Page 1

LE920A4 Auto

HW User Guide

Doc#: 1VV0301261

Rev. 4.3 – 2017-12-07

Page 2

LE920A4 HW User Guide

Doc#: 1VV0301261

SPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE

NOTICE

While reasonable efforts have been made to assure the accuracy of this document, Telit

assumes no liability resulting from any inaccuracies or omissions in this document, or from

use of the information obtained herein. The information in this document has been carefully

checked and is believed to be reliable. However, no responsibility is assumed for

inaccuracies or omissions. Telit reserves the right to make changes to any products

described herein and reserves the right to revise this document and to make changes from

time to time in content hereof with no obligation to notify any person of revisions or changes.

Telit does not assume any liability arising out of the application or use of any product,

software, or circuit described herein; neither does it convey license under its patent rights

or the rights of others.

It is possible that this publication may contain references to, or information about Telit

products (machines and programs), programming, or services that are not announced in

your country. Such references or information must not be construed to mean that Telit

intends to announce such Telit products, programming, or services in your country.

COPYRIGHTS

This instruction manual and the Telit products described in this instruction manual may be,

include or describe copyrighted Telit material, such as computer programs stored in

semiconductor memories or other media. Laws in the Italy and other countries preserve for

Telit and its licensors certain exclusive rights for copyrighted material, including the

exclusive right to copy, reproduce in any form, distribute and make derivative works of the

copyrighted material. Accordingly, any copyrighted material of Telit and its licensors

contained herein or in the Telit products described in this instruction manual may not be

copied, reproduced, distributed, merged or modified in any manner without the express

written permission of Telit. Furthermore, the purchase of Telit products shall not be deemed

to grant either directly or by implication, estoppel, or otherwise, any license under the

copyrights, patents or patent applications of Telit, as arises by operation of law in the sale

of a product.

COMPUTER SOFTWARE COPYRIGHTS

The Telit and 3rd Party supplied Software (SW) products described in this instruction

manual may include copyrighted Telit and other 3rd Party supplied computer programs

stored in semiconductor memories or other media. Laws in the Italy and other countries

preserve for Telit and other 3rd Party supplied SW certain exclusive rights for copyrighted

computer programs, including the exclusive right to copy or reproduce in any form the

copyrighted computer program. Accordingly, any copyrighted Telit or other 3rd Party

supplied SW computer programs contained in the Telit products described in this instruction

manual may not be copied (reverse engineered) or reproduced in any manner without the

express written permission of Telit or the 3rd Party SW supplier. Furthermore, the purchase

of Telit products shall not be deemed to grant either directly or by implication, estoppel, or

otherwise, any license under the copyrights, patents or patent applications of Telit or other

3rd Party supplied SW, except for the normal non-exclusive, royalty free license to use that

arises by operation of law in the sale of a product.

Rev. 4.3 Page 2 of 123 2017-12-07

Page 3

LE920A4 HW User Guide

Doc#: 1VV0301261

USAGE AND DISCLOSURE RESTRICTIONS

I. License Agreements

The software described in this document is the property of Telit and its licensors. It is

furnished by express license agreement only and may be used only in accordance with the

terms of such an agreement.

II. Copyrighted Materials

Software and documentation are copyrighted materials. Making unauthorized copies is

prohibited by law. No part of the software or documentation may be reproduced,

transmitted, transcribed, stored in a retrieval system, or translated into any language or

computer language, in any form or by any means, without prior written permission of Telit

III. High Risk Materials

Components, units, or third-party products used in the product described herein are NOT

fault-tolerant and are NOT designed, manufactured, or intended for use as on-line control

equipment in the following hazardous environments requiring fail-safe controls: the

operation of Nuclear Facilities, Aircraft Navigation or Aircraft Communication Systems, Air

Traffic Control, Life Support, or Weapons Systems (High Risk Activities"). Telit and its

supplier(s) specifically disclaim any expressed or implied warranty of fitness for such High

Risk Activities.

IV. Trademarks

TELIT and the Stylized T Logo are registered in Trademark Office. All other product or

service names are the property of their respective owners.

V. Third Party Rights

The software may include Third Party Right software. In this case you agree to comply with

all terms and conditions imposed on you in respect of such separate software. In addition

to Third Party Terms, the disclaimer of warranty and limitation of liability provisions in this

License shall apply to the Third Party Right software.

TELIT HEREBY DISCLAIMS ANY AND ALL WARRANTIES EXPRESS OR IMPLIED

FROM ANY THIRD PARTIES REGARDING ANY SEPARATE FILES, ANY THIRD PARTY

MATERIALS INCLUDED IN THE SOFTWARE, ANY THIRD PARTY MATERIALS FROM

WHICH THE SOFTWARE IS DERIVED (COLLECTIVELY “OTHER CODE”), AND THE

USE OF ANY OR ALL THE OTHER CODE IN CONNECTION WITH THE SOFTWARE,

INCLUDING (WITHOUT LIMITATION) ANY WARRANTIES OF SATISFACTORY

QUALITY OR FITNESS FOR A PARTICULAR PURPOSE.

NO THIRD PARTY LICENSORS OF OTHER CODE SHALL HAVE ANY LIABILITY FOR

ANY DIRECT, INDIRECT, INCIDENTAL, SPECIAL, EXEMPLARY, OR CONSEQUENTIAL

DAMAGES (INCLUDING WITHOUT LIMITATION LOST PROFITS), HOWEVER CAUSED

AND WHETHER MADE UNDER CONTRACT, TORT OR OTHER LEGAL THEORY,

ARISING IN ANY WAY OUT OF THE USE OR DISTRIBUTION OF THE OTHER CODE

OR THE EXERCISE OF ANY RIGHTS GRANTED UNDER EITHER OR BOTH THIS

LICENSE AND THE LEGAL TERMS APPLICABLE TO ANY SEPARATE FILES, EVEN IF

ADVISED OF THE POSSIBILITY OF SUCH DAMAGES.

Rev. 4.3 Page 3 of 123 2017-12-07

Page 4

LE920A4 HW User Guide

Doc#: 1VV0301261

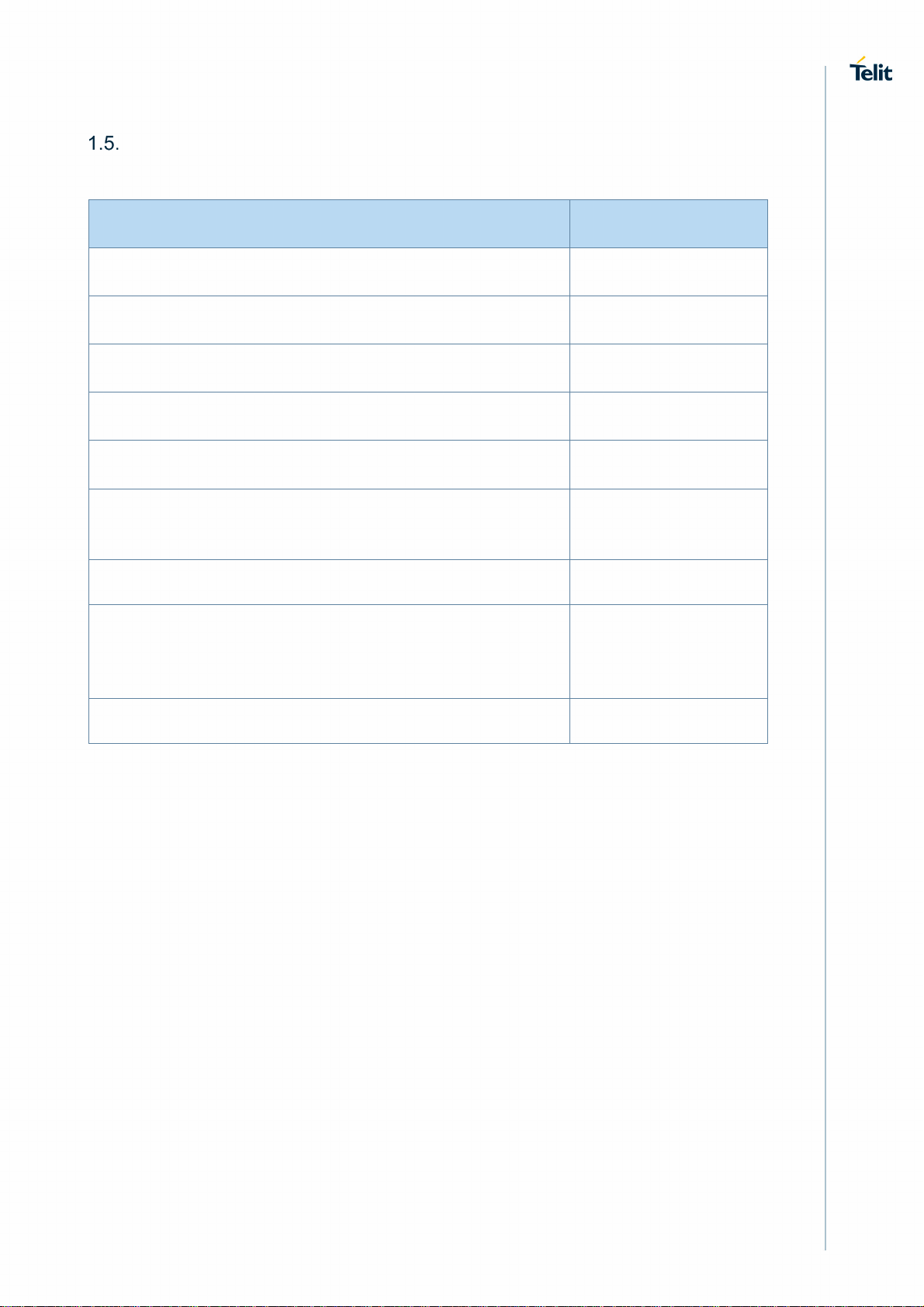

APPLICABILITY TABLE

This documentation applies to the following products:

Table 1: Applicability Table

Module Name Description

LE920A4-NA North America regional variant (AT&T, T-Mobile)

LE920A4-NV (*) North America regional variant (Verizon)

LE920A4-EU Europe regional variant

HE920A-EU (*) Non-LTE Europe variant

LE920A4-CN China variant

LE920A4-AP (*) APAC variant

(*) Variants which were not designed yet

Rev. 4.3 Page 4 of 123 2017-12-07

Page 5

LE920A4 HW User Guide

Doc#: 1VV0301261

CONTENTS

1. INTRODUCTION .............................................................................................9

Scope ............................................................................................................. 9

Audience......................................................................................................... 9

Contact Information, Support .......................................................................... 9

Text Conventions ...........................................................................................10

Related Documents .......................................................................................11

2. GENERAL PRODUCT DESCRIPTION ......................................................... 12

Overview........................................................................................................12

Applications ...................................................................................................12

General Functionality and Main Features.......................................................13

Block Diagram ...............................................................................................15

Environmental Requirements .........................................................................17

2.5.1. Temperature Range .......................................................................................17

2.5.2. RoHS Compliance .........................................................................................17

Frequency Bands ...........................................................................................18

2.6.1. RF Bands per Regional Variant .....................................................................18

2.6.2. Reference Table of RF Bands Characteristics ...............................................18

RF parameters ...............................................................................................21

2.7.1. Sensitivity ......................................................................................................21

2.7.2. Output power .................................................................................................21

Mechanical Dimensions .................................................................................22

Weight ...........................................................................................................22

3. MODULE CONNECTIONS ............................................................................ 23

Pin-out ...........................................................................................................23

Signals That Must Be Connected ...................................................................37

LE940A4 LGA Pads Layout ...........................................................................40

4. ELECTRICAL SPECIFICATIONS ................................................................. 41

Absolute Maximum Ratings – Not Operational ...............................................41

Recommended Operating Conditions ............................................................41

Logic Level Specifications ..............................................................................41

4.3.1. 1.8V Pads - Absolute Maximum Ratings ........................................................42

4.3.2. 1.8V Standard GPIOs ....................................................................................42

4.3.3. 1.8V SD Card Pads .......................................................................................43

4.3.4. 1.8V SIM Card Pads ......................................................................................43

4.3.5. Dual Voltage Pads - Absolute Maximum Ratings ...........................................44

Rev. 4.3 Page 5 of 123 2017-12-07

Page 6

LE920A4 HW User Guide

Doc#: 1VV0301261

4.3.6. SD Card Pads @ 2.95V .................................................................................44

4.3.7. SIM Card Pads @2.95V.................................................................................44

5. HARDWARE COMMANDS ........................................................................... 46

Turning on the Module ...................................................................................46

Initialization and Activation State ...................................................................46

Turning off the Module ...................................................................................48

5.3.1. Shutdown by Software Command ..................................................................49

5.3.2. Hardware Shutdown ......................................................................................49

5.3.3. Unconditional Hardware Reset ......................................................................51

5.3.4. Unconditional Hardware Shutdown ................................................................52

6. POWER SUPPLY .......................................................................................... 54

Power Supply Requirements ..........................................................................54

General Design Rules ....................................................................................56

6.2.1. Electrical Design Guidelines ..........................................................................56

6.2.1.1. + 5V Input Source Power Supply Design Guidelines ......................................56

6.2.1.2. + 12V Input Source Power Supply Design Guidelines ....................................57

6.2.1.3. Battery Source Power Supply Design Guidelines ...........................................59

6.2.2. Thermal Design Guidelines ............................................................................59

6.2.3. Power Supply PCB Layout Guidelines ...........................................................60

7. ANTENNA(S) ................................................................................................ 62

GSM/WCDMA/TD-SCDMA/LTE Antenna Requirements ...............................62

GSM/WCDMA/TD-SCDMA/LTE Antenna – PCB Line Guidelines ..................63

GSM/WCDMA/TD-SCDMA/LTE Antenna – Installation Guidelines ................64

Antenna Diversity Requirements ....................................................................64

GPS/GNSS Antenna Requirements ...............................................................65

7.5.1. Combined GPS/GNSS Antenna .....................................................................65

7.5.2. Linear and Patch GPS/GNSS Antenna ..........................................................66

7.5.3. Front End Design Considerations ..................................................................66

7.5.4. GPS/GNSS Antenna – PCB Line Guidelines .................................................66

7.5.5. GPS/GNSS Antenna – Installation Guidelines ...............................................67

8. HARDWARE INTERFACES .......................................................................... 68

USB Port........................................................................................................69

8.1.1. USB OTG support ..........................................................................................70

HSIC Interface ...............................................................................................70

Ethernet Connectivity (optional) .....................................................................71

8.3.1. SGMII Interface..............................................................................................71

8.3.2. Ethernet Control Interface ..............................................................................71

Rev. 4.3 Page 6 of 123 2017-12-07

Page 7

LE920A4 HW User Guide

Doc#: 1VV0301261

Serial Ports ....................................................................................................72

8.4.1. Modem Serial Port 1 ......................................................................................72

8.4.2. Modem Serial Port 2 ......................................................................................74

8.4.3. RS232 Level Translation ................................................................................75

Peripheral Ports .............................................................................................77

8.5.1. SPI – Serial Peripheral Interface ....................................................................77

8.5.2. I2C - Inter-integrated Circuit ...........................................................................78

8.5.3. SD/MMC Card Interface .................................................................................78

8.5.4. WiFi (SDIO) Control Interface ........................................................................80

Audio Interface ..............................................................................................81

8.6.1. Analog Audio .................................................................................................81

8.6.2. Analog Audio Characteristics .........................................................................82

8.6.2.1. Analog Inputs Characteristics ........................................................................82

8.6.2.2. Analog Output Characteristics .......................................................................84

8.6.3. Digital Audio ..................................................................................................85

8.6.3.1. Short Frame Timing Diagrams .......................................................................86

8.6.3.2. Long Frame Timing Diagrams ........................................................................88

General Purpose I/O ......................................................................................90

8.7.1. Using a GPIO Pad as Input ............................................................................91

8.7.2. Using a GPIO Pad as an Interrupt Source .....................................................92

8.7.3. Using a GPIO Pad as Output .........................................................................92

9. MISCELLANEOUS FUNCTIONS .................................................................. 93

Indication of Network Service Availability .......................................................93

RTC – Real Time Clock .................................................................................93

VAUX Power Output ......................................................................................93

ADC Converter ..............................................................................................95

9.4.1. Description .....................................................................................................95

9.4.2. Using ADC Converter ....................................................................................95

Using the Temperature Monitor Function .......................................................95

Fuel Gauge (optional) ....................................................................................95

GNSS Characteristics ....................................................................................97

10. MOUNTING THE MODULE ON YOUR BOARD ........................................... 98

General ..........................................................................................................98

Finishing & Dimensions .................................................................................98

Recommended Foot Print for the Application .................................................99

Stencil ............................................................................................................99

PCB Pad Design .......................................................................................... 100

Recommendations for PCB Pad Dimensions (mm) ...................................... 100

Rev. 4.3 Page 7 of 123 2017-12-07

Page 8

LE920A4 HW User Guide

Doc#: 1VV0301261

Solder Paste ................................................................................................ 101

10.7.1. Solder Reflow .............................................................................................. 101

11. APPLICATION GUIDE ................................................................................ 103

Debug of the Module in Production .............................................................. 103

Bypass Capacitor on Power Supplies .......................................................... 104

SIM Interface ............................................................................................... 105

11.3.1. SIM Schematic Example .............................................................................. 105

EMC Recommendations .............................................................................. 105

Download and Debug Port ........................................................................... 106

11.5.1. Fast Boot Mode ........................................................................................... 106

11.5.2. Recovery Boot Mode ................................................................................... 106

Antenna Detection ....................................................................................... 107

12. PACKING SYSTEM .................................................................................... 108

Tray ............................................................................................................. 108

Tape & Reel ................................................................................................. 111

Moisture Sensitivity ...................................................................................... 112

13. SAFETY RECOMMENDATIONS................................................................. 113

14. CONFORMITY ASSESSMENT ISSUES ..................................................... 114

FCC/ISED Regulatory notices ...................................................................... 114

15. ACRONYMS ................................................................................................ 116

16. DOCUMENT HISTORY ............................................................................... 119

Rev. 4.3 Page 8 of 123 2017-12-07

Page 9

LE920A4 HW User Guide Introduction

Doc#: 1VV0301261 Scope

1. Introduction

Scope

This document introduces the Telit LE920A4 module and presents possible and

recommended hardware solutions for developing a product based on this module. All the

features and solutions detailed in this document are applicable to all module variants,

where “module” refers to the variants listed in the applicability table.

