Page 1

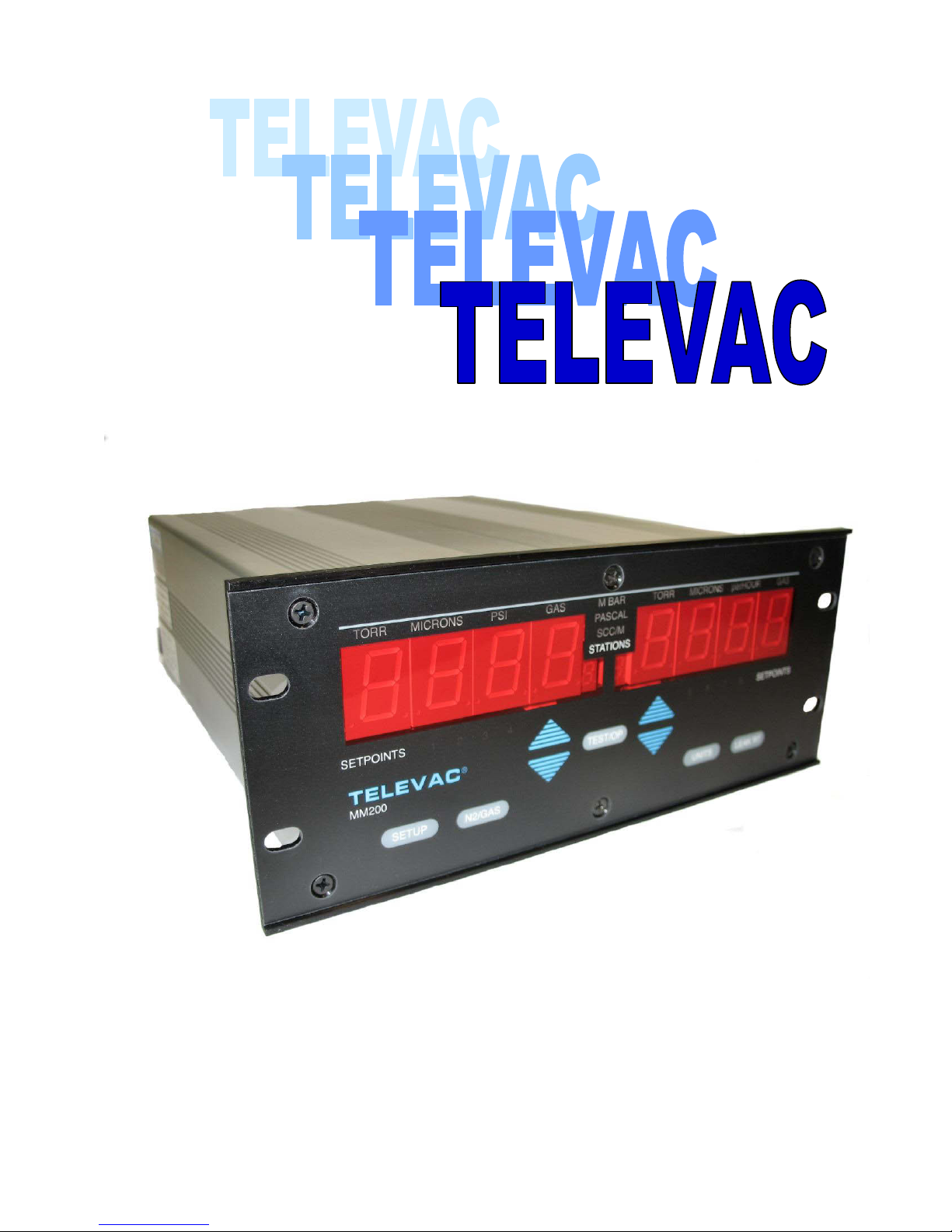

MM200

TELEVAC

A DIVISION OF THE FREDERICKS COMPANY

2400 PHILMONT AVE.

HUNTINGDONVALLEY, PA 19006

Page 2

TELEVAC

PARTS

#

QTY

ITEM DESCRIPTION

1

1

MM200

2

1

Instruction Manual

3

1

AC Power Cable

4

1

Power supply module

5

1 SET

Rubber Feet

1 3 4

5

INSTRUMENT MANUAL

VACUUM GAUGE MODEL MM200

160Phone:(215) 947-2500 fax:(215) 947-7464 e-mail:sales@televac.com web site:www.televac.com

MM-200_im REV M

Page 1 of 160

Page 3

TELEVAC

TABLE OF CONTENTS

INSTRUMENT MANUAL

VACUUM GAUGE MODEL MM200

SECTION TITLE PAGE

TABLE OF CONTENTS 1

100 INTRODUCTION 10

101 DESCRIPTION 10

102 STANDARD FEATURES 11

Measurement Expansion 11

Sensor interface Modules 11

Computer Interface Modules 11

Non-volatile Memory 11

Display 11

Keyboard 11

CPU Configuration 11

103 SETPOINT RELAYS 11

104 VACUUM GAUGE TUBES 11

Diaphragm 12

Thermocouple 12

Convection 12

Cold Cathode 12

Hot Cathode 12

Capacitance Diaphragm Gauge 13

200 INITIAL CHECKOUT 14

201 UNPACKING AND INSPECTION PROCEDURES 14

202 INVENTORY 14

203 INTIAL CHECK PROCEDURES 14

Correct Operating Voltage 14

Initial Displays 15

160Phone:(215) 947-2500 fax:(215) 947-7464 e-mail:sales@televac.com web site:www.televac.com

MM-200_im REV M

Page 2 of 160

Page 4

TELEVAC

INSTRUMENT MANUAL

VACUUM GAUGE MODEL MM200

SECTION TITLE PAGE

300 INSTALLATION 18

301 MODULE CONFIGURATION 18

302 LINE VOLTAGE SELECTION 23

303 GAUGE CONTROLLER INSTALLATION 23

Freestanding 23

Rack Mounted 23

304 GAUGE SENSOR INSTALLATION WARNINGS 24

305 VACUUM CONNECTION FITTINGS 25

NPT Pipe Thread Connections 25

0-ring Compression Fittings 25

Conflat Flange Fittings 25

KF Flange Connections 26

Cajon Fittings 26

306 GAUGE SENSOR INSTALLATION 26

307 REMOVAL AND INSTALLATION OF MODULES 27

308 DESCRIPTION OF MODULES 28

Power Supply Module 28

Setpoint Relay Module 29

Communications Module 29

Thermocouple Module 30

Convection Module 31

Diaphragm Module 31

Cold Cathode Module 32

3D Hot Cathode Resident Module (I² R Degas) 32

3E Hot Cathode Resident Module (EB Degas) 34

3F Hot Cathode Mini BA Module (software ver. 2.31 or higher) 35

Capacitance Diaphragm Modules 38

160Phone:(215) 947-2500 fax:(215) 947-7464 e-mail:sales@televac.com web site:www.televac.com

MM-200_im REV M

Page 3 of 160

Page 5

TELEVAC

INSTRUMENT MANUAL

VACUUM GAUGE MODEL MM200

SECTION TITLE PAGE

400 OPERATION 40

401 DISPLAY DESCRIPTION DEFINITIONS 40

Station Number 40

Data Display 41

Units 41

Gas Type 41

Leak Rate Indicator 41

Setpoint Relay Status Indicator 41

402 ERROR INDICATIONS 41

403 KEYPAD DESCRIPTION 42

PUSHBUTTON Functions 43

TEST/OP Pushbutton 43

SETUP Pushbutton 43

N2/GAS Pushbutton 43

UP/DOWN Arrows 43

UNITS Pushbutton 43

LEAK RT Pushbutton 43

404 RELAY SETPOINTS 43

Range of Use 44

Changing Sensor Assignment 44

405 ANALOG 0-10V OUTPUTS 45

0-10V Outputs 46

0-10V Output Options 49

406 INITIAL OPERATION SETUP SEQUENCE 50

Pressure Readings 50

Relay Setup 50

Gas 51

Measurement Units 51

Leak rate 51

407 3F HOT CATHODE MODULE (Mini BA) (software ver. 2.31 or higher) 52

Sensitivity 52

Degas 52

Filament 52

160Phone:(215) 947-2500 fax:(215) 947-7464 e-mail:sales@televac.com web site:www.televac.com

MM-200_im REV M

Page 4 of 160

Page 6

TELEVAC

INSTRUMENT MANUAL

VACUUM GAUGE MODEL MM200

SECTION TITLE PAGE

500 SETUP 53

501 INTIALIZATION 53

Initial Displays 53

502 USE OF PUSHBUTTONS 54

TEST/OP Pushbutton 54

Return to Normal Operation 54

Self-Diagnostic Test 54

UP/DOWN Arrows 56

SETUP Pushbutton 56

Cold Cathode Setup 56

3D & 3E Hot Cathode Setup 59

Degass Timer 62

Relay Setpoints 62

SP#1 – Station Assignment 62

SP#1 – Setpoint Selection 62

UNITS Pushbutton 63

N2/GAS Pushbutton 64

LEAK RT Pushbutton 64

HANDLING UNITS 64

For versions 2.31 or higher. Refer to Section 6.2, page 602

503 3F HOT CATHODE MODULE (Mini-BA) 65

F (AUTO or SELF or BOTH) 65

FIL (ON or OFF or RDY) 65

DGAS (0FF or ON) 65

DGAS (# time) 65

FIL NBR (1 or 2) 65

SENS (# sensitivity) 65

160Phone:(215) 947-2500 fax:(215) 947-7464 e-mail:sales@televac.com web site:www.televac.com

MM-200_im REV M

Page 5 of 160

Page 7

TELEVAC

INSTRUMENT MANUAL

VACUUM GAUGE MODEL MM200

SECTION TITLE PAGE

600 COMMUNICATIONS 66

601 RS232 INTERFACING WITH COMPUTER USING MICROSOFT HYPER 66

TERMINAL

602 RS232 / RS485 PROTOCOL FOR SOFTWARE VERSIONS 2.31 OR HIGHER 67

RS232 or RS485 67

STD or ALT 67

UNIT #xx 67

PREF #xx 67

RS485 Prefix and Addresses Table – For Software Ver. 2.31 or Higher 68

New Commands For MM200 - For Software Ver. 2.31 or Higher 69

Commands That Have Been Updated For 3F Modules 69

Commands For The 3F Hot Cathode MINI-BA Module 70

603 COMMUNICATIONS – FOR SOFTWARE VER. 1.35 – 2.31 70

604 RS232/RS485 COMMANDS 70

RS232/RS485 70

Communications 75

Configuration 77 Data

Output 79

Display 81

Gas 82

Hot Cathode 83

Leak Rate 84

Outputs 85

Set Point Setting Values 88

Convection Gauge 4A atmosphere Adjustment 92

Zeroing Thermocouple, Convection, and Diaphragm Gauges 92

RS232/RS485 Command Summary 95

RS485 Host Command Set 99

RS232 Commands Used To Implement RS485 101

Alternate address Scheme for RS485 102

Special Commands 102

RS232 Hardware 103

RS485 Hardware 103

605 COMMUNICATIONS – FOR SOFTWARE VER. 1.21 – 1.34 104

RS232 Protocol 104

606 COMMAND SUMMARY – FOR SOFTWARE VER. 1.19 – 1.20 105

Hardware 108

Commands 109

“B” Mode Commands 109

Cold Cathode 110

160Phone:(215) 947-2500 fax:(215) 947-7464 e-mail:sales@televac.com web site:www.televac.com

MM-200_im REV M

Page 6 of 160

Page 8

TELEVAC

INSTRUMENT MANUAL

VACUUM GAUGE MODEL MM200

SECTION TITLE PAGE

606 COMMAND SUMMARY – FOR SOFTWARE VER. 1.19 – 1.20

Communications 111

127 Data Output 113

Hot Cathode 115

Leak Rate 116

Output Formats 117

Set Points 117

Set Point Setting Values 118

607 COMMUNICATIONS – FOR SOFTWARE VER. 1.0 – 1.19 119

RS232 Protocol 119

RS232 Hardware 127

Special Commands 127

160Phone:(215) 947-2500 fax:(215) 947-7464 e-mail:sales@televac.com web site:www.televac.com

MM-200_im REV M

Page 7 of 160

Page 9

TELEVAC

INSTRUMENT MANUAL

VACUUM GAUGE MODEL MM200

SECTION TITLE PAGE

700 CALIBRATION 128

701 ELECTRICAL "VERIFICATION" 128

Equipment Required 128

Procedure 129

702 VACUUM CALIBRATION 129

Equipment Required 130

Procedure 131

703 CALIBRATION FOR ALTERNATE GASSES 133

800 SPECIFICATIONS 134.

801 CONTROLLER SPECIFICATIONS 134

802 CONTROLLER DIMENSIONS 134

803 SENSORS 135

804 ORDERING INFORMATION 135

900 TROUBLESHOOTING 137

901 PRELIMINARY TROUBLESHOOTING 137

902 SETUP OF MODULE BOARDS 138

Setpoint relay module 138

Digital interface module 140

Thermocouple module 141

Convection module 143

Cold Cathode module 145

Diaphragm modules 149

Capacitance Diaphragm module 151

3D Hot Cathode module 153

3E Hot Cathode module 154

903 DRAWINGS AND SCHEMATICS 155

904 CLEANING COLD CATHODE GAUGE TUBES 156

905 SUPPRESSOR INSTALLATION FOR NOISY ENVIRONMENTS 157

160Phone:(215) 947-2500 fax:(215) 947-7464 e-mail:sales@televac.com web site:www.televac.com

MM-200_im REV M

Page 8 of 160

Page 10

TELEVAC

INSTRUMENT MANUAL

VACUUM GAUGE MODEL MM200

SECTION TITLE PAGE

1000 MISCELLANEOUS 158

CALIBRATION MODE 158

DIAPHRAGM GAUGES 158

INSTALLATION OF EPROMS 159

160Phone:(215) 947-2500 fax:(215) 947-7464 e-mail:sales@televac.com web site:www.televac.com

MM-200_im REV M

Page 9 of 160

Page 11

TELEVAC

INSTRUMENT MANUAL

VACUUM GAUGE MODEL MM200

100 INTRODUCTION

This manual provides information pertaining to the installation, operation, and maintenance of the Televac MM 200

vacuum gauge. Various sensor modules, their options, and associated sensors are covered in this manual.

