Page 1

HDO9000

Oscilloscopes

Getting Started Guide

Page 2

II

700 Chestnut Ridge Road

Chestnut Ridge, NY 10977

1.800.5.LECROY • teledynelecroy.com

HDO9000 Oscilloscopes

Getting Started Guide

© 2019 Teledyne LeCroy, Inc. All rights reserved.

Unauthorized duplication of Teledyne LeCroy documentation materials is strictly prohibited. Customers are permitted to

duplicate and distribute Teledyne LeCroy documentation for internal educational purposes.

Teledyne LeCroy is a trademark of Teledyne LeCroy, Inc. Other product or brand names are trademarks or requested

trademarks of their respective holders. Information in this publication supersedes all earlier versions. Specifications are

subject to change without notice.

930536-00 Rev A,

January, 2019

930536-00 Rev A

Page 3

Welcome

Thank you for buying a Teledyne LeCroy product. We’re certain you’ll be pleased with the detailed features unique to our instruments. This guide is

intended to help you set up an HDO9000 oscilloscope and learn some basic operating procedures, so you're quickly working with waveforms.

• See the MAUI Oscilloscopes Remote Control and Automation Manual for comprehensive information on remote control of HDO9000.

• See the HDO9000 Oscilloscopes Operator’s Manual for detailed information on the operational features of the HDO9000.

Both manuals can be downloaded from the Oscilloscope Manuals page on our website at: teledynelecroy.com/support/techlib

Introduction

Introducing HDO9000 Oscillosocopes 2

Safety 2

Overview

Front of Oscilloscope 4

Powering On/Off 5

Side of Oscilloscope 6

Connecting to External Devices/Systems 7

Back of Oscilloscope 8

Front Panel 9

Touch Screen Display 10

Basics

Changing the Display 12

Working with Traces 14

MAUI with OneTouch 15

Vertical (Channel) 20

Digital 22

Horizontal (Timebase) 24

Zoom 27

Triggers 28

Cursors 30

Measurements & Statistics 31

Math 32

Memories (Reference Waveforms) 33

Decode 34

WaveScan 35

Spectrum Analyzer 36

History Mode 37

Saving and Sharing Data 38

Maintenance

Software Options 39

Cleaning 40

Language Selection 40

Calibration 40

Firmware Updates 41

Switching Windows Users 41

Service 42

Support 43

Reference

Windows License Agreement 43

Warranty 43

Certifications 44

HDO9000 Getting Started Guide

1

Page 4

INTRODUCTION

Introducing HDO9000

HDO9000 high definition oscilloscopes leverage HD1024 technology to

deliver 10 bits of resolution on up to 4 GHz of bandwidth. The large, bright,

15.4” capacitive touch screen combined with the MAUI with OneTouch

user interface results in an unsurpassed user experience. Equipped with

a 40 GS/s sample rate and an extensive toolbox, the HDO9000 ensures

uncompromised performance when debugging in high definition.

HD1024

HD1024 high definition technology enables dynamic reconfiguration

of the ADC to achieve 10 bits of vertical resolution. By automatically

determining the best ADC configuration for each measuring condition,

the HDO9000 always provides the optimal resolution. HD1024 plus a low

noise system architecture delivers superior signal fidelity up to 4 GHz,

resulting in ENOB in excess of 7 bits.

MAUI with OneTouch

MAUI with OneTouch introduces a new paradigm for oscilloscope user

experience. Dramatically reduce set up time with revolutionary drag-anddrop actions, and use familiar touch screen gestures like pinch, swipe and

flick to intuitively interact with the instrument.

Mixed Signal Option

The 16 integrated digital channels and tools designed to view, measure

and analyze both analog and digital signals enable fast debugging of

mixed signal designs.

Comprehensive Analysis Tools

HDO9000 has the most comprehensive trigger, decode, math, measure

and application toolsets available in its class. Apply statistical and

frequency analysis tools to enhance understanding of complex behaviors.

WaveScan® lets you to search acquisitions using more than 20 criteria,

while LabNotebook concisely documents and stores your results.

Key Specifications

Detailed specifications are on the product datasheet at teledynelecroy.com.

Bandwidth 1 GHz to 4 GHz

Analog Channels 4

Memory per Channel 64 Mpts/ch 4-channel operation

Sample Rate 10 GS/s 4-channel operation

Vertical Resolution 10-bit

Digital Channels (optional) 16

Digital Sample Rate 1.25 GS/s

Min. Detectable Pulse Width 2 ns

Max. Input Frequency 250 MHz

128 Mpts/ch 2-channel operation

20 GS/s 2-channel operation

Safety

Observe generally accepted safety practices in addition to the precautions

specified here.

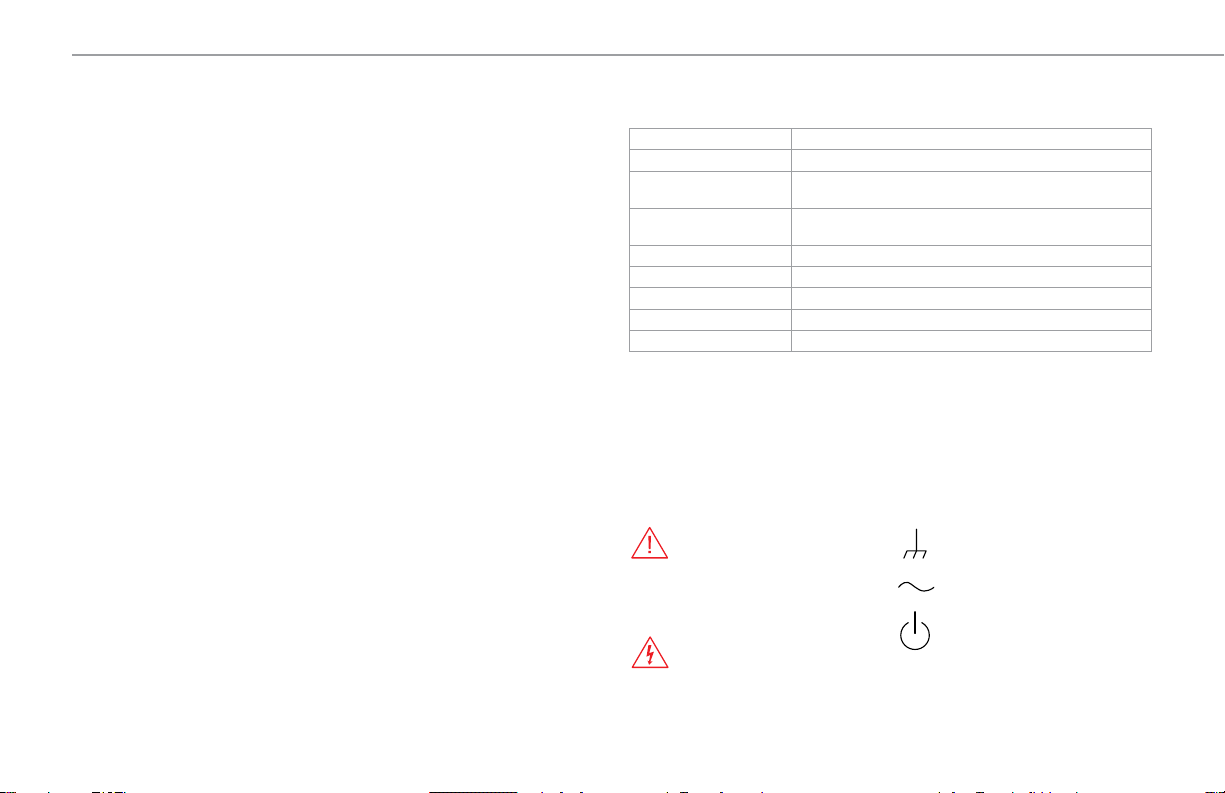

Symbols

CAUTION of potential damage

to equipment, or WARNING of

potential bodily injury. Refer to

manual. Do not proceed until the

information is fully understood

and conditions are met.

WARNING. Risk of electric shock

or burn.

Frame or chassis terminal

Alternating current

Power On/Standby

2

930536-00 Rev A

Page 5

SAFETY

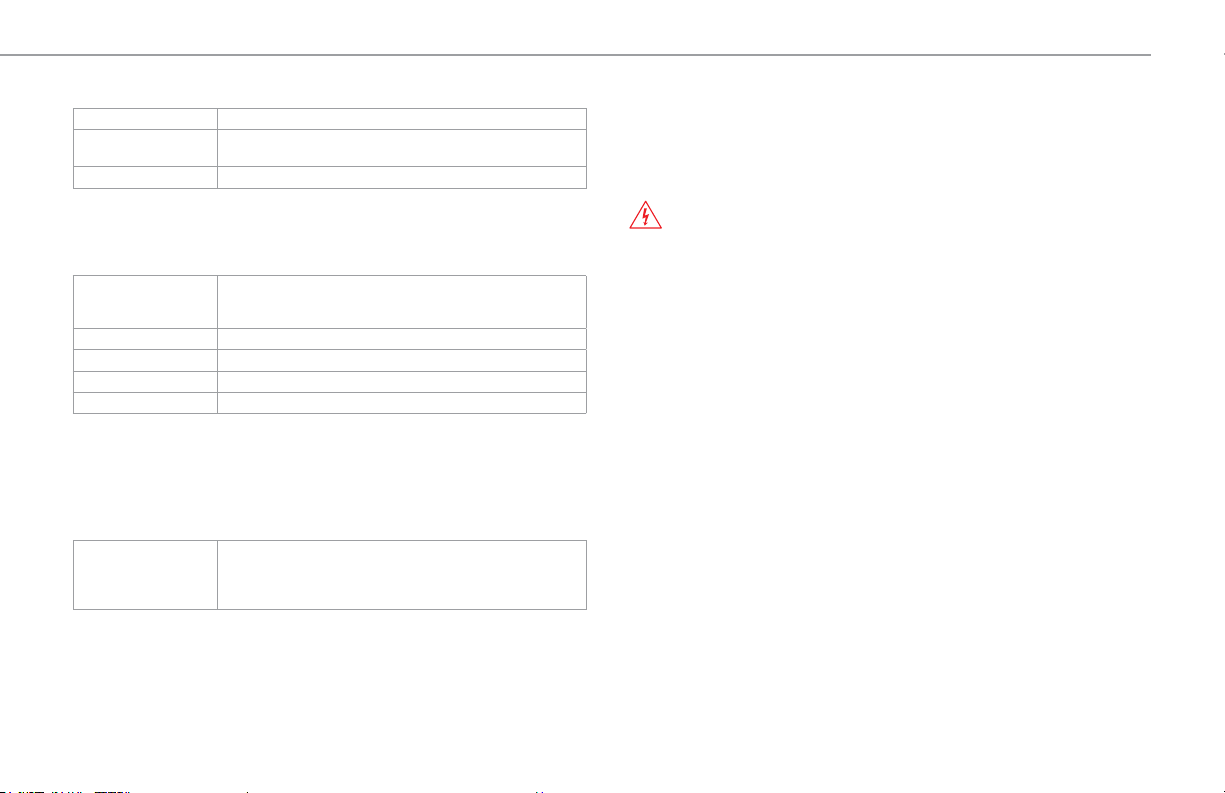

Operating Environment

Temperature 5 °C to 40 °C

Humidity Maximum RH 90% (non-condensing) up to 31 °C

Altitude Up to 10,000 ft (3,048 m) at or below 30 °C

decreasing linearly to RH 50% at 40 °C

Power

AC Power 100-240 VAC (±10%) at 50/60 Hz (±10%) or

Consumption

Nominal 415 W / 415 VA

Maximum* 500 W / 500 VA

Standby 15 W

* All PC peripherals and active probes connected to four channels.

