Page 1

e

the

113

teleprinter

T.M

.

TELETYPE

,

InrI:'

REPAIR MANUAL

for

BASIC

TERMINALS

without

an

Internal

Data

Set

Page 2

©

1978

by

Teletype Corporation

All rights reserved

Printed

in

U.S.A.

Page 3

The

43

TELEPRINTER

REPAIR MANUAL

REP

AIR

MANUAL

391

Comments concerning

be

welcomed. This

Corporation. This

sheet

sheet

this manual.

content,

may

be removed

may

usability,

also be used

and

adequacy

and

mailed directly

for

ordering additional copies

of

this manual will

to

Teletype

of

Comments

to:

Order manuals from:

Mail To:

Teletype Corporation

5555

Touhy

Skokie,

Dept.

3212

IL

Avenue

60076

Dept. 2181-3

Page 4

The

43

TELEPRINTER

REPAIR

Issue

MANUAL

1,

April

391

1978

This

manual

Terminals

The

manual

that

parts

43

Basic

interface

information

provides

without

is

include repair, servicing

KSR

or a TTL

for

All replaceable

sembly,

included

adjustments

on

wiring diagrams

isolation using

or

shop

facilities are required

teleprinter

perform

installed

The

43

tion

extracted

and

schematic diagrams

sheets

terminals

or

simulate on-line

on

location.

Teleprinter Circuit Diagram, Manual

for

the

components.

complete

an

internal

intended

and

RO

for

Sprocket

interface. Manual

all versions

components

and

an

oscilliscope

or

components

from

this

manual.

for

convenience

REPAIR

MANUAL

INTRODUCTION

repair

data

field

or

and

or

Friction

information

set

(modem)

shop

how

369

of

the

Basic

43

Teleprinter.

are identified in

troubleshooting

and

charts

or

volt-ohmmeter.

for

and

interface

The

are provided

repair operations, however

or

local strapping

testing when

component

each circuit are

of

field

or

shop

for

43

and

major

use

and

is arranged

to

operate

Feed

provides

the

instructions

Teleprinters,

complete

manual along

information.

for

No specially designed

may

the

385,

provides

layouts, lead designations

combined

personnel

into

when

Basic

Teleprinter

components.

into

various

for

with

an

servicing

with

Waveforms are

additional

trouble

standard

be

required

teleprinter

circuit

single

informa-

fold-out

repairing

the

EIA

disas-

tools

43

to

is

not

major

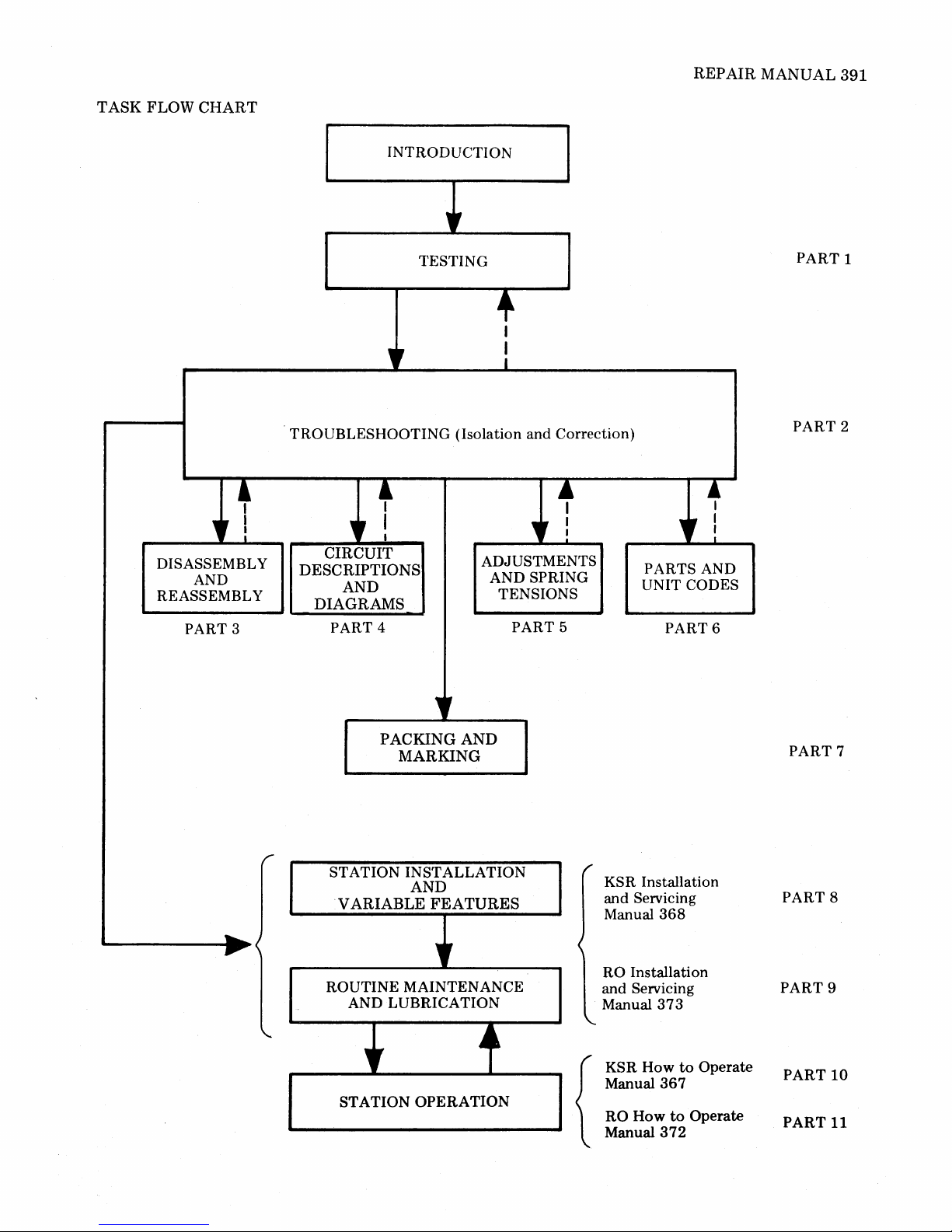

The

task

flow

chart

servicing activities

Spare

units

and

and

parts

on

the

for

Service personnel should

before

attempting

Corporation

on

43

Teleprinters.

service

Technical Training Center,

the

next

page illustrates

associated

manual

repair are available

be

properly

or

repair

trained

of

the

312-982-3940,

parts.

from

and

have access

43

Teleprinter.

the

intended

Teletype

Contact

for

courses available

repair

Corporation.

to

these spares

Teletype

or

Page 5

The

43

TELEPRINTER

REP

AIR

MANUAL

PART

PART 9

PART

PART

PART

PART

PART

PART

PART

TABLE

1

2

3

4

5

6

7

TESTING

TROUBLESHOOTING

DISASSEMBL

CIRCUIT DESCRIPTION AND DIAGRAMS

ADJUSTMENTS

PARTS

PACKING

OF

CONTENTS

Y AND REASSEMBLY

AND SPRING TENSIONS

AND UNIT CODES

AND MARKING

SUPPLEMENTAL MANUALS INCLUDED

8

KSR INSTALLATION AND

ROUTINE

SERVICING MANUAL

RO INSTALLATION AND ROUTINE SERVICING MANUAL

368

373

Issue 3

Issue 2

PART

PART

10

11

KSR HOW

RO HOW

TO

TO

OPERATE

OPERATE

MANUAL

MANUAL

367

372

Issue 2

Issue 2

Page 6

REPAIR

MANUAL

391

TASK

FLOW

CHART

+

DISASSEMBL Y

REASSEMBLY

" !

AND

PART 3

INTRODUCTION

"

TESTING

+

I

I

I

"

TROUBLESHOOTING (Isolation and Correction)

+

" !

CIRCUIT

DESCRIPTIONS

AND

DIAGRAMS

PART 4

ADJUSTMENTS

AND SPRING

TENSIONS

l

" :

PART 5

~

I

" I

PARTS AND

UNIT CODES

PART

6

PART

PART

1

2

......

~

PACKING

MARKING

r

ST ATION INSTALLATION

AND

VARIABLE

ROUTINE MAINTENANCE

AND LUBRICATION

,r

STATION

AND

FEATURES

"

.4

~

OPERATION

KSR Installation

and Servicing

Manual

RO Installation

and Servicing

Manual

KSR

How

Manual

RO

{

How

Manual

368

373

367

to

372

to

Operate

Operate

PART

PART 8

PART

PART

PART

7

9

10

11

Page 7

PART 1-TESTING

MANUAL

391,1-1

GENERAL

1.

TEST

2.

KSR

3.

OFF-LINE

V ARIABLE

CHECKOUT

A.

B.

4.

RO

OFF-LINE

V ARIABLE

CHECKOUT

A.

B. Variable

1.

GENERAL

1.01

RO

Teleprinter.

1.02

nents

are

operate

ating

conditions.

1.03

not

provided in

is

found

and

is

used

this

in

CONTENTS PAGE

....................

EQUIPMENT

TESTING

TESTS

FEATURES

...................

Loopback

Variable Features

TESTING

TESTS

FEATURES

...................

Loopback

This

part

provides testing

and

procedures

The

information

determine

if

operating

for

extended

Endurance,

electrical

parameter

this

to

some

extent

to

isolate

part.

.............

.................

...............

Mode

............

Checkout

..................

...............

Mode

Features

properly

for

in

th~

terminal

periods

............

Checkout

the

this

and

under

environmental

testing

part.

This

type

in

Part

2,

and

correct

...

requirements

43

Basic

KSR

part

is

intended

and

its

compo-

will

continue

normal

oper-

extreme

information

of

information

Troubleshooting

troubles

indicated

12

12

12

15

15

20

20

20

and

to

to

or

is

(b) A questionable

teleprinter

1

2

repair.

(c) A questionable teleprinter, in service

received

3

3

properly

1.05

or

requires repair.

Following installation

ance calls

this

part

or

an

HTO

manual should

the

teleprinter

1.06

On

is operational.

trouble

verification

test

station

isolate

After

confined

1.07

(if available) should

the

trouble

correction

to

the

specific

The

checkout

table

form

in a specific sequence. A response is given

verify

the

test

condition

1.08

factory

1.09

step

performed

factory,

1.10

Always

given.

results

If

the

in

any

to

make sure

properly.

refer

to

Teleprinters

minal

perform

The

of

indicated

step

Data

locally developed

and

procedures

If

test

station

procedure

Note:

late

The

most

to

is

should

local

on-line

component

operates

from a customer,

at a location,

installation

be

performed

calls, a local

test

under

within

or

of a trouble,

area

that

routines

with

test

has

passed.

the

test

steps are based

installed

properly

or

routine

either

checkout

to

test

the

direction

be

performed

to

the

the

was failing.

are

presented

conditions

tests in

or

requires

is

operating

mainten-

the

testing

using

make

or a trouble

teleprinter.

test

may

arranged

the

on

all previous steps.

response is

of a test

that

the

If

the

procedure,

procedure

results

not

repeat

are

still unsatis-

obtained

has

Page 2-1, Troubleshooting.

with

TAUs

Unit

must

external

perform

remote, a copy

be

available

tests

specified

tests

for

or

be

testing

actual

at

the

in

these

with

no

associated

arrangements

On-Line Tests.

of

the

test

station.

this

part

teleprinters.

in

the

or

in

the

sure

of

a

to

be

in

to

order

satis-

the

been

Ter-

with

testing

simu-

1.04

The

testing

should

normally

(a) A repaired

before

being

information

be

used

teleprinter

returned

is

placed in service.

provided herein

to

determine

operating

properly

to a customer

if:

or

--1.11

Before

the

remote

an

on-line

testing

vided with advance details

under

terminal

option

test,

such as,

(KSR

exceptions

telephone

or

RO) (friction

present,

test

station

about

speed,

can

be

must

the

number,

or

etc.

performed,

be

pro-

teleprinter

type

of

sprocket)

Page 8

391,

1-2

1.12

Before proceeding

procedure,

(a) Is

grounded

teleprinter

check

and

(b) Are all cable

(c) Are

printer

with

the

following:

connected

polarized ac

connectors

paper

and

the

to

outlet?

fully seated?

ribbon

installed?

(d) Are

Page

to

2-1.

Manuals

any

option

(Part 8 or

exceptions

368

(KSR)

9)

present?

and

Procedures in Off-Line Tests are based

factory

exceptions

as

furnished

shown

options

are present,

in

the

KSR

being present.

the

test

response will

or

RO

Variable

Checkout.

1.13

index

head

All references

second delay,

two

character

indicates

the

to

to

spaces

next

columns

allow

the

to

the

character

are

right.

position

printed.

2.

TEST

EQUIPMENT

and

2.01 Off-Line

cedures are provided

Tests where

are

not

connector

external

available.

terminals, as follows, should

Variable

communication

To

perform

Feature

to

simulate On-Line

these

checkout

a properly

properly

373

(RO),

on

standard

If

option

Features

after

a one-

print

head

The

Test pro-

test

devices

tests,

be

strapped

Refer

be

to

print

to

be

the

before

proceeding

terminals should

specified

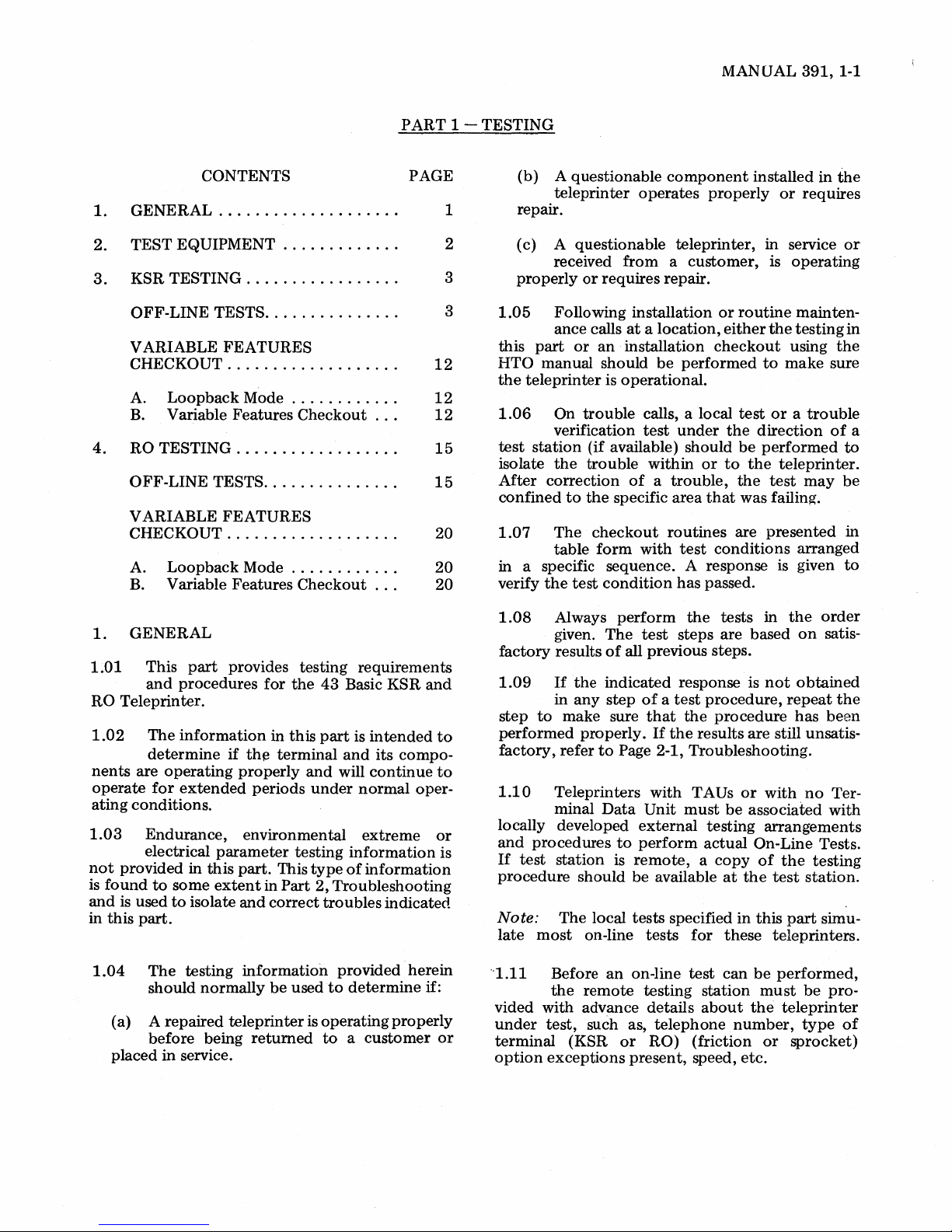

Note:

during

Contact

Department,

a

43

Teleprinter

vides

:S

5

6

25)

7)

4)

2.02

Teleprinters

checks off-line

devices are

2.03

both

EIA INTERFACE

SEND DATA

RECEIVE DATA

CLEAR TO SEND

DATA SET READY

DATA TERM READY

ANALOG LOOP

GND

REQUEST TO SEND

A

43

KSR

CAA

or

to

not

A

volt-ohmmeter

arrangements

perform

when

available

measure ±12 volts

continuity

checks is required.

with

the

tests.

be

connected

the

test

steps.

