Page 1

REV.

A

∆

DESCRIPTION E.C.N. DATE DRAWN CHECKED

ALL RIGHTS RESERVD, NO PARTS OF THIS DOCUMENT MAY BE REPRODUCED, STORD IN

RETRIEVAL SYSTEM, OR TRANSMITTED IN ANY FORM OR BY ANY MEANS, ELECTRONIC,

MECHANICAL PHOTOCOPYING, RECORDING OR OTHERWISE WITHOUT THE PRIOR WRITTEN

PERMISSION OF TELEMATICS WIRELESS LTD. NOR USED IN WHOLE OR IN PART FOR ANY

PURPOSE OR FOR ANY CUSTOMER EXCEPT TELEMATICS WIRELESS.

NAME:

ASTM READER –FP-300RA

User Manual

PROD/PROJ: ASTM Reader

PROPRIETARY INFORMATION

DESIGNED G.F.K. 11-Aug-2005 SHEET/OF

CHECKED M.N. 11-Aug-2005

APPROVED A.S. 11-Aug-2005

Q.A. A.S. 11-Aug-2005

1

38

SIZE

214072018 0 0 0

Page 2

Note:

This device complies with Part 15 of the FCC Rules.

Operation is subject to the following two conditions:

1) This device may not cause harmful interference, and

2) This device must accept any interference received, including interference that may

cause undesired operation.

WARNING! Changes or modifications to this unit not expressly approved by Telematics

Wireless Ltd. could void the user's authority to operate the equipment.

The digital portion of the transceiver has been tested and found to comply with the limits for a

Class B digital device, pursuant to part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference in a residential installation. This equipment

generates, uses and can radiate radio frequency energy and, if not installed and used in accordance

with the instructions, may cause harmful interference to radio communications. However, there is

no guarantee that interference will not occur in a particular installation. If this equipment does

cause harmful interference to radio or television reception, which can be determined by turning the

equipment off and on, the user is encouraged to try to correct the interference by the following

measure:

-Increase the separation between the equipment and receiver.

The antenna and therefore the unit, used for this transmitter must be installed to normally provide

minimum separation distance of at least 2 meters from all persons and must not be co-located or

operating in conjunction with any other antenna or transmitter.

The Reader is sold with power cable with molded ferrite that provide common-mode filtering.

Recommended ferrite manufacturer: Fair-Rite, part number: 0444164281.

The communication cables shall be installed by professional installer, placing ferrites on the cables

that are supplied with unit.

Recommended ferrite manufacturer: Fair-Rite, part number: 0444164281.

2140-72018-00-0A REV: A Page 2 Of 38

Page 3

FP300RA User Manual

Table Of Contents

CHAPTER 1: INTRODUCTION ..........................................................................................5

1.1 SCOPE......................................................................................................................................5

1.2 GENERAL DESCRIPTION ..........................................................................................................6

1.2.1 Purpose and Use..............................................................................................................6

1.2.2 Main Technical Characteristics.......................................................................................7

1.2.3 Maintenance Utility ........................................................................................................7

1.2.4 Additional Equipment Needed........................................................................................7

1.3 PHYSICAL DESCRIPTION ......................................................................................................... 8

1.4 FUNCTIONAL DESCRIPTION.....................................................................................................9

1.4.1 Normal Mode..................................................................................................................9

1.4.1.1 Normal Mode Functions .............................................................................................9

1.4.1.2 Transponder Access Capabilities................................................................................ 9

1.4.1.3 Air Interface................................................................................................................ 9

1.4.1.4 Multilane Support .....................................................................................................10

1.4.1.5 Lane Discrimination Support....................................................................................11

1.4.1.6 Support for Reader Synchronization.........................................................................11

1.4.1.7 Active List.................................................................................................................11

1.4.1.8 Hot Lists....................................................................................................................12

1.4.2 Maintenance Mode .......................................................................................................12

1.4.2.1 Configuration ............................................................................................................12

1.4.2.2 Communication Zone Calibration.............................................................................12

1.4.2.3 Self-Test....................................................................................................................12

1.4.3 Host Communication ....................................................................................................13

1.4.4 Real-Time Clock...........................................................................................................13

CHAPTER 2: INSTALLATION.......................................................................................... 14

2.1 GENERAL...............................................................................................................................14

2.2 INSTALLATION REQUIREMENTS ............................................................................................14

2.2.1 Integration in Systems...................................................................................................14

2.2.2 Safety Considerations ...................................................................................................15

2.2.3 Mechanical Data ...........................................................................................................15

2.3 INSTALLATION GUIDELINES..................................................................................................16

2.3.1 Power Requirements .....................................................................................................16

2.3.2 Antennas .......................................................................................................................16

2.3.2.1 Antenna Mounting Position Requirements............................................................... 17

2.3.2.2 FP-300RA-to-Antenna Cabling ................................................................................ 17

2.3.3 Communication Cables.................................................................................................17

2.3.4 Grounding and Lightning Protection Requirements .....................................................18

2.4 INSTALLATION PROCEDURE..................................................................................................18

2.4.1 Tools and Materials.......................................................................................................18

2.4.2 Preparation for Installation ...........................................................................................18

2.4.3 FP-300RA Installation Procedure .................................................................................18

2.4.3.1 Physical Installation .................................................................................................. 18

2.4.3.2 Cable Connections ....................................................................................................19

2.4.3.3 Final Inspection.........................................................................................................19

CHAPTER 3: OPERATION ................................................................................................20

3.1 SCOPE....................................................................................................................................20

3.2 POWER-UP.............................................................................................................................20

3.3 FP-300RA CONFIGURATION .................................................................................................21

3.3.1 Setting Host Interface Parameters................................................................................. 21

3.3.2 Setting Initial Tx Mode.................................................................................................21

3.3.3 Setting TDMA Mode ....................................................................................................22

2140-72018-00-0A REV: A Page 3 Of 38

Page 4

FP300RA User Manual

3.3.4

Setting Transponder Access Parameters .......................................................................22

3.3.5 Setting Burst Mode .......................................................................................................22

3.3.6 Setting SYNC Mode .....................................................................................................22

3.3.7 Setting Multilane Mode ................................................................................................ 23

3.3.8 Setting Lane Discrimination .........................................................................................23

3.3.9 Setting Digital I/O.........................................................................................................24

3.3.10 Save Current Settings....................................................................................................24

3.4 HOT LIST CONFIGURATION ...................................................................................................24

3.4.1 Get Hot List Status........................................................................................................ 24

3.4.2 Remove Hot List...........................................................................................................24

3.4.3 Add New Hot List.........................................................................................................24

3.4.4 Set Hot List Auto Function ........................................................................................... 25

3.4.5 Add Transponder to Hot List ........................................................................................25

3.4.6 Remove Transponder from Hot List .............................................................................25

3.4.7 Saving the Hot List ....................................................................................................... 25

APPENDIX A: CONNECTION DATA ..............................................................................26

A-1 ANTENNA CONNECTORS .......................................................................................................26

A-2 POWER INPUT CONNECTOR................................................................................................... 26

A-3 DIGITAL INTERFACE CONNECTOR ........................................................................................26

A-4 HOST INTERFACE CONNECTOR .............................................................................................27

A-5 MAINTENANCE INTERFACE CONNECTOR..............................................................................28

A-6 AUXILIARY INTERFACE CONNECTOR ................................................................................... 28

APPENDIX B: MAINTENANCE UTILITY...................................................................... 30

B-1. SCOPE....................................................................................................................................30

B-2. INSTALLATION ......................................................................................................................30

B-2.1 Hardware and Software Requirements .........................................................................30

B-2.2 Installation Procedure ...................................................................................................30

B-2.3 Preliminary Configuration ............................................................................................30

B-3. MAIN WINDOW .....................................................................................................................31

B-3.1 Monitor Area.................................................................................................................31

B-3.2 Active List Area............................................................................................................31

B-3.3 Log File......................................................................................................................... 32

B-3.4 Sending Periodic Status Request ..................................................................................32

B-3.5 Setting the Communication Mode ................................................................................32

B-3.6 Setting/Resetting the Digital Output Port ..................................................................... 32

B-3.7 Information Fields.........................................................................................................32

B-3.8 Requests Area ............................................................................................................... 33

B-3.9 Setting Area ..................................................................................................................33

B-4. FILE MENU ............................................................................................................................ 34

B-5. FP-300RA CONFIGURATION WINDOW .................................................................................35

B-6. HOT LIST ............................................................................................................................... 36

B-6.1 Auto-Function...............................................................................................................36

B-7. RF SETTING WINDOW...........................................................................................................37

B-7.1 Get Button.....................................................................................................................37

B-7.2 Set Default Button ........................................................................................................37

B-7.3 Tx Mode........................................................................................................................37

B-7.4 Transmitter....................................................................................................................38

B-7.5 Receiver ........................................................................................................................38

B-7.6 Vector Modulator..........................................................................................................38

B-7.7 Calibration Process .......................................................................................................38

2140-72018-00-0A REV: A Page 4 Of 38

Page 5

FP300RA User Manual

Chapter 1: Introduction

1.1 Scope

This manual covers the characteristics, applications, installation, configuration and maintenance of

the FP-300RA reader, an advanced and flexible roadside component offered by Telematics

Wireless for use in electronic Automatic Vehicle Identification (AVI) systems.