100-120 VAC (±10%) at 400 Hz (±5%)

Automatic AC Voltage Selection

Measuring Terminal Ratings

Ratings apply to inputs C1-C4 and Ext In.

Maximum Input Voltage 50 Ω coupling ≤ 5 Vrms

Measuring terminals have no rated measurement category (CAT) per IEC/EN 61010-1:2010.

Measuring terminals are not intended to be connected directly to supply mains.

1 MΩ coupling ≤ 400 Vpk max. (Peak AC ≤ 10 kHz + DC)

derating at 14 dB/decade from 10 kHz to 2 MHz,

10 Vpk max. above 2 MHz

Precautions

Use proper power cord. Use only the power cord shipped with this

instrument and certified for the country of use.

Maintain ground.

instrument. Connect line cords only to outlets with safety ground contacts.

WARNING. Interrupting the protective conductor inside or outside

the oscilloscope, or disconnecting the safety ground terminal,

creates a hazardous situation. Intentional interruption is prohibited.

Connect and disconnect properly. Do not connect/disconnect probes or

test leads while they are connected to a live voltage source.

Observe all terminal ratings. Do not apply a voltage to any input that

exceeds the maximum rating of that input. Refer to the markings next to

the BNC terminals for maximum allowed values.

Use only within operational environment listed. Do not use in wet or

explosive environments.

Use indoors only.

Keep product surfaces clean and dry.

Do not block the cooling vents. Leave a minimum six-inch (15 cm) gap

between the instrument and the nearest object. Keep the underside clear

of papers and other objects.

Exercise care when lifting and carrying. Unplug and use the built-in

carrying handle to move the instrument.

Do not remove the covers or inside parts. Refer all maintenance to

qualified service personnel.

Do not operate with suspected failures. Check body and cables regularly.

If any part is damaged, cease operation immediately and sequester the

instrument from inadvertent use.

The AC inlet ground is connected to the frame of the

HDO9000 Getting Started Guide

3

Page 6

OVERVIEW

Front of Oscilloscope

A. Capacitive Touch Screen Display

B. Front Panel

4

930536-00 Rev A

A

B

C. Power On/Standby Button

D. Input Channels 1-4

E. EXT In

F. AUX Out

G. USB 2.0 Port

H. Mixed Signal Interface

I. LBUS Port

G

C

D

E

F

I

J

H

J. Cal Out and Ground Terminals

K. Tilting Feet

K

Page 7

OVERVIEW

The touch screen display is the principal viewing and control center of

the oscilloscope. See p.10 for an overview of its components.

The front panel houses hard controls for different acquisition settings.

Operate the instrument using front panel controls, touch screen controls,

or a mix that is convenient for you. See "Front Panel" on p.9.

Channels 1–4 are used to input analog signal. EXT can be used to input

an external trigger signal.

AUX out can be configured to send a pulse to another device upon a

trigger event or Pass/Fail outcome.

The LBUS port may be used with the optional 8-Channel Sync to provide

precise synchonization with other instruments, or the HDA125-xx-LBUS

for high-speed digital analysis and triggering.

Cal out emits a signal that can be used to compensate passive probes.

HDO9000 oscilloscopes are compatible with the included passive probes

and all ProBus active probes that are rated for the oscilloscope’s bandwidth.

Probe specifications and documentation are at teledynelecroy.com/probes.

Supplied with the Mixed Signal

models, the digital leadset connects

to the Mixed Signal interface to

input up-to-16 lines of digital data.

Two digital banks with separate

threshold and hysteresis controls

make it possible to simultaneously

view data from different logic

families. Each flying lead has a

signal and a ground connection. A

variety of ground extenders and

flying ground leads are available for

your probing needs.

To achieve optimal signal integrity, connect the ground at the tip of the flying

lead for each channel used in measurements. Use either the provided ground

extenders or flying ground leads to

make the ground connection.

To connect the leadset to the

oscilloscope, push the connector

into the mixed signal interface until

you hear a click.

To remove the leadset, press in and

hold the buttons on each side of the

connector, then pull out to release it.

Powering On/Off

Plug the line cord only into a grounded AC power outlet. See Power in

“Safety” for ratings. Press the Power button to turn on the oscilloscope. The

button will light to show the oscilloscope is operational.

CAUTION. Do not power on or calibrate with a signal attached.

Press the Power button again or use or the File > Shutdown menu option

to execute a proper shut down process and preserve settings.

CAUTION. Do not press and hold the Power button. This will

execute a hard shutdown, but may not preserve setups and data.

The Power button does not disconnect the oscilloscope from the AC

power supply, but puts it into "Standby" mode. Some “housekeeping”

circuitry continues to draw power. The only way to fully power down the

instrument is unplug the AC line cord from the outlet. We recommend

unplugging the instrument if it will remain unused for a long period of time

CAUTION. Do not change the Windows® Power setting to System

Standby or System Hibernate. Doing so may cause failure.

HDO9000 Getting Started Guide

5

Page 8

OVERVIEW

Side of Oscilloscope

B C

D

A.

HDMI 1.4 and DisplayPort 2.0 Ports

B.

USB 3.1 Gen 1 Ports (4)

A

C.

Ethernet Ports (2)

D.

Audio Mic and Speaker

E.

USBTMC Port (1) for remote control

E

6

930536-00 Rev A

Page 9

OVERVIEW

Connecting to External Devices/Systems

See the HDO9000 Oscilloscopes Operator’s Manual for more instructions on

connecting to external devices.

Audio/USB Peripherals

Connect the device to the appropriate port. These connections are “plugand-play” and do not require further configuration. Use the Windows

control panel to make adjustments. Choose File > Minimize to go to the

Windows desktop.

External Monitor

The HDMI and DisplayPort interfaces support Ultra HD monitors. Connect

the monitor to a video output on the side of the instrument. You can

use an adapter if it does not have an HDMI or DP cable. Go to Display >

Display Setup > Open Monitor Control Panel to configure display settings

using the Windows control panel. Be sure to select the oscilloscope as the

primary display.

To use the Extend Grids feature, configure the second monitor to extend,

not duplicate, the oscilloscope display. If the external monitor is touch

screen enabled, the MAUI user interface can be controlled through touch

on the external monitor.

Note: The oscilloscope touch screen uses Fujitsu drivers. Because of

potential conflicts, external monitors with Fujitsu drivers cannot be used

as touch screens, only as displays.

LAN

The HDO9000 is preset to accept a DHCP network address over a TCP/IP

connection. Connect an ENET cable from either port to a network access

device. Go to Utilities > Utilities Setup > Remote to find the IP address.

To assign the oscilloscope a static IP address, open Net Connections

from the Remote dialog and use the Windows networking dialogs to

configure the device address. Go to File > File Sharing to configure email.

Remote Control

You can control the instrument over a LAN using VICP (TCP/IP) or

VXI-11 (LXI). Use a standard ENET cable to connect to a network access

point, and be sure the instrument is on the same subnet as the controller.

You can also connect directly using TCP/IP, but depending on the

controller, you may need to use a cross-over cable.

Note: To use LXI on Windows 10 oscilloscopes, switch to the

Administrative User LCRYADMIN (p.41).

USBTMC and GPIB (with the optional USB-GPIB adapter) can also be used

to make a remote connection. To change the remote control setting from

the default VICP (TCP/IP), go to Utilities > Utilities Setup > Remote.

Printer

HDO9000 supports USB printers that are compatible with the Windows

OS installed on the oscilloscope. Connect the printer to any host USB

port, then go to File > Print Setup > Print and select Printer to configure

settings. Choose Properties to open the Windows print dialog.

Aux Out and Cal Out

The oscilloscope can output a pulse upon a trigger event or Pass/Fail

outcome. Connect a BNC cable from Aux Out on the front of the instrument

to the other device. Go to Utilities > Utilities Setup > Aux Output to

configure the output.

The Cal Out hook on the front can be set to output a direct current or

square wave of custom amplitude and frequency. Use the Aux Output

dialog to configure Cal Out.

Reference Clock

To input or output a reference clock, connect a BNC cable from Ref In

or Ref Out on the back of the instrument to the other instrument. Go to

Timebase > Horizontal Setup > Clock Source to configure the clock.

HDO9000 Getting Started Guide

7

Page 10

OVERVIEW

A

A.

Built-in Carrying Handle

B.

Ref In and Ref Out to input/

output external Reference Clock

8

930536-00 Rev A

B

C.

AC Power Inlet

D.

