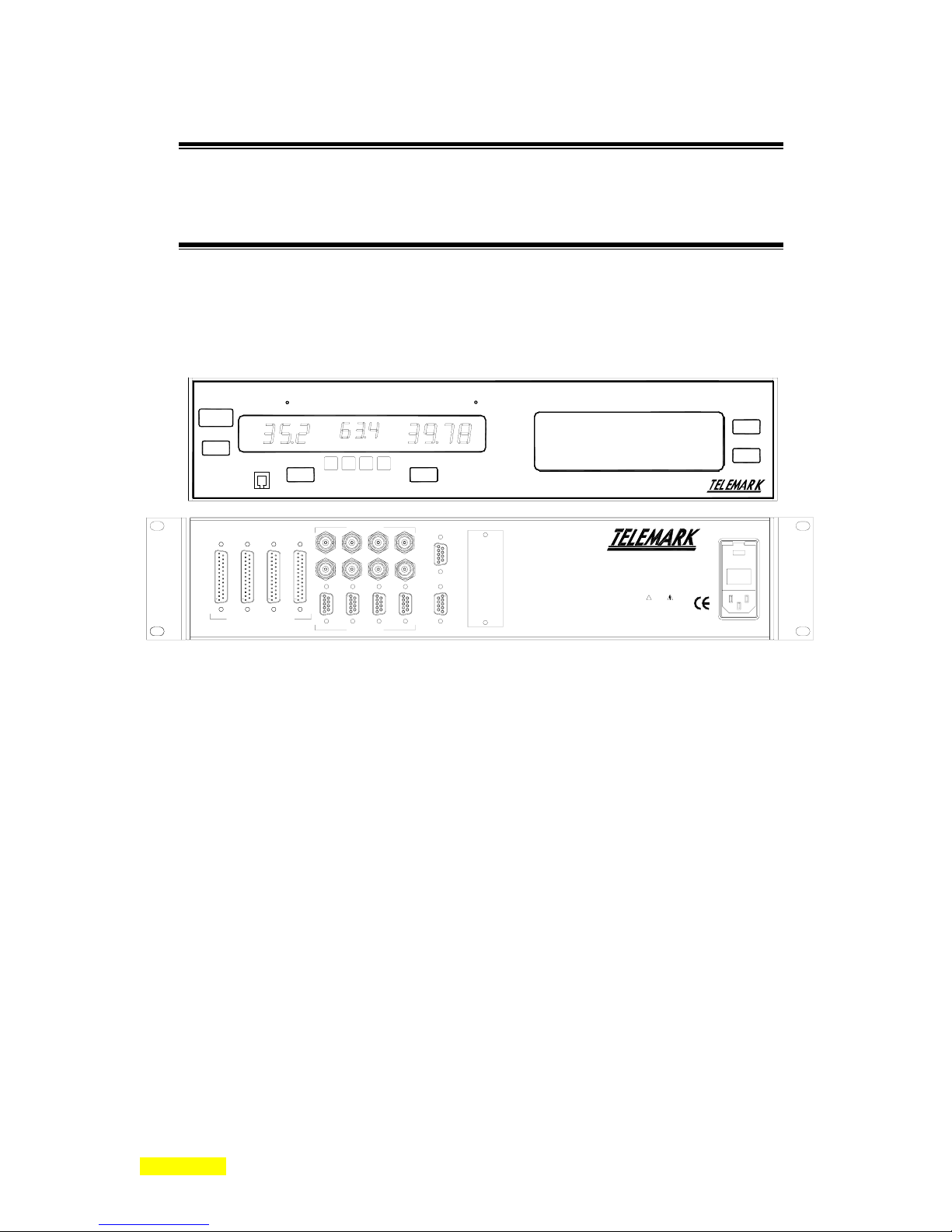

Telemark

Model 880

Thin Film

Deposition Controller

STOP

START

RATE-A/SEC POWER-% THICKNESS-KA

MANUAL

CONTROL

MANUAL

ZERO

MODEL 880

DEPOSITION CONTROLLER

MENU

STATUS

Users Manual

June 7 2003,

518-030 Preliminary

p

Model 880 DEPOSITION CONTROLLER

TFC-2002 JM

USERS MANUAL 518-030

Rev <preliminary> June 7, 2003

.current:

Telemark Model 880 Deposition Controller

>

y

RATE-A/SEC POWER-% THICKNESS-KA

MANUAL

MANUAL ZERO

CONTROL

I/O 4 1/O 3 I/O 2 I/O 1

INPUTS / OUTPUTS

SENSORS

7 5 3 1

8 6 4 2

7 5 3 1

8 6 4 2

SOURCE

RS232

MEM

COMM OPTION

MODEL 880

DEPOSITION CONTROLLER

FUSE: 2 x 2.00 AMP

QUICK-ACTING (F) 250v

90-264 vac, 50-60 Hz, 230VA MAX

!

WARNING

The power cord protective

grounding conductor must be

connected to ground. No user

serviceable parts inside. Refer

servicing to qualified personnel.

>

STOP

START

.overview w/ generalizations only

intro to user interface, overview from general to specific

=

overview w/ generalizations and intro to specifics as generalizations are developed.

Telemark reserves the right to change any information contained in this manual without notice

<

©

Copyright Sycon Instruments, Inc. & Telemark 2003

®

AMPHENOL

®

is a registered trademark of Tyco/Amp, Inc.

AMP

ConFlat

®

Is a registered trademark of IBM Corporation

IBM

Microsoft

Microdot

SWAGELOK

Windows

is a registered trademark of Allied Corporation

®

is a registered trademark of Varian Associates, Inc.

®

is a registered trademark of Microsoft Corporation

®

®

®

is a registered trademark of Microdot Inc.

is a trademark owned by Crawford Fitting Company

is a registered trademark of Microsoft Corporation

.

MENU

STATUS

SECTION 0.XX

e page 1 of 275 ^

p

Model 880 DEPOSITION CONTROLLER

y

Warranty

The model 880 Deposition Controller is guaranteed against faulty materials, function, and workmanship for

a period of 12 months after delivery from Telemark. Components which are purchased by Telemark from

other manufactures will be guaranteed for any lesser time that such manufacturer warrants its product to

Telemark. This warranty is valid only for normal use where regular maintenance is performed as instructed.

This warranty shall not apply if repair has been performed or an alteration made by anyone other than an

authorized Telemark representative or if a malfunction occurs through abuse, misuse, negligence, or

accident. No charge will be made for repairs made under warranty at Telemark's facilities. Freight costs

both ways will be at customer's expense. Telemark reserves the right for final warranty adjustment.

.

User Responsibility

The user is responsible for proper operation an ordinary maintenance of the equipment, following

procedures described in this manual, including reference documents. Proper operation includes timely

replacement of parts that are missing, broken, or plainly worn. If the user has a reasonable doubt about

understanding the use or installation of a component, Telemark Technical Service should be called.

It is vitally important that the user properly install the equipment as described in the Installation sections of

this manual. The warranty will be void if the equipment is improperly installed.

Alteration of the design or any function of the equipment voids the warranty and is entirely the

responsibility of the user.

Safety Warning

General Precautions: Human contact with the voltages present within and around a vacuum system can be

fatal. Make sure that the input power is turned off before opening the doors or removing panels. Short all

HV feedthrough connections with a grounding hook before accessing the controller main body.

Disclosure

The disclosure of this information is to assist owners of Telemark equipment to properly operate and

maintain their equipment, and does not constitute the release of rights hereof. Reproduction of this

information and equipment described herein is prohibited without prior written consent from Telemark.

SECTION 0.XX

e page 2 of 275 ^

p

Model 880 DEPOSITION CONTROLLER

y

SECTION 1.0

.specifications/included materials

(no intro here) unpacking.

Introduction

Unpacking

The Model 880

interfaces and analog outputs (see the following spare parts included list). If the essential OSC-100A

oscillator or crystals were ordered at the same time, they will also be included. The unit operates from 90

to 264 VAC with no adjustments required. If it is ever necessary to return the unit to Telemark, for any

reason, call and obtain a Return Material Authorization number (RMA#).

comes with a power cord and connectors for the RS-232 interface, the I/O

Description

The Model 880 provides both automatic control of single or multi-layer film deposition in either a

production or development environment and improved predictability and repeatability of deposited film

characteristics through dependable digital control of the deposition process. It runs unattended in the fully

automatic mode and provides a wide number of benefits including performance limit access and setting by

the end user.

SECTION 1.1

.[please read and understand this manual before proceeding w/ equipment useage].

Please read and understand the contents of this manual before proceeding with equipment useage in a

working system. This manual will take the reader through the appropriate setup and example steps,

providing along the way, an understanding of how the Model 880 instrument is used. A test mode is

available from the SERVICE menu for simulated out of system experiments. Crystal sensor head

information is simulated (actually rate info is simulated for the film) allowing setup of various

parameters/programming elements without crystal failure halting the simulated process. The power supply

control voltage output is, however, active while in the test mode. All these terms will be described shortly.

This manual is organized into a number of main sections: specifications, generalized overview,

menu programming specifics and setup, hardware setup, detailed host communications, microbalance

theory and maintenance. If any further assistance is needed, please contact Telemark (see section 1.6).

The specifications section describes Model 880 product specifics, both hardware and software,

along with related necessary and optional product specifics. The software specifics include programmable

parameter lists. The generalized overview section answers the what, the how is it used and the how does it

work questions about the Model 880, that is, the solutions this product can provide. This section is intended

to discuss the concepts of main functions and elements with only enough detail to make the

conceptualization clear. In addition, rudimentary specifics are given in a number of other areas as an

introduction or a primer for the next section. This is information you typically only need to look at once.

