Page 1

Information included herein is controlled by the Export Administration Regulations

(EAR) and may require an export license, license exception or other approval from the

appropriate U.S. Government agency before being exported from the United States or

provided to any foreign person. Diversion contrary to U.S. law is prohibited.

rapidCAST™

User’s Guide

P/N 95J-8000-00 (March 2018)

© 2018 Teledyne Oceanscience, Inc. All rights reserved.

Page 2

Page ii

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

TABLE OF CONTENTS

INTRODUCTION .................................................................................................................................................1

RAPIDCAST OVERVIEW.......................................................................................................................................3

Terminology ................................................................................................................................................. 4

Mechanical Requirements ........................................................................................................................... 6

Electrical Requirements ............................................................................................................................... 8

Power Connectors ................................................................................................................................ 8

Power Cable Connections .................................................................................................................... 9

Performance Specifications and Operational Limits .................................................................................... 11

INSTALLATION ...................................................................................................................................................14

Unpacking the rapidCAST system ................................................................................................................. 15

Safety ........................................................................................................................................................... 15

Important Safety Warnings .................................................................................................................. 15

Important Deployment Warnings ........................................................................................................ 16

Lockout Procedure ............................................................................................................................... 16

Installing the rapidCAST Interface Software ................................................................................................ 16

Software Architecture .......................................................................................................................... 17

A Tour of the RapidCAST Interface ....................................................................................................... 17

Cable Connections........................................................................................................................................ 18

Antenna Position .......................................................................................................................................... 22

Switch Functions .......................................................................................................................................... 23

LED Functions ............................................................................................................................................... 24

Installing the rapidCAST System ................................................................................................................... 25

Environmental Conditions .................................................................................................................... 25

Lifting the RapidCAST System ............................................................................................................... 26

Installing the Pipe Mount ..................................................................................................................... 27

Installing the Winch on the Pipe Mount .............................................................................................. 28

Installing the Control Module .............................................................................................................. 29

Line Properties ..................................................................................................................................... 30

Line Routing Procedure ........................................................................................................................ 31

Installing and Connecting the Probe .................................................................................................... 32

Installing the Probe Software ....................................................................................................................... 33

Verifying Probe Communications ................................................................................................................. 33

INITIAL SETUP ...................................................................................................................................................35

Power up Sequence ..................................................................................................................................... 36

Connecting the Winch to a PC ...................................................................................................................... 36

Verifying Basic Motion Functionality ........................................................................................................... 37

Adjusting the LevelWind Position ................................................................................................................ 38

Line Management ................................................................................................................................ 39

Checking for Line Fouling ..................................................................................................................... 39

Defining Positions ........................................................................................................................................ 40

Setting the Home Position ........................................................................................................................... 40

Dock Position........................................................................................................................................ 41

Comm Position ..................................................................................................................................... 42

Launch Position .................................................................................................................................... 43

Recovery Position ................................................................................................................................. 43

Saving and Loading Workspaces .................................................................................................................. 45

CURVE FITTING & DIVE TABLE CREATION .................................................................................................................47

Using Auto-Depth ......................................................................................................................................... 48

What Auto-Depth Does and Does Not Do ............................................................................................ 48

Auto-Depth Customizable Parameters ................................................................................................. 49

Auto Depth Status ................................................................................................................................ 50

Page 3

Page iii

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

Using Coverage ............................................................................................................................................ 50

Using Auto-Repeat ....................................................................................................................................... 51

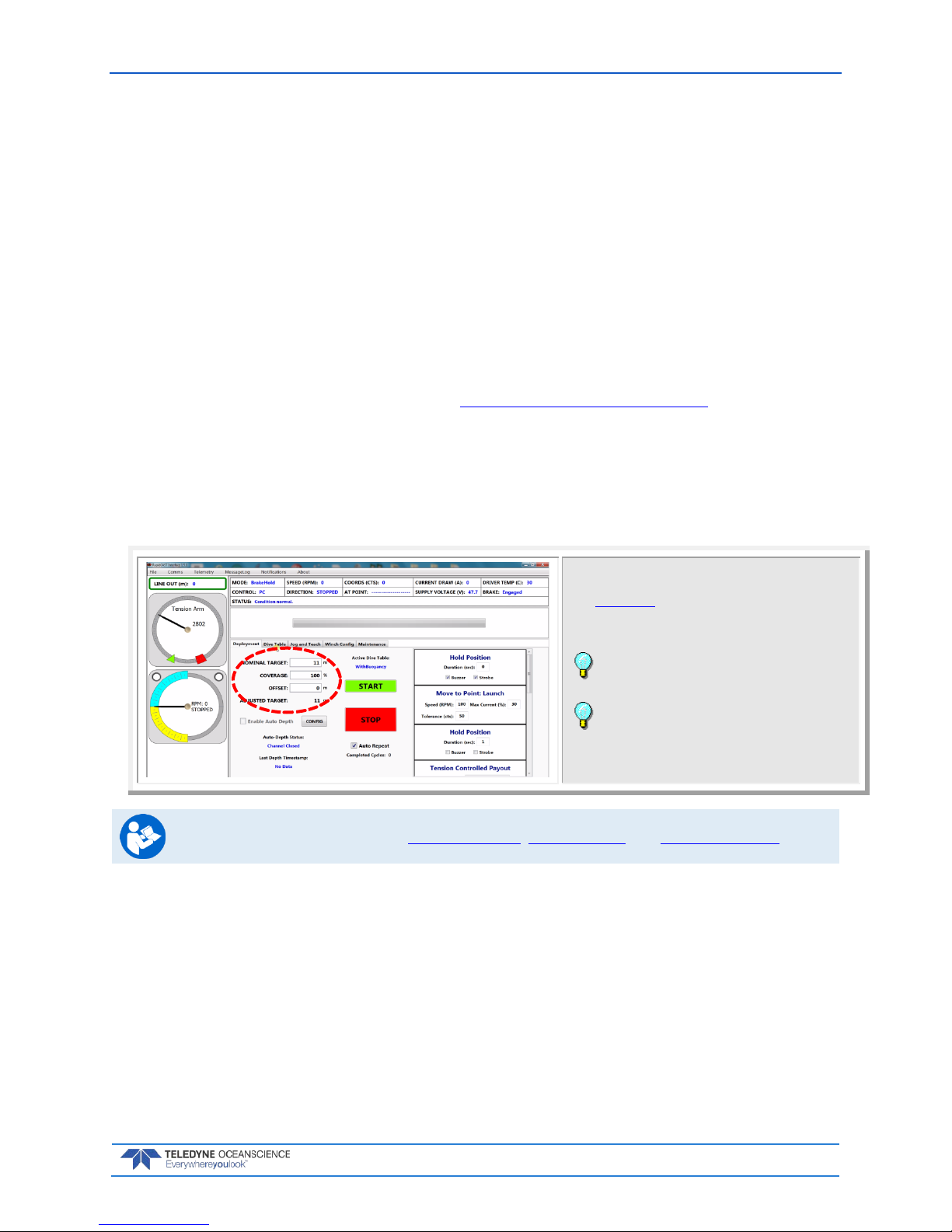

PERFORMING YOUR FIRST CAST ............................................................................................................................52

Step 1 –Setup ............................................................................................................................................... 53

Step 2 – Set Target Depth ............................................................................................................................ 53

Step 3 – Set Parameters ............................................................................................................................... 54

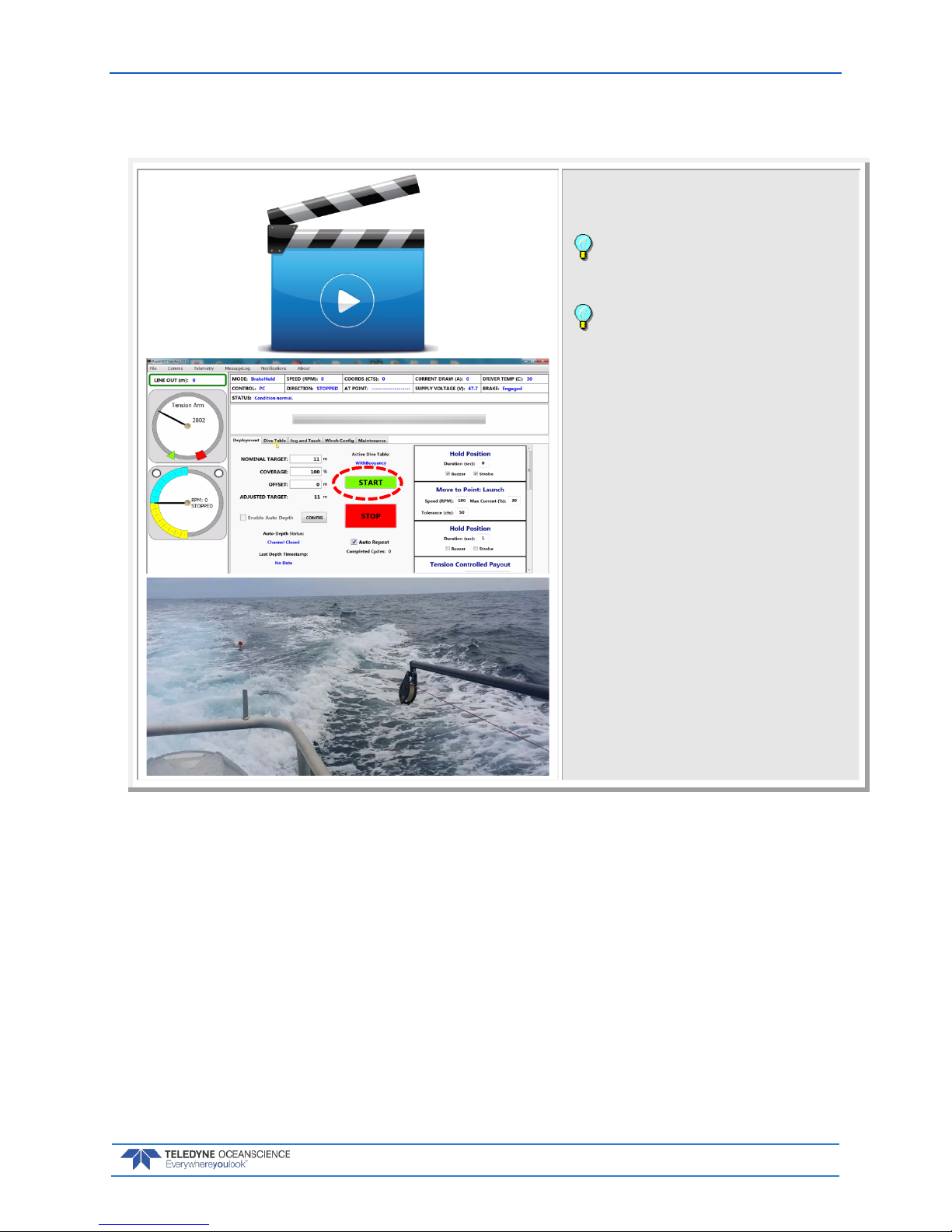

Step 4 – Move to Point Launch .................................................................................................................... 55

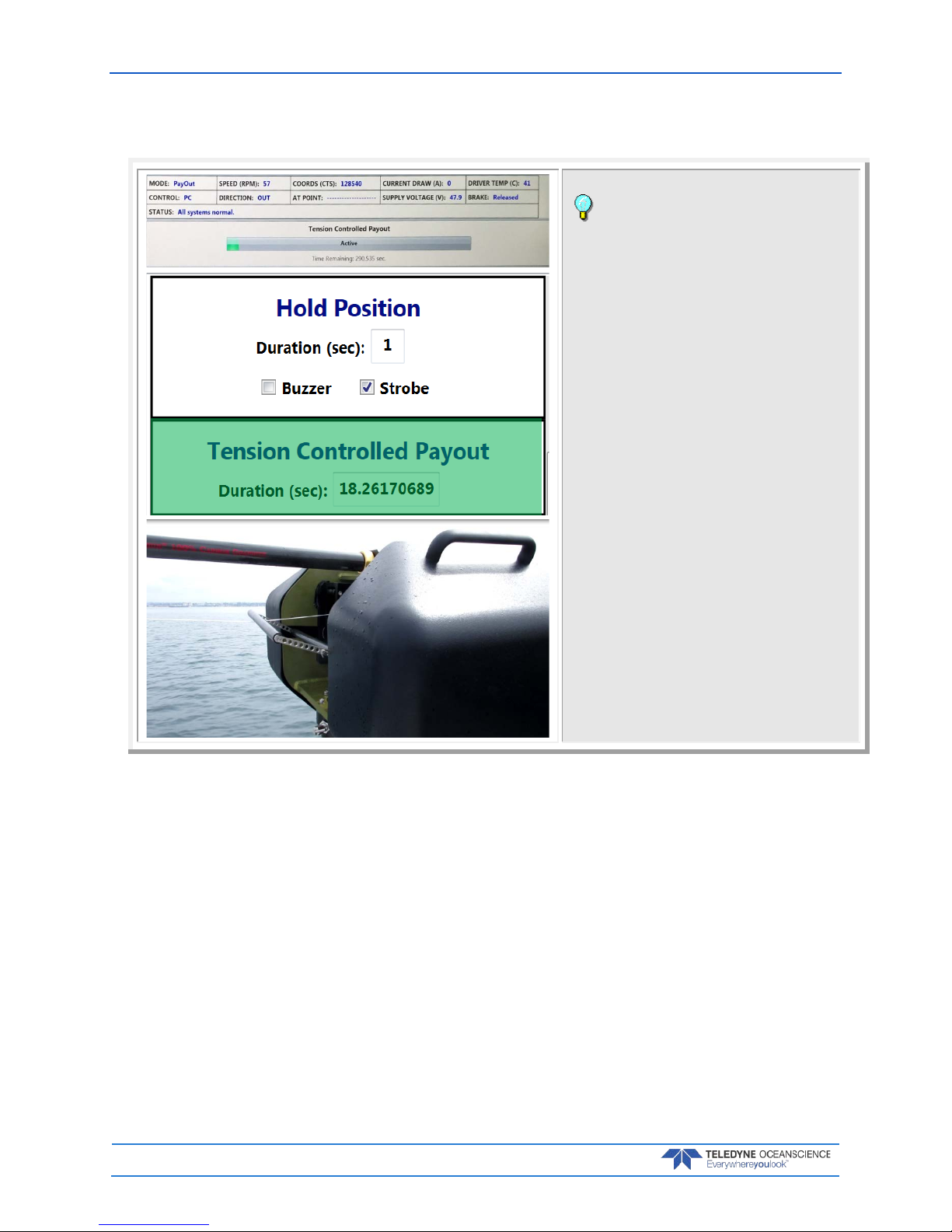

Step 5 – Tension Controlled Payout ............................................................................................................. 56

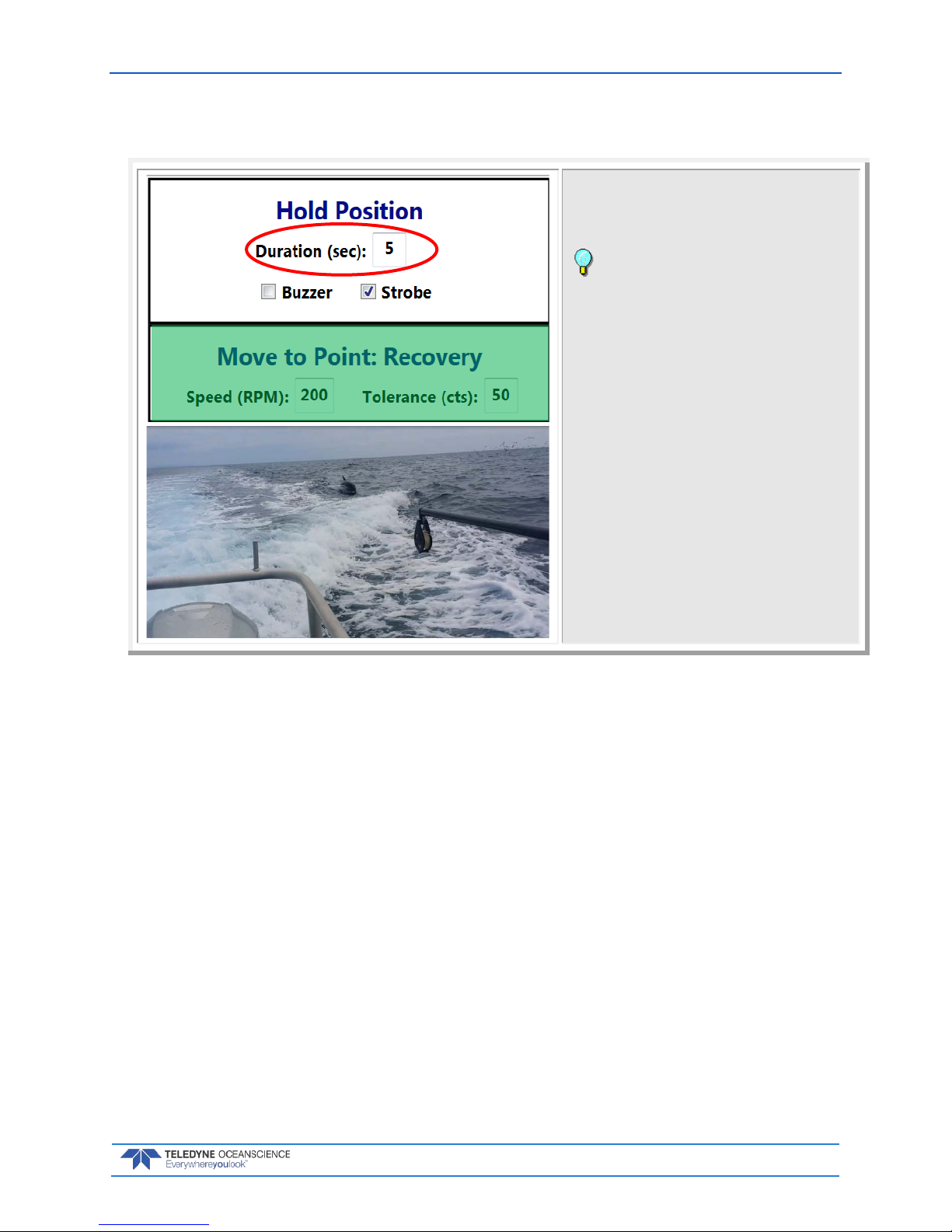

Step 6 – Move to Point Recovery ................................................................................................................. 57

Step 7 – Move to Point Comm ..................................................................................................................... 58

Complete ...................................................................................................................................................... 58

DISASSEMBLY AND PACKING .................................................................................................................................60

USING THE CONFIGURATION SETTINGS ....................................................................................................................61

RESOLVING FAULT CONDITIONS .............................................................................................................................62

