Page 1

T3DMM4-5 / T3DMM5-5 / T3DMM6-5

4½, 5½ and 6½ Digit Digital Multimeters

Quick Start Guide

Version 1.1

September, 2018

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 2

Contents

General Safety Summary.............................................................. 1

Daily Maintenance and Cleaning.................................................. 7

General Inspection........................................................................ 8

Dimensions.................................................................................... 9

Handle Adjustment.......................................................................10

Front Panel ...................................................................................11

Rear Panel.....................................................................................14

Starting the Multimeter ............................................................... 17

User Interface............................................................................... 18

Measurement Connections ......................................................... 19

Connecting to USB and LAN Ports............................................ 22

Using the Built-in Help System...................................................23

Troubleshooting.......................................................................... 24

© 2018 Teledyne LeCroy, Inc. All rights reserved.

Teledyne Test Tools is a brand and trademark of Teledyne LeCroy, Inc.

Other product or brand names are trademarks or requested trademarks

of their respective holders. Specifications, prices, availability and

delivery subject to change without notice.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 3

General Safety Summary

Read the following precautions carefully to avoid any personal

injuries, or damage to the instrument or products connected to it.

Use the instrument only as specified.

Use only the power cord supplied for the instrument.

Ground the instrument. The instrument is grounded through the

ground conductor of the power cord. To avoid electric shock,

always connect to grounded outlets. Make sure the instrument is

grounded correctly before connecting its input or output terminals.

Connect the signal wire correctly. To avoid damage, observe

input polarity and maximum voltage/current ratings at all times.

Observe all terminal ratings and signs on the instrument to

avoid fire or electric shock. Before connecting to the instrument,

read the manual to understand the input/output ratings.

Do not operate with suspected failures. If you suspect that the

instrument is damaged, contact the Teledyne LeCroy service

department immediately.

Do not operate in wet/damp conditions.

Do not operate in an explosive atmosphere.

Keep the surface of the instrument clean and dry.

Avoid touching exposed circuits or wires. Do not touch

exposed contacts or components when the power is on.

Do not operate without covers. Do not operate the instrument

with covers or panels removed.

Use only the fuse specified for the instrument.

Use proper overvoltage protection.

Use anti-static protection. Operate in an anti-static protected

area. Ground measurement cable conductors before connecting

to the instrument to discharge any static electricity before

connecting the cables to the instrument.

Observe ventilation requirements. Ensure good ventilation.

Check the vent and fan regularly to prevent overheating.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Quick Start 1

Page 4

2 Quick Start

Safety Terms and Symbols

The following terms may appear on the instrument:

DANGER:

Direct injury or hazard may occur.

WARNING:

Potential injury or hazard may occur.

CAUTION:

Potential damage to instrument/property may occur.

CAT I

(1): IEC Measurement Category I, applicable for making

measurements on ‘other’ circuits that are not directly connected to

mains. See p. 6.

CAT II:

IEC Measurement Category II, applicable for making

measurements on circuits connected directly to utilization points

(socket outlets and similar points) of the low voltage mains installation.

See p. 5.

(1) CAT I as defined in IEC/EN 61010-031:2008. Note that

Measurement Category I was removed in IEC/EN 61010-031:2015

and replaced by ‘O’, indicating "other circuits that are not directly

connected to mains."

The following symbols may appear on the instrument:

CAUTION

Risk of

injury or

damage.

Refer to

manual.

WARNING

Risk of

electric

shock or

burn

Earth

Ground

Terminal

Protective

Conductor

Terminal

Frame or

Chassis

Terminal

ON/

Standby

Power

Alternating

Current

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 5

Operating Environment

Temperature: 0 °C to 40 °C

Humidity: 5% to 90% relative humidity (non-condensing) up to

+30 °C. Upper limit derates to 50% relative humidity (non-

condensing) at +40 °C.

Altitude: ≤ 2000 m

Use indoors only.

Pollution Degree 2. Use in an operating environment where

normally only dry, non-conductive pollution occurs. Temporary

conductivity caused by condensation should be expected.

AC Power

Input Voltage & Frequency: 100-120 V at 50/60 Hz

or 200-240 V at 50/60 Hz

Manual AC selection with a slide switch.

Power Consumption: 20 W maximum

Mains Supply Connector: CAT II per IEC/EN 61010-1:2010,

instrument intended to be supplied from the building wiring at

utilization points (socket outlets and similar).

Fuse Type

Current Input Terminal: 250 VAC F 10 A, 3 AG

AC Mains: 250 VAC F 300 mA, 5x20 mm

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Quick Start 3

Page 6

4 Quick Start

Input Terminal Protection Limitation

Protection limitation is defined for the input terminal.

