Page 1

The Fredericks Company

MX2A Active Thermocouple Gauge

Instruction Manual

The Fredericks Company - Televac

2400 Philmont Avenue

Huntingdon Valley, PA 19006

web: www.frederickscompany.com

email: sales@frederickscompany.com

tel: +1 215 947 2500

fax: +1 215 947 7464

Page 2

CONTENTS LIST OF FIGURES

Contents

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.1 Disclaimer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.3 Operating Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.4 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.5 Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2 Electrical Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.3 Menu Navigation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.4 Menu Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.5 Explanation of Menu Items and Navigation . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.5.1 Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.5.2 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.5.3 Set Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.5.4 Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.5.5 Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.6 Analog Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3 RS-485 Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.1 Changing Communications Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.2 Communications Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.3 RS-485 Command List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.4 RS-485 Sample Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.5 RS-485 Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

List of Tables

1 Operating Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 RS-485 Communication Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3 RS-485 Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4 RS-485 Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5 Understanding the Sample Commands: ppse, PPSE, and Baaa . . . . . . . . . . . . . . . . . 16

6 Examples for ppse, PPSE, and Baaa . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

7 Error Code Explanations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

List of Figures

1 MX2A Dimensional Drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 MX2A Electrical Connection Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3 Graph of MX2A Gas Dependence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4 Graph of Analog Output Functions Available on the MX2A . . . . . . . . . . . . . . . . . . . . . 13

email: sales@frederickscompany.com tel: +1 215 947 2500 web: frederickscompany.com mx2a_im rev F 1 of 17

Page 3

Instruction Manual MX2A Active Thermocouple Gauge

1 Introduction

1.1 Disclaimer

All information in this manual is subject to change without notice. The Fredericks Company assumes

no responsibility for inaccuracies in product specifications or any liability arising from product use.

Please contact Televac at sales@televac.com or call 215-947-2500 with comments or questions.

1.2 Description

The MX2A is a thermocouple vacuum gauge with a range of 1 × 10−4Torr to 1000 Torr. It utilizes a

Televac thermocouple vacuum sensor, part number 2-2126-0YY. It has a two color OLED display with

selectable units of Torr, Millibar, and Kilopascal. Settings can be changed through RS-485 communications with a PC or on the unit using four capacitive touch buttons located on the top of the unit. The

MX2A has 2 set points, one relay and one open collector, and a selectable analog output option. The

analog output has a variety of options including four linear outputs, linear by decade, logarithmic,

and non-linear.

email: sales@frederickscompany.com tel: +1 215 947 2500 web: frederickscompany.com mx2a_im rev F 2 of 17

Page 4

Instruction Manual MX2A Active Thermocouple Gauge

1.3 Operating Specifications

Table 1: Operating Specifications

Operating Range 1 × 10−4to 1000 Torr

Communications RS-485

Programmable Set Points 2

Set Point 1 Open Collector

Set Point 2 Relay

Analog Output 7 selectable 0 to 10 V

Supply Voltage +22 to +26 V DC

Maximum Power 8 W

Supply Voltage +22 to +26 V DC

Calibration Medium Dry air or nitrogen

Overpressure 150 PSI

Digital Output Resolution 2 significant digits with exponent

Analog Output Resolution 16 bits

Operating Temperature 0◦C to 50◦C

Storage Temperature −20◦C to 60◦C

Bakeout Temperature

Brass (P/N: 2-8910-110)

Stainless (P/N: All Others)

Response Time ≤ 2 second

Accuracy

1 mTorr to 10 mTorr

10 mTorr to 10 Torr

10 Torr to 100 Torr

100 Torr to 1000 Torr

Analog Output

Standard Resolution

1 mTorr to 500 mTorr

500 mTorr to 5 Torr

5 Torr to 50 Torr

50 Torr to 500 Torr

500 Torr to 1000 Torr

Display Readable Distance 3 m (10 feet)

100◦C (electronics removed)

200◦C (electronics removed)

