Page 1

English

MAG8

FIRE CONTROL PANEL

Installation and Operation Manual

C1293

Page 2

2

Fire Control Panel MAG8 - Installation and Operation Manual

CONTENTS

Guarantee ....................................................................................................................3

1. Using the MAG8 controls .......................................................................................4

1.1 MAG8 Operation Modes .............................................................................5

1.2 LED Indication for the Status of the Zones (1-8) .........................................5

1.3 LED Indication for the Technical Faults in the System ................................5

1.4 LED Indication for the System Status .........................................................6

1.5 Buttons for Programming and Operation ....................................................6

1.6 Switch for Changing the Access Levels ......................................................6

2. Installing the MAG8 Panel .....................................................................................7

3. Initial Power-up of MAG8 Panel ............................................................................8

4. Connecting the Zone Circuits ...............................................................................8

5. Connecting the Sounders Circuits .......................................................................9

6. Connecting FAULT and FIRE Relay Circuits ........................................................9

7. Class Change Function ........................................................................................10

8. Connecting of Repeater Panel ............................................................................10

9. Programming Master Panel Mode.......................................................................10

10. Programming Repeater Panel Mode .................................................................10

11. Programming Single Panel Mode......................................................................10

12. Programming Wireless Receiver Mode ............................................................ 11

13. Sounder Delay Mode .......................................................................................... 11

14. Double Action Mode ...........................................................................................11

15. Instant Action Mode ...........................................................................................11

16. Operating Instructions .......................................................................................13

16.1 Sound Signalization ................................................................................13

16.2 Service Modes ........................................................................................13

17. Connection Diagram ..........................................................................................16

18. Technical Specications ....................................................................................17

FIRE ALARM RECORD .............................................................................................18

SERVICE RECORD ...................................................................................................18

FIRE ALARM EVENT LOG ........................................................................................19

SPARE PARTS KIT ....................................................................................................19

WARNING

The system has to be installed by a qualied person to the latest Fire Alarm and Installation

Regulations which are mandatory in the applicable country of installation.

Before commencing the installation of this Fire Alarm Panel, ensure it is sited in a position, which

is visible to the Fire Brigade when entering the premises, and where ease of access is provided

for users and service engineers. Space must be available to easily open external and internal

doors.

The Electrical Supply to the panel must be isolated and must not be capable of being accidentally

switched off. A ‘Lockable Switch fuse Unit’ positioned within 2 meters of the panel should be

clearly labelled FIRE ALARM - DO NOT SWITCH OFF.

EN 54-2/4 compatible panels.

All specications are subject to change without notice.

Technical Support help: +359 (2) 9694 800

Page 3

3

Fire Control Panel MAG8 - Installation and Operation Manual

!

GUARANTEE

The guarantee terms are determined by the serial number (barcode) of the electronic device!

During the guarantee period the manufacturer shall, at its sole discretion, replace or repair any defective product

when it is returned to the factory. All parts replaced and/or repaired shall be covered for the remainder of the

original guarantee, or 6 months, whichever period is longer. The original purchaser shall immediately send manufacturer a written notice of the defective parts or workmanship.

International Guarantee

Foreign customers shall possess the same guarantee rights as those any customer in Bulgaria, except that manufacturer shall not be liable for any related customs duties, taxes or VAT, which may be payable.

Guarantee Procedure

The guarantee will be granted when the appliance in question is returned. The guarantee period and the period

for repair are determined in advance. The manufacturer shall not accept any product, of which no prior notice has

been received via the RAN form at: http://www.teletek-electronics.com/en/support/Service

The setup and programming included in the technical documentation shall not be regarded as defects. Teletek

Electronics bears no responsibility for the loss of programming information in the device being serviced.

Conditions for waiving the guarantee

This guarantee shall apply to defects in products resulting only from improper materials or workmanship, related

to its normal use. It shall not cover:

• Devices with destroyed serial number (barcode);

• Damages resulting from improper transportation and handling;

• Damages caused by natural calamities, such as re, oods, storms, earthquakes or lightning;

• Damages caused by incorrect voltage, accidental breakage or water; beyond the control of the manufacturer;

• Damages caused by unauthorized system incorporation, changes, modications or surrounding objects:

• Damages caused by peripheral appliances (unless such peripheral appliances have been supplied by the

manufacturer:

• Defects caused by inappropriate surrounding of installed products;

• Damages caused by failure to use the product for its normal purpose; Damages caused by improper

maintenance;

• Damages resulting from any other cause, bad maintenance or product misuse.

In the case of a reasonable number of unsuccessful attempts to repair the product, covered by this guarantee, the

manufacturer’s liability shall be limited to the replacement of the product as sole compensation for breach of the

guarantee. Under no circumstances shall the manufacturer be liable for any special, accidental or consequential

damages, on the grounds of breach of guarantee, breach of agreement, negligence, or any other legal notion.

Waiver

This Guarantee shall contain the entire guarantee and shall be prevailing over any and all other guarantees, ex-

plicit or implicit (including any implicit guarantees on behalf of the dealer, or adaptability to specic purposes), and

over any other responsibilities or liabilities on behalf of the manufacturer. The manufacturer does neither agree,

nor empower, any person, acting on his own behalf, to modify, service or alter this Guarantee, nor to replace it with

another guarantee, or another liability with regard to this product.

Unwarranted Services

The manufacturer shall repair or replace unwarranted products, which have been returned to its factory, at its

sole discretion under the conditions below. The manufacturer shall accept no products for which no prior notice

has been received via the RAN form at: http://www.teletek-electronics.com/en/support/Service

The products, which the manufacturer deems repairable, will be repaired and returned. The manufacturer has

prepared a price list and those products, which can be repaired, shall be paid for by the Customer. The devices

with unwarranted services carry 6 month guarantee for the replaced parts.