1. Main Input (HI and LO) Terminals

HI and LO terminals are used for Voltage, Resistance,

Capacitance, Continuity, Frequency, Diode and Temperature

measurement. Two protection limitations are defined:

HI-LO protection limitation: 1000 VDC or 750 VAC. This is

the maximum measurable voltage. The limitation can be

expressed as 1000 Vpk.

LO ground protection limitation: LO terminal can “float” 500

Vpk relative to the ground safely. The maximum protection

limitation of HI terminal relative to the ground is 1000 Vpk.

Therefore, the sum of the “float” voltage and the measured

voltage can’t exceed 1000 Vpk.

2. Sampling (HISense and LOSense) Terminals

HISense and LOSense terminals are used for 4-wire Resistance

measurement. Two protection limitations are defined:

HISense-LOSense protection limitation: 2000 Vpk.

LOSense-LOSense protection limitation: 2 Vpk.

3. Current Input (I) Terminal

The I terminal is used for current measurement. The

maximum current which can go through the I terminal is

limited to 10 A by the fuse on the back panel.

NOTE:

Voltage on the current input terminal corresponds to voltage on

the LO terminal. To keep good protection, only use a fuse of the

specified type and value to replace this fuse.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 7

IEC Measurement Category II Overvoltage Protection

To avoid the danger of electric shock, the Digital Multimeter

provides overvoltage protection for line-voltage mains

connections that meet both of the following conditions:

1. The HI and LO input terminals are connected to the mains

under Measurement Category

II conditions described in the

warning below.

2. The maximum line voltage of the mains does not exceed:

300 VAC for T3DMM4-5

600 VAC for T3DMM5-5 and T3DMM6-5

WARNING:

IEC Measurement Category II includes electrical devices

connected to mains at an outlet on a branch circuit, such as most

small appliances, test equipments, and other devices that

plug into a branch outlet or socket.

The multimeter is capable of making measurements with the HI

and LO inputs connected to mains in such devices (≤ 300 VAC

for T3DMM4-5 and ≤ 600 VAC for T3DMM5-5/T3DMM6-5) or to

the branch outlet itself.

However, the HI and LO terminals of the multimeter can’t be

connected to mains in permanently installed electrical devices

such as the main circuit-breaker panels, sub-panel disconnected

boxes and permanently wired motors. Such devices and circuits

are prone to exceed the protection limits of the multimeter.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Quick Start 5

Page 8

6 Quick Start

Limits for Measurements on Other Circuits

Not Directly Connected to Mains

Max. rated input voltage: 1000 Vrms

Transient overvoltage: 4000 Vpk

WARNING:

Voltages above 300 VAC (for T3DMM4-5) or 600 VAC

(T3DMM5-5 / T3DMM6-5) can only be measured in circuits that

are isolated from mains. However, there may be transient over

voltage in circuits that are isolated from mains. The multimeter is

able to withstand occasional transient overvoltage up to 4000 Vpk.

Please don’t use this instrument to measure circuits where

transient overvoltage may exceed this level.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 9

Daily Maintenance and Cleaning

Maintenance

Protect the liquid crystal display from direct sunlight when

storing or using the instrument.

NOTE:

To avoid damage to the instrument or test leads, please don’t

place them in mist, liquid or solvent.

Cleaning

Regularly clean the instrument and test leads.

● Wipe the external dust off the instrument and test leads using a

soft rag. Be careful not to scratch the display screen when

cleaning. Do not allow any liquid to enter the instrument.

● Use a damp soft rag to clean the instrument after removing the

power plug. Or use 75% isopropyl alcohol / water solvent to get

a more thorough cleaning.

NOTE:

To prevent the surface of the instrument or test leads from

damage, please don’t use any corrosive or chemical cleaning

reagents.

Please make sure the instrument is fully dry before

reconnecting the power to avoid short circuits or personal injury.

Quick Start 7

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 10

Please check the instrument according to the following steps.

1. Inspect the shipping container.

Keep the shipping container and packaging material until the

contents of the shipment have been completely checked and the

instrument has passed both electrical and mechanical tests. It is

always good practice to save the shipping container and packaging

for use when returning the power supply to Teledyne LeCroy for

service or calibration.

The consigner or carrier will be responsible for damage to the

instrument resulting from shipping. Teledyne LeCroy will not

provide free maintenance or replacement in this instance.

2. Inspect the instrument.

If the instrument is found to be damaged, defective or fails in

electrical or mechanical tests, please contact the Teledyne LeCroy

service department immediately.

