Page 1

SENTINEL V SELF-CONTAINED

SENTINEL V REAL-TIME

OPERATION MANUAL

Information included herein is controlled by the Export Administration Regulations (EAR) and may

require an export license, license exception or other approval from the appropriate U.S. Government

agency before being exported from the United States or provided to any foreign person. Diversion

contrary to U.S. law is prohibited.

P/N 95D-6002-00 (September 2017)

© 2017 Teledyne RD Instruments, Inc. All rights reserved.

Page 2

Page ii

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

Page 3

TABLE OF CONTENTS

CHAPTER 1 – SELF-CONTAINED SENTINEL V OVERVIEW ...............................................................................................1

Sentinel V Features ...................................................................................................................................... 2

Available Options ......................................................................................................................................... 5

System Inventory ......................................................................................................................................... 6

Software Overview ....................................................................................................................................... 6

Computer Considerations ............................................................................................................................ 7

Power Considerations .................................................................................................................................. 8

Touch Sensor Response / System Beeps ...................................................................................................... 9

Connecting to the Sentinel V ADCP .............................................................................................................. 9

Using the Wireless Connection ............................................................................................................ 10

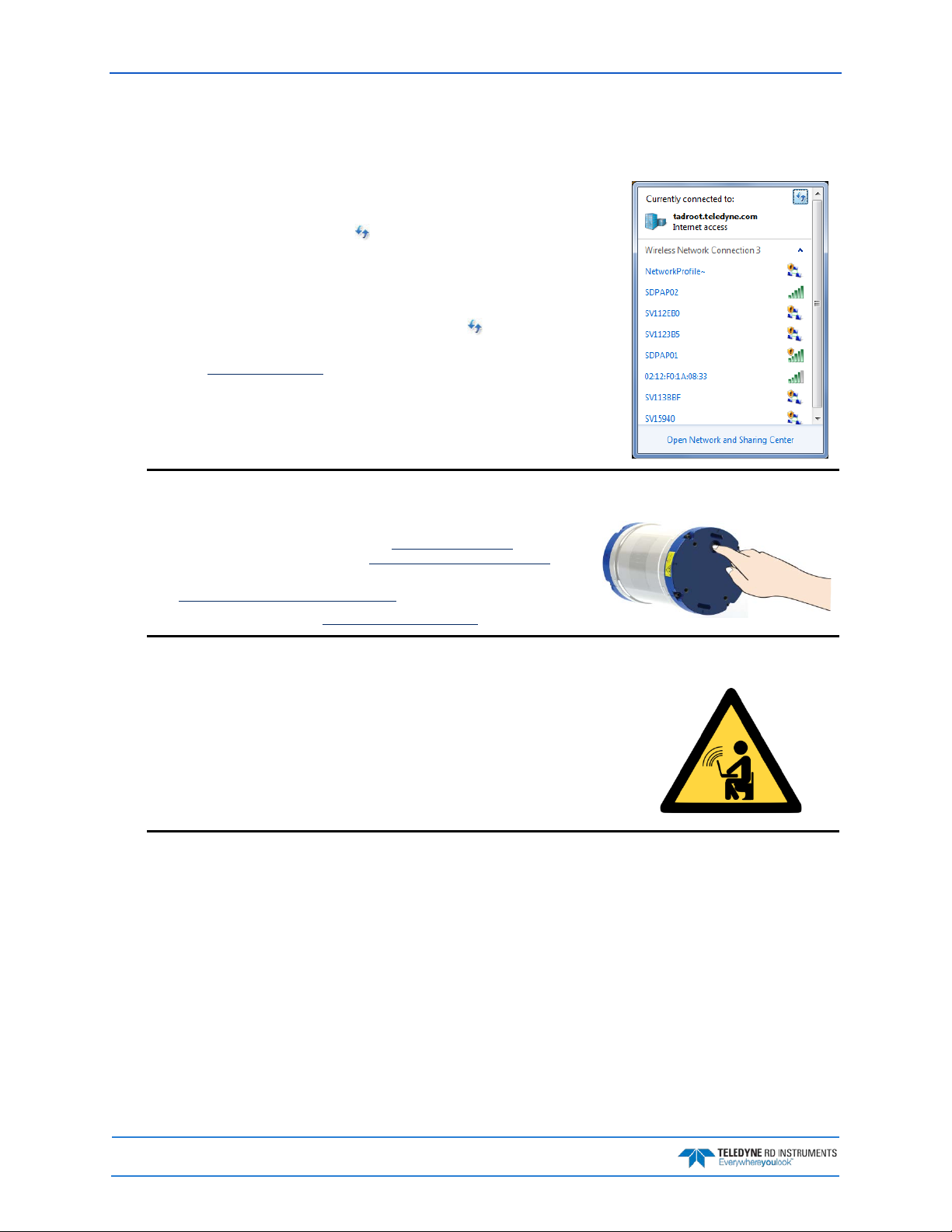

Touch Sensor ................................................................................................................................. 11

Connect .......................................................................................................................................... 11

Start ReadyV .................................................................................................................................. 12

Connecting to another ADCP................................................................................................................ 14

Restoring a ReadyV Lost Connection .................................................................................................... 15

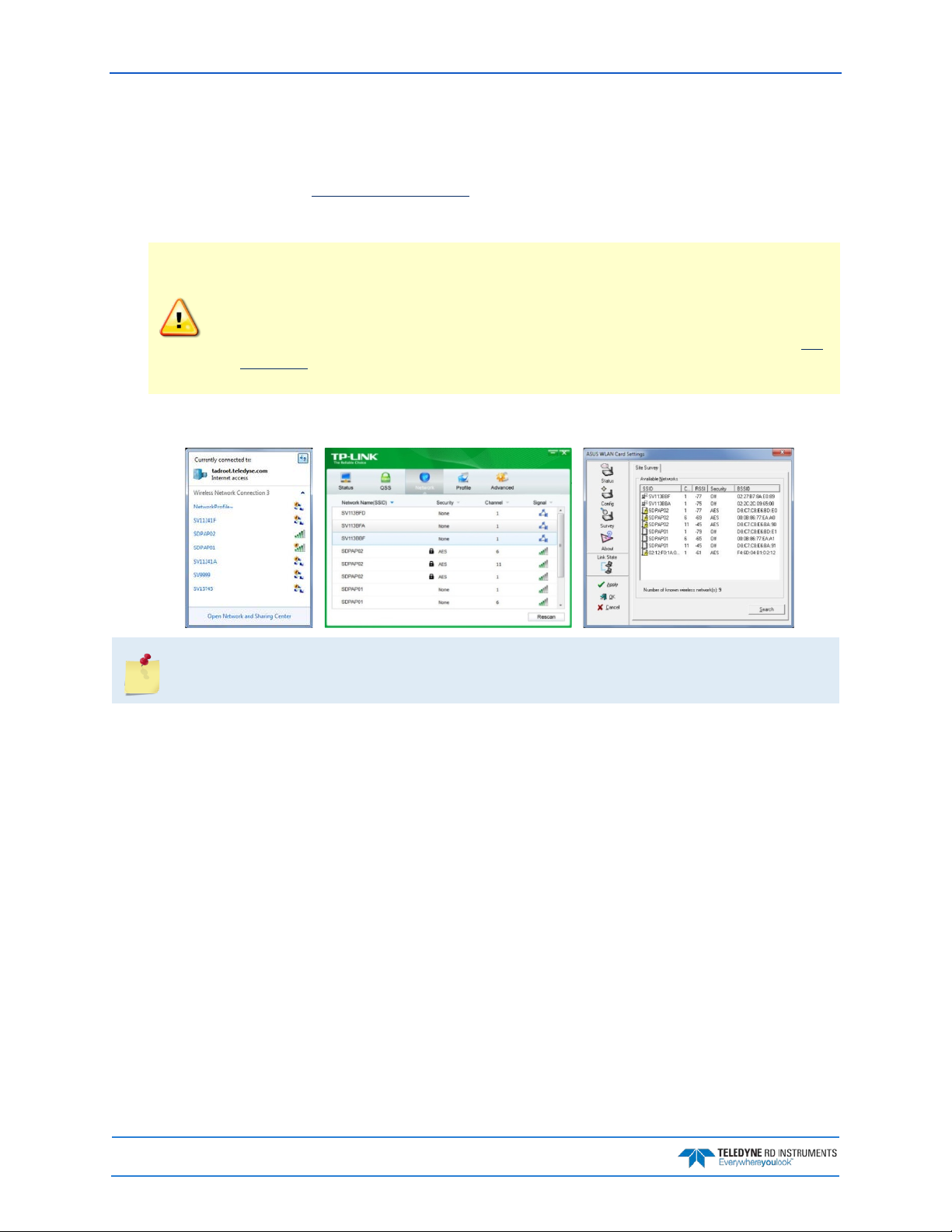

Wireless Connection Common Issues .................................................................................................. 16