The closest equivalent product, available at the time, shall replace the products, the manufacturer deems unrepairable. The current market price shall be charged for every replaced product.

This manual contains information on limitations regarding product use

and function and information on the limitations as to liability of the

manufacturer.

The entire manual should be carefully read!

Page 4

4

Fire Control Panel MAG8 - Installation and Operation Manual

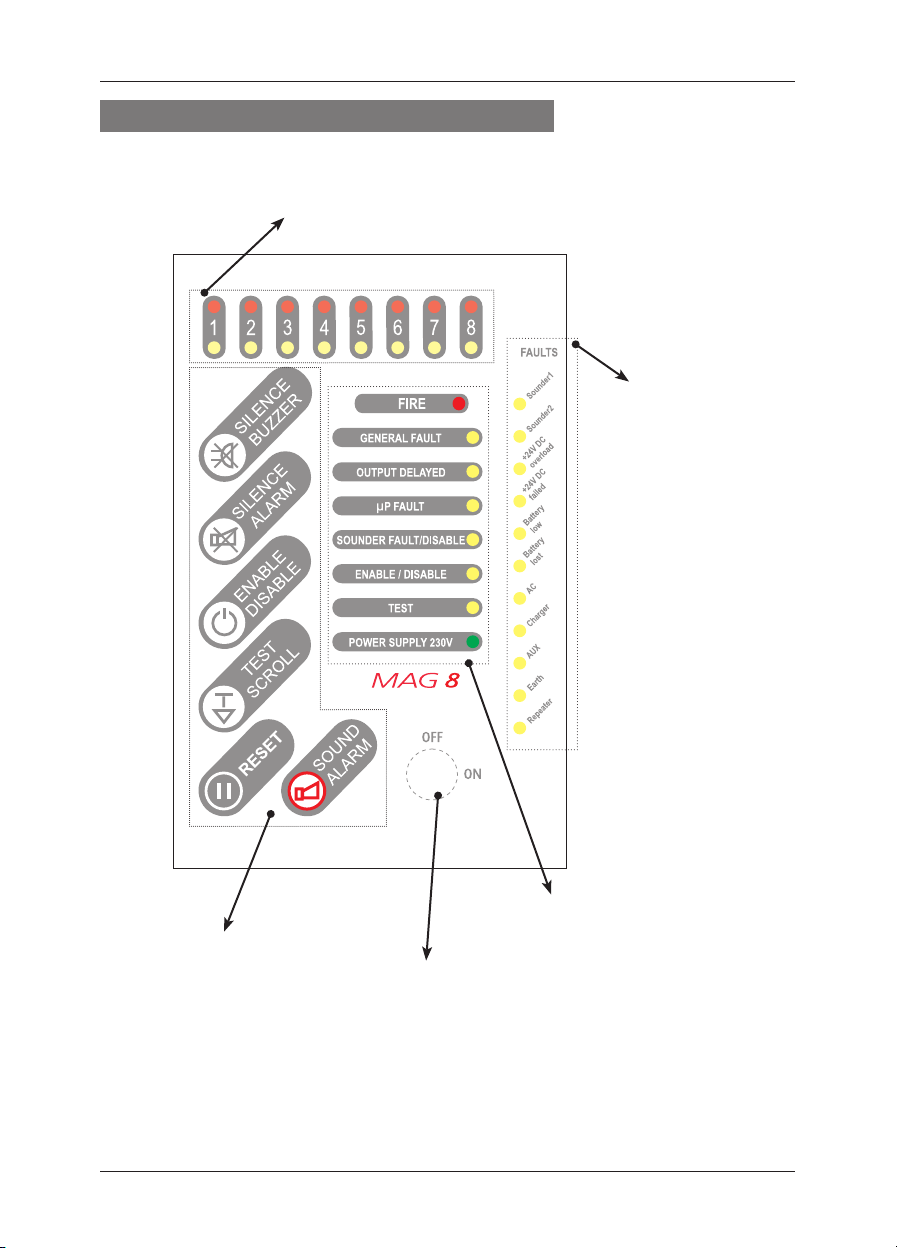

1. Using the MAG8 Controls

LED indication for the status of

the zones - see item 1.2.

LED indication for

the technical faults

in the system - see

item 1.3.

This indication is not

visible from the user.

To examine the

faults in the system

the engineer has

to remove the front

cover of the box.

Buttons for programming and

operation - see item 1.5.

LED indication for the system status - see item 1.4.

Switch for changing over

between Access Levels 1

and 2 - see item 1.6.