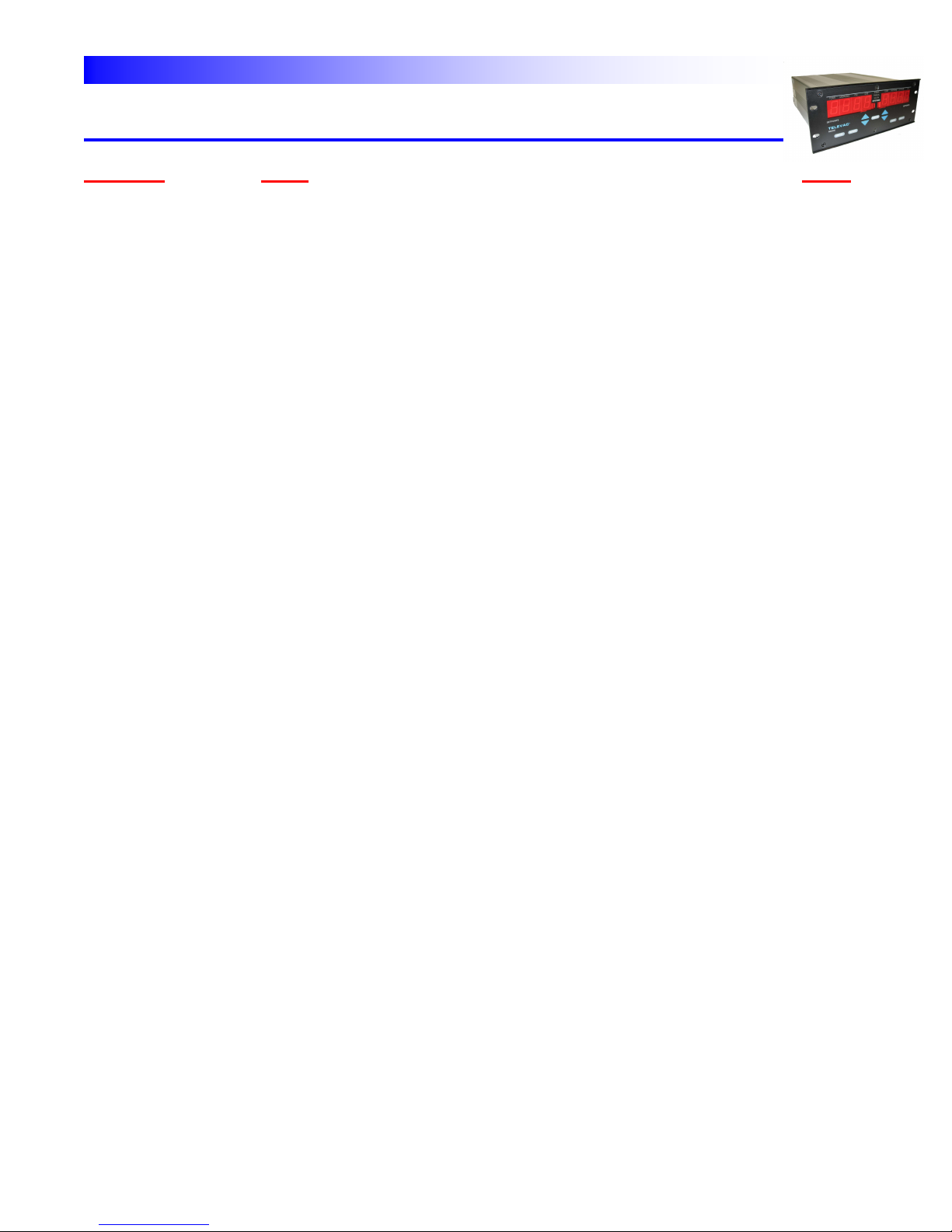

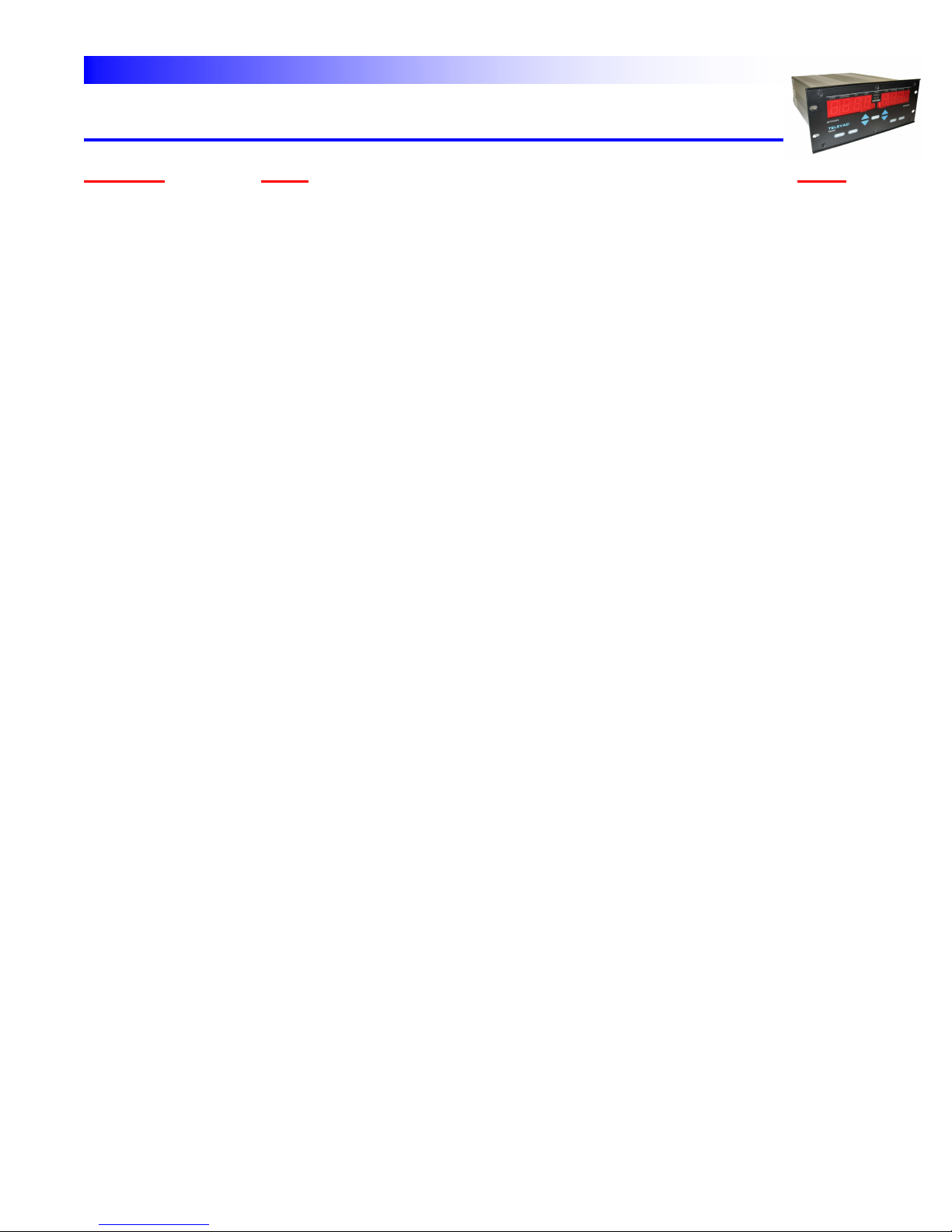

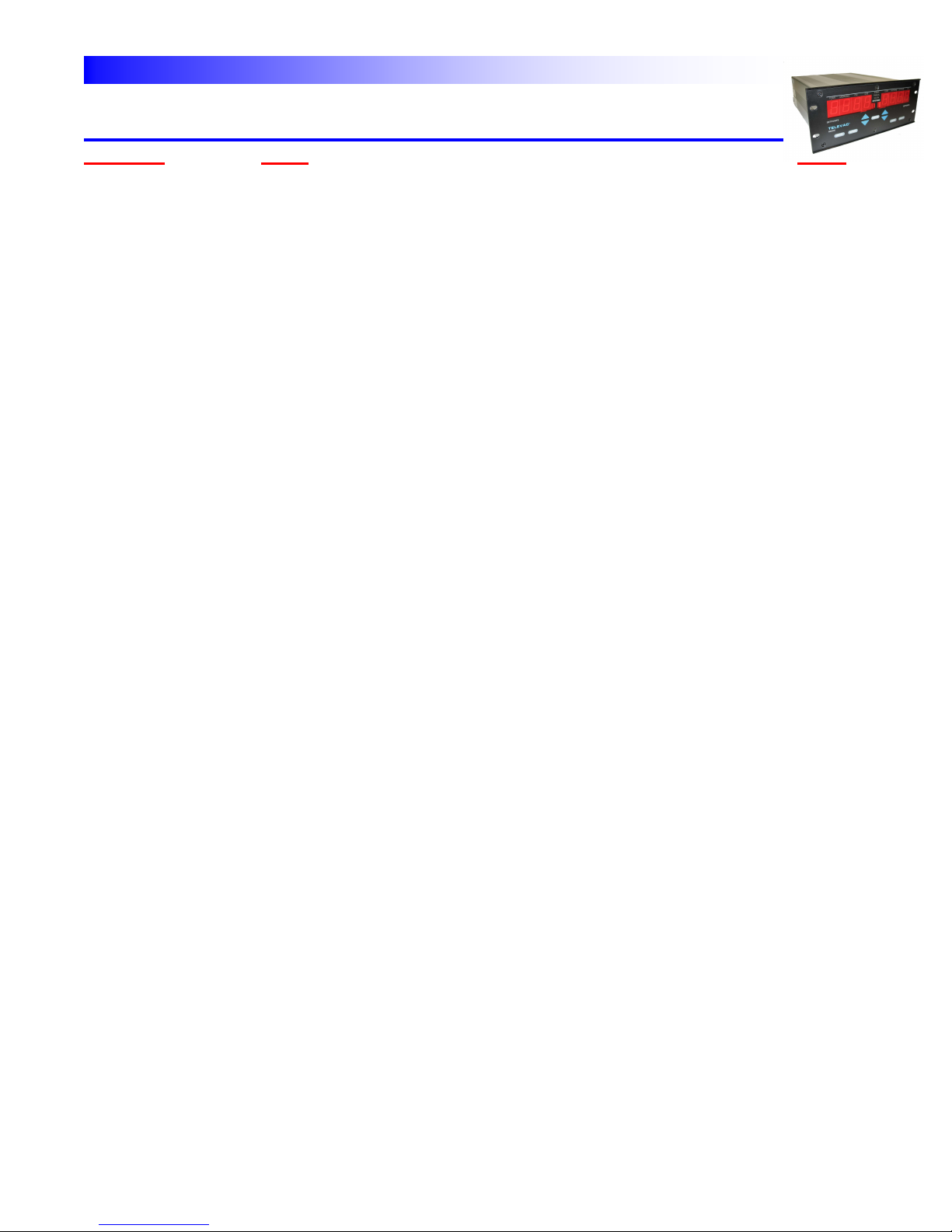

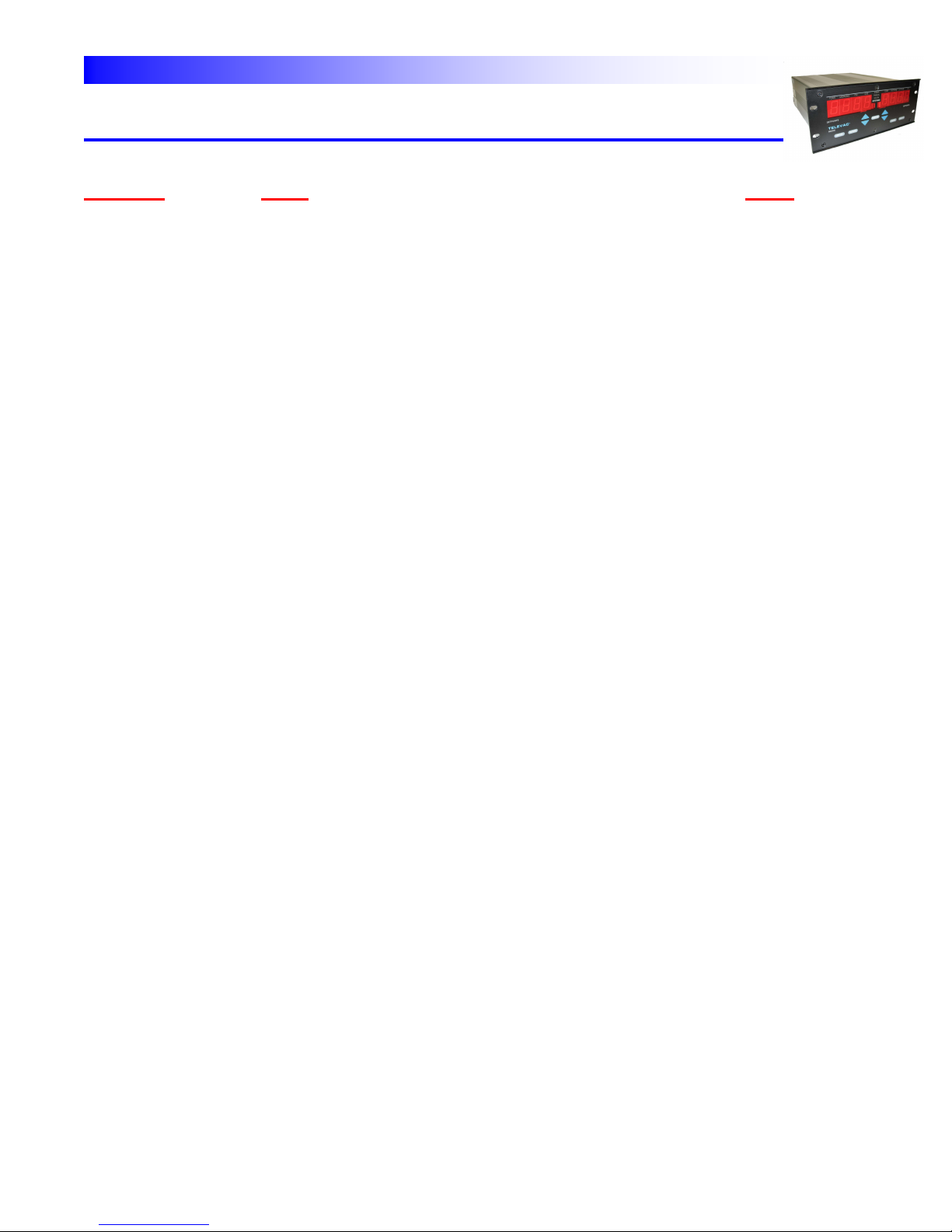

Fig. 1.1 - TELEVAC Modular Gauge

101 DESCRIPTION

The TELEVAC MM200 programmable vacuum gauge controller consists of a basic electronic unit and modular

sensor signal processing interface boards. These components utilize the latest in digital and analog technology

and provide a versatile, easy to use means for measuring pressure (vacuum). With the appropriate system and

sensors, pressures ranging from 10

vacuum chamber leak-up rate can be measured. A large selection of sensors and mounting configurations, as well

as hardware control interfaces, are available for user convenience.