CHAPTER 1A – REAL-TIME SENTINEL V OVERVIEW .....................................................................................................21

Sentinel V Real-Time Features ..................................................................................................................... 22

Available Real-Time Options ................................................................................................................ 23

Health & Environment Monitoring Sensors ......................................................................................... 24

Comparing Self-Contained & Real-Time ............................................................................................... 25

Real-Time System Inventory ........................................................................................................................ 26

Real-Time Software Overview ...................................................................................................................... 27

Real-Time Computer Considerations ........................................................................................................... 28

Real-Time Power Considerations ................................................................................................................. 29

Real-Time Touch Sensor Response / System Beeps ..................................................................................... 30

Real-Time ADCP Commands ........................................................................................................................ 30

Connecting to the Sentinel V Real-Time ....................................................................................................... 31

Using Sentinel V RT Utilities ................................................................................................................. 32

Using Ethernet Communications .......................................................................................................... 33

Using Directed UDP Output ........................................................................................................... 33

Using UDP broadcast Output ......................................................................................................... 34

Using the Sentinel-V Real-Time Utilities Page ...................................................................................... 34

Installing Sentinel-V Real-Time Firmware Upgrades ...................................................................... 34

Downloading Sentinel V Real-Time Log Files ................................................................................. 36

Installing Feature Upgrades ......................................................................................................................... 37

Using the Trigger .......................................................................................................................................... 38

CHAPTER 1C – SWITCHING RT AND SC MODES .........................................................................................................39

Switching RT and SC Modes ......................................................................................................................... 39

Switching to the Sentinel V Real-Time Mode ....................................................................................... 40

Switching to the Sentinel V Self-Contained Mode ............................................................................... 41

CHAPTER 2 – USING READYV ...............................................................................................................................43

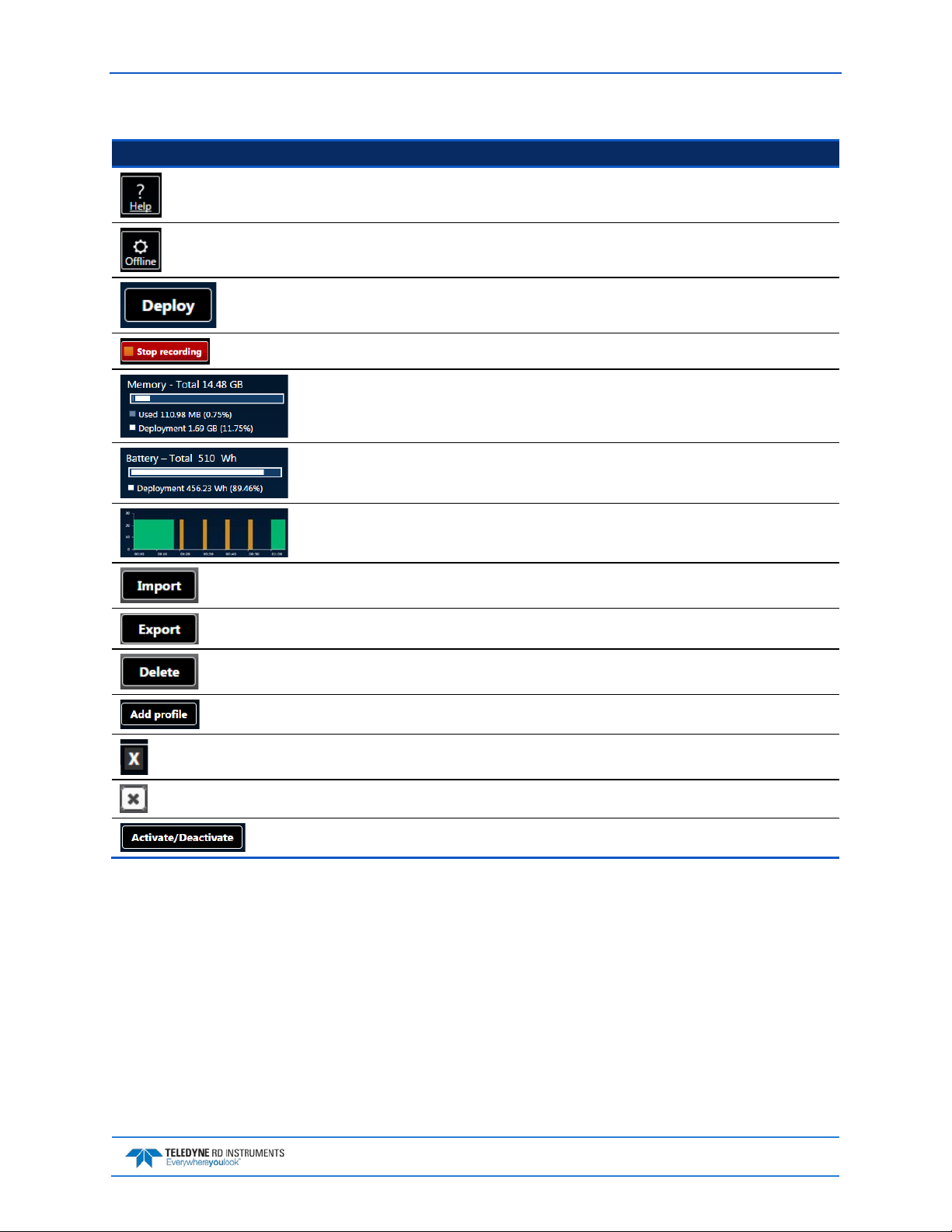

ReadyV Interface Features ........................................................................................................................... 44

Using the Home Panel .................................................................................................................................. 46

Using the ReadyV Panels ...................................................................................................................... 47

Creating and Saving Scenarios.............................................................................................................. 48

Collecting Waves Data .......................................................................................................................... 50

Example Waves Setups .................................................................................................................. 51

Opening a Saved Scenario .................................................................................................................... 51

Deleting a Saved Scenario .................................................................................................................... 52

Using the Set Sampling Strategy Panels ....................................................................................................... 53

Page iii

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

Page 4

Error Messages ..................................................................................................................................... 54

Step 1: Scenario .................................................................................................................................... 54

Step 2: Settings..................................................................................................................................... 55

Using Real-Time Serial Data Output ............................................................................................................. 55

Serial Port Application Notes ............................................................................................................... 57

Step 3: Profiling .................................................................................................................................... 59

Using the Review System Panel ................................................................................................................... 61

Sensor Data .......................................................................................................................................... 62

Activating and Deactivating Features ................................................................................................... 64

Using the Download Data Panel ................................................................................................................... 65

Using Download Managers .................................................................................................................. 67

Using the System Check Panel ..................................................................................................................... 68

Installing Firmware Upgrades .............................................................................................................. 69

ReadyV Log Files ................................................................................................................................... 70

Using the Review Resources Panel ............................................................................................................... 70

Using the Deployment Checklist Panel ........................................................................................................ 72

Starting or Stopping Deployments ....................................................................................................... 73

Running ReadyV Offline ............................................................................................................................... 74

CHAPTER 3 - INSTALLATION ..................................................................................................................................75

Attaching the Handle ................................................................................................................................... 76

Transducer Cover ......................................................................................................................................... 76

Mounting the Instrument ............................................................................................................................ 77

WorkHorse to Sentinel V Mount Adapter .................................................................................................... 79

Connecting Cables and Dummy Plugs .......................................................................................................... 80

Using the AC Power Adapter ........................................................................................................................ 81

Cable Wiring Diagrams ................................................................................................................................. 82

Connecting the External Battery Case .......................................................................................................... 83

Using Bottom Mounts .................................................................................................................................. 84

Using Buoy Mounts and Load Cages ............................................................................................................ 86

Using an Over-the-Side Mount..................................................................................................................... 87

Over-the-Side Mounting Special Considerations ................................................................................. 87

Routing Cables ............................................................................................................................................. 88

Using a Sea Chest ......................................................................................................................................... 90

