Teledyne Lecroy T3AWG3K Series, T3AWG3254, T3AWG3354, T3AWG3258, T3AWG3358 Operator's Manual

...Page 1

Operator’s Manual

T3AWG3K Series

Simple TrueArb

Rev. 1.7

Page 2

2

Summary

GENERAL SAFETY SUMMARY ................................................................................................................................. 4

TO AVOID FIRE OR PERSONAL INJURY ................................................................................................................................. 4

Use Proper Power Cord ......................................................................................................................................... 4

Ground the Product ............................................................................................................................................... 4

Observe All Terminal Ratings ................................................................................................................................ 4

Power Disconnect .................................................................................................................................................. 4

Do Not Operate Without Covers ........................................................................................................................... 4

Do Not Operate With Suspected Failures .............................................................................................................. 4

Avoid Exposed Circuitry ......................................................................................................................................... 4

Do Not Operate in Wet/Damp Conditions. ........................................................................................................... 4

Do Not Operate in an Explosive Atmosphere. ....................................................................................................... 4

Keep Product Surfaces Clean and Dry. .................................................................................................................. 4

Provide Proper Ventilation .................................................................................................................................... 4

SAFETY REQUIREMENTS ................................................................................................................................................... 5

Safety Symbols ...................................................................................................................................................... 5

ENVIRONMENTAL CONSIDERATIONS ..................................................................................................................... 7

PRODUCT END-OF-LIFE HANDLING .................................................................................................................................... 7

EQUIPMENT RECYCLING ................................................................................................................................................... 7

PREFACE ................................................................................................................................................................ 7

PACKAGE CONTENTS ....................................................................................................................................................... 7

RECOMMENDED ACCESSORIES .......................................................................................................................................... 8

MECHANICAL CHARACTERISTICS ........................................................................................................................................ 8

KEY FEATURES................................................................................................................................................................ 9

INSTALLING YOU INSTRUMENT ............................................................................................................................ 10

OPERATING REQUIREMENTS ........................................................................................................................................... 10

ENVIRONMENTAL REQUIREMENTS.................................................................................................................................... 11

POWER SUPPLY REQUIREMENTS ...................................................................................................................................... 11

CLEANING ................................................................................................................................................................... 11

CALIBRATION ............................................................................................................................................................... 12

ABNORMAL CONDITIONS ............................................................................................................................................... 12

POWER THE INSTRUMENT ON AND OFF ............................................................................................................................ 12

PROTECT YOUR INSTRUMENT FROM MISUSE ..................................................................................................................... 13

OBTAINING THE LATEST VERSION RELEASES ....................................................................................................................... 13

INSTALL SIMPLE TRUEARB APPLICATION ........................................................................................................................... 13

INSTRUMENT OVERVIEW ..................................................................................................................................... 16

FRONT PANEL T3AWG3352/3252 ............................................................................................................................... 16

FRONT PANEL T3AWG3354/3254 ............................................................................................................................... 17

FRONT PANEL T3AWG3358/3258 ............................................................................................................................... 18

Page 3

3

Analog Outputs ................................................................................................................................................... 18

Marker Output .................................................................................................................................................... 18

Trigger In ............................................................................................................................................................. 19

Soft keyboard and rotary knob ........................................................................................................................... 20

Numeric Keypad .................................................................................................................................................. 21

REAR PANEL T3AWG3352/3252 ................................................................................................................................. 22

REAR PANEL T3AWG3354/T3AWG3254 – REAR PANEL T3AWG3358/T3AWG3258 ..................................................... 23

External Modulation Input Connector ................................................................................................................. 24

Reference Clock Input Connector ........................................................................................................................ 24

Reference Clock Output Connector ..................................................................................................................... 24

Digital Output connector .................................................................................................................................... 24

Sync In / Sync Out Connectors ............................................................................................................................. 25

QUICK START GUIDE ............................................................................................................................................ 26

SIMPLE TRUEARB APPLICATION ........................................................................................................................... 30

SIMPLE TRUEARB TOUCH UI .......................................................................................................................................... 30

USER INTERFACE DESCRIPTION ........................................................................................................................................ 32

SEQUENCER AREA ........................................................................................................................................................ 33

Sequencer area items .......................................................................................................................................... 35

Sequencer Toolbar .............................................................................................................................................. 36

WAVEFORM AREA ........................................................................................................................................................ 37

Status Toolbar ..................................................................................................................................................... 42

COMMAND BAR ........................................................................................................................................................... 42

SETTINGS .................................................................................................................................................................... 45

Device Settings .................................................................................................................................................... 45

Channel Settings ................................................................................................................................................. 50

Marker Settings ................................................................................................................................................... 54

Sequencer Settings .............................................................................................................................................. 55

WAVEFORM LIST .......................................................................................................................................................... 57

CONFIGURATIONS ............................................................................................................................................... 60

SAVE AS... .................................................................................................................................................................. 60

EXPORT CONFIGURATION ............................................................................................................................................... 60

LOAD FROM… ............................................................................................................................................................. 61

REMOTE CONTROL ............................................................................................................................................... 61

REMOTE DESKTOP CONNECTION ..................................................................................................................................... 62

CALIBRATION AND DIAGNOSTIC .......................................................................................................................... 63

LICENSE ................................................................................................................................................................ 64

APPENDIX A – DIGITAL OPTION AND ACCESSORIES ............................................................................................. 66

1.1 T3AWG3-8DIG-SMA ................................................................................................................................... 69

1.2 B. T3AWG3-8DIG-TTL ................................................................................................................................. 70

CERTIFICATIONS ................................................................................................................................................... 72

Page 4

4

EMC COMPLIANCE ....................................................................................................................................................... 72

SAFETY COMPLIANCE .................................................................................................................................................... 72

ENVIRONMENTAL COMPLIANCE....................................................................................................................................... 73

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to this product or any

products connected to it.

To avoid potential hazards, use this product only as specified.

Only qualified personnel should perform service procedures.

To Avoid Fire or Personal Injury

Use Proper Power Cord

Use only the power cord specified for this product and certified for the country of use.

Ground the Product

This product is grounded through the grounding conductor of the power cord. To avoid electric shock, the

grounding conductor must be connected to earth ground. Before making connections to the input or

output terminals of the product, ensure that the product is properly grounded.

Observe All Terminal Ratings

To avoid fire or shock hazard, observe all ratings and markings on the product. Consult the product

manual for further ratings information before making connections to the product.

Power Disconnect

The power cord provides Mains disconnect.

Do Not Operate Without Covers

Do not operate this product with covers or panels removed.

Do Not Operate With Suspected Failures

If you suspect that there is damage to this product, have it inspected by qualified service personnel.

Avoid Exposed Circuitry

Do not touch exposed connections and components when power is present. Do Not Operate in

Wet/Damp Conditions.

Do Not Operate in an Explosive Atmosphere.

Keep Product Surfaces Clean and Dry.

Provide Proper Ventilation

Refer to the manual’s installation instructions for details on installing the product so it has proper

ventilation.

Page 5

Operator’s Manual Simple TrueArb Application

5

Safety Requirements

This section contains information and warnings that must be observed to keep the instrument operating

in a correct and safe condition. You are required to follow generally accepted safety procedures in

addition to the safety precautions specified in this section.

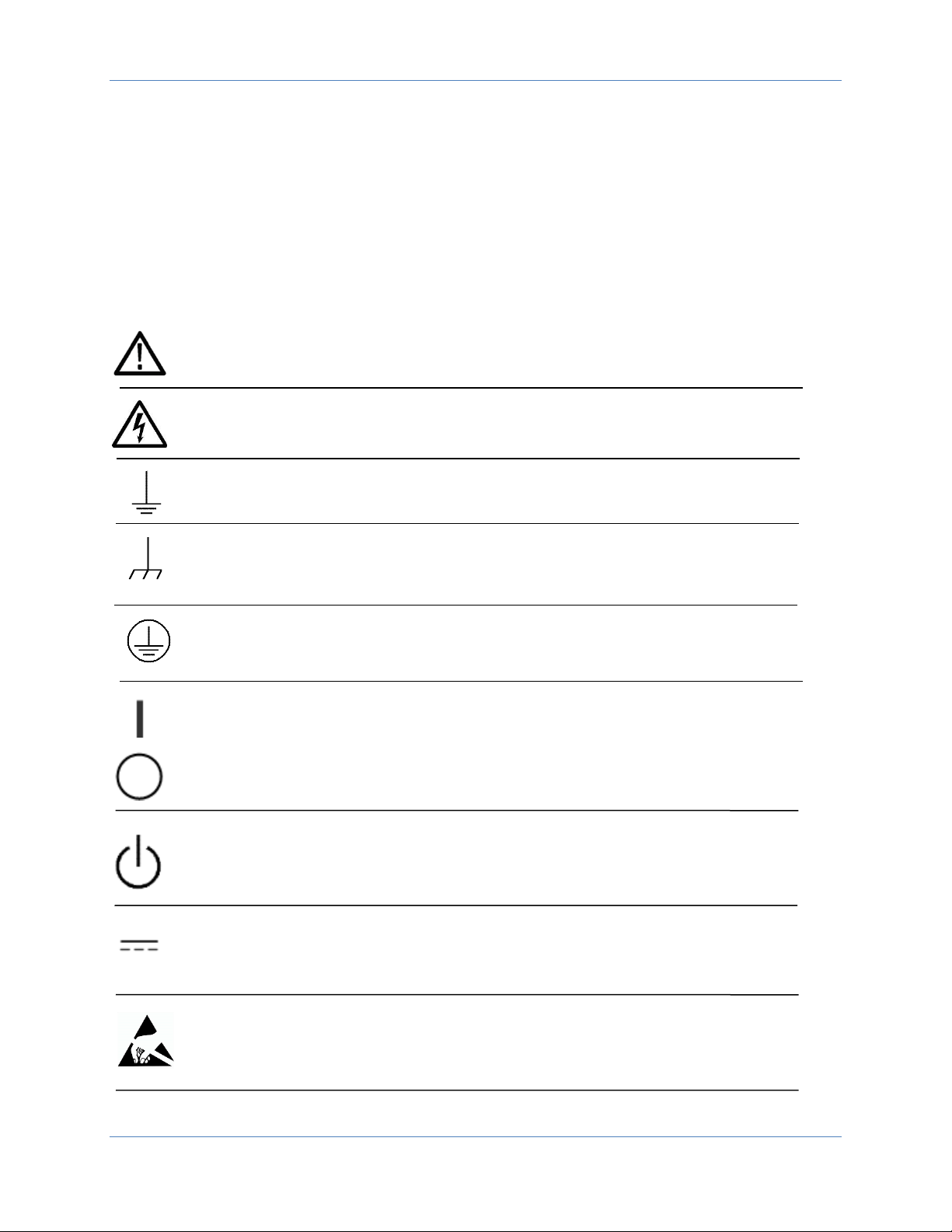

Safety Symbols

Where the following symbols appear on the instrument’s front or rear panels, or in this manual, they

alert you to important safety considerations.

This symbol is used where caution is required. Refer to the accompanying information or

documents in order to protect against personal injury or damage to the instrument.

This symbol warns of a potential risk of shock hazard.

This symbol is used to denote the measurement ground connection.

This symbol is used to denote a frame or chassis connection.

This symbol is used to denote a safety ground connection.

On (Supply). This is the DC power connect/disconnect switch at the back of the

instrument.

Off (Supply). This is the DC power connect/disconnect switch at the back of the

instrument.

This symbol is used to denote Power. It is located on the front panel and denotes

Power On/Off status of the instrument.

This symbol is used to denote Direct Current.

This symbol is used to denote that the device connectors are sensitive to electrostatic

discharge

Page 6

Operator’s Manual Simple TrueArb Application

6

CAUTION

The CAUTION sign indicates a potential hazard. It calls attention to a procedure, practice or condition

which, if not followed, could possibly cause damage to equipment. If a CAUTION is indicated, do not

proceed until its conditions are fully understood and met.

WARNING

The WARNING sign indicates a potential hazard. It calls attention to a procedure, practice or condition

which, if not followed, could possibly cause bodily injury or death. If a WARNING is indicated, do not

proceed until its conditions are fully understood and met.

CAT I

Installation (Overvoltage) Category rating per EN 61010-1 safety standard and is applicable for the

instrument front panel measuring terminals. CAT I rated terminals must only be connected to source

circuits in which measures are taken to limit transient voltages to an appropriately low level.

Page 7

Operator’s Manual Simple TrueArb Application

7

Environmental considerations

Product End-of-life Handling

Observe the following guidelines when recycling an instrument or component.

Equipment Recycling

Production of this equipment required the extraction and use of natural resources. The equipment may

contain substances that could be harmful to the environment or human health if improperly handled at

the product’s end of life. In order to avoid release of such substances into the environment and to

reduce the use of natural resources, we encourage you to recycle this product in an appropriate system

that will ensure that most of the materials are reused or recycled appropriately.

The symbol shown to the left indicates that this product complies with the European

Union’s requirements according to Directive 2002/96/EC on waste electrical and electronic

equipment (WEEE).

Preface

This manual describes the installation and operation of Arb T3AWG-3K Series using the Simple TrueArb

software. Basic operations and concepts are presented in this manual.

The easiest touch screen display interface allows to create waveforms scenarios, only in few screen

touches.

In summary the True Arb technology provides AWG capabilities to the instrument where every data

point is used to generate the output signal which has been stored in memory; the software architecture

makes arbitrary waves easier to manipulate and more flexible once they’ve been created and it adds

sequencing features to the instrument.

Package Contents

The standard T3AWG3K Series package includes the following:

• T3AWG325X or T3AWG335X Arbitrary Waveform Generator equipment

• Power Cord

• Performance/Calibration Certificate

Page 8

Operator’s Manual Simple TrueArb Application

8

• Quick Start Guide

• CE certificate

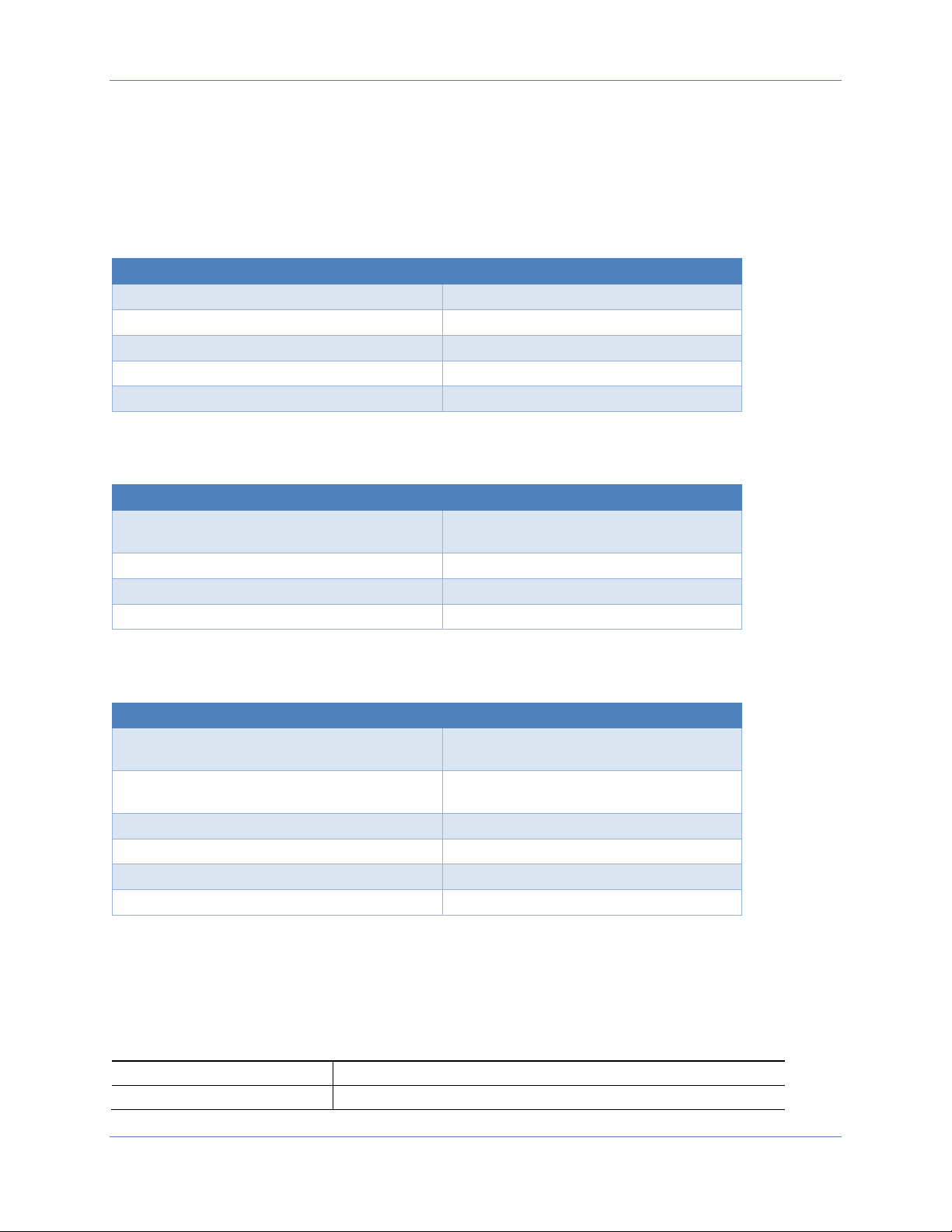

Recommended Accessories T3AWG3352/3252

Item

Description

T3AWG3-8DIG/T3AWG3-8DIG-UPGRADE

8 Bit digital outputs (requires LVDS cable)

T3AWG3-8DIG-TTL

LVDS to LVTTL digital adapter probe

T3AWG3-8DIG-SMA

LVDS to SMA digital adapter cable

T3AWG3-8DIG-MSCAB

Digital output LVDS cable

T3AWG3-RACKMOUNT

Rack Mount Kit

Recommended Accessories T3AWG3354/3254

Item

Description

T3AWG3-16DIG-4CH/T3AWG3-16DIGUPGRADE-4CH

16 Bit digital outputs (requires 2 x LVDS

cables)

T3AWG3-8DIG-TTL

LVDS to LVTTL digital adapter probe

T3AWG3-8DIG-SMA

LVDS to SMA digital adapter cable

T3AWG3-8DIG-MSCAB

Digital output LVDS cable

Recommended Accessories T3AWG3358/3258

Item

Description

T3AWG3-16DIG-8CH/T3AWG3-16DIGUPGRADE-8CH

16 Bit digital outputs (requires 2 x LVDS

cables)

T3AWG3-32DIG-8CH/T3AWG3-32DIGUPGRADE-8CH

32 Bit digital outputs (requires 4 x LVDS

cables)

T3AWG3-8DIG-TTL

LVDS to LVTTL digital adapter probe

T3AWG3-8DIG-SMA

LVDS to SMA digital adapter cable

T3AWG3-8DIG-MSCAB

Digital output LVDS cable

T3AWG3-SYNC

SYNC accessories for T3AWG3K-8CH

Mechanical Characteristics

Model T3AWG3352-T3AWG3252

Net Weight

6.5kg

Net Weight with Package

7 kg

Page 9

Operator’s Manual Simple TrueArb Application

9

Overall Dimensions

Height: 143 mm

Width: 362 mm

Depth: 258 mm

Model T3AWG3354-T3AWG3254

Net Weight

6.5kg

Net Weight with Package

7 kg

Overall Dimensions

Height: 160 mm

Width: 450 mm

Depth: 340 mm

Model T3AWG3358-T3AWG3258

Net Weight

10.8kg

Net Weight with Package

11.3 kg

Overall Dimensions

Height: 160 mm

Width: 450 mm

Depth: 340 mm

Key features

The following list describes some of the key features of the T3AWG335X and T3AWG325X

• High resolution, high sampling rate: 16 Bits, 1.2GS/s

• Best output frequency vs amplitude trades off: 350Mhz, 48V voltage window

• 3 operating modes in the same instruments: Function Generator, Arbitrary Waveform Generator

or Digital Pattern Generator

• Very long memory: up to 1 GSample per channel

Page 10

Operator’s Manual Simple TrueArb Application

10

• T3AWG3352/3252 Mixed signal generation: 2 analog output + 8 digital outputs (with T3AWG3-

8DIG option)

• T3AWG3354/3254 Mixed signal generation: 4 analog output + 16 digital outputs (with T3AWG3-

16DIG-4CH option)

• T3AWG3358/3258 Mixed signal generation: 8 analog output + 32 digital outputs (with T3AWG3-

32DIG-8CH option)

• Simple touch screen user interface to create complex waveforms scenarios just in few screen

touches

• Large 7 inch, 1024x600 capacitive touch LCD

• Touchscreen or Keypad data entering

• Windows 10 operating system

• USB and LAN interfaces

• Compact case size with the possibility of rack mounting in 3U

Installing you instrument

Unpack the instrument and check that you received all items listed in the Package Content paragraph.

