Page 1

CA824

INSTALLATION MANUAL

3.3 version

September 2004

WARNING

This manual contains information on limitations regarding product use and function and information on the

limitations as to liability of the manufacturer. The entire manual should be carefully read.

Page 2

2 CA824 Installation manual

CONTENTS

INTRODUCTION .....................................................................................................................................3

RCOMMENDATIONS FOR INSTALLING THE CA824 ALARM SYSTEM................................................3

PHYSICAL AND LOGICAL SYSTEM LEVEL ...........................................................................................4

BEFORE PROGRAMMING THE CA824 ALARM SYSTEM ....................................................................5

STEP-BY-STEP PROGRAMMING OF SYSTEM PARAMETERS ..........................................................6

LEAVING PROGRAMMING MODE..........................................................................................................6

NEW PnP HARDWARE IDENTIFICATION PROCEDURE ....................................................................6

REMOVING MODULES FROM THE SYSTEM.......................................................................................7

DISABLING SYSTEM MODULES............................................................................................................7

CA824 ALARM SYSTEM CHARACTERISTICS ......................................................................................7

CA824 control panel box..........................................................................................................................8

CA824 control panel ..............................................................................................................................11

CA824 control panel resources .............................................................................................................12

Power supply unit ..................................................................................................................................12

CA824 control panel fuses ....................................................................................................................12

CA824 control panel indications ............................................................................................................12

CA824 control panel terminals ..............................................................................................................12

Technical specification of CA824 control panel.....................................................................................13

LCD824 keypad module ........................................................................................................................14

LCD824 keypad module resources.......................................................................................................14

Technical specifications of LCD824 keypad module.............................................................................15

LED816 keypad module ........................................................................................................................16

LED816 keypad module resources .......................................................................................................16

Technical specifications of LED816 keypad module.............................................................................17

MRI4/8 input (ZONE) expander module.................................................................................................18

MRI4/8 input expander module resources............................................................................................18

Technical specifications of MRI4/8 input expander module...................................................................18

MRO8 output expander module resources ...........................................................................................19

MRO8 output expander module (PGM) .................................................................................................19

Technical specifications of MRO8 output expander module .................................................................19

Installation box for input and output expander modules ........................................................................20

Technical specifications of the expander installation box......................................................................20

DIO32 module (Dynamic indication) .....................................................................................................21

Use of DIO32 module ............................................................................................................................21

DIO32 module resources ......................................................................................................................21

Adjusting the DIO32 module..................................................................................................................22

Technical specifications of DIO32 module ............................................................................................22

PR864 Proxi Reader Module .................................................................................................................23

Purpose of PR864 Proxi Reader Module ..............................................................................................23

Resources of PR864 Proxi Reader Module ..........................................................................................23

Technical specifications of PR864 Proxi Reader module .....................................................................23

SUPPLEMENT A - Menu structure chart for programming the CA824 alarm system ..........................24

ENGINEER PROGRAMMING MENU STRUCTURE CHART ...............................................................25

SUPPLEMENT B – Chart for user programmable menus....................................................................27

Page 3

CA824 Installation manual 3

RCOMMENDATIONS FOR INSTALLING THE CA824 ALARM SYSTEM

The CA824 Alarm system has been designed and tested according to electromagnetic compatibility

standards.

The following recommendations need to be observed for the proper performance of the alarm system:

1. Make sure the alarm system is securely earthed (neutral).

2. Insulate the low and high voltage cables and use different input box plug-ins.

3. Avoid any connecting conductor loops in the box or their positioning above or below the printed-circuit

board.

4. No additional relays should be placed in the CA824 Alarm system box, as switching these may cause

electromagnetic interference.

4.1. Use only relays with good insulation between plugs and winding.

4.2. The relays connected to open collector outputs must be designed for 12 V DC control voltage and

winding impedance greater than 400 Ω.

5. A quad conductor cable connects the motherboard with the modules. Using this cable for making any

other connections such as a telephone line, control flashlight signals, sirens or relays is not recom-

mended.

6. When placing the connecting cables avoid canals or cable forms housing high voltage wirings. This

is especially important where these cables are to be used for supplying power to electric motors,

luminescent lamps or three-phase voltage. Where this is impossible, use sheathed wiring where the

sheath should be earthed only in the alarm system box.

INTRODUCTION

This manual presents the information needed to install CA824 Alarm System modules.

The manual consists of two parts:

- general information about installing system modules

- description of devices and installation details

The manual includes a chart of the structure of menus, which will help detect and access system

configurations.

The following keys are used for programming:

A left arrow for back moves within the menu structure

A right arrow for forward moves within the menu structure

The ENT key for confirmation of any corrections / a transition to the following level of

menu structure

ENT

The CLR key for rejection of any corrections / a transition to prior level menu structure

CLR

Page 4

4 CA824 Installation manual

PHYSICAL AND LOGICAL SYSTEM LEVEL

Any security system established on CA824 principles should be regarded as a physical and logical

entity.

At its physical level it comprises of all modules, together with all their resources – inputs and outputs.

Limitations at this level consist of the number of modules, which can be connected to the bus – no more

than 15. As to the resources – there are no limitations at this level to the number of inputs or puts. In

practice, this would mean that the actual number of modules connected to the bus could be backed up

by more inputs and outputs than those maintained at the logical level.

The logical level of the system includes the zones, their types, their attached areas, etc; the programmable outputs (PGM) together with their performance logics; the user codes with all their adjustments;

the specified areas, etc. In other words, the logical level allocates the resources at a physical level and

configures performance of the system as a security station.

Zones are limited up to 24 logical numbers, whereas programmable outputs (PGM) are up to 16 logical

numbers. the logical number 00 is used to initialize the resources of any arbitrary module, which are not

to be utilized.

The modules engaged by the system can be activated in “double zoning” performance mode or deactivated in that mode. The “double zoning” mode is universal for all devices and means that two sensors

can be connected to any input of a given device. Hence, 2*N sensors can be connected to a module

which has N number of inputs. Two menu inputs correspond to one physical input. These are located at

address 8.0.xx.0, where device inputs can be configured and therefore 2*N zones can be attached to

module inputs in programming mode.

Where the double zoning option has not been activated, only one sensor can be connected to one input,

thus attaching only one zone to this input, when in programming mode. Therefore, where one module

has N inputs in this mode, no more than N sensors can be connected to it.

Only one zone can be connected to one input, irrespective of whether the double zoning mode is active

or not.

Figure 2 in Item 4.3 – Zone Hardware – describes how to connect sensors.

Module inputs will be processed only after they are assigned a number for the zone they are connected

to. This is done separately for each individual module at address 8.0.xx.0, Inputs config. XX designates

the number of the module from the list of devices included in the system. The parameters of the respective zone also have to be assigned at address 4.1.

This address is inaccessible for modules without inputs.

Elaboration on Table 1. The columns indicate which inputs of the menu, rows 2 & 3, correspond to a

given physical input in row 1. In Figure 2, input numbers for Zone 1 are in row 2. Input numbers for Zone

1 in Figure 2 are in row 3. For example – 1 and N+1 inputs from the menu at address 8.0.xx.0 correspond to first physical input. Input number 1 corresponds to Zone 1 and input number N+1 corresponds

to Zone 2.