There is one basic electronics unit, which accepts modules for all gauge types as well as relay modules and digital

interface modules. Several sensors are presently available. These are described in Section 104. Other sensor

modules will be available in the future. User-installed modules permit expansion. The controller provides a choice

of display data formats, display

-11

Torr through 7.5 x 10

+ 3

(10 Bar) are accurately monitored. Additionally,

160Phone:(215) 947-2500 fax:(215) 947-7464 e-mail:sales@televac.com web site:www.televac.com

MM-200_im REV M

Page 10 of 160

Page 12

TELEVAC

INSTRUMENT MANUAL

VACUUM GAUGE MODEL MM200

102 STANDARD FEATURES

MEASUREMENT EXPANSION - The electronics unit can support additional measurement modules. These

additional modules can be any mix of the above listed sensors.

SENSOR INTERFACE MODULES - Each gauge has several available sensor interface modules (See Section 300).

These modules contain the signal conditioning and measurement circuitry required to operate the sensor properly.

They also provide the user with a scalable analog output of pressure.

COMPUTER INTERFACE MODULES - The computer interface provides a means for electronic communication

with the gauge controller. An RS232 and an RS485 serial data link is provided. The data format is discussed in

Section 600.

NON-VOLATILE MEMORY - The instrument contains non-volatile memory (EEPROM) that saves all programmable

SETUP parameters when the instrument power is off.

DISPLAY - The display system for all gauges has two large multiplexed light emitting diode (LED) displays. Each

display can show a maximum of four (4) digits of data including an exponent. The display also has smaller displays

which indicate selected station number, selected measurement units, alternate gas type, and setpoint relay status.

KEYPAD - The keypad is a tactile feel, non-membrane unit that provides keys for programming and control

operations. The number of keys has been optimized for simple operation.

CPU CONFIGURATION - The central processing unit (CPU) provides the operator choices for the display format,

measurement units, communications format and baud rates as well as the ability to lock out keyboard parameter

changes.

103 SETPOINT RELAYS

The Process Control Relay or Setpoint Relay Module provides four (4) relays per module (eight maximum. These

relays are assignable to any installed station.

104 VACUUM GAUGE TUBES

This instrument supports several types of vacuum gauge tubes (sensors). Combinations of sensors can be used to

cover a wide range of absolute pressures. These

sensors can also be used to make measurements in several locations.

160Phone:(215) 947-2500 fax:(215) 947-7464 e-mail:sales@televac.com web site:www.televac.com

MM-200_im REV M

Page 11 of 160

Page 13

TELEVAC

INSTRUMENT MANUAL

VACUUM GAUGE MODEL MM200

104 VACUUM GAUGE TUBES (cont.)

DIAPHRAGM GAUGE - Measures absolute pressure by detecting very small deflections of a metal diaphragm via

a strain gauge. It is not sensitive to gas type. These sensors are temperature compensated, but do respond to

rapid changes of temperature. Temperature changes cause zero shifts. Users should note that occasional

adjustments of the zero point are normal for sustaining accuracy with this type of sensor, and provision for making

this adjustment should be included in the installation. Fine adjustment of the zero and atmospheric point is

accomplished at the rear panel on the diaphragm module. Sensor range: 1E: 1 to 800 Torr; 1F: 1000 to 9999

mbar.

THERMOCOUPLE GAUGE - Measures absolute pressures by determining the heat loss from a fine wire filament.

The response of the sensor depends on the gas type. These sensors are compensated for room temperature

variation and are calibrated for vertical operation but operate with little error in any orientation. "Zero" calibration

potentiometers are provided for occasional adjustment as required. Sensor range: 10-3 to 20 Torr.

CONVECTION GAUGE - Measures absolute pressures by determining the heat loss from a fine wire filament. The

response of the sensor depends on the gas type. These sensors are compensated for room temperature variation

and are calibrated for operation in the VERTICAL POSITION ONLY. ZERO and ATM (atmospheric pressure)

calibration potentiometers are provided for occasional adjustment as required. Sensor range: 10-3 to 10+3 Torr.

COLD CATHODE GAUGE - A high vacuum sensor that measures pressure by ionizing the residual gases in a

magnetron discharge. The body of the gauge serves as the cathode, and is at ground potential. The anode

operates at voltages up to 3000 volts. A permanent magnet traps electrons in the gauge to sustain the discharge at

very low pressure. This type of gauge may be less precise in its reading than hot cathode gauges and, like the hot

cathode gauge, is also sensitive to gas type. However, it is relatively rugged and has no filament to burn out, so

that it is often used in applications where hot cathode gauges are not reliable. Cold cathode tubes might experience

ignition time delay when trying to turn them on at high vacuum. The 7FCS quick start gauge has a thermo emission

igniter inside so every time when power applies to MM200 the filament goes on for 5 second to start ionization

chain reaction.There are various designs to cover different pressure (vacuum) ranges. Refer to Table 4.1. Sensor

range: 10

-11

to 10-2 Torr.

HOT CATHODE GAUGE - Hot cathode gauges typically have the Bayard-Alpert geometry and are used for high

vacuum measurements. Both glass enclosed and nude sensors are available. These sensors measure absolute

pressures by sensing the ion current generated by the interaction of a beam of electrons from a hot filament with

gas molecules in the vacuum system. This kind of gauge is sensitive to gas types. Filaments can be tungsten or

Thoria-Coated Iridium. The Iridium filaments don't burn out as readily if accidentally exposed to air when hot, but

can be attacked by chlorides and fluorides, which decompose the coating. Tungsten filaments also run noticeably

hotter. It is normal for such gauges to have a residual current (the x-ray limit), which may introduce significant

errors below 10

outgassing when the hot filament is turned on. Degassing is often used to accelerate this process prior to making

measurements at very low pressures. Sensor range: 10

-10

Torr depending on construction. It is also normal for sensors to generate significant amounts of

-11

to 10-2 Torr.

The pressure range for various sensors is shown in Table 4.1.

160Phone:(215) 947-2500 fax:(215) 947-7464 e-mail:sales@televac.com web site:www.televac.com

MM-200_im REV M

Page 12 of 160

Page 14

TELEVAC

NOTE:

Capacitance Diaphragm Gauge Tubes with a range of greater than 1 Torr will not control the Cold

Cathode automatic turn on!

INSTRUMENT MANUAL

VACUUM GAUGE MODEL MM200

104 VACUUM GAUGE TUBES (cont.)

CAPACITANCE DIAPHRAGM GAUGE - Measures absolute pressure by detecting very small deflections of a

metal diaphragm via a change in capacitance between the diaphragm and one or more electrodes. It is not

sensitive to gas type. These sensors are temperature compensated, but do respond to rapid changes of

temperature. Temperature changes cause zero shifts. In some cases the gauges are heated for stability and to

prevent condensation of process gasses. Users should note that occasional adjustments of the zero point are

normal for sustaining accuracy with this type of sensor, and provision for making this adjustment should be included

in the installation. Fine adjustment of the zero and atmospheric point is accomplished at the rear panel on the

diaphragm module. Sensor ranges (full scale):

5A = 1000 Torr; 5B = 100 Torr; 5C = 10 Torr

5D = 1 Torr; 5E = 0.1 Torr; 5F = special

160Phone:(215) 947-2500 fax:(215) 947-7464 e-mail:sales@televac.com web site:www.televac.com

MM-200_im REV M

Page 13 of 160

Page 15

TELEVAC

INSTRUMENT MANUAL

VACUUM GAUGE MODEL MM200

200 INITIAL CHECKOUT

201 UNPACKING AND INSPECTION PROCEDURES

1. Remove the Vacuum Gauge Controller from its shipping container

2. Carefully examine the unit for damage that may have occurred during shipping. This is especially important

if you notice signs of obvious rough handling on the outside of the cartons. REPORT ANY DAMAGE TO

THE CARRIER AND TO TELEVAC IMMEDIATELY.

3. DO NOT discard any packing materials until you have taken inventory and completed the check

procedures. You may wish retain the packing material for later use.

4. If the instrument must be returned to TELEVAC be sure to contact the service department (215-947-2500)

for a Return Material Authorization (RMA) number. Items will not be accepted without an assigned RMA.

They must be packaged, insured and shipped with transportation charges prepaid to:

TELEVAC - Division of

The Fredericks Company

2400 Philmont Avenue

Huntingdon Valley, PA 19006

202 INVENTORY

Compare the contents of the shipping containers with the invoice to be sure you received all necessary equipment.

203 INITIAL CHECK PROCEDURES

For the Initial Check Procedure you need only the control unit and the power cord. Do not connect any sensors,

cables or other devices to the unit for this check.

CORRECT OPERATING VOLTAGE - Before connecting the power cord, check the line voltage selector, which is

part of the power supply board at the rear of the unit. For 100-120V application the arrow should point to the

embossed "110" on the switch as shown in Fig. 2.1. To change to 220-240V, use a small screwdriver to turn the

switch from its position to align the arrow with the embossed "220" on the switch. (220V not permitted for

Capacitance Diaphragm Gauges. Make sure that the power switch is OFF and then plug the power cord into the

unit's socket and an appropriate outlet.

It is recommended that a surge protector circuit is used or make sure that your power line is safe from power surge.

The noise (power surge) through the power line may alter the contents of a non-volatile memory (known as data

memory) in EEPROM and cause the controller to operate erratically.

160Phone:(215) 947-2500 fax:(215) 947-7464 e-mail:sales@televac.com web site:www.televac.com

MM-200_im REV M

Page 14 of 160

Page 16

TELEVAC

CC 7E

RS485

POSITION #0 #1 #2 #3 #4 #5 #6 #7

INSTRUMENT MANUAL

VACUUM GAUGE MODEL MM200

WARNING: Voltages may exist on rear panel connectors.

DO NOT touch the exposed connectors when power is connected to the

instrument.

Note that the rear panel configuration shown in Fig. 2.1 is just one of the many possible combinations of gauges

and relay modules. This configuration has the following characteristics:

MM200 - Microprocessor with power supply,

4 relays, 5 stations and RS232

SLOT 0 - Power supply

SLOT 1 - S1- Setpoint relay module

SLOT 2 - S1- Setpoint relay module

SLOT 3 - T1- Dual thermocouple module (2 stations)

SLOT 4 - C1- Dual convection module (2 stations)

SLOT 5 - B1- Blank panel

SLOT 6 - C1- Cold cathode module (1 station)

SLOT 7 - R1- RS232 /RS485 module

INITIAL DISPLAYS - The front panel (shown in Fig. 2.2) is used to observe the displays and to execute the initial

self-test of the unit. Remove the protective plastic covering over the displays. Turn the power on by pressing the

rear panel power switch to ON. The initial display shows the word "SOFt" followed by a number indicating which

software version is present (See Fig. 2.3).

160Phone:(215) 947-2500 fax:(215) 947-7464 e-mail:sales@televac.com web site:www.televac.com

MM-200_im REV M

Page 15 of 160

Page 17

TELEVAC

Fig. 2.2 – Front Panel

.

Fig. 2.3 – Software Version

INSTRUMENT MANUAL

VACUUM GAUGE MODEL MM200

160Phone:(215) 947-2500 fax:(215) 947-7464 e-mail:sales@televac.com web site:www.televac.com

MM-200_im REV M

Page 16 of 160

Page 18

TELEVAC

Fig. 2.4 - Typical Initial Display

INSTRUMENT MANUAL

VACUUM GAUGE MODEL MM200

This message is followed by an error code, if any errors are present. (see Section 900). If no errors are present,

the initial display for the installed sensor modules appears.

In the initial right-hand display, the default mode is to display the lowest number station installed (except ionization

type gauge if there are other than ionization gauges installed). Since no sensor and/or cable is plugged in, the

right-hand display reads "CAbL" and the adjacent small number reads the corresponding station number (typically

#1). The left hand display shows the lowest number ionization (cold cathode or hot cathode) station installed

(station #7 in the example shown in Fig. 2.4). Since the high voltage power is off, the display reads "OFF". (See

Fig. 2.4). If no ionization gauge is installed, the left-hand display shows the second lowest station installed.

Fig. 2.4 shows the correct initial display for this configuration. If a display does not appear, check the power outlet

and the main fuse on the rear of the unit.

If further checkout is desired, refer to Section 502.

Assuming that the initial display check is successful, the instrument if ready for installation. Otherwise contact your

TELEVAC Service Department (See front cover).

160Phone:(215) 947-2500 fax:(215) 947-7464 e-mail:sales@televac.com web site:www.televac.com

MM-200_im REV M

Page 17 of 160

Page 19

TELEVAC

INSTRUMENT MANUAL

VACUUM GAUGE MODEL MM200

300 INSTALLATION

301 MODULE CONFIGURATION

A controller is normally ordered with various optional sensor interface modules and they are factory installed before

shipment. Before installation, verify that the selection of modules will accomplish the desired results in your

application. If additional modules are required or you have any questions about using this gauge in your

application, please call Televac at 215-947-2500. If you wish to add modules, refer to Section 307 AND 308.

One possible configuration for this gauge was shown in Section 203. The allowable configurations are restricted by

the number of cold cathode and/or hot cathode ionization stations installed.

The MM200 has six slots, which can be populated with various Televac modules. There is also a half slot that can

be used to insert a communications module. This is the only slot into which the communications module can be

inserted. This board will currently accommodate an RS232/RS485 interface. The other slots can be fitted with

various combinations of the following currently available boards:

PCB #

TYPE 6200 STA SLOT DESCRIPTION

1E -220 2 1 A dual diaphragm module.

