Telesis XPRESS EP/TLM Quick Start Manual

XPRESS

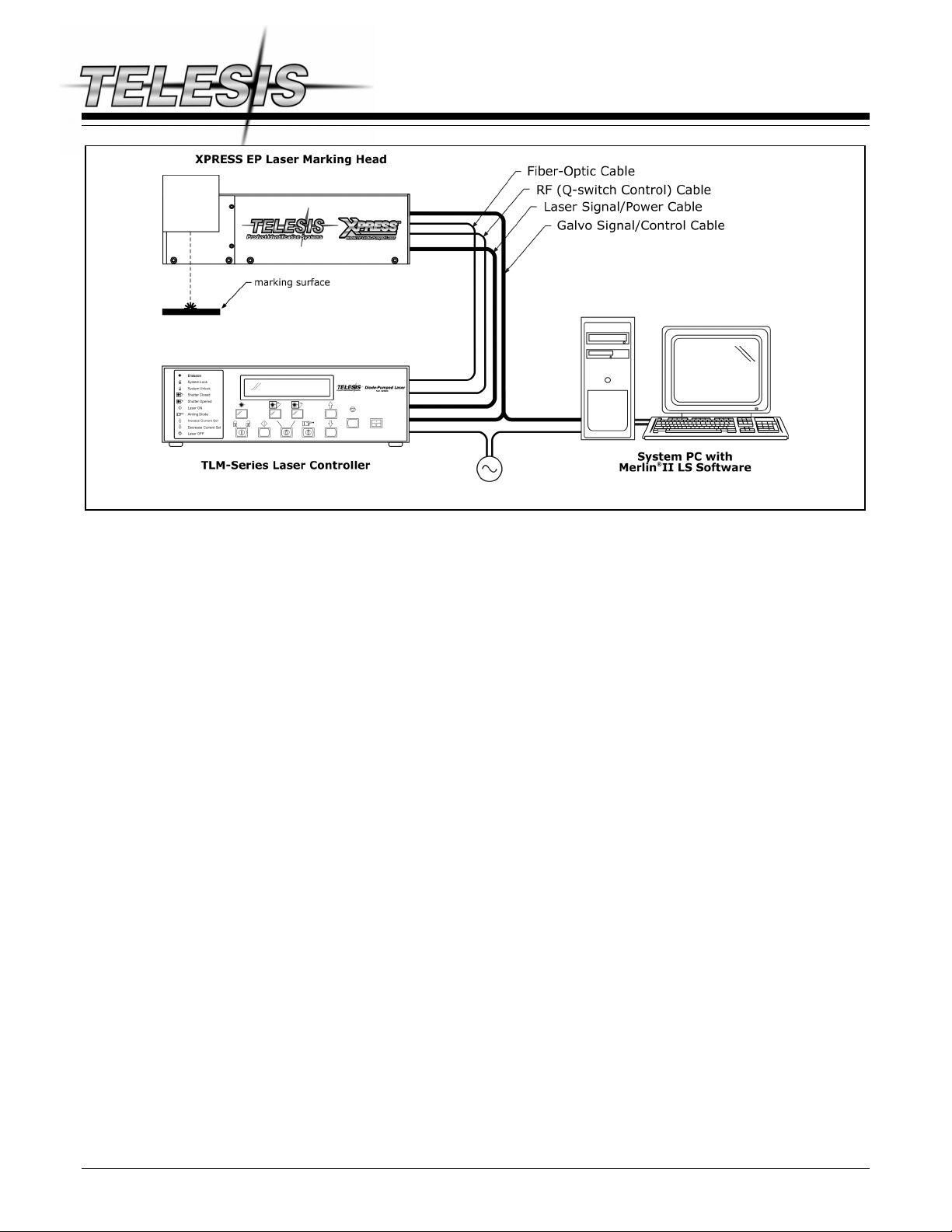

XPRESS EP/TLM Laser Marking System General Arrangment

™

EP / TLM Laser Marking System

System Overview

The XPRESS EP/TLM is an advanced, fiber-coupled diode

end-pumped laser marking system. The laser beam quality and

Q-switched pulse characteristics are optimized for applications

that require high beam quality and stability. This system is a very

good choice for general-purpose laser marking, scribing,

trimming, and other material processing applications.