Kensington Lock

C

D

Page 11

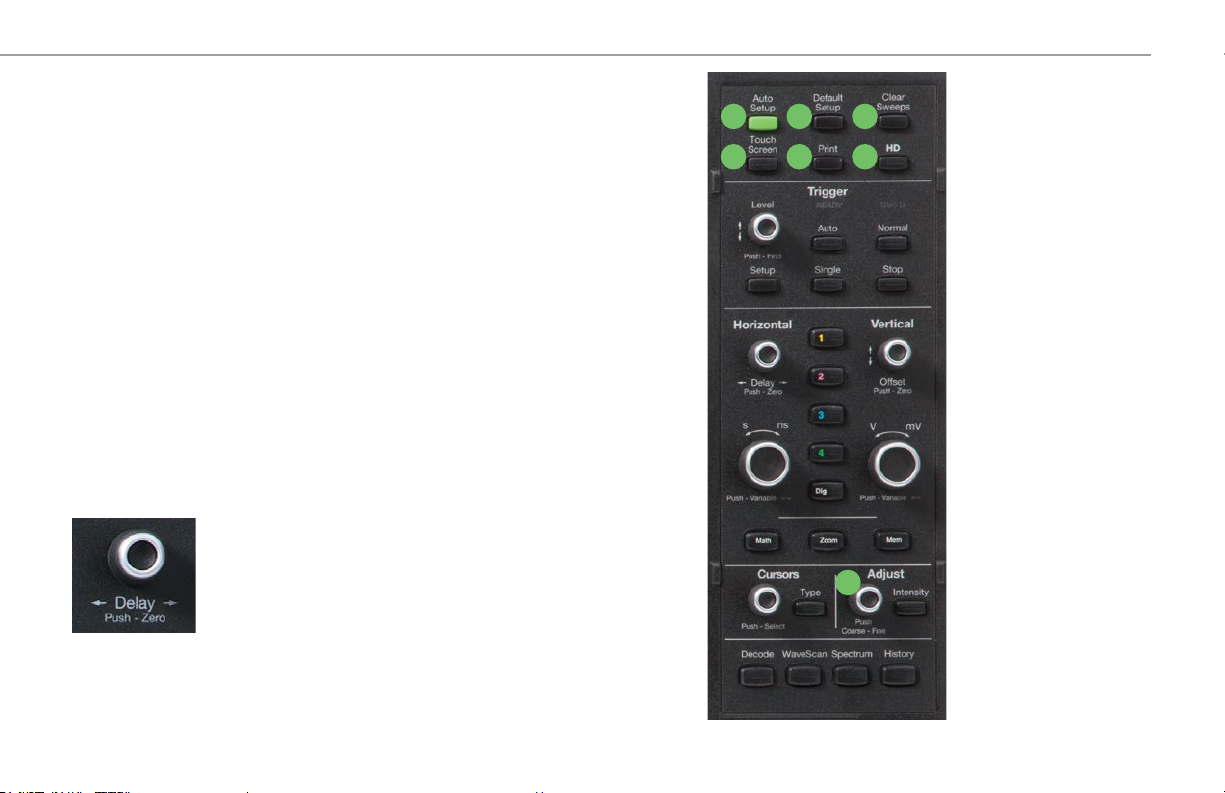

Front Panel

Most of the front panel controls duplicate functionality available through the

touch screen display. They are covered in more detail in the Basics section

and in the HDO9000 Oscilloscopes Operator’s Manual. Below are some special

front panel controls.

A.

Auto Setup turns on and configures all channels with a signal attached.

The edge trigger level is set to the signal mean.

B.

Default Setup returns all channels to the factory default settings.

C.

The Print button captures the screen and handles it according to your

Print setting (print to file on USB drive, create LabNotebook entry, etc.). It

can be set to capture only the grid rather than the full screen.

D.

The Touch Screen button enables or disables touch screen functionality.

E.

Clear Sweeps resets math and measurement counters.

F.

The HD button enables/disables HD1024 operation.

G.

The front panel Adjust knob changes the value in the highlighted data

entry field when turned. Pushing the Adjust knob toggles between coarse

(stepped) or fine adjustments when the knob is turned.

All the knobs on the front panel function one way if

turned and another if pushed like a button. The first

label describes the knob’s principal “turn” action, while

the second describes its “push” action.

Many front panel buttons light to indicate the function

is active.

OVERVIEW

A B C

D E F

G

HDO9000 Getting Started Guide

9

Page 12

OVERVIEW

Touch Screen Display

The entire display is active. Use your finger to touch, drag-and-drop, swipe, pinch and flick. Many controls that display information also work as “buttons”

to access other functions. If you have a mouse installed, you can click anywhere you can touch to activate a control; in fact, you can alternate between

clicking and touching, whichever is convenient for you.

10

F G

930536-00 Rev A

A

B

C D

E

H

I

A. Menu Bar

B. Grid

C. Cursor

D. Trigger Level Indicator

E. Trigger Time Indicator

F. Trace Descriptor Box

G. Add New Box

H. Timebase and Trigger

Descriptor Boxes

I. Horizontal Cursor

Readout

J. Setup Dialogs

J

Page 13

OVERVIEW

A drop-down menu bar lets you access set up dialogs and other

functions. All functionality can be accessed through either the menu bar

or other touch screen shortcuts.

If an action can be “undone” (such as recalling a setup), a small

Undo button appears at the far right of the menu bar. Click this

to return to the previous oscilloscope display.

The grid displays the waveform traces. It can be configured to show

different grid modes.

Cursors show where measurement points have been set. Touch-and-drag

cursor indicators to quickly reposition the measurement point. Horizontal

cursor readouts appear below the Timebase and Trigger descriptors.

Trigger Level and Trigger Time indicators appear at the edge of the grid

when a trigger is set, color-coded to match the trigger channel.

Trace Descriptor boxes appear along the bottom of the grid, one for each

open trace. They adjust in size and detail as more are opened.

The Add New box sits next to the trace descriptor boxes. Use it to turn on

new traces or the Measure table. See "MAUI with OneTouch" on p.15.

Timebase and Trigger descriptor boxes appear at the right of the display.

Timebase and Trigger settings only apply to channel traces. Touch the

descriptor box to open the corresponding set up dialog.

Dialogs appear at the bottom of the display for entering set up data. The

top dialog will be the main entry point for the selected function. Related

dialogs appear as a series of tabs behind the main dialog.

A toolbar along the bottom of the main Channel, Math, Memory and

Digital dialogs initiates frequent actions without closing the underlying

dialog. The actions always apply to the active (highlighted) trace.

Apply measurement parameters.

Display a zoom of the trace.

Apply a math function to the trace.

Open the Serial Decode dialog

(if decoder options installed; else disabled).

Copy the active trace to the corresponding

internal memory (e.g., C2 to M2).

Scale the waveform to fit the grid.

Move the active trace to the next grid.

Apply a custom label to the trace.

HDO9000 Getting Started Guide

11

Page 14

BASICS

Changing the Display

The grid is 8 Vertical divisions representing the full number of Vertical

levels (at current resolution) and 10 Horizontal time divisions. The value

represented by each division depends on the scale settings of the traces

that appear on it.

8 Vertical

Divisions

Full

Vertical

Levels

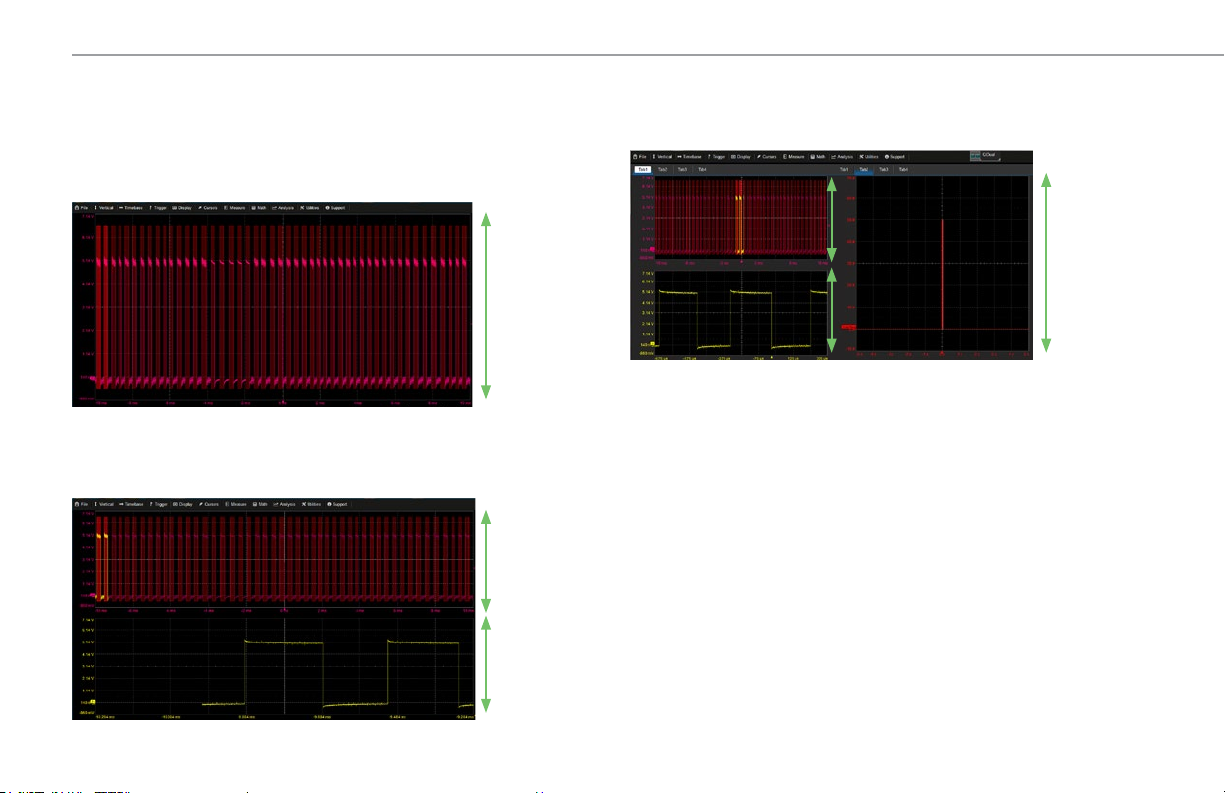

Multi-Grid Display

The grid can be divided into multiple grids each representing the full

number of Vertical levels. A variety of multi-grid modes are available.

Full

Vertical

Levels

Full

Vertical

Levels

Q-Scape Multi-Tab Display

If you have installed the Q-Scape option, the grid area can be divided into

multiple tabs. Each tab can show a single grid or a multi-grid mode.

8 Vertical

Divisions

Full

Vertical

Levels

Display Mode vs. Grid Mode

The Display Mode determines whether the touch screen has a single display

or tabs each representing a separate display. The Grid Mode allows selection

of a particular grid style in each display.