The information included in this manual is organized as follows:

Chapter 1 – Introduction

Chapter 2 – Installation

Chapter 3 – Operation

Appendix A –

Connection Data

Appendix B –

Maintenance Utility

For additional information on the FP-300RA technical specifications, its systems integration, help

in interfacing to the FP-300RA, and other issues regarding utilization of FP-300RA advanced

characteristics, contact Telematics Wireless.

Presents the manual scope and organization, and describes the

FP-300RA reader functions and capabilities.

Provides the information needed to plan the FP-300RA

installation, and detailed installation instructions.

Provides information on the FP-300RA operating modes.

Presents the information needed to connect to the FP-300RA.

Presents the functions of the FP-300RA maintenance utility,

instructions for its installation on a PC, and covers its utilization

for configuration and calibration of FP-300RA units.

2140-72018-00-0A REV: A Page 5 Of 38

Page 6

FP300RA User Manual

1.2 General Description

1.2.1 Purpose and Use

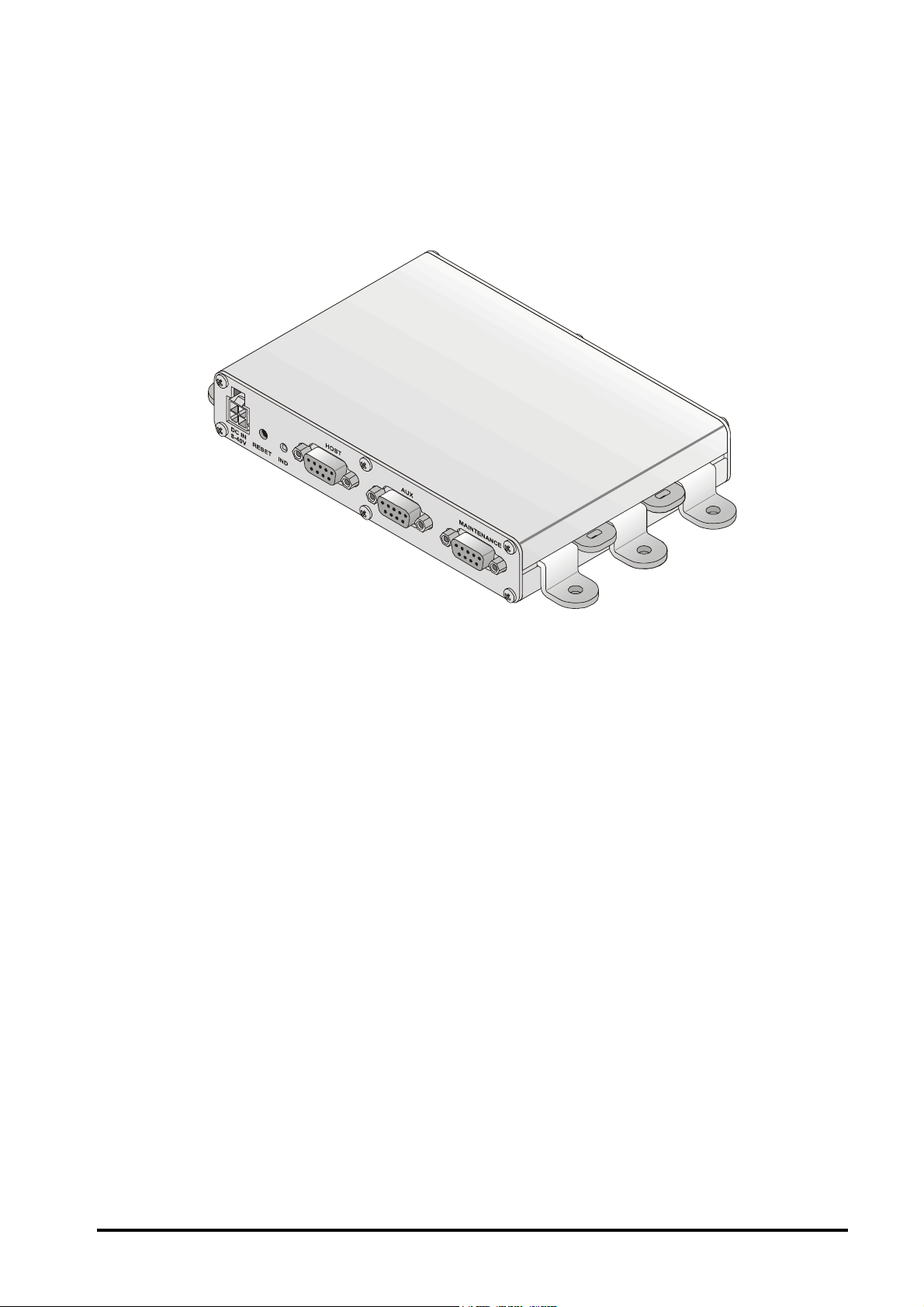

The FP-300RA reader offered by Telematics Wireless is a versatile, compact and reliable unit

that serves as the roadside component of a vehicle identification system. Figure 1-1 shows a

general view of the FP-300RA.

Figure 1-1: FP-300RA, General View

The FP-300RA can automatically identify passing transponders; depending on the system

operator’s requirements and the specific activities configured by the operator, the FP-300RA

can also retrieve information from the transponder, write information to the transponder and

instruct it to alert the driver by audio or visual means (beeps, red/yellow/green indicators, etc.).

Multiple digital inputs and outputs can be used to read the status of external sensors, and

activate various devices. An auxiliary interface can be used as an additional serial

communication port to further extend system capabilities and versatility; this port can also be

used for synchronizing multiple FP-300RA.

The FP-300RA activities are transmitted on-line to host computers. The FP-300RA

communicates with the host computer via a programmable serial interface that provides full

control over the FP-300RA operation, and enables collecting extensive vehicle-related data. A

local maintenance port can be used to configure and maintain the FP-300RA, independently of

the communication with the host computer. These ports also provide control over the digital

I/O and auxiliary port.

The FP-300RA can be used in a wide range of applications, for example, electronic toll

collection systems, border crossing, access control, Weigh In Motion (WIM) stations,

electronic seal systems, vehicle-related services such as parking and gas station payment, and

many other applications.

The FP-300RA may be operated from DC sources in the range of 8 to 30 VDC, including

batteries. It has low power drain (less than 5 W) and very compact size.

2140-72018-00-0A REV: A Page 6 Of 38

Page 7

FP300RA User Manual

1.2.2 Main Technical Characteristics

The FP-300RA is a complete user-configurable RF and data processing unit that supports twoway communications with in-vehicle transponders (“tags”) using the ASTM V6 Slotted-Aloha

Time Division Multiple Access (TDMA) protocol. The physical layer is compatible with

ASTM PS111-98.

The FP-300RA communicates with transponders that enter its communication zone at speeds

of up to 125 mph (200 kph). The communication uses the 902 to 928 MHz ISM band, with

software-configurable synthesized transmit frequency; the data rate is 500 kbps, with ASK

modulation. A fixed receiver frequency within the ISM band is used (915 MHz default).

The FP-300RA can use many types of antennas, to match the spatial resolution needed in the

desired operation mode (single lane or multilane). It has an integrated antenna-switching unit

for multilane sites, supporting up to 4 lanes. The FP-300RA antenna switching rate is

configurable; when switching to a lane, the FP-300RA also automatically switches to the RF

parameters selected for that lane during the site calibration process.

