Page 1

5 Commonwealth Ave

Woburn, MA 01801

Phone 781-665-1400

Toll Free 1-800-517-8431

Visit us at www.TestEquipmentDepot.com

T3DAQ1-16

Data Acquisition System

User Manual

Page 2

T3DAQ1-16 User Manual

General Safety Summary

Read the following precautions carefully to avoid any personal injuries, or damage to the instrument or products connected to it. Use the instrument only as specified.

Use only the power cord supplied for the instrument.

Ground the instrument.

The instrument is grounded through the ground conductor of the power cord. To avoid electric

shock, always connect to grounded outlets. Make sure the instrument is grounded correctly before

connecting its input or output terminals.

Connect the signal wire correctly.

To avoid damage, observe input polarity and maximum voltage/current ratings at all times.

Observe all terminal ratings and signs on the instrument to avoid fire or electric shock.

Before connecting to the instrument, read the manual to understand the input/output ratings.

Do not operate with suspected failures.

If you suspect that the instrument is damaged, contact the Teledyne LeCroy service department

immediately.

Do not operate in wet/damp conditions.

Do not operate in an explosive atmosphere.

Keep the surface of the instrument clean and dry.

Avoid touching exposed circuits or wires.

Do not touch exposed contacts or components when the power is on.

Do not operate without covers.

Do not operate the instrument with covers or panels removed.

Use only the fuse specified for the instrument.

Use proper overvoltage protection.

Use anti-static protection.

Operate in an anti-static protected area. Ground measurement cable conductors before connecting

to the instrument to discharge any static electricity before connecting the cables to the instrument.

Observe ventilation requirements.

Ensure good ventilation. Check the vent and fan regularly to prevent overheating.

i

Page 3

T3DAQ1-16 User Manual

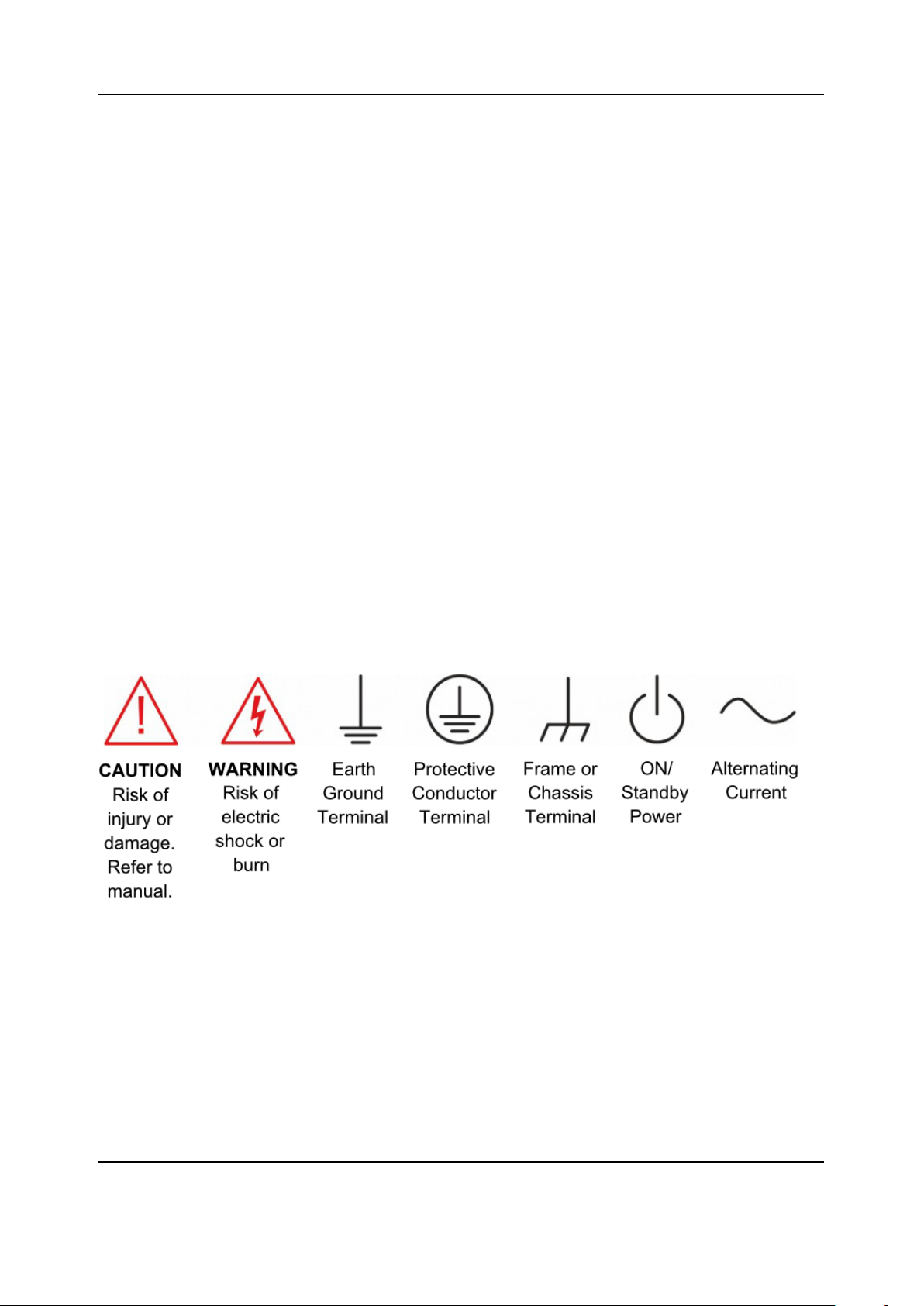

Safety Terms and Symbols

The following terms may appear on the instrument:

DANGER: Direct injury or hazard may occur.

WARNING: Potential injury or hazard may occur.

CAUTION: Potential damage to instrument/property may occur.

CAT I1: IEC Measurement Category I, applicable for making measurements on ‘other’ circuits that

are not directly connected to mains. See p. v.

CAT II: IEC Measurement Category II, applicable for making measurements on circuits connected

directly to utilization points (socket outlets and similar points) of the low voltage mains installation.

See p. v.

1) CAT I as defined in IEC/EN 61010-031:2008.

Note that Measurement Category I was removed in IEC/EN 61010-031:2015 and replaced by ‘O’, indicating ”other cir-

cuits that are not directly connected to mains.”

Saftey Symbols

The following symbols may appear on the instrument:

ii

Page 4

T3DAQ1-16 User Manual

Operating Environment

Temperature: 0 °C to 40 °C

Humidity: 5% to 90% relative humidity (non-condensing) up to +30°C. Upper limit derates to 50%

relative humidity (non-condensing) at +40°C.

Altitude: ≤ 2000 m

Use indoors only.

Pollution Degree 2. Use in an operating environment where normally only dry, non-conductive

pollution occurs. Temporary conductivity caused by condensation should be expected.

AC Power

Input Voltage & Frequency:

100-120 V at 50/60 Hz

200-240 V at 50/60 Hz

Manual AC selection with a slide switch.

Power Consumption: 20 W maximum

Mains Supply Connector: CAT II per IEC/EN 61010-1:2010, instrument intended to be supplied

from the building wiring at utilization points (socket outlets and similar).

Fuse Type

Current Input Terminal: 250 VAC F 10 A, 3 AG

AC Mains: 250 VAC F 300 mA, 5x20 mm

iii

Page 5

T3DAQ1-16 User Manual

Input Terminal Protection Limitation

Protection limitation is defined for the input terminal.

1. Main Input (HI and LO) Terminals

HI and LO terminals are used for Voltage, Resistance, Capacitance, Continuity, Frequency,

Diode and Temperature measurement. Two protection limitations are defined:

• HI-LO protection limitation: 1000 VDC or 750 VAC. This is the maximum measurable

voltage. The limitation can be expressed as 1000 Vpk.

• LO ground protection limitation: LO terminal can “float” 500 Vpk relative to the ground

safely. The maximum protection limitation of HI terminal relative to the ground is 1000

Vpk. Therefore, the sum of the “float” voltage and the measured voltage can’t exceed

1000 Vpk.

2. Sampling (HISense and LOSense) Terminals

HISense and LOSense terminals are used for 4-wire Resistance measurement. Two protection limitations are defined:

• HISense-LOSense protection limitation: 2000 Vpk.

• LOSense-LOSense protection limitation: 2 Vpk.

3. Current Input (I) Terminal

The I terminal is used for current measurement. The maximum current which can go through

the I terminal is limited to 10 A by the fuse on the back panel.

NOTE: Voltage on the current input terminal corresponds to voltage on the LO terminal. To

keep good protection, only use a fuse of the specified type and value to replace this fuse

iv

Page 6

T3DAQ1-16 User Manual

IEC Measurement Category II Overvoltage Protection

To avoid the danger of electric shock, the Data Acquisition Unit provides overvoltage protection for

line-voltage mains connections that meet both of the following conditions:

1. The HI and LO input terminals are connected to the mains under Measurement Category II

conditions described in the warning below.

2. The maximum line voltage of the mains does not exceed: 600 VAC for the instrument.

WARNING:

IEC Measurement Category II includes electrical devices connected to mains at an outlet on a

branch circuit, such as most small appliances, test equipment, and other devices that plug into a

branch outlet or socket.

The DAQ is capable of making measurements with the HI and LO inputs connected to mains in

such devices (≤ 600 VAC) or to the branch outlet itself.

However, the HI and LO terminals of the DAQ can’t be connected to mains in permanently installed

electrical devices such as the main circuit-breaker panels, sub-panel disconnected boxes and permanently wired motors. Such devices and circuits are prone to exceed the protection limits of the

DAQ.

Limits for Measurements on Other Circuits Not Directly Connected to Mains

Max. rated input voltage: 1000V

Transient overvoltage: 4000V

WARNING:

Voltages above 600 VAC can only be measured in circuits that are isolated from mains. However,

there may be transient over voltage in circuits that are isolated from mains. The DAQ is able to

withstand occasional transient overvoltage up to 4000 Vpk. Please don’t use this instrument to

measure circuits where transient overvoltage may exceed this level.

rms

pk

v

Page 7

T3DAQ1-16 User Manual

Daily Maintenance and Cleaning

Maintenance

Protect the liquid crystal display from direct sunlight when storing or using the instrument.

NOTE: To avoid damage to the instrument or test leads, please don’t place them in mist, liquid or

solvent.

Cleaning

Regularly clean the instrument and test leads.

• Wipe the external dust off the instrument and test leads using a soft rag. Be careful not to

scratch the display screen when cleaning. Do not allow any liquid to enter the instrument.

• Use a damp soft rag to clean the instrument after removing the power plug. Use 75% isopropyl alcohol or water solvent to get a more thorough cleaning.

NOTE: To prevent the surface of the instrument or test leads from damage, please don’t use any

corrosive or chemical cleaning reagents. Please make sure the instrument is fully dry before reconnecting the power to avoid short circuits or personal injury.

vi

Page 8

T3DAQ1-16 User Manual

Introdution to T3DAQ1-16

Teledyne Test Tools T3DAQ1-16 is a 16 channel Data Acquisition System incorporating the latest

4.3 inch (10.92 cm) dual-display technology which can be configured to show Data Histograms,

Data fluctuation Trends, Bar Graph, Statistics or the traditional Number mode, all in an easy to use

interface. The T3DAQ features 12 multi-purpose + 4 current channels and supports various measurement functions. It provides a convenient and versatile solution for test applications that require

multiple measurement points or signals and is an ideal tool for R& D burn-in and production testing.

A great feature of the Teledyne Test Tools T3DAQ is its ability to make highly accurate True RMS

AC Voltage and Current measurements, meaning no loss of accuracy even when measuring complex voltage and current waveforms.

The T3DAQ provides various measurement modes to satisfy a wide range of application requirements. 12 Multi-purpose channels can be configured individually for various scan requirements.

The Channel configuration function allows user to configure different parameters such as measurement type, range, scan mode, number of scan cycles, and duration of scan. Similarly, the

scan control menu provides flexibility to schedule, start, and stop the scan. Scanning data can be

viewed live during a scan and can also be saved for future use. An internal 1 GB flash memory is

available for data logging and to save configuration files. The T3DAQ also features a USB Host

interface to use a USB flash drive to collect data without being connected to a PC.

The T3DAQ is equipped with LAN and USBTMC interfaces for remote control of the device. The

device can be controlled remotely using EasyDMM software. The graphical interface of the software makes it easy to configure measurements, setup and execute scans or troubleshoot the

design. Live measurement data can be viewed in numeric digits or graphically by trend chart, bar

graph and histogram. The data can be manually or automatically exported as CSV files for further

analysis.

Main features:

• 4.3” TFT-LCD Display

• Dual display, Chinese and English Menu

• Built-in front panel accessible help system

• File management (support for U-disc and local storage)

