Teli CS8620i, CS8620Hi, CS8630i, CS8630H, CS8620Ci Operation Manual

...

CCD Monochrome

Video Camera

Operation Manual

Model

CS8620i (EIA) CS8620Ci (CCIR)

CS8630i (EIA) CS8630Ci (CCIR)

CS8620Hi (EIA) CS8620HCi (CCIR)

CS8630H (EIA) CS8630HC (CCIR)

BEFORE USE - GENERAL SAFETY

INSTRUCTIONS

This instruction manual contains important information for the

operator (user) and/or people around him/her to avoid personal

injury, or property damage to him/her or people around him/her by

using this product correctly. Prior to use, read this operation

manual carefully to fully understand its instructions for correct

use.

OWNER’S RECORD

Please fill in the blank below the model name and product serial

number, which is found on bottom chassis of your device. Keep

this number for your record.

Model Name

Serial No.

WARNINGS & CAUTIONS

[Definition of markings]

The meaning of each mark used in this instruction manual is given

below.

DANGER

This mark warns the user that improper use,

indicated with this mark, may cause death or

severe personal injuries against the user or

people around him/her.

CAUTION

This mark warns the user that improper use,

indicated with this mark, may cause personal

injuries (*1) or material damages (*2) against

the user or people around him/her.

Notes

*1 : Personal injuries mean wounds, burns, electric shocks ,

and others for which the person injured need not to be

hospitalized nor to be cared for the long term.

*2 : Material damages mean any direct or consequential

damages related to property or material loss.

This mark indicates what the user SHOULD NOT

DO. The details of things which the user should not

do are described next to this mark.

This mark indicates what the user MUST DO. The

details of things which the user must do are described

next to this mark.

This mark indicates that the user must be alert against

a possible DANGER. The details of the danger which

the user must be aware of are described next to this

mark.

This mark indicates that the user are given a CAUTION

against possible hazards. The details of the caution

which the user must be aware of are described next to

this mark.

●Handling Precautions

DANGER

MUST

If any overheating sign is observed, discontinue

use immediately.

In the event that smoke, smell, or any other

overheating sign is observed, turn its power switch

OFF immediately, and remove its camera cable

from camera connector. Do NOT try to continue to

use your camera. To do so in spite of a clear sign of

a malfunction invites a fire, an electric shock

hazard, or any other serious damage. In such case,

after confirming that there is no risk of a fire

accident, contact us or our dealer/distributor

through which you purchased this device for repair

service. To avoid hazard, do NEVER attempt to

repair it yourself.

MUST

If any malfunctioning sign is observed, discontinue

use immediately.

Do NOT try to use this device when it is

obviously malfunctioning. (Example: No images

on the monitor) In the event of a malfunction, turn

its power switch OFF immediately, and remove its

camera cable from camera connector. In such case,

contact us or our dealer/distributor through which

you purchased this device for repair service.

MUST

If any liquid gets into the device, discontinue use

immediately.

In the event that water, or any other type of

liquid gets into the body, do NOT try to continue

to use the device. To do so invites a fire or an

electric shock hazard. In such case, turn its

power switch OFF immediately, and then

remove its camera cable from camera connector.

After that, contact us or our dealer/distributor

through which you purchased this device for

repair service/technical advice.

MUST

Connection/Disconnection only AFTER

power OFF.

When you connect/disconnect camera connector,

make sure to turn power SW OFF first. This

camera is not designed for “hot-plugging”. Do

NEVER make connection/disconnection while

power ON. Doing so might cause a breakdown.

DANGER

MUST

Use manufacturer-recommended peripheral

devices (option units) only.

Make sure to use option units specified in this

operation manual onl y. When connected with

any other non-guaranteed peripheral devices,

your camera might fail to perform its full

capacity. In the worst case, it might cause a fire

or breakdown.

NEVER

pull apart

Do NOT disassemble this device.

Do NOT attempt to pull apart, repair, or modify

your camera yourself. To do so might lead to a

fire or an electric shock accident. Contact us or

the dealer/distributor from which you purchased

the device for repair/modification.

DON’T

Do NOT supply any power other than specified.

This device is designed to work only under

specified voltage. Do NOT attempt to supply

the device with power other than specified.

Supplying the device with any unspecified

power invites a fire or an electric shock hazard.

(CS8600 series --- DC+12V)

DON’T

Do NOT use the camera in a high-humidity

environment.