The high transmit power (software-controllable up to 31.2 dBm) and the high selectivity, highsensitivity receiver with software-controllable squelch level ensure reliable communication and

high performance with minimal external support.

1.2.3 Maintenance Utility

Telematics Wireless offers a dedicated reader maintenance utility for the FP-300RA, that can

be installed on any PC running Microsoft® Corp. Windows 2000, Xp. The FP-300RA

connects to one of the free serial communication ports of the PC using a null modem cable.

The maintenance utility provides full control over FP-300RA RF and data processing

parameters, enables monitoring its operation and updating the FP-300RA software.

1.2.4 Additional Equipment Needed

The only additional accessories that have to be provided are:

Antennas for the specific installation requirements, with the required coaxial cables

for connection to the reader.

The number of antennas required and their radiation pattern depend on the

application mode:

• Single-lane mode: single transmit/receive antenna.

• Multilane mode: one antenna per active lane, with the option to add one

separate transmit antenna.

DC source capable of providing the required supply voltage (8 to 30 VDC) at

maximum 5 W.

Means for communicating with the host (serial asynchronous communication link).

2140-72018-00-0A REV: A Page 7 Of 38

Page 8

FP300RA User Manual

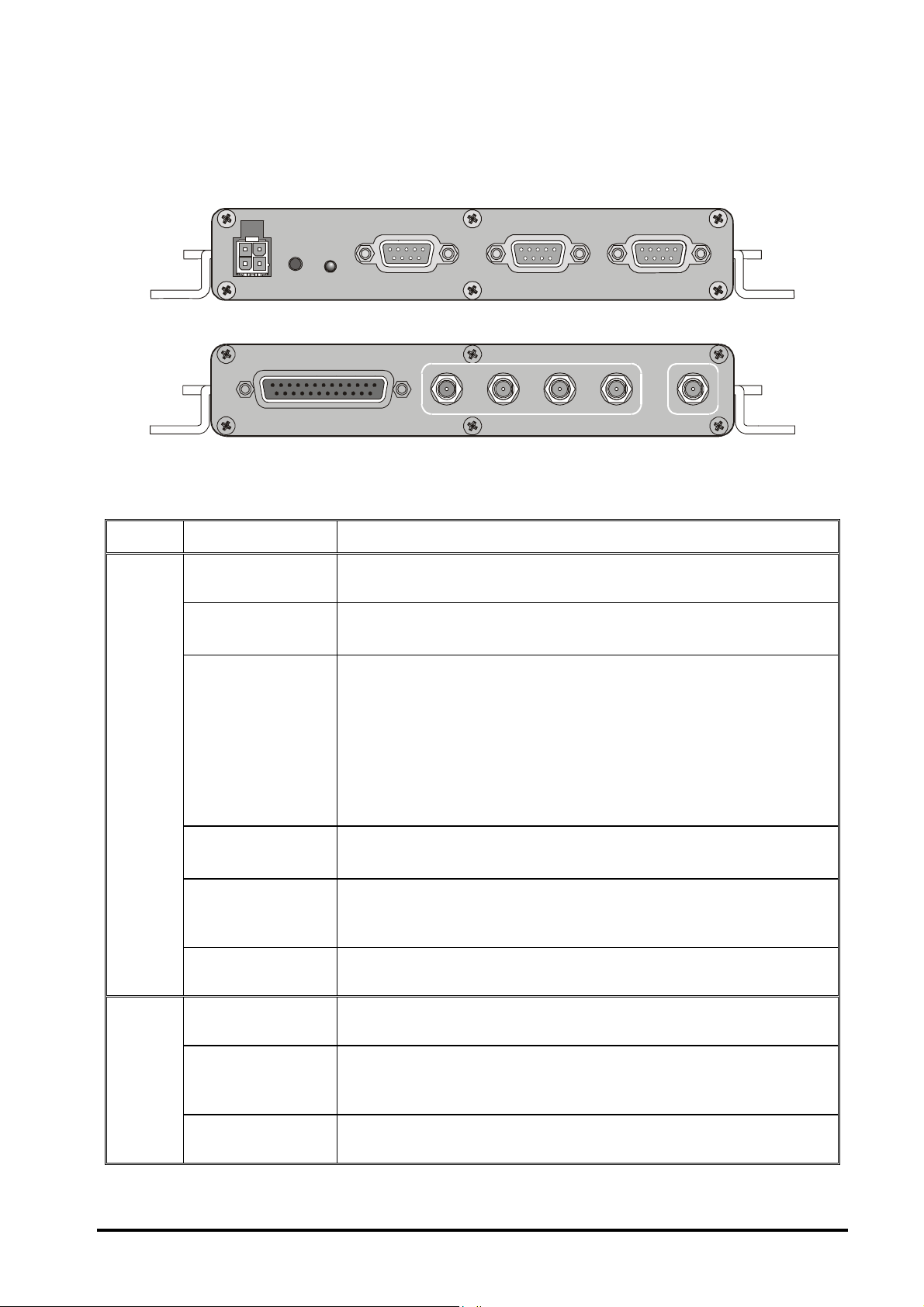

1.3 Physical Description

Figure 1-2 and Figure 1-3 show the components located on the FP-300RA (see Figure 1 for

orientation). The functions of the various components are described in Table 1-1.

DC IN

8-30V

RESET IND

AUXHOST MAINTENANCE

Figure 1-2: FP-300RA, Host Side Panel

MULTILANE ANT

I/O

4 3 2 1

Figure 1-3: FP-300RA, Antenna Side Panel

Table 1-1: Controls

Side Item Function

DC IN Connector

4-pin connector used to connect the DC input voltage, and enable

external resetting by dry-contact closure to ground.

RESET Push-

Internal push-button used to initiate cold restart of the FP-300RA.

button

ANT

MAIN

Host

Antenna

IND Indicator Status indicator, provides the following indications:

1. Flashing in green: normal operation, no tags detected

Flashing in orange: normal operation, tags detected

Fast flashing in red: mute mode (transmission disabled)

Steady red: FP-300RA malfunction detected

Alternating off-orange-green sequence: software downloading

in progress

HOST Connector 9-pin D-type female connector includes a serial asynchronous RS-

232 DTE interface used for connection to the host computer.

AUX Connector

9-pin D-type female connector, includes a serial asynchronous RS232 DTE interface used for connection to auxiliary devices, or as

synchronization pulse input or output.

MAINTENANCE

Connector

I/O Connector

9-pin D-type female connector, includes a serial asynchronous RS232 DTE interface used for maintenance.

25-pin D-type female connector, used to connect to the digital I/O

interface.

MULTILANE

SMA connectors for connection to the secondary antennas.

ANT 1, 2, 3, 4

Connectors

MAIN ANT

SMA connector for connection to the main antenna.

Connector

2140-72018-00-0A REV: A Page 8 Of 38

Page 9

FP300RA User Manual

1.4 Functional Description

The FP-300RA has two operating modes:

Normal mode

Maintenance mode.

1.4.1 Normal Mode

1.4.1.1 Normal Mode Functions

The functions performed by the FP-300RA during operation in the normal mode are as

follows:

• Provide communication with transponders passing through its communication zone,

using the configured mode (either single lane or multilane)

• Support lane discrimination functionality.

• Maintain a list of the transponders that are currently detected within the FP-300RA

communication zone (active list)

• Perform preassigned functions (called auto-functions) on transponders detected to

enter the communication zone (hot list)

• Perform various functions on transponders in response to host requests

• Send event and status reports to the host.

1.4.1.2 Transponder Access Capabilities

The FP-300RA can access transponders with the following commands:

• Read/write transponder internal or external memory

• Operate transponder driver interface

• Send transponder to sleep mode, with or without driver alert

• Write time stamp into the transponder memory.

1.4.1.3 Air Interface

The air interface is based on ASTM V6 protocol. The FP-300RA performs the following

tasks:

• Send frame control messages according to the selected mode (open-road or lane-

based timing).

• Receive activation messages from transponders.

• Detect and report new transponders that entered the communication zone.

• Send and receive data to/from transponders and report the results to the requesting

entity.

2140-72018-00-0A REV: A Page 9 Of 38

Page 10

FP300RA User Manual

1.4.1.4 Multilane Support

The FP-300RA has five antenna connectors: one serves for connection to the main antenna,

and four additional connectors serve for connection to secondary antennas.