• Real 6-5 digit (2,200,000 count) readings resolution

• True-RMS AC Voltage and AC Current measuring

• 1 GB flash memory for mass storage configuration files and data files

• Built-in cold terminal compensation for thermocouple

• Standard interface: USB Device, USB Host, LAN

• USB & LAN remote interfaces support common SCPI command set

vii

Page 9

Contents

General Safety Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

Daily Maintenance and Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

Introdution to T3DAQ1-16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

1 Quick Start 1

General Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

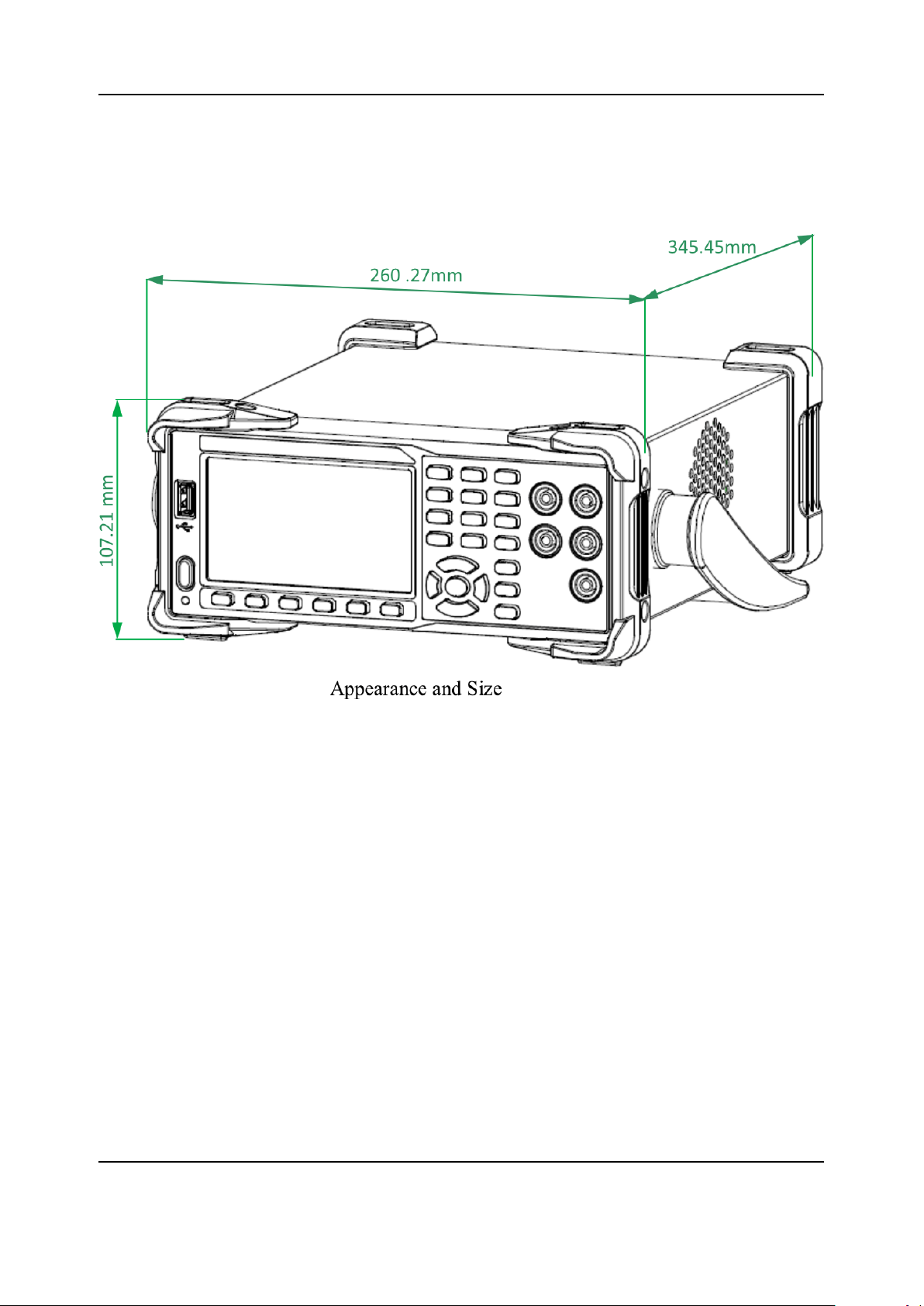

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

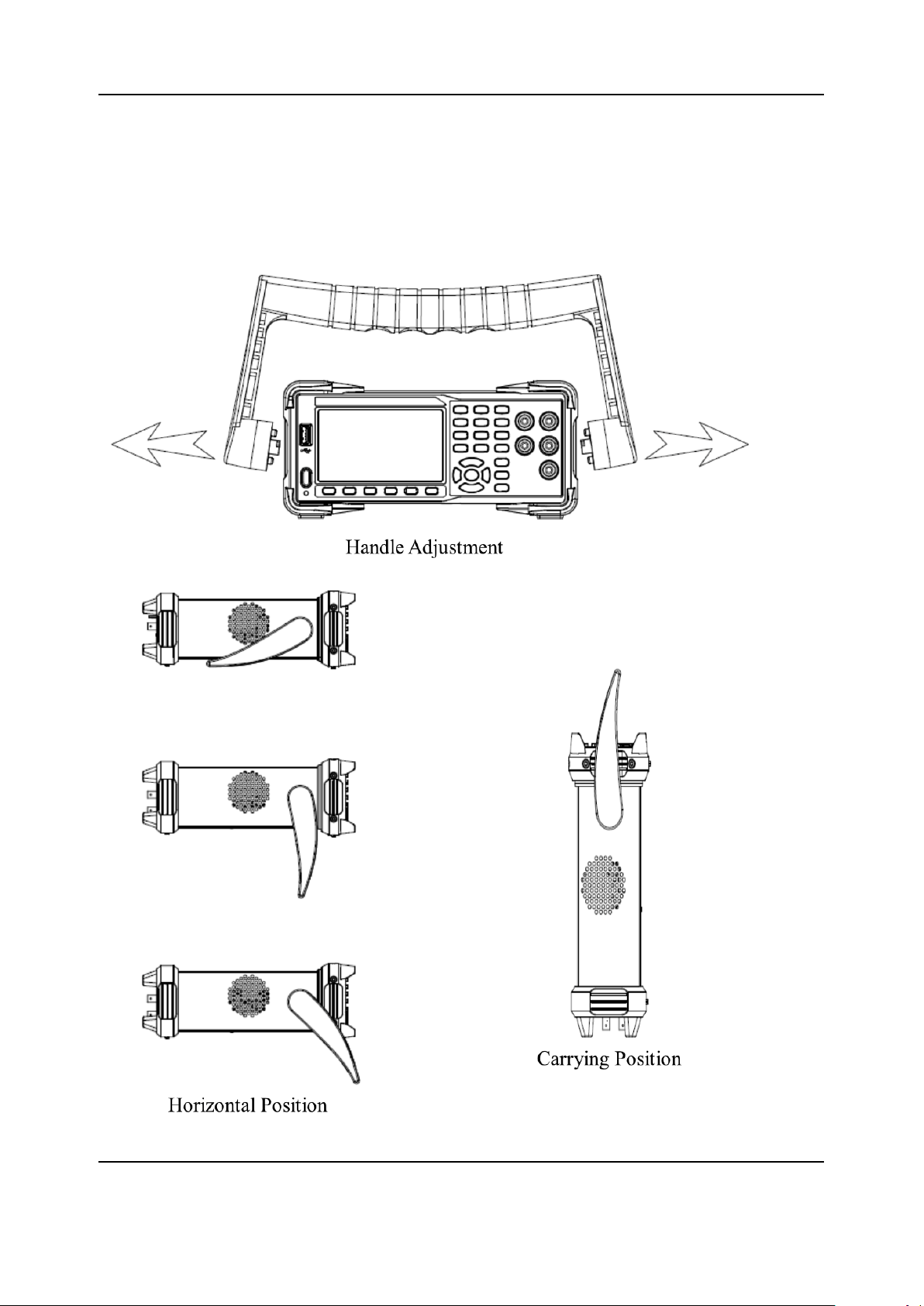

Handle Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Rear Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Starting the DAQ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Measurement Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Connecting to USB and LAN Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Using the Built-in Help System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2 Function and Operation 22

Measurement Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Basic Measurement Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Dual-display Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Utility Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Acquire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Help System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Math Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Display Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Trigger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Hold Measurement Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

3 Measurement Tutorial 90

Display Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Crest Factor Errors (non-sinusoidal inputs) . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Loading Errors (AC Voltage) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

viii

Page 10

T3DAQ1-16 User Manual

4 General Troubleshooting 93

5 Appendix 95

Certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

© 2021 Teledyne LeCroy, Inc. All rights reserved.

Teledyne Test Tools is a brand and trademark of Teledyne LeCroy, Inc. Other product or brand

names are trademarks or requested trademarks of their respective holders. Specifications, prices,

availability and delivery subject to change without notice.

ix

Page 11

Chapter 1

Quick Start

General Inspection

Please check the instrument according to the following steps.

1. Inspect the shipping container.

Keep the shipping container and packaging material until the contents of the shipment have

been completely checked and the instrument has passed both electrical and mechanical

tests. It is always good practice to save the shipping container and packaging for use when

returning the power supply to Teledyne LeCroy for service or calibration.

The consigner or carrier will be responsible for damage to the instrument resulting from shipping. Teledyne LeCroy will not provide free maintenance or replacement in this instance.

2. Inspect the instrument.

If the instrument is found to be damaged, defective or fails in electrical or mechanical tests,

please contact the Teledyne LeCroy service department immediately.

3. Check the accessories.

Please check that you have received the accessories on the packing list:

1 DAQ

1 Test Lead Set

1 USB Cable

If the accessories are incomplete or damaged, please contact Teledyne LeCroy immediately.

1

Page 12

T3DAQ1-16 User Manual

Dimensions

2

Page 13

T3DAQ1-16 User Manual

Handle Adjustment

To adjust the handle position of the DAQ, grip the handle by the two sides and pull outward. Then,

rotate the handle to the appropriate position.

3

Page 14

T3DAQ1-16 User Manual

Front Panel

A USB Host

Users can store the current state or measurement data into a USB storage device. Users

can also read the state files or updated firmware from a USB storage device.

B Power Key

Turn the instrument on or off.

C LCD Display

The instrument provides a 4.3 inch high resolution color TFT-LCD display screen with 480*272

pixels that displays the function menus, measurement parameter settings, system status, and

prompt messages.

D Menu Operation Keys

Press any softkey to activate the corresponding menu.

4

Page 15

T3DAQ1-16 User Manual

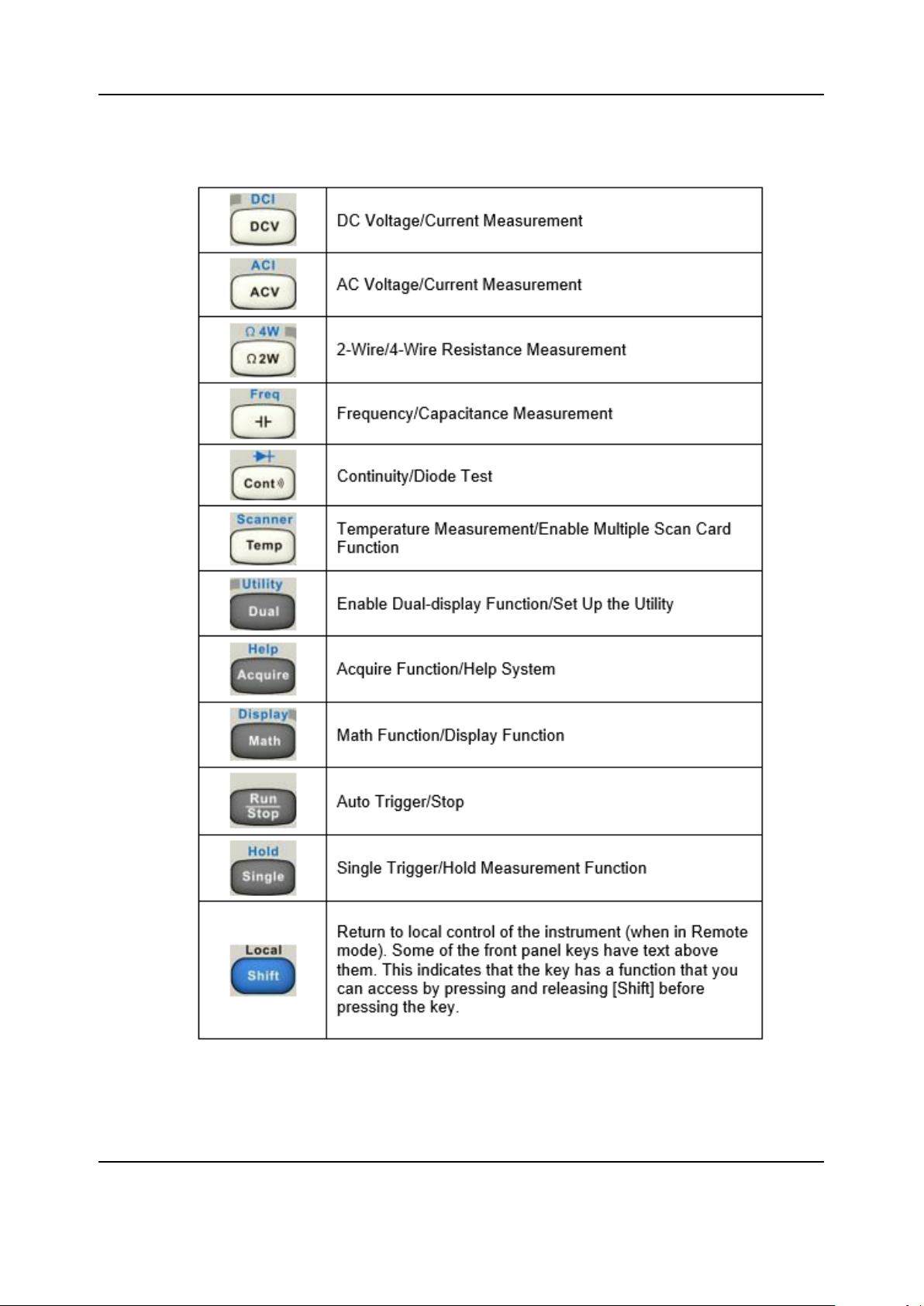

E Measurement and Assistant Function Keys

5

Page 16

T3DAQ1-16 User Manual

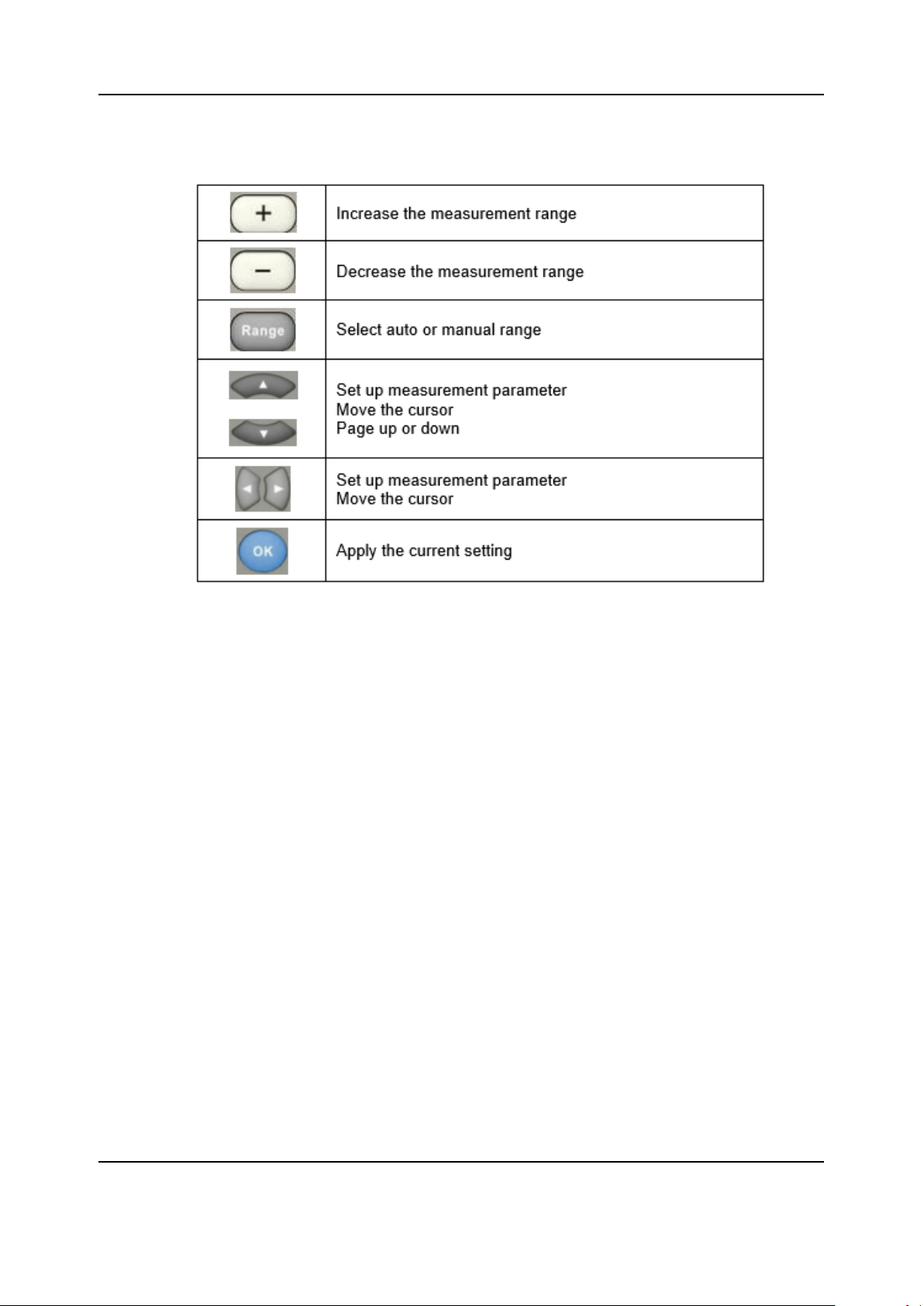

F Range and Direction Keys

G Signal Input Terminals

The measured signal (device) will be connected into the DAQ through these terminals. Different measurement objects have different connection methods.

For details, please refer to “Measurement Connections”.