1F -224 2 1 A dual diaphragm module.

2A -186 2 1 A dual thermocouple module.

3D -226 1 4 A single hot cathode module with Joule de-gassing.

3E -232 1 4 A single hot cathode module with EB de-gassing.

4A -215 2 1 A dual convection module.

7B -227 1 2 A single cold cathode module.

7E -223 1 2 A single cold cathode module.

7F -245 1 1 A single cold cathode module (7F UHV or 7E as req'd)

7F -253 1 1 An interface to the 7ER & 7FR remote modules.

SP -211 4 1 A four relay Process Control relay board.

3F -290 2 2 A dual Mini BA module

The 3D and 3E modules occupy four slots each.

The 7B and 7E modules occupy one and a half slots. One of these can be combined with the RS232/RS485 digital

interface module so that no space is wasted. In other locations, they will take up two slots.

The 7F module takes up only one slot. It is used with the 7F UHV tube down to 10

-11

Torr or with multiple 7E gauge

tubes where space available in the MM200 is limited.

The 7FCS module has a phone jack labeled “starter” at the back panel to plug the igniter cable in.

The 7F 6200-253 module can interface with 7ER & 7FR gauge tubes which have the remote electronics

modules.

160Phone:(215) 947-2500 fax:(215) 947-7464 e-mail:sales@televac.com web site:www.televac.com

MM-200_im REV M

Page 18 of 160

Page 20

TELEVAC

INSTRUMENT MANUAL

VACUUM GAUGE MODEL MM200

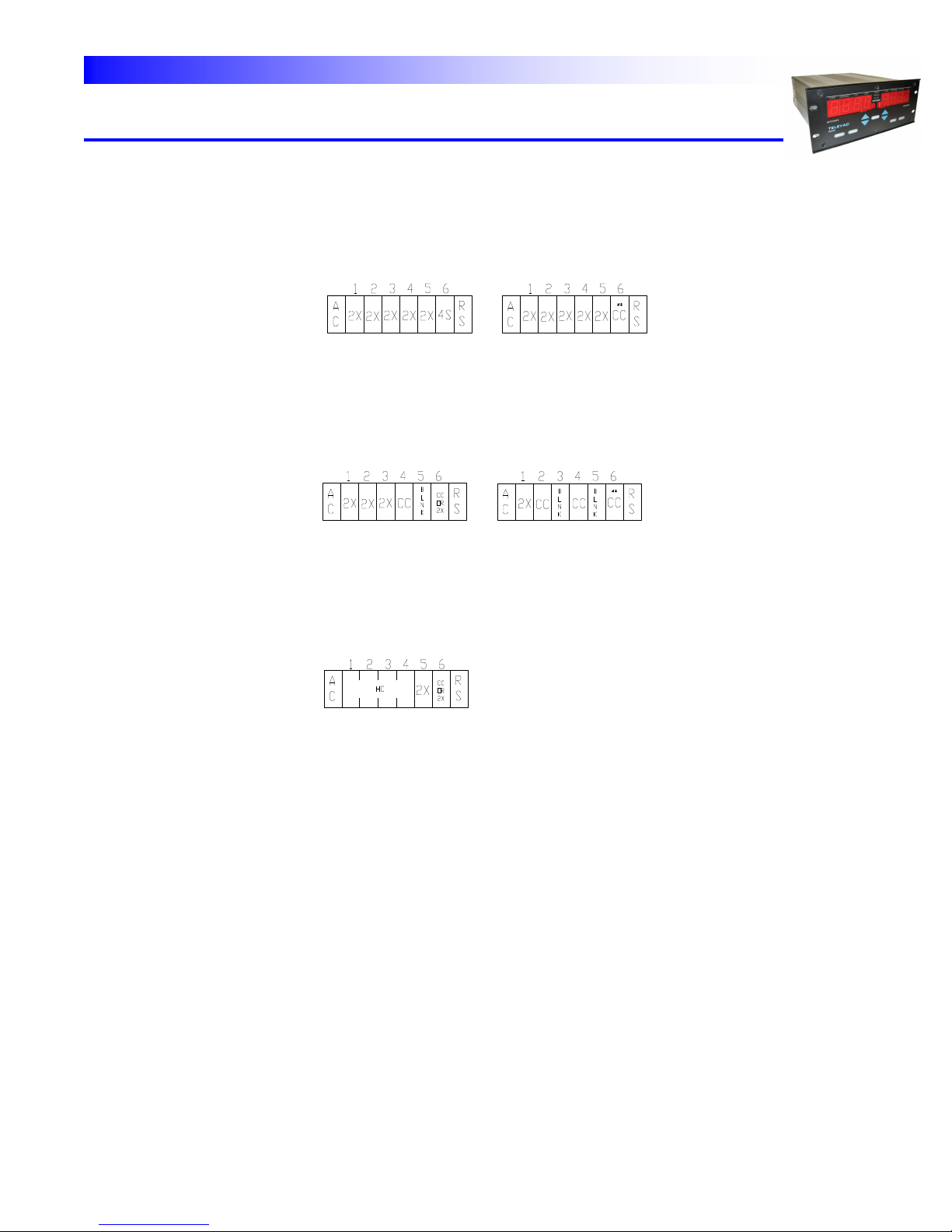

The maximum number of stations that can be configured is ten. This can be done

only if all stations are any mixture of dual modules (e.g., 1E, 1F, 2A, 4A, 5A/B).

WARNING: If any cold cathode gauge modules are installed, no sensors should be

assigned to station number ten (10).

If there is one relay module installed, then five other slots are available, and still up

to ten stations can be installed. With two relay modules, four slots are available,

and up to eight stations can be accommodated.

Setpoints must be consecutively numbered starting with number 1 (1 through 4) or

number 5 (5 through 8).

WARNING: All relays must be assigned to a station when first installed, even if they will

not be used (any station will suffice).

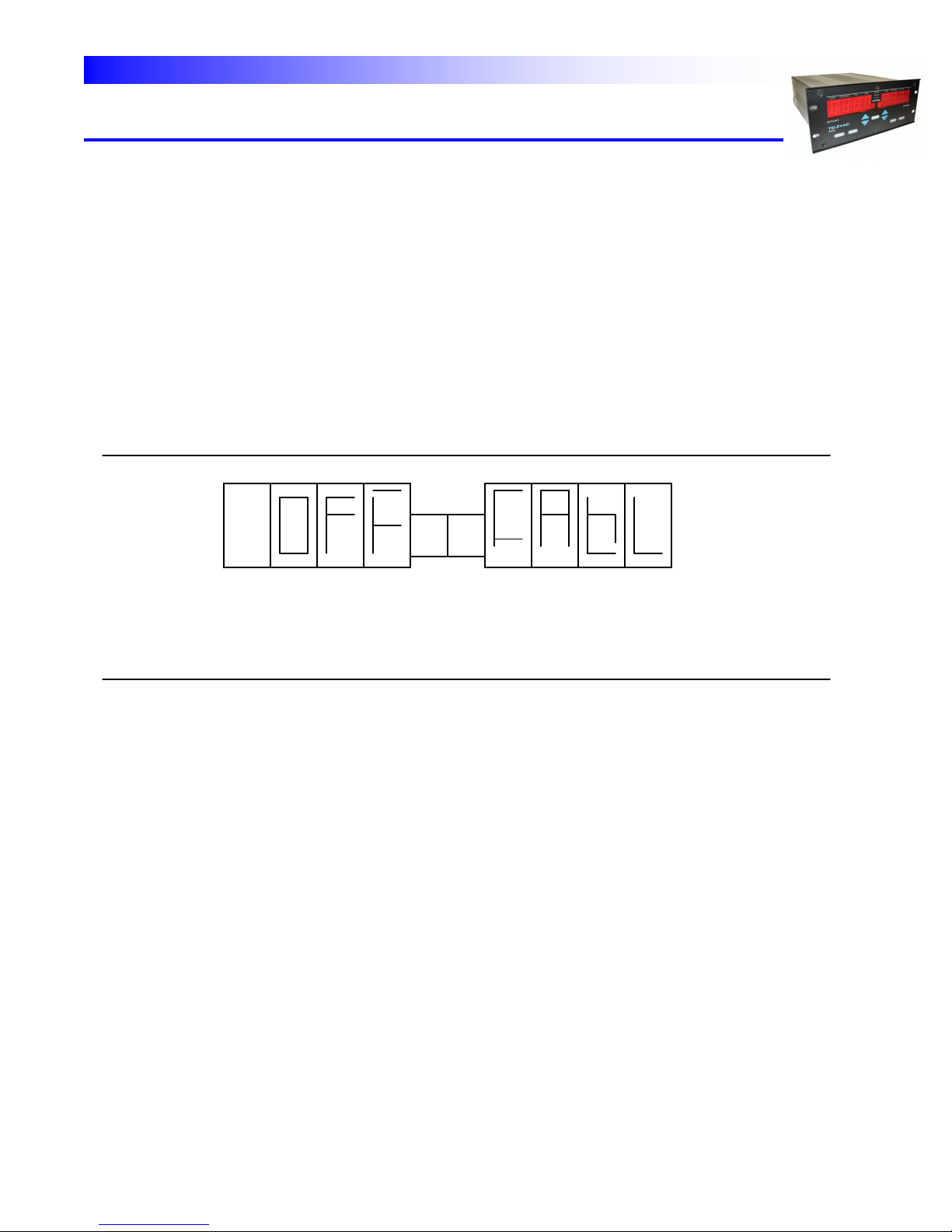

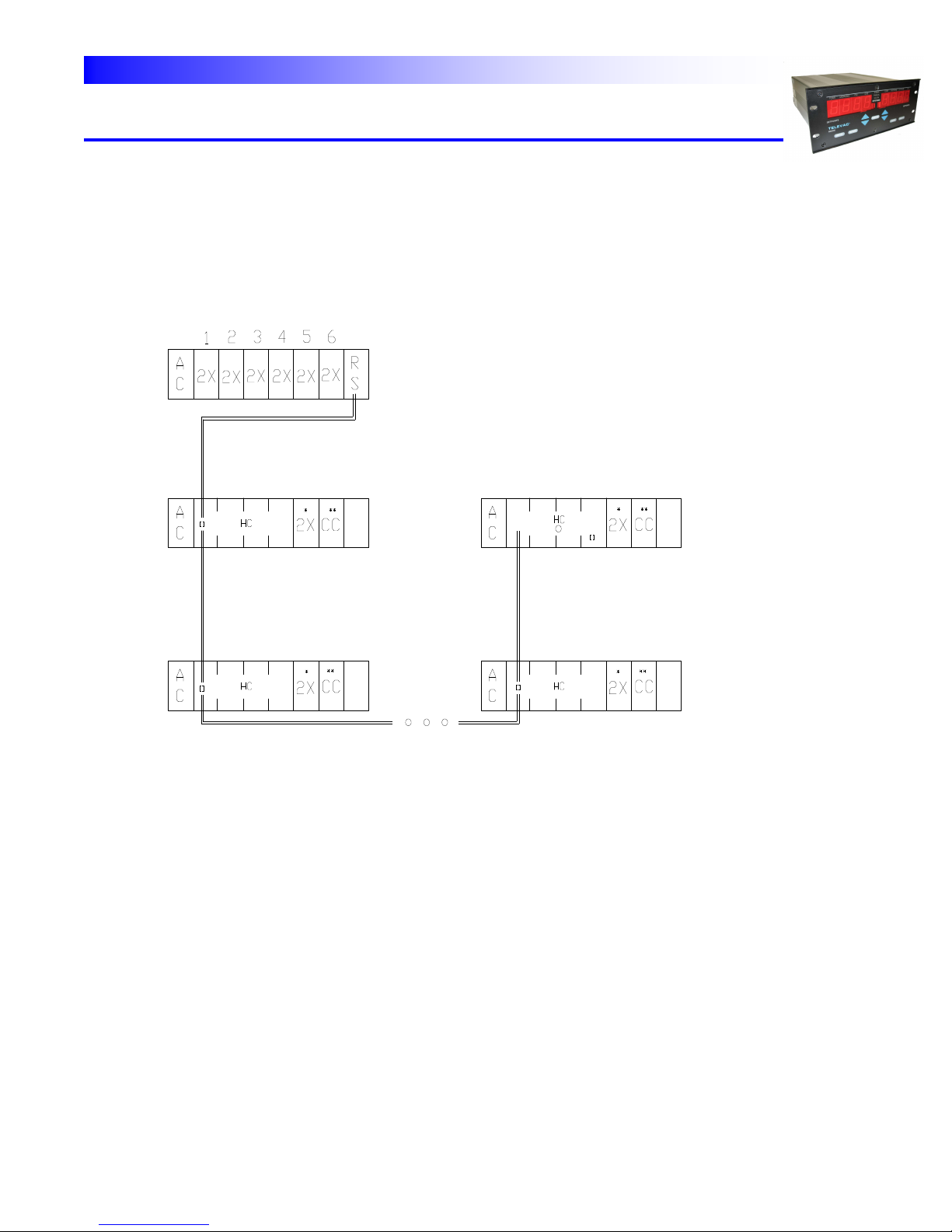

Allowable configurations for the MM200 are shown in

Table 3.1.

