Teledyne TapTone T4000 APX Installation Manual

TapTone T4000 APX

Installation

Manual

M-412-073

Rev. B

This page left blank.

TapTone T4000 APX

Installation Manual

M-412-073

Rev. B

(English)

North Falmouth, Massachusetts

TELEDYNE TAPTONE

49 Edgerton Drive

02556-2828 USA

Phone: 508-563-1000

Fax: 508-564-9945

www.taptone.com

This page left blank

M-412-073 Table of Contents

Table of Contents

1.0 Introduction ................................................................................... 1

1.1 T4000 ACX Acoustic / Cocked Crown / X-Ray Inspection System .. 1

1.2 T4000 PX Proximity / X-ray Inspection System ................................ 2

1.3 T4000 SSV-X Fill_xr Level Inspection System ................................. 3

2.0 Safety Precautions ........................................................................ 4

2.1 General Safety Precautions ............................................................. 4

2.2 Specific Cautions and Warnings ................................ ...................... 5

2.3 Safety Label Descriptions ................................................................ 5

2.4 System Lockout / Tag-out Procedure ............................................... 7

3.0 Installation Instructions ................................................................ 8

3.1 T4000 Sensor Configurations .......................................................... 8

3.1.1 Acoustic Configuration (T4000 A) .............................................. 8

3.1.2 Acoustic/Cocked Crown Configuration (T4000 AC) ................... 9

3.1.3 Proximity Configuration (T4000 P) ........................................... 10

3.1.4 Dual Proximity Configuration (T4000 DP) ................................ 11

3.1.5 X-ray Configuration (T4000 X) ................................................. 12

3.1.6 Acoustic/X-ray Configuration (T4000 AX) ................................ 13

3.1.7 Proximity/X-ray Configuration (T4000 PX) ............................... 14

3.1.8 Acoustic/Cocked Crown/X-ray Configuration (T4000 ACX) ..... 15

3.1.9 Acoustic/Proximity/X-ray Configuration (T4000 APX) .............. 16

3.2 T4000 AC, P Stand Installation ...................................................... 17

3.2.1 RTV Crank Stand Installation .................................................. 17

3.2.2 Conveyor Mount Frame Installation (CMS) .............................. 19

3.3 T4000 X-ray Installation ................................................................. 21

3.3.1 Key Points to X-ray Sensor Installation.................................... 21

3.3.2 Stand Tube Cutting Procedure ................................................ 21

3.3.3 Stand Assembly Procedure ..................................................... 22

3.3.4 X-Ray Sensor Installation Procedure ....................................... 23

3.3.5 X-ray Detector Mask Installation .............................................. 24

3.4 Rejector Assembly Installation ....................................................... 25

3.4.1 Ram Installation....................................................................... 26

3.4.2 Air Regulator Installation ......................................................... 27

3.4.3 Connecting the Air ................................................................... 28

3.4.4 Rejector Electrical Connection................................................. 29

3.5 Shaft Encoder Installation ............................................................. 30

3.5.1 Shaft Encoder Mechanical Specifications ................................ 30

TELEDYNE TAPTONE i

M-412-073 Table of Contents

3.5.2 Shaft Encoder Electrical Specifications ................................... 30

3.5.3 Shaft Encoder Installation Instructions..................................... 31

3.5.4 Electrical Connections ............................................................. 32

3.6 Electrical Power Connections ........................................................ 33

3.6.1 AC Power Connections ........................................................... 33

3.6.2 Sensor Cable Connections ...................................................... 35

3.7 Initial Mechanical Setup ................................................................ 37

3.7.1 Acoustic Sensor Setup ............................................................ 37

3.7.2 Cocked Crown Sensor Setup .................................................. 37

3.7.3 Proximity Sensor Setup ........................................................... 37

3.7.4 X-ray Setup ............................................................................. 38

3.7.5 Reject Acknowledge Sensor Setup ......................................... 39

3.7.6 Trigger Sensor Setup .............................................................. 39

3.7.7 Trigger Timing Setup ............................................................... 40

Appendix A – Warranty .......................................................................... 42

Appendix B – Technical Specifications ................................................ 43

B.1 Electronic Control Box Specifications ............................................ 43

B.2 Fill_xr Sensor Specifications .......................................................... 44

Appendix C – X-Ray Safety Survey Plot – B-412-119 ........................... 45

Reference Manuals

M-412-102 TapTone T4000 Operations Manual (English)

M-412-073 TapTone T4000 ACX Installation Manual (English)

M-412-074 TapTone T4000 ACX Operations & Maintenance Manual (English)

M-412-066 TapTone T4000 User’s Manual (English)

Preface

All information within this manual is a copyright of Teledyne TapTone and may not be

duplicated without the written consent or approval from Teledyne TapTone.