3. Check the accessories.

Please check that you have received the accessories on the

packing list. If the accessories are incomplete or damaged, please

contact Teledyne LeCroy immediately.

General Inspection

8 Quick Start

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 11

Dimensions

260.27mm

107.21 mm

T3DMM4-5: 293.75mm

T3DMM5-5: 293.75mm

T3DMM6-5: 345.45mm

Quick Start 9

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 12

Handle Adjustment

To adjust the handle position of the Multimeter, grip the handle by

the two sides and pull outward. Then, rotate the handle to the

appropriate position.

Handle Adjustment

Carrying Position

Horizontal Position

10 Quick Start

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 13

Front Panel

Front Panel Overview

USB Host

Users can store the current state or measurement data into a

USB storage device. Users can also read the state files or

updated firmware from a USB storage device.

Power Key

Turn the instrument on or off.

LCD Display

The instrument provides a 4.3 inch high resolution color TFT-LCD

display screen with 480*272 pixels that displays the function

menus, measurement parameter settings, system status, and

prompt messages.

Menu Operation Keys

Press any softkey to activate the corresponding menu.

C

D

A

B

B

A

C

D

E

F

G

Quick Start 11

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 14

DC Voltage / Current Measurement

AC Voltage / Current Measurement

2-Wire / 4-Wire Resistance Measurement

Frequency / Capacitance Measurement

Continuity / Diode Test

Temperature Measurement / Enable

Multiple Scan Card Function

Enable Dual-display Function / Set Up the Utility

Acquire Function / Help System

Math Function / Display Function

Auto Trigger / Stop

Single Trigger / Hold Measurement Function

Return to local control of the instrument (when in

Remote mode).

Some of the front panel keys have text above them.

This indicates that the key has a function that you

can access by pressing and releasing [Shift] before

pressing the key.

Measurement and Assistant Function Keys

E

12 Quick Start

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 15

Range and Direction Keys

Increase the measurement range

Decrease the measurement range

Select auto or manual range

Set up measurement parameter

Move the cursor

Page up or down

Set up measurement parameter

Move the cursor

Apply the current setting

Signal Input Terminals

The measured signal (device) will be connected into the

multimeter through these terminals. Different measurement

objects have different connection methods. For details, please

refer to “Measurement Connections”.

G

F

Quick Start 13

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 16

Rear Panel

Rear Panel Overview

Power Socket

The multimeter accepts two types of AC supplies. Please use

the power cord provided in the accessories to connect the

multimeter to the AC power through this socket.

Note: The correct voltage scale must be first selected (through the

Voltage Selector) before power connection.

Power Fuse

The multimeter is already installed with a power fuse before

leaving factory. To change the fuse please:

1) Turn off the multimeter and remove the power cord.

2) Press down the block tongue using a straight screwdriver

(in the direction of the dotted arrow in the figure below)

and pull out of the fuse seat.

3) Select a proper voltage scale.

4) Replace a specified fuse.

5) Reinstall the fuse seat into the slot.

I

G

H

F

E

A

B

C

D

A

B

J

!

14 Quick Start

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 17

Changing the fuse

AC Voltage Selector

Select the correct voltage scale (110 V or 220 V) for the

AC supply used.

Inspection card (option)

An optional 16-channel Data Acquisition Module can be

installed in the instrument.

USB Device

Connect the PC through this interface. You can use SCPI

commands or PC software to control the Multimeter remotely.

LAN

Through this interface, the multimeter can be connected to

the network for remote control.

VMC Output

The mutlimeter outputs a low-true pulse from the [VM Comp]

connector after every measurement

E

G

F

D

C

!

Quick Start 15

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 18

Ext Trigger

Trigger the multimeter by connecting a trigger pulse through

the [Ext Trig] connector. Note the external trigger source must

be selected.

Current Input Fuse

The multimeter is already installed with a current Input fuse

to provide 10 A maximum input protection before leaving

factory. To replace a new one, please:

1) Turn off the multimeter and remove the power cord.

2) Turn the fuse seat counterclockwise as shown in the

figure using a straight screw driver and then pull out the

fuse seat

3) Place a new 10 A specified fuse.

4) Reinstall the fuse seat into the slot.

Instrument Kensington Lock Point

A Kensington lock (not supplied) can be used to lock the

multimeter to a fixed place if necessary.

I

H

J

16 Quick Start

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 19

Starting the Multimeter

Before connecting the instrument to a power

source please adjust the AC voltage selector on the

rear panel of your multimeter according to your local

power supply voltage. Then connect the power cord as

shown in the following figure.

Connecting the Power Cord

Press the Power key on the front panel to turn on the multimeter.