Experienced users (those familiar with deposition controllers) should at least thumb through this section to

take an inventory of what is available. The menu programming specifics and operational details section

provides detailed information about product programming. Experienced users (those familiar with

deposition controllers) may decide to start here. If some elements are unclear, check back to the previous

section. The table of contents and index are helpful in this pursuit. This section provides descriptions for the

programming of film parameters and process steps, descriptions of menu navigation, descriptions of

screens, descriptions of fixed front panel keys, descriptions of run modes, parameter details, memory

defaults, programming summaries, etc. The hardware setup section describes and illustrates connectors,

interconnections, peripherals, mechanical connections, and the Model 880 as a component in a larger

system. Detailed host communications are found in the following section x6. See section x7 for

MANUAL DESCRIPTION

SECTION 1.XX

e page 3 of 275 ^

p

b

Model 880 DEPOSITION CONTROLLER

Microbalance theory and thickness reading calibration with its attendant density, z factor (a material

reference table of elements is included) and tooling determination. Each section builds on the previous

sections such that no new elements are used that haven't been defined.

.Some sage advice that is

seldom heeded.

.

If all else fails

read the manual.

You can lead a customer to water

ut you can't make them read the

manual.

y

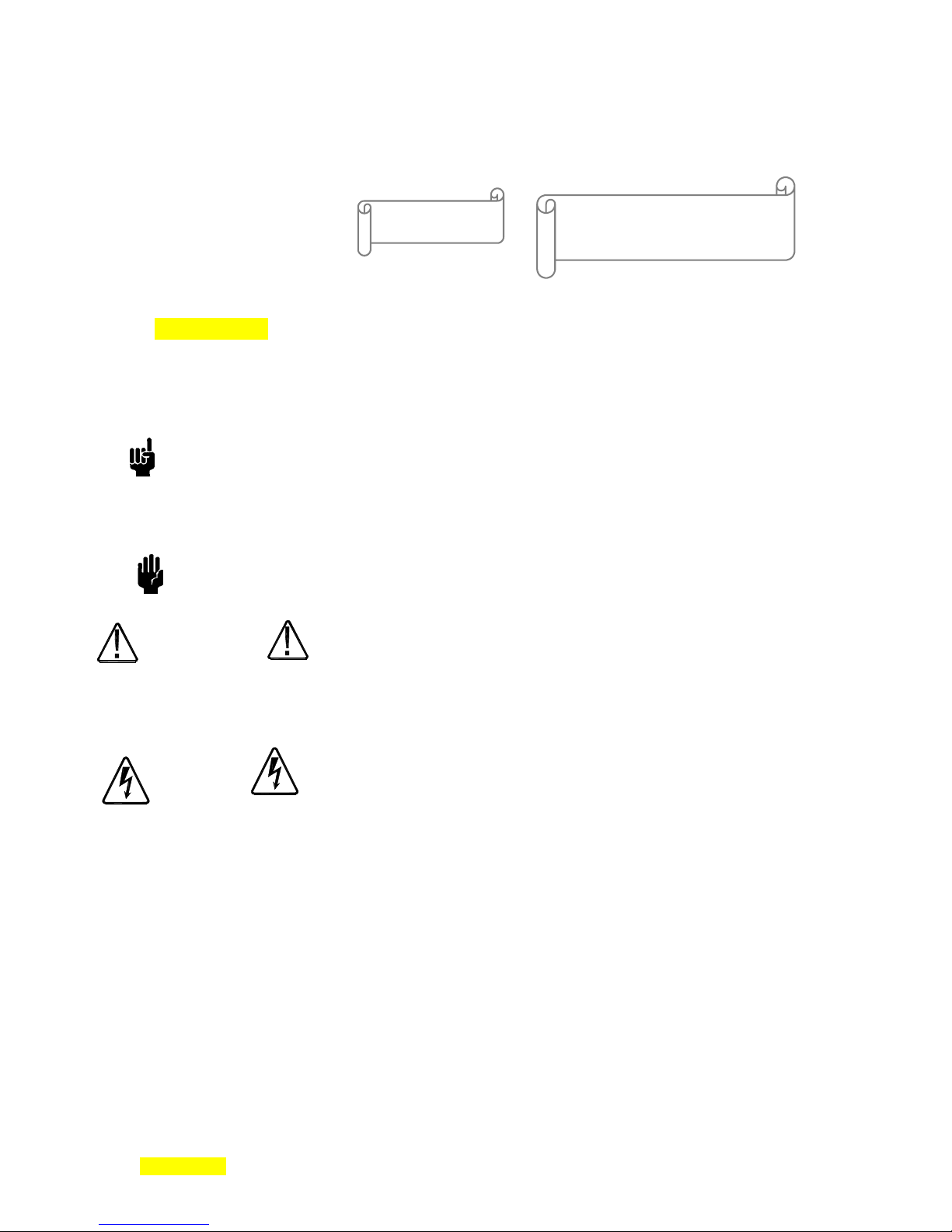

SECTION 1.2 DESCRIPTION OF SYMBOLS

Please familiarize yourself with the following warning/safety/caution symbols found within this manual

and their general meaning:

Note

Caution

Static

Sensitive

.note the following warning/safety/caution symbols [desc. of each].

Note: Highlights an important fact or condition.

Caution: Warns of a condition that could cause damage to deposition controller, connected or

associated equipment. Also warns if some action taken could result with an undesireable and/or

unexpected outcome.

or

: Warns of a condition that will likely cause damage to the deposition controller, connected or

!

associated equipment. Also warns of a possible unsafe situation for the user. Examples are static

sensitivities, maximum component ratings, broken fuses, etc.

or

Hazardous

Voltages

Present

SECTION 1.XX

: Warns of a condition that is hazardous to user, deposition controller, connected or associated

equipment.

e page 4 of 275 ^

p

Model 880 DEPOSITION CONTROLLER

y

SECTION 1.3

TABLE OF CONTENTS

TITLE PAGE................................................................................................................................................ 1

WARRANTY................................................................................................................................................ 2

INTRODUCTION [1.XX] ............................................................................................................................ 3

S

ECTION

1.0 ................................................................................................................................................ 3

Unpacking Instructions........................................................................................................................... 3

ECTION

S

1.1 ................................................................................................................................................ 3

Manual Description: Usage, Organization, Section Contents Summary ............................................... 3

ECTION

S

1.2 ................................................................................................................................................ 4

Description of Symbols Found in Manual .............................................................................................. 4

ECTION

S

ECTION

S

1.3

TABLE OF CONTENTS

...................................................................................................... 5

1.4 .............................................................................................................................................. 11

STC-Spare Parts (included w/ Model 880)........................................................................................... 11

STC-Optional Parts .............................................................................................................................. 11

ECTION

S

1.5 .............................................................................................................................................. 11

STC-Optional Crystal Sensor Parts...................................................................................................... 11

ECTION

S

1.6 .............................................................................................................................................. 12

Contact Information ............................................................................................................................. 12

ECTION

S

1.7 .............................................................................................................................................. 13

Product Specifications.......................................................................................................................... 13

S

ECTION

1.8 ............................................................................................................................................. 14

Programmable Parameter Lists........................................................................................................... 14

Programmable Parameter Dependency Lists ..................................................................................... 17

ECTION

S

1.9 .............................................................................................................................................. 19

Sensor Specifications............................................................................................................................ 19

SIMPLE QUICK GENERALIZED OVERVIEW [2.XX]..................................................................... 21

ECTION

S

2.0 .............................................................................................................................................. 21

For What Is The Model 880 Used? [The Problem, The Solution]........................................................ 21

ECTION

S

2.1 .............................................................................................................................................. 22

How Is It Used?.................................................................................................................................... 22

ECTION

S

2.2 .............................................................................................................................................. 26

How Does It Work? .............................................................................................................................. 26