Do NOT place your camera near a humidifier,

or in other high-humidity environment. To do so

might cause a fire or an electric shock accident.

●Handling Precautions

CAUTION

CAUTION

If the camera is operated in the electromagnetic

field, there may be cases where beat noises

(vertical, horizontal, or oblique stripes) appear in

the video output. In that case, take preventive

measures on the electromagnetic-wave

generating source so that your camera do not

receive the interference by the

electromagnetic-wave. Take extra precautions

against electromagnetic-wave-interference if

your camera is used with a servomotor, inverter,

or other electromagnetic-wave-generating

equipment.

CAUTION

Avoid giving a strong shock against the camera

body. It might cause a breakdown or damage. If

your camera is used in a system where its camera

head is subjected to strong repetitive shocks, its

camera head is possible to break down. If you

intend to use your camera in such a situation,

make sure to use an optional camera-connector

-fixing-hardware to connect the connector-plug

to the camera body.

CAUTION

When the camera is not in use, put a lens or a

lens-cap onto the camera head so that the image

pickup plane of CCD is protected from dust,

foreign object, or any other flaw-causing object.

If the glass plane (image pickup plane) gets dirty,

clean it with a cotton swab. When it needs to be

cleaned with a cleaner, be sure NOT to use any

organic solvent other than ethyl alcohol. As a

countermeasure against condensation, when the

camera is moved from a warm

condition/environment to a cold one, take

appropriate precautions to prevent condensation

from forming on the camera.

CAUTION

Do not pull strongly the camera

cable/camera-head nor swing it. The stress from

pulling or swinging may cause damage in the

coating of the cable, or breaks in the inside

wires.

CAUTION

Avoid short-circuiting signal output. Othe rwise,

it may cause a malfunction.

CAUTION

Do NEVER expose its camera head to any

intensive light (such as direct sunlight).

Otherwise, its inner image pickup device might

get damaged.

This equipment has been tested and found to comply with the

limits for a class A digital device, pursuant to Part 15 of the FCC

Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, can

radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment

in a residential area is likely to cause harmful interference in

which case the user will be require to correct the interference at

his own expense.

This device complies with Part 15 of the FCC rules. Operation is

subject to the following two conditions: (1) This device may no t

cause harmful interference, and (2) This device accept any

interference received, including interference that may cause

undesired operation.

RESTRICTION FOR USE

In the case where a malfunction of this camera (e.g. video output

cut-off) can be expected to lead to a significant accident, avoid

using this device for such system build-in use.

DISCLAIMER (LIMITED WARRANTY)

We assume no responsibility and shall be held harmless for

damage or loss incurred by the user in the following cases.

1.In the case where damage or loss is caused by fire, earthquake,

or other acts of Gods, acts by a third party, misuse by the user

deliberately or erroneously, or use under extreme operating

conditions.

2.In the case where any indirect, additional, consequential

damages (e.g. loss of expected interest, suspensi on of business

activities) are incurred as results of a malfunction or

non-functioning of this device, we shall be exempted from

assuming responsibility for such damages.

3.In the case where damage or loss is caused by incorrect use

which is not in line with the instructions g iven in this

operation manual.

4.In the case where damage or loss is caused by a malfunction

resulting from bad connection with other equipment.

5.In the case where damage or loss is caused by repair or

modification done by the user.

PRODUCT DESCRIPTION

Model CS86xxi is a miniature camera series featuring its

ultra-small light-weight body. The CS86xxi camera series is

designed mainly for factory automation, machine vision, and

image measurement application.

FEATURES

⑤

DC IN/SYNC

This connector is for DC power input, external sync signal

(1) High resolution

input, and video output, to be connected with a power supply,

The 380,000 pixel CCD realizes the horizontal resolution of

sync-signal generator, and video monitor.

570TV lines.

High-density images with minimum moire-fringes & beatings

(4) DIP SW

are obtained. (CCIR: 440,000 pixels, 560TV lines)

(2) Ultra-compact & light-weight body

Using the rear-panel DIP switch, you ca

n

make various mode setting.

Each numbered switch is OFF in LEF

T

position, and ON in RIGHT position.

1

2

3

4

5

6

7

8

9

0

O

N

The camera features its ultra-small light-weight body. Its super small body will free you from much of your space restriction

problem. The camera is driven by DC12V.

(3) Electronic shutter

The built-in electronic shutter allows this camera to

capture a fast-moving object clearly and sharply.