CHAPTER 4 - MAINTENANCE .................................................................................................................................93

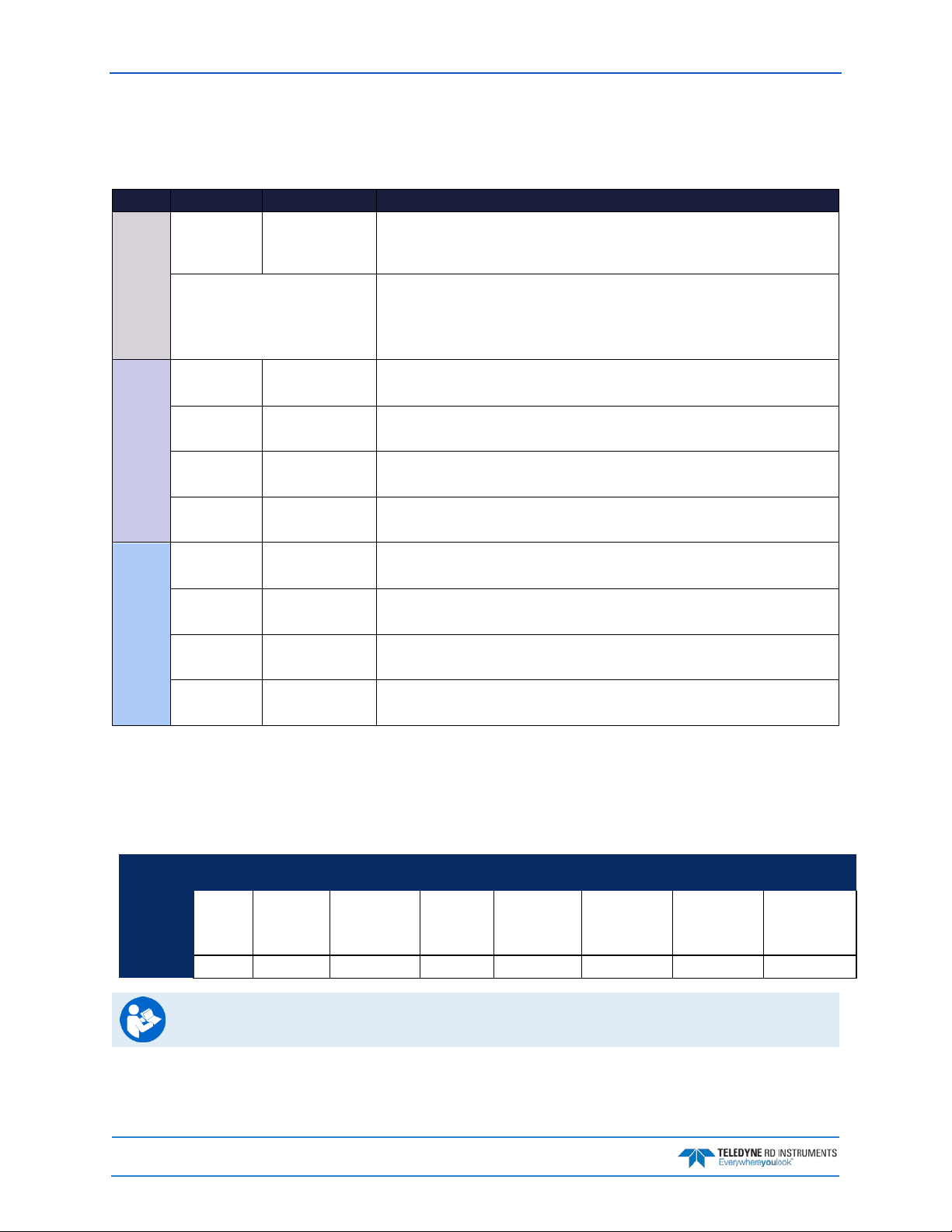

Maintenance Schedule ................................................................................................................................. 94

Calibration Items .................................................................................................................................. 94

Maintenance Items and Inspection ...................................................................................................... 95