If the multimeter does not start normally, then try the following:

1. Make sure the power cord is in good connection and connected

to the multimeter and the wall socket.

2. Ensure that the wall socket has power and is turned on.

3. Try to restart the multimeter, if it fails, check the power fuse and

replace with a new one if necessary.

4. If the problem still remains, please contact the Teledyne LeCroy

service department for help.

!

Quick Start 17

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 20

User Interface

Measurement

Function

Measuremet

Result

Trigger Mode

LAN Status Icon

Control Mode

Range

Operation Menu

User Interface Display

18 Quick Start

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 21

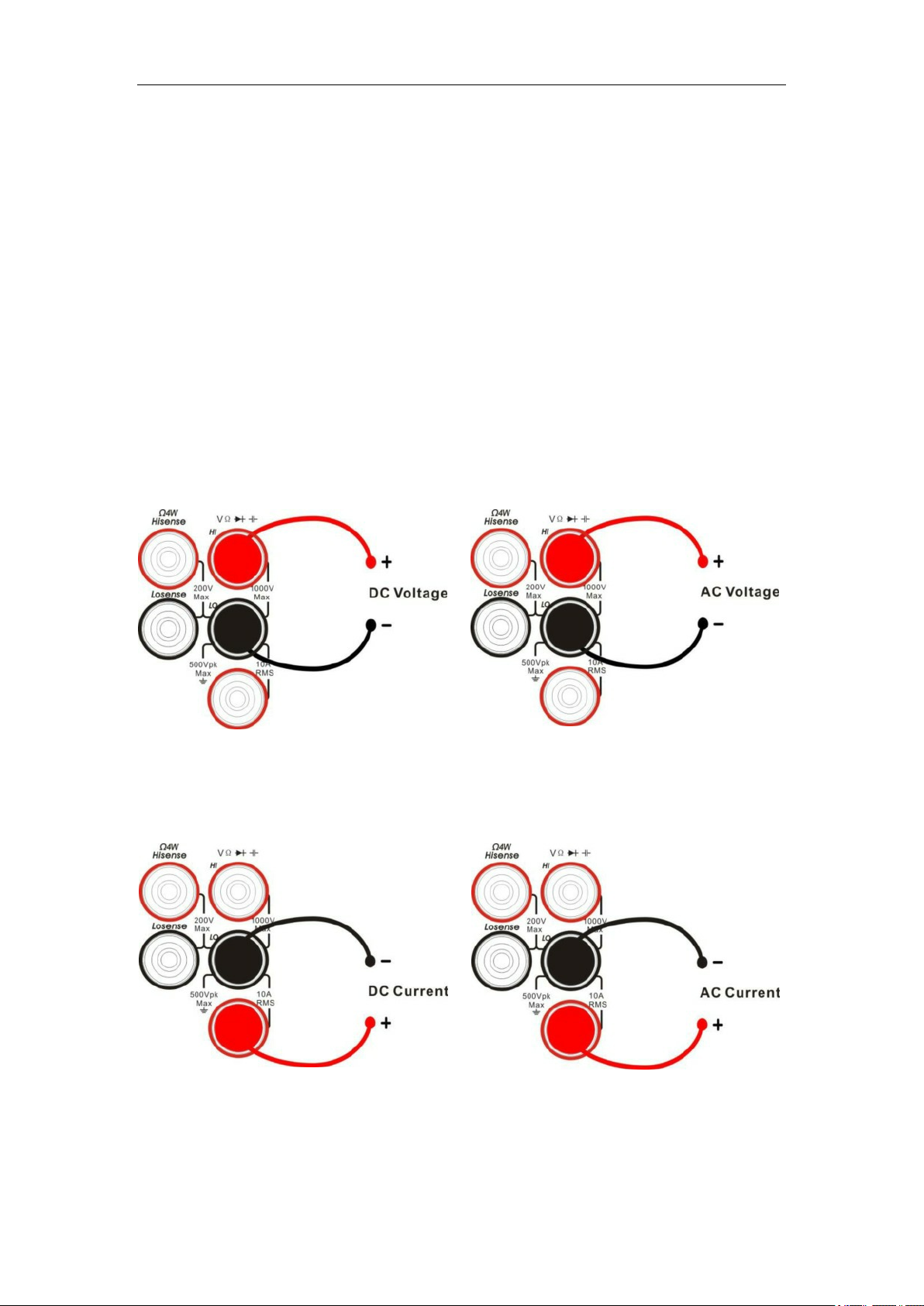

Measurement Connections

The Digital Multimeter is designed with many measurement

functions. After selecting the desired measurement function, please

connect the signal (device) under test to the multimeter according to

the method below. Do not switch the measurement function

when measuring as it may cause damage to the multimeter.