(4) AGC (Automatic Gain Control)

This series is equipped with AGC function. With the

[Shutter-speed Setting] X : Don’t care

AGC, the camera obtains optimal images constantly

even when the amount of incoming light fluctuates.

(5) Restart/Reset

When the restart/reset function set ON, the camera

captures images at any timing given by R.R. pulse

input (VD input).

Remark : CS8620Hi, CS8620HCi are possible for a restart/reset

operation only at the field integration mode.

(6) SS (Special shutter) & RTS (Random trigger shutter)

This camera is fitted with special shutter and random trigger

shutter function, which allows the camera to capture images

cued by external trigger input.

(7) Near-infrared region sensitivity

(Model -----H type only)

The CCD integrated in the model CS8620Hi,

CS8620HCi,CS8630H, and CS8630HC has a near infrared-region sensitivity. These models capture clear

images even under near-IR shooting condition.

CS8600i Series Spec Lookup Table

Model name

Image

size

TV

format

Near

IR

SS /

RTS

R.R.

CS8620i

1/2 type

EIA

× ○ ○

CS8620Hi

1/2 type

EIA

○ ○ ○

CS8630i

1/3 type

EIA

× ○ ○

CS8630H

1/3 type

EIA

○ ○ ○

CS8620Ci

1/2 type

CCIR

× ○ ○

CS8620HCi

1/2 type

CCIR

○ ○ ○

CS8630Ci

1/3 type

CCIR

× ○ ○

CS8630HC

1/3 type

CCIR

○ ○ ○

CONFIGURATION

(1) Camera body 1

・・・・・・・・・・・・・・・・・・・・

・・・・

・・・

(2) Accessory

Operation Manual(English

)

1

Operation Manual(Japanese

)

1

CONNECTION / MODE / REAR-PANEL SWITCH

(1) Connector Pin Assignment

Compatible plug: HR10A-10P-12 S

(Manufactured by HIROSE ELEC.)

External sync.

Pin

No.

HD VD VS/SYNC R.R.

Internal sync.

1 GND GND GND GND

2 +12V +12V +12V +12V

3 GND GND GND GND

4

VIDEO

OUT

VIDEO

OUT

VIDEO

OUT

VIDEO OUT

5 GND GND GND GND

6 HD IN ----- HD IN HD OUT*

7 VD IN

VS/SYNC

IN

R.R. IN VD OUT*

8 GND GND GND GND

9

CLOCK

OUT

CLOCK

OUT

CLOCK

OUT

CLOCK

OUT

10 WEN OUT WEN OUT ----- WEN OUT

11 TRIG IN TRIG IN TRIG IN TRIG IN

12 GND GND GND GND

No.

SHUTTER

OFF

1/125 1/250 1/500

1 X X X X

2 X X X X

3 OFF ON OFF ON

4 OFF OFF ON ON

5 OFF OFF OFF OFF

6 OFF OFF OFF OFF

7 X X X X

8 X X X X

9 X X X X

0 X X X X

No. 1/1,000 1/2,000 1/4,000 1/10,000

1 X X X X

2 X X X X

3 OFF ON OFF ON

4 OFF OFF ON ON

5 ON ON ON ON

6 OFF OFF OFF OFF

7 X X X X

8 X X X X

9 X X X X

0 X X X X

No. Flicker-less 1FLD 2FLD 4FLD

1 X X X X

2 X X X X

3 OFF ON OFF ON

4 OFF OFF ON ON

5 OFF OFF OFF OFF

6 ON ON ON ON

7 X X X X

8 X X X X

9 X X X X

0 X X X X

No. 6FLD 8FLD 10FLD

Pulse-width

1 X X X X

2 X X X X

3 OFF ON OFF ON

4 OFF OFF ON ON

5 ON ON ON ON

6 ON ON ON ON

7 X X X X

8 X X X X

9 X X X X

0 X X X X

[Mode Setting]

GAIN TRIGGER Polarity

No.

MGC AGC POSI NEGA

1

X X X X

2

X X X X

3

X X X X

4

X X X X

5

X X X X

6

X X X X

7

X X

OFF ON

8

X X X X

9

X X X X

0 OFF ON

X X

Integration Mode Gamma Correction

No.

Frame Field 1.0 0.45

1

X X X X

2

X X X X

3

X X X X

4

X X X X

5

X X X X

6

X X X X

7

X X X X

8 OFF ON

X X

9

X X

OFF ON

0

X X X X

* HD VD output is available via inner SW selection under internal

sync operation.