Teledyne TapTone reserves the right to make changes to the manual without obligation to

notify any person(s) or entities of revisions. It is recommended that the installation of your

Teledyne TapTone equipment is performed or supervised by an authorized Teledyne

TapTone representative.

TELEDYNE TAPTONE ii

M-412-073 List of Figures

Table of Figures

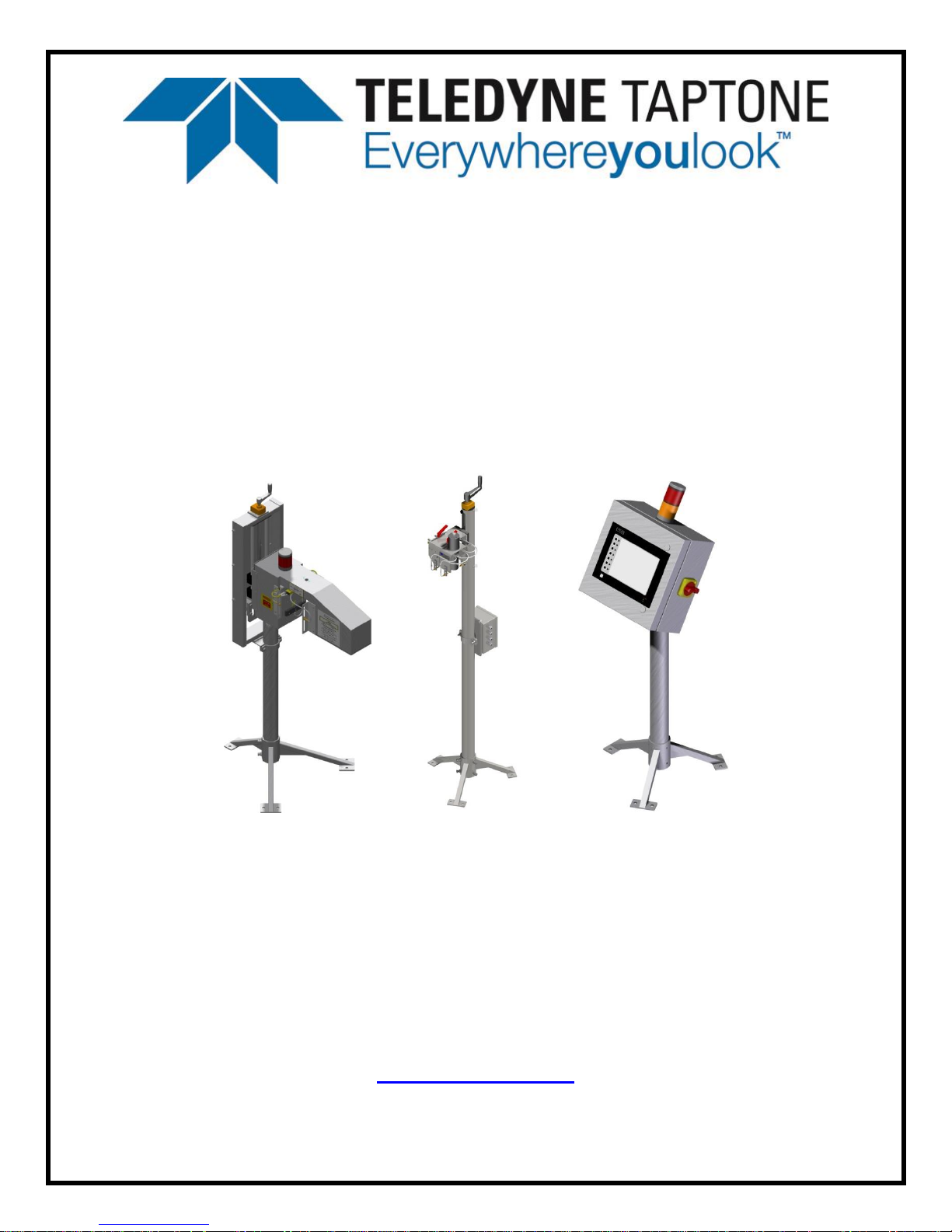

Figure 1-1 T4000 ACX System .............................................................................................................................. 1