±1 mTorr

±10%

±30%

±10%

±5 mV

1 mTorr

10 mTorr

100 mTorr

1 Torr

10 Torr

email: sales@frederickscompany.com tel: +1 215 947 2500 web: frederickscompany.com mx2a_im rev F 3 of 17

Page 5

Instruction Manual MX2A Active Thermocouple Gauge

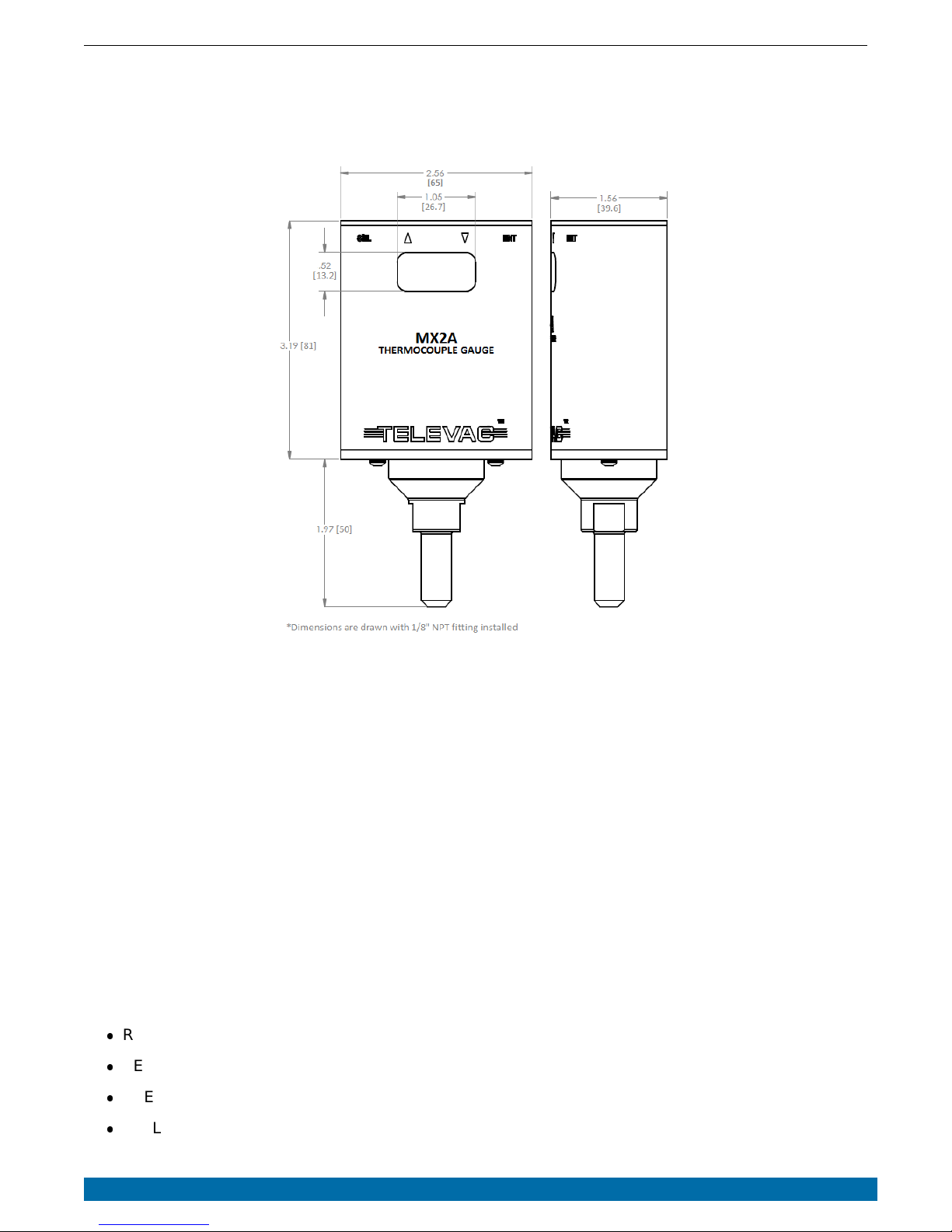

1.4 Dimensions

Figure 1: MX2A Dimensional Drawing

1.5 Safety Information

START BY READING THESE IMPORTANT

SAFETY INSTRUCTIONS AND NOTES

In these instructions the word “product” refers to the MX2A and all of its approved parts and accessories. NOTE: These instructions do not and cannot provide for every contingency that may arise in