6

Page 17

T3DAQ1-16 User Manual

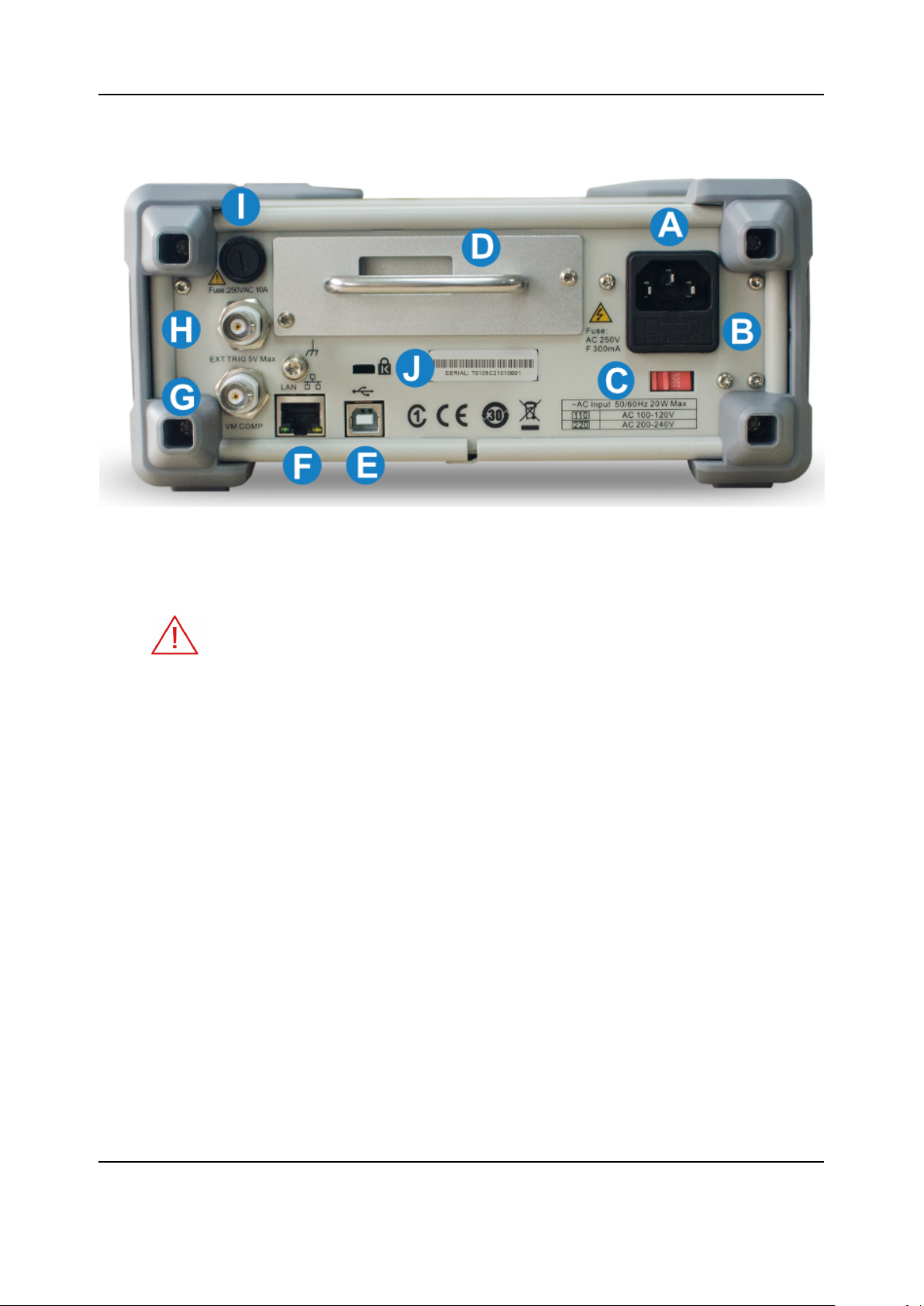

Rear Panel

A Power Socket

The DAQ accepts two types of AC supplies. Please use the power cord provided

in the accessories to connect the DAQ to the AC power through this socket.

Note: The correct voltage scale must be first selected (through the Voltage Selector) before power connection.

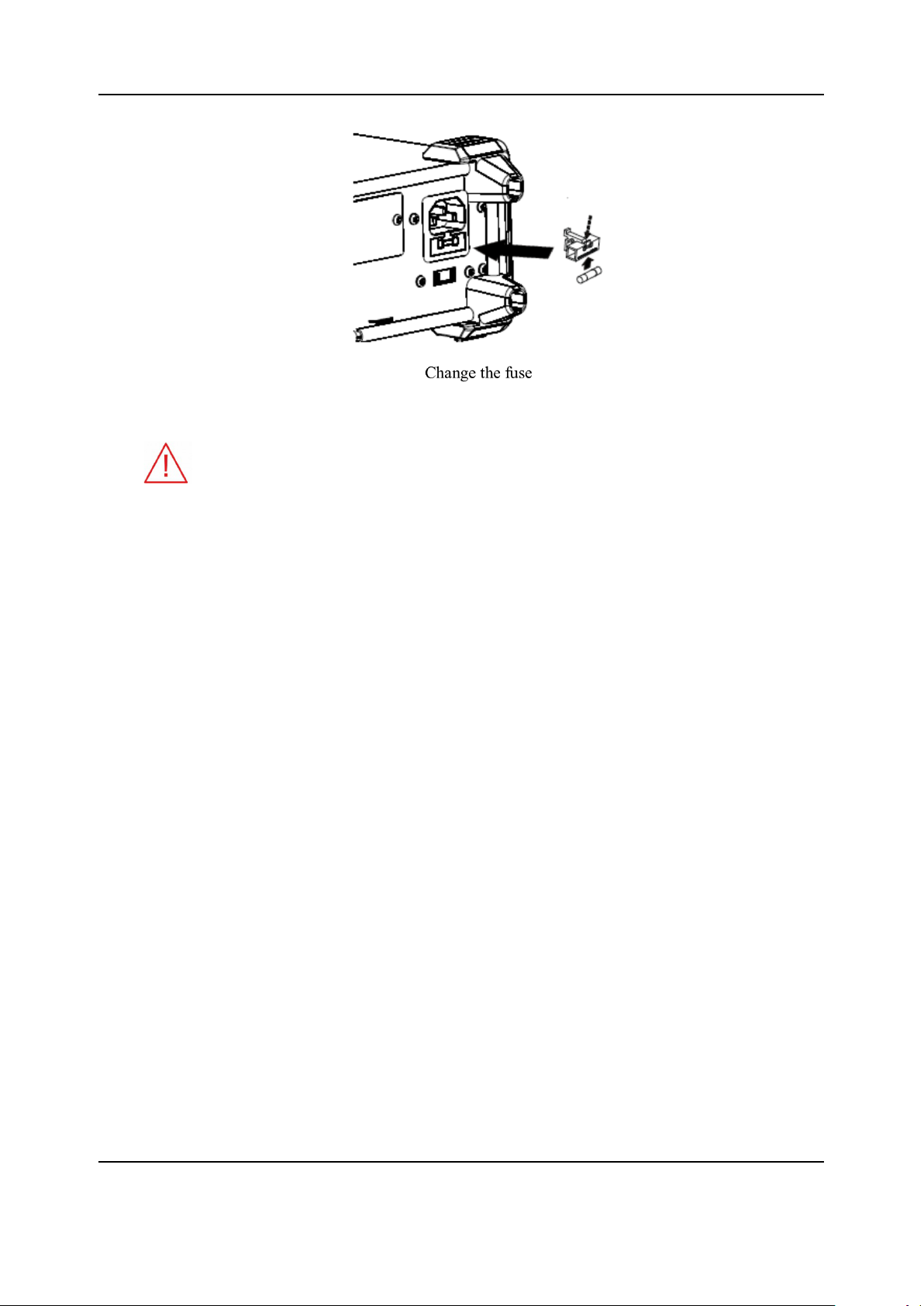

B Power Fuse

The DAQ is already installed with a power fuse before leaving factory. To change the fuse

please:

• Turn off the DAQ and remove the power cord.

• Press down the block tongue using a straight screwdriver (in the direction of the dotted

arrow in the figure below) and pull out of the fuse seat.

• Select a proper voltage scale.

• Replace a specified fuse.

• Reinstall the fuse seat into the slot.

7

Page 18

T3DAQ1-16 User Manual

C AC Voltage Selector

Select the correct voltage scale (110 V or 220 V) for the AC supply used.

D 16-channel Data Acquisition Module

E USB Device

Connect the PC through this interface. SCPI commands or PC software can be used to

control the DAQ remotely.

F LAN

Through this interface, the DAQ can be connected to the network for remote control.

G VMC Output

The DAQ outputs a low-true pulse from the [VM Comp] connector after every measurement.

H Ext Trigger

Trigger the DAQ by connecting a trigger pulse through the [Ext Trig] connector. Note the

external trigger source must be selected.

I Current Input Fuse

The DAQ is already installed with a current Input fuse to provide 10 A maximum input protection before leaving factory. To replace a new one, please:

(a) Turn off the DAQ and remove the power cord.

(b) Turn the fuse seat counterclockwise as shown in the figure using a straight screw driver

and then pull out the fuse seat

(c) Place a new 10 A specified fuse.

(d) Reinstall the fuse seat into the slot.

J Instrument Kensington Lock Point

A Kensington lock (not supplied) can be used to lock the DAQ to a fixed place if necessary.

8

Page 19

T3DAQ1-16 User Manual

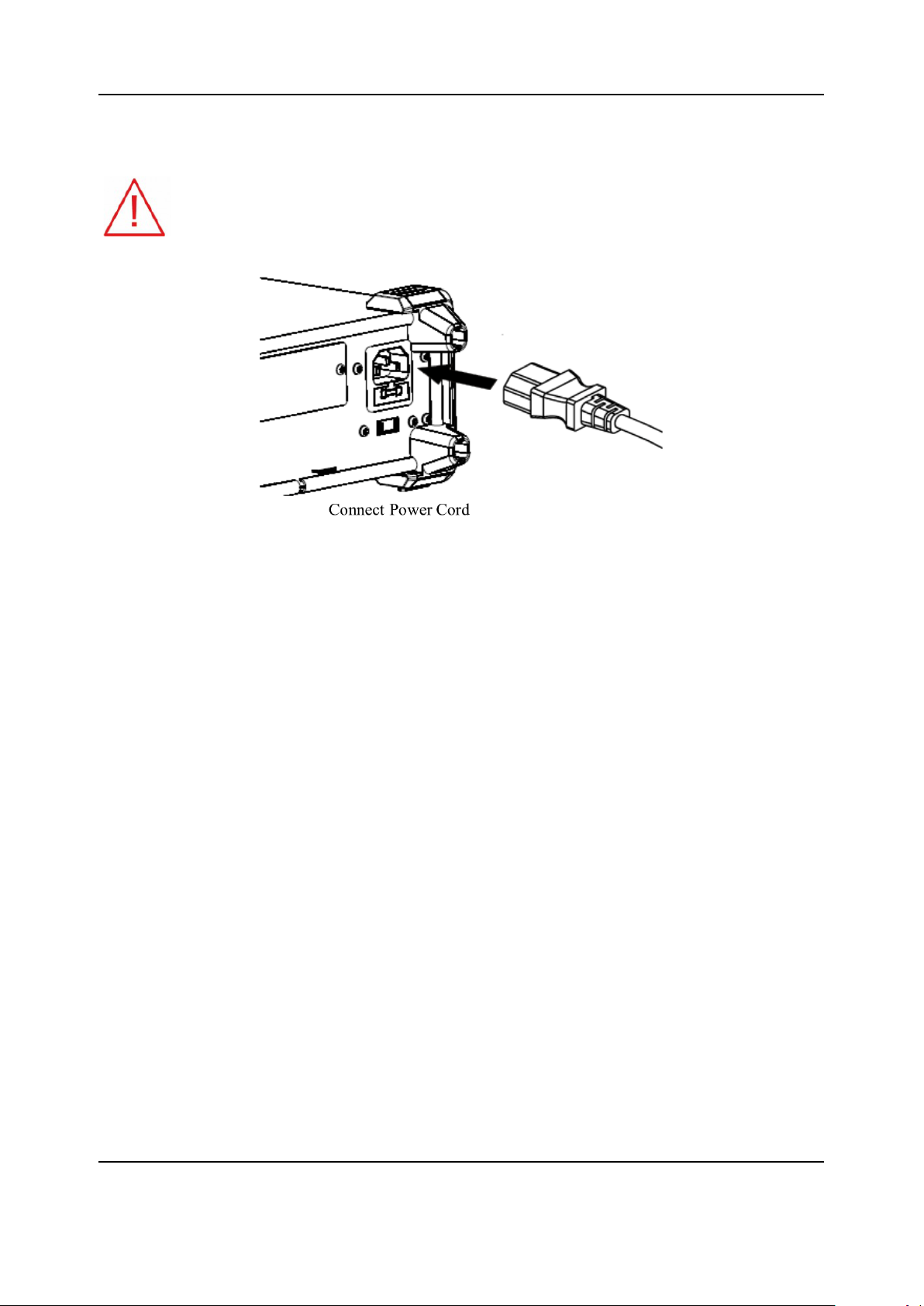

Starting the DAQ

Before connecting the instrument to a power source please adjust the AC voltage

selector on the rear panel of your DAQ according to your local power supply voltage.

Then connect the power cord as shown in the following figure.

Press the Power key on the front panel to turn on the DAQ. If the DAQ does not start normally,

then try the following:

1. Make sure the power cord is in good connection and connected to the DAQ and the wall

socket.

2. Ensure that the wall socket has power and is turned on.

3. Try to restart the DAQ, if it fails, check the power fuse and replace with a new one if necessary.

4. If the problem still remains, please contact the Teledyne LeCroy service department for help.

9

Page 20

T3DAQ1-16 User Manual

Operating Instructions

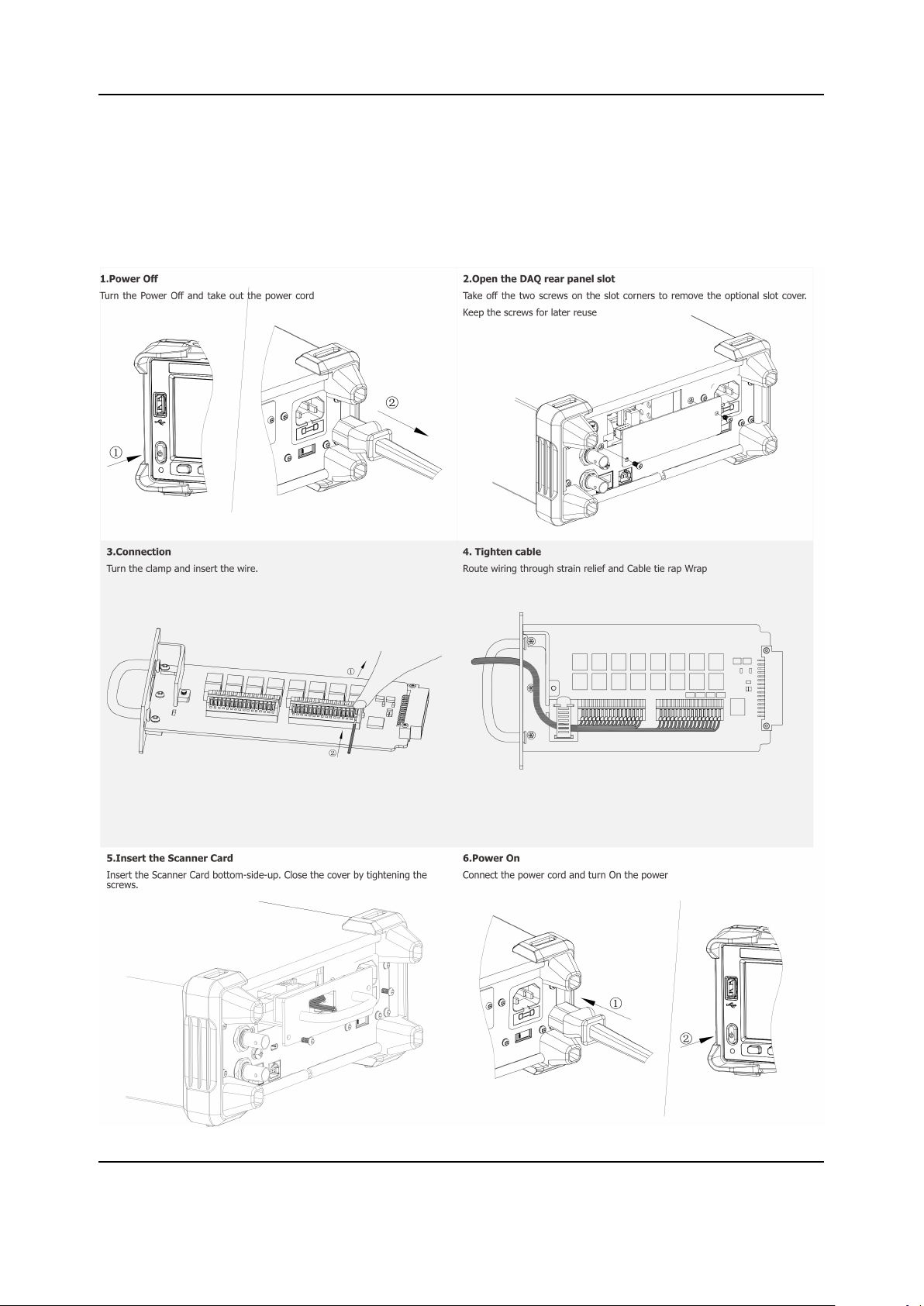

NOTE: The Scanner Card is not designed to be ”Hot Swappable”.