The XPRESS-series unique L-shaped design features a continuous

wave (CW)/Q-switched Nd:YVO

remote fiber-coupled diode pumping source. With average diode

life of greater than 20,000 working hours the XPRESS EP offers

the user “best-in-class” reliability.

The robust mechanical and optical design allows the Telesis

XPRESS EP to operate in industrial conditions with respect to

shock, vibration, and dust.

The XPRESS EP/TLM laser marking system offers these

advantages:

end-pumped laser with a

4

• Reliable, long, maintenance-free performance

• Compact size and modular construction

• Remote, fiber-coupled pumping diode

• Exceptional beam quality and stable output power

• Active (thermo-electrical) temperature control of the

laser crystal and pumping diode

• Active AO Q-switching

• Air cooling

• Visible red diode for dry run / positioning

• Large digital display for marker status, settings, and

error condition monitoring

• Standard 115/230VAC operation

• DoD-compliant Unique Identification (UID) marking

System Configuration

The XPRESS EP/TLM basic package consists of the following:

• TLM-Series Laser Controller – contains pumping diode,

RF driver, and other electrical components

• Fiber Optic / Umbilical Assembly

• XPRESS EP Laser Marking Head – contains sealed

resonator, beam expander, turning mirror, galvanometer

assembly, visible red light positioning laser

• Software – Merlin II LS Laser Marking Software

• System Computer – supplied by Telesis or by customer

The modular design allows for major components to be easily

replaced and returned to Telesis if in need of repair.

Laser System Options

• Desktop computer or Notebook computer with powered

cardbus-to-PCI expansion enclosure

• Externally-mounted focus-finder diode

• Tool post w/ manual hand crank for z-axis adjustment

• Pushbutton station (start/abort)

• I/O Options:

TTL via PCI-DIO24 Card (Kit #53920)

Opto-isolated via Merlin DCIO Module (Kit #53928)

TMC090 Controller (for auxiliary axes; additional I/O)

• Programmable X-, Y, or Z-axis (TMC090 required)

• Rotary drive fixture (TMC090 required)