NOTE. The instrument does not ship with a product software CD. To reinstall the product software,

follow the instructions in the paragraph “Obtaining the Latest Software Releases” to get the latest

software release and the instructions in the paragraph “Install Simple TrueArb Application” to install the

application

Operating Requirements

CAUTION. To ensure proper cooling, keep sides of the instrument clear of obstructions.

Place the instrument on a cart or bench, observing clearance requirements:

• Top: 20 mm (0.8 in)

• Left and right side: 150 mm (5.9 in)

• Bottom: 20 mm (0.8 in)

• Rear: 75 mm (3 in)

CAUTION. Ensure that the equipment is positioned in a way that the disconnecting device can be readily

accessible.

The instrument is intended for indoor use and should be operated in a clean, dry, nonconductive

environment. Occasionally a temporary conductivity that is caused by condensation must be expected.

This location is a typical office/home environment. Temporary condensation occurs only when the

product is out of service.

Page 11

Operator’s Manual Simple TrueArb Application

11

Environmental requirements

Before using this product, ensure that its operating environment is maintained within these parameters:

Temperature

Operating +5 °C to +40 °C (+41 °F to 104 °F)

Non-operating -20 °C to +60 °C (-4 °F to 140 °F)

Humidity

Operating 5% to 80% relative humidity with a maximum wet

bulk temperature of 29 °C at or below +40 °C, non-condensing.

Non-operating 5% to 95% relative humidity with a maximum wet

bulb temperature of 40 °C at or below +60 °C, non- condensing.

Altitude

Operating 3,000 m (9,843 feet)

Non-operating 12,000 m (39,370 feet)

Power supply requirements

WARNING. To reduce the risk of fire and shock, ensure that the mains supply voltage fluctuations do

not exceed 10% of the operating voltage range.

No manual voltage selection is required because the AC Adapter automatically adapts to line voltage.

Source Voltage and Frequency

100 to 240 VAC ±10% @ 45-66 Hz

Power Consumption

T3AWG3352/3252 Maximum: 100W

T3AWG3354/3254 Maximum: 130W

T3AWG3358/3258 Maximum: 150W

WARNING - Electrical Shock Hazard

Only use the power cord provided with your instrument

Cleaning

WARNING. To avoid personal injury, power off the instrument and disconnect it from line voltage

before performing any other following procedures.

Inspect the arbitrary waveform generator as often as operating conditions require. To clean the exterior

surface, perform the following steps:

Page 12

Operator’s Manual Simple TrueArb Application

12

• Remove loose dust on the outside the instrument with a lint-free cloth. Use care to avoid

scratching the front panel display.

• Use a soft cloth dampened with water to clean the instrument. Use a 75% isopropyl alcohol

solution as a cleaner.

CAUTION. To avoid damage to the surface of the arbitrary waveform generator, do not use any

abrasive or chemical cleaning agents.

Calibration

The recommended calibration interval is one year. Calibration should be performed by qualified

personnel only.

Abnormal Conditions

Operate the instrument only as intended by the manufacturer.

If you suspect the instrument’s protection has been impaired, disconnect the power cord and secure the

instrument against any unintended operation.

The instrument’s protection is likely to be impaired if, for example, the instrument shows visible damage

or has been subjected to severe transport stresses.

Proper use of the instrument depends on careful reading of all instructions and labels.

WARNING

Any use of the instrument in a manner not specified by the manufacturer may impair the instrument’s

safety protection.

Power the Instrument On and Off

Power On

• Insert the AC power cord into the power receptacle on the rear panel.

• Use the front-panel power button to power on the instrument.

• Wait until the system shows windows desktop.

• The Simple TrueArb software will start automatically

Page 13

Operator’s Manual Simple TrueArb Application

13

Power Off

• Close the application in use.

• Press the front-panel power button to power off the instrument.

Protect Your Instrument from Misuse

Check Input and Output Connectors

When connecting a cable, be sure to distinguish the input connector from the output connectors to avoid

making the wrong connection.

CAUTION. Do not short output pins or apply external voltages to Output connectors. The instrument

may be damaged.

CAUTION. Do not apply excessive inputs over ±15 Vpk to Trigger Input connector. The instrument may be

damaged.

Obtaining the Latest Version Releases

The latest release of the software may not be installed on your instrument. The latest version could be

found on Teledyne LeCroy website (www.teledynelecroy.com) in the support area

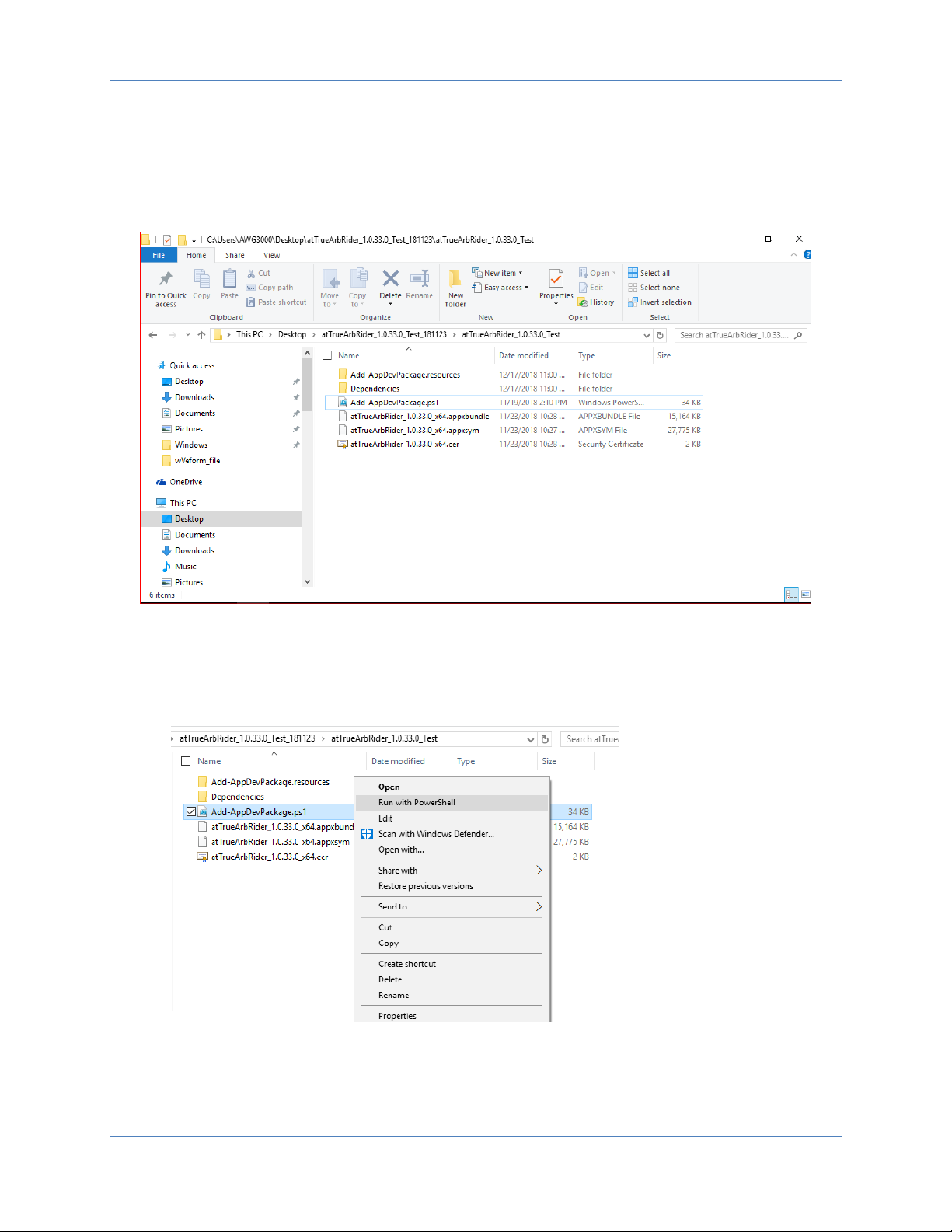

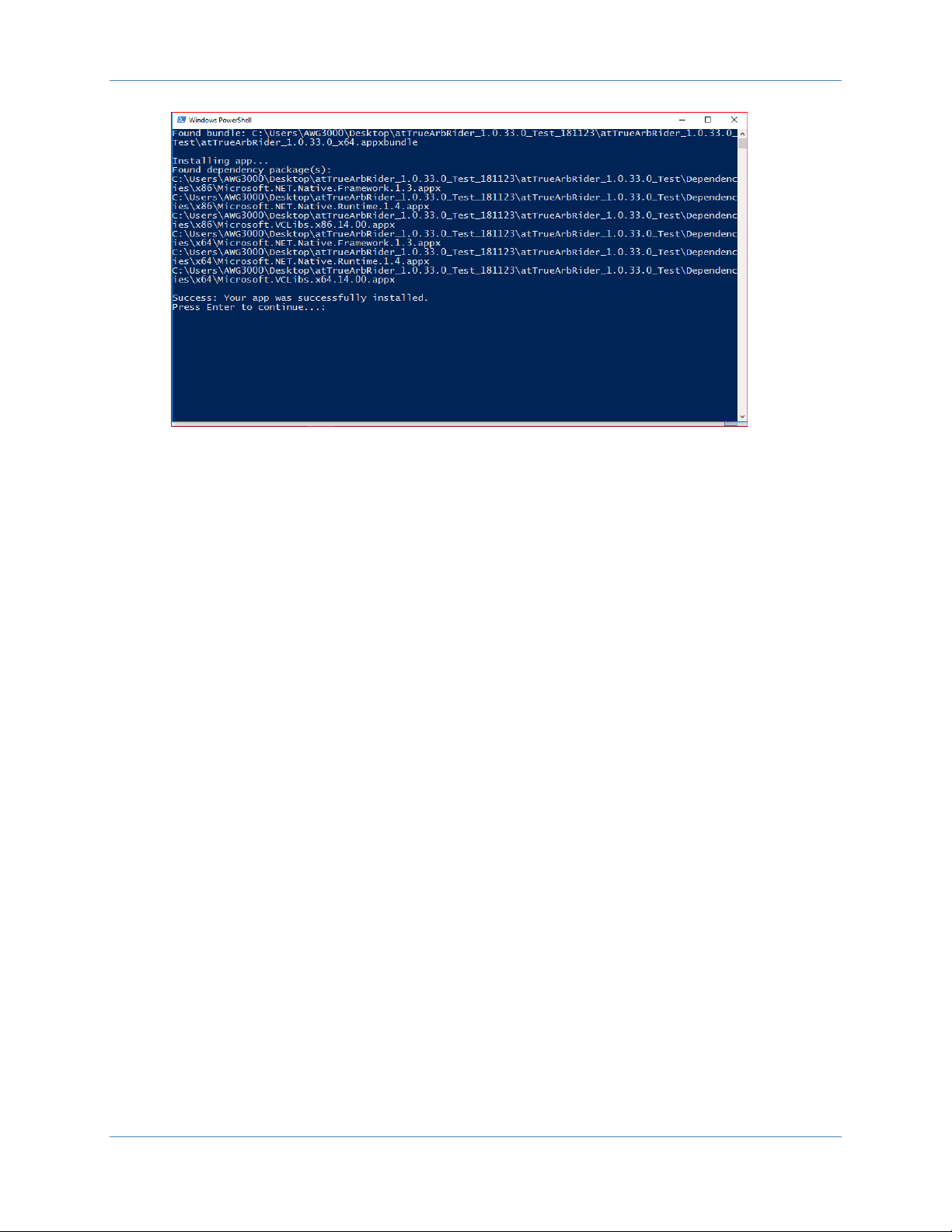

Install Simple TrueArb Application

Page 14

Operator’s Manual Simple TrueArb Application

14

If your instrument has already installed another version of the Simple TrueArb application, DO NOT

uninstall it otherwise you will loose all the configurations and projects.

1. Download the Simple TrueArb setup package from Teledyne Lecroy website and decompress

it to instrument’s local disk.

2. Right click on the “Add-AppDevPackage.ps1” file and select Run with PowerShell to start the

installation.