connection with the installation, operation, or maintenance of this product. Should you require further

assistance, please contact Televac at the email address on the second page of this manual.

This product has been designed and tested to offer reasonably safe service provided it is installed,

operated, and serviced in strict accordance with these safety instructions.

These safety precautions must be observed during all phases of operation, installation, and service

of this product. Failure to comply with these precautions or with specific warnings elsewhere in this

manual violates safety standards of design, manufacture, and intended use of the instrument. Televac

disclaims all liability for the customer’s failure to comply with these requirements.

READ Instructions – Read all safety and operating instructions before operating the product.

RETAIN instructions – Retain the safety and operating instructions for future reference.

HEED warnings – Adhere to all warnings on the product and in the operating instructions.

FOLLOW instructions – Follow all operating and maintenance instructions.

email: sales@frederickscompany.com tel: +1 215 947 2500 web: frederickscompany.com mx2a_im rev F 4 of 17

Page 6

Instruction Manual MX2A Active Thermocouple Gauge

ACCESSORIES – Do not use accessories not recommended in this manual as they may require a

technician to restore the product to its normal operation.

The MX2A qualifies as a Safety Extra-Low Voltage (SELV) device. As such, it represents little to no

hazard concerning electrical shock or burns.

Do not substitute parts or modify instrument. Because of the danger of introducing additional hazards, do not install substitute parts or perform any unauthorized modifications

to the product. Return the product to Televac for service and repair to ensure that safety

features are maintained. Do not use this product if it has unauthorized modifications.

The MX2A is not designed to be serviced by the operator. Any service should be done by a Televac technician. However, in the event of any attempt to service the unit, please remove the power

supply to minimize the risk of harm.

The 2A sensor is user-replaceable and additional 2A sensors can be ordered from Televac by the

operator. Do not attempt to use other sensors with the MX2A remote. Using another sensor may

result in damage to the MX2A and voids any warranty in place.

2 Setup

2.1 Installation

Each MX2A is designed to be used in conjunction with a 2A sensor. The 2A sensor can be mounted in

any orientation for accurate measurement up to 10 Torr. For measurements up to atmosphere, mount

the 2A sensor in an upright position. The sensor should be mounted close to the area where vacuum

measurement is desired. Failure to mount the 2A in a vertical position will decrease the accuracy of

the measurement between 10 Torr and atmosphere, but will leave the accuracy below 10 Torr unaffected. Each 2A sensor has a key that only allows the MX2A to mate with the sensor in the proper

orientation. Rotate the MX2A until the correct alignment is obtained and the MX2A is able to slide

onto the 2A sensor. Connect the power connector to the top of the unit and be sure to tighten the

screws so that a firm connection is maintained.

Try to avoid connecting the MX2A to the vacuum chamber by long or narrow piping as this may

affect the accuracy and response time of the unit. Avoid mounting the unit near a heater within the

chamber as this may affect the measurement accuracy. Excessive vibration of the unit may affect

accuracy and decrease the life of the unit. Exposure to oils and other contaminants will decrease the

accuracy and decrease the life of the sensor. Do not expose the unit to corrosive gases.