By default, the oscilloscope is in Normal Display Mode (a single display with

no tabs) with the Auto Grid Mode enabled. Auto adds a grid for each new

trace, up to 16 grids, until no more grids are available. Other grid modes

create a fixed number and orientation of grids; the icon shows the result.

The various Q-Scape Display Modes divide the screen into tabbed displays.

Many of the same grid functions you can perform in Normal mode, such as

moving traces to other grids, you can also perform in the Q-Scape modes.

To modify the touch screen display, choose Display > Display Setup from the

menu bar and make your selections from the Display dialog.

12

930536-00 Rev A

Page 15

BASICS

Extended Display

If you have a second monitor connected, you can extend the display of

traces across both the oscilloscope screen and the external monitor. Select

Extend Grids on 2nd Monitor from the Display dialog, then choose a grid

mode from the Extended Display pop-up menu. Both screens will share this

grid mode. Drag-and-drop descriptor boxes to move traces between displays.

Note: When a Q-Scape Display Mode is extended, only Tab 1 is moved to

the second display.

Oscilloscope with an extended display.

Line and Intensity

The trace style can be set to a series of separate

sample Points or a continuous vector Line.

Grid Intensity makes the grid lines dimmer or

brighter relative to the trace.

When more data is available than can actually be

displayed, Trace Intensity helps to visualize significant events by applying

an algorithm that dims less frequently occurring samples. The front panel

Intensity button sets the Adjust knob to control the trace intensity setting.

Trace with Intensity 100%

Trace with Intensity 40%.

HDO9000 Getting Started Guide

13

Page 16

BASICS

Working With Traces

Trace Descriptor Boxes

Channel (C1-C4), Zoom (Z1-Z12), Math (F1-F12), Memory (M1-M12) and

Digital (Digital1-Digital4) descriptor boxes appear along the bottom of

the grid area when a trace is turned on. Descriptor boxes summarize,

activate, arrange and configure the traces they represent.

Trace Context Menu

The trace context menu is a quick way to apply math, measurements or

labels to traces. To open the context menu, right-click with your mouse or

touch-and-hold on the trace descriptor box until a white circle appears,

then release.

Active vs. Inactive Trace

Although several traces may be open and appear on the display, only one at

a time is active. This is true for all traces, regardless of the type. All actions

apply to the active trace until another is selected.

Touch a trace or its descriptor box to activate it and bring it to the foreground.

When the descriptor box appears highlighted in blue, front panel controls and

touch screen gestures apply to that trace.

Inactive. Controls will not

work for this trace.

Active. Controls will work

for this trace.

Adjusting Setups

On setup dialogs, many entries can be made by selecting from the pop-up

menu that appears when you touch a control.

On some pop-up menus, you can choose to display

options as a list or as icons.

When an entry field appears highlighted in blue after

touching, it is active and the value can be modified by

turning the front panel knobs. Fields that don’t have

a dedicated knob (as do Vertical Offset or Horizontal

Delay) can be modified using the Adjust knob.

If you have a keyboard installed, you can type

entries in an active (highlighted) data entry

field. Or, you can touch again, then “type” the

entry by touching keys on the virtual keypad

or keyboard.

To use the virtual keypad, touch the soft keys

exactly as you would a calculator. When you

touch OK, the calculated value is entered in

the field.

14

930536-00 Rev A

Page 17

BASICS

MAUI with OneTouch

Touch, drag, swipe, pinch and flick can be used to create and change setups with one touch. Just as you change the display by using the setup dialogs,

you can change the setups by moving different display objects. Use the setup dialogs to refine OneTouch gestures to precise values.

As you drag & drop, valid targets are outlined with a white box. When you’re moving over invalid targets, you’ll see the “Null” symbol ( Ø ) under your

finger tip or cursor.

Turn On

To turn on a new channel, math, memory, or zoom trace, drag any

descriptor box of the same type to the Add New (“+”) box. The next trace

in the series will be added to the display at the default settings. It is now

the active trace.

If there is no descriptor box of the desired type on the screen to drag,

touch the Add New box and choose the trace type from the pop-up menu.

To turn on the Measure table when it is closed, touch the Add New box

and choose Measurement.

HDO9000 Getting Started Guide

15

Page 18

BASICS

Copy Setups

To copy the setup of one trace to another of the same type (e.g., channel to

channel, math to math), drag-and-drop the source descriptor box onto the

target descriptor box.

To copy the setup of a measurement (Pn), drag-and-drop the source

column onto the target column of the Measure table. You can do the same

for a query (Qn) on the Pass/Fail readout table.

Change Source

To change the source of a trace, drag-and-drop the descriptor box of the

desired source onto the target descriptor box. You can also drop it on the

Source field of the target setup dialog.

To change the source of a measurement, drag-and-drop the descriptor box of

the desired source onto the parameter (Pn) column of the Measure table. You

can do the same to a query (Qn) on the Pass/Fail readout table.

16

930536-00 Rev A

Page 19

BASICS

Position Cursors

To change cursor measurement time/level, drag cursor markers to new

positions on the grid. The cursor readout will update immediately.

To place horizontal cursors on zooms or other calculated traces where the

Horizontal Scale has forced cursors off the grid, drag the cursor readout

from below the Timebase descriptor to the grid where you wish to place the

cursors. The cursors are set at either the 5 (center) or 2.5 and 7.5 divisions of

the grid. Cursors on the source traces adjust position accordingly.

Change Trigger

To change the trigger level, drag the Trigger Level indicator to a new position

on the Y axis. The Trigger descriptor box will show the new voltage Level.

To change the trigger source channel, drag-and-drop the desired channel (Cn)

descriptor box onto the Trigger descriptor box. The trigger will revert to the

last trigger set on that channel.

HDO9000 Getting Started Guide

17

Page 20

BASICS

Store to Memory

To store a trace to internal memory, drag-and-drop its trace descriptor box

onto the target memory (Mn) descriptor box.

Move Trace

To move a trace to a different grid, drag-and-drop the trace descriptor box

onto the target grid.

Scroll

To scroll long lists of values or readout tables, swipe the selection dialog or

table in an up or down direction.

Pan

To pan a trace, activate it to bring it to the forefront, then drag the waveform

trace right/left or up/down. If it is the source of any other trace, that trace will

move, as well.

To pan at an accelerated rate, swipe the trace right/left or up/down.

18

930536-00 Rev A

Page 21

BASICS

Zoom

To create a new zoom trace, touch then drag

diagonally to draw a selection box around the

portion of the trace you want to zoom. Touch

the Zn descriptor box to open the zoom factor

controls and adjust the zoom exactly.

To "zoom in" on any trace,

unpinch two fingers over the

trace horizontally.

To "zoom out" on any trace,

pinch two fingers over the

trace horizontally.

Turn Off

To turn off a trace, flick the trace descriptor box toward the bottom of

the screen.

HDO9000 Getting Started Guide

19

Page 22

BASICS

Vertical (Channel)

Vertical controls adjust traces along the Y axis. Traces represent eight Vertical divisions of the source signal at the selected number of units per division. The

zero level is at the center grid line unless you add positive or negative Offset. The front panel Volts knob also controls the Vertical Scale of zoom, math and

memory traces.

Channel Descriptor BoxFrom the Front Panel

Pre-Processing Summary List

Turn on/activate

channel trace

and open set up

dialog.

Raise/lower

Offset from zero.

Push to return to

zero Offset.

Coupling

Gain Setting

Offset Setting

# Sweeps Averaged / Segment #

20

930536-00 Rev A

Raise/lower

Volts/div.

Push to toggle

between coarse

and fine scale

adjustments.

Vertical Cursor Positions

Page 23

From the Touch Screen

Drop a channel descriptor on the Add New box, or touch the Add New box

and choose Channel. Touch new Cn descriptor to open the Cn setup dialog.

BASICS

Enter Attenuation for passive

and other vendors' probes.

Enter Volts/div and Offset. Rescale channel

Enter Coupling

for cables/probes.

Apply optional

Bandwidth Filters.

trace, or change

Vertical Unit of grid.

Make any other

Pre-Processing settings.

HDO9000 Getting Started Guide

21

Page 24

BASICS

Digital

On Mixed Signal models, digital selections are added to the Vertical menu, and the front panel Vertical knobs control active Digital line and bus traces.

From the Front Panel

Turn on/activate

digital traces.

930536-00 Rev A

22

Turn Offset to

raise/lower group

Vertical Position,

the top of lowest bit

relative to center.

Turn Volts to raise/

lower Group Height,

the total Vertical

divisions occupied

by group.

Digital Descriptor Box

# Digital Lines in Group

Digital Sample Rate

Digital Memory

Digital Displays

Line trace shows high, low and transition points for each line.

Bus trace collapses lines into hex values.

Activity indicators show when line is high, low, or transitioning.

Page 25

BASICS

From the Touch Screen

From the menu bar, choose

Vertical>Digital n Setup. Touch

Digitaln descriptor to open the

Digitaln setup dialog.

Choose Display

Mode of individual

lines, bus trace,

or both.

Optionally, choose

a new Label for

the lines. Select

Custom to enter

unique names.

Display buttons

switch lead banks

as you select lines.

Line Activity

indicators show

the state of each

line: high, low, or

transitioning.

On the Logic Setup tab, choose a

standard Logic Family, or enter a

custom Threshold and Hysteresis.

Separate controls allow you to set

different values for each lead bank.

Use checkboxes

to select lines in

the group.

Optionally, enter

a custom line

name in the field

beneath.

Enter digital trace

Vertical Position

and Group Height

in divisions.