Table 1. Correspondence between the physical inputs and the input numbers of the menu located at address

8.0.xx.0 for double zoning mode.

Physical input number

1

Input number from the menu for Zone 1

N+1

Input number from the menu for Zone 2

1

2

N+2

2

.....

.....

.....

N

2*N

N

Table 2. Correspondence between the physical inputs and the numbers of the inputs in the menu located at address

8.0.xx.0 for deactivated double zoning mode.

Physical input number

1

Input number from the menu

122

.....

.....NN

Page 5

CA824 Installation manual 5

BEFORE PROGRAMMING THE CA824 ALARM SYSTEM

Carefully read this manual to learn about system options and programming procedures.

Any necessary changes to system configurations have to be set prior to programming, in order to comply with the specifications of your security system.

Alterations to system configurations can be done at any time.

Fig. 1 shows LCD buttons on the keyboard.

Module inputs are processed only after they are assigned the number of the zone to which they are

connected. This is done for every module separately at address 8.0.xx.0. Input config. XX designates the

number of the module within the list of devices, which have been included in the system. The parameters of the respective zone also need to be assigned, at address 5.1.

This address is inaccessible for modules with no outputs.

Any arbitrary number of physical outputs can be connected to one PGM. These outputs can belong to

different system devices.

Both figures and letters can be keyed in. The letters, and their

respective figure association, are shown in Fig. 1.

Any figure or letter can be introduced depending on the number

of clicks on the button. The PRG button changes capital to small

case and vice-verse. Special symbols like space or coma can

be introduced via the 1 and 0 buttons. The correspondence between the number of button clicks and the symbol to be displayed is shown in Table 1.

The arrows will move the cursor within the edited section. Pressing ENT confirms any changes. Pressing CLR rejects the

changes.

Fig. 1. LCD keyboard buttons

Table 3. Correspondence between the number of button clicks and the respective symbol

2 3 4 5 6 7 81

0

1

2

3

4

5

6

7

8

9

0

.

,

:

!

< >

1

-

=

+

$ %

@

/

2

3

4

5

6

7

8

9

A B C ? ? ?

?

D E F ? ? ?

?

G H I ? ? ? ?

J K L

M N O

P Q R S

T U V

W X Y Z

? ? ? ?

? ? ? ?

?

? ?

?

? ? ?

? ? ?

B

u

tto

n

Number of clicks

Page 6

6 CA824 Installation manual

STEP-BY-STEP PROGRAMMING OF SYSTEM PARAMETERS

I. It is necessary to design a model of your security system and to establish a scheme describing this

model in order to begin programming (showing the type and number of sensors, their interconnections,

any specific requirements towards system configuration). Then the system can be integrated and programmed.

II. If the system is to be programmed for the first time, it would be necessary to Load factory settings.

III. Loading factory settings

Use the RESET jumper on the motherboard. Proceed as follows:

- Power down the system – both battery and mains;

- Place the RESET jumper on the motherboard;

- Power up the system, wait 8 seconds and remove the RESET jumper. System factory configurations

have now been restored, all modules identified and the system configured. The Engineer Code is 7777.

The manager code is 0000.

System factory configurations for inputs and outputs are issued in Table 2 and Table 3.

The RESET jumper is used only to perform RESET and should be removed during system operation.

IV. All areas must be disarmed when adjustments to any settings of the system, which has already been

programmed, are going to be made. Access will thus be enabled to the engineer menu, where programming is done.

V. Introduce engineer code to access engineer menu. Once in programming mode, it is recommended

to observe the following steps in order to reduce the risks of mistake or omission.

VI. Assign zone numbers, the logical inputs are to be connected to, and the number of the PGM, to which

the device outputs are to be directed, by observing the requirements of your own security system. This

procedure is described in Item 8.

VII. Program areas within the system. This procedure is described in Item 6.

VIII. Program station user codes. The procedure is described in Item 3.

IX. Program zones according to requirements – make changes to the names of the zones, to the type

and attributes of the zones, define system area attachment. The procedure is described in Item 4.

X. Program PGM. The procedure is described in Item 5.

XI. Program system timers (entry time, exit time, bell time, date, etc.). The procedure is described in

Item 2.

XII. Program other parameters.

XIII. Exit programming mode after the system is programmed in order for your new adjustments to be

adopted.

XIV. Access the engineer menu and check the performance of the zones. The procedure is described in

Item 1.

XV. Exit engineer menu and test the performance of the system according to your requirements.

XVI. Go back to programming mode and set the dialer. The procedure is described in Item 7.

During Engineer programming mode is active activations of Zones and Tampers will not affect in the

system.

After Engineer programming mode is leaved all active zones and Tampers will affect in the system.

Only one LCD keypad can be in Engineer programming at the same time.

Engineer programming mode is allowed only when all areas in the system ar disarmed.

Page 7

CA824 Installation manual 7

LEAVING PROGRAMMING MODE

To exit programming mode press CLR several times until the display shows 9) Engineer out good-bye?,

and then confirm by pressing ENT.

If the system siren is triggered, introduce a valid user code, select from the list the area which caused

the alarm and then press the DISARM button to stop it. It would be sufficient to merely introduce this

code to stop the siren by introducing a code, where this is permitted.

NEW PnP HARDWARE IDENTIFICATION PROCEDURE

Every module from the CA824 system set has a singular number, recorded during the production process. This number consists of two parts – batch number and device type, and is used to carry out the

new hardware identification procedure or to load factory settings. After this procedure is completed,

each identified device is assigned a number, singular to the system, and used to indicate the location of

the module within the list of devices, which comprise the security system. The module uses it to participate in the exchange along the bus.

The PnP procedure is used to include the new modules within the logical structure of the system, which

are connected to the communication network.

Input? Zone? Type Area Zone parameters

1 1 Entry/Exit 1 AutoZoneShutdown, Chime, Audible

2 2 Follow 1 AutoZoneShutdown, Stay, Audible

3 3 Instant 1 AutoZoneShutdown, Stay, Force, Audible

4 4 Instant 1 AutoZoneShutdown, Stay, Force, Audible

5 5 Instant 1 AutoZoneShutdown, Stay, Force, Audible

6 6 Instant 1 AutoZoneShutdown, Stay, Force, Audible

7 7 Panic 1

8 8 Tamper 1

Table 2 System factory configurations for inputs

Table 3 System factory configurations for outputs

Output ? PGM? Parameters of PGM

1 1 ARM area 1

2 2 Alarm, Tamper

3 3 Technical trouble

4 4 Siren

Page 8

8 CA824 Installation manual

REMOVING MODULES FROM THE SYSTEM

The following has to be executed in case of physical removal of the module from the system:

The respective module can be removed from the list of modules by executing the Remove command at

address 8.0.xx.5., where xx is the module number in the device list. All adjustments set for a module,

after a Remove function, will be retained. Factory settings, however, will be preserved in the device itself.

Following this procedure, the device can be connected to another system.

A Remove procedure must be performed fore a faulty device, designated to be removed, after which the

new module should be connected and function 8.1. Add hardware carried out. Thus, the new device will

have the same settings as the old one.

DISABLING SYSTEM MODULES

This is done where a module has to remain physically connected to the system, but will not be in use:

1. 1. Issuing a command at address 8.0.xx.3 can disable the respective module. Disable, where xx is

the number of the module in the list of devices. The settings and the singular number of the module,

subject to this function, will be retained, but all communications with it will be terminated.