If a specific feature is applicable to a specific product only, it will be clearly marked.

NOTE:

Module refers to all modules listed in the Applicability Table.

This document takes into account all the basic functions of a wireless module; a valid

hardware solution is suggested for each function, and incorrect solutions and common

errors to be avoided are pointed out.

Obviously, this document cannot embrace every hardware solution or every product that

can be designed. Obviously, avoiding invalid solutions must be considered mandatory.

Where the suggested hardware configurations need not be considered mandatory, the

information given should be used as a guide and a starting point for properly developing

your product with the Telit module.

NOTE:

The integration of the module within a user application must be done

according to the design rules described in this manual.

Audience

This document is intended for Telit customers, especially system integrators, about to

implement their applications using the Telit module.

Contact Information, Support

For general contact, technical support services, technical questions and report

documentation errors, contact Telit Technical Support at:

• TS-EMEA@telit.com

• TS-AMERICAS@telit.com

• TS-APAC@telit.com

• TS-SRD@telit.com

Rev. 4.3 Page 9 of 123 2017-12-07

Page 10

LE920A4 HW User Guide Introduction

Doc#: 1VV0301261 Text Conventions

Alternatively, use:

http://www.telit.com/support

For detailed information about where you can buy the Telit modules or for

recommendations on accessories and components visit:

http://www.telit.com

To register for product news and announcements or for product questions contact Telit’s

Technical Support Center (TTSC).

Our aim is to make this guide as helpful as possible. Keep us informed of your comments

and suggestions for improvements.

Telit appreciates feedback from the users of our information.

Text Conventions

The following conventions are used to emphasize specific types of information:

DANGER:

Danger – This information MUST be followed or catastrophic equipment

failure or bodily injury may occur.

WARNING:

Caution or Warning – Alerts the user to important points about integrating the

module, if these points are not followed, the module and end user equipment

may fail or malfunction.

NOTE:

Tip or Information – Provides advice and suggestions that may be useful

when integrating the module.

All dates are in ISO 8601 format, i.e. YYYY-MM-DD.

Rev. 4.3 Page 10 of 123 2017-12-07

Page 11

LE920A4 HW User Guide Introduction

Doc#: 1VV0301261 Related Documents

Related Documents

Table 2: Related Documents

Document Title Document Number

Ref 1: LE920A4 AT Command User Guide 80490ST10778A

Ref 2: LE920A4 Software Guide 1VV0301332

Ref 3: Generic EVB HW User Guide 1VV0301249

Ref 4: LE920A4 Interface Board HW User Guide 1VV0301248

Ref 5: Digital Voice Interface_Application_Note 80000NT11246A

Ref 6: Telit_LE920A4_LE910Cx_WiFi_Interface_Application_Note_r1

Ref 7: Antenna Detection Application Note 80000NT10002A

Ref 8: High-Speed Inter-Chip USB Electrical Specification,

version 1.0

(a supplement to the USB 2.0 specification, Section 3.8.2)

Ref 9: ETH_Expansion_board_Application Note

80490NT11511A

80490NT11622A

Rev. 4.3 Page 11 of 123 2017-12-07

Page 12

LE920A4 HW User Guide General Product Description

Doc#: 1VV0301261 Overview

2. General Product Description

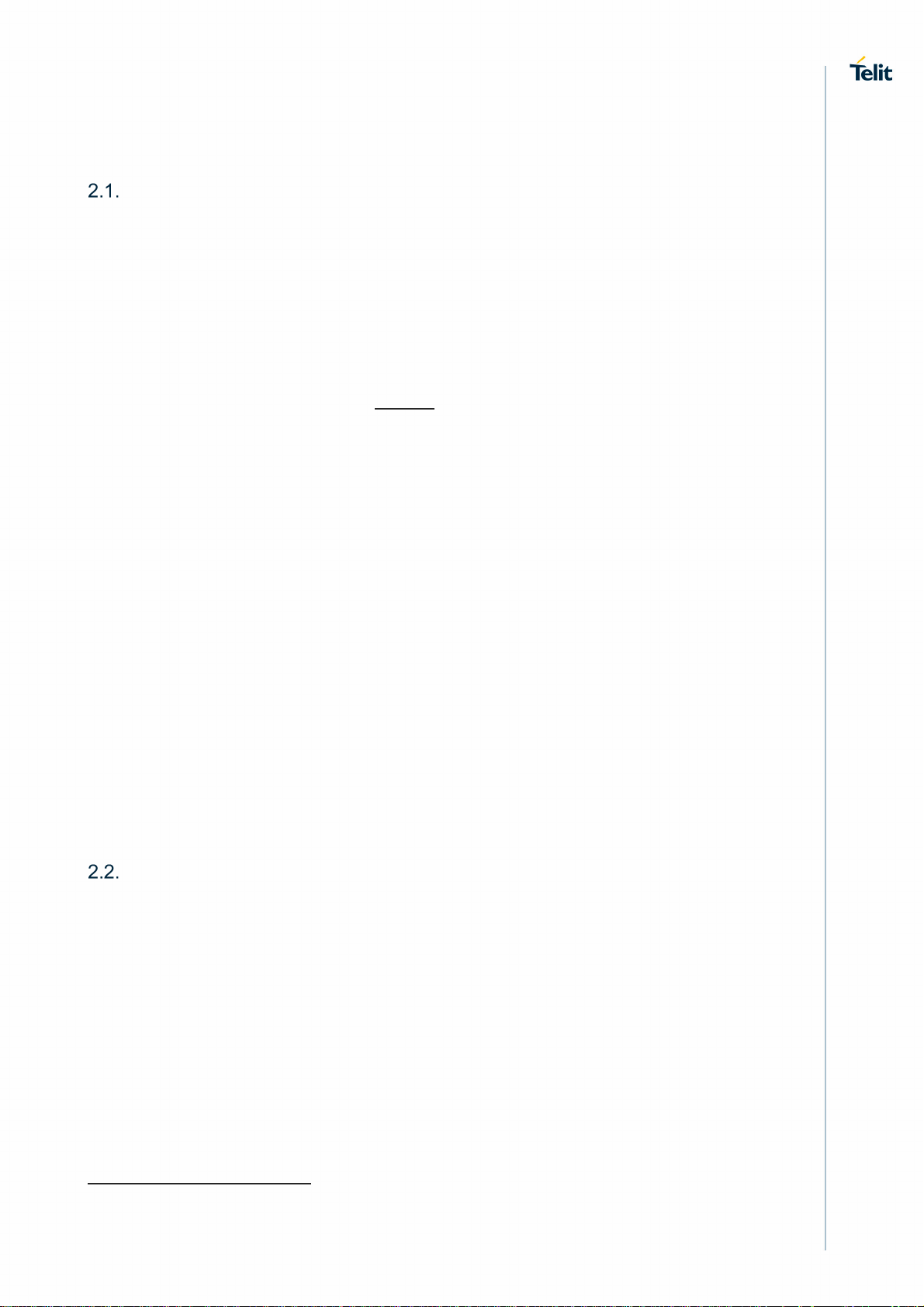

Overview

The LE920A4 module is Telit’s platform for automotive telematics on-board units (OBU's)

for applications, such as automotive telematics and eCall, based on the following

technologies:

• 4G cellular for voice and data communication

• GNSS (optional) - GPS, GLONASS, BeiDou, Galileo, QZSS, for positioning

service

• Embedded security

o ARM Trust Zone services (optional)

• Designed for automotive markets1 quality needs

In its most basic use case, the module can be applied as a wireless communication frontend for telematics products, offering GNSS and mobile communication features to an

external host CPU through its rich interfaces.

The module can further support customer software applications and security features. The

module provides a software application development environment with sufficient system

resources for creating rich on-board applications. Thanks to a dedicated application

processor and embedded security resources, product developers and manufacturers can

create products that guarantee fraud prevention and tamper evidence without extra effort

for additional security precautions.

The module can be self-sufficient and serve as a fully integrated solution for applications,

such as location-based cellular telematics, navigation, road pricing and eCall. In such a

case, the customer would simply complement the module with a power supply, speaker

amplifier, microphone, antennas, and an HMI (if applicable).

The module is available in hardware variants as listed in Table 1: Applicability Table. The

designated RF band sets per each variant are detailed in Section 2.6, Frequency Bands.

Applications

The module can be used for telematics applications where tamper-resistance,

confidentiality, integrity, and authenticity of end-user information are required, for

example:

• Emergency call

• Telematics services

• Road pricing

• Pay-as-you-drive insurance

• Stolen vehicles tracking

• Internet connectivity

1

In accordance with Telit’s Robustness Validation, using AEC-Q100-defined qualification tests

Rev. 4.3 Page 12 of 123 2017-12-07

Page 13

LE920A4 HW User Guide General Product Description

•

Up to 48

kHz sample rate, 16 bit words

•

Data rates up to 4 MHz

4 Gbit DDR.

Doc#: 1VV0301261 General Functionality and Main Features

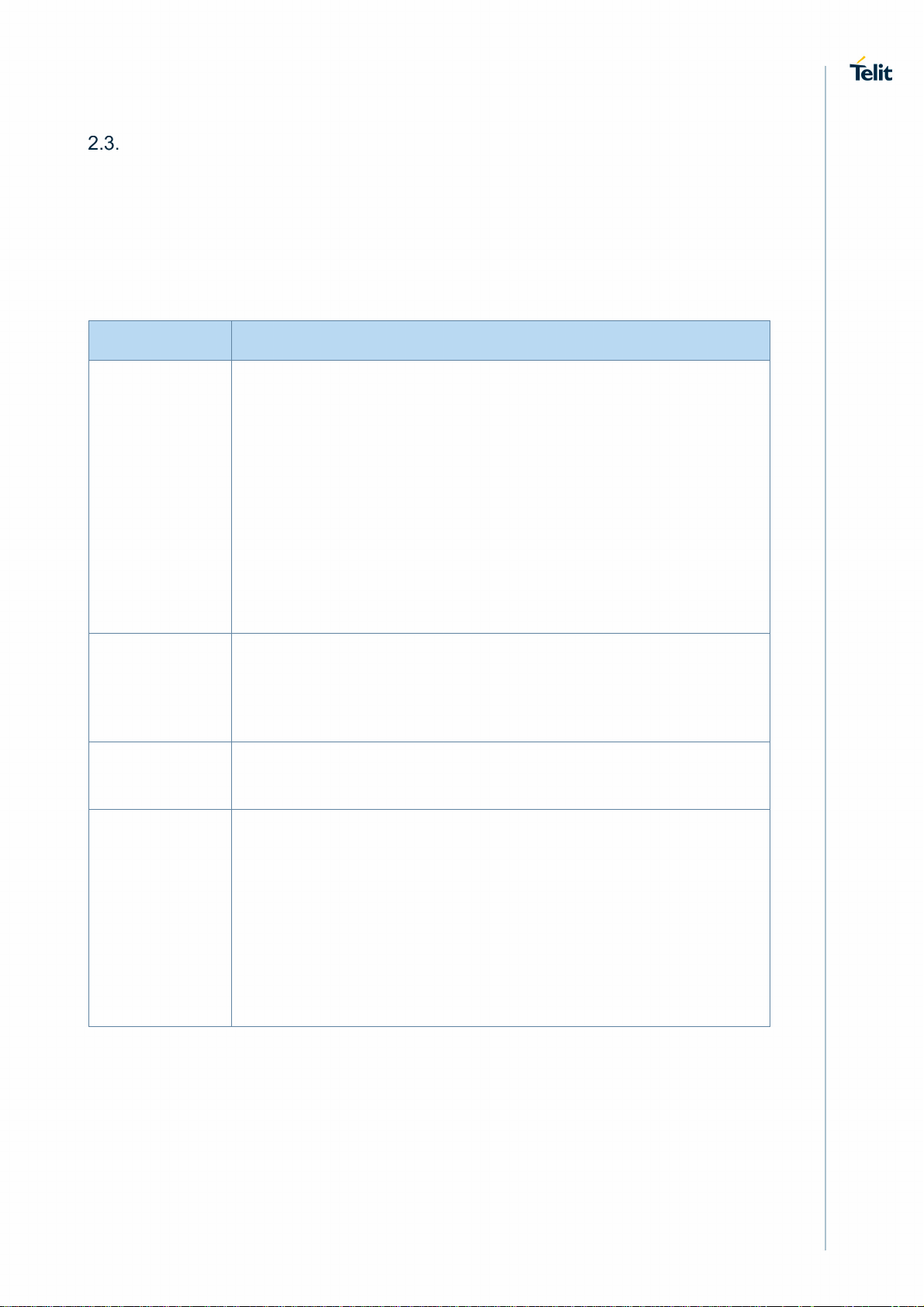

General Functionality and Main Features

The LE920A4 family of automotive cellular modules features an advanced LTE and multiRAT modem together with a powerful on-chip application processor and a rich set of

interfaces.

The major functions and features are listed below:

Table 3: Main Features

Function Features

Modem

Audio

subsystem

Two USIM ports

– dual voltage

• Multi-RAT cellular modem for voice and data communication

o LTE FDD/TDD Cat4 (150/50 Mbps DL/UL)

o GSM/GPRS/EDGE

o WCDMA up to DC HSPA+, Rel.9

o TD-SCDMA (China variant only)

• Support for European eCall , US E911, and ERA Glonass

• Support for SIM profile switching

• Regional variants with optimal choice of RF bands for

worldwide coverage of countries and MNOs

• State-of-the-art GNSS solution with

GPS/GLONASS/BeiDou/Galileo/QZSS receiver

• Embedded analog codec with two microphone inputs

• Embedded analog codec with one stereo or two mono

outputs

• PCM/I2S digital audio interface

• Class B and Class C support

• Hot-swap support

Application

processor

Rev. 4.3 Page 13 of 123 2017-12-07

Application processor to run customer application code

• 32 bit ARM Cortex-A7 up to 1.2 GHz running the Linux

operating system

• Flash + DDR are large enough to allow for customer’s own

software applications

• Default memory configuration is 4 Gb (512 MB) Flash + 2 Gb

(256 MB) RAM

• Other memory configurations can be supported upon request,

for example: 2 Gbit Flash + 2 Gbit DDR or 4 Gbit Flash +

Page 14

LE920A4 HW User Guide General Product Description

•

Antenna ports

Doc#: 1VV0301261 General Functionality and Main Features

Function Features

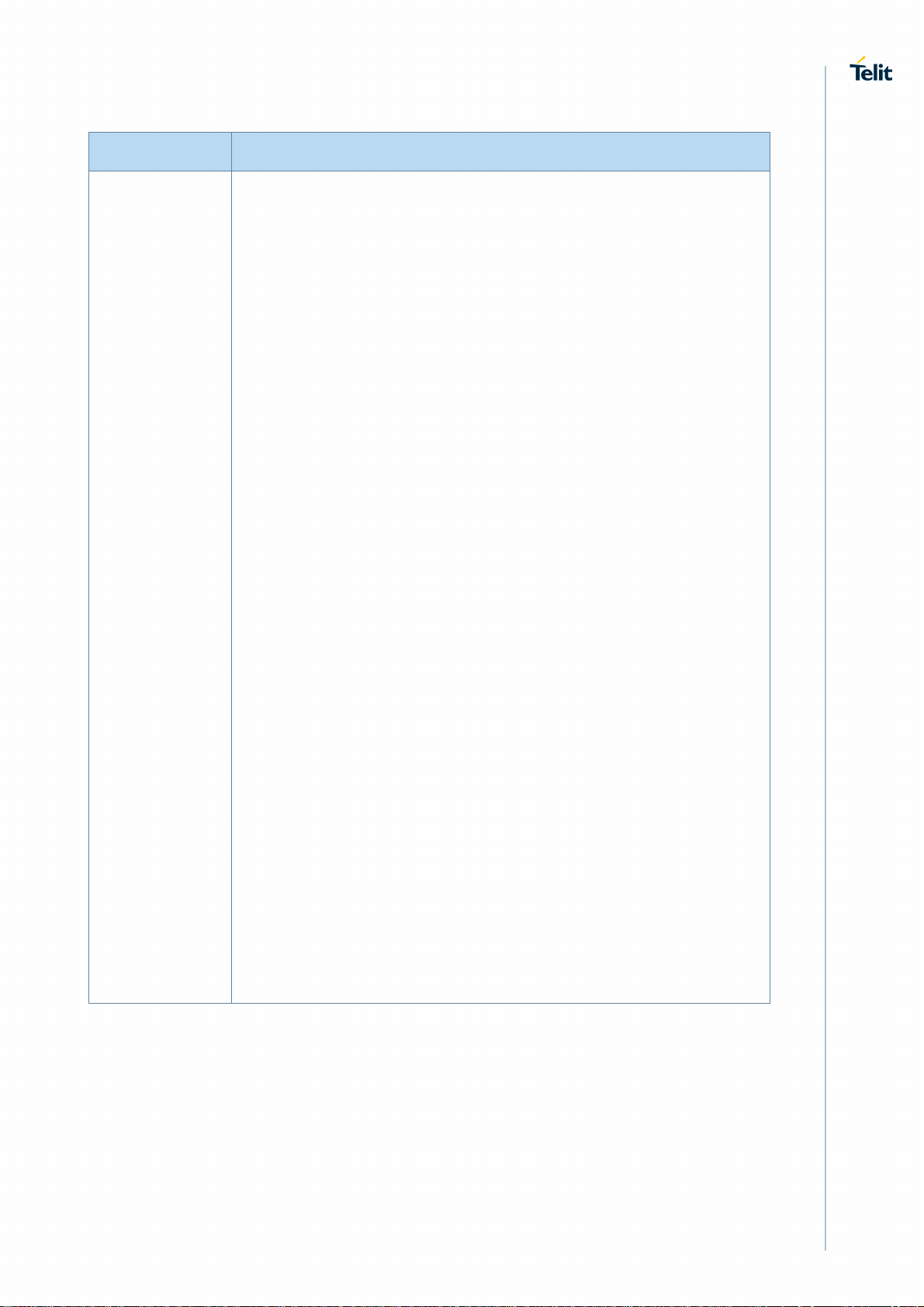

Interfaces Rich set of interfaces, including:

• SD/MMC Card Interface supporting SD3.0 standard

• SDIO for external WiFi transceiver supporting SDIO3.0

standard

• SGMII for external Ethernet transceiver (optional)

o Compliant with IEEE802.3

o Full duplex operation at 1 Gbps

o Half/full duplex operation at 10/100 Mbps

o Support for VLAN tagging

o Support for IEEE1588, PTP (Precision Time Protocol)

• USB2.0 – USB port is typically used for:

o Flashing of firmware and module configuration

o Production testing

o Accessing the Application Processor’s file system

o AT command access

o High-speed WWAN access to external host

o Diagnostic monitoring and debugging

o Communication between Java application environment

and an external host CPU

o NMEA data to an external host CPU

• HSIC

o High-speed 480 Mbps (240 MHz DDR) USB transfers are

100% host driver compatible with traditional USB cable

connected topologies

o Bidirectional data strobe signal (STROBE)

o Bidirectional data signal (DATA)

o No power consumption unless a transfer is in progress

o Maximum trace length 10 cm

o Signals driven at 1.2V standard LVCMOS levels

• Peripheral Ports – SPI, I2C, UART

• GPIOs

• Analog audio I/F

Rev. 4.3 Page 14 of 123 2017-12-07

Page 15

LE920A4 HW User Guide General Product Description

Doc#: 1VV0301261 Block Diagram

Function Features

Major software

features

• Advanced security features

o Boot integrity of firmware up to customer applications

o Disable/secure re-enable of debug

o Embedded security

• FOTA (optional)

• Telit Unified AT command set

• Java VM (optional) with the following features:

o Rich and standardized application environment for

customer applications

o State-of-the-art and high performance Java SE8

embedded Virtual Machine

o Oracle Java SE8 Embedded, Compact Profile 1

o JIT-enabled

Form factor Form factor (40x34mm), accommodating the multiple RF bands in

each region variant

Environment

and quality

requirements

The entire module is designed and qualified by Telit for satisfying the

environment and quality requirements for use in automotive

applications2.

Single supply

The module generates all its internal supply voltages.

module

RTC RTC is maintained as long as VBATT is supplied

Operating

temperature

Range -40 °C to +85 °C

(conditions as defined in Section 2.5.1,Temperature Range)

Block Diagram

Figure 1 shows an overview of the internal architecture of the module.

It includes the following sub-functions:

• Application processor, Modem subsystem and Location processing with their

external interfaces. These three functions are contained in a single SOC.

• RF front end, including antenna diagnosis circuitry

• Analog Audio codec for attaching external speaker amplifier and microphone

• Rich IO interfaces. Depending on which of the module’s software features are

enabled, some of its interfaces that are exported through multiplexing may be used

internally and thus may not be usable by the application.

• PMIC with the RTC function inside

2

In accordance with Telit’s Robustness Validation, using AEC-Q100-defined qualification tests

Rev. 4.3 Page 15 of 123 2017-12-07

Page 16

LE920A4 HW User Guide General Product Description

Doc#: 1VV0301261 Block Diagram

Figure 1: High-level Block Diagram

GNSS_Sync

GNSS Antennna

ANT

DIAG

Location

JTAG

HSICI2C

Memories

Modem

Application

Processor

UART

GPIO

USB2.0SGMIISPI

Frontend

2xSDIO

RF

RTC

PMIC

Audio

CODEC

ANT

DIAG

Ear / Line out

Microphone

SIM

PCM In/out

VBATT_PA

Cellular Antenna 1

Cellular Antenna 2

VBATT

ADC

Rev. 4.3 Page 16 of 123 2017-12-07

Page 17

LE920A4 HW User Guide General Product Description

Doc#: 1VV0301261 Environmental Requirements

Environmental Requirements

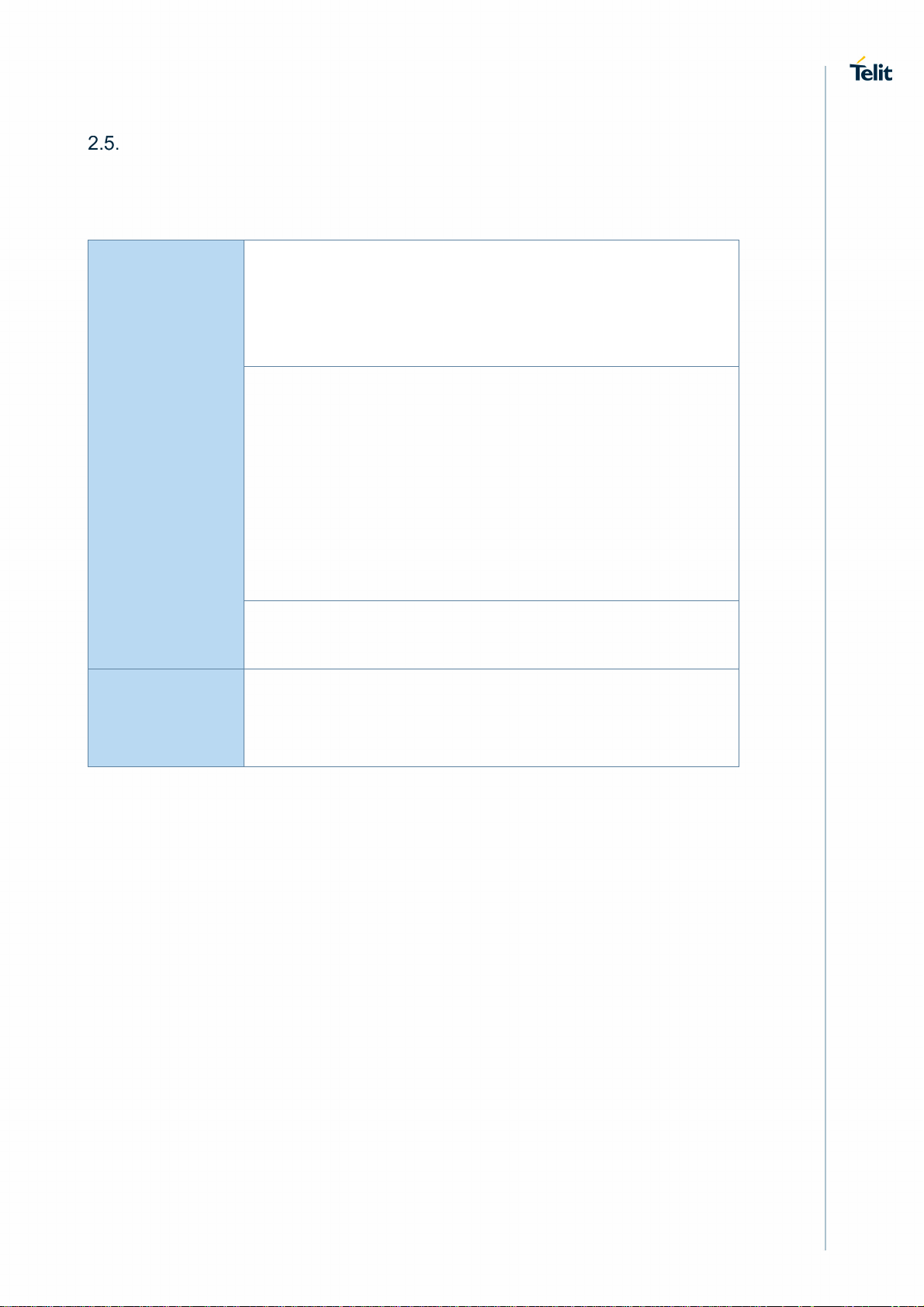

2.5.1. Temperature Range

Table 4: Temperature Range

Operating

temperature

range

Storage and nonoperating

temperature

range

-20 ~ +55°C

This range is defined by 3GPP (the global standard for

wireless mobile communication). Telit guarantees its modules

to comply with all the 3GPP requirements and to have full

functionality of the module with in this range.

-40 ~ +85°C

Telit guarantees full functionality within this range as well.

However, there may possibly be some performance deviations

in this extended range relative to 3GPP requirements, which

means that some RF parameters may deviate from the 3GPP

specification in the order of a few dB. For example: receiver

sensitivity or maximum output power may be slightly degraded.

Even so, all the functionalities, such as call connection, SMS,

USB communication, UART activation etc., will be maintained,

and the effect of such degradations will not lead to malfunction.

–40°C ~ +95°C

eCall must be functional (until the module is broken)

–40°C ~ +105°C

2.5.2. RoHS Compliance

As a part of Telit corporate policy of environmental protection, the module complies with

the RoHS (Restriction of Hazardous Substances) directive of the European Union (EU

directive 2011/65/EU).

Rev. 4.3 Page 17 of 123 2017-12-07

Page 18

LE920A4 HW User Guide General Product Description

Doc#: 1VV0301261 Frequency Bands

Frequency Bands

The operating frequencies in GSM850, EGSM900, DCS1800, PCS1900, WCDMA & LTE

modes conform to the 3GPP specifications.

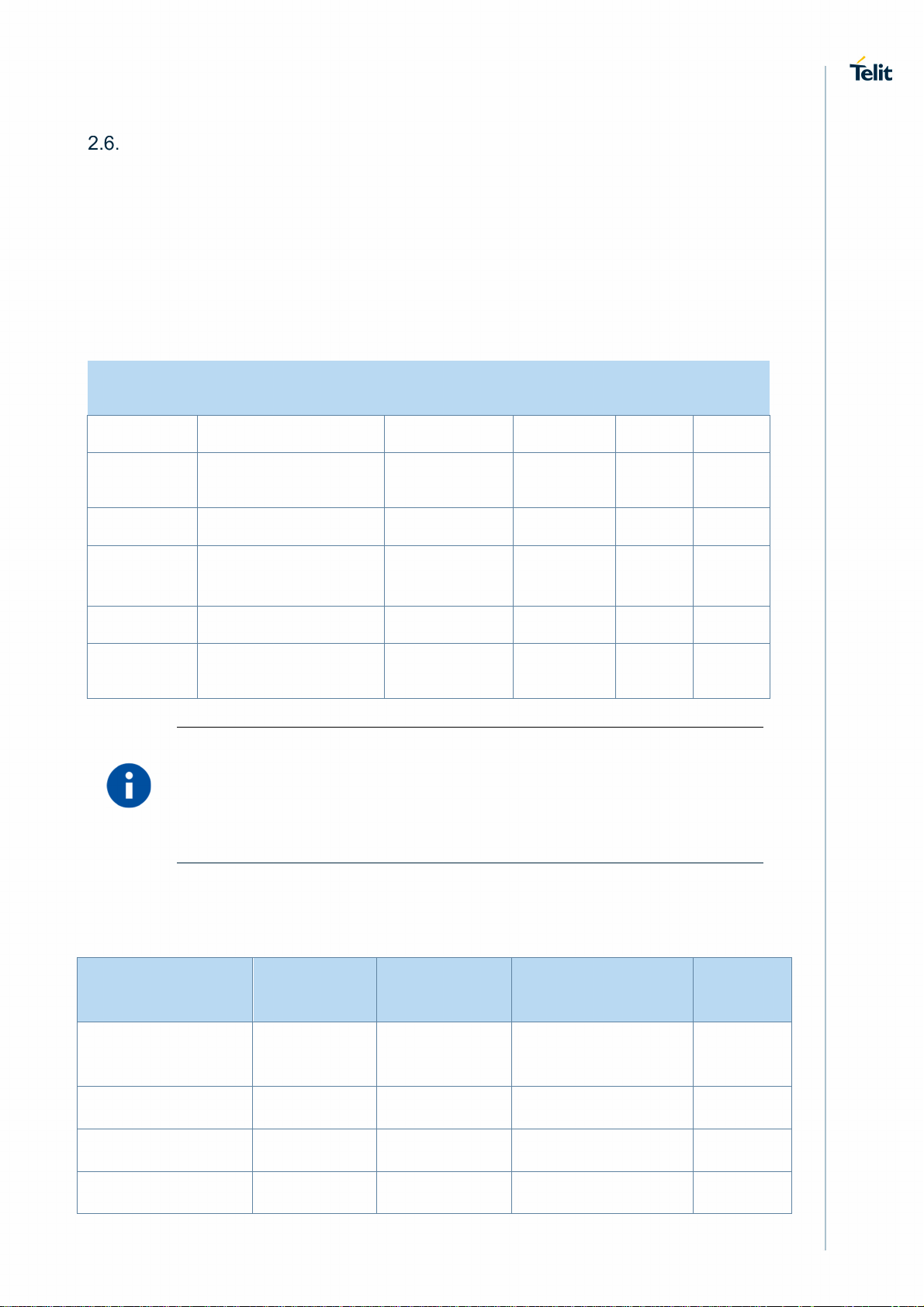

2.6.1. RF Bands per Regional Variant

Table 5 summarizes of all region variants within the module family, showing the supported

band sets in each variant.