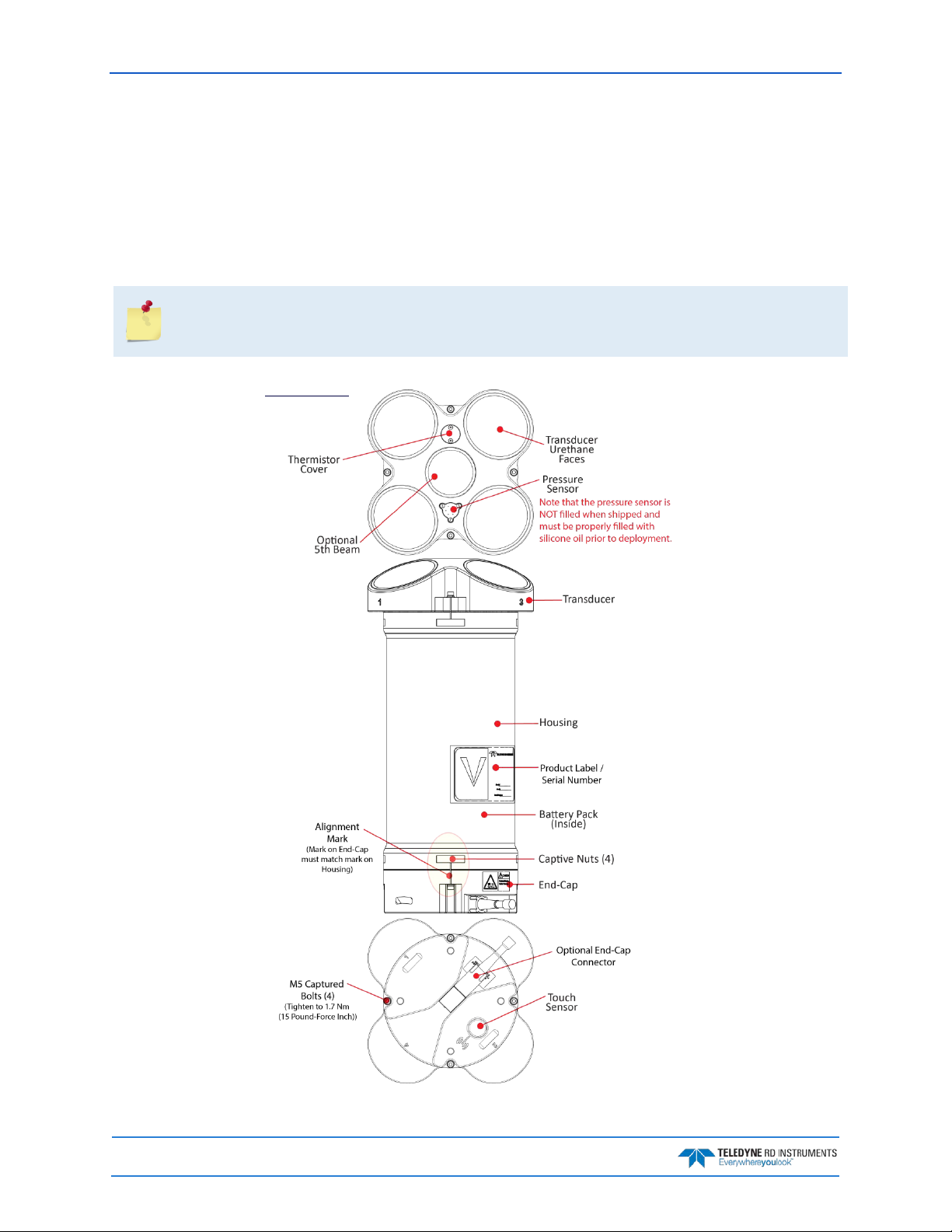

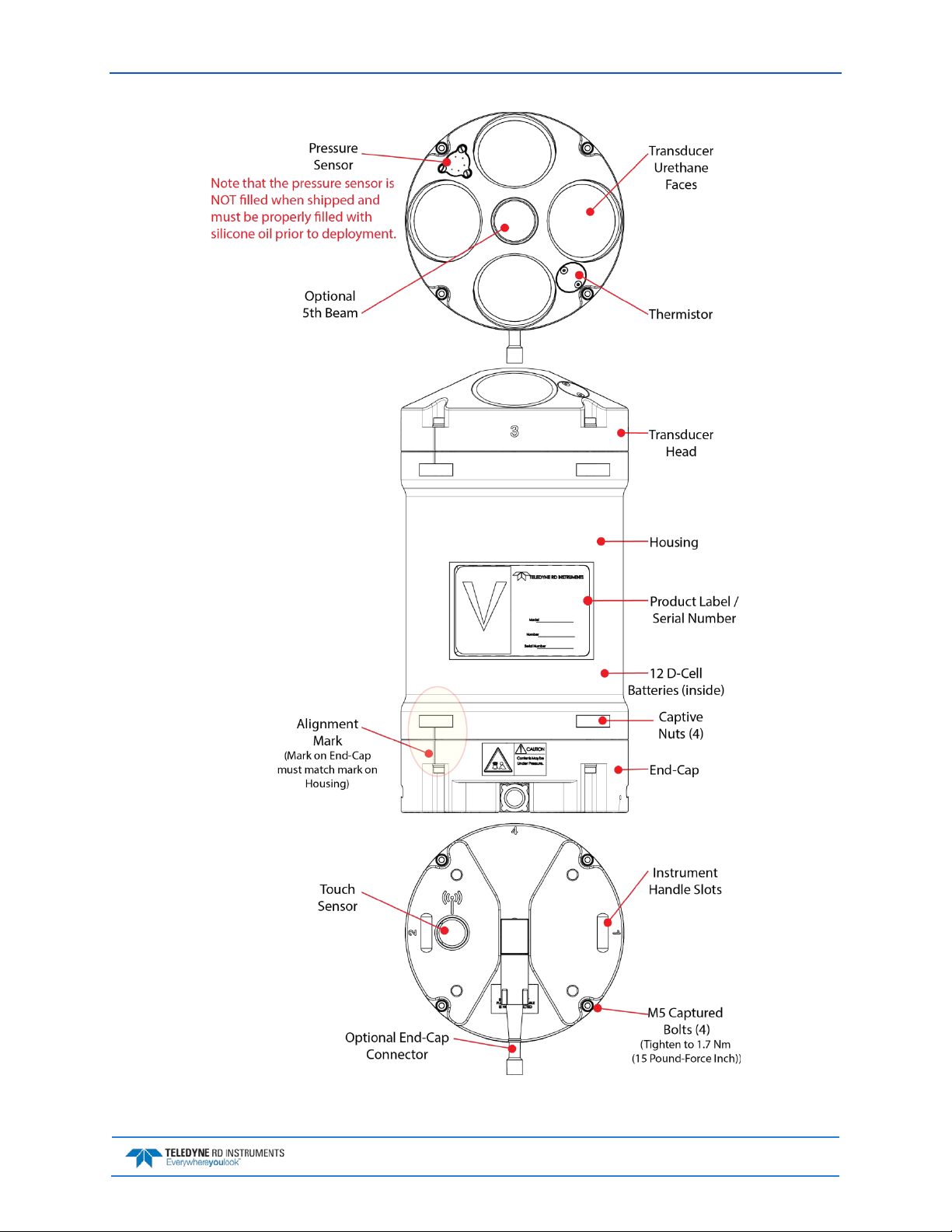

Parts Location Drawings ............................................................................................................................... 96

Tools and Spares Parts ................................................................................................................................. 97

Disassembly and Assembly Procedures ....................................................................................................... 102

Disassembling the Sentinel V ............................................................................................................... 102

Removing the End-Cap ................................................................................................................... 102

Removing the Transducer Head Assembly ..................................................................................... 103

Reassembling the Sentinel V ................................................................................................................ 104

Replacing the End-Cap ................................................................................................................... 104

Replacing the Transducer Head Assembly ..................................................................................... 106

Replacing the Sentinel V Battery .................................................................................................................. 107

Testing the Lithium Battery Pack.......................................................................................................... 107

Replacing the Battery Pack ................................................................................................................... 108

Replacing Individual D Cell Batteries .................................................................................................... 109

Replacing the External Battery Case Packs ........................................................................................... 111

Calibrating the Compass .............................................................................................................................. 112

Compass Calibration............................................................................................................................. 114

Using the Compass Calibration Stand .................................................................................................. 116

Calibration Score .................................................................................................................................. 118

Troubleshooting a Low Calibration Score............................................................................................. 119

Page iv

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

Page 5

Restore to Factory Defaults .................................................................................................................. 119

Periodic Maintenance .................................................................................................................................. 120

Running the Built-in Tests .................................................................................................................... 121

Testing the Sentinel V Self-Contained ............................................................................................ 121

Testing the Sentinel V Real-Time ................................................................................................... 121

Setting the Date and Time .................................................................................................................... 122

Setting the Date and Time on Self-Contained Systems .................................................................. 122

Setting the Date and Time on Real-Time Systems ......................................................................... 123

Replacing the O-Ring ............................................................................................................................ 124

Filling the Pressure Sensor Cavity with Oil ........................................................................................... 125

Zero the Pressure Sensor ..................................................................................................................... 127

Cleaning the Thermistor Cover............................................................................................................. 127

Replacing the Desiccant ....................................................................................................................... 128

Replacing the Captive Nuts .................................................................................................................. 129

Replacing the Battery Springs .............................................................................................................. 130

Replacing the Battery Separators ......................................................................................................... 130

Preventing Biofouling ........................................................................................................................... 131

Removing Biofouling ............................................................................................................................ 132

CHAPTER 5 - TROUBLESHOOTING ...........................................................................................................................133

Troubleshooting Steps ................................................................................................................................. 134

Troubleshooting Communication Issues ...................................................................................................... 134

Determining if the System is RT or SC .......................................................................................................... 135

Troubleshooting Wireless Issues .................................................................................................................. 135

Troubleshooting Serial Issues ....................................................................................................................... 136

Troubleshooting Ethernet Issues ................................................................................................................. 137

Troubleshooting UDP Issues ................................................................................................................. 137

Troubleshooting ReadyV Issues ................................................................................................................... 138

ReadyV Does Not Start ......................................................................................................................... 138

Solving Partially Cut Off Screen Issues ................................................................................................. 138

Solving Download Data Issues .............................................................................................................. 138

Troubleshooting a Built-In Test Failure ........................................................................................................ 140

Troubleshooting Data Problems .................................................................................................................. 140

Using Board-Level Ethernet Connection ...................................................................................................... 141

Open the Transducer............................................................................................................................ 141

Connecting to the ADCP via Ethernet................................................................................................... 141

Replacing the Transducer Head Assembly ........................................................................................... 143

Troubleshooting a System Reset Issue ......................................................................................................... 143

CHAPTER 6 - RETURNING SYSTEMS TO TRDI FOR SERVICE ............................................................................................145

Shipping the ADCP ....................................................................................................................................... 146

Returning Systems to the TRDI..................................................................................................................... 147

Returning Systems to TRDI Europe .............................................................................................................. 148

CHAPTER 7 - SPECIFIC ATIONS ................................................................................................................................151

Outline Installation Drawings ....................................................................................................................... 157

CHAPTER 8 – REAL-TIME COMMANDS ....................................................................................................................183

Data Communication and Command Format .............................................................................................. 184

Command Input Processing ................................................................................................................. 184

Data Output Processing........................................................................................................................ 185

Command Summary ..................................................................................................................................... 186

Command Descriptions ................................................................................................................................ 189

? – Help Menus .............................................................................................................................. 189

Break .............................................................................................................................................. 190

OL – Display Feature List ................................................................................................................ 190

Y – Display Banner ......................................................................................................................... 191

Sensor Commands ....................................................................................................................................... 192

Available Sensor Commands ................................................................................................................ 192

Page v

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

Page 6

Standard Sensor Commands ................................................................................................................ 192

AZ – Zero Pressure Sensor ............................................................................................................. 192

Bottom Track Commands ............................................................................................................................. 193

Available Bottom Track Commands ..................................................................................................... 193

BA - Evaluation Amplitude Minimum ............................................................................................. 194

BC - Correlation Magnitude Minimum ........................................................................................... 194

BE - Error Velocity Maximum ......................................................................................................... 194

BF - Manual Fixed Altitude ............................................................................................................. 195

BP – Bottom-Track Pings per Ensemble ......................................................................................... 195

BX – Maximum Search Altitude ..................................................................................................... 196

Expert Bottom Track Commands ......................................................................................................... 197

#BB – Bottom Blank ....................................................................................................................... 197

#BH – Gain Switch Threshold ......................................................................................................... 197

#BI – Gain Switch Altitude .............................................................................................................. 197