Page 5

5

Fire Control Panel MAG8 - Installation and Operation Manual

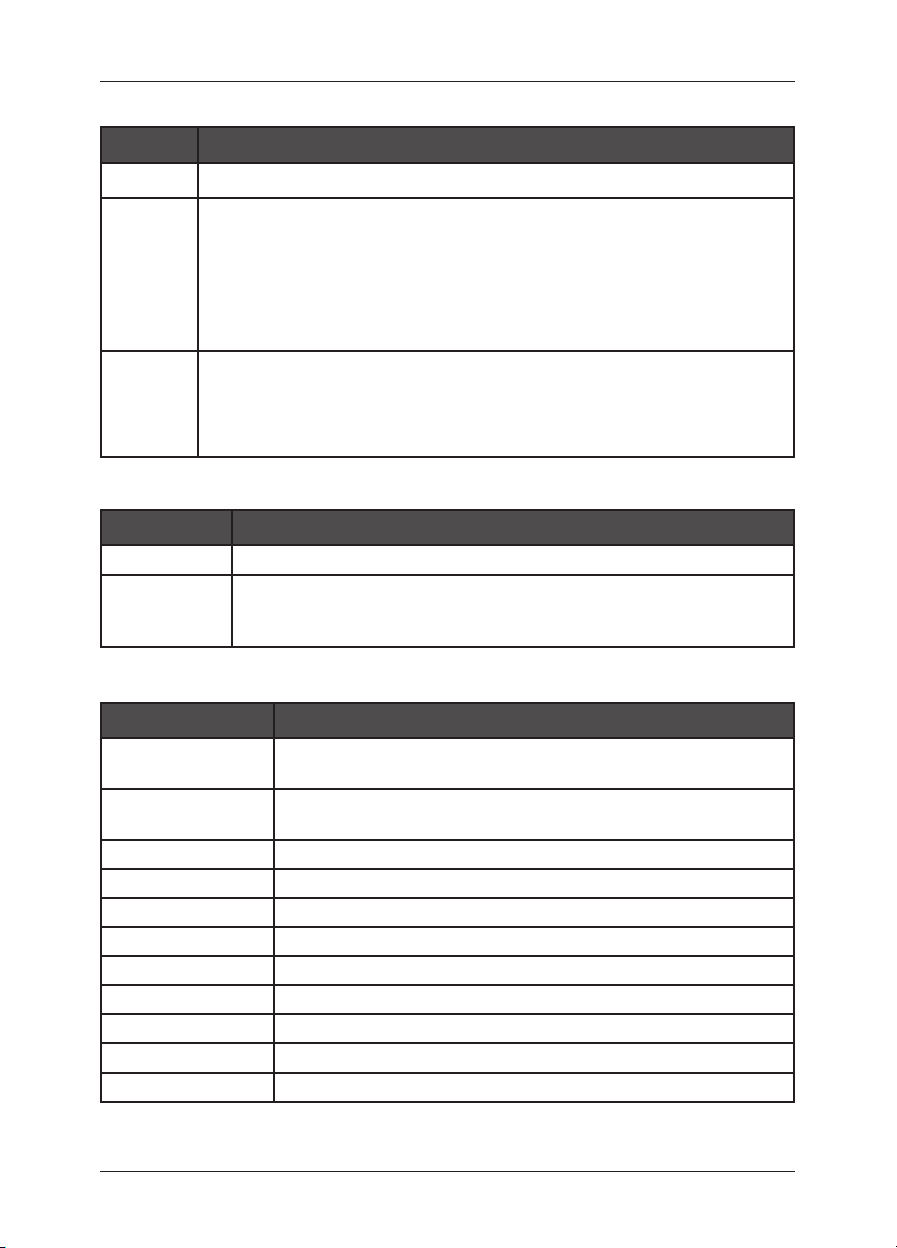

1.1 MAG8 Operation Modes:

MODE Indication

Normal • Only the “POWER SUPPLY 230V” green LED is illuminated.

• The “FIRE” red LED and the zone red LED will ash together on receipt

of a FIRE condition and become steady after the “SILENCE ALARM”

Fire

Fault

button is pressed.

• An internal buzzer will operate until silenced.

• The external sounders will operate.

• The FIRE relay will energize.

• The “GENERAL FAULT” yellow LED will illuminate together with a zone

yellow LED or any of the FAULTS LED.

• An internal buzzer will sound.

• The FAULT relay will de-energize.

1.2 LED indication for the status of the zones (1-8):

ZONE LED Indication

Red Fire in the zone.

Technical fault in the zone - open or short circuit; detector removed

Yellow

from its base.

Zone test - the LED is ashing during the test procedure.

1.3 LED indication for the technical faults in the system:

FAULT Fault description

Sounder 1

Sounder 2

+24V DC Overload Overload of “+24” VDC power supply.

+24V DC Failed Absence of “+24” VDC power supply.

Battery Low Low battery condition; broken battery (high battery resistance).

Battery Lost Battery loss.

AC Mains Supply loss.

Charger Battery charger fault.

AUX Auxiliary supply fault.

Earth Short circuit to earth.

Repeater Repeater fault or missing.

Sounder Circuit One fault - open or short circuit, reverse

connected sounder, or bad sounder parameters.

Sounder Circuit Two fault - open or short circuit, reverse

connected sounder, or bad sounder parameters.