3. When the application has been installed, press the “Enter” button to continue.

Page 15

Operator’s Manual Simple TrueArb Application

15

Page 16

Operator’s Manual Simple TrueArb Application

16

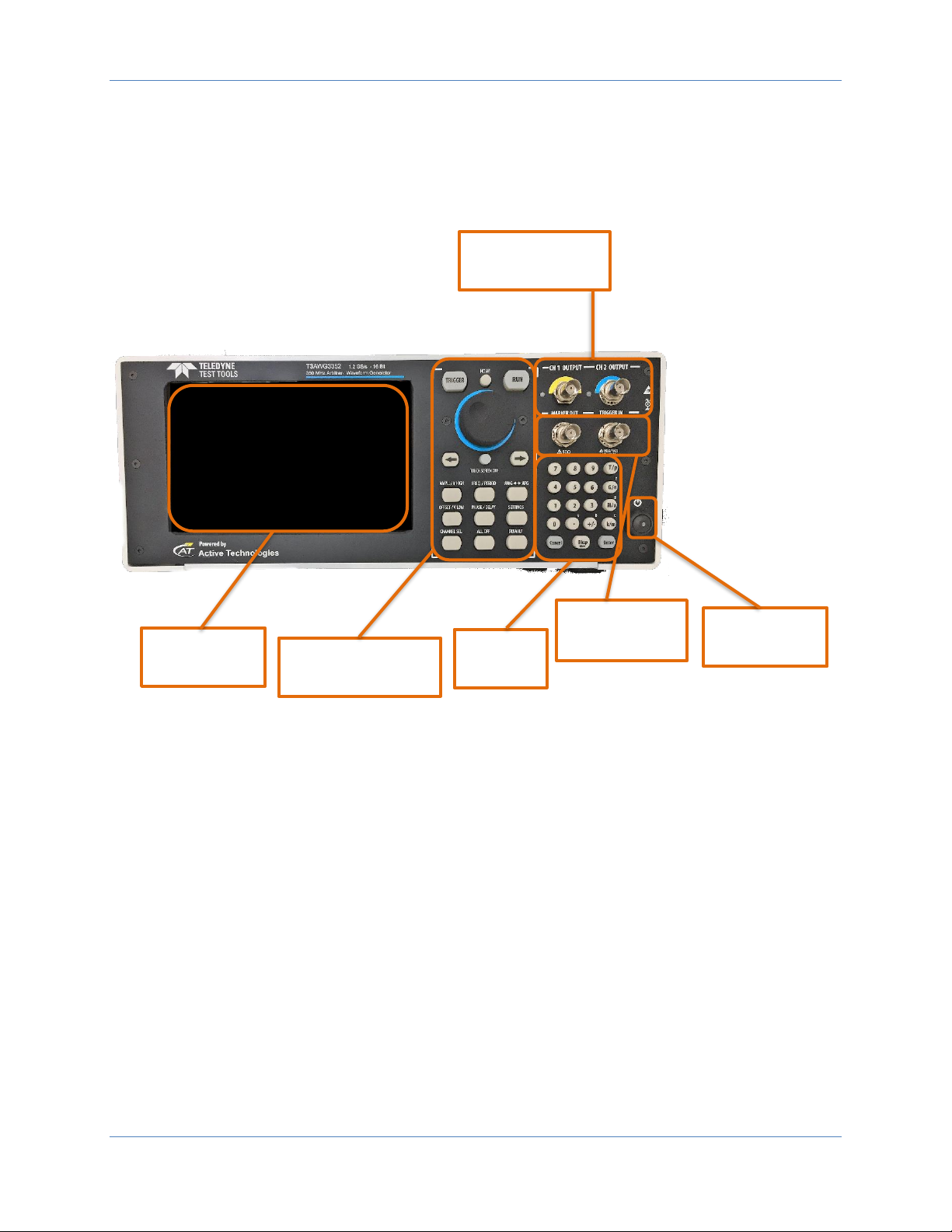

Instrument Overview

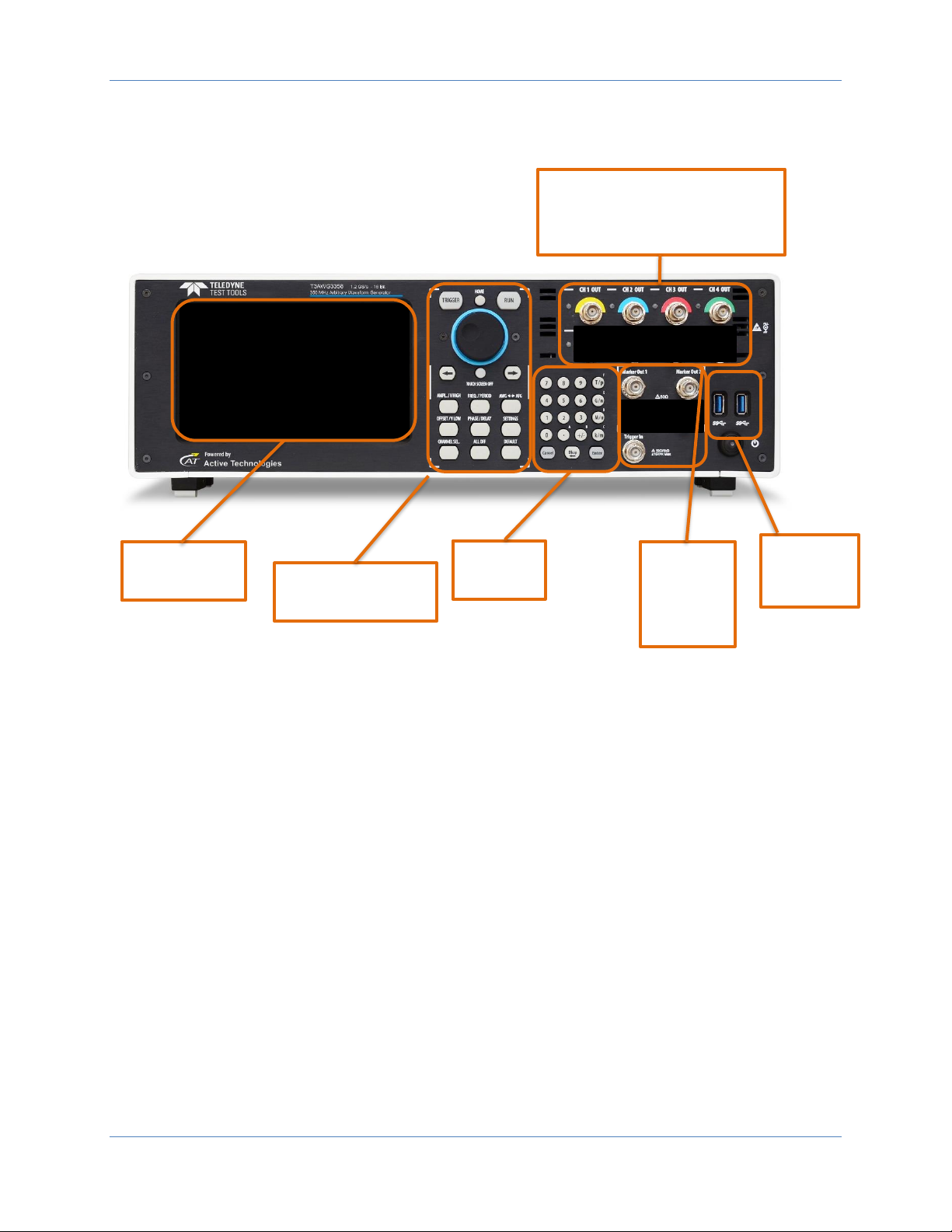

Front Panel T3AWG3352/3252

7” Capacitive

Touch Screen

Soft Keyboard and

Rotary Knob

Numeric

Keypad

Power on/off

button

Single ended

analog outputs

Trigger In and

Marker Output

Page 17

Operator’s Manual Simple TrueArb Application

17

Front Panel T3AWG3354/3254

7” Capacitive

Touch Screen

Soft Keyboard and

Rotary Knob

Single ended analog outputs

Trigger In

and

Marker

Output

Numeric

Keypad

2 USB 3.0

ports

Page 18

Operator’s Manual Simple TrueArb Application

18

Front Panel T3AWG3358/3258

The Touch screen functionalities and features are described in the Simple TrueArb Application

paragraph.

Analog Outputs

The T3AWG-3K Series instrument has 2/4/8 analog output channels, each one is single-ended and the

connector type is a standard BNC.

Marker Output

The Marker Out is a digital output channel that generates a pulse related to the analog waveform. Its

impedance is 50 Ohm and the output voltage amplitude ranges from 1 V to 2.5 V into 50 Ohm load.

The Marker Out generates a digital pulse synchronous with the waveform depending on the Run Mode.

To set the Marker Out parameters refer to the Marker Settings.

The connector type is a standard BNC.

7” Capacitive

Touch Screen

Soft Keyboard and

Rotary Knob

Single ended analog outputs

Trigger In

and

Marker

Output

Numeric

Keypad

2 USB 3.0

ports

Page 19

Operator’s Manual Simple TrueArb Application

19

Marker Out Specification

Value

Connector

1 BNC for each pair of channels on the Front Panel

Output impedance

50 Ω

Output level (into 50 Ω)

1 V to 2.5 V

Important Note:

the Marker Out 1 is linked to the Channel 1 and Channel 2, the Marker Out 2 is linked to the Channel

Out 3 and Channel Out 4, the Marker Out 3 is linked to the Channel Out 5 and Channel Out 6, the

Marker Out 4 is linked to the Channel Out 7 and Channel Out 8.

Model

Marker Out Connectors

T3AWG3352/3252

1 BNC on the Front Panel

T3AWG3354/3254

2 BNCs on the Front Panel

T3AWG3358/3258

4 BNCs on the Front Panel

Trigger In

The Trigger In (TRG. IN connector on the front panel) allows to control the generation by an external

signal source. It has a selectable impedance of 1 kOhm or 50 Ohm. To know how to set the trigger

parameters or the Run Mode refer to the paragraph “Trigger ”. In Continuous mode the Trigger In

doesn’t have any effect.

Trigger In Specification

Value

Connector

BNC on the Front Panel

Number of connectors

1

Input impedance

1 kΩ or 50 Ohm selectable

Slope/Polarity

Positive or negative selectable

Trigger In signal (blue, top) that starts a burst of sine waveform (red, bottom)

Page 20

Operator’s Manual Simple TrueArb Application

20

Soft keyboard and rotary knob

Most of the buttons you use with Simple TrueArb application are virtual ones on the touchscreen, but a

few physical buttons control basic functions, such as the setting of amplitude, offset, frequency, etc.

A physical numeric keypad is available on the front-panel and it can be used instead of the virtual

numeric pad.

A useful central knob is available for fine-tuning and adjustments during the on the fly set up operation.

The rotary knob will change the value in continuous, analog fashion. The push button rotary knob lets

you to change the value increment between Coarse and Fine adjustment.

The → key will move the selected digit to the right and the key will move the selected digit to right.

You can keep pressed the rotating knob and rotate it on the right or on the left to change the Delta

increment.

Rotary Knob

Rotary Push Button

Digit Selection Arrows

Page 21

Operator’s Manual Simple TrueArb Application

21

Button

Description

HOME

If you are in a sub-menu page, use this button to return to the main page.

TRIGGER

Use this button to send an internal trigger to the instrument.

RUN

Use this button to start and stop the signal generation. If the button is on and green the

instrument is running while if it is off the instrument is stopped. Bushing the

button will change the instrument state.

LEFT ARROW

Once the virtual numeric keypad will be opened, use this button to move to the left the

digit selection cursor.

RIGHT ARROW

Once the virtual numeric keypad will be opened, use this button to move to the right the

digit selection cursor.

TOUCH SCREEN

OFF

Use this button to disable the touch screen.

AMPL./V HIGH

Use this button to set the high voltage level or the amplitude of the waveform.

FREQ/PERIOD

Use this button to set the period or the frequency of the waveform.

AWG <-> AFG

Use this button to switch between AFG mode and AWG operating mode.

OFFSET/V LOW

Use this button to set the low voltage level or the offset of the waveform.

PHASE/DELAY

N.A.

SETTINGS

Use this button to open the Settings page

CHANNEL SEL.

Use this button to change the output selection in the user interface

ALL OFF

Use this button to turn off all the outputs.

DEFAULT

Use this button to restore the default settings.

Numeric Keypad

The physical numeric keypad lets you to set the parameter value and their measure unit.

Ones a parameter to be edited is selected by using the touch panel or the soft keyboard each number

pressed in the keypad will be displayed in the display. The Bksp key is provided for deleting erroneous

key presses. The [+/-] key will toggle the sign of the number being entered and may be pressed after

terminating the entry. After the sign and the numeric portion of the desired value have been entered,

the pressing of the multiplier button applies the parameter. The Enter button closes the virtual keyboard

and will apply the entered value.

Page 22

Operator’s Manual Simple TrueArb Application

22

When you select a parameter on the user interface, if you press a Unit Measure Range button it will

automatically update the available range allowed for that parameter.

Unit Measure Range Button

Unit Measure Range

T/p

Tera / pico

G/n

Giga / nano

M/u

Mega / micro

k/m

Kilo / milli

For example if you select the Frequency parameter and you press k/m the unit measure range will be

kHz, if you press M/u it will be MHz, if you press G/n it will be GHz, if you press T/p nothing will happen

because that range is not available for the selected parameter.

If both the two unit of measure of a Unit Measure Range button are available for the selected

parameter (i.e. Mega and Micro), if you press the range button M/u, the range will switch accordingly

between Mega and Micro.

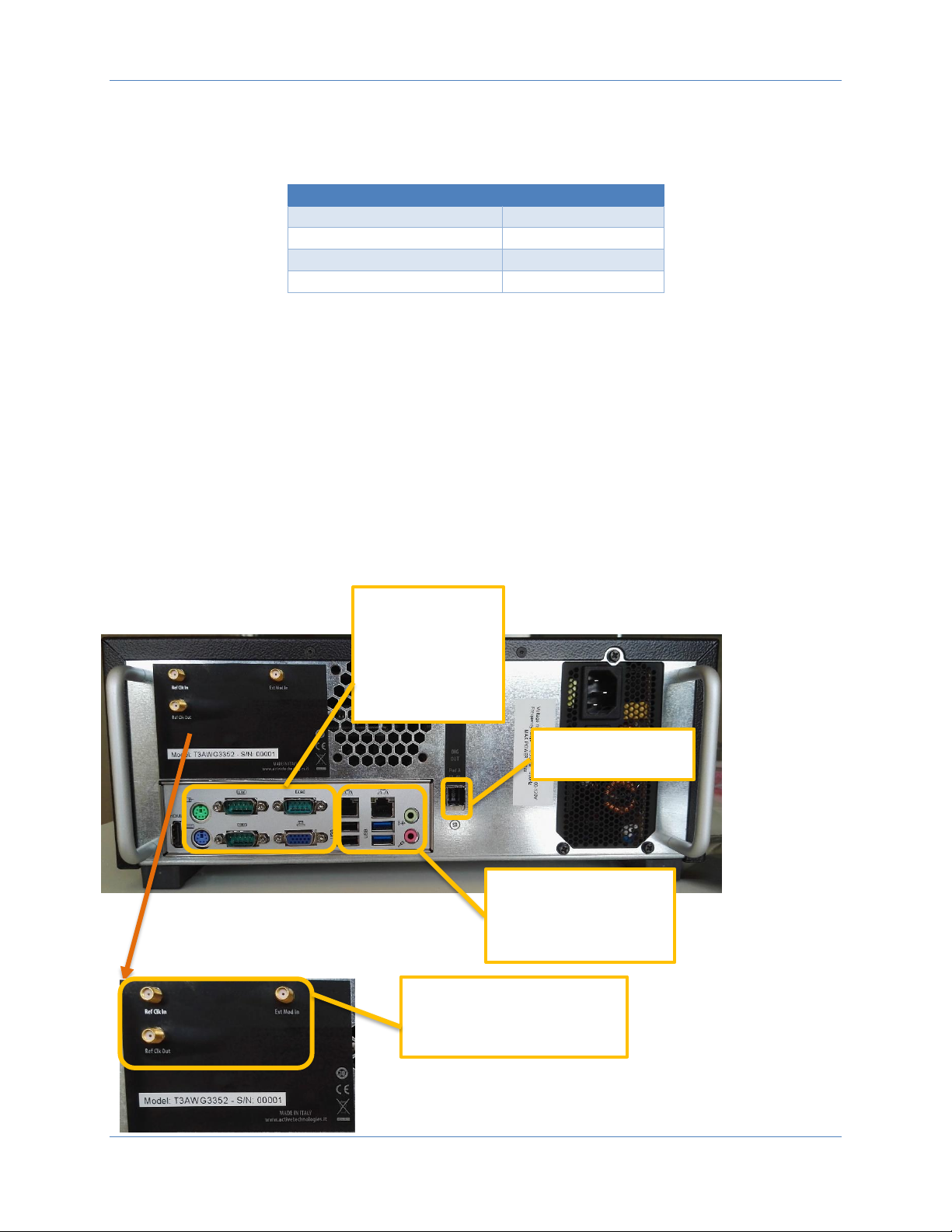

Rear Panel T3AWG3352/3252

The callouts on this image gives the description of the corresponding connectors.

Digital Output

Connector

• HDMI port

• VGA Out port

• PS/2 Mouse &

Keyboard ports

• 3 COM ports

• 2 USB 2.0 ports

• 2 USB 3.0 ports

• 2 LAN port

• Audio IN/OUT

• Ref Clk In: 5 to 100 MHz

• 10 MHz Ref Clock Output

• External Modulation Input

Page 23

Operator’s Manual Simple TrueArb Application

23

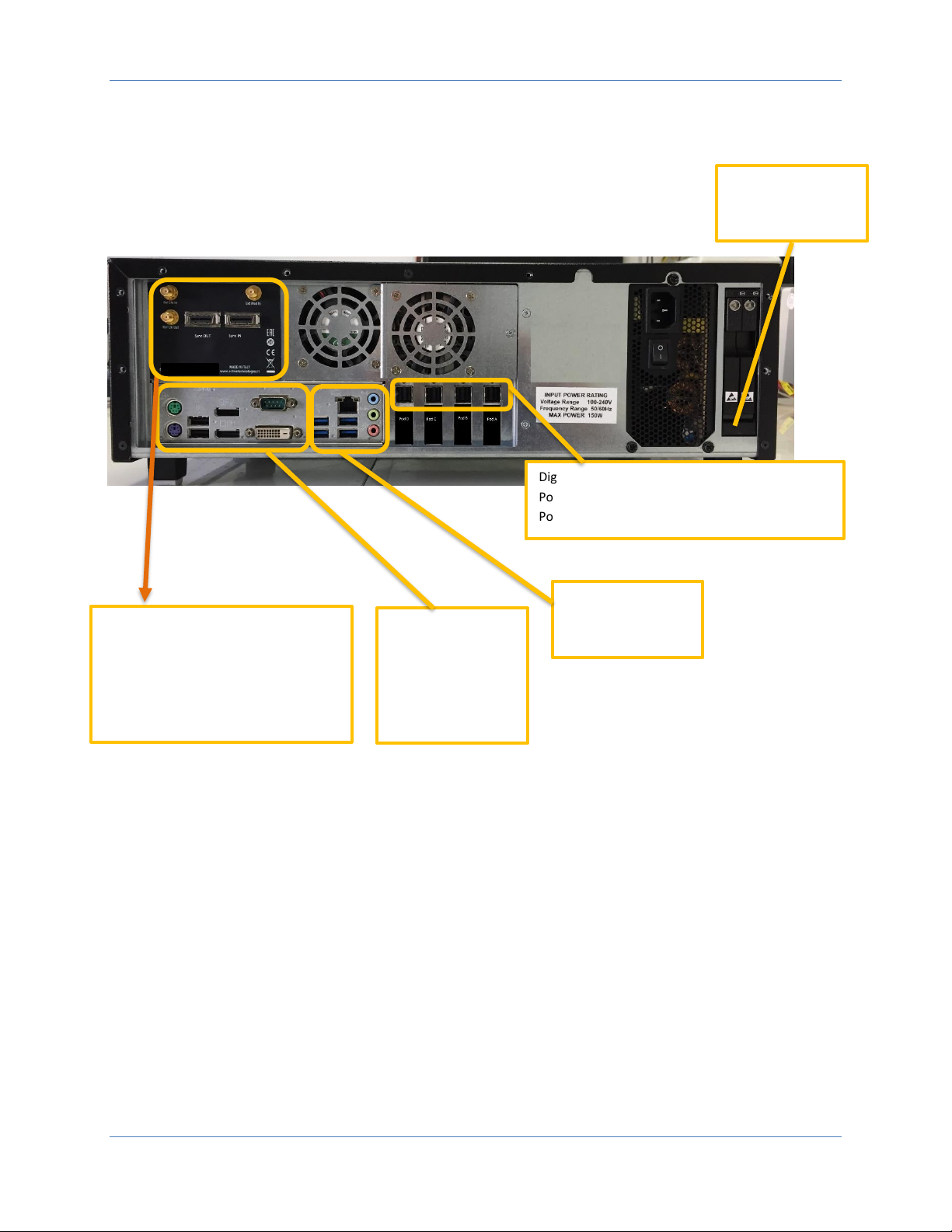

Rear Panel T3AWG3354/T3AWG3254 and

Rear Panel T3AWG3358/T3AWG3258

Digital Output Connectors:

Pod D, Pod C, Pod B, Pod A (T3AWG3358/3258)

Pod B, Pod A (T3AWG3354/3254)

• DVI port

• VGA Out port

• PS/2 Mouse &

Keyboard ports

• 2 DP ports

• 2 USB 2.0

• 4 USB 3.0 ports

• 1 Ethernet port

• Audio IN/OUT ports

• Ref Clk In: 5 to 100 MHz

• 10 MHz Ref Clock Output

• External Modulation Input

• Sync OUT / Sync IN Connectors

(T3AWG3358/3258 only)

• 2 slots for

Removable SSD

Page 24

Operator’s Manual Simple TrueArb Application

24

External Modulation Input Connector

Important Note: this connector is not used by TrueArb application.

Reference Clock Input Connector

The T3AWG-3K can use an external clock source to generate the sampling clock frequency.

This feature allows to synchronize the generator with an external clock.

The connector type is a SMA.

Reference Clock Output Connector

This connector outputs the internal 10Mhz reference clock used to synthesize the DAC sampling clock. If

the clock source is internal it produces a signal at 10 MHz, if the source is external it is disabled.

The connector type is a SMA.