Figure 1-2 T4000 PX System ................................................................................................................................. 2

Figure 1-3 T4000 SSV-X System ........................................................................................................................... 3

Figure 2-1 Safety Labels ........................................................................................................................................ 5

Figure 2-2 X-ray Safety Labels .............................................................................................................................. 6

Figure 3-1 Transducer Stand Assembly (RTV) .................................................................................................... 17

Figure 3-2 Conveyor Mount Stand Dimensions (CMS) ........................................................................................ 19

Figure 3-3 Conveyor Mounted Transducer Assembly ......................................................................................... 20

Figure 3-4 Stand Tube Cutting Diagram .............................................................................................................. 21

Figure 3-5 X-ray Mechanical Assembly Diagram ................................................................................................. 22

Figure 3-6 X-ray Mechanical Installation Diagram ............................................................................................... 23

Figure 3-7 X-ray Detector Mask ........................................................................................................................... 24

Figure 3-8 Rejector Specifications ....................................................................................................................... 25

Figure 3-9 Rejector Assembly Adjustment Points ................................................................................................ 26

Figure 3-10 Rejector Regulator / Lubricator Mounting ......................................................................................... 27

Figure 3-11 Rejector Regulator / Lubricator Air Connections .............................................................................. 28

Figure 3-12 Rejector Power Connection .............................................................................................................. 29

Figure 3-13 Shaft Encoder Specifications ............................................................................................................ 30

Figure 3-14 Shaft Encoder Warnings ................................................................................................................... 30

Figure 3-15 Shaft Encoder Mounting Drawing ..................................................................................................... 31

Figure 3-16 Shaft Encoder Wiring ........................................................................................................................ 32

Figure 3-17 AC Power Selector Switch ................................................................................................................ 33

Figure 3-18 AC Power Wiring Diagram ................................................................................................................ 34

Figure 3-19 Proximity Head Cable Connections .................................................................................................. 35

Figure 3-20 Acoustic Head Cable Connections ................................................................................................... 35

Figure 3-21 X-ray Head Cable Connections ........................................................................................................ 36

Figure 3-22 X-ray Height Adjustment ................................................................................................................... 38

Figure 3-23 Trigger Sensor Adjustments ............................................................................................................. 40

TELEDYNE TAPTONE iii

M-412-073 Chapter 1: Introduction

1.0 Introduction

1.1 T4000 ACX Acoustic / Cocked Crown / X-Ray Inspection System

The T4000-ACX combines acoustic sensor to find low pressure or vacuum and cocked crown

to fine crown defects. The x-ray is used to detect both over and under-filled containers.

Acoustic/Cocked Crown

Acoustic Leak inspection detects low pressure or vacuum

RTV Floor stand for easy mounting

12” of travel for height adjustment

Digital indicator for accurate change-over

Fill_xr X-ray Features include:

Underfill and Overfill inspections with one head.

Angled or straight control box

Stainless steel design.

Digital counter for accurate product change-over.

X-ray lamp monitoring to turn off X-rays when bulb is burned out.

Up to 25 mm fill height detection range.

Tripod floor stand for easy installation

Options include:

Downed container rejection

High Cap Inspection

Missing Cap Inspection

Missing Label

UV Tamper Band Detection

TELEDYNE TAPTONE 1

Figure 1-1 T4000 ACX System

M-412-073 Chapter 1: Introduction

1.2 T4000 PX Proximity / X-ray Inspection System

The T4000-PX combines proximity sensor with x-ray fill level inspections (Fill_xr) for food

cans, beverage cans and pop button glass containers.

Proximity

Proximity detects low pressure or vacuum

RTV Floor stand for easy mounting

12” of travel for height adjustment

Digital indicator for accurate change-over

Fill_xr Features include:

Underfill and Overfill inspections with one head.