Please make sure the instrument is turned off before installation or removal of the Scanner Card.

Hot swapping the card could cause damage to the instrument and is not covered under warranty.

10

Page 21

T3DAQ1-16 User Manual

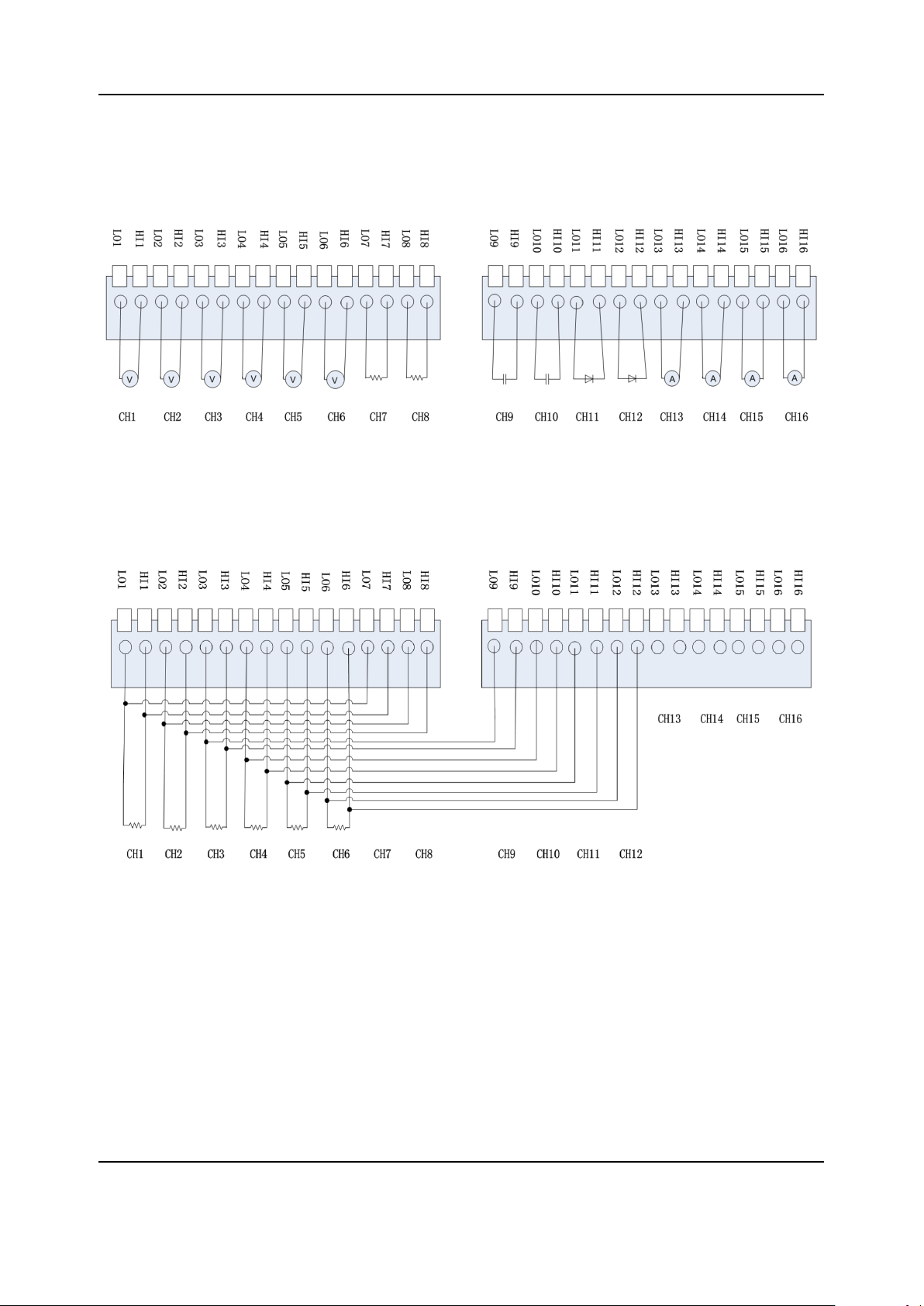

Scanner Card Connections

An example of 2-wired connection application is shown below.

First 12 channels can be used to measure DCV/DCI ACV/ACI/CAP/FREQ/DIODE/CONT/TEMP

and the last 4 channels are dedicated to current measurement.

4-Wire Resistance measurement example is shown below.

CH1 to CH6 can be used for measurements and CH7 to CH12 can be used as sense channels. To

minimize voltage errors, the remote sense connections (CH7,CH8 etc..) should be made as close

to the device-under-test (DUT) as possible.

11

Page 22

T3DAQ1-16 User Manual

Front Panel Operations

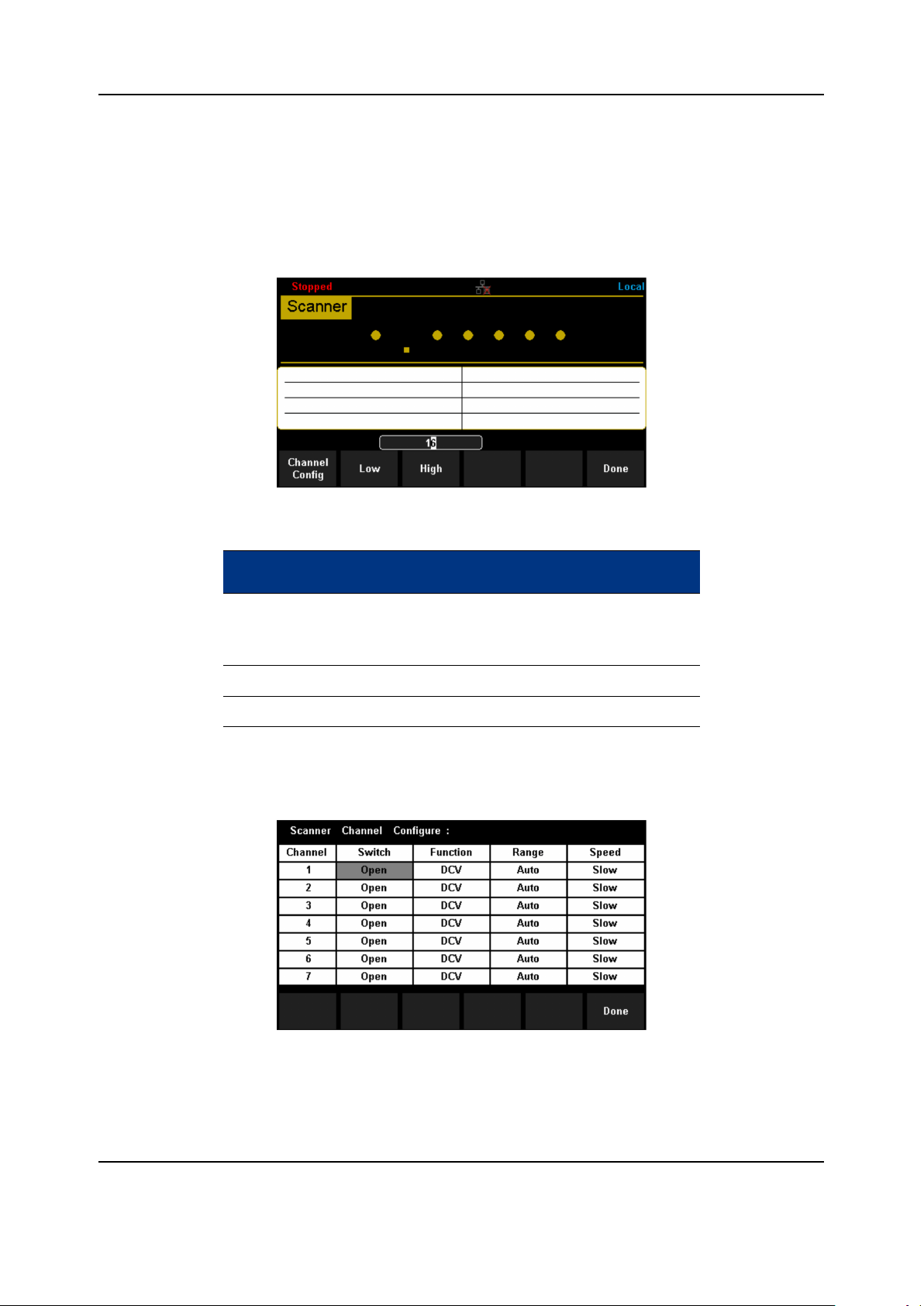

Scanner mode functions can be accessed by pressing ”Shift” and ”Temp” buttons.

The following table gives a short description about different functions available.

Function

Menu Settings Description

Mode Scan/Step Set the operation mode

Sets the duration between

each scan loop (Scan mode)

0ms-

Time

Cycles Auto/Man

Channel

Setup

Start On/Off Start or stop scan operation

Exit Exit the scanner function

1. Operation mode setup

•Scan: Measures all specified channel ranges (Channel MIN-MAX) for each trigger event. Time

settings are applied between each scan for the whole channel range.

•Step: Measures a single channel in the specified range (Channel MIN-MAX) at each trigger event.

Time settings are applied for each channel.

2. Time setup

Use the direction keys to set the duration between each scan loop (Scan mode) or between each

scanned channel (Step mode)

999.999s

or between each scanned

channel (Step mode)

Sets the number of scan operations

Sets the scanned channel

range, measurement function, and measurement parameters

3. Cycles

•Auto: The instrument will scan specified channel circularly after the scan operation start and you

should stop the operation manually.

12

Page 23

T3DAQ1-16 User Manual

•Manual: Sets the number of scan operations by direction keys. The range of the setting is from 1

to 999. After starting the scan operation the instrument will not stop scanning until reaches cycle

number.

4. Channel setup

Press the [Channel Setup] to enter the setup interface.

The table below gives a brief description of Function menu.

Function

Menu Description

Open/close the channel and set the meaChannel Config

surement function, measurement parame-

ters of specified channel.

Low Set the low value of scanned channel range.

High Set the high value of scanned channel range.

Press the [Channel Setup] to enter the channel configuration interface and set the channel switch, function,

range and speed.

The range setting is applicable for the following functions: DC/AC Voltage (DCV/ACV), 2/4 Wire Resistance

(2W/4W), Capacitance (CAP), Frequency (FRQ).

Ranges available for various functions is given below.

13

Page 24

T3DAQ1-16 User Manual

Function

Menu Description

DCV/ACV/

FRQ Auto, 200mV, 2V, 20V, 200V

DCI/ACI 2A (fixed)

Auto, 200Ω, 2kΩ, 20kΩ, 200kΩ, 2MΩ, 10MΩ,

2W/4W

The scanner function provides two measurement speeds: Fast (50 reading/s) and Slow (5 reading/s). (Fast:

1PLC, Slow: 10 PLC)

The speed setting is applicable for the following functions: DC/AC Voltage (DCV/ACV), 2/4 Wire Resistance

(2W/4W)

100MΩ

Operating instructions:

• Move the cursor to choose the wanted parameter by direction keys and the background color of

cursor’s position turns to gray.

• Select the current item by pressing “OK” key and the background color of the selected item turns

to green.

• Set the parameter by up and down direction keys.

• Press “OK” key again to store the setting of the selected item of which the background turns back

to gray. Move the cursor and repeat the prior steps to set the next parameter.

• Press [Done] to save the current settings and return to the higher level menu.

5. Channel range setting

Select [High] or [Low] and then input numerical value by direction keys. Note: The upper limit value

should be always bigger than the lower limit value.

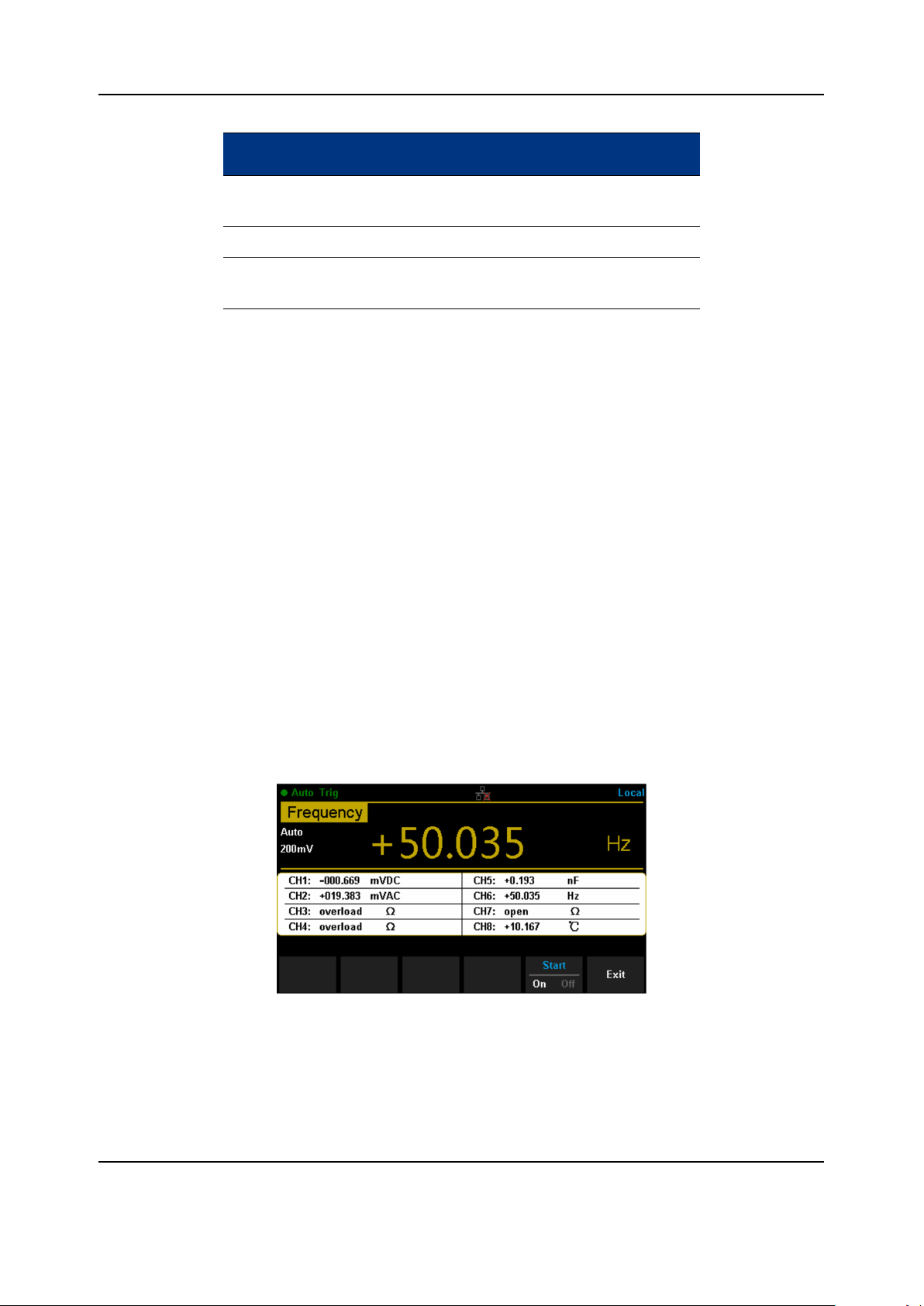

6. Start scan operation

Set the [Start] to on to start the scan operation

The upper part of the interface displays the function, range, and result of the current channel. The

table below records the measurement result of each channel.

7. Enter trend chart and statistics mode (optional operation)

Press ”Shift” and ”Math” to open trend chart and statistics function.