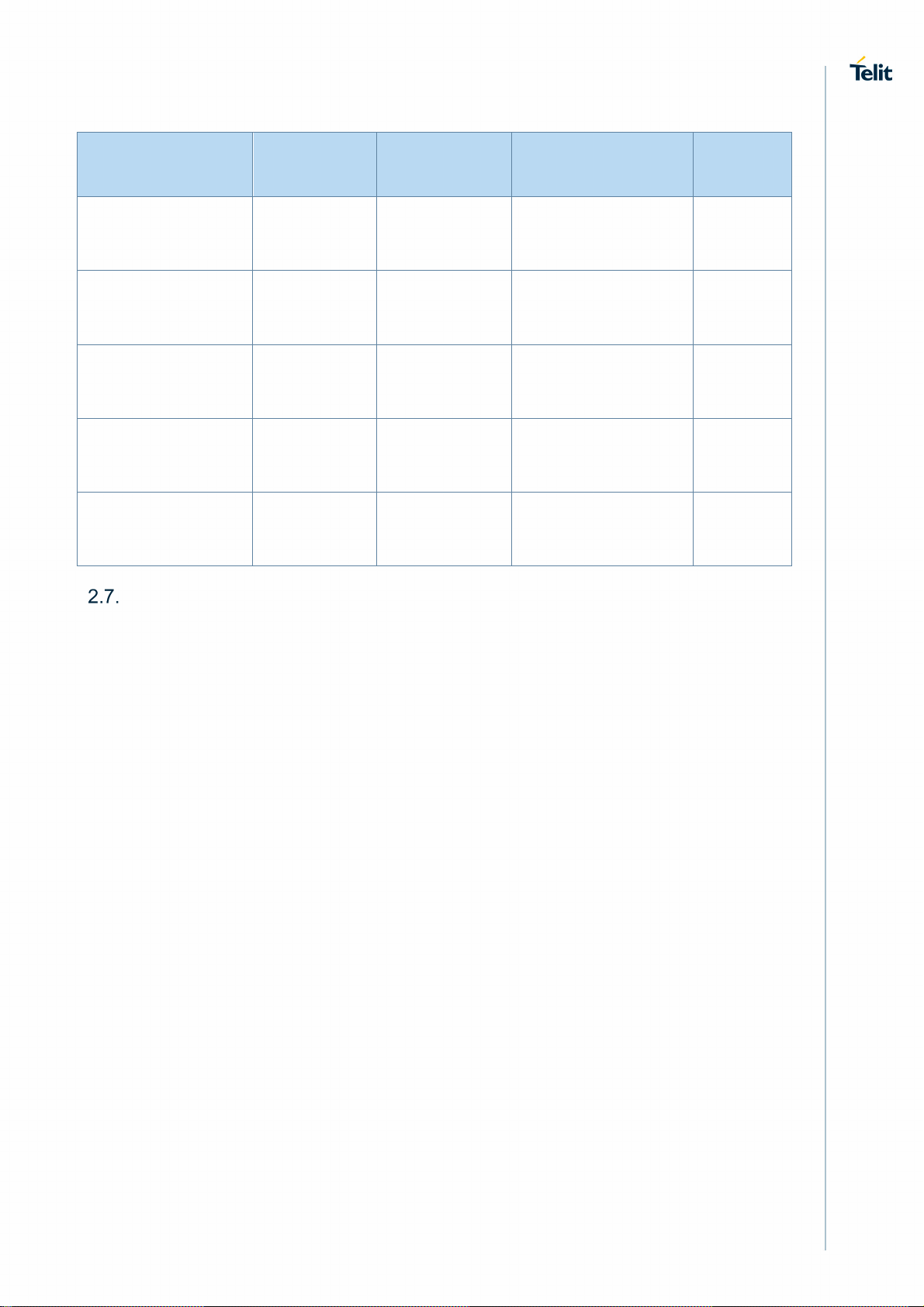

Table 5: RF Bands per Regional Variant

Region

Variant

LE920A4-NA 2, 4, 5, 7, 12 - 2, 4, 5 - 2, 5

LE920A4-NV

(TBD)

LE920A4-EU 1, 3, 5(*), 7, 8, 20, 28(*) - 1, 3, 5(*), 8 - 3, 8

HE920A-EU

(Non-LTE,

TBD)

LE920A4-CN 1, 3, 5, 8, 26 38, 39, 40, 41M 1, 5, 8 34, 39 3, 8

LE920A4-AP

(TBD)

2, 4, 5, 7(*), 13 - 2, 5 - -

- - 1, 3, 5, 8 - 2, 3, 5,

1, 3, 5, 7, 8, 19, 21, 26,

28

LTE FDD LTE TDD HSPA+

- 1, 3, 5, 6, 8,

19

TD-

SCDMA

8

- 2, 3, 5,

8

NOTE:

(*) Optional bands with a different schedule than the standard configuration,

can be removed if not required

Band 41M for China: 2,555-2,655 MHz

2G

2.6.2. Reference Table of RF Bands Characteristics

Table 6: RF Bands Characteristics

Mode

Freq. Tx

(MHz)

PCS 1900 1850.2 ~

1909.8

DCS 1800 1710 ~ 1785 1805 ~ 1880 512 ~ 885 95 MHz

GSM 850 824.2 ~ 848.8 869.2 ~ 893.8 128 ~ 251 45 MHz

EGSM 900 890 ~ 915 935 ~ 960 0 ~ 124 45 MHz

Rev. 4.3 Page 18 of 123 2017-12-07

Freq. Rx

(MHz)

1930.2 ~

1989.8

Channels

Tx-Rx

Offset

512 ~ 810 80 MHz

Page 19

LE920A4 HW User Guide General Product Description

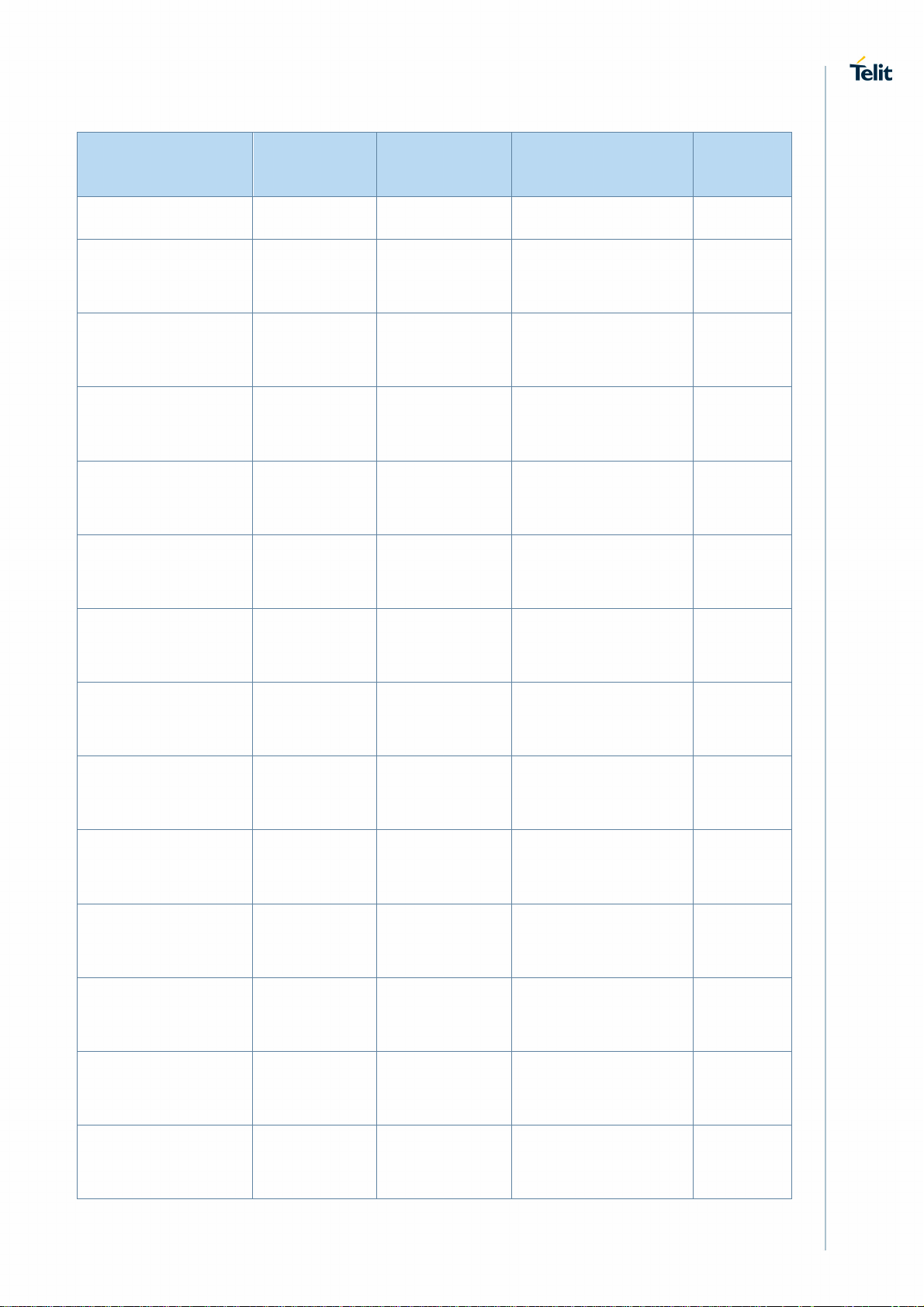

Doc#: 1VV0301261 Frequency Bands

Mode

Freq. Tx

(MHz)

Freq. Rx

(MHz)

Channels

880 ~ 890 925 ~ 935 975 ~ 1023 45 MHz

WCDMA 2100 – B1 1920 ~ 1980 2110 ~ 2170 Tx: 9612 ~ 9888

Rx: 10562 ~ 10838

WCDMA 1900 – B2 1850 ~ 1910 1930 ~ 1990 Tx: 9262 ~ 9538

Rx: 9662 ~ 9938

WCDMA 1800 – B3 1710 ~ 1785 1805 ~ 1880 Tx: 937 ~ 1288

Rx: 1162 ~ 1513

WCDMA AWS – B4 1710 ~ 1755 2110 ~ 2155 Tx: 1312 ~ 1513

Rx: 1537 ~ 1738

WCDMA 850 – B5 824 ~ 849 869 ~ 894 Tx: 4132 ~ 4233

Rx: 4357 ~ 4458

Tx-Rx

Offset

190 MHz

80 MHz

95 MHz

400 MHz

45 MHz

WCDMA 900 – B8 880 ~ 915 925 ~ 960 Tx: 2712 ~ 2863

Rx: 2937 ~ 3088

WCDMA 1800 – B9 1750 ~

1784.8

1845 ~ 1879.8 Tx: 8762 ~ 8912

Rx: 9237 ~ 9387

WCDMA 800 – B19 830 ~ 845 875 ~ 890 Tx: 312 ~ 363

Rx: 712 ~ 763

TDSCDMA 2000 –

B34

TDSCDMA 1900 –

B39

2010 ~ 2025 2010 ~ 2025 Tx: 10054 ~ 10121

Rx: 10054 ~ 10121

1880 ~ 1920 1880 ~ 1920 Tx: 9404 ~ 9596

Rx: 9404 ~ 9596

LTE 2100 – B1 1920 ~ 1980 2110 ~ 2170 Tx: 18000 ~ 18599

Rx: 0 ~ 599

LTE 1900 – B2 1850 ~ 1910 1930 ~ 1990 Tx: 18600 ~ 19199

45 MHz

95 MHz

45 MHz

0 MHz

0 MHz

190 MHz

80 MHz

Rx: 600 ~ 1199

LTE 1800 – B3 1710 ~ 1785 1805 ~ 1880 Tx: 19200 ~ 19949

95 MHz

Rx: 1200 ~ 1949

Rev. 4.3 Page 19 of 123 2017-12-07

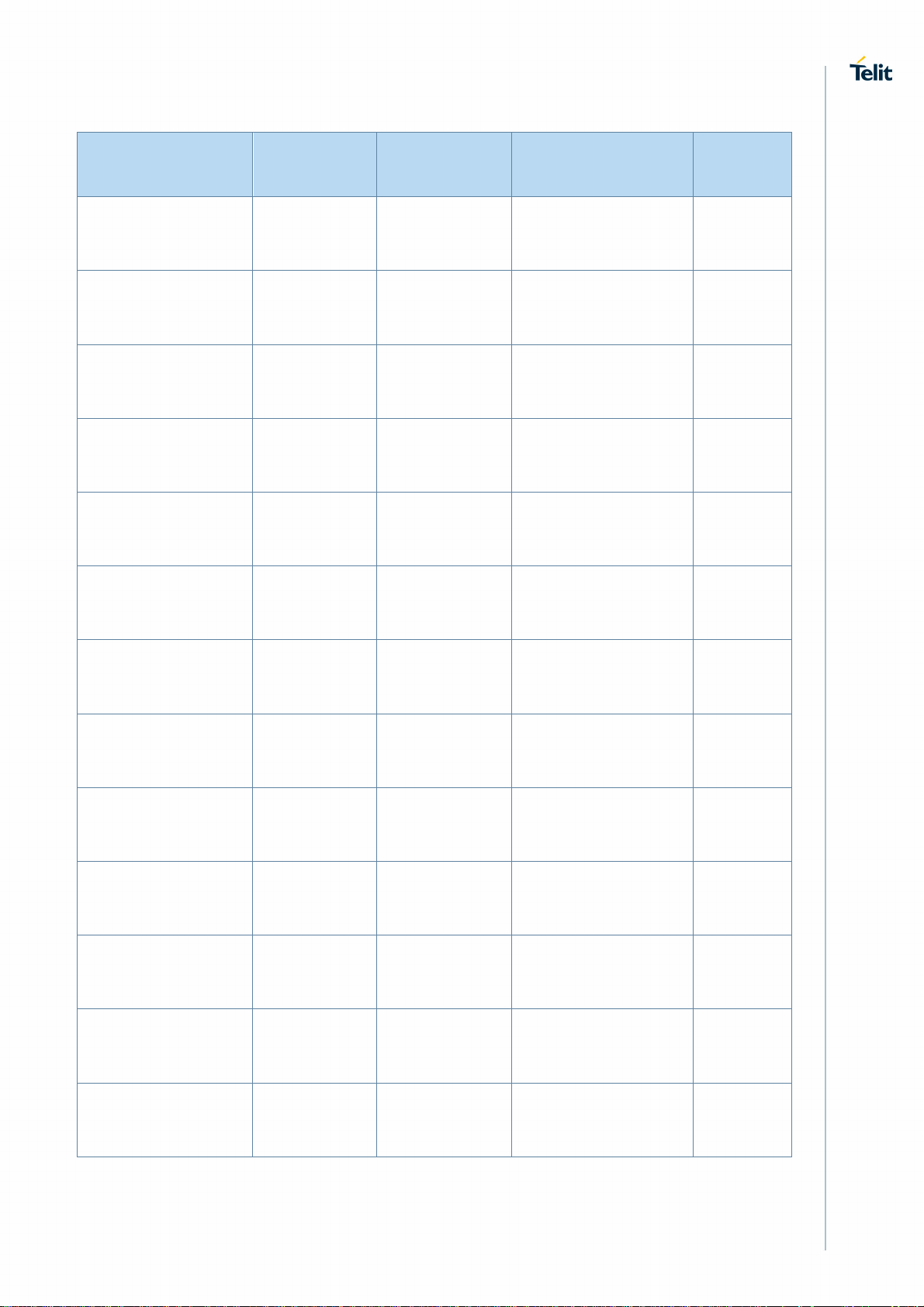

Page 20

LE920A4 HW User Guide General Product Description

Doc#: 1VV0301261 Frequency Bands

Mode

Freq. Tx

(MHz)

Freq. Rx

(MHz)

Channels

LTE AWS – B4 1710 ~ 1755 2110 ~ 2155 Tx: 19950 ~ 20399

Rx: 1950 ~ 2399

LTE 850 – B5 824 ~ 849 869 ~ 894 Tx: 20400 ~ 20649

Rx: 2400 ~ 2649

LTE 2600 – B7 2500 ~ 2570 2620 ~ 2690 Tx: 20750 ~ 21449

Rx: 2750 ~ 3449

LTE 900 – B8 880 ~ 915 925 ~ 960 Tx: 21450 ~ 21799

Rx: 3450 ~ 3799

LTE 1800 – B9 1749.9 ~

1784.9

1844.9 ~

1879.9

Tx: 21800 ~ 2149

Rx: 3800 ~ 4149

LTE AWS+ – B10 1710 ~ 1770 2110 ~ 2170 Tx: 22150 ~ 22749

Tx-Rx

Offset

400 MHz

45 MHz

120 MHz

45 MHz

95 MHz

400 MHz

Rx: 4150 ~ 4749

LTE 700a – B12 699 ~ 716 729 ~ 746 Tx : 23010 ~ 23179

Rx : 5010 ~ 5179

LTE 700c – B13 777 ~ 787 746 ~ 756 Tx : 27210 ~ 27659

Rx : 9210 ~ 9659

LTE 700b – B17 704 ~ 716 734 ~ 746 Tx: 23730 ~ 23849

Rx: 5730 ~ 5849

LTE 800 – B19 830 ~ 845 875 ~ 890 Tx: 24000 ~ 24149

Rx: 6000 ~ 6149

LTE 800 – B20 832 ~ 862 791 ~ 821 Tx: 24150 ~ 24449

Rx: 6150 ~ 6449

LTE 1500 – B21 1447.9 ~

1462.9

1495.9 ~

1510.9

Tx: 24450 ~ 24599

Rx: 6450 ~ 6599

30 MHz

-31 MHz

30 MHz

45 MHz

-41 MHz

48 MHz

LTE 850+ – B26 814 ~ 849 859 ~ 894 Tx: 26690 ~ 27039

45 MHz

Rx: 8690 ~ 9039

Rev. 4.3 Page 20 of 123 2017-12-07

Page 21

LE920A4 HW User Guide General Product Description

Doc#: 1VV0301261 RF parameters

Mode

LTE 700 – B28 703 ~ 748 758 ~ 803 Tx : 27210 ~ 27659

LTE TDD 2600 –

B38

LTE TDD 1900 –

B39

LTE TDD 2300 –

B40

LTE TDD 2500 –

B41M

Freq. Tx

(MHz)

2570 ~ 2620 2570 ~ 2620 Tx: 37750 ~ 38250

1880 ~ 1920 1880 ~ 1920 Tx: 38250 ~ 38650

2300 ~ 2400 2300 ~ 2400 Tx: 38650 ~ 39650

2555 ~ 2655 2555 ~ 2655 Tx: 40265 ~ 41215

Freq. Rx

(MHz)

Channels

Rx : 9210 ~ 9659

Rx: 37750 ~ 38250

Rx: 38250 ~ 38650

Rx: 38650 ~ 39650

Rx: 40265 ~ 41215

RF parameters

Tx-Rx

Offset

45 MHz

0 MHz

0 MHz

0 MHz

0 MHz

2.7.1. Sensitivity

The module’s maximum sensitivity levels are as follows:

• -108 dBm @ 2G

• -113 dBm @ 3G

• -102 dBm @ 4G FDD (BW=5 MHz)

2.7.2. Output power

LE920A4 typical values for Max output level are as follow:

• 2G:

- LB: 33dBm

- HB: 30dBm

• 3G/TD-SCDMA: 24dBm

• 4G (FDD & TDD):23dBm @1RB.