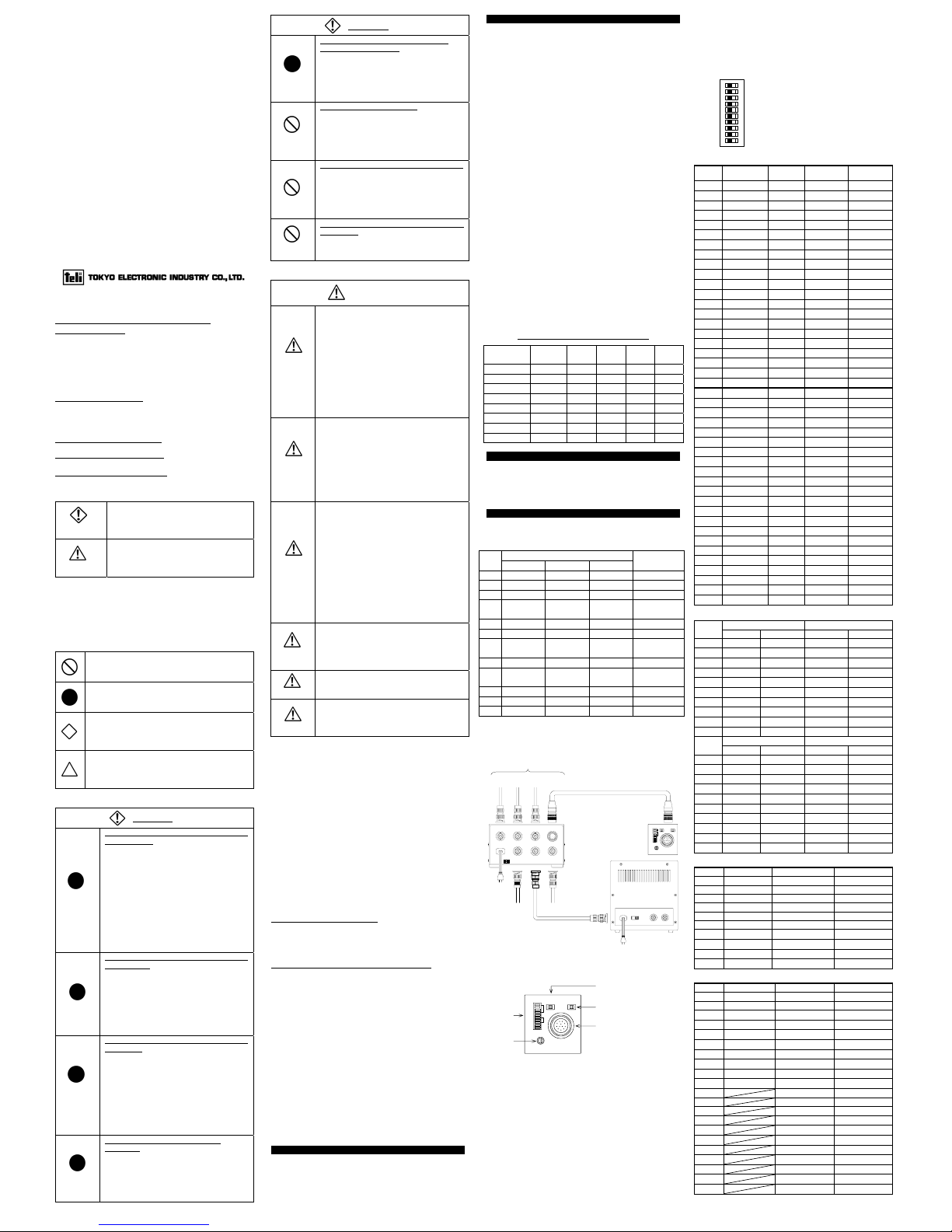

(2) Connection Example

TR

IN OUT

VIDEO OUT/

DC IN/SYNC

M GAIN

HD/VD

HIGH 75Ω

HD/VD

SHUT

FR/FL

TRIG

γ

M/AGC

MODE

HD

HIGH-75Ω

VIDEO OUTVIDEO IN

SERIAL No.

CLOCK OUT

HD

AC100V IN

TOKYO ELECTRONIC INDUSTRY CO.,LTD.