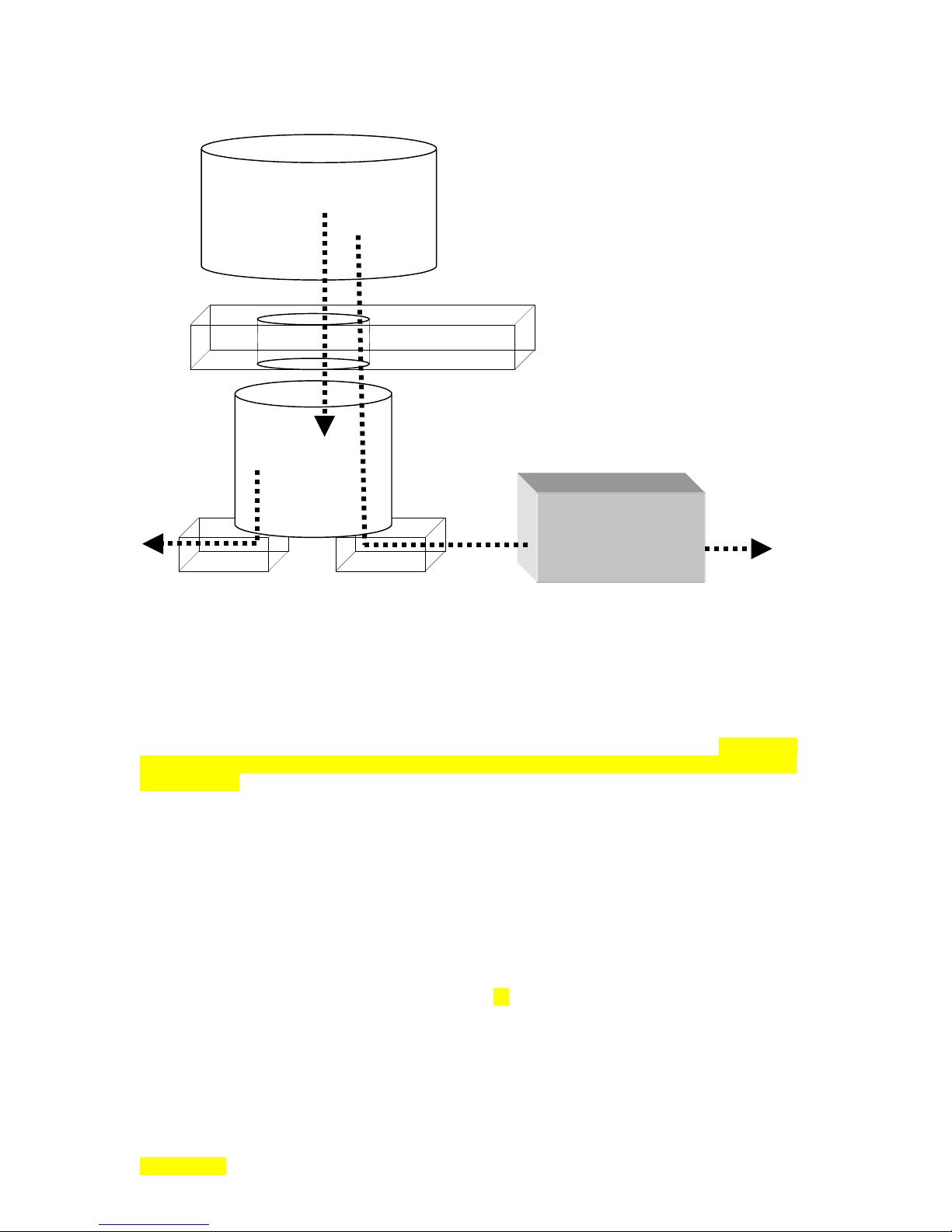

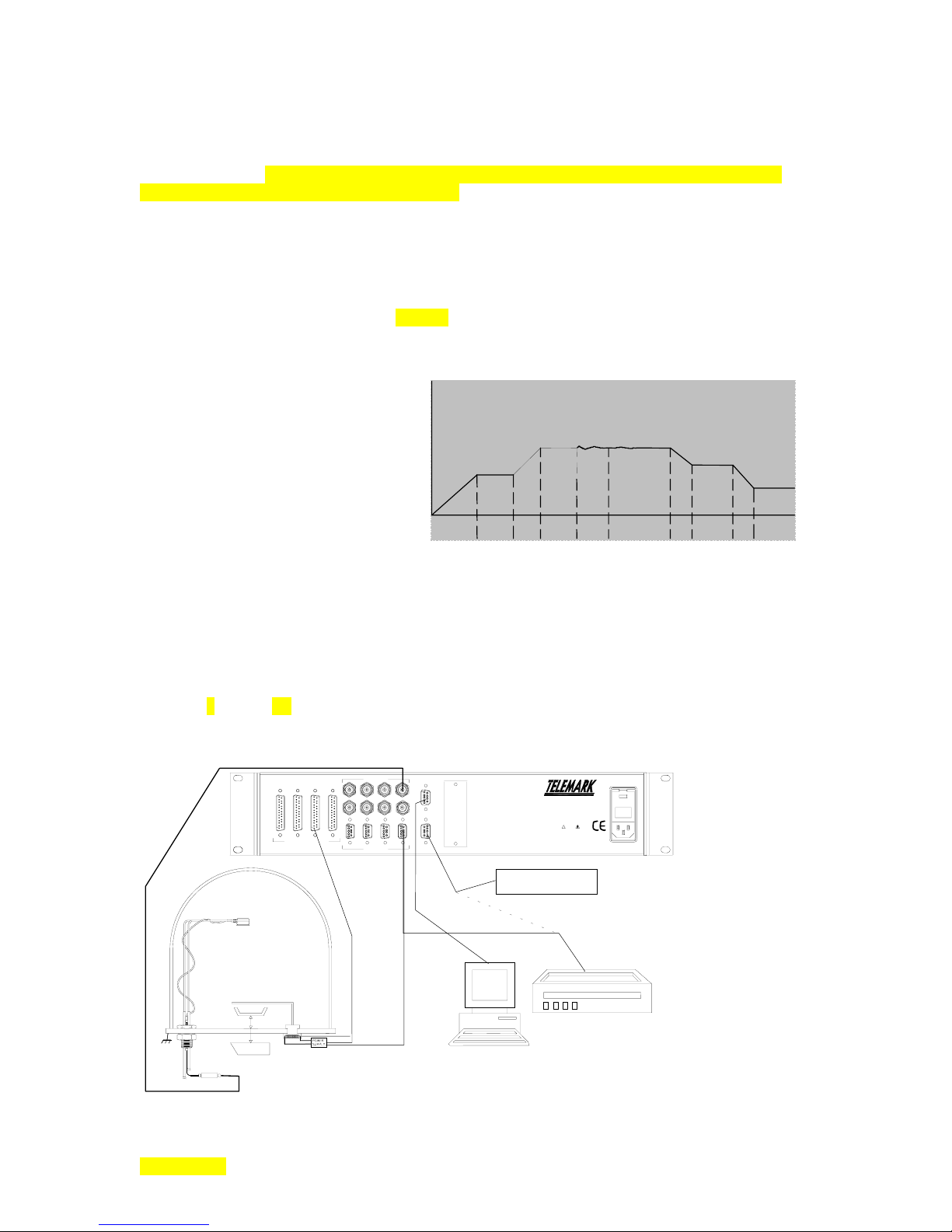

Hardware Setup Discussion ................................................................................................................. 29

Sensor Head: Hardware Generalizations............................................................................................. 30

Power Supply Connection .................................................................................................................... 32

Strip Chart Recorder Connection......................................................................................................... 32

RS-232 Communications Connection................................................................................................... 32

Grounding Stud .................................................................................................................................... 33

Input Card Options............................................................................................................................... 33

Installation/Removal Of Sensor Cards, Input Cards, Output Cards .................................................... 34

Pendant (hand controller) .................................................................................................................... 35

LCD Contrast/Bias ............................................................................................................................... 35

Graphical Display ................................................................................................................................ 35

Mounting .............................................................................................................................................. 35

System Hardware Connections............................................................................................................. 35

Programmable Hardware Setup Discussion ........................................................................................ 36

Select RunTime Mode: Sequencing/Non-Sequencing, Manual Mode, Test Mode............................................ 36

Memory Storage of Menu Parameters ............................................................................................................... 36

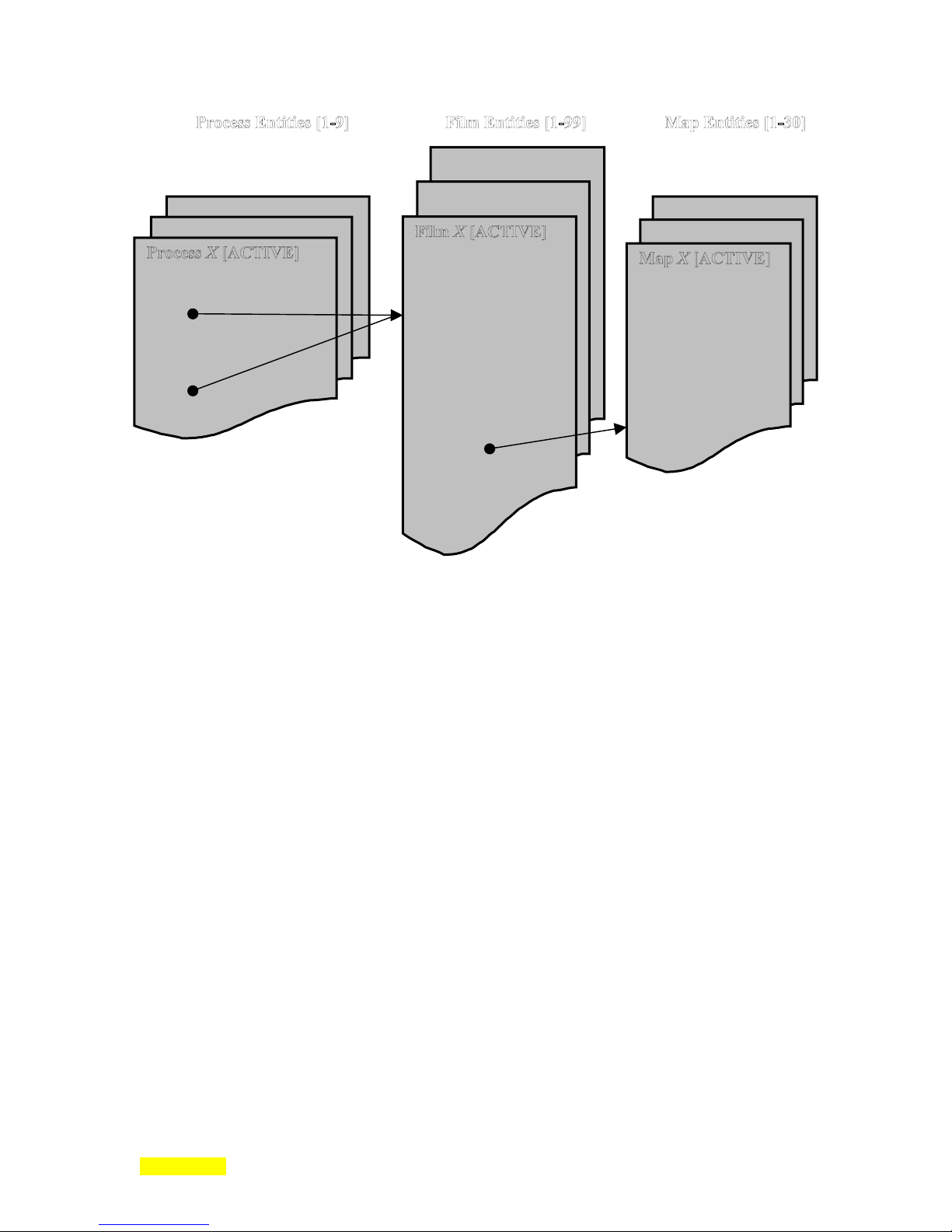

Films & Processes / Active, Non-Active ........................................................................................................... 36

Menu Parameter Dependencies.......................................................................................................................... 36

Tooling: Material Density & Z-Factor............................................................................................................... 37

SECTION 1.XX

e page 5 of 275 ^

p

Model 880 DEPOSITION CONTROLLER

Power Related Menu Parameters....................................................................................................................... 37

Power Related Menu Parameter Dependencies ................................................................................................. 38

y

Initial Programming Setups (menu parameters) .................................................................................. 40