Angled or straight control box

Stainless steel design.

Digital counter for accurate product change-over.

X-ray lamp monitoring to turn off X-rays when bulb is burned out.

Up to 25 mm fill height detection range.

Tripod floor stand for easy installation

Options include:

Downed container rejection

High Cap Inspection

Missing Cap Inspection

Missing Label

UV Tamper Band Detection

TELEDYNE TAPTONE 2

Figure 1-2 T4000 PX System

M-412-073 Chapter 1: Introduction

1.3 T4000 SSV-X Fill_xr Level Inspection System

The T4000 stand-alone fill height inspection Sensor (T4000 SSV-X) Fill_xr is designed for the

inspection of fill height in a variety of containers. This model allows for mounting of the X-ray

head assembly over the inspection conveyor. The 0.9 meter (3 ft) tripod stand makes

installation easy. The X-ray sensor comes standard with a 4.5 meter (15 ft.) quick disconnect

water-proof cable. The X-ray lamp on sensor indicates when the X-ray module is transmitting.

Fill_xr Features include:

Underfill and Overfill inspections with one head.

Angled or straight control box

Stainless steel design.

Digital counter for accurate product change-over.

X-ray lamp monitoring to turn off X-rays when bulb is burned out.

Up to 25 mm fill height detection range.

Tripod floor stand for easy installation

Options include:

Downed container rejection

High Cap Inspection

Missing Cap Inspection

Missing Label

Reject air pressure monitoring kit

TELEDYNE TAPTONE 3

Figure 1-3 T4000 SSV-X System

M-412-073 Chapter 2: Safety Precautions

2.0 Safety Precautions

2.1 General Safety Precautions

Please refer to the following safety instructions before and during operation of the system:

Only personnel trained in machine operations must operate the system.

Internal maintenance should only be performed by personnel specifically trained on the

system.

CAUTIONS!

PERSONAL INJURY OR EQUIPMENT DAMAGE MAY RESULT IF THE FOLLOWING

SAFETY PRECAUTIONS AND WARNINGS ARE NOT OBSERVED AT ALL TIMES.

Do not operate the system with the enclosure open. Always turn power and air

supply OFF before opening the enclosure.

Do not disconnect any electrical connections when the system power is on.

Damage to electrical components may occur.

Use lockout/tag-out equipment to prevent injury or damage when servicing the unit.

Before connecting an external device, power down both the TapTone system and the

external device. After power is off, connect device then turn power on.

The internal electronics of this equipment are sensitive to electrostatic discharge

(ESD) and proper precautions must be adhered to when handling any electrical

components of the system.

Do not place radial or axial load on the shaft encoder when mounting to the conveyor.

Internal damage to the encoder disk will occur.

Avoid high pressure spray with aggressive cleaning solvents on components like the

photo triggers, lamps and touch screen display.