2. 1. Where necessary, the module can again be integrated with the regular performance of the system by issuing a command at address 8.0.xx.4. Enable, where xx is the number of the module in the list

of devices. After this function is executed, communication with it the will be renewed.

This can be done at address 8.1. Add hardware in engineer programming mode. This mode is used

when the network is extended to include new modules or when a faulty module is being replaced. The

new module must have been connected beforehand to the System bus.

Upon starting a PnP procedure, the principle system module passes an identification command to the

bus modules for new devices. This procedure takes 20 seconds and concludes when a list of bus

related devices is compiled. This list can be viewed at address 8.0. in engineer programming mode.

If positioned over a specific module, the display will show its singular number and the module number in

the list of bus devices.

CA824 ALARM SYSTEM CHARACTERISTICS

CA824 alarm system consists of CA824 control panel and up to 15 additional expander modules. Connection between modules is four wire common bus based on RS485.

Expander modules list:

- LCD824 keyboard

- LED816 keyboard

- MRI4/8 zone expander module

- MRI8 programmable output expander module

- DIO32 dynamic indication module

An inteligent PnP procedure is implemented which allows easy configuring the system.

Programming of system parameters is possible from LCD824 in the system, service LCD824 or through

telephone line.

Maximium number of zones 24 fully programmable zones

Zone programming 10 types of zones and 7 parameters

Maximum programmable outputs 16

Programmable outputs programming 7 groups of events in the system

Maximum number of areas 8 fully independent

Maximum number of users in the system 31 + 1 Manager + 1 Engineer

Event LOG 256 events recorded with date and time of

occurence

Digital communicator built-in CA824 control panel

Page 9

CA824 Installation manual 9

Fig. 2 CA824 control panel box

CA824 control panel box

TAMPER button

Front lid

Bottom

CA 864 control panel

Transmitter support strap

Pull lid forward 3

Lift lid up

2

Undo screws

1

4

Remove earthing cable

+BATT-BLACKRE

D

F AUX

2A

F PGM

2A

RED

YELLGRN

BLACK

BUS CONNECTION

LED

COM MUNICATOR

SERVICE

BUS CONNECTOR

RESET

B1 A 1 AB

CA 824

IN8GNDIN7IN6GNDIN5IN4GNDIN3IN2GNDIN1AC + AUX - + PGM OUT1 OUT2 OUT3BELL

F BATT

2A

1

6

3

5

1

4

12V / 7 Ah

battery

F - 0,63 A

Mains

transformer

50 / 60 Hz

15-25 V / 50VA

1

2

1 - Support opening

2 - CA 824 control panel

3 - Mains power supply terminal

4 - Signal cable openings

5 - Mains power supply cable

opening

6 - TAMPER button for box

self-protection

Page 10

10 CA824 Installation manual

CA824 control panel plastic box

Fig. 2a CA824 control panel plastic box

2

111

Unscrew (1)

Remove cover (2)

1

7

866

6

6

6

6

5

4

3

2

2

2

2

F - 0,63 A

Acc

u

m

u

l

ato

r

ca

ble

1 - Central support

opening (behind PCB)

2 - S

3 - CA 864 control panel

4 - Mains power supply

terminal

5 - Main cable opening

7 -

8 - Tamper button for box

self-protection

upport opening

6 - Add. cable openings

Mains power supply

opening

Mains

transformer

50 / 60 Hz

15-25 V / 50VA

12V / 7 Ah

battery

Room for additional modules

Room for add. Modules

or transmitter

Use to fix

main power supply cable

Page 11

CA824 Installation manual 11

Idle device inputs (INPx) can be connected to the detectors as per the selected connection scheme.

The possible options for connecting the detectors to the inputs are given in Fig. 3. Attention must be paid

to programming the type of input connection in the system. The status of the Wire EOL and Doubling

configurations is indicated for every connection option.

!The Wire EOL and DOUBLING parameters have to be configured for all system inputs!

The necessary balance resistors have been placed in the spare parts pack accompanying the module.

!The sensors with contacts that by-pass the 1 kΩ resistors form first zone in double zoning, and

the sensors with contacts that by-pass the 2 kΩ resistors form second zone!

Fig. 3 Connecting sensors to CA824 system

inputs

NC NC

1K 2,2K

Zone input GND

Without EOL

(Wire EOL=OFF, DOUBLING=ON)

Double style

NCNCTAMPER

TAMPER

1K 2,2K

GNDZone input

Without EOL, Open line recognition TAMPER

(Wire EOL=OFF, DOUBLING=ON)

TAMPER

TAMPER

NC NC

GND

Zone input

1K 2,2K

EOL

1 k

With EOL, Open line and Short on line

recognition (TAMPER)

(Wire EOL=ON, DOUBLING=ON)

Single style

TAMPER

NC

EOL

1K

1K

Zone input GND

With EOL, Open line and Short on line

recognition (TAMPER)

(Wire EOL=ON, DOUBLING=OFF)

Without EOL

(Wire EOL=OFF, DOUBLING=OFF)

NO

Zone input GND

Normally open

1K

NC

Zone input GND

Normally closed

1K

Page 12

12 CA824 Installation manual

When connecting outputs attention must be paid to the system output load-carrying capacities (PGM).

Figure 4 gives examples for connecting a relay to a light-emitting diode.

! When powering the system up after resetting factory configurations all system inputs are in

OFF status - +12 V voltage!