CAMERA

WEN

TRIGGER

VIDEO OUT

VD

IGGER

To be connected if necessary

VD/VS/SYNC/R.R

(Either one)

Camera Cable (option)

Camera Adapter

CA130C

(Rear Panel)

CCD Camera

CS86xxi Series

(Rear Panel)

AC100V

50/60Hz

Clock Output

Video Cable

AC100V50/60Hz

Video Monitor

(Rear Panel)

WEN

* Make sure that video output is properly 75-ohm terminated.

[Restart Reset / Special Shutter]

No. Normal Restart Reset Special Shutter

1 OFF ON ON

2 OFF ON ON

3 OFF ON ON

4 OFF ON ON

5 OFF ON ON

6 OFF ON ON

7

X X X

8

X X X

9

X X X

0 X X X

(3) Rear SW, Potentiometer, Connector

[Random trigger shutter]

No. Normal Mode 1,2 Mode 3,4

1 OFF OFF OFF

2 OFF OFF ON

3 OFF

X X

4 OFF

X X

5 OFF

X X

6 OFF

X X

7

X X X

8

X X X

9

X X X

0 X X X

No. Mode 5,6 Mode 7,8

1 OFF ON

2 OFF OFF

3

X X

4

X X

5

X X

6

X X

7

X X

8

X X

9

X X

0 X X

IN OUT

VIDEO OUT/

DC IN/SYNC

M GAIN

HD/VD

HIGH 75Ω

HD/VD

SHUT

FR/FL

TRIG

γ

M/AGC

①

②

③

④

⑤

CS86xxi Series

Rear View

①

Gain adjustment potentiometer

This manual gain adjuster is enabled under Manual Gain

Control setting (Gain selection SW: MGC). Turned

clockwise, video amplification gain increases.

②

Mode selection SW

This is the camera mode selection switch.

③

75-ohm termination ON/OFF SW

This SW switches external-sync input terminal 75-ohm

termination ON/OFF. When set in right side, the

termination is 75-ohm. When set in left, it is 10k-ohm.

The initial factory setting is in OFF position

.

④

HD VD IN/OUT selection SW

This is the HD VD sync-signal IN/OUT selection switch.

The status is HD VD IN when set in left side, HD VD OUT

when in right. The initial setting is EXT.

D3002864 A

t1 t2

VD

HD

Specification

Material Lens-mount, Rear panel : Aluminum die-cast

Cover : Anticorrosio aluminum alloy

Processing Lens-mount, Rear panel : Cation coati g

Cover : Leather sati coating

n

n

n

OPERATION

(1) Connect each system component as illustrated in Section 4

above.

(2) Turn the power switch of the video monitor ON.

(3) Feed power to the camera.

(4) Confirm that images appear on the video monitor. Adjust the

lens aperture so that the optimal illumination is obtained.

(5) While monitoring the images on the video monitor, adjust the

lens-focus so that the sharpest images are obtained.

(6) Adjust sensitivity. The factory setting is in MGC (Manual Gain

Control). AGC (Automatic Gain Control) mode is also available.

The selection is made via DIP SW selection on the rear side.

Under the MGC mode, the rear-panel M GAIN potentiometer is

enabled for manual gain adjustment by an user.

(7) Select gamma factor. The factory setting is 1.0. The selection

between 1.0 and 0.45 is made via the rear DIP SW selection.

(8)

Select the electronic shutter ON/OFF. The factory setting is in

OFF position. To set E-shutter ON, use the rear-panel DIP SW.

(9) Select integration mode . The selection between the frame/field

integration is made via the rear DIP SW selection. The initial

factory setting is the frame integration.

(10) Set restart/reset, special shutter, or random trigger shutter

mode as necessary. The factory setting is all in OFF position.

Each function is set ON/OFF via the rear DIP SW selection.

(11) If you need HD VD output, use the rear SW under internal

sync operation.

(12) For connection with an image processor and other

peripheral devices, this camera is provided with CLK OUT

(Clock output function).