TELEDYNE TAPTONE 4

M-412-073 Chapter 2: Safety Precautions

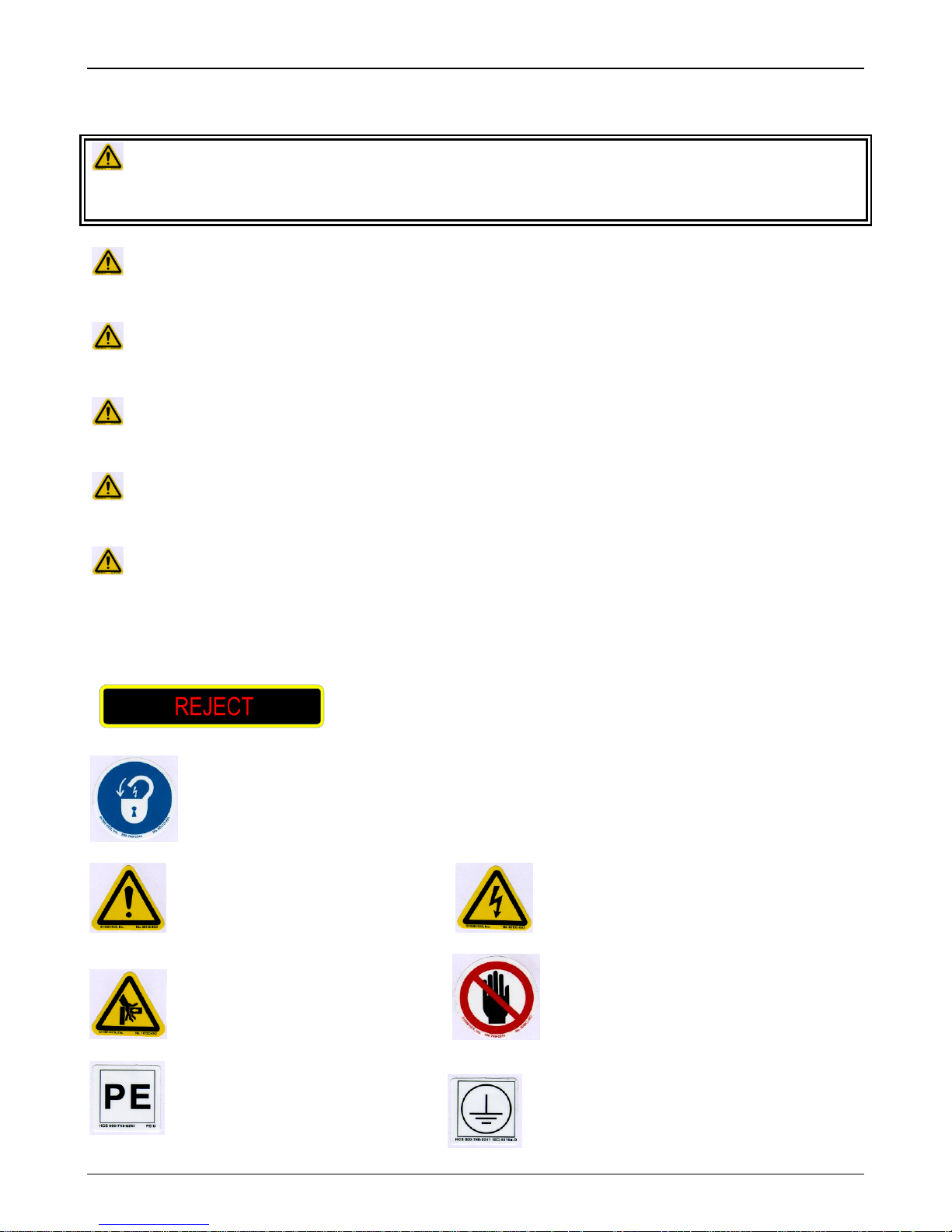

Lock-out electrical power before servicing.

General danger. (see manual)

Hazard electrical shock.

Hazard hand crush.

Stay clear.

Protective Earth.

AC input ground wire

only.

General Chassis Earth Ground.

Denotes reject lamp.

2.2 Specific Cautions and Warnings

WARNINGS! PERSONAL INJURY OR EQUIPMENT DAMAGE MAY RESULT IF THE

FOLLOWING SAFETY PRECAUTIONS AND WARNINGS ARE NOT OBSERVED AT ALL

TIMES.

Do not operate the system with the safety guards open. Failure to do so may cause

severe injury.

Keep hands clear of the rejector ram, conveyor belts and inspection bridges whenever

the system is in operation.

Do not operate this equipment with long hair or baggy loose clothing. Serious injury

may occur if it gets caught in any moving parts.

WARNING! - Keep hands clear of X-ray tunnel when X-ray lamp is on. X-ray energy is

transmitting when the X-ray lamp is ON.

WARNING! - This X-ray system MUST NOT be operated without the tunnel safety

shields installed.

2.3 Safety Label Descriptions

TELEDYNE TAPTONE 5

Figure 2-1 Safety Labels

M-412-073 Chapter 2: Safety Precautions

Denotes X-ray lamp.

Indicates X-ray caution

and emission direction.