Fig. 4. Connecting relay and light-emitting diode to CA824 output

+ PGM

Output x

1 k

Ω

NCNOCOM

+ PGM

Output x

Page 13

CA824 Installation manual 13

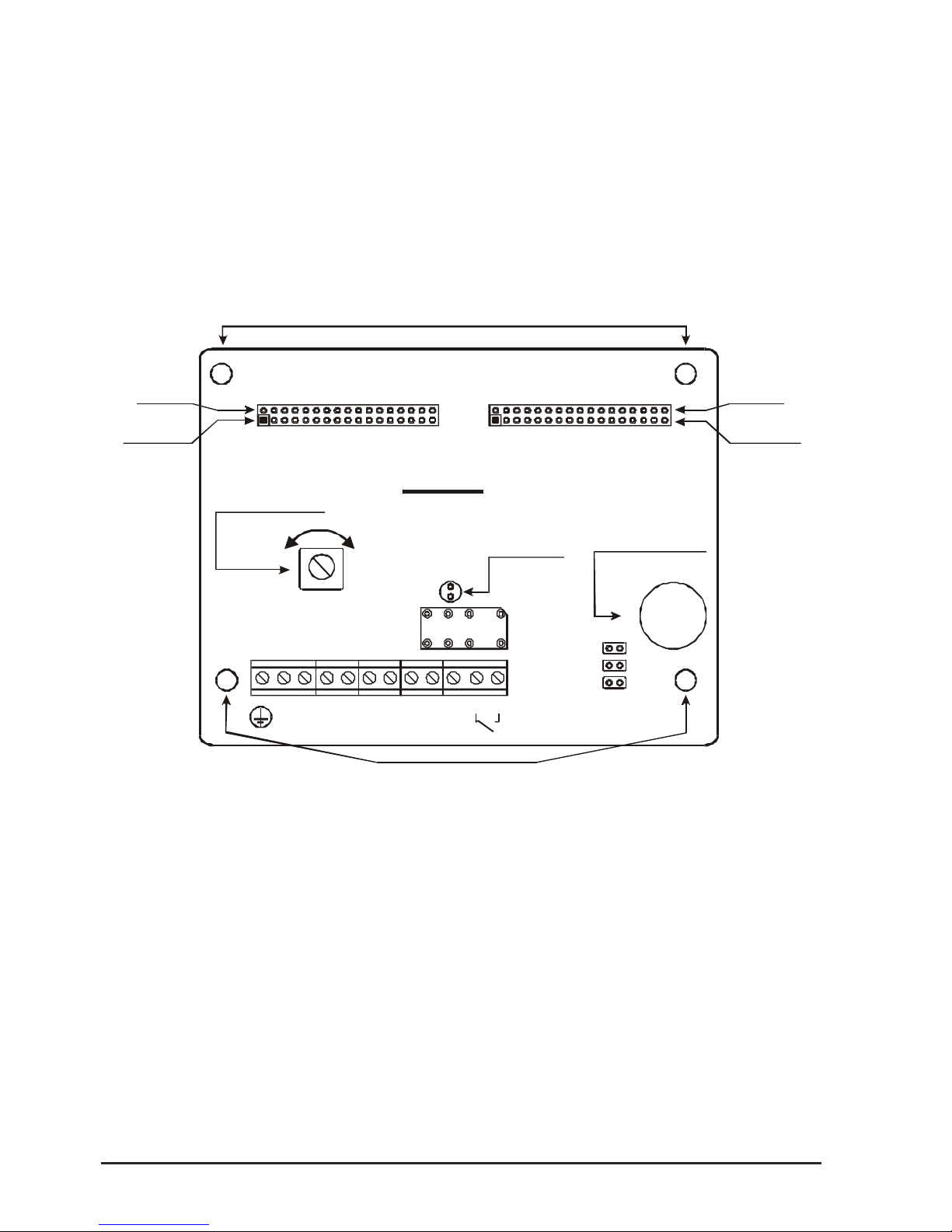

CA824 control panel

The scheme of the CA824 control panel is provided in Fig. 5.

All CA824 system modules are connected via a quad system bus. The colours should correspond to the

colours marked on the terminal of the modules (see Fig. 5).

Fig. 5. CA824 control panel

BELL CONNECTING STYLE

BELL+PG

M

+PGM

GNDSELF DRIVE SOUNDER

EXTERNAL DRIVE

SOUNDER

( OPEN COLLECTOR, Im

ax = 1A )

EXTERNAL POWER SUPPLY CONNECTING STYLE

+

-

POWER SUPPLY UNI

T

BUSDEVICE BUSDEVIC

E

BLACKGREENYELLOWREDBLACKGREENYELLOWRE

D

12VNO

BELL

REDYELLGRNBLACK

REDYELLGRNBLACK

BUS DEVICE No2BUS DEVICE No15FROM LINETO PHON

E

REDYELLGRNBLACK

AC

15 -25V

25 VA

AUX POW ER

SUPPLY

PROGRAMMABLE

OUTPUTS

OPEN

COLLECTOR

Imax = 100mA

PGM,

BELL

POW ER

ZONE

S( SEE FIGURES FOR DETAILS )

PGM

POWER

OUT

BUS DEVICE No

1

+BATT-BLACK

RED

F AUX

2A

F PGM

2A

REDYELLGRNBLACKBUS CONNECTION

LED

COMMUNICATOR

SERVICE

BUS CONNECTOR

RESET

B1 A1 AB

CA 824

IN8

GNDIN7IN6GNDIN5IN4GNDIN3IN2GNDIN1AC + AUX - + PGM OUT1 OUT2 OUT3 BELL

F BATT

2A

2A TOTAL

Page 14

14 CA824 Installation manual

Power supply unit

The system power supply unit is located in the control panel box.

The auxiliary power supply voltage of the mains transformer should be within 15 – 25 V and of 50 VA.

!A 12 V / 7 Ah battery is connected to the CA824!

The supply to the module is connected to the system bus – RED and BLACK terminals.

Supply for control panel sensors is fed from +AUX+ and GND terminals.

Supply for auxiliary devices of the control panel (light indicators, relays, etc.) is fed from +PGM and GND

terminals.

!The RED and BLACK terminals on the system bus CANNOT BE USED to supply auxiliary devices (sensors, light indicators, relays, etc.) That supply can be controlled from the control panel

process block and can be interrupted!

An auxiliary power supply unit for the system is connected according to the scheme shown in Fig. 6.

CA824 control panel resources

There are eight inputs at the control panel - INP1..INP8. These inputs are expanded to 16 for the double

zone.

There are five outputs at the control panel - OUT1..OUT3 and BELL output. Outputs OUT1, OUT2 and

OUT3 are programmable outputs. Output BELL has a power supply of up to 2 A to GND.

The CA824 control panel has an integrated digital dialler for transmitting messages to the central monitoring station via telephone line. The conductors from the telephone line socket are connected to terminals A and B. The telephone device is connected to terminals A1 and B1. No polarity has to be observed

when connecting the telephone line to the control panel.

CA824 control panel fuses

F BATT fuss – A 2A battery fuss.

F AUX fuss – A 2A peripheral device power supply fuss. Output at + AUX.

F PGM fuss – A 2A power supply fuse for PGMx and +PGM outputs.

Fig. 6. Connecting the auxiliary supply block to the CA824 system

Power supply unit

System busd

evice

BLACK

GREEN

YELLOW

RED

BLACK

GREEN

YELLOW

RED

+

-

12V NO

System bus

device

CA824 control panel indications

Green LED COMMUNICATOR - The light-emitting diode lights when the integrated digital dialler has

engaged the telephone line.

CA824 control panel terminals

MEMORY RESET – Producer default configurations can be restored by placing a bridging terminal and

feeding power supply to the control panel. This is recommended while installing the system and prior to

programming the parameters.

Producer default configurations can be restored at any time.

SERVICE BUS CONNECTOR – A service LCD keypad is connected to this terminal. The keypad

allows for adjustments to be done to parameters of a system not connected to an LCD keypad.

Page 15

CA824 Installation manual 15

Technical specification of CA824 control panel

Inputs - 8, can be expanded to 16

Outputs - 4

Quad system bus for connecting modules - Bus Connection

Mains transformer - 15-25 V, 50 VA

Battery charge - 13,8 V / 3 A

Battery - 12 V, 7 Ah

Consumption - nom 60 mA, max 100 mA

Sensor power supply (+AUX) - 13,8 V / 2 A

Auxiliary devices power supply (+PGM) - 13,8 V / 2 A

Auxiliary modules supply

(RED and BLACK terminals from System Bus) - 13,8 V / 2 A, self-restoring

Working temperature - (-20°C) to (+50°C)

Metal box dimensions - 320 x 265 x 80 mm

Page 16

16 CA824 Installation manual

LCD824 keypad module

The keypad front panel with liquid crystal display (LCD) is given in Fig. 7.

The back LCD keypad panel is given in Fig. 8.

A chart of the main LCD keypad plate is given in Fig. 9.