Menu Parameter Values & Programming After Memory Purge........................................................................ 40

Menu Parameter Values & Programming After Factory Restored Memory ...................................................... 41

I/O Programming Introduction ............................................................................................................ 42

Boolean Logic Discussion ................................................................................................................................. 43

Simple I/O Program Examples .......................................................................................................................... 44

How To Develop I/O Programs............................................................................................................ 48

MENU PROGRAMMING AND OPERATION DETAILS [3.XX] ...................................................... 49

ECTION

S

3.0 .............................................................................................................................................. 49

LCD Touch Panel Overlay ................................................................................................................... 49

Front Panel Definitions ........................................................................................................................ 50

S

ECTION

3.1 .............................................................................................................................................. 56

Navigating Through Model 880 Menus................................................................................................ 56

Menu Tree............................................................................................................................................. 57

ECTION

S

3.2 .............................................................................................................................................. 58

RunTime Screen Description................................................................................................................ 58

ECTION

S

3.3 .............................................................................................................................................. 60

Main Menu Description........................................................................................................................ 60

ECTION

S

3.4 .............................................................................................................................................. 63

Films And Processes............................................................................................................................. 63

ECTION

S

3.5 .............................................................................................................................................. 63

Film Edit/Review Mode ........................................................................................................................ 63

Film Parameter Checksum................................................................................................................................. 67

Film Parameter Lock Code................................................................................................................................ 67

Film Parameter: Source Sensor Map Select....................................................................................................... 68

Review SS MAP................................................................................................................................................ 68

Selecting the Active Film in Non-Sequencing Mode......................................................................................... 69

Detailed Film Parameter Descriptions ................................................................................................ 71

Detailed Map Parameter Descriptions................................................................................................. 79

S

ECTION

3.6 ............................................................................................................................................. 83

Editing Processes................................................................................................................................. 83

Process Lock Code ............................................................................................................................................ 93

Factory Restoration vs. Purged Settings ............................................................................................................ 93

Changing Memory Settings ............................................................................................................................... 93

ECTION

S

3.7 .............................................................................................................................................. 93

Set Active Process................................................................................................................................. 93

ECTION

S

3.8 .............................................................................................................................................. 94

Non-Sequencing Differences ................................................................................................................ 94

ECTION

S

3.9 .............................................................................................................................................. 96

Software Controlled RunTime Screen Keys.......................................................................................... 96

L/Q key (Crystal Quality).................................................................................................................................. 96

SMPL key (Sample and Hold)........................................................................................................................... 96

ECTION

S

3.10 ............................................................................................................................................ 97

Manual Power Control......................................................................................................................... 97

Using Pendent.................................................................................................................................................... 97

Using LCD keys ................................................................................................................................................ 98

ECTION

S

3.11 ............................................................................................................................................ 99

Model 880 Shutter Delay...................................................................................................................... 99

ECTION

S

3.12 ............................................................................................................................................ 99

Deposition Source Control Loop Description ...................................................................................... 99

ECTION

S

3.13 .......................................................................................................................................... 101

Film Phases And Parameter Groups.................................................................................................. 101

ECTION

S

3.14 .......................................................................................................................................... 102

System Configuration ......................................................................................................................... 102

ECTION

S

3.15 .......................................................................................................................................... 103

SECTION 1.XX

e page 6 of 275 ^

p

Model 880 DEPOSITION CONTROLLER

y

Detailed System Configuration Related Parameters.......................................................................... 103

ECTION

S

3.16 .......................................................................................................................................... 105

Communications Configuration Related Parameters......................................................................... 105

Detailed Communications Configuration Related Parameters......................................................................... 106

ECTION

S

3.17 .......................................................................................................................................... 108

Model 880 Crystal Failure Processing............................................................................................... 108

ECTION

S

3.18 .......................................................................................................................................... 112

Process Accounting ............................................................................................................................ 112

ECTION

S

3.19 .......................................................................................................................................... 114

OPTions/INFo .................................................................................................................................... 114

Checksum Validation ........................................................................................................................ 115

Checksums And Parameters After Purge............................................................................................116

ECTION

S

3.20 .......................................................................................................................................... 118

Memory Module Programming & Usage........................................................................................... 118

Memory Module Data Transfer ....................................................................................................................... 120

Memory Module Placement............................................................................................................................. 121

ECTION

S

3.21 .......................................................................................................................................... 122

Programming Example....................................................................................................................... 122

Entering The TEST Mode................................................................................................................................ 122

ECTION

S

3.22 .......................................................................................................................................... 130

Product Programming Summary........................................................................................................ 130

ELECTRICAL CONNECTIONS AND DESCRIPTIONS [4.XX] ..................................................... 135

ECTION

S

4.0 ............................................................................................................................................ 135

Sensor Head Installation .................................................................................................................... 135

ECTION

S

4.1 ............................................................................................................................................ 138

Electrical Connections And Descriptions........................................................................................... 138

ECTION

S

4.2 ............................................................................................................................................ 138

Line Power ......................................................................................................................................... 138

ECTION

S

4.3 ............................................................................................................................................ 138

Rack Mounting.................................................................................................................................... 138

ECTION

S

4.4 ............................................................................................................................................ 138

Vacuum System Grounding ................................................................................................................ 138

ECTION

S

4.5 ............................................................................................................................................ 140

Sensor Connections ............................................................................................................................ 140

ECTION

S

4.6 ............................................................................................................................................ 140

Analog Control Voltage Connections................................................................................................. 140

Control Voltage Output Connection................................................................................................... 140

ECTION

S

4.7 ............................................................................................................................................ 141

Analog Recorder Output Connection ................................................................................................. 141

Analog Recorder Output Specifications ............................................................................................. 141

ECTION

S

4.8 ............................................................................................................................................ 143

I/O Interface ....................................................................................................................................... 143

ECTION

S

4.9 ............................................................................................................................................ 146

Relay Outputs (Factory I/O Program) ............................................................................................... 146

ECTION

S

4.10 .......................................................................................................................................... 147

Remote Inputs (Factory I/O Program) ............................................................................................... 147

ECTION

S

4.11 .......................................................................................................................................... 147

RS-232 Serial Communications Interface........................................................................................... 147

ECTION

S

4.12 .......................................................................................................................................... 148

Communications Options ................................................................................................................... 148

I/O PROGRAMMING [5.XX]................................................................................................................ 149

ECTION

S

5.1 ............................................................................................................................................ 149

I/O Programming Introduction .......................................................................................................... 149

ECTION

S

SECTION 1.XX

5.2 ............................................................................................................................................ 153

e page 7 of 275 ^

p

Model 880 DEPOSITION CONTROLLER

y

Boolean Definitions............................................................................................................................ 153

ECTION

S

5.3 ............................................................................................................................................ 154

States And Events ............................................................................................................................... 154

ECTION

S

5.4 ............................................................................................................................................ 159

Steady State vs. Edges ........................................................................................................................ 159

ECTION

S

5.5 ............................................................................................................................................ 159

Input Functions................................................................................................................................... 159

ECTION

S

5.6 ............................................................................................................................................ 160

Output Functions................................................................................................................................ 160

ECTION

S

5.7 ............................................................................................................................................ 160

Softnodes And Sync Events................................................................................................................. 160

ECTION

S

5.8 ............................................................................................................................................ 161

Internal Operations ............................................................................................................................ 161

ECTION

S

5.9 ............................................................................................................................................ 162

Operate Menu..................................................................................................................................... 162

ECTION

S

5.10 .......................................................................................................................................... 162

Memory Menu..................................................................................................................................... 162

ECTION

S

5.11 .......................................................................................................................................... 163

Editing An I/O Program ..................................................................................................................... 163

I/O Programming Tree....................................................................................................................... 165

ECTION

S

5.12 .......................................................................................................................................... 168

I/O Setup Edit Menu ........................................................................................................................... 168

ECTION

S

5.13 .......................................................................................................................................... 169

Edit/Change Menu.............................................................................................................................. 169

COMPUTER INTERFACING [6.XX].................................................................................................. 191

ECTION

S

6.0 ............................................................................................................................................ 191

Host Port Interface............................................................................................................................. 191

THEORY AND CALIBRATION [7.XX] .............................................................................................. 261

ECTION

S

EASUREMENT THEORY

7.0 M

.................................................................................................... 261

Equation 1 .......................................................................................................................................... 261

ECTION

S

7.1 C

ALIBRATION

..................................................................................................................... 262

Thickness ............................................................................................................................................ 262

Density Determination....................................................................................................................... 262

Z-Factor Determination ..................................................................................................................... 262

Tooling Dtermination ......................................................................................................................... 262

Material Reference Table:.................................................................................................................. 264

Aluminum Through Indium............................................................................................................................. 264

Indium Intimonide Through Terium................................................................................................................ 265

Thallium Through Zirconium Oxide................................................................................................................ 266

MAINTENANCE/PROBLEM SOLUTIONS [8.XX]........................................................................... 267

ECTION

S

8.0 ............................................................................................................................................ 267

Warnings/Cautions ............................................................................................................................. 267

User Correctable System Problems.................................................................................................... 267

ECTION

S

8.1 R

EPLACING

ENSOR CRYSTAL

A S

....................................................................................... 268

Cautions/Procedural Steps................................................................................................................. 268

ECTION

S

8.2

PERSISTENT CRYSTAL FAIL INDICATION

........................................................................ 268

Discussion .......................................................................................................................................... 268

Hardware Issues ................................................................................................................................. 269

ECTION

S

ECTION

S

8.3

8.4

SYSTEM BATTERY AND MEMORY CONSIDERATIONS

................................................................................................................................270

S

FAQ

..................................................... 270

Procedure to Change Battery ............................................................................................................. 270

GLOSSARY .............................................................................................................................................. 271

SECTION 1.XX

e page 8 of 275 ^

p

Model 880 DEPOSITION CONTROLLER

INDEX....................................................................................................................................................... 273