The FP-300RA can transmit and receive using any one of the antenna connectors; the

selection of transmit and receive antennas is made every TDMA frame.

Table 1-2 lists the antenna configurations used for single lane and multilane operation.

Table 1-2: Antenna Configurations

Operation Mode Tx Antenna Rx Antenna

Single lane mode Main antenna Main antenna

Multilane mode with one Tx

Main antenna Secondary antenna according

communication zone

Multilane mode with separate

lane Tx and Rx communication

zones

Secondary antenna

according to the multilane

setup

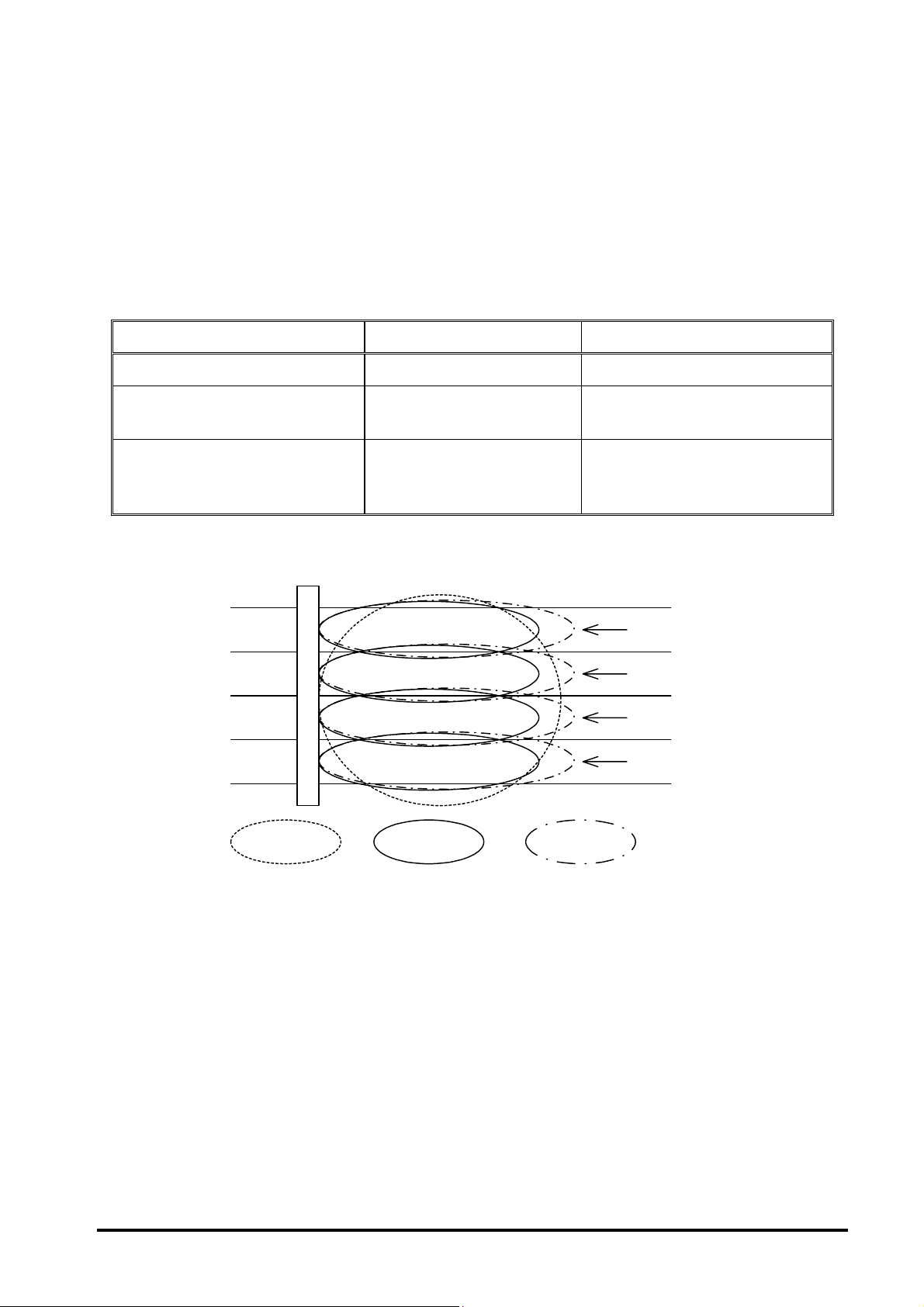

Figure 1-4 shows typical multilane site communication zones.

GANTRY

Single Tx

zone

Rx zone

Lane Tx zone

Figure 1-4: Identification of Antenna Used in the Various Operation Modes

to multilane setup

Secondary antenna according

to the multilane setup

Lane 1

Lane 2

Lane 3

Lane 4

The multilane parameters that can be configured include:

• Number of active lanes

• Switching time, i.e., number of frames per lane.

The FP-300RA enables calibrating the communication zone of every lane independently.

2140-72018-00-0A REV: A Page 10 Of 38

Page 11

FP300RA User Manual

1.4.1.5 Lane Discrimination Support

The FP-300RA lane discrimination function enables detecting on which lane the transponder

entered the communication zone.

The lane discrimination parameters that can be configured include:

• Detection of lane in which a transponder enters or leaves the communication zone

• Search window size

• Minimum number of activation messages that must be received

• Minimum delta (difference between the numbers of activation messages received in

each lane) needed to identify the lane.

1.4.1.6 Support for Reader Synchronization

The FP-300RA supports the master-slave synchronization mode:

• When configured as synchronization master, the FP-300RA outputs

synchronization pulses via its AUX port, at RS-232/422 levels.

• When configured as slave, the FP-300RA synchronizes its air interface to the

synchronization pulses received via its AUX port, at RS-232/422 levels.

While operating in the slave mode, the FP-300RA sends messages reporting loss and regaining

of synchronization through the host and maintenance interfaces.

1.4.1.7 Active List

The FP-300RA maintains a list of transponders that are currently in the FP-300RA

communication zone: this list is the active list, and can include up to 100 transponders. The

FP-300RA will send the active list to the host upon host’s request.

The criteria for adding transponders to the active list are:

• New activation message has been received

• A successful data access is performed with a transponder that is not in the list.

The FP-300RA can check if any transponder is still within its communication zone by selfinitiated data access (ping). Ping reads the transponder internal memory contents. The time

between consecutive pings can be set by commands, or pinging can be disabled altogether.

The criteria for removing a transponder from the active list are:

The transponder failed to respond to an FP-300RA command (auto-function, ping or

host request)

If the ping function is disabled, then:

If the transponder has not been accessed, i.e., it is in the out-of-link state, it

will be removed after a configurable number of frames from the last received

activation message

If the transponder has been accessed, i.e., it is in the link-granted state, it will

be removed 10 seconds after the last access.

2140-72018-00-0A REV: A Page 11 Of 38

Page 12

FP300RA User Manual

1.4.1.8 Hot Lists

The FP-300RA supports up to 20 hot lists with a total of 1024 transponders:

2. A hot list consists of an automatically-performed function (auto-function), a

digital output command and a list of transponders.

3. A transponder can be included in only one hot list.

4. Hot list 0 is the default hot list and contains no transponders.

When a transponder enters the communication zone, the FP-300RA checks whether it is a

member of a predefined hot list: if positive, the corresponding hot list auto-function and digital

output command are performed.

1.4.2 Maintenance Mode

The tasks performed in the maintenance mode are as follows:

Configuration

Communication zone calibration

Self-test.

1.4.2.1 Configuration

The FP-300RA configurable parameters are divided into two groups:

Parameters that can be changed only via the maintenance interface

Parameters that can be changed via either the host or the maintenance interface.

The current configuration is stored in non-volatile memory. When the FP-300RA is restarted, it

looks for the last saved configuration and uses it.

If no valid configuration is found, the FP-300RA sets the configuration parameters to their

default values. The configurable parameters are explained in Appendix C.

1.4.2.2 Communication Zone Calibration

The FP-300RA has built-in transmit power and digital squelch control. The FP-300RA stores

the transmit power and digital squelch settings for every active lane and use it when switching

between lanes. The calibration procedure (explained in Appendix E), enables setting every

lane’s communication zone.

1.4.2.3 Self-Test

The FP-300RA supports two types of tests, destructive and non-destructive. Non-destructive

test enables the FP-300RA to continue operating in normal mode, whereas the destructive test

terminates the normal mode.

