farther than 20cm from the human body and there

are no co-located transmitter then the Telit FCC/IC approvals can be re-used by the

end product

• If the device antenna is located closer than 20cm from the human body or there are

co-located transmitter then the additional FCC/IC testing may be required for the

end product (Telit FCC/IC approvals cannot be reused)

Page 62

HW User Guide Template

1VV0301493 Rev. 2 Page 62 of 86 2018-05-11

7. AUDIO SECTION

The Telit digital audio interface (DVI) of the ML865C1 Module is based on the I2S serial

bus interface standard. The audio port can be connected to end device using digital

interface, or via one of the several compliant codecs (in case an analog audio is needed).

Electrical Characteristics

The product is providing the DVI on the following pins:

Pin

Signal

I/O

Function

Type

48

DVI_WA0

O

Digital Audio Interface (Word

Alignment / LRCLK)

CMOS 1.8V

47

DVI_RX

I

Digital Audio Interface (RX)

CMOS 1.8V

46

DVI_TX

O

Digital Audio Interface (TX)

CMOS 1.8V

45

DVI_CLK

O

Digital Audio Interface (BCLK)

CMOS 1.8V

Codec examples

Please refer to the Digital Audio Application note.

Page 63

HW User Guide Template

1VV0301493 Rev. 2 Page 63 of 86 2018-05-11

8. GNSS SECTION

ML865C1 module includes a state-of-art receiver that can simultaneously search and track

satellite signals from multiple satellite constellations. This multi-GNSS receiver uses the

entire spectrum of GNSS systems available: GPS, GLONASS, BeiDou, Galileo, and QZSS.

GNSS Signals Pin-out

RF Front End Design

The ML865C1 Module contains a pre-select SAW filter but doesn’t contain the LNA needed

to reach the maximum sensitivity. Active antenna (antenna with a built-in low noise

amplifier) must be used and must be supplied with proper bias-tee circuit.

8.2.1. Guidelines of PCB line for GNSS Antenna

• Ensure that the antenna line impedance is 50ohm.

• Keep the antenna line on the PCB as short as possible to reduce the loss.

• Antenna line must have uniform characteristics, constant cross section, avoid

meanders and abrupt curves.

• Keep one layer of the PCB used only for the Ground plane, if possible.

• Surround (on both the sides, over and under) the antenna line on PCB with Ground,

avoid having other signal tracks facing directly the antenna line of track.

• The ground around the antenna line on PCB has to be strictly connected to the

Ground Plane by placing vias once per 2mm at least.

• Place EM noisy devices as far as possible from antenna line.

• Keep the antenna line far away from power supply lines.

• Keep the antenna line far away from GSM RF lines.

• If you have EM noisy devices around the PCB hosting the module, such as fast

switching ICs, take care of the shielding of the antenna line by burying it inside the

layers of PCB and surround it with Ground planes, or shield it with a metal frame

cover.

• If you do not have EM noisy devices around the PCB hosting the module, use a

strip-line on the superficial copper layer for the antenna line. The line attenuation will

be lower than a buried one.

GNSS Antenna Requirements

GNSS active antenna must be used or integrated in the application.

Pin

Signal

I/O

Function

Type

37

ANT_GNSS

I

GNSS Antenna (50

ohm)

CMOS

1.8V

33

GNSS_LNA_EN

O

GNSS External LNA

Enable

Page 64

HW User Guide Template

1VV0301493 Rev. 2 Page 64 of 86 2018-05-11

8.3.1. GNSS Antenna specification

Item

Value

Frequency range

1559.0 ~ 1610.0 MHz

Gain

20 ~ 30dB

Impedance

50 ohm

Noise Figure of LNA

< 1.5 (recommended)

DC supply voltage

DC 1.8 ~ 3.3V

VSWR

≤ 3:1 (recommended)

8.3.2. GNSS Antenna – Installation Guidelines

• The antenna must be installed according to the antenna manufacturer’s instructions to

obtain the maximum performance of GNSS receiver.

• The antenna location must be evaluated carefully if operating in conjunction with any

other antenna or transmitter.

• The antenna must not be installed inside metal cases or near any obstacle that may

degrade features like antenna lobes and gain.