2.2 Electrical Information

Power connectors and adaptors for use with the MX2A are available for purchase from Televac. Operators wishing to create their own adaptors should refer to the pin out of the MX2A below. Each

connection labeled “Floating” has no connection and should remain so.

email: sales@frederickscompany.com tel: +1 215 947 2500 web: frederickscompany.com mx2a_im rev F 5 of 17

Page 7

Instruction Manual MX2A Active Thermocouple Gauge

Figure 2: MX2A Electrical Connection Information

Pin Description

1 Analog Output (Ground)

2 RS-485 (-)

3 SP2 NC

4 SP2 NO

5 SP1 Open Drain

6 Floating

7 Floating

8 Supply Voltage

9 Analog Output (0 to 10 V)

10 RS-485 (+)

11 SP2 Com

12 SP1 Source

13 Floating

14 Floating

15 Ground

2.3 Menu Navigation

The MX2A contains many operator customizable features. Changing these features is possible through

the menu or via RS-485 communications. To navigate the menu simply use the buttons found on top

of the MX2A. The four buttons include the SEL button, an UP arrow, a DOWN arrow, and an ENT button.

Using the SEL button allows the operator to change between menu categories. Using the ENT button

allows the user to enable value editing and save values in addition to toggling between options where

appropriate. Using the UP and DOWN arrows allows navigation through menu options. The UP and

DOWN arrow buttons are also used to edit values.

email: sales@frederickscompany.com tel: +1 215 947 2500 web: frederickscompany.com mx2a_im rev F 6 of 17

Page 8

Instruction Manual MX2A Active Thermocouple Gauge

2.4 Menu Structure

1. Measurement

2. Calibration

(a) Vacuum

(b) 10 Torr

(c) Atmosphere

(d) Resolution High/Low

(e) Default

(f) Diagnostic

(g) Analog Output Adjustment

(h) Gas Type

3. Set Points

(a) SP1L

(b) SP1H

(c) SP2L

(d) SP2H

4. Units

(a) Torr/kPa/mbar

5. Output

(a) Analog Output

i. Logarithmic

ii. Linear by Decade

iii. Non-linear

iv. Linear 4

v. Linear 3

vi. Linear 2

vii. Linear 1

(b) RS-485 I/O

i. Address

ii. Parity

iii. Stop Bits

iv. Baud Rate

2.5 Explanation of Menu Items and Navigation

Below is a general explanation of each level of the menu structure of the MX4A.

2.5.1 Measurement

The measurement screen contains the reading of the sensor in easy-to-read blue digits and includes

units. In addition to the digital reading, the yellow bar on the measurement screen provides an analog

indication of the pressure based on a logarithmic scale. At 1000 Torr the yellow bar should stretch

across the width of the screen. At 0 Torr the yellow bar will disappear, and at 1 Torr, the yellow bar

will be half way across the screen.

email: sales@frederickscompany.com tel: +1 215 947 2500 web: frederickscompany.com mx2a_im rev F 7 of 17

Page 9

Instruction Manual MX2A Active Thermocouple Gauge

2.5.2 Calibration

To reach the calibration screen:

Navigate to the measurement screen.

Press SEL once.

Press the UP and DOWN arrows to navigate between panes under the calibration heading.

To ensure that the unit always displays with the most accuracy, the MX2A includes a number of

operator-configurable calibration points. While the MX2A is factory calibrated, the use of the included

calibration points may become necessary after extended use, contamination, etc. If accuracy is critical, it is recommended to return the sensor to TELEVAC for NIST-traceable calibration.

Note: Calibration should be performed in the following order: vacuum adjustment, 10 Torr adjustment, 760 Torr adjustment. Failing to calibrate in this order will result in inaccuracies.

Note 2: CHANGING CALIBRATION SETTINGS VOIDS NIST-TRACEABLE CALIBRATIONS!

A. Vacuum (Zero)

To reach the vacuum screen:

The vacuum screen is the first pane of the calibration screen.

Press ENT to unlock the vacuum screen.

Press UP or DOWN to adjust the reading.

When the desired reading is reached, press ENT to save and lock the change.

The vacuum calibration point allows the gauge to adjust the pressure reading at high vacuum

(“zeroing”). This should be used only when the operator knows that the unit is pumping down

below 10−4Torr and the unit reads a non-zero number. When the vacuum is below the range

of MX2A measurement (preferably as low as 10−5Torr), adjust the unit until it blinks between

.0000 and .0001.