#BY – Transmit Length ................................................................................................................... 198

Control System Commands .......................................................................................................................... 199

Available Control System Commands .................................................................................................. 199

Control System Command Descriptions ............................................................................................... 199

CB – Serial Port Control .................................................................................................................. 199

CF – Set Control Flags..................................................................................................................... 200

CK – Save Command Parameters to Flash ..................................................................................... 201

CN - Network Configuration Menu ................................................................................................ 201

CR – Restore Command Defaults ................................................................................................... 203

CS – Start Pinging (Go) ................................................................................................................... 204

CState – Pinging State Query ......................................................................................................... 204

CStop – Stop Pinging ...................................................................................................................... 204

CT – Turnkey Mode ........................................................................................................................ 205

CU - Set Update Mode ................................................................................................................... 206

CW – Output the Last Stored Ensemble ......................................................................................... 207

Expert Control System Commands ....................................................................................................... 208

#CC – Update Global Variables ...................................................................................................... 208

#CG – Set Beam Matrix Output Frequency .................................................................................... 208

#CR – Reboot System ..................................................................................................................... 208

#CM – Set System Communication Mode ..................................................................................... 209

Environmental Commands ........................................................................................................................... 210

Available Environmental Commands ................................................................................................... 210

Environmental Command Descriptions ................................................................................................ 210

EA – Heading Alignment ................................................................................................................ 210

EB – Heading Bias ........................................................................................................................... 211

EC – Speed of Sound ...................................................................................................................... 211

ED – Depth of Transducer .............................................................................................................. 212

EH – Heading .................................................................................................................................. 212

EM – Disable Beam ........................................................................................................................ 213

EP – Pitch (Tilt 1) ............................................................................................................................ 213

ER – Roll (Tilt 2) .............................................................................................................................. 213

ES – Salinity .................................................................................................................................... 214

ET – Temperature .......................................................................................................................... 214

EU – System Orientation ................................................................................................................ 214

EX – Coordinate Transformation .................................................................................................... 215

EZ – Sensor Source ......................................................................................................................... 218

Expert Environmental Command Descriptions .................................................................................... 219

#EI - Roll Misalignment Angle ........................................................................................................ 219

#EJ - Pitch Misalignment Angle ...................................................................................................... 220

Fault Log Commands .................................................................................................................................... 221

Available Fault Log Commands ............................................................................................................ 221

Fault Log Command Descriptions ......................................................................................................... 221

FC – Clear Fault Log ........................................................................................................................ 221

Page vi

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

Page 7

FD – Display Fault Log .................................................................................................................... 221

Performance and Testing Commands .......................................................................................................... 222

Available Performance and Testing Commands ................................................................................... 222

Performance and Testing Command Descriptions ............................................................................... 222

PA – Run Go/No-Go Tests .............................................................................................................. 222

PC – User Interactive Built-In Tests ................................................................................................ 223

PD – Set Output Format ................................................................................................................. 225

PF – Results from most recent PA tests ......................................................................................... 225

PS – Display System Parameters .................................................................................................... 225

PT – Built-In Tests........................................................................................................................... 227

Sync/Trigger Commands .............................................................................................................................. 228

Available Sync/Trigger Commands ....................................................................................................... 228

SA – Trigger Events ........................................................................................................................ 228

SM – Trigger Mode ........................................................................................................................ 228

ST – Trigger Timeout ...................................................................................................................... 229

Timing Commands ....................................................................................................................................... 230

Available Timing Commands ................................................................................................................ 230

Standard Timing Commands ................................................................................................................ 230

TE – Time Per Ensemble ................................................................................................................. 230

TP – Time Between Pings ............................................................................................................... 231

TS – Set Real-Time Clock ................................................................................................................ 231

Expert Timing Commands .................................................................................................................... 232

#TM – Set Minimum Time Between Pings ..................................................................................... 232

Water Profiling Commands .......................................................................................................................... 233

Available Water Profiling Commands ................................................................................................... 233

Standard Water Profiling Commands ................................................................................................... 234

WB – Bandwidth ............................................................................................................................ 234

WC – Correlation Threshold ........................................................................................................... 234

WD – Data Out ............................................................................................................................... 235

WF – Blank after Transmit ............................................................................................................. 235

WM – Water Profiling Mode .......................................................................................................... 236

WN – Number of Bins .................................................................................................................... 236

WP – Number of Pings ................................................................................................................... 236

WS – Bin Size .................................................................................................................................. 237

WV – Ambiguity Velocity ............................................................................................................... 237

Expert Water Profiling Commands ....................................................................................................... 238

#WA – False Target Threshold ....................................................................................................... 238

#WE - Error Velocity Threshold ...................................................................................................... 238

#WJ – BroadBand Receiver Gain .................................................................................................... 239

#WT – Transmit Length .................................................................................................................. 239

Vertical Beam Profile Commands ................................................................................................................. 240

Available Vertical Beam Profile Commands ......................................................................................... 240

Standard Vertical Beam Profile Commands ......................................................................................... 240

ZP – Vertical Beam Number of Pings.............................................................................................. 240

Expert Vertical Beam Profile Commands ............................................................................................. 241

#ZB – Vertical Beam Bandwidth ..................................................................................................... 241

#ZC – Vertical Beam Correlation Threshold ................................................................................... 241

#ZD – Vertical Beam Data Out ....................................................................................................... 241

#ZF – Vertical Beam Blanking Distance .......................................................................................... 242

#ZJ – Vertical Beam Gain ................................................................................................................ 242

#ZM – Vertical Beam Profile Mode ................................................................................................ 243

#ZN – Vertical Beam Number of Bins ............................................................................................. 243

#ZS – Vertical Beam Bin Size .......................................................................................................... 244

#ZV – Vertical Beam Ambiguity Velocity ........................................................................................ 244

CHAPTER 9 – OUTPUT DATA FORMAT .....................................................................................................................245

Comparing Sentinel V PD0 to WorkHorse PD0 ............................................................................................. 246

PD0 Output Data Format ............................................................................................................................. 248

Page vii

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

Page 8

Header Data Format ............................................................................................................................. 249

Fixed Leader Data Format .................................................................................................................... 251

Variable Leader Data Format ............................................................................................................... 256

Velocity Data Format............................................................................................................................ 261

Correlation Magnitude, Echo Intensity, and Percent-Good Data Format ............................................ 263

Transformation Matrix Format ............................................................................................................ 266

Sentinel V Specific Structures ............................................................................................................... 268

Sentinel V System Configuration .................................................................................................... 268

Sentinel V Ping Setup ..................................................................................................................... 270

Sentinel V ADC Data ....................................................................................................................... 272

Sentinel V Features Data ................................................................................................................ 273

Vertical Beam Data ............................................................................................................................... 276

Vertical Beam Leader ..................................................................................................................... 276

Vertical Beam Velocity Data Format .............................................................................................. 278

Vertical Beam Correlation Magnitude, Percent Good Data Format, and Amplitude ..................... 279

Bottom-Track Data Format .................................................................................................................. 281

Reserved BIT Data Format .................................................................................................................... 285

Checksum Data Format ........................................................................................................................ 285

Diagnostic Structures ........................................................................................................................... 286

Sentinel V Event Log ...................................................................................................................... 286

Wave Parameter Structures ................................................................................................................. 287

Wave Parameters .......................................................................................................................... 287

Wave Parameters2 – Sea and Swell ............................................................................................... 289

APPENDIX A - COASTAL SURVEY WITH SV RT AND WINRIVER II ....................................................................................291

APPENDIX B - NOTICE OF COMPLIANCE ...................................................................................................................293

Date of Manufacture .................................................................................................................................... 294

Environmental Friendly Use Period (EFUP) .................................................................................................. 294

WEEE ............................................................................................................................................................ 294

CE ................................................................................................................................................................. 295

Material Disclosure Table ............................................................................................................................. 296

APPENDIX C - GPL COMPLIANCE NOTICE .................................................................................................................297

GPL Compliance ........................................................................................................................................... 298

GNU General Public License ................................................................................................................. 298

GNU Lesser General Public License ...................................................................................................... 303

APPENDIX D – END USER LICENSE AGREEMENT .........................................................................................................311

APPENDIX E – QUICK START CARDS........................................................................................................................315