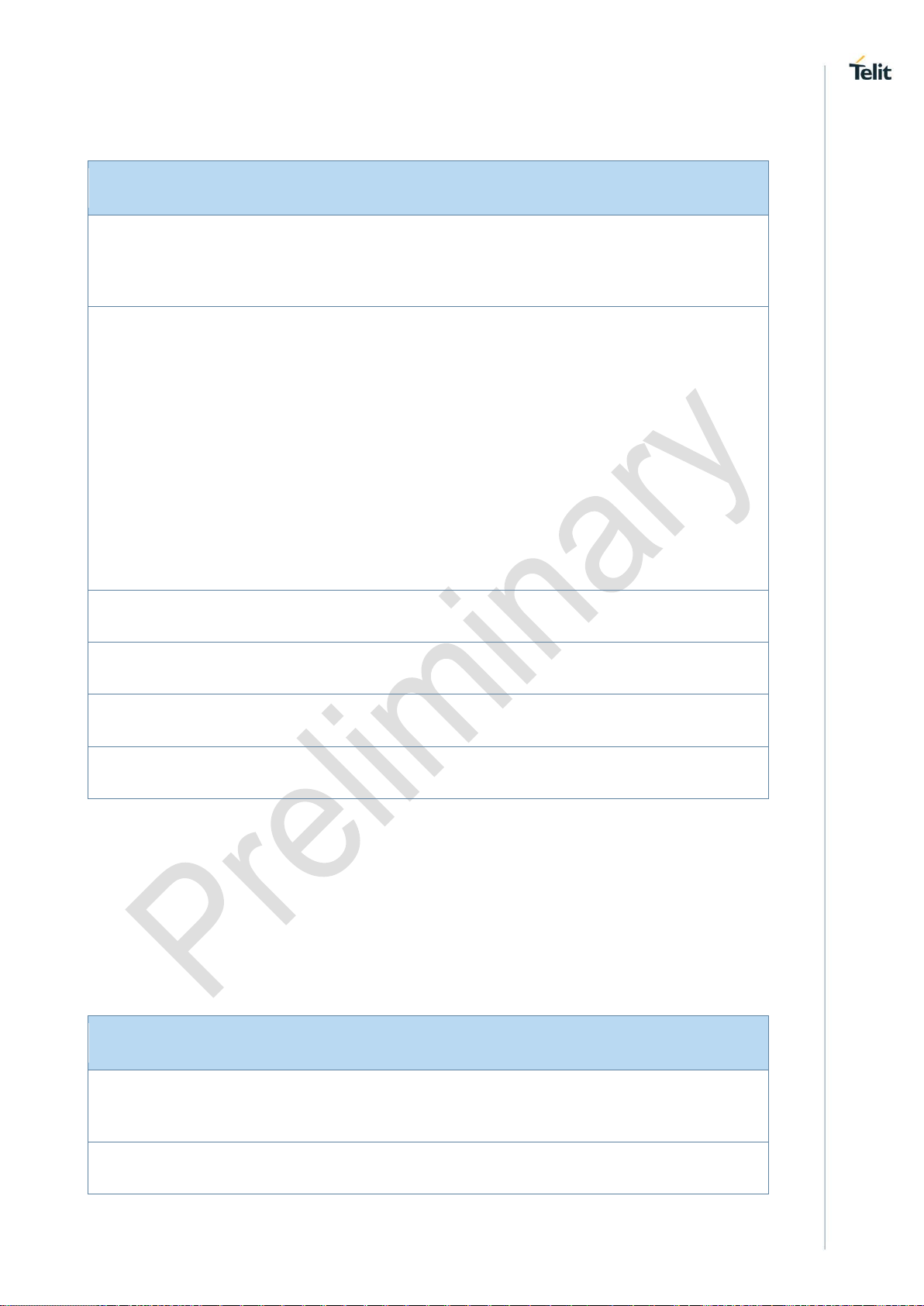

8.3.3. Powering the External LNA (active antenna)

The LNA of active antenna needs a source of power because 1.8V or 3V DC voltage

needed by active antenna is not supplied by the ML865C1 module, but can be easily

included by the host design.