COPY PARAMETER LISTS.................................................................................................................. 274

y

FIGURES

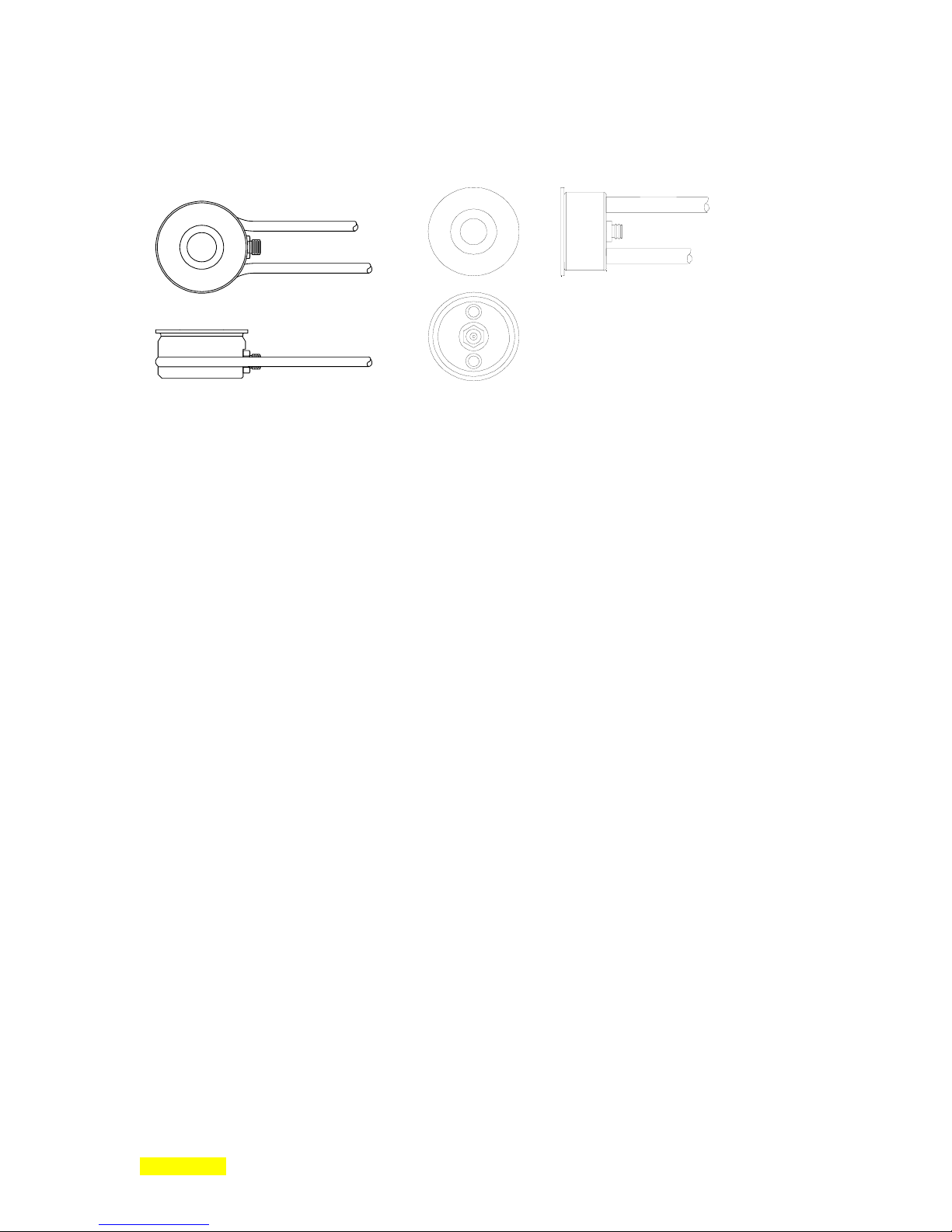

Standard Sensors.................................................................................................................................. 20

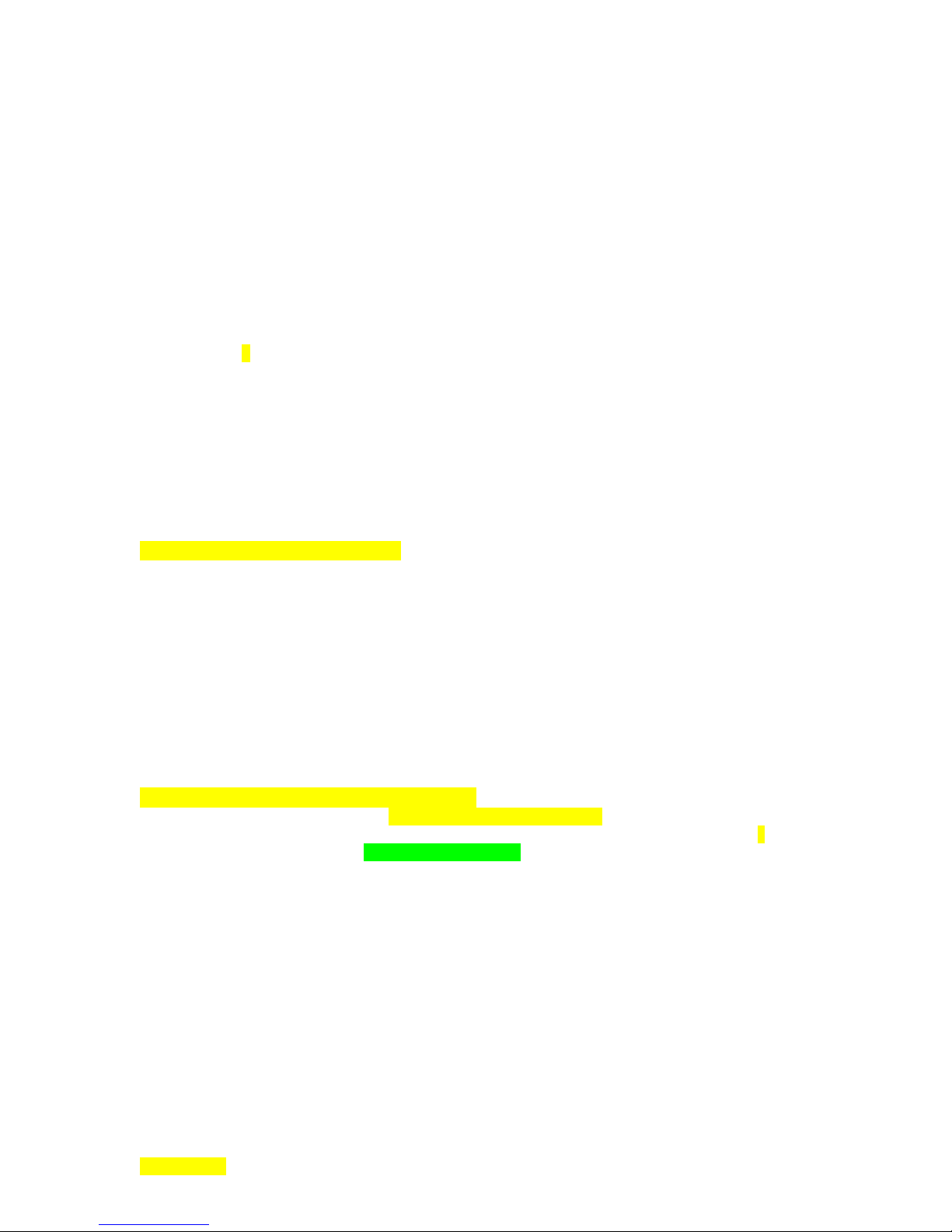

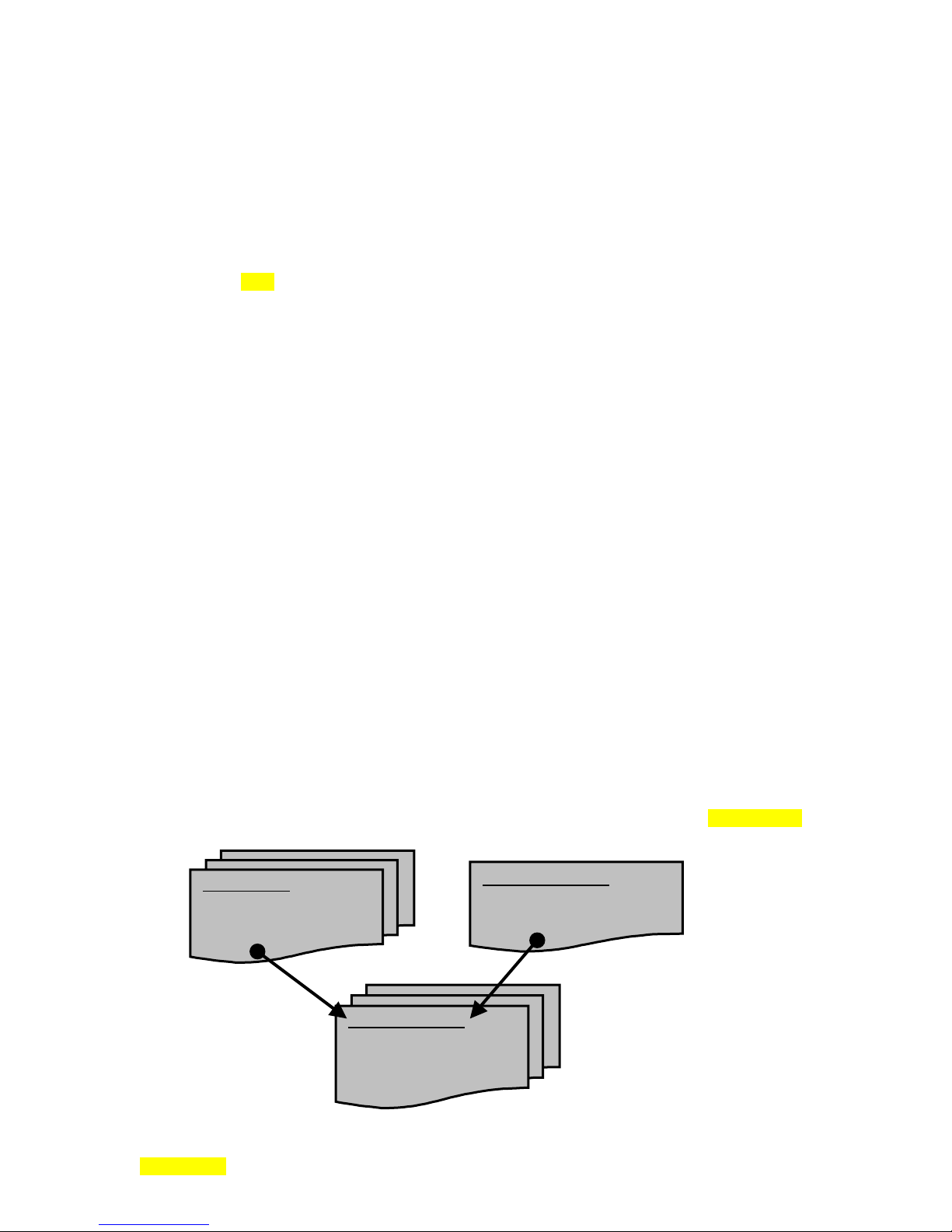

Sequencing / Non-Sequencing Modes................................................................................................... 23