160Phone:(215) 947-2500 fax:(215) 947-7464 e-mail:sales@televac.com web site:www.televac.com

MM-200_im REV M

Page 19 of 160

Page 21

TELEVAC

10 8*

9 8*

MAX MAX

# #

STATIONS RELAYS

MAX MAX

# #

STATIONS RELAYS

8 8*

8 4*

MAX MAX

# #

STATIONS RELAYS

5 8*

INSTRUMENT MANUAL

VACUUM GAUGE MODEL MM200

Table 3.1a - Examples of Allowable Configurations for the MM200

MAX MAX MAX MAX

# # # #

STATIONS RELAYS STATIONS RELAYS

EPLANATION OF TERMS USED

2X = Dual station Thermocouple, Convection, Diaphragm, 7F Cold Cathode or single slot 7E cold

cathode

CC = Single station (two slot) Cold Cathode module (** shared space with RS232)

4S = Four setpoint module - * Can substitute for a 2X module

RS = RS232 or RS485

HC = Resident Hot Cathode module

160Phone:(215) 947-2500 fax:(215) 947-7464 e-mail:sales@televac.com web site:www.televac.com

MM-200_im REV M

Page 20 of 160

Page 22

TELEVAC

MM200

MAX MAX

# #

STATIONS RELAY

10

+ 48

8 (SUBSTITUTE 4S FOR 2X)

RS485 LINK TO UP TO

16 REMOTE MODULES

INTERNAL TERMINATION

RESISTOR AT LAST UNIT

Up to 48 remote sensors consisting of

Up to 16 hot cathode remote modules

(with no displays) each with up to

2 additional sensors in a daisy

chain hook up of up to 4000’

* optional local thermocouple,

convection, diaphragm or cold

cathode gauges. Maximum is

2 additional sensors but only 1

cold cathode

REMOTE HOT CATHODE MODULE(S) VIA` MM200

One of several possible combinations using the remote hot cathode module

INSTRUMENT MANUAL

VACUUM GAUGE MODEL MM200

160Phone:(215) 947-2500 fax:(215) 947-7464 e-mail:sales@televac.com web site:www.televac.com

( CONTINUED)

MM-200_im REV M

Page 21 of 160

Page 23

TELEVAC

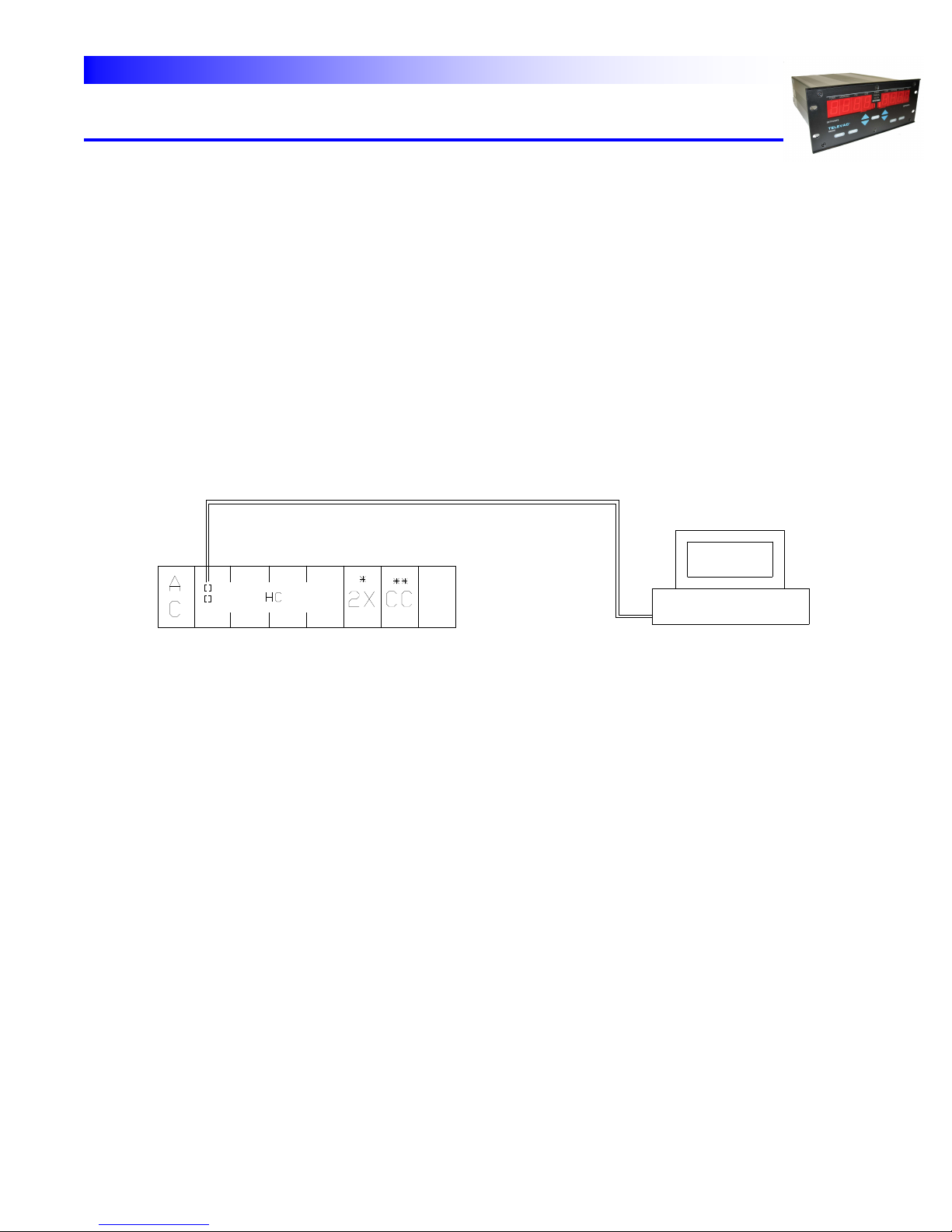

(CONTINUED)

RS232 Link

Computer

* Optional thermocouple, diaphragm,

convection or cold cathode gauges.

Maximum # remote station = 3

Including the hot cathode.

REMOTE HOT CATHODE MODULE(S) VIA COMPUTER

INSTRUMENT MANUAL

VACUUM GAUGE MODEL MM200

Table 3.1c – Allowable Configuration for the MM200 (Continued)

160Phone:(215) 947-2500 fax:(215) 947-7464 e-mail:sales@televac.com web site:www.televac.com

MM-200_im REV M

Page 22 of 160

Page 24

TELEVAC

INSTRUMENT MANUAL

VACUUM GAUGE MODEL MM200

302 LINE VOLTAGE SELECTION

The instruments are shipped from the factory with the line voltage set at 110 for 100-120 VAC operation and

operates at 50-60 Hz. If 200-240 VAC operation is desired, refer to Section 203 for procedure.

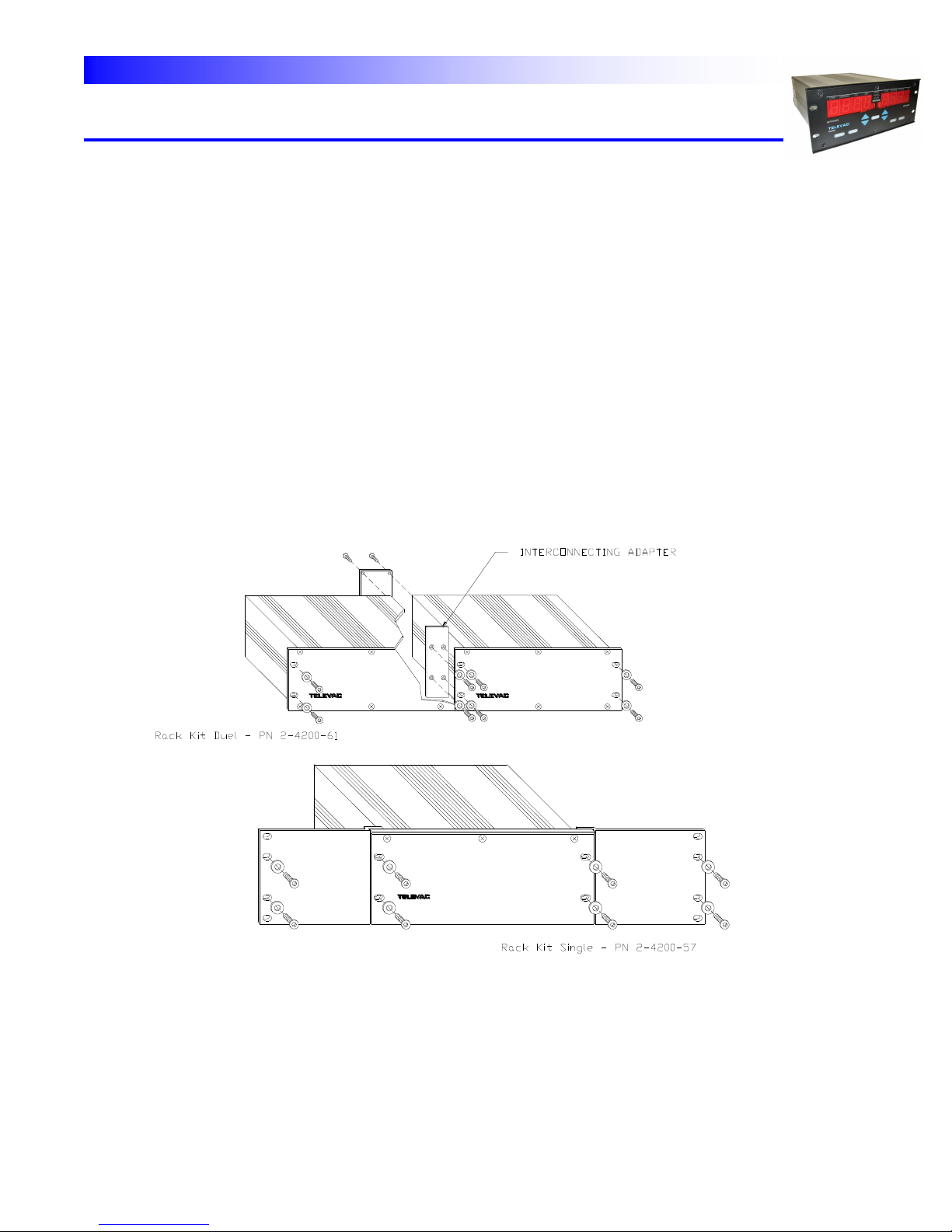

303 GAUGE CONTROLLER INSTALLATION

FREE STANDING

The instrument can be used as a freestanding unit, panel mounted or mounted in a standard 19" rack.

RACK MOUNTED - A rack adapter kit is required to rack mount one or two controllers in a standard 19" rack.

Refer to Fig. 3.2 for component configuration.

For one controller, install the small interconnecting adapter to the unit and then the long filler panel to the interconnecting adapter. Use the four (4) screws, nut and washers provided. Alternately use the adapter fillers.

For two controllers, install the two (2) small interconnecting adapters, in front and in back, between the two units.

Fig. 3.2 – Rack Adapter Details

160Phone:(215) 947-2500 fax:(215) 947-7464 e-mail:sales@televac.com web site:www.televac.com

MM-200_im REV M

Page 23 of 160

Page 25

TELEVAC

INSTRUMENT MANUAL

VACUUM GAUGE MODEL MM200

304 GAUGE SENSOR INSTALLATION WARNINGS

--------------------------------------------------------------------

WARNING: OVERPRESSURE - Do not use quick connects or other friction type connections

where positive pressure exists within sensors, such as in backfilling operations.

--------------------------------------------------------------------

WARNING: SENSOR LOCATION - The gauge sensors should be located as close as possible

to the section of the vacuum system where pressure measurement is important.

Valves or other constrictions between the sensor and the area where pressure

measurement is required may cause erroneous readings or increase the response

time.

--------------------------------------------------------------------

WARNING: CONTAMINATION - Be careful during handling and installation to prevent any

loose debris or contamination of any type from entering the gauge sensors. It is

good practice to not handle the inside surfaces of any vacuum sensor.

--------------------------------------------------------------------

WARNING: Implosion and Explosion - Hot Cathode Ionization Gauges

If handled roughly, glass ionization gauges may implode under vacuum causing

flying glass, which may injure personnel. Be sure that cabling to the gauge tube

has proper strain relief so that cable tension cannot break the glass. If pressurized

above atmospheric pressure, glass tubes may explode, causing dangerous flying

glass. A substantial shield should be placed around vacuum glassware to prevent

injury to personnel.

--------------------------------------------------------------------

WARNING: Temperature - Hot Cathode Ionization Gauges

During degas operations, the envelope of glass ION gauge tubes becomes heated

much more than in normal operation. Be sure that materials that are heat sensitive

are not in contact with the gauge tube, and be sure that the gauge tube is not

located where personnel might come in contact with it.

--------------------------------------------------------------------

CAUTION: Breakage - Hot Cathode Ionization Gauges

If the ConFlat flanges are of the rotatable type, check that the flange bolt ring does

not drop on the glass tube during installation and cause breakage.

--------------------------------------------------------------------

160Phone:(215) 947-2500 fax:(215) 947-7464 e-mail:sales@televac.com web site:www.televac.com

MM-200_im REV M

Page 24 of 160

Page 26

TELEVAC

INSTRUMENT MANUAL

VACUUM GAUGE MODEL MM200

305 VACUUM CONNECTION FITTINGS

Six types of vacuum connection fittings are used in the

gauge system: NPT, O-ring compression, ConFlat flange,

KF, CAJON 8VCR and CAJON 8VCO. (See Table 3.2). A discussion of each is provided below

1. NPT PIPE THREAD CONNECTIONS - These connections should be sealed using vacuum sealing compound

such as TORR-SEAL, Teflon tape or paste. TORR-SEAL is a trademark of Varian Associates Inc.

2. O-RING COMPRESSION FITTINGS - Insert the tubulation of the gauge sensor into the fitting carefully to

avoid damage to the O-ring inside the fitting. The connection is then hand-tightened to create a seal. Do not

over tighten the connection.

If necessary, a small amount of vacuum grease may be used to obtain a good vacuum seal.

3. CONFLAT FLANGE FITTINGS - ConFlat and similar compatible types made by other manufacturers are

widely used for attaching devices to ports on high vacuum systems. These flanges utilize knife-edge surfaces

and compression of copper gaskets to secure a vacuum seal. Be careful not to damage or contaminate the

knife-edges or gaskets during handling operations. (Do not touch copper gasket with hands.) Copper

gaskets should be utilized when high temperature or ultra-high vacuum operation is intended. Tighten all

flange bolts evenly and fully in a crisscross pattern. Do not use copper gaskets more than once. If the flange

is to be baked, pre-lubricate the bolt threads with an antiseize compound (FelPro R C 100 or equivalent).

160Phone:(215) 947-2500 fax:(215) 947-7464 e-mail:sales@televac.com web site:www.televac.com

MM-200_im REV M

Page 25 of 160

Page 27

TELEVAC

INSTRUMENT MANUAL

VACUUM GAUGE MODEL MM200

CAUTION: Be careful that the anti-seize compound does not come in contact with the gaskets or the

vacuum parts of the flange.