The electrical characteristics of the GPS_LNA_EN signal are:

Example of external antenna bias circuitry:

Level

Min [V]

Max [V]

Output High Level

1.6

1.9

Output Low Level

0V

0.3

Page 65

HW User Guide Template

1VV0301493 Rev. 2 Page 65 of 86 2018-05-11

GNSS Characteristics *

The table below specifies the GNSS characteristics and expected performance

The values are related to typical environment and conditions Table 1 GNSS Characteristics

(* external LNA)

Parameters

Typical

Measurement

Notes

Sensitivity

Standalone or MS Based

Tracking Sensitivity

-161 dBm

Navigation

-158 dBm

Cold Start Sensitivity

-146 dBm

TTFF

Hot

<1s

GNSS Simulator test

Warm

21s

GNSS Simulator test

Cold

32s

GNSS Simulator test

Min Navigation update rate

1Hz

Dynamics

2g

A-GPS

Supported

Page 66

HW User Guide Template

1VV0301493 Rev. 2 Page 66 of 86 2018-05-11

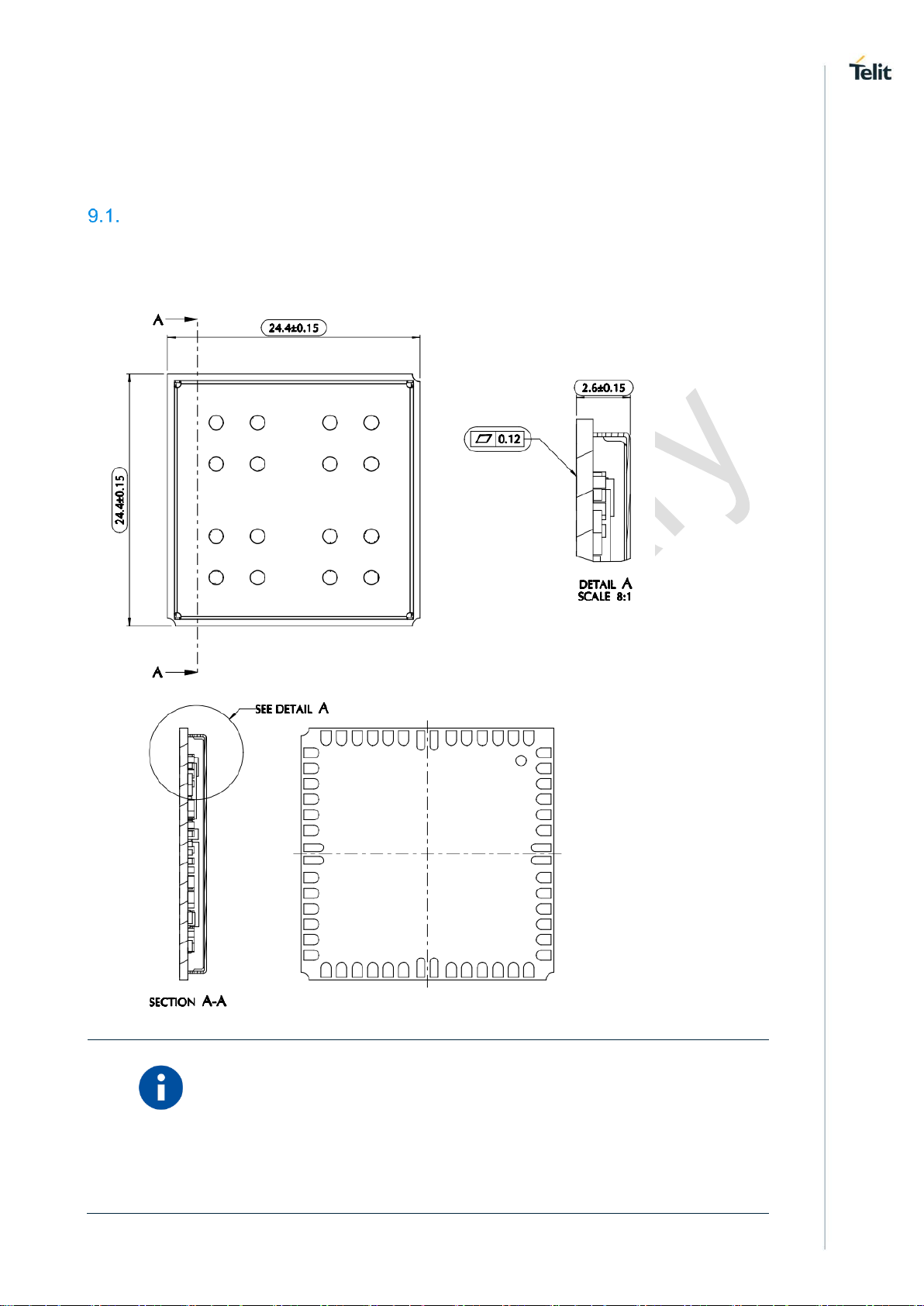

9. MECHANICAL DESIGN

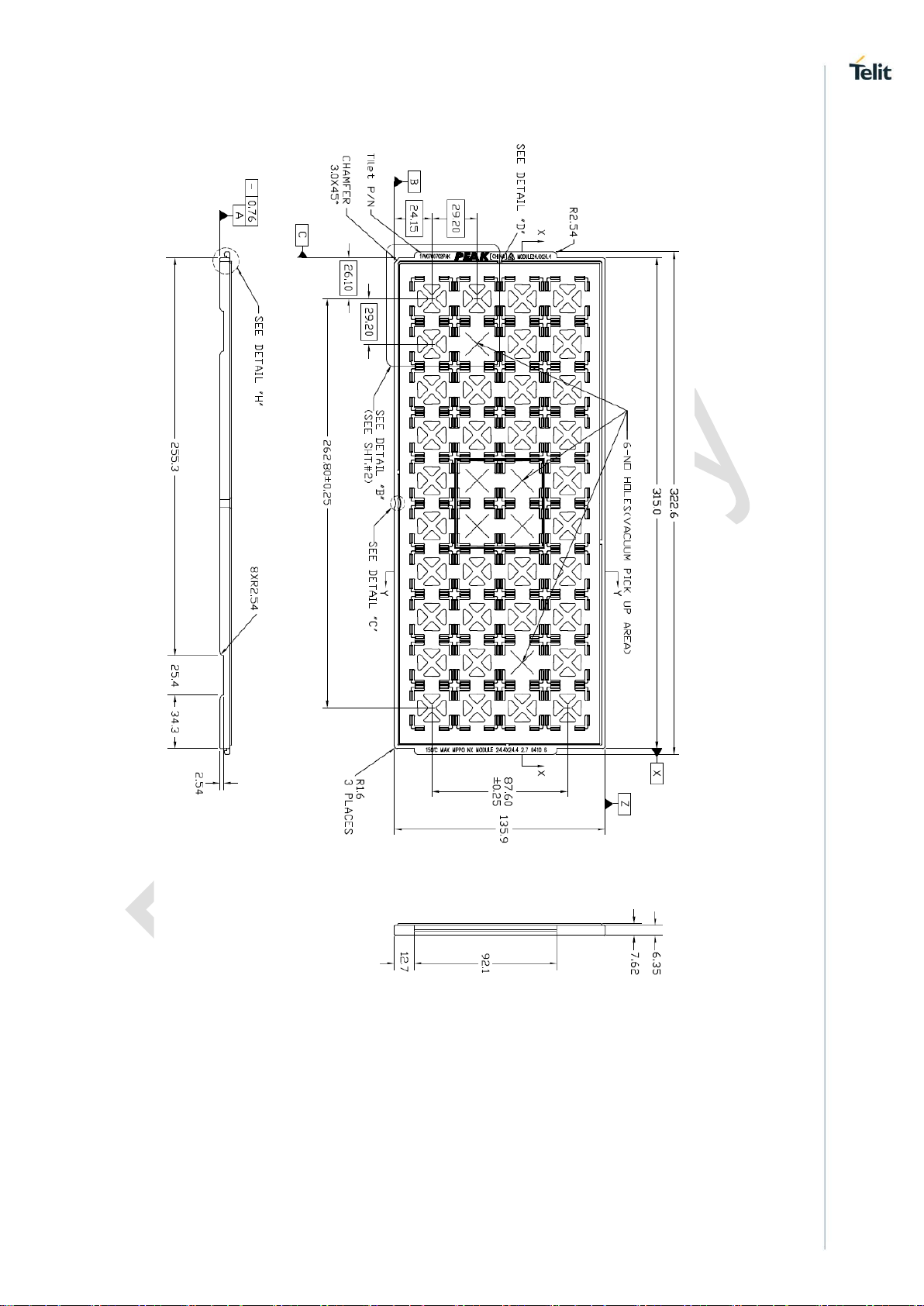

Drawing

NOTE:

Dimensions in mm.

General Tolerance ±0.1, Angular Tolerance ±1°, The tolerance is not

cumulative.

Page 67

HW User Guide Template