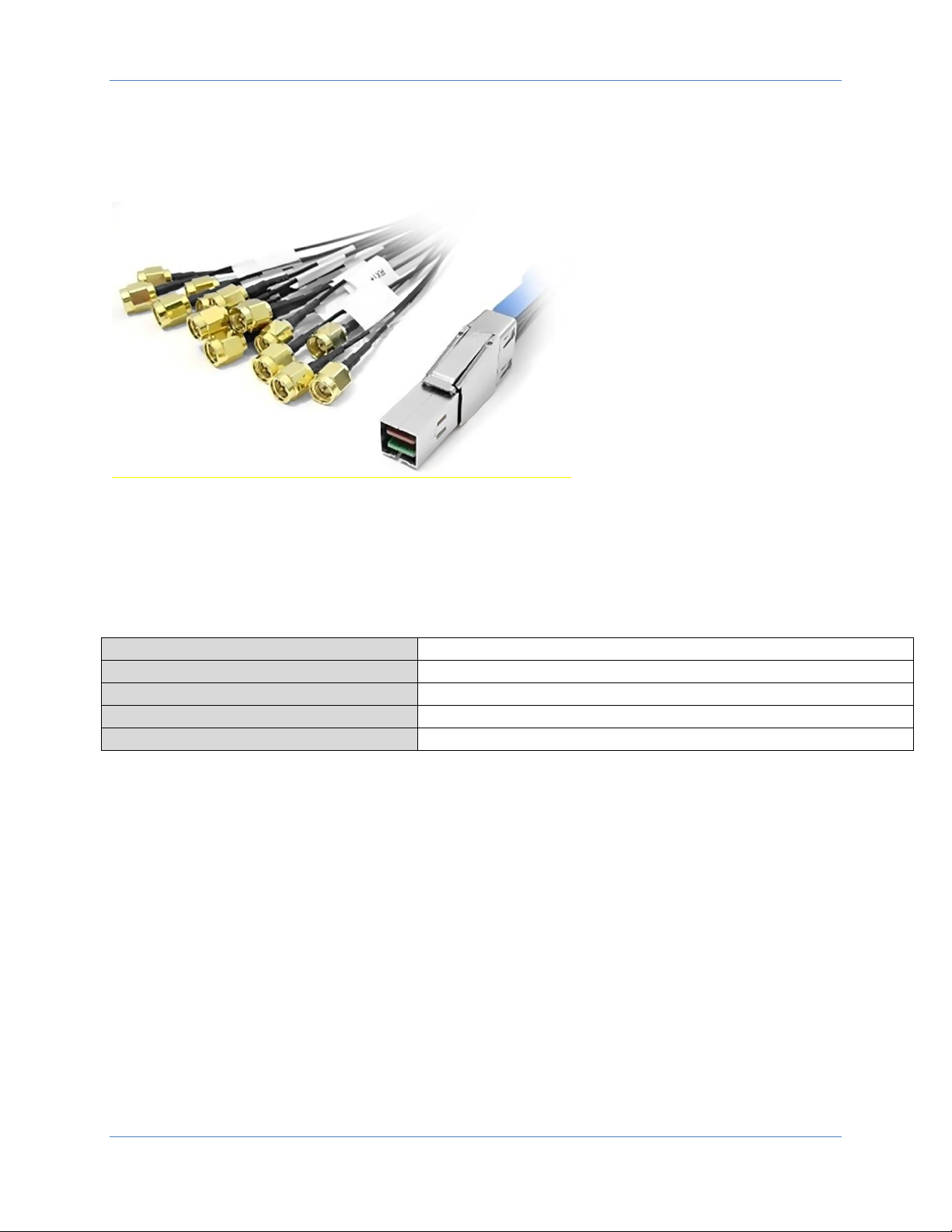

Digital Output connector

The T3AWG-3K series has optional 8/16/32-bit digital outputs, synchronized with the corresponding analog

channels.

The digital output pins are native LVDS standard and the maximum update rate is 1.2 Gbps for the T3AWG335X

(1.0 Gbps for the T3AWG325X).

The output connector is a customized version of the Mini-SAS HD standard connector. An optional

adapter cable to convert from Mini-SAS HD to SMA is available.

The mixed signal generation is a great solution for digital designs and validation, system synchronization and

DAC/ADC tests.

Model

Connector Name

T3AWG3352/3252

Pod A

T3AWG3354/3254

Pod A, Pod B

T3AWG3358/3258

Pod A, Pod B, Pod C, Pod D

The digital output connector and the digital cable should be connected as shown in the picture below.

Page 25

Operator’s Manual Simple TrueArb Application

25

Digital Connector on Two Channels model

Sync In / Sync Out Connectors

The purpose of those connectors is to connect and synchronize together multiple instruments: up to 4

instruments can be linked together.

Those connectors are available on T3AWG3358/T3AWG3258 models only.

Page 26

Operator’s Manual Simple TrueArb Application

26

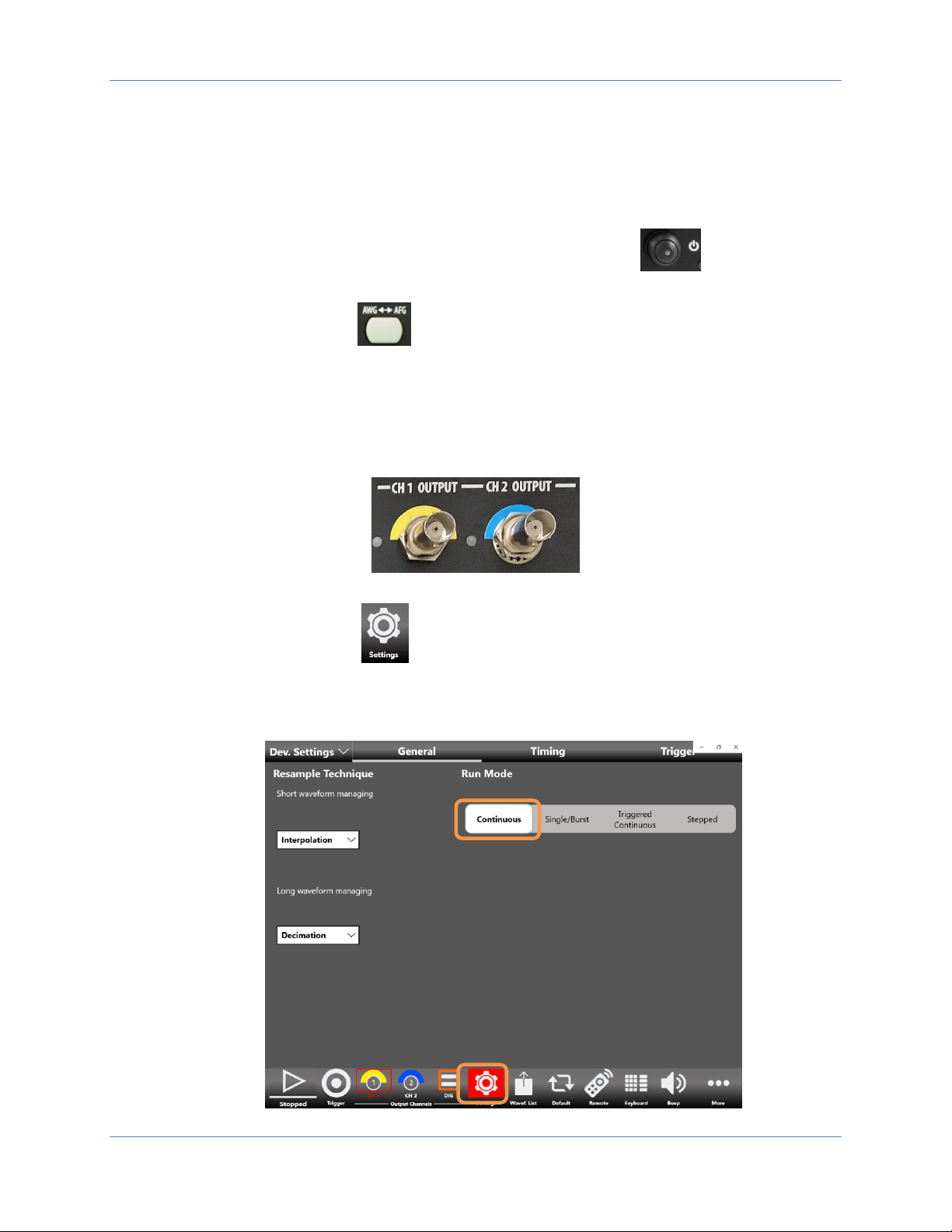

Quick Start Guide

If you are a beginner user, you can follow the steps here below to generate your first waveform.

1. Connect the power cord and the push the front-panel on/off switch to turn on the

instrument.

2. Press the AWG/AFG button to switch from the Simple AFG to the Simple TrueArb

application. Wait until the Simple TrueArb application is executed and ready to accept new

commands.

3. Connect the Output 1 of the instrument to the oscilloscope input with a cable, select 50 Ohm

load on the oscilloscope input.

4.

5. Touch the settings button on the Simple TrueArb UI to open the instrument settings

window

6. Select Dev. Settings → General page, select Continuous as Run Mode

Page 27

Operator’s Manual Simple TrueArb Application

27

7. Touch again the setting button to close the instrument settings window

8. By default the CH1, CH2 are disabled: it means that the outputs are mechanically disconnected

from the load and the digital outputs are in OFF state.

9. The waveform sequencer located at the top of the application starts by default with a single

entry with a sine waveform. Touch the Add Entry button to insert a new entry into the

Channel1.

10. Touch the dropdown waveform list and change it from Sine to Ramp.

Page 28

Operator’s Manual Simple TrueArb Application

28

11. Swipe down to switch from Channel 1 to Channel 2. In the Channel 2 by default the two

sequencer entries will be two Sine Waveforms.

12. Enable the output channels by pressing the CH1 and CH2 buttons located in the bottom of the

application so that they are no more grayed out.

Page 29

Operator’s Manual Simple TrueArb Application

29

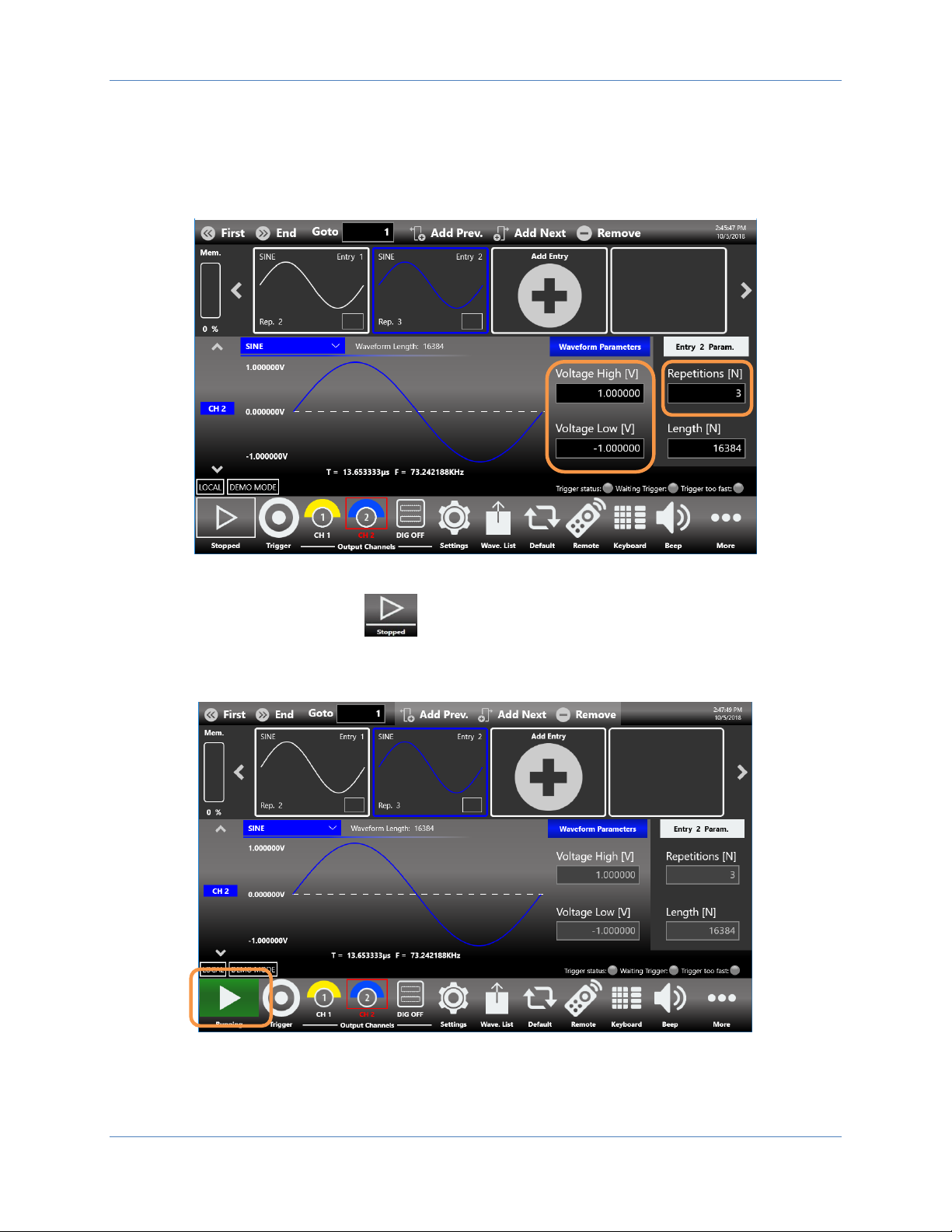

13. Touch the Entry 1 and set the Repetition[N]=2 than touch the Entry 2 and set Repetition[N]=3.

14. You can change the Amplitude/Voltage High and Offset/Voltage Low for each entry.

15. Press the RUN/STOP button and check the generated waveforms on the oscilloscope:

the Entry 1 should be repeated two times and the Entry 2 should be repeated three times.

Page 30

Operator’s Manual Simple TrueArb Application

30

Simple TrueArb Application

The T3AWG-3K includes a 7” capacitive touch screen and Simple touch user interface based on a Microsoft

Windows 10 platform.

You can control instrument operations using one or all of the following entering methods:

• Touch Screen and Front-panel soft key controls

• Keyboard and mouse

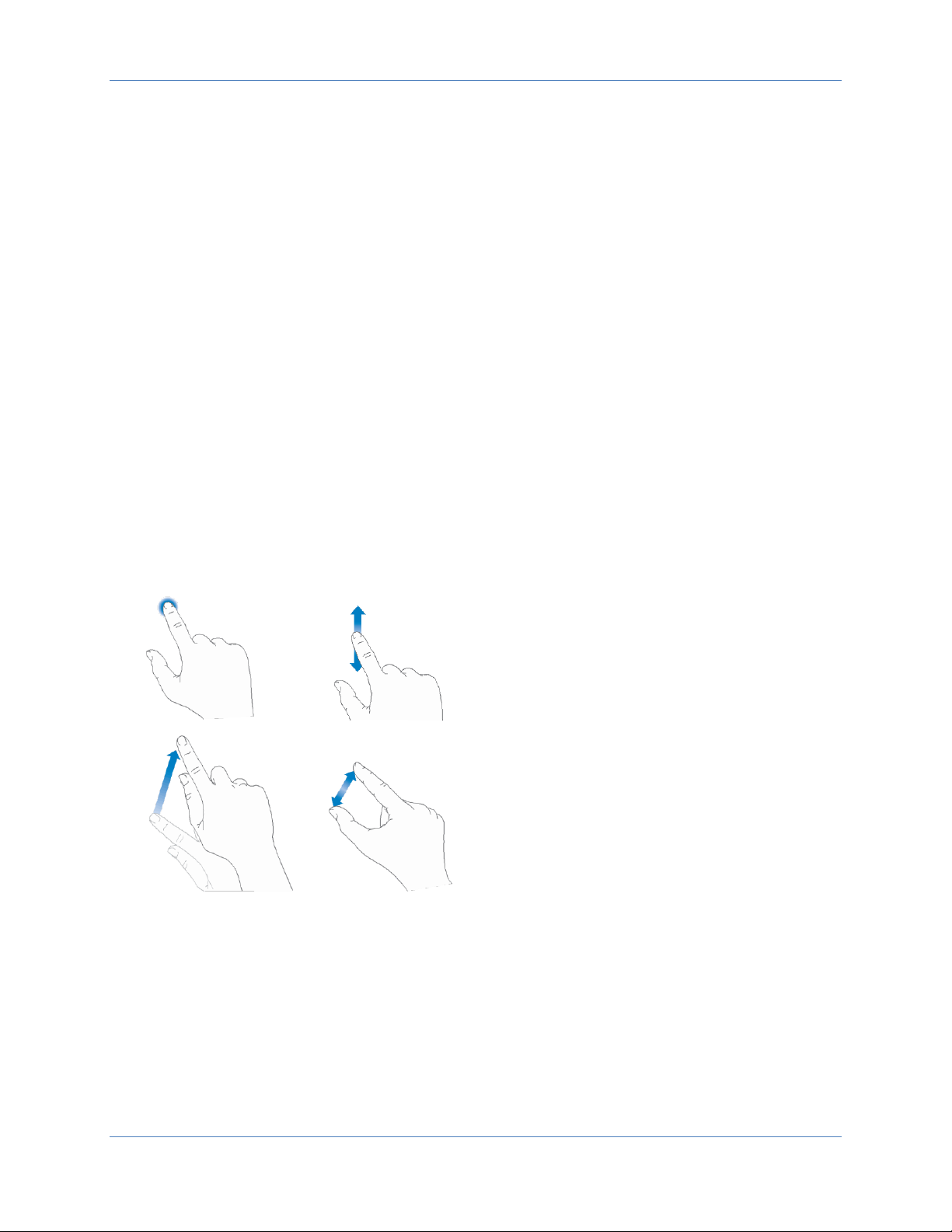

Simple TrueArb Touch UI

Simple TrueArb UI is designed for touch to drive simplicity in operating with an Arbitrary Waveform

Generator, by using the today’s modern technique, used on Tablet or smart phones, available in

capacitive touch-screen displays.