Teletype

312-982-2000,

Interface

~~

.:

V

11)

1~

~

1)

3)

6)

Test

TTL

INTERFACE

RECEIVE

SEND DATA

TERMINAL READY

DATA READY

DIGITAL LOOP

ANALOG LOOP

REQUEST TO SEND

Operator

CAB

can

be

tests

external

for

on-line

or

equivalent means

and

+5 volts

The

remaining

or

measured as

Corporation

for

availability

Box, which pro-

shown

as follows:

DAT,&

f

+5V

·12V

+12V

GND

Console,

substituted

and

variable

communication

Use

meter.

(Indicators

vided

Test

box.)

43K101/

in

feature

operation.

and

perform

Sales

of

volt

pro-

on

RO

test

to

Page 9

3.

KSR TESTING

OFF-LINE TESTS

TABLE A

OFF-LINE TEST PROCEDURES

MANUAL

391,1-3

TEST

Power

On/Off

Printer

Option

431.a.

432.a.

STEP

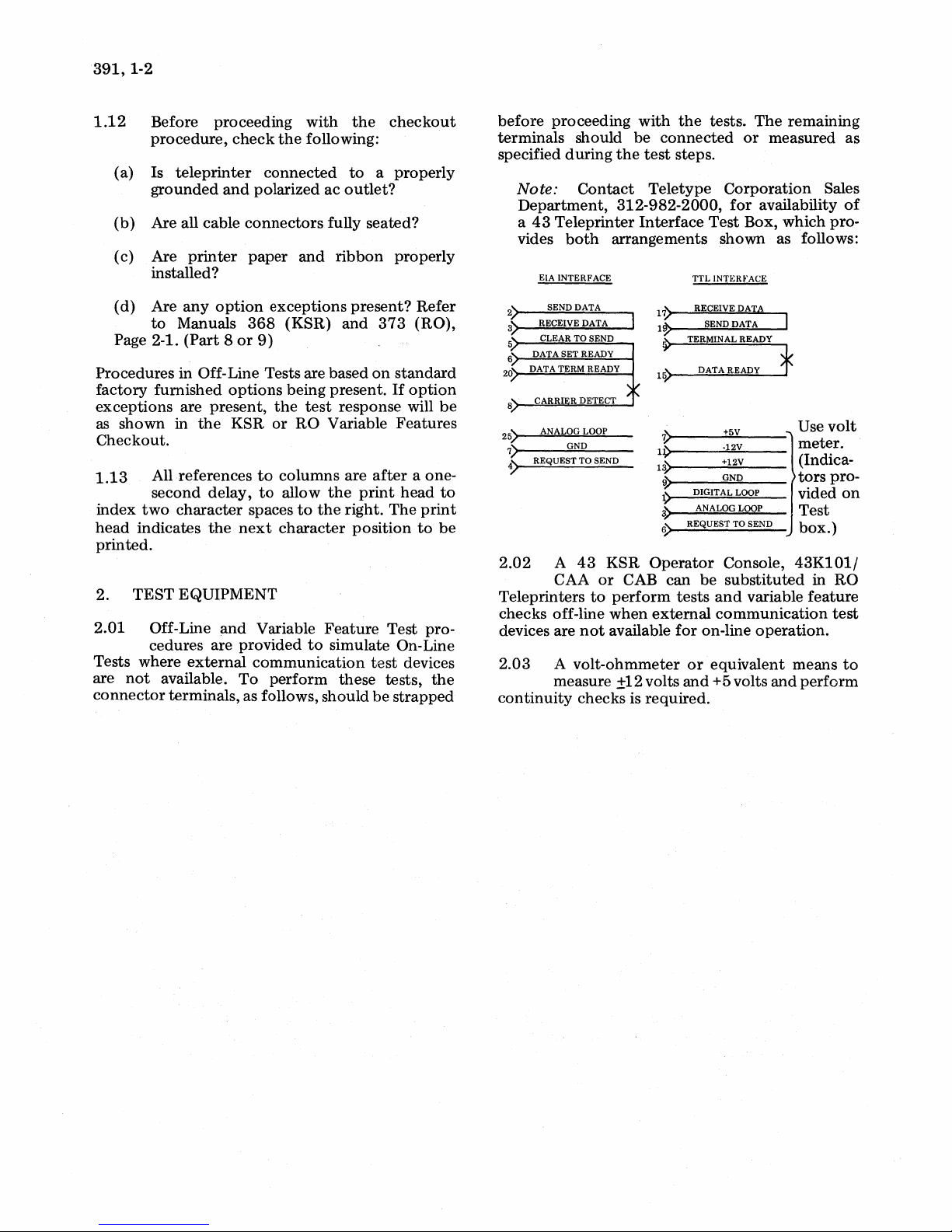

1.

2.

3.

PROCEDURE

ON

t

OFF

(Rear

~PRINT

HEAD

MARKER

I 10

"PRINT

Hold

PRINTER

approximately eight lines are printed.

INDICATOR

TEST

key

SCALE

depressed

View)

until

~

RESPONSE

Print

head returns

left-hand margin.

Paper feeds

TERM

ANSW)

Print

first

mark

scale.

ALARM

(LOCAL-TALK)

Characters

Fig.

1.

431

and

any

exceptions.)

Bell rings

line. (Right-Hand Margin

and

Test Message.)

to

READY (AUTO

turns

head

marker

on

and

printed

(Refer

432b

at

end

to

next

line.

on.

points

indicator

LOCAL

turn

as

to

Options

and c for

of

each

the

on.

in

to

Note

1:

First line

~nopqrstuvwxyZ{:

• ".tX&/().+,-.IOt23456789:;<=>!@ABCDEF6HIJKLMNOPDRSTUVUXYZ(\]h_'abcdefghiJklMnopqrstuvwxyz{

• ".tX&'()*+,-.IOt23456789:;<=>?@ABCDEFGHIJKlHNOPURSTUVUXYZ[\)'_'abcdefghiJklMnopqrstuvwxyz{

• ".tX&'()*+,-.IOt23456789:;<=>!@ABCDEF6HIJKLHNOPDRSTUVUXYZ[\]'_'abcdefghijklMnopqrstuvwxyz{ }P

• "'$X&'().+,-.I0123456789:;<=>?@ABCDEF6HIJKLHNOPDRSTUVUXYZ(\]h_'abcdefghijklMnopqrstuvwxyz{

• ".tX&'().+,-.IOt23456789:;<=>?@ABCDEF6HIJKLHNOPGRSTUVUXYZ[\]h_'abcdefghijklMnopqrstuywxyz{

• "'$X&'()*+,-.IOt23456789:;<=>?@ABCDEF6HIJKLMNOPGRSTUVUXYZ[\]h_'abcdefghijklMnopqrstuvwxyz{

• "ItX&'().+,-.IOt23456789:;<=>?@ABCDEF6HIJKlMNOPGRSTUVUXYZ[\]A_'abcdefghijklMnopqrstuvwxyz{

• "'$%&'().+,-.IOt23456789:;<=>?@ABCDEF6HIJKLMNOPDRSTUVUXYZ[\]h_'abcdefghijklMnopqrstuvwxyz{

Note

See

/ does

"tllVW>:YZ{:}"

•

'"I.X&'().+,-./01234567891;<=>?@ABCDEFGHIJKlHNOPQRSTUVUXYZC\J~_'abcdefghiJkl"~

pqrstuyw)(yz{I}"

•

~"I.X"().+,-.I0123456789:;<=>"ABCDEFGHIJKlHNOPQRSTUVUXYZC\]h_'abcdefghiJkl"n

pqrstuywxyz{!}"

•

!"N.X&'()*+,-./0123456789:;<=)?IABCDEFGHIJKlHNOPQRSTUVUXYZC\JA_'abcdefghijkl"n

pqrstllYW)(Yz{:}"

•

!"N.%&~()*+,-./Ot23456789:;<=)?@ABCDEFGHIJKlHNOpaRSTUVUXYZ(\JA_'~bcdefghijkl"n

pqrstllYWXYz{:}-"'

1.

may

}

....

start

with

any

character

Sprocket Feed -

Friction Feed

for

13

-10

Fig. 1

sprocket

Characters

Characters

or

friction feed printers.

per

inch

Note

2:

The lower case

not

print

per

inch

on

80

character line.

}N

}H

}H

}H

}N

}N

}N

"0"

\

Page 10

391,

1-4

KSR OFF-LINE TEST (Cont)

TABLE A (Cont)

OFF-LINE TEST PROCEDURES

TEST

Printer

(Cont)

Operator

Console

STEP

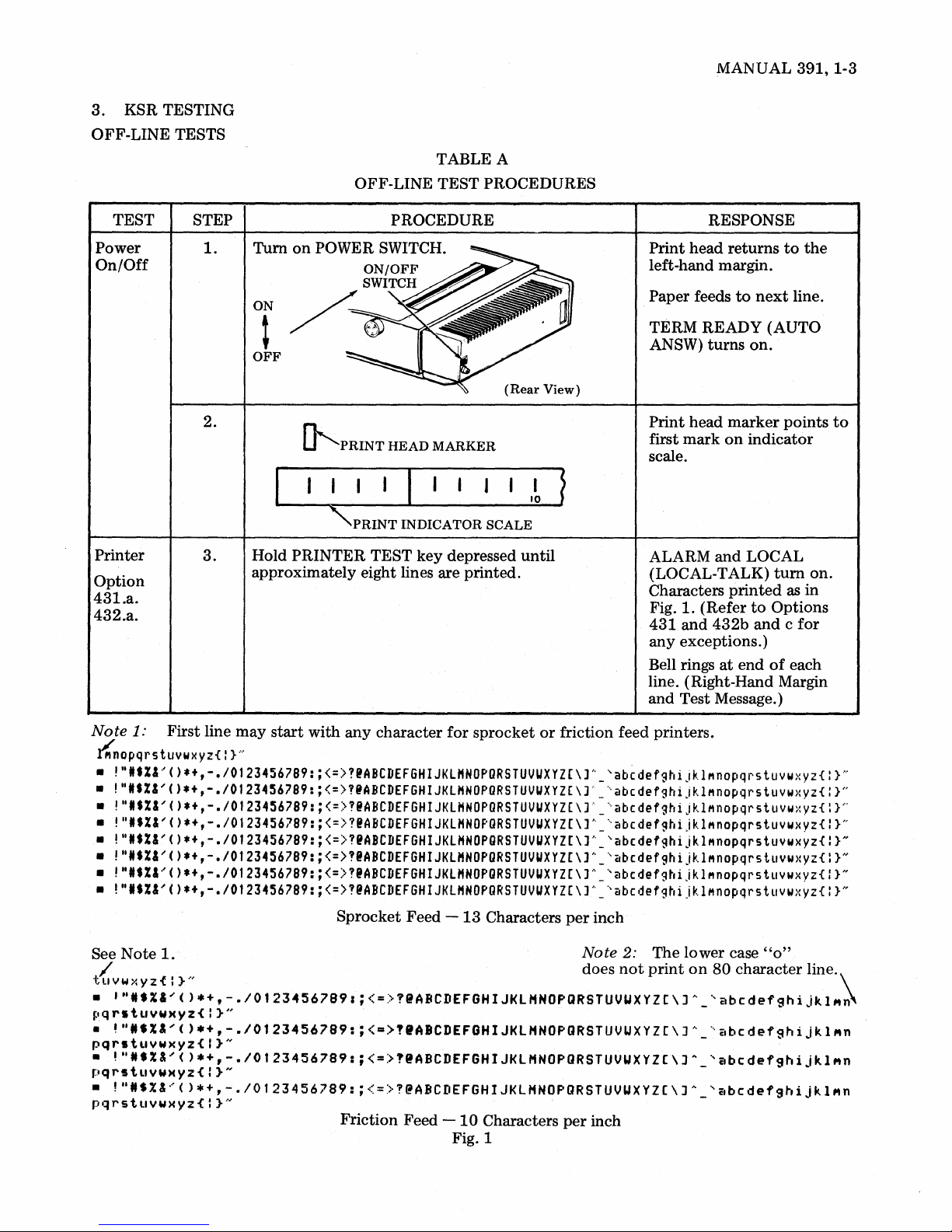

4.

5.

6.

PROCEDURE

Release

Hold CTRL

PRINTER

key

depressed

TEST key.

key.

Place CAPS LOCK

Starting with

to

right, depress unshaded keys

key

in

top

row and moving from

and

depress RETURN

DOWN position.

left

in

Fig. 2.

RESPONSE

ALARM

turns

off.

Character printing stops.

Print head is

left-hand margin

to

feeds

Characters

next

printed

returned

and

line.

as

to

paper

in

Fig. 3.

TEST STEP

Operator

Console

(Cont)

7.

8.

9.

Fig. 2

1234567890-+'OWERTYUIOP=\ASDFGHJKL;~{ZXCVBNM,.1

Fig. 3

'1

23456?890-+

···qwer'tyuiop:=\asdf'3hjkl;··

{z;.:cvbnf"l,

.1

Fig. 4

TABLE A (Cont)

OFF-LINE TEST PROCEDURES

RESPONSE

head

is

Depress RETURN

PROCEDURE

and

then

LINE

FEED

key.

Print

left-hand margin

feeds

to

next

Depress

to

left

Depress RETURN and

and

release CAPS LOCK

UP position. Starting with

to

right, depress each unshaded

then

top

LINE

key

row

key

FEED

so

it

returns

and

moving

in Fig. 2.

key.

Characters

printed

Fig. 4.

Print head returns

hand

margin

to

next

line.

returned

and

line.

as

to

and

paper

to

paper

in

left-

feeds

Page 11

TABLE A (Cont)

OFF-LINE TEST PROCEDURES

lV1ANUAL

391,

1-5

TEST STEP

Operator

Console

(Cont)

10.