Rev. 4.3 Page 21 of 123 2017-12-07

Page 22

LE920A4 HW User Guide General Product Description

Doc#: 1VV0301261 Mechanical Dimensions

Mechanical Dimensions

The module’s overall dimensions are as follows:

• Length: 34 mm, +/- 0.15 mm tolerance

• Width: 40 mm, +/- 0.15 mm tolerance

• Thickness: 2.9 mm, +/- 0.15 mm tolerance

NOTE:

A typical label thickness of 0.11 mm should be considered in addition to the

module thickness

Weight

The nominal weight of the module is 9.0 gram.

Rev. 4.3 Page 22 of 123 2017-12-07

Page 23

LE920A4 HW User Guide Module Connections

Doc#: 1VV0301261 Pin-out

3. Module Connections

Pin-out

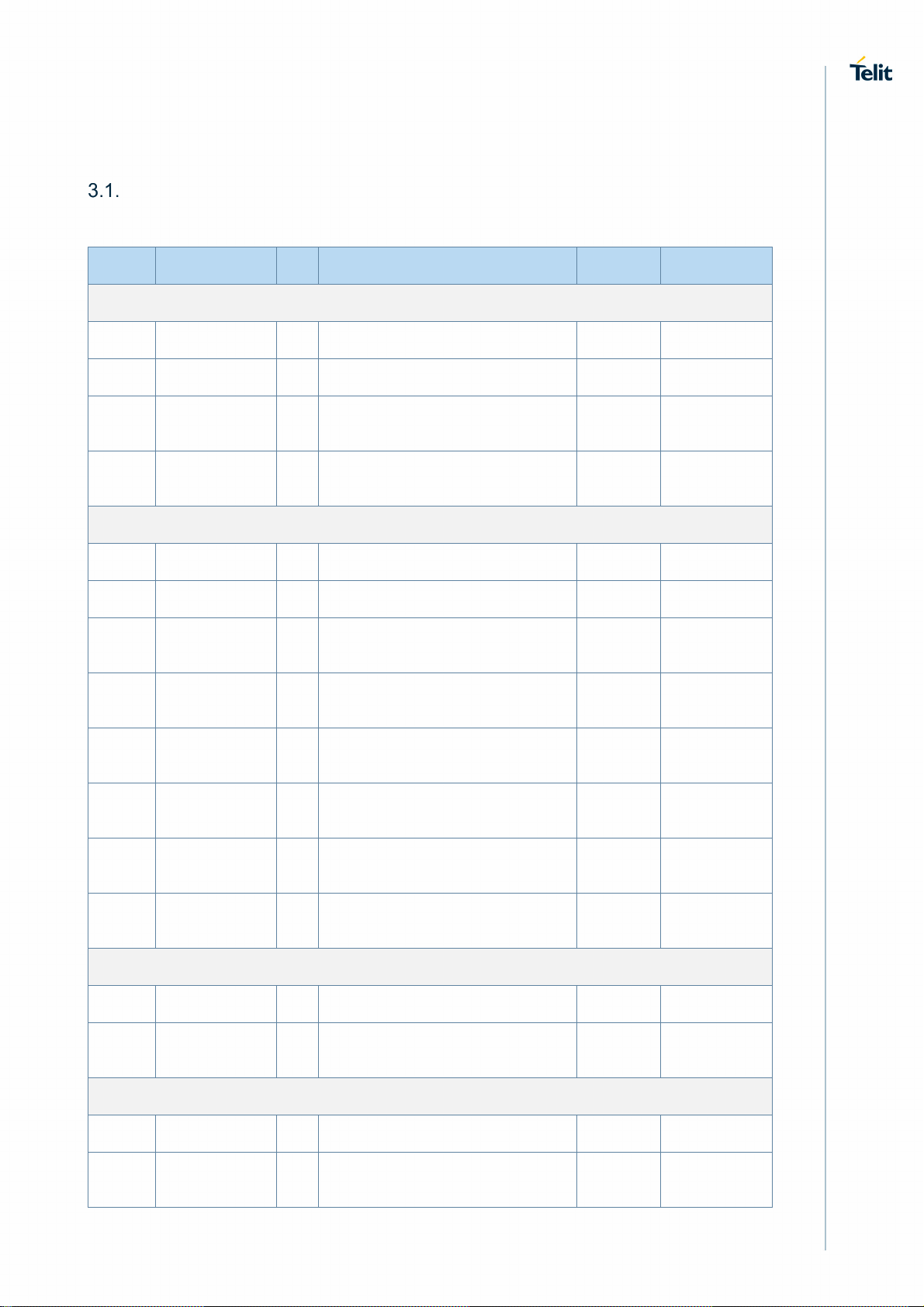

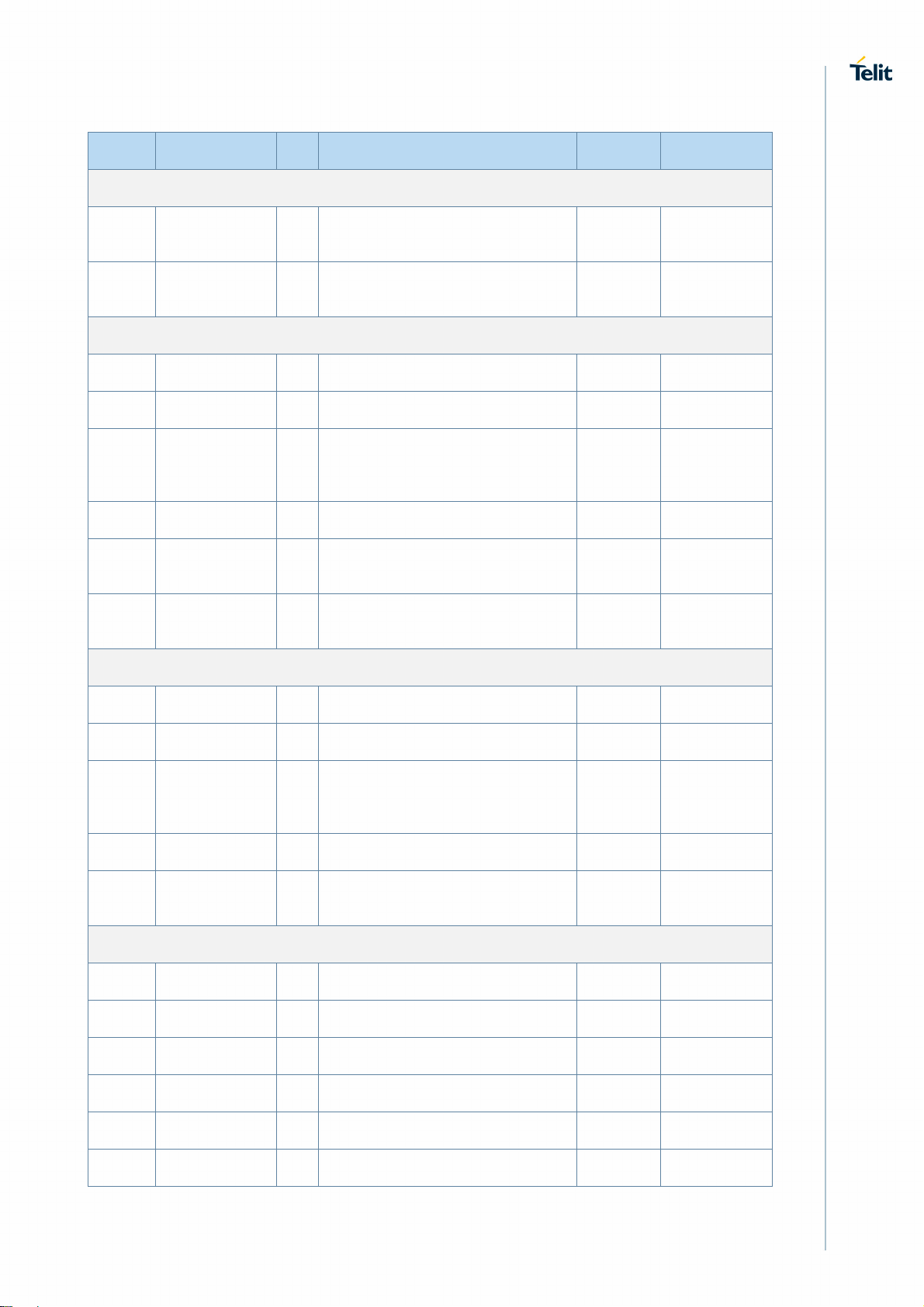

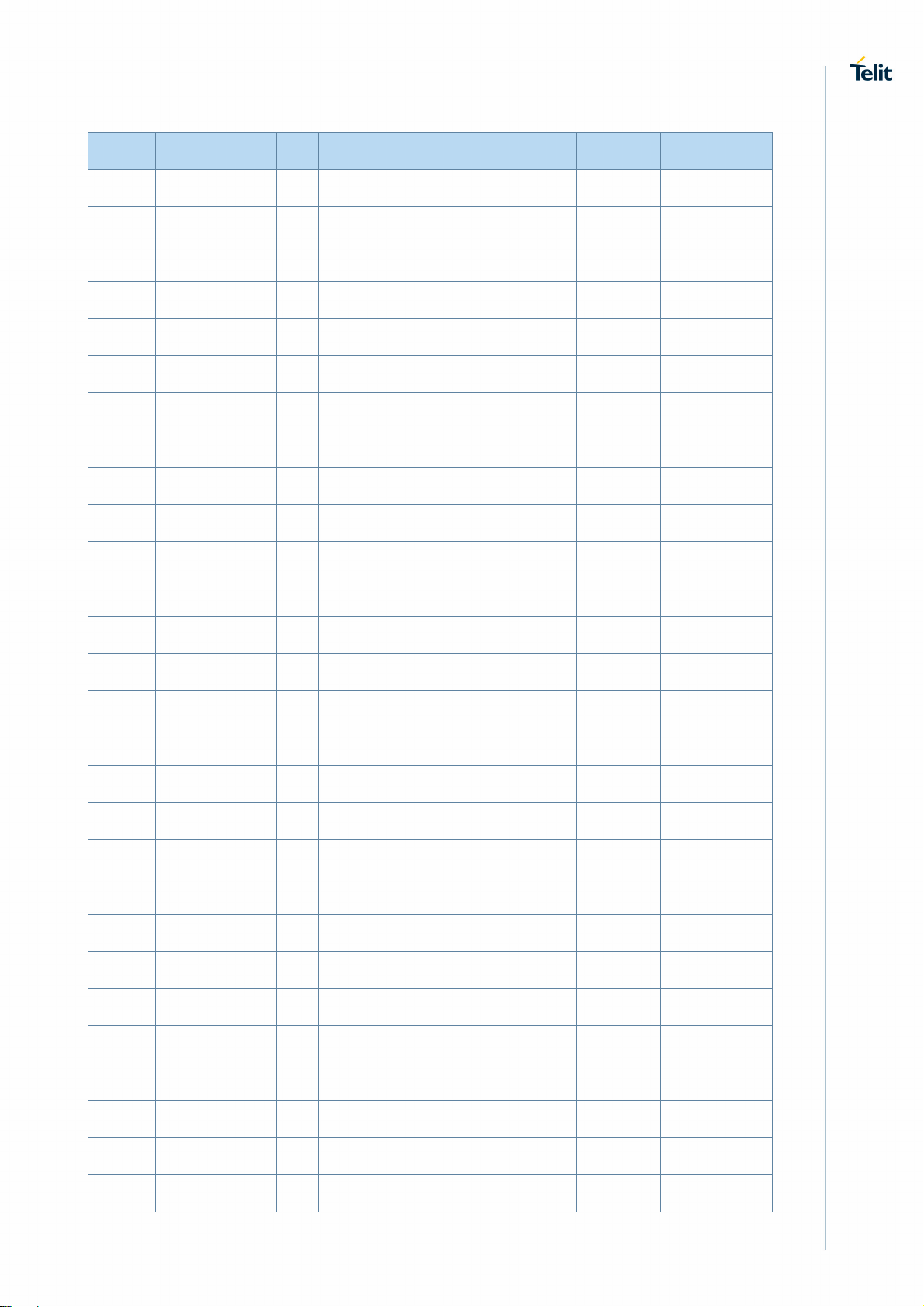

Table 7: Pin-out

PAD Signal I/O Function Type Comment

USB HS 2.0 Communication Port

D19 USB_D+ I/O USB differential data(+)

F19 USB_D- I/O USB differential data(-)

A18 USB_VBUS AI Power sense for the internal USB

transceiver

B19 USB_ID AI USB ID for supporting USB2.0

OTG

Asynchronous UART

AH19 C103/TXD I Serial data input (TXD) from DTE 1.8V

AF19 C104/RXD O Serial data output to DTE 1.8V

AA18 C105/RTS I

AK19 C106/CTS O Output for Clear To Send signal

AG18 C107/DSR O Output for Data Set Ready (DSR)

AC18 C108/DTR I Input for Data Terminal Ready

AE18 C109/DCD O Output for Data Carrier Detect

Input for Request To Send signal

(RTS) from DTE

(CTS) to DTE

to DTE

(DTR) from DTE

(DCD) to DTE

Power

1.8V

1.8V

1.8V Alternate Fn

1.8V Alternate Fn

1.8V Alternate Fn

GPIO_32

GPIO_34

GPIO_33

AJ18 C125/RING O

Asynchronous Auxiliary UART

AB19 TX_AUX O Auxiliary UART (Tx Data to DTE) 1.8V

AD19 RX_AUX I Auxiliary UART (Rx Data from

SPI – Serial Peripheral Interface

P19 SPI_CLK O SPI clock output 1.8V

M19 SPI_MISO I

Output for Ring Indication (RI) to

DTE

DTE)