HDO9000 Getting Started Guide

23

Page 26

BASICS

BASICS

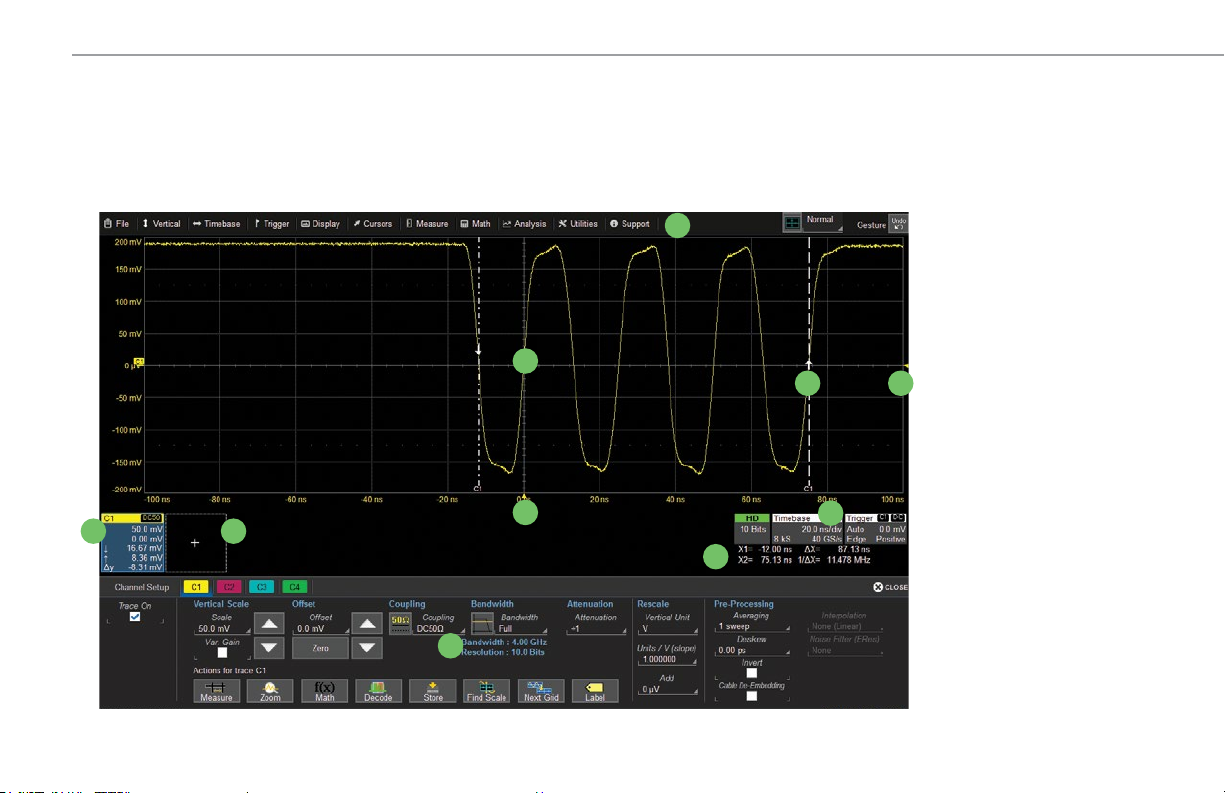

Horizontal (Timebase)

Horizontal controls adjust traces along the X axis. Analog traces usually represent one acquisition of the source signal for 10 divisions of the selected Time

per division. The trigger event is shown at the center of the grid, unless you add positive or negative Delay time. The front panel Time knob also controls the

Horizontal Scale of zoom, math and memory traces, allowing you to "zoom in" to see more detail or "zoom out" to see the bigger picture.

From the Front Panel

Raise/lower trigger Delay.

Push to remove Delay.

Raise/lower Time/div.

Push to toggle between

coarse and fine scale

adjustments.

Timebase Descriptor Box

Sampling Mode

(blank in real-time)

# Samples

Trigger Delay

(Position)

Time/div

Sample Rate

24

930536-00 Rev A

Page 27

From the Touch Screen

Touch the Timebase

descriptor to open

Timebase setup dialog.

Turn on/off

HD Mode.

BASICS

Enter Time/div.

Select

Sampling

Mode.

Optionally, enter Delay,

(negative) time before trigger

or (positive) time after trigger

event to show.

Set To Zero

removes Delay.

Enter fixed Sampling

Rate or Maximum Points

of memory to use in

acquisition.

Lower number of

Active Channels to

increase sample rate

and memory.

HDO9000 Getting Started Guide

25

Page 28

BASICS

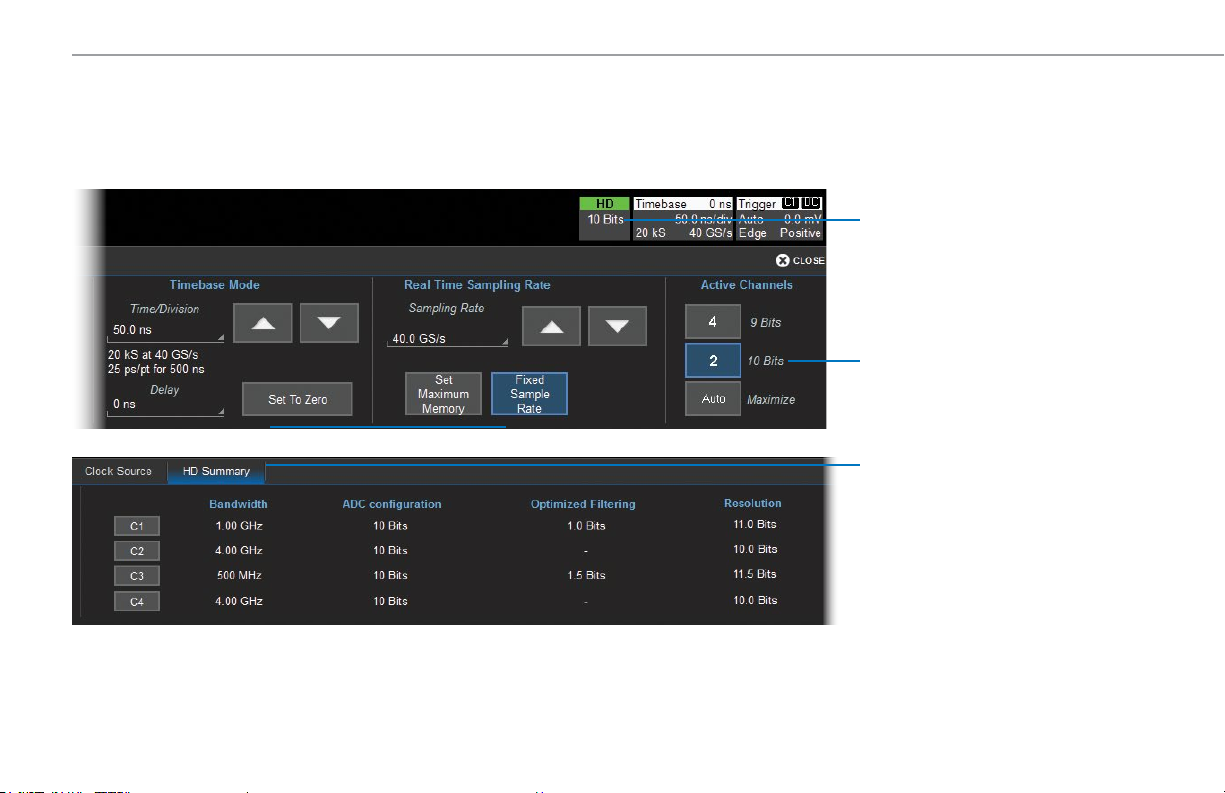

HD Mode

The HDO9000 with HD1024 high definition technology offers more quantitization levels and greater precision when digitizing waveforms. HD1024 allows for

dynamic ADC configuration based on the number of active channels and applies bandwidth filtering when the sample rate is reduced below 10 GS/s to prevent

aliasing and increase resolution. When HD1024 is off, the oscilloscope operates in continuous 8-bit resolution.

HD descriptor box shows bits of

resolution due to the ADC configuration.

It is hidden when HD Mode is Off.

When HD Mode is On, Active Channels

shows the ADC configuration options:

9-bit, 10-bit, or Maximize based on actual

active channels. (When HD Mode is Off,

it shows maximum sample rate per

channel.)

HD Summary dialog shows per channel:

Bandwidth due to combined manual

•

bandwidth filters, anti-aliasing filters,

and coupling setting

Bits resolution for which the ADC

•

Configuration is optimized due to the

Active Channels selection

Bits resolution gained due to all the

•

Optimized Filtering of bandwidth

Total Resolution (the sum of ADC

•

Configuration and Optimized Filtering)

26

930536-00 Rev A

Page 29

BASICS

Zoom

Zoom traces (Zn) display a magnified portion of another trace. Any trace can be zoomed, although Zoom is most useful for channel traces, as it allows you to

see the source at the original Timebase at the same time as the Zoom "close up."

From the Front Panel

When you use the front panel Zoom button, a new Zoom trace is created for

When Zoom button is lit, use

Horizontal Scale knob to

change zoom magnification.

Press to create Zooms of all

open traces.

From the Touch Screen

Draw a Zoom box over a

portion of the source trace.

Repeat on another section to

reposition the Zoom trace.

every open trace, showing a 10x magnification of the source trace.

The zoomed portion of the source trace is highlighted, so that the area

corresponding to the zoom is more visible.

The Zoom descriptor box

shows the Zoom Source

and Horizontal Scale, which

differs from the Timebase.

HDO9000 Getting Started Guide

27

Page 30

BASICS

Trigger

Triggers tell the oscilloscope when to perform an acquisition. The acquisition starts as soon as the trigger is armed and all trigger conditions are

met, unless postponed by a Holdoff count of time or number of trigger events. Trigger types and modes are described at more length in the HDO9000

Oscilloscopes Operator’s Manual.

From the Front Panel

Turn to

Raise/lower

trigger Volt/

Amp Level.

Push to

Find Level.

Open Trigger

setup dialog.

930536-00 Rev A

28

Trigger

armed.

Select Trigger Mode:

Auto – trigger after preset period if no valid trigger.

Normal – trigger repeatedly when all conditions met.

Single – trigger once when all conditions met.

Stop – stop acquisition.

Trigger

fired.

Trigger Descriptor Box

Trigger Source

Trigger Coupling

Trigger Mode

Trigger Type Trigger Slope

Trigger Level

Trigger Indicators

Level

Position

Pre/Post-Trigger – appears at corner of grid

when trigger point is no-longer visible.

Page 31

From the Touch Screen

Touch Trigger

descriptor to open

Trigger setup dialog.

Choose

trigger Type.

BASICS

Choose trigger

Source channel.

Set other conditions,

such as Coupling and

Slope (vary by

trigger type).

Set trigger Level,

or Find Level based

on the input signal.

Icon summarizes the

trigger selections.