!Any single LCD824 keypad can service all areas within the system!

LCD824 keypad module resources

The LCD keypad module has one input marked as ZONE IN. There are two inputs for the double zone

keypad.

The LCD keypad module has one output marked as OUT. This is a programmable output.

The LCD keypad module houses a self-protection key. This is a double action key and has been configured

by the producer.

The BLACK, GREEN, YELLOW and RED terminals are used to connect the module to the system bus.

Power supply from the +AUX and +PGM control panel is used to feed the auxiliary devices (sensors,

relays, etc.).

!The RED and BLACK terminals of the system bus CANNOT BE USED to supply auxiliary devices (sensors, light indicators, relays, etc.). This supply can be controlled by the processing

block at the control panel and can be interrupted!

Fig. 7. Front panel of CA824 LCD keypad

LCD display

Indicators

Keys

Protective lid

Page 17

CA824 Installation manual 17

Technical specifications of LCD824 keypad module

Inputs - 1, can be expanded to 2

Outputs - 1

Quad system bus for connecting to control panel

Consumption - nom 35 mA, max 60 mA

Auxiliary devices power supply (+AUX and +PGM from control panel) - 13,8 V / 2 A

Working temperature - (0°C) to (+50°C)

LCD keypad dimensions - 115 x 135 x 25 mm

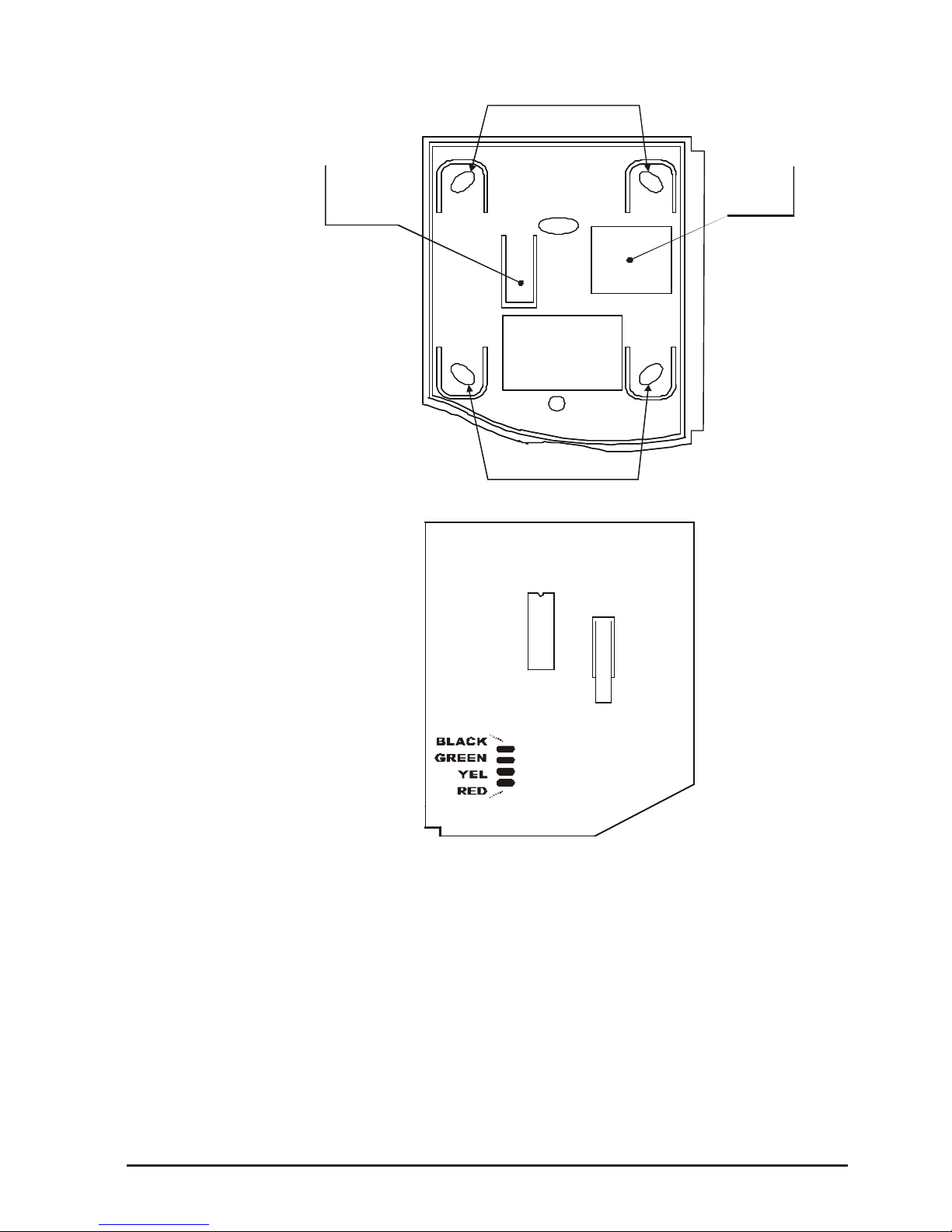

Fig 8. LCD824 keypad bottom

Support opening

Support opening

Signal

cable

opening

Reciprocating

plate for

TAMPER

button

TAMPER

BUZZER

BLACK

GREEN

YELLOW

RED

ZONE IN

GND

OUT

Fig. 9. LCD824 keypad

motherboard

Page 18

18 CA824 Installation manual

LED816 keypad module

The keypad front panel with light-emitting indication (LED) is given in Fig. 10.

The back LED keypad panel is given in Fig. 11.

A chart of the main LED keypad plate is given in Fig. 12.

!A LED816 keypad can service a maximum of two areas within the system!

!Where the keypad services one area the indication displays the first 16 zones in the area!

!Where the keypad services two areas the indication displays the first 8 zones in the area of the

first one (1 to 8 light-emitting diodes) and the first 8 zones in the area of the second one (9 to 16

light-emitting diodes)!

LED816 keypad module resources

The LED keypad module has no inputs or outputs

The LED keypad module houses a self-protection key. This is a double action key and has been configured

by the producer.

The BLACK, GREEN, YELLOW and RED platforms are used to connect the module to the system bus.

Fig. 10. LED816 keypad front panel

A

R

M

M

E

M

CLR ENT

0

1 2 3

4 5 6

7 8 9

P

R

O

G

D

I

S

A

R

M

System / area status

Zones 1 to 8 or first area zones

Zones 9 to 16 or seccond area zones

Protective lid

Keys

Page 19

CA824 Installation manual 19

Technical specifications of LED816 keypad module

Inputs - none

Outputs - none

Quad system bus for connecting to control panel

Consumption - nom 15 mA, max 60 mA

Auxiliary devices power supply (+AUX and +PGM from control panel) - 13,8 V / 2 A

Working temperature - (0°C) to (+50°C)

LED kypad dimensions - 75 x 85 x 18 mm

Fig. 12. LED816 keypad motherboard

TAMPER

Fig. 11. LED816 keypad bottom

Support openings

Support openings

Signal

cable

opening

Reciprocating

plate for

TAMPER

button

Page 20

20 CA824 Installation manual

MRI4/8 input (ZONE) expander module

A zone expander image has been provided in Fig. 13.