All the important instrument controls and settings are always one touch away:

• swipe down gesture to change the output channel

• swipe left or right to navigate through the sequencer entries

• pinch in-out to zoom the waveform graph

• use the touch-friendly virtual numeric keyboard to modify the parameters and to entry new

values on the fly

Page 31

Operator’s Manual Simple TrueArb Application

31

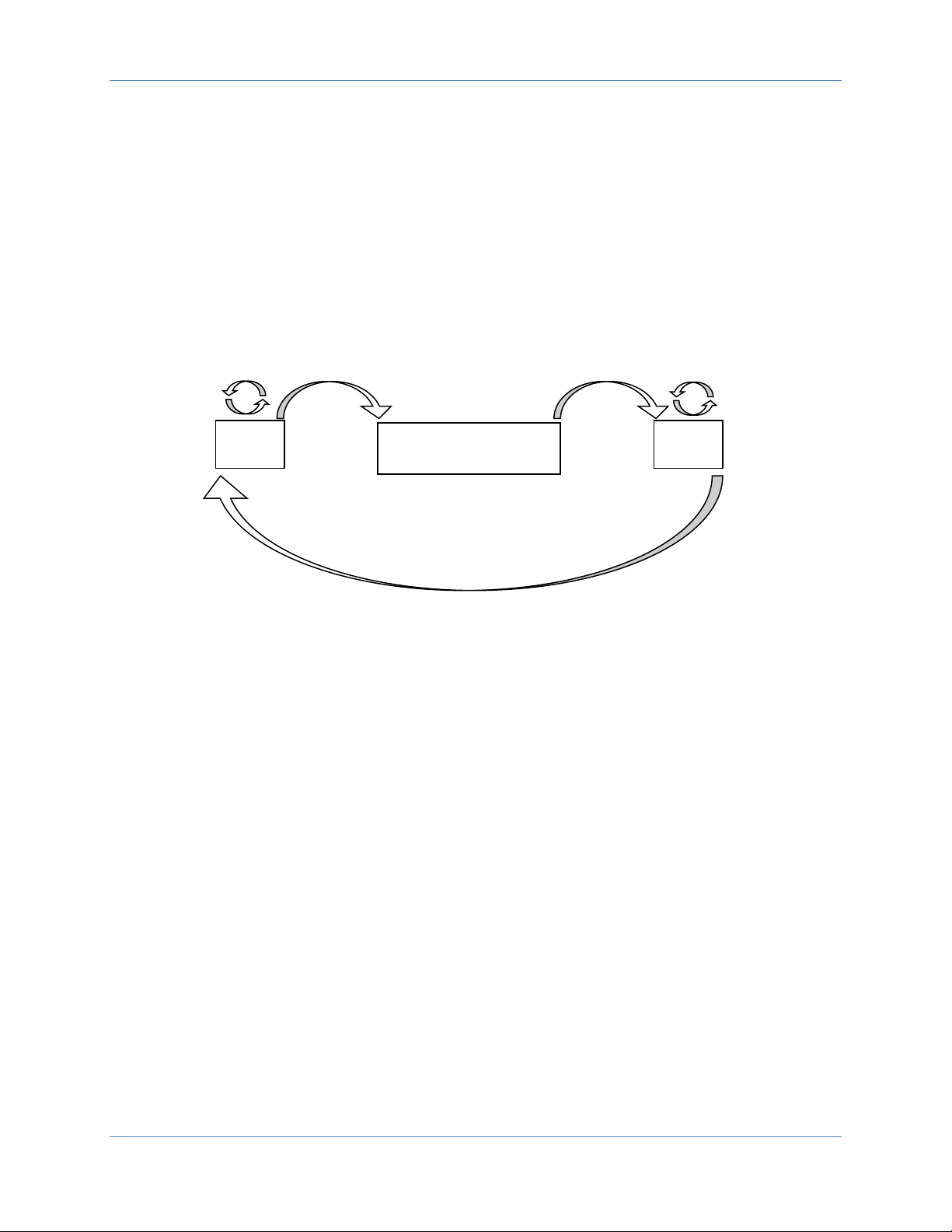

It is sometimes necessary to create long waveform files to fully implement a DUT test. In case where

portions of a waveforms must be repeated, the waveform sequencer functionalities can save you a lot of

memory-intensive waveform programming.

The Sequencer allows you to define the set of waveforms that will be generated, their sequence, the

number of repetitions for each waveform and the generation conditions.

The sequencer is mainly used for the following two purposes:

▪ Output waveform longer than hardware memory

▪ Change the output waveform quickly on a specific trigger conditions

A sequence is made of multiple entries; each entry contains analog and digital waveforms properly

formatted.

IMPORTANT NOTE

The T3AWG-3K Series has a unique sequencer for all channels. Therefor the length and repetitions of

each sequencer entry are common to all output channels. In the same way all analog and digital outputs

share the same sampling clock. In this way they are synchronized each other.

∞

Entry 2

4

Entry 1

(square)

Entry 3

(sine)

Page 32

Operator’s Manual Simple TrueArb Application

32

User Interface Description

The Simple TrueArb software environment provides an easy access to all instrument features and

parameters.

The TrueArb user interface consists of four main elements:

• Sequencer Area: the sequencer contains a list of entries that the user can add/remove to

create its own waveform scenario. Each entry can be repeated or changed in length. The

sequencer is common to all channels.

• Sequencer Toolbar: this bar is contains elements that are used to navigate, add and remove

the sequencer items that will be described below.

• Waveform Area: It contains the Waveform Graph and the Waveform Parameters related to

the selected entry.

• Command Bar: in this bar there are elements to control the instrument operations, to

modify the instrument settings and to manipulate waveforms.

Sequencer Area

Waveform Area

Sequencer Toolbar

Command Bar

Page 33

Operator’s Manual Simple TrueArb Application

33

As mentioned, the display is 7” capacitive touch screen display and you can use the gestures like in a

mobile phone:

If you use the Swipe up or down gesture on the Waveform Area you can switch between

the Output Channel 1, Output Channel 2, …, Output Channel N page.

If you use the Swipe left or right gesture on the Sequencer Area you can navigate through

the sequencer entries.

Sequencer Area

The sequencer starts by default with a single entry with a Sine Waveform. You can touch on the “Add

Entry Button” to insert a new entry into the sequencer.

The TrueArb inserts by default a Sine waveform into the new Entry

To modify the waveform of an entry of the sequencer, you can touch the waveform dropdown list that

will open showing a list of all the waveforms available in the “Waveform List” (predefined or imported).

Page 34

Operator’s Manual Simple TrueArb Application

34

Important Note: if you need to modify the waveform of the other channel that by default are

automatically set to sine waveform when you add a new entry in the sequencer, you should use the

swipe up/down gesture on the Graph Area or press the up/down arrow on the left side of the graph to

change the Output Channel page. Than you can change the waveform by pressing the dropdown

waveform list

IMPORTANT NOTES

• The maximum number of allowed sequencer entries is limited to 100 even if the hardware can

support up to 16384 entries. The maximum number of 16384 entries is supported by remote

instrument programming.

Change the Output channel page

Page 35

Operator’s Manual Simple TrueArb Application

35

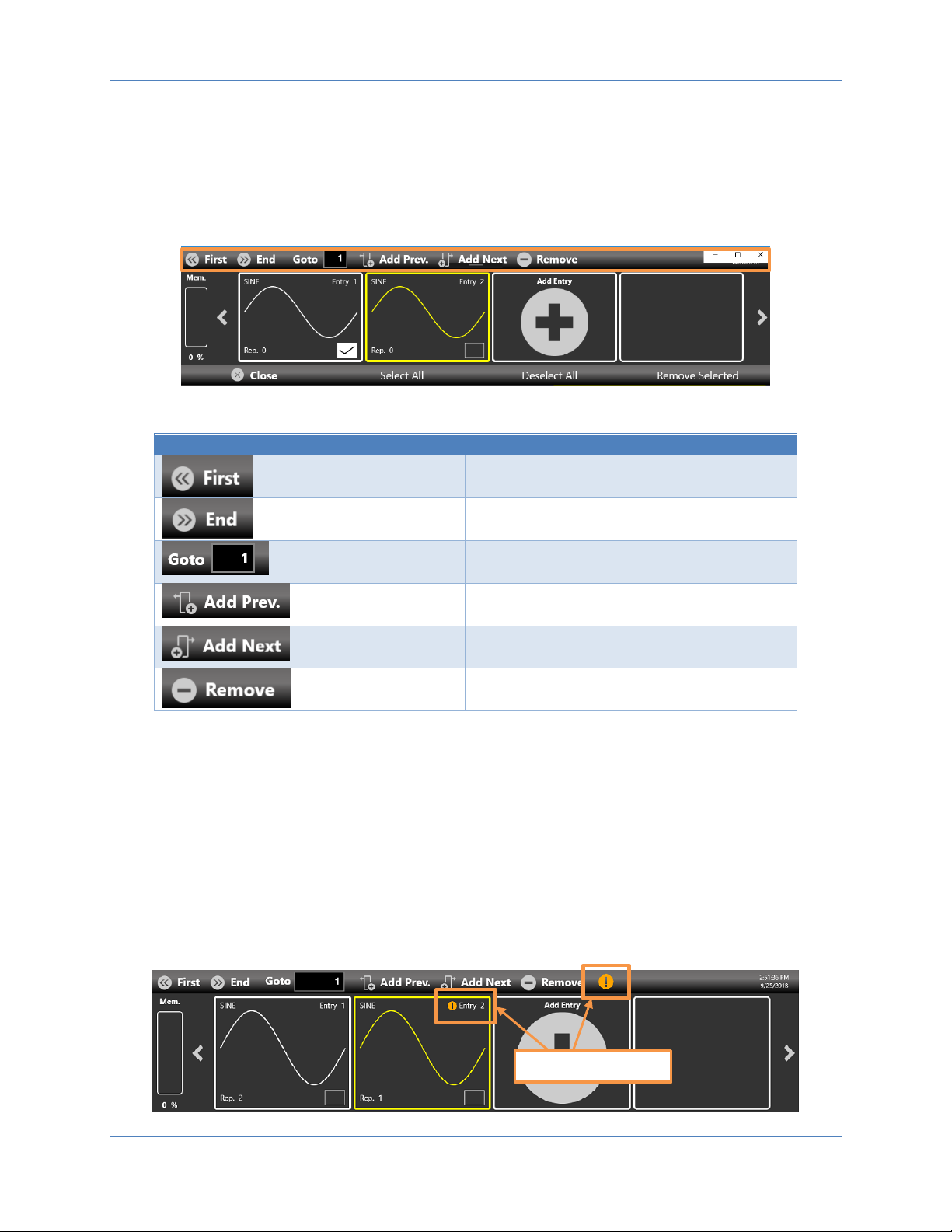

Sequencer area items

• Memory Usage. Shows the percentage of memory used to store the waveforms placed in

the sequencer

•

Sequencer Entry. Each sequencer item contains several information:

➢ The index of the Entry (Entry N). Each entry is enumerated starting from 1 up to 16384.

➢ The name of the Waveform assigned to the selected output channel in that entry. Each

output channel can have a different waveform assigned to the same sequencer entry.

➢ The number of Repetitions. Each entry can be repeated from 0 up to 4294967295 times.

If you touch the selection button in the entry, a second bar will open that will let you to:

➢ Select All the entries

➢ Deselect All the entries,

➢ Remove the Selected entry

➢ Close the bar.

Selection Button

Page 36

Operator’s Manual Simple TrueArb Application

36

Sequencer Toolbar

This sequencer toolbar contains several buttons to navigate and control the sequencer that are

described here below in detail:

Sequencer Toolbar

Description

First Entry Button – Press this button to go

to the first entry.

Last Entry Button – press this button to go to

the last entry.

Goto Entry Button – Use this button to go to

the Entry N.

Add Prev. Button – Use this button to add a

sequencer entry before the selected entry.

Add Next. Button – Use this button to add a

sequencer entry after the selected entry.

Remove Button – Use this button to remove

the selected entry.

Sequencer Warnings

Warnings are shown in the sequencer toolbar in case one or more channel waveforms have been

assigned to an entry with a different length. The upper warning gives is general warning that notifies this

condition. Additional warnings are displayed inside the entries where the warning condition is detected.

In presence of warnings the application will modify the mismatching waveforms during the execution to

match the entry length using the strategy specified in the Sample increasing/decreasing strategy

parameter (Device Settings -> General page)

Warnings

Page 37

Operator’s Manual Simple TrueArb Application

37

Waveform Area

This area is divided in two main sections, the Waveform Graph area that contains a graphical

representation of the channel waveform and the Waveform Parameters area.

The Waveform Graph gives a description of the waveform assigned to the current channel and

sequencer entry. The waveform is described as:

➢ The waveform shape

➢ The waveform duration and frequency

➢ The waveform amplitude

The waveform length in term of number of samples as it was originally defined in the Waveform

List (described below)

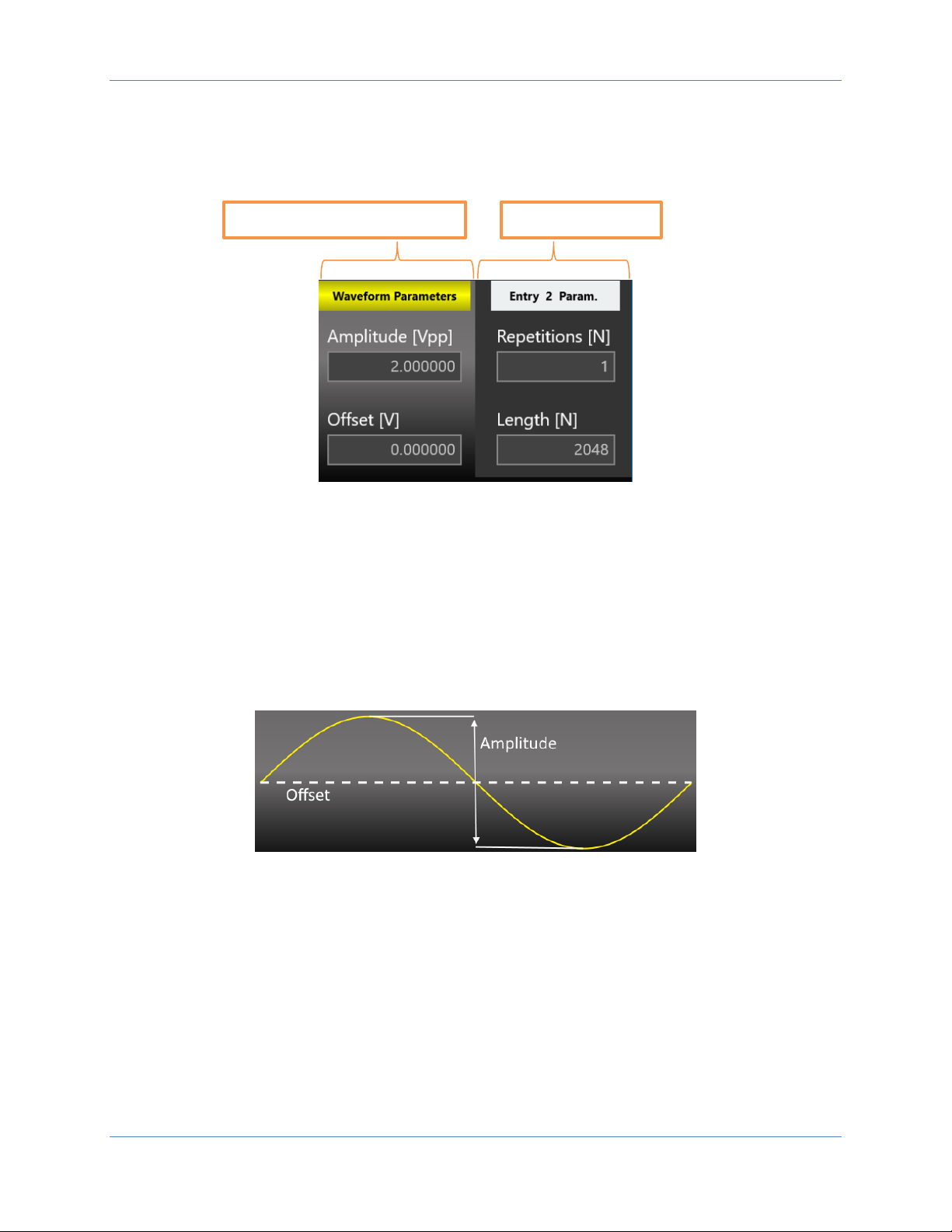

The Waveform Parameters area is divided in two parts. The left part contains the vertical parameters of

the selected waveform in terms of Amplitude[Vpp] and Offset[V] or Voltage High[V] / Voltage Low [V].

These two parameters can be specified independently for each sequencer entry and for each output

channel.

In the right part there are the Repetitions[N] and the Entry Length[N] for the selected sequencer entry.

These two parameters are specific for the selected sequencer entry. In particular Repetitions[N] is the

number of repetitions of the selected sequencer entry.

These parameters are common to all the channels in the same sequencer entry.

Note: Repetitions[N]=1 means that the waveform is executed only once.

Waveform Graph

Page 38

Operator’s Manual Simple TrueArb Application

38

Amplitude[Vpp] parameter

It defines the difference between the maximum value and the minimum value of the waveform

expressed in Volts.

Offset[V]

It defines the voltage of (Vmax+Vmin)/2 expressed in Volts where Vmax is the maximum level of the

waveform and Vmin is the minimum level of the waveform

Voltage High[V]

It defines the maximum level of the waveform expressed in Volts

Voltage Low[V]

It defines the minimum level of the waveform expressed in Volts

Waveform Vertical Parameters

Entry Parameters

Page 39

Operator’s Manual Simple TrueArb Application

39

IMPORTANT NOTES

• The maximum value of repetitions is infinite: Repetitions[N]=Infinite

• Entry Length[N]=2048 is the length of the selected sequencer entry

• The minimum entry length is 32 samples. The entry length granularity is :

o 1 if the entry length is > 384

o 16 if entry length is ≥ 32 and ≤ 384 samples

• The Waveform length is the original length of the waveform in term of number of samples

• The entry length can be different from the waveform length because the entry length is the

same for all the instrument channels while the waveform length can be different. In case the

entry length and the waveform length are different the original waveform will be manipulated

(resampled/cut/extended) to match the entry length

• The maximum value of repetitions is infinite. To set the repetitions to infinite open the On-

Screen Keyboard and press the “INF” button.