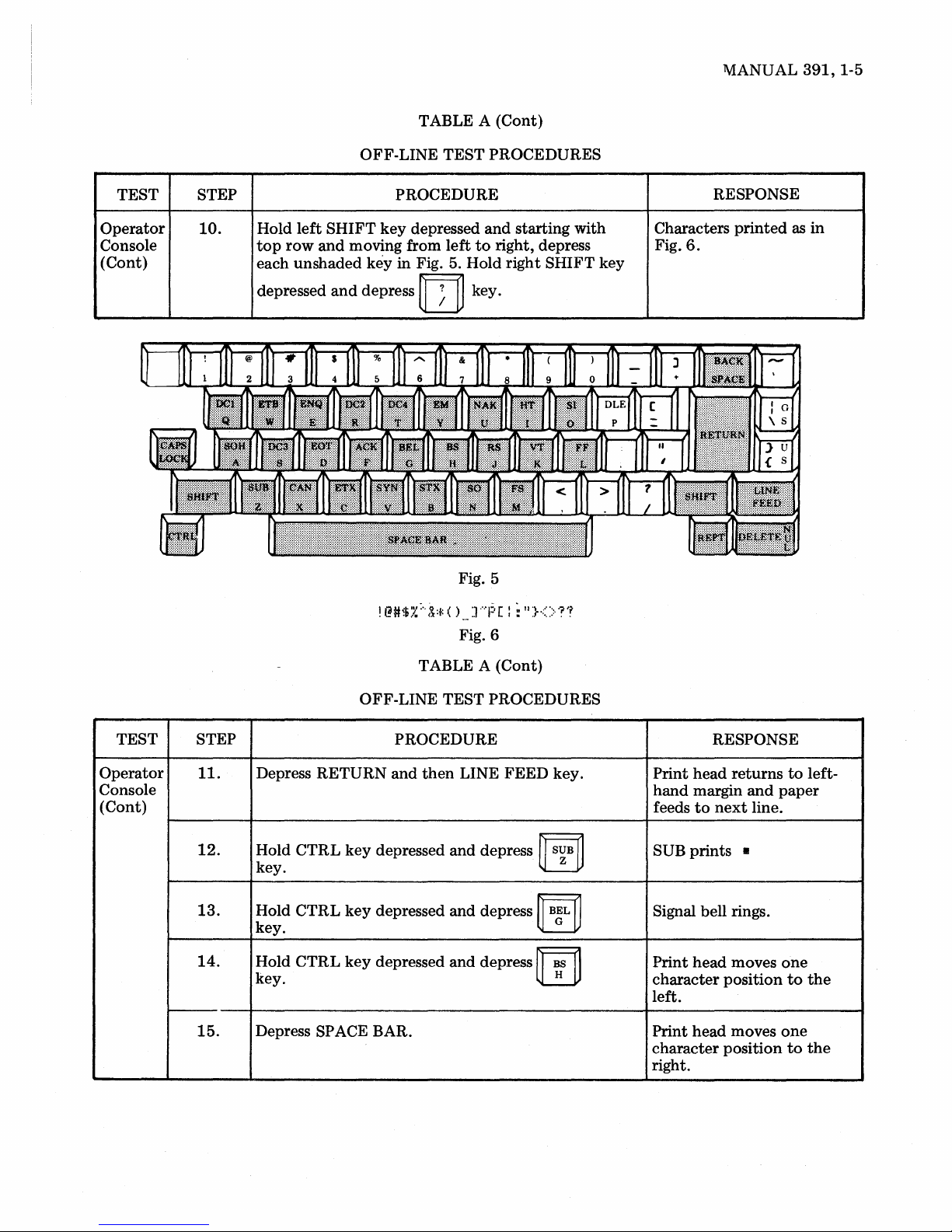

PROCEDURE

Hold left SHIFT key depressed and starting with

top

row and moving from left

each unshaded

depressed

key in Fig. 5. Hold right SHIFT key

and

depress

!

@#$:.~

rn

;"

(~:t:

Fig. 5

( )

... ] ....

Fig. 6

to

right, depress

key.

1:·

[ : :

II

}<>

'?'f

RESPONSE

Characters printed

Fig.

6.

as

in

TEST STEP

Operator

Console

(Cont)

II.

12.

13.

14.

15.

TABLE A (Cont)

OFF-LINE TEST PROCEDURES

PROCEDURE

Depress RETURN and then LINE FEED key.

Hold

CTRL

key.

Hold

CTRL

key.

Hold

CTRL

key. H

Depress SPACE BAR.

key

key

key

depressed

depressed

depressed

and

and

and

depress

depress

depress

~

S~B

~

"ilL

rn

~

~

RESPONSE

head returns

Print

hand margin and paper

feeds

to

next

SUB prints 8

Signal bell rings.

Print head moves

character position

left.

Print head moves

character position

right.

line.

to

one

to

one

to

left-

the

the

Page 12

391,1-6

KSR OFF-LINE TESTS (Cont)

TABLE A (Cont)

TEST

Operator

Console

(Cont)

Cover

Inter-

lock

Right

Margin

and

Signal

Bell

STEP

16.

17.

18.

19.

20.

21.

OFF-LINE TEST

PROCEDURE

Depress BACK SPACE key.

Depress LINE FEED key.

Depress

Depress TERM READY

Raise cover.

Close cover.

Depress RETURN and

Space

(See

Space

and

print

1.13)

print

hold

head

head

REPT and

(AUTO ANSW) key.

the

to

column

to

column

PROCEDURES

rn

LINE

125

73

keys.

FEED

(sprocket feed).

(friction feed).

key.

RESPONSE

head

is

printed

is

reached.

turns

to

next

moves

Print

character position

left.

Paper feeds

The k

of

line

, Signal bell rings

line.

TERM READY

ANSW) goes off. LOCAL

(LOCAL-TALK)

ALARM

ALARM goes off.

Print head returns

hand margin

feeds

to

and

line.

one

to

next

until

at

end

(AUTO

and

on.

to

paper

line.

the

end

of

left-

Margin

Set

and

Clear

(Remem-

ber

Lower

Case)

22.

23.

24.

25.

Depress

Depress

Depress

Depress

Depress SPACE BAR nine times.

Depress

(ESCL lower case.)

~

""Ii'

~

key.

SPACE BAR six times.

SPACE BAR

ESC

and

ESC and

then

then

two

times.

~

c~

~

rn

L

key. (ESCx)

key.

Signal bell operates as

is

character b

printed.

Signal bell does

Print head moves six

ate.

character positions

right.

Signal bell operates

times.

Print head returns

left-hand margin and indi-

cates beginning

Print head moves

Column 10.

being

not

of

to

oper-

to

two

to

line.

the

Page 13

TABLE A (Cont)

OFF-LINE

TEST

PROCEDURES

MANUAL

391,

1-7

TEST

Margin

Set

and

Clear

(Cont)

STEP

26.

27.

28.

29.

30.

3l.

PROCEDURE

Space

print

head

to

Column

Depress ESC and

Depress

Depress BACK SPACE key.

Space

Depress SPACE BAR.

Depress

Depress ESC

Depress SPACE

Depress ESC

RETURN

print

SPACE BAR.

head

and

and

then

~

D~2

key.

to

Column 50.

then

m key (ESC

BAR

four

then

~

EJ:

5l.

~

key. (ESCr)

times.

~

key

m

(ESCw).

)·

RESPONSE

Print

head

returns

margin

Signal bell rings.

Signal bell operates.

Print

5l.

Signal bell rings.

Print

Column

Print

Column

Print

hand

and

(Column

head

head

head

head

margin

paper

indicates

remains

5l.

moves

55.

returns

(Column

feeds

10).

to

to

to

to

left

Column

at

left-

10)

next

line.

Turn

off

before

If

connector

Loopback

proceeding

the

43

TEST

POWER switch

to

Teleprinter Interface

(TTL

or

STEP

32.

~---

32.a.

and

Step

32.

EIA). See instructions furnished

Place

teleprinter

or

32

b.

1------------------

EIA

INTERFACE -Connect

Term

Ready.

Turn

on

connect

Test

Teleprinter

the

Box

OFF-LINE

test

arrangement

is available,

TABLE A (Cont)

TEST

PROCEDURE

in

loopback

POWER switch.

shown

connect

with

mode:

Carrier

the

test

box.

PROCEDURES

Perform 32 a

Detect

test

on

to

box

Data

Page 1-2

to

to

the

teleprinter

1----------

Print

left-hand margin.

feeds

turns

EIA

INTERFACE

CONNECTOR

+

12

V will

pin 4 (Issue

GND will be

pin

7.

the

interface

RESPONSE

head is

to

on.

next

be

2A

returned

line.

present

connector

interface

to

Paper

DATA

present

Logic Card)

on

on

Page 14

391,

1-8

KSR OFF-LINE TESTS (Cont)

TABLE A (Cont)

OFF-LINE TEST PROCEDURES

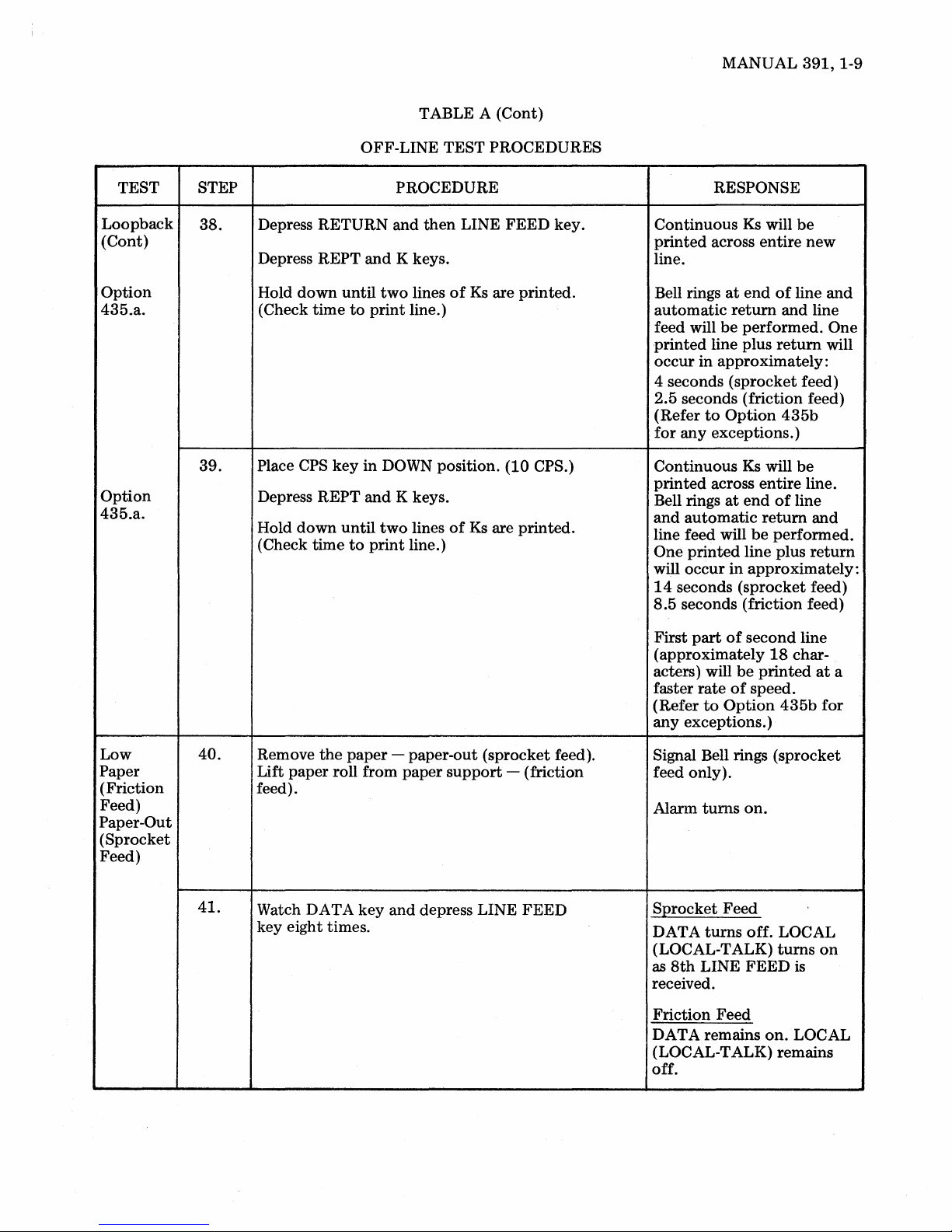

TEST

Loopback

(Cont)

----

Option

434.a.

STEP

32.b.

33.

TTL

INTERFACE -

Data

Ready.

Measure

interface

Tum

Depress

(PARITY ON).

Place DUPLEX

DUPLEX).

Place CAPS LOCK

continuity

connector.

on

Teleprinter POWER switch.

and

release PARITY

key

PROCEDURE

Connect

between

in

UP

key

in DOWN position.

Terminal Ready

pins 6

key

position (HALF-

and 9 on

to

UP position

to

TTL

RESPONSE

Print

head

is

returned

left-hand margin. Paper

feeds

to

next

line. Meter

0

should read

(Issue

2A

DA T A

INTERFACE

+5 V

pin

-12

pin

+

pin

GND will

9.

AANNAALLOOGG is

printed.

434b

turns

dc

7.

V

dc

II.

12 V dc

13.

for

ohms

Logic Card).

on.

CONNECTOR

will be

will

(Refer

present

be

will

be

be

present

to

any

exceptions).

present

present

on

Option

to

on

on

on

pin

----

Option

433.a.

----

34.

35.

36.

37.

Type

the

following:

ANALOG

Depress SPACE BAR.

Place DUPLEX key.in DOWN position

DUPLEX).

Type

the

following:

TEST

Watch TERM READY (AUTO ANSW)

hold

CTRL

Depress

Hold

key.

INTRPT

CTRL

key

key

depressed

key.

depressed

and

depress

and

depress RETURN

(FULL

key,

then

~

E~T

~

key.

TEST is

DATA

(AUTO ANSW) indicators

flash as

depressed.

433b

INTRPT

momentarily.

Signal bell rings.

Print

printed.

and

TERM READY

EOT key

(Refer

for

any exceptions.)

turns

on

head

does

not

is

to

Option

return.

Page 15

MANUAL

391,

1-9

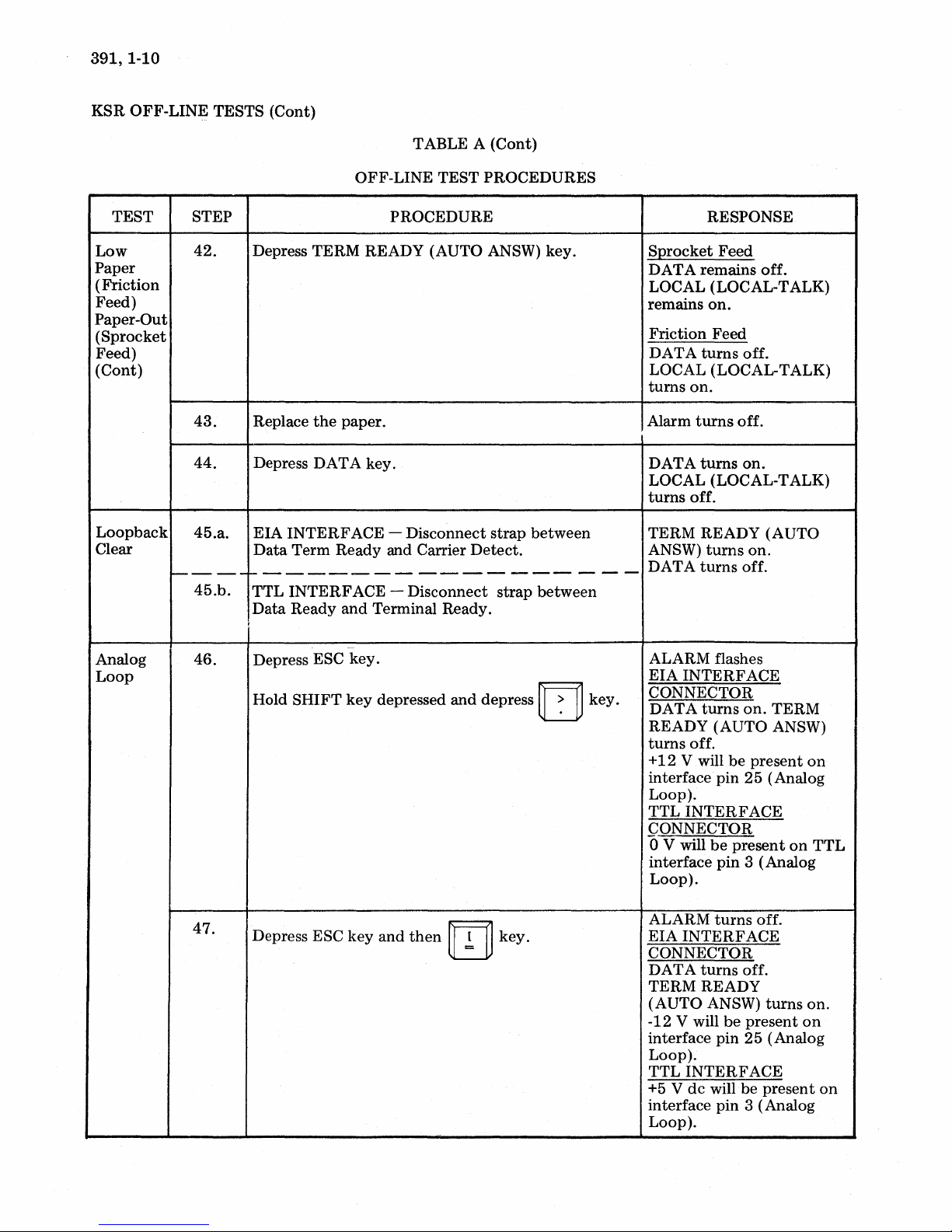

TEST

Loopback

(Cont)

Option

435.a.

Option

435.a.

STEP

38.

39.

OFF-LINE TEST PROCEDURES

PROCEDURE

Depress RETURN and

REPT

and

Depress

down

time

CPS

until

key

Hold

(Check

Place

Depress REPT

down

Hold

(Check time

until

to

K keys.

two

to

print

line.)

in

DOWN position. (10 CPS.)

and

K keys.

two

print

line.)