SPI data Master Input Slave

Output

1.8V

1.8V

1.8V

Alternate Fn

GPIO_31

Rev. 4.3 Page 23 of 123 2017-12-07

Page 24

LE920A4 HW User Guide Module Connections

Doc#: 1VV0301261 Pin-out

PAD Signal I/O Function Type Comment

K19 SPI_MOSI O

N18 SPI_CS O SPI chip select output 1.8V

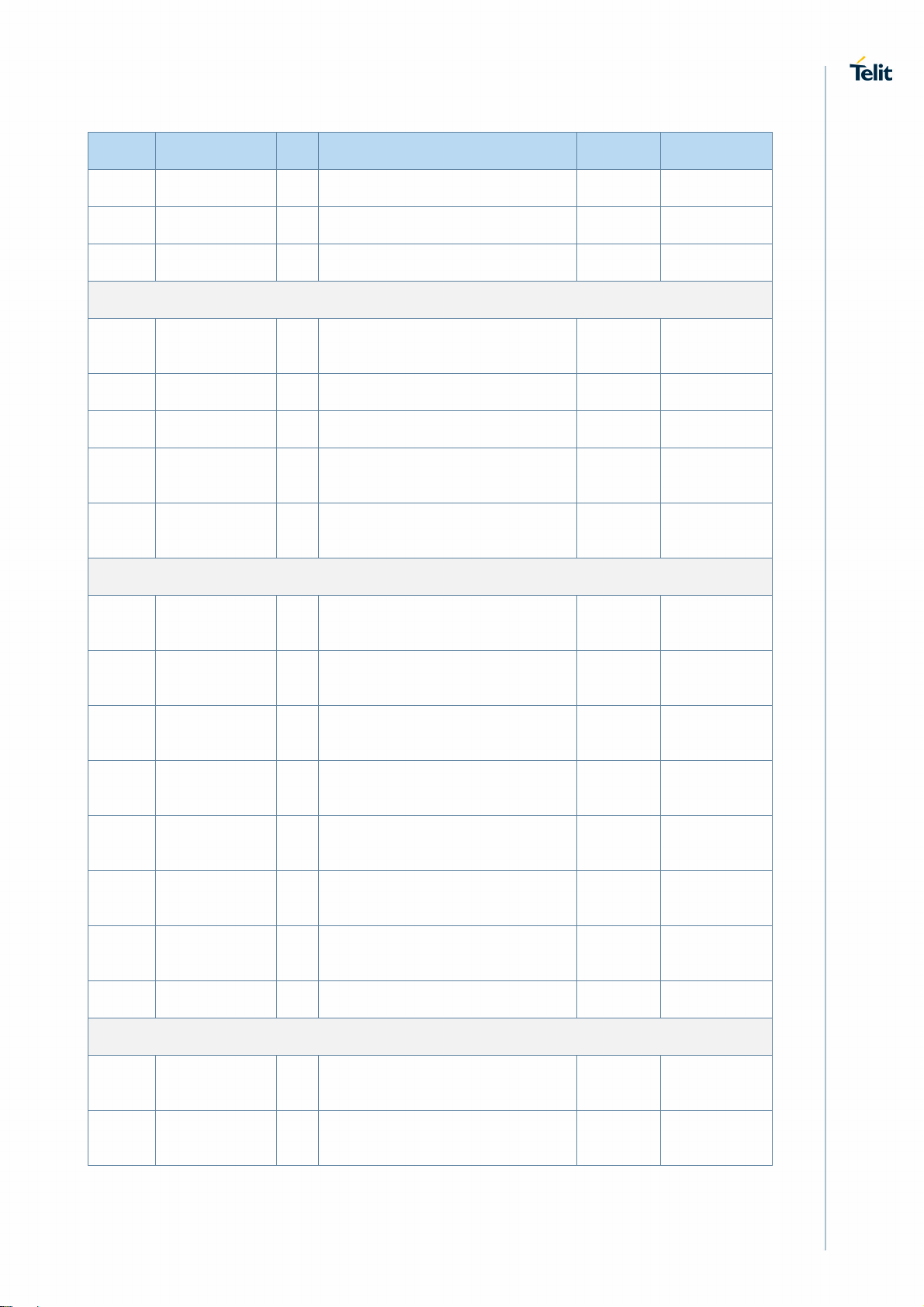

SD/MMC Card Interface

AH17

AD17 SD/MMC_CLK O SD card clock 1.8/2.95V

Y17

AF17

AB17

W17

U17 SD/MMC_CD I SD card detect input 1.8V Active Low

SD/MMC_CM

D

SD/MMC_DAT

A0

SD/MMC_DAT

A1

SD/MMC_DAT

A2

SD/MMC_DAT

A3

SPI data Master Output Slave

Input

I/O SD command 1.8/2.95V

I/O SD Serial Data 0 1.8/2.95V

I/O SD Serial Data 1 1.8/2.95V

I/O SD Serial Data 2 1.8/2.95V

I/O SD Serial Data 3 1.8/2.95V

1.8V

S17 VMMC -

WiFi (SDIO) Interface

AB3

AM3 WiFi_SD_CLK O WiFi SD clock 1.8V

AD3

AF3

AH3

AK3

Y3 WiFi_SDRST O WiFi Reset / Power enable control 1.8V Active Low

AA4

WiFi_SD_CM

D

WiFi_SD_DAT

A0

WiFi_SD_DAT

A1

WiFi_SD_DAT

A2

WiFi_SD_DAT

A3

WLAN_SLEEP

_CLK

Power supply for MMC card pullup resistors

I/O WiFi SD command 1.8V

I/O WiFi SD Serial Data 0 1.8V

I/O WiFi SD Serial Data 1 1.8V

I/O WiFi SD Serial Data 2 1.8V

I/O WiFi SD Serial Data 3 1.8V

O WiFi Sleep clock output 1.8V

1.8/2.95V

X4 RFCLK2_QCA O WiFi low-noise RF clock output 1.8V

Rev. 4.3 Page 24 of 123 2017-12-07

Page 25

LE920A4 HW User Guide Module Connections

Doc#: 1VV0301261 Pin-out

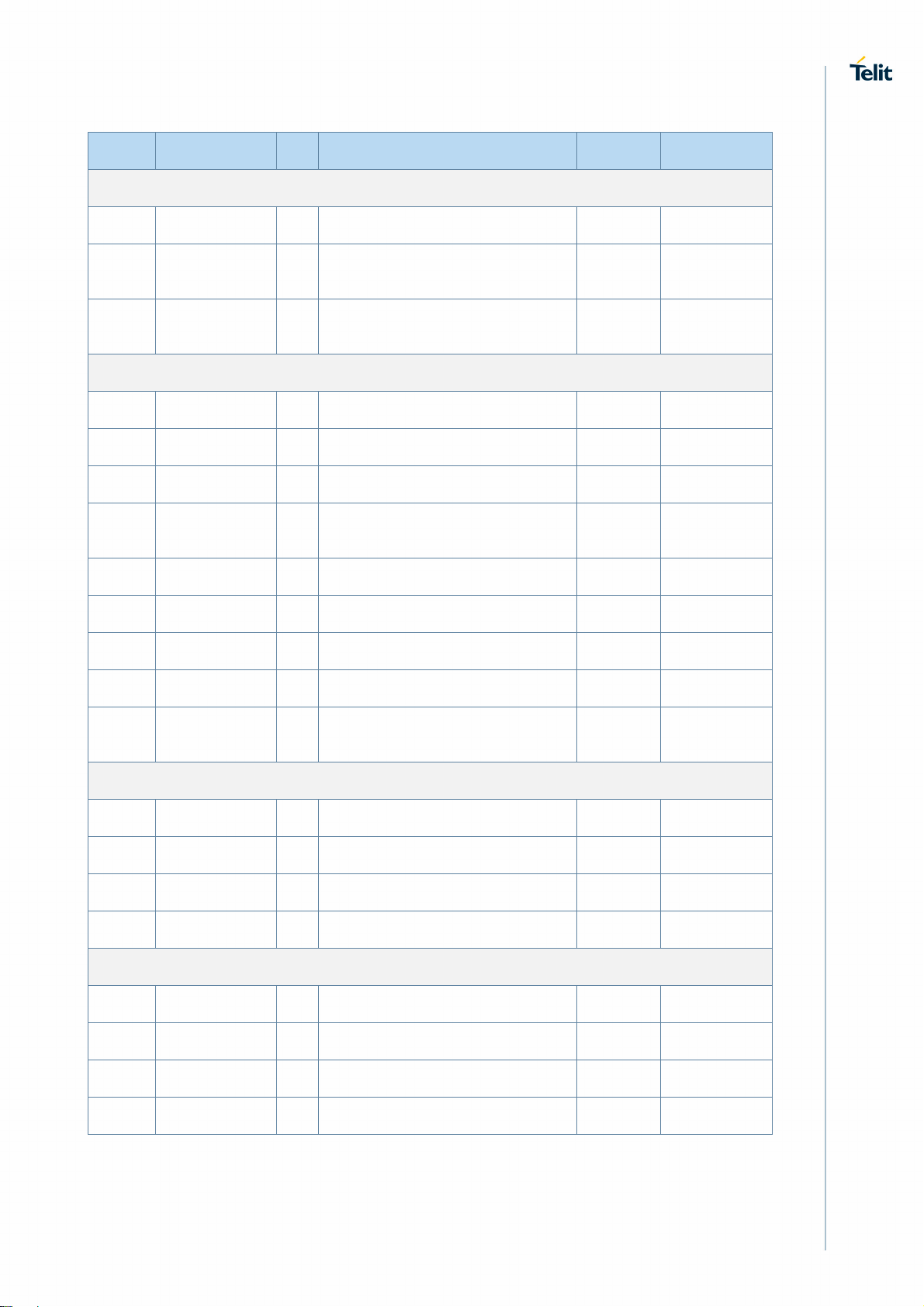

PAD Signal I/O Function Type Comment

LTE-WiFi Coexistence

AS3 WCI_TX O

AT2 WCI_RX

SIM Card Interface 1

A10 SIMCLK1 O External SIM 1 signal – Clock 1.8/2.85V

B11 SIMRST1 O External SIM 1 signal – Reset 1.8/2.85V

B9 SIMIO1 I/O External SIM 1 signal - Data I/O 1.8/2.85V

B7 SIMIN1 I External SIM1 signal - Presence 1.8V Active low

A8 SIMVCC1 - External SIM1 signal – power

E8 Reserved for

ESIM_RST

SIM Card Interface 2

Wireless coexistence interface

TXD

Wireless coexistence interface

I

RXD

supply for SIM1

I Reserved for eSIM signal – Reset 1.8/2.85V Reserved

1.8V

1.8V

Internally PU

20 kΩ to

SIMVCC1

1.8/2.85V

C16 SIMCLK2 O External SIM 2 signal – Clock 1.8/2.85V

D17 SIMRST2 O External SIM 2 signal – Reset 1.8/2.85V

E16 SIMIO2 I/O External SIM 2 signal – Data I/O 1.8/2.85V Internally PU

20kΩ to

SIMVCC2

C18 SIMIN2 I External SIM 2 signal – Presence 1.8V Active low

D15 SIMVCC2 - External SIM2 signal – Power

supply for SIM2

Analog Audio interface

B5 EAR1_MT+ AO Earphone signal output1, phase + Audio

A4 EAR1_MT- AO Earphone signal output1, phase - Audio

B3 MIC1_MT+ AI Mic signal input1, phase + Audio

A2 MIC1_MT- AI Mic signal input1, phase - Audio

G6 MICBIAS AO Mic BIAS Audio

1.8/2.85V

E2 EAR2_MT+ AO Earphone signal output2, phase + Audio

Rev. 4.3 Page 25 of 123 2017-12-07

Page 26

LE920A4 HW User Guide Module Connections

Doc#: 1VV0301261 Pin-out

PAD Signal I/O Function Type Comment

D1 EAR2_MT- AO Earphone signal output2, phase - Audio

C2 MIC2_MT+ AI Mic signal input2, phase + Audio

B1 MIC2_MT- AI Mic signal input2, phase - Audio

Digital Voice Interface (DVI)

D11 DVI_WA0 O Digital Voice interface (WA0

master output)

C8 DVI_RX I Digital Voice interface (Rx) 1.8V

D9 DVI_TX O Digital Voice interface (Tx) 1.8V

C10 DVI_CLK O Digital Voice interface (CLK master

output)

C12 REF_CLK O Reference clock for external

Codec

General Purpose Digital I/O

F9 GPIO_01 I/O GPIO_01 1.8V Alternate Fn

E10 GPIO_02 I/O GPIO_02 1.8V Alternate Fn

F11 GPIO_03 I/O GPIO_03 1.8V Alternate Fn

E12 GPIO_04 I/O GPIO_04 1.8V Alternate Fn

1.8V

1.8V

1.8V

I2C

I2C

I2C

I2C

F13 GPIO_05 I/O GPIO_05 1.8V

E14 GPIO_06 I/O GPIO_06 1.8V Alternate Fn

W19 GPIO_10 I/O GPIO_10 1.8V Alternate Fn

AN4 GPIO_20 I/O GPIO_20 1.8V

RF Section

AD1 Antenna I/O GSM/EDGE/UMTS/LTE main

antenna (50 Ohm)

AU9 ANT_DIV I UMTS/LTE antenna diversity input

(50 Ohm)

RF

RF

Alternate Fn

I2C

I2C

I2C

Rev. 4.3 Page 26 of 123 2017-12-07

Page 27

LE920A4 HW User Guide Module Connections

Doc#: 1VV0301261 Pin-out

PAD Signal I/O Function Type Comment

GPS Section

S1 ANT_GPS I GPS antenna (50 Ohm) RF

V2 GPS_LNA_EN O Enables the external regulator for

GPS LNA

W3 GPS_SYNC O GPS sync signal for Dead

Reckoning

Miscellaneous Functions

AN8 RESET_N I Reset input Active low

AS1 ON_OFF_N I Power ON / Power OFF input Active low

AN12 SHDN_N I Unconditional Shutdown input Active low

P17 VAUX/PWRM

ON

D5 ADC_IN1 AI Analog/Digital Converter Input 1 Analog

E6 ADC_IN2 AI Analog/Digital Converter Input 2 Analog

F7 ADC_IN3 AI Analog/Digital Converter Input 3 Analog

AU3 STAT_LED O Status Indicator LED 1.8V

O Supply output for external

accessories / Power ON monitor

1.8V

1.8V

1.8V

AN10 SW_RDY O Indicates that the boot sequence

has completed successfully

SGMII Interface

ZZ11 SGMII_RX_P AI SGMII receive - plus PHY

ZZ13 SGMII_RX_M AI SGMII receive - minus PHY

ZZ15 SGMII_TX_P AO SGMII transmit - plus PHY

ZZ17 SGMII_TX_M AO SGMII transmit - minus PHY

Ethernet PHY Control Interface

G14 MAC_MDC O MAC to PHY Clock 2.85V

G12 MAC_MDIO I/O MAC to PHY Data 2.85V

G8 ETH_RST_N O Ethernet PHY Reset 2.85V

G10 ETH_INT_N I Ethernet PHY Interrupt 1.8V

1.8V

Rev. 4.3 Page 27 of 123 2017-12-07

Page 28

LE920A4 HW User Guide Module Connections

Doc#: 1VV0301261 Pin-out

PAD Signal I/O Function Type Comment

HSIC Interface

A14 HSIC_DATA I/O High-speed inter-chip interface -

data

A16 HSIC_STB I/O High-speed inter-chip interface -

strobe

I2C Interface

C14 I2C_SCL I/O I2C clock 1.8V

D13 I2C_SDA I/O I2C Data 1.8V Internal PU

Power Supply

AP17 VBATT - Main Power Supply (Digital

Section)

AP19 VBATT -

AR18 VBATT - Main Power Supply (Digital

Main Power Supply (Digital

Section)

Section)

1.2V

1.2V

Internal PU

2.2 kΩ to

1.8V

2.2 kΩ to

1.8V

Power

Power

Power

AR20 VBATT - Main Power Supply (Digital

Section)

AS17 VBATT_PA - Main Power Supply (RF Section) Power

AS19 VBATT_PA - Main Power Supply (RF Section) Power

AT18 VBATT_PA - Main Power Supply (RF Section) Power

AU17 VBATT_PA - Main Power Supply (RF Section) Power

AU19 VBATT_PA - Main Power Supply (RF Section) Power

AT20 VBATT_PA - Main Power Supply (RF Section) Power

A0 GND - Ground

N0 GND Ground

R0 GND - Ground

T0 GND - Ground

V0 GND - Ground

Power

X0 GND - Ground

Rev. 4.3 Page 28 of 123 2017-12-07

Page 29

LE920A4 HW User Guide Module Connections

Doc#: 1VV0301261 Pin-out

PAD Signal I/O Function Type Comment

AA0 GND - Ground

AC0 GND - Ground

AE0 GND - Ground

AG0 GND - Ground

AJ0 GND - Ground

AL0 GND - Ground

AN0 GND - Ground

AR0 GND - Ground

AV0 GND - Ground

ZZ1 GND - Ground

F1 GND - Ground

M1 GND - Ground

P1 GND - Ground

U1 GND - Ground

W1 GND - Ground

Y1 GND - Ground

AB1 GND - Ground

AF1 GND - Ground

AH1 GND - Ground

AK1 GND - Ground

AU1 GND - Ground

N2 GND - Ground

R2 GND - Ground

T2 GND - Ground

X2 GND - Ground

AA2 GND - Ground

AC2 GND - Ground

AE2 GND - Ground

Rev. 4.3 Page 29 of 123 2017-12-07

Page 30

LE920A4 HW User Guide Module Connections

Doc#: 1VV0301261 Pin-out

PAD Signal I/O Function Type Comment

AG2 GND - Ground

AJ2 GND - Ground

AL2 GND - Ground

AN2 GND - Ground

AR2 GND - Ground

D3 GND - Ground

P3 GND - Ground

AP3 GND - Ground

C4 GND - Ground

AR4 GND - Ground

AT4 GND - Ground

AP5 GND - Ground

AS5 GND - Ground

AU5 GND - Ground

A6 GND - Ground

C6 GND - Ground

AR6 GND - Ground

AT6 GND - Ground

D7 GND - Ground

AP7 GND - Ground

AS7 GND - Ground

AU7 GND - Ground

T8 GND - Ground

V8 GND - Ground

X8 GND - Ground

AA8 GND - Ground

AR8 GND - Ground

AT8 GND - Ground

Rev. 4.3 Page 30 of 123 2017-12-07

Page 31

LE920A4 HW User Guide Module Connections

Doc#: 1VV0301261 Pin-out

PAD Signal I/O Function Type Comment

AV8 GND - Ground

U9 GND - Ground

W9 GND - Ground

Y9 GND - Ground

AP9 GND - Ground

AS9 GND - Ground

T10 GND - Ground

V10 GND - Ground

X10 GND - Ground

AA10 GND - Ground

AR10 GND - Ground

AT10 GND - Ground

AV10 GND - Ground

U11 GND - Ground

W11 GND - Ground

Y11 GND - Ground

AP11 GND - Ground

AS11 GND - Ground

AU11 GND - Ground

A12 GND - Ground

T12 GND - Ground

V12 GND - Ground

X12 GND - Ground

AA12 GND - Ground

AR12 GND - Ground

AT12 GND - Ground

AV12 GND - Ground

B13 GND - Ground

Rev. 4.3 Page 31 of 123 2017-12-07

Page 32

LE920A4 HW User Guide Module Connections

Doc#: 1VV0301261 Pin-out

PAD Signal I/O Function Type Comment

AP13 GND - Ground

AS13 GND - Ground

AR14 GND - Ground

AT14 GND - Ground

AV14 GND - Ground

B15 GND - Ground

AP15 GND - Ground

AS15 GND - Ground

AU15 GND - Ground

AN16 GND - Ground

AR16 GND - Ground

AT16 GND - Ground

AV16 GND - Ground

B17 GND - Ground

AK17 GND - Ground

AM17 GND - Ground

E18 GND - Ground

G18 GND - Ground

T18 GND - Ground

V18 GND - Ground

X18 GND - Ground

AL18 GND - Ground

AN18 GND - Ground

AV18 GND - Ground

ZZ19 GND - Ground

H19 GND - Ground

Y19 GND - Ground

AM19 GND - Ground

Rev. 4.3 Page 32 of 123 2017-12-07

Page 33

LE920A4 HW User Guide Module Connections

Doc#: 1VV0301261 Pin-out

PAD Signal I/O Function Type Comment

A20 GND - Ground

L20 GND - Ground

N20 GND - Ground

AV20 GND - Ground

Reserved

C0 Reserved - Reserved

E0 Reserved - Reserved

G0 Reserved - Reserved

J0 Reserved - Reserved

L0 Reserved - Reserved

AT0 Reserved - Reserved

K1 Reserved - Reserved

AM1 Reserved - Reserved

G2 Reserved - Reserved

J2 Reserved - Reserved

L2 Reserved - Reserved

AV2 Reserved - Reserved

ZZ3 Reserved - Reserved

F3 Reserved - Reserved

H3 Reserved - Reserved

K3 Reserved - Reserved

M3 Reserved - Reserved

S3 Reserved - Reserved

U3 Reserved - Reserved

E4 Reserved - Reserved

G4 Reserved - Reserved

J4 Reserved - Reserved

L4 Reserved - Reserved

Rev. 4.3 Page 33 of 123 2017-12-07

Page 34

LE920A4 HW User Guide Module Connections

Doc#: 1VV0301261 Pin-out

PAD Signal I/O Function Type Comment

N4 Reserved - Reserved

R4 Reserved - Reserved

T4 Reserved - Reserved

V4 Reserved - Reserved

AG4 Reserved - Reserved

AJ4 Reserved - Reserved

AL4 Reserved - Reserved

AV4 Reserved - Reserved

ZZ5 Reserved - Reserved

F5 Reserved - Reserved

AM5 Reserved - Reserved

AN6 Reserved - Reserved

AV6 Reserved - Reserved

ZZ7 Reserved - Reserved

AM7 Reserved - Reserved

AP1 Reserved - Reserved for RESET_N in case

that backward compatibility to

LE920 is needed (instead of Pad

AN8)

ZZ9 Reserved - Reserved

AM9 Reserved - Reserved

AM11 Reserved - Reserved

AM13 Reserved - Reserved

Refer to Sec.