Page 6

6

Fire Control Panel MAG8 - Installation and Operation Manual

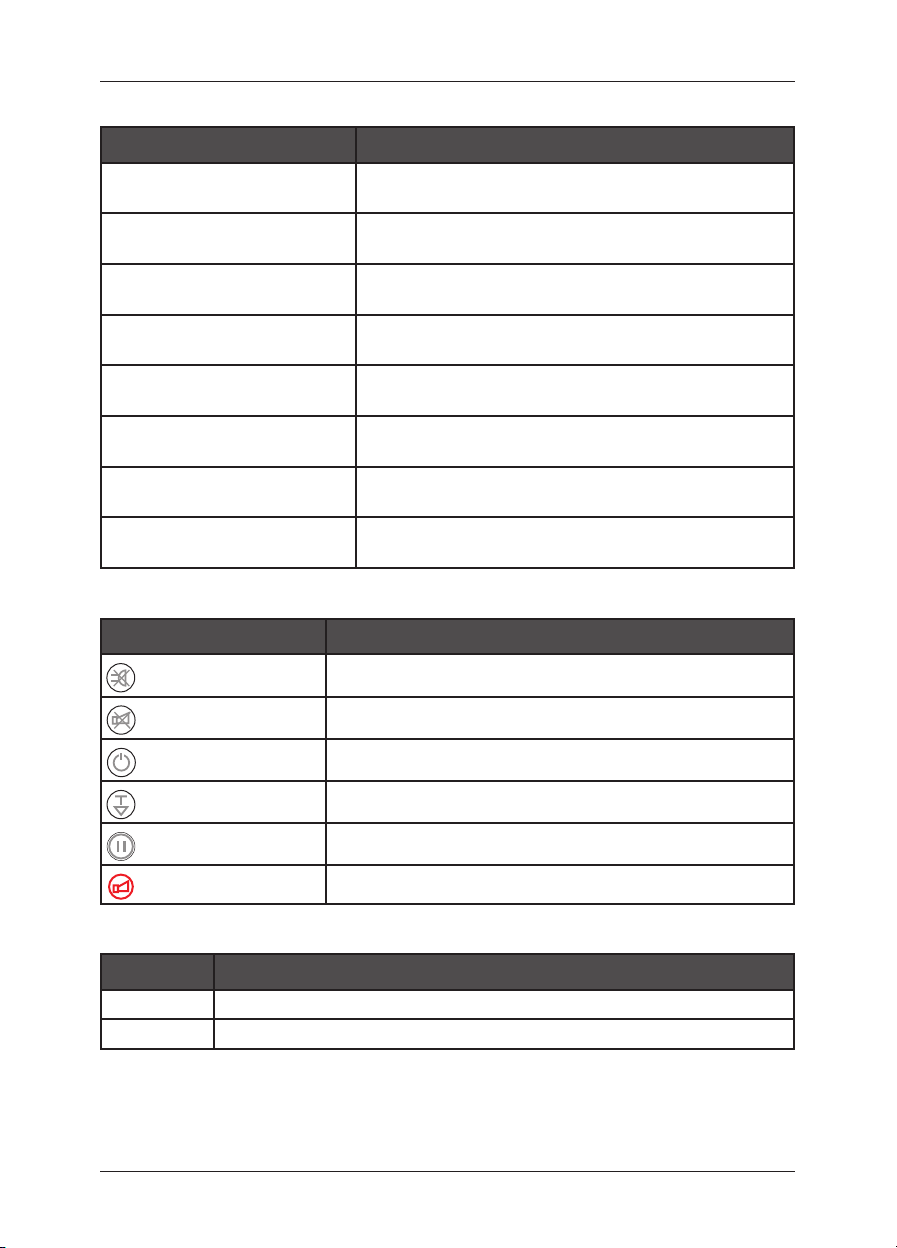

1.4 LED indication for the system status:

LED Indication

FIRE

(red)

GENERAL FAULT

(yellow)

OUTPUT DELAY

(yellow)

µP FAULT

(yellow)

SOUNDER FAULT/DISABLE

(yellow)

ENABLE / DISABLE

(yellow)

TEST

(yellow)

POWER SUPPLY 230V

(green)

Fire in the premises.

Main Fault indicator.

Lights permanently at programmed outputs time delay

(a jumper is set on the TIME DELAY terminal).

Processor break down.

Trouble in the sounder circuit - open or short circuit;

reverse connected sounder.

Lights permanently at disabled zones/sounders. Blinks

during enabling/disabling of zones or sounders.

Blinks during “One Man” Test together with the LED

of the tested zone.

Lights on permanently in normal operating mode,

indicates presence of main power supply 230V.

1.5 Buttons for programming and operation:

Button Description

SILENCE BUZZER Deactivating the internal buzzer.

SILENCE ALARM Deactivating sounders.

ENABLE / DISABLE Enabling / Disabling of Zones / Sounders.

TEST / SCROLL Test mode; Scroll forward zones.

RESET Initialization; Conrm the introduced changes.

SOUND ALARM Activating sounders.

1.6 Switch for changing over between Access Levels 1 and 2:

Position Description

OFF

ON Access Level 2 - all buttons at the front panel are active.

Access Level 1 - only the “SILENCE BUZZER” button is active.

Page 7

7

Fire Control Panel MAG8 - Installation and Operation Manual

2. Installing the MAG8 Panel

• Choose the best location for the panel position, with an ambient temperature between

-5°C and 40°C, away from heating sources, environmental dust and potential water

ingress.

• Remove all packaging and inspect visually the panel for any damage.

• Remove the outer cover - undo the two screws at the bottom of the cover. Stow the

cover in a safe position.

• Inspect the internal PCB and make sure the internal components are rmly in place.

• Remove the PCB from the plastic box. Stow in a safe location.

• Choose which cable entry points to knock out and carefully remove the knock-outs.

• Use the template on the back side of the packaging box to drill the mounting holes on

the wall.

• Fix the plastic housing into mounting position and insert xing screws.

• Tighten all the xing screws.

• Route the external cables onto the back box, make off connection glands etc., DO NOT

make any connections at this stage. ENTER THE MAINS CABLE THROUGH ITS

OWN CABLE ENTRY POINT AND KEEP MAINS WIRING AWAY FROM SYSTEM AND

OTHER LOW VOLTAGE WIRING.

• Fit the EOL modules from the supplied additional parts one-by-one to every zone

terminal. ATTENTION: Observe the polarity - the red wire to “+” point and the black

wire to “-” point.

• Fit the EOL resistors from the supplied additional parts one-by-one to the sounders

terminal.