TABLE A

then

LINE FEED key.

lines

of

lines

of

(Cont)

Ks

are printed.

Ks

are printed.

RESPONSE

Continuous

printed

Ks

will

across entire

be

new

line.

at

end

of

line

Bell rings

automatic

feed will

printed

occur

be

line plus

in approximately:

return

performed. One

return

and

and line

will

4 seconds (sprocket feed)

2.5 seconds (friction feed)

to

(Refer

for

Option

any exceptions.)

Continuous

printed

Bell rings

and

across

at

automatic

line feed will

One

printed

will occur

14

seconds (sprocket feed)

8.5

seconds (friction feed)

in

435b

Ks

will

be

entire

line.

end

of

line

return

be

line plus

and

performed.

return

approximately:

Low

Paper

(Friction

Feed)

Paper-Out

(Sprocket

Feed)

40.

41.

the

Remove

paper

Lift paper roll from

feed).

Watch DATA key

key eight times.

- paper-out (sprocket feed).

paper

support

and

depress LINE

- (friction

FEED

part

of

First

second

(approximately

rate

to

be

of

speed.

Option

acters) will

faster

(Refer

any

exceptions.)

line

18

char-

printed

435b

at

for

Signal Bell rings (sprocket

feed only).

turns

Alarm

on.

S:Qrocket Feed

DATA

(LOCAL-TALK)

as

8th

turns

LINE

off. LOCAL

turns

on

FEED

is

received.

Friction Feed

on.

DATA remains

(LOCAL-TALK)

LOCAL

remains

off.

a

Page 16

391,1-10

KSR

OFF-LINE

TESTS

(Cont)

TEST

Low

Paper

(Friction

Feed)

Paper-Out

(Sprocket

Feed)

(Cont)

Loopback

Clear

Analog

Loop

STEP

42.

43.

44.

45.a.

----

45.b.

46.

TABLE A

OFF-LINE

PROCEDURE

Depress

Replace

Depress

EIA

Data

TERM

the

DATA

INTERFACE -Disconnect

Term

READY (AUTO ANSW)

paper.

key.

Ready

and Carrier

TEST

------------------

TTL

INTERFACE -Disconnect

Data

Ready

I

Depress ESC

Hold

SHIFT

and

Terminal Ready.

-

key.

key

depressed

and

(Cont)

PROCEDURES

key.

strap

between

Detect.

strap

between

depress IT]

key.

RESPONSE

SQrocket

DATA

LOCAL (LOCAL-TALK)

remains

Friction

DA

LOCAL (LOCAL-TALK)

turns

Alarm

DATA

LOCAL (LOCAL-TALK)

turns

TERM

ANSW)

DATA

ALARM flashes

EIA

CONNECTOR

DATA

READY

turns

+12

interface

Loop).

TTL

CONNECTOR

o V will

interface

Loop).

Feed

remains

on.

Feed

T A

turns

off.

on.

turns

off.

turns

on.

off.

READY

turns

on.

turns

off.

INTERFACE

turns

on.

(AUTO

off.

V will

be

present

pin

25

INTERFACE

be

present

pin

3 (Analog

off.

(AUTO

TERM

ANSW)

(Analog

on

on

TTL

47.

Depress ESC

key

and

then

m

key.

ALARM

EIA

CONNECTOR

DATA

TERM

(AUTO

-12 V will

interface

Loop).

TTL

+5 V

interface

Loop).

turns

INTERFACE

turns

off.

READY

ANSW)

be

pin

25

INTERFACE

dc

will be

pin

3 (Analog

off.

turns

present

(Analog

present

on.

on

on

Page 17

MANUAL

391,

1-11

TEST

Digital 48.

Loop

Low

Paper

(Friction

Feed)

Paper-Out

(Sprocket

Feed)

STEP

49.

50.

51.

TABLE A

OFF-LINE

PROCEDURE

TTL

INTERFACE

Hold

SHIFT

TTL

INTERFACE

then

m key.

Sprocket

Friction

support.

Depress TERM READY (AUTO ANSW) key.

key

Feed

- Remove paper.

Feed -Lift

~

depressed

TEST

- Depress ESC key.

- Depress ESC key

paper

(Cont)

PROCEDURES

and

depress

roll from

paper

rn

roll

key

RESPONSE

o V will

interface pin 1 (Digital

Loop).

+5 V

TTL

(Digital

Signal bell rings

feed only).

TERM

ANSW)

LOCAL (LOCAL-TALK)

and

TERM

ANSW)

LOCAL (LOCAL-TALK)

and

be

present

dc

will

interface

Loop).

READY

turns

ALARM

READY

remains off.

ALARM

be

present

pin 1

(sprocket

(AUTO

off.

turn

(AUTO

remain

on

on.

TTL

on.

on

52.

53.

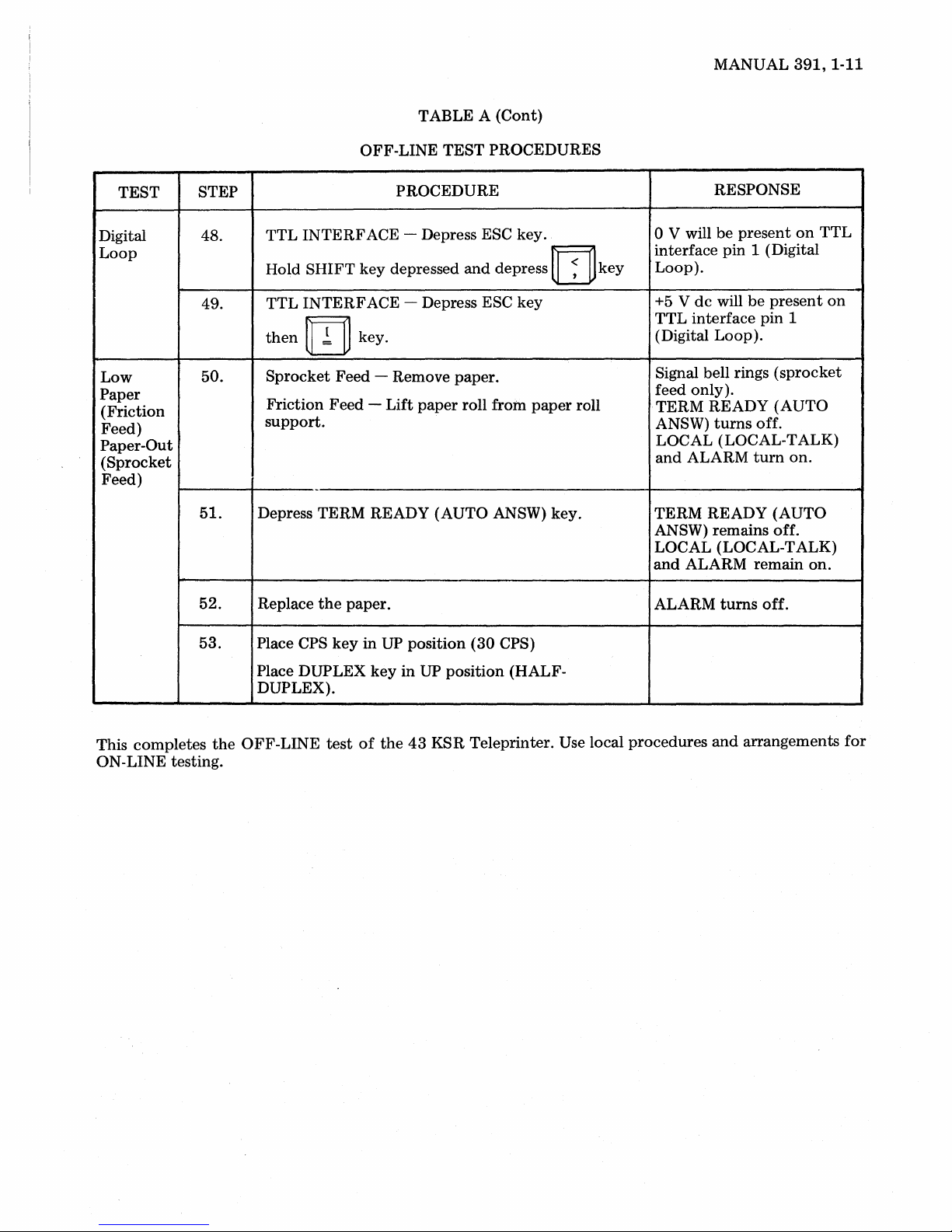

This

completes

ON-LINE testing.

the

Replace

Place CPS

Place DUPLEX

DUPLEX).

OFF-LINE

the

test

paper.

key

in

of

UP

key

the

position

in

UP

position

43

KSR

(30

CPS)

(HALF-

Teleprinter. Use local

ALARM

procedures

turns

off.

and

arrangements

for

Page 18

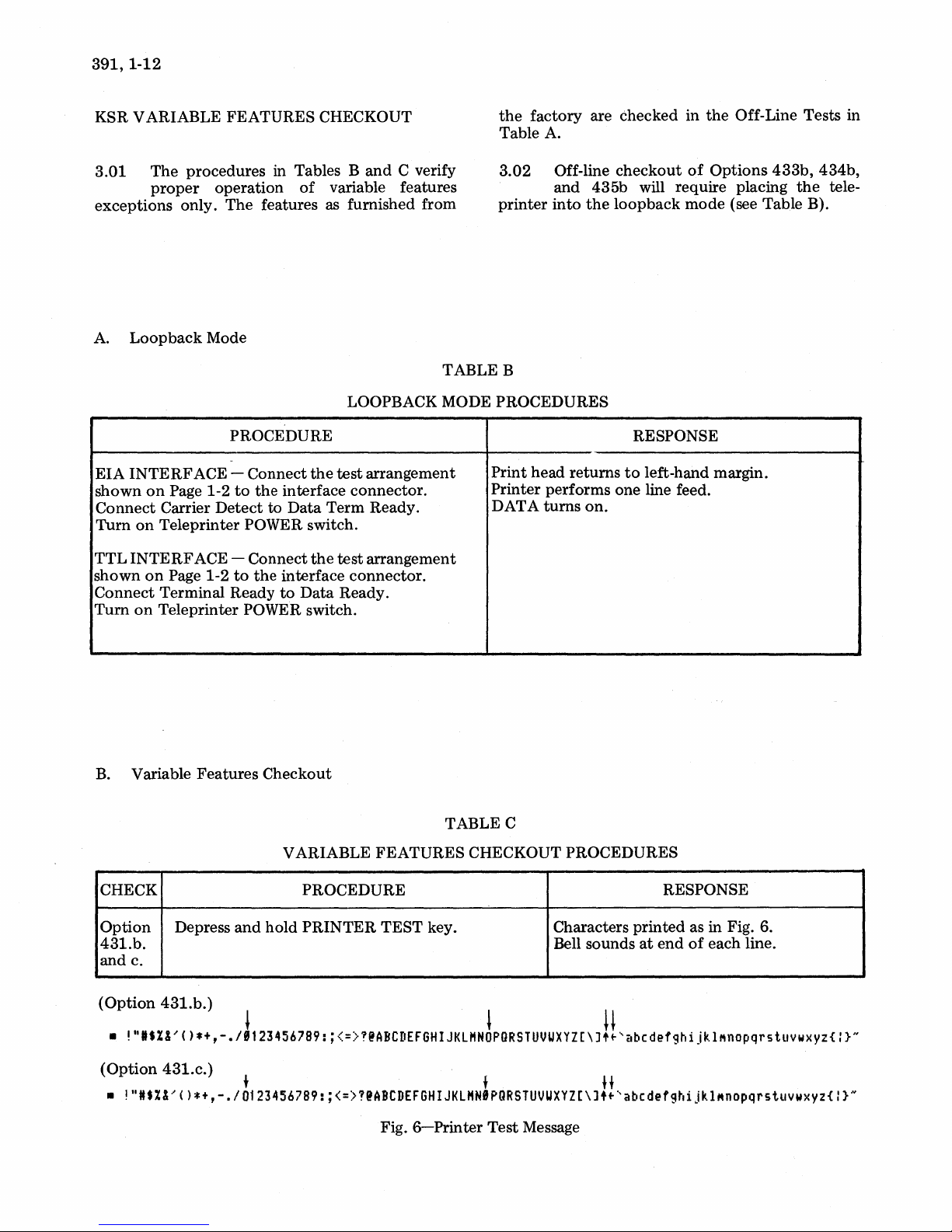

391,1-12

KSR VARIABLE FEATURES CHECKOUT

the

factory are checked in

Table A.

the

Off-Line Tests in

3.01

exceptions only.

A.

EIA

shown

Connect

Turn

TTL

shown

Connect

Tum

The

procedures in Tables

proper

Loopback

INTERF

on

on

INTERF

on

on

ACE - Connect

Page 1-2

Carrier

Teleprinter POWER switch.

ACE - Connect

Page 1-2

Terminal Ready

Teleprinter POWER switch.

operation

The

features as furnished from

Mode

PROCEDURE

to

the

Detect

to

to

the

Band

of

variable features

LOOPBACK MODE PROCEDURES

the

test

interface connector.

Data

Term Ready.

the

test

interface connector.

to

Data

Ready.

C verify

arrangement

arrangement

3.02

printer

TABLE B

Print head returns

Printer performs one line feed.

DATA

Off-line

and 435b will require placing

into

turns

checkout

the

loopback

on.

of

Options

mode

RESPONSE

to

left-hand margin.

(see Table B).

433b,

the

434b,

tele-

B.

Variable Features Checkout

V ARIABLE FEATURES CHECKOUT PROCEDURES

CHECK

Option

431.b.

and c.

(Option

•

!",.%&,()*+,-./J'234567B9:;<=>T@ABCDEFGHIJKLHN~PGRSTUVUXYZ[\J!!'abCdefghijkl~nOpqrstuvwXYZ{:}N

(Option

•

!"It%&'()*+,-./0123456789:;<=>?@ABCDEFGHIJKLHNIPQRSTUVUXYZ[\J

Depress

431.b.)

431.c.)

and

+ f H

PROCEDURE

hold

PRINTER

TABLE C

TEST key.

Fig.

6-Printer

Test

RESPONSE

Characters printed as in Fig. 6.

at

end

Bell sounds

Message

••

'abcdefghijkl~nopqrstuvwxY2{:}N

of

each line.

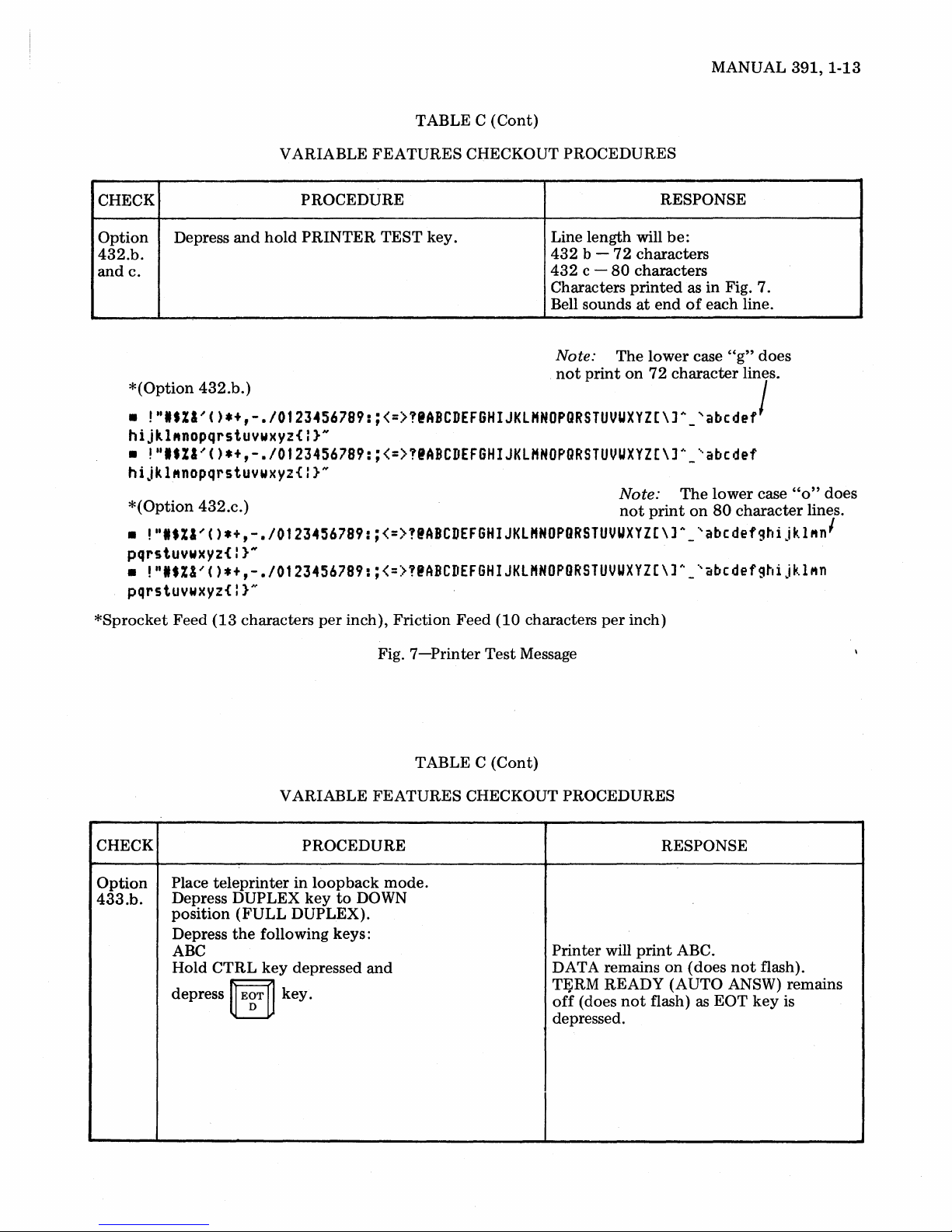

Page 19

MANUAL

391,

1-13

CHECK

Option

432.b.

andc.