5.3.3,

Unconditional

Hardware

Reset

AU13 Reserved - Reserved

AN14 Reserved - Reserved

F15 Reserved - Reserved

AM15 Reserved - Reserved

G16 Reserved - Reserved

J16 Reserved - Reserved

Rev. 4.3 Page 34 of 123 2017-12-07

Page 35

LE920A4 HW User Guide Module Connections

Doc#: 1VV0301261 Pin-out

PAD Signal I/O Function Type Comment

L16 Reserved - Reserved

N16 Reserved - Reserved

R16 Reserved - Reserved

T16 Reserved - Reserved

V16 Reserved - Reserved

X16 Reserved - Reserved

AA16 Reserved - Reserved

AC16 Reserved - Reserved

AE16 Reserved - Reserved

AG16 Reserved - Reserved

AJ16 Reserved - Reserved

AL16 Reserved - Reserved

F17 Reserved - Reserved

H17 Reserved - Reserved

K17 Reserved - Reserved

M17 Reserved - Reserved

C20 Reserved - Reserved

E20 Reserved - Reserved

G20 Reserved - Reserved

J20 Reserved - Reserved

R20 Reserved - Reserved

T20 Reserved - Reserved

V20 Reserved - Reserved

X20 Reserved - Reserved

AA20 Reserved - Reserved

AC20 Reserved - Reserved

AE20 Reserved - Reserved

AG20 Reserved - Reserved

Rev. 4.3 Page 35 of 123 2017-12-07

Page 36

LE920A4 HW User Guide Module Connections

Doc#: 1VV0301261 Pin-out

PAD Signal I/O Function Type Comment

AJ20 Reserved - Reserved

AL20 Reserved - Reserved

AN20 Reserved - Reserved

R18 Reserved - Reserved

S19 Reserved - Reserved

U19 Reserved - Reserved

L18 Reserved - Reserved

J18 Reserved - Reserved

H1 Reserved - Reserved

AE4 Reserved - Reserved

AC4 Reserved - Reserved

WARNING:

GPIO_20 and WCI_RX are used as special HW flags during boot.

If they are used as GPIOs, they must be connected via a 3-state buffer to

avoid any undesirable effect during the boot.

NOTE:

When the UART signals are used as the communication port between the

Host and the Modem, RTS must be connected to GND (on the module side)

if flow control is not used.

If the UART port is not used, UART signals can be left floating.

NOTE:

Unless otherwise specified, RESERVED pins must be left unconnected

(floating).

The only exceptions are listed in the Section 3.2, Signals That Must Be

Connected.

Rev. 4.3 Page 36 of 123 2017-12-07

Page 37

LE920A4 HW User Guide Module Connections

Doc#: 1VV0301261 Signals That Must Be Connected

Signals That Must Be Connected

Table 8 lists the signals that must be connected even if not used by the end application.