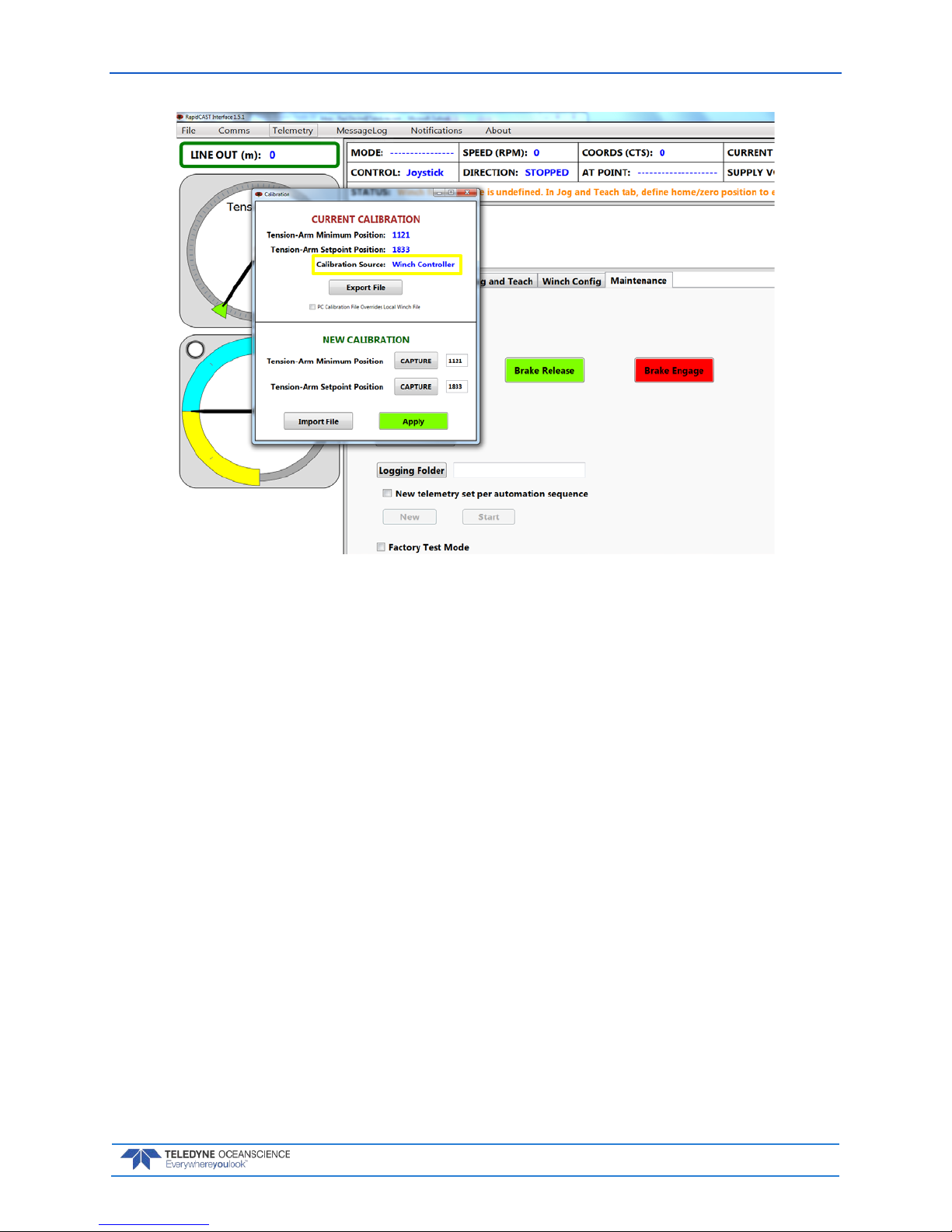

TENSION ARM CALIBRATION .................................................................................................................................69

USING THE GUI WINDOWS AND CONTROLS .............................................................................................................72

UPDATING THE WINCH SOFTWARE .........................................................................................................................74

MAINTENANCE PROCEDURES ................................................................................................................................75

Tailspool ....................................................................................................................................................... 76

Shackle Replacement ................................................................................................................................... 78

Loop Splice ................................................................................................................................................... 79

Inline Splice .................................................................................................................................................. 80

Replacing the Spool ...................................................................................................................................... 80

Removing the Spool ............................................................................................................................. 80

Reassembling the Spool Module .......................................................................................................... 81

APPENDIX A - INSTALLATION DRAWINGS .................................................................................................................83

LIST OF FIGURES

Figure 1. Winch Assembly Overview ......................................................................................................... 4

Figure 2. Interface Module Overview........................................................................................................ 4

Figure 3. Control Module Overview .......................................................................................................... 5

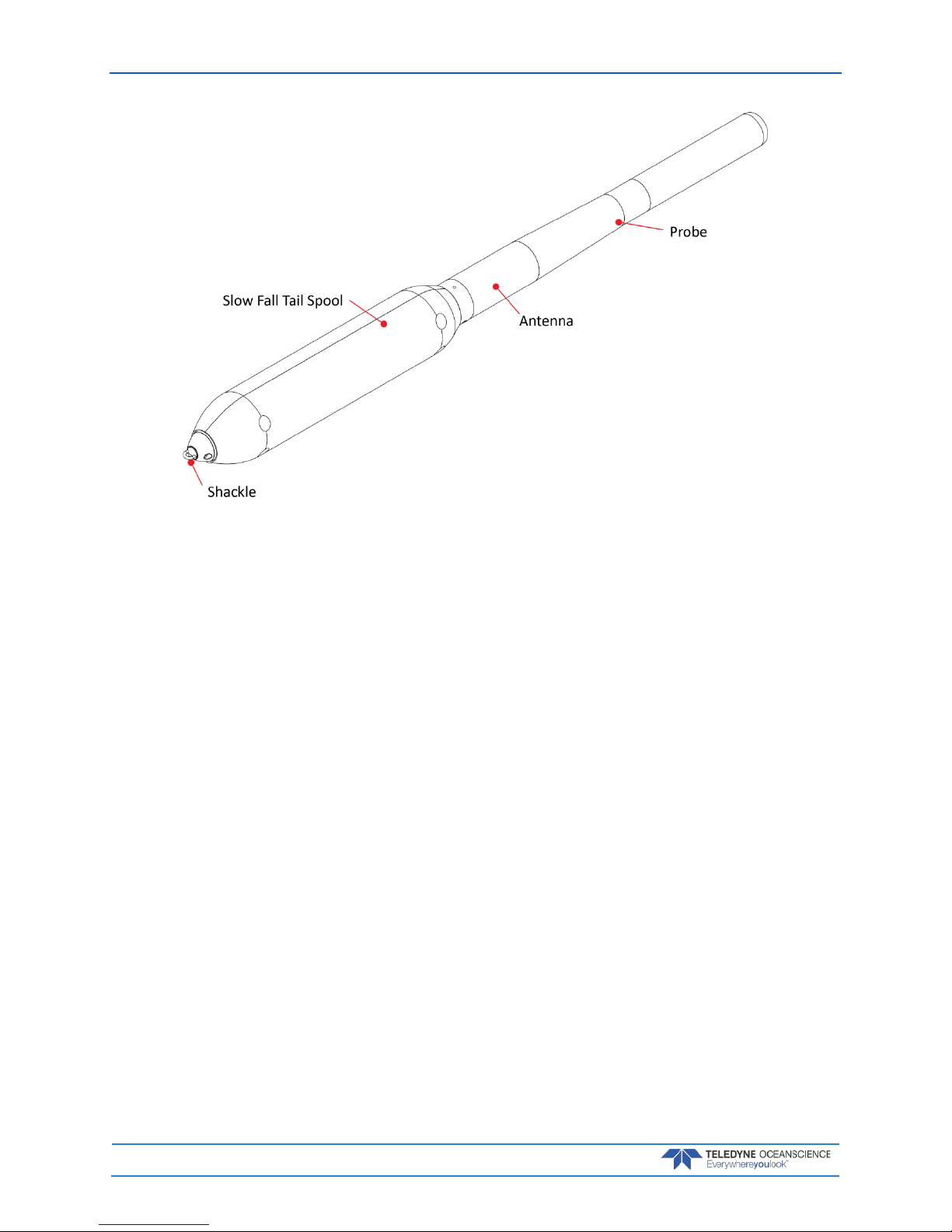

Figure 4. Probe Assembly Overview .......................................................................................................... 6

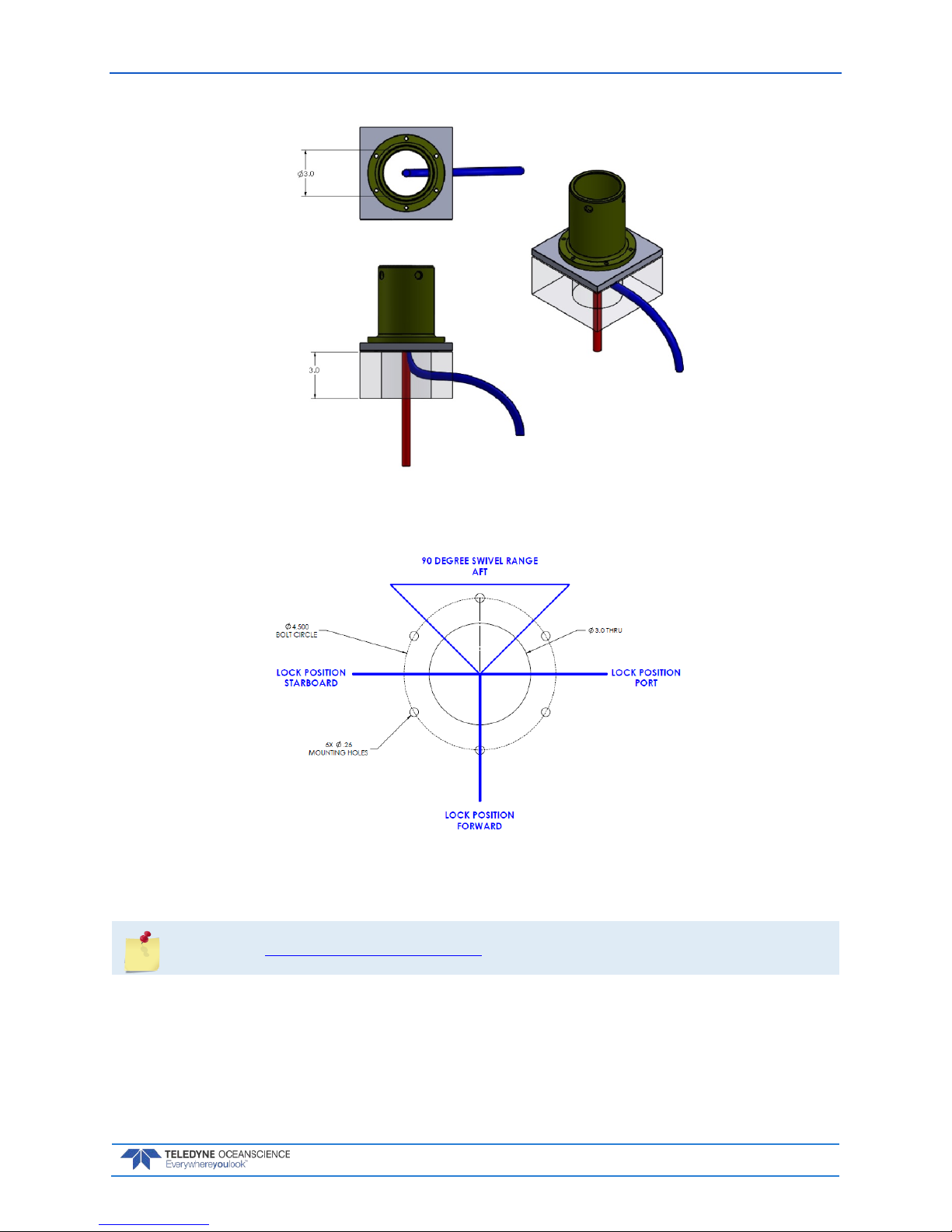

Figure 5. Cable Clearance Requirements .................................................................................................. 7

Figure 6. Mounting Requirements ............................................................................................................ 7

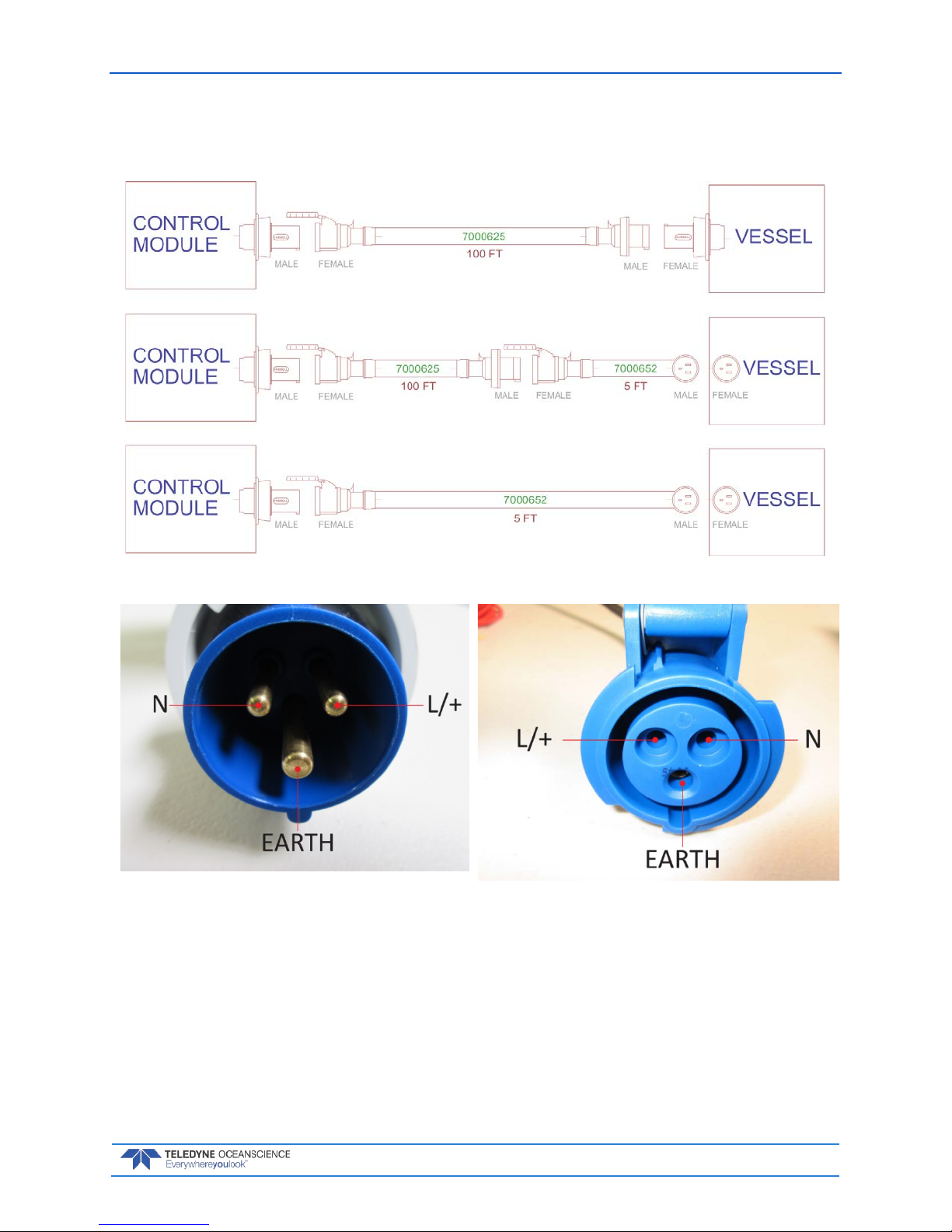

Figure 7. Power Cable Connections ........................................................................................................... 9

Figure 8. 7000625 Cable Plug/Termination ............................................................................................... 9

Figure 9. 60309 Vessel Socket / Receptacle/ Outlet ................................................................................. 9

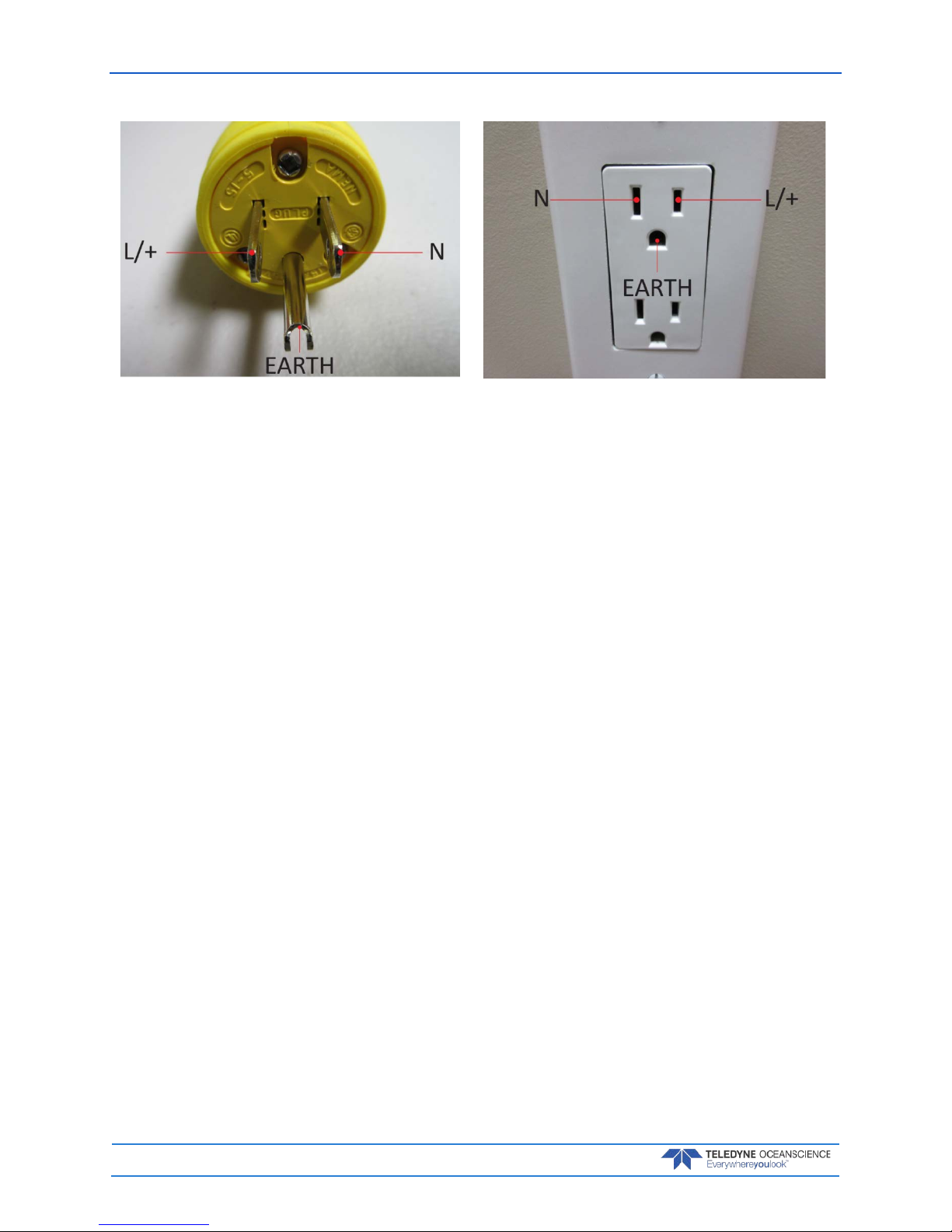

Figure 10. 7000652 Cable Plug/Termination ............................................................................................. 10

Figure 11. Vessel Socket/Receptacle/Outlet ............................................................................................. 10

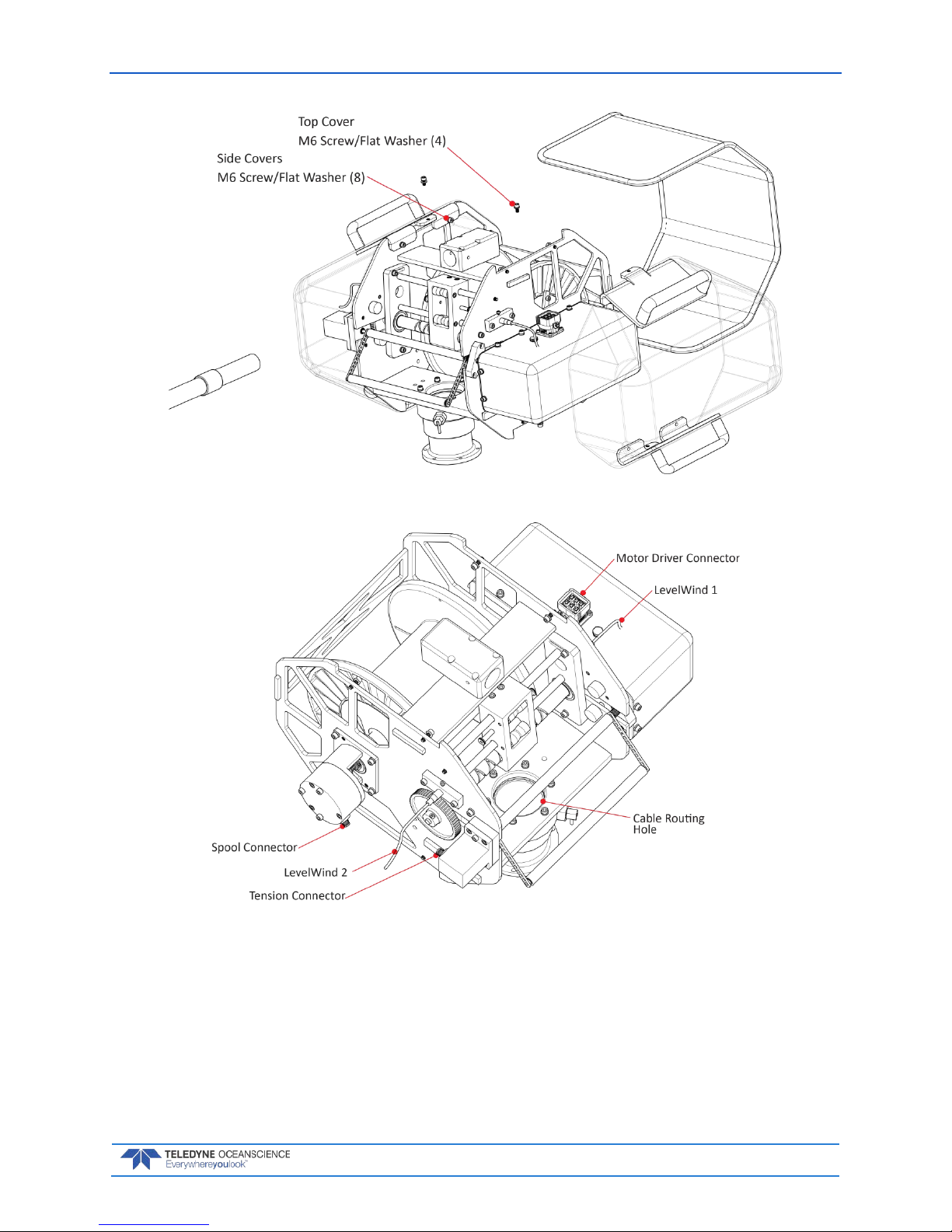

Figure 12. Removing the Winch Assembly Covers .................................................................................... 19