*(Option

•

Depress

!"'.ZI~C)*+,-.I0123456789:;<=>!'ABCDEFGHIJKLHNOPQRSTUVUXYZ[\]A_

and

432.b.)

hijkl"nopqrstuvwxyz{I}N

•

!"'.ZI'C)*+,-.I0123456789:;<=>!@ABCDEFGHIJKLHNOPQRSTUVUXYZ[\]~_'abedef

hijkl"nopqrstuvwxyz{l}"

*(Option

•

!"'.ZI'C)*+,-.I0123456789:;<=>!@ABCDEFGHIJKLHNOPORSTUVUXYZ[\]A_'abcdefghijklMn

432.c.)

pqrstuvwxyz{I}N

•

!"'.Z&'C)*+,-.I0123456789:;<=>!@ABCDEFGHIJKLHNOPORSTUVUXYZ[\]h_'abcdefghijklMn

pqrstuvwxyz{l}"

VARIABLE

PROCEDURE

hold

PRINTER

TABLE C

FEATURES

TEST

key.

(Cont)

CHECKOUT PROCEDURES

RESPONSE

Line length will

432

b -

72

432

c -

80

Characters

Bell sounds

Note:

not

The

print

be:

characters

characters

printed

at

end

lower

on

72

Note:

not

print

as in Fig. 7.

of

each line.

case

"g"

character

'abedef

The

lower

on

80

does

lines.

/

case

character

"0"

does

lines.

'

*Sprocket

CHECK PROCEDURE

Option

433.b.

Feed

(13

characters

VARIABLE FEATURES CHECKOUT PROCEDURES

Place

teleprinter

Depress DUPLEX

position

Depress

ABC

Hold CTRL

depress

(FULL

the

ij

EgT

DUPLEX).

following keys:

key

~

key.

per

inch), Friction Feed (10 characters

in

loopback

key

to

depressed

Fig.

mode.

DOWN

and

7-Printer

TABLE

Test

Message

C (Cont)

per

inch)

will

Printer

DATA remains

TFiRM

off

(does

depressed.

print

READY (AUTO ANSW) remains

not

flash) as

RESPONSE

ABC.

on

(does

not

EOT

flash).

key

is

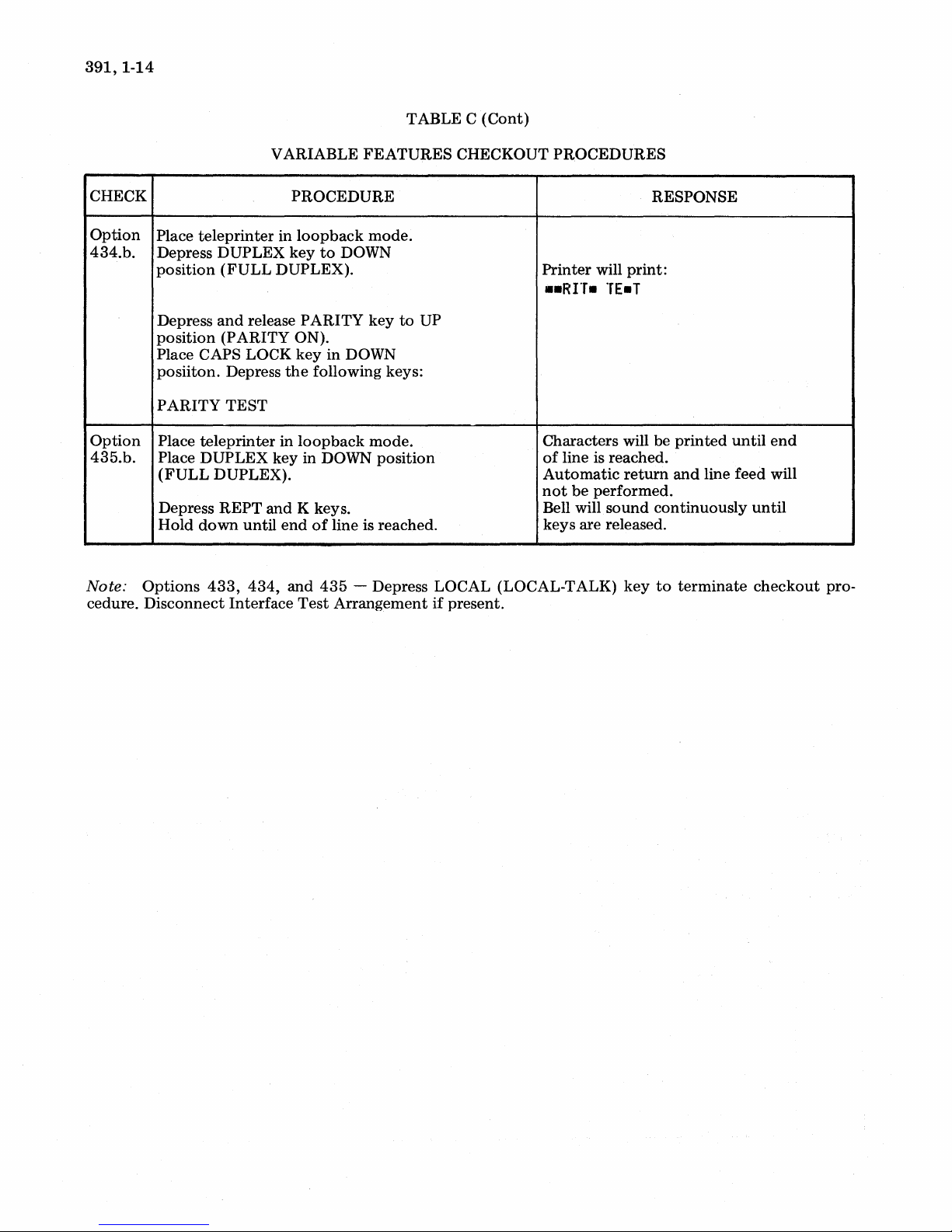

Page 20

391,1-14

CHECK

Option

434.b.

Option

435.b.

VARIABLE

Place

teleprinter

Depress

position

Depress

position

Place CAPS LOCK

posiiton.

PARITY

Place

Place

(FULL

Depress

Hold

DUPLEX

(FULL

and

(PARITY

Depress

TEST

teleprinter

DUPLEX

DUPLEX).

REPT

down

in

DUPLEX).

release

in

key in DOWN

and

until

end

FEATURES

PROCEDURE

loopback

key

to

PARITY

ON).

key

the

following keys:

loopback

K keys.

of

mode.

DOWN

key

in

DOWN

mode.

line is reached.

TABLE C

to

UP

position

(Cont)

CHECKOUT

PROCEDURES

Printer

••

Characters

of

Automatic

not

Bell will

keys

will

print:

Rrr.

TE.T

will be

line is reached.

return

be

performed.

sound

are released.

RESPONSE

printed

and

continuously

until

line feed will

end

until

Note:

cedure.

Options

Disconnect

433,

434,

Interface

and

Test

435

- Depress LOCAL (LOCAL-TALK)

Arrangement

if

present.

key

to

terminate

checkout

pro-

Page 21

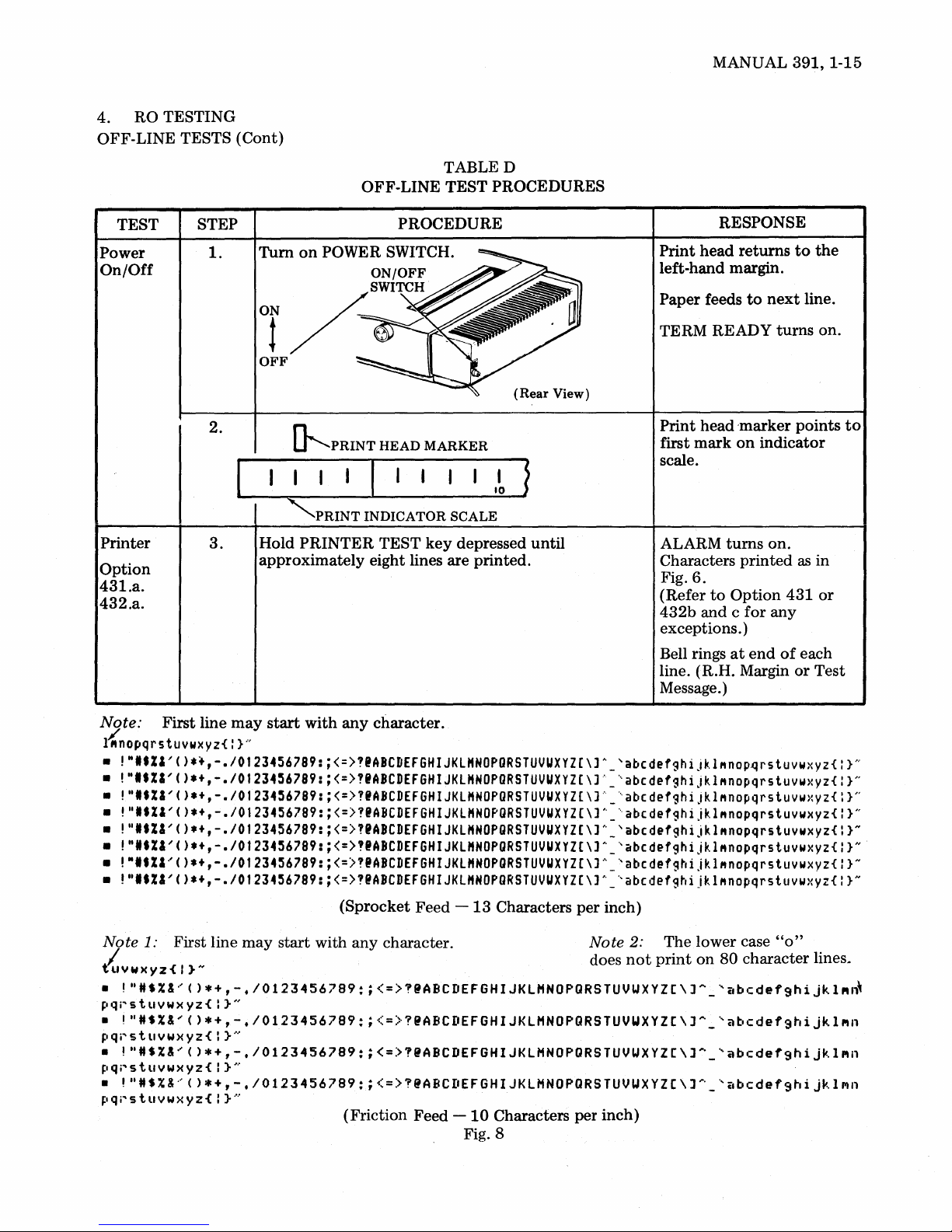

4. RO TESTING

OFF-LINE TESTS

(Cont)

OFF-LINE

TABLED

TEST

PROCEDURES

MANUAL

391,

1-15

TEST

Power

On/Off

Printer

Option

431.a.

432.a.

STEP PROCEDURE

1.

Turn

on

POWER SWITCH.

2.

3.

~PRINT

"'PRINT

Hold

PRINTER

approximately

HEAD

MARKER

INDICATOR

TEST

SCALE

key

depressed

eight lines are printed.

(Rear

until

View)

RESPONSE

Print

head

returns

left-hand margin.

Paper feeds

TERM READY

Print

first

mark

to

head

'marker points

on

next

turns

indicator

scale.

ALARM

Characters

Fig.

(Refer

432b

6.

to

and c

turns

printed

Option

for

on.

any

exceptions. )

Bell rings

at

end

of

line. (R.H. Margin

Message.)

to

line.

as

431

each

or

the

on.

to

in

or

Test

Note:

l{nopqrs

•

•

•

•

• !"

•

•

•

Note

Iu

•

~lqj"stllYWXYZ{:

•

pqi"stllYwxyz{:

•

pqr'stllYwxyz{:

•

~Iqr'stllvwxyz{:

First line

may

start

with

any

character.

tuvwxyz{ : }..,

!"'.ZI'().~,-.I0123456789:·<=>?IABCDEFGHIJKLHNOPORSTUVUXYZ(\]A_'abcdefghiJkl"nop~rstuvwxyz{

!"'.ZI'()*+,-.I01234~6789:

!"'.%I'()*+,-.I01234~6789:

!"'.ZI'()*+,-./0123456789:

••

ZI'()*+,-.I0123456789:

!"'.ZI'().+,-.I01234~6789:

!"ltZI'()*+,-.I0123456789:

!"I.ZI'()*+,-.I0123456789:

1:

First line

Y W)( Y z { I } N does

!"HS%&'()*+,-.I0123456789:;<=>?@ABCDEFGHIJKlHNOPQRSTUVUXYZC\J~_'abcdef9hijkl"~

}"

may

start

<=>"ABCDEFGHIJKlHNOPORSTUVUXYZ(\]~_'abcdefghijkl"nopqrstuvwxyz{

<=>?'ABCDEFGHIJKL"NOPORSTUVUXYZ(\]~_'abcdefghiJkl"nopqrstuvwxyz{

<=>"ABCDEFGHIJKlHNOPORSTUVUXYZ[\]A_'abcdefghiJkl"nopqrstuvwxyz{

<=>?IABCDEFGHIJKlHNOPORSTUVUXYZ(\]A_'abcdefghijkl"nopqrstuvwxyz{

<=>"ABCDEFGHIJKlHNOPORSTUVUXYZ(\]A_'abcdefghijkl"nopqrstuvwxyz{

<=)?IABCDEFGHIJKlHNOPORSTUVUXYZ(\]A_'abcdefghijkl"nopqrstuvwxyz{

<=>"ABCDEFGHIJKlHNOPORSTUVUXYZ(\]A_'abcdefghijklMnopqrstuvwxyz{

(Sprocket Feed

with any character. Note

-13

Characters

per

inch)

2:

not

The lower case

print

on

80 character

"0"

}N

}N

}N

}H

}N

}N

}N

}N

lines~

!"HS%&'()*+,-.I0123456789:;<=>?@ABCDEFGHIJKlHNOPQRSTUVWXYZC\JA_'abcdefghijkl"n

}"

!"HS%&'()*+,-.I0123456789:;<=>?@ABCDEFGHIJKlHNOPQRSTUVUXYZC\J~_'abcdef9hijkl"n

!"

H S % &.' ( ) * + , - • I 0 1 2 3 4 5 6 7 8 9 : ; < = > ? @

},

}

....

..