Process / Film / Map Relationships...................................................................................................... 25

Back Panel Connections (Overview).................................................................................................... 29

Electrical Connections From Crystal Through Remote Oscillator (Overview) ................................... 30

Input Bd. Jumpers (Overview).............................................................................................................. 33

Installation/Removal Of Back Panel PCB Cards ................................................................................. 35

I/O Programming Notation .................................................................................................................. 44

I/O Programming Description.............................................................................................................. 44

I/O Programming: User Programmable Front Panel Keys/LEDs....................................................... 45

Example I/O Programs......................................................................................................................... 45

I/O Programming: Modulo 100 Counter Addresses............................................................................. 47

Touch Panel Overlay............................................................................................................................ 49

Front Panel and Key Descriptions ....................................................................................................... 50

Typical RunTime Screen....................................................................................................................... 50

Status Key Screens................................................................................................................................ 51

Manual Mode Screens .......................................................................................................................... 52

Status Screen Selector Function ........................................................................................................... 54

Start Key Menu..................................................................................................................................... 54

Start (Key) Process Flowchart ............................................................................................................. 55

Menu Tree............................................................................................................................................. 57

RunTime Screen.................................................................................................................................... 58

Main Menu Screen................................................................................................................................ 60

Executive Menu .................................................................................................................................... 62

Films & Process Storage...................................................................................................................... 63

Review Film Menu................................................................................................................................ 64

Non-Sequencing Mode Screen.............................................................................................................. 69

Rate Sampling, Sample And Hold Operation ....................................................................................... 75

Main Process Review/Edit Screen........................................................................................................ 83

Service Menu, Memory Configurations................................................................................................ 93

Setting the Active Process (Sequencing Mode)..................................................................................... 94

Setting The Active Film (Non-Sequencing Mode.................................................................................. 94

RunTime Screen (Non-Sequencing Mode)............................................................................................ 95

RunTime Screen: L/Q ........................................................................................................................... 96

RunTime Screen: Sample & Hold......................................................................................................... 96

Hand Controller/Pendent ..................................................................................................................... 97

Manual Power Control......................................................................................................................... 98

Typical Run Cycle............................................................................................................................... 101

System Configuration Screens............................................................................................................ 102

Communications Menu Screen ........................................................................................................... 105

Process Accounting Screens............................................................................................................... 112

Options Info Screens........................................................................................................................... 114

Memory Module.................................................................................................................................. 118

RunTime Screen With Test Mode Enabled ......................................................................................... 122

Electrical Connections To Back Panel............................................................................................... 135

Crystal Head Mounting ...................................................................................................................... 135

Rear Panel.......................................................................................................................................... 138

Recommended System Grounding ...................................................................................................... 139

SECTION 1.XX

e page 9 of 275 ^

p

Model 880 DEPOSITION CONTROLLER

y

Rate Mode Recorder Output............................................................................................................... 142

I/O: Input Configuration Jumpers...................................................................................................... 143

I/O: Input Configuration Jumpers...................................................................................................... 145

RS232 Interface Cable........................................................................................................................ 148

I/O Programming Menu Screen.......................................................................................................... 149

Relay Ladder Notation........................................................................................................................ 153

Stack I/O Operations .......................................................................................................................... 161

I/O Programming Menu Screen Descriptions .................................................................................... 163

I/O Programming Menu Tree............................................................................................................. 165

I/O Programming Menu Descriptions................................................................................................ 166

I/O Programming Edit Menu Description.......................................................................................... 168

I/O Programming EDT/CHG Screens 1-5.......................................................................................... 171

I/O Programming: I/O program Entry ............................................................................................... 174

I/O Programming: Inserting An Empty Rung..................................................................................... 179

I/O Programming: Changing the Rung ..............................................................................................179

I/O Usage of Hand Controller/Pendent.............................................................................................. 188

Making An RS232 Cable..................................................................................................................... 191

Communications Setup Mode ............................................................................................................. 193

Equation 1 .......................................................................................................................................... 261

Density Calculation............................................................................................................................ 262

Z-Factor Calculation.......................................................................................................................... 262

Typical Tooling Factors ..................................................................................................................... 263

Sensor Feedthrough Connections....................................................................................................... 269

TABLES

ACTORY SETTINGS

F

OOLEAN LOGIC

B

ACTORY SETTINGS

F

HASES AND PARAMETERS

P

HECKSUMS AFTER PURGED

C

RODUCT PROGRAMMING SUMMARY TABLES

P

ACTORY RELAY OUTPUT PROGRAM

F

RUTH TABLE

T

VENT AND STATE

E

VENT AND STATE

E

ACTORY INSTALLED

F

ODULO

M

IXED DELAY

F

ESPONSE CHARACTER TABLE

R

ATERIAL REFERENCE TABLE

M

......................................................................................................................................... 154

OUNTER PROGRAM

6 C

& P

ROCESS PROGRAMS

, P

............................................................................................... 41

....................................................................................................................................... 43

ROCESS PROGRAMS

, P

............................................................................................... 93

..................................................................................................................... 101

FTER FACTORY RESTORED MEMORY

/ A

................................................... 116

........................................................................................ 130

...................................................................................................... 146

IST

ID L

ID L

.................................................................................................................... 155

IST

.................................................................................................................... 158

ROGRAM

I/O P

....................................................................................................... 181

............................................................................................................. 185

ULSE WIDTH

I/O P

ROGRAM

........................................................................................ 186

............................................................................................................... 194

................................................................................................................ 264

SECTION 1.XX

e page 10 of 275 ^

SECTION 1.4

.included parts: STC-2002, power cord, spare parts.

p

Model 880 DEPOSITION CONTROLLER

y

Model 880 Spare Parts

POWER CORD [120 VAC] (1) 600-004

FUSES (2 x 2.00A 250VAC F-type) 356-014

OPTOCOUPLED INPUTS 25 PIN MALE CONNECTOR (1) 402-222

RELAY OUTPUTS 25 PIN FEMALE CONNECTOR (1) 404-020

EMI HOOD FOR 25 PIN CONNECTORS (2)..........................404-021

RS-232 9 PIN MALE CONNECTOR (1)..................................404-011

EMI HOOD FOR 9 PIN CONNECTOR (1)..............................404-009

RACK MOUNT EARS (2) ........................................................016-012

RACK MOUNT HDWR (4) ......................................................094-006

MANUAL (this manual)............................................................518-029

CONNECTOR KIT / PARTS ....................................................516-017

HAND CONTROLLER (1) .......................................................500-198

COMMUNICATIONS SOFTWARE TOOLS DISK (1)...........500-046

ASSEMBLY PART NUMBER

(included with Model 880)

Optional Model 880 Hardware / Software

MEMORY MODULE/STRIP CHART INTERFACE PCB 500-212

TRANSPORTABLE MEMORY MODULE (32K) ..................500-210

TRANSP. MEMORY MODULE SOFTWARE FOR PC..........500-TBD

TRANSP. MEMORY MODULE CABLE FOR PC..................500-TBD

SECTION 1.5

Optional Sensor Parts

Description................................................................. Telemark Part Number

Sensor Body (Low Profile) .......................................................550-222

Sensor Cap (Low Profile)...........................................................550-223

30 inch In-Vacuum Coax Cable ................................................500-024

10 inch In-Vacuum Coax Cable ................................................500-023

Crystals (box of 10) ...................................................................500-117

Standard Feedthroughs

1" BOLT STANDARD .............................................................500-016

2 3/4" ConFlat STANDARD ....................................................500-017

Standard Sensors

LOW PROFILE .........................................................................500-042

RIGHT ANGLE.........................................................................500-088

SECTION 1.XX

e page 11 of 275 ^

Model 880 DEPOSITION CONTROLLER

Cables

10' OSC TO CONTROL UNIT CABLE ...................................500-026

30' OSC TO CONTROL UNIT CABLE ...................................500-027

6" OSC TO FEEDTHROUGH COAX CABLE ........................500-025

Crystal / Oscillator Package

6" OSC TO FEEDTHROUGH COAX CABLE ........................500-025

10' OSC TO CONTROL UNIT CABLE ...................................500-026

OSCILLATOR UNIT ...............................................................OSC-100A

10 CRYSTALS ..........................................................................500-117

(includes the following 4 item numbers)

SECTION 1.6 Contact Information

Model 880

Model 880 DEPOSITION RATE CONTROLLER

Sensor Package and Feedthrough Not Included

500-109

Website www.telemark.com

SECTION 1.XX

page 12 of 275

p

Model 880 DEPOSITION CONTROLLER

y

SECTION 1.7 PRODUCT SPECIFICATIONS

Model 880 Thin-Film Thickness and Rate Controller Specifications

High Resolution ±0.02Hz(5-6MHz), 0.0088 Angstroms/Measurement (for Aluminum)

High Accuracy ±0.5% thickness + 1 count

High Speed Ten measurements/second

Measurement Range 500KA Aluminum Equivalent

Standard Sensor Crystal 6 MHz AT cut, Plano/Convex

Sensor Capacity 2 per sensor PCB card [4 PCB cards max.]