4. KF FLANGE CONNECTIONS - These connections consist of a centering ring and clamp. The centering ring

is self-centering and aids in alignment. The clamps should be finger-tightened until both flanges are firmly in

contact with the O-ring seal.

Use a new gasket whenever the gauge is reconnected, unless gasket retainer assemblies are used.

5 CAJON FITTINGS - If necessary, a small amount of vacuum grease may be used on the O-ring to obtain a

good seal.

306 GAUGE SENSOR INSTALLATION (Refer to Table 3.3 for Gauge Sensor Installation)

Table 3.3 - Gauge Sensor Installation

GAUGE

TYPE MOUNTING INLET

ORIENTATION

Diaphragm A Vertical, down, desired

Convection A Vertical, down, required

Thermocouple A Vertical, down, desired

Cold Cathode B NA

Hot Cathode-glass C Horizontal

Hot Cathode-nude C NA

A - To prevent debris from entering the gauge sensor and to provide the highest accuracy, it is recommended that

the gauge sensor be installed with its main body vertical. Do not mount the sensor in areas where gases are

allowed to stream directly into the gauge tube since damage to the filament could result. Install cable to sensor and

chassis sockets. Connector is keyed to provide proper orientation at the sensor socket. Do not force connector

into socket.

B - The gauge sensor can be mounted in any position. The magnet should not be closer than 1" to any magnetic

material. Additionally, when mounting the sensor take into account that the field of the gauge magnet may disturb

beams of charged particles in the vacuum system. Install shielded high-voltage BNC connector to gauge and

chassis sockets before turning on the power.

C - The gauge sensor can be mounted in any position. It is important that gauge have good

communication with the vacuum space for accurate pressure readings, especially at lower pressures.

160Phone:(215) 947-2500 fax:(215) 947-7464 e-mail:sales@televac.com web site:www.televac.com

MM-200_im REV M

Page 26 of 160

Page 28

TELEVAC

INSTRUMENT MANUAL

VACUUM GAUGE MODEL MM200

307 REMOVAL AND INSTALLATION OF MODULES

Mounting screws are located at the top and the bottom of each module. To remove a module, remove both screws

and pull on the rear panel of the module. If necessary, use a small screwdriver to start the module moving by

prying between the module and the enclosure. The module will then slide out easily (See Fig. 3.3).

Fig. 3.3 - Removal / Installation of Modules

To install a module, slide it in place along the track and firmly press it into the mating socket connector. Reinstall

screws.

If you wish to add optional modules, install them as outlined below:

WARNING: TO AVOID POSSIBLE SHOCK, DISCONNECT THE POWER CORD FROM THE

CONTROLLER.

160Phone:(215) 947-2500 fax:(215) 947-7464 e-mail:sales@televac.com web site:www.televac.com

MM-200_im REV M

Page 27 of 160

Page 29

TELEVAC

INSTRUMENT MANUAL

VACUUM GAUGE MODEL MM200

1. Remove the sensor interface module from its packaging. Examine it for shipping damage. If damaged,

refer to Section 201.

2. Place jumpers in the desired position to select station numbers, setpoint station assignment, etc. as

described in Section 902.

3. Remove the two screws holding the blank cover plate over the module position you plan to use.

4. Align the module with the slots in the instrument and push into place. Press to secure edge connector into

the connector on the motherboard.

5. Reinstall the two screws.

308 DESCRIPTION OF MODULES

Various types of modules are available for installation in

the MM200 gauge. Descriptions of available modules follow as they appear from the rear panel. For detailed

descriptions of available modules and their setup, see Section 902.

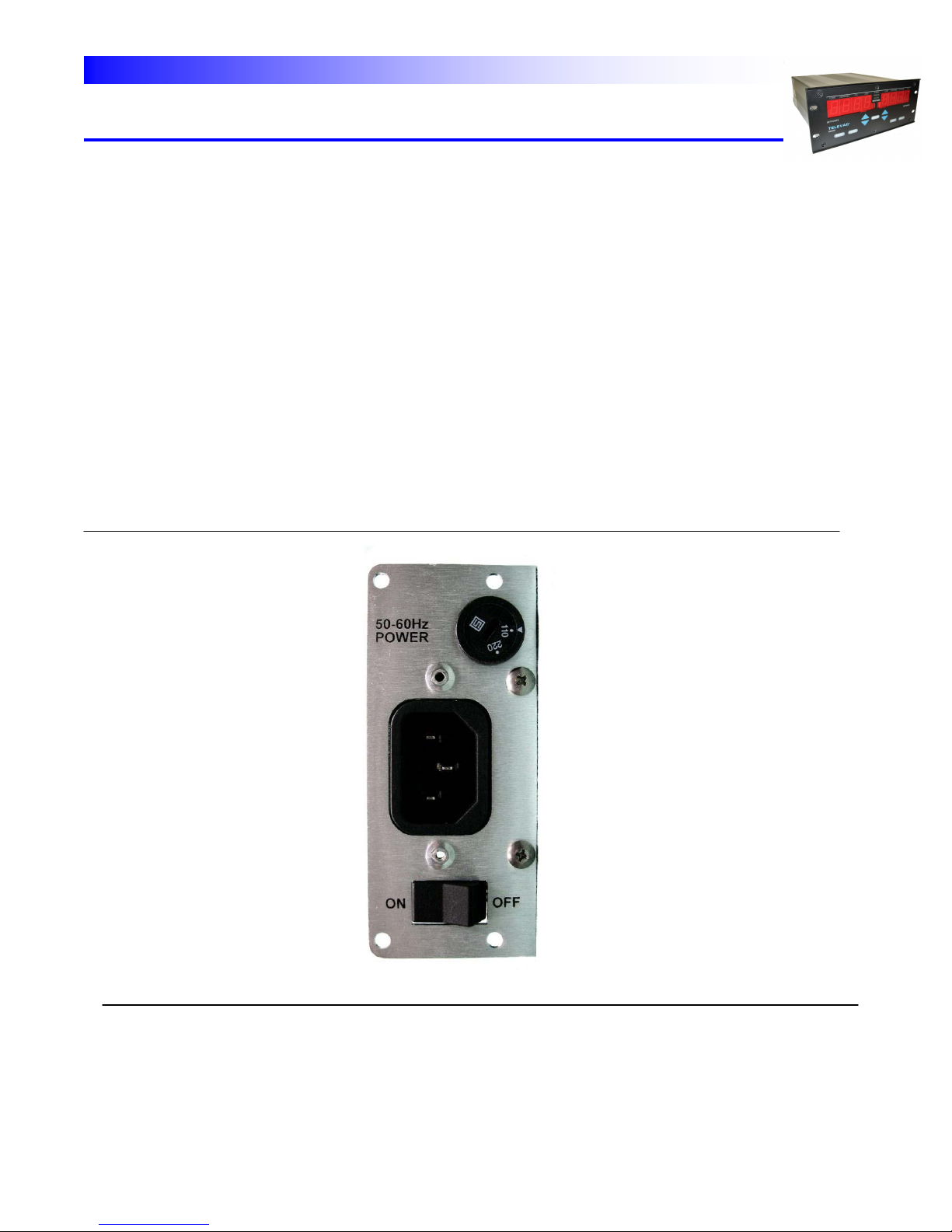

POWER SUPPLY MODULE - The power supply module is located in module slot "0" on the left rear of the

instrument. It contains a plug socket for the power cord, a voltage selection switch and an on/off switch. (Fig. 3.4).

Fig. 3.4 - Power Supply Module

160Phone:(215) 947-2500 fax:(215) 947-7464 e-mail:sales@televac.com web site:www.televac.com

MM-200_im REV M

Page 28 of 160

Page 30

TELEVAC

TOP

MID1

MID2

BOTTOM

INSTRUMENT MANUAL

VACUUM GAUGE MODEL MM200

SETPOINT RELAY MODULE - The rear panel of the setpoint process control relay module is shown in Fig. 3.5.

Three (3) terminals are available for each of the four (4) relays. These are NC (Normally Closed), NO (Normally

Open) and C (Common).

Fig. 3.5 - Rear Panel of the Setpoint Relay Module

COMMUNICATIONS MODULE - The rear panel of the module is shown in Fig. 3.6. It features a DE9S (female)

connector for the RS232 or RS485 interface cable. A SETUP lock switch is used to permit or to lock out the

capability to reset or reassign relays using the SETUP function. Two (2) phone jacks are also shown. The larger

one (3.5 mm) is labeled LEAK AUDIO and is used to provide an audible signal whose pitch (frequency) is a function

of the instantaneous pressure. The smaller one (2.5 mm) is labeled GAS SW and is used to remotely switch the

display to the "alternative gas" (See Section 401). See Figure 9.2 for RS485 termination. An alternate function

provided by the smaller phone jack is to accept an enable 24-volt signal that would prevent operation of ion type

gauges if not present.

Fig. 3.6 - Rear Panel of the Communications Module

160Phone:(215) 947-2500 fax:(215) 947-7464 e-mail:sales@televac.com web site:www.televac.com

MM-200_im REV M

Page 29 of 160

Page 31

TELEVAC

INSTALLATION SCREW

UPPER AND LOWER

SENSOR ID NUMBER

[FIVE] *

FOUR PIN

CONNECTOR

(FEMALE)

SPAN OR

ATMOSPHERE ADJUST

(DIAPHRAGM, CONVECTION, CDG)*

ZERO ADJUST

0-10V OUTPUT

DI 1E

TC 2A

CV 4A

CDG

XXX

INSTRUMENT MANUAL

VACUUM GAUGE MODEL MM200

THERMOCOUPLE MODULE - The rear panel of the thermocouple module is shown in Fig. 3.7. The gauge tube

cables can be connected by inserting the cable connector into the socket and turning the shell clockwise to engage

the screw threads for retention of the connector.

The thermocouple module is designed to work with the type 2A thermocouple gauge tube. Special electronics have

been added to the 2A thermocouple module to allow the 2A gauge tube to operate up to 20 Torr (20,000 microns).

An analog "0-10V" output (normally 0 to 10VDC) is available at the connector in the center of the panel. This

output covers the range of 0 to 1000 microns only in order to give good definition to the data in this lower range.

Other outputs are also available. An optional 0 to 10 mVDC is also available (See Section 902). There are three

terminals available. The center terminal is a common ground and negative terminal for both the upper and lower

thermocouple stations. The upper and lower terminals are the positive signals for the upper and lower stations,

respectively.

Between the cable connector and the analog “0-10V” output terminal is a "zero" potentiometer for the thermocouple

gauge tube. This potentiometer is used, if required, to adjust the current to the thermocouple sensor "heater",

which can be used to compensate, over a limited range, for effects of contamination from the process in the

vacuum chamber. The ATM adjust is not used for the thermocouple gauges.

Fig. 3.7 - Rear Panel of the Thermocouple, Convection and Diaphragm Modules

160Phone:(215) 947-2500 fax:(215) 947-7464 e-mail:sales@televac.com web site:www.televac.com

MM-200_im REV M

Page 30 of 160

Page 32

TELEVAC

INSTRUMENT MANUAL

VACUUM GAUGE MODEL MM200

CONVECTION MODULE - The rear panel of the convection module is also shown in Fig. 3.7. The only difference

that can be seen from the rear panel is the use of the letters CV instead of TC. The gauge tube cables can be

connected by inserting the cable connector into the socket and turning the shell clockwise to engage the screw

threads for retention of the connector. Note that the convection cable has different wiring and markings from the

thermocouple cable.

The convection module is designed to work with the type 4A convection gauge tube. Special electronics have been

provided in the 4A convection module to allow it to operate up to above atmospheric pressure (approximately 1000

Torr).

An analog "0-10V " output (normally 0 to 10VDC) is available at the connector in the center of the panel. This

output covers the range of 10-3 to 10+3 Torr. An a optional 0 to 10 mvDC is also available (See Section 902). There

are three terminals available. The center terminal is a common ground and negative terminal for both the upper

and lower convection stations. The upper and lower terminals are the positive signals for the upper and lower

stations, respectively.

Between the cable connector and the analog "0-10V " output terminal is a ZERO potentiometer for the convection

gauge tube. This potentiometer is used, if required, to adjust the zero at 1 x 10-5 Torr. It can be used to

compensate, over a limited range, for effects of contamination from the process in the vacuum chamber. A second

potentiometer marked ATM is used to adjust the gauge at atmospheric pressure. This should be set the known

value of absolute atmospheric pressure on the gauge - not referred to sea level as is used by the weather bureau

or airports.

DIAPHRAGM MODULES - The rear panel of the diaphragm modules are also shown in Fig. 3.7. The only

difference that can be seen from the rear panel of a thermocouple module is the use of the letters DI instead of TC

and the presence of a SPAN potentiometer. The gauge tube cables can be connected by inserting the cable

connector into the socket and turning the shell clockwise to engage the screw threads for retention of the

connector. Note that the diaphragm cables have different wiring and markings from the thermocouple cable.

The diaphragm modules are designed to work with the type 1E or 1F diaphragm gauge tubes.

Range 1E: 1 to 1000 Torr; 1F: 1000 to 9999 mbar.

An analog "0-10V " output (normally 0 to 10VDC) is available at the connector in the center of the panel. An

optional 0 to 10 mvDC is also available (See Section 902). There are three terminals available. The center terminal

is a common ground and negative terminal for both the upper and lower diaphragm stations. The upper and lower

terminals are the positive signals for the upper and lower stations, respectively.

Between the cable connector and the analog "0-10V” output terminal is a ZERO potentiometer. This potentiometer

is used, if required, to adjust the zero at a pressure two decades below the lower limit of the gauge. It can be used

to compensate, over a limited range, for effects of contamination from the process in the vacuum chamber. A

second SPAN potentiometer is used to adjust the 1E gauge at atmospheric pressure or the 1F gauge at 10,0000

mbar. A known value of absolute atmospheric pressure - not referred to sea level should be used for setting the

1E.