2140-72018-00-0A REV: A Page 12 Of 38

Page 13

FP300RA User Manual

1.4.3 Host Communication

The FP-300RA supports communication with a host. Two types of messages are used:

FP-300RA-initiated message used to report events, e.g., a new transponder

Messages sent in response to host requests.

The message set is presented in Appendix D.

1.4.4 Real-Time Clock

The FP-300RA has an internal real time clock (RTC) with a resolution of 10 millisecond.

Whenever the FP-300RA is restarted, the RTC starts running from an initial value of 00:00

January 1, 2000. Therefore, the host must make the translation to “normal” time.

The FP-300RA RTC can be set via the host and/or maintenance interface.

2140-72018-00-0A REV: A Page 13 Of 38

Page 14

FP300RA User Manual

Chapter 2: Installation

2.1 General

This Chapter provides the information needed to install FP-300RA readers.

The information presented in this Chapter is organized as follows:

• Installation requirements – Section 2.2.

• Installation guidelines – Section 2.3.

• Installation procedures – Section 2.4.

Before starting the installation procedures, make sure to review the Safety Information

section at the beginning of this manual.

2.2 Installation Requirements

2.2.1 Integration in Systems

Figure 2-1 shows the connections needed to integrate an FP-300RA unit in a typical electronic

vehicle identification system. Use the information appearing in Chapter 1 and Appendix A,

that covers the FP-300RA interface characteristics and connection data, to prepare cables in

accordance with the specific requirements of each location.

MAINTENANCE

To Maintenance PC

To Auxiliary

Devices

To Host Computer

To DC Power Source

(8 - 30V)

AUX

HOST

DC IN

FP-

300RA

MAIN ANT

MULTILANE ANT

1

2

3

4

I/O

To Sensors

& Controlled Devices

To Main

Antenna

To Secondary

(Lane) Antennas

Figure 2-1: FP-300RA Connections

2140-72018-00-0A REV: A Page 14 Of 38

Page 15

FP300RA User Manual

2.2.2 Safety Considerations

In addition to the electrical connections shown in Figura 2-1, the FP-300RA case must be

connected to protective grounding.

Protective devices, complying with the applicable international standards and the national and

local regulations, must be used on all the lines connected to the FP-300RA, to protect against

lightning discharges and accidental contact with high-voltage lines.

The FP-300RA must be properly grounded whenever cables are

connected to its connectors. To ground the FP-300RA, attach its case

to a high-quality, low resistance protective grounding system, in a

Warning

way that ensures good electrical contact.

2.2.3 Mechanical Data

Figure 2-2 provides mechanical data for planning the installation of an FP-300RA unit.

193.7

177

3PL.

3

4PL

4PL

35.4

6

4PL

160.8

2PL.

R1

TYP

35.4

6PL.

5.2

123

2PL

AUX HOST MAINTENANCE

27.5

DC IN

RESET IND

8-30V

Figure 2-2: FP-300RA Mechanical Data

2140-72018-00-0A REV: A Page 15 Of 38

Page 16

FP300RA User Manual

2.3 Installation Guidelines

The FP-300RA is intended for installation in protected cabinets that prevent direct exposure to

sun radiation, rain, dust and dirt. It does not require forced air cooling.

The following sections provide additional information needed for successful utilization of the

FP-300RA.

2.3.1 Power Requirements

The FP-300RA operates on 8 to 30 VDC, and its maximum power drain is 5W. A suitable

power source must be provided as part of the installation.

Separate power supply lines should be routed to each FP-300RA unit.

The FP-300RA does not have an ON/OFF power switch, and will start operating as soon as

power is connected. Therefore, it is recommended to install a circuit breaker, which will also

serve as an ON/OFF switch, to protect the supply line of each FP-300RA.

2.3.2 Antennas

The type of antenna to be used with the FP-300RA is generally determined by the FP-300RA

application and communication zone requirements.

In most installations, two types of antenna are used:

• For wide communication zone applications, a wide beam antenna is

recommended. The antenna can be mounted above the lane or beside the road.

• For narrow communication zones, where lane-to-lane and/or cross-lane

discrimination is required, a narrow beam antenna can be used. This antenna must

be mounted over the center of the lane.

For either type of antenna, the positioning of the antenna must be carefully set to achieve the

required communication zone pattern. For installations subject to external interference, lower

gain antennas can be used.

Contact Telematics Wireless if you need help in selecting suitable antennas.

The antenna (ANT) connectors of the FP-300RA must always be terminated

Note:

in matched (50Ω) loads. Connect 50Ω loads with minimal rating of 1W to any

FP-300RA ANT connector not connected to an antenna.

When the installation procedures call for connecting RF cables to the

FP-300RA antenna connectors before the corresponding antennas are

installed, connect the loads at the antenna ends of the cables.

2140-72018-00-0A REV: A Page 16 Of 38

Page 17

FP300RA User Manual

2.3.2.1 Antenna Mounting Position Requirements

FP-300RA antennas are mounted in accordance with the application requirements and antenna

manufacturer's instructions. Consider the following position requirements:

• Height: for above-the-lane installation, the antennas can be mounted on a gantry,

overpass, or other above-the-lane facility. Each antenna must be mounted at a

sufficient height to meet local vertical clearance requirements.

Any antenna can be damaged and/or misaligned if struck. If snow buildup on vehicles is

possible, mounting height must include clearance for snow buildup for the highest

anticipated vehicle using the lane(s).

• Multilane applications: each antenna should be mounted over the center of its

lane. For lane discrimination, antennas should be mounted over the center of the

highway or group of lanes to be included in the FP-300RA communication zone.

• Beside-the-road installation: the antenna(s) can be pole mounted.

Antennas must be mechanically positioned to provide the appropriate beam orientation for the

communication zone wanted. Suitable arrangements must be provided to permit mechanical

adjustment of antenna direction, to achieve the beam pattern and communication zone wanted.

2.3.2.2 FP-300RA-to-Antenna Cabling

The maximum distance between the FP-300RA and its antenna is limited by cable signal loss.

Generally, the total signal loss between the antenna and the FP-300RA must be less than 3 dB.

Any losses on antenna patch panels or switching matrices must also be taken into

consideration.

For installations where the FP-300RA-to-antenna cable length is less than 125 feet (38 meters),

you may use Times LMR 600/400, Andrew type LD F4-50A 1/2-inch Heliax, or other cables

with similar or better characteristics.

Cable routes should be carefully planned, to ensure they follow the shortest path yet are far

from sources of strong electrical interference such as electrical motors, air conditioning

equipment, two-way radios, etc. Make sure that cables are physically protected, for example,

by routing them within cable ducts: sharp bends, distortion of the cable outer shield, etc., may

increase the attenuation by an unpredictable amount.

2.3.3 Communication Cables

The cables connecting the FP-300RA communication ports (auxiliary, maintenance and in

particular the connection to the host computer) must be shielded. Communication-grade cables

consisting of twisted pairs with external shield should be used, and the shield must be

grounded at one end.

Cables should be run through grounded conduits, to minimize external interference.

2140-72018-00-0A REV: A Page 17 Of 38

Page 18

FP300RA User Manual

2.3.4 Grounding and Lightning Protection Requirements

All the FP-300RAs, antennas, mounting poles, cabinets, cable conduits and cables must be

properly grounded in accordance with the applicable regulations, to prevent injury to personnel

or damage to equipment from lightning or other high voltage sources.

Ground bonding points must be free of paint and corrosion. Star washers should be placed on

screws to ensure good electrical contact.

For installations where a complete bonded ground connection is not possible for the entire

antenna-to-FP-300RA cabling, a separate lightning arrester must be installed for each antenna

cable at a point near the RF connection to the FP-300RA cabinet.

2.4 Installation Procedure

2.4.1 Tools and Materials

No special tools and materials are required for FP-300RA installation.

2.4.2 Preparation for Installation

Refer to the site installation plan, and make sure all the required components, cables, and

accessories are available.

Identify the prescribed physical location of each system component, and find the grounding

points.

Before installing any item (FP-300RA, cabinet, mounting accessory, antenna, cable conduit,

etc.), thoroughly clean the surface on which it will be mounted.

2.4.3 FP-300RA Installation Procedure

2.4.3.1 Physical Installation

Use the following general procedure to install the FP-300RA in the prescribed location:

1. Identify the exact location and position of the FP-300RA.

2. Mark the 6 holes to be drilled in accordance with the information appearing in

Figure 2-2, and then drill using an appropriate drill tip.