14

Page 25

T3DAQ1-16 User Manual

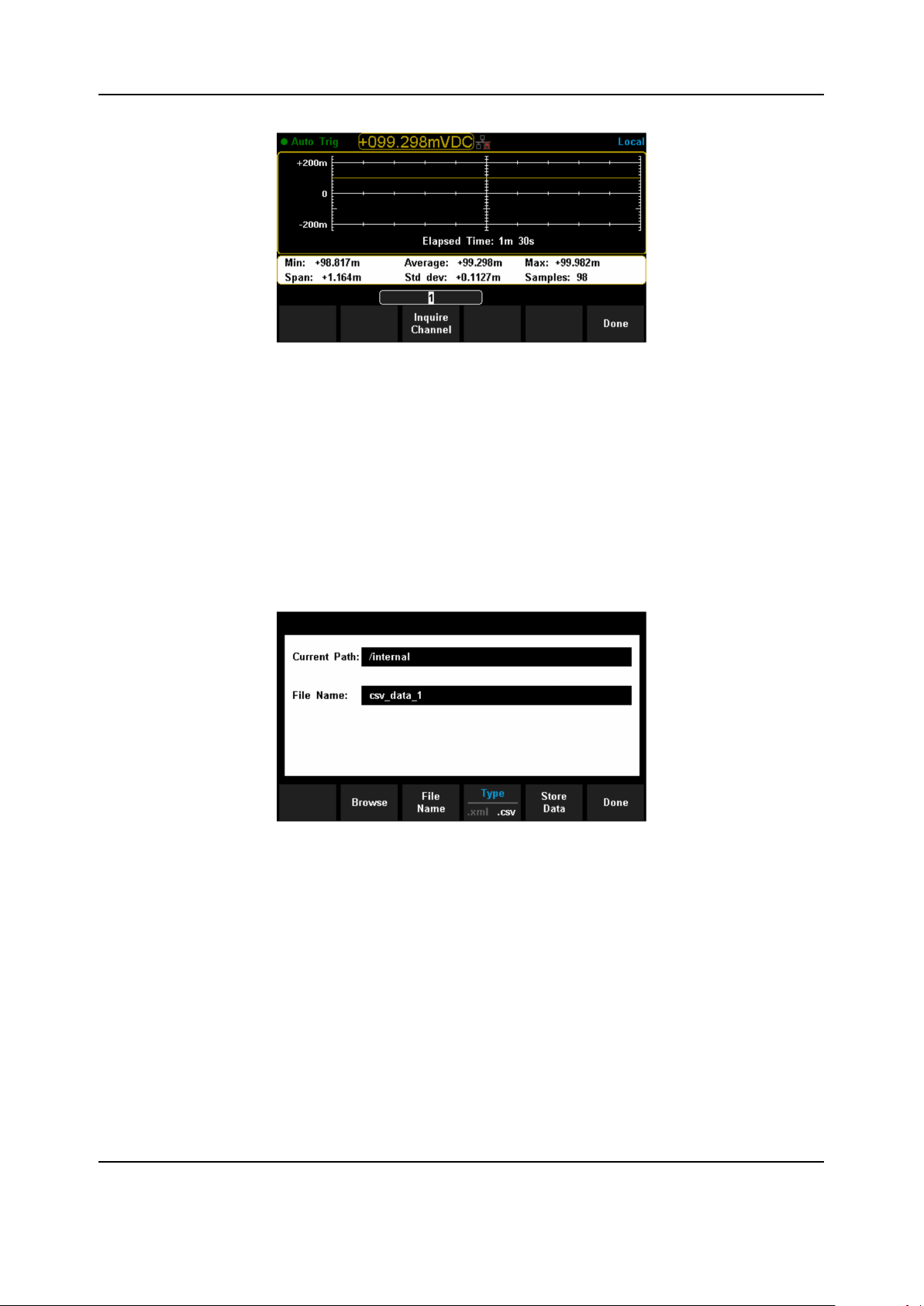

Set the [Inquire Channel] by direction keys and the interface displays the minimum, average, maximum, span, standard deviation, samples and trend chart of measurement results of the setting

channel during the scan operation. Press [Done] to return to higher level menu.

8. Stop scan operation

Set the [Start] to off to stop the scan operation. If the [Cycles] is set to manual, then the instrument

will stop scan when it reaches the cycle number

9. Store measurement data (optional operation)

Press ”Shift” and ”Dual”, then Select [Store/Recall] → [Store Settings] to enter the storage function

interface.