Standard CE

TELEDYNE TAPTONE 6

Figure 2-2 X-ray Safety Labels

M-412-073 Chapter 2: Safety Precautions

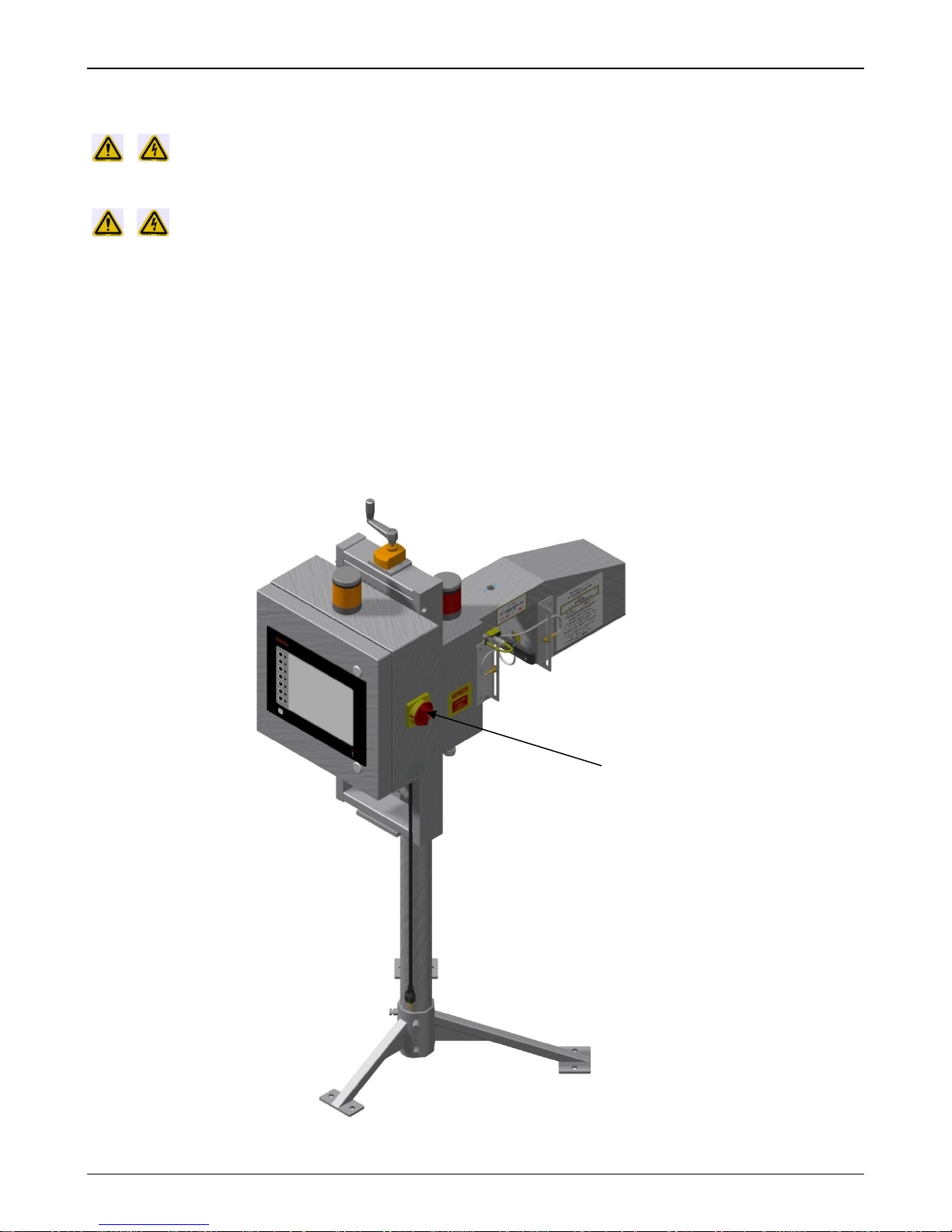

AC Power Switch

2.4 System Lockout / Tag-out Procedure

NOTICE! – Technicians MUST use a Lockout / Tag-out pad lock on each system

power switch whenever service is required

DANGER! – Never remove a pad-lock that was placed on the system by someone

else. Other technicians may be doing service to the system at the same time.

1. Turn the system main power switch to the OFF (0) position for both the inspection

electronics enclosure and the compression belt motor control enclosure.

2. Place a pad-lock through one of the three switch lock loops on both of the power

switches. A maximum of three pad-locks may be place on each switch.

3. Remove your pad-lock once your service is complete to resume normal operations. Do

not remove any other pad-locks that may be place on the system by other technicians as

they may be performing a different service procedure.