• Re-t the PCB to the plastic box.

• Connect the mains supply and earth to the main terminal block. DO NOT switch on the

main electrical supply at this stage.

• Position the battery in an upright position.

• When you nish with power up and testing steps, and the panel is in normal operation

mode close the front cover using the screws and nuts from the spare parts kit:

Page 8

8

Fire Control Panel MAG8 - Installation and Operation Manual

!

!

3. Initial Power-up of MAG8 Panel

ATTENTION: It has been assumed that prior to making the connection

at the panel, the integrity of the system ALL wiring has been

comprehensively tested, including insulation to earth.

• Connect the battery leads from the power supply box to the positive and negative

battery terminals.

• Switch on the mains power supply.

• If the buzzer and indicator LED’s are operating, press the RESET button.

• The panel must be in Normal Operation Mode - only POWER SUPPLY 230V will be

illuminated. NOTE: The “Battery Low” LED might light on initially until the battery is

charging up to the required level.

If in Normal Operating Mode other LED’s are illuminated and the buzzer is

sounding, carefully check all fuses and connections. Refer to the Faults and

If by some chance the fault will not cancel, and only on the advice of our Technical

Support Department, return the PCB CHASSIS ONLY to your supplier. DO NOT

return the metal / plastic box.

System status LED description and the connection diagram on the inside of

the external cover will assist in identifying the trouble.

ATTENTION: Do not short out the battery terminals because any

internal protection will switch on and the panel will stop function!

4. Connecting the Zone Circuits

• Disconnect the mains power supply and the battery connection.

• Remove the EOL-module from the Zone 1 terminal on the main module and t it to the

last detector of the Zone 1 circuit as observe the polarity:

• Ensure all terminations are made correctly and all detector heads are set into their

bases.

• Connect Zone 1 circuit to the panel terminal block.

• Power up the panel with the mains and battery.

• Press “

• The panel is in Normal Operation Mode - only POWER SUPPLY 230V lights on.

RESET” button.

If General Fault and zone 1 FAULT LED’s illuminate, there is a wiring/

connection problem. Check the polarity of the connection, the connection of

the devices and whether a head is removed. Check the EOL proper polarity

and position.

Page 9

9

Fire Control Panel MAG8 - Installation and Operation Manual

!

brown

black

red

10K

LEGEND

Sounders

S1 S2 SN

!

• Operate ALL detection devices applicable to this zone, to ensure correct receipt of a re

signal and the correct operation of the panel controls. Refer to the User Instructions on

the inside of the panel.

• Repeat the connection process for the other zones stated above. ENSURE the supply

voltages are initially disconnected prior to each stage.

Once the connections of all zones are completed, connect and test

any of the other auxiliary circuits BEFORE connecting the sounder

circuits.

5. Connecting the Sounder Circuits

• Disconnect the mains power supply and the battery connection.

• Remove the EOL-Resistor from the terminal block of sounder circuit 1 (SND 1) and t

to the last sounder of circuit one:

• Check all sounder connections.

• Connect sounder circuit ONE to the panel terminal block.

• Apply mains and battery power.

• Press “

• The panel must be in Normal Operation Mode - only POWER SUPPLY 230V will be

illuminated.

• Activate a zone Call Point. The sounders should operate. Press the RESET button.

Repeat the connection process for the second external sounder circuit, as stated above.

ENSURE the supply voltages are initially disconnected prior to each stage.

RESET” button.

If GENERAL FAULT and SOUNDER FAULT/DISABLE LED’s illuminate,

there is a wiring/ connection problem. Check the polarity of the connection of

each of the devices, the polarity of the connection of the devices to the Panel

terminal block or whether an earth fault exists.

6. Connecting FAULT and FIRE Relay Circuits

The relays with changeover contacts are intended for control of low voltage devices.

Attention: No mains power should be supplied to the clamps of the

FAULT and FIRE relays.

After the connection is established, test each of the circuits for external

device control.

Page 10

10

Fire Control Panel MAG8 - Installation and Operation Manual

Rx

Tx

Tx

Rx

7. Class Change Function

To use the class change function connect the terminals of a switch with normally open

contacts to the CC (Class Change) clamps of the main module terminal. The working

mode of the sounders will be:

- when the switch is pressed - one second sounder on, one second sounder off;

- when the switch is depressed - the sounder is off.

8. Connecting of Repeater Panel

A second MAG8 can be connected to the MAG8 Fire Alarm panel as a Repeater (Slave)

panel. The function of the Repeater is to double the light and sound indication and the

button control of the rst panel at a distance up to 1000 m. For the purpose, to both of

the panels have to be assigned specic priorities: The rst re alarm panel shall be the

system Master and the second - Slave.

The Master panel is congured by setting a jumper on the Master position of the main

module, and the Slave - with a jumper on the Slave position (see the connection diagram

on page 16).

To add a repeater panel in the re system follow the steps:

• Turn off the main and the stand-by power supplies.

• Connect the repeater to the main MAG8 using the repeater interface:

Master

panel

MAG8

Position of the

jumper on the

panel PCB.

• Turn on the main and the stand-by power supplies of the Slave panel.

• Turn on the main and the stand-by power supplies of the Master panel.

Repeater

panel

MAG8

9. Programming Master Panel Mode

In order to program the Master Panel mode:

• Set a jumper on the Master position of the main module.

• Press the “

RESET” button to introduce changes.

10. Programming Repeater Panel Mode

In order to program the Repeater Panel mode:

• Set a jumper on the Slave position of the main panel module.

• Check for jumper on the Wireless terminal and remove if present.