HDO9000 Getting Started Guide

29

Page 32

BASICS

Cursors

Cursors set measurement points on the Vertical or Horizontal axis of a trace (or both). The five preset cursor types are described in more detail in the

HDO9000 Oscilloscopes Operator’s Manual. All show the absolute value where the cursor intersects the waveform and the delta of the two lines.

From the Front Panel

From the Touch Screen

Vertical Cursor

readout on

descriptor boxes.

Choose

Cursor Type.

930536-00 Rev A

30

Adjust cursor position.

Push to select different lines.

Apply cursor. Continue pressing

to cycle through cursor types.

Cursors > Cursor Setup

opens the Cursor dialog.

Touch-and-drag cursor to

reposition measurement

point.

Horizontal Cursor readout

below Timebase. Drag onto

zooms to reset cursors on

the rescaled traces.

Set exact Cursor Position

using dialog. Track moves

both lines together.

Page 33

BASICS

Measurements and Statistics

Measurements are waveform parameters that can be expressed as numerical values, such as amplitude or frequency. You can measure up-to-twelve

parameters on one or more traces and view the active readout in a table below the grid. Statistics can be added to the readout, along with histicons, a

miniature histogram of the statistical distribution. You can also gate measurements to limit them to a specific portion of the trace, or plot a histogram,

trend or track of the measurement over time.

Measure > Measure

Setup opens the

Measure dialog.

Touch Measure column

to re-open Measure

dialog if closed.

Measure dialog to

add/remove Satistics

and Histicons,

turn on Standard

Measurements, or

Clear Sweeps.

Pn dialogs to

configure user-defined

measurement set.

Action buttons quickly

plot Histogram, Trend or

Track of measurement.

Turn on Help Markers

to show what is being

measured on waveform.

Enter Gates (in div) to constrain

span of measurement, or just drag

gate markers from edge of grid.

Touch Pn cell to

re-open Pn setup.

HDO9000 Getting Started Guide

31

Page 34

BASICS

Math

Math creates a new trace that displays the result of applying a mathematical function (e.g., Sum, Product, FFT) to one or more source traces. Operations

can be chained by using one math function as a source for the other. The math trace always opens in a separate grid from the source and can be viewed

along side it. One important distinction between math functions and measurement parameters is that the result of math is always another waveform,

whereas the result of measurement is a number.

Math > Math

Setup or front

panel Math

button opens

Math dialog.

Units and scale

on Fn descriptor.

Math tab to

turn on/off functions.

Fn tab to set up/

change function.

Make other

settings on

the function

subdialog

(varies by

operation).

32

930536-00 Rev A

Choose Source trace(s)

to operate on and math Operator.

Use Zoom controls to

rescale math trace.

Page 35

BASICS

Memories (Reference Waveforms)

Memories are traces stored for reference that can be recalled to the display for comparison with other traces. A memory can be zoomed or measured for

better analysis of historical data. You can store up-to-twelve internal memories (M1-M12). After that, new memories will overwrite previously stored data.

To store a new memory:

Touch the Add New box and

choose Memory to turn on the

next memory trace.

Then, drag the descriptor box of

the trace you want stored onto

the new Mn descriptor box.

OR

Choose Math > Memory Setup. On the Mn tab, select the trace you want

stored in Copy From Waveform, then touch Copy Now.

Optionally, add Notes or Labels to the stored memory.

To recall a stored memory:

Press the front panel Mem(ory) button to open the Memories dialog, then

check On next to M1-M12.

Internal memories persist only until the oscilloscope is rebooted. To store

memories indefinitely, save them to a trace (.trc) file by choosing

File > Save Waveform.

The trace file can later be recalled into one of the internal memories for

viewing by choosing File > Recall Waveform. Only files saved with the .trc

extension can be recalled.

HDO9000 Getting Started Guide

33

Page 36

BASICS

Decode

The Decode front panel button opens the dialogs for conguring serial trigger and decode options. Decoders apply software algorithms to extract encoded

information from physical layer waveforms measured on your oscilloscope. Waveforms are annotated to provide fast, intuitive understanding of the

relationship between protocol and signal. Serial triggers fire upon finding complex, user-defined patterns and events in the data stream.

View decoding

on the colored

overlays.

When multiple

decoders are

running, touch the

Index cell to dropin the detailed

decoding. Touch

any cell other than

Index and Protocol

to zoom.

Generate eye

diagrams with

TDME options.

Touch data cells to

zoom that single

record of data. The

zoomed record is

highlighted in the

table and on the

decode trace.

When there is more

data than fits in

a table cell, touch

the white triangle

to pop-up the full

decoding.

34

930536-00 Rev A

Touch drop-down arrow

in header to filter column.

Select Source trace and Protocol.

Make required settings on the subdialogs.

Page 37

BASICS

WaveScan

Press the WaveScan front panel button to open the WaveScan dialogs. WaveScan Search and Find enables you to search for unusual events in a single

capture, or to scan for a particular event in many acquisitions over a long period of time. A predefined set of scan modes (similar to trigger setups) enable

a quick search for events of interest. The results are time stamped, tabulated, and can be selected for individual viewing.

Result table lists

found events.

Touch an event

to zoom it.

Choose scan

Mode (event to

find) and Source

trace to scan.

Select different views of the scan: event table

with/without time stamps, overlay or zoom.

Take action when an event is found,

such as sounding a beep.

Color overlays

mark events on the

source trace.

Zoom of selected

event.

HDO9000 Getting Started Guide

35

Page 38

BASICS

BASICS

Spectrum Analyzer

Use the Spectrum front panel button to launch Spectrum Analyzer, which lets you quickly and easily use the Fast Fourier Transform (FFT) for frequency

analysis. The controls are the same as you would find on an RF spectrum analyzer. You set the inputs and desired frequency span, and the oscilloscope

automatically generates output in units relevant to the frequency domain. A spectrogram generator displays 2D or 3D renderings of historical data.

Tabular readout

of marker

measurements.

FFT trace with

marked peaks and

frequencies.

2D or 3D

spectrogram

shows history of

spectra.

Use Peaks/

Markers dialog

to mark and

tabulate peaks, or

set measurement

markers on

frequencies.

36

930536-00 Rev A

Choose type and

source of input.

Specify frequency span

of interest.

Page 39

BASICS

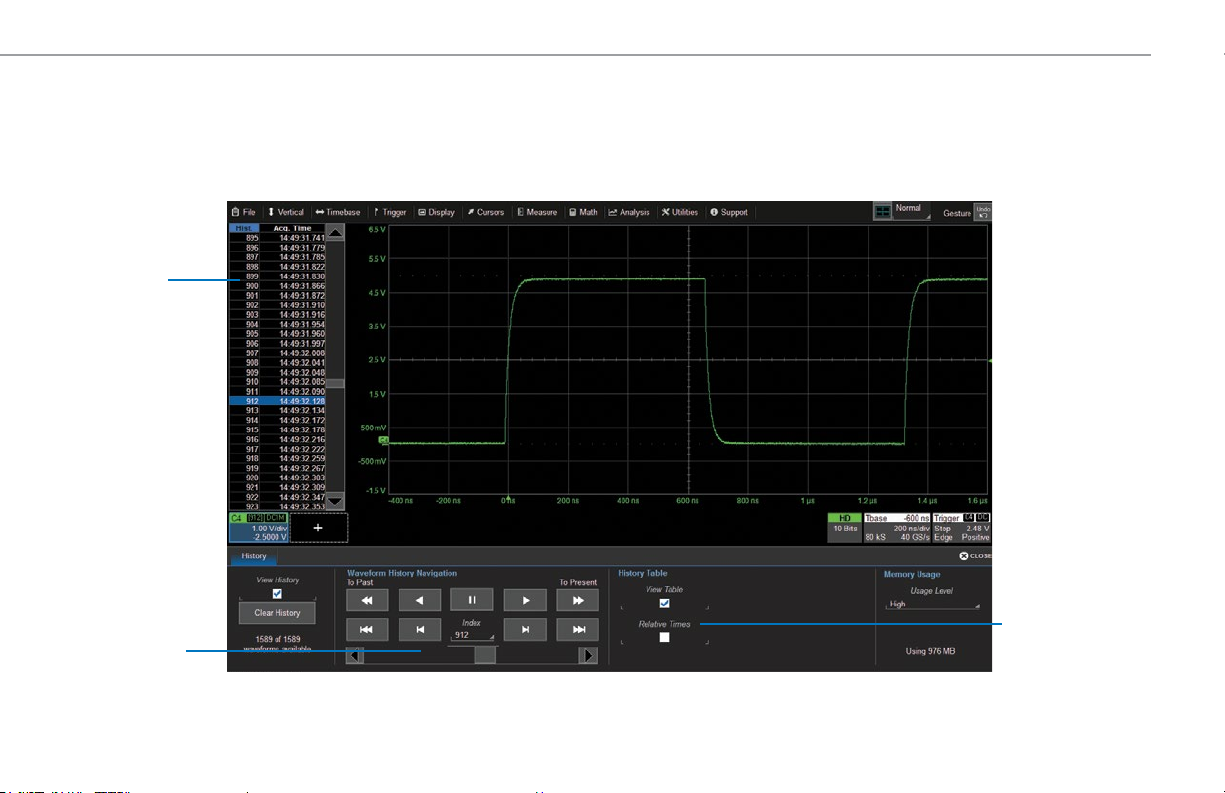

History Mode

The History front panel button puts the instrument into History Mode, allowing you to review any acquisition in the oscilloscope’s history buffer, which

automatically stores all acquisitions until full. Each record is indexed and time-stamped with either the absolute time since beginning of history or the time

relative to where you are in the history. Not only can individual acquisitions be restored to the grid, you can "replay" history at varying speeds to capture

detailed changes in the waveforms over time.

Select row of

History table

to view that

acquisition.

Auto Play buttons

and slider bar

“replay” history

to find events of

interest.

View History table

using absolute time

or relative time.

HDO9000 Getting Started Guide

37

Page 40

BASICS

Saving and Sharing Data

Use the oscilloscope File menu options to save and recall data. See the

HDO9000 Oscilloscopes Operator’s Manual for more information on using

these features.

LabNotebooks

LabNotebooks are composite files (.LNB) containing setups, waveform

data and screen image as they were at the moment of capture. Creating a

LabNotebook can be as simple as pressing the Print button as you work.