MRI4/8 input expander module resources

The zone expander module has four inputs marked as INPUT1…INPUT4. There are eight inputs for the

double zone expander.

The zone expander module has two outputs marked as OUT1 and OUT2. These are programmable

outputs.

The BLACK, GREEN, YELLOW and RED terminals are used to connect the module to the system bus.

Power supply from the +AUX and +PGM control panel is used to supply auxiliary devices (sensors,

relays, etc.).

!The RED and BLACK terminals of the system bus CANNOT BE USED to supply auxiliary devices (sensors, light indicators, relays, etc.). This supply can be controlled by the processing

block at the control panel and can be interrupted!

Technical specifications of MRI4/8 input expander module

Inputs - 4, can be expanded to 8

Outputs - 2

Quad system bus for connecting to control panel – Bus Connection

Consumption - nom 15 mA, max 20 mA

Auxiliary devices power supply (+AUX and +PGM from control panel) - 13,8 V / 2 A

Working temperature - (0°C) to (+50°C)

Inputs module dimensions - 92 x 43 mm

Fig. 13 MRI4/8 input expander

TAMPER LOOP

SERVICE LED

Page 21

CA824 Installation manual 21

MRO8 output expander module (PGM)

An output expander module image is given in Fig. 14.

MRO8 output expander module resources

The output expander module has no inputs.

The output expander module has eight inputs marked as OUT1…OUT8. These are programmable

outputs.

The BLACK, GREEN, YELLOW and RED terminals are used to connect the module to the system bus.

Power supply from the +AUX and +PGM control panel is used to supply auxiliary devices (sensors,

relays, etc.).

!The RED and BLACK terminals of the system bus CANNOT BE USED to supply auxiliary devices (sensors, light indicators, relays, etc.). This supply can be controlled by the processing

block at the control panel and can be interrupted!

Technical specifications of MRO8 output expander module

Inputs - none

Outputs - 8

Quad system bus for connecting to control panel – Bus Connection

Consumption - nom 15 mA, max 100 mA

Auxiliary devices power supply (+AUX and +PGM from control panel) - 13,8 V / 2 A

Working temperature - (0°C) to (+50°C)

PGM expander module dimensions - 92 x 43 mm

Fig. 14 MRO8 PGM output expander

TAMPER LOOP

SERVICE LED

Page 22

22 CA824 Installation manual

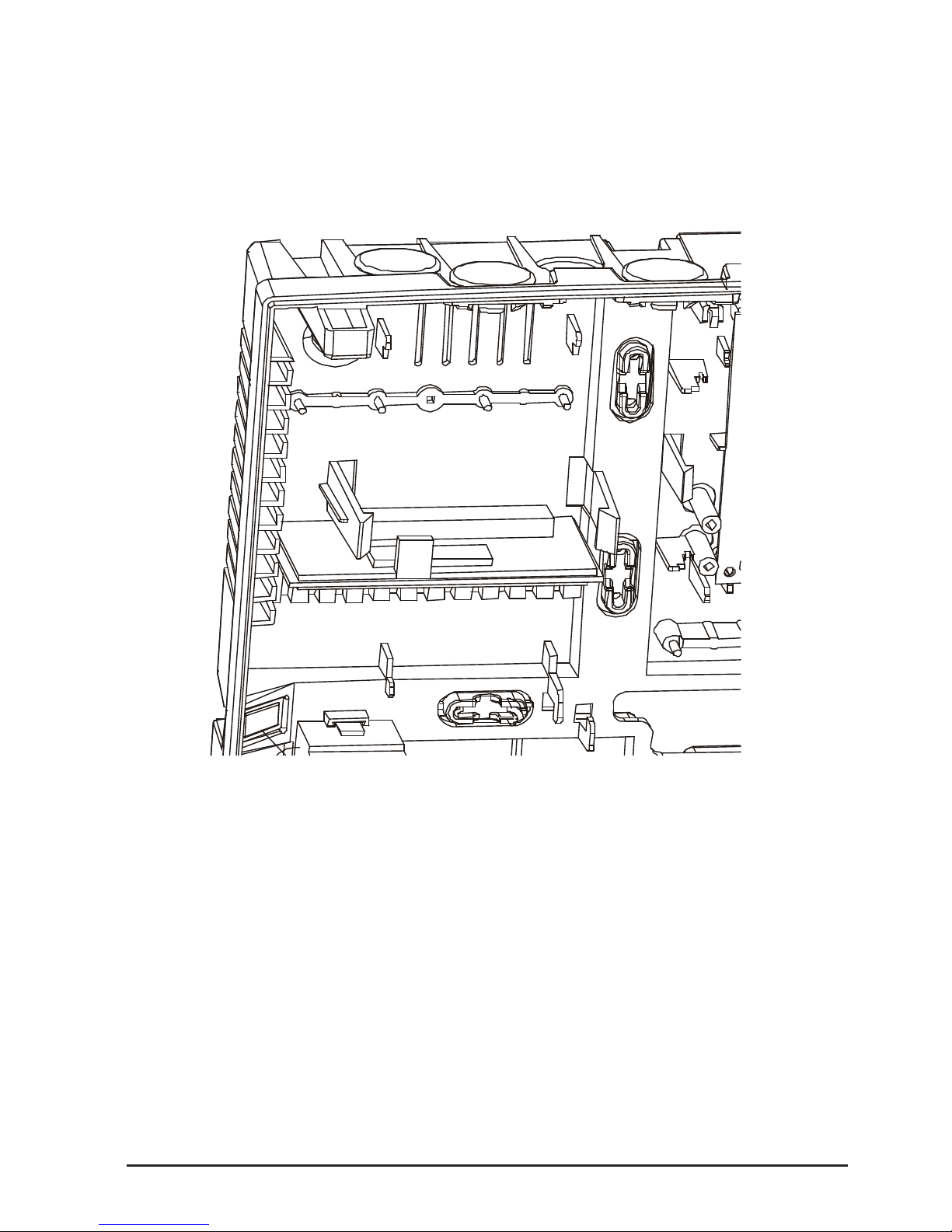

Installation box for input and output expander modules

The terminals are installed in the box (fig. 15) by the producer. A maximum of two input and/or output

expanders can be installed in one box, as shown in Fig. 15.

The self-protection key is installed and configured by the producer.

Technical specifications of the expander installation box

Box dimensions - 128 x 103 x 54 mm

terminal

terminal

TAMPER button for box self-protection

Expander board

(inputs or outputs

Expander board

(inputs or outputs)

Lid support

openings

Wall support openings

Wall support openings

Fig. 15 Installation box for Input and Output expander modules

Page 23

CA824 Installation manual 23

Installation for input and output expander modules in plastic box

The producer has provided additional positions for extra modules and devices for the plastic box (fig.

15a). Up to four expanders for inputs and/or outputs can be fitted together with control panel and

accumulator, as it is shown on fig. 15a.

Fig. 15a Installation for Input and Output expander modules

Room for second

expander module

Expander module

Page 24

24 CA824 Installation manual

DIO32 module (Dynamic indication)

A layout of the DIO dynamic indication module is given in Fig. 16.

Use of DIO32 module

The DIO32 module is designed to make dynamic indication mnemo-panels. Visualisation of the system

area status (ALARM / MEMORY, NORMAL, ARM and DISARM) or of the system zone status (TAMPER/

FIRE, ALARM / MEMORY, OPEN or CLOSE) is possible. The zones have been divided into two areas –

from 1 to 32 and from 33 to 64.