LIST OF FIGURES

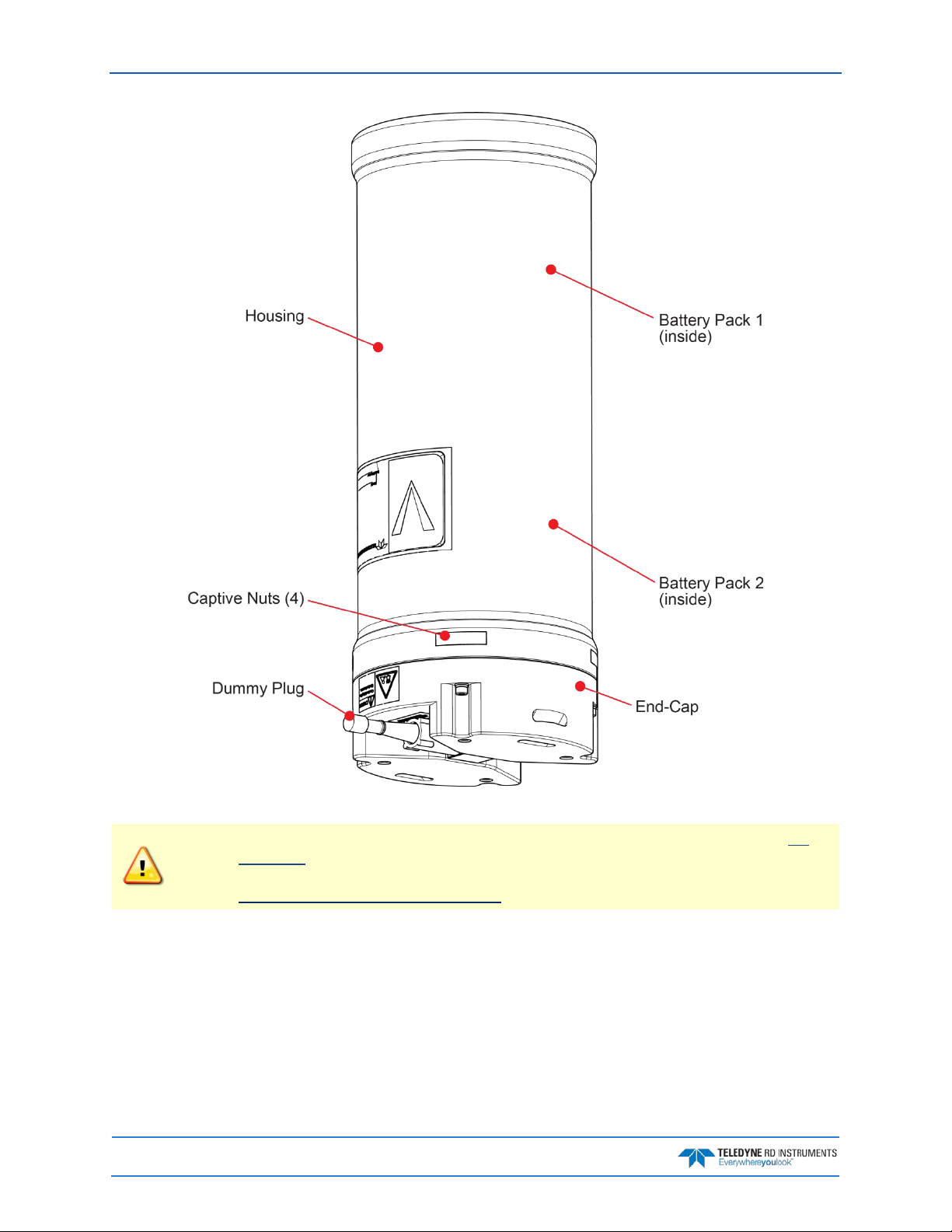

Figure 1. Sentinel V100 5 Beam Overview with Battery Pack and Optional End-Cap Connector .............. 2

Figure 2. Sentinel V20 with D Cell Batteries and Optional End-Cap call out beam numbers .................... 3

Figure 3. External Battery Case Overview ................................................................................................. 4

Figure 4. Using the ReadyV Wireless Connection ................................................................................... 13

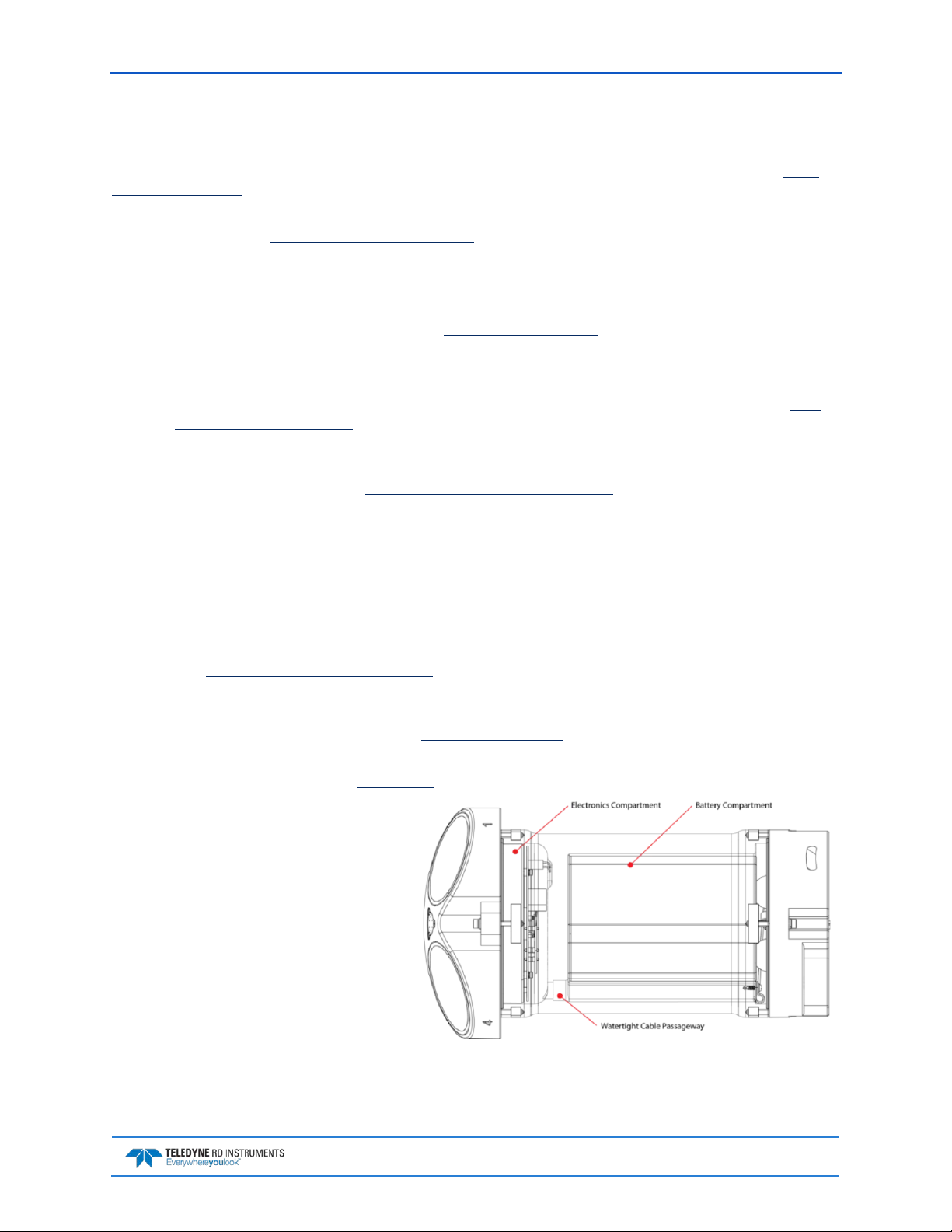

Figure 5. Real-Time (RT) Housing Overview ............................................................................................ 22

Figure 6. Sentinel V Real-Time Serial Connection ................................................................................... 31

Figure 7. Sentinel V Real-Time Ethernet Connection .............................................................................. 31

Figure 8. Sentinel V RT Utilities Page....................................................................................................... 36

Figure 9. Home Panel .............................................................................................................................. 46

Figure 10. Creating a Scenario Flow Chart ................................................................................................ 47

Figure 11. Set Sampling Strategy Panels ................................................................................................... 53

Figure 12. Recommended Computer Power Options Setting for Real-Time Serial Data Output .............. 58

Figure 13. Review System Panel ................................................................................................................ 61

Page viii

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

Page 9

Figure 14. Pitch, Roll and Heading ............................................................................................................ 62