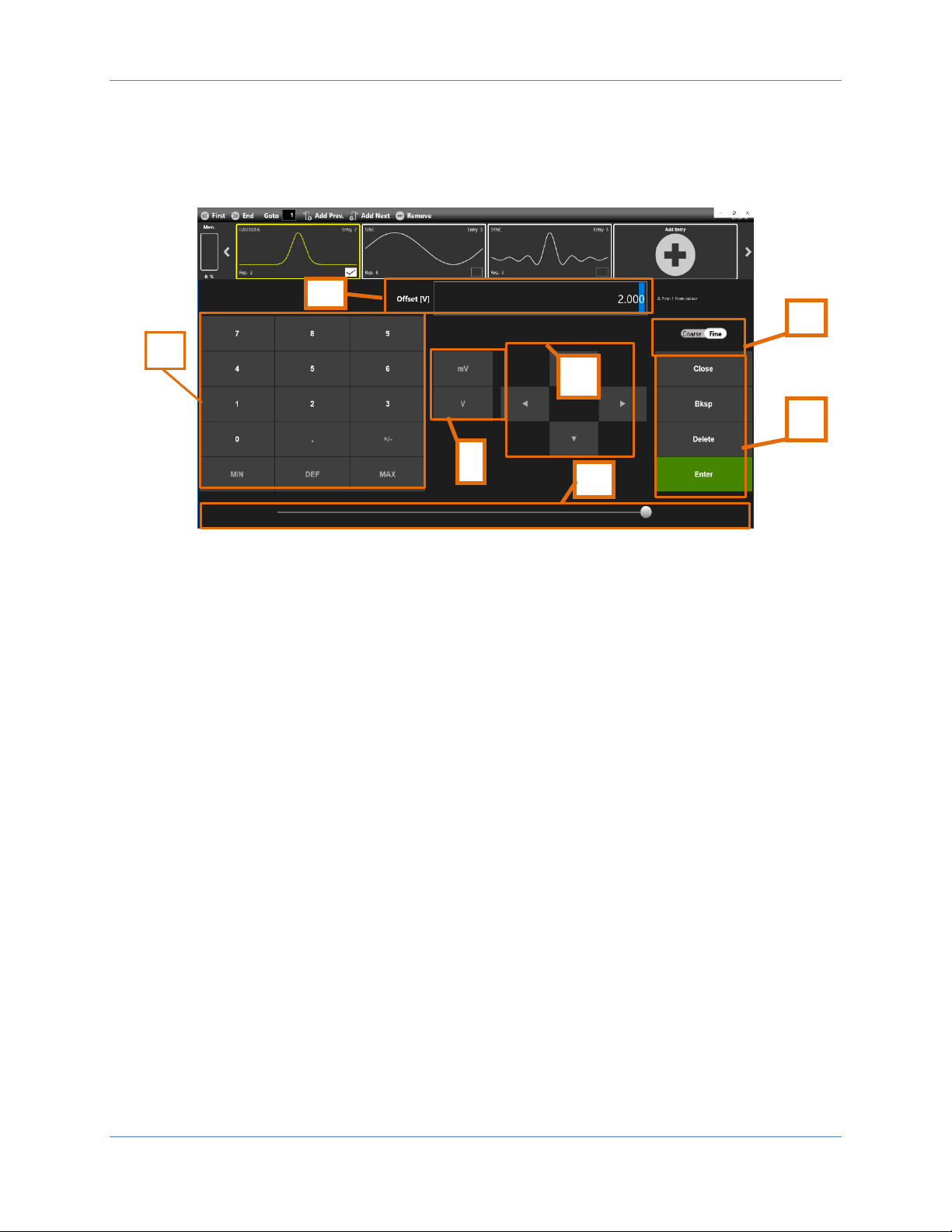

You can touch the parameter area to open the Virtual numeric keypad, edit the parameter value and its

measure unit.

Page 40

Operator’s Manual Simple TrueArb Application

40

Below there is a description of the keypad items:

1. Parameter Name and Value: This area of the virtual keyboard displays the parameter name,

value and unit of measure.

2. Numeric Keypad: this area contains the keys to edit the number that will be displayed in the

area 1. The [+/-] key will toggle the sign of the number being entered and can be pressed at the

end of the number editing.

Touch the “MIN” and “MAX” buttons to set the minimum and maximum allowed value for the

selected parameter. Use the “DEF” button to set the default value.

3. Arrows: The left/right arrows allow to move the cursor or select the different digit position as

the arrows on the front panel. The up/down arrows allow to modify the value.

4. Measurement Unit: After typing the numeric value these buttons can apply a different

multiplier of the measurement unit. When a measurement unit is pressed, the value is applied

on the fly.

5. Coarse / Fine: the coarse/fine button let you to modify the granularity of the increment.

You can increment or decrement the selected parameter using the UP/DOWN arrows button or

rotating knob on the front panel.

When Fine is selected, the increment is of 1 unit at the current cursor position.

When Coarse is pressed, the Delta increment is displayed in the parameter area and the

parameter value changes in steps of the selected increment.

You can keep pressed the knob and rotate it on the right or on the left to change the Delta

Coarse increment.

6. Control Buttons: The “Close” button closes the virtual keypad without applying any changes on

the instrument while the “Enter” button confirms the changes and it applies them on the

instrument.

6.

7.

2.

4

5.

3.

Page 41

Operator’s Manual Simple TrueArb Application

41

“Bksp” (backspace) button is provided for deleting erroneous key presses, “Delete” button

deletes all digit of the textbox.

7. The horizontal scrollbar allows to change quickly the selected value. The position specifies the

value between the allowed minimum and the maximum.

The increment/decrement value entered by the rotary knob or by the scrollbar are applied to

the instrument on the fly.

Waveform warnings

A warning is shown in the waveform graph in case the channel waveforms length is different from the

entry length. The upper warning gives is general warning that notifies this condition. Additional

warnings are displayed inside the entries where the warning condition is detected.

In presence of warnings the application will modify the mismatching waveforms during the execution to

match the entry length using the strategy specified in the Sample increasing/decreasing strategy

parameter (Device Settings -> General page)

Warning: channel waveform length

and entry length are different

Page 42

Operator’s Manual Simple TrueArb Application

42

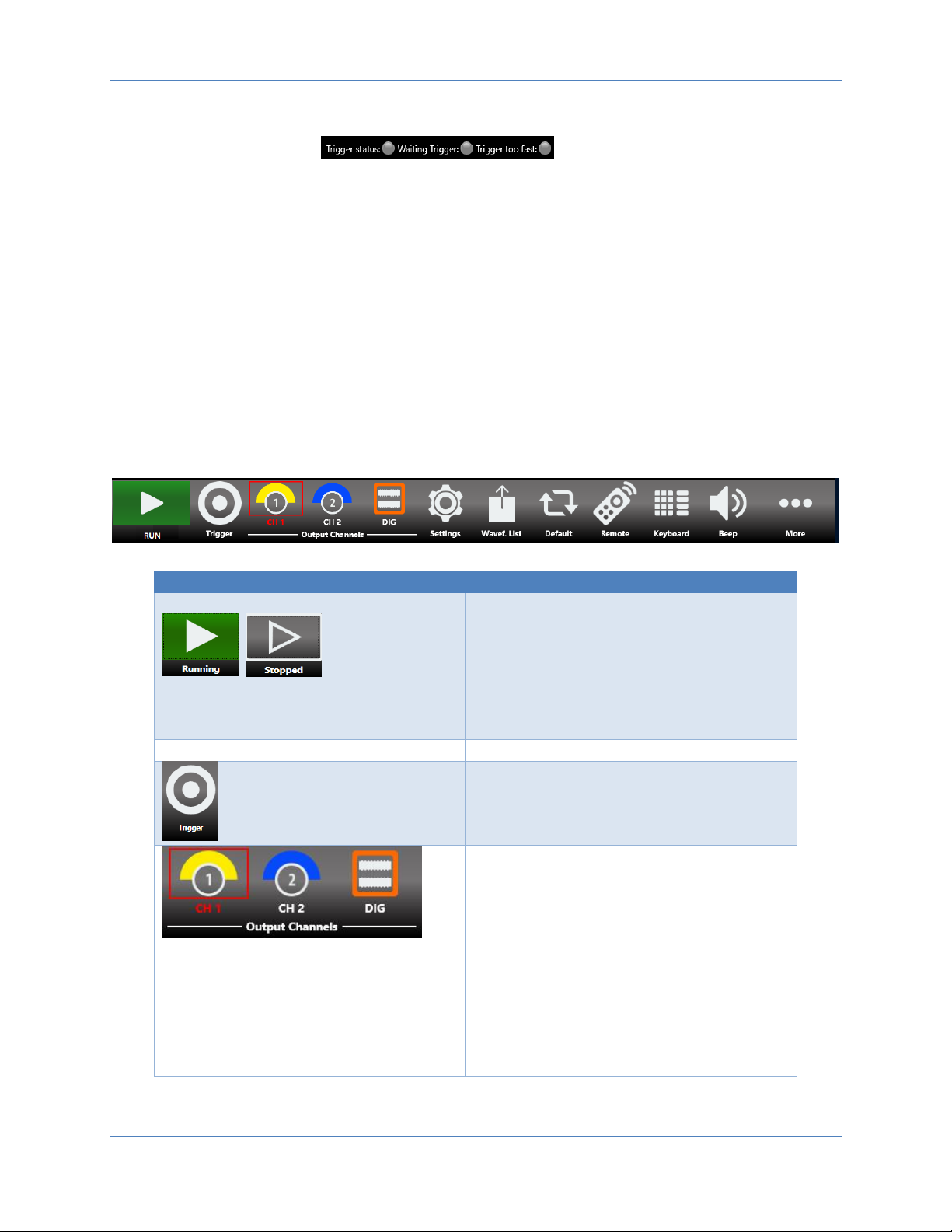

Status Toolbar

Trigger Information indicator: provides information on the trigger

signal condition.

o The Trigger status led notifies you that the instrument has received a trigger signal

o The Waiting Trigger led notifies you when the instrument is waiting for a trigger signal.

o The Trigger too fast led notifies you that the trigger event has been latched, but the

trigger frequency is too high and the instrument cannot be rearmed before the

completion of the previous trigger event. In this situation some trigger events may be

lost.

Command Bar

The command bar contains several touch buttons to control the instrument and its layout changes

depending on the model (in the 4/8 channel models some buttons can be located in the More menu

instead of in the Command Bar). Below a detailed description of this bar is provided.

Command Bar Buttons

Description

RUN/STOP Button – Use this button to set

the instrument in Running state (or Ready to

receive a Trigger) or in the Stopped state. If

the button is green the instrument is running

while if it is grey the instrument is stopped.

Pushing the button will change the

instrument state.

Trigger Button – Use this button to send an

internal software trigger to the instrument.

Independently from the setting this trigger is

always received.

Output Channels Buttons - Press CH1,

CH2,…,CH N, DIG to change the Output

Channel page.

If you press again the Channel button, you

will turn it OFF/ON.

When a channel is OFF, it is mechanically

disconnected from the output.

The DIG button means “Digital” and it will

connect/disconnect the Digital Signals. When

digital signals are disabled they will keep

logic “zero” value at the output.

Page 43

Operator’s Manual Simple TrueArb Application

43

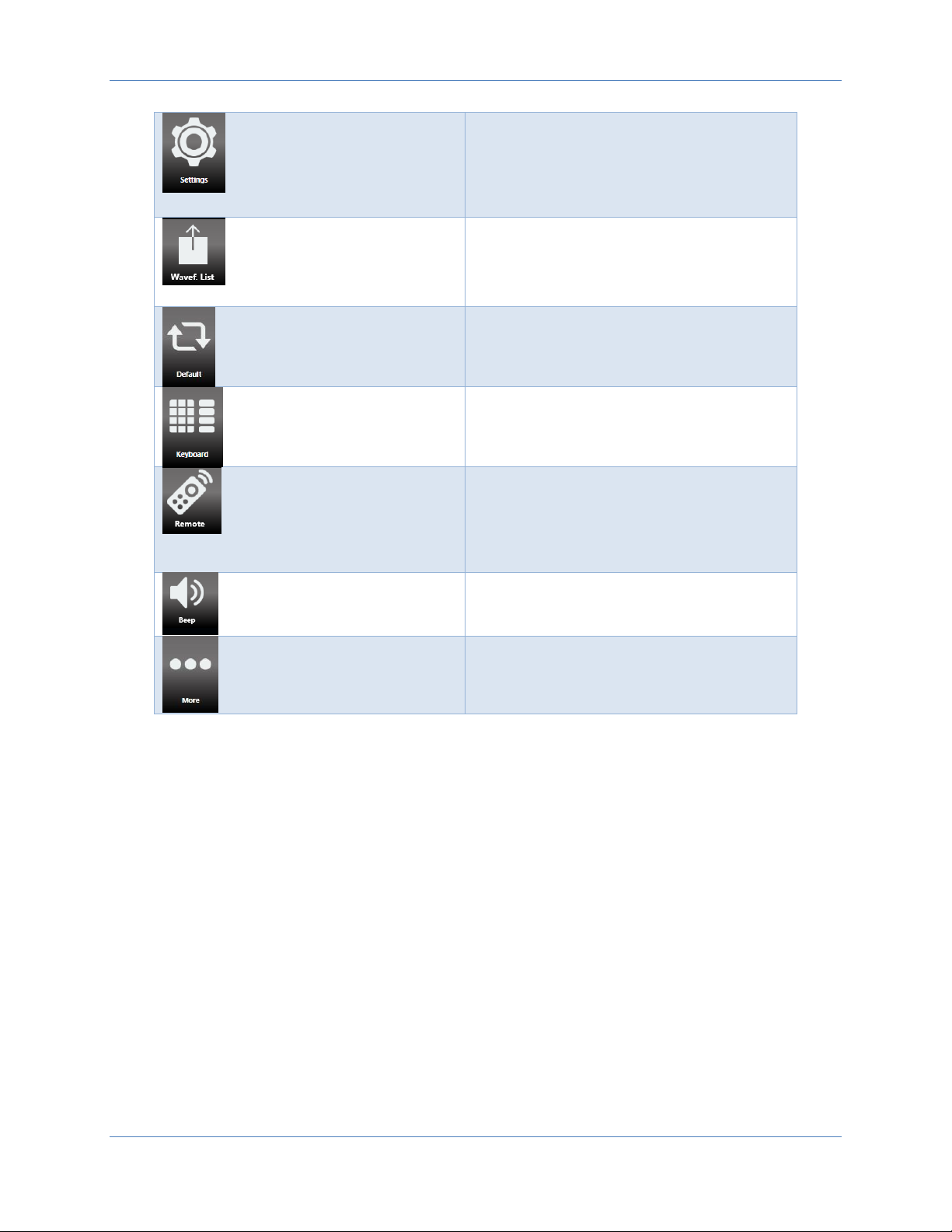

Settings Button – Use this button to open

the output channel Settings, device Settings,

Marker Settings and Sequencer Settings. (For

more information, please refer to the

relative section).

Wavef. List – Use this button to open a page

where you can Import/Export a waveform

from file. (For more information, please refer

to the relative section).

Default – Use this button to restore the

default value of all parameters of the

instrument.

Numeric Keyboard Button – Use this button

to enable or disable the virtual numeric

keyboard.

Remote – Use this button to open the SCPI

server page. In that page you can enable or

disable the SCPI server and see the sequence

of commands sent to the instrument and its

response.

Beep – Use this button to enable or disable

the beep audio signal when the user touches

a button.

More Button – Use this button to have

access to other instrument features. These

buttons are explained in the following table.

Page 44

Operator’s Manual Simple TrueArb Application

44

More Button Menu Items

Description

Exit Button – Press this button to close the

application.

Full/Float Button – press this button to

maximize or reduce the application screen;

in this way you can access to Windows OS.

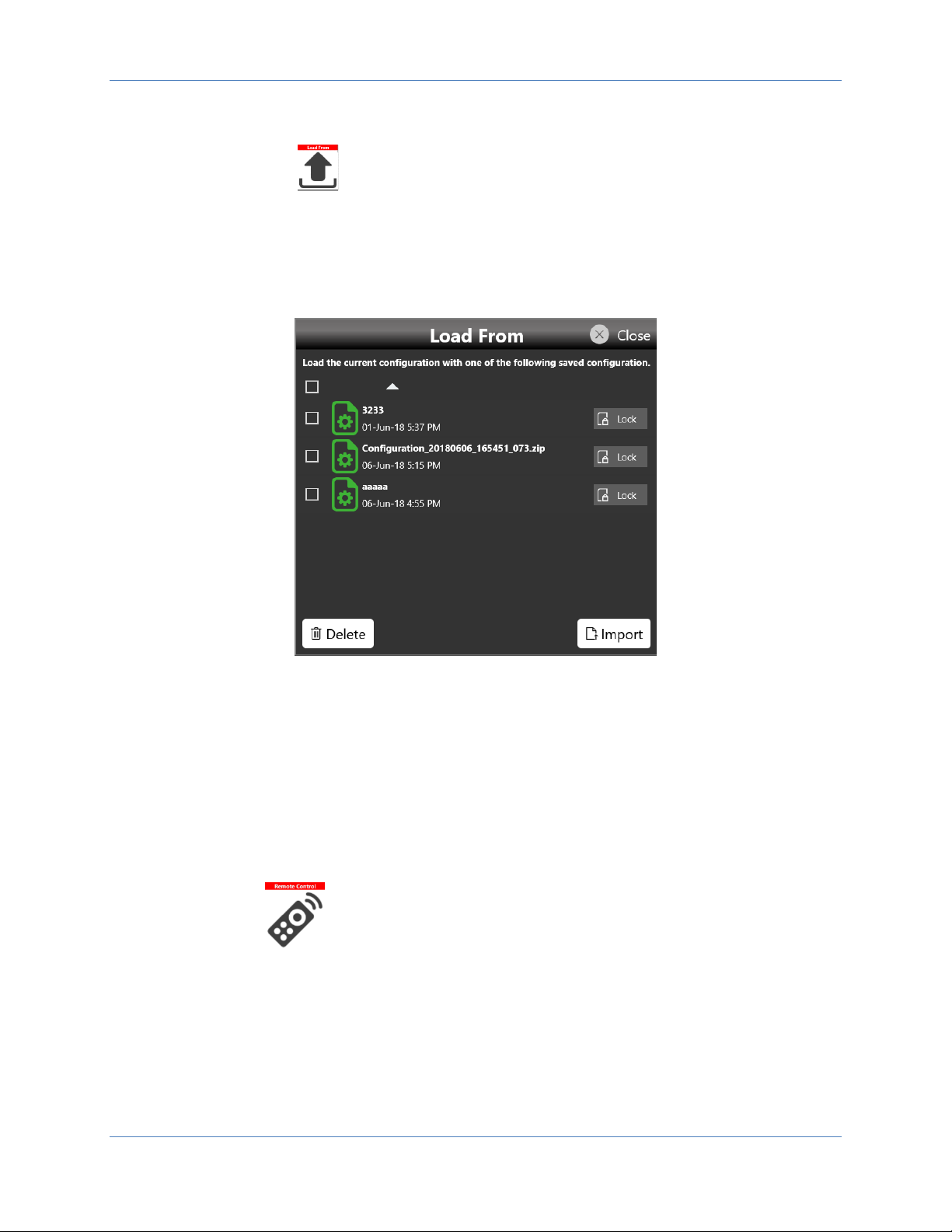

Load From Button – Use this button to load a

configuration file. (For more information,

please refer to the relative section).