For users calibrating against a NIST calibrated standard, maximum accuracy for the MX2A can

be obtained by calibrating the MX2A to .0050 Torr instead of the normal .0000 Torr reading.

B. 10 Torr

To reach the 10 Torr adjustment screen:

Navigate to the calibration screen.

Press DOWN one time.

Press ENT to unlock the 10 Torr adjustment screen.

Press UP or DOWN to adjust the reading.

When the desired reading is reached, press ENT to save and lock the change.

The 10 Torr calibration point allows the gauge to adjust the pressure reading at 10 Torr. This

should be used only when the operator knows that the unit under calibration is compared to a

reference gauge that is NIST traceable calibrated and reading near 10 Torr.

C. Atmosphere

To reach the atmosphere screen:

Navigate to the calibration screen.

Press DOWN two times.

Press ENT to unlock the atmosphere adjustment screen.

Press UP or DOWN to adjust the reading.

When the desired reading is reached, press ENT to save and lock the change.

email: sales@frederickscompany.com tel: +1 215 947 2500 web: frederickscompany.com mx2a_im rev F 8 of 17

Page 10

Instruction Manual MX2A Active Thermocouple Gauge

The atmosphere calibration point allows the gauge to adjust the pressure reading at atmosphere

(760 Torr). This should be used only when the operator knows that the unit is exposed to atmosphere or is compared to a reference gauge that is NIST calibrated and reading near 760

Torr.

For users calibrating against a NIST calibrated standard, maximum accuracy for the MX2A can

be achieved by adjusting the unit between 740 Torr and 780 Torr.

D. Resolution High/Low

To reach the resolution high/low screen:

Navigate to the calibration screen.

Press DOWN three times.

Press ENT to unlock the resolution high/low screen.

Press UP or DOWN to adjust the reading.

When the desired reading is reached, press ENT to save and lock the change.

The resolution of the MX2A is set to low by default. Under this setting the resolution is determined

by the accuracy of the gauge. The gauge will automatically adjust the resolution based on the

pressure. The MX2A always displays four digits on the calibration screen. For operators who are

looking for more resolution on the measurement screen, the MX2A can be set to high resolution

and will display four digits on the measurement screen.

E. Default

To reach the default screen:

Navigate to the calibration screen.

Press DOWN four times.

Press ENT twice to trigger a reset to the factory defaults.

The default screen resets all calibration point adjustments to the default values. This feature

should only be used when necessary. Warning: RESTORING TO DEFAULT CALIBRATION SETTINGS

VOIDS THE CALIBRATION!

F. Diagnostic

To reach the diagnostic screen:

Navigate to the calibration screen.

Press DOWN five times.

The diagnostic screen is used by Televac technicians when inspecting the MX2A for any problems.

Under no circumstance does the operator need to access or consider this screen.

G. Analog Output Adjustment

To reach the analog output screen screen:

Navigate to the calibration screen.

Press DOWN six times.

Press ENT to unlock the analog output adjustment screen.

Press UP or DOWN to adjust the reading.

When the desired reading is reached, press ENT to save and lock the change.

The analog output accuracy for the MX2A generally agrees with the digital reading. However,

in extreme temperatures or in significant humidity, the agreement may change slightly. For

uses of the MX2A where the analog output accuracy is critical, an adjustment is available to

ensure accuracy. When making this adjustment use a calibrated voltmeter to measure the analog

output voltage when the MX2A is at a very stable pressure. Compare this voltage reading to the

expected voltage. The expected voltage can be determined based on the formulae in the section

of this manual entitled Analog Output.

email: sales@frederickscompany.com tel: +1 215 947 2500 web: frederickscompany.com mx2a_im rev F 9 of 17

Page 11

Instruction Manual MX2A Active Thermocouple Gauge

H. Gas Type

The 2A sensor exhibits different sensitivities to different gases. The default gas is set to air.