• Press the “

RESET” button to introduce changes.

11. Programming Single Panel Mode

No jumper is set on the Master or Slave position in Single Panel Mode of the MAG8.

In order to program the Single Panel mode:

• Check whether there are jumpers set on the Master or Slave position. Remove if any.

• Press the “

RESET” button to introduce changes.

Page 11

11

Fire Control Panel MAG8 - Installation and Operation Manual

12. Programming Wireless Receiver Mode

In order to program the Wireless Receiver mode:

• Set a jumper on the Wireless position of the main module.

• Press the “

RESET” button to introduce changes.

13. Sounder Delay Mode

This is an option for setting a delay on the Sounders activation when the panel enters

FIRE mode. The indication on the front panel - the FIRE LED, however, will light up

immediately in case of a re event, regardless of whether a sounder delay has been set.

When the programmed sounder delay period expires, during which the user can possibly

nd out the cause for the alarm event, the panel enables the sounders. The sounders

can be silenced by pressing the “

In case of a false re alarm the user must press the “

normal working mode.

Attention: The re alarm panel MAG8 is capable to distinguish the activation of automatic

re alarm detector and call point. In case of call point activation, the programmed sounder

time delay will be ignored and the sounders will be activated immediately.

In order to program MAG8 for Sounder Delay for an interval up to 10 minutes:

• Examine the Table for Sounder Delay Programming (in minutes):

SILENCE ALARM” button on the front panel.

RESET” button to return to

• Depending on the selected time delay, set a jumper at the TIME DELAY terminals,

marked in Figure 10 as 1, 2, 3, and 4.

• Press the “

Example: In order to program sounder delay of 3 minutes, set jumpers on positions 1

and 2.

RESET” button to introduce changes.

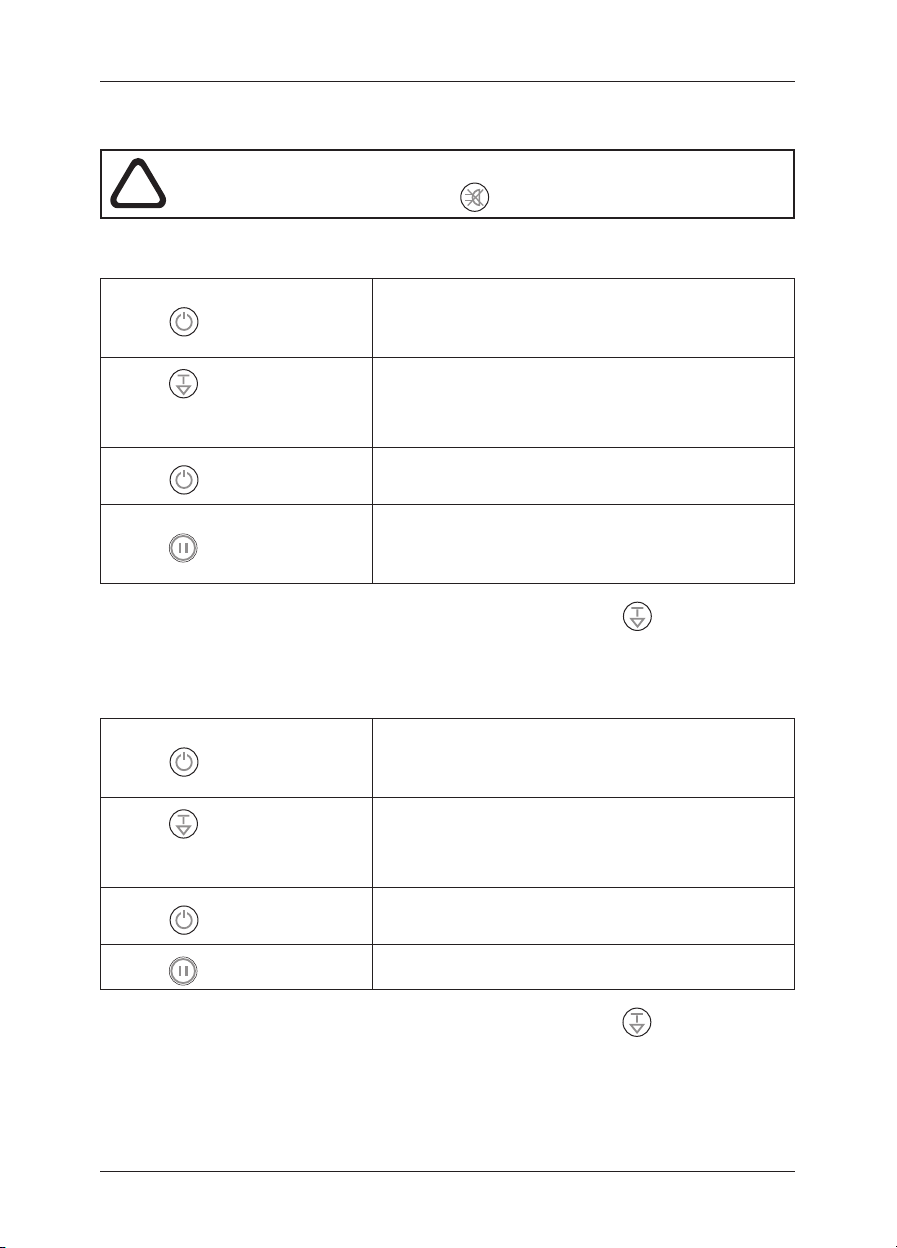

14. Double Action Mode

The purpose of introducing a Double Action mode is to avoid false alarms. When the

MAG8 panel has been programmed to function in this mode, in case of a re alarm

signal, the panel does not starting the sounders at once and waits for the alarm event to

be repeated within a specic time interval. The time interval has been set by default and

cannot be adjusted. For MAG8 it is 3 minutes.