SPECIFICATION

(1) TV system (EIA) Based on EIA standard

(CCIR) Based on CCIR standard

(2) Image sensor Interline CCD

・Total pixel counts

(EIA) 811(H)×508(V)

(CCIR) 795(H)×596(V)

・Active pixel counts

(EIA) 768(H)×494(V)

(CCIR) 752(H)×582(V)

・Video output pixel counts

(EIA) 756(H)×485(V)

(CCIR) 742(H)×575(V)

・Cell size

(CS8620i,CS8620Hi) 8.4×9.8μm

(CS8620Ci,CS8620HCi) 8.6×8.3μm

(CS8630i,CS8630H) 6.35×7.4μm

(CS8630Ci,CS8630HC) 6.5×6.25μm

・Scanning area

(CS8620i,CS8620Ci, 6.5×4.85mm

CS8620Hi,CS8620HCi) (type-1/2)

(CS8630i,CS8630Ci, 4.8×3.6mm

CS8630H,CS8630HC) (type-1/3)

・H drive frequency (Internal sync)

(EIA) 14.31818MHz ±100ppm

(CCIR) 14.18750MHz ±100ppm

(3) Scanning lines

(EIA) 525 lines

(CCIR) 625 lines

(4) Scanning format 2 : 1 interlace

(5) Sync System Internal/External

(aut omatic change over)

(6) Scanning frequencies (intern al synchronization

Horizontal drive (H) mode)

(EIA) 15.734kHz ±100ppm

(CCIR) 15.625kHz ±100ppm

Vertical drive (V)

(EIA) 59.94Hz ±100ppm

(CCIR) 50.0Hz ±100ppm

(7) Aspect ratio 4:3

(8) Sensitivity

・Standard (GAIN:MGC,γ=1.0)

(CS8620i,CS8620Ci 200 lx 、F5.6 (3100K)

CS8630i,CS8630Ci)

(CS8620Hi,CS8620HCi) 400 lx 、F11 (3100K)

(CS8630H,CS8630HC) 400 lx 、F8 (3100K)

・Minimum (GAIN:MAX、γ=0.45)

(CS8620i,CS8620Ci) 0.2 lx 、F1.4

(CS8 630i,CS8630Ci) 0.2 lx 、F1.4

(CS8620Hi,CS8620HCi) 0.1 lx 、F1.4

(CS8630H,CS8630HC) 0.2 lx 、F1.4

(9) Video output VS:1.0V(p-p) /75Ω

VS (Video + SYNC)

(10) Resolution

Horizontal

(EIA) 570 TV lines

(CCIR) 560 TV lines

Vertical

(EIA) 485 lines (350 TV lines)

(CCIR) 575 lines (410 TV lines)

(11) S/N 60dB(p-p)/rms (typical)

(GAIN:MGC、γ=1.0)

(12) Input signal

①External sync pulses HD・VD/SYNC/VS

・Pulse level HD、VD、SYNC:2~6V(p-p)

VS:1.0(SYNC0.3)V(p-p)

・

Input impedance

75Ω/ High Switch-able by the

panel SW

(Initial factory setting: High)

・Scanning system 2 : 1 interlace

・Polarity Negative

・Pulse width HD:6.4±3μs

VD:150~800μs

・Frequency

Horizontal (fH)

(EIA) fH=15.734kHz ±2%

(CCIR) fH=15.625kHz ±2%

Vertical (fV)

(EIA) fV=2fH/525

(CCIR) fV=2fH/625

・Scanning lines

(EIA) 525 lines

(CCIR) 625 lines

・Phase different The difference in phase

between the falling edge of

VD and that of HD is shown in

the figure below.

1st FIELD for EIA 2nd FIELD for EIA

2nd FIELD for CCIR 1st FIELD for CCIR

t1=0±5μS t2=(1/2)fH±5μS

②Shutter trigger (TRG)

・Pulse level VL=0~0.5V VH=2~5V

・

Input impedance

High impedance

・Polarity Positive

・Pulse width 2μs~1/4s

(13) Output sign al

①HD/VD pulses Under internal sync operation ,

output available by the panel

SW selection

(Initial factory setting: IN)

・ Output level HD: 4.5±0.5V(p-p)

(high impedance) VD: 5.0±0.5V(p-p)

・ Scanning system 2 : 1 interlace

・ Polarity Negative

・ Pulse width

(EIA) HD: 6.36±1μs, VD: 572±10μs

(CCIR) HD: 6.41±1μs, VD: 480±10μs

・Frequency

Horizontal (fH)

(EIA) fH=15.734kHz ±100ppm

(CCIR) fH=15.625kHz ±100ppm

Vertical (fV)

(EIA) fV=2fH/525

(CCIR) fV=2fH/625

・Scanning lines

(EIA) 525 lines

(CCIR) 625 lines

②Clock pulse

・Output level 2.0±0.3V(p-p)

(high impedance)

・Frequency (Under internal synchronization)

(EIA) 14.31818 MHz±100ppm

(CCIR) 14.18750 MHz±100ppm

③ WEN Under random trigger shutter

operation, WEN is output

during the period starting from

the VIDEO OUT START VD

falling edge through the VIDEO

OUT END VD falling edge.