Figure 13. Winch Assembly Connectors .................................................................................................... 19

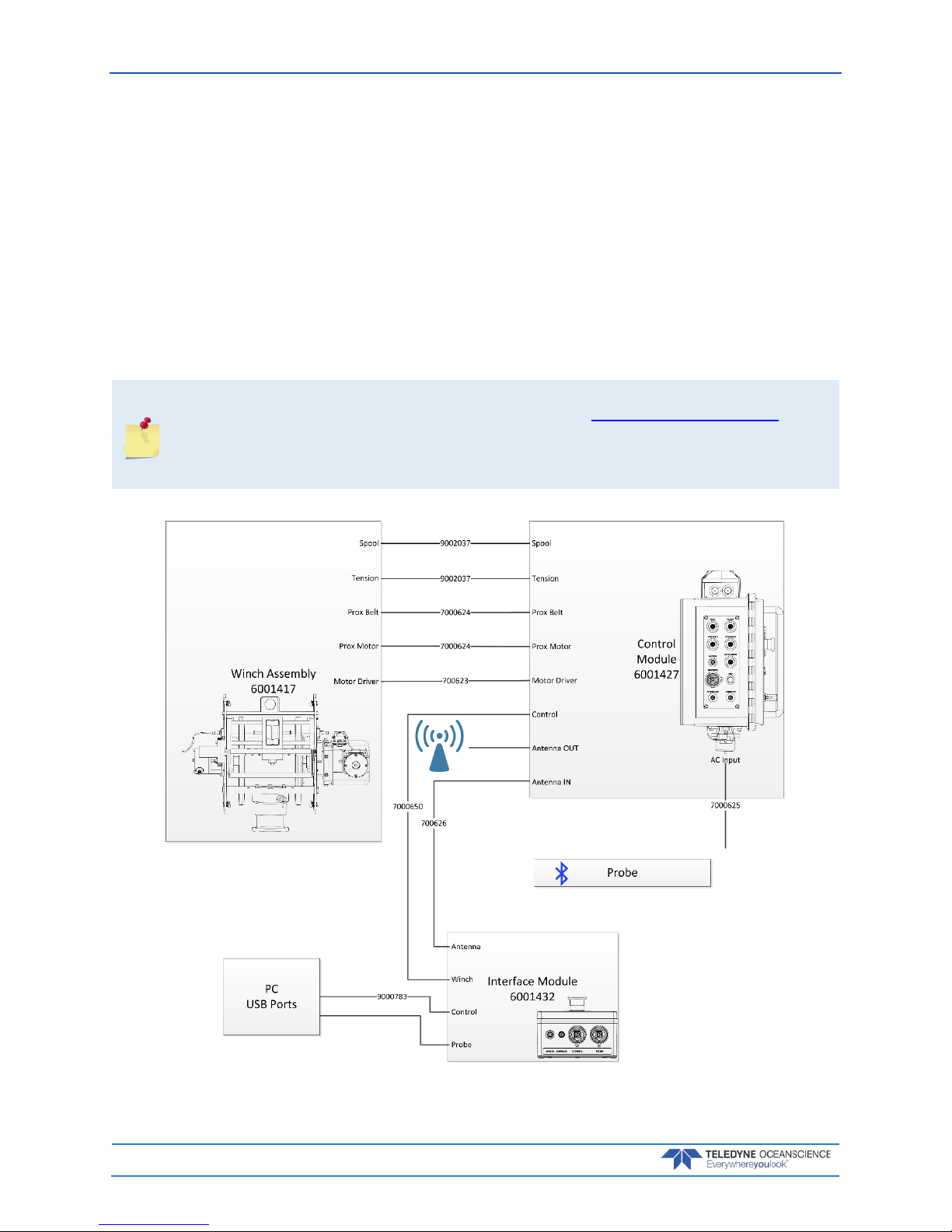

Figure 14. rapidCAST Cable Connections (Large Vessels) .......................................................................... 20

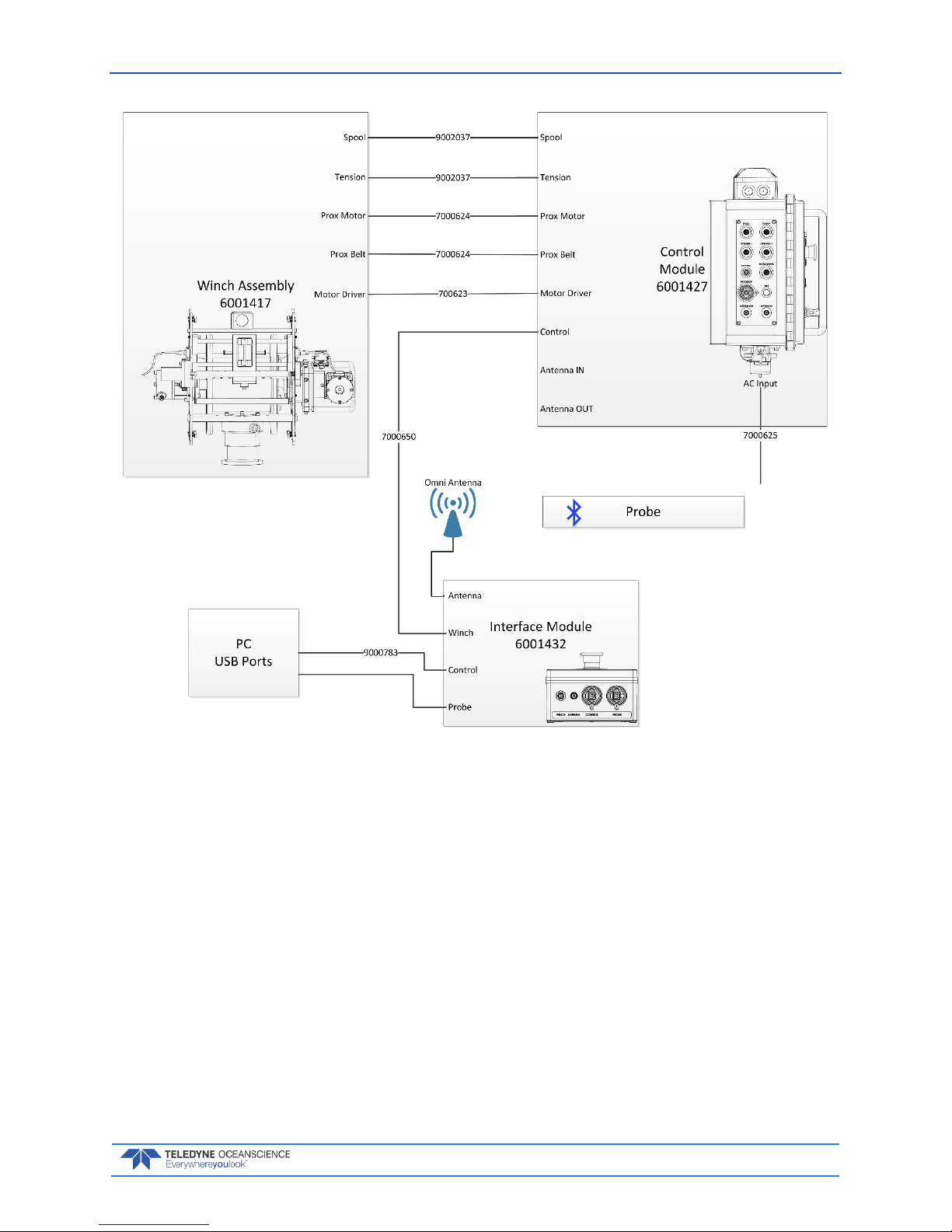

Figure 15. rapidCAST Cable Connections (Small Vessels) .......................................................................... 21

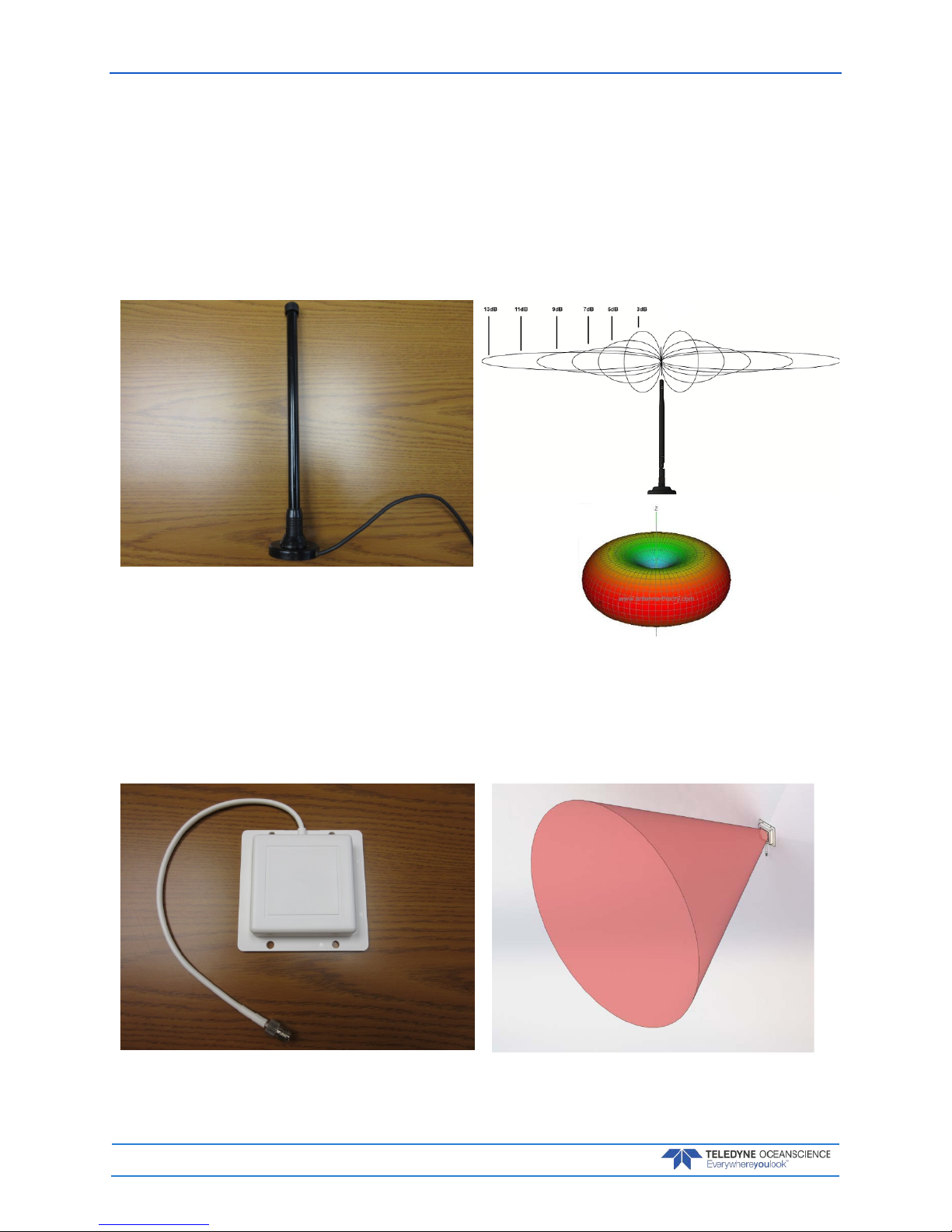

Figure 16. Omni Antenna .......................................................................................................................... 22

Figure 17. Patch Antenna .......................................................................................................................... 22

Figure 18. Control Module ........................................................................................................................ 23

Figure 19. Interface Module ...................................................................................................................... 23

Figure 20. Center of Mass (CM) Location .................................................................................................. 26

Figure 21. Attaching Pipe Mount .............................................................................................................. 27

Page 4

Page iv

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

Figure 22. Pipe Mount Installed on UCTD Adapter Plate .......................................................................... 27

Figure 23. Installing the Winch on the Pipe Mount ................................................................................... 28

Figure 24. Mounting the Control Module ................................................................................................. 29

Figure 25. Control Module Dimensions ..................................................................................................... 29

Figure 26. Line Routing Procedure ............................................................................................................ 31

Figure 27. Installing the Probe .................................................................................................................. 32

Figure 28. Assigning the COMM Ports ....................................................................................................... 36

Figure 29. Jog and Teach Tab .................................................................................................................... 37

Figure 30. LevelWind Adjustment ............................................................................................................. 38

Figure 31. Line Management .................................................................................................................... 39

Figure 32. Dock Position ............................................................................................................................ 41

Figure 33. Comm Position ......................................................................................................................... 42

Figure 34. Launch Position ........................................................................................................................ 43

Figure 35. Recovery Position ..................................................................................................................... 44

Figure 36. Workspace Files........................................................................................................................ 45

Figure 37. Packing the Winch .................................................................................................................... 60

Figure 38. Winch Configuration Settings ................................................................................................... 61

Figure 39. Tension Arm Calibration ........................................................................................................... 71

Figure 40. Bad shackle ............................................................................................................................... 76

Figure 41. Good Shackle ............................................................................................................................ 76

Figure 42. Bad Loop splice, worn and torn ................................................................................................ 76

Figure 43. Good Loop Splice ...................................................................................................................... 76

Figure 44. BAD Inline Splice ....................................................................................................................... 77

Figure 45. Good Inline Splice ..................................................................................................................... 77

Figure 46. Shackle Replacement ............................................................................................................... 78

Figure 47. Loop Splice ............................................................................................................................... 79

Figure 48. Inline Splice .............................................................................................................................. 80

Figure 49. Removing the Encoder ............................................................................................................. 81

Figure 50. Removing the Spool ................................................................................................................. 81

Figure 51. Spool Retention Points ............................................................................................................. 82

Figure 52. Spool Installed .......................................................................................................................... 82

LIST OF TABLES

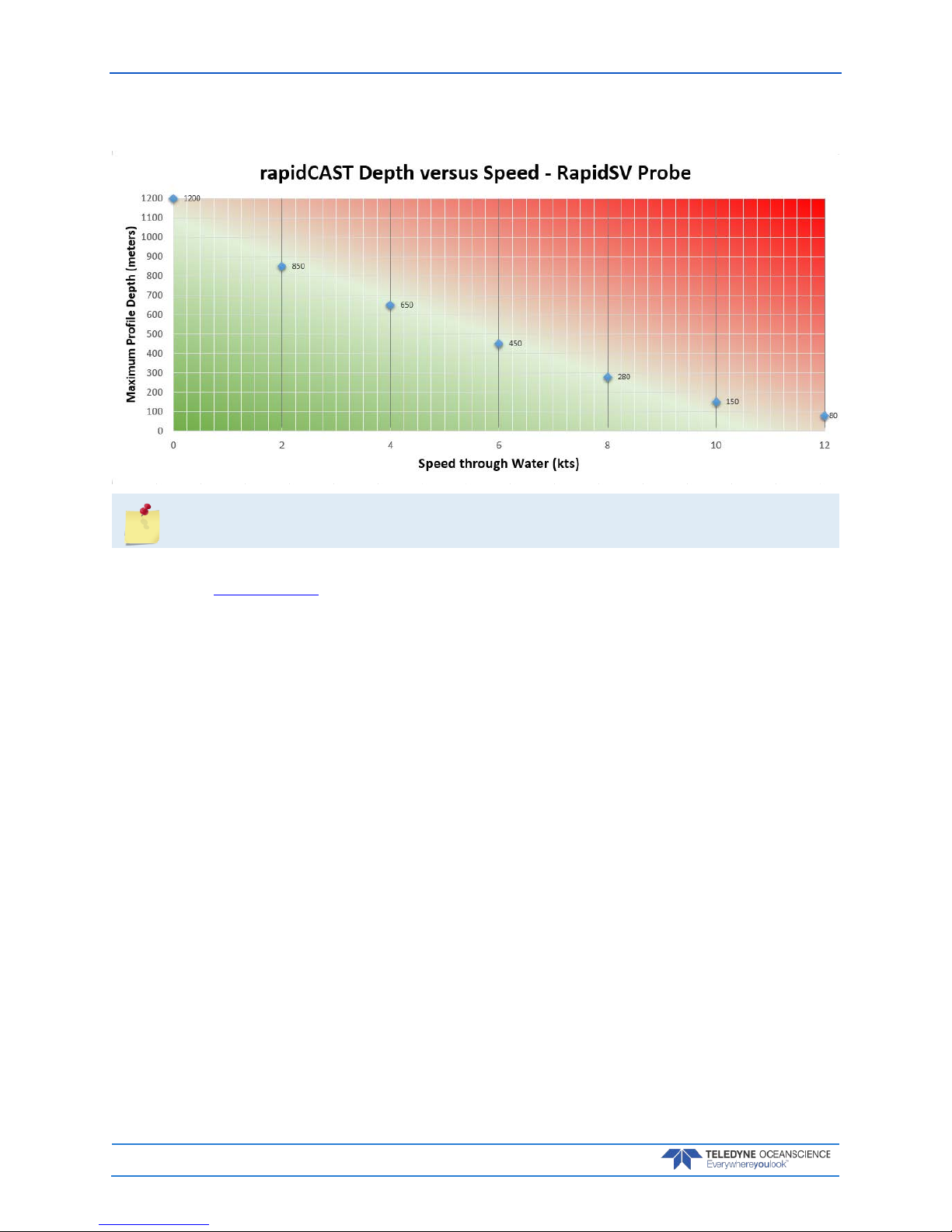

Table 1. rapidCAST Depth versus Speed ................................................................................................ 12

Table 2. Inventory .................................................................................................................................. 15

Table 3. Spare Parts Kit 71JK6004-00 ..................................................................................................... 75

Page 5

Page v

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

REVISION HISTORY

March 2018

• Added Depth versus Speed table to specifications.

February 2018

• Added the Export Administration Regulations (EAR) statement

• Corrected inventory list part numbers

• Corrected part number for shackle on Figure 46

March 2017

• Updated the Lockout procedure

• Updated the RapidCAST Interface tour

• Updated Maintenance procedures with table showing the spare parts kit 71JK6004-00

• Added instructions for Disassembly and Packing

• Added the outline installation drawings to Appendix A

October 2016

• Added Replacing the Spool to the maintenance procedures

• Updated the tension arm calibration

May 2016

• Updated manual to include changes from rapidCAST Interface software version 1.5.1

• Added Line Properties, Line Management, and Checking for Line Fouling sections

• Updated Adjusting the LevelWind Position

• Updated the Profiling Capability specification from 500m at 8 kts to >500m at 5 kts

• Updated phone numbers

April 2016

• Revised most assembly drawings and figures.

• Updated Resolving Fault Conditions

• Added Appendix A – Installation Drawings

September 2015

• Initial release.

Page 6

Page vi

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

NOTES

Page 7

rapidCAST User’s Guide March 2018

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

Page 1

Introduction

Dear Valued Customer,

Thank you for purchasing your rapidCAST

TM

system. Teledyne Oceanscience has a support team in place

to assist you with understanding, operating, and deploying your rapidCAST system. Included with your

system is documentation regarding the setup and deployment of the rapidCAST. We strongly encourage

you to thoroughly read through this documentation to maximize your user experience.