DIO32 module resources

The DIO module has one programmable output marked PGM. This is a potential output. The programmable PGM output has been duplicated by a “dry” contact relay. The relay contacts are labelled COM,

NO and NC.

The BLACK, GREEN, YELLOW and RED terminals are used to connect the module to the system bus.

Auxiliary devices (sensors, sound indicators, etc.) are powered by the +AUX and +PGM control panel or

by the +12V power supply tapped at the +PGM clamp.

!Attention must be paid that the RED (+12V) clamp system bus supply is tapped to the + PGM

clamp. This supply can be controlled by the processing block at the control panel and can be

interrupted!

Two ….. type couplings have been placed on the board. These couplings are designed to connect the

light-emitting diodes at the mnemo-panel. The Anode/Cathode correspondence has to be observed

when connecting these light-emitting diodes – Fig. 16 – Anode row and Cathode row.

!Connect light-emitting diodes only to the light-emitting diode indication outputs!

Fig. 16 DIO32 dynamic indication module

BUZZER

LED

JP1

JP2

JP3

BUZZER

AREAS / ZONES

1 - 32 / 33 - 64

DIO - 32

ver. 2.0

LED LIGHT CONTROL

-

+

123456789

10111213141516

333435363738394041424344454647

48

495051525354555657585960616263

64

RED

YELLOW

GREEN

BLACK

+PGM

PGM

NO

NC

COM

TEST

ANODE

CATHODE

ANODE

CATHODE

LED brightness

adjustment

Sound signal for

integrated

programmable

output

(JP1 - CLOSED)

Office

indication

Support openings

Support openings

12345678910111213141516171819202122232425262728293031321234567891011121314151

6

AREAS (ARMED or DISARMED)

(JP2 - OPEN)

AREAS (ALARM/MEMORY or NORMAL STATE)

(JP2 - OPEN)

ZONES (JP2 - CLOSED; JP3 - OPEN for 1 - 32 ZONE or JP3 - CLOSED for 33 - 64 ZONE)

Page 25

CA824 Installation manual 25

Adjusting the DIO32 module

To adjust the DIO32 module use JP1, JP2 and JP3 jumper connectors:

- JP1:

Where the JP1 jumper connector has been placed, the board-located zoom repeats the PGM output

status – the PGM zoom emits a continuous sound signal if PGM output is active.

Where the JP1 jumper connector has been removed, the board-located zoom is switched off. This does

not interfere with PGM output performance.

- JP2:

Where the JP2 jumper connector has been placed, the LED indication outputs will visualize the system

zone status. Depending on the configuration adjustments with JP3 jumper connector, the status of 1 to

32 or 33 to 64 zones will be displayed.

Where the JP2 jumper connector has been removed, the LED indication outputs will visualize the system area status as follows:

—> the left-hand side coupling light-emitting diodes (1 to 16):

constant light – the area is in ALARM or MEMORY state

no light – the area is in regular NORMAL state

—> the right-hand side coupling light-emitting diodes (17 to 32):

constant light – the area is armed

no light – the area is disarmed

- JP3:

Where the JP3 jumper connector has been placed, the LED indication outputs will visualize the status of

zones 33 to 64 zone. The JP2 jumper connecter has to be placed.

Where the JP3 jumper connector has been removed, LED indication outputs will visualize the 1 to 16

zone status. The JP2 jumper connector has to be placed.

Zone information data is as follows:

LED blinks – the zone is in TAMPER or FIRE state

constant LED light – the zone is in ALARM or MEMORY state. Where the zone is in neither of the

specified states, this indication means an open/closed zone

no LED light – the zone is in normal state.

LED brightness can be regulated with the help of the LED LIGHT CONTROL potentiometer.

A normal open contact button can be connected to the TEST clamps. Regular check-ups of mnemo-

panel integrity can be performed.

Pressing and holding the TEST button until all LEDs light up permanently can initiate the mnemo-panel

integrity test. LED1 only will be displayed after the button is released (see Fig. 16). A single click will take

you over to the following LED – 2, 3, 4 … 32. The next TEST button click will resume mnemo-panel

operation mode.

!Mnemo-panel operation mode will automatically resume if the TEST button is not pressed within

30 seconds!

Technical specifications of DIO32 module

Inputs - none

Outputs - 1 potential, duplicated with relay; sound indication option together with output status indication

LED outputs - 32

Quad system bus for connecting to control panel - Bus Connection

Consumption - max 200 mA (LED’s connected)

Auxiliary devices power supply (+AUX and +PGM from control panel) - 13,8 V / 2 A

Working temperature - (0°C) to (+50°C)

DIO module dimensions - 125 x 85 mm

Support openings dimensions - 114 x 67 mm

Page 26

26 CA824 Installation manual

TAMPER

COM

NO

RED

GREEN

YELLOW

BLACK

???. 17 Proxi Reader CA864

PR864 Proxi Reader Module

The Proxi Reader module is given in Fig. 17.

Resources of PR864 Proxi Reader Module

Proxi Reader Module has an in-built relay with unplugged contacts. The contacts of the relay are designated by COM and NO.

Proxi Reader Module as an in-built sound indicator to send sound signals when operating the module.

Proxi Reader Module has an in-built three-colour LED indication light diode to send light signals when

operating the module.

The BLACK, GREEN, YELLOW ? RED clamps are to connect the Module to the System Bus.

The plugs in the control panel +AUX and +PGM are used for any additional devices (relays, sound

indicators, etc.).

Purpose of PR864 Proxi Reader Module

The purpose of Proxi Reader Module is to operate proxy-cards in the system.

A module can operate all the cards in the system. Besides, the module has an in-built relay. It is used to

set the electronic lock of the door.

Technical specifications of PR864 Proxi Reader module

Inputs - none

Number of outputs – one relay with normally open contact to plug the power supply to the electronic lock.

Quad system bus for connecting to control panel - Bus Connection

Consumption - max 170 mA

Working temperature - (0°C) to (+50°C)

Page 27

CA824 Installation manual 27

SUPPLEMENT A - Menu structure chart for programming the CA824 alarm system

The programming chart allows for quick scan of all program menus for the CA864 Alarm System configurations.

There are two options for attaining to a specific programming menu.

1. Use the left/right arrows to browse the menus, ENT to confirm and CLR to reject.

2. Use the menu short code. Here you only introduce the figure (quick access code) shown in the chart

of the respective menu and the system is immediately positioned in the desired menu. This method is

quicker than the previous one, because it only needs several clicks on the button. It also protects from

misclicks.

A detailed description of the menus can be found in the MENU section. These have been listed by quick

access code.