・Polarity Positive

・Diagram The circuit is shown in the

figure below.

(14) Sensitivity setting Mode selecti on via panel SW

(Initial factory setting: MGC)

AGC(Automatic Gain Control)

MGC (Manual Gain Control)

(15) MGC Manual sensitivity adju stment

available

(16) Gamma 1.0 / 0.45 selectable via rear panel

DIP switch

(Initial factory setting: 1.0)

(17) White clip Clip-level: 820±40mV(p-p)

(Excluding SYNC)

(18) Electronic shutter Normal shutter

The following shutter speed setup

is possible by rear panel DIP

switch selection.

Normal,1/125,1/250, 1/500,

1/1000,1/2000, 1/4000, 1/10000s,

and Flicker-less (Initial Factory

setting: Normal)

Slow-speed shutter

1FLD,2FLD, 4FLD, 6FLD,8FLD,

and 10FLD

(19) Random trigger shutter RTS Mode selection available

1

Shutter-speed Switch

Setting

Internal sync

SYNC

Non-reset

2

Shutter-speed TRIG

Pulse-width Setting

Internal sync

SYNC

Non-reset

3

Shutter-speed Switch

Setting

Internal sync

SYNC Reset

4

Shutter-speed TRIG

Pulse-width Setting

Internal sync

SYNC Reset

5

Shutter-speed Switch

Setting

HD / VD IN

(*1)

SYNC

Non-reset

6

Shutter-speed TRIG

Pulse-width Setting

HD / VD IN

(*1)

SYNC

Non-reset

7

Shutter-speed Switch

Setting

HD / VD IN

(*2)

SYNC

Non-reset

8

Shutter-speed TRIG

Pulse-width Setting

HD / VD IN

(*2)

SYNC

Non-reset

*1: Consecutive HD / Consecutive VD IN

*2: Consecutive HD / Single VD IN

(20) Special shutter User-defined shutter-timing and

shutter-speed cued and timed by

shutter trigger and restart / reset

pulse input ON / OFF selectable

via rear panel DIP SW

(Initial factory setting: OFF)

(21) CCD integration mode Field / Frame storage(integration)

Switch-able by rear panel DIP

Switch Selection (Initial factory

setting:frame integration)

(22) Restart/Reset Restart / Reset function available

via rear panel DIP-SW selection

(Initial factory setting: OFF)

Remark : CS8620Hi, CS8620HCi are possible for a

restart/reset operation only at the field

integration mode.

(23) Power source DC12V±10%[Ripple level

: Less than 10mV(p-p)]

(24) Power consumption approx. 1.3W

(25) Ambient condition

・Performance assurance

Tem pe r at u re 0 ℃~40℃

Humidity 20~80% (No condensing)

・Operation assurance

Temperature -10℃~50℃

Humidity 20~80% (No condensing)

・Storage

Temperature -20℃~60℃

Humidity 20~95% (No condensing)

(26) Lens mount C-mount

(27) Flange back 17.526mm

(28) Dimensions 29(W)×29(H)×31(D)mm

(Ex cluding protruding part)

(29) Mass Approx. 50g

(30) Option unit

・Power adapter CA130C (AC100V)

・Power / Video connector (Maker : Hirose denki)

HR10A-10P-12S

・Camera cable CPSC2000 (2m)