Air and dry nitrogen are approximated to have the same sensitivity and using either does not

require any compensation. For users who wish to measure the pressure of Argon gas, the MX2A

includes an Argon correction option.

To change the MX2A between air/nitrogen and argon modes:

Navigate to the calibration screen.

Press DOWN seven times.

Press ENT to unlock the gas type screen.

Press UP or DOWN to change between the gas modes.

When the appropriate mode is selected, press ENT to save and lock the change.

Figure 3: Graph of MX2A Gas Dependence

2.5.3 Set Points

To reach the set point screen:

Navigate to the measurement screen.

Press SEL two times.

The set point screen contains set point 1 low.

email: sales@frederickscompany.com tel: +1 215 947 2500 web: frederickscompany.com mx2a_im rev F 10 of 17

Page 12

Instruction Manual MX2A Active Thermocouple Gauge

To access set point 1 high, set point 2 low, or set point 2 high, press DOWN from the initial set

point screen.

When the correct set point is selected, press ENT to unlock the set point adjustment screen.

Press UP and DOWN to change the value.

When the desired reading is reached, press ENT to save and lock the change.

The MX2A contains two set points for the convenience of the operator. Set point 1 is an N-Channel

60 V MOSFET open collector. It has a maximum current rating of 1 A. The data sheet can be found

at www.vishay.com/docs/69958/si2308bd.pdf. Set point 2 is a relay with a maximum switching

voltage of 220 V DC (250 V AC) and a maximum switching current of 2 A. The data sheet can be found

at www.te.com/catalog/pn/en/1393788-3.

2.5.4 Units

To reach the units screen:

Navigate to the measurement screen.

Press SEL three times.

Press ENT to unlock the units screen.

Press UP and DOWN to navigate between units.

When the desired unit is reached, press ENT to save and lock the change.

Depending on the process or the region, the desired units for the MX2A may vary. To accommodate

this need, the MX2A includes a unit adjustment feature. The MX2A can be set to display the units in

Torr, kPa, or mbar.

2.5.5 Output

To reach the output screen:

Navigate to the measurement screen.

Press SEL four times.

Press UP and DOWN to navigate between the analog output and RS-485 panes.

When the desired field is present, press ENT to enter the heading.

The MX2A features a number of analog outputs and RS-485 digital output and input.

A. Analog Output

To toggle the analog output type:

Navigate to the analog output screen.

Press ENT to unlock the screen.

Press UP or DOWN to set the desired output type.

When the desired analog output is reached, press ENT to save and lock the change.

The types of analog output are listed below. For more information on the types of output, please

see the heading in this manual labeled Analog Output.

(a) Logarithmic

(b) Linear by Decade

(c) Non-linear

email: sales@frederickscompany.com tel: +1 215 947 2500 web: frederickscompany.com mx2a_im rev F 11 of 17

Page 13

Instruction Manual MX2A Active Thermocouple Gauge

(d) Linear 4

(e) Linear 3

(f) Linear 2

(g) Linear 1

B. RS-485 I/O

To make changes under the RS-485 I/O screen:

Navigate to the RS-485 I/O screen.

Press UP or DOWN to reach the desired RS-485 setting.

Press ENT to unlock the setting.

Press UP or DOWN to change the fields.

Press ENT to save and lock the change.

The RS-485 settable fields are listed below. Please see the sections labeled RS-485 Communications and Changing Communications Parameters for more details and a complete list of

commands. Listed below are the fields within the RS-485 I/O screen.

(a) Address

(b) Baud Rate

(c) Stop Bits

(d) Parity

2.6 Analog Output

The MX2A provides the option for outputting the vacuum reading in an analog form. Operators who

wish to use PLCs to monitor processes should find this function useful. There are seven different

analog output formats to choose between. The formats include Logarithmic, Linear by Decade, Nonlinear, Linear 4, Linear 3, Linear 2, and Linear 1.