Page 28

28 CA824 Installation manual

ENGINEER PROGRAMMING MENU STRUCTURE CHART

1)Display Log

1)All Areas

2)Select Area

3)Zone Walk test

4)PGM Test

5)System TRBLs

6)Dialer

2)Private Display

3)Edit Logo

1)Entry Time

Area 01 . . . 08

2)Exit Time

3)Bell Cut-off

4)Double Knock T

5)Line monitor T

6)Comm.Test Time

7)AC-trbl delay

1)User Codes 1)Rename Code

2)User rights

3)User Attributes

2)Code Length

3)Eng.Code Menu 1)ChangeEng.Code

4)Zones 1)Definition

Zone 01 . . . 24

1)Rename zone

2)Zone Type

3)Attach to Area

2)Auto Shut Down

3)Zones Hardware

1)Maintenance

2)Timers

3)Users

2)Show Open Z-s

7)LCD settings

Area 01 . . . 08

User Code 01 . . . 31

Instant

Entry delay

Follow

24h Burglary

Fire

Panic

Tamper

Medical

24h Technical

Keyswitch

- Full arming

- Time Set

- Disarming

- Bypass

- Manager

- Stay arming

- Force arming

- Log view

- AutoZoneShutD.

- Bypass enabled

- Stay

- Force

- Double knock

- Chime

- Audible

4)Parameters

To Outputs Menu

ENT

ENT

ENT

ENT

ENT

ENT

ENT

ENT

ENT

ENT

ENT

ENT

ENT

ENT

ENT

ENT

0)Contrast

1)Back light

1)Events In Queue

2)Dialer Test

ENT

4)Code options

4)User Proxi Card

ENT

0)Add Card

1)Arm/D. Rights

2)Entry rights

3)Remove Card

PGM 01 . . . 16

ENT

Area 01 . . . 08

ENT

- Doubling

- Wire EOL

ENT

Page 29

CA824 Installation manual 29

5)Outputs

Output 01 . . . 16

1)System Events

2)SystemTroubles

3)Arming Area

4)Bypass Z. in A.

5)Alarm in Area

6)Panic in Area

7)Tamper in Area

8)Normal State

6)Split System 1)Define areas

Area 01 . . . 08

1)Rename

2)Area options

3)Define common

2)KBD assign

7)Dialer 1)Tel. numbers 1)Ctrl. Station1

2)Ctrl. Station2

3)Ctrl. Station3

4)Ctrl. Station4

Area 01 . . . 08

3)Report options

4)Group report

7)Wait dial tone

8)Up/down load

1)PC phone N:

2)Number Of rings

3)Panel ID number

4)PC ID number

5)Call Back

6)Answer machine

8)System edit

1)Add hardware

Device 01 . . . 16

0)Inputs config

1)Outputs config

2)Assign trouble

3)Disable

4)Enable

5)Remove

9)Engineer out

0)Device config

2)Account number

- Siren

- Fire Alarm

- Burglary Alarm

- Panic

- Ambush Code

- Technical Alarm

- Medical

- Fire Reset

- Tamper

- Low Battery

- AC loss

- Line Error

- Comm. error

- Fuse blow up

- Device Fault

- OneTouchArming

- Audible Panic

- Audible Tamper

- AudibleMedical

- Aud. Techn. Al.

- Arm/Disarm

- Alarm/Restore

- Tamper/Restore

- Trouble/Rest.

- Medical/Rest.

- Fire/Restore

- System

ENT

ENT

ENT

ENT

ENT

ENT

ENT

ENT

ENT

ENT

ENT

ENT

ENT

ENT

ENT

ENT

5)Enable Dialer

6)Dialer Protocol

ENT

Ademco contact ID

SIA

Device 01 . . . 16

ENT

Page 30

30 CA824 Installation manual

SUPPLEMENT B – Chart for user programmable menus

Arming

3) Full arming

4) Stay arming

5) Force arming

6) Instant arming

Disarming

Programming 1) Own code 0) Rename

1) Change code

2) User codes 0) Rename code

1) Change code

2) User rights

0) Add Card

2) Entry Rights

3) User Attributes

5) User Proxi Card

3) Time set

5) Chime

6) LCD settings

2) Private Display

3) Edit Logo

Memory (Log file) 0) All Areas

1) Select Area

TRBL (troubles)

BPS (Bypass zone)

01 Area name

. . .

16 Area name

01 Area name

. . .

16 Area name

01 Area name

. . .

16 Area name

C.01 - Code Name

. . .

C.96 - Code Name

01 Area name

. . .

16 Area name

. . .

16 Area name

01 Area name

. . .

16 Area name

01 Area name

0) UnlockEngineer

1) UDL user codes

4) Engineer rights

4) User Time Slot

0) Areas: 12345678

1) Areas: 9

10 12 1 4 16

11 13 15

3) Remove Card

1) Arm/D Rights0) Contrast

1) Back light

Page 31

CA824 Installation manual 31

Guarantee

During the guarantee period the manufacturer shall, at its sole discretion, replace or repair any defective product when it is returned to the factory. All parts replaced and/or repaired shall be covered for

the remainder of the original guarantee, or for ninety (90) days, whichever period is longer. The original

purchaser shall immediately send manufacturer a written notice of the defective parts or workmanship, which written notice must in all cases be received prior to expiry of the guarantee.

International Guarantee

Foreign customers shall enjoy the same guarantee rights as those enjoyed by any customer in Bulgaria,

except that manufacturer shall not be liable for any related customs duties, taxes or VAT, which may be

payable.

Guarantee Procedure

This guarantee will be granted when the appliance in question is returned. The manufacturer shall

accept no product whatsoever, of which no prior notice has been received.

Conditions for waiving the guarantee

This guarantee shall apply to defects in products resulting only from improper materials or

workmanship, related to its normal use. It shall not cover:

§ Damages resulting from transportation and handling;

§ Damages caused by natural calamities, such as fire, floods, storms, earthquakes or lightning;

§ Damages caused by incorrect voltage, accidental breakage or water; beyond the control of

the manufacturer;

§ Damages caused by unauthorized system incorporation, changes, modifications or

surrounding objects:

§ Damages caused by peripheral appliances (unless such peripheral appliances have been

supplied by the manufacturer:

§ Defects caused by inappropriate surrounding of installed products;

§ Damages caused by failure to use the product for its normal purpose; Damages caused by

improper maintenance;

§ Damages resulting from any other cause, bad maintenance or product misuse.

In the case of a reasonable number of unsuccessful attempts to repair the product, covered by this

guarantee, the manufacturer’s liability shall be limited to the replacement of the product as the sole

compensation for breach of the guarantee. Under no circumstances shall the manufacturer be liable

for any special, accidental or consequential damages, on the grounds of breach of guarantee, breach

of agreement, negligence, or any other legal notion.

Waiver

This Guarantee shall contain the entire guarantee and shall be prevailing over any and all other

guarantees, explicit or implicit (including any implicit guarantees on behalf of the dealer, or adaptability

to specific purposes), and over any other responsibilities or liabilities on behalf of the manufacturer.

The manufacturer does neither agree, nor empower, any person, acting on his own behalf, to modify

or alter this Guarantee, nor to replace it with another guarantee, or another liability with regard to this

product.

Unwarranted Services

The manufacturer shall repair or replace unwarranted products, which have been returned to its

factory, at its sole discretion under the conditions below. The manufacturer shall accept no products

for which no prior notice has been received.

The products, which the manufacturer deems repairable, will be repaired and returned. The

manufacturer has prepared a price list and those products, which can be repaired, shall be paid for

every repaired appliance.

The closest equivalent product, available at the time, shall replace the products manufacturer deems

unrepairable. The current market price shall be charged for every replaced product.

Page 32

18020325

Loading...

Loading...