Flashback LabNotebooks to restore the oscilloscope to the exact state it

was in when the file was saved. Waveforms and tables are displayed as

they were for new analyses to be performed.

LabNotebook files can be edited, annotated and exported into a

preformatted HTML, .RTF or .PDF report. They can also be extracted into

their component setup, waveform and screen image files.

Setup, Waveform and Table Data

The current oscilloscope configuration can be saved to internal setup

panels or setup (.LSS) files and later recalled.

Waveform data can be stored to trace (.TRC) files and later recalled into

memories to restore the waveform display to the screen.

Table data can be saved to either ASCII (.TXT) or Excel (.CSV) files.

When multiple waveforms or tables are displayed, one command saves

All Displayed to separate, autonamed files.

Screen Captures

The front panel Print button captures an image of the screen, which will

then be handled according to your chosen Print method (sent to a printer,

saved to an image file, etc.). Before printing or saving the capture, use the

drawing tools to annotate the image, same as with LabNotebooks.

You can also use the touch screen File > Save Screen Image.

File Sharing

If the oscilloscope is networked, LabNotebooks, reports and other

user data files can be emailed directly from the instrument or saved to

accessible network devices.

Files can also be transferred to a USB drive through any of the host USB

ports. Stored user data files are located on the D: drive.

38

930536-00 Rev A

Page 41

Software Options

Many software options are available to extend the capabilities of a

HDO9000. To purchase an option, contact your Teledyne LeCroy sales

representative. You will receive a license key via email that activates the

optional features on the oscilloscope. To install the key on the oscilloscope:

1. From the menu bar, choose Utilities > Utilities Setup > Options.

2. Touch Add Key.

3. Enter the new license key and click OK.

4. Reboot the instrument.

Q-Scape Multi-Tabbed Display (HDO9K-QSCAPE) architecture speeds your

understanding of your design with 4x the display area. Configure each tab with

the grid style you want. Quickly drag traces to new tabs.

Advanced Customization Package (HDO9K-XDEV) supports user-defined

measurement parameters and math functions. Algorithms can be created in

your favorite programming language, such as MATLAB.

Cable De-embedding Option (HDO9K-CBL-DE-EMBED) gives you the ability to

quickly and easily remove the effect of cables by entering an attenuation table or

attenuation constants that are typically provided by the cable manufacturer.

Digital Filter Package (HDO9K-DFP2) implements a set of linear-phase

Finite Impulse Response (FIR) and IIR filters to remove undesired spectral

components such as noise.

Electromagnetic Compliance Package (HDO9K-EMC) offers specialized

measurements to test a design’s susceptibility to EM discharge.

Electric-Telecom Pulse Mask Test (HDO9K-ETPMT) performs automated

compliance mask tests on a wide range of electrical telecom standards.

MAINTENANCE

JITKIT (HDO9K-JITKIT) makes it easy to understand the basic system

jitter performance of clock signals and clock-data activities through a

wide variety of common jitter measurements.

Eye Doctor II (HDO9K-EYEDRII) provides the channel emulation and

de-embedding tools for the next generation of serial data standards. It

seamlessly integrates into Teledyne LeCroy’s SDA II and SDA III software

for eye diagram and jitter analysis. SDA II (HDO9K-SDAII) delivers

integrated jitter and timing analysis for clock and data signals to help you

characterize your design, prove compliance, and determine why a device

or host fails compliance.

DDR Debug Toolkit (HDO9K-DDR*-TOOLKIT) provides test, debug and

analysis tools for the entire DDR design cycle. The unique DDR analysis

capabilities provide automatic Read and Write burst separation, bursted

data jitter analysis, and DDR-specific measurement parameters. Available

for DDR2, DDR3, and DDR4 signal analysis.

Spectrum Analyzer (HDO9K-SPECTRUM) creates an RF Spectrum Analyzer-like

environment for analyzing frequency-dependent effects. Use the FFT on the

oscilloscope with little or no concern about the details of setting up an FFT.

Power Analysis Software (HDO9K-PWR) provides exceptional ability to

measure and analyze the operating characteristics of power conversion

devices and circuits, such as device power switching, control loop

modulation, and line power harmonics.

Serial Data Mask Package (HDO9K-SDM) adds eye pattern mask testing

capability to the instrument.

Many Serial TDME Options provide added insight when debugging serial data.

For the latest list, go to teledynelecroy.com/serialdata.

HDO9000 Getting Started Guide

39

Page 42

MAINTENANCE

Cleaning

Clean the outside of the oscilloscope using a soft cloth moistened

with water or isopropyl alcohol solution. Do not use harsh or abrasive

cleansers. Dry thoroughly before using. Do not submerge the instrument

or allow moisture to penetrate it.

CAUTION. Do not attempt to clean internal parts.

Language Selection

To change the language that appears on the oscilloscope touch screen, from

the menu bar, choose Utilities > Preference Setup > Preferences and make

your Language selection.

You can also select at power on by touching the Language icon

when it appears at the upper-right of the touch screen.

Reboot the oscilloscope after changing language.

Calibration

The oscilloscope is calibrated at the factory prior to shipment. Schedule

an annual factory calibration as part of your routine maintenance.

HDO9000 incorporates automatic calibration routines to maintain

accuracy in between factory calibrations. Go to Utilities > Preference

Setup > Calibration to select the method used:

Stored Calibration uses cached calibration files to recalibrate the

instrument at start-up. As long as the oscilloscope is used at or near

sea level within a temperature range of 19-30 °C, this calibration routine

should be sufficient to maintain specified performance. The instrument

will dynamically recalibrate if the temperature goes outside of the

stored calibration range. If you know you will be operating outside this

temperature range, do a Calibrate All to minimize recalibration.

Dynamic Calibration recalibrates the oscilloscope at start-up and every

time there is a change to any of the acquisition settings that directly

affect the performance of the ADCs. When one setup is calibrated at a

particular ambient temperature, the calibration is entered in a calibration

table and reused for the duration of the session. These calibration entries

persist only for a single session; Dynamic Calibration restarts when the

instrument is restarted or you change the principal acquisition settings.

Two manual calibration routines can be used to recalibrate immediately

before sensitive measurements or when there is a significant change of

environmental characteristics that could affect the performance of the

ADCs:

Calibrate Current State calibrates at the current vertical and horizontal

settings. This calibration takes 5 seconds but is valid for only this setup

at the current temperature ±2.5 °C.

Calibrate All calibrates all possible combinations of vertical and

horizontal settings. This calibration is valid for the current temperature

and takes about four to five hours. Perform it when the ambient

temperature is stable from the time of calibration to the time of

operation. We recommend that you run Calibrate All when:

• The instrument is operating outside the 19-30 °C range and the

operating temperature changes while outside that range. Calibrate

All is only valid for ± 2.5 °C of the last calibration temperature when

operating outside of the 19-30 °C range.

• The instrument is moved to a new operating environment.

• It has been six months since the previous manual calibration.

CAUTION. Remove all inputs from the oscilloscope prior to manual

calibration.

40

930536-00 Rev A

Page 43

MAINTENANCE

Firmware Updates

Free firmware updates are available periodically from the Teledyne LeCroy

website at teledynelecroy.com/support/softwaredownload. Registered

users will receive email notification when a new update is released.

CAUTION. Do not install any XStreamDSO software version prior to

8.6.1.x on Windows 10 oscilloscopes. Doing so will disrupt the normal

behavior of the software, unless you run the recovery procedure.To

download and install the update:

1. From the oscilloscope desktop (File > Exit) or a remote PC, launch the

browser and visit the software download page at the URL above.

2. Click the link to Oscilloscope Downloads > Firmware Upgrades.

3. Enter the required model information and account login. If you don’t

yet have an account, create one now.

4. Follow the instructions to save the installer to a location on the

oscilloscope D: drive or a USB storage device.

5. On the oscilloscope, use Windows Explorer to browse to the installer

file (xstreamdsoinstaller_x.x.x.x.exe) and double-click it to launch the

XStream Setup wizard.

6. If prompted, enter the password SCOPEADMIN, all uppercase.

7. Follow the wizard prompts.

8. When installation is complete, power cycle the instrument.

CAUTION. The installation may take several minutes, depending on

the length of time since your last update. Do not power down the

oscilloscope at any point during the installation process.

Switching Users

Windows 10 oscilloscopes only.

Windows 10 oscilloscopes are by default set to operate from the LeCroyUser

account, but you must run the oscilloscope from the Administrative User,

LCRYADMIN, in order to change Windows settings, run certain compliance

packages or use LXI remote control.

Note: To install software or change Windows settings, it is sufficient to

supply the administrative user password, SCOPEADMIN.

To switch to the LCRYADMIN account:

1. Exit the XStreamDSO application by choosing File > Exit.

2. Open the Windows Start menu

3. Hover over the Teledyne LeCroy logo and select user LCRYADMIN.

4. Enter the administrative password SCOPEADMIN (all uppercase).

5. Double-click the StartDSO icon on the oscilloscope desktop.

To return to the default user, repeat this procedure selecting LeCroyUser and

entering the password lecroyservice (all lowercase).

You may create as many new users on the oscilloscope as you wish provided

you are logged in as LCRYADMIN when doing so. Use the standard Windows

tools to add users.

Note: As long as there are any Standard (non-administrative) users, the

oscilloscope will reboot into the last active Standard user, regardless of

whether you've switched to an administrative user. The only way to change

this is to give LeCroyUser and all other users Administrator privileges.

Contact Customer Support for instructions on changing user privileges and

creating new users on the oscilloscope.

.

HDO9000 Getting Started Guide

41

Page 44

MAINTENANCE

Service

If the HDO9000 cannot be serviced on location, contact your

service center for a Return Material Authorization (RMA) code and

instructions where to ship the product. All products returned to the factory

must have an RMA.

Return shipments must be prepaid. Teledyne LeCroy cannot accept

COD or Collect shipments. We recommend air freighting. Insure the item

you’re returning for at least the replacement cost. Follow these steps for a

smooth product return.

1. Remove all accessories from the device.

2. Pack the product in its case, surrounded by the original packing

material (or equivalent). Do not include the manual.

3. Label the case with a tag containing:

• The RMA

• Name and address of the owner

• Product model and serial number

• Description of failure or requisite service.

4. Pack the product case in a cardboard shipping box with adequate

padding to avoid damage in transit.