Figure 15. Raw Pitch .................................................................................................................................. 63

Figure 16. Raw Roll .................................................................................................................................... 63

Figure 17. Activating and Deactivating Features ....................................................................................... 64

Figure 18. Download Data Panel ............................................................................................................... 65

Figure 19. System Check Panel .................................................................................................................. 68

Figure 20. Updating the Firmware ............................................................................................................ 69

Figure 21. Review Resources Panel ........................................................................................................... 70

Figure 22. Deployment Panel .................................................................................................................... 72

Figure 23. Handle ...................................................................................................................................... 76

Figure 24. Transducer Cover ..................................................................................................................... 76

Figure 25. Mounting the Instrument ......................................................................................................... 77

Figure 26. Example Sentinel V End-Cap Mount ......................................................................................... 77

Figure 27. Gimbal Bottom Mount ............................................................................................................. 78

Figure 28. 81D-5000 Mounting Clamp Adapter Kit ................................................................................... 79

Figure 29. 81D-5001 End-Cap Mounting Plate Adapter Kit ....................................................................... 79

Figure 30. Removing the End-Cap Connector 8-Pin Dummy Plug ............................................................. 80

Figure 31. Using the Real-Time Serial Output and AC Power Adapter ...................................................... 81

Figure 32. 73D-3112 – Underwater Y-Mold Cable Serial Cable with 8-pin Connector .............................. 82

Figure 33. 73D-3113 – Underwater Y-Mold Cable Ethernet Cable ............................................................ 82

Figure 34. 73D-3101 – External Battery Case Cable with 8-pin Connector ............................................... 82

Figure 35. Connecting the External Battery Case ...................................................................................... 83

Figure 36. Example of a Teledyne RD Instruments PVC Bottom Mount ................................................... 84

Figure 37. Example of a Bottom Mounted ADCP ...................................................................................... 84

Figure 38. Trawl Resistant Bottom Mount ................................................................................................ 85

Figure 39. Deep-Water Mount .................................................................................................................. 86

Figure 40. Buoy Mount with External Battery .......................................................................................... 86

Figure 41. Subsurface Buoy ....................................................................................................................... 86

Figure 42. Buoy Mount .............................................................................................................................. 86

Figure 43. Load Cage ................................................................................................................................. 87

Figure 44. Do not use Zip-Ties Directly on Cables ..................................................................................... 88

Figure 45. Cables Protected with Abrasion Resistant Sleeving ................................................................. 89

Figure 46. Transducer View ....................................................................................................................... 95

Figure 47. End-Cap View ........................................................................................................................... 95

Figure 48. Sentinel V Assembly Overview ................................................................................................. 96

Figure 49. Sentinel V Exploded View (Battery Pack) ................................................................................. 98

Figure 50. Sentinel V Exploded View (Individual D cell) ............................................................................ 99

Figure 51. Sentinel V Exploded View (RT Housing) .................................................................................. 100

Figure 52. Sentinel V External Battery Case Exploded View .................................................................... 101

Figure 53. Replacing the End-Cap ........................................................................................................... 104

Figure 54. End-Cap Mounting Hardware ................................................................................................. 105

Figure 55. Battery Pack ........................................................................................................................... 108

Figure 56. D cell Battery Replacement .................................................................................................... 110

Figure 57. External Battery Case Internal Cable Connections ................................................................. 111

Figure 58. Calibrating the Compass ......................................................................................................... 112

Figure 59. Upward or Downward Facing Deployment Hand-Held Compass Calibration ........................ 115

Figure 60. Compass Calibration Stand ..................................................................................................... 117

Figure 61. Set the Date and Time ............................................................................................................ 122

Figure 62. Using the O-Ring Removal Tool .............................................................................................. 124

Figure 63. Filling the Pressure Sensor Cavity with Oil ............................................................................. 125

Figure 64. Pressure Sensor Cavity with Sand .......................................................................................... 126

Figure 65. Zero the Pressure Sensor ....................................................................................................... 127

Figure 66. Thermistor and Pressure Sensor ............................................................................................ 128

Figure 67. Replacing the Captive Nuts .................................................................................................... 129

Figure 68. Individual D cell Battery Compartment .................................................................................. 130

Figure 69. Biofouling on a Sentinel V ADCP ............................................................................................. 132

Figure 70. Ethernet Connection .............................................................................................................. 141

Page ix

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

Page 10

Figure 71. Power I/O Cable Connection .................................................................................................. 141

Figure 72. 96D-6000 Sheet 1 ................................................................................................................... 158

Figure 73. 96D-6000 Sheet 2 ................................................................................................................... 159

Figure 74. 96D-6000 Sheet 3 ................................................................................................................... 160

Figure 75. 96D-6000 Sheet 4 ................................................................................................................... 161

Figure 76. 96D-6000 Sheet 5 ................................................................................................................... 162

Figure 77. 96D-6001 Sheet 1 ................................................................................................................... 163

Figure 78. 96D-6001 Sheet 2 ................................................................................................................... 164

Figure 79. 96D-6001 Sheet 3 ................................................................................................................... 165

Figure 80. 96D-6001 Sheet 4 ................................................................................................................... 166

Figure 81. 96D-6001 Sheet 5 ................................................................................................................... 167

Figure 82. 96D-6002 Sheet 1 ................................................................................................................... 168

Figure 83. 96D-6002 Sheet 2 ................................................................................................................... 169

Figure 84. 96D-6002 Sheet 3 ................................................................................................................... 170

Figure 85. 96D-6002 Sheet 4 ................................................................................................................... 171

Figure 86. 96D-6003 Sheet 1 ................................................................................................................... 172

Figure 87. 96D-6003 Sheet 2 ................................................................................................................... 173

Figure 88. 96D-6003 Sheet 3 ................................................................................................................... 174

Figure 89. 96D-6003 Sheet 4 ................................................................................................................... 175

Figure 90. 96D-6003 Sheet 5 ................................................................................................................... 176

Figure 91. 96D-6004 Sheet 1 ................................................................................................................... 177

Figure 92. 96D-6004 Sheet 2 ................................................................................................................... 178

Figure 93. 96D-6004 Sheet 3 ................................................................................................................... 179

Figure 94. 96D-6004 Sheet 4 ................................................................................................................... 180

Figure 95. 96D-6005 Sheet 1 ................................................................................................................... 181

Figure 96. Sentinel-V Utilities Page ......................................................................................................... 206

Figure 97. X, Y, and Z Velocities ............................................................................................................... 216

Figure 98. Sentinel V Real-Time Coordinate Transformation .................................................................. 217

Figure 99. Sentinel V Real-Time Pitch and Roll ........................................................................................ 217

Figure 100. WorkHorse ADCP PD0 Standard Output Data Buffer Format ................................................. 246

Figure 101. Sentinel V Real-Time ADCP PD0 Output Data Buffer Format ................................................. 247

Figure 102. Header Data Format ............................................................................................................... 249

Figure 103. Fixed Leader Data Format ...................................................................................................... 252

Figure 104. Variable Leader Data Format ................................................................................................. 258

Figure 105. Velocity Data Format .............................................................................................................. 261

Figure 106. Correlation Magnitude, Echo Intensity, and Percent-Good Data Format .............................. 263

Figure 107. Transformation Matrix Format ............................................................................................... 267

Figure 108. Sentinel V System Configuration ............................................................................................ 268

Figure 109. Sentinel V Ping Setup ............................................................................................................. 271

Figure 110. Sentinel V ADC Data ............................................................................................................... 273

Figure 111. Sentinel V Features Data Configuration ................................................................................. 274

Figure 112. Vertical Beam Leader ............................................................................................................. 277

Figure 113. Vertical Beam Velocity Data Format ...................................................................................... 278

Figure 114. Vertical Beam Correlation Magnitude, Amplitude, Percent-Good ......................................... 279

Figure 115. Bottom-Track Data Format..................................................................................................... 282

Figure 116. Reserved BIT Data Format ...................................................................................................... 285

Figure 117. Checksum Data Format .......................................................................................................... 285

Figure 118. Sentinel V Event Log Configuration ........................................................................................ 286

Figure 119. Wave Parameters ................................................................................................................... 287

Figure 120. Wave Parameters2 – Sea and Swell ....................................................................................... 289

LIST OF TABLES

Table 1. Supported Operating Systems and Browsers ............................................................................. 7