Displays 240 x 64 pixel monochrome LCD with Backlight

12 digit LED display (7 segments each digit)

4 discrete indicator LEDs

Operation Menu driven "Windowing Type"

LCD Touch Panel (12 x 4 key matrix)

with 6 fixed function membrane keys

and 4 user programmable fixed membrane keys

Film Storage (Standard) 1 Active Film Program

98 Alternate Film Programs (with 30 Sensor maps)

9 Sequence recipes, 99 steps per recipe, system total is 250 steps

External Storage (Optional) Film Parameters for films 1-99 and System Parameters I/O programs,

and Process Accounting Can be stored in Transportable Data Module

(Optional)

Hardware I/O (Standard) per card: 8 SPDT Relays, 1.0 Amp @ 24 VDC Maximum

per card: 8 Optocoupled Inputs (Electrically Isolated), 5-24VDC [4

slots for input and/or output cards]

Computer Interface RS-232C (Sycon Format or ASCII)

Protocols

Communication Options DeviceNet, PROFIBUS, CANopen, others

Analog Outputs: 12 bit resolution (2 per sensor card, each for use as control or recorder)

As Control Outputs 2.5, 5, 10 volt @10ma. isolated output with range

menu programmable (maximum 2 control outputs per sensor card)

As Recorder Outputs 0 to 10 volt @ 10ma, isolated, function programmable

(rate, thickness, power, deviation, computer remote) (maximum 1

recorder output per sensor card and per system)

Power Control:

Automatic Three Mode Closed Loop Control (PID)

Manual Hand Controller

Rack Mount full width rack mount (std.). 3

Power Requirements 90-264VAC, 50-60Hz (

1.4A rms@120VAC, 0.7A rms@230VAC)

Weight (without options) 6 lbs. [with: 1 Sensor card, 1 Input Card, 1 Output Card]

card=0.216 lbs., Input card=0.135 lbs., Output card=0.14 lbs.

Operating Range 0 to 50°C ambient (power supply/LCD display)

Humidity non-condensing: 5% - 85% RH

1/2

" H, 8

5/8

" D

Sensor

SECTION 1.XX

e page 13 of 275 ^

p

Model 880 DEPOSITION CONTROLLER

y

SECTION 1.8

.programmable parameter list (1.4).

__________________________________________________________________

key examples:

Full Parameter Name

Parameter Name ⇒ Param N

(text) ⇒ implied parameter text in parenthesis

__________________________________________________________________

Film Parameter List:

Review Film (Edit Film)

(Material) Density 0.40 to 99.99 gm/cc

(Material) Z-Factor 0.100 to 9.999

Setpoint Thickness Limit 0.000 to 999.999 KÅ

Final Thickness Limit (Trigger) 0.000 to 999.999 KÅ (non-sequencing only)

Setpoint Time Limit 0:00 to 99:59 MM:SS

Soak 1 Power level Value 0.0 to 100.0%

Power Ramp 1 Time (to pwr level) 0 to 99:59 MM:SS

Power Soak 1 Time (@ pwr level) 0 to 99:59 MM:SS

Soak 2 Power level Value 0.0 to 100.0%

Power Ramp 2 Time (to pwr level) 0 to 99:59 MM:SS

Power Soak 2 Time (@ pwr level) 0 to 99:59 MM:SS

Soak 3 Power level Value 0.0 to 100.0%

Power Ramp 3 Time (to pwr level) 0 to 99:59 MM:SS

Deposit Rate (requested) 0.0 to 999.9 A/S

Rate Ramp Mode OFF / ON

New Deposit Rate (Value) 0.0 to 999.9 A/S

Rate Ramp Time (Duration) 0:00 to 99:59 MM:SS

Rate Ramp (Thickn) Trigger Point 0 to 999.999 KÅ

Control Loop –Proportional term- 1 to 9999

Control Loop –Integral term- 0.0 to 99.9 sec

Control Loop –Derivative term- 0.0 to 99.9 sec

Max Power Limit 0.0 to 100.0%

Abort Max Power SWitch OFF/ON

Max Power Dwell 0:01-99:59 MM:SS

Shutter Delay Mode OFF, ON

Shutter Delay TIMEOUT 0:01-99:59 MM:SS

Shutter Delay QUALITY 1-50%

(XTAL) RATE SAMPLING OFF,TIMED,INTELL.

(XTAL) SAMPLE INTERVAL 0:01-99:59 MM:SS

(XTAL) SAMPLE DWELL TIME 0:01-99:59 MM:SS

(XTAL) SAMPLE QUAL 1-50%

(XTAL) SAMPLE ALARM TIME 0:01-99:59 MM:SS

FILM Fail Mode ABORT IF FAIL, TIME POWER

Control Loop Qual Limits 0 to 9

XTAL Stability S (Limits) 0 to 9

XTAL Life Bounds 0.0-100.0%

Plot Vert Scale Volts 1, 5, 10, 50, 100

Plot Horiz Scale H 1 to 600 samples

Data Plot Type Rate /Rate Deviation /Power

Programmable Parameter Lists

⇒ Abbreviated Menu Name

[Menu end point: Review Film Menu path: Main/Review Film]

SECTION 1.XX

e page 14 of 275 ^

p

Model 880 DEPOSITION CONTROLLER

y

Source Sensor MAP SELECT 1 - 30

POCKET SELECT 0 – 63 Pockets

ETCHING MODE OFF/ON

Process Step elements:

Review Processes (Edit Process) (Edit Process Steps [1-99]) Mode (Skip, Stop, Auto,

[Menu end point: Review Processes Menu path: Main/Review Processes]

End, Wait), Film# (1-99), Thickness (0.0 - 999.999 KÅ)

Main Menu values:

[Menu end point: Main Menu Menu path: fixed front panel MENU key/ Main Menu]

Next Active Process (Select)* 1 of 9 processes [sequencing mode only]

Next Active Film (Select)* 1 of 99 films [non-sequencing mode only]

[*NOTE: press touch key enclosing digit to select 1 of the 9 processes or 99 films (press digits + ENTer on invoked submenu)]

RunTime Screen parameters:

[Menu end point: RunTime screen Menu path: programming Menu/ fixed front panel STATUS key/RunTime screen]

(Crystal Quality Indicator Select) L/Q, Loop x, Qual xx

(Crystal Sample Select) (not selected [blank]), SMPL, SMPL+Time, HOLD+Time

START key sequence

STOP key

MANUAL key

ZERO key

MENU key

STATUS key

(fixed front panel)

(fixed front panel)

(fixed front panel)

(fixed front panel)

(fixed front panel)

(fixed front panel)

Zeroes the thickness value

Switches from RunTime screen to MAIN menu screen

PROCess X:

(Note

Stops the running process

message change after each START process key press)

(non-seq mode: stops the 1 inherent process [film])

Switches to manual mode from a running process only. Toggle action.

Switches to RunTime screen from any menu screen, to detailed power

and crystal info screens from RunTime screen

Zero Power

Zero Thickness

Force Fail

1

Zero thickness does not affect film thickness value, only Source Sensor card value (use to set tooling factor, diagnose

problems, etc. )

2

If the PROCess X: status message does not change when the START key is pressed, check for "STOP: INValid XXX "

message or check the OPT/INF menu, page 2 for cards not installed which are enabled in software (MIA). Cycle AC power

OFFON to re-sync.

System Configuration values:

[non-active process]

1

zero channel 1-8, zero all, re-verify

[non-active process]

zero channel 1-8, zero all [1st STATUS key press from RunTime]

fail channel 1-8, fail all, re-verify

[Menu end point: System Config Menu path: Main/Executive menu/System Configuration]

[2nd STATUS key press from RunTime]

[2nd STATUS key press from RunTime]

LCD Contrast / Bias LOW, MEDIUM, HIGH

Password Lock # 0 - 9999

(Process) Run Number 0 to 9999

Recorder Function

Recorder Out Channel

Absolute Rate, Rate Deviation, Power, Thickness, Computer Remote, I/O Control, Off

1 – 8 selects an analog output channel for use (if not off and not used as a source)

Real Clock Time HH/MM

Real Clock Date MM/DD/YY

Need Source/Sensor Card 1 OFF/ON

Need Source/Sensor Card 2 OFF/ON

Need Source/Sensor Card 3 OFF/ON

Need Source/Sensor Card 4 OFF/ON

I/O Slot 1 Type UNUSED (DISABLED) / INPUT / OUTPUT

I/O Slot 2 Type UNUSED (DISABLED) / INPUT / OUTPUT

I/O Slot 3 Type UNUSED (DISABLED) / INPUT / OUTPUT

I/O Slot 4 Type UNUSED (DISABLED) / INPUT / OUTPUT

Memory Module IFC OFF/ON

Communication values:

[Menu end point: Comm. Setup Menu path: Main/Executive menu/Communications Setup]

COM/IO Lock Code 0 - 9999

Keyboard Beep OFF / ON

RS232 Baud Rate 300, 1200, 2400, 9600

RS232 Protocol Sycon, ASCII

2

SECTION 1.XX

e page 15 of 275 ^

p

Model 880 DEPOSITION CONTROLLER

y

Source Sensor Map elements:

[Menu end point: Review SS Map Menu path: Main/Review SS Map]

Source Sensor Full Power Volts 2.5, 5, 10 full scale volts

Source Sensor Max Power Value 0.0% - 100.0%

Source Sensor Analog Output Chnl 1 – 8 Channel Selection

Master Tooling Value 10.0% - 400.0%

Minimum Start Xtal Channels 1 – 8 minimum channels

Minimum Backup Xtal Channels 0 – 7 minimum channels

Minumum Active Xtal Channels 1 – 8 minimum channels

(Xtal) Channel Drop Filter NONE, BALANCE

[Mask dropped Xtal channel Failure]

averaging mode only

Indexer Synchronization Mode NONE, DELAY, FEEDBACK

Indexer Synchronization Time 2 – 999 seconds

Channel 1 Start Mode OFF, ACTIVE, STANDBY

Channel 1 Fail Action (Mode) NONE, ABORT FILM

Channel 1 Backup List X – XXXXXXXX (1 item list to 8 item list), [where X = 1 to 8 (in

each position w/o redundancies, list extends to 0-8 for a 1 item list)]