・Tripod adapter

・IR cut filter

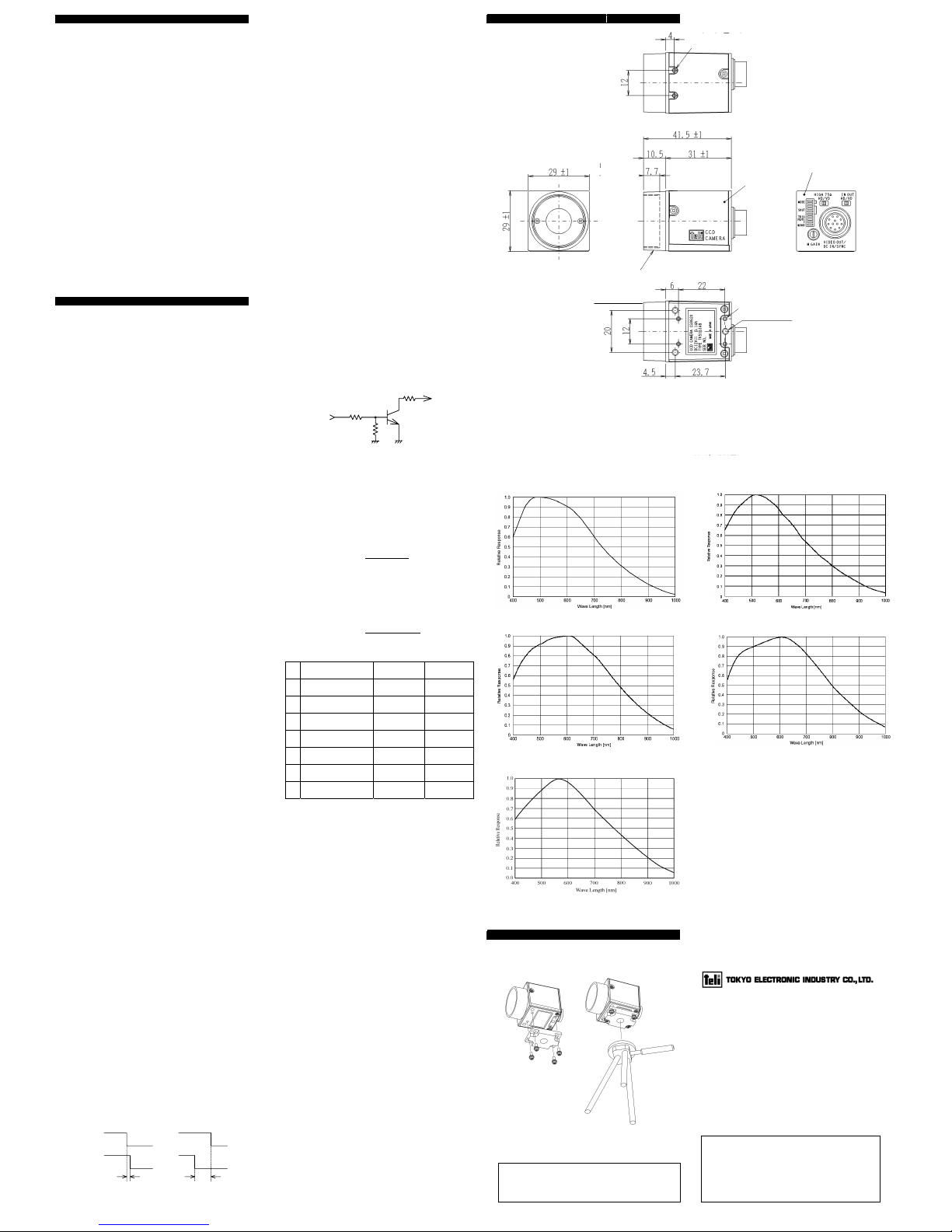

DRAWINGS

Typical spectral response

[The lens characteristics and light source characteristics is no t

reflected in the table.]

CS8620i,CS8620Ci

CS8620Hi

CS8630H,CS8630HC

HOW TO FIX CAMERA

(1) Use tripod

If you use tripod, use camera mounting kit (optional) and fix

camera.

(2) Use fixing holes on the bottom of camera

If you use fixing holes on the bottom of camera, Please use

screw (M2 and M3).

Please use screw length less then 3mm.

2-M2 depth 3

CS8630i,CS8630Ci

CS8620HCi

Head Office 7-1, 4 chome, Asahigaoka, Hino-city,

Tokyo 191-0065, japan

・Telephone (042)-589-8771

・Facsimile (042)-589-8774

Kansai Branch Nitto Building, 1-2, 2chome,

Sakaemachi-dori, Chuo-ku,

Kobe, Hyogo 650, japan

・Telephone (078)-321-3461

・Facsimile (078)-321-3463

Fukuoka Division Yen Building, 7-21, 3 chome, Hirao,

Chuo-ku, Fukuoka 810, Japan

・Telephone (092)-523-3395

・Facsimile (092)-523-3397

Dealership

WEN

2SC4176

51

10k

4700

CAUTION

If the screw is long, it touches with printed circuit board,

and it causes some trouble and accident.

3-M3 depth 3

4-M2 depth 3

Lens screw

all-in depth

Cover

Lens mount

Rear panel

D3002864 A

Loading...

Loading...