Table 8: Mandatory Signals

PAD Signal Notes

AP17, AP19, AR18, AR20, AS17,

AS19, AT18, AU17, AU19, AT20

A0, N0, R0, T0, V0, X0, AA0, AC0,

AE0, AG0, AJ0, AL0,

AN0, AR0, AV0, ZZ1, F1, M1, P1, U1,

W1, Y1, AB1, AF1,

AH1, AK1, AU1, N2, R2, T2, X2, AA2,

AC2, AE2, AG2,

AJ2, AL2, AN2, AR2, D3, P3, AP3, C4,

AR4, AT4, AP5,

AS5, AU5, A6, C6, AR6, AT6, D7, AP7,

AS7, AU7, T8, V8, X8, AA8, AR8, AT8,

AV8, U9, W9, Y9, AP9, AS9, T10, V10,

X10, AA10, AR10, AT10, AV10, U11,

W11, Y11, AP11,

AS11, AU11, A12, T12, V12, X12,

AA12, AR12, AT12,

AV12, B13, AP13, AS13, AR14, AT14,

AV14, B15, AP15,

VBATT &

VBATT_PA

GND

AS15, AU15, AN16, AR16, AT16,

AV16, B17, AK17,

AM17, E18, G18, T18, V18, X18, AL18,

AN18, AV18,

ZZ19, H19, Y19, AM19, A20, L20, N20,

AV20

AS1 ON/OFF Main power on off signal

AN12 SHDN_N Emergency power off

D19 USB_D+ If not used, connect to a

test point or an USB

connector

F19 USB_D- If not used, connect to a

test point or an USB

connector

A18 USB_VBUS If not used, connect to a

test point or an USB

connector

Rev. 4.3 Page 37 of 123 2017-12-07

Page 38

LE920A4 HW User Guide Module Connections

Doc#: 1VV0301261 Signals That Must Be Connected

PAD Signal Notes

AH19 C103/TXD If not used, connect to a

test point

AF19 C104/RXD If not used, connect to a

test point

AA18 C105/RTS If flow control is not used,

connect to GND

AK19 C106/CTS If not used, connect to a

test point

AB19 TX_AUX If not used, connect to a

test point

AD19 RX_AUX If not used, connect to a

test point

AD1 Antenna MAIN antenna

AU9 ANT_DIV

S1 ANT_GPS

J2, L2, F3, H3, K3, E4, AN14 Reserved Connect to a test point for

Telit internal use

AN4 GPIO_20 If not used, connect to a

test point

AT2 WCI_RX If not used, connect to a

test point

AS1 ON/OFF Main power on off signal

AN12 SHDN_N Emergency power off

D19 USB_D+ If not used, connect to a

test point or an USB

connector

F19 USB_D- If not used, connect to a

test point or an USB

connector

A18 USB_VBUS If not used, connect to a

test point or an USB

connector

AK19 C106/CTS If not used, connect to a

test point

Rev. 4.3 Page 38 of 123 2017-12-07

Page 39

LE920A4 HW User Guide Module Connections

Doc#: 1VV0301261 Signals That Must Be Connected

PAD Signal Notes

AB19 TX_AUX If not used, connect to a

test point

AD19 RX_AUX If not used, connect to a

test point

AD1 Antenna MAIN antenna

AU9 ANT_DIV

S1 ANT_GPS

J2, L2, F3, H3, K3, E4, AN14 Reserved Connect to a test point for

Telit internal use

AN4 GPIO_20 If not used, connect to a

test point

AT2 WCI_RX If not used, connect to a

test point

Rev. 4.3 Page 39 of 123 2017-12-07

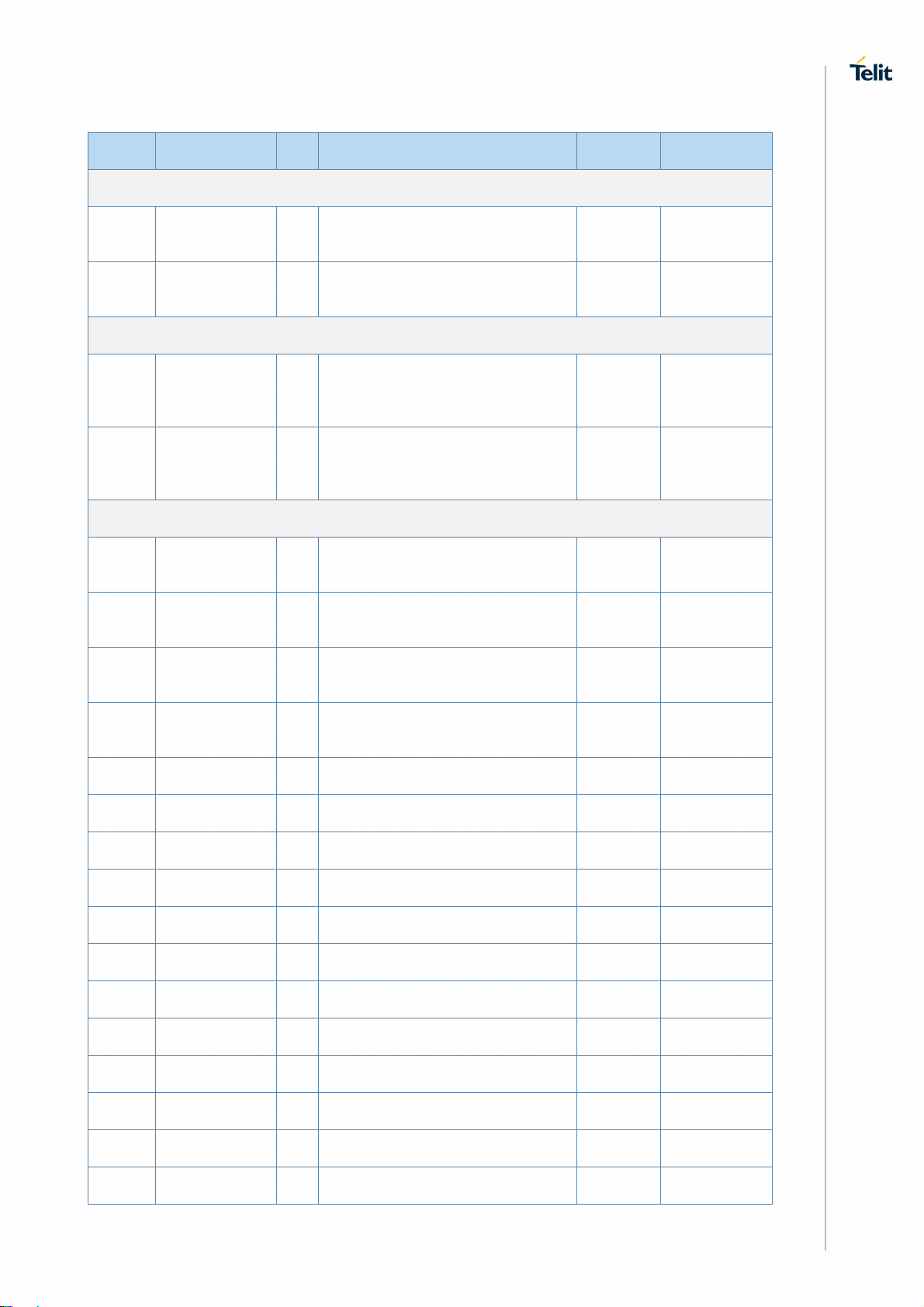

Page 40

LE920A4 HW User Guide Module Connections

GPS_

_EN

WiFi

_TGPIO

WiFi_SD

PIO14

WiFi_SD

O15

WiFi_SD

O16

WiFi_SD

O17

WiFi_SD

O18

WiFi_SD

PIO19

WLAN_S

LK

VAUX/

MON

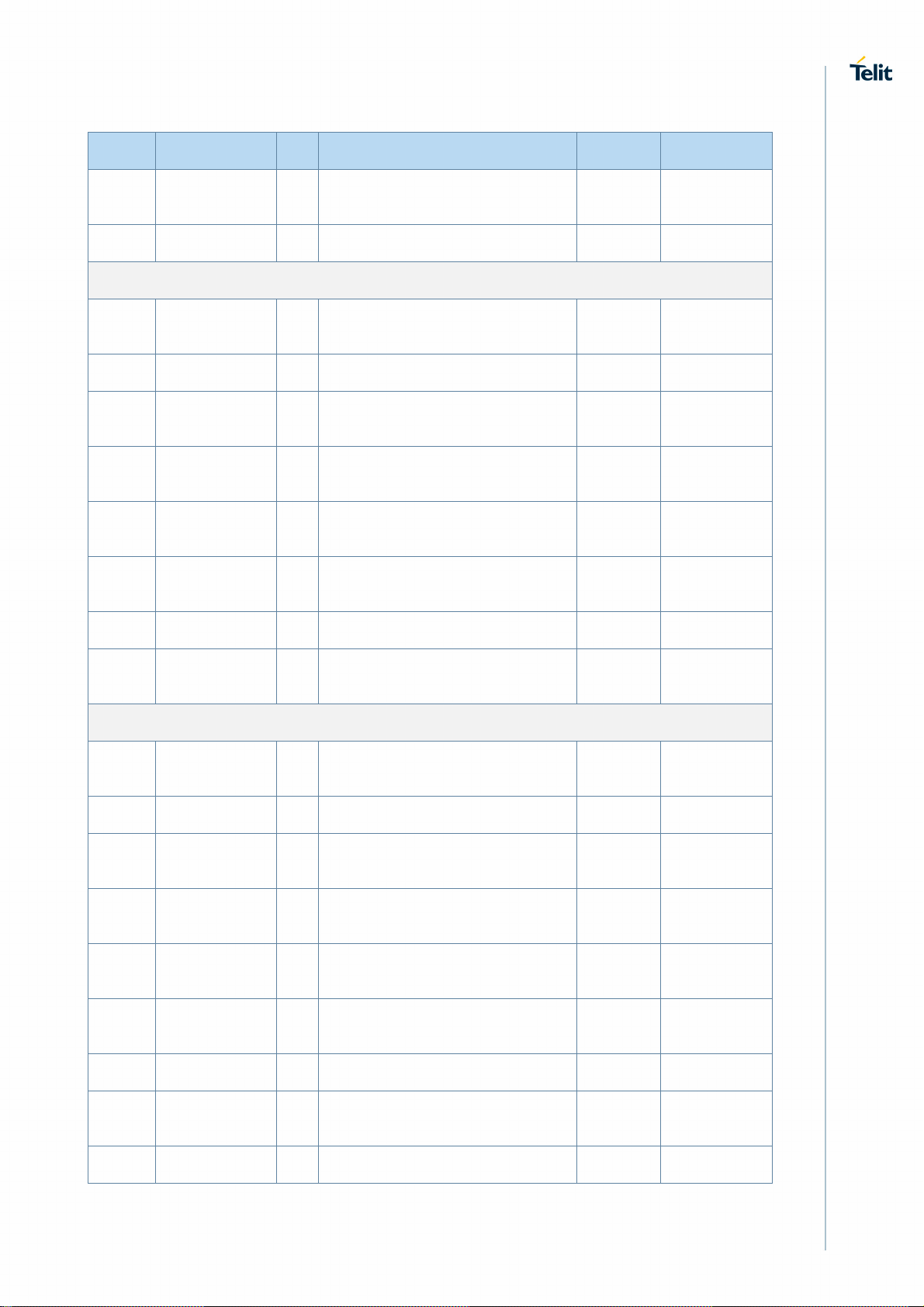

Rev. 4.3 Page 40 of 123 2017-12-07

zz A B C D E F G H J K L M N P R S T U V W X Y AA AB AC AD AE AF AG AH AJ AK AL AM AN AP AR AS AT AU AV

RESERVEDRESERVEDRESERVEDRESERV

0

1

GND

2

RESERVEDMIC1

3

4

RESERVEDEAR1

5

6

RESERV

7

ED

8

SIMVCC1 DVI_RX

RESERV

9

ED

10

SIMCLK1

SGMII_R

11

X_P

12

SGMII_R

13

X_M

14

SGMII_T

15

X_P

16

SGMII_T

17

X_M

18

19

GND USB_ID

20

GND

MIC2

EAR2

_MT-

_MT-

MIC1

MIC2

_MT-

_MT+

EAR1

_MT-

_MT+

GND GND

SIMIN1 GN D

SIMIO1

SIM

RST1

GND

GND

HSIC_D

ATA

GND SIMVCC2

HSIC_S

TB

GND

USB

_VBUS

GND

EAR2

_MT+

_MT+

GND

RESERVEDRESERVEDRESERV

GND

ADC

_IN1

ADC

_IN2

eSIM

RST

DVI

_TX

DVI

TGPIO

_CLK

_02

DVI

_WAO

REF

TGPIO

_CLK

_04

I2C

SDA

I2C

TGPIO

_SCL

_06

SIMCLK2 SIMIO2

SIM

RST2

SIMIN2 GN D GND

USB

_D+

RESERVEDRESERVEDRESERVEDRESERV

TGPIO

GND

_21

RESERVEDRESERVEDRESERV

RESERVEDRESERVEDRESERVEDJTAG_T

RESERV

ED

MIC_BIA

S

ADC

_IN3

ETH_RS

T_N

TGPIO

_01

ETH_IN_

N

TGPIO

_03

MAC_

MDIO

TGPIO

_05

MAC_

MDC

HW_KE

Y

RESERVEDRESERVEDRESERVEDRESERVEDRESERVEDRESERVEDRESERVEDRESERVEDRESERVEDRESERVEDRESERVEDRESERVEDRESERVEDRESERV

RESERVEDRESERVEDLED_DR

VRTC

USB

GND

_D-

RFU GND GND GND GND GND GND GND GND GND GND GND GND GND RFU G ND

ED

TGPIO

GND GND

_22

GND GND GND

ED

ORIGIN

RFU RFU RFU RFU RFU

ED

New xE920 (34 mm X 40 mm) Form Factor Pin MAP

V_EN

TGPIO_12TGPIO_11SPI

SPI

_MOSI

ED

SPI

_MISO

GND GND

_CS*

ANT

GND GND GND GND ANT 1 GND GND GND ANT 2

_GPS

GND GND GND GN D GN D G ND GND GND GND

LNA

RESERVEDRESERVEDGPS_PP

GND

GND GND GND GND

GND GND GND

GND GND GND GND

GND GND GND

GND GND GND GND SHDN GND GND G ND

MMC

VMMC

PWR

TGPIO

_07

SPI

_CLK

RESERVEDRESERVEDRESERVEDRESERVEDRESERVEDRESERVEDRESERVEDRESERVEDRESERV

_CD

GND GND GND

TGPIO

TGPIO

_08

_09

MMC

_DAT3

TGPIO

_10

_SDRST

CMD_TG

0_TGPI

MMC

_CLK

1_TGPI

I2C_SCL

RESERVEDRESERVEDRESERVEDTGPIO

_AUX

MMC

_DAT1

C109/

C107/

DCD

DSR*

C104/

RXD

S

RFCLK2

_QCA

MMC

_DAT0

GND

LEEP_C

C105/

RTS*

I2C_SDA

_AUX

MMC

_DAT2

C108/

DTR*

TX

_AUXRX_AUX

2_TGPI

MMC

_CMD

C103/

TXD

C125/

RING*

ED

3_TGPI

CLK_TG

_20

RESERV

ED

LED_DR

V

RFU GND GND GND

RESET_

N

RESERV

ED

SW_

RDY

RESERV

ED

RESERV

ED

JTAG_P

S_HOLD

RESERV

ED

GND GND GND GND

ED

GND GND VBATT

GND GND VBATT

C106/

GND VBATT

CTS*

RFU RFU VBATT

RESERVEDON

GND

GND GND GND

GND GND

GND GND GND

GND GND

GND GND GND

_OFF*

WCI_RX

WCI_TXDSTAT

GND GND RFU

GND GND RFU

GND GND GND

GND GND GND

GND GND GND

VBATT

_PA

VBATT

VBATT

_PA

VBATT

GND

D

_LED

ANT

_DIV 1

ANT

_DIV 2

VBATT

_PA

_PA

VBATT

_PA

_PA

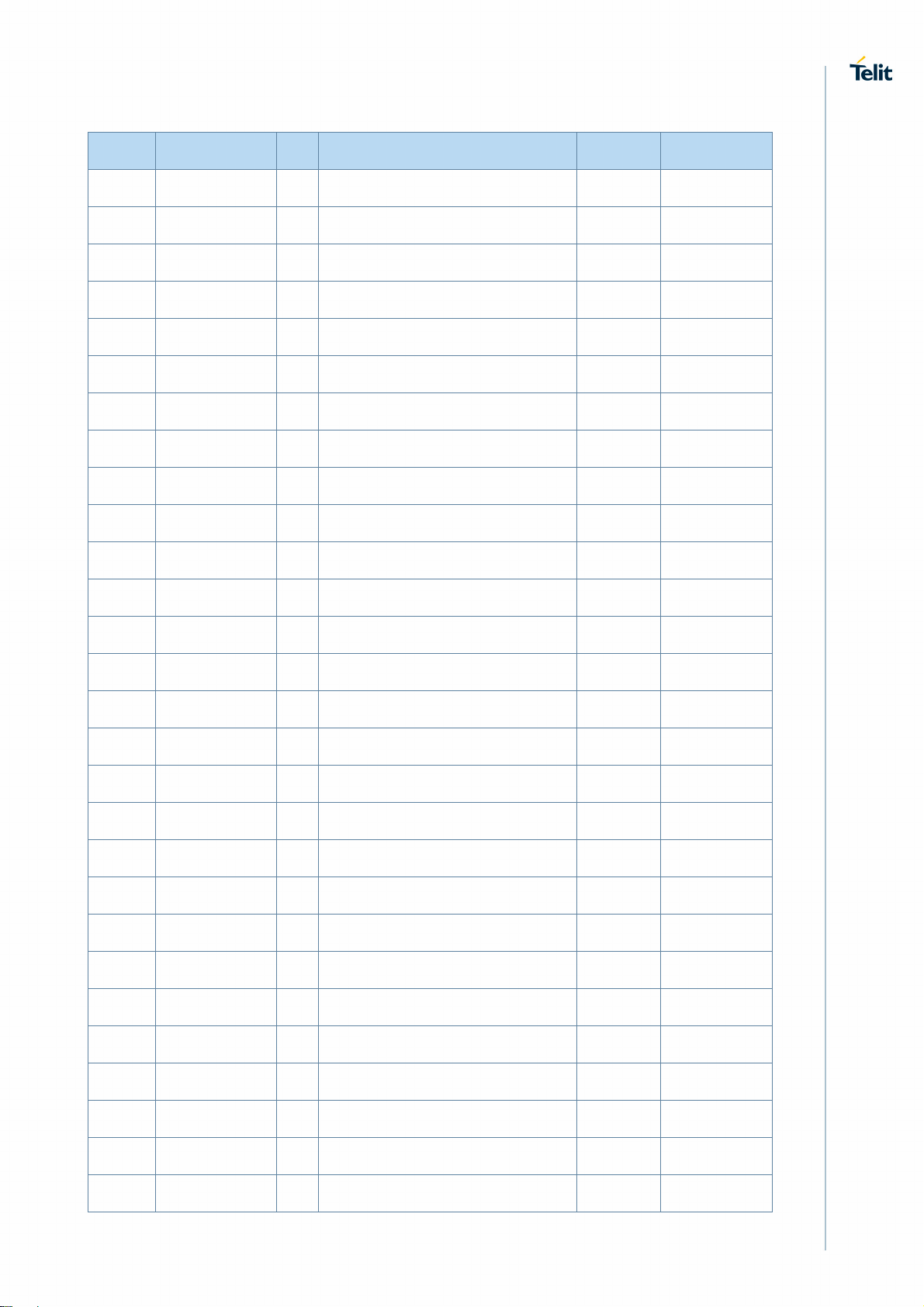

Figure 2: LGA Pads Layout

LE940A4 LGA Pads Layout

RFU

GND

GND

Doc#: 1VV0301261 LE940A4 LGA Pads Layout

Page 41

LE920A4 HW User Guide Electrical Specifications

Doc#: 1VV0301261 Absolute Maximum Ratings – Not Operational

4. Electrical Specifications

Absolute Maximum Ratings – Not Operational

WARNING:

A deviation from the value ranges listed below may harm the module.

Table 9: Absolute Maximum Ratings – Not Operational

Symbol Parameter Min Max Unit

VBATT Battery supply voltage on VBATT pin -0.5 +6.0 [V]

VBATT

TRANSIENT

VBATT_PA Battery supply voltage on VBATT_PA

Transient voltage on pin VBATT (< 10

ms)

-0.5 +7.0 [V]

-0.3 +6.0 [V]

pin

Recommended Operating Conditions

Table 10: Recommended Operating Conditions

Symbol Parameter Min Typ Max Unit

T

Ambient temperature -40 +25 +85 [°C]

amb

VBATT Battery supply voltage on

VBATT pin

VBATT_PA Battery supply voltage on

VBATT_PA pin

I

BATT_PA + IBATT

Peak current to be used to

dimension decoupling

capacitors on VBATT_PA

pin

3.4 3.8 4.2 [V]

3.4 3.8 4.2 [V]

- 80 2000 [mA]

Logic Level Specifications

Unless otherwise specified, all the interface circuits of the module are 1.8V CMOS logic.

Only few specific interfaces (such as USIM and SD Card) are capable of dual voltage I/O.

Rev. 4.3 Page 41 of 123 2017-12-07

Page 42

LE920A4 HW User Guide Electrical Specifications

Doc#: 1VV0301261 Logic Level Specifications

The following tables show the logic level specifications used in the module’s interface

circuits. The data specified in the tables below is valid throughout all drive strengths and

the entire temperature ranges.

NOTE:

Do not connect the module’s digital logic signals directly to the OEM’s digital

logic signals with a level higher than 2.7V for 1.8V CMOS signals.

4.3.1. 1.8V Pads - Absolute Maximum Ratings

Table 11: Absolute Maximum Ratings - Not Functional

Parameter Min Max

Input level on any digital pin when on -0.3V +2.16V

Input voltage on analog pins when on -0.3V +2.16 V

4.3.2. 1.8V Standard GPIOs

Table 12: Operating Range – Interface Levels (1.8V CMOS)

Pad Parameter Min Max Unit Comment

VIH Input high level 1.25V -- [V]

VIL Input low level -- 0.6V [V]

VOH Output high level 1.4V -- [V]

VOL Output low level -- 0.45V [V]

IIL Low-level input leakage

current

IIH High-level input leakage

current

RPU Pull-up resistance 30 390 [kΩ] See Note

-1 -- [uA] No pull-up

-- +1 [uA] No pull-down

RPD Pull-down resistance 30 390 [kΩ] See Note

Ci Input capacitance -- 5 [pF]

Rev. 4.3 Page 42 of 123 2017-12-07

Page 43

LE920A4 HW User Guide Electrical Specifications

Doc#: 1VV0301261 Logic Level Specifications

NOTE:

Pull-up and Pull-down resistance of GPIO5 is different from those mentioned

above.

GPIO5 pull resistance is specified as 10KΩ to 50KΩ.

4.3.3. 1.8V SD Card Pads

Table 13: Operating Range – SD Card Pads Working at 1.8V

Pad Parameter Min Max Unit Comment

VIH Input high level 1.27V 2V [V]

VIL Input low level -0.3V 0.58V [V]

VOH Output high level 1.4V -- [V]

VOL Output low level 0 0.45V [V]

IIL Low-level input leakage

current

IIH High-level input leakage

current

RPU Pull-up resistance 10 100 [kΩ]

RPD Pull-down resistance 10 100 [kΩ]

Ci Input capacitance 5 [pF]

-2 - [uA] No pull-up

- 2 [uA] No pull-down

4.3.4. 1.8V SIM Card Pads

Table 14: Operating Range – SIM Pads Working at 1.8V

Pad Parameter Min Max Unit Comment

VIH Input high level 1.35V 2V [V]

VIL Input low level -0.3V 0.43V [V]

VOH Output high level 1.35V 1.875V [V]

VOL Output low level 0V 0.4V [V]

IIL Low-level input leakage

current

IIH High-level input leakage

current

Rev. 4.3 Page 43 of 123 2017-12-07

-2 - [uA] No pull-up

- 2 [uA] No pull-down

Page 44

LE920A4 HW User Guide Electrical Specifications

Doc#: 1VV0301261 Logic Level Specifications

Pad Parameter Min Max Unit Comment

RPU Pull-up resistance 10 100 [kΩ]

RPD Pull-down resistance 10 100 [kΩ]

Ci Input capacitance 5 [pF]

4.3.5. Dual Voltage Pads - Absolute Maximum Ratings

Table 15: Absolute Maximum Ratings - Not Functional

Parameter Min Max

Input level on any digital pin when on -0.3V +3.6V

Input voltage on analog pins when on -0.3V +3.6 V

4.3.6. SD Card Pads @ 2.95V

Table 16: Operating Range – For SD Card Pads Operating at 2.95V

Pad Parameter Min Max Unit Comments

VIH Input high level 1.9V 3.1V [V]

VIL Input low level -0.3V 0.7V [V]

VOH Output high level 2.1V 3.05V [V]

VOL Output low level 0V 0.4V [V]

IIL Low-level input leakage

current

IIH High-level input leakage

current

RPU Pull-up resistance 10 100 [kΩ]

RPD Pull-down resistance 10 100 [kΩ]

-10 [uA] No pull-up

10 [uA] No pull-down

Ci Input capacitance 5 [pF]

4.3.7. SIM Card Pads @2.95V

Table 17: Operating Range – For SIM Pads Operating at 2.95V

Pad Parameter Min Max Unit Comment

VIH Input high level 2.1V 3.1V [V]

VIL Input low level -0.3V 0.55V [V]

Rev. 4.3 Page 44 of 123 2017-12-07

Page 45

LE920A4 HW User Guide Electrical Specifications

Doc#: 1VV0301261 Logic Level Specifications

Pad Parameter Min Max Unit Comment

VOH Output high level 2.25V 3.1V [V]

VOL Output low level 0V 0.4V [V]

IIL Low-level input leakage

-10 [uA] No pull-up

current

IIH High-level input leakage

10 [uA] No pull-down

current

RPU Pull-up resistance 10 100 [kΩ]

RPD Pull-down resistance 10 100 [kΩ]

Ci Input capacitance 5 [pF]

Rev. 4.3 Page 45 of 123 2017-12-07

Page 46

LE920A4 HW User Guide Hardware Commands

Doc#: 1VV0301261 Turning on the Module

5. Hardware Commands

Turning on the Module

To turn on the module, the ON/OFF pad must be asserted low for at least 1 second and

then released.

The maximum current that can be drained from the ON/OFF pad is 0.1 mA. This pin is

internally pulled up; customers should expect to see ~ 800 mV on the output.

Figure 3 illustrates a simple circuit to power on the module using an inverted buffer output.

Figure 3: Power-on Circuit

Initialization and Activation State

After turning on the module, the module is not yet activated because the SW initialization

process of the module is still in process internally. It takes some time to fully complete the

HW and SW initialization of the module.

For this reason, it is impossible to access the module during the Initialization state.

As shown in Figure 4, the module becomes operational (in the Activation state) at least 20

seconds after the assertion of ON_OFF.

NOTE:

During the Initialization state, AT commands are not available. The DTE host

must wait for the Activation state prior to communicating with the module.

Rev. 4.3 Page 46 of 123 2017-12-07

Page 47

LE920A4 HW User Guide Hardware Commands

Doc#: 1VV0301261 Initialization and Activation State

Figure 4: Module Initialization and Activation

VBATT

1 Sec < T_Hold < 2 Sec

ON_OFF

T_RDY < 20 Sec

SW_RDY

OK to Send AT

commands

V_AUX

PWRMON

18 Sec < T_PWRMON < 20 Sec

All interfaces and pins

configured

OFF State Initialization State Active State

NOTE:

During SW initialization of the module, the SW configures all pads and

interfaces to their desired mode. When PWRMON goes high, this indicates

that the initialization of all I/O pads is completed.

NOTE:

To check whether the module has completely powered on, monitor the

SW_RDY hardware line. When SW_RDY goes high, the module has

completely powered on and is ready to accept AT commands.

NOTE:

Do not use any pull-up resistor on the ON_OFF line as it is internally pulled

up. Using a pull-up resistor may cause latch-up problems on the module’s

power regulator and improper powering on/off of the module. The ON_OFF

line must be connected only in an open collector configuration.

NOTE:

For systems not requiring controlled power ON/OFF, automatic power on can

be supported by shorting the ON_OFF signal directly GND. In this case, the

module will start power on sequence immidiately after VBATT supply is

applied

Rev. 4.3 Page 47 of 123 2017-12-07

Page 48

LE920A4 HW User Guide Hardware Commands

Doc#: 1VV0301261 Turning off the Module

NOTE:

To avoid a back-powering effect, it is recommended not to apply any HIGH

logic level signal to the digital pins of the module when it is powered OFF or

during an ON/OFF transition.

NOTE:

Active low signals are labeled with a name that ends with “_N”

Turning off the Module

Turning off the device can be done in different ways:

• AT#SHDN software command

• Hardware shutdown using ON/OFF pad

• Hardware Unconditional Shutdown using the SHDN_N

When the device is shut down by a software command or a hardware shutdown, it issues

a detach request to the network, informing the network that the device will not be

reachable any more.

NOTE:

To check if the device has powered off, monitor the PWRMON hardware

line. When PWRMON goes low, this indicates that the device has powered

off.

NOTE:

To avoid a back-powering effect, it is recommended to avoid having any

HIGH logic level signal applied to the digital pins of the module when it is

powered OFF or during an ON/OFF transition.

NOTE:

Using RESET_N for resetting the module is not recommended.

Rev. 4.3 Page 48 of 123 2017-12-07

Page 49

LE920A4 HW User Guide Hardware Commands

Doc#: 1VV0301261 Turning off the Module

5.3.1. Shutdown by Software Command

The module can be shut down by a software command.

When a shutdown command is sent, the module goes into the Finalization state and at the