T ECHNICAL S UPPORT

If you have technical issues or questions involving a specific application or deployment, contact:

Phone: +1 (858) 842-2600

FAX: +1 (858) 842-2822

Email: Oceanscience.Support@teledyne.com

If you have technical issues or questions involving a specific application or deployment with your instru-

ment, contact our Field Service group:

S ALES

Our products are available from Oceanscience directly or from representatives throughout the world.

Please contact us for more information:

E-mail: Oceanscience.Sales@teledyne.com

V IDEOS

Additional training support is available via videos:

• Overview and Deployment

Page 8

March 2018 rapidCAST User’s Guide

Page 2

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

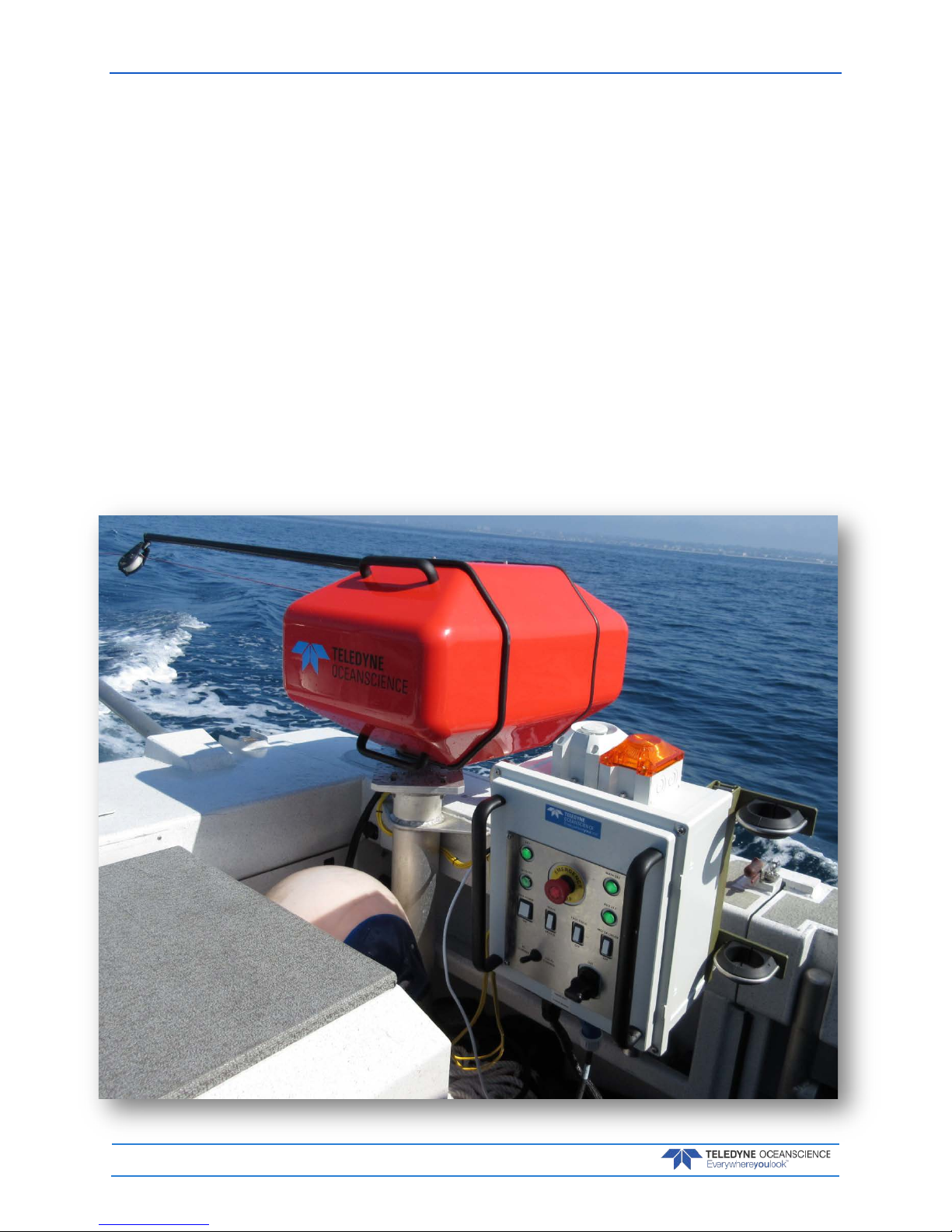

The rapidCAST delivers a probe to a user-specified target depth while the vessel is underway, and retrieves the probe automatically. Using an entirely new active tension management system, payout behavior is precisely controlled to ensure the probe depth is known at all times - even without a conducting cable! Data transfer is achieved using an automated Bluetooth connection.

rapidCAST provides:

• A Tension Control System that allows the probe to fall freely under the influence of gravity

even when the probe is tethered to the winch.

• Line tension is measured in real-time, and the rotation speed of the spool is quickly modulated

to minimize tugging on the probe.

• If tension rises above the setpoint, the spool speeds up, and if tension falls below the setpoint,

the spool slows down until equilibrium is restored.

• The Tension Control System prevents the ship from dragging the probe, and ensures that the

probe falls freely despite surface disturbances such as waves, swells, heaving, pitching, and rolling.

Page 9

rapidCAST User’s Guide March 2018

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

Page 3

rapidCAST Overview

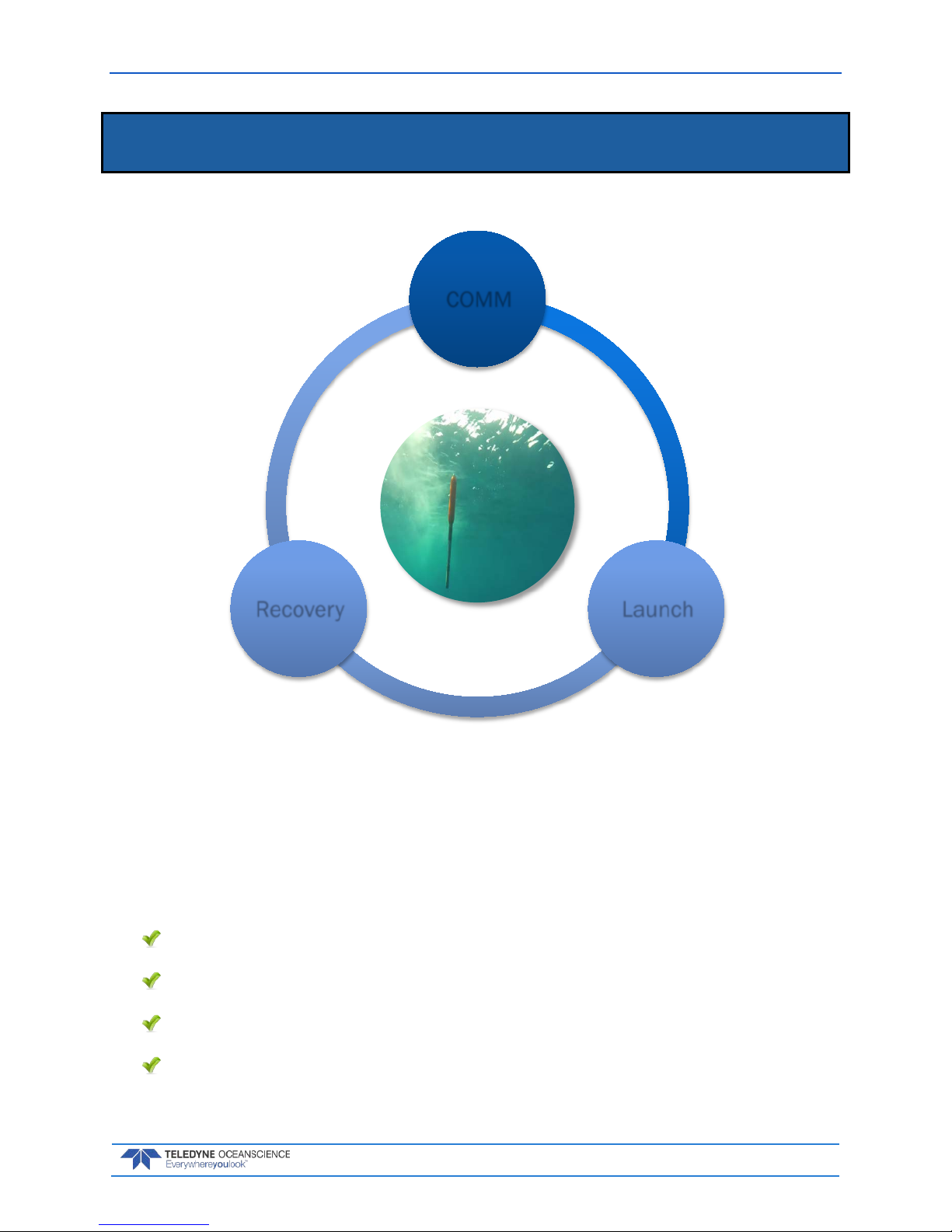

THE RAPIDCAST OVERVIEW INCLUDES THE FOLLOWING:

Terminology

Mechanical Requirements

Electrical Requirements

Performance Specifications and Operational Limits

COMM

LaunchRecovery

Page 10

March 2018 rapidCAST User’s Guide

Page 4

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

Terminology

Use this section to learn the terms that will be used throughout the manual.

Figure 1. Winch Assembly Overview

Figure 2. Interface Module Overview

Page 11

rapidCAST User’s Guide March 2018

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

Page 5

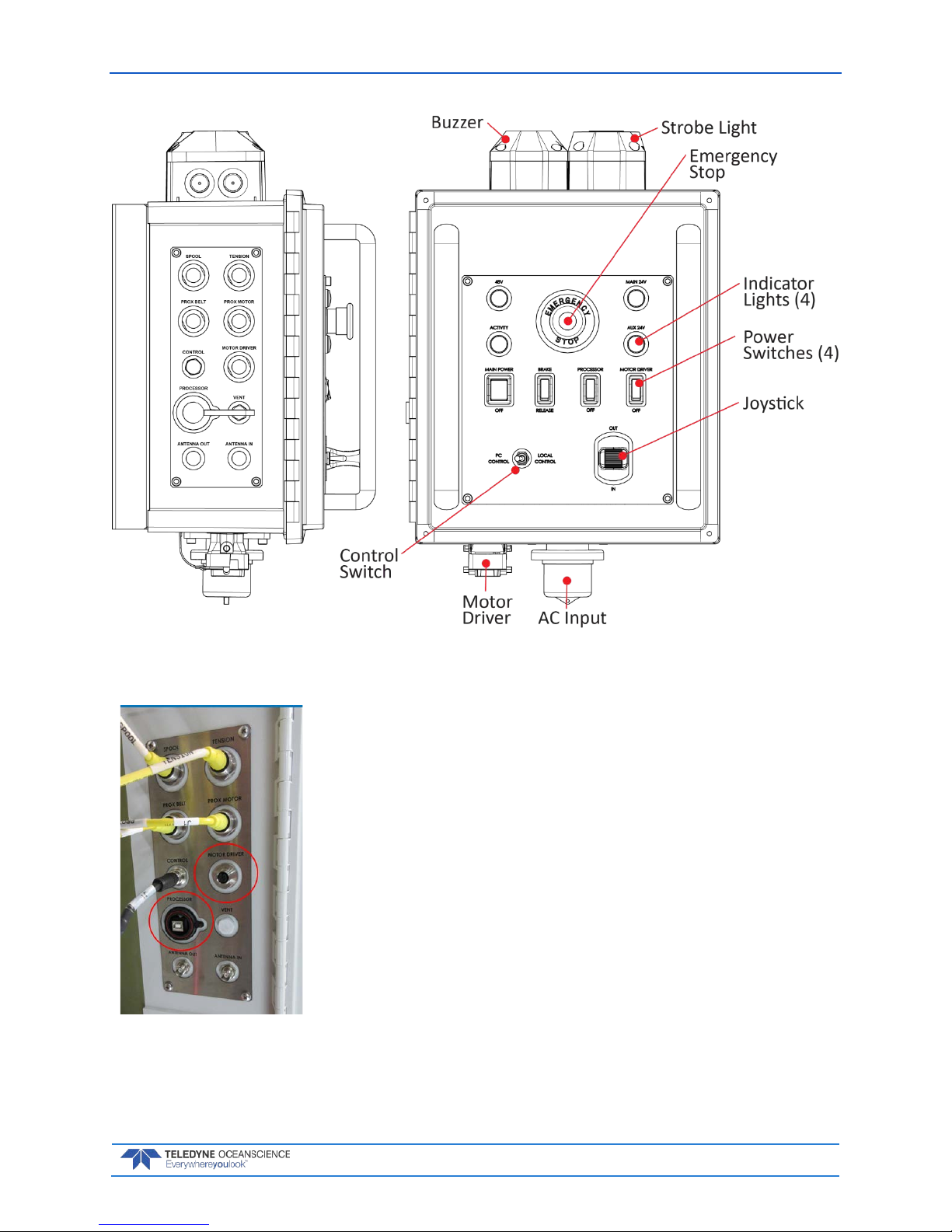

Figure 3. Control Module Overview

• The top four connectors are latching non-threaded push-pull

types.

• The Control and Antenna connectors are threaded and screw

on.

• Ensure that connectors are fully-seated; otherwise water re-

sistance may be compromised!

• Connectors circled in red are used only in special circum-

stances and are normally left disconnected. Make sure the

caps are on during a deployment to protect the connectors.

Page 12

March 2018 rapidCAST User’s Guide

Page 6

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

Figure 4. Probe Assembly Overview

Mechanical Requirements

Mounting Requirem ents: The ideal deployment location is in the center of the vessel, with deployment directly over the aft rail, but other locations may be possible. The swivel base should be mounted

within 24 inches of the aft rail. Oceanscience can provide designs for mounting options if necessary. Installation of a serial cable running from the rapidCAST electronic control module to the survey PC is required. As the probe uses wireless Bluetooth telemetry, no cabling is required for data download.

The figure below depicts mounting and cable clearance requirements. Routing of the winch power and

data cables must be taken into consideration. The bolt circle should be oriented as shown below because

the swivel base has built in stops to control the rotation of the winch, see Figure 6. The mounting platform

should be able to withstand a moment of 70ft-lbs with little to no deflection. Below the mounting platform, a 3.0 inch clearance is required for cable routing. Straight down cable routing is shown in RED.

Sideways cable routing is also possible if there is a minimum 3.0 inch clearance, shown in BLUE.

Page 13

rapidCAST User’s Guide March 2018

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

Page 7

Figure 5. Cable Clearance Requirements

Figure 6. Mounting Requirements

See Appendix A - Installation Drawings for a detailed Pipe Mount Installation Drawing.

Page 14

March 2018 rapidCAST User’s Guide

Page 8

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

Profiling Depth: The nominal specification is 500m at 8kts, which requires ~1500m of line. As the vessel speed decreases, the achievable cast depth increases up to the maximum pressure rating of the probe

for long stationary casts. As very deep casts are much longer in duration, the vessel cannot be moving appreciably as this will waste available line to account for the movement of the ship. As the vessel speed increases above 8kts, the achievable depth decreases to maintain the profiler in a safe condition during recovery (low line tension). The maximum vessel speed under normal operation is 12kts. The motor rpm

and braking time may be adjusted by the user to suit the survey conditions.

As long as the vessel retains a nominal forward motion to prevent entangling of the line in the ship propeller. The maximum profile depth is then limited by the amount of line on the rapidCAST spool and the

probe pressure rating of 2000m.

Line Type: Hollow Spectra line of 500lb breaking strength with an 800lb leader.

Line Length: The maximum amount of line that can be loaded is about 3000m. Typically, 1500m is

used. Line length does not directly correlate to maximum cast depth underway. This depends on ship

speed because the total line paid out is a product of ship movement and probe depth.

Electrical Requirements

Input Voltage: 90 — 264 VAC RMS, Single Phase

Input Frequency 47 — 63 Hz

Max Current (at 115 VAC Input): 16 A

Max Current (at 230 VAC Input): 10 A

Inrush Current (Cold Start): 50 A Typical

Power Connectors

The rapidCAST system ships with 2 power cables, offering flexibility in the connectors used for power.

• Part Number 7000625 - 100-ft Power Cabl e Ter m inated with IEC 60309 250V 16A, 6H, Blue

P+N+E Plug, that mates to IEC 60309 250V 16A, 6H, Blue P+N+E Socket

• Part Number 7000652 - 5-ft Cable Adapter Terminated with NEMA 5-15P Plug, that mates to

NEMA 5-15R Receptacle

Page 15

rapidCAST User’s Guide March 2018

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

Page 9

Power Cable Connections

The diagram below shows how the power cables may be connected.

Figure 7. Power Cable Connections

Figure 8. 7000625 Cable Plug/Termina-

tion

Figure 9. 60309 Vessel Socket / Recepta-

cle/ Outlet

Page 16

March 2018 rapidCAST User’s Guide

Page 10

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

Figure 10. 7000652 Cable Plug/Termination Figure 11. Vessel Socket/Receptacle/Outlet

Page 17

rapidCAST User’s Guide March 2018

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

Page 11

Performance Specifications and Operational

Limits

Winch Length 48cm (18.89”)

Length with Davit 200cm (78.74”)

Width 71cm (27.95”)

Height 46cm (18.11”)

Weight 36kg (79.36 lbs.)

Input Voltage 48 VDC/ 2.0 kW

Line Capacity 3000m

Construction Aluminum/Delrin/Titanium/Stainless Steel

Probe Recovery Speed 0.5-2m/s (1.5-6.6 fps)

Mount Swivel base (12cm diameter)

Hardware Stainless Steel

Control Module Weight 14kg (30.86 lbs.)

Length 52cm (20.47”)

Width 34cm (13.34”)

Height 29cm (11.42”)

Input Power 90-264 VAC (47-63 Hz)

Output Power 48 VDC

Davit Length 160cm (63”)

Diameter 5cm (2”)

Weight 1.18kg (2.6 lbs.)

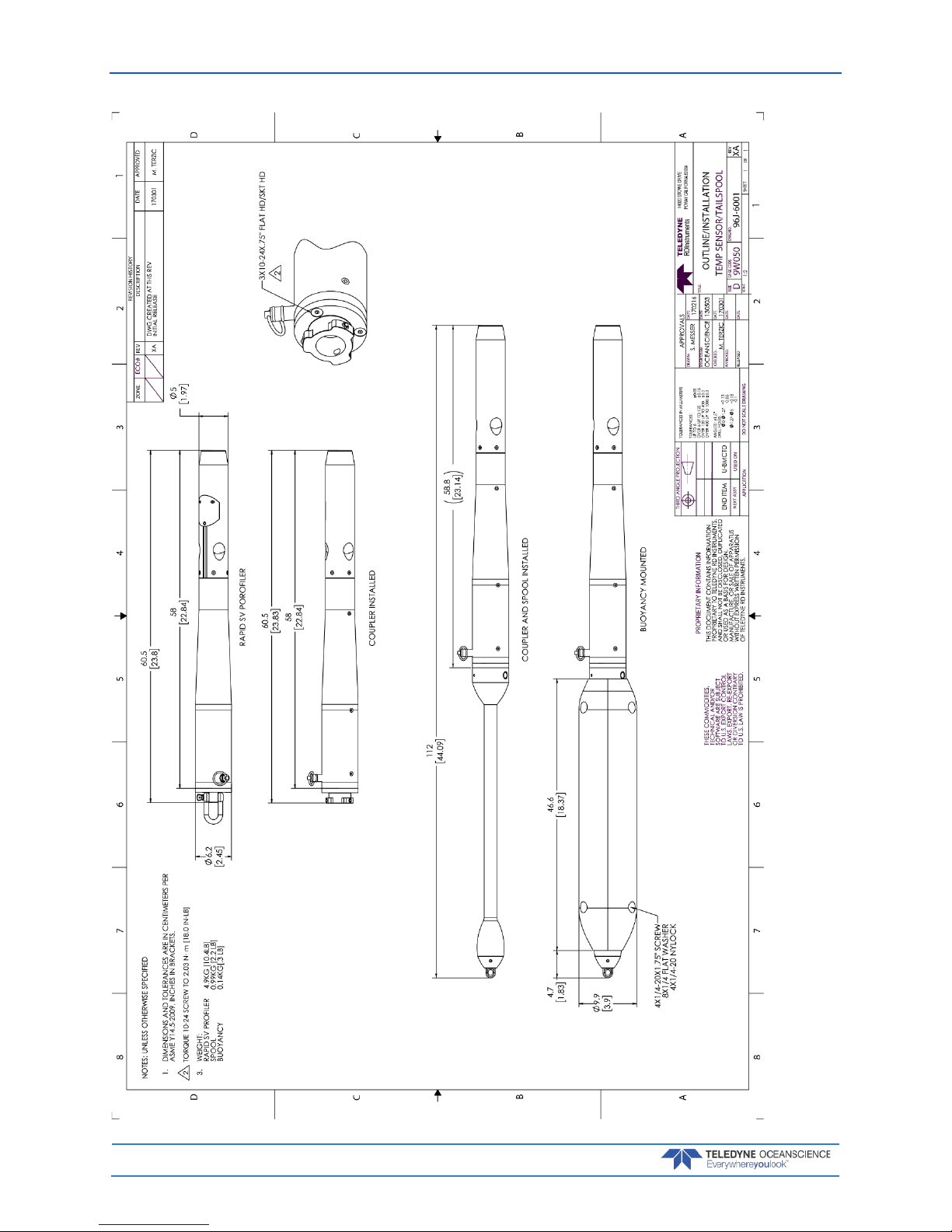

Valeport rapidSV Probe Length (with tail spool) 111cm (43.70”)

Diameter 5cm (1.96”)

Weight (in air) (without tail spool) 4.48kg (9.87 lbs.)