ABC

II

(Friction Feed -

E F G H I J K l H N 0 P Q R

10

Characters per inch)

STU

V U X Y Z [ \ J

.... _ .,

it

bed

e f 9 h i j

",

1 III n

Fig. 8

Page 22

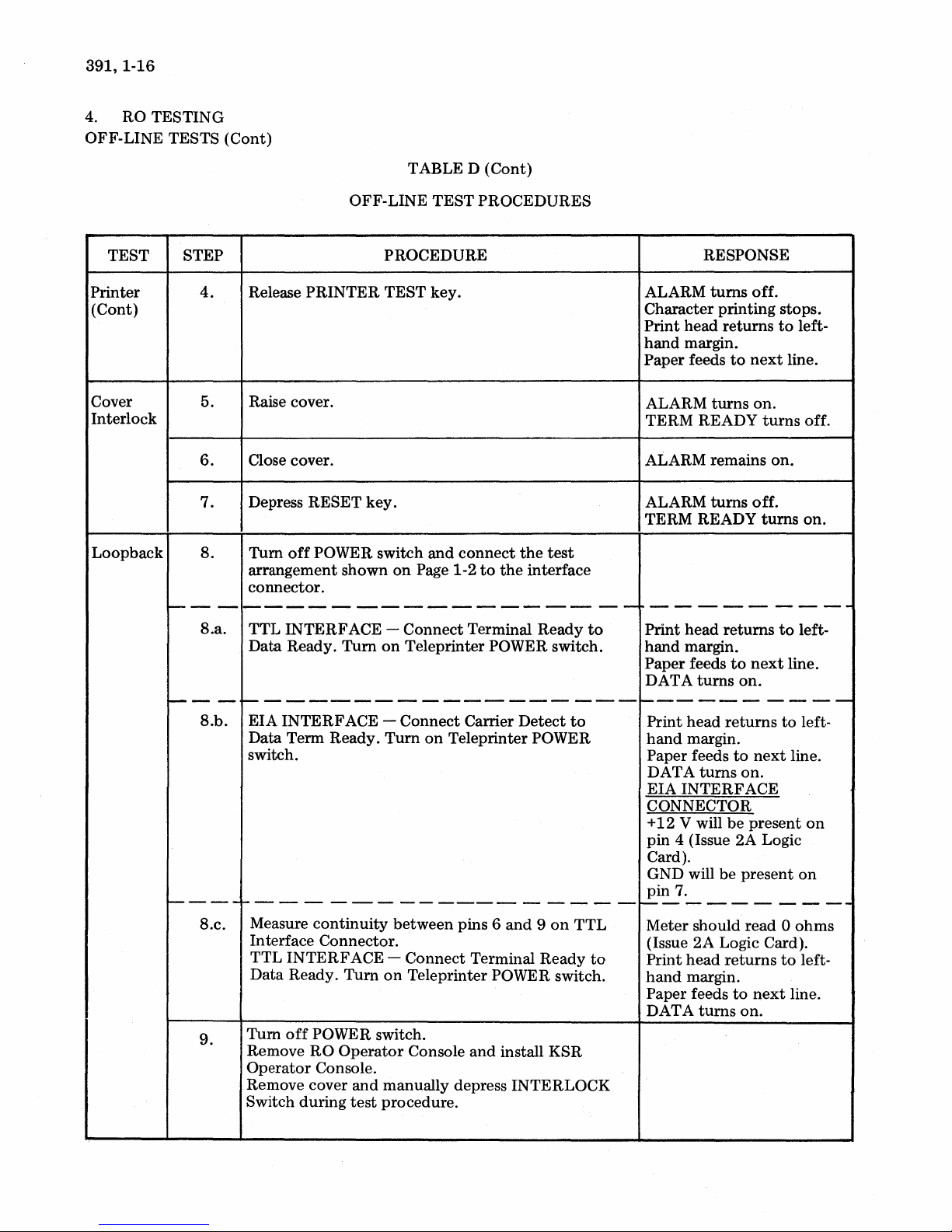

391, 1-16

RO TESTING

4.

OFF-LINE TESTS (Cont)

TABLE D (Cont)

TEST STEP

Printer

(Cont)

Cover

Interlock

Loopback

---

i---

1-----

4.

5.

6.

7.

S.

Release PRINTER TEST key.

Raise cover.

Close cover.

Depress RESET key.

Tum

off

POWER switch

arrangement shown

connector.

-----------------

S.a.

- -

S.b.

TTL INTERFACE - Connect Terminal Ready

Data Ready. Turn

~-----------------

EIA INTERFACE - Connect Carrier Detect

Data Term Ready.

switch.

1------------------

S.c.

9.

Measure

In terface Connector.

TTL INTERFACE Data Ready.

Tum

Remove

Operator Console.

Remove cover

Switch during

continuity

off

POWER switch.

RO

OFF-LINE

PROCEDURE

on

Turn

Turn

on

Operator

and

manually depress INTERLOCK

test

procedure.

TEST PROCEDURES

and

connect

on

Page 1-2

Teleprinter POWER switch.

on

between pins 6

Connect Terminal Ready

Teleprinter POWER switch.

Console

to

the

Teleprinter POWER

and 9 on

and

install KSR

the

test

interface

to

to

TTL

to

RESPONSE

ALARM

Character printing stops.

Print head returns

hand

Paper feeds

ALARM

TERM READY

ALARM remains on.

ALARM

TERM READY

10---------

--

Print head returns

hand margin.

Paper feeds

DATA

turns

margin.

turns

turns

turns

----------

Print head

hand

margin.

Paper feeds

DAT A

EIA INTERFACE

CONNECTOR

+

pin

Card).

GND will be present

pin

turns

12

V will

4 (Issue 2A Logic

7.

1-----------

Meter should read 0

(Issue 2A Logic Card).

head

Print

hand

margin.

Paper feeds

DAT A

turns

off.

to

next

on.

turns

off.

turns

to

next

on.

returns

to

next

on.

be

present

returns

to

next

on.

to

line.

to

line.

to

line.

to

line.

left-

off.

on.

left-

left-

on

on

ohms

left-

Page 23

TABLE D (Cont)

MANUAL

391,

1-17

TEST STEP

Loopback

(Cont)

~---

10.

10.a.

II.

OFF-LINE

Tum

on

POWER switch.

f----------------

Depress

(P ARITY ON).

Place DUPLEX

DUPLEX).

Place CAPS LOCK

Type

ANALOG

Depress SPACE BAR.

and

the

following:

release PARITY

key

TEST

PROCEDURE

in

UP position (HALF-

key

in

PROCEDURES

key

to

DOWN position.

UP position

--

RESPONSE

TERM READY

[TTL

7.

V will

11.

V will be

13.

9.

turns

Interface

be

present

be

be

present

ANSW)

----------

W

+5 V will

pin

-12

pin

+

12

pin

GND will

pin

AANNAALLOOGG is

printed.

(AUTO

on.

Onl~

present

present

on

on

on

on

f-----

Option

433.a.

---

12.

13.

14.

Place DUPLEX

DUPLEX).

Type

the

TEST

Watch TERM READY (AUTO ANSW) key then'

hold

CTRL

Depress

Hold CTRL

key.

INTRPT

key

following:

key

depressed

key.

key

depressed

in

DOWN position (FULL

and

depress

and

depress RETURN

~

Eg"

~

key.

TEST

DATA

(AUTOANSW)

flash as

depressed.

(Refer

for

INTRPT

tarily. Signal bell rings.

Print

return.

is

printed.

and

EOT

to

Option

any

exceptions.)

turns

head does

TERM READY'

key

is

433b

on

momen-

not

Page 24

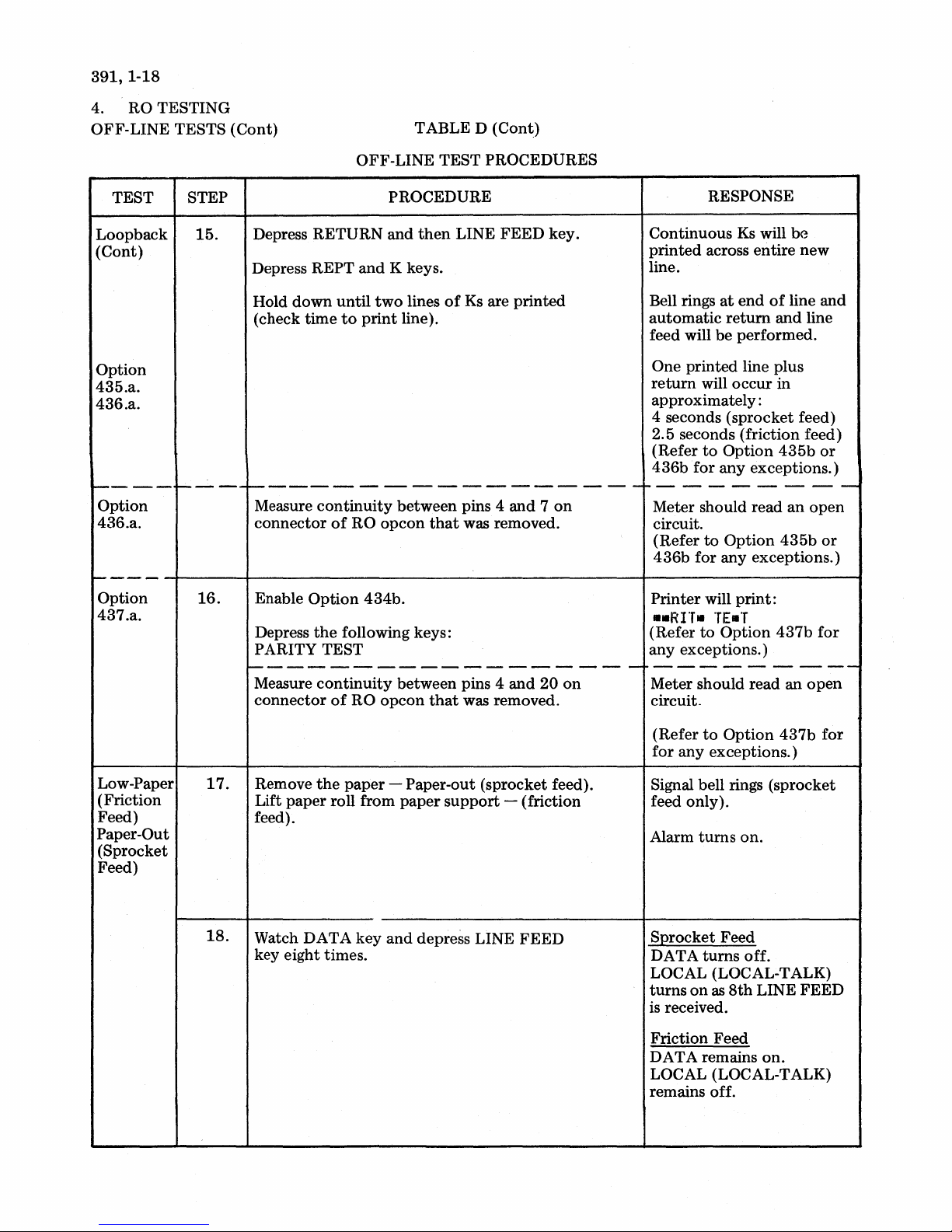

391,1-18

4. RO TESTING

OFF-LINE TESTS (Cont)

TABLE D (Cont)

TEST STEP

Loopback

(Cont)

Option

435.a.

436.a.

1-----

Option

436.a.

r---'-

1-----

Option

437.a.

15.

16.

OFF-LINE TEST

PROCEDURE

Depress RETURN and

Depress

Hold

(check time

REPT

down

and

until

to

print

K keys.

two

line).

then

lines

LINE

of

1----------------------

Measure

connector

Enable

Depress

PARITY TEST

continuity

of

RO

Option

the

434b.

following keys:

between pins 4

opcon

that

1--------------------

Measure

connector

continuity

of

RO

opcon

between pins 4 and

that

PROCEDURES

FEED

Ks

are printed

was removed.

was removed.

key.

and 7 on

20

on

RESPONSE

Continuous

printed

line.

Bell rings

automatic

feed will

One printed line plus

return

approximately:

4 seconds (sprocket feed)

2.5 seconds (friction feed)

(Refer

436b

ro-

-

-

--

Meter should read

circuit.

(Refer

436b

Printer will

..RI"T.

(Refer

any exceptions.)

---------

Meter should read

circuit.

Ks

will

across entire

at

end

of

return

be

will occur in

to

Option

for any exceptions.)

- -

to

Option

for any exceptions.)

TE.T

to

Option

and

performed.

435b

----

an

435b

print:

437b

an

be

new

line

line

open

and

or

--

open

or

for

-

Low-Paper

(Friction

Feed)

Paper-Out

(Sprocket

Feed)

17.

18.

Remove

Lift

feed).

Watch DATA key

key eight times.

the

paper

paper

roll from

- Paper-out (sprocket feed).

paper

support

and

depress LINE

- (friction

FEED

to

(Refer

for

Signal bell rings (sprocket

feed only).

Alarm

S:Qrocket Feed

DATA

LOCAL (LOCAL-TALK)

turns

is

received.

Friction Feed

DATA remains

LOCAL (LOCAL-TALK)

remains off.

Option

any exceptions.)

turns

turns

on

as

8th

437b

on.

off.

LINE FEED

on.

for

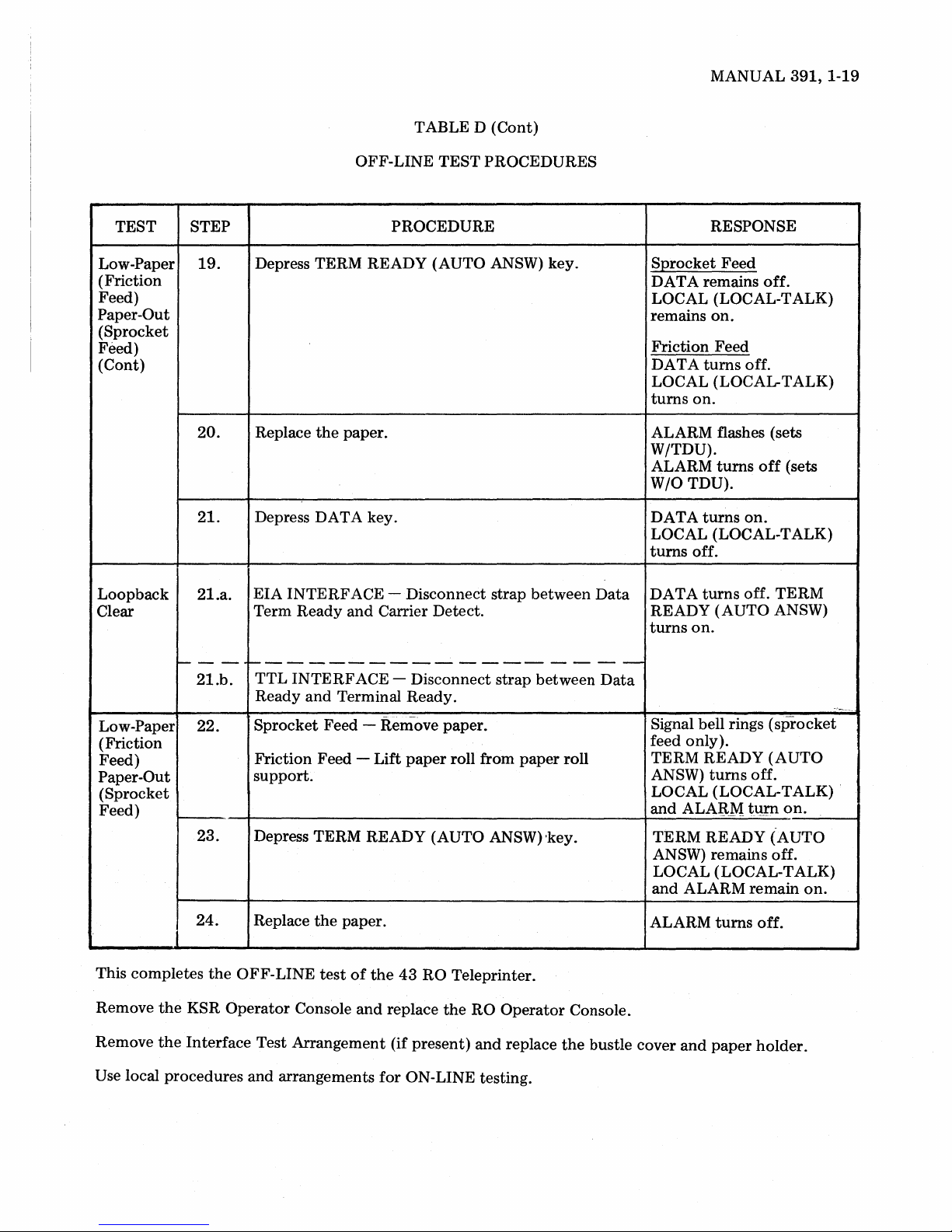

Page 25

TABLE D (Cont)

MANUAL

391,1-19

TEST

Low-Paper

(Friction

Feed)

Paper-Out

(Sprocket

Feed)

(Cont)

Loopback

Clear

STEP

19.