Figure 2-3 Lock-out Switch Locations

TELEDYNE TAPTONE 7

M-412-073 Chapter 3: Installation Instructions

3.0 Installation Instructions

3.1 T4000 Sensor Configurations

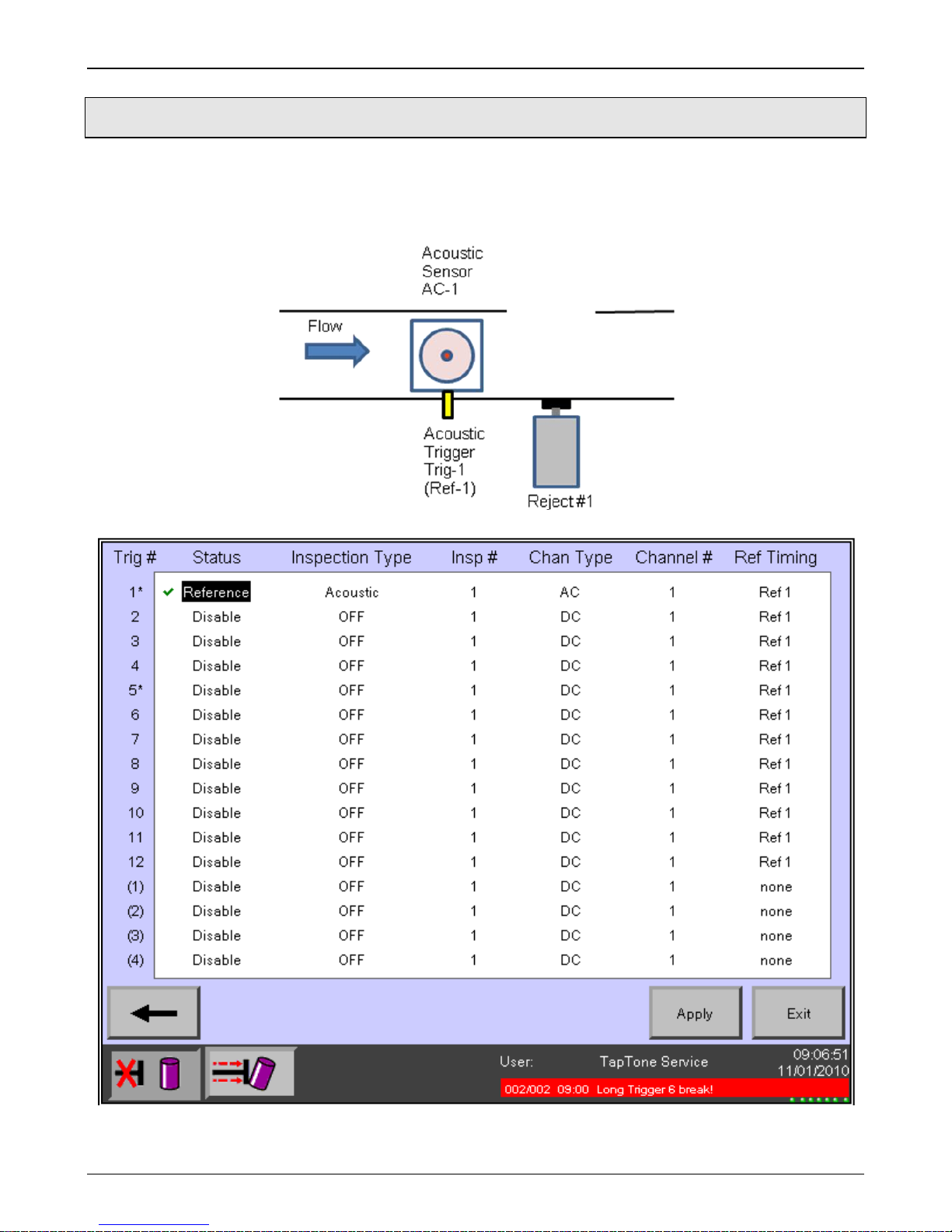

3.1.1 Acoustic Configuration (T4000 A)

TELEDYNE TAPTONE 8

M-412-073 Chapter 3: Installation Instructions

Acoustic

AC-1

Cocked

DC-4

Flow

Acoustic

(Ref-1)