Save As – Use this button to Save the

Current configuration into an existing one or

create a new one. (For more information,

please refer to the relative section).

Export – Use this button to export the

current configuration. (For more

information, please refer to the relative

section).

Remote Control Button – Use this button to

open the SCPI server page. In that page you

can enable or disable the SCPI server and see

the sequence of commands sent to the

instrument and its response.

Change Format – Use this button to change

the waveform vertical parameters from

Voltage High(V) and Voltage Low(V) to

Amplitude(Vpp)/Offset(V)

Change Application – Use this button to

switch from AWG to AFG application.

About Button – Use this button to check the

credits, the software and firmware release

number and the instrument serial number.

Help Button – Use this button to open the

User Manual.

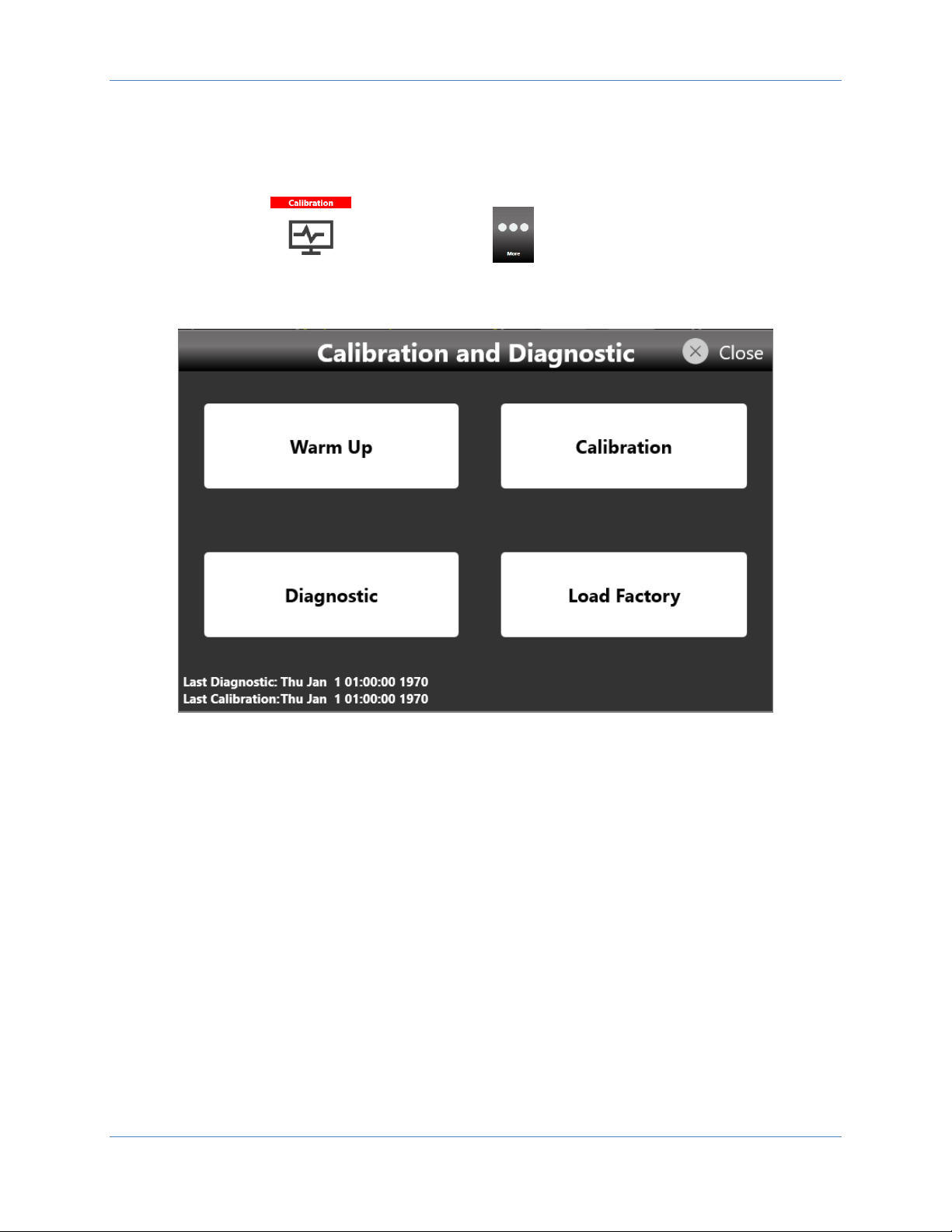

Calibration button – Use this button to enter

the Calibration and Diagnostic page. (For

more information, please refer to the

relative section).

Page 45

Operator’s Manual Simple TrueArb Application

45

Waveform Editor – Use this button to open

the Waveform Editor software. (For more

information please refer to the Waveform

Editor User Manual).

License button – Use this button to enter the

License setup page. (For more information,

please refer to the relative section).

Settings

Touch the “Settings” button to open the page relative to the Device Settings, Channel Settings,

Marker Setting and Sequencer Setting.

Device Settings

The device settings are common for all the instrument and they are grouped in General settings, Timing

settings and Trigger settings.

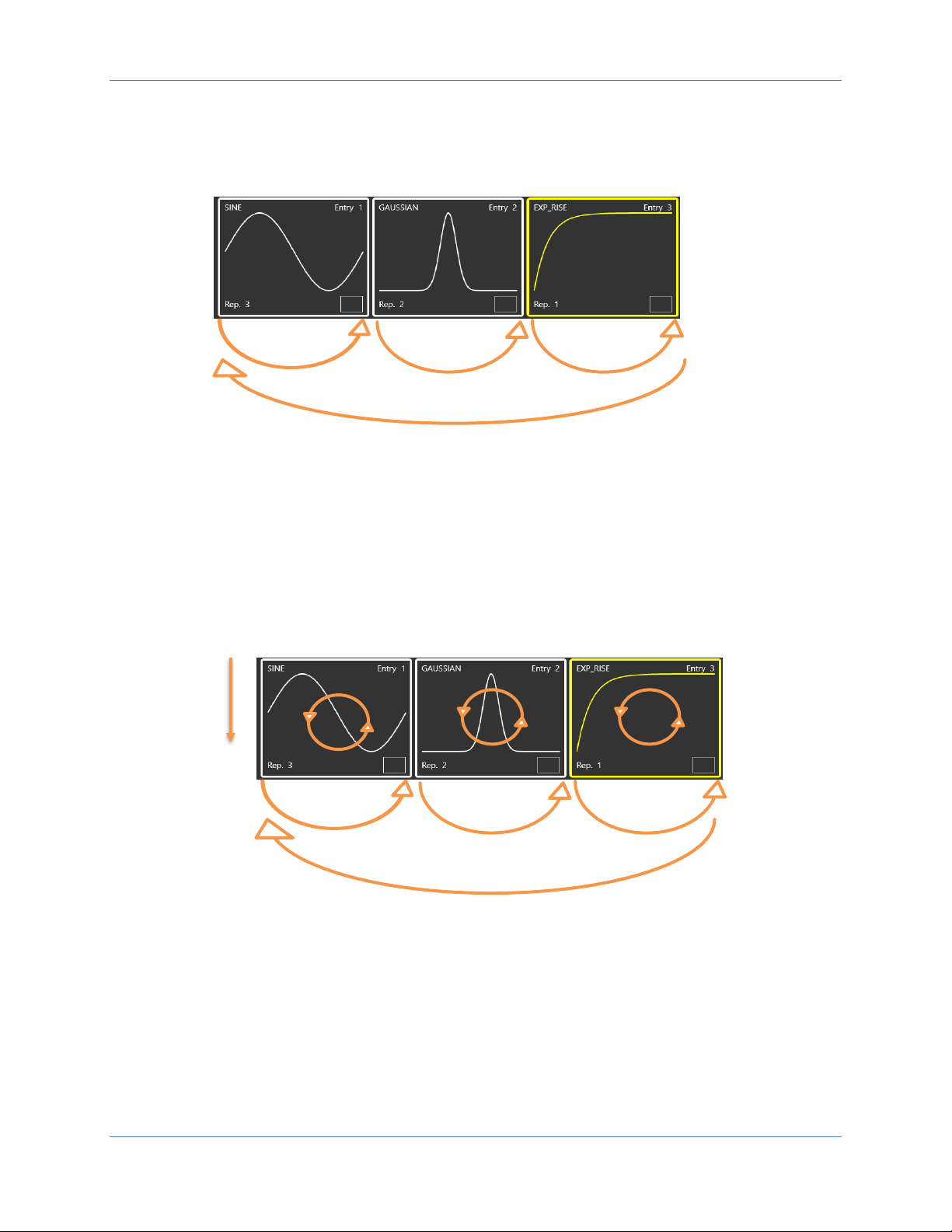

General

Run Mode

The Run Mode defines the sequencer execution flow:

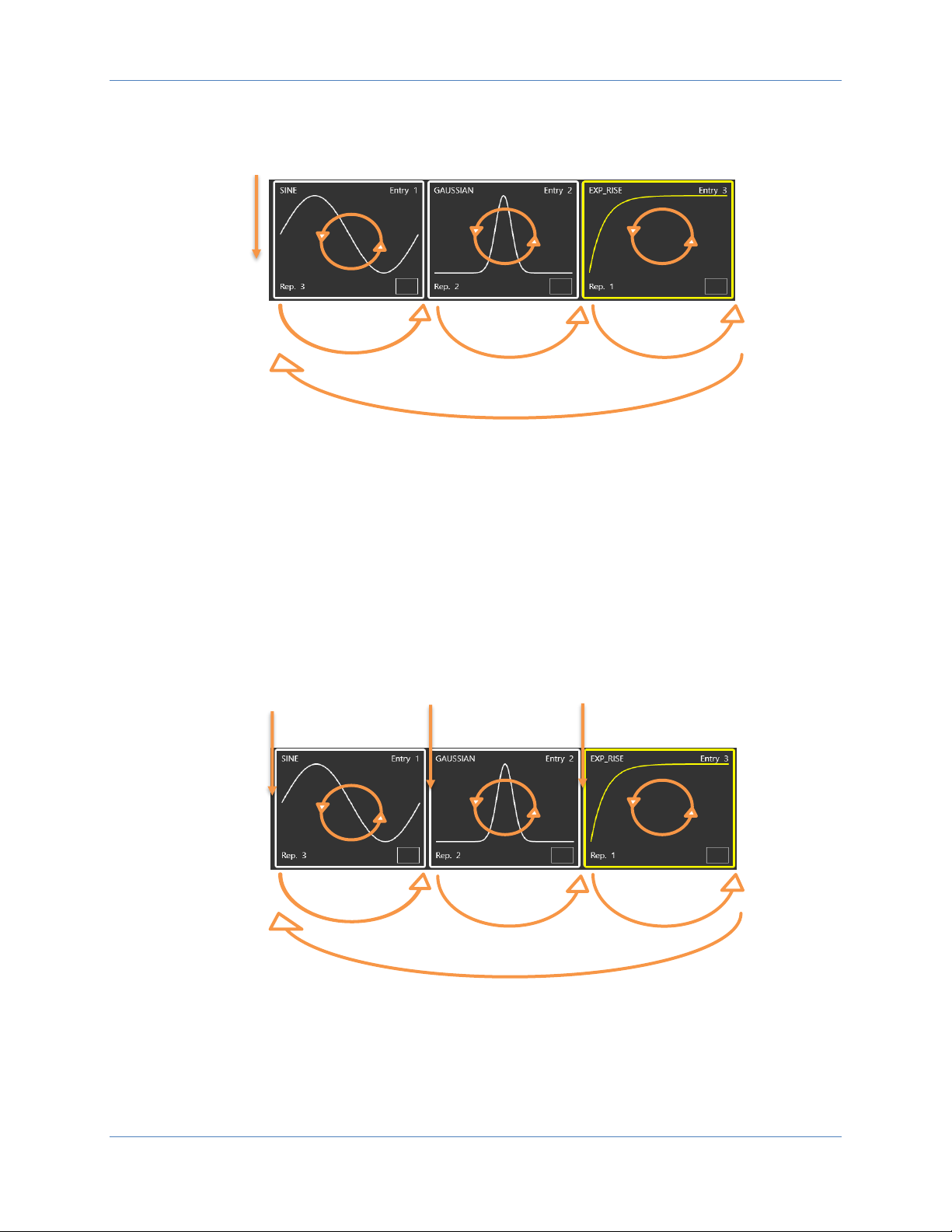

• Continuous: when the RUN/STOP button is pressed each waveform will loop as written in the

entry repetition parameter and the entire sequence is repeated circularly until the user presses

the RUN/STOP button as shown in the picture below

Page 46

Operator’s Manual Simple TrueArb Application

46

• Single/Burst: when the RUN/STOP button is pressed the instrument waits for a trigger event.

When the trigger event occurs each waveform will loop as written in the entry repetition

parameter and the entire sequence will be repeated circularly many times as written in the

Burst Count[N] parameter. If you set Burst Count[N]=1 the instrument is in Single mode and the

sequence will be repeated only once.

• Triggered Continuous: when pressing the RUN/STOP button the instrument waits for a trigger

event. When the trigger event occurs each waveform will loop as written in the entry repetition

parameter and the entire sequence will be repeated circularly until the user will press the

RUN/STOP button.

∞

2

3

3

2

1

N if burst / 1 if single

Start Trigger

2

3

3

2

1

Page 47

Operator’s Manual Simple TrueArb Application

47

1

• Stepped: after pressing the RUN/STOP button each entry waits for a trigger event before its

execution. The waveform of the entry will loop as written in the entry repetition parameter.

After the generation of an entry has completed, the last sample of the current entry or the first

sample of the next entry is held until the next trigger is received. At the end of the entire

sequence the execution will restart from the first entry.

Note: if you set Infinite repetitions on one entry, the Trigger event lets you jump to the next

one.

Wait Trigger On

Defines the behaviour of the output during the wait trigger condition in the Triggered Run Modes. If

“First sample” is selected the first waveform sample of the next entry is held until the next trigger is

received. If “Last sample” is selected the last waveform sample of the current entry is held until the next

trigger is received.

Start Trigger

Start Trigger

Trigger

Trigger

2

3

∞

2

3

3

2

1 3 2

1

Page 48

Operator’s Manual Simple TrueArb Application

48

Resampling Strategy

It defines the strategy to adapt the original waveform length to the sequencer entry length. The

“Sample increasing strategy” parameter defines the strategy used to adapt the waveform length to the

sequencer entry length in the case where the original waveform length is shorter than the sequencer

entry length. The techniques adopted can be:

• Interpolation: it performs a linear interpolation between the waveform samples

• Return Zero: it fills with ‘0’s the tail of the waveform

• Hold Last: it holds the last value of the waveform

• Samples Multiplication: it repeats the waveform samples

The “Sample decreasing strategy” parameter defines the strategy used to adapt the waveform length to

the sequencer entry length in the case where the original waveform length is longer than the sequencer

entry length. The techniques adopted can be:

• Decimation: it reduces the number of samples maintaining the waveform shape

• Cut tail: it cuts the tail of the waveform reducing its size

• Cut head: it cuts the head of the waveform reducing its size.

Timing

• Sampling Clock[Hz]: specifies the Arbitrary Waveform Generator Sample Rate.

• Sampling Clock Source: specifies the clock source as Internal or External.

If Internal Clock is selected, the sampling clock is synthesized using a reference clock generated

internally.

Page 49

Operator’s Manual Simple TrueArb Application

49

If External is selected, the sampling clock is synthesized using the clock provided externally to

the Ref.Clock In SMA connector.

When the External is selected, the Reference Clock[Hz] control will appear and the user needs to

specify the Reference Clock frequency[Hz].

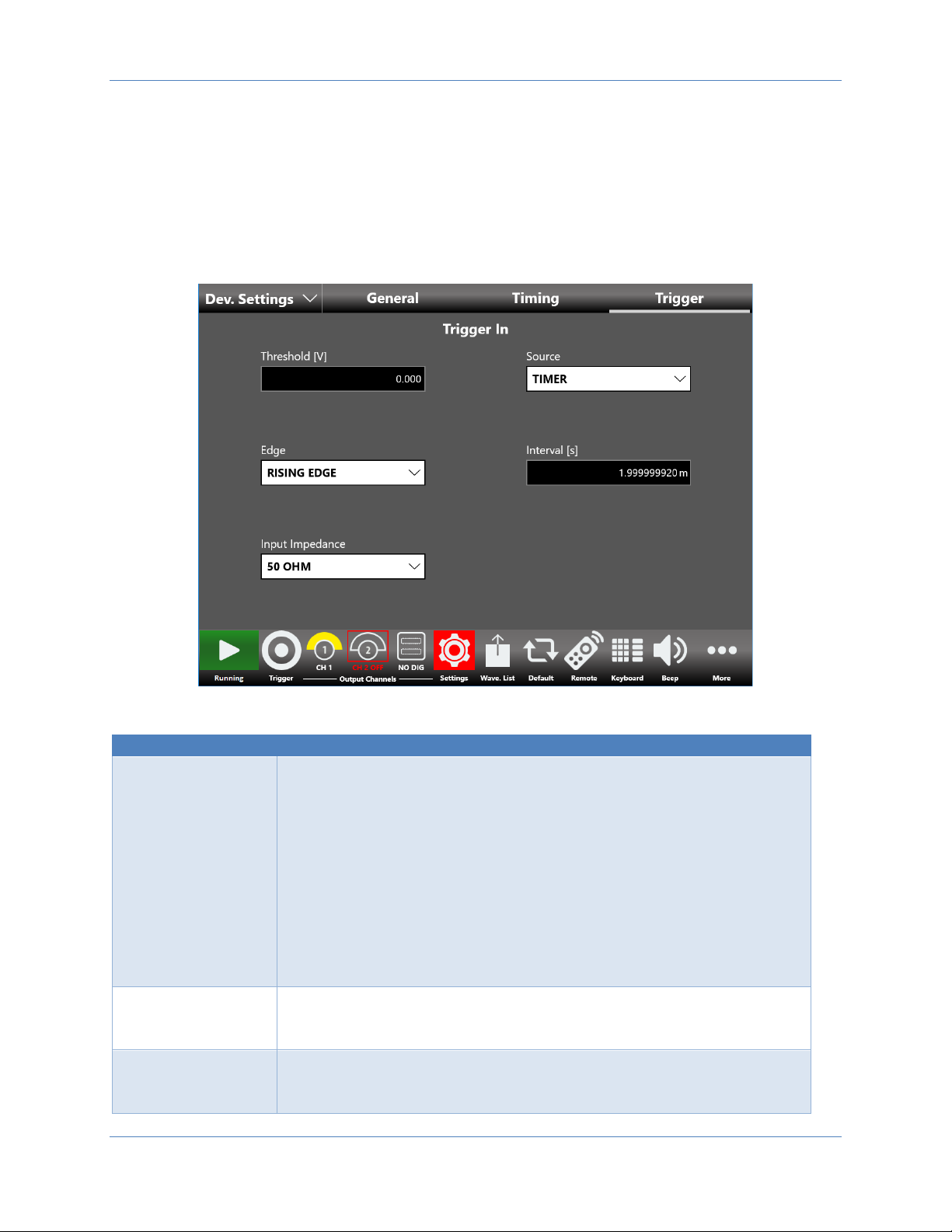

Trigger

The Trigger settings are common for all the channels

Trigger In Setting

Description

Source

Trigger Button: the Trigger event is provided to the instrument by the

Trigger button on the keyboard or Trigger button on the menu bar or

from a Remote Command.