Page 12

12

Fire Control Panel MAG8 - Installation and Operation Manual

Time Time

Attention: The re alarm panel MAG8 is capable to distinguish the activation of automatic

re alarm detector and call point. In case of call point activation, the programmed

DOUBLE Action mode will be ignored and the sounders will be activated immediately.

In order to program the MAG8 panel for Double Action mode:

• Set a jumper on the DOUBLE terminal of the main module.

• Press the “

RESET” button to introduce changes.

Example 1: In this case the re panel will not activate the sounders and the signalization

on the front panel because during time interval 2 no second alarm signal is generated.

Example 2: In this case the re panel will activate the sounders and the signalization on

the front panel because during time interval 2, two alarm signals are generated.

15. Instant Action Mode

Where in the protected site there are zones, which need the sounders and the LED

indication to be enabled instantaneously, the panel provides instant action operation

mode. This mode can be programmed individually for every single zone, depending

on its designation. In instant action mode, in case of an alarm event occurring in the

zone, the sounders are immediately enabled, i.e. this mode is of priority by zones

compared to Double Action and Sounder Delay modes.

In order to program Instant Action mode for a selected zone:

• Set a jumper on the terminal that corresponds to the number of the zone.

• Press the “

RESET” button to introduce changes.

Example: If the designation of ZONE 1 requires instant activation of all automatic re

alarm detectors connected in the line, set a jumper at Z1 terminals.

Page 13

13

Fire Control Panel MAG8 - Installation and Operation Manual

16. Operating Instructions

16.1 Sound Signalization

Signal Description

Short beeps

Continuous

beep

Interrupted

beep

After pressing the “

the panel.

Fire and/ or Fault operating mode. The signal can be stopped by

pressing the “

remains.

After pressing the “

zones/sounders and the “

Man” test mode of zones. The signal can be stopped by pressing the “

SILENCE BUZZER” button, but the LED indication remains.

RESET” button and upon the initial start-up of

SILENCE BUZZER” button, but the LED indication

ENABLE/DISABLE” button to enable/disable

TEST/SCROLL” button to access “One

16.2 Service Modes

Zone Enable / Disable

Each zone of MAG8 can be enabled or disabled.

Z To disable a zone:

DISABLE/ ENABLE LED blinks.

• Press ENABLE/ DISABLE:

• Press

til you reach the zone which has

to be disabled:

• Press

TEST/ SCROLL, un-

ENABLE/ DISABLE:

The ZONE 1 yellow LED blinks if ZONE 1 is enabled and lights permanently if ZONE 1 is disabled.

The respective zone yellow LED blinks.

The yellow LED of the disabled zone lights up permanently.

• Press

RESET:

Z To enable a zone:

• Press ENABLE/ DISABLE:

• Press

you reach the zone which has to

enable:

• Press

• Press

TEST/SCROLL, until

ENABLE/ DISABLE:

RESET:

At this step the zone is disabled.

DISABLE/ ENABLE LED blinks.

The ZONE 1 yellow LED blinks if ZONE 1 is enabled and lights permanently if ZONE 1 is disabled.

The yellow LED of the disabled zone lights up permanently.

The yellow LED of the enabled zone blinks.

At this step the zone is enabled.

Page 14

14

Fire Control Panel MAG8 - Installation and Operation Manual

!

Sounders Enable / Disable

A sound signalization is activated at every Service Mode entering. The

signalization is off by pressing “

SILENCE BUZZER” button.

Z To disable the sounders:

DISABLE/ ENABLE LED blinks.

• Press ENABLE/ DISABLE:

The ZONE 1 yellow LED blinks if ZONE 1 is enabled and lights permanently if ZONE 1 is disabled.

• Press

til you reach the last zone in the

system:

• Press

• Press

You can exit the sounder disabling mode also by pressing the “

button, as in that case the you reject the procedure.

TEST/ SCROLL, un-

ENABLE/ DISABLE:

RESET:

The SOUNDER FAULT/DISABLE LED will start

blinking.

The SOUNDER FAULT/DISABLE LED lights up

permanently.

The SOUNDER FAULT/DISABLE and ENABLE/

DISABLE LEDs light up permanently.

At this step the sounders are disabled.

Z To enable the sounders:

DISABLE/ ENABLE LED blinks.

• Press ENABLE/ DISABLE:

• Press

til you reach the last zone in the

system:

• Press

TEST/ SCROLL, un-

ENABLE/ DISABLE:

The ZONE 1 yellow LED blinks if ZONE 1 is enabled and lights permanently if ZONE 1 is disabled.

The SOUNDER FAULT/DISABLE LED lights up

permanently.

The SOUNDER FAULT/DISABLE LED will start

blinking.

TEST/ SCROLL”

• Press

You can exit the sounder enabling mode also by pressing the “

button, as in that case the you reject the procedure.

RESET:

At this step the sounders are enabled.

TEST/ SCROLL”

Page 15

15

Fire Control Panel MAG8 - Installation and Operation Manual

“One Man” Test

The “One Man” Test mode gives the installer the possibility to test the efciency of the

system - whether the detectors react to smoke, heat, etc.

Z To “One Man” Test a zone:

TEST LED will start blinking.

• Press TEST/ SCROLL:

µP Fault LED lights off. All other system indication

LEDs light on permanently.