Doc. No. 40213 – 1 of 6

XPRESS™ EP / TLM Laser Marking System

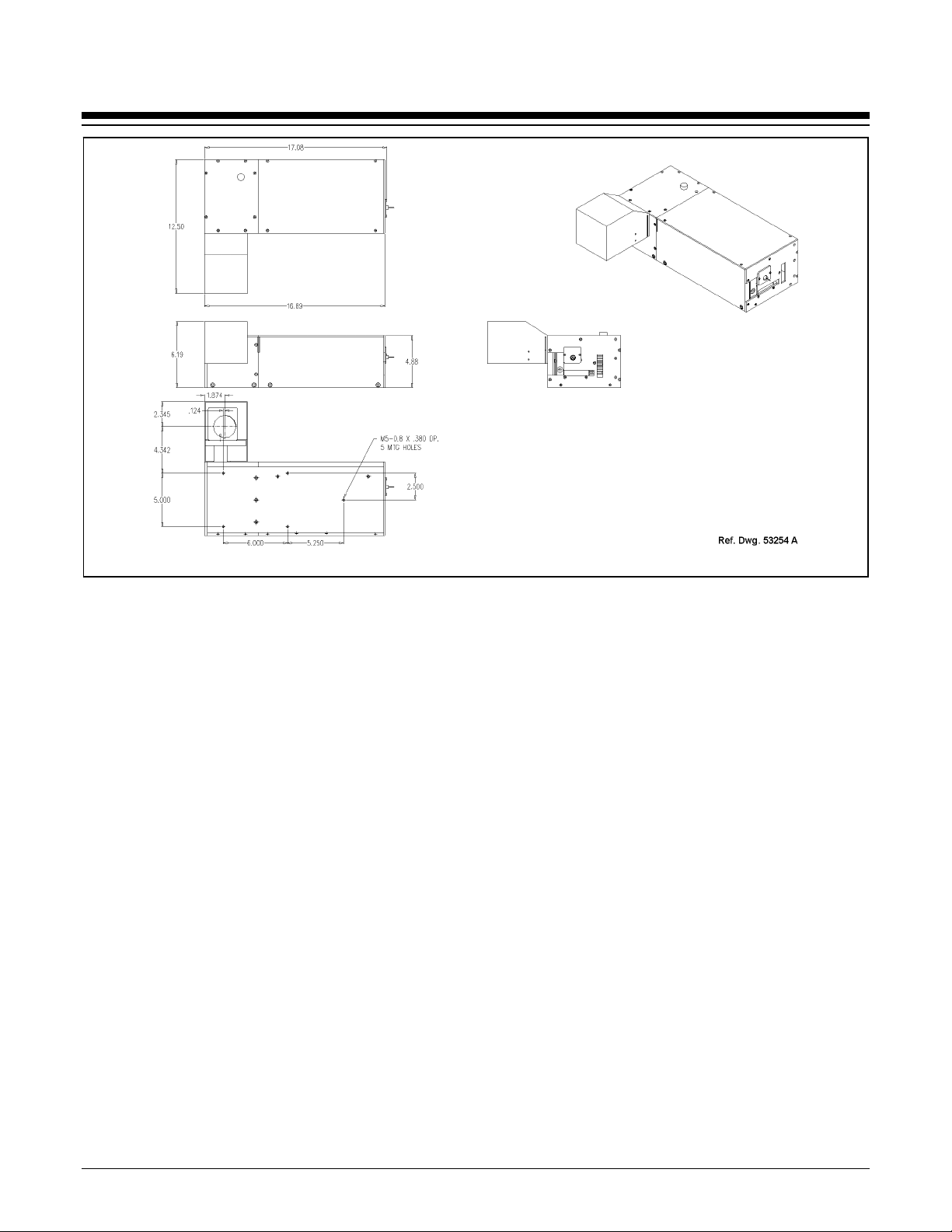

XPRESS EP Laser Marking Head Dimensions and Mounting Details

System Setup

Complete installation procedures are provided in the

XPRESS EP/TLM Installation/Maintenance Manual. The

following procedures are listed for reference only to provide a

general overview of the installation process.

1. Equipment should remain powered down and in OFF

position until mounting is complete.

2. Place computer, monitor, keyboard, and laser controller in

desired location. Locate controller as close as practical to

laser marking head. Standard cable length is 1.75 meters

(5.74 feet) long between the laser marking head and the

laser controller. An optional 4.75-meter (15.58-ft.) fiber

optic cable is also available.

3. Place the laser marking head on selected mounting.

a. Do not bend or kink fiber optic cable. The fiber

optic cable will tolerate approximately 300 mm

(12 in.) diameter bend without damage.

b. Allow a minimum distance of 150 mm (6 in.) at

rear of the laser marking head. This will provide

sufficient room for a proper bend radius of fiber optic

cable.

c. Do not block or obstruct exhaust fan. Note location

of exhaust fan on right side of the laser marking head.

This fan must have adequate clearance to ensure

proper cooling.

4. Mount laser marking head using any three of five factorytapped M5-0.8 mounting holes provided.

a. Locate five pre-drilled M5-0.8 mounting holes. The

one nearest the galvanometer output is referred to as

the "origin". All other mounting hole dimensions are

referenced to this hole. Refer to the Mounting and

Dimension Details drawing more information.

b. Telesis recommends using a minimum of three (3)

attach points for mounting the laser marking head,

one of which should be the origin mounting hole.

c. Mounting bolts must not extend into laser marking

head more than 9.5 mm (.38 in.) to avoid

interference with internal components.

d. The leading edge of customer-supplied mounting

fixture should extend no greater than 25.4 mm (1 in.)

from origin mounting hole to allow clearance for

beam output lens.

e. As viewed from front of the laser marking head in

upright position, center of output beam is 11.0287 cm

(4.342 in.) from origin mounting hole.

5. Secure the laser marking head to mounting fixture using

M5-0.80 bolts and lock washers. Do not over tighten bolts.

6. Ensure laser controller power switch (front panel) is OFF.

7. Select proper fuse arrangement, then connect power cable.

8. Connect fiber-optic cable to laser marking head. Connect

remaining cables, as applicable.

9. Refer to XPRESS EP/TLM Operation Supplement for proper

startup procedure. Refer to laser marking system Operation

Manual for complete information on using system software.

Doc. No. 40213 – 2 of 6

Loading...

Loading...