Internal Memory 1000 casts

Depth Rating 2000m

Pressure Resolution ±0.001% range

Accuracy ±0.05% range

Range 0-200 dBar

Temperature (if fitted) Resolution 0.001C

Accuracy ±0.01C

Range -5 to 35C

Sound Velocity Resolution 0.001m/s

Accuracy ±0.02m/s

Range 1375 - 1900m/s

Profiling Capability >500 m at 5 kts or deeper at slow speeds

(see Table 1, page 12)

Page 18

March 2018 rapidCAST User’s Guide

Page 12

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

Table 1. rapidCAST Depth versus Speed

The table above applies to the RapidSV probe. Call for details on other probes.

Each standard spool is delivered with 1954 meters of line, of which 1700 meters can be used for normal

operation (see Line Properties, page 30). Typically, only 1200 meters of line are used.

Deployments less than 100 meters deep:

• The buoyancy tailspool can be used. In this configuration, the probe will fall at approximately

3 m/sec.

The following general specification applies:

• Boat speed relative

Deployment greater than 100 meters deep:

• The buoyancy tailspool CANOT be used. In this configuration use the plain tailspool, the probe

will fall at approximately 4 m/sec.

Page 19

rapidCAST User’s Guide March 2018

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

Page 13

Quick Review

Check that you know the

Terminology used.

Reference Figure 1 through

Figure 4.

Check that the boat meets

the Mechanical and

Electrical Requirements

Reference page 6 to 8.

Page 20

March 2018 rapidCAST User’s Guide

Page 14

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

Installation

I NSTALLATION INCLUDES THE FOLLOWING STEPS:

Unpacking the rapidCAST system

Installing the RapidCAST Control Software

Learning Cable Connections and Switch Functions

Mounting the Winch

Verifying Probe Communications

COMM

LaunchRecovery

Page 21

rapidCAST User’s Guide March 2018

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

Page 15

Unpacking the rapidCAST system

Included with the rapidCAST:

Table 2. Inventory

Packed in

transit case:

Part Number Description Quantity

6001752:

CASE,

TRANSIT,

RCAST,

WINCH

6001417 ASSY, WINCH, RAPIDCAST 1 ea

7000625 CABLE, AC POWER, RCAST, 30.5M 1 ea

7000652 CABLE, AC POWER, RCAST, 1.5M 1 ea

75JK6001-00 Documentation kit contains the RapidCAST Interface software program, USB RS-485

Driver, manuals, and backup driver software.

1 ea

9002211 CABLE, RF, TNC STRAIGHT PLUG, LMR400, 40M 1 ea

9002104:

CASE,

TRANSIT,

RCAST, DAVIT

71J-5001-00 ASSY, DAVIT, RCAST, W/PULLEY 1 ea

9002209 SHOULDER STRAP, DAVIT CASE, RCAST 1 ea

6001754:

CASE,

TRANSIT,

RCAST,

CONTROL

MODULE

6001427 ASSY, CONTROL MODULE, RAPIDCAST 1 ea

6001432 ASSY, INTERFACE MODULE, RAPIDCAST 1 ea

8000592 MOUNT, PIPE FLANGE, RCAST 1 ea

6001436 ASSY, PROBE BRACKET, RCAST 2 ea

6001751 KIT, TOOLS AND SPARES, RCAST 1 ea

7000650 CABLE, TELEMETRY AND CONTROL, RCAST 1 ea

6000617 SET, TAILSPOOL W/BULKHEAD, RCAST/UCTD 1 ea

6000630 SET, TAILSPOOL W/BULKHEAD, RCAST/UCTD, W/BUOYANCY MODULE 1 ea

8000112 TRAINING PROBE, RCAST/UCTD 1 ea

9002212 CABLE, RF, TNC STRAIGHT PLUG, LMR400, 5M 1 ea

9002173 ANTENNA, 2.4 GHz 8dBi FLAT PATCH W/ TNC CONNECTOR 1 ea

Safety

Important Safety Warnings

Do not put your hands inside the frame unless the system is Locked Out.

Always assume the system is live.

When in doubt use Emergency Stop.

Stand clear of line, do not stand in loops or wrap line around your hand.

Page 22

March 2018 rapidCAST User’s Guide

Page 16

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

Important Deployment Warnings

Never go past the maximum line payout.

Line is taped on the spool. Never get in to the bottom RED layer or you will lose a probe.

If the winch cannot pull the line in or the brake is not working, STOP the vessel immediately.

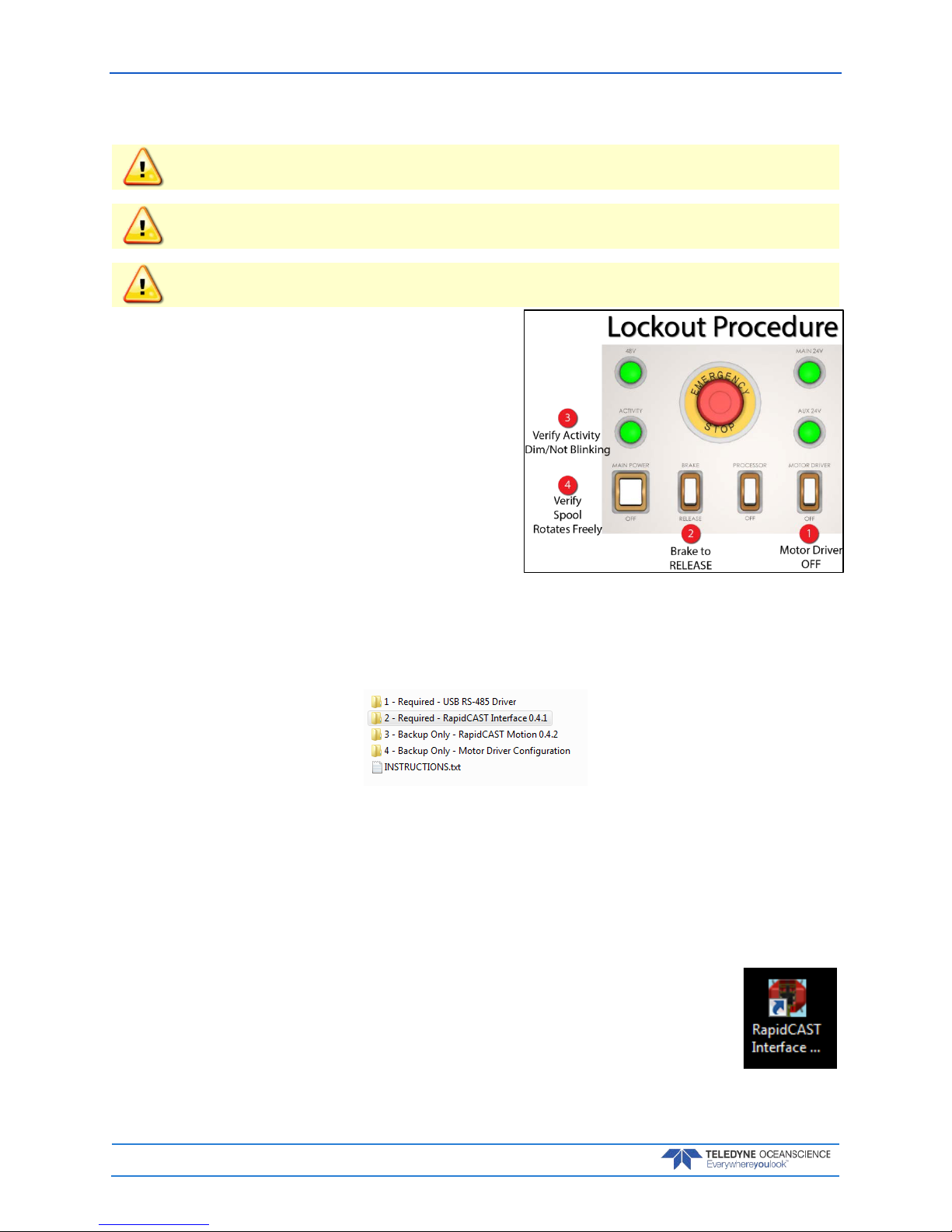

Lockout Procedure

To lock out the system:

1. Switch Motor Driver OFF.

2. Switch Brake to RELEASE.

3. Check to ensure Activity Light is Dim/Not blinking.

4. Check to see if the spool rotates freely.

The system is now SAFE.

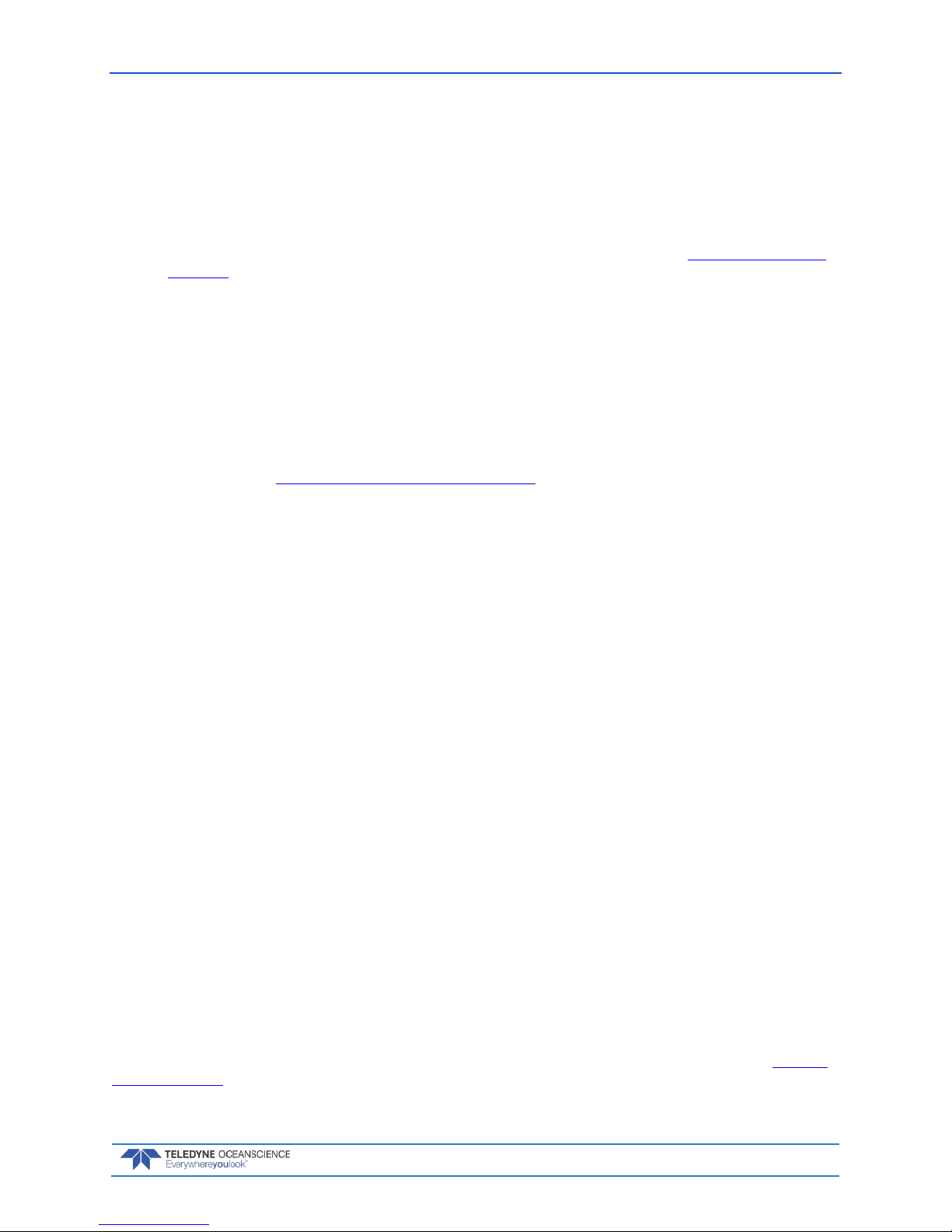

Installing the rapidCAST Interface Software

The rapidCAST Control Software is located on the documentation CD.

To install the drivers and software:

1. Connect the system and apply power. Connect the PC to the Control U S B por t of Ra pid CA S T Interface Module, which should automatically install two USB Serial Port devices on the PC.

Make note of the serial port numbers because they will be used for:

Lower Comm port for Telemetry

Higher Comm port for Control

2. Install the USB RS-485 Driver located in the 1 – Required – USB RS-485 Driver folder of the documentation CD, specifically the RS-422/485 USB Adapter.

3. Install the RapidCAST Interface software by double-clicking on the RapidCAST

Interface X.xx.exe file (where X.xx is the version number) located in the 2 – Required – RapidCAST Interface X.xx folder. Administrator access is required to

properly install the software. A desktop icon is added: Double-click to run the

software.

Page 23

rapidCAST User’s Guide March 2018

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

Page 17

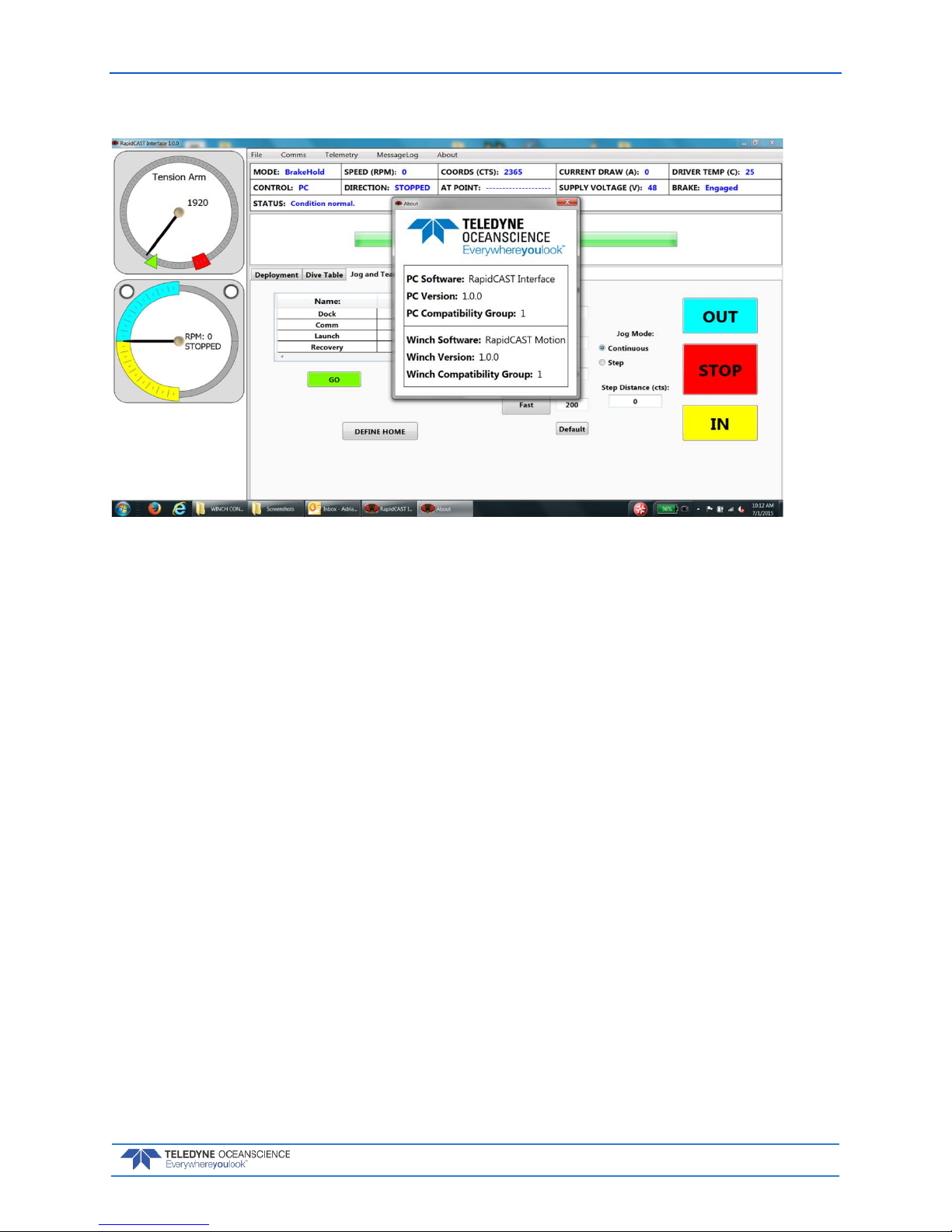

Software Architecture

RapidCAST encompasses 2 types of software: RapidCAST Motion and RapidCAST Interface.

• RapidCAST Motion is firmware that resides inside the Control Module, responsible for real-time

motion control and winch operation. It exposes a text-based interface that allows the winch to be

controlled via string messages. Due to the large number of messages required, however, users do

not interact directly with RapidCAST Motion. When new functionality is introduced through future software releases, RapidCAST Motion can be upgraded in the field (see Updating the Winch

Software).

• RapidCAST Interface is a graphical user interface that runs on a PC and is the primary method for

operating the winch. It functions as a messaging and task management layer that transmits commands to RapidCAST Motion, hiding the latter’s complexity behind a friendly and intuitive graphical interface.

As needs arise, Teledyne Oceanscience may modify or upgrade either software independently of the other.

Because of their message-based infrastructure, RapidCAST Motion and RapidCAST Interface must have

the same Compatibility Group to ensure proper function. A Compatibility Group is simply a number that

identifies whether a particular version of RapidCAST Motion or RapidCAST Interface are “speaking the

same language” and are therefore fully compatible.

The About window (see Using the GUI Windows and Controls) identifies the software versions on the

Control Module and on the PC, as well as their respective Compatibility Groups. If there is a mismatch,

the About menu item will be red. If there is a compatibility mismatch, the system should not be

operated, and the software needs to be upgraded or downgraded until their Compatibility

Groups match.