For example, when the test leads are connected to the related

current terminals, AC voltage measurement should not be used.

DCV Measurement ACV Measurement

DCI Measurement ACI Measurement

Quick Start 19

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 22

Resistance Measurement (2-wire) Resistance Measurement (4-wire)

Capacitance Measurement

Continuity Measurement Frequency/Period Measurement

Connect the test leads and tested

circuit as in the diagram below.

The HI terminal and HI Sense

should be connected to one end

of the DUT. The LO terminal and

LO Sense should be connected to

the other end of the DUT.

20 Quick Start

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 23

Temperature Measurement

( For RTD and thermcouple sensors)

Diode Measurement

Quick Start 21

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 24

Connecting to USB and LAN Ports

The Digital Multimeter has LAN and USB I/O ports. Connect to

the ports as in the diagrams below:

Connect to LAN

Connect to USB Device Port

Connect to USB Host Port

Find Quality Products Online at: sales@GlobalTestSupply.com

22 Quick Start

www.GlobalTestSupply.com

Page 25

Using the Built-in Help System

To access the built-in help system, press [Shift] + [Acquire],

then use the direction keys to choose the help item you want.

Finally, press [ O K ] to obtain help.

The help listings are as follows:

1. Basic Measurements

2. Measuring Temperature

3. Measuring Capacitance

4. Math Function

5. Dual-display Function

6. Saving and Recalling Information

7. Optional Multiple Scan Card

8. The convention and Tips for Softkeys

Quick Start 23

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 26

Troubleshooting

The commonly encountered failures and their solutions are listed

below. When you encounter those problems, please resolve them

using the following steps. If the problem remains, please contact the

Teledyne LeCroy service centre and provide your device Information

including serial number.

The screen has no display after pressing the power

key.

1. Check whether the power cord is fully connected.

2. Check whether the power fuse has blown or has failed. If the

fuse needs to be changed, please use the specified fuse.

3. Restart the instrument after finishing the above checks.

4. If the instrument still doesn’t start up properly, please contact

the Teledyne LeCroy service center.

The reading doesn’t change when a current signal is input.

1. Check whether the test lead is correctly inserted into the HI

and LO terminals of current measurement.

2. Check whether the current fuse at the back panel has blown.

3. Check whether the DCI or ACI measurement function is

enabled.

4. Check whether the DCI measurement function is used to

measure AC current.

24 Quick Start

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 27

The reading is abnormal when a voltage signal is input.

1. Check whether the test lead is correctly inserted into the HI

and LO terminals for voltage measurements.

2. Check whether the the DCV or ACV measurement function is

enabled.

3. Check whether the DCV measurement function is used to

measure AC voltage.

The USB storage device cannot be identified.

1. Check whether the USB storage device is in good condition.

2. Make sure the USB storage device you used is a flash

storage device. This instrument does not support hardware

storage types.

3. Check the capacity of your USB storage device. It is

recommended that the capacity of the USB storage device is

no larger than 8G bytes and FAT formatted.

4. Restart the instrument, then insert the USB storage

device.

5. If the problem persists, please contact the Teledyne LeCroy

service centre.

Quick Start 25

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 28

ABOUT TELEDYNE TEST TOOLS

Company Profile

Teledyne LeCroy is a leading provider of oscilloscopes, protocol analyzers and related test and measurement

solutions that enable companies across a wide range of industries to design and test electronic devices of all types.

Since our founding in 1964, we have focused on creating products that improve productivity by helping engineers

resolve design issues faster and more effectively. Oscilloscopes are tools used by designers and engineers to

measure and analyze complex electronic signals in order to develop high-performance systems and to validate

electronic designs in order to improve time to market.

The Teledyne Test Tools brand expands on the Teledyne LeCroy product portfolio by adding a comprehensive range

of test equipment solutions for its customers. The new range of product solutions deliver engineers with a broad

range of quality test solutions that enables speed to market product validation and design. More and more

designers, engineers and lecturers are relying on Teledyne Test Tools to meet their testing, education and

electronics validation needs with confidence and within budget.

Location and Facilities

Headquartered in Chestnut Ridge, New York, Teledyne Test Tools and Teldyne LeCroy have sales, service and

development subsidiaries in the US and throughout Europe and Asia. Teledyne Test Tools and LeCroy products are

employed across a wide variety of industries, including semiconductor, computer, consumer electronics, education,

military/aerospace, automotive/industrial, and telecommunications.

930339-00 RevA

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Loading...

Loading...