3. Thoroughly clean the surface on which the FP-300RA will be mounted. Make

sure to remove any burrs.

4. Insert a flat washer and a star washer on each of the 6 fastening screws. Prepare

additional flat washers and star washers for insertion under the nuts.

5. Place the FP-300RA on the mounting position, and fasten it with the 6 screws

and nuts.

2140-72018-00-0A REV: A Page 18 Of 38

Page 19

FP300RA User Manual

2.4.3.2 Cable Connections

Caution

The FP-300RA does not have an ON/OFF power switch, and will start

operating as soon as power is connected. Make sure that no power is

supplied until authorization to start operations is received.

1. Identify the cables to be connected to the FP-300RA in accordance with the site

installation plan.

2. Visually inspect the connectors for any signs of damage: do not attempt to

connect if shell or pins are bent. Thoroughly clean using a soft, clean brush to

remove dirt and foreign matter.

3. Route each cable to the prescribed connector and mate the connectors. For each

D-type connector, secure the connection by tightening the two screws; use a

wrench to tighten RF connectors. Do not exert excessive force.

4. Four cable tying points are provided around the FP-300RA: use cable ties to

secure the cables. To prevent stress caused by bending, make sure to leave

enough slack.

2.4.3.3 Final Inspection

1. Visually inspect the installation for proper execution, good workmanship and

compliance with the applicable practices and regulations.

2. Check cable connections, and check their routes. Make sure that cables are

securely routed and fastened.

3. Inspect the installation of the other system components in accordance with the

applicable instructions.

4. Correct any problems detected during the inspection.

5. After the inspection is successfully completed, refer to Chapter 3 to continue

with the preliminary configuration.

Do not apply power to the FP-300RA before explicit authorization is

received from the person in charge. The FP-300RA may start

transmitting as soon as power is applied, resulting in possible

Warning

exposure of personnel working near the antennas to microwave

radiation.

The FP-300RA must not be allowed to transmit without being

connected to an antenna, or to other matched (50Ω) load.

2140-72018-00-0A REV: A Page 19 Of 38

Page 20

FP300RA User Manual

Chapter 3: Operation

3.1 Scope

This Chapter provides the information needed to prepare a new FP-300RA for operation in

your system, using the FP-300RA maintenance utility provided by Telematics Wireless. The

information appearing in this Chapter is organized as follows (this is also the recommended

order of execution):

• Power-up instructions – see Section 3.2.

• FP-300RA configuration – see Section 3.3.

• Preparing hot lists – see Section 3.4.

• Calibration of communication zone – see Section 3.5.

• Software and firmware downloading – see Section 3.6.

The information appearing in this Chapter assumes that you are familiar with the FP-300RA

maintenance utility. If necessary, refer to Appendix B for information on this utility.

3.2 Power-Up

Before performing the other activities described in this Chapter, power up the FP-300RA and

connect it to the PC running the maintenance utility.

Do not apply power to the FP-300RA before explicit authorization is

received from the person in charge. The FP-300RA may start

transmitting as soon as power is applied, resulting in possible

Warning

To apply power to the FP-300RA:

1. Check that power may be applied to the FP-300RA.

exposure of personnel working near the antennas to microwave

radiation.

The FP-300RA must not be allowed to transmit without being

connected to antenna, or to a suitable (50Ω) load.

To avoid transmitting when personnel works near the antennas

and/or when no antennas are connected, for example, during

preparations for first time-operation and during maintenance,

connect 50Ω, 1W loads to the FP-300RA antenna connectors. Do not

disconnect the loads as long as the FP-300RA is powered.

2. Apply power and monitor the FP-300RA IND indicator: it should start

flashing in green.

2140-72018-00-0A REV: A Page 20 Of 38

Page 21

FP300RA User Manual

• Orange flashing indicates that transponders have been detected within

Notes:

the communication zone of the FP-300RA. This is possible only when

the FP-300RA is connected to antennas.

• Fast red flashing indicates that transmission has been disabled

(muted). This is a normal indication. However, steady red means that

a malfunction has been detected: press the RESET push-button of the

FP-300RA and check that the problem disappears after the FP-300RA

restarts. If the indicator lights steadily in red, service is required.

To connect the FP-300RA to the maintenance PC:

1. Identify the serial COM port of the PC that is configured for communication

with the FP-300RA (if necessary, see details in Appendix B).

2. Connect a 9-pin/9-pin null modem cable between the COM port of the PC and

the MAINTENANCE connector of the FP-300RA.

3. Start the maintenance utility.

4. After the PC establishes communication with the FP-300RA, the monitoring

window of the maintenance utility should show the information retrieved from

the FP-300RA.

At this stage, you may continue to the other preparation and configuration activities.

3.3 FP-300RA Configuration

Before starting, obtain the list of prescribed parameters for the FP-300RA being installed from

the person in charge.

Start the configuration procedure by clicking the Setting – Config button of the main window

of the maintenance utility to display the RVCC Configuration window.

Make sure that the FP-300RA configuration is set to the default parameters. You can click the

Return to Factory Default button (the FP-300RA will restore the default values and reboot

itself).

3.3.1 Setting Host Interface Parameters

Set the host interface baud rate and word format, and then click Set.

3.3.2 Setting Initial Tx Mode

Setting the initial Tx mode to Mute enables a slow host to boot before receiving messages

from the FP-300RA.

When using the Mute initial Tx mode, the host must change the FP-300RA mode to Normal.

2140-72018-00-0A REV: A Page 21 Of 38

Page 22

FP300RA User Manual

3.3.3 Setting TDMA Mode

The TDMA mode enables:

• Set TDMA frame type to either Open Road (default) or Lane Based.

• Internal Act, External Act: Enable/disable internal/external activation messages

from transponders.

• “F” EH: Set the extended header type: “1111…” or “10101…” (default).

• Sleep Time: Set the sleep interval used when commanding a transponder to “sleep”.

3.3.4 Setting Transponder Access Parameters

The transponder access parameters are as follows:

• Net Re-entry Delay: Set the time transponder activation messages are ignored after

transponder sleep command.

• Max Access Retries: Set the number of times the FP-300RA tries to access a

transponder before it is declared lost.

• Ping Function, Ping rate: Enable/disable the ping function and set the ping rate.

• Tag Lost Timeout: Set the number of frames in which transponder activation

messages have not been detected before a transponder declared lost. If the

transponder was previously accessed (either by ping, auto-function or a host

request), then the tag will be declared lost 10 seconds after the last access.

3.3.5 Setting Burst Mode

The primary use of the burst mode is during communication zone calibration. When the burst

mode is enabled, the FP-300RA will be in the normal Tx mode for the number of frames

selected by Frames ON and will then enter the mute Tx mode for the number of frames

selected by Frames OFF. To make sure that all the transponders will lose synchronization to

the FP-300RA, set Frames OFF to more than 15.

3.3.6 Setting SYNC Mode

The PF300RA SYNC mode can be set to None, Master or Slave, by click the corresponding radio

button. The default SYNC pulse timing values are set according to field tests.

If required, the SYNC pulse timing can be adjusted as explained below.

• SYNC Slave Mode: in this mode, you can adjust the delay between the falling edge

of the SYNC pulse and the start of a new frame, designated SYNC to FCM, can be

adjusted in the range of 800 ±15 µsec.

9676 -0+580 µsec

FCM SDM1 SDM2 SDM3 SDM14 Activation FCMEH

SYNC to FCM

2140-72018-00-0A REV: A Page 22 Of 38

Page 23

FP300RA User Manual

• SYNC Master Mode: in this mode, the SYNC pulse duration and timing can be

adjusted.

FCM SDM1 SDM2 SDM3 SDM14 Activation FCMEH

9800 µsec

SYNC on time

SYNC off time

If the Master reader is in burst mode then it will send the SYNC pulse while it in OFF state

and block the SYNC pulse while in ON state.

3.3.7 Setting Multilane Mode

The FP-300RA can support up to 4 lanes. The default setting is single lane using the MAIN

antenna connector for Tx and Rx. The multilane setting enables:

• Set multilane mode using the MAIN antenna for Tx and MULTILANE antennas for

Rx

• Set multilane mode using MULTILANE antennas for Tx and Rx.

The multilane parameters are:

• Lane: Number of active lanes (1 to 4).