20.

2l.

2l.a.

OFF-LINE

TEST

PROCEDURES

PROCEDURE

Depress TERM READY (AUTO ANSW) key.

Replace

the

paper.

Depress DATA key.

EIA

INTERFACE

Term

Ready

- Disconnect strap between

and

Carrier Detect.

Data

RESPONSE

SQrocket

DATA remains

Feed

off.

LOCAL (LOCAL-TALK)

remains

on.

Friction Feed

DA

T A

turns

off.

LOCAL (LOCAL-TALK)

turns

on.

ALARM flashes (sets

W/TDU).

ALARM

W/O

DATA

turns

TDU).

turns

off

on.

(sets

LOCAL (LOCAL-TALK)

turns

off.

DATA

turns

off.

TERM

READY (AUTO ANSW)

turns

on.

----

21.b.

Low-Paper 22.

~-----------------

TTL

INTERFACE

Ready

Sprocket

and

Terminal Ready.

Feed - Remove paper.

(Friction

Feed)

Paper-Out

Friction Feed -

support.

(Sprocket

Feed)

24.

This completes

the

the

KSR

Interface

Remove

Remove

23.

Depress TERM READY (AUTO ANSW) 'key.

the

the

OFF-LINE

Operator

Replace

Console

test

paper.

of

and

Test Arrangement (if present)

Use local procedures and arrangements

- Disconnect strap between

Lift

paper

roll from

the

43

RO Teleprinter.

replace

for

the

ON-LINE testing.

RO

Operator

and

replace

paper

Data

roll

Console.

the

bustle cover

Signal bell rings

(sprocket

feed only).

TERM READY

ANSW)

turns

(AUTO

off.

LOCAL (LOCAL-TALK) .

and

ALA:B.M

t\!J'Il

on.

TERM READY (AUTO

ANSW) remains off.

LOCAL (LOCAL-TALK)

and

ALARM

ALARM

and

turns

paper

remain

off.

holder.

on.

~

Page 26

391,1-20

RO VARIABLE FEATURES CHECKOUT

4.01

only. The features

are checked in

A.

Remove RO

KSR Operator Console.

EIA

; shown

Connect Carrier Detect

Tum

TTL

'shown

'Connect Terminal Ready

Tum

The procedures in Table F verify

operation

Loopback Mode

INTERF

on

Page 1-2

on

Teleprinter POWER switch.

INTERF

on

Page 1-2

on

Teleprinter POWER switch.

of

variable feature exceptions

as

furnished from

the

off-line tests in Table D.

PROCEDURE

Operator

ACE - Connect

ACE - Connect

Console and install

the

to

the

interface connector. Printer performs one line feed.

to

Data Term Ready.

to

the

interface connector.

to

Data

LOOPBACK MODE PROCEDURES

test

the

test arrangement

Ready.

the

arrangement

proper

factory

TABLE E

4.02

teleprinter

the

Console (See Table E.)

Print head returns

DATA

Off-line

through

RO

turns

into

the

Operator

on.

checkout

437b

Console

RESPONSE

to

of

Options

will require placing

loopback

left-hand margin.

mode

with

and

a KSR

433b

the

replacing

Operator

B.

Variable Features

CHECK

Option

431.b.

andc.

(Option

•

!"It%'~()*+,-./112J456789:;<=>1'ABCDEFGHIJKl"NOPORSTUVUXYZ[\]+~'abcdet9hiJklMnopqrstuvwxyz{I}N

(Option 431.c.)

•

!lIlt%,~()*+,-./m23456789:;<=>?@ABCDEFGHIJKl"N!PORSTUVUXYZ[\]ti'abCdef9hijklMnOpQrstuYWXYZ{I}N

Depress

431. b. )

Checkout

TABLE F

FEATURES CHECKOUT PROCEDURES

TEST key.

and

VARIABLE

PROCEDURE RESPONSE

hold

PRINTER

~ ~

~

Fig.

9-Printer

Test Message

Characters

Bell sounds

~~

printed

at

end

as in Fig. 9.

of

each line.

Page 27

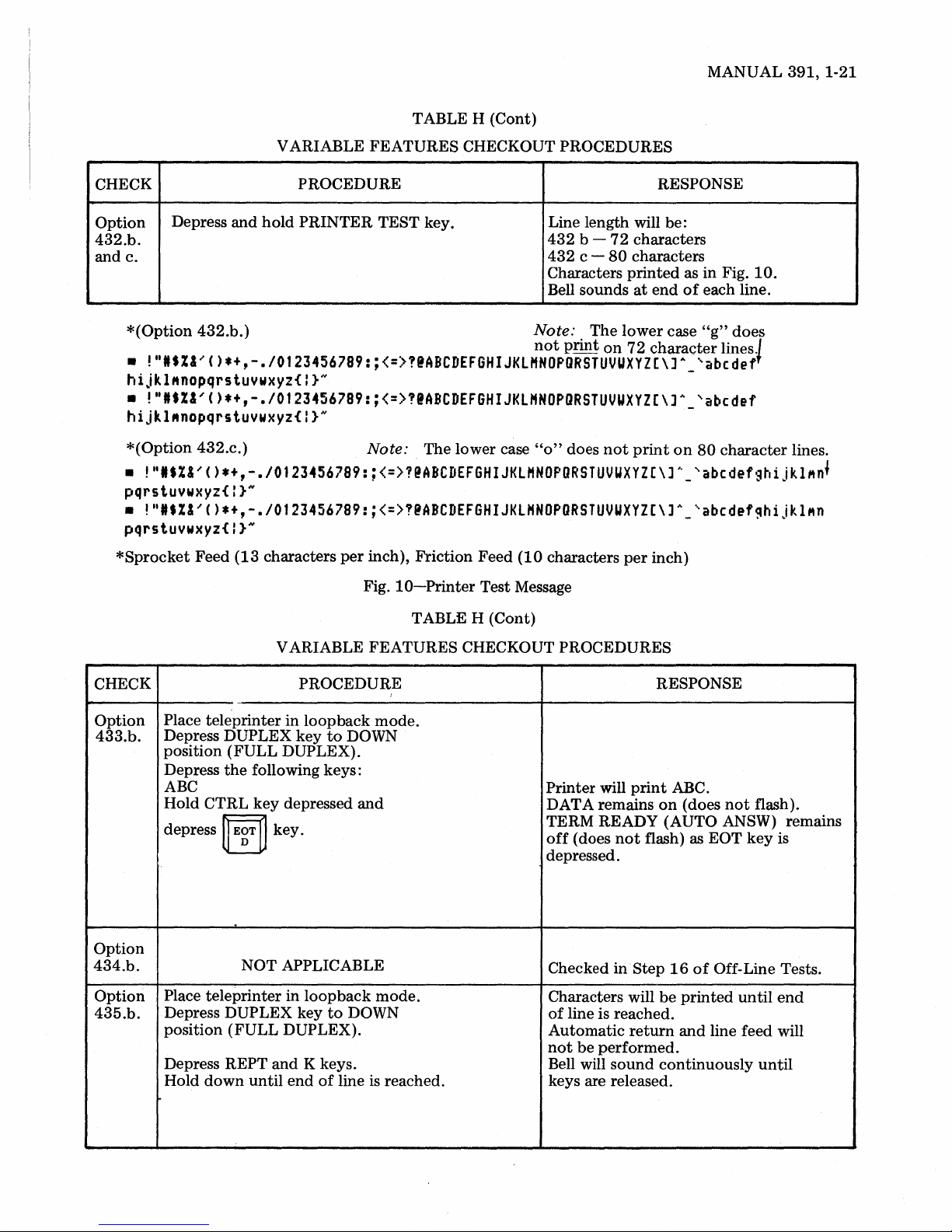

TABLE H (Cont)

MANUAL

391,1-21

CHECK

Option

432.b.

and

c.

*(Option

•

Depress

!"IS%I'()*+,-.I0123456789:;<=>?@ABCDEFGHIJKLHNOPORSTUVUXYZ[\)A

and

432.b.)

hijkl"nopqrstuywxyz{I}N

•

!ttIS%&'()*+,-.I01234S6789:;<=>?@ABCDEFGHIJKLHNOPORSTUVUXYZ[\]A_

hijkl"nopqrstuywxyz{I}N

*(Option

•

!"IS%I'()*+,-.I0123456789:;<=>1@ABCDEFGHIJKLHNOPORSTUVUXYZ[\]A_'abcdefghijkl"n

432.c.)

pqrstuywxyz{:}N

•

!"IS%I'()*+,-.I0123456789:;<=>!@ABCDEFGHIJKLHNOPORSTUVUXYZ[\]A_'abcdef~hijkl"n

pqrstuywxyz{:}N

*Sprocket

Feed

(13

V ARIABLE

PROCEDURE RESPONSE

hold

PRINTER

characters

FEATURES

TEST key.

CHECKOUT PROCEDURES

Note: The lower case

per

inch), Friction Feed

Fig.

10-Printer

Line length will be:

432

432

Characters

Bell sounds

Note: . The

not

"0"

(10

characters

Test Message

b c -

pnnt

does

72

characters

80

characters

printed

at

lower

on

72

not

print

per

end

character

inch)

as in Fig.

of

each line.

case

"g"

-'abcdef

'abcdef

on

80

10.

does

lines.J

character

lines .

f

V ARIABLE FEATURES CHECKOUT PROCEDURES

CHECK PROCEDURE

Option

433.b.

Option

434.b.

Option

435.b.

Place teleprinter in

Depress

position

Depress

ABC

Hold

depress

Place

Depress DUPLEX key

position

Depress REPT

Hold

DUPLEX key

(FULL

the

following keys:

CTRL

teleprinter

down

key

ij

EgT

NOT APPLICABLE

(FULL

until

loopback

DUPLEX).

depressed

~

key.

in

loopback

DUPLEX).

and

K keys.

end

to

to

of

line is reached.

I

mode.

DOWN

and

mode.

DOWN

TABLE H (Cont)

RESPONSE

Printer

DATA remains

TERM READY

off

depressed.

Checked

Characters will

of

Automatic

not

Bell will

keys are released.

will

print

(does

not

flash) as EOT

inStep

line is reached.

return

be

performed.

sound

ABC.

on

(does

not

flash).

(AUTO ANSW) remains

key

is

16

of

Off-Line Tests.

be

printed

and

continuously

until

end

line feed will

until

Page 28

391,1-22

RO

VARIABLE FEATURES CHECKOUT (Cont)

CHECK

Option

436.b.

Option

437.b.

VARIABLE

PROCEDURE

Place teleprinter

Depress DUPLEX

in

loopback

key

to

DOWN

position (FULL DUPLEX).

Place CPS

key

in DOWN position

(10 CPS).

Depress REPT

Hold

down

and

until

K keys.

two

lines

printed.

Measure

1 7

Enable

Place

continuity

on

RO

Option

teleprinter

opcon

434b.

between

connector.

in

loopback

TABLE H

FEATURES

mode.

of

Ks

are

pins 4

and

mode.

(Cont)

CHECKOUT PROCEDURES

RESPONSE

Continuous Ks will

entire line.

at

return

end

and

Bell rings

matic

performed.

One printed line plus

occur

in

approximately:

14

seconds (sprocket feed)

8.5 seconds (friction feed)

part

of

First

imately

printed

second line (approx-

18

characters) will be

at

a faster

Meter should read

be

printed

of

line

and

line feed will

return

rate

of

speed.

0 ohms.

across

auto-

be

will

Place

CAPS

Depress

(FULL

DUPLEX).

Depress

PARITY

Measure

20

on

RG.

LOCK

DUPLEX key

the

following keys:

TEST

continuity

opcon

key in DOWN position.

to

DOWN position

between

pins 4

and

connector.

Note: Disconnect Interface Test arrangement,

Printer will

PARITY TEST.

Meter should read 0 ohms.

if

present. Replace RO

print:

operator

console.

Page 29

MANUAL

391,2-1

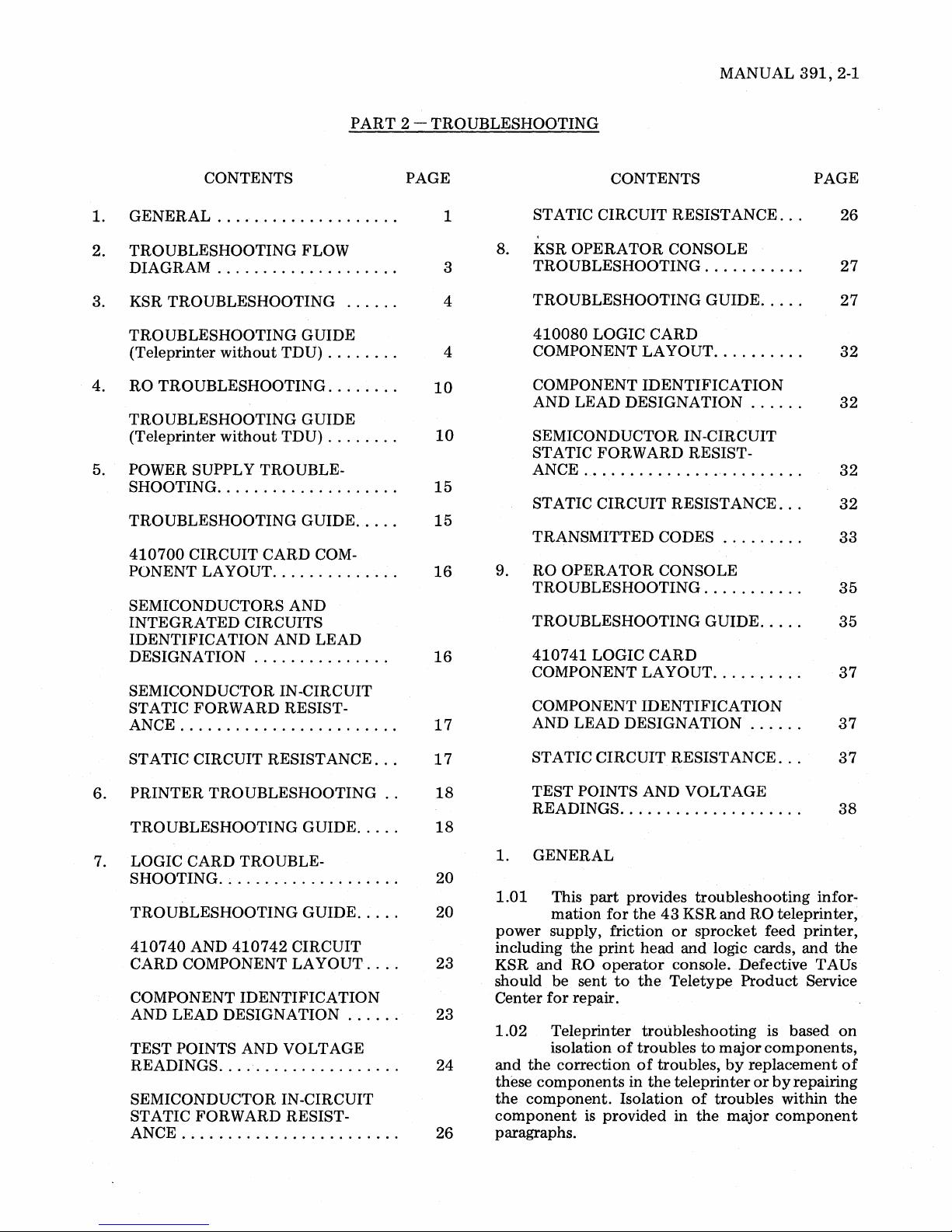

CONTENTS

1.

GENERAL

TROUBLESHOOTING FLOW

2.

DIAGRAM

TROUBLESHOOTING

KSR

3.

TROUBLESHOOTING GUIDE

(Teleprinter

4.

RO

TROUBLESHOOTING

TROUBLESHOOTING GUIDE

(Teleprinter

5.