15

Page 26

T3DAQ1-16 User Manual

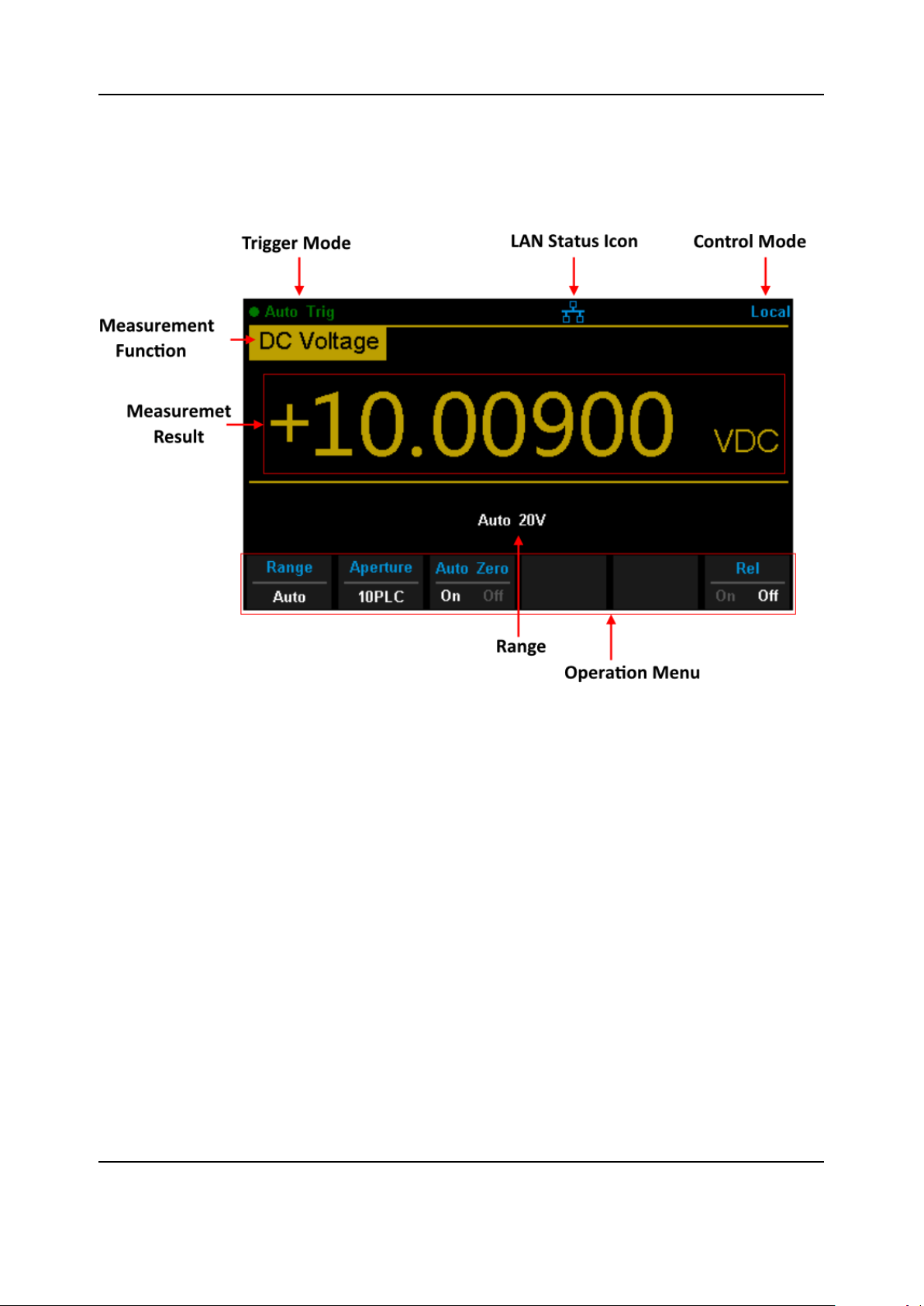

User Interface

16

Page 27

T3DAQ1-16 User Manual

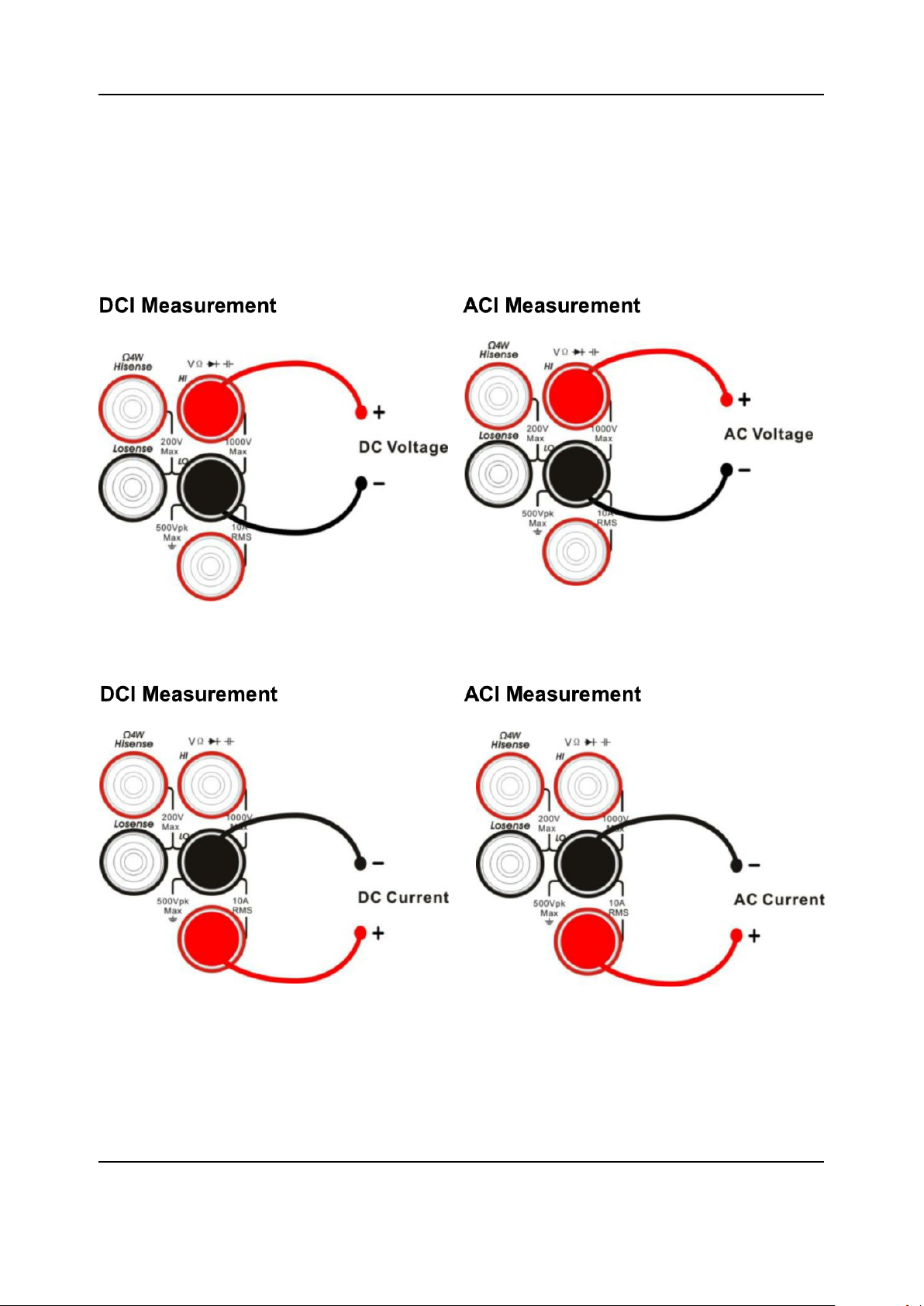

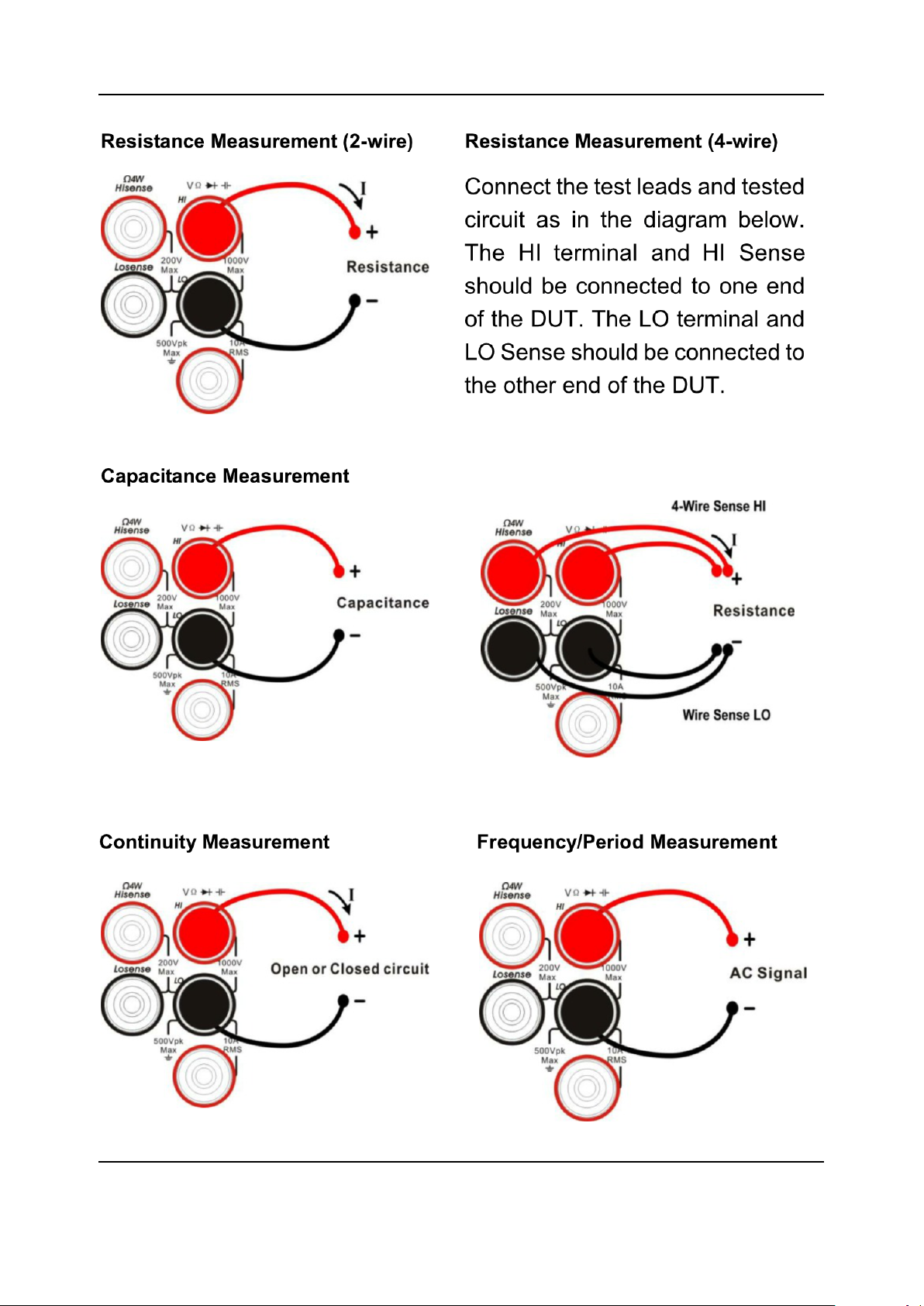

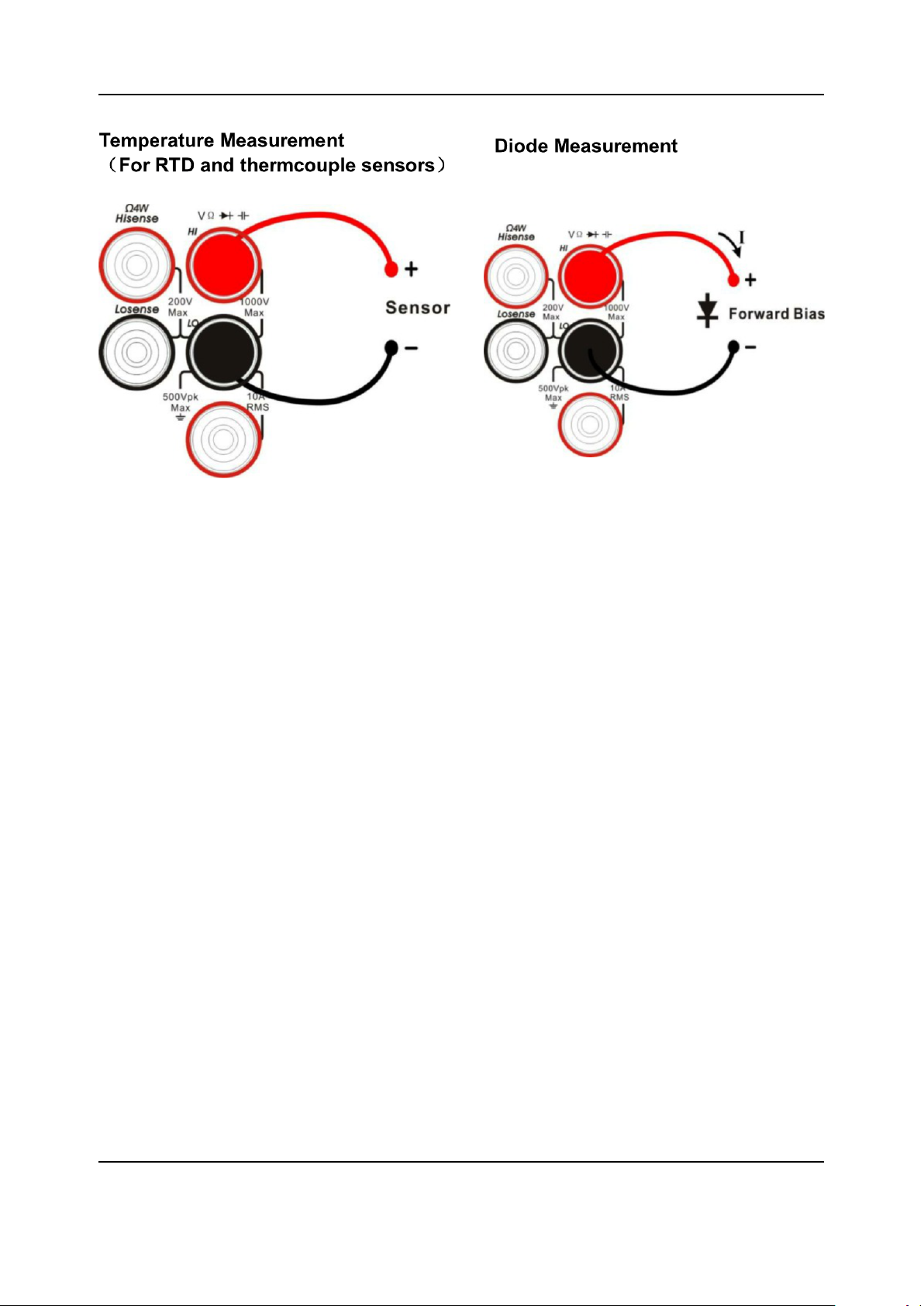

Measurement Connections

The DAQ is designed with many measurement functions. After selecting the desired measurement function, please connect the signal (device) under test to the DAQ according to the method

below. Do not switch the measurement function when measuring as it may cause damage to the

DAQ. For example, when the test leads are connected to the related current terminals, AC voltage

measurement should not be used.

17

Page 28

T3DAQ1-16 User Manual

18

Page 29

T3DAQ1-16 User Manual

19

Page 30

T3DAQ1-16 User Manual

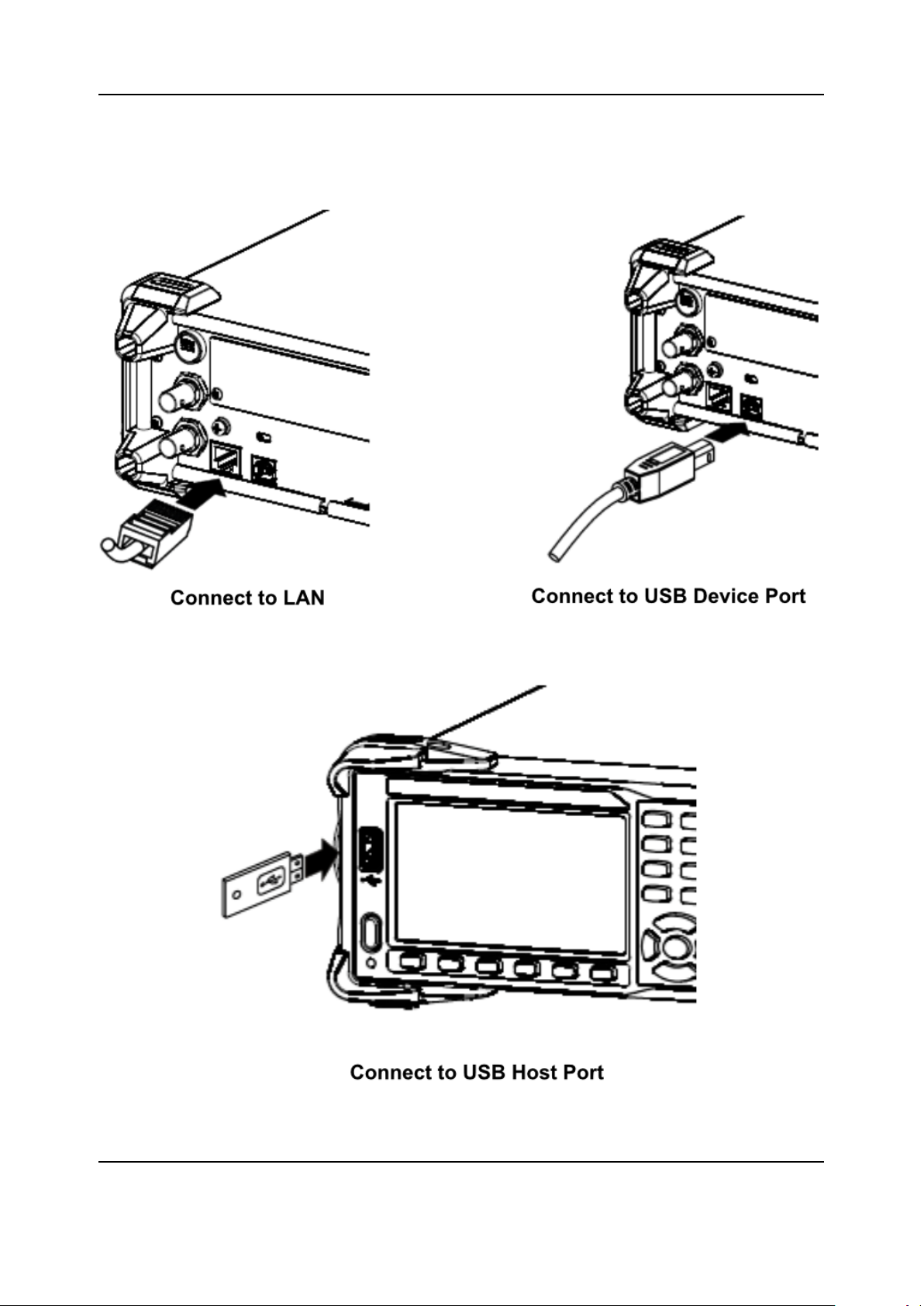

Connecting to USB and LAN Ports

The DAQ has LAN and USB I/O ports. Connect to the ports as in the diagrams below:

20

Page 31

T3DAQ1-16 User Manual

Using the Built-in Help System

To access the built-in help system, press [Shift] + [Acquire], then use the direction keys to choose

the help item you want. Finally, press [ OK ] to obtain help. The help listings are as follows:

1. Basic Measurements

2. Measuring Temperature

3. Measuring Capacitance

4. Math Function

5. Dual-display Function

6. Saving and Recalling Information

7. Optional Multiple Scan Card

8. The convention and Tips for Softkey

21

Page 32

Chapter 2

Function and Operation

Measurement Configuration

Most measurement parameters are user-defined. Changing a measurement parameter will change

the measurement precision and speed, as well as the input impedance. An appropriate measurement parameter based on the actual application will ensure faster measurement or higher measurement precision.

The default measurement configurations of the DAQ can ensure the accuracy of the measurement

results in most cases. Users can directly use these defaults for any measurement or modify the

parameters of the measurement function as required.

The parameters for different measurement functions differ, see the table below

Functions Parameters

DCV Range, Integration Time, DC impedance, Auto zero

DCV Range, AC filter

ACV Range, Integration Time, Auto zero

DCI Range, Integration Time, DC impedance, Auto zero

ACI Range, AC filter

OHM (2WR, 4WR) Range, Integration Time, Auto zero

CAP Range

CONT Short-circuit resistance

DIODE Breakover voltage

FREQ/PERIOD Gate time

TEMP N/A

22

Page 33

T3DAQ1-16 User Manual

Range

T3DAQ provides auto and manual range selecting modes. In auto mode, the DAQ selects a proper

range automatically according to the input signal. In manual mode, you can use the front panel

key or menu key to set the range. The auto mode can bring a lot of convenience for users while

the manual mode provides higher reading precision.

Method 1: use the front panel key to set the range.

Method 2: Use the menu key to select the range.

Enter the specific measurement function and select [Range] in the menu to show the range setting

options, as shown in the figure below, then press the menu operation key to activate the corresponding configuration.

Note:

1. “overload” will be displayed when the input signal exceeds the currently set range.

2. By default, the range is set to Auto at power-on or after a reset.

3. Auto mode is recommended if you are not sure about the measurement range in order to protect

the instrument and obtain accurate data.

4. The range of CONT measurement is fixed at 2kΩ.

23

Page 34

T3DAQ1-16 User Manual

Integration Time and Resolution

Integration time is the period during which the DAQ’s analog-to-digital (A/D) converter samples

the input signal for a measurement. The longer the integration time, the slower the measurement

speed will be and the higher the resolution will be. The shorter the integration time, the faster the

measurement will be and the lower the resolution will be. The integration time applies to DCV,

DCI, 2WR and 4WR measurements.

T3DAQ1-16 expresses the integration time by the number of power line cycles, the unit is PLC. The

DAQ automatically detects the input power line frequency at power-on. If the frequency is 50Hz,

the integration time can be set to 0.005PLC, 0.05PLC, 0.5PLC, 1PLC, 10PLC, 100PLC and the

default is 10PLC. If the frequency is 60Hz, the Integration time can be set to 0.006PLC, 0.06PLC,

0.6PLC, 1PLC, 10PLC, 100PLC and the default is 10PLC.

T3DAQ1-16 can make measurements with reading resolutions of 4½, 5½ and 6½ digits. It automatically selects a reading resolution according to the measurement settings.

1. In DCV, DCI and OHM measurements, press [Aperture] to set the integration time, as shown in

the diagram below (take DCV measurement for instance). The integration time affects the resolution.

The table below shows the relationship between reading resolution and integration time.

Resolution Integration time

4½ 0.005PLC/0.006PLC

0.05PLC/0.06PLC

5½ 0.5PLC/0.6PLC

6½ 1PLC

10PLC

100PLC

24

Page 35

T3DAQ1-16 User Manual

2. In ACV, ACI ,FREQ/PERIOD measurements, the resolution is fixed at 6½ digits.

3. In CAP measurements, the resolution is fixed at 4½.

4. The instrument always displays 2 digits after the decimal point in CONT measurement.

5. In DIODE measurements, the resolution is fixed at 5½.

6. In TEMP measurements, the resolution is fixed at 5½.

25

Page 36

T3DAQ1-16 User Manual

DC Impedance

DC impedance applies to DCV measurements. The default is “10MΩ”. In the range of 200mV, 2V

or 20V, you can choose “>10GΩ” to reduce the loading error on the measured object, caused by

the multimeter load.

In the range of 200 mV, 2 V or 20 V under DCV measurement, press [Input Z] in the menu to

perform the setting, as shown in the diagram below.

• 10MΩ: set the input impedance in all ranges to 10MΩ.

• 10GΩ: set the input impedances in ranges of 200mV, 2V and 20V to 10GΩ, while in ranges

200V and 1000V, the impedance is still 10MΩ.

26

Page 37

T3DAQ1-16 User Manual

Auto Zero

Auto zero (Auto Zero) applies to DCV, DCI, 2WR and 4WR measurements. Enter the specific

measurement function and press [Auto Zero] in the menu to perform the setting, as shown in

diagram below (take DCV measurement for instance).

• ON: the DAQ internally disconnects the input signal and measured circuit after each measurement and takes a zero reading. It then subtracts the zero reading from the preceding

reading (displaying the difference between the measurement value and zero value during the

measurement), in order to reduce the impact of offset voltage from input circuit on measurement result.

• OFF: disable the auto zero function.

27

Page 38

T3DAQ1-16 User Manual

AC Filter

AC filter applies to ACV and ACI measurements. It can optimize the low frequency accuracy

and minimize the AC settling time. T3DAQ1-16 provides three types of AC filters (>3Hz, >20Hz,

>200Hz).

The AC filter to be used is determined by the input signal frequency. You should generally select

the highest frequency filter whose frequency is less than that of the signal you are measuring, because the higher frequency filters result in faster measurements. For example, when measuring

a signal between 20Hz and 200Hz, use the 20Hz filter. If measurement speed is not an issue,

choosing a lower frequency filter may result in quieter measurements, depending on the signal

that you are measuring.

Press [Filter] in the menu of ACV or ACI measurement to show the setting options, as shown in

diagram below (take ACV measurement for instance).

Then press the menu operation key to activate the corresponding configuration.

28

Page 39

T3DAQ1-16 User Manual

Short-circuit Resistance

This function only applies to a continuity test. When the measured circuit has a resistance lower

than the short-circuit resistance, the circuit is considered as connected and the beeper sounds (if

sound is on). The default short-circuit resistance is 50Ω and the setting is stored in non-volatile

memory.

When continuity test is enabled, set the [Threshold] (equal to short-circuit resistance) using the

direction keys. The range is from 1Ω to 2000Ω .

29

Page 40

T3DAQ1-16 User Manual

Gate Time

Gate time (also called Aperture Time) applies to the FREQ / PERIOD function. It decides the resolution of a low-frequency measurement. The longer the gate time, the higher the resolution of the

low-frequency measurement and the slower the measurement, and vice versa.

In FREQ / PERIOD measurement, press [Gate Time] to show the setting options, as shown in

diagram below (take FREQ measurement for instance).

The gate time can be set to 1ms, 10ms, 100ms or 1s and the default is 100 ms. You can select a

desired gate time by pressing the corresponding softkey.

30

Page 41

T3DAQ1-16 User Manual

Basic Measurement Functions

To Measure DC Voltage

Range: 200mV, 2V, 20V, 200V, 1000V

Max Resolution: 100nV (in the range of 200mV)

Input Protection: 1000 V protection is available on all ranges and a 10% over-range for all

ranges except 1000 V range. If the reading exceeds the range, “overload” will be displayed.

Operating Steps:

1. Enable the DCV measurement

Press [DCV] on the front panel to enter the DC Voltage measurement interface, as shown in

Diagram below.

DC Voltage Measurement Interface

2. Make the connection

Connect the test leads with the measured signal by referring to “Measurement Connec-

tions”.

3. Set the range

Press [Range] to select a range for the measurement. You can also use the [+], [-], and

[Range] keys on the front panel to select the range. Auto (autorange) automatically selects

the range for the measurement based on the input. Autoranging is convenient, but it results

in slower measurements than using a manual range. Autoranging goes up a range of 110%

of the present range, and changes down a range when the measurement is below 10% of

the present range.

31

Page 42

T3DAQ1-16 User Manual

4. Set the Integration

Press [Aperture] and choose the number of power-line cycles (PLCs) to use for the measurement. Selecting 100PLC provides the best noise rejection and resolution, but the slowest

measurements.

5. Autozero setting

Press [Auto Zero] to enable or disable this function. Autozero provides the most accurate

measurements, but requires additional time to perform the zero measurement. With autozero enabled (On), the DAQ internally measures the offset following each measurement. It

then subtracts that measurement from the preceding reading. This prevents offset voltages

present on the DAQ’s input circuitry from affecting the measurement accuracy.

6. Specify the DC input impedance (Only for Manual 200mV, 2V and 20V ranges)

Press [Input Z] to set the DC resistance as “10M” (default value) or 10G”. Users can execute

the DC voltage measurement directly without modifying this parameter if they wish.