A. Logarithmic

The Logarithmic output is the most useful and accurate output for covering the entire range of

the 2A with an analog output. This format uses the formula below to convert the output voltage

into a pressure measurement:

Pressre (Torr) = 10

For example, a voltage reading of 3.075 Volts corresponds to pressure of .07 Torr.

.6× (3.075− 5)

10

B. Linear by Decade

The Linear by decade output spans the entire range of the MX2A. It uses the units digit of

the voltage reading to communicate the decade of the pressure reading and the units after

the decimal to communicate the specific pressure using the very generalized expression below,

where A, B, C, and D are digits ranging from 0-9:

Votge = A.BCD → Pr essre(Torr) = 10

For example, a voltage reading of 8.367 Volts corresponds to a pressure of 36.7 Torr.

8− 6

10

× .367 = 36.7 Torr

.6× (Votge− 5)

= .07 Torr

A− 6

× .BCD

C. Non-linear

The Non-linear option outputs the raw signal collected by the 2A sensor. The raw signal is

converted to the pressure using a many-point linearization process done by the MX2A. This

feature is used for diagnostic purposes.

email: sales@frederickscompany.com tel: +1 215 947 2500 web: frederickscompany.com mx2a_im rev F 12 of 17

Page 14

Instruction Manual MX2A Active Thermocouple Gauge

D. Linear 4

The Linear 4 output is one of four linear outputs that cover a select range of the MX2A with a linear scale. The scale extends from .001 to 1 Torr, with each .010 Volt of the output corresponding

to .001 Torr.

Pressre (Torr) = Votge × (.1)

E. Linear 3

The Linear 3 output is one of four linear outputs that cover a select range of the MX2A with a linear scale. The scale extends from .01 to 10 Torr, with each .010 Volt of the output corresponding

to .01 Torr.

Pressre (Torr) = Votge × (1)

F. Linear 2

The Linear 2 output is one of four linear outputs that cover a select range of the MX2A with a linear scale. The scale extends from .1 to 100 Torr, with each .010 Volt of the output corresponding

to .1 Torr.

Pressre (Torr) = Votge × (10)

G. Linear 1

The Linear 1 output is one of four linear outputs that cover a select range of the MX2A with a linear scale. The scale extends from 1 to 1000 Torr, with each .010 Volt of the output corresponding

to 1 Torr.

Pressre (Torr) = Votge × (100)

Figure 4: Graph of Analog Output Functions Available on the MX2A

email: sales@frederickscompany.com tel: +1 215 947 2500 web: frederickscompany.com mx2a_im rev F 13 of 17

Page 15

Instruction Manual MX2A Active Thermocouple Gauge

3 RS-485 Communications

This gauge communicates with the host computer through an RS-485 interface. Each communication correspondence consists of a command line sent by the host computer and a response from the

gauge.

To communicate with the MX2A via RS-485, the user must have an RS-485 capable device to send

commands to the MX2A. Each command must be preceded by a * and will be an S, R, W, RC, or WC.

See the Communications Specifications heading for information on what settings are necessary to

properly communicate with the MX2A.

3.1 Changing Communications Settings

The communication parameters, (baud rate, address, etc.), are changed through the local menu.

Please see the section in this manual entitled Explanation of Menu Items and Navigation for more

information on navigating and editing within the menu. Below are provided some specifics on the

RS-485 Communications of the MX2A.