Channel 1 Tooling Value 10.0% - 400.0%

Channel 1 Weight 10.0% - 400.0%

Channel 2 Start Mode OFF, ACTIVE, STANDBY

Channel 2 Fail Action (Mode) NONE, ABORT FILM

Channel 2 Backup List X – XXXXXXXX,

[X = 1 to 8 (in each position w/o redundancies)] see CH1

Channel 2 Tooling Value 10.0% - 400.0%

Channel 2 Weight 10.0% - 400.0%

Channel 3 Start Mode OFF, ACTIVE, STANDBY

[need 2nd Source Sensor Card for Channels 3 & 4]

Channel 3 Fail Action (Mode) NONE, ABORT FILM

Channel 3 Backup List X – XXXXXXXX,

[X = 1 to 8 (in each position w/o redundancies)] see CH1

Channel 3 Tooling Value 10.0% - 400.0%

Channel 3 Weight 10.0% - 400.0%

Channel 4 Start Mode OFF, ACTIVE, STANDBY

Channel 4 Fail Action (Mode) NONE, ABORT FILM

Channel 4 Backup List X – XXXXXXXX,

[X = 1 to 8 (in each position w/o redundancies)] see CH1

Channel 4 Tooling Value 10.0% - 400.0%

Channel 4 Weight 10.0% - 400.0%

Channel 5 Start Mode OFF, ACTIVE, STANDBY

[need 3rd Source Sensor Card for Channels 5 & 6]

Channel 5 Fail Action (Mode) NONE, ABORT FILM

Channel 5 Backup List X – XXXXXXXX,

[X = 1 to 8 (in each position w/o redundancies)] see CH1

Channel 5 Tooling Value 10.0% - 400.0%

Channel 5 Weight 10.0% - 400.0%

Channel 6 Start Mode OFF, ACTIVE, STANDBY

Channel 6 Fail Action (Mode) NONE, ABORT FILM

Channel 6 Backup List X – XXXXXXXX,

[X = 1 to 8 (in each position w/o redundancies)] see CH1

Channel 6 Tooling Value 10.0% - 400.0%

Channel 6 Weight 10.0% - 400.0%

Channel 7 Start Mode OFF, ACTIVE, STANDBY

[need 4th Source Sensor Card for Channels 7 & 8]

Channel 7 Fail Action (Mode) NONE, ABORT FILM

Channel 7 Backup List X – XXXXXXXX,

[X = 1 to 8 (in each position w/o redundancies)] see CH1

Channel 7 Tooling Value 10.0% - 400.0%

Channel 7 Weight 10.0% - 400.0%

Channel 8 Start Mode OFF, ACTIVE, STANDBY

Channel 8 Fail Action (Mode) NONE, ABORT FILM

Channel 8 Backup List X – XXXXXXXX,

[X = 1 to 8 (in each position w/o redundancies)] see CH1

Channel 8 Tooling Value 10.0% - 400.0%

Channel 8 Weight 10.0% - 400.0%

SECTION 1.XX

e page 16 of 275 ^

p

Model 880 DEPOSITION CONTROLLER

y

I/O Function elements:

I/O Relay Functions user I/O program

[Menu end point: I/O Setup Menu path: Main/Executive menu/ I/O Setup]

(8 Form C Relays per card [4 slots available for I or O cards])

I/O Input Functions user I/O program + PCB jumpers

(8 Inputs per card [4 slots for I or O cards])

I/O Setup Memory: save/swap, Operate: run/stop

I/O Programming Edit (Program): IN, NOT, AND, OR, XOR, POSitive, NEGative,

OUT, TRiP, SET, CLeaR, ARM, DRoP, (events/states/logical

operators), (softnodes) and (numeric elements).

Arithmetic operators/elements: KON# (to input constants), ADD,

SUBtract, MULtiply, DIVide, MODulus, EQUals, GReaTer than,

LESs than, and SELect. Editing: backspace, left/right arrows (to move

cursor), delete, undo, insert/delete line.

(Front Panel LEDs [4 discrete]) I/O programming elements (see table x in section 5xx and Section 2.2)

(User Front Panel Keys [4]) I/O programming elements (see table x in section 5xx and Section 2.2)

Pendent Keys (beyond specified Manual Mode use: I/O programming elements

[see table xxx in section 5xx ])

Service Menu values:

[Menu end point: Service Menu path: Main/Service]

(Test Mode Select) Test Off, Test On [Test Mode won't remain in effect if power is cycled)

(Seq/Non-seq Mode Select) Seq(uencing Mode Select en)able, Non-seq(uencing Select enabled)

(Memory Contents) as is (no modification), purged, factory (defaults) [see section x.2.2xx ]

(Reset) Arm reset, reset armed [Provide a product reset when back panel power

switch is not accessible. Also, use to generate ACCEPT key if not

present (e.g. to end the Test mode when in the Test mode).]

<<< move the following depenency lists to end of section 2.22? >>>

[Prerequisite states that must be in effect for the following parameters to be fully functional]

Film Parameter Dependency List:

Material Density Not Applicable

Material Z-Factor N.A.

Setpoint Thickness Limit N.A.

Final Thickness Limit (Trigger) Service Menu Parameter: Non Seq / Accept (Bug: 2

Setpoint Time Limit N.A.

Soak 1 Power level Value N.A.

Power Ramp 1 Time (to pwr level) N.A.

Power Soak 1 Time (@ pwr level) N.A.

Soak 2 Power level Value N.A.

Power Ramp 2 Time (to pwr level) N.A.

Power Soak 2 Time (@ pwr level) N.A.

Soak 3 Power level Value N.A.

Power Ramp 3 Time (to pwr level) N.A.

Deposit Rate (requested) N.A.

Rate Ramp Mode N.A.

New Deposit Rate Value Film Parameter: Rate Ramp Mode = ON

Rate Ramp Time Duration Film Parameter: Rate Ramp Mode = ON

Rate Ramp (Thickn) Trigger Point Film Parameter: Rate Ramp Mode = ON

Control Loop –Proportional term- N.A.

Control Loop –Integral term- N.A.

Control Loop –Derivative term- N.A.

Max Power Limit N.A.

Abort Max Power SW N.A.

Max Power Dwell Film Parameter: Abort Max Power SW = ON

nd

µP not reset)

SECTION 1.XX

e page 17 of 275 ^

p

Model 880 DEPOSITION CONTROLLER

y

Shutter Delay Mode N.A.

Shutter Delay TIMEOUT Film Parameter: Shutter Delay Mode = ON

Shutter Delay QUALITY Film Parameter: Shutter Delay Mode = ON

(XTAL) RATE SAMPLING N.A.

(XTAL) SAMPLE INTERVAL (Film Parameter: (XTAL) RATE SAMPLING = Timed

or

Film Parameter: (XTAL) RATE SAMPLING = Inteli)

(XTAL) SAMPLE DWELL TIME Film Parameter: (XTAL) RATE SAMPLING = Timed

(XTAL) SAMPLE QUAL Film Parameter: (XTAL) RATE SAMPLING = Inteli

(XTAL) SAMPLE ALARM TIME Film Parameter: (XTAL) RATE SAMPLING = Inteli

FILM Fail Mode N.A.

Control Loop Qual Limits N.A.

XTAL Stability S Limits N.A.

XTAL Life Bounds N.A.

Plot Vert Scale Volts N.A.

Plot Horiz Scale H N.A.

Data Plot Type N.A.

Source Sensor MAP SELECT N.A.

POCKET SELECT N.A.

ETCHING MODE N.A.

Main Menu value Dependency List:

Next Active Process (Select)

If N/A, must use START + Reset / Start Proc keys to start a process.

Next Active Film (Select)

1

Service Menu: Sequence Able + Accept keys (for Sequencing Mode)2

1

Service Menu: Non-Sequence + Accept keys (Non-Sequencing Mode)2

Review Process (Select) Service Menu: Sequence Able + Accept keys (for Sequencing Mode)

Review Film (Select) N.A.

Review Source/Sensor Map (Sel)

[NOTE1: press to invoke number entry submenu, sequence of 1 or 2 digits is entered or discarded]

N.A.

Note2: [the Seq Able / Non Seq key shows the current mode upon entry into the

Service menu, changing the mode toggles key text and generates the Accept

key that in turn needs to be pressed to accept new mode described on the key

in text]

RunTime Screen parameter Dependency List:

(Crystal Quality Indicator Select) L/Q, Loop x, Qual xx Film Parameters

(Crystal Sample Select) Film Parameter: (XTAL) Rate Sampling = Timed or Intelligent?

Running in deposit mode

(Crystal Select) System Config Parameter: Need Source/Sensor Card X

Review Source Sensor Map Element Parameters:

Minimum Start Xtal Channels

Minumum Active Xtal Channels

Channel X Start Mode

(Process X) Main Menu Parameter: [Next Process] Digit

Fixed Front Panel START key: sequence from N/A to 1

Service Menu: SEQuence enABLE

Layer X (layer = step) Review Processes X: EDIT: CHANGE, INSERT, DELETE

Service Menu: SEQuence enABLE

FILM Review Processes X: EDIT: CHANGE, INSERT, DELETE films

Review Film X:

[non-sequencing mode]

(Manual mode) Running Process + Pressing fixed front panel MANUAL key +

attached Pendent

[sequencing mode]

[sequencing mode]

Layers/steps

[sequencing mode]

2

SECTION 1.XX

e page 18 of 275 ^

p

Model 880 DEPOSITION CONTROLLER

y

MAP# Film Parameter: Review Source/Sensor Map Select