7. Set the relative value (Optional operation)

Press [Rel] to start or stop the Relative math function. When it is started, the reading displayed is a value which comes from the result of actual measurement value minus the relative

value that has been set. The default relative value is the measurement value when the function is started. (For details, please refer to “Math Functions” in Chapter 2).

8. Read the measurement value

The DAQ measures the input signal according to the current measurement settings and displays the measurement result on the screen.

9. Perform math operations (advanced)

You can perform math operations (Statistics, Limit, dBm, dB and REL) on every DCV measurement reading. For details, please refer to “Math Operations”.

10. Display the graph (advanced)

You can analyze the measurement data by using the “Bar Meter”, “Trend Chart” or “Histogram

display”. For details, please refer to “Display Mode”.

32

Page 43

T3DAQ1-16 User Manual

To Measure DC Current

Range: 200µA, 2mA, 20mA, 200mA, 2A, 10A

Max Resolution: 0.1nA (in the range of 200µA)

Input Protection: a 10A protection fuse is available in all ranges and a 10% over-range for

all ranges except 10A range. If the reading exceeds the range, “overload” will be displayed.

Operating Steps:

1. Enable the DCI measurement

Press [Shift] and [DCV] on the front panel to enter the DC Current measurement interface,

as shown in the diagram below.

2. Make the connection

Connect the test leads with the measured signal by referring to “Measurement Connec-

tions”.

3. Set the range

Press [Range] to select a range for the measurement. You can also use the [+], [-], and

[Range] keys on the front panel to select the range. Auto (autorange) automatically selects

the range for the measurement based on the input. Autoranging is convenient, but it results in

slower measurements than using a manual range. Autoranging goes up to 110% of a range

and changes up a range at 110% of the present range, and changes down a range when

below 10% of the present range.

4. Set the Integration Time

Press [Aperture] and choose the number of power-line cycles (PLCs) to use for the measurement. Selecting 100PLC provides the best noise rejection and resolution, but the slowest

measurements.

33

Page 44

T3DAQ1-16 User Manual

5. Autozero setting

Press [Auto Zero] to enable or disable this function. Autozero provides the most accurate

measurements but requires additional time to perform the zero measurement. With autozero enabled (On), the DAQ internally measures the offset following each measurement. It

then subtracts that measurement from the preceding reading. This prevents offset voltages

present on the DAQ’s input circuitry from affecting the measurement accuracy.

6. Set the relative value (Optional operation)

Press [Rel] to start or stop the Relative math function. When it is started, the reading displayed is a value which comes from the result of actual measurement value minus the relative

value that has been set. The default relative value is the measurement value when the function is started. (For details, please refer to “Math Functions” in Chapter 2.)

7. Read the measurement value

The DAQ measures the input signal according to the current measurement settings and displays the measurement result on the screen.

8. Perform math operations (advanced)

You can perform math operations (Statistics, Limit and REL) on every DCI measurement

reading. For details, please refer to ”Math Functions”.

9. Display the graph (advanced)

You can analyze the measurement data by using the “Bar Meter”, “Trend Chart” or “Histogram

display”. For details, please refer to “Display Mode”.

34

Page 45

T3DAQ1-16 User Manual

To Measure AC Voltage

Range: 200mV, 2V, 20V, 200V, 750V

Max Resolution: 100nV (in the range of 200mV)

Input Protection: 750V protection is available in all ranges and a 10% overrange for all

ranges except 750V range. If the reading exceeds the range, “overload” will be displayed.

Operating Steps:

1. Enable the ACV measurement

Press [ACV] on the front panel to enter the AC Voltage measurement interface, as shown in

the diagram below.

2. Make the connection

Connect the test leads with the measured signal by referring to “Measurement Connec-

tions”.

3. Set the range

Press [Range] to select a range for the measurement. You can also use the [+], [-], and

[Range] keys on the front panel to select the range. Auto (autorange) automatically selects

the range for the measurement based on the input. Autoranging is convenient, but it results

in slower measurements than using a manual range. Autoranging goes up a range at 110%

of the present range, and down a range when below 10% of the present range.

4. Set the filter

Press [Filter] and choose the filter for the measurement. The instrument provides three different AC filters, “>3Hz”, “>20Hz” and “>200Hz”. You should generally select the highest

frequency filter whose frequency is less than that of the signal you are measuring.

35

Page 46

T3DAQ1-16 User Manual

5. Set the relative value (Optional operation)

Press [Rel] to start or stop the Relative math function. When it is started, the reading displayed is a value which comes from the result of actual measurement value minus the relative

value that has been set. The default relative value is the measurement value when the function is started. (For details, please refer to “Math Functions” in Chapter 2.)

6. Read the measurement value

The DAQ measures the input signal according to the current measurement settings and displays the measurement result on the screen.

7. Perform the math operation (advanced)

You can perform math operations (Statistics, Limit, dBm, dB and REL) on every ACV measurement reading. For details, please refer to “Math Operations”.

8. Display the graph (advanced)

You can analyze the measurement data by using the “Bar Meter”, “Trend Chart” or “Histogram

display”. For details, please refer to “Display Mode”.

36

Page 47

T3DAQ1-16 User Manual

To Measure AC Current

Range: 200µA, 2 mA, 20 mA, 200 mA, 2A, 10A

Max Resolution: 0.1nA (in the range of 200µA)

Input Protection: 10A protection is available in all ranges and a 10% over-range for all

ranges except the 10A range. If the reading exceeds the range, “overload” will be displayed.

Operating Steps:

1. Enable the ACI measurement

Press [Shift] and [ACV] on the front panel to enter the AC current measurement interface, as

shown in the diagram below.

2. Make the connection

Connect the test leads with the measured signal by referring to “Measurement Connec-

tions”.

3. Set the range

Press [Range] to select a range for the measurement. You can also use the [+], [-], and

[Range] keys on the front panel to select the range. Auto (autorange) automatically selects

the range for the measurement based on the input. Autoranging is convenient, but it results

in slower measurements than using a manual range. Autoranging goes up a range at 110%

of the present range, and down a range when below 10% of the present range.

4. Set the filter

Press [Filter] and choose the filter for the measurement. The instrument provides three different AC filters, “>3Hz”, “>20Hz” and “>200Hz”. You should generally select the highest

frequency filter whose frequency is less than that of the signal you are measuring.

37

Page 48

T3DAQ1-16 User Manual

5. Set the relative value (Optional operation)

Press [Rel] to start or stop the Relative math function. When it is started, the reading displayed is a value which comes from the result of actual measurement value minus the relative

value that has been set. The default relative value is the measurement value when the function is started. (For details, please refer to “Math Functions” in Chapter 2.)

6. Read the measurement value

The DAQ measures the input signal according to the current measurement settings and displays the measurement result on the screen.

7. Perform the math operation (advanced)

You can perform the math operations (Statistics, Limit and REL) on every ACI measurement

reading. For details, please refer to “Math Functions” in Chapter 2.

8. Display the graph (advanced)

You can analyze the measurement data by using the “Bar Meter”, “Trend Chart” or “Histogram

display”. For details, please refer to “Display Mode”.

38

Page 49

T3DAQ1-16 User Manual

To Measure Resistance

Range: 200Ω, 2kΩ, 20kΩ, 200kΩ, 1MΩ, 10MΩ, 100MΩ

Max Resolution: 100µΩ (in the 200Ω range)

Input Protection: 1000 V protection is available in all ranges and a 10% over-range for all

ranges. If the reading exceeds the range, “overload” will be displayed.

T3DAQ1-16 provides 2-wire and 4-wire resistance measurements. When the measured resistance

is lower than 100kΩ, the 4-wire resistance measurement is recommended to reduce the measurement error caused by the test lead resistance and contact resistance between the probe and the

testing point. These two resistances should not be ignored when compared to the measured resistance.

Operating Steps:

1. Enable 2-wire/4-wire resistance measurement

Press [Ω2W] on the front panel to enter the 2-wire resistance measurement interface, as

shown in the below diagram.

39

Page 50

T3DAQ1-16 User Manual

Press [Shift] and [Ω2W] on the front panel to enter the 4-wire resistance measurement interface, as shown in the diagram below.

2. Make the connection

Connect the test leads with the measured signal by referring to “Measurement Connec-

tions”.

3. Set the range

Press [Range] to select a range for the measurement. You can also use the [+], [-], [Range]

and keys on the front panel to select the range. Auto (autorange) automatically selects the

range for the measurement based on the input. Autoranging is convenient, but it results in

slower measurements than using a manual range. Autoranging goes up a range at 110% of

the present range, and down a range when below 10% of the present range.

4. Set the Integration

Press [Aperture] and choose the number of power-line cycles (PLCs) to use for the measurement. Selecting 100PLC provides the best noise rejection and resolution, but the slowest

measurements.

5. Autozero setting

Press [Auto Zero] to enable or disable this function. Autozero provides the most accurate

measurements, but requires additional time to perform the zero measurement. With autozero enabled (On), the DAQ internally measures the offset following each measurement. It

then subtracts that measurement from the preceding reading. This prevents offset voltages

present on the DAQ’s input circuitry from affecting the measurement accuracy.

6. Set the relative value (Optional operation)

Press [Rel] to start or stop the Relative math function. When it is started, the reading displayed is a value which comes from the result of actual measurement value minus the relative

value that has been set. The default relative value is the measurement value when the function is started. (For details, please refer to “Math Functions” in Chapter 2.)

40

Page 51

T3DAQ1-16 User Manual

7. Read the measurement value

The DAQ measures the input signal according to the current measurement settings and displays the measurement result on the screen.

8. Perform the math operation (advanced)

You can perform the math operations (Statistics, Limit and REL) on every resistance measurement reading. For details, please refer to “Math Operations” in Chapter 2.

9. Display the graph (advanced)

You can analyze the measurement data by using the “Bar Meter”, “Trend Chart” or “Histogram

display”. For details, please refer to “Display Mode”.

41

Page 52

T3DAQ1-16 User Manual

To Measure Capacitance

Range: 2nF, 20nF, 200nF, 2µF, 20µF, 200µF, 2mF, 20mF, 100mF

Max Resolution: 1pF (in the range of 2nF)

Input Protection: 1000V protection is available in all ranges. If the reading exceeds the

range, “overload” will be displayed.

Operating Steps:

1. Enable the Capacitance measurement

Press [ ] on the front panel to enter the Capacitance measurement interface, as shown

in the diagram below.

2. Make the connection

Connect the test leads with the measured signal by referring to “Measurement Connec-

tions”.

3. Set the range

Press [Range] to select a range for the measurement. You can also use the [+], [-], [Range]

and keys on the front panel to select the range. Auto (autorange) automatically selects the

range for the measurement based on the input. Autoranging is convenient, but it results in

slower measurements than using a manual range. Autoranging goes up a range at 110% of

the present range, and down a range when below 10% of the present range.

4. Set the relative value (Optional operation)

Press [Rel] to start or stop the Relative math function. When it is started, the reading displayed is a value which comes from the result of actual measurement value minus the relative

value that has been set. The default relative value is the measurement value when the function is started. (For details, please refer to “Math Functions” in Chapter 2.)

42

Page 53

T3DAQ1-16 User Manual

5. Read the measurement value

The DAQ measures the input signal according to the current measurement settings and displays the measurement result on the screen.

6. Perform the math operation (advanced)

You can perform the math operations (Statistics, Limit and REL) on every capacitance measurement reading. For details, please refer to “Math Functions”.

7. Display the graph (advanced)

You can analyze the measurement data by using the “Bar Meter”, “Trend Chart” or “Histogram

display”. For details, please refer to “Display Mode”.

Remember to disconnect power to the DUT and short the legs or connections of the electrolytic capacitors before measuring the electrolytic capacitors.

43

Page 54

T3DAQ1-16 User Manual

To Measure Frequency or Period

Frequency (Period) Range: From 3Hz to 1MHz (from 0.33s to 1µs).

Input Signal Range: 200mV, 2V, 20V, 200V, 750V.

Input Protection: 750V protection is available in all ranges.

Operating Steps:

1. Enable the Freq/Period measurement

Press [Shift] and [ ] on the front panel, then select [Freq] to enter the frequency measurement interface, as shown in the diagram below.

Select [Period] to enter the period measurement interface, as shown in the diagram below.

2. Make the connection

Connect the test leads with the measured signal by referring to “Measurement Connec-

tions”.

44

Page 55

T3DAQ1-16 User Manual

3. Set the range

Press [Range] to select a range for the measurement. You can also use the [+], [-], [Range]

and keys on the front panel to select the range. Auto (autorange) automatically selects the

range for the measurement based on the input. Autoranging is convenient, but it results in

slower measurements than using a manual range. Autoranging goes up a range at 110% of

the present range, and down a range when below 10% of the present range.

4. Set the gate time

Press [Gate Time] and choose the measurement aperture of 1ms, 10ms, 100ms (default), or

1s.

5. Set the relative value (Optional operation)

Press [Rel] to start or stop the Relative math function. When it is started, the reading displayed is a value which comes from the result of actual measurement value minus the relative

value that has been set. The default relative value is the measurement value when the function is started. (For details, please refer to “Math Functions” in Chapter 2.)

6. Read the measurement value

The DAQ measures the input signal according to the current measurement settings and displays the measurement result on the screen.

7. Perform the math operation (advanced)

You can perform math operations (Statistics, Limit and REL) on every measurement reading.

For details, please refer to “Math Functions”.

8. Display the graph (advanced)

You can analyze the measurement data by using the “Bar Meter”, “Trend Chart” or “Histogram

display”. For details, please refer to “Display Mode”.

45

Page 56

T3DAQ1-16 User Manual

To Test Continuity

Test Current Source: 1mA

Max Resolution: 0.01Ω

Input Protection: 1000V Input Protection

Open-circuit Voltage:

Beep Threshold (short-circuit resistance): from 0Ω to 2000Ω

This function measures the resistance of the circuit with about 1mA current source. When the

measured resistance is lower than the short-circuit resistance (Threshold), the beeper sounds (if

the Beeper is on). Otherwise, “open” is displayed on the screen.

Operating Steps:

1. Enable the Cont measurement

Press [Cont] on the front panel to enter the Continuity test interface, as shown in the diagram

below.

<8V

2. Make the connection

Connect the test leads with the measured signal by referring to “Measurement Connec-

tions”.

3. Set the short-circuit resistance (Threshold)

Enter a desired value using the direction keys. The range is from 0Ω to 2000Ω and the default

is 50Ω.

4. Read the measurement value

The DAQ measures the input signal according to the current measurement settings and displays the measurement result on the screen.

46

Page 57

T3DAQ1-16 User Manual

5. Perform the math operation (advanced)

You can perform math the operation (Statistics, Limit) on every measurement reading. For

details, please refer to “Math Functions”.

6. Display the graph (advanced)

You can analyze the measurement data by using the “Bar Meter”, “Trend Chart” or “Histogram

display”. For details, please refer to “Display Mode”.

Before testing continuity remember to disconnect the DUT power and discharge all of the

DUT capacitors, to avoid damage to the DAQ.

47

Page 58

T3DAQ1-16 User Manual

To Test Diode

Test Current Source: 1mA

Voltage Measurement Range: 0V 4V

Max Resolution: 10µV

Input Protection: 1000V Input Protection

Open-circuit Voltage: <8V

This function measures the forward voltage drop on the diode. When the voltage is lower than the

Threshold, the beeper sounds (if the beeper is on).

Operating Steps:

1. Enable the Diode measurement

Press [Shift] and [Cont] on the front panel to enter the Diode test interface, as shown in the

diagram below.

2. Make the connection

Connect the test leads with the measured signal by referring to “Measurement Connec-

tions”.

3. Set the Threshold

Enter a desired value using the direction keys. The range is from 0V to 4V and the default is

2V.

4. Read the measurement value

The DAQ measures the input signal according to the current measurement settings and displays the measurement result on the screen. If the reading exceeds the threshold, “open”

will be displayed.

48

Page 59

T3DAQ1-16 User Manual

5. Evaluate the results of a measurement

Reverse the probes and measure the forward voltage drop on the diode again. Evaluate the

diode according to the following rules:

• If the DAQ displays “open” when in the reverse bias model, it indicates that the diode is

normal.