• Press

again:

• Press

again to continue with the system testing:

Continue the system testing by pressing the “

the “One Man” Test mode is automatic after the end of the test procedure in the last Zone

8, or at any time by pressing “

TEST/ SCROLL

TEST/ SCROLL

The ZONE 1 yellow LED starts blinking.

ZONE 1 is in test mode. Test a detector from this

zone whether it react to smoke, heat, etc.

TEST LED will continue blinking.

The ZONE 1 yellow LED lights out (the zone is

not longer in test mode). The ZONE 2 yellow LED

blinks in yellow.

ZONE 2 is in test mode. Test a detector from this

zone whether it react to smoke, heat, etc.

TEST/ SCROLL” button. The exit from

RESET” button.

Quick Reference Operation Examples

• To disable Zone 3, do in sequence:

→ → → → → → →

→

At the end the yellow Zone 3 LED and

ENABLE / DISABLE LED light on

To enable back the Zone 3 do the same steps. At the end the Zone 3 and ENABLE /

DISABLE LED are off.

• To disable the sounders, do in sequence:

→ → → → → →

x 8 times

To enable back the sounders do the same steps. At the end the SOUNDER FAULT/

DISABLE and ENABLE / DISABLE LED are off.

LEGEND:

- The LED is off; - The LED is on; - The LED blinks

At the end the SOUNDER FAULT/

DISABLE LED and ENABLE / DIS-

ABLE LED light on

Page 16

16

Fire Control Panel MAG8 - Installation and Operation Manual

17. Connection Diagram

Page 17

17

Fire Control Panel MAG8 - Installation and Operation Manual

18. Technical Specications

Zones 8 xed zones

Maximum number of detectors per zone Up to 32 devices*

*

Including 20 (or 32 SensoMAG) automatic detectors and/ or manual call points.

Thresholds for zone conditions

• 0 - 2 mA Open circuit fault condition.

• 2 - 10 mA Normal condition.

• 10 - 110 mA Fire Alarm condition.

• 110 mA - Short circuit Short circuit condition.

Power Supply

Main Power supply 230V AC ±10%; 0.315A fuse

Standby Power supply, accumulator 1 x 12V/7Ah (7.2Ah); 4.5A fuse

type Sealed Lead-Acid, 150x95x65mm

Maximum charging current for the battery 0.3 A

Battery high resistance Ri < 0.45Ω

Consumption

Maximum current available for system

devices (with fully charged battery) 0.7 A

Minimum current for standby power supply mains failure 0.125 A

Maximum current for standby power supply 4,5 A

Outputs

Sounder Circuit 1 24V / 0.5A; 0.5A fuse (PTC)

Sounder Circuit 2 24V / 0.5A; 0.5A fuse (PTC)

Fault Relay, volt free changeover contacts** 3A @ 24V DC

Fire Relay, volt free changeover contacts** 3A @ 24V DC

**

Note: These functions may not be used to provide any “Options with requirements” as specied

in EN 54-2.

Auxiliary output 24V DC, 0.3A fuse (PTC)

Cabling Maximum 2.5mm diameter

Environment

Working temperature -5 to 40°C

Storage temperature -20 to 60°C

Humidity 0 to 95%

Compatible modules

MR8 - 8 Relay Module

ML - Log Memory Module

Attention: It is possible to connect only one module to the MAG8 re panel at the same

time!

Page 18

18

Fire Control Panel MAG8 - Installation and Operation Manual

FIRE ALARM RECORD

Installation Address: .......................................................................................................

Contact Person: .......................................................................................................

Telephone: .......................................................................................................

Fax: .......................................................................................................

Date Completed: .......................................................................................................

Commissioned By: .......................................................................................................

Contract Reference: .......................................................................................................

Service Intervals: Monthly / Quarterly / Half Yearly / Annually

ZONE

No

1

2

3

4

5

6

7

8

* Ion - Ionisation sensor, Ph - Photoelectric sensor, RoR - Rate of Rise sensor, F/T - Fixed

Temperature sensor, CP - Call Point

LOCATION

TOTALS:

DETECTOR TYPE and QUANTITY

PER ZONE

Ion Ph RoR F/T CP Circuit1 Circuit2

SOUNDERS

(Zone Quantity and

Related Circuit)

System Installed By: .........................................................................................................

Telephone / Fax: ................................................................................................................

SERVICE RECORD

Date Visit

Completed

Zones Tested Faults Rectied

1 2 3 4 5 6 7 8 Name:

1 2 3 4 5 6 7 8 Name:

1 2 3 4 5 6 7 8 Name:

1 2 3 4 5 6 7 8 Name:

Signature of

Engineer

Next Due

Page 19

19

Fire Control Panel MAG8 - Installation and Operation Manual

FIRE ALARM EVENT LOG

DATE TIME

yes / no

SPARE PARTS KIT

FIRE

ZONE

number

FAULT

yes/no and

TYPE

ACTION

TAKEN

Name

No Component Description Q-ty

1

2

3

4

5

6

7

8

Fuse

0.315A, 5x20

Key, 10mm 2

Screw, 2.9x13 mm,

DIN7981

Screw with interrupted

thread, M3x16

Locknut, M3 2

Plastic cap, 20mm 4

Resistor 10K ±1%,

0,25W

EOL Module 9

1

2

2

3

Page 20

Address: 14A Srebarna Str., 1407 Soa, Bulgaria

Tel: (+359 2) 9694 800, Fax: (+359 2) 962 52 13

e-mail: info@teletek-electronics.bg

www.teletek-electronics.com

18020753, RevB, 09/2015

Loading...

Loading...