Table 2. Supported Operating Systems and Browsers for Sentinel V Real-Time Utilities Page .............. 28

Page x

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

Page 11

Table 3. Blank Distance, Range, and Cell Size ........................................................................................ 60

Table 4. Underneath Vessel Mounting of a Sentinel V20/V50 ADCP ..................................................... 90

Table 5. Underneath Vessel Mounting of a Sentinel V100 ADCP ........................................................... 91

Table 6. Tools and Spares Parts ............................................................................................................. 97

Table 7. Compass Calibration Score ..................................................................................................... 118

Table 8: Sentinel V ADCP Spare Parts .................................................................................................. 120

Table 9: Sentinel V ADCP Repair Kits ................................................................................................... 120

Table 10: High Bandwidth Water Profiling ............................................................................................. 152

Table 11: Low Bandwidth Water Profiling ............................................................................................. 152

Table 12. Bottom Track Range and Accuracy ......................................................................................... 153

Table 13: Profile Parameters .................................................................................................................. 153

Table 14: Echo Intensity Profile ............................................................................................................. 153

Table 15. Real-Time Trigger ................................................................................................................... 153

Table 16: Transducer and Hardware ...................................................................................................... 154

Table 17: Standard Sensors .................................................................................................................... 155

Table 18: Sentinel V Battery Power Specifications ................................................................................ 156

Table 19: Environmental Specifications ................................................................................................. 156

Table 20: Outline Installation Drawings ................................................................................................. 157

Table 21: Sentinel V Real-Time Input Command Summary ................................................................... 186

Table 22. Maximum Fixed Altitude ........................................................................................................ 195

Table 23. Maximum Search Altitude ...................................................................................................... 196

Table 24: Serial Port Control .................................................................................................................. 200

Table 25: Set Control Flags ..................................................................................................................... 200

Table 26: Restore Command Defaults ................................................................................................... 204

Table 27. Turnkey Mode Actions ........................................................................................................... 205

Table 28: Coordinate Transformation Processing Flags ......................................................................... 215

Table 29: Sensor Source Switch Settings................................................................................................ 218

Table 30: Synchronization Parameters .................................................................................................. 228

Table 31: Bandwidth Control ................................................................................................................. 234

Table 32. Blank Distance ........................................................................................................................ 236

Table 33. Cell Size .................................................................................................................................. 237

Table 34. Vertical Beam Blank Distance ................................................................................................. 242

Table 35. Vertical Beam Cell Size ........................................................................................................... 244

Table 36: Header Data Format ............................................................................................................... 250

Table 37: Fixed Leader Data Format ...................................................................................................... 253

Table 38: Variable Leader Data Format ................................................................................................. 258

Table 39: Velocity Data Format .............................................................................................................. 262

Table 40: Correlation Magnitude Data Format ...................................................................................... 263

Table 41: Echo Intensity Data Format .................................................................................................... 264

Table 42: Percent-Good Data Format .................................................................................................... 265

Table 43. Transformation Matrix Format ............................................................................................... 267

Table 44. Sentinel V System Configuration ............................................................................................ 269

Table 45. Sentinel V Ping Setup ............................................................................................................. 271

Table 46. Sentinel V ADC Data ............................................................................................................... 273

Table 47. Sentinel V Features Data ........................................................................................................ 275

Table 48. Vertical Beam Leader ............................................................................................................. 277

Table 49: Vertical Beam Correlation Magnitude Data Format ............................................................... 279

Table 50: Vertical Beam Amplitude Data Format................................................................................... 280

Table 51: Vertical Beam Percent-Good Data Format ............................................................................. 280

Table 52: Bottom-Track Data Format..................................................................................................... 283

Table 53: Reserved for TRDI Format ...................................................................................................... 285

Table 54: Checksum Data Format .......................................................................................................... 285

Table 55. Sentinel V Event Log Format .................................................................................................. 286

Table 56. Wave Parameters ................................................................................................................... 288

Table 57. Wave Parameters2 – Sea and Swell ....................................................................................... 289

Table 58. Toxic or Hazardous Substances and Elements Contained in Product ..................................... 296

Page xi

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

Page 12

MANUAL REVISION HISTORY

September 2017

• Added Using Sentinel V RT Utilities software

• Added Ethernet communications

• Added using *.feature files for upgrades

• Added Using the Trigger

• Added troubleshooting Ethernet communications

• Updated specifications

• Added Sea Chest to Installation chapter

• Combined Commands and Output Data Format guide into the Sentinel V Operation Manual.

• Updated BF, BX, and #CM commands.

• Added appendix on using Sentinel V Real-Time system with WinRiver II software.

February 2017

• Updated the inventory list.

• Added RS-422 to RS-232 information to RT system.

• Updated troubleshooting section with troubleshooting serial issues.

January 2017

• Added the Sentinel V Real-Time system.

• Added a Maintenance Schedule, Calibration Items, and Maintenance Items and Inspection ta-

bles to the beginning of Chapter 4, Maintenance

• Updated the pressure sensor oil fill procedure.

• Updated the outline installation drawings.

• Updated the Troubleshooting section.

• Updated the specifications.

September 2015

• Added changing the format type to Page Source to save and import files correctly in Safari.

• Updated Figure 49, page 98 and Figure 52, page 101 with battery spacer note.

• Added removing the battery spacer to the battery replacement section when usin g lit hiu m bat -

tery packs.

• Added End User License Agreement (EULA).

May 2015

• Updated System Inventory.

• Added an external battery pack overview drawing.

• Added the lithium battery option and how to use the lithium battery.

Page xii

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

Page 13

• Updated Supported Operating Systems and Browsers.

• Updated Chapter 2 to show new ReadyV screens.

• Removed ReadyVLite chapter.

• Updated compass calibration procedures to show new ReadyV screens.

• Updated the specifications.

March 2015

• Added note to not have 50 or more data files on the recorder when deploying.

• Added caution about firmware version 47.16.xx.xx is not backward compatible.

• Added information about using a Gimbal Bottom Mount.

January 2015

• Updated Available Options

.

• Updated Supported Operating Systems and Browsers Table 1, page 7 for Internet Explorer 11.

• Added Collecting Waves Data to Chapter 2, Using ReadyV.

• Added real-time serial data output setup to Chapter 4, Installation.

• Added adjusting the screen and font size to the Using the Home Panel section.

• Updated the standard compass calibration procedure in Chapter 5. Added the High-Dip compass

calibration procedure and Using the Compass Stand section.

• Updated ReadyV screen captures to 47.14 version firmware.

• Added warning that external battery case batteries are shipped inside the case but not connected.

• Added training video links.

April 2014

• Updated overview graphics Figure 1 and 2 to show pressure sensor oil fill caution.

• Updated Supported Operating Systems and Browsers Table 1, page 7.

• Updated system inventory to show kit part numbers.

• Corrected IP address when connecting via Ethernet port in Chapter 6 (ICN 156).

November 2013

• Updated the System panel to show feature activation in chapter 2.

• Updated the Timing Panel to show Vertical Beam enable in chapter 2.

• Added using the AC Adapter information to chapter 4.

• Updated the compass calibration procedure in chapter 5.

• Updated specifications – V100 maximum cell size changed from 8m to 6m.

August 2013

• Added a flow chart on creating scenarios to Using ReadyV chapter 2.

• Updated Deleting a Scenario section in chapter 2.

• Updated the oil fill procedure in chapter 5.

Page xiii

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

Page 14

• Updated the compass calibration procedure in chapter 5.

July 2013

• Added a Compass Calibration Guide and updated the compass calibration procedure.

• Changed input power from +9 to 24VDC to +12 to 20VDC.

• Updated graphics to show longer housing.

• Added table showing supported operating systems and browsers.

• Added IP address 192.168.0.2 to W irel ess Conn ec tion section.

• Corrected sign convention for the Pitch and Roll table on page 29.

• Updated ReadyV screen captures for data recorder and built-in tests.

• Updated the ReadyVLite chapter.

• Updated specifications and outline installation drawings.

• Updated Troubleshooting section.

December 2012

• Changed time the network is available after power up from three minutes to two.

• Updated ReadyV system panel screen capture.

• Added ReadyVLite chapter.

• Added battery Velcro

®

strap and updated exploded system views.

• Added creating, opening, and deleting scenario files.

• Added Sentinel V Bandwidth specification.

• Updated description for range.

• Updated applying antifouling paint section.

• Added minimum screen resolution to Computer Considerations section.

March 2012