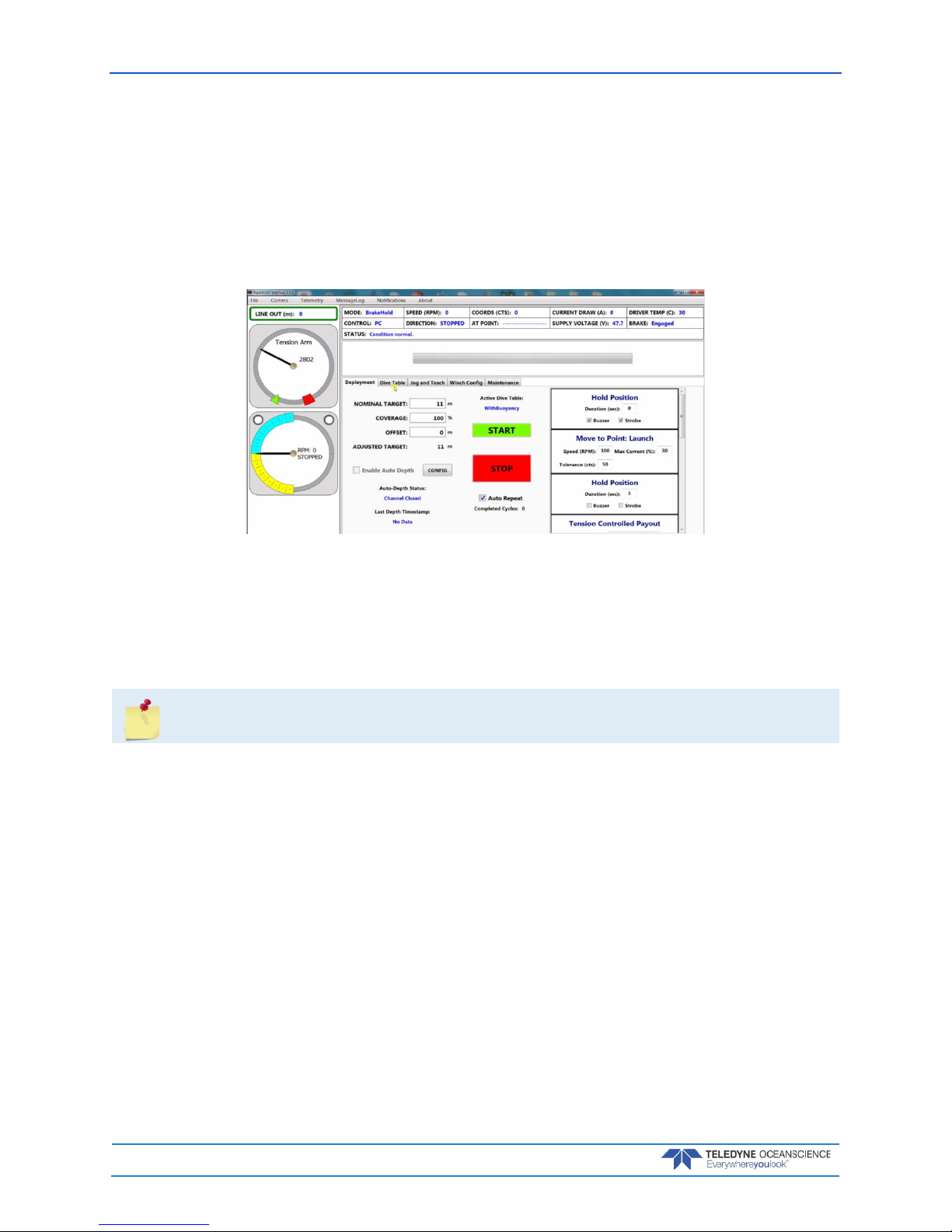

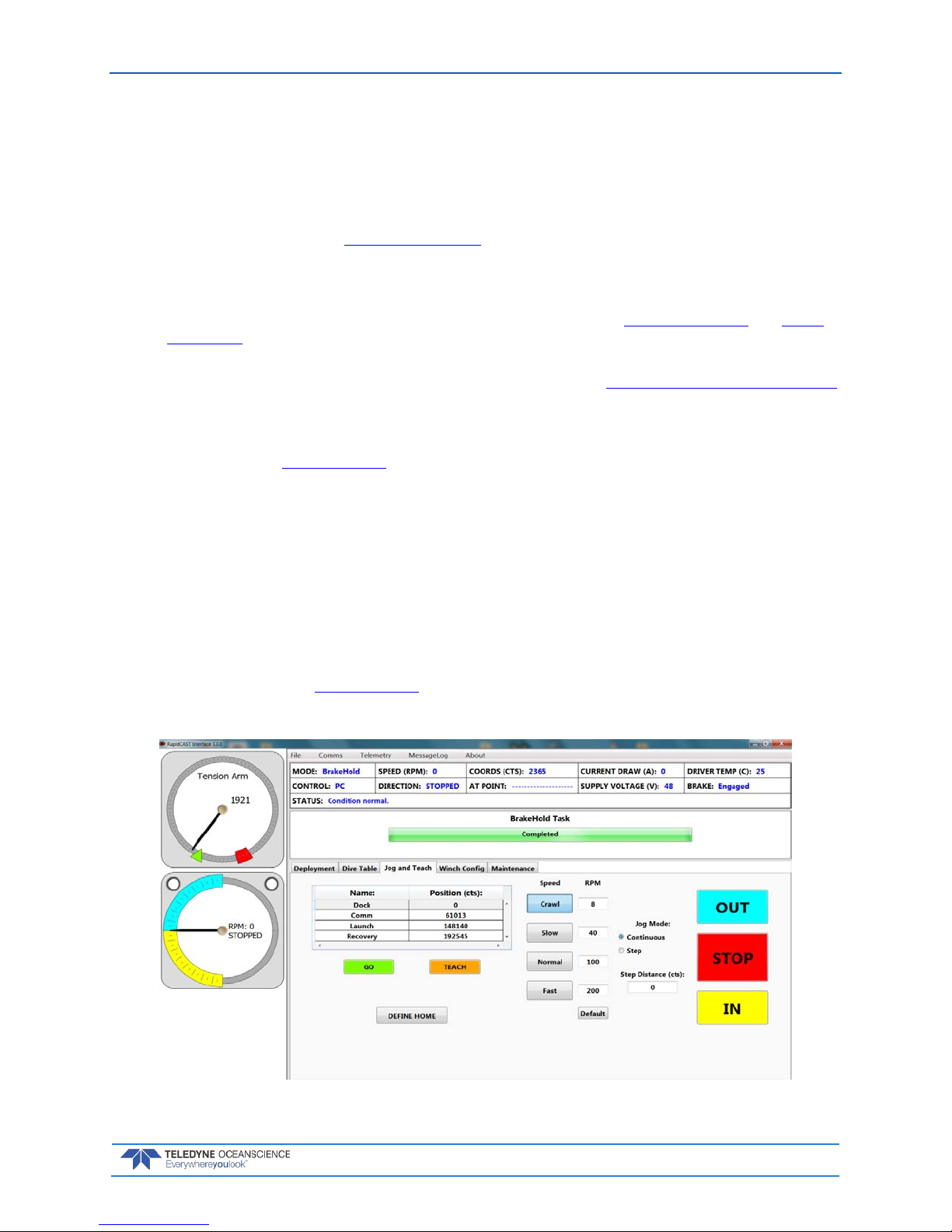

A Tour of the RapidCAST Interface

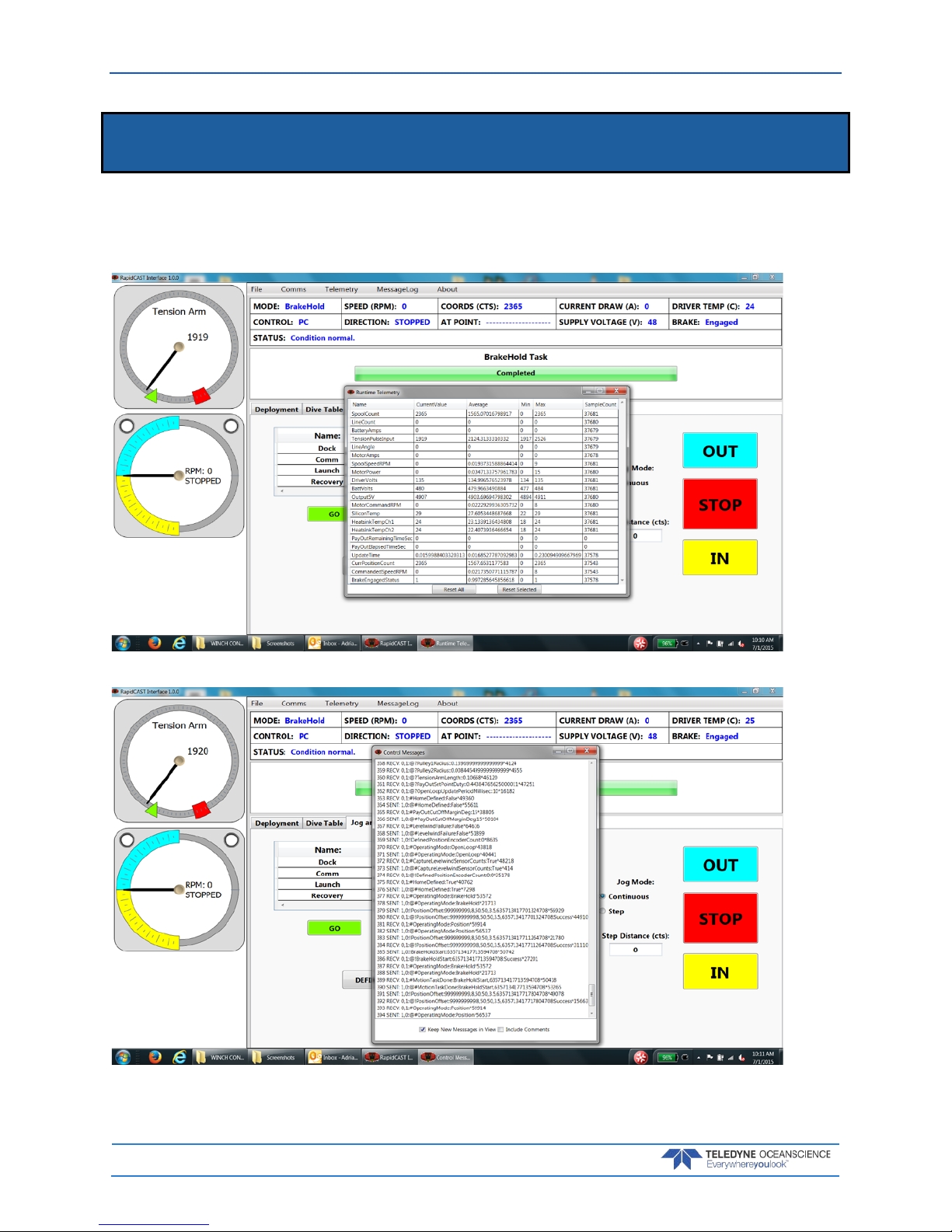

The Dashboard is the top panel and gives the operator a snapshot of the winch’s health and current state.

Important information such as the spool’s speed and rotation direction, the power-supply voltage, and

brake status are reported here. The Dashboard keeps the user informed of the system’s critical operating

parameters.

The Task Bar is the second section. It reports the winch’s current assigned task and provides a progress

estimate.

The bottom panel is the Tab Group, which is a collection of tabbed windows grouped according to common functionality. The Tabs are organized as follows:

• Deployment: Allows the user to set deployment depth, as well as monitor and control an auto-

mated deployment.

• Dive Table: Identifies the dive table used to calculate the Tension-Controlled Payout duration

from a target depth. Allows the user to define the polynomial coefficients of additional dive tables

and switch between them.

• Jog and Teach: Allows the user to jog (move) the winch as well as define positions.

• Winch Config: Allows the user to modify advanced operating parameters.

• Maintenance: Contains a grouping of varied tasks associated with system maintenance and atypi-

cal activities such as software updates and health logging.

A Gauge Cluster on the left provides a graphical representation of the Tension Arm position as well as the

spool’s speed and rotation direction. When the Tension Arm is at its lowest position, the angular gauge in

the Interface Software should show the Tension Arm pointing at the far edge of the red zone. If the Tension Arm is not depicted at this position when the arm is fully relaxed, calibration is needed (see Tension

Arm Calibration).

Page 24

March 2018 rapidCAST User’s Guide

Page 18

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

The spool indicator shows the speed of the line out (blue) and line in speed (yellow). The two white circles

represent the LevelWind position, and blink when the LevelWind is at the full left/right positions.

Line Out - Calculating the length of line paid out depends on how tightly the spool is packed, as well as

the amount of line loaded on the spool (both of which affect the spool’s effective circumference – an important variable when calculating line length). The spool’s circumference decreases as more line is paid

out, and though this behavior has been mathematically modelled as part of the line-length calculation, the

values given by the Line Out display should still be treated as an approximation. Line length is measured

relative to the encoder zero position (“home”). It may be negative if the winch has rotated inward relative

to zero.

Driver Temp: Displays the temperature of the motor controller. This value will increase or decrease depending on the load applied to the motor. Note: Motor will shut down at 70C.

Supply voltage: Indicates the state of the 48V supply, which powers the Spool Motor.

Cable Connections

The system is shipped with the winch end of the cables pre-connected for ease of installation.

The following is for reference.

To remove the covers (only necessary if cables are not connected on the winch end):

1. Remove the covers on the winch assembly.

2. First, remove the four (4) screws and flat washers on the top cover. Slide the top cover toward the

rear of the winch to remove it.

3. Remove the fours screws and flat washers on each side cover and slide the cover down, and then

pull the bottom handle to release the bottom bracket.

4. Next, slide the cover up and pull out slightly to remove it.

Page 25

rapidCAST User’s Guide March 2018

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

Page 19

Figure 12. Removing the Winch Assembly Covers

Figure 13. Winch Assembly Connectors

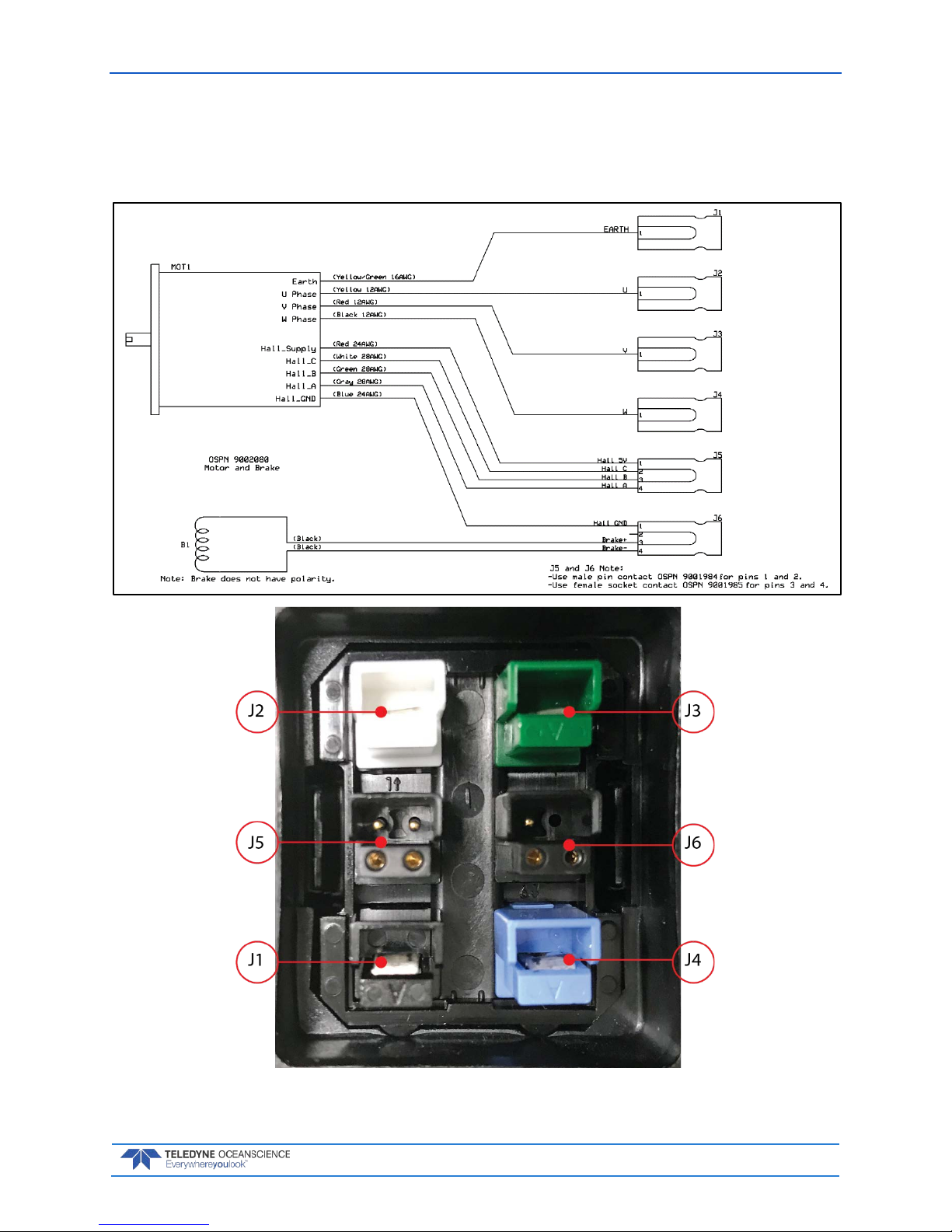

To Connect the Cables:

1. Route all five (5) cables through the cable routing hole. Ensure that the cables do not interfere

with the motion of the spool, LevelWind, or tension arm.

2. Connect the Motor Driver cable between the Control Module and Winch. The Motor Driver connector is located under the motor side cover on top of the motor.

3. Connect the Spool cable between the Control Module and Winch. The Spool connector is located

under the belt side cover.

Page 26

March 2018 rapidCAST User’s Guide

Page 20

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

4. Connect the Tension cable between the Control Module and Winch. The Tension connector is located under the belt side cover.

5. Connect the LevelWind PROX sensor cables between the Control Module and Winch. The LevelWind1 connector is located under the motor side cover; the LevelWind2 connector is located under the belt side cover.

6. Use Figure 12 to re-install the winch assembly covers.

7. Connect the Control cable between the Control Module and Interface Module.

8. Connect the Antenna cable between the Control Module and Interface Module. Connect the Patch

antenna to the Control Module (larger vessels use Figure 14). Alternately, you can connect the

Omni antenna directly to the Interface Module and omit using the 9002211 cable (smaller vessels

use Figure 15).

9. Connect the AC power cable to the Control Module.

Do not connect the 9000783 USB cable to PC computer until the rapidCAST Interface

software is installed and the system is powered up. See Connecting the Winch to a PC for

details.

The Processor connector on the Control Module is not used for normal operation. Keep the

dust cap installed.

Figure 14. rapidCAST Cable Connections (Large Vessels)

Page 27

rapidCAST User’s Guide March 2018

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

Page 21

Figure 15. rapidCAST Cable Connections (Small Vessels)

Page 28

March 2018 rapidCAST User’s Guide

Page 22

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

Antenna Position

The rapidCAST system includes two types of antenna. The size of the vessel will determine which antenna

to use.

Omni Antenna – Use this antenna when the distance between the Interface Module and Control Module is less than 10 meters. See Figure 15 for cable connections.

The antenna is Omni directional (the best reception is around the antenna in a doughnut shape; do not

orientate the antenna by pointing the tip of the antenna at the probe).

Figure 16. Omni Antenna

Patch Antenna – Use this antenna when the distance between the Interface Module and Control Module is over 10 meters. See Figure 14 for cable connections.

Orientate the antenna as shown in Figure 17. The best reception is when the probe is in the center of the

approximately 30 degree cone.

Figure 17. Patch Antenna

Page 29

rapidCAST User’s Guide March 2018

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

Page 23

Switch Functions

Emergency Stop – Removes all power except the 24 VDC Auxiliary power to maintain lights. There are

two emergency stop buttons; one on the Control Module and one on the Interface Module. If the emergency stop button is pushed in, turn and pull out to restore power. The rapidCAST system will reboot in a

few seconds.

Main Power – Turn switch off to remove all power to the system.

Brake – Removes the 24 VDC power to the winch break motor. Processor – Removes the 24 VDC to the

Control Module processor.

Motor Driver – Removes the 48 VDC to the motor controllers.

Control Switch – The switch changes control between the PC running the rapidCAST Interface Software

(PC Control position) and the joystick (Local Control position). When the switch is in:

• PC Control position, the Activity light will flash two rapid blinks and then 1 second off

• Local Control position the Activity light will flash three rapid blinks and then 1 second off.

Joystick – If the toggle switch is in the Local Control position, use the joystick to manually operate the

winch. OUT will deploy cable; IN will retract cable. The winch is limited to 100 RPM maximum while using the joystick.

When the joystick is not actively being used, the toggle switch should be set to PC Control to

properly engage the brake.

Figure 18. Control Module Figure 19. Interface Module

The control panel is equipped with a joystick that allows the spool to be controlled directly by

an operator on deck. Local control is convenient when the user needs to operate the spool

without having to coordinate with a person running the PC. The joystick is typically used

when retrieving the probe out of the water and bringing it on deck, or when putting the

probe back into the water. The joystick is sensitive and should be operated slowly!

Page 30

March 2018 rapidCAST User’s Guide

Page 24

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

LED Functions

LEDs on the Control Module provide a snapshot of power supply health and system status. During normal operation, all LEDs should be lit. These LEDs consist of:

48V LED (GREEN): Indicates the state of the 48V supply which powers the Spool Motor.