Cocked

Trig-7

Reject #1

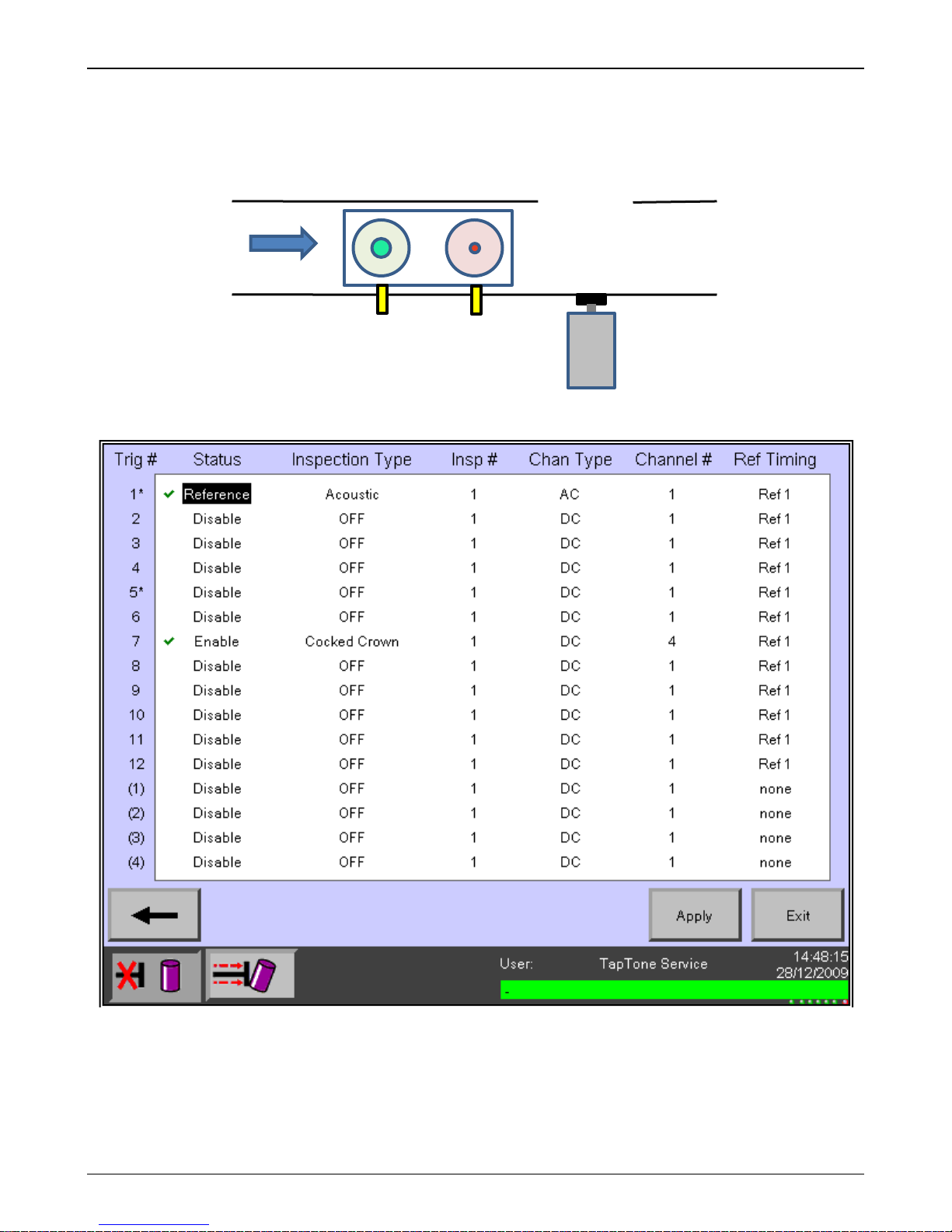

3.1.2 Acoustic/Cocked Crown Configuration (T4000 AC)

Crown

Sensor

Sensor

Crown

Trigger

Trigger

Trig-1

TELEDYNE TAPTONE 9

M-412-073 Chapter 3: Installation Instructions

3.1.3 Proximity Configuration (T4000 P)

TELEDYNE TAPTONE 10

Loading...

Loading...