Telford Tornado Stainless, Tempest Stainless Installation Manual

Tel 01952 257963 Fax 01952 253452

Furrows Business Park, Haybridge Road

Wellington, Telford, Shropshire TF1 2FE

www.telford-group.com

WATERHEATER MANUFACTURERS ASSOCIATION

STAINLESS

Tornado & Tempest Stainless

™

Installation Guide

PRODUCTS

2

MAINS PRESSURE DOMESTIC HOT WATER APPLIANCE

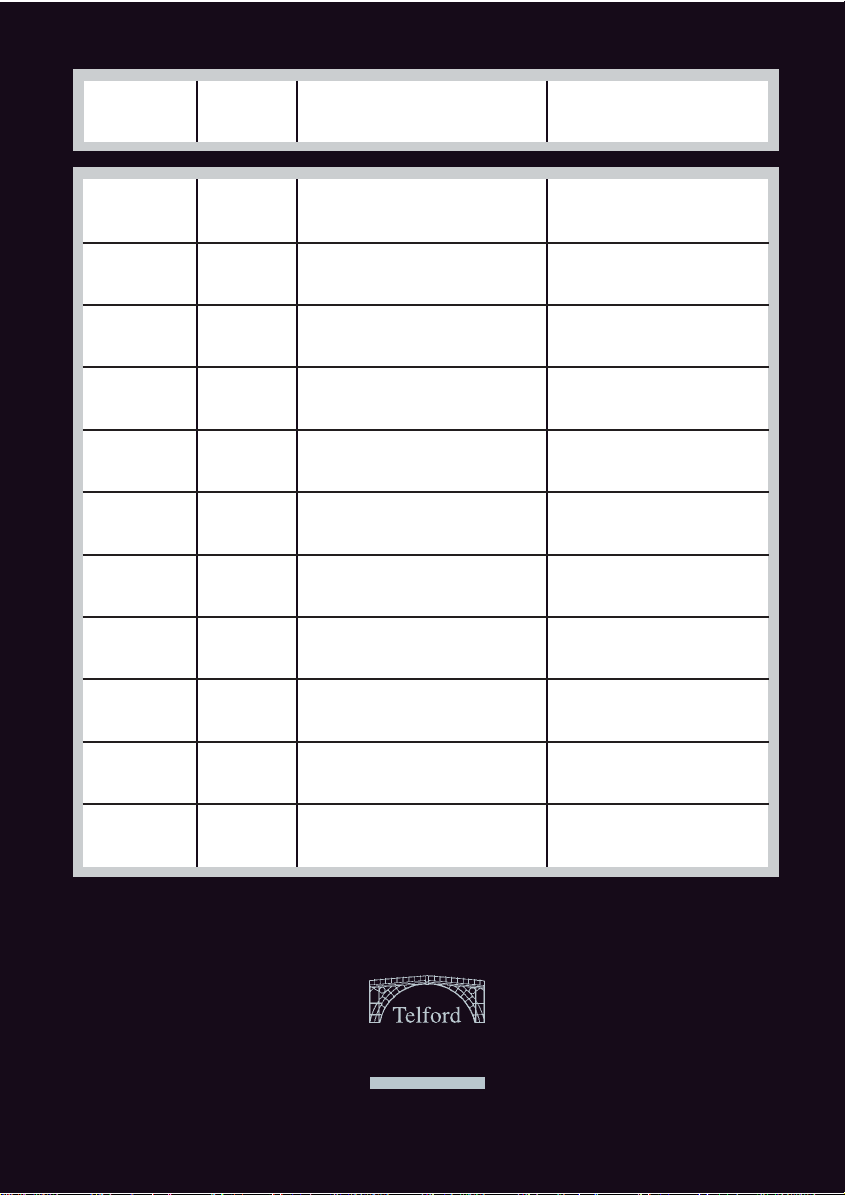

STORAGE

CAPACITY

IN LITRES

90

125

150

170

200

250

300

Tempest & Tornado Stainless

Mains pressure domestic hot water cylinder

WARNING TO USER:

This appliance must be serviced annually by a competent person.

Failure to comply with the above will invalidate the manufacturer’s

warranty.

Do not remove or adjust any component part of this unvented

water heater: Contact the installer.

If this unvented water heater develops a fault, such as a flow of hot

water from the discharge pipe, switch the heater off and contact

the installer.

WARNING TO INSTALLER:

This installation is subject to building regulation approval, notify

Local Authority of intention to install.

Use only manufacturer’s recommended replacement parts.

Installed by:

Name: ..................................................................................

Address: ..............................................................................

.............................................................................................

Tel. No.: ...............................................................................

Completion Date: .................................................................

Water Supply Pressure

Max

12 Bar

Min

1.5Bar

Electric Immersion Heaters

14“/3kW • 230V AC

Operating Pressure

3 BAR

Expansion Vessel charge Pressure

3 BAR

Expansion relief valve setting

5 BAR

Pressure & Temperature relief valve setting

7 BAR • 90ºC

Maximum Primary working Pressure

3 BAR

APPLIANCE SERIAL NO:

Weight and litre capacity

Indirect Direct

Technical help line: 01952 257961

Telford Copper Cylinders Limited Unit 22 Furrows Business Park Telford TF1 2FE

WEIGHT

WHEN FULL

IN KGS

125

165

195

220

250

310

360

Ltrs Kgs

STAINLESS

PRODUCTS

Date Parts Engineer/

Replaced Company

Installed and

Commissioned

First Annual

Service

Third Annual

Service

Fourth Annual

Service

Fifth Annual

Service

Sixth Annual

Service

Seventh Annual

Service

Eighth Annual

Service

Ninth Annual

Service

Tenth Annual

Service

STAINLESS

PRODUCTS

14

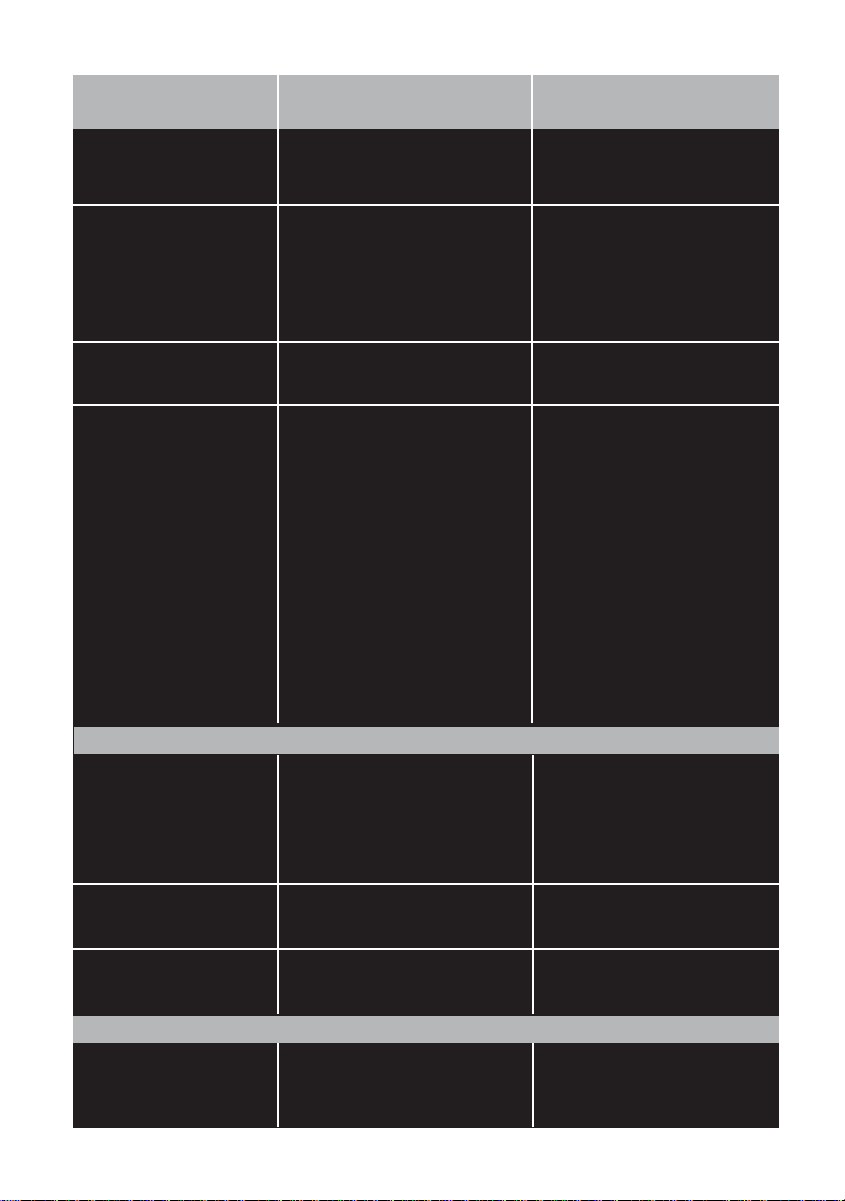

SYMPTOM POSSIBLE ACTION

CAUSES

No flow

Low Pressure

Intermittent discharge

from P&T or P valve(s)

Continuous

discharge from

P&T or P valve(s)

Mains service valve not open

Blocked filter.

Service valve not fully open or

partially blocked filter.

Restricted delivery pipework

Low mains pressure.

Expansion vessel pressure below

3.0 bar or faulty.

Wrongly set or faulty Inlet Pressure

Reducing Valve.

Defective expansion relief valve or

debris or scale on seating of valve.

Defective or incorrectly set cylinder

thermostat (ie temperature set too

high) allowing water to overheat.

Crossflow from uncontrolled cold

water mains supply to mixer tap or

shower valves.

Faulty expansion vessel.

Open stop valve or replace.

Clean filter in base of Pressure

Reducing Valve.

Ensure service valve is fully open or

clean filter in PRV.

Replace damaged or

old pipework.

Check incoming mains pressure or

discuss with local water supplier

Replenish or replace in accordance

with instructions in the maintenance

section.

Replace PRV

Operate expansion relief valve

mechanism to clear debris.

If discharge does not stop replace

expansion relief valve.

Check setting and operation of

cylinder thermostat (55-65

o

C).

Replace if necessary.

Check mixer taps and shower valve

and fit check valves or area

pressure controls if required.

Alternatively supply cold water to

mixer tap or shower valves from

balanced supply position on inlet

control set.

Recharge or replace.

Water fails to heat

Not enough

hot water

Water not

hot enough

Water fails to heat

Boiler not working. Pump and/or

control valve not operating.

Cylinder thermostat upper limit stat

has operated.

Cylinder too small.

Boiler not providing enough heat.

Cylinder thermostat settings

incorrect.

Upper limit cut-out switch has

operated in immersion heater.

Check boiler controls.

Check control functions and

replace faulty parts.

Reset the button on the dual

cylinder thermostat after

investigating cause of overheating.

Check storage specification is

adequate. Telford Service

Department can help.

Adjust thermostat to between 55

o

C

and 65

o

C. Ensure boiler

thermostat is set to above 75

o

C.

Turn off electricity supply, open

cap of I/H and reset cut-out

(red button) or press external reset

button if fitted.

PROBLEM Solving:

INDIRECT

DIRECT

Loading...

Loading...