ON: The power supply is functioning.

OFF: The power supply is inactive. This may be due to a lack of input AC power, a power supply mal-

function, the Main Power Switch being in the OFF position, the Control Cable being disconnected, or

Emergency Stop being pressed.

MAIN 24V (GREEN): Indicates the state of the 24V supply which powers the Motor Brake.

ON: The power supply is functioning.

OFF: The power supply is inactive. This may be due to a lack of input AC power, a power supply mal-

function, the Main Power Switch being in the OFF position, the Control Cable being disconnected, or

Emergency Stop being pressed.

AUX 24V (GREEN): Indicates the state of the 24V supply which powers the Processor, the Tension Arm

and Spool Encoders, the LevelWind Proximity Sensors, and other low-power digital electronics.

ON: The power supply is functioning.

OFF: The power supply is inactive. This may be due to a lack of input AC power, a power supply mal-

function, or the Main Power Switch being in the OFF position.

Unlike other LEDs, this LED should remain ON even when Emergency Stop is pressed or the

Control Cable is disconnected.

ACTIVITY LED (GREEN): Indicates the state of the Motor Driver.

Slow Blink (1 Sec. On + 1 Sec. Off): The Motor Driver is powered but is not yet ready for normal

operation. If the Motor Brake is released in this state, the Motor will add passive regenerative resistance to the rotation of the spool. The degree of resistance is proportional to the speed of rotation,

i.e., attempts by hand to move the spool faster will result in stiffer resistance.

Single Fast Blink (0.5 Sec. On + 1.5 Sec. Off): The Motor Driver is ready for normal operation,

and the winch is currently under PC control.

Three Fast Blinks (3X 0.5 Sec. On + 0.5 Sec. Off): The Motor Driver is ready for normal operation, and the winch is currently under Local (Joystick) control.

OFF: The Motor Driver is not receiving power and is therefore inactive. This may be due to a lack of

input AC power, the Main Power Switch being in the OFF position, the Control Cable being disconnected, or Emergency Stop being pressed. If the Motor Brake is released while the Motor Driver is unpowered, the spool can be rotated easily with minimal resistance (regenerative braking is disabled).

EMERGENCY STOP LED (RED): Allows the Emergency Stop to be located in dark environments and

indicates its state.

ON: The Emergency Stop has not been pressed, and the system is ready for normal operation.

OFF: The Control Module Emergency Stop and/or Interface Module Emergency Stop may have been

pressed, the Control Cable may be disconnected, the Main Power Switch may be in the OFF position,

or the Control Module is not receiving input AC power.

Page 31

rapidCAST User’s Guide March 2018

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

Page 25

Installing the rapidCAST System

Environmental Conditions

The RapidCAST is rated to IP65. All exterior components are sealed and water-tight when the cables are

mated. Dust caps should be installed on connectors when they are not in use.

Overall, the system has very good UV resistance, but should not be left outdoors for extended periods of

time, i.e. months.

When installed in cold/wet environments near freezing (0°C), ice may form on the system. Due to the

mechanical nature of the system, it is necessary to prevent and de-ice the system prior to and during operation. Store the system inside or cover it when not in use to prevent icing.

Hot environments (greater than 30°C) require careful consideration of the environmental conditions. The

radiative heat from the sun and ship deck can cause ambient shipboard temperatures to exceed 40°C.

When operating in a hot environment the following items should be considered:

1. Deep casts at higher ship speeds will generate the most heat because the motor is working hard

for an extended period of time.

2. Shallow casts at lower ship speeds will generate the least amount of heat.

3. Consider reducing the duty cycle of the system and allow it to cool off between casts if heat gener-

ation is excessive.

4. Remove the orange side cover on the motor side during operation to assist with cooling.

The RapidCAST system monitors the temperature of the Motor Controller which has a maximum allowed

temperature of 70°C. If the Motor Controller temperature reaches 70°C, the brake will engage and the

motor will no longer be powered. The Motor Controller will re-activate when the temperature drops below 70°C. If this condition occurs, the user should re-evaluate the duty cycle.

Page 32

March 2018 rapidCAST User’s Guide

Page 26

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

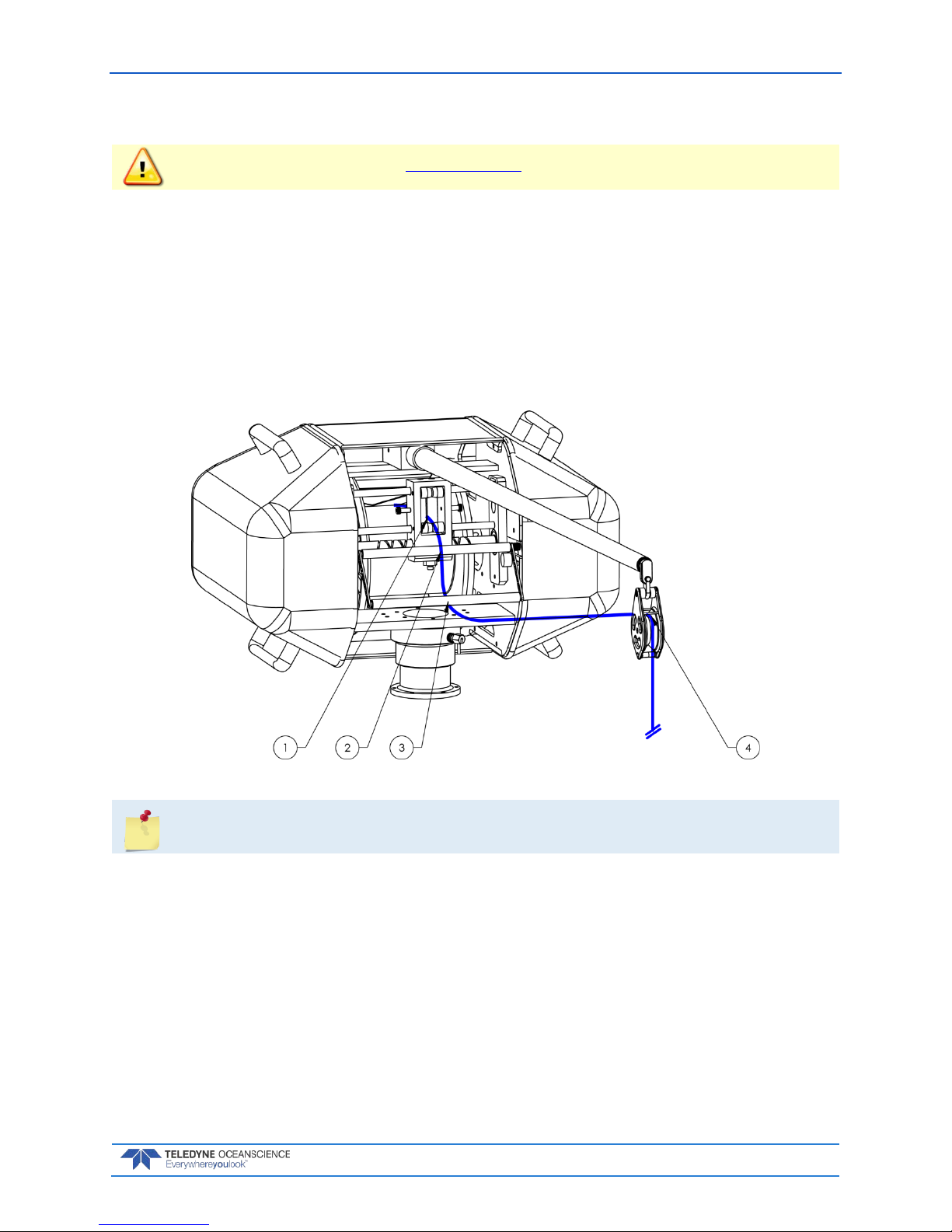

Lifting the RapidCAST System

DO NOT USE THE TENSION ARM AS A LIFT POINT. The tension arm is not load bearing and

could be damaged if it is used as a lifting point.

The system should be lifted by any of the four (4) handles available on the covers. If the covers are removed, the system can be lifted by the frame.

The top handles can accommodate lifting slings if a crane is available for loading. The center of mass is

located approximately where shown in the figure below.

Figure 20. Center of Mass (CM) Location

Page 33

rapidCAST User’s Guide March 2018

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

Page 27

Installing the Pipe Mount

A custom mounting plate is required to mount the Pipe Mount, PN 8000592.

An adapter is available from Oceanscience that will facilitate the installation of a RapidCAST where an

Underway CTD was previously installed. One such adapter is shown below.

Attach the pipe mount to the custom mounting plate using 6 X M6 or 6 X ¼-20 screws as shown below:

Figure 21. Attaching Pipe Mount Figure 22. Pipe Mount Installed on UCTD Adapter

Plate

Page 34

March 2018 rapidCAST User’s Guide

Page 28

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

Installing the Winch on the Pipe Mount

1. Pipe Mount

2. Disengage the winch spring pin by pulling and then rotating. Slide the winch on to the pipe mount

and rotate the winch back and forth until it is fully seated on the pipe mount.

3. Install the davit and retaining pin. Block is oriented downward as shown in Figure 23.

4. Engage the spring pin by rotating until it engages in the slot.

Figure 23. Installing the Winch on the Pipe Mount

Optional mounting shown using a custom pedestal rather than the ship’s rail.

Page 35

rapidCAST User’s Guide March 2018

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

Page 29

Installing the Control Module

The control module has two standard 1-5/8 inch strut channels located on the back. These will accept

standard pipe mounts (not included). The control module is mounted within 8 feet of the winch and to the

ship’s rail or other available mounting location

Figure 24. Mounting the Control Module

Figure 25. Control Module Dimensions

Page 36

March 2018 rapidCAST User’s Guide

Page 30

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

Line Properties

Spectra Line is composed of braided High-Molecular-Weight-Polyethylene.

• Negligible stretching means line does not snap back violently if severed under load.

• Rated tensile strength of 226 kg.

• Can splice multiple segments together.

• Spectra Line is very sensitive to heat, especially heat caused by friction. Portions of line that

have been exposed to high heat should not be used, as heat permanently damages the line and

makes it prone to breaking.

Never wrap line around fingers or limbs while the winch is powered, as the line’s high tensile

strength can cause serious injury if body parts get caught by line as the winch is moving.

The very bottom layer of line is attached to the spool via adhesive tape and is not fixed in a

permanent way. This is intentional. If the probe is snagged by a submerged obstacle, the idea

is to allow the probe to be pulled cleanly off the spool once line runs out, rather than allow

the winch to be damaged by a permanently tethered probe.

Mission-critical cruises would typically carry backup line and probes. Backup winches,

however, are less likely to be carried, so the probe was considered the more expendable

element in this worst-case scenario.

Each spool is loaded with a grand total of ~1954 meters of line, of which ~1700 meters can be

used for normal operation. The line is spliced in three main sections:

• 55 m of “Leader” Red Line: When reeling in the probe, this warns users that the

probe is near the vessel.

• 1645 m of White Line: Normal line used for deployment.

• 254 m of “Terminal” Red Line: Bottom part of the spool. The RapidCAST winch

software prevents this portion from being paid out, and in fact, automatically stops

deployment before this portion of line is reached. If, for some reason, the winch

ends up using this segment of line (perhaps through misconfiguration, improper

homing, or this safeguard is overridden). If line is still being deployed and you start

to see red line, use the EMERGENCY STOP BUTTON.

Page 37

rapidCAST User’s Guide March 2018

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

Page 31

Line Routing Procedure

IMPORTANT!!! Follow the lockout procedure before routing the line.

Before routing the line, remove the short section of Duct Tape (PN 9002203) that is securing the line to

the spool. The spools are shipped with the line secured to the spool. Removal of the middle cover may be

necessary.

Line routing procedure:

1. Thru LevelWind rollers.

2. Over tension arm rotational axis roller.

3. Under tension arm outer roller.

4. Under the two horizontal pins in block and thru.

Figure 26. Line Routing Procedure

For shipping and storage, secure the line to the spool using a short 15cm piece of the

included Duct Tape (PN 9002203)

Page 38

March 2018 rapidCAST User’s Guide

Page 32

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

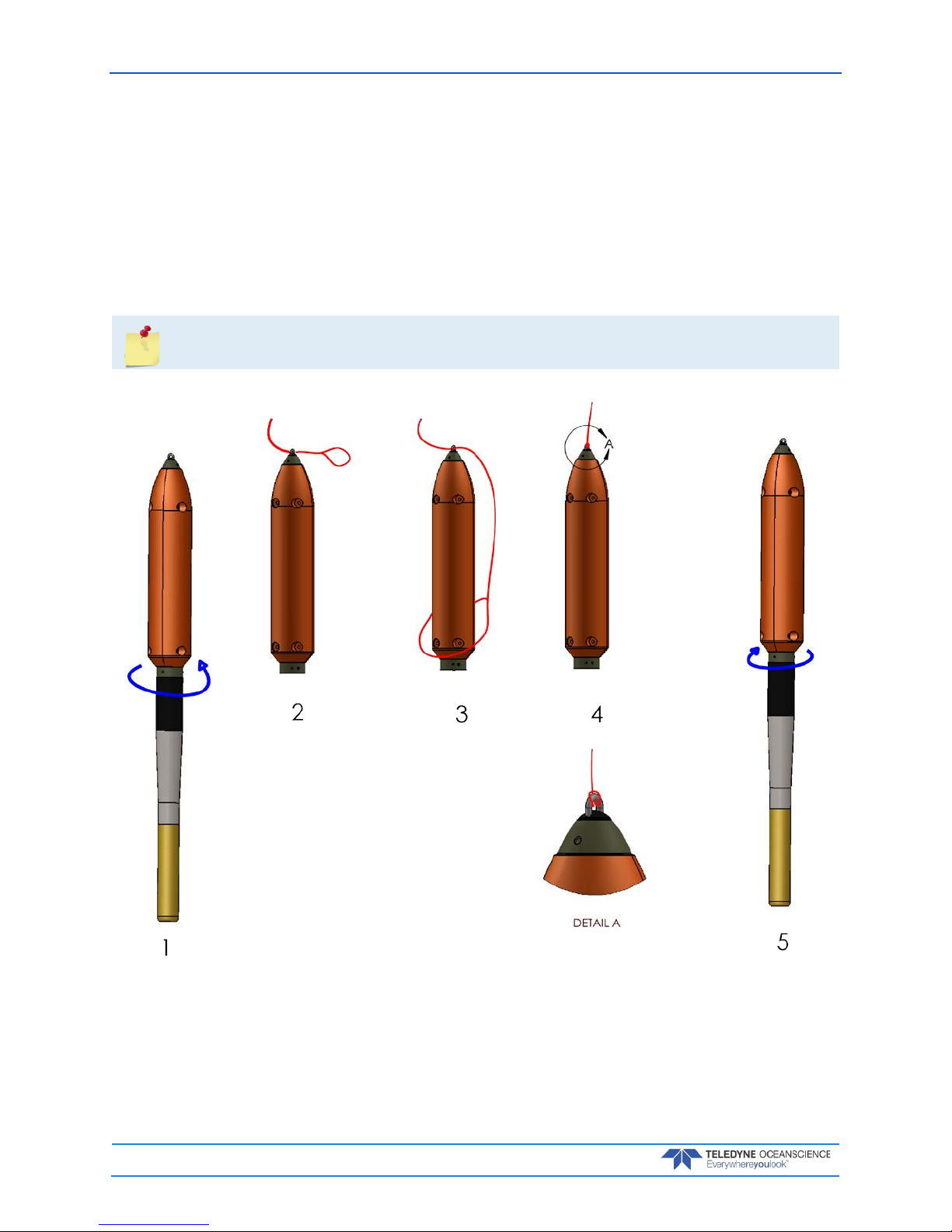

Installing and Connecting the Probe

1. Remove tailspool - depress white button and rotate tailspool as shown while holding probe.

2. Pass end of winch line thru shackle on tailspool.

3. Slide tailspool thru eye of winch line.

4. Pull winch line tight at shackle as shown. Make sure the eye of the line is not twisted and the eye

lines are evenly tensioned when the line is pulled.

5. Re-install tailspool - rotate tailspool onto probe until white button engages and is springy when

pushed. **

**there is only one position where the tailspool will mate with the probe.

Figure 27. Installing the Probe

Page 39

rapidCAST User’s Guide March 2018

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

Page 33

The orange buoyancy tailspool module has a maximum depth rating of 100 meters. If you are

deploying deeper than 100 meters, switch to the plain tailspool.

During intensive surveys, the probe loop splice should be replaced daily by cutting 50cm of

line from the end and re-splicing the termination. See Loop Splice for instructions. The entire

line section should be replaced after 1000 casts as a preventative measure.

Installing the Probe Software

Follow the instructions shipped with the probe to install the probe software onto the same computer running the rapidCAST Interface software.

Verifying Probe Communications

Follow the instructions shipped with the probe to verify that it can communicate using Bluetooth with the

probe software.

The current version of Valeport rapidSVLog software is extremely conservative and reports a

“low battery” warning even when there is still plenty of charge left. Actual low battery is

when voltage is 1.0V or less.

Page 40

March 2018 rapidCAST User’s Guide

Page 34

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

Quick Review

Check that you have all of

the rapidCAST parts.

If you are missing parts,

contact Oceanscience

support or call +1 (858) 842-

2600.

Check that the system is

installed.

Reference figures Figure 12

through Figure 27.

Check that the cables are

connected.

Reference figures Figure 14

and Figure 15.

Check that the rapidCAST

Interface Software is

installed

Reference page 16.

Verify you can

communicate with the

probe

Reference page 33

Page 41

rapidCAST User’s Guide March 2018

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

Page 35

Initial Setup

I NSTALLATION INCLUDES THE FOLLOWING STEPS:

Connecting the Winch to a PC

Verifying Basic Motion Functionality

Setting the Home Position

Defining the Dock, Comm, Launch, and Recovery Positions

Saving and Loading Workspaces

COMM

LaunchRecovery

Page 42

March 2018 rapidCAST User’s Guide

Page 36

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

Power up Sequence

1. Main Power Switch set to OFF position (down)

2. Control Switch set to PC Control

3. Brake, Processor, and Motor Driver Switches are powered ON (up)

4. Connect and check all cable connections are secure

5. Turn power ON by switching the Main Power Switch to ON (up)

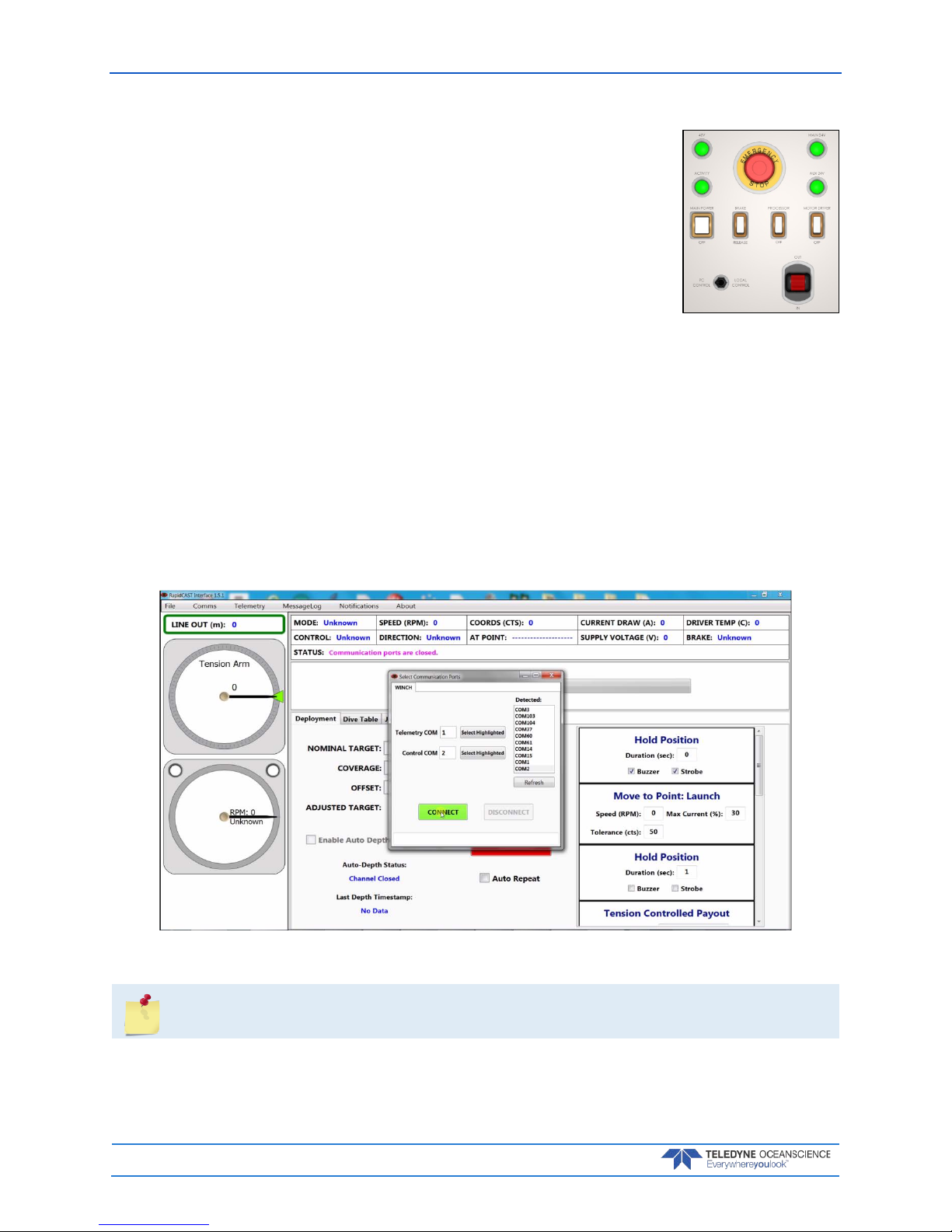

Connecting the Winch to a PC

To connect the winch to the PC and verify communication:

1. Apply power to the Control Module, follow Power Up Sequence .

2. Start the RapidCAST Interface software. The Select Communication Ports dialog will open. To reopen this screen, click the Comms menu.