5. Mark the outside of the box with the shipping address. Add:

• ATTN: <RMA code assigned by Teledyne LeCroy>

• FRAGILE

6. If returning a product to a different country:

• Mark the shipment “Return of US manufactured goods for warranty

repair/recalibration.“

• List any cost of service in the Value column and the original purchase

price “For insurance purposes only”.

• Be very specific about the reason for shipment. Duties may have to be

paid on the value of the service.

930536-00 Rev A

42

Service Plans

Extended warranty, calibration, and upgrade plans are available for purchase. Contact your Teledyne LeCroy sales representative or

customersupport@teledynelecroy.com to purchase a service plan.

Service Centers

For a complete list of Teledyne LeCroy offices by country, including our

sales and distribution partners, visit: teledynelecroy.com/support/contact

Teledyne LeCroy

700 Chestnut Ridge Road

Chestnut Ridge, NY, 10977, USA

teledynelecroy.com

Sales and Service:

Ph: 800-553-2769 / 845-425-2000

FAX: 845-578-5985

contact.corp@teledynelecroy.com

Support:

Ph: 800-553-2769

customersupport@teledynelecroy.com

Page 45

REFERENCE

Support

Online Documentation

Online Help is available by selecting Support > Dynamic Help from the

oscilloscope display menu bar. You can also select Support > OneTouch

Help for a demonstration of MAUI with OneTouch.

Teledyne LeCroy publishes a free Technical Library on its website at

teledynelecroy.com/support/techlib. Manuals, tutorials, application

notes, white papers, and videos are available to help you get the most out

of your Teledyne LeCroy products.

The HDO9000 Oscilloscopes Operator’s Manual can be downloaded from

teledynelecroy.com/web/hdo8000-manual. This PDF document contains

more extensive operating procedures than are found here.

The Datasheet published on the product page contains the detailed

product specifications.

Technical Support

Registered users can contact their local Teledyne LeCroy service center

to make Technical Support requests by phone or email. For a complete

list of offices, visit teledynelecroy.com/support/contact.

You can also submit Technical Support requests via the website at

teledynelecroy.com/support/techhelp.

Windows License Agreement

The XStreamDSO oscilloscope application runs on the Microsoft Windows

operating system. Teledyne LeCroy’s agreement with Microsoft prohibits

users from installing third-party software on HDO9000 oscilloscopes that

is not relevant to measuring, analyzing or documenting waveforms.

Warranty

NOTE: THE WARRANTY BELOW REPLACES ALL OTHER WARRANTIES, EXPRESSED

OR IMPLIED, INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTY OF

MERCHANTABILITY, FITNESS, OR ADEQUACY FOR ANY PARTICULAR PURPOSE OR

USE. TELEDYNE LECROY SHALL NOT BE LIABLE FOR ANY SPECIAL, INCIDENTAL,

OR CONSEQUENTIAL DAMAGES, WHETHER IN CONTRACT OR OTHERWISE. THE

CUSTOMER IS RESPONSIBLE FOR THE TRANSPORTATION AND INSURANCE

CHARGES FOR THE RETURN OF PRODUCTS TO THE SERVICE FACILITY.

TELEDYNE LECROY WILL RETURN ALL PRODUCTS UNDER WARRANTY WITH

TRANSPORT PREPAID.

The product is warranted for normal use and operation, within

specifications, for a period of three years from shipment. Teledyne LeCroy

will either repair or, at our option, replace any product returned to one of

our authorized service centers within this period. However, in order to do

this we must first examine the product and find that it is defective due to

workmanship or materials and not due to misuse, neglect, accident, or

abnormal conditions or operation.

Teledyne LeCroy shall not be responsible for any defect, damage,

or failure caused by any of the following: a) attempted repairs or

installations by personnel other than Teledyne LeCroy representatives; b)

improper connection to incompatible equipment; or c) for any damage

or malfunction caused by the use of non-Teledyne LeCroy supplies.

Furthermore, Teledyne LeCroy shall not be obligated to service a product

that has been modified or integrated where the modification or integration

increases the task duration or difficulty of servicing the instrument. Spare

and replacement parts, and repairs, all have a 90-day warranty.

The instrument's firmware has been thoroughly tested and is presumed

to be functional. Nevertheless, it is supplied without warranty of any kind

covering detailed performance. Products not made by Teledyne LeCroy

are covered solely by the original manufacturer's warranty.

HDO9000 Getting Started Guide

43

Page 46

REFERENCE

Certications

Teledyne LeCroy certifies compliance to the following standards as of

the time of publication. Please see the EC Declaration of Conformity

document shipped with your product for current certifications.

EMC Compliance

EC DECLARATION OF CONFORMITY - EMC

The instrument meets intent of EC Directive 2014/30/EU for Electromagnetic

Compatibility. Compliance was demonstrated to the following specifications

listed in the Official Journal of the European Communities:

EN 61326-1:2013, EN 61326-2-1:2013 EMC requirements for electrical

equipment for measurement, control, and laboratory use.

Electromagnetic Emissions:

EN 55011:2010, Radiated and Conducted Emissions Group 1, Class A

EN 61000-3-2/A2:2009 Harmonic Current Emissions, Class A

EN 61000-3-3:2008 Voltage Fluctuations and Flickers, Pst = 1

Electromagnetic Immunity:

EN 61000-4-2:2009 Electrostatic Discharge, 4 kV contact, 8 kV air, 4 kV

vertical/horizontal coupling planes

4

EN 61000-4-3/A2:2010 RF Radiated Electromagnetic Field, 3 V/m,

80-1000 MHz; 3 V/m, 1400 MHz - 2 GHz; 1 V/m, 2 GHz - 2.7 GHz

EN 61000-4-4/A1:2010 Electrical Fast Transient/Burst, 1 kV on power

supply lines, 0.5 kV on I/O signal data and control lines

EN 61000-4-5:2006 Power Line Surge, 1 kV AC Mains, L-N, L-PE, N-PE

EN 61000-4-6:2009 RF Conducted Electromagnetic Field, 3 Vrms,

0.15 MHz - 80 MHz

EN 61000-4-11:2004 Mains Dips and Interruptions, 0%/1 cycle,

70%/25 cycles, 0%/250 cycles

4 5

1

2 3

4

4

1

To ensure compliance with all applicable EMC standards, use high-quality shielded interface cables.

2

Emissions which exceed the levels required by this standard may occur when the instrument is

connected to a test object.

3

This product is intended for use in nonresidential areas only. Use in residential areas may cause

electromagnetic interference.

4

Meets Performance Criteria “B” limits of the respective standard: during the disturbance, product

undergoes a temporary degradation or loss of function or performance which is self-recoverable.

5

Performance Criteria “C” applied for 70%/25 cycle voltage dips and for 0%/250 cycle voltage

interruption test levels per EN61000-4-11.

European Contact:*

Teledyne LeCroy Europe GmbH

Im Breitspiel 11c

D-69126 Heidelberg

Germany

Tel: + 49 6221 82700

AUSTRALIA & NEW ZEALAND DECLARATION OF CONFORMITY – EMC

The instrument complies with the EMC provision of the Radio Communications

Act per the following standards, in accordance with requirements imposed by

Australian Communication and Media Authority (ACMA):

AS/NZS CISPR 11:2011 Radiated and Conducted Emissions, Group 1, Class A.

Australia / New Zealand Contacts:*

RS Components Pty Ltd. RS Components Ltd.

Suite 326 The Parade West Units 30 & 31 Warehouse World

Kent Town, South Australia 5067 761 Great South Road

Penrose, Auckland, New Zealand

* Visit teledynelecroy.com/support/contact for the latest contact information.

44

930536-00 Rev A

Page 47

REFERENCE

Safety Compliance

EC DECLARATION OF CONFORMITY – LOW VOLTAGE

The oscilloscope meets intent of EC Directive 2014/35/EU for Product

Safety. Compliance was demonstrated to the following specifications as

listed in the Official Journal of the European Communities:

EN 61010-1:2010 Safety requirements for electrical equipment for

measurement, control, and laboratory use – Part 1: General requirements

EN 61010-2:030:2010 Safety requirements for electrical equipment

for measurement, control, and laboratory use – Part 2-030: Particular

requirements for testing and measuring circuits

The design of the instrument has been verified to conform to the

following limits put forth by these standards:

Mains Supply Connector: Overvoltage Category II, instrument intended

•

to be supplied from the building wiring at utilization points (socket

outlets and similar).

Measuring Circuit Terminals: No rated measurement category.

•

Terminals not intended to be connected directly to the mains supply.

Unit: Pollution Degree 2, operating environment where normally only

•

dry, non-conductive pollution occurs. Temporary conductivity caused

by condensation should be expected.

U.S. NATIONALLY RECOGNIZED AGENCY CERTIFICATION

The oscilloscope has been certified by Underwriters Laboratories (UL) to

conform to the following safety standard and bears the UL Listing Mark:

UL 61010-1 Third Edition – Safety standard for electrical measuring and

test equipment.

CANADIAN CERTIFICATION

The oscilloscope has been certified by Underwriters Laboratories (UL) to

conform to the following safety standard and bears the cUL Listing Mark:

CAN/CSA-C22.2 No. 61010-1-12. Safety requirements for electrical

equipment for measurement, control and laboratory use.

Environmental Compliance

END-OF-LIFE HANDLING

The instrument is marked with this symbol to indicate that it

complies with the applicable European Union requirements to

Directives 2012/19/EU and 2013/56/EU on Waste Electrical and

Electronic Equipment (WEEE) and Batteries.

The instrument is subject to disposal and recycling regulations that vary

by country and region. Many countries prohibit the disposal of waste

electronic equipment in standard waste receptacles. For more information

about proper disposal and recycling of your Teledyne LeCroy product,

please visit teledynelecroy.com/recycle.

RESTRICTION OF HAZARDOUS SUBSTANCES (RoHS)

HDO9000 and its accessories conform to the 2011/65/EU RoHS2 Directive.

ISO Certification

Manufactured under an ISO 9000 Registered Quality Management System.

Intellectual Property

All patents pertaining to the HDO9000 can be found on our website at:

teledynelecroy.com/patents/

HDO9000 Getting Started Guide

45

Page 48

930536-00 Rev A

January, 2019

© 2019 Teledyne LeCroy, Inc. All rights reserved.

Loading...

Loading...