160Phone:(215) 947-2500 fax:(215) 947-7464 e-mail:sales@televac.com web site:www.televac.com

MM-200_im REV M

Page 31 of 160

Page 33

TELEVAC

ADJUST

ANALOG OUTPUT

COLD CATHODE

CABLE CONNECTION

INSTRUMENT MANUAL

VACUUM GAUGE MODEL MM200

COLD CATHODE MODULE - The rear panel of the cold cathode module is shown in Fig. 3.8. The gauge tube

cables can be connected by inserting the cable connector into the socket and turning the shell clockwise to engage

the lugs for retention of the connector. An analog output (normally 0 to 10VDC) is available at the connector in the

center of the panel. There are three terminals available. The lower terminal is a common ground and negative

terminal for both the upper two terminals. The upper two terminals are for + 10 volts and + 10 millivolts

respectively. Above the analog “0-10V " output terminal is a 10-3, a 10-5 or a span adjust potentiometer. These

potentiometers are used, if required, for calibration and to compensate, over a limited range, for effects of

contamination from the process in the vacuum chamber. There is a phone jack labeled “starter” above the

potentiometers for the 7FCS 6200-285 module only. The "ION-ON" potentiometer is not used for the MM200 and its

setting is ignored.

Fig. 3.8 - Rear Panel of the Cold Cathode Gauge Module

3D HOT CATHODE RESIDENT MODULE (I2 R DEGAS) - The rear panel of the 3D hot cathode resident module

with resistive (I2 R) degas is shown in Fig. 3.9. This module occupies 4 module slots. The module must be within

10' (100' with a special cable) of the sensor (gauge tube). No station should be numbered higher than #5.

The sensor power and control cable is connected to the socket in lower right-hand side of the module. Push plug

straight in until the connector "clicks" into a locked position. To remove, press on the sides of the connector, until

the locks are released, and then pull straight out. The sensor ion collector cable is connected to the module via a

BNC connector located in the left-hand middle of the module. Push the mating connector in and twist clockwise to

secure. Above the BNC connector is a case ground connection used to connect the unit independently to a "good

earth ground". Below the BNC connector is a switch marked TUBE TYPE and above the sensor power cable

connector is a sensitivity selector switch. For use see Table 3.4.

160Phone:(215) 947-2500 fax:(215) 947-7464 e-mail:sales@televac.com web site:www.televac.com

MM-200_im REV M

Page 32 of 160

Page 34

TELEVAC

INSTRUMENT MANUAL

VACUUM GAUGE MODEL MM200

Table 3.4 Tube Type

Rotary Sensitivity Sensitivity Glass Tube Nude Tube

Switch Switch

0 10/12.5 12.5 Plain 2160-1xx

1 10/12.5 12.5 Coated 2162-1xx

2 10/12.5 10 Plain 2161-2xx I2R 2164-352

3 10/12.5 10 Coated 2163-2xx

0 20/25 25 Plain EB 2166-452

1 20/25 25 Coated

2 20/25 20 Plain

3 20/25 20 Coated

Note: Switch position with power off or turn power ON/OFF after switching.

There is no filament selector switch for use with dual filament sensors on this unit as this is done through front

panel commands. It is necessary to switch the filaments when the filament power is off. It may also be necessary

to reverse the cable connector.

An analog output is available at the connector in the lower left of the panel. There are three terminals available.

The lower terminal is a common ground and negative terminal for both the upper two terminals. The upper two

terminals are for + 10 volts and + 10 millivolts respectively.

Refer to Section 502.3 Hot Cathode Setup for further information.

Fig. 3.09 Rear Panel of the Resident 3E Hot Cathode Gauge Module

160Phone:(215) 947-2500 fax:(215) 947-7464 e-mail:sales@televac.com web site:www.televac.com

MM-200_im REV M

Page 33 of 160

Page 35

TELEVAC

INSTRUMENT MANUAL

VACUUM GAUGE MODEL MM200

3E HOT CATHODE RESIDENT MODULE (EB DEGAS) - The rear panel of the 3E hot cathode resident module

with electron beam (EB) degas is shown in Fig. 3.9. This module occupies 4 module slots. The module must be

within 10' (100' with a special cable) of the sensor (gauge tube). No station should be numbered higher than #5.

The sensor power and control cable is connected to the socket in lower right-hand side of the module. Push plug

straight in until the connector "clicks" into a locked position. To remove, press on the sides of the connector, until

the locks are released, and then pull straight out. The sensor ion collector cable is connected to the module via a

BNC connector located in the left-hand middle of the module. Push the mating connector in and twist clockwise to

secure.

Above the BNC connector is a case ground connection used to connect the unit independently to a "good earth

ground".

Below the BNC connector is a switch marked TUBE TYPE. Switch position with power off or turn power ON/OFF

after switching. See Table 3.4.

An analog output is available at the connector in the lower left of the panel. There are three terminals available.

The lower terminal is a common ground and negative terminal for both the upper two terminals. The upper two

terminals are for + 10 volts and + 10 millivolts respectively.

There is no filament selector switch for use with dual filament sensors on this unit as this is done through front

panel commands. It is necessary to switch the filaments when the filament power is off.

Refer to Section 502.3 Hot Cathode SETUP for further information.

Fig. 3.10 Rear Panel of the Resident 3E Hot Cathode Gauge Module

160Phone:(215) 947-2500 fax:(215) 947-7464 e-mail:sales@televac.com web site:www.televac.com

MM-200_im REV M

Page 34 of 160

Page 36

TELEVAC

INSTRUMENT MANUAL

VACUUM GAUGE MODEL MM200

3F HOT CATHODE MINI-BA MODULE (Software ver. 2.31 or higher) - The 3F hot cathode mini-BA module

occupies 2 slots inside the mm200 unit. If one module is to be installed, it must be configured to station 5. If a

second module is to be installed, it must be configured to station 6.

Place 5 jumpers vertically for station 5. If two 3F hot cathode mini-BA modules are to be used, place 5 jumpers

vertically in station 6 for the second module.

When installing the modules into the unit, make sure that the card edge fingers align with the connectors inside the

unit. Make sure that the module is properly seated in the connectors then install the 4 screws per module in the

back panel.

160Phone:(215) 947-2500 fax:(215) 947-7464 e-mail:sales@televac.com web site:www.televac.com

MM-200_im REV M

Page 35 of 160

Page 37

TELEVAC

INSTRUMENT MANUAL

VACUUM GAUGE MODEL MM200

(Software ver. 2.31 or higher)

The rear panel of the hot cathode mini-BA module is shown below. The gauge tube cables are connected to the ion

collector and the 9-pin ion gauge connector. An analog output (normally 0 to 10 VDC) is available at the connector

in the upper right as shown below. There are three terminals available. The lower terminal is a common ground and

negative terminal for both the upper two terminals. The upper two terminals are for +10 volts and +10 millivolts

respectively.

3F hot cathode mini-BA back panel

160Phone:(215) 947-2500 fax:(215) 947-7464 e-mail:sales@televac.com web site:www.televac.com

MM-200_im REV M

Page 36 of 160

Page 38

TELEVAC

INSTRUMENT MANUAL

VACUUM GAUGE MODEL MM200

Software ver. 2.31 or higher)

MINI-BA GAUGE TO 3F MODULE WIRING DIAGRAM

160Phone:(215) 947-2500 fax:(215) 947-7464 e-mail:sales@televac.com web site:www.televac.com

MM-200_im REV M

Page 37 of 160

Page 39

TELEVAC

NOTE:

Capacitance Diaphragm Gauge Tubes with a range of greater than 1 Torr will not control the Cold

Cathode automatic turn on!

INSTRUMENT MANUAL

VACUUM GAUGE MODEL MM200

CAPACITANCE DIAPHRAGM MODULES - The rear panel of the capacitance diaphragm modules are also

shown in Fig. 3.7. The only difference that can be seen from the rear panel of a thermocouple module is the use of

the letters CDG instead of TC and the presence of a SPAN potentiometer. The gauge tube cables can be

connected by inserting the 5-pin cable connector into the socket and turning the shell clockwise to engage the

screw threads for retention of the connector. Note that the capacitance diaphragm cables have different wiring and

markings from the thermocouple cable.

The capacitance diaphragm modules are designed to work with the type 5__ capacitance diaphragm gauge tubes.

Ranges are as follows:

SOFT 1.33 AND LOWER SOFT 1.34 AND HIGHER

Full Scale: Full Scale:

5A: 1 Torr 5A: 1000 Torr

5B: 1000 Torr 5B: 100 Torr

5C: 10 Torr 5C: 10 Torr

5D: 1 Torr

5E: 0.1 Torr

5F: special

An analog "0-10V" output (normally 0 to 10VDC) is available at the connector in the center of the panel. An

optional 0 to 10 mvDC is also available (See Section 902). There are three terminals available. The center terminal

is a common ground and negative terminal for both the upper and lower diaphragm stations. The upper and lower

terminals are the positive signals for the upper and lower stations, respectively.

Between the cable connector and the analog "0-10V " output terminal is a ZERO potentiometer. This potentiometer

is used, if required, to adjust the zero at a pressure two decades below the lower limit of the gauge. A second

SPAN potentiometer is used to adjust the 5__ capacitance diaphragm gauge at the maximum (full scale) value for

the sensor.

160Phone:(215) 947-2500 fax:(215) 947-7464 e-mail:sales@televac.com web site:www.televac.com

MM-200_im REV M

Page 38 of 160

Page 40

TELEVAC

INSTRUMENT MANUAL

VACUUM GAUGE MODEL MM200

160Phone:(215) 947-2500 fax:(215) 947-7464 e-mail:sales@televac.com web site:www.televac.com

MM-200_im REV M

Page 39 of 160

Page 41

TELEVAC

STATION NUMBER

MEASURING

UNITS

MEASURING

UNITS

MEASURING

UNITS

INSTRUMENT MANUAL

VACUUM GAUGE MODEL MM200

400 OPERATION

Turn the power switch, located on the rear panel, to the ON position. If the gauge is installed in a rack or cabinet

where the power switch is not accessible, power may be left on without damage to the instrument.

401 DISPLAY DESCRIPTION AND DEFINITIONS

Fig. 4.1 shows the front panel of the gauge controller with all LED segments displayed. A definition of each display

is provided.

STATION NUMBER - This number corresponds to the sensor whose pressure (vacuum) is being displayed. This

sensor is located at a particular location in the vacuum system.

Figure 4.1 - Front Panel of Gauge Controller

The gauge controller can have one (1) to ten (10) stations. The station numbers are normally factory assigned but

can be re-assigned at installation. Stations are selected via the UP/DOWN arrows. The 10 th station, if installed, is

indicated by an "A".

DATA DISPLAY - The simultaneous display of two stations each present 4 digits of measurement (normally for

thermocouple #1 and the primary ionization gauge - cold cathode or hot cathode). It can also display programming

data for the station or setpoint selected via the UP/DOWN

160Phone:(215) 947-2500 fax:(215) 947-7464 e-mail:sales@televac.com web site:www.televac.com

MM-200_im REV M

Page 40 of 160

Page 42

TELEVAC

INSTRUMENT MANUAL

VACUUM GAUGE MODEL MM200

pushbuttons. The ionization gauge display flashes "OFF" until it is turned on by the controlling thermocouple

station (usually TC#1). The high voltage to the gauge tube will be off during this time.

Normally, the thermocouple station data are indicated in microns in a numerical format for pressures above 1

micron. The ionization gauge stations are indicated in Torr below 1 micron (10-3 Torr) using an exponential format.

In the exponential format, positive and negative exponent can be used. The display of negative and positive

exponents is done as follows:

3.0 x 10-7 is displayed as 3.0-7

3.0 x 10+2 is displayed as 3.0E2

UNITS: TORR, MICRONS, MBAR, PA, PSI - Use the UNITS pushbutton to select the desired pressure

measurement unit to be displayed. Also available is MICRONS per HR used for leak rate and, in the future,

SCC/M for flow rate display.

GAS TYPE: (N2 or GAS) - These abbreviations indicate the gas type that is being measured by the selected

sensor. The gas type has been selected by the operator via front panel programming using the N2/GAS

pushbutton. The alternate gas type is factory programmed and is typically argon. Display letters periodically flash

ArG (for argon) and He (for helium gas). Other gas types may be available on special order.

LEAK RATE INDICATOR - This is a trend representation of displayed data and indicates the rate of change of

pressure. Full scale is approximately 9999 microns/hour. A positive number indicates pressure increases, a

negative number indicates pressure decreases. This feature is activated via the LEAK RT pushbutton.

SETPOINT RELAY STATUS NUMBERS - The setpoint relay status lights show the status of each relay. If the

number is illuminated, then the relay has been energized due to the pressure on the assigned sensor falling below

the "on" setpoint. These numbers are not lighted during the self-diagnostic function. They are out during the

initialization routine after power-up. Relays are located on the optional setpoint module board.

402 ERROR INDICATIONS

Using internal diagnostics, the gauge software system continuously monitors the unit to verify proper operating

conditions during power-up and normal operations. Any error conditions that are detected are displayed on the

LED in the form of an error code message reading "Err" in the data display. This display comes up automatically

after power-up or whenever the self-diagnostic test is run. The display also indicates the particular error condition

detected. Refer to Section 502.1 for a more detailed explanation of error messages.

160Phone:(215) 947-2500 fax:(215) 947-7464 e-mail:sales@televac.com web site:www.televac.com

MM-200_im REV M

Page 41 of 160

Page 43

TELEVAC

1 2 3 4 5

6

INSTRUMENT MANUAL

VACUUM GAUGE MODEL MM200

403 KEYPAD DESCRIPTION

Fig. 4.2 shows the front panel of the gauge controller with the various control pushbuttons identified.

Fig. 4.2 - Control Pushbuttons

160Phone:(215) 947-2500 fax:(215) 947-7464 e-mail:sales@televac.com web site:www.televac.com

MM-200_im REV M

Page 42 of 160

Page 44

TELEVAC

INSTRUMENT MANUAL

VACUUM GAUGE MODEL MM200

PUSHBUTTON FUNCTIONS

1. TEST/OP PUSHBUTTON - Returns the instrument to normal operation at any time when in the SETUP

mode. Initiates the Self-diagnostic test.

2. SETUP PUSHBUTTON - Allows PCR upper and lower setpoints to be viewed. Allows UP/DOWN arrows

to raise or lower setpoints unless the SETUP switch on the optional RS232 module is in the LOCK position.

3. N2/GAS PUSHBUTTON - Change gauge sensitivity to correspond to a gas other than air or nitrogen (N2).

Gauges other than diaphragm types respond differently to different gases. (See Section 700). The program uses

argon for the other gas unless otherwise programmed at factory. This function is inhibited when the SETUP switch

on the optional RS232 module is in the LOCK position. (Also see Section 502.5).