• If the DAQ shows voltage about 0V and the instrument beeps persistently when in forward and reverse bias model, it indicates that the diode is short

• If the DAQ shows “open” when in the forward and reverse model, it indicates that the

diode is open.

6. Perform the math operation (advanced)

You can perform the math operation (Statistics, Limit) on every measurement reading. For

details, please refer to “Math Functions”.

7. Display the graph (advanced)

You can analyze the measurement data by using the “Bar Meter”, “Trend Chart” or “Histogram

display”. For details, please refer to “Display Mode”.

Before testing continuity remember to disconnect the DUT power and discharge all of the

DUT capacitors, to avoid damage to the DAQ.

49

Page 60

T3DAQ1-16 User Manual

To Measure Temperature

T3DAQ1-16 can directly measure the temperature using TC (Thermocouple) and THERM (Thermistor) sensors.

Operating Steps:

1. Enable the Diode measurement

Press on the front panel to enter the Temperature measurement interface, as shown in the

diagram below.

2. Make the connection

Connect the test leads with the measured signal by referring to “Measurement Connections”.

3. Set the type of sensor

Press [Load] and use the direction keys to choose a desired temperature sensor. Press [Define] to view the configurations. Then press [Read] to apply the current temperature sensor

configurations.

50

Page 61

T3DAQ1-16 User Manual

4. Set the display mode

Press [Display] to choose the display mode. The DAQ supports three display modes: Temperature Value, Measured Value and All (Temperature Value and Measured Value will be

shown on the display together).

5. Set the unit of temperature

Press [Units] to choose the unit of temperature. The DAQ supports three units: °C ,°F , °K.

6. Set the relative value (Optional operation)

Press [Rel] to start or stop the Relative math function. When it is started, the reading displayed is a value which comes from the result of actual measurement value minus the relative

value that has been set. The default relative value is the measurement value when the function is started. (For details, please refer to “Math Functions” in Chapter 2.)

7. Read the measurement value

The DAQ measures the input signal according to the current measurement settings and displays the measurement result on the screen.

51

Page 62

T3DAQ1-16 User Manual

8. Perform the math operation (advanced)

You can perform the math operation (Statistics, Limit and REL) on every measurement reading. For details, please refer to “Math Functions”.

9. Display the graph (advanced)

You can analyze the measurement data by using the “Bar Meter”, “Trend Chart” or “Histogram

display”. For details, please refer to “Display Mode”.

52

Page 63

T3DAQ1-16 User Manual

Dual-display Function

Dual-display function is used to improve the test and measurement functions. Press [Dual] to open

the Dual-display function and the upper right corner will show “Dual”. Now press a function key if

this function can be used as the second display, it will be displayed in the second Display area.

The Main Display will display the function that is selected before the Dual-display function is turned

on. All the available combinations are listed in the table below (shade is available).

For example, press [DCV]→ [Dual]→ [ACV] to enter the following interface.

Instruction:

1. If the same measurement function is used in both Main and second Display.

• The readings in both displays will update at the same time.

• If math function (dBm, dB) is used in Main Display, when opening the second Display,

the math operation will be stopped automatically. The second Display will show the

same measurement result as Main Display.

• If math function (Statistics, Limits, Relative) is used in Main Display, when starting the

second Display, the result will still be shown in the Main Display, and the second Display

will show the same measurement result as the Main Display.

2. If different measurement functions are used in both Main and the second Display.

53

Page 64

T3DAQ1-16 User Manual

• The readings in both displays will update alternately.

• If math function (dBm, dB) is used in Main Display, when opening the second Display,

the math operation will be stopped automatically. The second Display will show the

second selected function normally.

• If math function (Statistics, Limits, Relative) is used in Main Display, when opening the

second Display, the result will still be shown in the Main Display and the second Display

will show the second selected function normally.

3. If Temperature function is used in Main Display, set the display mode ( [Temp]→[Display]→[All]).

Then the result will be shown in the Main Display and the current measurement value is shown

in the second Display.

4. Auto Range is adopted by the second Display. If the same measurement function is used in

both displays, so does the range.

5. Measured data in the second Display cannot be saved into “History”.

54

Page 65

T3DAQ1-16 User Manual

Utility Function

The Utility function enables users to set up system parameters and interface parameters of the

DAQ.

Press [Shift] and [Dual] to enter the operating menu of Utility function, as the following diagram

shows.

Function Menu Description

Store/Recall Store or recall state files.

Manage File Create a new file, copy, rename or delete a file.

I/O Config Configure LAN.

Test/Admin Provide board test function.

System Setup Configure instrument’s user settings.

55

Page 66

T3DAQ1-16 User Manual

Store and Recall

The Store/Recall function enables users to store and recall the instrument state and data files in

the local storage as well as in the USB storage. After entering the function menu of Utility, press

[Store/Recall] to enter the interface as shown in the diagram below.

Function Menu Description

Store Settings Store state or data files.

Recall settings Recall state files.

Power On Select the state that is loaded at power-up.

Delete all the files stored in local storage and restore the

Security Erase

Set to Defaults Restore the instrument to factory default state.

Done Return to the higher level menu.

instrument to factory default state.

56

Page 67

T3DAQ1-16 User Manual

Store Settings

Store settings allows you to save the system configuration (as .xml) or measurement data (as .csv)

into the internal memory or an external USB storage device. After entering into the function menu

of Store/Recall, press [Store Settings] to enter the following interface.

Table below shows the different functions available.

Function Menu Settings Description

Browse Choose the location that file will be saved.

File Name Input the file name.

Type .xml/.csv Choose the type of file that will be saved.

Store Data Store the specified file.

Done Return to the higher level menu.

57

Page 68

T3DAQ1-16 User Manual

Operating Steps:

1. Set the storage directory

Press [Browse] to enter the following interface, then use the direction keys or menu operation

keys to choose the storage directory. Press [Select] to set the current directory as storage

location and Return to the higher level menu.

2. Set the file name

Press [File Name] to enter the following interface and input the name of the stored file.

The method of inputting a file name:

• Press direction keys to select a desired character in the input area.

• Press “OK” key on the front panel to input selected char in the input area.

• Press [Clear All] to clear all input chars.

• Press [Delete Char] to delete the letter on which the cursor is currently placed.

• Press [Previous Char] to move the cursor in the file name area to the previous char.

• Press [Next Char] to move the cursor in the file name area to the next char.

• Press [Done] to save the current file and return to the higher level menu.

58

Page 69

T3DAQ1-16 User Manual

• Press [Cancel] to cancel the current operation and return to the higher level menu.

3. Set the type of stored file

Press [Type] to set the type of stored file.

• .xml: save the current system configuration as an “.xml” file.

• .csv: save the current measurement result as a “.csv” file.

4. Save the file

Press [Store Data] to store the specified file.

5. Exit

Press [Done] to return to the higher level menu.

59

Page 70

T3DAQ1-16 User Manual

Recall Settings

Recall settings allows you to read the system configuration from the internal memory or an external

USB storage device. After entering the function menu of Store/Recall, press [Recall Settings] to

enter the following interface.

Use direction keys or menu operation keys to choose the state file with the suffix “.xml”.

• Press [Select] to read the file and restore the instrument to a specified state.

• Press [Cancel] to return to higher level menu.

Power On

Select a system configuration to be used at power-on from “Default” and “Last” (configuration at

last power-off). The setting will be available at the next power-on.

Security Erase

Press [Security Erase], the instrument will display a prompt message “Are you sure you want to

delete all stored files?”. Press [Yes] to confirm. The instrument will delete all the files stored in

local storage and restore the instrument to the factory default state.

Set to Defaults

Press [Set to Defaults] and the instrument will be restored to factory default state.

60

Page 71

T3DAQ1-16 User Manual

Manage File

The Manage Files function allows you to create, copy, delete, and rename files and folders in the

instrument’s internal flash memory or on a USB drive attached to the front panel. It also allows you

to capture the current screen to a bitmap (*.bmp) file. After entering the function menu of Utility,

press [Manage File] to enter the interface as shown in the diagram below.

Press [Action] and select [Folder], [Capture Display], [Copy], [Rename] or [Delete] to do the corresponding operation.

• Folder – To create a folder, Browse to the internal or external location for the folder, press

File Name, enter a folder name and press Done. Press Create Folder > Done.

• Capture Display – To save a screen capture, Browse to the internal or external location for

the screen capture. Press File Name, enter a name and press Done. Press Save Screen >

Done.

• Copy – To copy a file or folder, press Copy. Browse to the folder or file to be copied and press

Select. Press Copy Path and select an internal or external path for copying. Press Perform

Copy > Done.

• Rename – To rename a file or folder, press Rename. Browse to the folder or file to be renamed

and press Select. Press New Name, enter a new name and press Done. Press Perform

Rename > Done.

• Delete – To delete a file or folder, press Delete and Browse to the folder or file to delete.

Press Select > Perform Delete > Done.

61

Page 72

T3DAQ1-16 User Manual

I/O Configuration

Press [I/O Config] to enter the following interface and set up the parameters.

LAN Settings

The DAQ enables users to operate the instrument remotely by LAN interface and store or recall

internet settings. You can look over current LAN settings and set up an IP address and subnet

mask. After entering into the function menu of Utility, press [I/O Config]. Select [On ]→[LAN Settings]→[Modify Settings] to enter the following interface.

Function Menu Description

IP Address Set up IP address.

Subnet Mask Set up subnet mask.

Gateway Set up gateway.

Cancel current operation and return to the higher level

Cancel

Done Save all changes and return to the higher level menu.

menu.

62

Page 73

T3DAQ1-16 User Manual

Board Test

T3DAQ1-16 provides self-test functions, including Key Test, LCDTest, Beeper Test and Chip Test.

Operating Steps:

1. Press [Shift] and [Dual], then choose [Test/Admin]→[Board Test] to enter the following interface.

Function Menu Description

Keyboard Test the instrument’s keys.

LCD Test the instrument’s LCD screen.

Beeper Test the instrument’s beeper.

Chip Test the instrument’s chips.

Done Return to the higher level menu.

63

Page 74

T3DAQ1-16 User Manual

2. Test the keys (select Keyboard).

Select [Key] to enter the key test interface, as displayed in the diagram below. The onscreen rectangle shapes represent the keys on the front panel. Test all keys and knobs and

you should also verify that all the back lit buttons illuminate correctly.

Before testing the keys the key shapes on the screen will be displayed in a blue color.

The on screen keys and knobs will change to a green color when tested. Press [Done]

to exit the test.

3. Test the LCD screen.

Select [LCD] to enter the screen test interface, the screen shows the message: “Press

‘Change’ to change. Press ‘Done’ to exit”. Press [Change] to start the test and observe

if the screen has changed color or other display errors as shown in the diagram below.

NOTE:

• Press [Change] to change the color of the screen. There are three colors: red,

blue and green.

• Press [Done] to exit the test.

64

Page 75

T3DAQ1-16 User Manual

4. Test the beeper.

Press [Beeper] to test the beeper. Under regular circumstances, press [Beeper] one time

and the instrument will beep one time.

5. Test the chips.

Press [Chip]→[Start] to enter chip test interface, as shown in the diagram below.

NOTE:

• If the test is passed, the corresponding result shows “pass”.

• If the test is failed, the corresponding result shows “fail”.

6. Press [Done] to exit the board test.

65

Page 76

T3DAQ1-16 User Manual

Firmware Update

The software of the DAQ can be updated directly via a USB flash drive, updating the current software version to the desired software version.

Operating Steps:

1. Copy the update file to the USB flash drive.

2. Insert the USB flash drive to the USB host interface on the front panel of the DAQ.

3. Press [Shift]→ [Dual]→ [System Setup]→ [Firmware Update], then press [Browse] and select

the update file. Next, press [Update]→ [Yes] to start updating the system software.

4. On completion of the update, the screen will show the message: “Firmware Update Done!”

Then you can remove the USB flash drive away.

5. Restart the DAQ and check the version information. Press [Shift]→ [Dual]→ [System Setup]→

[System Info] to check if the software and hardware version has updated. If not, and the update has failed, you will need to update once more following the above operating steps.

6. After checking, press [Done] to exit the system information interface.

NOTE:

Do not disconnect the power or turn off the instrument while the instrument is updating.

66

Page 77

T3DAQ1-16 User Manual

System Setup

Press [Shift] and [Dual], then select [System Setup] to enter the following interface.

Function Menu Description

Language Select the display interface language.

Firmware Update Update software version.

Screen Setup the screen protection function.

System Info View system information.

Done Return to the higher level menu.

1. Select language.

The DAQ supports two languages, English and Chinese. Press [Language] to select the

Language of the menu.

2. Set up the screen protection timer.

Press [Screen] to set screen protection as 1 Min, 5 Mins, 15 Mins, 30 Mins,1 Hour, 2 Hours

or 5 Hours according to different demands. Activate the screen saver program and screen

saver will be on if no action is taken within the time that you have selected. Press any button

to resume.

3. View system information.

Press [System Info] to view system information, including start-up times, software version,

hardware version, production ID and serial number, as shown in the following diagram.

67

Page 78

T3DAQ1-16 User Manual

68

Page 79

T3DAQ1-16 User Manual

Acquire

Sampling is a process of acquiring and digitizing a signal. The optional Trigger methods of the DAQ

include Auto Trigger, Single Trigger and External Trigger. Press [Acquire] to enter the interface

shown as the following diagram:

Function Menu Description

Trg Src Set the source of trigger.

Slope Set the slope polarity of external trigger.

Delay Set the delay.

Samples/Trigger Set the number of samples per trigger.

Set the polarity output pulse signal when the sampling signal

VMC Out

is finished.

69

Page 80

T3DAQ1-16 User Manual

Auto Trigger

Auto Trigger parameters that need to be set up include delay, samples/trigger and VMC out.

Operating Steps:

1. Press [Acquire], then select [Trg Src]→[Auto] or press [Run/Stop] on the front panel directly

to enable Auto Trigger.

2. Set the delay.

Delay is the waiting time after the trigger signal is sent out and before the acquiring starts.

Press [Delay] to select Auto or Manual mode. When choosing Manual mode, the Left and

Right keys are used to select the numerical digit to adjust. The Up and Down keys are used

to change the selected digit value.

3. Set the number of samples per trigger.

Press [Samples/Trigger] to set the sample count. Left and Right keys are used to switch the

number of a numerical value, Up and Down keys are used to change the selected value.

Sample Count

• Sample Count indicates the number of samples taken when the DAQ receives a

Single Trigger event (samples per trigger).

• The range of sampling points should be between 1 and 599999999.

• The default value of the Sample Count is 1.

4. Set the VMC Out.

The DAQ outputs a pulse signal through the VM COMP interface on the rear panel after the

sampling signal is finished. Press [VMC Out] to choose Positive or Negative polarity.

70

Page 81

T3DAQ1-16 User Manual

Single Trigger

Single Trigger parameters that need to be set up include delay, samples/trigger and VMC out.

Operating Steps:

1. Press [Acquire], then select [Trg Src]→ [Single] or press [Single] on the front panel directly

to enable Single Trigger.

2. Set the delay.

Press [Delay] to select Auto or Manual mode.

3. Set the number of samples or trigger.

Press [Samples/Trigger] to set sample count.

4. Set the VMC Out.

The DAQ outputs a pulse signal through the VM COMP interface on the rear panel after the

sampling signal is finished.

Press [VMC Out] to choose Positive or Negative polarity.

71

Page 82

T3DAQ1-16 User Manual

External Trigger

The external trigger signal will be input via EXT TRIG interface on the rear panel. External trigger

parameters that need to be set up include delay, samples/trigger, slope and VMC out.

Operating Steps:

1. Press [Acquire], then select [Trg Src]→ [Ext] to enable the External Trigger.

2. Set the polarity of slope.

Press [Slope] to choose Positive or Negative polarity.

3. Set the delay.

Press [Delay] to choose Auto or Manual mode.

4. Set the number of samples or trigger.

Press [Samples/Trigger] to set sample count.

5. Set the VMC Out.

In External Trigger mode, the DAQ could output a pulse signal through the VM COMP interface on the rear panel after the sampling signal is finished.

72

Page 83

T3DAQ1-16 User Manual

Help System

T3DAQ1-16 provides a powerful built-in help system. You can recall help information at any time

while using the instrument. You also can get a functionality help for every button on the front panel