• Lane Switch: Number of frames the FP-300RA will use an antenna before

switching to the next antenna.

3.3.8 Setting Lane Discrimination

The lane discrimination function enables to determine the lane in which the transponder has

been detected. The lane discrimination can be made in two ways:

• Try to determine the lane when the transponder enters the communication zone

• Try to determine the lane when the transponder leaves the communication zone.

• Try to determine the lane as soon as possible or when the transponder leaves the

communication zone.

The lane discrimination parameters are:

• Window: the number of frames, counted from the first detection of a transponder,

in which the FP-300RA tries to determine the lane. This parameter is ignored if

lane discrimination is made when the transponder leaves the communication zone.

• Min. Act. Msg: minimum number of activation message, required for reliable lane

determination.

• Min. Delta: minimum difference in the number of activation messages received

from each lane that is required for reliable lane determination.

2140-72018-00-0A REV: A Page 23 Of 38

Page 24

FP300RA User Manual

3.3.9 Setting Digital I/O

The digital I/O setting enables:

• Set the digital output setting when the FP-300RA is powered up

• Set the input sense function by:

• Selecting the required input, Sense mask.

• Set the polarity for each selected input, Sense polarity.

3.3.10 Save Current Settings

After completing the FP-300RA configuration, click the Save current setting button. The FP300RA will save the settings and reboot.

3.4 Hot List Configuration

The hot list function enables the FP-300RA to activate a predefined transponder access

function when a transponder enters the FP-300RA communication zone. To configure the hot

list, click the Setting – Hot Lists button of the main window of the maintenance utility to

display the Hot List Control window.

3.4.1 Get Hot List Status

• Click the Get Hot Lists to get the list of currently-defined hot lists

• Select the desired hot list in the HL ID – AF ID window to view the hot list

members and the predefined auto-function.

3.4.2 Remove Hot List

• Select the desired hot list in the HL ID – AF ID window, or type the hot list ID in

the Selected HL field.

• Click the Clear hot list(s) button. If the selected hot list is 255, default hot list,

then all the hot lists will be removed, and the auto-function of the hot list 255

(default hot list), will be set to No Auto Function.

3.4.3 Add New Hot List

A new hot list is added by setting its auto function, or by adding a transponder.

2140-72018-00-0A REV: A Page 24 Of 38

Page 25

FP300RA User Manual

3.4.4 Set Hot List Auto Function

• Select the desired hot list in the HL ID – AF ID window, or type the hot list ID in

the Selected HL field.

• Select the auto-function type and its parameters in the Auto Function area.

• Select the digital output setting in the Auto Function area.

• Click the Set Auto Function button.

• If the hot list is already defined, then its auto-function is replaced.

• If not, then a new hot list is defined.

3.4.5 Add Transponder to Hot List

• Select the desired hot list in the HL ID – AF ID window, or type the hot list ID in

the Selected HL field.

• Enter the transponder ID in the Selected Tag ID.

• Click Add TAG button:

• If the transponder is already a member of the specified hot list, the FP-

300RA will reject the command (reject code 07)

• If the transponder is already a member of the another hot list, the FP-

300RA will change the transponder hot list

• If the hot list is not defined, then a new hot list is defined.

3.4.6 Remove Transponder from Hot List

• Select the transponder in the Members window or enter the transponder ID in the

Selected Tag ID.

• Click the Rem TAG button. If the transponder is not in the specified hot list, the

FP-300RA will reject the command (reject code 0A).

3.4.7 Saving the Hot List

Click the Set Hot list button to make the current hot lists setting the FP-300RA default hot list.

2140-72018-00-0A REV: A Page 25 Of 38

Page 26

FP300RA User Manual

Appendix A: Connection Data

A-1 Antenna Connectors

The FP-300RA has five SMA female antenna connectors, one designated MAIN and four

additional connectors designated MULTILANE 1, 2, 3 and 4.

The antenna functions depend on the selected operation mode (single lane, multiple lanes with

single transmit zone or multiple lanes with separate lane zones).

A-2 Power Input Connector

The FP-300RA has one 4-pin connector, designated DC IN, used to connect the DC input

voltage, and to enable external resetting by dry-contact closure to ground. Table A-1 lists the

pin functions.

Table A-1: DC IN Connector, Pin Functions

Pin Function

1 Input voltage

2 Ground

3 External reset (active low, with internal pull-up)

4 Ground

A-3 Digital Interface Connector

The digital interface connector is a 25-pin D-type female connector, designated I/O. The

connector is used to connect to the FP-300RA digital interface, which includes 8 inputs and 7

outputs, all referenced to ground. Table A-2 lists the connector pin functions.

Table A-2: I/O Connector, Pin Functions

Pin Designation Pin Designation Pin Designation

1 IN1 15 IN4 21 OUT4

2 IN3 16 IN6 22 OUT5

3 IN5 17 IN8 23 OUT6

4 IN7 18 OUT1 24 OUT7

5 to 13 GND 19 OUT2 25 GND

14 IN2 20 OUT3

2140-72018-00-0A REV: A Page 26 Of 38

Page 27

FP300RA User Manual

A-4 Host Interface Connector

The host interface connector is 9-pin D-type female connector designated HOST. Its

communication parameters are configured by means of the MAINTENANCE interface.

The connector includes a serial asynchronous DTE interface used for connection to the host

computer. Two interfaces can be selected:

• RS-232 interface: Table A-3 lists the connector pin functions for this mode.

• RS-422 interface: Table A-4 lists the connector pin functions for this mode.

Table A-3: HOST Connector, Pin Functions for RS-232 Interface

Pin Designation Function

1 N.C. Not connected

2 TxD Transmit data output

3 RxD Receive data input

4 N.C. Not connected

5 GND Signal ground

6 N.C. Not connected

7 CTS Clear to send input

8 RTS Request to send output

9 N.C. Not connected

Table A-4: HOST Connector, Pin Functions for RS-422 Interface

Pin Designation Function

1 RxD- Receive data input (-)

2 TxD+ Transmit data output (+)

3 RxD+ Receive data input (+)

4 TxD- Transmit data output (-)

5 GND Signal ground

6 RTS- Request to send output (-)

7 CTS+ Clear to send input (+)

8 RTS+ Request to send output (+)

9 CTS- Clear to send input (-)

2140-72018-00-0A REV: A Page 27 Of 38

Page 28

FP300RA User Manual

A-5 Maintenance Interface Connector

The maintenance interface connector is 9-pin D-type female connector designated

MAINTENANCE. The connector includes the serial asynchronous RS-232 DTE interface used

for connection to a PC running the maintenance utility. Its communication parameters are 9600

bps, 1 start bit, 8 data bits, no parity, one stop bit. Table A-5 lists the connector pin functions.

Table A-5: MAINTENANCE Connector, Pin Functions

Pin Designation Function

1 N.C. Not connected

2 TxD Transmit data output

3 RxD Receive data input

4 N.C. Not connected

5 GND Signal ground

6 N.C. Not connected

7 RTS Request to send output

8 CTS Clear to send input

9 N.C. Not connected

A-6 Auxiliary Interface Connector

The auxiliary interface connector is 9-pin D-type female connector designated AUX. The

connector includes a serial asynchronous RS-232 DTE interface used for connection to

auxiliary devices, or for synchronization pulses. Its communication parameters are configured

by means of the MAINTENANCE interface.

• RS-232 interface: A-6 lists the connector pin functions for this mode.

• RS-422 interface: A-4 lists the connector pin functions for this mode.

Table A-6: AUX Connector, Pin Functions for RS-232 Interface

Pin Designation Function

1 N.C. Not connected

2 TxD Transmit data output or SYNC pulse output

3 RxD Receive data input or SYNC pulse input

4 N.C. Not connected

5 GND Signal ground

6 N.C. Not connected

7 CTS Request to send output

8 RTS Clear to send input

9 N.C. Not connected

2140-72018-00-0A REV: A Page 28 Of 38

Page 29

FP300RA User Manual

Table A-7: AUX Connector, Pin Functions for RS-422 Interface

Pin Designation Function

1 RxD- Receive data input (-)

2 TxD+ Transmit data output (+)

3 RxD+ Receive data input (+)

4 TxD- Transmit data output (-)

5 GND Signal ground

6 RTS- Request to send output (-)

7 CTS+ Clear to send input (+)

8 RTS+ Request to send output (+)

9 CTS- Clear to send input (-)

2140-72018-00-0A REV: A Page 29 Of 38

Page 30

FP300RA User Manual

Appendix B: Maintenance Utility

B-1. Scope

This Appendix provides installation and general operating instructions for the FP-300RA

maintenance utility, version 1.0.