Timer: The Trigger event is internally generated by a Timer. The Timer

count interval is set by Interval [s] textbox.

Trigger In Connector: the Trigger event is generated by the signal applied

externally on the BNC connector (TRIGGER IN) when it crosses the

selected Threshold with the selected Slope. You can select Threshold

value and Slope using the relative textbox and slider.

Note: The Trigger buttons and the Trigger from remote command are

always active, independently from the selecting Trigger Source.

Interval [s]

Sets the timer count interval. It has effect only when the trigger Source is

Timer. The edited value is automatically rounded to the closest value that

the hardware can implement.

Edge

The Slope can be positive or negative. When Rising Edge is selected the

trigger is detected when the signal on the “TRIGGER IN” BNC connector

crosses the threshold from low to high. The Falling Edge option is the

Page 50

Operator’s Manual Simple TrueArb Application

50

opposite.

“Both Edges” means that Trigger is sensitive to both edges of the signals.

It has effect only when the selected Source is External.

Threshold [V]

It is the threshold that the external signal applied to the “TRIGGER IN”

connector must cross to issue a Trigger event to the instrument. It has

effect only when the selected Source is External.

Impedance

It selects if the “TRIGGER IN” connector impedance: 1 KOhm or

terminated into 50 Ohm.

Channel Settings

The channels settings page allows to manage the parameters of the analog and digital channels

CH 1, CH2, …, CH N analog channel page

• Amplitude Scale[%]: this parameter that can be modified at run-time to adjust the waveform

amplitude while the instrument is running and it is applied to all the waveforms contained in the

sequencer. It is expressed in % and it has a range of 0% to 100%. 100% means that the

waveform keeps its original amplitude.

• Skew[s]: this parameter defines a fine time delay among the analog output channels in order to

de-skew the outputs. The resolution is about 3 ps and depends on the sampling frequency as well

Page 51

Operator’s Manual Simple TrueArb Application

51

as the maximum time skew allowed. The edited value is automatically rounded to the closest

value that the hardware can implement.

• Output Impedance: defines the output impedance of the analog outputs. It can be set 50 Ohm

or Low Impedance (5 Ohm).

• Polarity: when “Negative” is selected the analog output signal will be inverted.

• Base Line Offset[V]: defines the DC offset value added to the output signal respect to the ground

level.

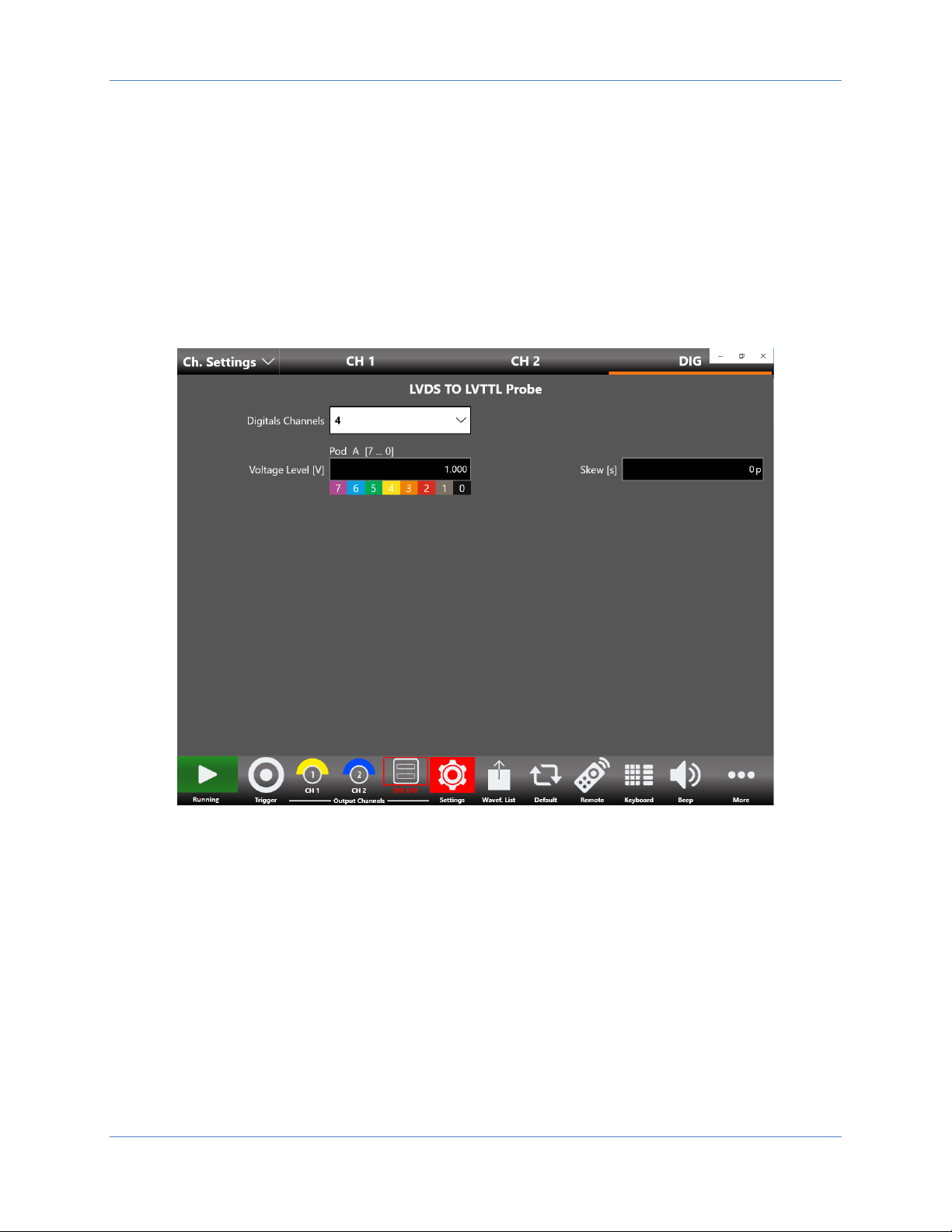

Digital Channels

Page 52

Operator’s Manual Simple TrueArb Application

52

• Digital Channels: it is possible to enable up to 8 digital line on two channels model, up to 16 on

four channels model and up to 32 on eight channels model.

If the Digital Channels number is 0, the DIG button will be disabled. If two or more

digital lines are selected the DIG button can be touched to enable/disable the digital

lines. Once the digital channels are enabled (≥ 2 digital channels selected) it is possible to access

to the Digital Channels Page (see the picture below) to define the digital waveform sequence as

for the analog channel page.

IMPORTANT NOTE: enabling the digital lines will cause a decrease of resolution in the analog

output channels as shown in the following table

Number

of digital

lines

CH1

Resolution

CH2

Res.

CH3

Res.

CH4

Res.

CH5

Res.

CH6

Res.

CH7

Res.

CH8

Res.

0

16 bits

16 bits

16 bits

16 bits

16 bits

16 bits

16 bits

16 bits

2

14 bits

16 bits

16 bits

16 bits

16 bits

16 bits

16 bits

16 bits

4

12 bits

16 bits

16 bits

16 bits

16 bits

16 bits

16 bits

16 bits

6

12 bits

14 bits

16 bits

16 bits

16 bits

16 bits

16 bits

16 bits

8

12 bits

12 bits

16 bits

16 bits

16 bits

16 bits

16 bits

16 bits

10

12 bits

12 bits

14 bits

16 bits

16 bits

16 bits

16 bits

16 bits

12

12 bits

12 bits

12 bits

16 bits

16 bits

16 bits

16 bits

16 bits

Page 53

Operator’s Manual Simple TrueArb Application

53

14

12 bits

12 bits

12 bits

14 bits

16 bits

16 bits

16 bits

16 bits

16

12 bits

12 bits

12 bits

12 bits

16 bits

16 bits

16 bits

16 bits

18

12 bits

12 bits

12 bits

12 bits

14 bits

16 bits

16 bits

16 bits

20

12 bits

12 bits

12 bits

12 bits

12 bits

16 bits

16 bits

16 bits

22

12 bits

12 bits

12 bits

12 bits

12 bits

14 bits

16 bits

16 bits

24

12 bits

12 bits

12 bits

12 bits

12 bits

12 bits

16 bits

16 bits

26

12 bits

12 bits

12 bits

12 bits

12 bits

12 bits

14 bits

16 bits

28

12 bits

12 bits

12 bits

12 bits

12 bits

12 bits

12 bits

16 bits

30

12 bits

12 bits

12 bits

12 bits

12 bits

12 bits

12 bits

14 bits

32

12 bits

12 bits

12 bits

12 bits

12 bits

12 bits

12 bits

12 bits

• Voltage Level[V]: this parameter defines the output voltage level (in Volt) of the LVDS to LVTTL

Digital Probe. Please note that it will take effect only when the Digital Option is installed in the

instrument and with the LVDS to LVTTL probe connected.

• Skew[s]: it sets the delay between the analog channels and the digital channels in order to de-

skew the analog and digital outputs. The skew between analog/digital channels depends on the

sampling frequency: the minimum skew is 1 clock cycle @ the sampling frequency. The edited

value is automatically rounded to the closest value that the hardware can implement.

Page 54

Operator’s Manual Simple TrueArb Application

54

Marker Settings

On the marker output page you can set the behaviour and parameters of the Marker signal that is

provided at the front panel MARKER OUT BNC connector.

On four and eight channels model, press the marker button to change the selection of the Marker signal.

The available Marker signals depend on the instrument Model, refer to the Marker Output section for a

complete description.

Page 55

Operator’s Manual Simple TrueArb Application

55

Marker Mode:

• Automatic: the marker has a behavior that depends on the Run Mode. In detail:

o Continuous: the instrument generates a Marker pulse of the duration from 6ns to 12 ns

(depending on the sampling frequency), synchronous with the analog outputs, for each

sequencer entry and for each repetition.

o Single/Burst: each time a trigger event has been received, while the instrument is

waiting for a trigger event, a Marker pulse is generated of the duration from 6ns to 12

ns (depending at the sampling frequency).

o Triggered Continuous: at the start event the instrument generates a Marker pulse of

the duration from 6ns to 12 ns (depending at the sampling frequency).

o Stepped: each time a trigger event is received, while the instrument is waiting for a

trigger event, a Marker pulse is generated of the duration from 6ns to 12 ns (depending

at the sampling frequency). In case an entry with infinite repetitions is being executed, if

a trigger event occurs, a Marker pulse will be generate and the execution will skip to the

next entry. In this case the Marker pulse is not synchronous with the waveform of next

entry

• Fixed To Low Voltage/ Fixed To High Voltage: the marker level is fixed to low level or high level.

• Replicate Digital 0: it means that The Marker Out will behave like the Digital line 0 output. This

choice is available only when the digital option is installed and the Digital Channels parameter

(Channel Settings -> DIG page) is > 0.

Marker Skew[s]: defines the skew between the marker and the analog channels. The resolution is 78 ps.

The edited value is automatically rounded to the closest value that the hardware can implement.

Voltage Level[V]: it sets the Marker high level Voltage. The Low level is fixed to 0V.

Sequencer Settings

The sequencer setting page contains some parameter to define the strategy to manage the length of the

sequencer entries in relationship with the length of the channel waveforms defined for each entry.

Page 56

Operator’s Manual Simple TrueArb Application

56

Sequencer item Length Strategy:

• Adapt to the longer analog waveform: if this option is selected the length of an entry of the

sequencer by default will be equal to the length of the longer channel waveform, among all

analog channels, assigned to the entry.

• Adapt to the shorter analog waveform: if this option is selected the length of an entry of the

sequencer by default will be equal to the length of the shorter channel waveform, among all

analog channels, assigned to the entry.

• Apply the default value: if this option is selected the length of an entry of the sequencer by

default will be equal to the value specified in the Sequencer Item Default Length [N] parameter

The length of each entry can be manually and individually overwritten by changing the Entry Length [N]

parameter in the Waveform Parameters section of the Waveform Area. Anyway if a change in any

channel waveform of the entry occur, the length of the entry will be recalculated using the strategy

specified in the Sequencer item Length Strategy parameter.

Sequencer Item Default Length [N]: this parameter specifies the length of the sequencer entries in the

case when the Sequencer item Length Strategy parameter is set to Apply the default value.

Warnings Enabled: this parameter enables or disables the warnings shown in the Sequencer Toolbar and

in the Waveform Area that notify that one or more channel waveforms have been assigned to an entry

with a different length. This situation will cause the application the modify the mismatching waveforms

during the execution to match the entry length using the strategy specified in the Sample

increasing/decreasing strategy parameter (Device Settings -> General page)

Page 57

Operator’s Manual Simple TrueArb Application

57

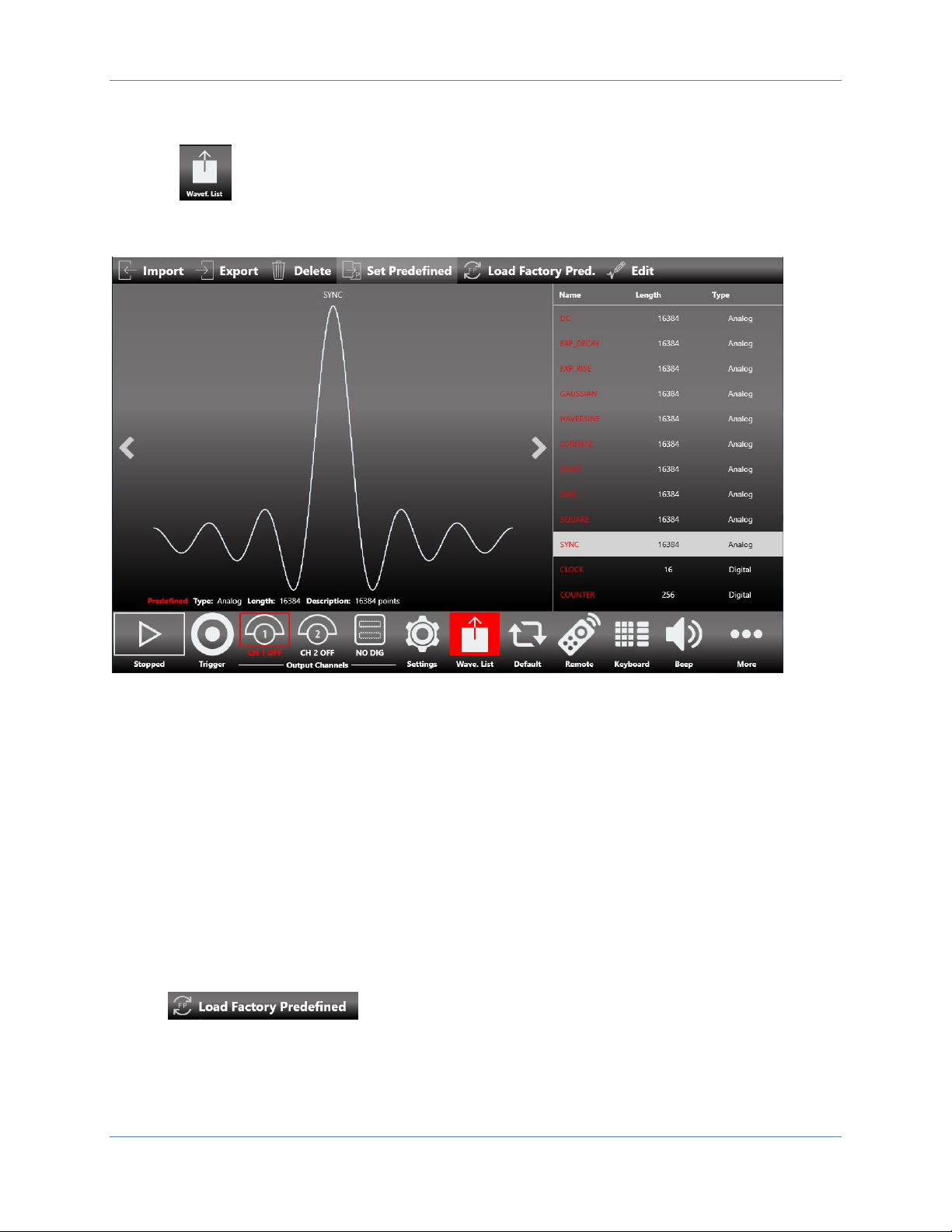

Waveform List

Press the button to open the Waveform List page that collects all the waveforms available in the

current configuration.

The T3AWG-3K series contains by default a set of Factory Predefined Waveforms that are common to all

configurations.

The Predefined Waveforms are the ones in red color on the list, the imported waveforms are the ones in

gray.

Please note that:

• You can build your own set of Predefined Waveform promoting waveforms in the list to

Predefined ones.

• You can delete a Predefined waveform for the exception of ZERO for digital waveforms and SINE

for analog waveforms.

• If you want to restore the Factory Predefined waveforms, you should press the

button. Please note that the imported waveforms previously

promoted as Predefined will not be deleted.

Page 58

Operator’s Manual Simple TrueArb Application

58

How to import an Analog/Digital waveform from a file

Import button allow you to import data from a file to create a new waveform

The supported file formats are:

• TXT – New line (\n) separated text file (one column only with no header)

• .ZIP – Compressed file in binary proprietary format

• .trc – LeCroy oscilloscope binary file format

1. Press the import button and the Windows File Browser will open, select the txt or zip file you

would like to import. The Import page will open.

2. In the Import dialog, the Name and Description fields will be automatically filled with default

values.

3. Select the Waveform Type you would like to import (“Analog” or “Digital”).