4. UP/DOWN ARROWS - Incrementally increase or decrease the number of the stations being displayed.

Increases or decreases the PCR setpoint values when the lockout switch is in the ENABLE position; reassigns set

point assignments. (See Section 502 for details).

5. UNITS PUSHBUTTON - Changes units of measurement for pressure from the default units to: TORR,

MICRON, PSI, MBAR, PASCAL. This does NOT change the analog 0-10V output values.

6. LEAK RT PUSH BUTTON - After a 15 second delay, displays average leak rate (or rate of change of

pressure) in the right hand display when depressed. Display is in MICRONS per HR.

404 RELAY SETPOINTS

Relay setpoints are used to control the four relay outputs located on the optional Setpoint Relay Module. Each

relay has a pair of setpoints, an upper and a lower value. These setpoints correspond to the pressure value of a

specified sensor. The relay is energized when the pressure goes below the "on" setpoint, and de-energized when

the pressure goes above the "OFF" setpoint. When the pressure is between the two setpoints, the relay remains in

its current state. To adjust the setpoints see Section 502.

Since the relays have a flash coating of gold, they can be used as either "dry circuit" (low power) or power relays

(up to 5 Amps). Use of the relay as a power relay forever impairs its use as a "dry circuit" relay.

The RELAY messages on the display indicate the status of the relays. If the RELAY is energized, the

corresponding relay number light is on. If it is de-energized, the light is off.

160Phone:(215) 947-2500 fax:(215) 947-7464 e-mail:sales@televac.com web site:www.televac.com

MM-200_im REV M

Page 43 of 160

Page 45

TELEVAC

INSTRUMENT MANUAL

VACUUM GAUGE MODEL MM200

RANGE OF USE

For relays assigned to the following types of sensors:

Cold Cathode - any value up to 10-2 Torr

Convection - 1 micron to 990 Torr

Diaphragm - 1 to 990 Torr

Hot Cathode - any value up to 10-2 Torr

Thermocouple - 1 micron to 3 Torr.

Settings above 3 Torr, if required, will have to be set experimentally and will differ depending on whether

the pressure is increasing or decreasing.

CHANGING SENSOR ASSIGNMENT

When changing sensor assignment TO A DIFFERENT TYPE OF SENSOR the following step must be taken to

assure proper operation:

Use the DOWN ARROW to RUN THE SET POINT TO ZERO BEFORE RESETTING IT to the desired setpoint.

Example 1: Controlling a Cross-over Valve.

Cross-over is the point at which the high vacuum pump (e.g., diffusion pump) is connected to

the vacuum system. This is usually done automatically at a pressure in the range of 80 to

100 microns.

Relay 1 is set to energize at a pressure of 80 microns on the signal from thermocouple sensor

#1, which monitors the pressure in the main chamber. When the pressure drops below 80

microns, a sequence of steps is initiated by the change in status of the relay, namely:

The roughing valve is closed, then the foreline is opened and then the large main valve is

opened. This connects the high vacuum pump directly to the vacuum chamber and allows

the high vacuum pumping to proceed.

A different upper and lower setpoint are programmed. While the system is pumping down, the

relay does not change its state until the pressure falls below the lower setpoint and does not

revert back to its normal position until the pressure rises above the upper setpoint.

Example 2: Pressure Control

The relay is set up in a similar manner in this example. In this case, the relay controls a valve

on a gas inlet line to roughly control the system pressure between 1 and 4 Torr.

160Phone:(215) 947-2500 fax:(215) 947-7464 e-mail:sales@televac.com web site:www.televac.com

MM-200_im REV M

Page 44 of 160

Page 46

TELEVAC

INSTRUMENT MANUAL

VACUUM GAUGE MODEL MM200

405 ANALOG 0-10V OUTPUTS

0-10V OUTPUTS - Recorder outputs of 0 to 10 volts (or mV) are available for all installed stations. (* See note).

The 0-10V outputs are in units of measurement, which are "normally" used, in the USA, for the sensor being used.

When the UNITS pushbutton is pushed to display alternate units of measure, the recorder output remains in the

original units of measurement so that no discontinuity occurs in the output data due to pushing this button.

The various outputs are available are shown in Table 4.1 along with the "normal" units of measurement.

linear

linear per decade

logarithmic

non-linear "traditional"

These various outputs can be assigned by the Televac factory or by the user via RS232 /RS485. See Table 4.1

and Section 1000 for details.

* Note : Special 0 to 5 VDC option is available in many cases.

160Phone:(215) 947-2500 fax:(215) 947-7464 e-mail:sales@televac.com web site:www.televac.com

MM-200_im REV M

Page 45 of 160

Page 47

TELEVAC

TORR/

MICRON

READS

TRDL OUT

NON-LINEAR

LINEAR PER

DECADE

1 Volt per

DECADE

(default)

LINEAR

10V = 1000

MICRONS

LINEAR

10V = 10

TORR

LOG

1.67V per

DECADE

RS232

CODE

Jumper

R4AN

R4AU

R4AT

R4AL

Volts

Volts

Volts

Volts

Volts

0-

0.000

4.000

0.000

0.000

-

1

0.013

4.100

0.010

0.001

0.000

5

0.065

4.500

0.050

0.005

1.165

10

0.124

5.100

0.100

0.010

1.667

20

0.238

5.200

0.200

0.020

2.168

30

0.344

5.300

0.300

0.030

2.462

40

0.450

5.400

0.400

0.040

2.670

50

0.546

5.500

0.500

0.050

2.832

60

0.638

5.600

0.600

0.060

2.964

70

0.730

5.700

0.700

0.070

3.075

80

0.816

5.800

0.800

0.080

3.172

90

0.898

5.900

0.900

0.090

3.257

100

0.980

6.100

1.000

0.100

3.333

150

1.350

6.150

1.500

0.150

3.627

200

1.670

6.200

2.000

0.200

3.835

300

2.285

6.300

3.000

0.300

4.129

400

2.630

6.400

4.000

0.400

4.337

500

2.992

6.500

5.000

0.500

4.498

800

3.824

6.800

8.000

0.800

4.838

1T

4.226

7.100

10.000

1.000

5.000

2 T

5.440

7.200

13.500

2.000

5.502

3T

6.080

7.300

“

3.000

5.795

4T

6.440

7.400

“

4.000

6.003

5T

6.772

7.500

“

5.000

6.165

10 T

7.412

8.100

“

10.000

6.667

20 T

7.782

8.200

“

13.500

7.168

30 T

7.910

8.300 “ “

7.462

40 T

7.936

8.400 “ “

7.670

50 T

7.976

8.500 “ “

7.832

60 T

8.006

8.600 “ “

7.964

80 T

8.042

8.800 “ “

8.172

100 T

8.072

9.100 “ “

8.333

120 T

8.124

9.120 “ “

8.465

150 T

8.180

9.150 “ “

8.627

160 T

8.224

9.160 “ “

8.674

170 T

8.256

9.170 “ “

8.717

180 T

8.280

9.180 “ “

8.759

200 T

8.328

9.200 “ “

8.835

300 T

8.756

9.300 “ “

9.129

400 T

9.208

9.400 “ “

9.337

500 T

9.544

9.500 “ “

9.498

600 T

9.772

9.600 “ “

9.630

760 T

10.000

9.760 “ “

9.801

900 T

10.142

9.900 “ “

9.924

1000 T

10.232

10.000

“ “ 10.000

INSTRUMENT MANUAL

VACUUM GAUGE MODEL MM200

4A CONVECTION GAUGE OUTPUTS OPTIONS

160Phone:(215) 947-2500 fax:(215) 947-7464 e-mail:sales@televac.com web site:www.televac.com

MM-200_im REV M

Page 46 of 160

Page 48

TELEVAC

RS 232

R7BM

R7BN

R7BE

R7BL

Volts

Volts

Volts

Volts

1X10-3

10.0

10.000

10.00000

10.00000

9X10-4

9.8

9.000

9.88561

9.84747

8X10-4

9.6

8.000

9.75772

9.67697

7X10-4

9.4

7.000

9.61275

9.48366

6X10-4

9.2

6.000

9.44538

9.26050

5X10-4

9.0

5.000

9.24743

8.99657

4X10-4

8.8

4.000

9.00515

8.67353

3X10-4

8.6

3.000

8.69280

8.25707

2X10-4

8.4

2.000

8.25257

7.67010

1X10-4

8.2

1.000

7.50000

6.66667

9X10-5

7.8

0.900

7.38561

6.51414

8X10-5

7.6

0.800

7.25772

6.34363

7X10-5

7.4

0.700

7.11275

6.15033

6X10-5

7.2

0.600

6.94538

5.92717

5X10-5

7.0

0.500

6.74743

5.66323

4X10-5

6.8

0.400

6.50515

5.34020

3X10-5

6.6

0.300

6.19280

4.92374

2X10-5

6.4

0.200

5.75257

4.33677

1X10-5

6.2

0.100

5.00000

3.33333

9X10-6

5.8

0.090

4.88561

3.18081

8X10-6

5.6

0.080

4.75772

3.01030

7X10-6

5.4

0.070

4.61275

2.81699

6X10-6

5.2

0.060

4.44538

2.59384

5X10-6

5.0

0.050

4.24743

2.32990

4X10-6

4.8

0.040

4.00515

2.00687

3X10-6

4.6

0.030

3.69280

1.59040

2X10-6

4.4

0.020

3.25257

1.00343

1X10-6

4.2

0.010

2.50000

0.00000

9X10-7

3.8

0.009

2.38561

8X10-7

3.6

0.008

2.25772

7X10-7

3.4

0.007

2.11275

6X10-7

3.2

0.006

1.94538

5X10-7

3.0

0.005

1.74743

4X10-7

2.8

0.004

1.50515

3X10-7

2.6

0.003

1.19280

2X10-7

2.4

0.002

0.75257

1X10-7

2.2

0.001

0.00000

INSTRUMENT MANUAL

VACUUM GAUGE MODEL MM200

7B2 - 0-10V OUTPUT OPTIONS

160Phone:(215) 947-2500 fax:(215) 947-7464 e-mail:sales@televac.com web site:www.televac.com

MM-200_im REV M

Page 47 of 160

Page 49

TELEVAC

MM200 0-10V OUTPUT FORMATS

1E & 1F DIAPHRAGM GAUGES

RS232

CODE

display

abbr

NAME

R1EN

Linr

LINEAR

0-1000 TORR/10BAR

0-10V

10V =1000 TORR/10BAR----------

* LIN/DEC

“

2.0V/DEC

“

RIEL

LoG3

LOG

“

3.33V/DEC

“

2A THERMOCOUPLE GAUGES

R2AN

Ln1t

LINEAR

0-1000 MICRONS

0-10V

10V =1000 MICRONS---------------

R2AL

LoG3

LOG

0-1000 MICRONS

3.33V/DEC

10V =1000 MICRONS

R2AT

2Atr

2A TRAD’L

0-20,000 MICRONS

0-10V

10V = 0 MICRONS (RL)

R2AC

2Ctr

2C TRAD’L

0-20,000 MICRONS

0-10V

10V = 0 MICRONS (RL)

R2AR

-Lin

LIN REV’D

1000 MICRONS-0

0-10V

10V = 0 MICRONS (RL)

3F, 3D & 3E HOT CATHODE GAUGES

R3DM

L-d1

LIN/DEC

10-11 TO 10-2 TORR

1.00V/DEC

10V = 10-2 TORR---------------------

R3DL

LG10

LOG

“

1.00V/DEC

10V = 10-2 TORR

R3Dx

Ln-x

LINEAR

0-10-x TORR

0-10V10v =

10V = 10-x (8=,>x>,=2)

R3FM

L-d1

LIN/DEC

10-11 TO 10-2 TORR

1.00V/DEC

9V =10-2 TORR ----------------------

R3FL

LG10

LOG

1.00V/DEC

9V =10-2 TORR

R3Fx

Ln-x

LINEAR

0-10-x TORR

0-10V

10V = 10-x(8=,>.x>,=2)

4A CONVECTION GAUGES

R4AN

L-d1

LIN/DEC

10-3 TO 1000 TORR

1.00V/DEC

10V = 1000 TORR--------------------

R4AU

Ln1t

LINEAR

0-1000 MICRONS

0-10V

10V =1000 MICRONS

R4AT

Ln10

LINEAR

0-10 TORR

0-10V

10V = 10 TORR

R4AL

LoG6

LOG

10-3 TO 1000 TORR

1.67V/DEC

10V = 1000 TORR

JMPR 4A NON-LIN

10-3 TO 1000 TORR

0-10V

10V = 760 TORR

* 2A TRAD’L

0-1000 MICRONS

0-10V

10V = 0 MICRONS (RL)

* 2C TRAD’L

0-20,000 MICRONS

0-10V

10V = 0 MICRONS (RL)

5A,B,C,D,E,F CAP DIAPHRAGM GAUGES

R5AN

Linr

LINEAR

0-FULL SCALE

0-10V

10V = FS--------------------------------

R5AL

LoG3

LOG

3 DECADES

3.33V/DEC

10V = FS

5A FS = 1000 TORR 5D FS = 1

TORR

5B FS = 100 TORR 5E FS = 0.1

7B COLD CATHODE GAUGE MODULE (2-6200-227)

R7BM

L-d2

LIN/DEC

10-7 TO 10-3 TORR

2.00V/DEC

10V = 10-3 TORR---------------------

R7BL

LoG3

LOG

10-6 TO 10-3 TORR

3.33V/DEC

10V = 10-3 TORR

R7BE

LoG4

EXT’D LOG

10-7 TO 10-3 TORR

2.50V/DEC

10V = 10-3 TORR

R7BN

Linr

LINEAR

10-6 TO 10-3 TORR

0-10V

10V = 10-3 TORR

R7BA

7Atr

7ACTRADL

10-5 TO 10-3 TORR

0-10V

10V = 10-3 TORR

R7BT

B7b

B7B2 TRADL

10-7 TO 10-3 TORR

0-10V

10V = 10-3 TORR

7E COLD CATHODE GAUGE

R7EM

L-d1

LIN/DEC

10-8 TO 10-2 TORR

1.00V/DEC

10V = 10-2 TORR (4-10V)----------

R7EL

LoG6

LOG

10-8 TO 10-2 TORR

1.67V/DEC