The FP-300RA maintenance utility runs under Microsoft Windows 2000, and uses the

standard Windows user interface. The utility is provided on a standard CD.

The information presented in this Appendix assumes that the user is familiar with the use of

Windows applications. If additional information is necessary, refer to the Windows 2000

User’s Reference Manual, available from Microsoft Corp.

B-2. Installation

B-2.1 Hardware and Software Requirements

The PC used to run the maintenance utility must have Windows 2000 already installed and

running before starting the installation of the utility.

Make sure the PC has a free serial communication (COM) port for communication with the

FP-300RA.

B-2.2 Installation Procedure

• Copy the files provided on the CD to the desired folder.

• Prepare a shortcut to the utility .EXE file on the desktop.

B-2.3 Preliminary Configuration

• Start the utility, e.g., by clicking the desktop shortcut.

• You will see a dialog box that prompts you to select the serial communication

(COM) port that will be used for communication with the FP-300RA.

• Select the desired port, e.g., COM1, on the Com option menu, and then click

the OK button to confirm and close the dialog box.

Figure B-1. COM Port Selection Box

You will see the main window.

2140-72018-00-0A REV: A Page 30 Of 38

Page 31

FP300RA User Manual

B-3. Main Window

Figure B-2 shows a typical main window, as seen after the PC is connected to an operational

FP-300RA. The window has a menu bar with two items: File and Help. The following sections

explain the various areas of the window.

Figure B-2 Typical Main Window

B-3.1 Monitor Area

The monitor area displays the request/command messages sent to the FP-300RA and its

response.

B-3.2 Active List Area

The active list area displays the transponders that are currently in the FP-300RA

communication zone. The active list is stored in the FP-300RA and can be read by clicking the

Get button in the Tag List area.

2140-72018-00-0A REV: A Page 31 Of 38

Page 32

FP300RA User Manual

B-3.3 Log File

The information displayed in the monitor area can be recorded in a log file by checking the

Enable Log box.

The log file is saved in the current directory. The file name is FP-300RA, followed by file

opening date and time. The current log file will be closed and a new one will be opened

according to the parameters defined by means of the Log Control window.

B-3.4 Sending Periodic Status Request

The maintenance utility can be configured to automatically send status requests by checking

the Enable Status Request Every box, and then entering the desired interval, in seconds, in

the adjacent field.

B-3.5 Setting the Communication Mode

The radio buttons in the Comm Mode are used to select the FP-300RA communication mode:

• Normal – normal operation.

• Mute – transmission disabled. For your safety, before replacing an antenna, the

FP-300RA must be turned off or set to Mute.

B-3.6 Setting/Resetting the Digital Output Port

The maintenance utility can set or reset any one of the seven FP-300RA digital outputs by

setting the required bit mask in the Digital Output are:

• To set a bit (“1”), check the bit box.

• To reset a bit (“0”), uncheck the bit box.

B-3.7 Information Fields

The main window contains the following information fields:

• Connected: displays the configured COM port, its data rate and the word format

(data bits – parity – stop bits).

• Reader TDMA mode

• FP-300RA loader software version (updated after cold reset)

• FP-300RA firmware version (updated by self-test result)

• FP-300RA application software version (updated by self-test result).

2140-72018-00-0A REV: A Page 32 Of 38

Page 33

FP300RA User Manual

B-3.8 Requests Area

The user can click buttons in the Requests area to cause the maintenance utility to send the

following request for information to the FP-300RA:

• Status

• Current FP-300RA communication mode

• FP-300RA current time

• Digital I/O settings.

The FP-300RA response is displayed in the monitor window and, if applicable, updates the

main window information field.

B-3.9 Setting Area

The buttons in the Setting area are used to configure the following FP-300RA parameters:

• Configuration (system parameters)

• Hot list parameters

• RF parameters

• Set FP-300RA time.

Each button, except Time, opens a control window. The Time setting uses the PC time.

2140-72018-00-0A REV: A Page 33 Of 38

Page 34

FP300RA User Manual

B-4. File Menu

Figure B-3 shows the File menu of the maintenance utility.

Figure B-3: File Menu Structure

The functions of the items included on the File menu are as follows:

Config COM

Reset Reader

Self Test

Upgrade

Msg monitor

Log control

Exit

Configure the PC COM port to be connected to the FP-300RA.

Send a reset command to the FP-300RA.

Send a self-test command to the FP-300RA.

Start FP-300RA software/firmware upgrade process.

Display the command/response messages details.

Enable selecting the maximum number of lines in the log file, or the

maximum time the log file remains open, even when the specified number

of lines has not yet been reached. In either case, the current log file is

closed and anew one is opened.

End the FP-300RA maintenance utility.

2140-72018-00-0A REV: A Page 34 Of 38

Page 35

FP300RA User Manual

B-5. FP-300RA Configuration Window

The FP-300RA Configuration window, shown in Figure B-4, is used to select the system

configuration parameters. In most cases, the configuration change is made when the focus is moved

from the changed parameter’s field.

For a description of the system parameters and their range of values, refer to the FP-300RA

Configuration Table section in Appendix C.

Figure B-4: Typical FP-300RA Configuration Window

2140-72018-00-0A REV: A Page 35 Of 38

Page 36

FP300RA User Manual

B-6. Hot List

The hot list functionality is described in Chapter 3. A typical Hot List Control window is shown in

Figure B-5

Figure B-5: Typical Hot List Control Window

The window includes the following buttons:

Get Hot Lists

Clear hot list(s)

Save HL

Load HL from file

Add TAG

Rem. TAG

Set Auto function

Get currently set hot lists.

Clear the selected hot list. Select 0 to clear all the hot lists.

Save the current hot list setting as default setting.

Load the hot list settings from a script file.

Add a selected transponder with Mask to a selected hot list.

Remove a transponder with Mask from a hot list.

Set the auto-function for the selected hot list.

B-6.1 Auto-Function

The auto-function is selected from the Function list. When a function is selected, the relevant data

field will be opened.

The Digital output setting is not applicable and the mask field should be 0.

2140-72018-00-0A REV: A Page 36 Of 38

Page 37

FP300RA User Manual

B-7. RF Setting Window

Figure B-6 shows a typical RF Setting window.

Figure B-6: Typical RF Setting Window

B-7.1 Get Button

Its function it to get the current RF parameters. When using the CW or modulated mode, the

actual transmit output power is measured and reported.

B-7.2 Set Default Button

Its function is to set the current RF parameters as the FP-300RA default RF parameters.

B-7.3 Tx Mode

Selects the transmitter operating mode:

Normal

Mute

CW

Modulated Tx

The TDMA air interface is active according to the current configuration.

The TDMA air interface is inactive (no transmission, no reception).

The FP-300RA continuously transmits a CW signal.

The FP-300RA continuously transmits a modulated signal.

Calibration

The TDMA air interface is active; the transmission is made via the antenna

selected with Tx Antenna and the reception is made via the antenna selected

with Rx Antenna.

BER Test

Used for FP-300RA receiver testing

mode

2140-72018-00-0A REV: A Page 37 Of 38

Page 38

FP300RA User Manual

B-7.4 Transmitter

Enables selecting the Tx antenna and the transmitter output power:

• In the normal mode, the selected setting will take effect when the FP-300RA will

switch to this antenna.

• In the calibration mode, the FP-300RA will switch to the selected antenna and the

selected output power will be adjusted to the new value on next frame.

B-7.5 Receiver

Enables selecting the Rx antenna and the receiver digital squelch:

• In the normal mode, the selected setting will take effect when the FP-300RA will

switch to this antenna.

• In the calibration mode, the FP-300RA will switch to the selected antenna and the

selected digital squelch will be adjusted to the new value on next frame.

B-7.6 Vector Modulator

The vector modulator is configured by the manufacturer and must not be changed unless

explicitly instructed to do so by an authorized Telematics Wireless representative.

B-7.7 Calibration Process

The calibration process section of the RF setting window is open when calibration Tx mode is

selected. The calibration procedure is explained in Appendix E

2140-72018-00-0A REV: A Page 38 Of 38

Loading...

Loading...