3.2 Communications Specifications

Table 2: RS-485 Communication Specifications

Interface RS-485 compatible

Data Transfer Method Synchronous/half duplicate method

Baud Rate 1200/4800/9600/19200/38400

Default Data Format 1 start bit, 8 data bits, 0 parity bits, 1 stop bit

Error Detection Parity bit

Parity Bit None/even/odd

Stop Bit 1

Transfer Distance Max 100 meters

email: sales@frederickscompany.com tel: +1 215 947 2500 web: frederickscompany.com mx2a_im rev F 14 of 17

Page 16

Instruction Manual MX2A Active Thermocouple Gauge

3.3 RS-485 Command List

Table 3: RS-485 Commands

Command Description

R1 Read units

R2 Read SP1L and SP1H

R3 Read SP2L and SP2H

W1 Set pressure units

W2 Set SP1L,SP1H

W3 Set SP2L,SP2H

W4 Set gas type

S1 Read pressure data

RC1 Read vacuum adjustment

RC2 Read 10 Torr adjustment

RC3 Read atmosphere adjustment

WC1 Write vacuum adjustment

WC2 Write 10 Torr adjustment

WC3 Write atmosphere adjustment

email: sales@frederickscompany.com tel: +1 215 947 2500 web: frederickscompany.com mx2a_im rev F 15 of 17

Page 17

Instruction Manual MX2A Active Thermocouple Gauge

3.4 RS-485 Sample Commands

Table 4: RS-485 Commands

Command Output Description

*0R1<CR> 0001 Units are in Pa

0002 Units in Torr

0003 Units in mbar

*0R2<CR> ppsePPSE Lower set point 1 given by ppse

Upper set point 1 given by PPSE

*0R3<CR> ppsePPSE Lower set point 2 given by ppse

Upper set point 2 given by PPSE

*0W10001<CR> 0001 Units are in kPa

*0W10002<CR> 0002 Units are in Torr

*0W10003<CR> 0003 Units are in mbar

*0W2ppsePPSE<CR> ppsePPSE Assign set point 1 lower to ppse and

Assign set point 1 upper to PPSE

*0W2ppsePPSE<CR> ppsePPSE Assign set point 2 lower to ppse and

Assign set point 2 upper to PPSE

*0W4xx<CR> GG Change gas type: N2=Nitrogen/Air, AR=Argon

*0S1<CR> ppse Vacuum reading is ppse

*0RC1<CR> Baaa Read Vac. adjustment

*0RC2<CR> Baaa Read 10 Torr adjustment

*0RC3<CR> Baaa Read Atm. adjustment

*0WC1Baaa<CR> PPSE Vac. adjustment is Baaa, reading is PPSE

*0WC2Baaa<CR> PPSE 10 Torr adjustment is Baaa, reading is PPSE

*0WC3Baaa<CR> PPSE Atm. adjustment is Baaa, reading is PPSE

Table 5: Understanding the Sample Commands: ppse, PPSE, and Baaa

Letters Description

pp Mantissa of pressure

s Sign of exponent (0 is negative and 1 is positive)

e Exponent of pressure

PP Mantissa of pressure

S Sign of exponent (0 is negative and 1 is positive)

E Exponent of pressure

B Sign of number (0 is negative and 1 is positive)

aaa Number between 000 and 499

email: sales@frederickscompany.com tel: +1 215 947 2500 web: frederickscompany.com mx2a_im rev F 16 of 17

Page 18

Instruction Manual MX2A Active Thermocouple Gauge

Table 6: Examples for ppse, PPSE, and Baaa

Letters Description

ppse=2412 Pressure = 2.4 × 10

ppse=8703 Pressure = 8.7 × 10

PPSE=3402 Pressure = 3.4 × 10

PPSE=5211 Pressure = 5.2 × 10

2

−3

−2

1

Baaa=0249 Adjustment = -249

Baaa=1382 Adjustment = 382

3.5 RS-485 Error Codes

Table 7: Error Code Explanations

Error Code

0N001

Command error (invalid character command or number

after character)

Description

0N002 Units error (invalid number received after “*0W1”)

0N003

0N004

Set point value error (invalid or out of range number after

“*0W2” or “*0W3”)

Calibration value error (invalid or out of range number

after “*0WC1”, “*0WC2”, “*0WC3”, or “*0WC4”)

0N005 Gas error (invalid characters after “*0W4”)

email: sales@frederickscompany.com tel: +1 215 947 2500 web: frederickscompany.com mx2a_im rev F 17 of 17

Loading...

Loading...