3. Select the Serial COM Ports that were assigned in Step 1 of Installing Drivers and Software.

Lower COM Port number for the Telemetry COM

Higher COM Port number for the Control COM

4. Once both the Telemetry COM and the Control COM have been assigned a COM Port Number, click the Connect button.

Figure 28. Assigning the COMM Ports

This step must be done each time the RapidCAST Interface software is started.

Page 43

rapidCAST User’s Guide March 2018

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

Page 37

Verifying Basic Motion Functionality

The purpose of this section is to explain simple tests that should be performed on a newly-installed winch

to verify that it is operational.

To verify basic motion functions:

1. Turn power ON using the Power Up Sequence.

2. Start the rapidCAST Interface software.

3. On the Control Module, set the Control Switch to the Local Control position.

4. Use the joystick to pay OUT and pay IN a few meters of cable. See Line Management and Check

for Fouling when playing out line.

5. Observe the LevelWind and line as it is comes off the spool. The direction of the LevelWind travel

and the direction cable is comes off the spool should match. See Adjusting the LevelWind Position

if an adjustment is needed.

6. While paying OUT cable, press the Emergency Stop button on the Control Module. Verify that

the break is engaged on the winch and power is off to the Control Module. ALL LEDs off except

for Aux 24V, see LED Functions.

7. Reset the Emergency Stop button and verify that the system powers up.

8. On the Control Module, set the Control Switch to the PC Control position.

9. In the software, open the Jog and Teach tab.

a. Click the Crawl button to set the speed to 8 RPM.

b. Set Jog Mode to Continuous.

c. Use the In, Out, and Stop buttons to deploy and retract a few meters of cable.

10. While deploying cable, press the Emergency Stop button on the Interface Module. Verify

that the break is engaged on the winch and power is off to the Control Module. ALL LEDs off except for Aux 24V, see LED Functions.

11. Reset the Emergency Stop button and verify that the system powers up.

Figure 29. Jog and Teach Tab

Page 44

March 2018 rapidCAST User’s Guide

Page 38

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

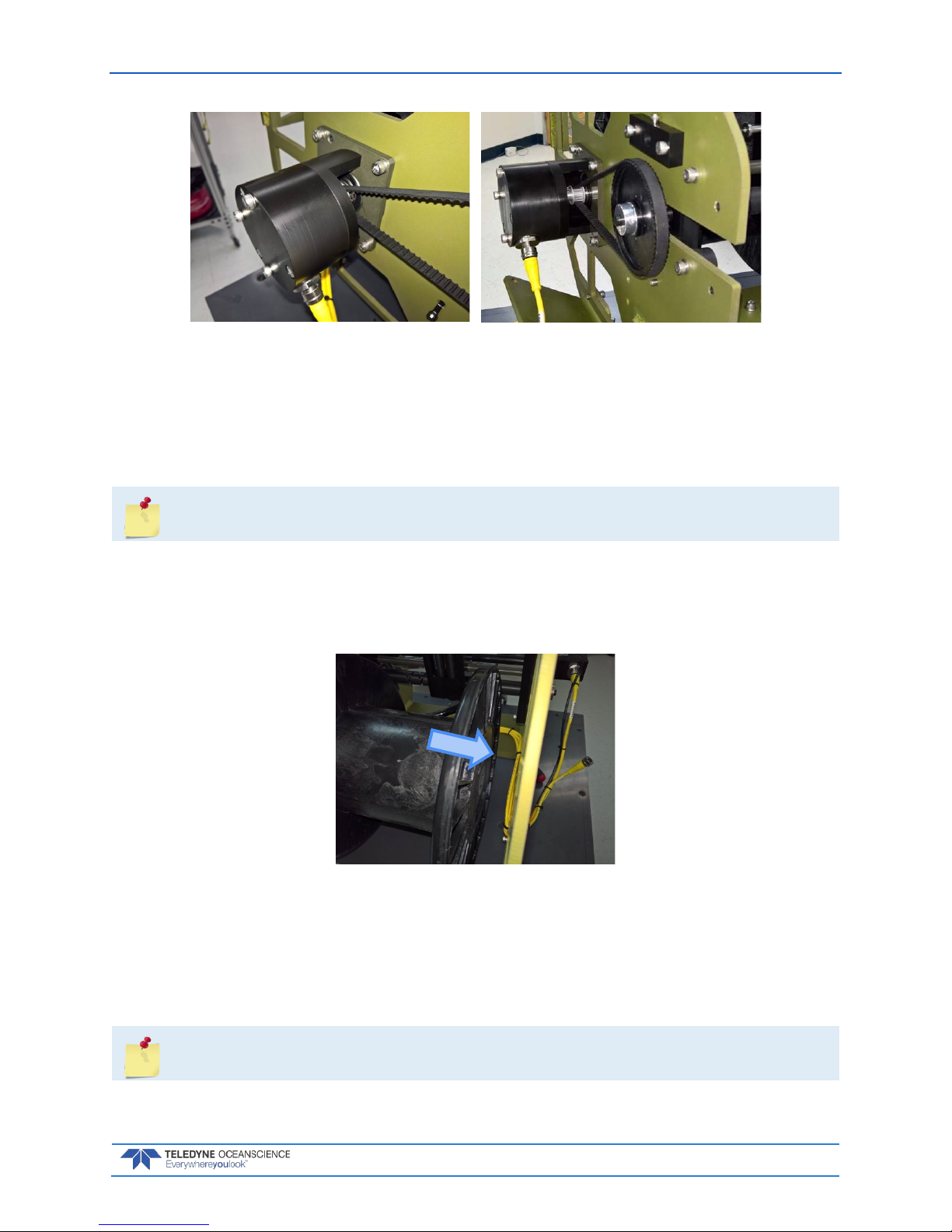

Adjusting the LevelWind Position

As line is deployed in or out, the direction of the LevelWind travel and the direction the line as it is rolled

off the spool should be in-line with each other. T he Level Wind’s reciprocating motion is generated entirely

mechanically via rotation of a diamond screw. The LevelWind Drive Belt links the diamond screw to the

spool. Spool rotation, in turn, drives the diamond screw. A pawl (dull blade) sits inside the diamond screw

grooves. As the diamond screw rotates, the pawl traces the contour of the groove and drags the follower

along with it. When the end of travel is reached, the diamond screw thread loops back on itself, which

causes the pawl to reverse direction and travel the opposite way.

To adjust the LevelWind position:

1. Follow Lockout Procedure to prevent winch operation while adjusting the LevelWind.

2. Disengage the LevelWind pawl by pulling down.

3. Move the LevelWind to match the position of the line as it comes of the spool.

4. Engage the LevelWind spring pin by releasing it. Ensure that the pin is fully seated into the diamond screw groove.

5. Manually pull off line and observe that the when the LevelWind travels the line on the spool

matches the direction of travel and location so that line is pulled straight off the spool.

LevelWind Out of Sync LevelWind in Sync

Figure 30. LevelWind Adjustment

Page 45

rapidCAST User’s Guide March 2018

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

Page 39

Line Management

While the probe is in the water or hanging in the air, it pulls on the line and keeps it under tension. This

helps prevent line fouling.

When the probe is on deck, line is not normally under tension. If the spool is rotated outward while there

is no tension on the line, loose loops can form. An operator may not notice loose loops due to the winch

covers concealing the spool, and these loops may “hop” the spool sidewall or snag internal winch components and cause fouling.

When feeding line to someone holding the probe on deck, it is important to remember that line is flexible.

The winch is incapable of “pushing” line out, so line should always be “pulled” under tension by the person requesting additional line.

Keep the line under tension when rotating the spool to guard against fouling.

Figure 31. Line Management

Checking for Line Fouling

The easiest way to detect line fouling is to inspect the spool visually. Another indication of fouling is if the

probe moves in a direction opposite what you expect:

• If you rotate the spool out, yet the probe moves closer…

• If you rotate the spool in, yet the probe moves farther...

These may indicate that line is wrapped around something undesirable.

Page 46

March 2018 rapidCAST User’s Guide

Page 40

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

Defining Positions

The following positions are dependent on vessel speed and environmental conditions. If either of these

conditions changes significantly, re-evaluate the positions.

Setting the Home Position

The Home position is the absolute topmost position, where the probe can’t go up any further. This is the

position at which the encoder value is set to zero.

To set the Home position:

1. Turn power on to the system and start the rapidCAST Interface software.

2. On the Control Module, set the Control Switch to the Local Control position (joystick control)

or PC Control position (use the In, Out, Stop and Speed buttons on the Jog and Teach tab).

3. Move the probe to the topmost position next to the swivel block at the end of the davit.

4. Click the Jog and Teach tab on the rapidCAST Interface software.

5. Click the Define Home button. On the Define Home dialog, click OK.

This step must be done each time the rapidCAST system is powered up.

The winch uses incremental encoders to track the spool position. Unfortunately, incremental

encoders lose their value when power is lost (winch is turned off). When power is regained

(winch is turned on) they always initialize at zero. So, if the winch is currently at the Launch

position, which originally had an encoder value of 12345 and then somehow power is lost at

this position and subsequently regained, the encoders will now think that they are at value 0

(which is not the case). To recover from this, the probe needs to be manually moved to the

home position and then the Home position is set once more.

Page 47

rapidCAST User’s Guide March 2018

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

Page 41

Dock Position

The Dock position is where the probe is completely out of the water and at the topmost position next to

the swivel block at the end of the davit. This is the position the winch will go to if the user wishes to bring

the probe back on board and is ready to swing the davit around to the deck.

To define the Dock Position:

1. Move the probe to the topmost position next to the swivel block at the end of the davit.

2. Click the Jog and Teach tab on the rapidCAST Interface software.

3. Click Dock and then click the Teach Button. On the Record Position dialog, click OK.

Home and Dock are essentially the same position.

Figure 32. Dock Position

Page 48

March 2018 rapidCAST User’s Guide

Page 42

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

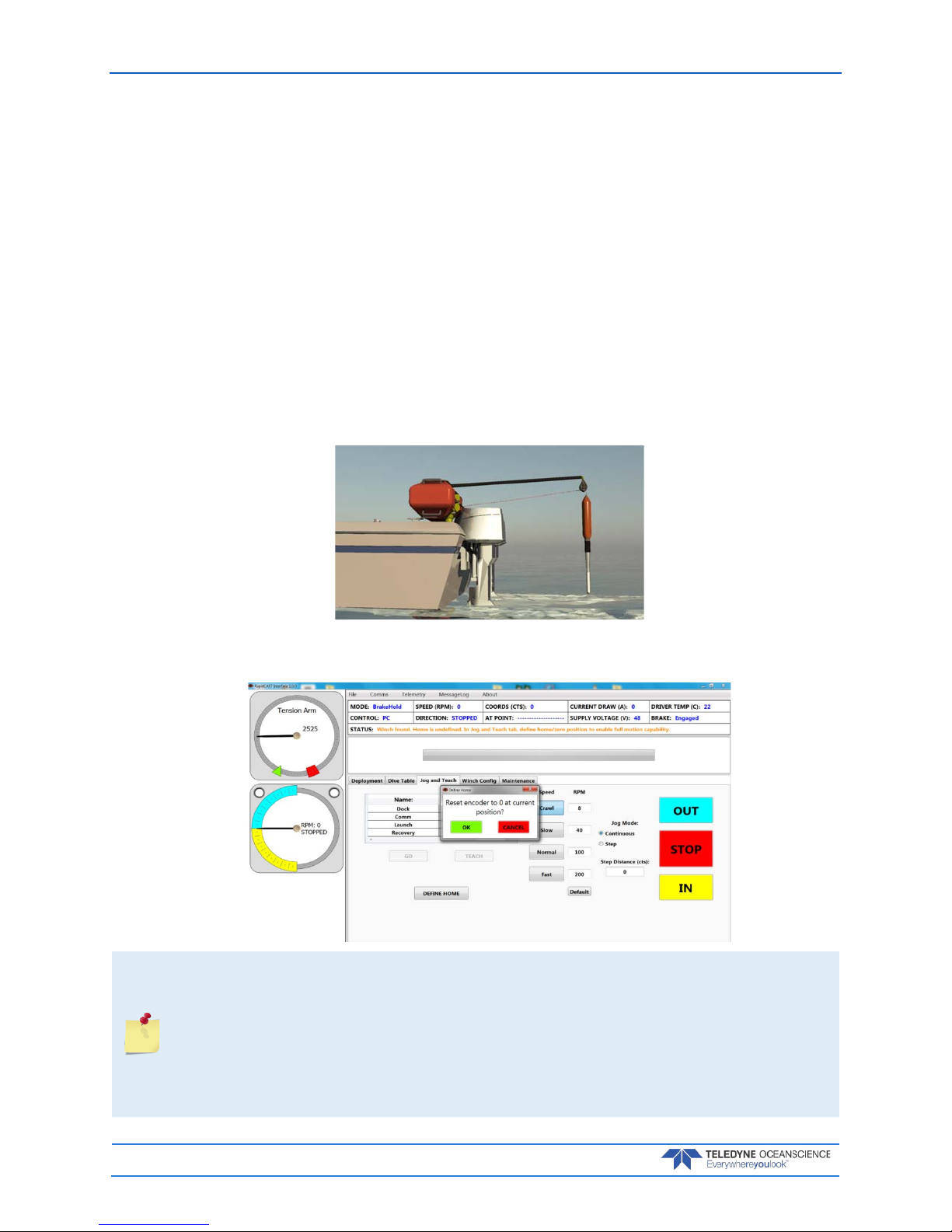

Comm Position

The Comm position is where the probe antenna is out of the water and is able to communicate with the

Bluetooth antenna. The front of the probe is in the water to maintain stability.

To define the Comm Position:

1. Move the boat forward at the desired survey speed.

2. Move the probe to where the probe antenna (the black portion of the probe) is out of the water.

3. Click the Jog and Teach tab on the rapidCAST Interface software.

4. Click Comm and then click the Teach Button. On the Record Position dialog, click OK.

Figure 33. Comm Position

The Comm Position will be closer to the vessel at slower speeds and farther out at higher

speeds due to the hydrodynamic characteristics of the probe.

The Comm Position may require updating during operation due to the line packing effects on

positional accuracy. As the line is wetted and tensioned during recovery, the Comm Position

could drift and will be further away from the ship than the intended position. In this case, redefine the Positions and continue the survey.

Page 49

rapidCAST User’s Guide March 2018

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

Page 43

Launch Position

The Launch position is located just outside the wake. This is the position you want the probe to be at just

before initiating the tension control algorithm.

To define the Launch Position:

1. Begin moving the boat forward.

2. Move the probe to just outside the wake.

3. Click the Jog and Teach tab on the rapidCAST Interface software.

4. Click Launch and then click the Teach Button. On the Record Position dialog, click OK.

Figure 34. Launch Position

Recovery Position

Typically set the Recovery position farther out from the Launch position. After the tension-controlled

payout has finished, the rapidCAST will start reeling the probe back in. The reel-in speed can be fairly

high (up to 200 RPM). The Recovery position is the point at which you are comfortable having the probe

Page 50

March 2018 rapidCAST User’s Guide

Page 44

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

return to the boat at potentially high speed. Once the probe reaches the Recovery position, the reel-in

speed will slow down when near the boat for safety and peace of mind.

To define the Recovery Position:

1. Begin moving the boat forward.

2. Move the probe to beyond the wake.

3. Click the Jog and Teach tab on the rapidCAST Interface software.

4. Click Recovery and then click the Teach Button. On the Record Position dialog, click OK.

Figure 35. Recovery Position

Page 51

rapidCAST User’s Guide March 2018

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

Page 45

Saving and Loading Workspaces

The rapidCAST can save all of the settings for communications, Dock, Comm, Launch, and Recovery positions, and Configuration Settings to a Workspace file (*.rcstprj file). The settings will be lost in the event

of a power cycle and can be recovered if they are saved.

To save a Workspace file:

1. Click File, Sa v e Wo r kspace.

2. Name the file and click Save. The *.rcstprj file extension will be added automatically.

To open a Workspace file:

1. Click File, Open Workspace.

2. Locate the file and click Open.

Figure 36. Workspace Files

Page 52

March 2018 rapidCAST User’s Guide

Page 46

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

Quick Review

Check that the

communication ports are

assigned.

Reference page 36

Check the Basic Motion

Functionality

Reference page 37

Check that the Home,

Dock, Comm, Launch, and

Recovery positions are set

Reference page 40

Page 53

rapidCAST User’s Guide March 2018

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

Page 47

Curve Fitting & Dive Table Creation

When gravity is the primary force acting on the probe, its depth can be predicted via a ballistic dive table.

The Dive Table is used to model the probe fall behavior during the deployment. Two tail spool options are

possible.

• Tailspool with buoyancy module is used for deployments <100m to gain greater accuracy

• Plain tailspool is used for deployments >100m

To switch between pre-defined dive tables:

1. Start the rapidCAST Interface software.

2. Click the Dive Table tab.

3. The CURRENT DEPTH-TO-TIME COEFFICIENTS IN USE table shows the currently used dive

table. To swap tables, select the Alternate Choice in the second table and click the Activate Se-

lected Row button.

The orange buoyancy tail spool module has a maximum depth rating of 100 meters. If you are

deploying deeper than 100 meters, switch to the plain tailspool.

If you have a new probe or are operating in an environment with varying water conditions, a

new dive table will need to be created. Please contact technical support for further assistance

with this.

Page 54

March 2018 rapidCAST User’s Guide

Page 48

EAR-Controlled Technology Subject to Restrictions Contained on the Cover Page.

Using Auto-Depth

If Auto-Depth is enabled, the target depth is automatically set via NMEA 0183 messages from a depth

sounder. DBT, DPT, DBK, and DBS sentences are supported. Serial communication is the supported

transmission protocol in this initial release. NMEA messages may be input to the rapidCAST Interface via

a physical serial port or a virtual serial port.

In cases where rapidCAST Interface and the hydrographic survey software both reside on the same PC, a

virtual serial port may be the easier option to implement. If the survey software is already receiving

NMEA messages to perform its job, and if it has data re-broadcast capability, the survey software may regurgitate the NMEA data through a virtual serial port, which rapidCAST Interface can connect to, without

requiring physical cabling.

Third-party software can be used to create virtual serial ports. This feature has been successfully tested

with EIVA NaviScan survey software working in conjunction with virtual serial ports provided by Eltima

Software, for example.

What Auto-Depth Does and Does Not Do

Enabling Auto-Depth simply allows the NMEA stream to automatically populate the “Nominal Target

Depth” field as depth readings are received on-the-fly. For operational safety, it does NOT automatically