POWER SUPPLY TROUBLE-

SHOOTING

TROUBLESHOOTING GUIDE

410700

PONENT

SEMICONDUCTORS AND

INTEGRATED

IDENTIFICATION AND LEAD

DESIGNATION

SEMICONDUCTOR IN-CIRCUIT

STATIC FORWARD RESISTANCE

....................

....................

without

without

....................

CIRCUIT CARD COM-

LAyOUT

........................

TDU)

TDU)

..............

CIRCUITS

...............

PART

......

........

........

........

.....

2 - TROUBLESHOOTING

PAGE

1

3

4

4

10

10

15

15

16

16

17

STATIC

8.

KSR

OPERATOR

TROUBLESHOOTING

TROUBLESHOOTING GUIDE

410080

COMPONENT

COMPONENT

AND LEAD DESIGNATION

SEMICONDUCTOR IN-CIRCUIT

STATIC

ANCE

ST ATIC CIRCUIT RESISTANCE

TRANSMITTED CODES

RO

9.

TROUBLESHOOTING

TROUBLESHOOTING

410741

COMPONENT

COMPONENT

AND LEAD DESIGNATION

.........................

OPERATOR

CONTENTS

CIRCUIT RESISTANCE

CONSOLE

...........

LOGIC

FORWARD

LOGIC

CARD

LAyOUT

IDENTIFICATION

CONSOLE

CARD

LAyOUT

IDENTIFICATION

..........

......

RESIST-

.........

...........

GUIDE

..........

......

.....

.....

...

...

PAGE

26

27

27

32

32

32

32

33

35

35

37

37

ST ATIC CIRCUIT RESISTANCE

PRINTER

6.

TROUBLESHOOTING GUIDE

LOGIC CARD TROUBLE-

7.

SHOOTING

TROUBLESHOOTING GUIDE

410740

CARD COMPONENT

COMPONENT IDENTIFICATION Center

AND LEAD

TEST

READINGS

SEMICONDUCTOR IN-CIRCUIT

STATIC FORWARD RESISTANCE

TROUBLESHOOTING

....................

AND

410742

DESIGNATION

POINTS AND VOLTAGE

....................

........................

CIRCUIT

LAYOUT

.....

.....

...

......

...

..

17

18

18

20

20

23

'

23

24

26

STATIC

TEST POINTS AND VOLTAGE

READINGS

GENERAL

1.

1.01

power

including

KSR

and

should be sent

for

1.02

and

the

these

components

the

component.

component

paragraphs.

CIRCUIT

....................

This

part

provides

mation

supply, friction

Teleprinter

isolation

correction

the

print

RO

operator

repair.

is

provided

for

the

head

to

the

troubleshooting

of

troubles

of

in

the

Isolation

RESISTANCE

43

or

and

console. Defective TAUs

Teletype

troubles,

teleprinter

in

troubleshooting

KSR

and

RO

sprocket

logic cards,

to

of

troubles

the

feed

Product

is based

major

components,

by

replacement

or

major

by

...

teleprinter,

within

component

37

38

infor-

printer,

and

the

Service

on

of

repairing

the

Page 30

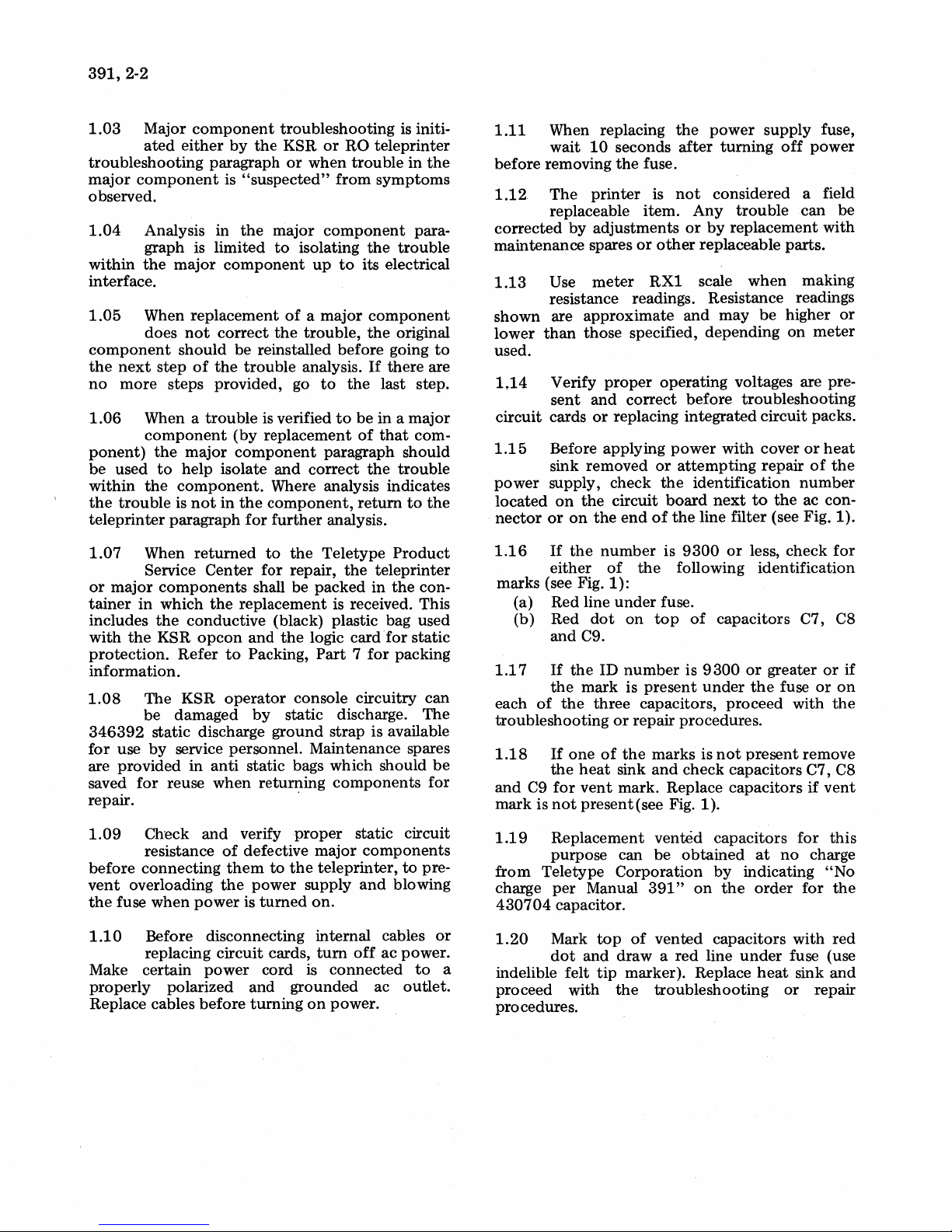

391,2-2

1.03

Major

ated

component

either

troubleshooting

major

component

observed.

1.04

Analysis in

graph is

within

the

major

interface.

1.05

component

the

no

1.06

When

next

more

When a

replacement

does

not

should

step

of

steps provided, go

component

ponent)

be

within

the

teleprinter

1.07

the

used

to

the

trouble

When

major

help

component.

is

not

paragraph

Service

or

major

tainer

includes

with

protection.

components

in

which

the

the

KSR

conductive

Refer

information.

1.08

346392

for

are provided

saved

The

KSR

be

damaged

static discharge

use

by

service personnel. Maintenance spares

for

reuse

in

repair.

by

paragraph

is

"suspected"

the

limited

component

correct

be

the

trouble

trouble

(by

component

isolate

in

the

for

returned

Center

the

replacement

opcon

to

operator

anti

static bags which should

when

troubleshooting

the

KSR

or

RO

teleprinter

or

when

trouble

from

symptoms

major

to

the

reinstalled

is verified

replacement

component

isolating

up

to

of a major

trouble,

before

analysis.

to

the

to

the

its electrical

component

the

original

going

If

there

last step.

be

in a major

of

that

paragraph should

and

correct

the

Where analysis indicates

component,

further

to

the

for repair,

shall be

return

analysis.

Teletype

the

packed

Product

teleprinter

in

the

is received. This

(black) plastic bag used

and

the

Packing,

logic card

Part 7 for

for

packing

console circuitry

by

static discharge.

ground

retur:r~ing

strap

is available

components

is initi-

in

the

para-

trouble

to

are

com-

trouble

to

the

con-

static

can

The

be

for

1.11

before

1.12

When replacing

wait

10

removing

The

printer

replaceable

corrected

maintenance

1.13

by

Use

adjustments

spares

meter

resistance readings. Resistance readings

shown

lower

are

approximate

than

those

used.

1.14

circuit cards

1.15

Verify

sent

and

or

Before applying

sink removed

power

located

nector

1.16

supply,

on

the

or

on

If

the

the

either

marks (see Fig.

(a) Red line

(b) Red

1.17

each

of

and

If

the

the

dot

C9.

the

mark

three

trOUbleshooting

1.18

and

mark

C9

is

If

the

for

not

one

heat

vent

present

the

seconds

the

fuse.

is

after

not

item.

or

or

other

RX1

and

specified,

proper

operating voltages are pre-

correct

replacing

before

integrated

power

or

attempting

check

circuit

number

of

end

the

the

board

of

the

is

9300

following

1):

under

fuse.

on

top

ID

number

is

is

present

capacitors,

or

repair procedures.

of

the

marks

sink

and

check

mark. Replace

(see Fig. 1).

power

supply

turning

off

fuse,

power

considered a field

Any

trouble

by

replacement

replaceable

scale

when

may

depending

be

can

parts.

making

higher

on

meter

with

troubleshooting

circuit

with

cover

repair

identification

next

to

the

packs.

or

heat

of

number

ac con-

line filter (see Fig. 1).

or

less,

check

identification

of

capacitors

9300

or

under

the

proceed

is

not

present

C7, C8

greater

fuse

with

remove

or

or

capacitors C7, C8

capacitors

if

vent

be

or

the

for

if

on

the

1.09

before

vent

the

1.10

Make certain

properly

Replace cables

Check

resistance

connecting

overloading

fuse

when

and

of

them

the

power

verify

defective

to

the

power

is

turned

proper

major

teleprinter,

supply

on.

Before disconnecting internal cables

replacing

polarized

circuit

power

before

cards,

cord is

and

grounded

turning

tum

on

static circuit

components

and

blowing

off

ac power.

connected

ac

power.

to

pre-

or

to

outlet.

1.19

from

charge

430704

1.20

a

indelible felt

proceed

Replacement

purpose can be

Teletype

per

Corporation

Manual

capacitor.

Mark

top

of

dot

and

draw a red

tip

marker). Replace

with

the

vented

capacitors

obtained

by

indicating

391"

on

the

vented

capacitors

line

under

troubleshooting

at

no

order

heat

or

for

this

charge

"No

for

the

with

red

fuse (use

sink

and

repair

procedures.

Page 31

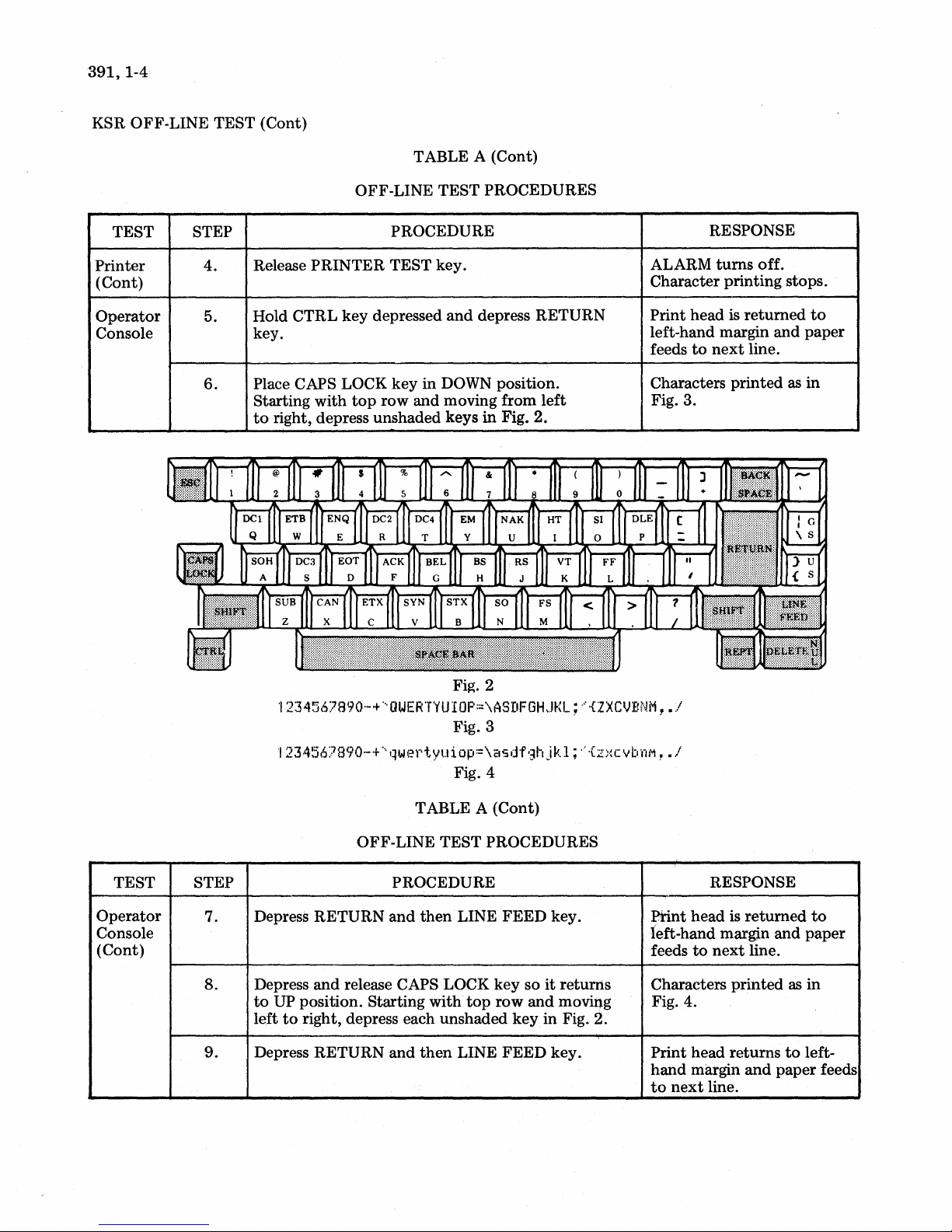

LINE

FILTER

CAPACITORS

MANUAL

391,

2-3

.............:::::::!!!~'t;t.L.;;;,

CAPACITOR

VENT

MARK

(Obs~rve

polarl~Y

replacmg.)

proper

when

CONNECTOR

AC

'Ii""

;,

"Js.

-~

~I!

II

4i:"-'7'

IDENTIFICA

NUMBER

Fig.

TION

1-430704

2. TROUBLESHOOTING FLOW DIAGRAM

III

PART

1

Paragraph 3

in

this

Part.

As

directed

Paragraph 3

in

this Part.

Paragraph 5,

and 9 in

this

and

in

and

6,

Part.

4

4

7, 8

,

LOCAL AND ON-LINE TESTS

TROUBLE IN

CONFIRM

REPLACE MAJOR COMPONENT

OR

OTHER

CORRECTIVE ACTION

TROUBLE CORRECTED

IN

TELEPRINTER

CIRCUIT

BOARD

Capacitor

Replacement

\JV

TELEPRINTER

/

r"

\V

DEFECT

......

'"

\V

NO

......

'"

YES

\/

ISOLATE AND CORRECT TROUBLE IN

MAJOR COMPONENT

FUSE

DISASSEMBL Y

AND

REASSEMBLY

PART

3

REINSTALL MAJOR COM-

PONENT IN

TELEPRINTER

i

PARTS AND

UNIT CODES

PARTS

\1

DISASSEMBL Y

AND

REASSEMBLY

PART 3

\1

CIRCUIT DESCRIP-

TION AND

DIAGRAMS

PART 4

\V

ADJUSTMENTS

SPRING

AND

TENSIONS

PART

5

Page 32

391,2-4

3.

KSR

TROP~~

....

ESHOOTING

TROUBLESHOOTING

QUESTIONS

1.

Are

any

of

the

mode

indicators

and

set

power

keys

if

proper

--

1a.

- - - - - - - - - -

Is

there

any

in

the

set?

(Indicators

power

lamp

is

on

turned

power

- - - -

1 b. Is

red

lamp

GUIDE

three

lit?

on.)

(Depress

indicator

indication

on